Content Editor/Designer

Mike Begley 01772 799 405 mike.begley@agriconnect.com

Picture Editor

Marcello Garbagnoli 01772 799 445 marcello.garbagnoli@agriconnect.com

Head of Commercial Solutions

Mike Hartley 01772 799 532 mike.hartley@agriconnect.com

Account Manager

Mark Jackson 01322 449 624, mark.jackson@agriconnect.com

Classified Advertisements

01772 799 400 fgclassified@agriconnect.com

Advertising Production

Justine Sumner 01772 799 437

01772 796

justine.sumner@agriconnect.com

Circulation and

Subscription rates:

1475-6994

© Farmers Guardian

£65

rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems.

Who would have thought this time 12 months ago that we would be talking about milk prices of 50ppl. But as we all know a lot can, and certainly does, happen in 12 months.

Freshways became the first processor to reach this milk price milestone, with its price rise coming into effect from September.

The company says it has made this move to reflect the ever-increasing costs of production faced by its farmers, but it also wants to secure the milk supply it requires going forward.

With more farmers choosing not to ‘turn on the taps’ in terms of milk volume, and UK and GB volumes being down compared to previous years, surely other processors will have to follow suit and we will start to see further 50ppl breakthroughs?

But as the last 12 months has certainly shown, it is not easy to predict what will happen.

Kingshay’s latest annual dairy costings focus report has shown that small improvements in efficiency can have more of an impact than ever in light of these high costs and high milk prices.

So as Kingshay’s Kathryn Rowland discusses in Dairy Matters (see p14-15), perhaps now is the time to look at the best ways to future-proof farming businesses? This, she suggests, could include re-investment in grassland improvements, infrastructure or cow management and comfort.

And finally, for all the latest dairy industry news and updates, make sure you visit the new online Dairy Hub at FGinsight.com/ dairy-farmer-hub, where you can also sign up for our dairy-specific e-newsletter.

VIEW

MILK PRICES

ANALYSIS

Dairy farmers have seen no ‘net’ benefit to their finances from record high milk prices with input cost rises can celling out the price increases.

Data from Defra showed farmgate prices have increased at roughly the same rate as agricultural input costs so far in 2022.

improvement in production. This deficit has persisted into 2022, even through the peak production period.”

She added the delayed re sponse in milk prices to rapid inflation suggested farmers will still be working to fully recover the relatively large cost increase from late last year.

STORAGE

NEW PRODUCTS

MACHINERY

firm

DAIRYING

GOOD EVANS

BUSINESS CLINIC

AHDB lead dairy analyst Patty Clayton said milk pro duction typically responds ‘positively’ to higher farmgate milk prices, assuming costs remain relatively stable.

She said: “However, with the rapid increase in input cost inflation since summer 2021, Great British milk production has been lagging behind year earlier levels.

“Despite milk prices increasing by more than 10ppl on average since the beginning of the year, we have not yet seen any significant

NFU dairy board chair Michael Oakes said there had been a lag from prices going up to milk prices catching up, but it was now in a place where it looked like there was a ‘light at the end of the tunnel’.

He said: “I have not met one farmer going out of their way to push for milk, nobody is chas ing those marginal litres. In the past people would have done.”

He said people were culling cows harder, reducing feed and growing as much grass as they could while holding back on fertiliser use.

one-quarter of dairy

to stop or are

ceasing milk production

next two years, a new study

NFU has revealed.

under 700 members

completed the Milk Production

which was designed to

producers’ thoughts on the industry at present.

those questioned, 15% said

were considering ceasing milk production, while another 7% said they planned to quit production altogether before 2024.

Smaller producers (those supplying fewer than one million litres) make up most of those intending to stop (12%) and also make up the largest group of those more likely to be unsure of continuing.

Mr Oakes said people were wondering what would happen next and whether prices were approaching the peak.

Farmers were uncertain whether prices would keep rising, which had been highlighted when Muller

announced a price hold for August.

Mr Oakes said many Muller farmers would nd the announcement disappointing, given many middle-ground

players were talking about paying in the region of 50ppl for August.

He said: “ is price will not get Muller any more milk as it will not incentivise farmers to increase production and could ultimately lead to less milk for the processor.”

JA farm which featured on a BBC Panorama programme showing shocking footage of animal abuse has been recertified by Red Tractor (RT) after meeting the requirements for a reapplication.

The undercover footage, which aired in February, sparked outrage among the public and farmers and led to the termination of the farm’s RT membership.

JDairy Crest, now owned by Saputo Dairy UK, has been given a £1.52 million fine after it admitted causing pollution incidents in Cornwall. For committing this catalogue of offences, the firm was fined £1.52m at the Crown Court on June 23.

JA new event, Grazewell, will explore how regenerative farming techniques can exploit the advantages of grassland farming to develop systems which are fit for the future.

It takes place on September 22, 2022, at Higher Thornton Farm, Kenn, Exeter EX6 7XH, from 9am until 5pm by permission of Chris and Sarah Berry. rFor more information, go to facebook.com/grazewellevent

Labour shortages are already reducing dairy production and contributing to food price inflation. That was the message from Arla as it warned the situation would get worse unless urgent action was taken.

A survey of 541 UK Arla farmers showed 80% of farmers looking for workers have received ‘very few’ or ‘zero’ applications from people with the right experience or qualification, with 61.3% finding it more difficult to recruit now than in 2019.

The survey revealed 4.3% of farmers had already cut the number of milkings, with 6% reducing the size of the herd and more saying they would take these steps or leave the industry if nothing changed.

Arla has been calling for specialist roles, such as herd manager, to be added to the Shortage Occupation List, and has also been engaging with the Institute of Agriculture and Horticulture and said it sup ports the focus on improved skills and qualifications for farm workers, as well as recruitment.

But it was now calling on the Government to go further.

Arla’s UK managing director Ash Amirahmadi said: “Addressing

the labour shortage and the implications this could have for food security is vitally important.

“Now is the time for all of us, across Government and industry, to work urgently and collaboratively to shift outdated misconceptions about farming and bring new talent into the industry.”

Mr Amirahmadi said he had written to the Secretary of State

JBoris Johnson has had plenty of criticism thrown his way since he took up a career in politics, writes Abi Kay. But until recently, none of it stuck.

For his long-suffering Minis ters, who had been wheeled out to defend his conduct on many occasions, the sexual harassment scandal involving Chris Pincher, his deputy chief whip, was the straw that broke the camel’s back.

Now, Mr Johnson’s time in Number 10 is drawing to a close. But what does this mean for dairy farmers?

As I write, Penny Mordaunt has, for the first time, become the bookies’ favourite to win the contest.

And what does she think about farming? I scoured Hansard, her website and social media channels to find out and the answer is ‘not much’.

The only time she ever spoke about any agriculture-related matter in Parliament was in 2013, when she gave a speech on poultry welfare for the sole purpose of saying c**k as many times as possible in the House of Commons after losing a bet

with the letter calling on Govern ment to accelerate the review of the labour market promised in the Food Strategy White Paper, and to com mit to a new cross-departmental strategy to bring talent into food and farming, making it a career of choice for people from all backgrounds.

He said: “This will need to include on-farm skills and training, but will also address teaching in schools, the

understanding and attitudes of careers advice providers, support for people wanting to change career and a marketing campaign aimed at promoting careers in our industry.

“If we do not act now the current shortages of people will only get worse, jeopardising production on farms, undermining our food secur ity and further fuelling higher prices for consumers.”

to her Royal Navy colleagues.

Most farmers would not find her record in Government, where she served as a Minister at the Department for Inter national Trade (DIT), much more encouraging.

During her time at DIT, she vigorously defended the trade deals recently signed by the UK, despite the fact that the Government’s own impact as sessments show they will reduce domestic farming output.

If recent accounts of civil servants at the department are to be believed, she did not take

her responsibilities there too seriously, with one claiming she had neglected her duties so consistently that they were ‘a Minister down’ for six months.

If – to borrow her campaign slogan – PM is to become PM, the agriculture industry will expect much more.

Wallace Gregg runs the family farm in mid-Antrim, near Ballymena, Northern Ireland, where he milks 180 pedigree Holsteins under the Frocess prefix and sells his milk to Dale Farm Co-op. Wallace is actively involved with Holstein UK, representing Northern Ireland at local and national level.

