SU BARESI & SU PERFORMER Hybrid Rye

SU Baresi and SU Performer are hybrid ryes with flexible end market potential for UK growers. With high-mass dry matter yields and consistently high methane content out of whole crop harvests, both are excellent choices for biogas. SU Baresi has shown stand out gas yield and quality. Both benefit from strong standing power and new genetics give improved brown rust resistance. When you’re after new generation biogas varieties, these are the two to go to.

Ask your merchant about availability or see more at elsoms.com

Talking Agronomy

‘Rotations tweaked as OSR crops succumb to

ENERGY CROPPING

Could forage oats be an AD feedstock option?

Pages 16-17

AGROFORESTRY

Finding a way forward for trees on-farm

Pages 34-36

GRAIN HANDLING

Intercrop cleaning – a degree of separation

Pages 37-39

Innovation in action for progressive arable farmers

Working in partnership for the UK grower elsoms.com

14

HYBRID RYE

Page

October 2023 Volume 46 Issue 10

CSFB’

November 29-30, 2023

NAEC Stoneleigh, Warwickshire

Learn the benefits of introducing livestock into your arable rotations at

SEMINAR 3 - Connecting bold thinkers in a time of change: Real stories from boots on the ground

You will learn how introducing livestock into your arable rotations can add value to your enterprise. Some of the benefits include:

• Improves soil health

• Helps with weed management without the need for machinery/fertiliser

• Converts the plant biomass into nutrients for the soil

• Improves soil structure and fertility

• Reduces soil erosion and compaction

register

your free

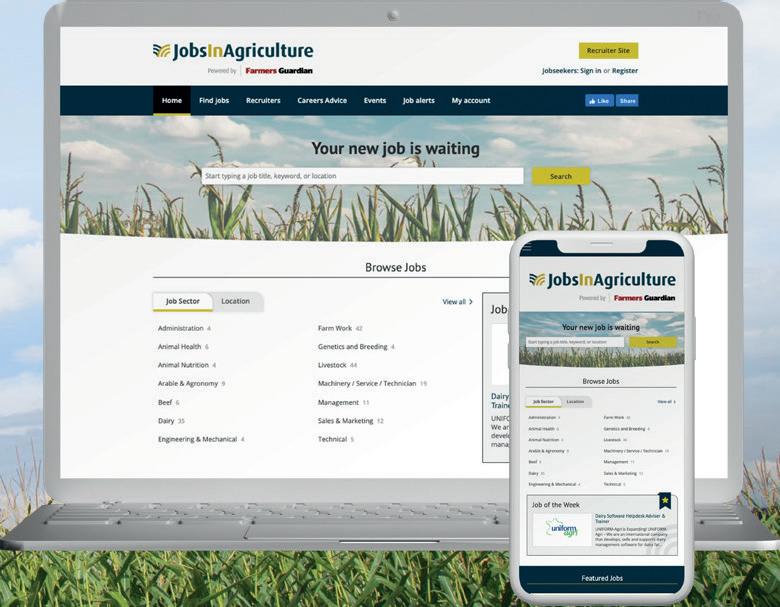

scan the QR code or visit Sponsored by In partnership with Be in with a chance to win a year-long digital subscription to Farmers Guardian. Scan the QR code and register using code AFMAG for this year’s CropTec Show before the deadline date: midnight GMT October 31, 2023 TERMS AND CONDITIONS APPLY: Entrants must be 18+ and reside in the UK. Competition ends October 31, 2023. Full terms and conditions are available on the registration form. PRIZE DRAW SCAN ME Read the latest news before the show!

To

for

ticket,

8

Business

6

Technical

16

28

34

Machinery

37

53

OCTOBER 2023

REGULARS 3 Comment

CONTENTS:

Talking Arable

seasons in a row of nuisance wild oats

Talking Agronomy Monitor OSR crops at the end of October to assess CSFB larvae numbers

Talking Roots

cool, dull summer has had a big effect on beet sugar content

Talking Policy

is important to highlight the link between crops and food to the public

Two

12

15

The

56

It

this season

maximising quality and selling at the best time will be

to claw back value

Identifying grain selling opportunities vital

Why

important

CropTec seminars set out to help farmers meet challenges

how some of the UK’s most forward-thinking arable businesses are tackling change

Could forage oats be an AD feedstock option? A familiar crop in the US, forage oats are being evaluated on-farm in the UK 26

Hear

Study highlights improvement in farm resilience

away from the plough to min-till has produced a range of benefits in a five-year farm trial

Switching

Finding a way forward for agroforestry

Why trees are a ‘win win’ for farming

Intercrop

cleaning – a degree of separation

Stripper

stripper header has

Simplicity key

veg

How post-harvest handling kit can help make the most of intercropping 40

head offers throughput increase and savings on fuel A

improved combine throughput on one Northants farm 49

for

and arable spraying workload

How one Notts farming business is meeting the challenges of protecting diverse veg and combinable crops

Small-scale

injection systems could offer an efficient

of

products to small areas Product news

New seed treatment gives sugar beet a kickstart BASIS news

Improve your soil know-how with new Soil Series online courses OCTOBER 2023 VOLUME 46 In this issue of 6 49 28

crop protection with high end precision Direct

way

applying

57

58

24 46

18

Agri-environment

Environment key to arable farm’s ethos

Why the environment is at the heart of all one Cambs farmer does

22 Technical

Pioneering pulse crops for climate-friendly farming

Could an expansion in pulse cropping help pave the way to net zero?

24

Crop nutrition

Developing a framework for improving N use efficiency

A wide-ranging fertiliser use efficiency trial could revolutionise N use

32 R&D

How septoria modelling is being used in the fight against fungicide resistance

An AHDB-funded project is aiming to deliver better strategies to manage fungicide resistance

46 Combines

Taking steps to secure future capacity

A draper header has provided a performance boost on-farm in Notts

OCTOBER 2023 CONTENTS: FEATURES 4 18

a word from the editor

Contacts

Group Editor – Arable

Teresa Rush 07917 271 989 teresa.rush@arablefarming.com

Senior Arable Technical Specialist

Alice Dyer 07966 445 458 alice.dyer@arablefarming.com

Arable Technical Specialist

Ash Burbidge, 07786 190 188 ashleigh.burbidge@agriconnect.com

Machinery Editor

Toby Whatley 07583 054 831 toby.whatley@arablefarming.com

Head of Creative Services

Gillian Green, 01772 799 417 gillian.green@agriconnect.com

Picture Editor

Marcello Garbagnoli 01772 799 445 marcelllo.garbagnoli@arablefarming.com

Key Accounts Manager

Jane Newton 01948 780 783 jane.newton@arablefarming.com

Key Accounts Manager

Mark Jackson 01322 449 624 mark.jackson@arablefarming.com

Account Manager

Chris Knowles 01772 799 550 chris.knowles@agriconnect.com

Sales Director

Mike Hartley 01772 799 532 mike.hartley@arablefarming.com

Advertising Production

Justine Sumner 01772 799 437 justine.sumner@arablefarming.com

Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com

© Agriconnect 2023

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher.

The contents of Arable Farming are subject to reproduction in information storage and retrieval systems. ISSN 0269-6797

Scorching September eventually reverted to more typical autumn weather, but not before the unseasonably hot, dry weather had delivered a few agronomy challenges in the form of hard-baked soils and burgeoning pest problems. Sadly, cabbage stem ea beetle appeared to have been lying in wait for the sun before taking every opportunity to decimate more than a few oilseed rape crops. To paraphrase the comments of one of our Talking Arable columnists this month, ‘money has already been lost on harvest 2024’ (see p10-11).

While the dry weather meant an easy finish to the 2022/23 harvest, it will be a season many growers will be glad to draw a line under. But as the new season gets underway, it is important to protect the quality of what has lately been harvested and market it effectively (see p6-7). Staying with that grain marketing theme, as Arable Farming went to press, plans for a consultation with industry this autumn over the possible introduction of a digital passport for combinable crops have been confirmed by the project’s Leadership Group. Will it get over the line this time round I wonder? News was also breaking of further progress in bringing forward precision plant breeding techniques in the UK –more on that in the next issue.

