TODAY ESTIMATING

Simplify Your Preconstruction Process

AI in Construction Has Landed

How to Estimate the Cost of Cast In Place Concrete Filled Pipe Pile

AMERICAN SOCIETY OF PROFESSIONAL ESTIMATORS

JULY/AUGUST 2023

AMERICAN SOCIETY OF PROFESSIONAL ESTIMATORS

ASPE BOARD OF DIRECTORS

President

M. Chris Morton, FCPE cmortonfcpe@outlook.com

First Vice President

Mike A. Alsgaard, CPE maalsgaard@fishbeck.com

Second Vice President

A. Keith Parker, CPE keithparker@circlebco.com

Immediate Past President

Mel D. Cowen, LCPE mel@cowen-est.com

Treasurer (Appointed) Paul Croke pcroke@hinrest.com

Northwest Governor

Steve Watkins steve.watkins@bnbuilders.com

Southwest Governor

Larry Lucero, CPE llucero@redlineinsulation.com

Central Plains Governor

Matthew Burress, CPE mburress@performanceservices.com

Southeast Governor

Danny Chadwick, CPE estimatordan@gmail.com

Northeast Governor Dexter Murphy, LCPE dextercmurphy@comcast.net

INDUSTRY DIRECTORS

Barbara J. Jackson, PhD, DBIA Barbara Jackon LLC

Jean Arnold, Esq Arnold & Arnold, LLP

INSIDE FROM THE EXECUTIVE DIRECTOR NEW MEMBERS SIMPLIFY YOUR PRECONSTRUCTION PROCESS AI IN CONSTRUCTION HAS LANDED 2023 CRITICAL CALENDAR CHAPTER MEETINGS 03 04 08 10 12 30 34 36 HOW TO ESTIMATE THE COST OF CAST IN PLACE CONCRETE FILLED PIPE PILE 2023 CHANDLER SUMMIT

WHAT IS

From the Executive Director

Please be assured that the leadership, volunteers, and staff are committed to this goal.

There is still much work to be done on the plans and priorities for ASPE in 2024 and beyond and a full report will be presented during the “State of the Society” session at Summit 2023 (September 21 – 23, Chandler, AZ), so stay tuned.

It’s summertime! I hope you are all enjoying the season with family and friends.

The ASPE Governance Committee gathered this past spring in Chicago for a strategic planning session that was expertly facilitated by former ASPE industry director Ujjval Vyas (Alberti Group, LLC). While the group brainstormed, analyzed, and debated numerous concepts and ideas, one main theme kept recurring: estimators are essential to the success of every construction project. Period. While this concept is widely recognized by those in the field, it is not necessarily shared by the broader construction industry, general contractors, and owners.

This is where ASPE comes in. As an organization, ASPE must continue (and step up) its efforts to advocate for, promote, and elevate the value of the estimator and estimating profession. The organization is built on a solid foundation that combines professional education, standard-setting certification testing, and the collective wisdom of thousands of professionals. Our challenge is to improve and evolve our programs and services while spreading the ASPE gospel far and wide.

Speaking of Summit 2023, are you registered to attend? If not, there is still time! Plan to join your industry colleagues at the Crowne Plaza-Chandler Golf Resort to reunite with old friends, make new professional connections, and learn about the latest industry trends, technology, and business solutions from respected experts in the field.

Finally, the Board of Directors election will occur between July 10th and July 21st. If you have not received it already, you will receive an email that contains information about the candidates and the link for you to cast your ballot. Please take the time to vote!

Information about all ASPE has to offer can be found at www.aspenational.org. Please feel free to reach out anytime with your ideas and input— I’d love to hear from you.

July / August | 3

Connect at: JWarren@ASPEnational.org 910.541.1480 - Direct Line LEARN . CERTIFY. JOIN

Welcome our April & May New Members

4 | Estimating Today Member Company Chapter Mark Lundell Reconstruction Experts, Inc. Los Angeles - 1 Pavel Raskin Vanir Construction Management Orange County - 3 Joshua Hogan San Diego - 4 Matt Meade Aegis Construction Management Denver - 5 James Zack DS Constructors, LLC Denver - 5 Steven Gilmour Hunter Contracting Arizona - 6 Timothy Snow Jr. Gleeds Atlanta - 14 Phil O’Neal JE Dunn Construction Co. Heartland - 32 Joyce Richardson White Diamond Group, LLC Middle Tennessee - 34 Jenny Zehring Turner Construction Company Southwestern Ohio - 38 Eric Johannesen Limoges Construction Viking - 39 Ricardo Lopez Aztec Contractors Rio Grande - 40 Andy White Southlake Group Dallas/Ft. Worth - 43 Jason Shaw Satterfield & Pontikes Const Dallas/Ft. Worth - 43 Ryan Leech Crawford Consulting Services Three Rivers - 44 Kenneth Hall Ram Jack of New Mexico Roadrunner - 47 Priyesh Shukla Torres Total Flooring Inc Tampa Bay - 48 Michael Knettel Young & Associates Tampa Bay - 48 Odlaumor Richards Tampa Bay - 48 Jeff DeFranco Turner Construction Orlando - 50 Christian Abugu University of Florida Orlando - 50 David Ornberg Reconstruction Experts, Inc. Great Salt Lake - 51 Cory Matthews GEMCO Constructors, LLC Central Indiana - 59 John Tibbetts Connecticut Carpentry Corporation Nutmeg - 60 Michael Nowoswiat SonicSpec Philadelphia - 61 Gianna Rogari Becker & Frondorf Philadelphia - 61 Timothy Kenny Becker & Frondorf Philadelphia - 61 Brian Wear Doors Inc. Davenport Quad Citiy - 71 Reed Festing-Smith Estes Construction Des Moines Area - 73 Nick Welter Downing Construction Des Moines Area - 73 Jeffrey Lane Sheetz, Inc. Central Pennsylvania - 76 Caleb Olvera Tradesman Drywall Central Pennsylvania - 76 Nick Walter Gray Construction Southeast MAL - 93 Jose Rivera CRM, Inc. Southeast MAL - 93 Chris Pearson Al Neyer, Inc. Southeast MAL - 93 Luke Terpstra CarbonSix Construction Northeast MAL - 94 Daniel Edmiston The Haynes Group Northeast MAL - 94

Congratulations to April & May New CPEs & AEPs Preconstruction in the Cloud

Jeremy Pant, CPE

Adam Mahas, AEP

Nicholas Redwine, CPE

and Veatch

Mahas Construction

Construction, Inc.

Bradley Brinkman, CPE National Grid

Stephen Walentynowicz, CPE Savarino Companies, LLC

Use STACK to power a 10x faster and more profitable preconstruction process. Quickly measure digital plans, collaborate with team members and finalize project estimates — all from one, easy-to-use, cloud-based platform.