Isuppose one of the best things about being a farmer is that every day, and indeed every season, is different so that we don’t get bored doing the same task every day. This spring has certainly been different and has resulted in major challenges to our business.

The objective was to make top quality first cut silage, so that we could lower feed rates of really expensive concentrate over the winter. However, the weather just didn’t play ball, with non-stop showers for the majority of May, combined with high growth rates which saw us only getting our first cut in the pit on Friday, May 27. Now we were fortunate to get the crop in dry, with no effluent, but quality was way down.

The hold up in silage making also meant that afterwards, grass was supposed to be coming into the grazing rotation, but has been very slow. This has meant we have had to buffer feed the cows at grass, more to keep the rotation at around 21 days.

Managing grass during these swings in weather and grass growth has been challenging, as we have tried to match demand with growth. However, like all dairy farmers, we just got on with it by pre-mowing paddocks and taking out surpluses and we will target high quality leafy second and third cut silage to improve our forage quality situation. The plus side to a late cut is that we should have no worries about running out of silage over winter.

We get our vet to scan and pregnancy diagnosis cows every four weeks and touch wood, we have had a quite successful year with pregnancies and we would OvSynch any cows that are not served after 70 days in milk. We have found this works well combined with a heat detection system when the cattle are inside.

Our normal practice on our farm was to run two Holstein bulls, one with the cows and one with the heifers, during June and July, to help catch the last few services, but I think we will stop this as both our Holstein bulls have turned cross and hard to handle, not to mention that Holstein bull calves are virtually worthless at the minute due to high costs.

As we are all aware, costs and inflation have

increased exponentially for everyone and although milk price has increased, unfortunately we entered into a fixed milk price scheme over a year ago which, at the time, seemed okay paying 29ppl for October to March and 26ppl for April to September, for about 15% of our milk supply. With current costs this decision is costing us a small fortune and our dairy co-op is in negotiations with the clients to see if they will make a goodwill payment towards these suppliers. I believe they should for two reasons.

Firstly, a fixed milk price scheme was never intended for either party to make or lose excessive amounts of money, but as a mechanism to guar antee supply at a reasonable price to help with forward planning. And secondly any participating farmers will probably never enter any such scheme again after getting ‘burned’ so badly this time and will resent the excessive profiteering these firms are carrying out at their expense.

In conclusion, a shout out to all the local agricultural shows that are back up and running after Covid-19. We were recently at our local show, Ballymena and had a great day, so thanks to all the volunteers that help at all the shows throughout the UK to help preserve this great part of our rural community.

Claire Eastham farms with her husband Martyn in Dorset, where they milk 120-spring calving cows. After gaining knowledge and experience working for other businesses, the couple started their own dairy farming journey in 2015 by taking on a share farming agreement before progressing to their current county council farm.

Martyn and I recently applied for a much larger opportunity on a longer Farm Business Tenancy (FBT).

Unfortunately, after making the final three, we were unsuccessful this time around, but this got me thinking about how vital it is to have a range of farm sizes.

By not having a range of farm sizes, we are cutting rungs out of the farming ladder, meaning it is stagnating as it takes so much longer to reach the next rung and free up space for those starting out.

Medium-sized holdings seem to have disappeared or amalgamated, which creates an easy solution for a landlord to only have to deal with one tenant.

We are fortunate to have our county council holding and are halfway through a 10-year FBT, so have no pressure to move. But we want to progress our business, are able to do so and should hand the opportunity back to the next new entrant.

As George Henderson wrote in The Farming Ladder: “Once started you will find others on the ladder too, some above and some below; give them all a helping hand.”

Many farmers will soon be faced with some tough choices due to a reducing Basic Payment Scheme (BPS), a lack of reliable labour and high input costs.

Do these farmers radically change system, give up or help someone else on their way by forming a joint venture?

Full of new fresh ideas and enthusiasm to push forward a business if both parties are open, this is a great way forward and an alternative way to give people that first chance.

If this Government was serious about helping new entrants into farming, there would be the retention of BPS or similar for under 45-year-olds – perhaps even with a scalable pay rate geared towards smaller holdings, low interest rate, Government-backed loans for those who propose a sensible business plan and a matching scheme for such joint ventures.

However, there also needs to be a variety of second and third rungs. I would say to any estates before taking back in hand or amalgamating, consider if you are cutting rungs out of the ladder and what that chain brings to the rural economy and communities.

Back on-farm, seemingly like the rest of the country, we are very dry with no real rain forecast, we have been

buffer feeding already to extend our grazing round and keep fresh grass going into the cows, but growth is so low.

We have grazed the herbal lays after letting them flower and so this long cover slowed the round down and with some trampling effect would have helped to nourish our soils.

Building organic matters to help with water retention and build drought resilience as well as improve carbon capture is our key focus on farm.

The noise increase was also noticeable as we crossed the threshold from a straight ryegrass and clover ley into our more diverse swards.

The variety of insects and butterflies was astounding. This was definitely the motorway of bug life. We cannot see how this is not the future of dairy grazing. We are on heavy soil and the birdsfoot trefoil and yarrow have performed exceptionally well.

This year we have so far used only 20kg of nitrogen on average per acre across the whole 264 acres and will still hope to utilise 10.5 tonnes of home-grown dry mat ter, so are well on the way to a very low input system.

The hay we grow has all been cut and baled and is heading into the shed as I type. It was perhaps a little overstood and not quite as sweet smelling as previous years, but this will be used for our dry cows come winter.

Breeding has finished and so we will have our PD sessions soon and possibly with the dry weather and good cull value we may sell our empty cows slightly earlier this year.

A 90% rate calved within six weeks is currently being achieved by a Leicestershire-based farming couple who started out as new entrants in the late 1990s. Wendy Short reports.

Gaynor and Kieran Wellwood operate a 10-month grazing regime for their 320-cow herd and try to match milk solids production to cow weight on their New Zealand-type system at Saltby Dairy, Melton Mowbray.

A breakdown of fertility performance gures shows the high calved in six weeks gure is made up of 90% calved during the period, with 78% for heifers in the rst three weeks, says Gaynor.

e o cial calving period runs from February 14 until May 10.

Gaynor says: “It is very important

for the business to maintain a tight block-calving period, as it simpli es management and allows the herd to be fed as one.

“ e designated limit is 12 weeks and any females which calve in the last three weeks of the block are sold as fresh calvers.

for aiming for a tight calving block. Our children work overseas and it suits us to have a non-milking period in January as we can y out to visit them.”

Replacements are selected from cows with high milk solids gures, a good breeding record and a clean bill of health.

e fertility year begins ve weeks pre-mating, when they are tail painted. Checked three or four times daily, the few individuals which show no signs of bulling are checked and treated by the farm vet before the planned start of mating.

e vet will also examine any animals which have not been served within the rst three weeks of the mating period.

Gaynor says: “In our opinion, the secret to maintaining a tight calving period is to use only easy-calving bulls; our calving assistance gure is 2%.

“Cows which calve without incident recover rapidly and are far more likely to get in-calf without

rThe yield average from the 320 KiwiCross females, which carry New Zealand Holstein Friesian and Jersey bloodlines, is 6,300kg at 4.57% butterfat and 3.66% protein

rThe herd is milked twice a day in a 24:48 herringbone rGaynor and Kieran are assisted by two full-time employees, while agricultural and veterinary students help out at calving time rGaynor also works part-time as an independent dairy consultant

“We also have personal reasonsGaynor and Kieran Wellwood. The tight calving period helps to simplify the management of the calves. PICTURES : Tim Scrivener

Cows are turned out during the day from February 20 and will stay out until mid-November.

issues in the following year. We also remove cows which are persistently prone to lameness and/or mastitis, as they will have reduced fertility.”

Longevity is another desirable trait, says Gaynor. “ e current average is 4.6 lactations, although the aim is for ve. ere are economic reasons for this target, but we are

also aware that we need to minimise our carbon footprint and longevity is an element of the rating system.

“Our milk buyer, Arla, has helped us with carbon auditing and the results were encouraging, although there is always room for improvement.”

e ideal cow weighs 500-525kg and is expected to produce its weight in milk solids on an annual basis. Gaynor says: “In our best year we achieved 6,000kg of milk from 300kg of concentrate per cow. However, in our worst year we had to feed 900kg/cow to get the same result.

“A lot depends on the weather and its e ect on grass growth. Over the past couple of years, grass performance has been held back by the cold spring, but conditions were be er this season.”

