Pages 20-21

Preparing for the disease season ahead

Pages 30-31

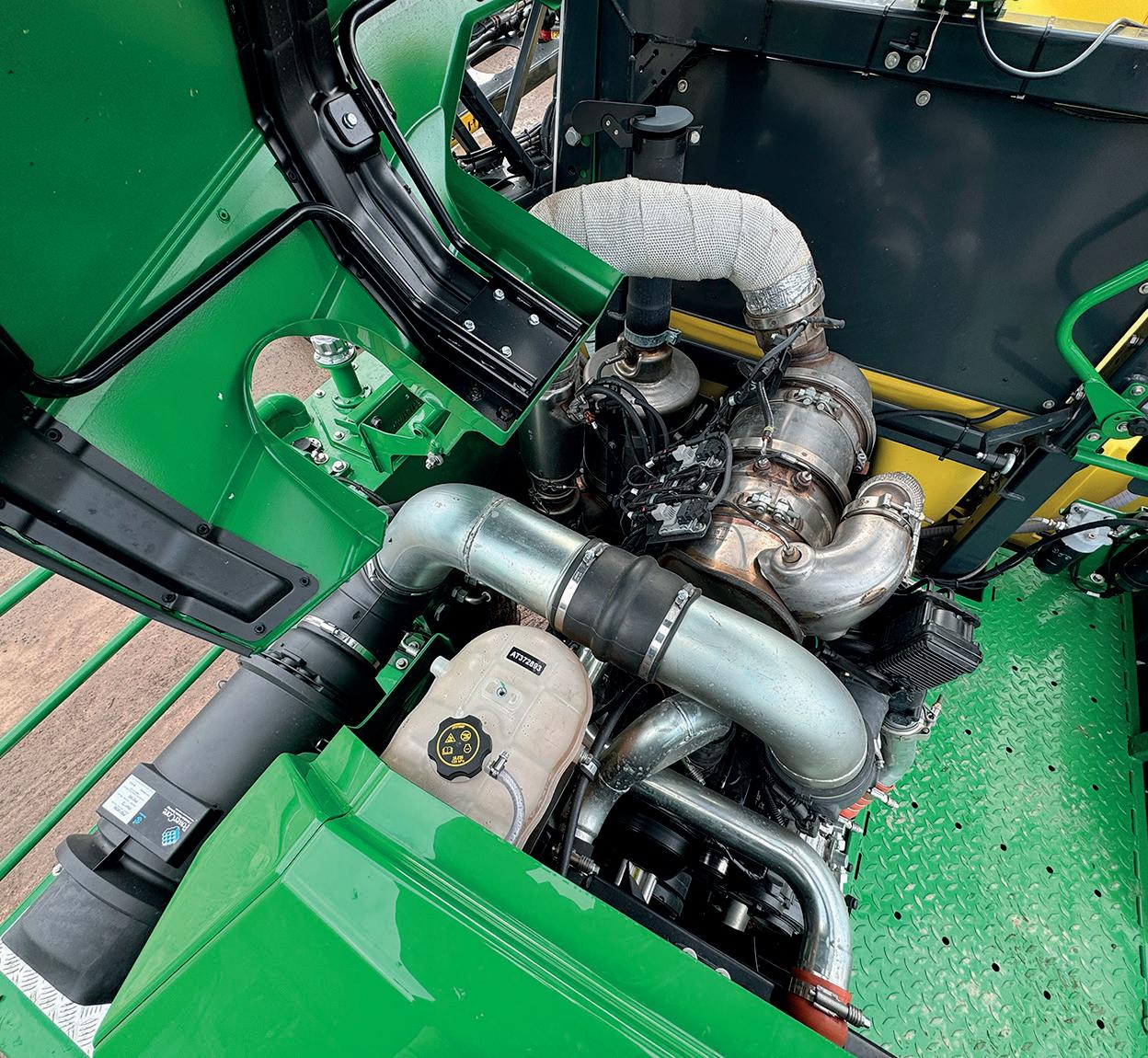

FIRST DRIVE T3 FUNGICIDES

John Deere 340M put through its paces

Pages 62-66

Pages 12 and 26 EVENT PREVIEWS

What to expect from Cereals and Groundswell

Pages 20-21

Preparing for the disease season ahead

Pages 30-31

FIRST DRIVE T3 FUNGICIDES

John Deere 340M put through its paces

Pages 62-66

Pages 12 and 26 EVENT PREVIEWS

What to expect from Cereals and Groundswell

John Deere offers a full range of sprayers. They are designed to make accurate spraying effortless. Starting from manual valve operation to fully automated systems, they’re packed with time-saving features like PowrSpray™ Active Pause, AutoSetup, Air Purge and more.

Ask your dealer for a demonstration and see how easy it is to be precise.

Taking

Find

what is in store at this year’s

How can you get involved?

Hear what two of last year’s winners have been up to since the awards

in the fields throughout the

at how the disease is adapting to

What help is available and what varieties are sparking interest this year?

Find

Analyse the potential

from

breeder

what growers can do to prepare

Licencing changes means increased access to hemp

What

consider before committing to energy

How to incorporate grain maize into arable rotations

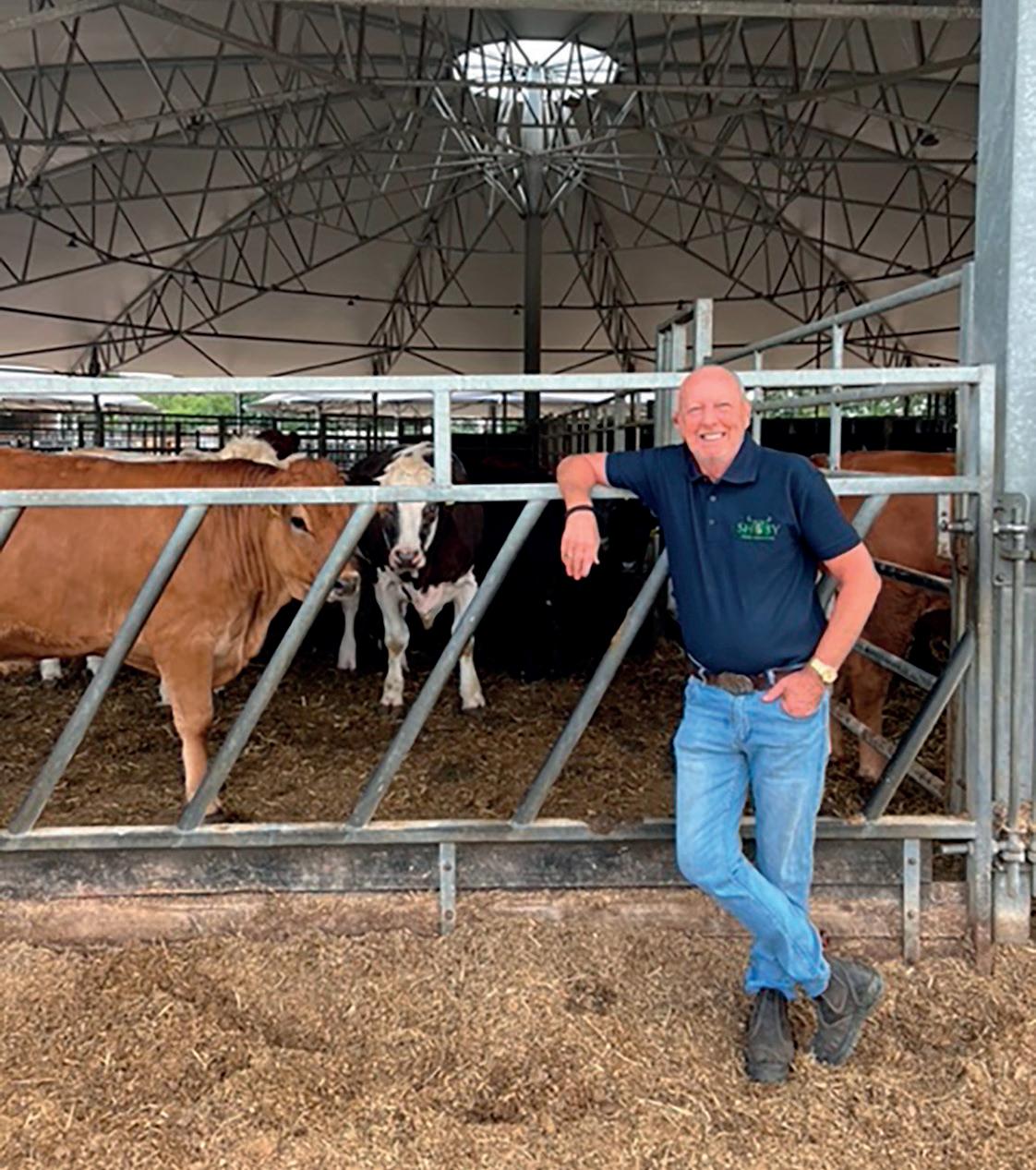

What is involved in switching from crops to forage?

Find

about the new release from Valtra

Arable Technical Specialist

Ash Ellwood, 07786 190 188 ashleigh.ellwood@agriconnect.com

Machinery Editor

Toby Whatley 07583 054 831 toby.whatley@arablefarming.com

Machinery and Farm Tech Specialist

James Huyton, 07787 242 185 james.huyton@agriconnect.com

Creative Services

Mike Begley, 01772 799 405 mike.begley@agriconnect.com

Katie Haydock, 01772 799 561 katie.haydock@agriconnect.com

Picture Editor

Marcello Garbagnoli 01772 799 445 marcelllo.garbagnoli@arablefarming.com

Key Accounts Manager

Jane Newton 01948 780 783 jane.newton@arablefarming.com

Key Accounts Manager

Mark Jackson 01322 449 624 mark.jackson@arablefarming.com

Account Manager

Chris Knowles 01772 799 550 chris.knowles@agriconnect.com

Sales Director

Mike Hartley 01772 799 532 mike.hartley@arablefarming.com

Advertising Production

Justine Sumner 01772 799 437 justine.sumner@arablefarming.com

Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com

© Agriconnect 2024

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Arable Farming are subject to reproduction in information storage and retrieval systems. ISSN 0269-6797

www.croptecshow.com November 29-30, 2024

Since our last edition in March, the weather has finally seemed to pick up and the sun has made more appearances in the last few weeks than it has in the last nine months.