Cyrus Martinez, AEP

Waseem Eskandar, AEP

Hassan Mutaib Mohammad, AEP

Faraz Ullah Hussaini Syed, AEP

July / August | 5 Name Company Chapter Richard Whitmer, CPE MKA International, Inc. Atlanta - 14 Matthew Creely,

Turner & Townsend Detroit - 17 Jason Hollenstein, CPE Structure Tone, Inc. Garden State - 26 Tyler McCann, AEP Stellar Construction Dallas/Ft. Worth - 43 Donald Vasil, CPE Crawford Consulting Services, Inc. Three Rivers - 44 Robb Ross,

Crawford Consulting Services, Inc. Three Rivers - 44

AEP

CPE

Black

Bud

Magnum

Plan, Spec & Document Management Make project takeoffs 10x faster & empower your team to work anytime, anywhere. Keeping project details & supporting documents organized has never been easier. Adjust costs, markup, tax, and overhead to create branded proposals with ease. Use robust markup, callout, sharing & invitation features to keep your entire team aligned. Cloud-based Quantity & Material Takeoff Detailed Cost & Estimating Proposal Generation Real-time Collaboration & Connectivity Your all-in-one solution for lightning-fast takeoff, complete estimating & bid-ready proposals. Create your FREE account today! GET STARTED stackct.com | (866) 702.6078

6 | Estimating Today Thank you to our Corporate Partners! Corporate Members Gold Anser Advisory Silver STACK Construction Technologies Bronze Delta Innovative Services, Inc. Basic ML Group Unfied Building Group Shaw Electric Inc. GW Builders, LLC. GFP Cement Contractors, LLC Bluebook | ConsensusDocs | DCD

July / August | 7 Create an account with the ASPE Employment Center! Our job board is an online resource for professionals looking to network and advance their careers. The job board offers seekers the tools needed to quickly find and apply for best jobs available only through the American Society of Professional Estimators. Manage Resumes Create Job Alerts Company Directory Resource Center Create your account and post your resume at https://bit.ly/3NTN9yR, and connect with hundreds of active employers!

CONNECTION

YOUR DIRECT

TO TOP ESTIMATING CAREERS

REGISTER TODAY!

September 21-23, 2023

ARIZONA

Join us in-person in Chandle r, AZ or virtually for another great Summit with a jam-packed agenda of speakers focused on providing next-lev el continuing educati on and thought provoking estimating presentations, panel discussions, interactive sessions, and more. Take the time to invest in your estimating career by attending Summit and networking with fellow professional estimators and sponsors. See you in September!

ABOUT CHANDLER AGENDA OVERVIEW

In the midst of downtown Chandle r, A Z lies the Crowne Plaza Chandler Golf Resort - a historic hotel venue for Summit 2023. Packed with on-site and local amenities, this is the place to be for daytime estimating presentations and networking, and evening time to explore the vibe of Chandler’s Sonoran desert culture and hospitality.

> The Art and Science of Risk

> ASPE Construction Analytics Presentation

> How to Estimate for Risk

> Value Engineering in Estimating

> Building Relationships During the Preconstruction Phase

> The Competitive Edge in Preconstruction

> And More!

PRICING

$1,095–In-person early registration through June 3 0th

$1,195–In-person late registration through August 23rd

$550–Virtual early registration through June 3 0th

$650–Virtual lat e registration aft er June 3 0th

$225–Guest ticket

8 | Estimating Today

THURSDAY – 9.21

–

FRIDAY – 9.22

–

Regional Meeting Break-outs Welcome Reception

Eldeen Pozniak

KEYNOTE: How to Get Through a Days Work and Have Something Left Over to Play With

David Hopkins, CPE | The Art and Science of Risk

Ed Zarenski | ASPE Construction Analytics Presentation

Eric Molinar

Justin McVaney, AEP

Matt Burress, CPE

Pete Fowler

Parker Anderson

Mike Villalba

SATURDAY

PANEL 1

Risky Business

PANEL 2

Process Engineering Our Estimating Department: The Business Case for Applying Lean Principles to Estimating

Andy Kleimola, CPC | How to Estimate for Risk

Kye Holtan-Brown | Preconstruction Communication: Ta les from the “Dark Side”

Rick Wyly, CPE, VMA | Value Engineering in Estimating

Larry Hendrick, LCPE, DBIA

Rick Wyly, CPE, VMA

PANEL 3

Building Relationships During the Preconstruction Phase

Paul Martin | Cost Awareness for You and Y our Team

STACK Demo Presentation

Greg Williamson, LCPE, LEED AP | T he Competitive Edge in Preconstruction

State of the Society and Awards

July / August | 9

2:00 – 3:00 3:30 – 4:30 4:45 – 5:45 11:30 – 12:30 10:15 – 11:15

9:00

10:00

9:00 – 10:00 10:15 – 11:15 1:30 – 3:00 4:00 – 5:00 11:30 – 12:30

– 9.23

5:15 – 6:15

6:00 6:00

8:00

5:00–

3:30 – 4:00

Simplify Your Preconstruction Process

By: Darcie Burroughs | Content Marketing Specialist | STACK Construction Technologies

By: Darcie Burroughs | Content Marketing Specialist | STACK Construction Technologies

Are you doing the same thing over and over again in your preconstruction process and expecting different results? It's insanity! When you have to repeat processes for generating an estimate and proposal for every project, the time adds up and so does the risk of making mistakes. If you’re still working with manual methods or disconnected systems, your business is trailing behind the tech leaders of the industry.

A contractor’s success hinges on completing projects on time and within budget, tasks that require an organizational strategy to achieve. Leveraging preconstruction technology to increase efficiency, streamline workflows, drive growth, mitigate risks, and connect teams sets you ahead of your competitors. So how do you know what to look for in your software solutions? Here are the most important factors to consider when purchasing construction technology:

• Never be tied to your desktop computer again! When using a cloud-based solu -

tion you’ll get real-time team collaboration, mobility, instant updates and backups, and a single source of truth for your data.

• Save time with centralized document management and sophisticated search features. The average construction professional spends 5.5 hours a week searching for the right information. Spend those 5.5 hours increasing profitability instead!

• Hyper-accurate takeoffs > manual methods. You’ll be able to bid more work in less time with accurate measurements and powerful automation.

• No more guestimates with detailed cost estimates and regional item cost data. Using a solution with prebuilt and customizable template libraries, grouping and labels, and reports sets you up for success.

• Professional and customizable proposals will set you apart from the competition. Find a solution that gives you customizable grouping, proposal alternatives for multiple bids, and allows adding

your branding and scope of work information.

• Connect and integrate with your other business tools and streamline your workflows! A solution with an open API will help move data across your platforms, automating business processes and help you gain strategic insight.

Find a solution that can do it all in one platform. Improve workflows, eliminate human error, collaborate with your teams, and save time. You’re able to turn your data into actionable business decisions allowing you to react proactively and maximize opportunities. Put distance between yourself and less advanced competitors with the right technology in your stack!

10 | Estimating Today

WE’RE BUILT A LITTLE DIFFERENTLY AT ANSER ADVISORY.

We are a national capital program and project advisory firm comprised of world-class subject matter experts who each work tirelessly to deliver mission-driven outcomes for our clients

Working with us, you’ll see how we are redefining consulting.

When it comes to cost estimating for construction projects or capital programs, we make the complex simple

Any project, any size, any location – we can provide the accurate cost estimating information you need.

WE’RE STRONGER THAN EVER.

OUR SPECIALTIES

Construction Management

Program Management

Project Management

Quality Assurance / Quality Control

Cost Estimating

Project Controls

Utility Management

Contract Administration

Energy and Sustainability

WHO WE ARE

1,200+ National Professionals

BINU MATHEW joins us and expands our expertise and experience into the New York / New Jersey area!

MICHAEL MARSHALL rejoins the Anser family and strengthens our presence in the Florida region!

200+ Local Florida Professionals

$15B+

Cost Estimating Program National Portfolio

100+ Programmatic / Conceptual Estimates Performed

PROUD TO PARTNER WITH ASPE!

All our Cost Estimating Leaders are ASPE Members.

world class people. consulting redefined.

How to Estimate the Cost of Cast In Place Concrete Filled Pipe Pile

Introduction

Foundation construction takes many different forms. A common method of foundation support is the concrete filled, steel shell, and pipe pile. This paper will guide the reader through the process of estimating the costs associated with the construction of this type of pile. The design of this pile is an example based on the author’s prior experience. The principles of estimating the costs of construction of this type of pile are the goal of this document.