Grass surplus to grazing is made into baled silage. e forage is supplemented with clamp silage that is bought-in by the tonne, while concentrates are fed in the parlour according to grazing conditions.

Fresh calvers start on 3kg/head/ day, dropping down to 1-2kg at peak grass production.

It is essential that only top quality silage is fed to milking cows to optimise performance, Gaynor says.

Meanwhile, dry cows and youngstock are o ered baled haylage.

e business operates DIY arti cial insemination and has ‘dabbled’ in the use of sexed semen, but the results to date have not matched the traditional product.

e lower end of the herd is inseminated with the Hereford and their beef calves are sold privately,

How do you make the best milking robot we’ve ever produced better? You add the ability to automate pregnancy checks and heat detection during milking. It’s called the DeLaval VMS™ V310 – and it is a total game changer. Talk to your dealer about how you can make it your milking system.

along with the dairy bull calves, at two or three weeks old.

Speakes Slipstream, LuckAt-Last Inspired, Busy Brook MGH Mordor and Drysdales Sovereign are among the latest bulls which have been selected from the KiwiCross portfolio.

Gaynor also picks out Crossans Critical, a sire which has had a positive in uence on performance, conformation and health traits.

Cows are usually fully housed in the cubicles by mid-November, a er which they are milked for four weeks and dried o . If the weather is favourable, they will be turned out during the day from February 20 onward. Rainfall in the area is relatively low at 575mm, but the clay soil is prone to poaching.

e average paddock size is two hectares (4.9 acres), with each containing two troughs mounted on concrete pads.

Cows enter the paddocks at about 2,700-2,800kg dry ma er (DM) per ha (1,125-1,166kg DM/ acre) and are removed at 1,500/kg DM/ha (607kg DM/acre).

Gaynor says: “Cows graze for only a few hours a day in the early turnout period. During that time

The top end of the herd, judged on milk solids figures, fertility and health, is inseminated with conventional semen to produce heifer replacements.

they will eat two-thirds of their DM requirement from grazed grass; as fresh calvers their intake potential is relatively low.

“ e average stocking rate over the year is 2.8 livestock units per hectare, which includes the youngstock kept on the grazing platform.”

e farm has an annual grass reseeding target of 10% and uses a mix of perennial ryegrasses, Timothy and white clover.

Fertiliser goes on to the land post-grazing and paddocks are also given a mid-season sulphur application. Residuals are controlled by pre or post-mowing where necessary.

e couple, who were born in Cheshire, started out as dairy farm workers in the mid-1980s.

ey took on their rst dairy farm tenancy in 1998, when they were awarded a county council tenancy on 14ha (37 acres) near Plymouth.

Progressing with Devon County Farms, they moved their 60 crossbred cows to a 51ha (127-acre) unit in 2003.

e Wellwoods had the good fortune to take over a unit with excellent infrastructure when they moved again in 2011, this time to

the 138ha (341-acre) Saltby Dairy on a Farm Business Tenancy. e site has a slurry lagoon, two se lement ponds and an irrigation lake, although the extended grazing season keeps slurry production to a minimum.

A number of milk producers have switched to block calving and Gaynor thinks there is room for a variety of production systems within the UK industry.

Having reached optimum cow numbers, the Wellwoods will continue to try and improve performance gures.

Gaynor says: “ e key to maintaining a high standard of herd fertility is to breed the right cow for the system and focus on a ention to detail at all times.

“One future aim is to try and enhance the herd’s performance e ciency, while at the same time continuing to work towards minimising the farm’s carbon footprint.”

Generally, the approach has been to supply higher levels of minerals to avoid deficiency problems, yet this can work to unnecessarily increase costs and impact the environment through excretion. A responsible approach ensures diets contain an optimum balance to support performance and farm profitability, while minimising consequences on the animal and environment.

Recently revised mineral requirements for dairy cows by NASEM 2021 have not only adjusted requirements, but now also acknowledge how the dairy cow may utilise different mineral sources. This means now is the optimum time to consider not only the amount, but also the source of minerals in diets.

As an example, UK dairy cow diets currently exceed the revised copper requirement by around 170% when taking into account an average mineral containing 2000mg/kg copper sulphate fed at 150g/h/d alongside compound and forages. Similarly, zinc requirements have also been reduced for dairy cows. Currently, supplementation of zinc oxide alongside what is supplied from background in the ration means UK dairy farmers could be oversupplying by an average

of 145%. However, manganese requirements have increased by 55% yet the UK still oversupplies manganese by an average of three times the updated requirement. Evidently, there is room for a more optimised mineral balance and while copper sulphate, zinc oxide and manganese oxide are the typical sources of these minerals in dairy cow supplements, their efficiency due to being an inorganic source is limited.

The majority of minerals oversupplied in supplements are in the form of inorganic minerals which have low bioavailability, meaning less is available for use by the animal. Sulphates are highly reactive in both the rumen and feed, impacting feed palatability, are susceptible to antagonism and harm rumen microbes due to their antimicrobial effects as demonstrated by their use in footbaths. Impacts on rumen microbes limits rumen fermentation and the overall effectiveness of a diet in terms of both animal performance and cost. Meanwhile, oxides are not a consistent source of mineral as a result of their origin and therefore can never be accurately balanced, increasing the risk of deficiency or toxicity.

The solution to concisely and responsibly meet the updated requirements through a better and more reliable source, are Hydroxy Trace Minerals (IntelliBond). IntelliBond minerals are more bioavailable, meaning less is more, and enables farms to reduce their mineral usage in a cost neutral way alongside improved animal performance and reduced environmental concern.

Accurately reviewing your mineral labels means not only considering the total amounts, but also sources used and feed rates. Higher total levels do not always equal quality. Studies have shown that 1000mg/kg copper IntelliBond offers the same bioavailable level as 2000mg/kg copper sulphate, with the added benefits of:

• More for less

• Palatability

• Ration digestion

• Sustainability

• Improved quality

Over the next 4 issues, we will explore the benefits to challenging the supply and source of minerals to enable UK dairy farmers to be at the forefront of a responsible mineral strategy and optimising their profitability on farm. In the meantime, if you want to start to take action now reach out to us at trouwnutrition.co.uk/intellibond

Kathryn Rowland has been at Kingshay for 20 years and originally hails from a dairy farming family. Heading up Kingshay’s farm services team, she has overseen the recent publication of the 11th edition of the annual Dairy Costings Focus Report.

The UK dairy industry has certainly seen its fair share of challenges; producers are having to juggle rising costs and labour challenges with contract obligations and seasonality, as well as respond to growing consumer demands and market influences.

But there are some tremendous opportunities too. Small improvements can have a big impact on the bottom line and producers could be mak ing more out of their milk contracts, as reflected in the latest Dairy Costings Focus Report.

Producers have doubled down on efficiencies and succeeded in boosting margins, health and fertility across the board. Margin over purchased feed (MOPF) averaged £1,920 per cow and 22.71ppl – some £206/cow and 2.57ppl more than last year.

In the last five years, cases of lameness and mas titis have fallen from 43 and 41 cases per 100 cows to 35 and 30 cases per 100 cows, respectively.

In fact, cases of all diseases in the report declined, demonstrating the correlation between improved health and fertility gains.

Calving interval rolled back by four days to 393 days and service also improved to 2.3 services per conception. And while there was no change to conception rate (38%) and culling for infertility

(6.7%), there was an improvement in both the 100-day in-calf rate and the 200-day not in-calf rate, the latter falling sharply from 16% to 13%.

Fertility remains the leading reason for cows leaving the herd at 25%. But the static culling rate, alongside this year’s fertility gains, indicates that producers have tightened up their breeding management and become more efficient.

Milk from forage has also been very strong over the last couple of years, despite falling shy of predictions. This year there have been a few challenges and forage quality was not quite there for some herds to get the best yields.

Within every production system there is a wide efficiency range. But even high margins are quickly being eaten into by soaring overhead and input costs and the cost of inefficiencies only becomes more pronounced as prices rise.

The milk price has soared, starting at 29.2ppl (March 2021) and closing at 36.9ppl (March 2022), averaging 33.6ppl for the year ending May 2022.

When we did this report this time last year we could not have predicted what has happened, but who could have? Luckily, the increase in milk price has tracked input costs and costs of produc tion. Nevertheless, this could change. Is 50ppl as high as milk prices will go or will they rise further?