As fields of spring crops have been drilled into lighter land, and the steady hum of tractors and mowers fills the countryside, fieldwork is finally underway across the UK.

What the weather has left is a potentially challenging disease season, in a year where the increased rainfall could have amplified diseases such as septoria, creating a reliance on growers implementing robust fungicide programmes at the T2 and T3 spray timings (p30-31)

Alongside plant protection, careful nutrition is also vital this season, with reduced crop rooting depths due to waterlogging and the potential for leached nutrients. Growers are advised to pay close attention to micronutrient availability in soils and crops (p21-22) and facilitate nutritional programmes to safeguard crops that can carry an attractive premium, such as milling wheat (p22-23)

Creating diversity within arable rotations has many benefits to growers, so take a deep dive with us as we look at how the licences on commercial hemp have changed in the UK, enabling easier access to markets (p38-40)

We also speak to a Norfolk contractor to investigate the practicalities of growing crops for energy, either through renting fields to growers, or growing the crops yourself (p44-46). Plus, find out how you can benefit from adding forage crops into your arable rotation (p50-51)

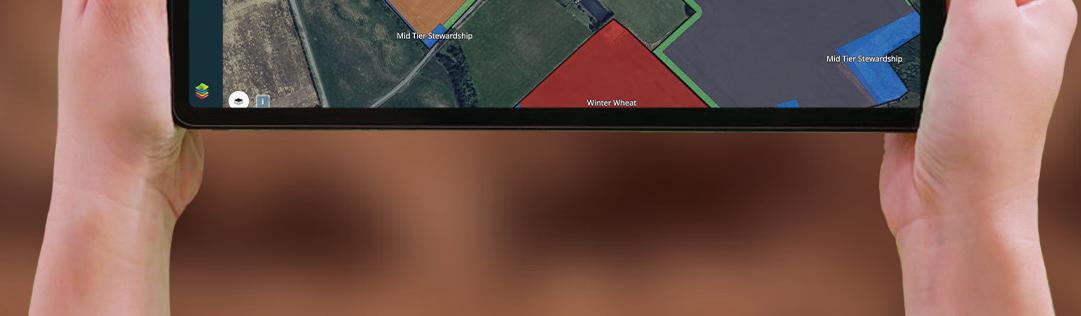

Our machinery team took a first drive of the John Deere 340M self-propelled sprayer which, since its launch at last year’s Agritechnica, has been met with significant UK market demand (p62-66)

Learn what is happening within neighbouring fields in your area, as we chat with eight agronomists from dif-

ferent regions of the UK to determine how crops are looking, and look ahead into the season for any developing risk factors (p56-59).

The arable industry has an exciting event season on the horizon and this edition includes show previews from Cereals 2024 (p12-15), Groundswell Festival (p26-28), Farm24 (p32-33), the British Farming Awards (p42-43) and CropTec (p7), all set to bring knowledge sharing and networking opportunities to the forefront of the industry.

We hope you enjoy our second 2024 offering of Arable Farming magazine. If you would like to know about our team of experienced journalists, find out more about us on the inside back cover, or get in touch via the panel of contacts on the left.

We wish you a prosperous season ahead.

Perform

Limus ® , the only urease inhibitor with TWO proven actives.

Limus® keeps your nitrogen where it needs to be, increasing yield by 5% compared to urea/UAN*.

Backed by robust ADAS trials data, Limus® is also proven to deliver up to a 3% yield uplift over a urease inhibitor with one active**.

Find your closest supplier at agricentre.basf.co.uk/limus

Global weather patterns are impacting grain markets, which could give a little comfort to British growers expecting their smallest harvest in years.

AHDB switched its short-term wheat market barometer dials to bullish, although the six-month dial remains neutral.

The current market is largely being made in Russia and the Black Sea, with a lack of rain in Russia through March and April, plus more attacks on Ukrainian Black Sea ports and tension in the Middle East also contributing to higher shipping costs.

AHDB senior market analyst Helen Plant said weather in other areas was having an impact.

“Following adverse weather and damage from leafhoppers, the Buenos Aries Grain Exchange cut its estimate of the Argentinian maize crop by three million tonnes to 46.5mt. Meanwhile, heavy rain and hot, dry conditions are causing concern for maize in different parts of Brazil,” she said.

There was some improvement in UK crop conditions, according to AHDB, based on data from Andersons and RSK ADAS.

At the end of April, 45% of the winter wheat crop was rated in good to excellent condition, which was up from 34% in March, but almost half the rate seen in the 2023 wheat crop at the same point. Winter barley

ratings were up from 38% to 56% in the month, but down from 90% the year before. Winter oilseed rape ratings were at 47% – up from 31% in March, but down from 66% the year before.

In March, AHDB estimated the wheat area for 2024 was down 15% on last year, with a 22% drop in winter barley and 29% increase in spring barley. The OSR area was estimated to be 28% lower.

JAgrochemical manufacturer

Sumitomo Chemical Agro Europe, best known for its biorational agricultural products and solutions,

aims to strengthen its market presence in both Europe and the UK with a signi cant pipeline of new products, according to Alberto

Ancora, general manager of the manufacturer.

Within the company’s immediate pipeline are several new conventional active ingredients currently in the UK approval system, including two new fungicides targeting diseases such as septoria, net blotch, ramularia and rusts. e firm is hopeful for approvals soon.

combining conventional chemistry with new biorational strategies as a solution for sustainable farming.

Green evolution

Mr Ancora said: “Beyond our conventional chemical portfolio, we have also made acquisitions and investments in biorational agriculture over the years, anticipating the current green evolution in European agriculture. We see signi cant potential in

“Although Sumitomo may be a new name to many UK farmers and agronomists, we have a rich history in agriculture going back 350 years. e company was born out of an idea of converting gases emi ed by copper mining into fertilisers, solving an environmental problem and providing a solution to farmers. at is a concrete example of our approach as a pioneer in sustainable agriculture.

“Sumitomo Chemical [UK] is working with NIAB and ADAS on trials to optimise the potential of these products and we hope to present our data on these new actives in the near future.”

JThree new theatres focusing on innovation, knowledge and profit will provide visitors to CropTec with practical advice to futureproof their farms.

The new additions have been made as the show, which is at the forefront of showcasing technical knowledge, products, services and solutions to the UK’s most progressive growers and agronomists, enters its 12th year.

The sessions will explore a range of topics, including crop varieties, eco-friendly fertilisers, pesticide regulations, diversification, and the role of artificial intelligence and robotics in arable farming.

The changes have been made as part of a refreshed event, with the show, run by Arable Farming’s parent company AgriConnect, making significant enhancements to its conference programme, aligning with evolving agricultural practices and industry trends.

Verity Hyland, CropTec event director, says: “CropTec’s purpose is to help the farming community thrive. By bringing together companies, visitors and industry experts, CropTec shines a light on the arable industry’s key topics, concerns and opportunities.”

Carrier XT can either be delivered as a trailed or mounted version. The working width is 4.25, 5.25 or 6.25m. All Carrier XT models can be equipped with a range of both single and double packer options. At the end of April, 45% of the winter wheat crop was rated in good to excellent condition, which was up from 34% compared with the end of March. MORE ONLINE The CropTec Show takes place on November 27-28, 2024, at the NAEC Stoneleigh. Find out more at croptecshow.com

Obstacles to sustainable practices including biologicals uptake could be overcome by existing agri-tech, if the regulatory environment can keep up. Teresa Rush reports.

The adoption of biological crop protection is being delayed by a regulatory environment which has failed to keep abreast of innovations that would make biological products easier and more effective to use.

This is according to a new report

– Precision spraying and biologicals –driving collaboration – launched at the World Agri-Tech Innovation Summit, which took place in the United States on March 19-20.

The report, produced by Agri-TechE in collaboration with Cambridge Consultants, draws on input from agronomists, agrochemical suppliers, formulators and equipment and machinery developers.

It reveals that there is significant market pull for biologicals from consumers and retailers keen to reduce chemical residues in food products and the environment. There is also a market push from the regulators looking to reduce the use of synthetic chemicals.

The report outlines the obstacles to adoption that could be overcome by existing agri-tech, accelerating the uptake of these products.

Dr Belinda Clarke, director of Cambridge-based Agri-TechE, is a co-author of the report.

rDevelopment, delivery and use of biologicals at scale requires new partnerships across the value chain

rCollaboration and commercial adoption has to be driven by the imperative to make it simple for growers to adopt and use biologicals. Focusing on improving their ease of use at the point of application is critical, so that they can be incorporated into existing practices

rEquipment innovations beyond spot spraying will be a key enabler of the uptake of

She says: “A desire for more sustainable practices in agriculture is driving interest in biological crop protection products, but the perception is that they are more costly to purchase, time-consuming to apply and less effective than the synthetic equivalents.

“Many of these reservations could be resolved by recent innovations in precision agriculture, which more easily enable ‘per row’ and ‘per plant’

biologicals. Regulation needs to reflect rapid technology advances for automation, and spot spraying benefits need to be realised. This will allow growers to apply local treatments in the volumes required for effective results and evolve away from broadcast, uniform applicationbased approaches

rEffective communication with, and education of, the whole supply chain is necessary to enable biologicals to become a core part of the toolkit of solutions available to growers

application cost-effectively within stringent spraying conditions. Unfortunately, the regulatory environment has not kept up with developments and is still centred around the ‘number of applications’ instead of the ‘total amount’ of active ingredient used across the field, and this is hindering developments.”

Advances in equipment – such as direct injection nozzles for sprayers – are reducing the cost of using biologicals, while robotics that enable automated application are increasing precision.

One of the examples in the report is the treatment of spider mites and russet mites in speciality crops. Autonomous UV-C equipment is used to apply predatory mites at night with more accuracy than humans, greatly increasing the

efficacy of the treatment. As navigation technologies improve, these developments are becoming more accessible.