Foundation design has been performed for thousands of years. Without it, the Megalithic Temples of Malta, dating back to 3600 BC and every still-standing structure built after would not have survived. In fact, poor foundation design almost ensures the failure, potentially cataclysmic in nature, of a structure. The earliest types of piles were fabricated from timber, placed in holes dug into the ground, and backfilled with soil. Since then, improvements in construction methods and materials have been driven by the desire to build safer, cheaper, higher, and more efficiently.

12 | Estimating Today

MasterFormat Information Division 31 00 00 - Earthwork 03 00 00 - Concrete Subdivision 31 60 00 - Special Foundations and Load-Bearing Elements 31 62 00 - Driven Piles 31 62 13 - Concrete Piles 31 62 13.13 - Cast-in-Place Concrete Piles 03 20 00 – Concrete Reinforcing 03 30 00 – Cast-in-Place Concrete

Over the years, new technologies have been developed and subsequently, a multitude of pile types currently exist and are used throughout the world.

The Cast-In-Place (or CIP) pile, as it is commonly referred to in the industry, is the topic of this paper. The typical CIP pile is constructed in order to support a structure or function as some type of structure in and of itself. They are used for building support, bridge support, utility support, and for many other purposes.

To begin, a work area will have to be prepared. An accessway may

need to be constructed should the route of travel not be suitable to support the heavy equipment that will be used in this operation.

To begin, a work area will have to be prepared. An accessway may need to be constructed should the route of travel not be suitable to support the heavy equipment that will be used in this operation. This can take the form of temporary access roads made of geotextile fabric and an aggregate of some sort, or a temporary structure may be required. This is all dependent upon site conditions and design requirements.

The proposed installation area will be cleared and made reasonably flat and level. Further, any ground preparation will be performed as necessary to facilitate construction. A plethora of equipment including a crane of sufficient capacity will be brought on site along with a set of pile leads, a pile hammer, and a power source for the hammer.

Next, steel pipe pile shells would be brought on-site. These piles may require splicing, which is the joining of two or more sections to make a single pipe section, and the installation of points on the end of the pile of some sort if required.

The pile leads will be assembled and raised to a vertical orientation by use of the crane. In certain situations, the pile could be installed on a slant. In this case, the pile leads would be held in the slanted orientation for driving piles. This would be called a “battered pile” and is used to combat the sliding and/or overturning of a structure.

The hammer will be installed in the leads and the crane will raise it to an appropriate height. The pipe pile will then be raised by the crane until it is completely within the leads and the entire assembly will be positioned

About the Author

Roy Huemer, CPE Garden State - 26 Roy@huemerllc.com

His career in construction began in 1986 and he currently trains estimators as well as consulting contractors in many fields of construction, educating them in the art of estimating and cost estimating.

He began his career in construction as a laborer working for a residential home builder. He later worked for civil design engineers as a draftsman. There he acquired skills in construction survey which led him to the field of heavy highway construction.

He joined the estimating group of contractors active in the New Jersey heavy civil construction field. Over the next 20 years, he gained the knowledge and experience to work, estimate, and manage heavy civil construction. He has also trained estimators in the general contracting, electrical, and mechanical fields as well as many other contracting disciplines.

July / August | 13

using surveyed layout information. The pile will be lowered to the ground, the hammer will be lowered upon the end of the pile, and the pile will be driven into the ground.

Once the pile is driven to the expected depth, the exposed top will be cut off. A fabricated rebar cage that will function as a connection between the pile and the proposed structure will then be installed and, in this case, the pile will be filled with concrete to provide added strength.

Types and Methods of Measurement

The following are the typical units one would encounter:

EA = Each – Used for a count of specific items i.e., number of piles, points, splices

LF = Linear Feet – Used for lengths of components i.e., pile, rebar

FT or ‘ = Feet – Used for length as well as elevation i.e., top of the pile, tip of the pile

IN or “ = Inches – Used for length typically shorter than one foot i.e., rebar clearances, pile wall thickness

CY = Cubic Yard – Used for the quantity of materials i.e., concrete, sand

LB = Pound – Used for weight i.e., crane capacity for lifting

LS = Lump Sum – Used for quantification of complex operations to sum them into a single value

TN = Ton or 2,000 pounds i.e., maximum crane capacity

Specific Consideration Factors

Initial Considerations

The information needed to estimate accurate and detailed costs for the construction of CIP piles would begin to be derived from construction documents provided by a licensed design engineer. These documents

would consist of plans and specifications that would include where the pile(s) would be located, into what material the pile will be driven, pile capacity, what forces would be allowed to be exerted upon the pile, pile diameter, pile wall thickness, type of steel, pile top elevation(s), pile tip elevations(s), whether splices are allowed and the methods with which a splice would be made, the need for a point or end plate, the need to fill the pile and with what material, whether that material is reinforced, whether the pile is coated and if so with what material.

The methods of measurement and payment can significantly impact the pricing the estimator must calculate in order to suitably respond to the proposal. In many cases, due to the volatility of final pay quantities, some project owners will provide line items for the work in the following manner:

• Mobilize Pile Driving Equipment

• Furnish Materials for Test Piles of XX size

• Install Test Piles of XX size

• Test Piles for capacity

• Furnish Materials for Production Piles of XX size

• Install Production Piles of XX size

Should this level of detail not be able to be incorporated into the contract in some form or other, the estimator’s risk analysis will have to incorporate said volatility of the quantities of work. It would behoove the estimator to encourage the proposal’s sponsor to incorporate these line items in order to not incur substantial costs due to the associated risks.

In that the subsurface materials can vary significantly in composition, the length of a pile can vary wildly. For example, bedrock can exist in one pile location at an elevation 50 feet below grade. Five feet in any direc-

tion an underground “cliff” can exist. This is where the bedrock drops or rises substantially, and the pile driven in that location can be much longer or shorter than anticipated.

Without the level of detail listed above, pricing the work will be challenging. For example, should the production pile item consist of supply and installation, and the quantity installed, being the basis of payment, should run shorter than expected, the contractor runs the risk of having compensation reduced while expense remains the same. Should the estimator account for an anticipated underrun of quantity and, in fact, the quantity overruns, the realized compensation may not cover the actual costs as well as overhead and profit for the work completed.

Equipment Selection

Many factors come into consideration when selecting equipment. It would all begin with the results of the Test Pile (discussed in the Miscellaneous Pertinent Information section below) that would dictate the order length of pile(s) and the hammer with which the pile would be driven. Both the pile length and hammer size and type would then be used to select the length of leads in which the pile and hammer would be mounted to ultimately drive the pile. All of this is used to subsequently choose the crane boom length that would place the pile hammer and leads on the proposed location and support the hammer within the leads while lifting the pile into driving position. This can be calculated as follows:

Design pile length + waste length + variable length to allow for mill rolling = total pile length

Total pile length + hammer length + rigging for hammer = minimum lead length

14 | Estimating Today

Minimum lead length + additional lead to achieving manufactured lengths = total lead length

Total lead length + rigging for assembly + increase for radius from a crane (the hypotenuse of the triangle) = maximum crane boom length.

Once the maximum crane boom length is determined, one can choose the crane from manufacturers’ catalogs that would provide crane sizes that would carry the appropriately sized boom length. Next, the capacity of the crane at the appropriate radius must be calculated by the following methodology:

Total lead weight + total pile hammer weight + total pile weight + rigging = total load.

Once the total load is calculated, the radius from the center of the crane to which the pile would be driven is then compared to the manufacturer’s load chart.

The total load must be less than the maximum capacity, at the maximum radius of driving in conjunction with the required boom length in order to safely lift the load according to the manufacturer of the crane. See the reference section for a typical crane used in this type of work for the details mentioned herein. It should be noted various agencies have specific safety factors that are placed upon these calculations and even though the manufacturer’s data may show safe lifting conditions, a multiplier of two times, three times, or as much as five times may be mandated.