In March, concentrate prices were averaging £274/tonne, with total feed costs at 9.34ppl.

Ammonium nitrate prices had rocketed to £839/t, while red diesel had jumped to 96ppl.

Health and fertility are a case in point for making significant marginal gains. The average cost of all health issues has increased by a staggering 28% to £29,068, with increased costs and a high milk value.

All estimated costs per case have gone up on last year; mastitis and lameness by £90 and £109, respectively. There still remains a huge gap between the top quartile of producers and the average, worth £13,482 in health costs.

While higher cull values and enhanced

efficiencies have seen infertility cost drop by 9.6% to 187ppl, further gains can be made. At a cost of £5.23/cow for each extra calving interval day, the sums quickly add up; £1,046/day in a 200-cow herd.

Not maximising forage use will be costly.

Ranked by milk from forage, purchased feed costs ranged from 7.85ppl in the top 25% to 11.13ppl in the bottom 25% – a difference of £52,692/year for a 200-cow herd. Winter feed costs are looking like they could be £40-£60 higher than summer contracts.

So where do I think this is all going? I would love to get my crystal ball out and say what the market might do over the next 12 months; Brexit, Covid-19 and Russia’s invasion of Ukraine will likely have a lasting impact and industry experts indicate that costs are not going down.

Looking ahead, there is a massive range in efficiency across systems and it is wider than ever. Some herds are losing money while some are nervous of tax bills due to considerable profit. And while producer numbers are declining, there is potential for shared farming partnerships to encourage younger entrants into dairy farming.

To keep pace, producers need to analyse costs of production quarterly and MOPF monthly and update forward budgets frequently to closely monitor financial performance.

Invest in areas which will future-proof your business. For many reinvesting in their swards, infrastructure, cow management and cow comfort have paid dividends and helped lower tax – shiny, new tractors need not apply.

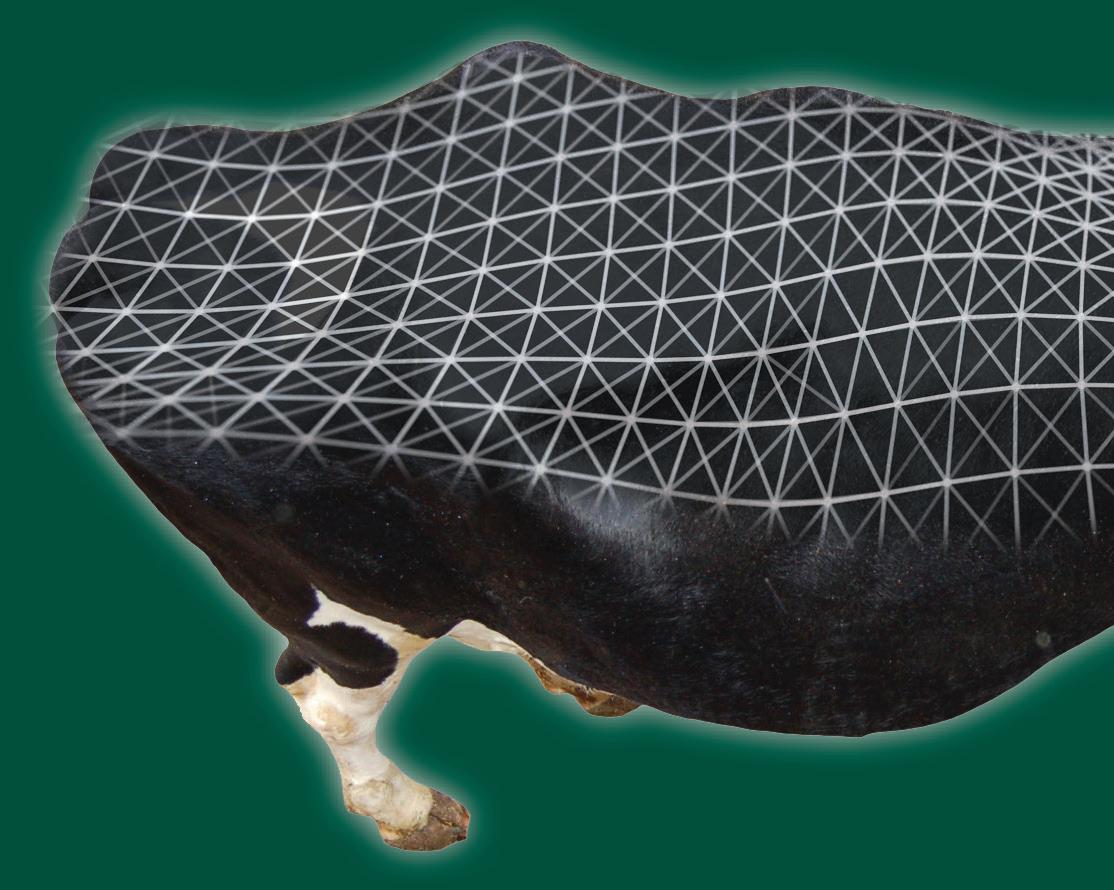

Irrespective of milk yield, herd size or system, all dairy herds have a degree of ketosis on-farm which, if not appropriately treated, will have a negative effect on health, fertility and milk production. Dairy Farmer reports.

It is crucial that ketosis is not just seen as a problem among high yielding herds, but instead presents a threat to all dairy cows says Kate Heller, ruminant technical con sultant at Elanco.

She says a study in Ireland showed that grazing herds averaging 6,758litres had 27% incidence of ketosis, which is directly comparable to what is seen in higher yielding herds, with the figure for this category standing at 28.5%.

“Every cow will experience a negative energy gap in the run up to calving and consequently will be at risk of ketosis.

Kate Heller says clinical ketosis is often just the tip of the iceberg where herd health is concerned.

JSam Bowker works on his Exeter-based family dairy farm and as a farm animal vet for Blackdown Farm Vets in Devon.

The farm runs 220 Irish Holstein cross cows on an autumn block calving system, with cows average 7,600 litres per cow over their lactation.

Since stepping back into a more active role on the farm, Mr Bowker has taken a keen interest in whole herd management, with a particular focus on the transition period.

This has delivered multiple improvements in production, health and fertility rates, including a 10% increase in conception across the herd.

“We try to breed all of our own replacements, so fertility is a key focus for us,” explains Mr Bowker.

“We have made a number of changes to how we handle the transition period, including introducing a specific TMR, and body condition scoring the whole herd.

“Far off dry cows are grazed on standing hay. Traditionally we just fed hay and dry cow rolls during the transition period but following work with our nutritionist, we now feed a transition specific TMR two to three weeks pre-calving to prime them for early lactation.

“The diet consists of mainly maize and chopped straw with some grass silage,

condition,” Ms Heller explains.

pointing any sick, old, fat, thin or twin-bearing (SOFT) cows, as well as those which have pre

drying off with a target score of between 2.75 and 3. When they come in for transition, they are scored again before moving onto the TMR, which helps to reach our goal for a body score of 3 at calving,” he explains.

“It is vital that we track all body scores to regulate cows that could be at risk of ketosis.

treated wheat, soya and dry cow minerals. This more intensive diet helps to reduce the negative energy gap,” he says.

The Bowkers have also increased a focus on body condition scoring (BCS) both pre- and post-calving.

“All cows are scored at

“When scoring the herd at transition, we also administer a monensin bolus to all cows that are at a heightened risk of the disease.

“This includes cows in their fourth lactation or older, any with a BCS 3.5 or over and any twin bearers, to assist with energy conversion.

“However, there are outliers in the herd which will be far more likely to suffer from the

“To identify those most at risk, I would recommend pinSam Bowker

rNutrition: Ensure adequate dry matter is available and introduce a transition specific diet.

rHerd environment: Avoid overcrowding or changing groups during the transition period.

rPrevent cows from getting

fat: Fat cows have are inclined to eat pre and during calving, resulting in increased fat mobilisation, speeding up the risk of ketosis.

rKnow your herd status: Regularly monitor your herd throughout the transition period and address any

viously su ered from a post calving disease or a previous case of ketosis. ese cows should be prioritised for preventative treatment.”

When thinking about ketosis, Ms Heller says many immediately presume that looking out for a suppressed appetite, reduction in milk and poor rumen ll alongside a smell of pear drops are the key indicators.

Clinical

However, by the time these symptoms are visible, clinical ketosis has already taken hold.