Recent travels took me west to Wiltshire and the Agroforestry Show. It is always a pleasure and a privilege to do a farm visit, and this one was no exception. Helen Browning hosted the show at Eastbrook Farm, an organic, mixed farming unit. There was plenty to see, hear and ponder and no shortage of arable farmers keen to explore how trees might fit into their enterprises. It was particularly interesting on one of the farm walks to observe how growers

instinctively applied their agronomy know-how to try and help address some of the challenges the Eastbrook team had encountered as they progressed their tree planting plans; a perfect example of how farmers can benefit from working together when the spurious barriers of farming sector and organic versus conventional are ignored.

That willingness to share experience – good and bad – is very much in evidence in this month’s issue. Read on to find out more about farmers looking for the ‘sweet spot’ where productivity and farming for the environment come together, farmers getting involved in cutting edge research, and farmers simply working out how to farm better. We hope we provide food for thought.

OCTOBER 2023

22 www.croptecshow.com November 29-30, 2023 5

Published

Agriconnect. Printed by

Printing,

1,

No responsibility can be accepted by Arable Farming for opinions expressed by contributors.

Arable Farming, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ

Origination

by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire, PR2 9NZ.

by

Precision Colour

Halesfield

Stirchley, Telford TF7 4QQ.

This year will be a harvest to forget for many growers. Maximising the quality that has been achieved and selling at the best time will be important if value is to be clawed back. Cedric Porter reports.

Identifying grain selling opportunities vital this season

The hot and dry weather at the beginning of September allowed the last of the 2023 harvest to be gathered in, preventing what had become a difficult harvest becoming a disastrous one.

At the end of August, AHDB reported winter wheat yields averaging about eight tonnes per hectare, but with a wide range from 5t/ha to 13t/ha. The figures are based on data collected by consultants RSK ADAS.

The lowest yielding areas were not those that experienced

the most summer rain, but lighter soils that suffered in the June heatwave.

Specific weights, Hagberg falling numbers and protein were average at best, with the lowest specific weights seen in the East and South. Many crops are only just meeting milling specifications, which means there is a lot of lower quality and lower value grain around trying to find a home.

Winter barley fared better, with yields in the range 6.2t/ha to 9t/ha, although specific weights were a little down on the long-term average. Screenings were low and grain nitrogen

and germination were acceptable. Spring barley has been more variable and given a late and wet start to the growing season, harvest was delayed. The later crops were planted, the greater the loss in quality. Spring oats also lagged behind winter ones with poor specific weights. Meanwhile, the mixed weather and cabbage stem flea beetle attacks meant that it was not a good season for oilseed rape, with yields below the long-term average.

More feed wheat

Grain prices are fundamentally driven by world supply and

demand, but the UK’s variable harvest means there are more national issues in play than in other years. Perhaps the most significant is a very large premium for milling wheat, with growers rewarded if they have the quality.

“In the first week of September, North West bread wheat was quoted at £269/tonne,” says Megan Hesketh, senior cereal and oilseed analyst at AHDB.

“That contrasted with £183.50/tonne for domestic feed wheat in East Anglia.”

A year ago, there was a £30/ tonne premium for the best quality milling wheat which was trading at £295/tonne. With more milling wheat not making the grade this year, the volume of feed wheat is higher, putting pressure on prices.

Even more pressure may be heaped on the feed wheat

OCTOBER 2023 6 BUSINESS

£/tonne 300 250 200 150 100 50 0 May 2024 price November 2024 price November 2023 price 2022 2023

Monthly feed wheat prices on the London ICE market in £/tonne

market, because of a decline in demand due to reduced pig and poultry production.

In the 12 months to the end of July 2023, 3.247 million tonnes of feed wheat were used by British feed processors, according to the AHDB. That was 6.6% less than the year before and one of the smallest annual usage rates in the last decade. Feed barley use also fell by 12.2% to 1.329 million tonnes.

Meanwhile, strong demand could support an already well-supported milling market. Total UK milling wheat usage was at 6.171 million tonnes in the year to July – up 2.6%. Of that, 84.9% was British grown. That proportion might be lower this season due to lack of supply. However, there might be some support for wheat that does not make the milling grade or is not

wanted by feed producers.

Wheat usage for distilling was at a record 1.048 million tonnes in the year ending July, 4.8% more than the year before as the UK’s bioethanol plants step up production.

Malting barley demand is also strong if growers can make the grade. Usage in the 12 months to the end of July 2023 was 1.970 million tonnes, which was 4.4% more than the year before and is now back above pre-pandemic levels. At the time of writing (September 14) premium malting sells for £62/ tonne more than feed. A year ago, the difference was about £25/tonne.

Export ready

Being export competitive this season will be important if the UK is to disperse a surplus of grain that could be in the region

of one to two million tonnes. There is a need for grain, including feed grain. In its latest world supply and demand report, the US Department of Agriculture said: “World wheat supplies are projected to decline 7.2 million tonnes to 1.055. billion, primarily on lower production for Australia, Canada, Argentina, and the EU, which is only partly offset by an increase for Ukraine. If realised, this would be the first year-toyear decline in global wheat production since 2018/19.

“Despite smaller global supplies, world consumption is nearly unchanged with decreased food, seed, and industrial use mostly offset by increased feed and residual use. Feed and residual use is raised by 1.0 million tons for both China and the EU due to wet weather during harvest that is

expected to result in higher amounts of lower-quality wheat used for feed.”

Overall world grain production projections were down 10 million tonnes in September compared to August at 2.802 billion tonnes, with total stocks down 1.1% to 765.8 million tonnes. That was similar to the figure a year ago, but consumption has risen by a similar percentage to a record 2.804 billion tonnes. A significant volume of stocks is locked away in Chinese stores and not available for world consumption.

Competitive

Analyst CRM Agri suggests that UK grain is becoming more competitive on export markets. It said: “Prices have been weighed by seasonal harvest pressure, and competition on international markets, particularly from Russia. November UK feed wheat continues to trade toward the export competitive end of the pricing spectrum. Prices from November onwards are export competitive, and close to the maximum vs the 10-year range.”

Looking at barley, CRM Agri said: “The discount of feed barley to feed wheat has continued to narrow, in line with the typical seasonal pattern. UK barley production is estimated at about 7-7.2mt, creating an export surplus. Spain’s poor harvest, and weak EU output overall, suggest a ready potential market for UK exports. However, European feed needs will also be provided for by an improved maize harvest.”

In mid-September, November 2023 wheat futures prices on the London ICE market were at £185/tonne. That compared to £261/tonne the year before. May 2024 pricing is showing at £10 uplift, while growers could sell crop from the 2024 harvest in November of that year at £195/tonne.

OCTOBER 2023 7 BUSINESS

Strong demand could support an already well-supported milling wheat market.

ALEXWilcox

Alex and Joanna Wilcox live and farm with their three sons at Hill Farm, near Downham Market on the Norfolk County Council Stow Estate. With 240 hectares of Fen silty clay loam, they grow winter milling wheat, winter feed barley, spring malting barley, spring beans and sugar beet.

With the spring beans and late sown spring barley safely harvested, and a performance that can only be described as ranging from acceptable to downright underwhelming, the old green combine is now finally parked up in the open-fronted shed at Poplar Farm.

The quality of the Lynx spring beans looks good, plus there was no need for any drying as they came off the field at 14% moisture. The greenness of the stems, even though glyphosate had been applied for over a fortnight, merely highlights the absolute need for a viable desiccant for this crop since the ridiculous diquat revocation. There are some potential replacement options in carfentrazone and pyrafluthen, but the work needs to be done to gain approvals and hopefully soon.

Due to yet more politically motivated geniuses producing yet more interesting science and the subsequent ban on neonic seed dressings, there is now a huge reduction in the UK oilseed rape area being grown annually and September is a much quieter month agronomically, with time to map out autumn cereal residual programmes and trawl through lots of trials data showing the pros and cons of various actives.