Soil Conditions

Soil borings should be incorporated into the contract documents and should be performed in sufficient quantity and location to accurately describe the subsurface conditions on the site. Soil Borings are frequently taken with the use of an

auger and a “spoon”. The auger would drill down into the soil, allowing for the retrieval of samples of the soil at different levels for classification. The spoon is a device that would be placed within the auger and blows of a certain force upon the spoon would determine the cohesivity of the soil and its ability to withstand force.

Site soil conditions can vary wildly, even within a relatively small area. Bedrock can range from depths of 5 feet below the surface to 100 feet below the surface within a 20-foot stretch of ground. Soil sampling can show a layer of soil that takes 3 blows to drive an auger 6 inches deep and in a stratum 5 feet below that, it could take 50 blows to drive the sample spoon 2 inches.

Specific Site Conditions

Existing site conditions as well as project staging can severely impact the productivity of the construction of these piles. Should overhead obstructions of any kind exist, this will limit the length of the section of the pipe pile that may be installed. This will subsequently impact the amount of work to be completed to install the pile.

Labor Availability

In some areas of the country, labor unions are in control of the people that will install these piles. If a project of significant scope is underway in the same area as the project being bid on, the availability of labor may be an issue. Further, across the industry, contractors are finding it increasingly more difficult to fill job openings with skilled personnel.

This can significantly impact productivity regardless of what the company’s history of performance on the scope of work has been. The potential lack of experienced personnel must be incorporated into produc-

tivity expectations as the impact on costs can be significantly more than the material itself in some parts of the country.

Weather

Pile driving is one of those components of a project that can take place in the rain, snow, heat, and cold for the most part. However, certain parts of the county do have specific weather impacts that will affect daily productivity. Lightning storms and high winds are two of these types of factors that must be considered and incorporated into the productivity of the crew.

Value Engineering Potential

The types of piles are legion. The earliest piles were in the form of timber poles, simply placed in previously dug holes. Then stones in their natural state were piled in narrow holes to serve the same purpose. Following that, the stones were cut into shapes more suitable for stacking. Afterward following the ability to fabricate iron and steel, shapes were derived for many structural construction purposes, and some were found to be quite efficient as foundation support.

H-piles, pipe piles, Z-piles, U-piles, and many more shapes are currently in use. Many configurations combine the available shapes to serve various construction needs. To this day, pile construction evolves and improves.

Alternatives to the designed pile should always be considered. Dependent upon contract documents, pricing said alternative sometimes may be incorporated into the estimate. In this case, the cost savings, reflected in the project pricing, could easily win the job.

July / August | 15

Overview of Cost and Markups

Labor

The labor costs in this estimate will be based upon New Jersey Prevailing Wage Determination, expiring in 2022 in addition to payroll taxes, workers’ compensation, and general liability.

Equipment

The equipment rates utilized are based on US Army Corps of Engineers document EP1110, dated 2020 escalated to today’s current rates. Ownership and operating costs will be combined.

Materials

Pricing is based upon recent information gathered from local suppliers.

Inderect Costs

Indirect costs such as on-site project management, safety, and job site facilities such as field offices, dumpsters, and sanitary facilities will be incorporated into the estimated costs via a percentage for Overhead and Profit.

Overhead

A generalized overhead for the estimate of 10% will be used to cover the costs of non-job-specific supervision, home office expenses, and other similar costs to the project. The actual value is company specific and can easily vary extensively and must be calculated for the specific company’s requirements. 10% shall be used for this example.

Profit

For this example, 10% will be utilized. All of these values would be dictated by each company bidding the work and should be derived by careful consideration and detailed mathematical backup.

Special Risk Considerations

Soils

The soil borings, when taken in sufficient quantity and depth, will give a detailed analysis of the materials through which the piles will be driven. Should insufficient boring information, i.e., lack of soil composition, gradation, density, and other characteristics, be provided the estimator takes on a substantial risk anticipating production.

Safety

Construction is inherently dangerous and pile driving is even more so. Fall protection, objects dropped from overhead, and unmarked utilities are just some of the considerations that must be addressed in a safety plan. The safety procedures set forth must be monitored and enforced to minimize the potential for injury on the site.

Scheduling

As piles are typically installed early in the construction sequence on new construction, conflicts with proposed work typically are not a significant issue. When this work is performed as a modification to existing structures, clearances for the equipment required to install this work must be examined in detail. A significant impact on this work will also be the relocation of existing overhead and underground utilities and the construction of new utilities in order to not impact the construction of these piles.

Ratios and Analysis

In that the plethora of variables regarding the construction of CIP piles preclude any consistent ratios for labor/equipment/material/productivity, the best source of cross-checking comes from the contractor’s own history.

This, of course, raises the chicken vs egg conundrum. To obtain production and cost data from one’s history, one must first construct the pile. To construct the pile, one must typically estimate the work. Without estimating and subsequently constructing the pile, history cannot be obtained. To combat this, an outside consultant well versed in the work required, region the work will be performed, labor market available, equipment required, and other aspects will be the best source of confirmation of costs.

Additionally, searching through public agencies’ published unit prices for contracts can be a valuable source of pricing confirmation. Typically, these public agencies will publish the unit prices provided by all bidders at some point.

Some agencies publish almost immediately after the bid opening while some publish only after the award of the project. Searching through the databases of unit prices for similar work in similar conditions will be a valuable guide to the estimator, provided due diligence regarding the pricing is performed.

Miscellaneous Pertinent Information

Test piles are the method by which a pile design would be confirmed on a project. That entails constructing a single pile per expected condition with the equipment, materials, and methodology anticipated. This paper will not be addressing said operation; however, the estimator should be aware the costs for these piles are markedly more than that for the production pile.

As witnessed by recent events, the volatility of material costs can significantly impact the price of the installed pile. From labor shortages due to pandemics or raw material

16 | Estimating Today

availability due to global instability, the estimator must be aware of these cost impacts and do their best to incorporate those costs.

Dependent upon quantity, procuring the pipe pile material may be limited to time limits known as “mill rollings”. Typically, the length and quantity of piles required would need custom fabrication, which happens at certain times as decided upon by the manufacturers. This will have potentially substantial impacts on the schedule should the mill rolling not be conducive to meeting schedule requirements.

Steel Pipe Piles are manufactured at steel processing plants. These are limited in number and as such their

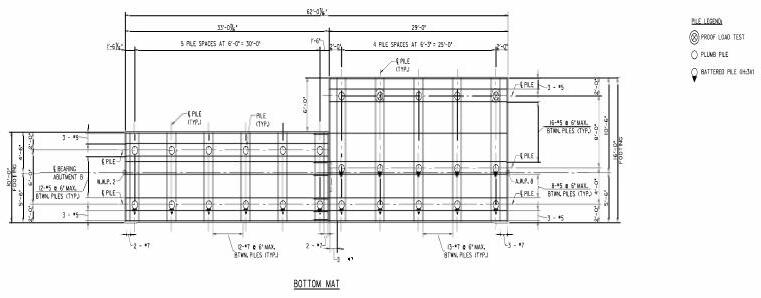

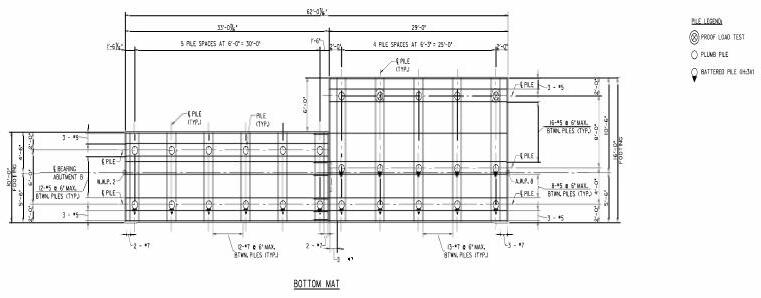

Details and Plans

Pile Detail

location can impact costs directly. Should the plant and the project to which the piles are to be shipped be located on viable waterways, piles in excess of 100 feet in length could be barged to the project location. Should over-the-road travel be dictated, over-length, overweight, and travel periods can impact delivery dates, times, and costs.