“Clinical ketosis is o en just the tip of the iceberg and indicates there are many more cows within the herd with high levels of ketone in their blood.

“ is in return will be a ecting their health and performance, but is classi ed

“The other key part of our transition management plan is conducting ketone tests on all fresh cows at 10 to 17 days in milk. This allows us to see any that may be at risk of high blood-ketone levels allowing us to react quickly to prevent ketosis.”

Tailored transition management has led to general increased herd health and better conception and fertility rates on the Bowkers’ farm.

“Since implementing an all-encompassing transition management plan we have seen a significant decrease in post-calving diseases with just one case of milk fever, one retained cleansing and no cases of displaced abomasum last year,” says Mr Bowker.

“Last year’s conception rates were 56% which is a huge increase on previous years.”

issues or symptoms immediately.

rTreat those at risk: Treat all at risk cows with a monensin bolus three to four weeks pre-calving.

Administering a bolus three to four weeks ahead of calving can reduce the

as sub-clinical ketosis, as no clinical signs are presented.

“By having a well-rounded, holistic approach to transition management, encom-

incidence of ketosis by up to 74%.

The active ingredient, monensin, is released into the rumen over 95 days, stimulating glucose production, to decrease the energy gap that leads to ketosis

passing nutrition, herd management and environment, farmers can get ketosis under control and see the bene ts of this in yield and herd health”, explains Ms Heller.

Buoyant milk prices and high bought-in feed costs provide added reasons to do a great job of making maize silage this season.

ith soaring feed costs it makes a lot of sense to maximise milk production from home-grown forage, says Volac silage scientist Dr Mark Leggett. Moreover, healthy milk prices add to this argument.

But there is another reason why it is important to retain as much feed value as possible when

Wensiling maize crops this season.

Higher fuel and fertiliser costs mean maize has cost more to grow this year. So any losses in dry matter (DM) and nutrient content which are allowed to occur will steal some of that extra investment, he adds.

Dr Leggett says: “With its high starch content, maize is an ideal source of home-grown metabolisable energy compared with buying-in energy from extra concentrate.

“However, a key challenge is that maize plants play host to a lot of undesirable micro-organisms – in the form of bacteria, yeasts and moulds [see infographic, above right].

“If allowed to multiply in the clamp, these can cause significant

feed value reductions, both during storage and when the resulting silage is fed out.”

Although difficult to quantify precisely, Dr Leggett says even typical losses in maize clamps equate to about one in every 10 trailer-loads of DM ensiled being lost, but they can be higher, for example two out of every 10 trailer loads if clamp management is not up to scratch. When spoilage occurs in the vulnerable top and shoulders of the clamp, he says half the DM in these areas can go to waste, or more.

Dr Leggett says: “The other important point to stress is that it is the most digestible parts of the DM that undesirable microbes feed on first – the sugars and starches.

A key challenge is that maize plants play host to a lot of undesirable micro-organisms

DR MARK LEGGETT

Clean the clamp To remove undesirable bacteria, yeasts and moulds before harvest surviving on old silage and in cracks

Harvest maize To provide a balance of: promptly at 30-33%

Starch content in cobs – for energy dry matter (DM)

Foliage that is still green – for digestibility

● Crop still sufficiently ‘soft’ for consolidation

Potential sources of undesirable microbes (bacteria, yeasts and moulds) on maize plants which feed on nutrients and interfere with preservation in the clamp

Leave at least 15cm Because the stem base is: of maize stubble

Low in nutritional value

● At risk from soil bacteria that interfere with fermentation

● At risk from yeasts and moulds

Chop to the So the maize is: optimum length

Short enough to aid clamp consolidation (1.5-2cm)

Long enough to perform in the rumen

Various fungal diseases living on the maize plant

with a

To reduce fermentation losses (due to inefficient dual-acting additive fermentation bacteria naturally present on the crop)

To target the yeasts and moulds that cause losses from heating

Dead or dying leaves and stem tissue harbouring yeasts and moulds

Fill the clamp in

To aid consolidation and keep air out: oxygen maximum 15cm trapped in silage allows yeasts and moulds to thrive layers, roll with (Typically, maize at 30% DM requires 25% of its sufficient weight weight arriving at the clamp/hour to consolidate it. and sheet thoroughly So 100 tonnes/hour requires 25t rolling constantly) (side sheets, an O2 barrier film and wellweighted top sheet)

“So not only is there less DM available to feed, but the DM that remains contains less energy for the cow.”

As an example, Dr Leggett says maize is notoriously prone to losses from aerobic spoilage (heating), caused by yeasts and moulds feeding on the silage in the presence of air.

But it is not just losses from heating which maize suffers from. Invisible losses from poor quality fermentations can account for as much as half the overall DM losses in maize clamps, he says.

So when planning how best to

conserve maize, it is important to consider both problems.

Dr Leggett says: “Preserving maize silage is not a single-step process. It requires a joined-up approach [see table, above]. This starts even before harvest by thoroughly cleaning the clamp to remove contamination from old silage.

“It doesn’t end until you can see the silage at feed-out is staying cool.

“Fortunately, some steps, such as achieving a good consolidation,

MAIZE silage heating is a sign that dry matter (DM) and nutrients are being ‘burned up’ by yeasts and moulds.

But besides heating, bad microbes can cause other problems.

Dr Leggett says: “Palatability can also be reduced, resulting in lower DM intake and greater rejection, which will push up bought-in feed requirements.

“Additionally, moulds can cause mycotoxins, requiring

Soil microbes and mould spores splashed up around the stem base, especially in muddy conditions

can benefit not only the fermentation but also help in reducing aerobic heating losses. An integral part is also to choose the correct type of additive. To target both sources of loss, I would advocate an additive which is dual-acting.

“The additive Ecocool, for example, contains two types of beneficial bacteria. The first, Lactobacillus plantarum MTD/1, which is also found in Ecosyl, is targeted at improving fermentation.

“But in Ecocool, MTD/1 is blended with a second bacterial strain, Lactobacillus buchneri PJB/1, which is included to inhibit yeast and mould growth. In trials, compared with untreated maize silage which contained 440 million colony-forming yeast units per gram after exposure to air, maize silage made with Ecocool contained less than 1,000.

“Ecocool has also been shown to keep maize silage cool and stable for more than 10 days after removal from the clamp.

remedial action. Both of these are added reasons to pay close attention to crop and clamp management and additive choice from the outset.

“Prevention is certainly better than cure.”

“With a lot at stake with high feed and milk prices, an additive looks a worthwhile investment.”

For more information on Volac’s Cut to Clamp initiative, visit cuttoclamp.com

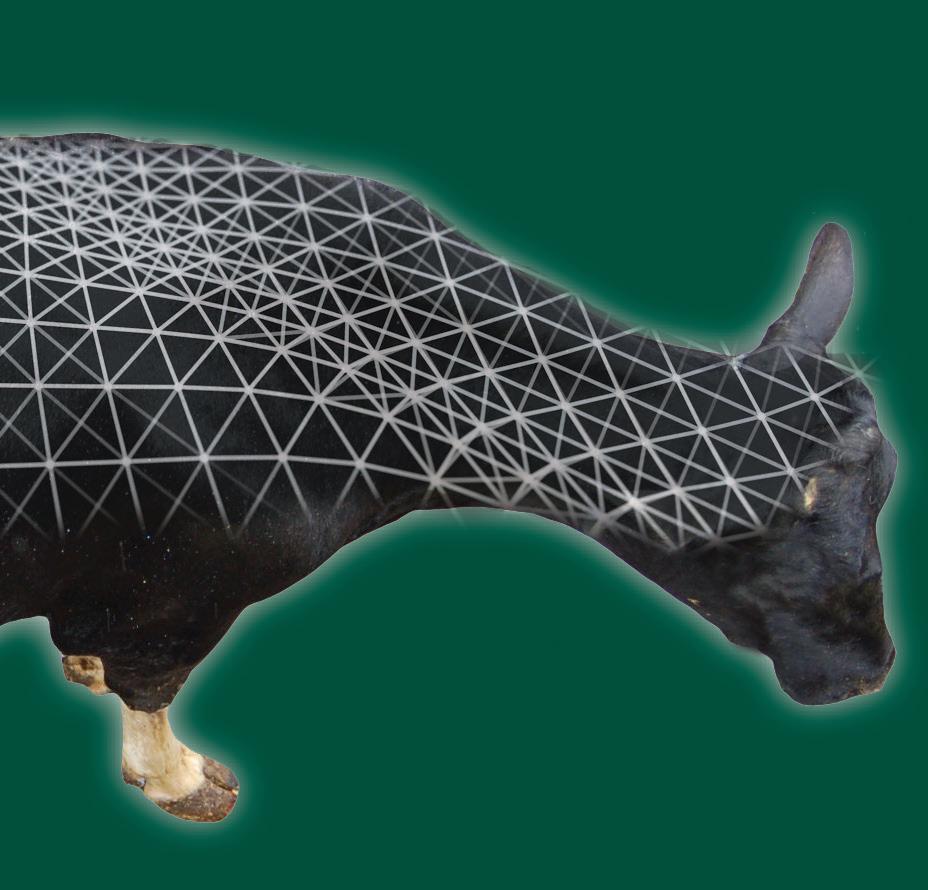

Speakers at a breeding conference organised by ProCROSS discussed issues of in-breeding, the future of the dairy industry and the role cross-breeding can play in the make-up of our herds. Katie Jones reports.