One old stalwart which will be coming back into

many of my programmes this year is triallate, with the classic pre-em herbicide effect of ‘I didn’t realise we had that problem until I stopped using it’ evident on several of my clients’ farms this last season. One grower was determined to reduce his autumn herbicide spend - aren’t we all? - and a decision to move away from triallate to a lower rate prosulfocarb was taken. The result was that the efficacy of the black-grass suppression seemed to have been just about maintained but the spring appearance of various brome species and wild oats all over the farm suddenly illuminated exactly what a great job the old Avadex was doing, albeit completely under the radar. So even if the winter wheat options will centre around the headline products of Proclus (aclonifen) or Luximo (cinmethylin), the rates and choice of their partner products will be equally as influential on how well things perform overall.

Wild oats

As for the wild oats, this seems to be the second year on the trot they have proved a real nuisance. With only a few viable contact options available, the need for effective residual chemistry targeted at this weed must become another major consideration in the herbicide stack decision process or the threat of a spread of target site resistance will rear its ugly head.

Farmer facts

rAlex studied for a National Diploma in agriculture at Moulton College before going onto Nottingham University to complete a BSc Hons degree in agriculture and agronomy

rHe is also a FACTS and BASIS diploma qualified agronomist working for Hutchinsons since 1997, with a significant portfolio of clients covering Bedfordshire, Northamptonshire, Lincolnshire, Cambridgeshire, Norfolk and Suffolk

OCTOBER 2023 8

This is the second year on the trot wild oats have proved a real nuisance

ALEX WILCOX

The old green machine finally parked up in the shed.

Otto and Bisto checking out the Lynx spring beans in the grain store.

With the price of sugar beet this season set at a viable £40 per tonne adjusted, the decision on fungicides and how many applications has been straightforward as the return on investment is very worthwhile. But what is a worry is how a new star product in its first year of approval has still struggled to control cercospora, which in the right conditions can

be a highly damaging disease. More work needs to be done as the current standard advice is to treat beet diseases at the first sign of infection which again seems a bit ‘horses and gates’. The golden rule that eradicating diseases is always a lot harder and more expensive than preventing infections occurring in the first place always applies.

On a final note, and going all cowboy, at the Hill Farm Ranch old Calamity Claim has reared its ugly head with our spring malting barley being delivered into the Wild Frontier.

Everything was going just dandy, all the samples were spot on with no issues identified, hands were spat on and shaken as the deal was done and the wagons

rolled in and out without so much as a single yee-ha, but don’t you just darn well know it, on the last two wagons we get a total of £1,785 in ‘dee-duck-shuns’, dang nab it.

Watch this space, I am currently getting all saddled up and six shooters holstered for a big showdown at the OK Saddlebow Corral.

OCTOBER 2023 9 TALKING ARABLE

Cercospora in the sugar beet.

ROB Beaumont

Rob farms on the Worcestershire/Herefordshire border with his parents and young family, growing combinable and forage crops with a mix of owned, tenanted and contracted land. An agronomist for Edaphos, Rob also hosts AHDB Monitor Farm events.

Autumn has landed with a heatwave. The emerging oilseed rape has been ravaged by flea beetle. Money has been invested - and lost - into harvest 2024 before we have even got going. The decision to replant (as of September 10) is on pause. Half the area at home has now been committed to spring cropping for arable silage. I have yet to decide what the rest will be; something to think about during the winter I suspect.

I know many have already given up on OSR and it’s looking like a beleaguered crop now. We need to find a consistent, non-insecticidal, way of getting crops through the savagery of the beetle attack. Too much of what we’re doing at the moment is purely down to luck and with margins as thin as they are, I don’t think it’s a viable option for us currently.

Farm facts

rFamily farm covering 200 hectares of mainly silty/clay loams, growing combinable and forage crops

rRob is BASIS and FACTS qualified, having also received a post graduate diploma in sustainable agriculture from Harper Adams

rCurrently in the third year of strip till establishment

rFarming operation is focused on reducing inputs and maintaining profitability

rRob is using cover crops and organic manures to build fertility

rUsing integrated pest management practices to reduce pesticide usage

Spring beans were poor this year so have been binned off for the winter option this time. We still have forage maize left to cut, which shouldn’t be too long now. It seems that this year, the most successful crops we have produced will end up in a silage pit. Thank goodness we farm in an area with demand for forage crops. We also grew six acres of sunflowers this summer. They have been a real ray

The demo Claas Tucano 560; a small combine with surprising output capabilities.

of sunshine (pardon the pun) in what has otherwise been a pretty rubbish harvest. I’m glad we took the decision to rip the poorly established beans out and put them in. We have sold enough cut flowers to cover costs and even raise a bit of money for the local primary school. If we manage to push the combine through them and harvest some seed that will be an added bonus. It may be the case that as the climate warms, things like sunflowers may become a viable option for inclusion in the arable rotation. We certainly need some profitable break crops.

Demo combine

In other news, we managed to have a Claas Tucano 560 on demo this harvest. It was a really impressive little combine. Small in size, but given it had a rotor instead of walkers and a 25ft header, some surprising output. Agriculture must be the only industry where someone hands you the keys to a £200,000 machine, does a few laps around the headland with you, and then lets you just get on with it. I’m not sure if I got the maximum out of it but it certainly goes on the contender list to replace our current John Deere. Attention is now starting to turn to autumn planting once again. As an agronomist, my advice in our area would be to wait until October to plant

OCTOBER 2023 10

Money has been investedand lost - into harvest 2024 before we have even got going ROB BEAUMONT

your wheat. As a farmer, I know I’ll be getting itchy after September 25. It’s like having a split personality sometimes. You know the best thing to do is follow the best evidence. October drilling reduces weed pressure, disease pressure and hopefully BYDV. On the other hand, you know if the weather turns to excrement, you won’t get anything in.

If the Government took all the subsidy/ environmental money and invested it into accurate long-range weather forecasting we’d probably boost agricultural productivity tenfold. If there is one thing I have been reminded of this year, it is that nature always has the final say on how our cropping performs. The best-laid plans and timely applications are all moot if sunshine and rain happen in the wrong order.

Fingers crossed the autumn planting campaign is kinder to us than harvest was. I shall be glad when this year has been put to bed.

OCTOBER 2023 11 TALKING ARABLE

Growers need a non-insecticidal way of getting OSR through the savagery of CSFB attack.

Gusto® IRON is a registered trademark of the ADAMA group. Gusto® IRON Always read the label and product information before use. For further product information, including warning phrases and symbols, refer to www.adama.com/uk or call The Technical Helpline on 01635 876 622. • High quality, long lasting, palatable bait • Superior mould resistance • Optimum pellet size and baiting points • Made with Desidro technology • Excellent value ferric phosphate The obvious choice for cost-effective slug control Gusto® IRON ADAMA Agricultural Solutions UK Ltd. Third Floor East, 1410 Arlington Business Park, Theale, Reading RG7 4SA. Telephone 01635 860 555. UKenquiries@adama.com For more information visit: www.adama.com/uk contains ferric phosphate. @AdamaUK_ 0562_ADAMA_Arable Farming_Gusto IRON Ad_188x137.indd 1 08/08/2023 14:45

Sunflowers have been a successful replacement for poorly-established beans.

GEORGE Swann

Iknew it was a bad start to the winter oilseed rape drilling when walking past the washing line in the back garden, where one of my work shirts was drying. In the middle of the back of the shirt sat a cabbage stem flea beetle, seemingly lifeless. However, upon inspection, it was very much alive and as bold as you like. I can confirm that non-bio washing powder on a 30degC wash does not kill them. At the time of writing, I have a lot of WOSR which I’ve been affectionately describing as being at the ‘critical condition’ stage — just emerging, tiny little cotyledon leaves, breaking the surface and coming under Rorke’s Drift levels of CSFB adult attack. Unfortunately, at the beginning of September, we had a combination of very hot days and nights with no rain when

Agronomist facts

JGeorge Swann is an independent agronomist, member of the Arable Alliance and a proud member of the Association of Independent Crop Consultants. He advises across South Yorkshire, north Nottinghamshire and North Lincolnshire. George has a BSc (Hons) in biology, is BASIS and FACTS qualified and has completed the BASIS Advanced Potatoes module. His expertise lies in helping his clients achieve economic maximum output while remaining as sustainable as possible for the future.

many crops were just starting to emerge, with hordes of the little beasties waiting for a feast.

Dry or drying seed beds, in some cases caused by growers needing to remediate harvest damage to fields caused by combines, trailers or balers, added to the problems.