More broadly, the use of synthetic biology was deemed by some respondents to be a game-changer for biological product development, but legislation around the use of GMOs, particularly in Europe, makes this route currently nonviable. Synthetic biology approaches could widen the choice of biological products available, reduce development time and open up the possibility for novel gene-based approaches too, says the report.

Dr Clarke is calling on the wider agricultural industry to work together to ensure that growers have access to innovative biological solutions, in order to help make agriculture more environmentally sustainable for the benefit of all.

“The industry urgently requires a more collaborative approach between formulators, equipment developers and regulators to fast-track these innovations,” she adds.

Dr Belinda Clarke

The full report is available at agri-tech-e. co.uk/precision-agri-tech-couldaccelerate-uptake-of-biologicals

WITH SIGNUM such are one way to improve results.

Growers know that pea and bean yields are notoriously unpredictable. Proven fungicides, such as Signum

Widely recognised as the best product for chocolate spot maximises pulse yields by stopping botrytis and rust in their tracks, whilst also keeping leaves greener for longer. Shown to increase yields by 20% compared to untreated bean crops and achieve £30/ha more margin than a builds yield and margin. for more.

control, Signum more farm standard programme*, Signum agricentre.basf.co.uk/signum

of Signum

*Based on two winter bean trials by PGRO and OAT in 2020 comparing two applications at 0.5kg/ha with two applications of azoxystrobin and tebuconazole, mean untreated yield of 4.2t/ha, no chocolate spot present. Beans price based on £200/t.

Warmer, wetter winters associated with climate change could be behind the spread of a hitherto incidental disease of the UK sugar beet crop. Teresa Rush reports.

Cercospora leaf spot (CLS) was first identified in the UK in the 1930s, but until recently had not been seen as a serious threat to sugar beet.

However, since 2020 the incidence of cercospora has been rising, leading scientists to question whether strains of the disease that are specifically adapted to UK conditions are evolving.

While control of the disease can be achieved with fungicides, a British Beet Research organisation (BBRO) study has identified cercospora isolates that are resistant to fungicides and traditional sugar beet fungicide actives may not provide sufficient levels of control.

Variety ratings for cercospora are now included on the BBRO Recommended List of sugar beet varieties, providing an indication of varietal susceptibility.

To help growers and agronomists manage the increasing cercospora threat, BBRO has developed a risk forecasting model, based on disease and weather data collected in the United States and mainland Europe, where cercospora is more prevalent.

rIs the UK’s changing climate having an impact on cercospora leaf spot (CLS)?

rWhat temperature and moisture conditions are associated with CLS development in the UK?

rDo we have a UK-adapted strain or strains?

New BBRO work is looking at the cercospora strains present in sugar beet crops to understand whether these are more adapted to UK conditions.

Launched in 2021, the model generates daily infection values using temperature and humidity data to calculate the cercospora risk at postcode level and alert growers directly if there is a clear risk of disease development in their crops.

Growers can also access the risk forecast via the BBRO website and technical bulletins.

Most recently, more outbreaks of cercospora have been seen in sugar

rWhat and where is the primary source of infection in the UK?

rWhat is the level of fungicide resistance to CLS in the UK?

rHow do we manage future variety susceptibility and tolerance?

beet fields than the model has predicted, prompting BBRO scientists to question whether CLS is behaving differently in the UK’s maritime climate.

Climate change is leading to warmer, wetter springs in the UK, and these are conditions known to favour the disease, but growers are also reporting development of cercospora in their crops much later in the season, through into October and November, says BBRO’s head of science Prof Mark Stevens.

“This is something we really

need to keep an eye on, because the last thing growers want when they have invested so much money in their crop is to lose the crop canopy, lose sugar, lose frost protection. We really do need to take this disease seriously,” says Prof Stevens.

Some of the current research and development work underway at BBRO includes evaluating the potential for early detection of cercospora spores in sugar beet fields using the Canadian ‘Spornado’ spore collector.

This is a solar-powered, 3D

rUtilises regional weather station monitoring

rExisting Weatherquest network of weather stations

rTwo-day weather forecasting window

rForecasts local risk across 1,239 6x6km squares across the sugar beet growing region

rFor more information, visit: bbro.co.uk/on-farm/ cercospora-risk/

Actives: Priori Gold (azoxystrobin + difenoconazole); Revystar (fluxapyroxad + mefentrifluconazole); Caligula (fluopyram + prothioconazole)

printed vacuum system, which ‘hoovers’ the air for spores, collecting them on a fine mesh for lab analysis and subsequent culture in the BBRO growth rooms.

A network of weather stations, together with leaf sensors within crop canopies, is being used in conjunction with the Spornado to help define the weather conditions conducive to cercospora development.

Disease monitoring at 2023 BeetField sites in Norfolk, Suffolk and Lincolnshire last season revealed cercospora infection levels of 26%, 37% and 7% respectively.

Prof Stevens adds: “The key factor that seemed to be driving that [disease development] was leaf wetness and we believe those conditions are probably more

important than temperature and humidity.

“We will be assessing these data and the spores caught this year and adapting the model if required,” says Prof Stevens.

While cercospora risk forecasting will help inform decisions on fungicide use in beet crops, BBRO work has shown there are isolates of the fungus that are resistant to some fungicide modes of action.

Isolates collected in the Cambridge area, for example, showed resistance to strobilurins and some insensitivity to triazoles.

A fungicide trial (see panel) conducted by BBRO at the Lincolnshire BeetField site in 2023 highlighted the benefit of two- and

• Perfect fit guaranteed for any make or model

• Ultra-strong and durable cast base frame

• Maintains full ground clearance and steering angle

• Full engine power transferable with

• Choice of speeds with LH or RH rotation

• Integrated oil system for longer trouble-free

three-spray programmes for control of cercospora.

Prof Stevens adds that while the cercospora threat at the site in Lincolnshire was not as high as at the Norfolk and Suffolk sites, there were still disease reduction and crop biomass benefits over time from the application of the twoand three-spray programmes compared to the no-spray and one-spray treatments – even more so when rust coverage levels, which reached 60% by the end of October, were taken into consideration.

The three-spray fungicide programmes gave the highest canopy biomass scores at harvest on January 4, 2024, with the four three-spray programmes delivering scores of between 6 and 7 on a scale of 0-10 (0 = no cover, 10 = full

rCercospora appears to develop at lower temperatures than the current model assumes

rThe hours/leaf wetness threshold needs further investigation – influence of crop canopy

rIn-crop sensors, especially leaf wetness, appear to be more accurate in predicting later disease progression

canopy cover), compared with 3-5 for the two-spray programmes and around 3 for the no-spray and one-spray programmes.

“The variety was Wren and it has given an excellent yield at 104 tonnes/hectare adjusted without a fungicide. But one spray is giving you a lift of up to 10 adjusted tonnes. There’s no significant difference between a two- and a three-spray strategy, but what you’re seeing is [a yield benefit] of up to 20 adjusted tonnes from the use of those fungicides in this situation,” says Prof Stevens.

Cercospora is very much on BBRO’s radar, he adds.

“We continue to talk to colleagues right across the globe, but we do need to be appreciative of whether cercospora under UK conditions is different and whether leaf wetness rather than temperature and humidity is more important,” he says.

The 2024 Cereals Event is due to take place at a new site on the chalky soils of North Hertfordshire. Martin Rickatson discovers what some of the key arable exhibitors will be highlighting on their stands and plots.

Expected to attract over 20,000 visitors across June 11-12, Cereals 2024 will see a number of developments unveiled by key arable industry suppliers, from new varieties and crop protection products, to niche

crop types which could enable growers to broaden rotations.

Among the exhibits on the KWS stand will be previews of several new combinable crop varieties, including the firm’s first hybrid barley. The company says that although recent breeding efforts have targeted

increased disease resistance, as well as physical resilience and lower input requirements, high yields and profit potential remain a core focus.

been the cleanest contender in National List trials, scoring 7 for septoria tritici, 8 for mildew and 9s for both yellow and brown rust.

The first hybrid winter barley from KWS is Inys, with a yield of 109% of controls and untreated yield of 93%.

Across all wheat groups, the firm has 10 new varieties on the AHDB candidate list for possible recommendation at the end of 2024, with plots of each on display. In addition, the company will show some new winter barleys on the current AHDB candidate list, plus a new spring barley.

KWS will also show its first hybrid winter barleys, which the firm says offer significant yield and resilience advantages. The first commercial launch is Inys, with a yield of 109% of controls and untreated yield of 93% attributed to its strong disease resistance profile.

The variety is also said to have high resistance to lodging and 10% lower brackling than the current market-leading variety.

Lee Bennett, of RAGT, says: “We already have a Group 4 hard variety, RGT Grouse, with similar characteristics, and given the positive quality feedback we’ve received so far, we are hoping this will represent the first human consumption wheat with no insecticide requirements, matching increasing farmer and buyer demand for such characteristics.

“The BYDV resistance comes from our Genserus [Genetic Security Virus] development programme and provides full-season protection against BYDV courtesy of the Bdv2 resistance gene, derived from a wild grass. A sector of our stand will be devoted to Genserus varieties alongside parent material without resistance.

There will also be two new oat additions currently on the AHDB candidate list. Beyond combinable crops, KWS also plans to showcase its new sugar beet CR+ genetics for improved cercospora control and potential fungicide savings.

RAGT’s stand will include the chance for visitors to learn about RGT Goldfinch, the company’s new Recommended List (RL) candidate winter wheat, which has bread-making potential and is both orange wheat blossom midge- and barley yellow dwarf virus (BYDV)-resistant.

The variety is believed to have

“None of the plots have received insecticide, giving visitors a chance to observe the difference first-hand. Beyond BYDV protection itself, benefits include no need to interrupt drilling to go spraying and zero effect on beneficials.”

LS Plant Breeding (LSPB) will be exhibiting for the first time under its new name, NPZ UK – a move the company says is a natural evolution that aligns its business here with its global parent company, German breeder NPZ (Norddeutsche Pflanzenzucht Hans-Georg Lembke).