Additionally, should over-the-road transport be required, the length of the pile to be transported will impact costs. Overlength or overweight permits as well as additional splicing will add costs and the relevant conditions must be analyzed to achieve the most economical outcome.

The pay quantity for this type of item constructed under the presumed specification is to the nearest rounded whole foot per unit installed. Pay quantity is the length of the pile that would be included in the calculation for compensation for the work. Some agencies will not pay for piles above grade yet are required for connection into the footing above while others will pay for all footage driven and cut off, whether incorporated into the structure or not. The calculations take these criteria into consideration.

July / August | 17

18 | Estimating Today

Plan and Elevation of the wall 1

Footing and Pile Plan Wall 1

July / August | 19 Footing and Pile Plan Wall 1 Plan and Elevation Wall 2

20 | Estimating Today

Footing and Pile Plan Wall 2

July / August | 21

Wall Sections and Pile Elevation

Takeoffs and Pricing

Takeoffs and Pricing

AS PE ‐ HT ETCO Cast in Pla ce Concrete Filled Pi pe Pile Material

PAY QUANTITY CALCULATIONS

Waste is estimated based upon experience. Some additional material w ill be removed f rom the exposed end of the pile after driving is complete as a result of damage from the pile hammer. Dependent upon the supplier, pile lengths w ould be ordered in increment of f ive (5) f oot intervals. This a ccounts f or the total pile length that would have to be ordered.

Pile points can be manuf a ctured in the f ield or purchased pre‐ manuf a ctured. Pre‐ manuf a ctured points are antcipated and would then be installed in the field.

S plices are determined by the pile lengths a ble to be provided by the manuf a cturer as w ell as the shi pping res tri cti ons a s a res ul t of job l oca ti on The l eng ths a re di cta ted by the pres um ed s i te a cces s l i m i ta ti ons

22 | Estimating Today 22

Production

StructureLocationPile SizePile TypeFtg ElevExp Tip ElevQtyFtg EmbedCalc Lf Exp Wall 1Ftg A18" x 0.5" WallVert128.6758.50none91.571.67 Wall 1Ftg A18" x 0.5" WallBatt128.6758.501on3161.575.55 Wall 2Ftg A18" x 0.5" WallVert124.8715.50none71.5110.87 Wall 2Ftg A18" x 0.5" WallBatt124.8715.501on3121.5116.87

Takeoff for

Plles based on Expected Pile Length

StructureLocationPile SizePile TypeCalc Lf Totals Wall 1Ftg A18" x 0.5" WallVert71.67 648 Wall 1Ftg A18" x 0.5" WallBatt75.55 1,216 Wall 2Ftg A18" x 0.5" WallVert110.87 777 Wall 2Ftg A18" x 0.5" WallBatt116.87 1,404 4,045 MATERIAL CALCULATIONS StructureLocationPile SizePile TypeCalc LfWaste1 Purchase EaPurchase total Wall 1Ftg A18" x 0.5" Wall V ert71.672 75 675 Wall 1Ftg A18" x 0.5" WallBatt75.552 80 1,280 Wall 2Ftg A18" x 0.5" Wall V ert110 872 115 805 Wall 2Ftg A18" x 0.5" WallBatt116.872 120 1,440 Lf T otal =4,200 Structure Location Pile SizeQty Total Length S pli ces EaS plices Total Wall 1Ftg A18" x 0.5" Wall9 75.00 19 Wall 1Ftg A18" x 0.5" Wall16 80 00 116 Wall 2Ftg A18" x 0.5" Wall7 115.00 2 14 Wall 2Ftg A18" x 0.5" Wall12 120 00 2 24 Total Points =44 63 Structure LocationCal c Lf Qty Lf T otalInt Dia (In) Cy / Pile Total CY Wall 1Ftg A 71.67 9.00 645.0317 4.1937.7 Wall 1Ftg A 75.5516 00 1208.7517 4.4270.7 Wall 2Ftg A 110.87 7.00 776.0917 6.48 45.4 Wall 2Ftg A 116 8712.00 1402.4117 6 83 82.0 Cy T otal = 235.7 1‐2‐3‐4‐117.00 5 EXPEC T ED PIL E L ENGT H Batter Pi pe Pile Material Min Interval2 5 Pay Qty Lf 72.00 76 00 111.00 Lf Total = 227.29 5 5 Pile Points 3 Pile S pli ces 4 Ma x LF 55 55 55 55 Concrete Area (SqIn) Total S plices=

227.29 227.29 227.29

July / August | 23

24 | Estimating Today

July / August | 25

26 | Estimating Today

Glossary

Bedrock – A solid rock layer in the ground either at or below the surface.

CRSI – Concrete Reinforcing Steel Institute.

Capacity, Design – Design load that would be placed upon a pile.

Capacity, Maximum – The highest load a pile would be able to support without failure.

Load – The amount of weight, either in tons or pounds that would be placed upon a pile either in a temporary or permanent condition.

Mill Rolling – Timeframe in which a steel mill will produce a specific type and size of the pile.

Pile Hammer – A device with which piles can be driven into the ground. Many different hammers are able to be used in this work. Vibratory, diesel, and air driven are the most common types.

Order Length – The length of the pile to be actually fabricated to be installed based upon information gathered from the construction of a Test Pile.

Pay Quantity – Contractual establishment of a method of calculation for compensation of an item of work. This will determine whether payment will be made for a portion of the pile installed or if all of the pile, including cut-off portions, will be included in payment.

Pile Leads – Lattice-type steel support frame that holds the pile in place and provides a track upon which the pile hammer would

glide while driving the pile into the ground.

Pile, Production – Piles installed utilizing information obtained from the test pile install process such as the maximum force of a hammer, expected travel of the ram, the weight of the ram, and blows per foot.

Pile, Test – Piles installed under the conditions the piles are expected to be installed while under monitoring the process to ensure steel strength is not exceeded and design capacity is reached by achieving a particular depth in order to achieve design bearing.

Pile Splice – Joining sections of steel pile as needed to achieve the required total pile length for anticipated installation.

Pile Top – Design elevation of the exposed end of the pile after driving.

Pile Tip – Elevation at which the end of the pile embedded in the substrate rests.

Pile Type, Batter – Pile installed intentionally on an angle to the foundation surface not 90 degrees. This is used to combat overturning or sliding forces amongst other purposes.

Pile Type, Vertical – Piles installed vertically at a 90-degree angle to the foundation surface.

Rebar – Steel bar used to provide strength to concrete as well as form of connection between the pile and foundation of the structure it will support.

Rigging – Materials with which a pile hammer is lifted in the air with

a crane or excavator.

Soil Boring – Sampling of soil at various depths in a potential location of a structure where soil types, soil gradation, soil density, groundwater elevation, potential bedrock elevation, and other impactful characteristics to the subgrade soil conditions.