This was very frustrating, as despite keeping the rolls tight behind any cultivation, it was a real struggle to keep any moisture.

There was plenty at four to five inches down, but the top half an inch where the seed was had really dried, causing the rape to stall coming out of the starting blocks.

Drilling

In my last article I wrote about the potential benefits of winter barley for growers wanting to establish oilseed rape and how the early drilling slot in the last few years has seemed to get away well before the usual August bank holiday CSFB invasion.

Again, this largely seems to have been the case and I have to say at the moment my better crops are those following winter barley.

Of course, there is the argument that the earlier drilled crops may be more susceptible to larvae attack with longer for the adults to lay their eggs and potentially more larvae in the plants.

I’m not 100% convinced of this yet, having sampled a range of crops and drilling dates. From what I’ve seen, there wasn’t always good correlation between drilling date and larvae numbers, unless a crop was very, very late drilled, well into September (not without other

potential risks) when I started to see a big drop off in larvae counts.

The main reason I wanted to talk about larvae in the stem is that this is potentially the largest concern for me when growing oilseed rape.

The loss of the crop at establishment may be very frustrating, but the crop not growing away in spring is a huge concern.

Growers need to be aware of thresholds and potential treatment options as well as being prepared to be out in oilseed rape crops at the end of October and early November to assess larvae numbers, either indirectly using adult trapping counts, or by plant assessment methods that assess larval numbers present in plants.

The emphasis on growers and agronomists to be getting accurate larvae assessment numbers as early as possible can’t be overstated, as once the propyzamide-containing products have been applied, this vastly reduces the options to change cropping plans should the worst occur.

The frustration for me when talking to growers having done larvae assessment is that it’s very difficult to forecast the consequences of different larval numbers on crop performance.

We don’t know that at 12 per plant or above we’re in big trouble but at eight per plant we should be fine.

There are so many other factors at play including drilling date, soil type and stem/size and thickness, with thick stems anecdotally able to tolerate more larvae, and, of course, the coming spring weather, which is also impossible to predict.

OCTOBER 2023 12

The need for early, accurate larvae number assessments can’t be overstated

TALKING AGRONOMY

• New herbicide coming soon

• New mode of action in cereals

• Control of grassweeds and broadleaved weeds

• For more information on Isoflex™ active, please visit www.isoflexactive.co.uk

@FMCAgroUK HERBICIDE NEW

Use plant protection products safely. Always read the label and product information before use. Unless otherwise indicated, trademarks with ® or ™ are trademarks of FMC. Isoflex™ active is not registered for sale or use. No offer for sale or use of this product is permitted prior to issuance of authorisation by HSE.

THINKING NEW PERFORMANCE

TALKING AGRONOMY

PHIL Warham

Rotations have been tweaked as OSR crops have succumbed to flea beetle attack

Just a few weeks ago we were all hoping for drier times after a month and a half of deluge and, thankfully, the weather gods were listening.

What had threatened to be a wash-out of a harvest quickly changed for the better. In the end, we were served up a relatively easy finish to the campaign, with everything bar a few beans cleared up by the bank holiday weekend. That is most unusual in this part of the world.

Winter and early drilled spring barleys performed well. Some early cut wheats were disappointing, and overall yields were average or a tad under, which I think is a result given the season. Admittedly it has been an expensive one in terms of inputs, but the return on spend has certainly been justified.

Agronomist facts

Winter beans looked well before harvest, but didn’t perform as well as spring varieties in this area. Perhaps we should reconsider the options and increase the proportion of spring crop, which could also help spread the workload.

Enough ground was cleared early on to get oilseed rape off to a good start. However, anything that was through the ground by early September was hammered by flea beetle during the heatwave in early September and the extreme heat then finished off these crops.

Rotations

Rotations have been tweaked as crops succumbed field by field. Overall, my customers have probably lost 50% of their OSR area. Given that sowings were a third down on last year anyway, the writing is surely on the wall until a solution to flea beetle is found. We all know that oilseed rape is a gambler’s crop; however, if the prize isn’t worth it, the gamble isn’t either.

On a brighter note, we have since received about 25mm of rain, which triggered a substantial and very welcome flush of grass-weeds. Patience will now really pay off – we still need to let as many seeds as possible chit before spraying them off ahead of winter cereals.

Pre-emergence wheat sprays will consist of a mix of aclonifen and flufenacet + DFF, or cinmethylin and pendimethalin on clean land. Avadex (triallate) is a somewhat emotive

subject among customers; given its cost it needs using respectfully. Winter barley will receive a reduced rate of aclonifen and flufenacet plus DFF.

Most growers have chosen their winter wheat varieties for the coming season. Soft wheat premiums have generally not been very exciting, so there seems to be a push towards milling varieties which still offer good premiums, or feed varieties for their better yields.

This season has been very different to last year; wheat disease ratings and standing power scores have been under considerable pressure. However, we must beware of knee-jerk reactions and consider consistency and previous form over several seasons, while limiting the area we put into something new and untried on-farm.

Sugar beet lifting is imminent and expectations are probably as high as I can remember. Crops made great progress through the summer and haven’t looked back.

Despite this, more juggling of rotations may be on the cards following reports that British Sugar and the NFU are again at loggerheads over beet pricing, with the offer for the 2024/25 crop apparently well below the current value of £40/t. Unless this is resolved soon, some growers may have to make some tough cropping decisions.

Maize harvest has started and yields are so far exciting. More about this in next month’s column.

OCTOBER 2023 14

JPhil Warham has been an agronomist with Agrovista for six years. He gained a degree in land and farm management at Harper Adams University and managed farms for several years afterwards. He now advises on combinable crops, cereals, maize and vining peas in Lincolnshire, Nottinghamshire and into Leicestershire. Key interests include direct drilling and soil health, as well as making farms profitable. In his spare time he is a keen runner and horseman.

DARRYLShailes

The cool, dull summer has had a big effect on beet sugar content

As the season slips from summer to autumn, we’ve had the hottest and sunniest period of weather so far this season. I can’t remember it being so hot in September before, but maybe it has been, and it’s just that the rest of the summer has been so cool and dull, so the contrast is playing tricks with my memory.

The plums are very ripe in the garden though, and have been picked and either made into jam or frozen for later. We’ve also been getting the cider ready from last year’s frozen juice for our own version of a wassail. We’re hoping the cider will help keep the neighbours happy when they’re helping to press this year’s crop. Although it’s looking okay, it is nowhere near the size of last year.

The cool and dull summer has had a big effect on the sugar content in the beet I’ve heard of being lifted, with 14% being quite common from the very earliest lifts, but hopefully that should increase with recent heat and sun. The early lift bonus has helped though, and some growers have decided to

crack on and get some beet lifted, and on with the next crop of wheat.

The recent BBRO meeting I attended discussed different varieties and their disease resistance, although when looking at some of the scores on the Recommended List, they didn’t really reflect what I saw in the trials. So as always, it is important to look at crops.

Beet cyst nematode

It is very interesting that we are seeing significant levels of cercospora in some fields, even though we’ve not really had the weather to trigger the BBRO warning system, apart from the odd spot on the Suffolk coast. There was some discussion around whether the UK cercospora populations may be more adapted to our weather and the model may need adjusting going forward.

Beet cyst nematode was also a point of discussion, as a lot has been seen this season. It is one of the failings of the current ALS-resistant varieties that there is no BCN-tolerant variety yet, especially as field infestations of BCN seem to go hand in hand with weedy beet populations, but hopefully, this will be possible in the next couple of years.

It was good to see so many people attend the Eurofins blight open day, at what was an excellent event this season as the blight populations were higher than we’ve seen in

recent years. There was also a lot of other leaf diseases, including alternaria, but also what looked like botrytis to me.

The main topics of discussion were managing blight with the current chemistry we have in light of the potential loss of mancozeb, and the changing resistance status of blight genotypes in the UK and mainland Europe.

There was a bit of new chemistry on display with the phosphonate group of chemistry looking to break through into the blight market shortly. Phosphonates bring a new mode of truly systemic chemistry that move quickly both to roots and leaves, so will be especially useful when applied early in the crop’s life.