The firm says the move’s timing

matches the progressive introduction of its next generation of hybrid oilseed rape varieties, the most recent of which is Maverick. To underline its new name and illustrate its breeding pipeline, NPZ UK has a 50% larger stand than that of LSPB at last year’s

and winter bean,

and winter combining pea and spring wheat varieties.

Bayer’s exhibit at Cereals 2024 will include a new hybrid OSR and a digital decision support tool that

enables remote monitoring of migration and distribution of key OSR pests.

Outperforming every other Dekalb hybrid bar one in both 2022 and

A cultivator drill so advanced it avoids any overlapping

2023, the new hybrid, DK Excentric, topped gross output tables on the four most demanding sites across those years; a trait Bayer claims underlines its environmental stress tolerance. Average gross output in two years of NIAB and Scottish

The New Amazone Cirrus 9004-2C Grand features a newly developed distributor head with its unique combination of individual row shut-off and instant seed delivery.

Over its 9 m width, you can achieve spotaccurate shut-off, perfect for short work. The newly-developed V-Compensation gives uniform seed delivery at every coulter regardless of differing pipe lengths - so inch-perfect seed cut-off at every headland angle to reduce seed use and restrict any overlapping to below 1%.

Along with the option to place fertiliser with the seed and our unique strip-wise reconsolidation, it’s yet another clever idea that works for you.

Agronomy trials was 5.11 tonnes per hectare, with average oil content of 45.4%. A growth habit that matches early planting requirements combines with flexibility to make it suited to sowing into September should soil, pest or weather conditions dictate, says Bayer.

Agronomic scores include an 8 for stem stiffness and 9 for lodging resistance, plus disease scores of 6 for light leaf spot and 7 for stem canker.

Marking five years since its formation from the merger of Dow AgroSciences, Pioneer and DuPont, Corteva Agriscience plans to display the efficacy of a number of new products. Among them is new clover-safe herbicide ProClova, launched last year onto the Irish market and currently going through the registration process in the UK.

Clover has an important potential role in matching growing interest in expanding and diversifying rotations plus reducing purchased fertiliser

use, suggests the company. Initially developed for weed control in rice, the product’s active ingredient is florpyrauxifen-benzyl, branded as Rinskor.

ProClova is said to have a much wider weed spectrum than other clover-safe herbicides when treating newly-sown leys including docks, dandelions, fat hen and, in particular, provides more consistency and reliability of control than the current standard on established docks. It can also be used in established grass.

We’re keen to show Cereals visitors what BlueN and Kinsidro Grow+ can do

JOHN SELLARS

Of more immediate interest is likely to be the company’s new biologicals business development, stemming from its recent acquisitions of specialists Stoller and Symborg.

John Sellars, of Corteva, says: “We’ve had a good response to this business area to date, and are keen to show Cereals visitors the results of what BlueN, a biostimulant containing bacteria that enables plants to fix nitrogen from the air and make it available to the plant, and Kinsidro Grow+, a low-rate

humic substance that mitigates stress, can do.”

For those seeking ideas and advice on alternative cropping, Premium Crops will have plots of alternative autumn- and springsown break crops – including HOLL OSRs – and cereals, alongside cover crop displays.

In addition, the firm will have displays of chickpeas, a crop which is the subject of a two-year feasibility study led by NIAB, looking at the crop’s potential to reduce on-farm fertiliser use and the greenhouse gas emissions associated with fertiliser production. The UK currently imports 60,000t of chickpeas annually.

Elsoms returns to Cereals for the first time since 2019 with a focus on its new soft-milling/distilling winter wheat Bamford, the highest-yielding Group 3 on the RL, with a rate of 106 for treated yield.

Grant Hawkins, of Elsoms, says: “Many growers may be seeing Bamford for the first time, and we will have a team on-hand to help them find the best way of extracting its full potential should they choose to grow it next season.

“With a 7 rating for septoria, plus high yellow rust and mildew scores, we have found a lot of interest in its combination of strong yield potential and high disease resistance.”

New from Senova will be three candidate Group 4 hard feed wheats: Rufus, Riley and Memphis. These are said to be very high-yielding types that currently sit at the top of the RL candidate list.

Three candidate two-row winter barley varieties will also make their debut: Organa, a BYDV-tolerant two-row; Kitty, a high-yielding feed with resistance to both strain 1 and strain 2 of Barley yellow mosaic virus and the highest specific weight of any barley variety; and Nos Olena, said to possess good grain quality, all-round performance and standing ability.

Also present will be Valentine, a new husked winter oat candidate, and Nova, a new spring oat.

Selecting the right variety is the cornerstone of any arable rotation and we learn some top tips from farmer and agronomist Rob Beaumont, about what guidance is available and what varieties are sparking interest this year.

Selecting an appropriate variety suited to a rotation is one of the key decisions that a farmer or agronomist makes during the season.

It is also one of the core parts of a comprehensive integrated pest management plan (IPM).

A particular variety of crop could be selected for a number of reasons, such as end market, disease resistance or yield potential. Knowing which factors are most important to the grower and their farming systems will help to make the best decision.

For example, in the south west of England, choosing a variety with the highest resistance to septoria in wheat might be the most important factor.

Whichever trait is required, the best place to find out information on a select variety is by checking the AHDB Recommend List(RL) for cereals and oilseeds.

The RL was first published in 1944 by NIAB and covered just a few wheat varieties and their suitability for various milling markets. Today, now under the publication of AHDB, it covers seven different crops under a full Recommended List and four crops

Varieties

under a separate Descriptive List (DL).

The RL is where varieties have been selected against a competitive benchmark of yield and agronomic targets, whereas the DLs do not.

A variety can lose its status on the RL if it falls below 2% of market share or slips below average for yield or agronomic performance.

The final decision on whether a variety is included or discarded from the list is made by three crop

JRob Beaumont farms on the Worcestershire/Herefordshire border with his parents and young family, growing combinable and forage crops on a mix of owned, tenanted, and contracted land. An agronomist for Edaphos, he also hosts AHDB Monitor Farm events.

committees, which include technical experts from across the industry and are chaired by either a farmer or agronomist.

The RL is a free publication that is available as either a hard copy, PDF, or downloadable as an app.

The app version of the RL is available on smartphones or tablets and includes a few interesting features which can make it more user-friendly than flipping backwards and forwards through a booklet or PDF.

Through the app, you can compare up to three varieties simultaneously which makes picking out differences a lot easier.

You can also see the parentage of each variety, which you cannot on paper or PDF copies. This feature is

particularly useful if the grower is wanting to construct a blend of varieties and needs to ensure maximum genetic diversity.

Finally, the RL app also contains an archive of predated RLs so you can go back and find information on varieties that are no longer included on the current list.

For example, winter wheat variety Theador is no longer included on the RL, but information on it may be of interest to some growers, due to its high disease resistance scores. The RL app is an easy to use tool and is a great way to quickly find and compare varieties to help growers in their variety decision-making processes.

Continues on page 18.

The best way to really get a view on how varieties are performing in a particular location or context, is to discuss it with your agronomist, or other growers, to see how they have got on.

Growers can also attend local open days throughout the summer and speak to some of

JFor Group 1 milling wheat growers, SY Cheer has been added to the Recommended List (RL).

SY Cheer is one of only five, Group 1 varieties on the RL. It has a score of 7 for yellow rust and 6 for septoria tritici, but only a 4 for eyespot.

However, the variety’s standout features are its high protein (13%) and high specific weight (79.5kg/hl).

For those growers looking for a high disease package, especially in higher rainfall areas, Group 2 variety Mayflower may fit the bill.

While not necessarily having the largest treated yield (97), it does have exceptional yellow rust and septoria resistance, 9 and 8.9 respectively.

JDespite the challenging economics of feed barley production there are some good varieties to choose from, especially for those growers who are looking for a second cereal and can utilise barley grain and straw for cattle enterprises.

New to the RL this year is two-row feed barley LG Capitol. Producing high UK yields (106) and a good specific weight (69.9kg/hl) with a mediumhigh resistance to lodging, this variety looks like an attractive proposition.

For those growers who want big barn fillers with lots of straw then the yield performance of the hybrid barley is hard to beat.

This variety could be particularly attractive to those growers looking to reduce fungicide inputs or add to a blend with other varieties to increase resilience.

Growers in the western parts of the UK will be familiar with the Group 4 varieties Champion and KWS Dawsum.

These have become popular varieties due to their hardy disease scores and good yields. However, one candidate variety to keep an eye on is LG Rebellion.

Initial results show it to be high yielding, high specific weight and early to mature with a good overall disease rating to match.

the experts running trials to gain a detailed perspective on a variety’s merits and weaknesses.

In short, there is a comprehensive supply of freely available, independent, reliable

information for growers to take advantage of.

Looking forward to 2024 there are some interesting varieties for growers to consider adding to their cropping plans.

Group 1 milling wheat SY Cheer has been added to the 2024 Recommended List and is one of only five Group 1 varieties.

Some growers find that hybrid varieties are competitive against grass-weeds as they can be planted slightly later than conventional two-row varieties.

Topping the hybrid list for yield is SY Thunderbolt at 107% over control. However, the hybrid barleys do tend to be taller and can be more prone to lodging issues if not carefully managed,

especially on high fertility sites.

Some growers may also find that hybrids are more competitive against grass-weeds as they can be planted slightly later than conventional two-row varieties which also aids with herbicide performance.

The limitation for growers looking to save seed is that hybrid barley cannot be sown for a second season.

Looking to oilseed rape variety choices, there are a few new possibilities on both the hybrid and conventional

JHybrids tend to be consistently higher yielding than the conventional varieties and offer interesting genetic traits such as resistance to pod shatter and turnip yellows virus.

LG Armada tops the RL this year at 107% yield in addition to offering these useful agronomic features.

Some speciality varieties, such as Crome and Crocodile, offer club resistance on susceptible sites.