References

New Jersey Prevailing Wage

Determination, expiring February 28, 2023 for Laborers, April 30, 2023 for Dockbuilders and June 3, 2023 for Operating Engineers

https://lwdwebpt.dol.state.nj.us/ archivewages/186095911-statewide-7-5-22.pdf

US Army Corps of Engineers document EP1110, dated 2020 https://usace.contentdm.oclc.org/ utils/getfile/collection/p16021coll9/ id/2442

CRSI Standard Hook Details and ASTM Standard Reinforcing Bars http://resources.crsi.org/ index.cfm/_api/render/ file/?method=inline&fileID=2CF0D551-FF69-58F7-140FBB7FB75FED71

Manitowoc 777 Crane Product Guide (including lifting charts) https://cranenetwork.com/uploads/ specs/cwusz0furetghx32manitowoc_777_175-ton_crawler_crane_ network.pdf

ICE HIH IP2 Product Guide https://www.iceusa.com/products/ new/equipment/pile-driving/hydraulic-impact-hammers-hih--47/ ip2--557/

July / August | 27

THE BENEFITS OF GETTING YOUR C i CE

How Getting Your CiCE Can Benefit Your Career:

•Excel in the workplace

•Gain new opportunities

•Propel your career

CONSTRUCTION ESTIMATING

ASPE’s very own Certificate in Construction

Estimating is comprised of six required courses focused on the core competencies and fundamentals necessary for a beginning estimator to master. This program is a comprehensive introduction to the foundational principles in plan reading, estimating math, bidding practices, materials and processes, preparing an estimate, and more. Whether you’re new to estimating, need a refresh, or are looking for a training program for your staff, ASPE’s Certificate in Construction

Estimating is the up-to-date solution to accessible online estimating education.

28 | Estimating Today

COURSES ARE:

Basic Estimating Math

Plan Reading for Estimating

Introduction to Construction Estimating I

Introduction to Construction Estimating II

Construction Materials and Processes I

Estimating and Bidding

WHO SHOULD EARN THIS CERTIFICATE:

Brand New Estimators

While there is no college degree in estimating, this certificate will educate you on all the ins-and-outs of the estimating profession so that you can jump into an exciting new career.

Field Workers Looking For An Office Job

If you’ve been working in the field for any amount of time, you know how hard the day-to-day demands can be on your body. With this certificate, you can learn a new skill and enjoy a career indoors, behind a desk.

Seasoned Estimators

Has it been a while since you refreshed your basic skillset in estimating? Or are you

WE CAN HELP YOU GET STARTED

July / August | 29 SCAN QR CODE TO REGISTER | 615.316.9200 | www.aspenational.org |

AI in Construction Has Landed

By: Doug Dockery | Chief Technology Officer | ConstructConnect

Artificial intelligence in the construction industry is here. It has emerged as a technology that is poised to transform our industry. As we enter this next frontier of construction technology, it is essential to understand what artificial intelligence is and how it offers unique solutions to advance the productivity and performance of the construction industry.

This article provides a foundational understanding of artificial intelligence in preconstruction. We’ll explore how AI offers ways to enhance the processes that drive business for better decision-making and strategic preconstruction planning.

What is Artificial Intelligence?

The data-rich, complex modern construction environment offers a potential advantage to those businesses that can harness data, produce intelligible insights, and make informed strategic decisions. AI is establishing a footing in the construction industry following years of development and imagination.

AI is here now because of advances in computing power, algorithms that follow precise steps, the large sets of data the industry produces, and innovations in the systems that combine these advances. The time to understand and integrate AI into your business is now.

Artificial intelligence is not a new idea, its roots can be traced back to the 1950s. Arthur Samuel, a pioneer in the field, defined it as “the field of study that gives computers the ability to learn without explicitly being programmed.” In other words, AI involves computers and systems that learn from experience. The purpose of AI is to make machines do things that humans are presently doing, but do them better and faster.

Artificial Intelligence, Machine Learning, and Deep Learning

Artificial intelligence is a field in data science that blends computer technology with hefty amounts of data to enable problem-solving. You may have experienced AI in a voice search with Amazon’s Alexa or Apple’s Siri. Search engines also power results with AI to collect and retrieve relevant information based on user inquiries. Videos suggested to you by YouTube or Netflix are AI-driven results that recommend titles based on learning your preferences and viewing habits.

You may hear machine learning mentioned in the same breath as artificial intelligence, but the terms are not

entirely interchangeable. Machine learning is a subset of artificial intelligence that learns from experience, adapts, and improves performance without being explicitly programmed.

A third part of artificial intelligence getting a lot of exposure today is deep learning. All AI aims to mimic human thinking, and deep learning is designed to extract maximum value from our way of processing information. Our brains use what scientists call neural networks, which are the collection of brain cells that help us process information by connecting signals. Deep learning uses artificial neural networks to process large amounts of data and solve problems with limited human help. These artificial intelligence networks are valued for their ability to handle lots of data, continue to improve as it trains and learns, and solve complex issues.

Artificial Intelligence in Preconstruction

Before building starts on a commercial construction project, a variety of people and teams from different disciplines and expertise must collaborate and plan how the

30 | Estimating Today

project will proceed. Preconstruction, as it’s called, refers to the phases of construction that take place before the actual construction work begins. Building owners, architects and engineers, trade contractors, general contractors, building product manufacturers, and many others take part in preconstruction.

The preconstruction process in commercial construction helps to ensure that the project is completed on time, within budget, and to the client’s satisfaction by identifying and addressing the sequence of people and events that will get the project completed.

Just like the projects being built, solid foundational work in preconstruction carries over greatly into the strength of the project. Variations in preconstruction stages occur depending on variables such as the type of structure or project (e.g., hotel, school, road, or bridge), project delivery methods, the scope of work involved, or if it is a public or private construction project.

AI In Preconstruction Project Stages

The following preconstruction project stages provide a framework for the steps before construction starts and how artificial intelligence is changing how this planning is performed.

Pre-Design: This phase includes the conceptual design, initial project planning, project development, and feasibility studies. The project team typically begins with the concept of the structure, performs a site analysis to identify potential obstacles, and develops a plan to address them. This phase also includes the development of a rough or working project scope and budget.

AI in the pre-design or initial project planning and development phase is helpful for feasibility studies to determine

if a project is viable. Risks can be identified and analyzed with various data, including financial data, market data, and data on the project's potential impact on the environment. Risk analysis can assist in deciding whether to proceed with the project. AI is a powerful tool at this stage because it offers thoroughness and accuracy, along with a general lack of bias.

Design Development: This phase includes the development of detailed design documents that steer the project. Documents included in this stage include architectural, structural, mechanical, electrical, and plumbing plans.

Design development is a critical phase in the project development process. It involves taking the conceptual design and turning it into a more detailed and buildable design, moving from general ideas to more specific ones. The design development phase is where many important decisions are made that will shape the final project, including cost, energy efficiency, and overall functionality. Artificial Intelligence can play a significant role in this phase by providing new tools and techniques to improve the efficiency and quality of the design development process.

Construction Documents: This phase includes the development of final construction documents, including detailed construction plans, building product specifications, and contract documents. The finalization of the construction schedule is prepared, which outlines the sequence and expected duration of all activities required to complete the project.

AI-based tools can be used to automate the process of extracting, analyzing, and processing data from construction documents. For example, natural language processing (NLP) can be used to analyze project requirements and create a detailed project scope document based on two-dimensional construction plans like PDF files. NLP has been around for over a half-century and is the component of AI that understands and interprets human language, written and spoken. This can save time and resources compared to the tedium of traditional methods, such as manual data entry or spreadsheet calculations.

Bidding and Negotiation: This phase includes distributing the plans to trades, contractors, and manufacturers for bidding. The project team will review the bids, negotiate with contractors, and select winning bids. For general contractors and trade contractors, this is the essential phase that includes producing and delivering detailed takeoffs and estimates to submit a competitive bid.