There were several potato breeders at Eurofins and it was very interesting to see the effect of their varieties under full and half programmes and how genetics can help in giving effective blight control.

With all resistance traits, in potatoes or any other crops, it’s important not to use genetics in isolation, but to use an integrated policy that also utilises fungicides to protect and enhance the genetics.

Over-reliance on any one method of control, be that varieties or single-site fungicides, will inevitably lead to resistance being selected for. So we must always protect genetics and use them to enhance control, not as the sole technology. Over and out.

15 ROOTS TALKING AGRONOMY

JDarryl Shailes is root crop technical manager for Hutchinsons, with a nationwide remit. He has been working in potato agronomy for more than 20 years.

Agronomist facts

OCTOBER 2023

Could forage oats be an AD feedstock option?

hat goes into an anaerobic digester determines what comes out, so careful choice of feedstocks is essential. Wholecrop hybrid rye and maize have become established as popular options, but now Suffolk-based plant breeder Bill Angus is hoping to add Everleaf forage oats to that list.

Forage oats are widely grown in North and South America for fodder and Mr Angus was first alerted to them through his links with New Zealand plant breeder Keith Armstrong, with whom he operates a shuttle breeding nursery.

Compared to conventional grain oats, Everleaf forage oats typically produce greater biomass and grow thicker, faster and taller, according to

WMr Angus. With a range of types being tested under UK growing conditions, they could bring agronomic and economic benefits to UK rotations.

“They are good at scavenging residual nitrates and phosphates left in the soil from previous cropping and they are a relatively low cost crop to grow, but they are completely different from a grain oat,” says Mr Angus, who is working with Paul Nickerson and Kent-based independent seed merchant T. Denne and Sons to evaluate the performance of forage oats on-farm and test their suitability for use as an AD feedstock.

Trial

A two-hectare trial has taken place in Kent this season on a farm supplying its own AD plant.

“The forage oats were

planted in late September [2022] at the same time as hybrid rye and triticale and harvested in very early July,” says Andrew Bourne, seeds manager at T. Denne and Sons.

The dry matter, freshweight and gas yield potential of the oats is being assessed and a

double cropping approach, which saw another forage oat planted into the stubble of the original crop in early July, is also being evaluated.

An evaluation and trials site in Yorkshire has also produced encouraging results.

From the work done so far, forage oats will be at the later end of the maturity spectrum for wholecrop cereals, but their performance this season, albeit on a very small scale, has been promising, says Mr Bourne.

Given current uncertainty around maize’s future viability because of an impending ban on use of some seed treatments on maize seed, and the relatively high cost of hybrid rye seed, forage oats could potentially be a useful alternative, he suggests.

“Big AD operators relying on two or three feedstock sources

OCTOBER 2023 16

A familiar crop in the United States, forage oats are being evaluated in the UK for their suitability for use in anaerobic digestion. Teresa Rush reports.

Big AD operators relying on two or three feedstock sources are interested in exploring diversity

ANDREW BOURNE

The dry matter, freshweight and gas yield potential of forage oats for AD is being assessed, as well as a double cropping approach.

are feeling a little bit vulnerable at the moment and are interested in exploring diversity.”

Two varieties from Mr Angus’ Global Oats breeding programme - Everleaf 001 and Everleaf 002 - will complete official National List 2 trials this autumn and once listing is confirmed can be made available commercially. Two varieties for

spring drilling follow in the pipeline.

Excellent standing power is a characteristic of all these varieties, says Mr Angus. In addition to good lodging resistance, forage oats are also resistant to take-all, which means they can be grown as an effective break crop. And, as they are not hybrids and are drilled at seed rates of around 200

seeds/sq.m, seed costs will be cheaper in comparison to hybrid rye or maize, which makes a double cropping approach viable, he maintains.

Autumn drilling means there are no concerns around spring planting on heavier land and, at the other end of the season, forage oats are earlier to harvest than maize, which means

MAXIMISE YOUR SLURRY WITH ULTIMATE PRECISION

BlackBird®: Spreading technology that achieves superior results

You want things to run perfectly in the field? Looking for flow-optimised geometry, outstanding distribution accuracy, minimum contamination and much more? Then, the latest cutting-edge trailing-shoe system BlackBird® by Vogelsang is the answer. Giving you consistent results. Get in touch now for more information: sales.uk@vogelsang.info or 01270 216 600

VOGELSANG – LEADING IN TECHNOLOGY

vogelsang.info

potential problems with soil structure damage can be avoided, adds Mr Bourne. Plans going forward are to boost seed production of Everleaf 001 and 002 and conduct more trials on-farm, with the aim of assessing overall suitability for AD gas production as well as agronomic and economic performance.

ENERGY CROPS TECHNICAL

Forage oats are good at scavenging residual nitrates and phosphates left in the soil from previous cropping

BILL ANGUS

Bill Angus pictured in July with forage oats (in right hand) and grain oats under evaluation in his Global Oats breeding programme in Suffolk.

For one arable farmer, the environment is at the heart of all he does — even though it has meant changing the way the family farm has been run. Jack Watkins finds out more.

Environment key to arable farm’s ethos

Finding the farming sweet spot is the mantra of Martin Lines, who combines management of his third-generation arable farm, near St Neots, Cambridgeshire, with the chairmanship of the Nature Friendly Farming Network.

“There is a sweet spot for your production and your soil, wherever you farm and whatever the context is,” he says.

“If you try to push output by buying inputs, whether it is fertiliser, sprays or veterinary medicines, your margins shrink.

“You get to the point where you are chasing yourself to pay the bills.

“If you can find your sweet spot, where you are using sunshine and rain and just a small amount of input, you will earn the most amount. That is the place I have sought to find.”

It has been a challenging journey, however for Papley Grove Farm. As well as unlearning a lot of what he was taught at college, he also had to contend with a father whose philosophy differed to his own.

“I attended college in 1989/90 and was offered various scholarships and travelling opportunities, but my father felt I was needed here on the farm.

“He put me into the business as a minor partner, but he held the cheque book until he died in 2018.

“He was an old school arable farmer whose mindset was to drill to the very edge of the field. You would be bashing the hedgerows with the sprayer boom.

“He was brought up with the

post-war attitude of farming every inch and feeding the world. My philosophy is to work with nature and feed people as best I can.”

The succession was gradual as Mr Lines assumed greater management responsibility over the last two decades of his father’s life. A first step was drawing down environmental payments for hedge planting.

Mr Lines says: “We had problems with hare coursers and fly tipping and I sold him the idea of planting them as natural barriers.

Yields

“When I started working as a contractor on an organic farm, and saw that some of their yields were similar to ours, that made me think.

“Then we went into a Higher Level Stewardship scheme and took awkward areas of fields and strips running alongside ditches out of production.

“I spoke to conservationists and began to understand what wildlife

MARTIN LINES

lived in these new habitat areas.”

A revelation came in 2013 when a crop of winter beans was attacked by black bean aphid.

Unable to spray in wet and windy conditions, Mr Lines found that ladybirds and hoverflies which had thrived in the uncut field edges did the job of eating the aphids anyway, meaning a huge saving on insecticide costs and time spent in the cab.

He says: “That was a real eye-opener and got me thinking about how to value habitat as being more than just pretty flowers.”

Mr Lines follows integrated pest management practices, which means controlling pests without using insecticides, but also to some extent living with pests.

“You actually want some aphids and slugs in the landscape because they are the food source for the good guys - predatory controllers such as ladybirds and beetles, which live in your uncultivated margins.

“But some of my fields range

OCTOBER 2023 18 FEATURE ENVIRONMENT

You actually want some aphids and slugs in the landscape because they are the food source for the good guys

Crops such as this heritage wheat are chosen to match the farm’s soils.

IT FEELS IMPOSSIBLE

to keep a lid on the creeping issue of black-grass, especially with a heavy soil like ours.

David Hurn

On Farm Grower

UNTIL

you start the season with the right balance of cover crops, consistently hand rogue survivors, and include Luximo® as part of your IPM strategy.

IT’S DONE.