Cross-breeding in dairy cattle is more relevant today than ever before, according to Amy Loeschke, of ProCross and Cre ative Genetics of California.

Ms Loeschke explained pure breeders should be ‘concerned’ that in-breeding is higher than it had ever been before and its rate was showing no signs of slowing.

And she said hybrid vigour was as effective as it had ever been due to these high levels of within breed genetic similarity.

She conceded that line breeding, which she described as ‘in-breeding with intent’ was use ful to concentrate desired genes.

She said: “Line breeding is a high-risk, expensive breeding programme to be taken on by genetic companies and you would expect to see more failures than successes.

“In-breeding comes with pure-breeding as selection can become too concentrated.”

She went on to explain that the consequences of reduced genetic

diversity included decreased fitness, expression of genetic defects and reduced additive genetic variance.

She highlighted how the in-breeding co-efficient - the probability that both copies of the same gene variant have been inherited from an ancestor com mon to both the sire and damhad risen in the US Holstein herd in recent years.

“In the US, Holstein females born in 2020 have an in-breed ing coefficient of 8.69% and for females born in 2021, this rose to 9.16%.

“For perspective, a first cousin mating would lead to a in-breed ing coefficient of 6.25%, a full sibling mating 25%, and a sire daughter mating 25%.”

She explained that while the US had an average annual increase in the in-breeding coefficient of 0.26%, this fig ure was 0.12% for Holsteins in Sweden and 0.10% in Denmark. This was, she said, because these

countries were limiting the influence of certain bulls.

Ms Loeschke added that she thought it was ‘crunch time’ for the Holstein breed.

“When the breed population falls below 40 unique individuals then we really are in trouble. We need make sure we are manag ing things so that we do not go down to this level. We have 40 to 50 unique individuals now for Holsteins, whereas some breeds have a figure as high as 75 unique individuals.”

She said this speeding up of in-breeding was important due to its negative financial implications.

“Various research has shown that there is a $25 penalty for every 1% increase in the in-breed ing co-efficient, so for America where the average in-breeding co-efficient is 9.16%, this would lead to a lifetime penalty of $229 or $0.23 per daily over an average herd lifetime of 2.69 years.”

Ms Loeschke said that cross-breeding would help limit the effect of in-breeding depres sion and take advantage of hybrid vigour when distinctively different breeds are crossed.

She added that cross-breeding could be expected to lead to a hybrid vigor of at least 10%.

“I often get asked if a four-breed rotation should be considered. And while the answer could be yes, you do not really gain a lot of hybrid vigour from four breeds, and it can also be difficult to find a complementary fourth breed.

“Three breeds will maximise hybrid vigour.”

When looking at cross-breeding in general, Ms Loeschke advised choosing distinct, pure breeds with sizable populations and progres sive selective programmes.

“Look for breeds that are com plementary in their strengths and weaknesses and only use the high est ranking bulls in each breed.”

JDairy farmer Peter Cock was an early adopter of the ProCROSS programme after he purchased Viking Red semen for use on his high yielding Holstein herd in 2012.

Back then the cows were averaging at a peak of 12,000 litres on three-times-a-day milking.

He said: “We had a desire to move to tighter calving blocks but found this challenging with the Holsteins.

“When people think of crossbreeding they will often think about spring calving herds of Jersey type cows, producing low value calves.”

However, he said this was not the case with his 600cow herd, which is now 75% cross-bred. “The herd is now averaging 8,300 litres with cows turned out in early March. We have seen a lift a 12 point lift in conception rates, which now stands at about 45%, an improvement in calving interval, vet input is almost nil, and the stillborn rate has halved.”

He said other benefits included an uplift in milk quality from 3.88% butterfat and 3.17% protein at the start of the period of transition, to 4.47% and 3.54% respectively.

JMarket analyst, Chris Walk land, gave some insight into the industry’s current situation and offered a few predictions for the future.

He suggested that while milk prices had been rising, he also thought the situation was ‘top ping out’, and said milk volumes were dropping off at a faster rate than in the previous five years.

“The processors do not like that, they have not got the milk.

“For the first time in years we have got milk recruitment in the UK; that is good for farmers.”

He also said that in the short-term, global milk volumes would be under pressure for the rest of the year due to farm

policy reform, high costs, and environmental pressures.

This he said meant that prices were ‘maxed out’ with buyers and sellers possibly looking at a stand-off.

He said the milk contract refer endum was ‘not good news’ and said the industry should ‘pre pare for bedlam’.

“Since October last year there has been 180 moves across 26 main processors. When it comes to fixed price contracts, one of the countries that pioneered this is Ireland. But now they are begging for mercy.

“We really need to get heads around what might be coming

down the line with contracts. If we get contracts wrong then we are going to be screwed.”

He also said a challenge going forward could be a desire from farmers to produce more milk.

“The big game changer could be farmers turning the tap on if the milk price goes to 50ppl.

“I understand the dilemma [this move would bring], but it would not be good for the market. How ever, I am not seeing a lot of farm ers wanting to produce more milk, and have not detected a massive exuberance on the part of farmers.

“While farmers are certainly juggling more money than they have before, they are not ac tually making any more money.”

J

The widest ever range of European cattle genetics will be heading to the UK, thanks to a new and intensified relationship between France’s largest breed ing organisation, Innoval, and Germany’s dominant breeding company, MASTERRIND.

Through Innoval’s exporting arm, Evolution International, genetics from up to 65% of the

French market will be sold in the UK through the MASTER RIND subsidiary, Mastergen.

Innoval’s French line-up is dominated by Holstein genetics but also features bloodlines from the Normande, Pie Rouge and Brown Swiss breeds.

Alison Dunphy, managing director of Mastergen, says: “Innoval runs an exceptional

programme of research and development and has one of the largest breeding programmes in the world. It represents 65% of the French market and distrib utes its semen in 70 countries.

“With over 6,000 Holstein males genotyped every year and one of the largest semen sexing laboratories in Europe, we can look forward to the continued

availability of diverse and industry-leading bloodlines.”

Much of the semen from Evolution will be marketed to UK customers by Mastergen it self, but existing routes, through third parties, will also be stepped up. This ensures farm ers committed to working with other breeding companies will have no disruption of supply.

Building a new clamp rather than relying on baled silage can help dairy farmers reduce costs, minimise use of plastic on-farm and lower their carbon footprint signi cantly, according to forage production specialists.

Over a 20-year period, costs of ensiling each tonne of silage would be halved, use of plastic would be nearly 20 times less and associated CO2 production would be reduced by nearly 95%, says Will Wilson, of forage systems specialists ARK Agriculture.

He says: “Modern high oxygen barrier lms combined with the latest technology in clamp building are giving producers a real opportunity to move their forage production forward and make the most e cient use of home-grown feed materials while minimising environmental impacts.

“It is a great example of new technology making established practices signi cantly more e cient and more aligned with processors and consumers’ desires to see farming reduce its carbon footprint.”

He adds that many of the practices producers have relied on are becoming ‘increasingly unacceptable’ in the era of more sustainable production and he says excessive plastic use is just one of those.

Looking at the construction of a 10-metre by 45m by 3m clamp

Developments in silage clamp construction and coverings are increasing the efficiency of silage production significantly while minimising waste and the associated carbon footprint of milk production. Dairy Farmer reports.

reveals some interesting comparisons to baled silage, he says.