Trade contractors, general contractors, and building supply manufacturers assess the project scope, identify opportunities to pursue, analyze bidding strategies, and

July / August | 31

AI in Construction Has Landed... continued

decide which projects clear the hurdle for success. Trade contractors can use the power of AI to streamline processes, automate repetitive tasks like takeoffs, and improve the speed at which decisions like vetting profitable projects are made.

Permitting and Approvals: This phase includes the submission of the construction documents to the appropriate governmental agencies, where appropriate, for review and approval. Artificial intelligence is used in this phase to validate building code compliance and manage the building permit process.

Finalize Preconstruction: This phase includes finalizing contracts, mobilization of the contractors, and the start of construction activities. Effective preconstruction planning and strategic decision-making are key components of profitability for trades, general contractors, and building product manufacturers.

The finalization of the construction schedule is prepared, which outlines the sequence and expected duration of all activities required to complete the project.

The preconstruction stages can become more complex due to the nature of the project, the inherent need for effective communication and collaboration among teams, and local and national regulations, among others. Time and budget issues are consistently make-or-break drivers of a profitable construction project. Technology like AI offers an opportunity to improve performance throughout the preconstruction lifecycle.

Where Else AI and Construction Are Teaming Up

Aside from preconstruction, AI is a technology continuing to emerge in other areas of construction, enabling improvements in performance and safety. Some examples include:

Predictive maintenance: AI can be used to analyze data from building systems, such as HVAC and electrical systems, to predict when maintenance will be needed and prevent equipment failure.

Site safety: AI-powered cameras and sensors (even some worn by workers) can monitor construction sites for potential safety hazards and alert workers and managers to potential dangers.

Robotics: The efficiency of AI and machine learning have found their way into robotic bricklaying, welding, and even building entire structures with 3D printing.

Project management: AI can optimize the allocation of labor and materials, making the scheduling of construction tasks more efficient and cost-effective.

Quality control: AI-powered cameras and sensors can monitor the quality of construction work, identify defects, and alert workers and managers to issues that need to be addressed.

Building performance: AI could be used to analyze data from building systems to optimize energy efficiency, indoor air quality, and other performance metrics. Simulating building efficiency with AI, for instance, allows the identification of potential energy-depriving areas for better design and construction.

The Knowledge and Insight Enhancer

It is common to hear that computers trained to think like humans are a threat to stealing jobs from people. But construction is inherently reliant on the vast institutional and individual knowledge, something that AI cannot replace. Where human judgment is involved, and we know that’s everywhere throughout the construction project lifecycle, AI does not have the capability we humans do.

It's more likely that certain roles and responsibilities will change as AI is implemented. AI combined with a company’s organizational knowledge will offer much greater strategic opportunities than those not adopting the technologies to streamline performance and make better data-driven decisions.

Bright Future for AI in Construction

The present and future of AI in the construction industry are promising as more AI-based tools and techniques become integrated into workflows. As technology advances, AI is expected to become an even more integral part of the construction process, helping to improve efficiency, reduce costs, and enhance construction performance outcomes. AI in the construction industry has landed. Get ready for it.

Reprinted with permission from ConstructConnect from Februay 23, 2023

32 | Estimating Today

AI in Construction Has Landed... continued

Unified Building Group (UBG) is a nationally licensed construction company with offices located in Broomfield, CO, West Palm and Pompano Beach, FL. UBG specializes in the telecommunications, corporate real estate, educational, power, energy, health care, restaurants, residential and commercial industries. UBG’s core capabilities range from real estate, site acquisition, investment, pre-construction, construction management, design build, to complete building lifecycle facilities management and maintenance. Our team has a combination of over 300 years of construction industry experience. UBG was formed to change the way the industry builds, collaborates and executes on projects. With branches in Arizona, California, Colorado and Florida, we are here to serve you!

The 2023 ASPE Membership Directory is now available in the Members Only section of ASPEnational.org. Please note that the information contained in the directory was generated on March 13, 2023, and does not reflect additions or revisions made after this date.

Up to $25,000 to be Awarded

You may view current member data anytime using the searchable online member database – learn how! -

Application Due Date - April 28, 2023

https://scribehow.com/shared/How_to_Search_ the_ASPE_Member_Database__oUkVfEKzSCmvhe4hl231-Q

July / August | 33

2023 Critical Calendar

34 | Estimating Today 4 SBO Closed for Independence Day 10 Board of Directors Election Opens 21 Board of Directors Election Closes 31 Board of Directors Election Results Announced July September 4 SBO Closed for Labor Day 21-23 2023 ASPE Summit - Chandler, AZ 25 SBO Closed Post-Summit October 2 2024 Membership Renewals Begin 2 2024 Certification Renewals Begin (CPE and AEP) November 23-24 SBO Closed for Thanksgiving December 25 - 26 SBO Closed for the Holidays 31 2024 Membership Renewals Due 31 2024 Certification Renewals Due (CPE and AEP)

BENEFITS OF BECOMING CERTIFIED

VALIDATE YOUR EXPERTISE

2015

EARN A DISTINGUISHED CERTIFICATION

ASPE CPE Certification is accredited by the Council of Engineering and Scientific Specialty Boards (CESB), and successfully credentialed candidates of the program earn recognition for their skills.

GAIN A COMPETITIVE ADVANTAGE

More projects across the country are seeking credentialed estimators as an extra assurance of the quality of work. Increasingly, local, state, and government agencies are moving towards requiring CPE certification.

BOOST CAREER OPPORTUNITIES

Enhance your career by opening doors to the diverse projects and career growth opportunities that the CPE credential confers.

PROGRAM REQUIREMENTS

CERTIFIED PROFESSIONAL ESTIMATOR (CPE)

• For estimators with more than 5 years professional experience

• 3 – 6 month timeline to complete

• Required to complete the General Estimating Knowledge (GEK) exam, Technical Paper submission, and Part I and Part II of the Discipline Specific Test (DST)

ASSOCIATE ESTIMATING PROFESSIONAL (AEP)

• For estimators with less than 5 years professional experience

• 3 month timeline to complete

• Required to pass the General Estimating Knowledge (GEK) exam

| 615.316.9200 | www.aspenational.org | SCAN QR CODE TO LEARN MORE

ASPE CHAPTER MEETINGS

ARIZONA

Arizona #6

Where: Varies

Website: n/a

Meeting Contact: Jerry Chandler j.chandler@cox.net

ARKANSAS

Arkansas #33

Where: Varies

Website: n/a

Meeting Contact: Jack Guess, CPE jguess@baldwinshell.com

NW Arkansas #79

Where: Varies

Website: n/a

Meeting Contact: Danny Chadwick, CPE estimatordan@gmail.com

CALIFORNIA

Los Angeles #1

Where: Virtual Website: laestimator.org

Meeting Contact: Bruce Danielson la1ofaspe@outlook.com

Golden Gate #2

Where: Virtual Website: aspe2.org

Meeting Contact: Robert Muir, CPE robmuir72@hotmail.com

Orange County #3

Where: Virtual Website: aspe-oc3.org

Meeting Contact: Troy Thomas constructionpro1984@yahoo.com

CALIFORNIA (CONTINUED)