I’m delighted with the job

Luximo®

Luximo® Use plant protection products safely. Always read the label and product information before use. For further product information including warning phrases and symbols refer to www.agricentre.basf.co.uk. Luxinum® Plus contains cinmethylin (Luximo ®). Stomp ® Aqua contains pendimethalin. Luxinum® Plus, Luximo ® and Stomp ® Aqua are registered Trademarks of BASF. © BASF 2023. All rights reserved. Real results from real farms are in. Scan the QR code or visit agricentre.basf.co.uk/luximo Luximo® A new dawn for weed control Available as Luxinum ® Plus + Stomp ® Aqua. Use as part of an IPM strategy.

FEATURE ENVIRONMENT

from 20 to 30 hectares and if there is an aphid in the middle, it is going to take a while before something comes for that.

“So, all the evidence shows that putting in-field flower strips within about 100 metres of each other enables them to move through the field more quickly.

“The other thing with insecticides is that they also kill the predators. And the first things to re-establish are the pests not the predators. So, you will soon have to spray again anyway.

“We have just taken on some new land, put in some habitat areas and are monitoring across three years.

“Now my agronomist does not just walk through the field looking for slugs and aphids, he is looking for beetles and ladybirds. He is worried that he is going to miss an aphid and that I am going to blame

Farm facts

rThe farm extends to 165 hectares, 10% of which is left as a non-cultivated habitat areas, and a further 12% planted with herbal leys

rA further 320ha is farmed under a mix of contract, rented and share farming agreements

rSoil is chalky boulder clay with 60% clay content

him, but we have to have the confidence to turn off the sprayer.”

Disease scores

Further measures to cut chemical usage and running costs have included planting more pest and disease resistant varieties. He is, he says, always looking at untreated, rather than treated disease scores snd when he does buy a new vsriety, he will always trial it on a smaller field.

“I also talk to seed breeders to understand where the stock comes from. If it is from a loamy soil area it is not going to thrive on our soil which has a high clay content.

“It is no use if it needs to be fed loads of fungicide. We are now planting some YQ heritage wheat varieties. Last year we got 6.5t/ha, with no inputs. on a second wheat.

“I will use biostimulants to give the crop a nudge, but if I can cut

my overheads and produce that amount, it is profitable.”

The farm has adopted a mix of autumn and spring sowing, depending on weed issues.

Eight years ago, he had a field of winter wheat which had horrendous issues with black-grass.

“I wanted to terminate it, but my father insisted we take it through to harvest. We ended up with a yield of 2.5t/ha.

“We lost a huge yield to black-grass and wasted money treating it. Spring cropping has enabled us to stop wasting money on grass-weed herbicides.

“The only use is a pre-emergence for black-grass and if you have not got on top of it with that, you have lost the battle anyway.

“I have experimented with spring beans, but it is a rather boom or bust crop in this area where the weather is so unpredictable, so my main spring concentration is on barley.”

The target is ending all artificial fertiliser use within five years. Machinery requirements and maintenance costs have been lowered by adopting direct drilling.

“So, we do not always get the highest yields, or have the most in the barn when wheat prices go high, but we will not have the biggest cheques to write when it goes the other way,” says Mr Lines.

“And we know our markets are going to become more unstable. For me sustainability is the key for us going forward.”

A local grazier’s sheep forage on the farm’s herbal leys and cover crops and it has enabled Mr Lines to contemplate opening up a new revenue stream of his own.

“We had a 100 head of cattle until BSE and foot-and-mouth in the 1990s made it uneconomic.

rCropping areas vary, but average yields are: first wheats 10-12t/ha, second wheats 8-9t/ha, spring barley 6-7t/ha, beans 4t/ ha. Largely sold through Camgrain, as well as spot selling

rTwo full-time workers employed on machinery

Use of good cover crop mixes has helped eliminate the need for added P and K applications. Nitrogen use has been halved, he says.

“But I am planning on bringing back a light-footed breed like the Shorthorn for the leys, which will be able to stay outdoors for long as possible.”

With an estimated 30,000 to 40,000 homes going up in the surrounding area, Mr Lines sees direct selling the meat from a farm

OCTOBER 2023 20

whose history is traceable back to the 11th century as a viable option.

His work for the Nature Friendly Farming Network takes up a huge amount of time. He was a founder member of the organisation, which was established in 2017 to give a stronger voice to farmers committed to managing their land for wildlife and the public good.

“Many accused me of being a mouthpiece for the Royal Society for the Protection of Birds. They have no direct influence but, along with many organisations, they have given some funding to the network because they want to work with farmers,” says Mr Lines.

“We are now recognised as a farming stakeholder across the UK (3,000 farmer members, and 8,000 public members) and we sit at the table of Government meetings.

“I have had the current Farming Minister Mark Spencer here and shown him how food security and a healthy environment go hand

in hand. Farm systems that work with their landscape’s capability is what the future of farming is going to be.”

OCTOBER 2023 21 Call us on 01799 533700 or visit us at ragt.uk G4

RGT BAIRSTOW Joint highest yielding soft wheat on the RL* Consistent performer Approved for distilling Good disease ratings Wide sowing window and excels when drilled late Excellent second wheat performance RGT Bairstow. Recommended List 2022/23. * Results based on yield performance across all UK regions. RAGT_Bairstow_AF_MP.indd 1 01/09/2023 10:01

WINTER WHEAT

Mr Lines’ first step towards nature friendly farming was the planting of hedgerows.

Measures to cut costs have included planting more pest and disease resistant varieties.

Natural predators such as ladybirds and hoverflies keep the aphid population down on the beans.

An ambitious new research project is aiming to leverage the potential of pulse crops to help UK agriculture bring about a reduction of 1.5 million tonnes of CO2e per annum – equating to 54% of the greenhouse gas (GHG) emissions reduction target for the industry.

The four-year, £5.9 million ‘Nitrogen efficient plants for climate smart arable cropping systems’ (NCS) project has two main aims: to increase the proportion of pulse cropping in arable rotations across the UK from 5% to 20% and to substitute up to 50% of imported soya meal used in livestock feed with more climate-friendly homegrown pulses and legumes.

A consortium of 17 UK companies and research institutes is participating in the project, and it is hoped that up to 200 UK farm businesses will also get involved.

PGRO chief executive Roger Vickers, who leads the project, says: “Everyone knows that pulses and legumes have considerable benefits for UK farming systems, but these have never been truly and accurately measured, so their value has been sorely underplayed and their potential to address the climate crisis has gone unrecognised.”

Five steps

There are five main steps within the project encompassing data gathering and capture, soil resilience analysis, pulse and legume feeding trials and practical application of findings.

The James Hutton Institute is leading a data gathering exercise. This will include data collected from farmers who Farm Carbon Toolkit will help to calculate their farm carbon footprint baseline and whose GHG emissions will be tracked throughout the project.

ADAS is heading up work to capture data from historic

Pioneering pulse for climate-friendly

An expansion in pulse cropping could help pave the way to net zero as well as providing benefits on-farm. Teresa Rush reports.

information and new on-farm trials to test the hypothesis that increased pulse cropping can substantially reduce carbon emissions from agriculture. New in-soil nutrient sensors from PBL Technology will be among the technology used in the data capture.

Feeding trials led by McArthur Agriculture will seek to better understand the end use of pulses and legumes in animal feeds, which is the only viable market for the output of an increased UK pulse area, maintains John McArthur managing director of project partner McArthur Agriculture.

He says: “One of the first points of call is to do a literature

review, which is being done at the moment by SRUC, of all the public papers relating to replacement of soybean meal usage with pulses and then also to look at the processing

techniques that may have been used. And then we’re going to look at processing techniques for enhancing the nutritive value of beans and peas.”

The focus will be on-farm

OCTOBER 2023 22

The NCS project aims to support growers to increase pulse cropping in arable rotations.

Godminster

Farm’s overall aim is to reduce the carbon footprint of our cows’ diet

PETE CHEEK

production

climate-friendly farming

processing techniques and the performance of these will also be assessed in terms of their economic viability and carbon mitigation potential.

Feeding trials

Feeding trials already completed at Godminster Farm in Somerset pave the way for further work to be completed as part of the NCS project, suggests Mr McArthur.

“Godminster Farm is already engaging with the guiding principles of the NCS project by adding beans to its crop rotations for inclusion in its cows’ rations, working towards the replacement of imported soya bean meal in organic dairy,” says Mr McArthur, who has been working with farm manager Pete Cheek since June

2022 on trialling post-harvest processing of beans supplied by Organic Arable.