“Such a clamp is going to cost about £80,000 to build and, at 0.7t/ cu.m, it will hold about 1,000t of grass silage, so every 1t stored costs about £80 in build costs. Over 10 years, that is going to be £8/t stored and, over 20 years, it will be £4/t.

“Wrapping a 700kg bale including contractor charges is about £7/bale, which equates to about £10/t – signi cantly more than the £8/t over the rst 10 years of the newly built clamp.

“Over a 20-year period, well within the serviceable life of a modern silage clamp, you will be storing your silage for much less than the same operation using big bales.” e numbers get even more

a ractive when you factor in plastic use, says Lucy Johnson, of silage lm specialists Silostop.

“You should be able to cover 22 x 700kg bales with six layers of lm for every 24kg roll of wrap, so that is about 1.09kg of plastic per bale or 1.54kg/t; 1,000t of wrapped bales will require 1,540kg of plastic per year, costing about £4,500/year at £75/roll.

“Looking at the clamp situation, a roll of 50m orange high oxygen barrier lm weighing 26kg will cover our 1,000t of clamped silage.

“Side wall lm will add a further 44kg, so that is 70kg.

“You will also need two 12m anti-UV covers weighing 120kg in total, but these will last for six years, so that is 20kg/year of plastic.

“ is is a total of 90kg of plastic used to produced 1,000t of forage in a clamped situation, compared to 1,540kg of plastic for the equivalent weight of baled silage – over 17 times more.”

Cost-wise, Ms Johnson says the plastic required for the big bales will cost £4,425/year at £75/roll, whereas the high oxygen barrier lm and covers for the clamp will cost about £870 for 1,000t of silage at current prices.

To clamp 1,000 tonnes of forage, about 90kg of plastic is required, compared to 1,540kg of plastic for the equivalent weight of baled silage.

She says: “Assuming both types of lm require the same amount of energy to produce and release the same amount of greenhouse gases in the production process, the lm will have a carbon footprint about 95% less than for the plastic required for the big bales.”

e numbers associated with clamped silage over the baled equivalent are impressive, but they are not the only advantages, she says.

“ e general direction of travel in dairying is for be er use of resources and proper management of waste, so unnecessary use of big bale silage is contrary to this.

“Bales are normally stored on porous hard-standing or soil, so e uent management is more dicult than with a properly designed and managed clamps.

“Baled silage also takes up more space on the ground as they can only really be stored three-high as a maximum. Even at three high, the bo om bales are compressed and this can allow air ingress and e uent leakage as the wrap moves.

“Baled silage also has more variability in terms of quality and is harder to evaluate for rations unless each separate eld is marked and fed accordingly. Clamped silage has more even quality as the forage is mixed thoroughly during the ensiling process.

“Wrapped bales are very vulnerable to bird damage both in eld and in the stack and do not forget all waste plastic on-farm must now be recycled by law.

“Waste companies do not tend to like bale wrap as it is thin plastic with high contamination levels due to the silage and soil contained, so it can be very expensive to deal with.”

Mr Wilson agrees, saying with

Will Wilson says clamps are as important as any other piece of infrastructure and are critical to the economics of production.

more dairy companies factoring the carbon footprint of the milk they are buying, high energy, high input practices will come under greater scrutiny in the future.

“A farm’s carbon footprint is increasingly being benchmarked by dairies and milk buyers with plastic use guring in these totals more and more. Historically, such things have been fairly low on the agenda for many milk producers, with other important management decisions taking priority.

“ e expansion in herd size over recent years has meant cow accommodation and manure storage have o en been seen as more important than the extra forage storage capacity needed for this, but things are changing.”

Home-grown forage is becoming even more important in the dairy pro tability equation and is seen as one of the most important ways to reduce input costs in the future with poor forage management less tolerated than ever, Mr Wilson says.

“Over lled clamps or poor compaction levels, for example, are not only bad news for cows, they are dangerous to operators and shorten the longevity of the clamps themselves. I think this is being recognised.

“We are de nitely starting to see be er producers realising good clamps are as important as any other piece of infrastructure on-farm and are critical to the economics of production.

“ ey represent a longer term investment than bagged silage, but the return on investment is signi cant and quickly achieved, particularly when used with the newer technology lms which reduce plastic use signi cantly and improve forage quality.

“Add in the tax e ciency of using Capital Allowances for construction and Countryside Stewardship grants available for roo ng silage clamps and I think we are going to see construction of new clamps becoming increasingly popular in the future.”

Sustainable management of inputs and people was the key message of the 2022 Positive Farmers Conference, Cork. Anna Bowen reports.

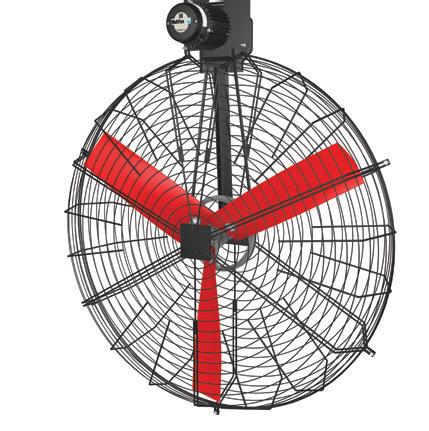

Changing milking intervals may have positive impacts on farm management and minimal effects on productivity, according to recent research from New Zealand.

Dr Paul Edwards, senior scientist at DairyNZ, explained he had led a trial at Lincoln University in New Zealand where the dairy herd was split into full-time twice-a-day milking, full-time three milkings in two days (three-in-two) and part-season three-in-two milking.

He said the trial showed that full time three-in-two milking resulted

in 5% less milk solids than trad itional twice-a-day milking.

However, he stressed that the drop in production could be offset by investing the time saved.

He asked: “What are you doing with that extra time? If you are spending 25% less time milking, is that time being spent on better farm management which balances out the loss of production or does it help staff have more time off and do a better job when working?”

Further trials looked at varying intervals between milkings in three-in-two systems and found no significant difference in milk solid

production, although protein produc tion decreased and fat increased with a longer interval between milkings.

Dr Edwards and his team have also investigated the sleeping patterns of people working on twice-a-day and three-in-two farms. The trials started recording data before calving.

He said: “After the third week of calving, people on three-in-two milking farms got an average of 27 minutes more sleep per night.

JDifferent approaches to managing stocking rates were explored by dairy farmers Barry Bateman and Mike Birmingham, together with Teagasc research officer Dr Brendan Horan.

Mr Bateman explained he had run high stocking rates to facilitate stocking additional units.

By contract rearing heifers and consolidating on one block, Mr Bateman said he had avoided the increased fuel and labour demands of running off-lying ground.

He explained his 211-cow spring calving herd was managed on 75 hectares (185 acres), utilising 13 tonnes of dry matter (DM)/ha (5.3t DM/acre). The stocking rate had ranged from 1.8 to three livestock units/ha (0.7-1.2 livestock units/acre).

He said: “We will average 2.7 cows/ha to comply with regulations, but in the past we have farmed a higher and lighter stocking rate.

“I enjoy the simple system that we have and financially there is never been a return for stocking heavier than this.”

He added that a lighter stocking rate was not necessarily easier to manage.

He said: “When you have a farm which grows a lot of grass, it can be difficult at a lower stocking rate.”

For Mr Birmingham, an easier life was a key driver for his stocking rate. His 37ha (91-acre) farm is stocked with 96 cows.

He said: “For the past few years we have been stocked at 2.6 cows/ha. This is a lifestyle stocking rate which gives us

time to do things such as watch my daughter’s sports matches and attend discussion group meetings.”

Mr Birmingham said he measured grass twice a week through summer and focused on improving swards through incorporating clover, achieving optimal soil indices and reducing nitrogen applications.

He said that in 2023 he aims to spread less than 200kg N/ha (81kg N/acre) and has already changed his approach to application based on clover content.

Dr Horan commended both farmers. He said: “These farms have done well by matching grass to demand and a really tight calving pattern. Stocking rate is a great tool

for increasing productivity and profitability of dairy farming.”

However, he added there were limits to this.

Dr Horan said: “You can still increase productivity once past the ideal stocking rate, which is where the risk is that profitability does not increase with productivity.