For troublesome weeds such as charlock, Clearfield varieties offer the opportunity

Recommended Lists (RL).

For growers who have persevered with OSR, hybrid varieties are now the most numerous on the RL.

to apply imazamox herbicides without damaging the crop.

They also present an opportunity to skip a preemergence herbicide and wait until the crop is established before spending money.

However, as yet, no breeders have produced a variety that is immune to flea beetle, stem weevil, slugs, pigeons or errant pheasants.

So, when buying OSR seed it is worth considering purchasing it from a supplier which will offer you a payback insurance if the crop fails due to early pest pressure.

JNew to the RL this year and bred in the UK by independent plant breeder, Mike Pickford, who has been focusing on the UK conventional OSR market for more than half a century, Pi Pinnacle has topped the OSR conventional RL for gross output and treated yields.

Grainseed reports that its new conventional winter OSR variety has produced the highest gross output across all AHDB regions over the past

three years of official trials and is now fully recommended for the whole of the UK.

Pi Pinnacle has the joint highest conventional gross output yield (102%) with Frontier’s Tom, with the highest east/west region of 103%.

The variety has good disease resistance with a 7 for light leaf spot and attractive agronomic features including 8 for lodging resistance and 9 for stem stiffness.

Pi Pinnacle has topped the RL for both gross output and treated yields.

Micronutrients can provide agronomic benefits to both winter and spring cereal crops, provided they are readily available for the crop to access at the right timings. Ash Ellwood finds out more.

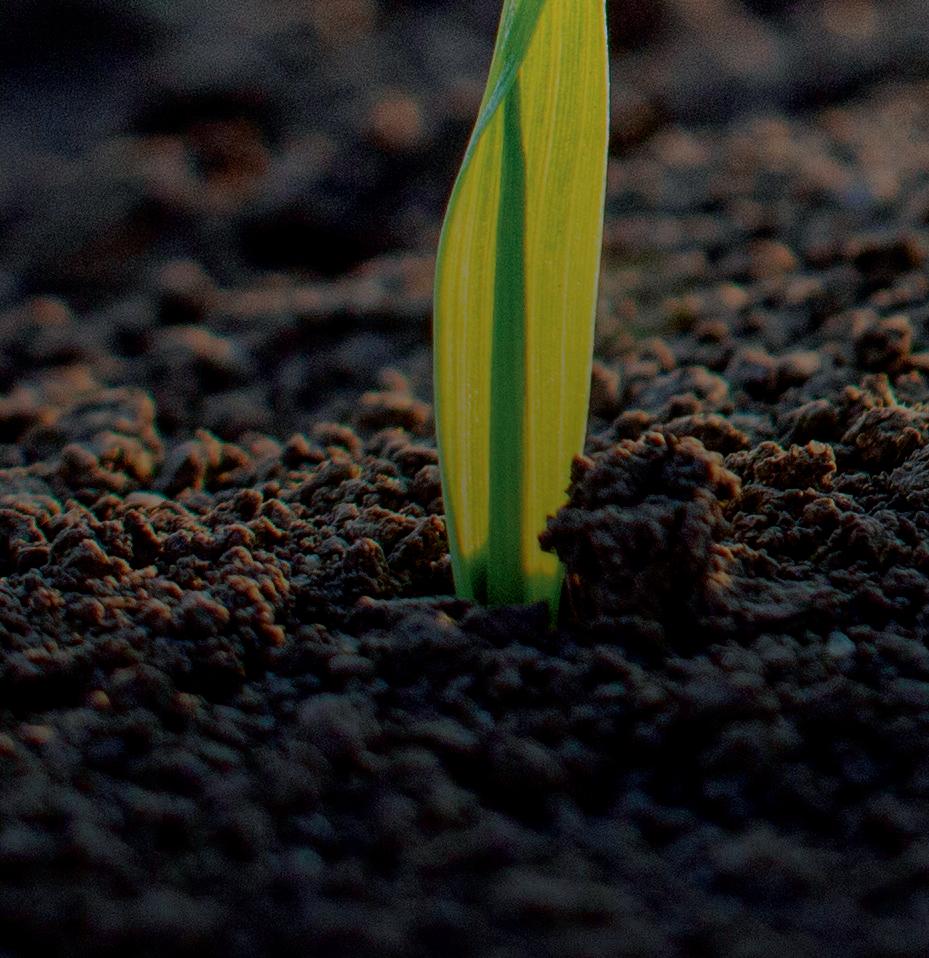

With the weather presenting a challenging start to the year for cereal crops due to wet, delayed drilling and consequential poor rooting, many crops could largely benefit from the addition of micronutrients into their spray programme, particularly later drilled spring crops.

A key driver of foliar multi-nutrient applications in winter wheat would be to keep the crop greener for longer.

Chris Harrold, product

Later drilled spring crops can benefit from foliar nutrients such as copper, zinc and magnesium applied around GS31, says Chris Harrold.

manager at Yara, says: “Many growers will be going through their winter barley and winter wheat crops in the coming weeks with the T2 fungicide and this often presents an opportunity to include some micronutrients into the mix.”

Magnesium is an important component of chlorophyll essential to the photosynthetic function. A foliar application of magnesium in late May or early June can provide benefits to winter cereals.

“I have had many conversations with both farmers and agronomists this year who are finding out from their tissue analysis results that magnesium is lower than expected.

“This could be down to a combination of factors like the excess rainfall which could have restricted nutrient availability and washed mobile nutrients through the soil profile,” he says.

Nutrient availability could also have been compromised due to poor rooting, he adds.

“Magnesium deficiencies tend to show up on the older leaves which suggests that the crop has not got enough magnesium and the

JIn winter wheat, T3 provides a secondary opportunity to provide highvalue crops such as milling wheat, with additional nutrients following the same magnesium, potassium, and phosphorus guidance.

“As an agronomist, I have seen growers applying magnesium to milling wheats at both timings but the requirement for phosphate and potassium would be dictated by a tissue analysis prior to applications,” says Mr Harrold.

nutrient is moving into the new growth making the older leaves look deficient. But, if you start to see deficiencies like this, it often means it is too late and the yield impact has already happened.”

To understand the levels of nutrients the crop has access to, Mr Harrold always recommends growers to complete a tissue testing analysis seven-10 days prior to any nutrient applications.

“At least then, the growers will

have a real snapshot of what is happening in the crop, and they can adjust dosages and nutrient inclusion accordingly,” he says.

Foliar potassium and phosphate are also important nutrients to be considered at the T2 timing, as they are vital for the energy transfer of nutrients into the grain.

“Potassium is also particularly important for water regulation and cell turgor within the crop, so if we do potentially go into a drought – like we have seen in other years – making sure crops are efficiently supplied with potassium is important,” adds Mr Harrold.

Spring cereals can often present a more challenging picture due to a shorter growing season and the increased speed at which cereals go through each growth stage.

For later drilled crops such as spring barley, spring wheat, and spring oats, Mr Harrold recommends growers check that they have not missed out on any manganese deficiencies early on.

“Do not delay getting manganese onto a spring crop,

most growers and agronomists will understand where their hotspot deficiencies are, so it is

JSpring barley trials investigating the effects of a multi-nutrient product, YaraVita Gramitrel, at the T1 timing, highlighted the crop’s ability to optimise grain set, build natural defences and maintain leaf area, according to Yara.

Continuing the trial over three years showed that

important to make sure these are treated early on,” he adds.

If the green leaf area has been lost due to manganese deficiencies, it cannot be restored once it has gone.

“This is important as we know, particularly with spring barley, that the number of tillers is important as they cannot compensate for their loss.”

At around growth stage 31 or stem extension, Mr Harrold says nutrients such as copper, zinc,

timely foliar micronutrient applications provided a consistent spring barley yield increase when comparing treated with untreated yields.

In 2021, 2022, and 2023 barley crops, treated at a T1 timing with two litres/

and magnesium are beneficial applications, but selecting a broad multi-nutrient product at the T1 application is advantageous, to make sure the crop is not lacking in any of those nutrients.

“Copper is important for lignification and helps fertilisation in the crop to prevent blind grains, which is something we sometimes see in barley and zinc is also important for grain number and size.

“When it comes to plant

hectare of Gamitrel, provided a three-yearly average increase of +0.18 tonnes/ha (2021 +0.2t/ha, 2022 +0.15t/ha and 2023 +0.21t/ha).

Mr Harold says: “This yield increase at current grain commodity grain values would give a 2.5:1 return on the cost of the investment.”

Do not delay getting manganese onto a spring crop

CHRIS HARROLD

structure, copper also promotes auxin levels which helps to optimise the canopy development,” says Mr Harrold.

A seeder that applies numerous products and suits a wide variety of implements.

25 years experience

Applies all small seeds, Avadex granules, cover crops and slug pellets

Powerful hydraulic fan

Garmin GPS control system

200l or 400l hopper

Configure the spec to suit your needs

12m/15m boom available

Dual hopper option

Excellent service and spares support

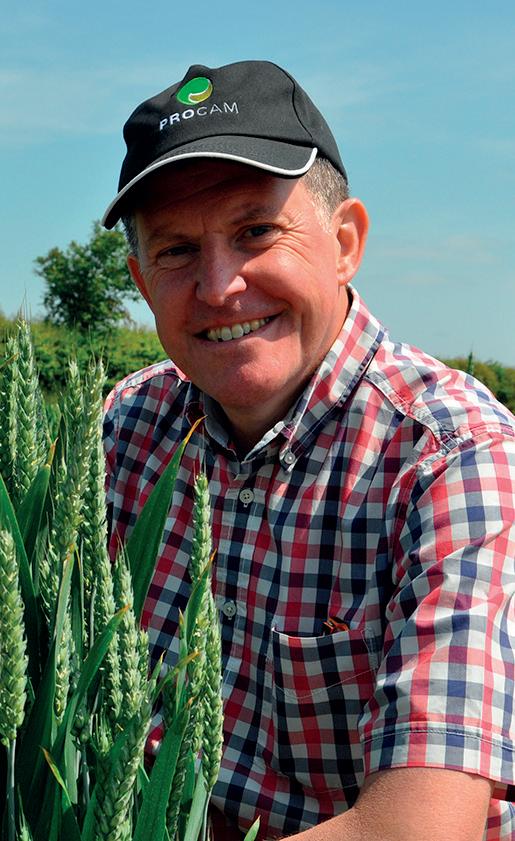

With strong milling wheat premiums available this season, Ash Ellwood gathers some top tips for growers to achieve premium grain quality.