Mr Cheek says: “Godminster Farm’s overall aim is to reduce the carbon footprint of our cows’ diet and deliver full traceability of all their rations by growing beans here on the farm.

“We roasted the beans with a Mecmar T05 roaster, they were then milled and incorporated into the cows’ diet as part of the parlour feed and in the total mixed ration.

“The next phase of our trial will be to roast the beans we are growing on-farm this year straight from the combine, rather than roasting beans we have bought in; this will allow us to store them safely and increase the amount we are able to add to the rations.”

Central to the NCS project will

be ‘Pulse Pioneers’ - a core group of farmers who will be paid to work with scientists to co-design crop and feeding trials to carry out on their farms. A PulsePEP (performance enhancing platform), led by ADAS has also been launched as part of the NCS project. This is intended to be a hub for the farmer-led community, bringing together those seeking to achieve the best from pulse crops and reduce carbon emissions, as well as providing a forum for discussion on best practice pulse cropping.

Workshop

A recent ‘Pulses of Brilliance’ workshop organised by the British On-Farm Innovation Network (BOFIN) and ADAS brought together farmers and project partners to develop ideas that farmers will take forward in the first year of on-farm trials.

Among the farmers present was John Seed, of Woodend Farm, Gavinton near Duns in the Scottish Borders. With an arable enterprise and 32,000 laying hens, he says his customers are pushing him towards reducing his carbon emissions and improving biodiversity on-farm.

“Our aim at the moment is to replace bought-in soya meal with home-grown beans,” he says.

Home-grown beans currently comprise up to 20% of the poultry ration used on the farm and Mr Seed calculates that he saves £90-£110/t by substituting soya with beans.

“So there is a real incentive,” he says.

However, he wants to understand more about the costs and risks associated with home-grown legumes.

“We are trying to produce as much of our own feed as we can, but it has been difficult to find information,” he adds.

Lincolnshire grower Phil Marris was also at the meeting and is also in search of more information. With just over 300

ROGER VICKERS

arable hectares on mixed soil types between Gainsborough and Scunthorpe he grows beans on his heavier land and has been growing lupins on his lighter soils after what he describes as a ‘disaster crop’ of beans, which was badly hit by drought and frost. He is keen to include pulse crops in the rotation but wants more technical advice, backed by sound science, including feeding information for livestock farmers who are potential end users of pulse crops.

Pulse crops have struggled to cement a place in modern arable farming’s shortened rotations, but with a range of environmental and economic pressures bearing down on agriculture, the time might just be right for them to make a return.

For more information, visit ncsproject.co.uk MORE ONLINE

Project partners

rAgrii, The Allerton Project/ GWCT, ADAS, Kelvin Cave, LC Beef Nutrition, Farm Carbon Toolkit, First Milk, PBL Technology, Wessex Water/YTL Group, AB

Agri, BOFIN, the James Hutton Institute, Cranfield University, McArthur Agriculture, SRUC, Leaf, UKRI/Innovate UK

OCTOBER 2023 23

PULSES TECHNICAL

The value of pulses has been sorely underplayed and their potential to address the climate crisis has gone unrecognised

AHDB’s Strategic Farm North near York is playing host to an exciting new fertiliser efficiency trial which could revolutionise nitrogen use. Emma Penny reports.

Developing a framework for improving N efficiency

ith fertiliser one of the most talked about inputs in terms of cost, efficiency, benefits and environmental impact, making better use of it must surely be a good thing. At last year’s stratospheric cost – despite its undoubted payback in terms of yield improvement - it felt like every kilo counted.

For both financial and environmental reasons, it would be the ‘gold-standard’ of management if nitrogen applied could be exactly what was used by the plant.

Last year, David Blacker achieved 93% nitrogen fertiliser use efficiency on his heavy soils at Church Farm on the northern outskirts of York. Speaking at a recent open day, held as the farm is the AHDB’s Strategic Farm North, David’s brother Clive, who is a farm technology and data specialist, explained more about the result, and the project it is part of.

“If you do one thing as a farmer, I think it should be to calculate your nitrogen use efficiency – NUE,” he said.

Working out nitrogen fertiliser use efficiency - NfUE – is a reasonably straightforward calculation, he explained.

“Work out all the N that has been applied to the crop, as fertiliser and the available N from any manure applied.

“Then calculate all the N removed – so that’s the yield [plus any straw if that is removed and baled, but not if it is chopped in field], and the grain protein.

Most merchants will give you your grain protein figure free of charge if you ask for it when they do sample checks before they buy your grain.”

These two figures – N in, and N out – are used to work out NfUE using a spreadsheet (see panel on p25).

“On one crop here, we knew we had applied 216kgN/ha, had removed 203kgN/ha, and the spreadsheet showed we had 93% NfUE, which I thought was fantastic.”

However, figures from previous years show much lower levels of NfUE – as low as 56% in 2018.

“I was horrified when we worked

it out. But when we looked at the figure for 2019 it went up to 63% after we had thought a bit more about timing and what the crop wanted, rather than just sticking with RB209 recommendations.”

Soil

So it is not as straightforward as it initially appears. He believes that to do it ‘properly’, the soil needs to be taken into account.

“But we really know nothing about the biology of soil,” he says.

While NfUE levels might look brilliant at 93%, sampling soils on the farm to 30cm, 60cm and 90cm had shown that there was 80kgN/ha available in the soil in

March and a retest in July after harvest showed 140kgN/ha available.

“I was horrified that we had so much left in the soil. This year, our spring sampling has shown we have 20-40kgN/ha available which is much less than previous spring levels,” said Mr Blacker.

Many farmers are already monitoring N levels in crops using hand-held spectrometers and applying a varied amount of N depending on the N in the leaf.

“Canopy management is something we are all familiar with, but all the information we gather at present doesn’t solve the question of what happens in the soil.”

The dilemma means he is now working on a new four-year NUE project (NUE Profits), funded by Innovate UK. The project kicked off in April and is in its first year.

“There are issues with pollution which water companies want to solve, plus we know 83% of our liability in terms of carbon comes from N so if we want to achieve net zero, we have to get a grip of NUE.”

The project is looking at new technologies which will help give an understanding of what is in the soil and what is being removed by crops.

The initial steps involve soil testing and Mr Blacker is using Hill Court Farm Research for this. It is able to ‘incubate’ the soil samples as they would be in the field. This means it can calculate the N which may become additionally available through mineralisation, but it won’t tell you when it will mineralise.

Prototype sensors are being

OCTOBER 2023 24 TECHNICAL CROP NUTRITION

WEvery arable farmer should investigate nitrogen efficiency on-farm, advises Clive Blacker.

used in the field to assess what is happening, with the probes gathering data and sending it off at regular intervals. Nitrate sensors are being used too, in order to see fluctuations throughout the seasons, and will give a reading of availability in the soil every 20 minutes.

Trial plots

The two trial plots at Church Farm also have ‘200 sensors/ sq.m’– meaning the crop itself. This year, it is being monitored using a device from China, which has been calibrated for UK conditions, and will provide spectral information on leaf area, N, P, K and NDVI - how much green or live material there is in the test area.

“We get a lot of readings very quickly,” Mr Blacker said. Yara’s N-Sensor is also being used, calibrated specifically to the test plot which acts as a calibration point for the N-Sensor.

While this project is new, much has already been learned. In April 2019, when the plots were first monitored, the cold, sunny weather meant crops were very deficient in nitrogen as the cold conditions limited uptake rates even though plenty of N was

available. The monitoring approach recommended a total of 180kgN/ha, saving 70kgN/ha compared with the farm’s usual 250kgN/ha application.

“In 2020, we had a very mild but dry spring, so we timed our fertiliser timings around rainfall events as water was a limiting factor to uptake, and we could see N uptake occurring in the plant within six days.

“In spring 2021, we faced a cold dry spell followed by sudden rainfall. We thought we knew

exactly what we needed to do, but we didn’t. It was a lot colder, so when we applied the fertiliser before the rain we were horrified that nothing happened – it took 21 days for the crop to take up N. The only difference we could see was the soil temperature was lower, and we think that if the soil temperature is less than 10 degC, then uptake is significantly reduced; there is a real correlation between that and reduced fertiliser uptake.