San Diego #4

Where: Virtual Website: aspesd4.org

Meeting Contact: Paul Chang, CPE pchang@balfourbeattyus.com

Sacramento #11

Where: Varies

Website: n/a

Meeting Contact: Bryan Hall bryan_hall@surewest.net

Silicon Valley #55

Where: Virtual Website: aspe55.org

Meeting Contact: Shawna Alvarado shawna@odonnellplastering.com

COLORADO

Denver #5

Where: Virtual Website: aspedenver.org

Meeting Contact: Jennifer Farmer, AEP jennifer@livingdesignstudios.com

CONNECTICUT

Nutmeg #60

Where: Back Nine Tavern Website: n/a

Meeting Contact: Lee Sullivan lee@lionsheadcc.com

Yankee #15

Where: n/a

Website: n/a

Meeting Contact: Bill Jacabacci jacabacci@gmail.com

DELAWARE

Delware #75

Where: Virtual Website: n/a

Meeting Contact: Brett Mucklow bmucklow@bpgsconstruction.com

DISTRICT OF COLUMBIA

Greater D.C. #23

Where: Varies

Website: n/a

Meeting Contact: Carlos Rosales aspe23president@gmail.com

FLORIDA

Tampa Bay #48

Where: The Pub Resturant Website: aspetampabay.com

Meeting Contact: Ray Velez reymvelez@gmail.com

Gold Coast #49

Where: Varies Website: n/a

Meeting Contact: Danny Chadwick, CPE estimatordan@gmail.com

Orlando #50

Where: Anser Advisory Website: https://aspeorlando50.com

Meeting Contact: Andrew Kleimola akleimola@anseradvisory.com

GEORGIA

Atlanta #14

Where: Virtual Website: n/a

Meeting Contact: Danny Chadwick, CPE estimatordan@gmail.com

36 | Estimating Today

ASPE CHAPTER MEETINGS (CONTINUED)

ILLINOIS

Chicago #7

Where: Virtual Website: n/a

Meeting Contact: Matt Burress, CPE mburress@performanceservices.com

INDIANA

Central Indiana #59

Where: Varies

Website: n/a

Meeting Contact: Jeremy Adkins, CPE jadkins@wccci.com

Old Fort #65

Where: Virtual Website: aspechapter65.org

Meeting Contact: Thad Berkes tberkes@designcollaborative.com

IOWA

Quad Cities #71

Where: Varies

Website: aspequadcities.org

Meeting Contact: Scott Robinson, LCPE scottr@jlbradyco.com

Greater Des Moines #73

Where: Varies

Website: iowaaspe73.org

Meeting Contact: Hui (Huey) Su huey@concordconst.com

LOUISIANA

New Orleans #9

Where: Varies

Website: n/a

Meeting Contact: Danny Chadwick, CPE estimatordan@gmail.com

MAINE

Maine #37

Where: Varies

Website: aspemaine.com

Meeting Contact: John Brockington, CPE jbrockington@woodwardcurran.com

MARYLAND

Baltimore #21

Where: Varies Website: n/a

Meeting Contact: Steve Dooley, CPE sdooley@phoenix-eng.com

MASSACHUSETTS

Boston #25

Where: Virtual Website: aspe17.org

Meeting Contact: Eric Rennell eric@rennellcapitalgroup.com

MICHIGAN

Detroit #17

Where: Virtual Website: aspe17.org

Meeting Contact: Glenn Frank, CPE glenn.frank@ymail.com

MISSOURI

St. Louis Metro #19

Where: AGC Training School

Website: aspe19stlouis.org

Meeting Contact: John Smith, CPE jpsmith@tarltoncorp.com

Heartland #32

Where: Varies Website:aspe32.org

Meeting Contact: Eric Soriano esoriano @hermeslandscaping.com

NEW JERSEY

Garden State #26

Where: Virtual Website: n/a

Meeting Contact: Robert Sibilia, CPE sibiliaconstructionservicesllc @gmail.com

NEW MEXICO

Roadrunner #47

Where: Fiestas Restaurant Website: n/a

Meeting Contact: Joshuah Crooker-Flint, CPE joshc@auiinc.net

NEW YORK

New York #10

Where: Virtual Website: n/a

Meeting Contact: Rose Jesse, CPE rosejesse.aspe@gmail.com

Empire State #42

Where: Athos Resturant

Website: n/a

Meeting Contact: Alvaro Garza, CPE Alvaro.garza@nationalgrid.com

OHIO

Southwestern Ohio #38

Where: Varies

Website: aspe-cincinnati.org

Meeting Contact: Dan Frondorf, CPE dan@dgfrondorf.com

July / August | 37

ASPE CHAPTER MEETINGS (CONTINUED)

OKLAHOMA

Landrun-OK City #80

Where: Varies

Website: aspeok.org

Meeting Contact: Mike Phillips, CPE michaelp@miller-tippens.com

OREGON

Columbia-Pacific #54

Where: Varies

Website: n/a

Meeting Contact: Steve Watkins steve.watkins@bnbuilders.com

PENNSYLVANIA

Three Rivers #44

Where: Varies

Website: n/a

Meeting Contact: Dexter Murphy, LCPE dextercmurphy@comcast.net

Philadelphia #61

Where: Varies

Website: na

Meeting Contact: Stephen Biddle SBiddle@oliverfps.com

Central Pennsylvania #76

Where: Loxley's Resturant

Meeting Contact: Shawn Buckwalter, CPE sbuckwalter@egsconstruction.com

TENNESSEE

Middle Tennessee #34

Where: Varies

Website: n/a

Meeting Contact:

Danny Chadwick, CPE estimatordan@gmail.com

TEXAS

Houston #18

Where: Varies

Website: n/a

Meeting Contact: Larry Lucero, CPE llucero@redlineinsulation.com

Rio Grande #40

Where: Varies

Website: n/a

Meeting Contact: Rodolfo Barba, CPE rodolfobarba1@gmail.com

Dallas/ Ft.Worth #43

Where: Virtual Website: sites/google.com/view/aspe-dfw

Meeting Contact: Steve Patmon ASPE.dfw@gmail.com

UTAH

Great Salt Lake #51

Where: Virtual Website: na

Meeting Contact: M. John Shampton, CPE mjohnshampton@gmail.com

VIRGINIA

Richmond #82

Where: Varies

Website: aspe-richmond.org

Meeting Contact: Sid Bass, CPE sbass@reynolds.edu

WASHINGTON

Puget Sound #45

Where: Virtual Website: na

Meeting Contact: Steve Watkins steve.watkins@bnbuilders.com

WISCONSIN

Brew City #78

Where: Varies

Website: na

Meeting Contact: Matt Washkoviak, CPE mattwashkoviak@camosy.com

Please Note: Information is subject to change. Report changes in your Chapter’s information with an email to Tina@ASPEnational.org

38 | Estimating Today

Classification Count (as of 6/6/2023) Affiliate AEP Corporate CPE Estimator Fellow Honorary Member LCPE Member Emeritus ME (CPE or LCPE) Student Total 49 53 8 375 626 23 5 97 11 30 30 1,307

Membership

July / August | 39 The industry standard for search! Exclusively for commercial construction professionals, like you! TheBlueBook.com/ASPE (844) 617-2478 BUILDING RELATIONSHIPS SINCE 1913 BUILDING RELATIONSHIPS SINCE 1913 • Quick & easy access to the nation’s largest database of qualified commercial construction professionals • Find exactly who you need, where and when you need them • Always available, always up-to-date

ASPE CORE VALUES

EDUCATION:

ASPE educates and mentors professional estimators for the sustainability of the construction industry.

PROFESSIONALISM:

ASPE promotes the lifelong pursuit of excellence and credibility in professional estimating.

ASPE CORE PURPOSE

ASPE is the construction industry’s leader and recognized authority in professional estimating through excellence in education, certification and standardization.

FELLOWSHIP:

ASPE develops a fellowship of professional estimators that connects and leads the construction industry.

215 Donelson Pike, #140710 • Nashville, Tennessee 37214 • 615.316.9200 • ASPEnational.org

By: Darcie Burroughs | Content Marketing Specialist | STACK Construction Technologies

By: Darcie Burroughs | Content Marketing Specialist | STACK Construction Technologies