The washout winter and spring could mean that this year’s milling wheat crops could face a challenge in meeting protein specifications – depleted soil nitrogen (N) due to leaching, and compromised N uptake due to poor rooting – requiring carefully tailored agronomy.

ProCam agronomist Justin Smith says: “Where soil testing has been carried out, results indicate that soil N levels have been 20-30kg per hectare below their usual levels in some places after all the rain.

“On top of that, root growth

has been seriously compromised by waterlogging, because roots have not had to reach down far to find moisture. So not only is there less soil N available, but affected plants will also have greater difficulty accessing what nutrients are actually there.”

Alongside nutritional applications at the T2 timing, T3 can provide another opportunity for growers to provide nutrients for milling wheat, according to Mike Thornton, head of crop production at ProCam.

Due to compromised rooting structures and depths, growers

could look towards alternative forms of N for milling wheat to ensure the applications made are utilised by the crop rather than left unobtainable by the roots

He says: “If we have not got the root structures to take up bagged nitrogen, growers could look towards liquid, foliar nitrogen and bacterial applications to boost growth at the T3 timing.”

Mr Smith says these risks will need factoring into mid- and late-season milling wheat nutrition, especially if the summer turns dry. However, there are multiple foliar-applied

Due

treatments now available to either replace or supplement soil-applied granular N. He says: “These products can range from endophyte bacteria, such as Azotic Techology’s product, Encera, which fixes atmospheric N inside the plant. To Unium Bioscience’s Twoxo Pro, which stimulates the plant to improve N uptake.

“For the traditional flag leaf [T2] and ear [T3] foliar N spray timings, Pro+ N-Viron PCA has the advantage that it not only provides N directly into the leaf in an efficient urea form, but it also contains pidolic acid, which helps plants use N more efficiently. Which treatments are applied and when needs to be based on individual field needs. If ever there was a year for tailored agronomy, this is it,” adds Mr Smith.

If the weather turns dry and soils dry during May and June, Mr Smith says this could further limit soil N uptake and impact on grain protein, making these types of treatments, which do not rely on root uptake of N, a particularly useful option.

JGood specific weights are also important for milling wheat crops, therefore it is important to protect crops against disease to safeguard grain fill.

Mr Smith says: “You want plump, well-filled grains. So, there are multiple reasons to protect photosynthetic green leaf areas against diseases throughout the season.

“It is important for growers to be aware of their chosen varieties’ disease ratings, which can be found within the 2024 AHDB Recommended Lists for Cereals and Oilseeds, to ensure prioritisation of fungicide applications.

Dry soils will also limit uptake of nutrients such as magnesium and potash, but a foliar application of Proplus Excel included at the T2 spray timing will provide both of these elements plus sulphur, adds Mr Smith.

Chris Harrold, product manager at Yara, agrees and says alongside N, growers should also pay attention to phosphate

“Septoria tritici is rampant this season, which will need controlling and several popular Group 1 winter wheat varieties also have low resistance ratings against yellow or brown rust. As well as using a triazole fungicide active against fusarium for the T3 ear spray, include a suitable strobilurin to stay on top of rust risks.

“It is not worth missing out on the good milling wheat premiums available. The last thing you want is a milling variety being sold for lowerpriced feed,” he says.

alongside potassium and magnesium at the T3 timing.

“As an agronomist, I would advise growers to be applying magnesium to milling wheats at both the T2 and T3 spray timings, but whether it is necessary to also apply phosphate and potassium would be dependant on a tissue analysis seven-10 days prior to the timing,” he says.

Reducing your emissions

• Low ammonia emissions granules

• Reduced carbon footprint from factory to field by 55% through abatement technology

• Half the emissions of urea + inhibitor*

Heavier granules go further

• Spreading accurately above 40m

• Can spread during windier conditions

Stronger granules are more resilient

• Don’t shatter on impact

• No dust

Compound granules for evenness

• No segregation in the hopper

• Uniform spread pattern

*DEFRA, NT26

New oilseed rape genetics being developed by DSV are building on traditional pod shatter characteristics to increase harvest security in light of increasingly variable growing conditions now experienced across Europe. Arable Farming reports.

DSV’s latest addition to the Recommended List (RL), DSV Dolphin, is the first of a new generation of hybrid varieties specifically developed to combine a key set of genetic traits to protect them against adverse weather conditions later in the season.

DSV marketing and sales manager, Sarah Hawthorne, says: “Pod shatter genetics, contained in several DSV oilseed rape varieties and others on the RL, have done much to highlight the issue of harvest seed shed.

“It is, however, now widely understood that how a variety

performs during its growth and at harvest is the function of many different characteristics rather than just a single gene or property of a variety.

“Other factors, such as the plant’s overall strength and health, its disease resistance and growth habit together with the actual physical form of the pod, are increasingly seen as fundamental to how it performs at harvest.”

Four key components

DSV breeders have been working on a core set of features around the concept of ‘powerful pods’ and have identified three key pod characteristics, which when included in varieties, contribute significantly to reduced seed losses in adverse conditions.

“These are greater flexibility

How a variety performs during its growth and at harvest is the function of many different characteristics rather than just a single gene or property

SARAH HAWTHORNE

of the pod structure, improved function of the pod valve margins and greater space around individual seeds.

“Increased flexibility, for example, gives pods a resilient ‘rattle-proof’ structure which makes them less friable and more able to absorb energy rather than break open in conditions with extremely high winds or hailstorms. This enhanced flexibility also allows pods to cope better with the uneven tensions produced from drying after rainfall, which can lead to seed pods splitting,” says Ms Hawthorne.

Varieties with ‘powerful pods’ also have a stronger valve margin.

“The mechanism at the base of the pod which effectively controls the opening of the valves, effectively the sides of the pod containing the seeds.

“This avoids early triggering of the opening process, particularly when pods are stressed such as in adverse weather or when going through the combine header.

“More space in individual pods also allows seeds to develop fully as they mature so a variety can reach its full yield potential, but it also stops growth stressing the pod, which can again lead to premature failure.”

Results from DSV’s own trials and an AHDB analysis of pod shatter results have underlined DSV Dolphin’s harvest performance.

“In random impact tests carried out at the DSV breeding

station at Thule in Germany, where pods from different varieties are bombarded with steel ball bearings in controlled conditions, DSV Dolphin achieved one of the best scores for seed retention.

“Results from an AHDB analysis in 2023 have shown little difference in the performance of DSV Dolphin with regard to seed loss compared to many of the most popular pod shatter varieties.”

Fully featured variety

Other factors working alongside DSV Dolphin’s ‘powerful pods’ seed protection features are a fully featured set of agronomic properties, Ms Hawthorne says.

“DSV Dolphin is recommended for the East/West region on the current RL with a gross output of 106%, the joint highest on the list, and this is supported by some stand-out features, including a 46.6% oil content.

“With TuYV resistance and scores of 7 for stem canker, 8 for lodging and a 9 for stem stiffness, DSV Dolphin is a simple to grow OSR well suited to the current economic and environmental climate. It also has a 7 for flowering and a 4 for maturity.

“It also has strong tolerance to verticillium wilt, as well as having some of the best tolerance to sclerotinia in DSV’s portfolio, with early senescence from either these conditions known to cause excessive seed loss before or at harvest.

“DSV Dolphin offers growers

a high level of protection from the growing threat of the TuYV virus now endemic across the UK where it has the potential to reduce yields by up to 20%.

“It also features RLM7+ and multi-gene resistance to stem canker and is an agronomist-friendly variety well suited to integrated crop management

systems due to its high resistance to light leaf spot with a score of 6.

“These features combined with its ‘powerful pods’ mean DSV

Dolphin is a variety suited to the demands of modern production and the increasing challenge of changing growing conditions,” Ms Hawthorne adds.

Flexible, reliable and easy to maintain:

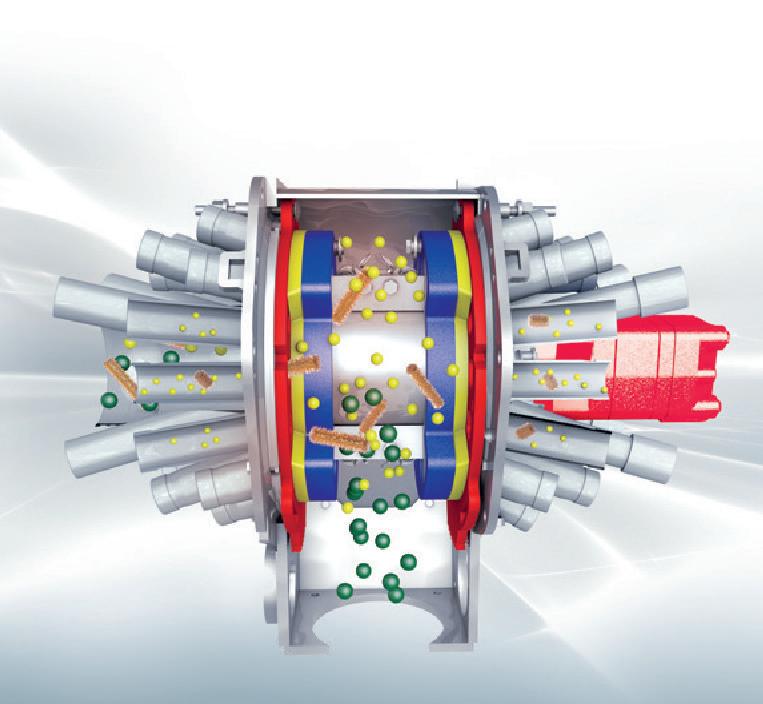

As a pioneer in agricultural technology, Vogelsang leads the way in environmental friendly spreading equipment. The dribble bar systems combined with the ExaCut distributor give the highest application of liquid manure nutrients.