“Last year, we didn’t get to the desired level of N in the plant until the flag leaf came out, so we knew we then needed to work out what to do in a dry season. As part of this, we are going to look at foliar N.”

Flexible

The varying conditions have meant being flexible with timings and application levels; this year, the crop received three applications, compared with four last year.

“Our biggest challenge has been getting David to delay applications so the crop gets the right amount at the time it needs it,” Mr Blacker said.

Crop modelling data and satellite weather information is also being used as part of the project, adding to the millions of

Working out NUE

data points being generated, and allowing monitoring of the canopy in each field.

“As the project is just in its first season and we are developing a framework for improving nitrogen efficiency - a ‘FINE’ approachthere is plenty of opportunity for farmers to join us if they are looking to reduce greenhouse gas emissions and improve nitrogen use efficiency.”

Mr Blacker said his key advice is that every arable farmer should investigate nitrogen efficiency.

“It is vital you understand that and use the information to make better decisions. Just the measurement process in its own right had a big impact on our farm, and it only cost us the time of analysis to do it in a basic way.

“If you’re keen to get more technical then please get in touch as we would be more than happy to have more farmers participate in our research going forward.”

25 CROP NUTRITION TECHNICAL OCTOBER 2023

Last season the desired level of N in the plant was not achieved until the flag leaf emerged.

A greater understanding of soil biology will help guide improvements in nitrogen efficiency, believes Clive Blacker.

JAgAnalyst, the business Clive Blacker is part of, has an NUE calculator which will evaluate your farm results. Find out more at aganalyst. co.uk/nue-calculator

CropTec takes place on November 29-30 at NAEC, Stoneleigh, a new venue for this year.

Seminars aim to help farmers ‘meet challenges’

Real stories from forward-thinking arable farming businesses are set to feature among the sessions in this year’s CropTec Show seminar programme.

The 2023 show seminars will also include sessions on crop protection, crop nutrition and new markets, as well as a discussion session with three progressive arable farmers.

‘Breaking down access to new markets to cultivate business resilience’ is the focus of the first session which will be chaired by NFU chief economics adviser Rohit Kaushish on day one and vice-president David Exwood on day two.

Changes to Government policy and the high costs of production make this topic particularly pertinent, believes Mr Exwood.

“In a fast-changing world, having more opportunities to

provide new and diverse income streams for farms is vital,” he says.

Mr Kaushish hopes the session will offer clarity on emerging support schemes and environmental markets as well as policy developments.

“Farmers are looking for new diversified income opportunities to manage market risk and uncertainty and are increasingly being approached by project developers in environmental

markets about new potential income streams. There are a lot of questions being asked at the moment on the potential of such markets at farm level; it is therefore a really good time to be exploring these markets in more detail, he says.

Crop nutrition

Past AHDB chair and former NFU president Sir Peter Kendall will chair a session delving into issues around crop nutrition. As agriculture strives to achieve its sustainability goals, this roundtable discussion will see experts explore the importance of low carbon crop nutrition, while looking at the future of fertiliser policy in a changing climate.

Panellists include Mark Tucker, business development and head of agronomy for session sponsor Yara, and independent agronomist David Boulton from Indigro.

“Anyone who has lived through the last 12 months of fertiliser prices will be considering really carefully all available options for plant nutrition in their system. Now is a great time to plan for the future,” says Sir Peter.

“I am looking forward to being part of this year’s CropTec at its new location. The show comes at a great time of year when we have the chance to review our previous harvest and plan for the spring season ahead of us.”

‘Connecting bold thinkers in a time of change: Real stories from boots on the ground’ is a new session, sponsored by Horsch. Former Elveden Estate farms director Andrew Francis, now at Team Ag, hopes the presentations from three innovative farmers will show the diversity of approaches as well as the similarities.

“It is always good to challenge yourself in how you go about doing the day job. Whatever the

OCTOBER 2023 26 EVENT CROPTEC SHOW

It is a really good time to be exploring these [environmental] markets in more detail

ROHIT KAUSHISH

components of your business are, any time is a good time to change,” he says.

Andrew Williams, manager of Home Farms in Nacton, will discuss his experience with robotics on a Suffolk farm producing conventional arable crops and organic vegetables. Robotics and other technologies are being developed at pace, so being prepared to make swift investment decisions is essential, he says.

“These innovations are going to arrive, come what may, so farming businesses need to get to grips with developments coming down the road.”

Jack Smith, farm director for A.G. Wright and Sons in Cambridgeshire, will explore the importance of data in decision making.

“There is a ‘sitting in the office’ answer, which needs to be squared with the ‘standing in a field’ answer,” he says. “It’s about

taking insights from both and coming to a sensible informed decision.”

Crop protection

The final session of the day tackles crop protection and changing regulation, with expert input from agronomists and plant breeders. David Schafer of RAGT will give an overview of breeding research to improve

Sponsors and supporters

levels and durability of varietal resistance for UK farmers. This will include RAGT’s work on barley yellow dwarf virus (BYDV) resistant wheat as well as new selection technologies to complement field scoring.

Other speakers include James Bairstow, agronomist and associate director for Strutt & Parker, who will share his expertise on integrated pest management (IPM) and Dave Bench, chief executive of CropLife UK, which represents the plant science industry.

Verity Hyland, event director for CropTec, says: “With the arable sector facing such historic changes, our seminar programme is designed to equip growers with the knowledge

they need to meet the challenges head on and maximise opportunities.

“As before, the CropTec seminar programme will bring the specialist knowledge of scientists, plant breeders, agronomists and policymakers together with the ‘boots on the ground’ expertise of some of the country’s most innovative farmers to create a unique learning opportunity.

“I would encourage anyone with an interest in the sector to come along and be informed and inspired. We look forward to welcoming you to Stoneleigh in November.”

Tickets for CropTec 2023 are free and available now by registering at croptecshow.com

Transforming Innovation

Expanding Horizons

For a resilient agriculture, environment, economy and society

CHAP is driving innovation to support the changing role of the grower – custodians of technology, innovation, diversification, environmental stewardship and more.

• An integrated perspective of agriculture, the environment, economy and society will be key to unlocking true net zero gains; CHAP is here to build those links.

• As one of the Agri-Tech Innovation Centres, CHAP is supported by a wider network of expertise and knowledge within agriculture, combining sector insight and opportunity.

• Breaking down silos to enable the integration of minds, technologies and systems, is a role CHAP is here to play.

chap-solutions.co.uk

CROPTEC SHOW EVENT

Funded by

MORE ONLINE

JCropTec Show 2023 is supported by sponsors UPL, Anglian Water, Horsch, Yara and Agri-EPI, and partner UKRI.

Farming businesses need to get to grips with developments coming down the road

ANDREW WILLIAMS

Switching to reduced and minimal cultivations from conventional plough-based systems has produced a range of commercial and environmental benefits, a major five-year farm trial has shown. Jonathan Wheeler reports.

Study highlights improvement in farm resilience

The initial five-year Conservation Agriculture and Sustainable Farming Project trial was completed on the Game and Wildlife Conservations Trust’s estate at Loddington, Leicestershire, and on Andy Barr’s farm at Lenham, Kent.

Covering three crop establishment systems across a full five-year rotation on the two farms with their contrasting soil types, the project has captured more than 80,000 data points to evaluate the agronomic, economic and biodynamic implications of sustainable

reduced or direct drill establishment techniques, compared to full tillage.

And the trial has just been extended by a further four years to enable issues raised by the initial findings to be further investigated.

The two farms presented contrasting scenarios, says Belinda Bailey, Syngenta’s sustainable farming manager, who led the work.

Loddington is a heavy land farm, while soil types at Lenham are much lighter.

In addition to Syngenta and GWCT, the other partners are NIAB and the European

Conservation Agriculture Federation (ECAF).

On the trial fields, both farms used their conventional rotations and compared three working systems.

These were ploughing to 15cm-20cm; reduced cultivations to 10cm-15cm and minimal/zero cultivation followed by a direct drill. The reduced and minimal/zero tillage systems used cover crops where appropriate.