Dribble bars are available in working widths of 7.5m right up to 36m and are retrofit-friendly.

VOGELSANG – LEADING IN TECHNOLOGY

Contact us at: 01270 216 600 | sales.uk@vogelsang.info vogelsang.co.uk

For more information visit

www.vogelsang.info/enuk/dribble-bar-systems

Plant breeder DSV has been working on a set of OSR variety features to reduce seed losses in adverse conditions.JUsing attention to detail and the full agronomic toolbox to repair damaged soils – not least after this season’s incessant waterlogging – to restore soil life and improve soil health and resilience, will be a central theme for ProCam.

Drawing on techniques such as ProCam’s soil analysis and nutrient planning service, SoilSense, together with the use of cover and companion cropping, and even precision farming, ProCam experts will be on-hand to help farmers looking to rebuild their soils for the future.

Allied to this, the incorporation of increasingly popular biological treatments, such as nitrogen-fixing endophyte bacteria, into programmes to reduce reliance on granular nitrogen fertiliser, will also be discussed, as well as how to incorporate Sustainable Farming Incentive options into rotations in sustainable and economically viable ways.

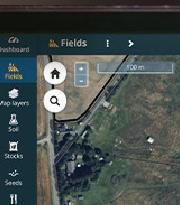

JWhat more could you know about your farm?

This is the question YAGRO is inviting farmers to ponder at Groundswell 2024.

We all know agricultural enterprises must ‘know their numbers’ to stay ahead, so YAGRO’s team of farm data experts will explore how their software can shine a light on all areas of arable operations.

They can highlight how to track in-season spends, understand costs of production in greater detail and benchmark performance.

The new ‘Chemical and Fertiliser Review, 2024’ will be available freely to farmers,

JEntering its eighth year, ‘the regenerative agriculture festival’ is set to take place at Lannock Manor Farm, Hertfordshire, on June 26-27,

2024. The event aims to provide a forum for farmers, growers or anyone interested in food production and the environment to learn about the theory and

practical applications of regenerative farming systems rFor more information and to purchase tickets, visit groundswellag.com

The annual regenerative agriculture festival Groundswell is set to take place in Hertfordshire in June. Ash Ellwood catches up with some of the arable exhibitors to see what will be spotlighted at this year’s event.

which delves into the costs and efficacy of the most popular inputs on-farm.

JAgrii and Weaving Machinery will come together on an interactive stand. Three different cover crop mixtures will be used across the demo plot, and pop-up marquees will host targeted discussions, all interspersed with complementary low-disturbance farm machinery.

Using the specialist agronomy

knowledge of the Agrii team, three cover crop mixes have been carefully selected for the demo plot to provide opportunities to discuss the merits of the different species and demonstrate what works well from a practical, agronomic and financial point of view.

In-keeping with the event’s no-till principles, Weaving will present its range of direct

drills and a selection of low-disturbance cultivators, thoughtfully paired with Agrii’s discussion topics, such as the tine versus disc crop establishment debate. One of the interactive stations will feature a soil pit, initiating conversations about the influence of various machinery and agronomic decisions on soil structure.

Continues over the page.

See us at Cereals at stand number 717

Clubroot spores live in the soil for up to 20 years and there is no viable method of removing them. So the best and quickest way to protect your oilseed rape crops from clubroot is to raise soil pH above 7. Granulated Calciprill breaks down quickly in soil moisture and the high surface area of its ultrafine particles reacts immediately, correcting acidity in the soil in a matter of weeks not months. Give your oilseed rape the best chance of avoiding clubroot by applying Calciprill now.

For more information: Contact David McLellan on 07710 712030 or scan the QR code

• Precise

• Fast-acting • Convenient • Efficient

JClayton has recently launched an exciting new BioSolutions range containing plant growthpromoting rhizobacteria (PGPR).

The Clayton Nutrient Use Efficiency (NUE) range, developed by PlantWorks and tailored to a wide range of crops, enhances NUE through the fixation of nitrogen and solubilisation of phosphate and potassium.

Crop development is also boosted through greater hormone production within the plant.

PGPRs, as contained in Clayton’s NUE range, are applied post-emergence as they thrive around the root system of a growing crop.

JThe world is waiting to see the impact of the Sustainable Farming Incentive (SFI). Will the interventions it promotes be sufficient to reduce greenhouse gas emissions, boost biodiversity and generate value in natural capital in line with expectations? And crucially – what are those expectations?

Dr Belinda Clarke, director of Agri-TechE, says urgent need for innovations to enable value capture through trusted solutions which measure and enhance nature-sensitive farming, is urgent.

She says: “SFI is a flagship initiative, but it is still unclear as to what its anticipated impact really is. I do not think we have a consistent view across the industry on that yet.

“Crucially, we need to understand benefits which will be rewarded and linked to improvements on the bottom line for farmers, either through increased productivity or other monetisation of natural capital

This makes them easy to apply by simply spraying them onto a growing crop in spring when temperatures are above 8degC, which helps to increase the microbial soil activity.

PlantWorks has trialled these products extensively with farmers and agronomists, showing wheat yields can be improved on average by 6% with similar yield uplift in root crops such as beet, carrots and onions. The Clayton NUE range is approved for use in organic crops.

JTimac Agro UK will be showcasing its innovative soil conditioners at Groundswell 2024, emphasising their role in enhancing

Delve into suitable arable Sustainable Farming Incentive options with advice and guidance on-hand across the two days.

In a tricky year, nutrition will be at the forefront of many growers’ minds to ensure maximum nutrient uptake and crop resilience.

the physical, chemical and biological fertility of soil.

By improving soil health, Timac’s solutions ensure maximum nutrient availability from both applied inputs and the soil’s natural reserves. This approach reduces dependency on highly soluble fertilisers, promoting a more

assets. We need data and evidence to provide those critical insights, so investors, banks, Government – anyone who is looking to make a business model out of natural capital – can trust and believe in this journey.”

JFor the seventh consecutive year, Affinity Water takes pride in being a headline sponsor of the upcoming Groundswell event, where it will underscore the significance of healthy soils and water quality. Demonstrating commitment

to promoting sustainable agricultural practices among farmers within catchment areas, Affinity Water will present its latest trials and share crucial findings.

Visitors at the event can anticipate educational rainfall simulator demonstrations near the big top tent, showcasing the efficacy of farming methods in preserving soil health and water quality.

Delegates are encouraged to visit the Affinity Water stand to engage with the team, discuss ongoing collaborations with farmers and receive a

sustainable and efficient nutrient management system. The team will be exploring the potential of soil conditioners in the drive for productivity on-farm and discussing the science behind them by demonstrating how they increase nutrient uptake and crop resilience.

complimentary water bottle. This event reflects Affinity Water’s dedication to fostering environmental awareness and supporting regenerative agricultural practices.

JAs Groundswell’s cover crop partner for the eighth year, Kings Crops plans to spotlight solutions which deliver for both food production and future farm resilience. With SFI options igniting new land management considerations for growers, Kings will be joined by Frontier Agriculture’s sustainable crop production experts and precision specialists at SOYL to demonstrate how field and crop production data can support future farm decisions. Together, advisers will also cover privately-funded sustainable farming opportunities which complement Government schemes, while plot tours will allow visitors to see mixtures which deliver practical benefits for both the environment and farm productivity.

When considering T3 applications, grower’s location and subsequent harvest date impacts which fungicide to use.

With a challenging start to the year, Ash Ellwood chats to a crop production specialist about the potential disease season ahead and what growers can do to prepare for T3 fungicide applications.

Depending on what the weather decides to do, this year’s key disease pressures could take a few different turns. At the time of writing in early May, earlier

drilled wheats generally have higher levels of septoria, even those that are the more resistant varieties. However, later drilled wheat varieties, due to being under more stress, are at a higher risk of yellow rust this season,

JEyespot has been reported in wheat varieties such as KWS Extase and crops that have poor rooting are at an increased risk.

Mr Thornton says:

“Eyespot infections do not look to be quite as bad this year [as last year] but, if crops have poor rooting, you do not want additional problems that will also affect the integrity of the straw.”

Brown rust is often a disease thought of later in the season,

according to Mike Thornton, head of crop production at ProCam.

Yellow rust appearing in wheat varieties has been reported by ProCam’s Sussex-based agronomists. Septoria has also been seen in wheat crops this year, partly due to the continued rainfall but when the weather warms up, Mr Thornton warns of potential increases in septoria pressures.

“When it does warm up, it could create a perfect storm.

“I am advising growers to think carefully before they cut [fungicide] rates or use

but Mr Thornton has already heard widespread reports of brown rust infections in Crusoe winter wheat and to a lesser extent in varieties with low brown rust disease ratings.

More stressed

“I am sure that has a lot to with the fact that crops are more stressed than usual, but a lot of these diseases heavily depend on the weather, which has been conducive to heightened disease this year.”

cheaper inputs in case we have a septoria surge.”

One of the key concerns for both winter and spring drilled crops this year is poor rooting systems, Mr Thornton says.

“When the ground is wet, crops do not go looking for moisture, so they end up with root systems very near to the soil surface.”

If the weather does dry and causes the water table to drop, the plants are then unable to respond, creating increased stress and vulnerability to disease.

“If the weather turns dry, this could create a yellow and brown rust favourable year whereas, if it stays wet but warms up, this will be perfect conditions for septoria to spiral,” he adds.

When considering T3 applications, grower’s location and subsequent harvest date can impact the fungicides chosen and the ultimate spend attached to the timing.

“Further south and in a reasonably warm summer, a crop between T3 and harvest will mature and senesce quicker than the North, so instead of harvesting in August, we are harvesting in July.

“If growers in the South want to knock-back rust, they might not be too worried about the persistency of the active at the T3 timing, as the crop is going to be ready to harvest soon.”

Further north, by the time crops are harvested, days are getting shorter and there is an increase in evening dew, which means growers might look for more persistent chemistry.

“Depending on what was applied at T2, growers could look for a strobilurin and triazole type fungicide at T3 to provide that additional persistency,” says Mr Thornton.

Analysing previously used actives at T2, such as Corteva’s Univoq (fenpicoxamid) or Syngenta’s new Miravis Plus (pydiflumetofen), can influence the levels of protection and subsequent fungicide spend required at the T3 timing.

“Both products are very potent against septoria and will last a

rFollow growth stages carefully: Crops can progress through their growth stages quite quickly and it is important to be regularly walking crops to ensure the fungicides are applied at the correct timings.

Mr Thornton says: “A lot of products would want to be on between growth stage 59 and GS61, but by GS63 it will be too late, even if it’s still got approval on the label.”

rConsider the preceding conditions: Analyse information, such as variety disease scores, cultivations, rainfall, and a mycotoxin test to help decide on rates or chemical choices to use for the T3.

rThink about nutrition: Right the way through the season it is worth completing tissue analysis tests to readily see what is both available and lacking.

“Often crops do not show themselves what is lacking and they often just look unhealthy, growers will then apply nitrogen, but it could be an entirely different nutrient that is lacking,” adds Mr Thornton.

long time, so growers might be tempted to use those at T2 so they can be less worried about septoria later on in the season,” says Mr Thornton.

With extended levels of persistency, growers can focus their T3 sprays on ear diseases, such as fusarium ear blight which can be controlled relatively cheaply in comparison.

“Actives such as prothioconazole, tebuconazole and prochloraz that can be mixed and matched often do not have the same restrictions in terms of numbers of applications in the way that strobilurin and SDHIs do,” he adds.

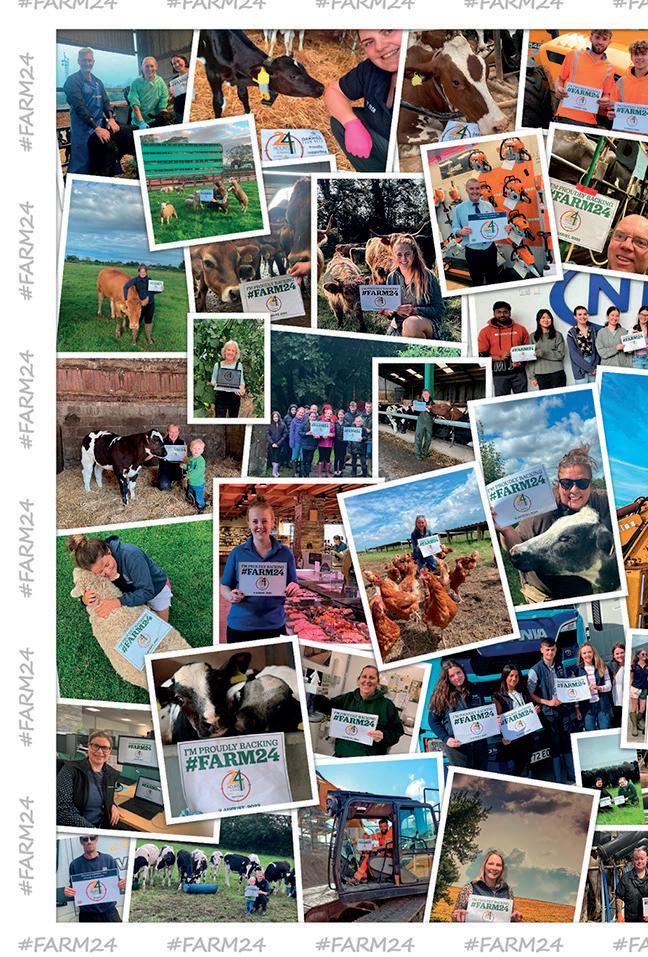

For the last nine years, 24 Hours in Farming has taken the nation by storm, and this ye

THERE is always a reason to celebrate farming, but looking back on the last year, it feels more important than ever to showcase agriculture to wider society.

Farmers Guardian’s social media campaign 24 Hours in Farming, sponsored by Morrisons, will be back once again on August 8-9 in a mission to educate the public on exactly what goes on in farming.

As farming’s biggest digital event, it allows the sector to come together and collectively shine a positive light on what farmers do day in, day out.

Reach of 32 million

Since its inception in 2015, farmers, chefs, sportspeople, celebrities and Government officials – including the Prime Minister – have taken to Instagram, X (formerly Twitter), Facebook and TikTok to post videos and pictures using the hashtag #Farm24, explaining what they are doing and, more importantly, why

It can feel like we are in an echo chamber, but the buzz #Farm24 creates filters out to parts of society that we cannot usually reach, as thousands of people across the food and farming industry share a little of their farming lives for the event. With a sustainability drive, new incentives to contend with and food security at the forefront of everyone's minds, why not come together to tell the true story of farming and remind the nation why British farmers are always worth supporting?

OLIVIA MIDGLEY

EDITOR OF FARMERS

GUARDIAN

With farming in the public eye now more than ever, it is time to unite as an industry and show the public what truly goes on in farming. #Farm24 is a fantastic opportunity for British farmers to counter the misinformation out there and show themselves for what they really are: Quality food producers, innovators and keepers of the countryside.

In 2023, we had 24 ambassadors

Two of the 2023 ambassadors:

Last year, Jamie Oliver supported the campaign and posted the following: “Big love and respect to our great British farmers on #Farm24 day. We’re lucky that the UK has some of the very best producers on the planet – hugely talented, passionate, hardworking people who are simply brilliant at what they do…”

ar it is back – bigger and better than ever.

Get involved

5am on August 8 – 5am on August 9

Every farmer has a story to tell. Perhaps you are part of a large generational family; maybe you came into the industry from a non-farming background; you might be farming in an innovative way, or simply be passionate about something. Whatever that is, show it to the nation and beyond by sharing your story on social media. Make sure to use the hashtag #Farm24 and tag Farmers Guardian and Morrisons.

3 1 2

4

Give consumers a truthful insight into farming, whether that is food production, careers or nature and sustainability Our #Farm24 mission

Unite the industry

Spread a positive farming message

Highlight the work that goes into producing food, for the nation

We are hugely proud of #Farm24 and bringing the story of British food and farming to a global audience through this campaign. We know our customers really value the work of British farmers, and being able to show the people and pride behind the products is fantastic. TECHNICAL AND

Working with a package of nozzle control upgrades to its Househam sprayer, H.A. Day and Sons is testing technology soon to be launched and set to rival pulse-width modulation spraying. Jane Carley reports.

Operators’ requirements for their sprayers remain highly individual, and the opportunity to work closely on the design and specification of a machine or retrofit new technology is a big plus for many.

Househam Sprayers is one of a handful of British manufacturers working in this way, and by using his own engineering background to collaborate with the company and its suppliers, James Wilson, of Gloucestershire farming business H.A. Day and Sons, is refining his machine to closely meet his needs.

The family farming partnership is based near Winchcombe on 800 hectares, of which 700ha is arable on a rotation of winter wheat, spring wheat, winter barley, oilseed rape and spring linseed. With liquid fertiliser, the spraying workload is around 7,000ha/year.

Partner Mr Wilson says: “We

purchased the 24-metre boom, 4,000-litre Househam Merlin in 2016, and by working with Househam, Lykketronic and Altek, we have been able to upgrade the spray control as we have gone along.”

The latest developments to the Househam range feature the improved Total Machine Control (TMC) V6 spray controller which offers Auto Nozzle Select (ANS) and turn compensation as standard features on twin line and above machines. The system can be easily upgraded all the way to Individual Nozzle Control (INC) by customers or available as a factory fitted option.

This system, Househam suggests, will offer all the benefits of pulse-width modulation (PWM) at a keener cost with greater reliability and future maintenance in mind.

The new system allows operators to use all generally available and recognised injector nozzles in their

Househam and its suppliers were happy to work with us and let me spec the machine up as we went along

JAMES WILSON

plant protection applications. Househam hopes to offer enhanced nozzle monitoring with the incorporation of the Altek Nozzle Spy system into the TMC and the ability to do variable application rates across the boom.

It is due to be unveiled at Cereals, and Arable Farming was able to get a glimpse of some of its benefits in this most challenging of spring seasons.

Utilising Lykketronic’s INC 2.0 system, a ‘daisy chain’ of modular control units are mounted on the boom of the sprayer controlling the quad version of Altek’s Smart-CSpray 124 nozzle bodies. H.A. Day’s Merlin has been upgraded to individual nozzle control with a TMC V6 system and is capable of using electrically-actuated air shut-off for each nozzle according to a prescription map.

Mr Wilson says: “It’s a step on the way to variable rate per nozzle, although at the moment it’s just on or off.

“We’re currently using EGNOS GPS on the Merlin which is accurate enough for this purpose, although we do have RTK on the farm. We were early adopters of individual nozzle control which seems to be a long time coming on

some machines, but Househam and its suppliers were happy to work with us and let me spec the machine up as we went along. You could say we are ‘guinea pigs’ but I’m happy with that.”

The quad nozzle body can be used in any combination with one to four nozzles on, which operator Andrew Cook says is particularly useful for liquid fertiliser.

“I can put it through two nozzles to get the 250 litres/ha on at higher forward speeds rather than having to use one large nozzle,” he says.

Nozzle selection from the cab is also handy on the catchy or busy days, he adds.

“If we’ve been doing liquid fertiliser in the morning, for example, it’s an easy wash out and then switch nozzles to go onto fungicides in the afternoon.”

Mr Wilson says that turn compensation will be useful for the many irregular-shaped fields on-farm.

“The quad nozzles will also help with this, giving the choice of rates needed to maintain the application rate on the turn,” he adds.

New developments

Further software updates to be unveiled by Househam will offer

H.A. Day and Sons has upgraded its 2016 Househam Merlin sprayer over time with the help of Househam and its suppliers to offer tech specified on the latest models.

improved nozzle monitoring via new nozzle flow meters, with easier toggling through three screens depending on the operation, says Househam’s senior technical engineer Alex Fisher.