“Higher stocking rates are easier to manage in most cases and can improve pasture quality right through to the mid-season and minimise that drop in sward quality.

“One of the challenges at farm level is that traditionally higher stocking rate has a negative environmental effect.”

In response to this, he said he had seen more farmers embracing clover, especially in light of high fuel and fertiliser prices.

“It might not seem a lot, but when people are ge ing ve hours of sleep a night, it is quite signi cant.

“Milking exibly can help people t work with routines such as school drop-o s. ree-in-two is a fortnightly schedule which does mean you do not know by the day of the

A change in milking intervals could have a positive impact on staff well-being and cow performance.

week how many milkings you have, you need to know the week too, which can drive people crazy.”

Dr Edwards concluded by reminding delegates that changing milking frequency needed to be accompanied by other changes, such as allocating dry ma er on a 48-hour rather than 24-hour routine, in order to meet farm objectives.

JThe Economic Breeding Index (EBI) is a valuable tool for dairy farmers but has room for improvement, according to Prof Donagh Berry, research officer at Teagasc.

He said: “I can unequivocally say that no index in the world has been scrutinised scientifically as much as the EBI.”

He added that research had shown that for every unit increase in EBI, net margin increased by €2 per lactation (£1.70/lactation).

Despite some industry questioning of their value, Prof Berry said he was confident in the benefits of genomic bulls.

He said: “Every time we look at it there does not appear to be any systematic issues with genomic evaluation. Some bulls drop and some bulls increase.

“I went back to the year 2014

and broke the animals available down into three groups: genomic bulls; non-genotyped bulls such as stock bulls; and proven bulls. I followed them for the next seven years and only retained animals which had more than 100 progeny in 2022.”

He added that the changes were impacted by a base change in evaluations in 2016 which recalibrated all animals and said there was variability in individual animals, with some genomic bulls plummeting in value. Proven bulls, by their nature, showed half the movement as genomic bulls.

Prof Berry said EBI as an evaluation held its value when checked against anticipated future trends in fixed cow numbers and greenhouse gas emissions, nitrogen restrictions and higher costs.

The dairy farming industry on the Faroe Islands might well be classed as small, but it is still vital for the country’s economy. Chris McCullough reports.

ith just over 1,140 dairy cows on 16 farms producing milk for 53,800 people, the dairy industry on the Faroe Islands is quite a vital sector.

Looking at a map, the Faroes are located halfway between Iceland and Norway, north west of Scotland, and extend to 1,400sq.km in size.

Faroe Islands is one of the three constituent countries which form the Kingdom of Denmark, along with Denmark and Greenland.

Aside from the shing industry there, which is by far the biggest in terms of food production, dairying, sheep farming and vegetable growing, are the main agricultural sectors.

Due to challenging climatic conditions, soil types and eld structures, most of the dairy cows on the Faroes are kept indoors.

One of the more modern farms

Wis owned by business partners

Roi Absalonsen, Nils Absalonsen and Esmar Sorensen, based at Vioareioi, in the north of the island.

Dairying has been a traditional enterprise on this farm for hundreds of years, but as Roi says, there have been major changes there in recent years.

Roi says: “We milk 120 cows which are yielding 32 litres per day on average at 4.2% bu erfat and 3.45% protein.

“ e milk is sold to MBM, the only dairy processor on the Faroe Islands. Our current price we receive for the milk is about seven Danish Krones or 94 euro cents per litre.

“Cows are being milked an average of 2.8 times per day through our two DeLaval VMS300 robots, with 60 cows grouped to each robot.”

Looking back at the history of the farm’s infrastructure, Roi’s grandad

built a new barn there in 1980. Roi’s uncle and business partner Nils took over the farm in 1987 and continued to milk cows.

However, with a restructured ownership, the trio decided to heavily invest in the farm and built a new barn for the cows in 2019. at was not the only investment required though, as extra quota needed to be purchased to increase cow numbers.

Roi says: “In total, we have about 60 hectares here on our farm and we manage to buy or rent another 5ha each year.

“Our cows are kept indoors all year long, but youngstock graze outdoors during summer from June to September.

“Nils, Esmar and myself rst drew up the plans to build a new barn in 2013. At that time, Nils had 212,000 litres of quota, so we bought another 320,000 litres that same year.

“With more quota purchased in

2019, we now have a total of 1.3 million litres to work with each year.”

Most of the cows in the herd are Holstein Friesians, plus there are a number of Norwegian Red cows. Arti cial insemindation is used across the herd.

e Faroe Islands has a quite mild climate, with temperatures dropping to 3degC or 4degC in winter. Summer days are mostly overcast with temperatures never really ge ing

Dairy industry in the Faroe Islands

rThe Faroe Islands are almost self-sufficient in dairy products, with the exception of cheese

rOver the past 10 years, milk production on the islands has increased by 10%, but the number of farms including dairy cattle has fallen from 28 farms in 2012 to 16 farms in 2021

rStatistics show that in 2012, the Faroe Islands produced 6.8 million litres of milk from 1,138 cows; this compares to 7.5m litres produced from 1,147 cows in 2021

rDue to advances in breeding, the average yield has also increased from 6,000 litres per cow in 2012 to 6,600 litres in 2021

15degC and

island

210 rainy or snowy

With this in mind, dairy farmers tend to keep their cows in during the year to avoid damaging the soils. Forage is transported into the

cow barn all summer and silage is fed in winter via a robotic feeding system.

Roi says: “We feed cows with a robotic TKS system, which is a Norwegian system. e robot is set to feed the cows eight to 10 times per day. ey are being fed grass and silage as well as mash

from the local brewery, plus concentrated feed.”

One of the main problems associated with dairy farming on the Faroe Islands is the lack of a slaughterhouse, therefore there is nowhere to kill cull cows.

Roi says: “This is a job we must take on ourselves. We slaughter older cows ourselves and sell the meat to the public, just like door to door selling. It is a tedious task, but it has to be done.”

Looking to the future, Roi and his

business partners have a goal to expand their milk production keeping a close eye on new technology.

He says: “We have invested heavily to reduce labour in the new barn with the milking robots and the robotic feeding system. At the moment we have ca le in a barn in a di erent location, so in the future we would like to extend the barn so we can house all ca le under one roof.”

For

Quality not quantity was the recipe for success for one regenerative cheese producer speaking at Groundswell, Hertfordshire. Chloe Palmer reports.

Moving away from the ‘treadmill of production’ towards producing an artisan, more nutritious product with a strong story is the way forward, according to several high pro le regenerative cheese producers and retailers speaking at this year’s Groundswell event.

Jonny Crickmore, of Fen Farm Dairy, Su olk, admi ed he ‘sleepwalked into pushing for a high yielding cow’ before he decided he wanted to do ‘something di erent’. A er looking at other business models, he realised ‘the value was in the tank’.

He said: “We considered what else we could do with our milk and set out on a mission to make our cheese. A er nine years, we are using most of the milk we produce from our Montebeliarde cows to produce our cheese, which is entirely consistent and sells across the UK.

“While developing our product we visited cheesemakers across the UK and France and realised the farmers who make good

cheese allow animals to graze on pastures which are diverse.

“ ey do not encourage cows to produce too much milk and we could see the way we farm in uences the quality of the cheese we make.

“For us, growing good quality grass silage and cu ing grass more frequently has allowed us to save £40,000 in concentrate costs and prevented our cows from becoming too fat.

“We are now direct sowing plantains and clovers into our grass leys and growing almost everything we feed. We are using less fertiliser and are now noticing a range of di erent plants growing in our swards.”

He added that he used spreadsheets to record data on everything he was doing, which showed although milk yield reduced, the quality of milk increased.

Mr Crickmore said: “We have taken control of our business and we are in a very strong position.

“I do not really need my milk buyer anymore.”

Clare Hill, regenerative agriculture director at FAI Farms and consultant supporting farms adopting regenerative agricultural methods, said the dominance of ‘yield-based models’ in dairying ran contrary to a regenerative approach.

She said: “Some milk processors are o ering 1ppl for regenerative practices, but this still incentivises production. Milk contracts and borrowing are based on high yields, so everything needs to support this, meaning inputs have to increase.

“If we are looking to scale up regenerative agriculture, it cannot be done top down as it is a bottom up approach. Regenerative agriculture is difficult to standardise and categorise, because it is a grass roots movement, so no-one can control it.”

James Ru er, of Paxton and Whit eld Cheesemongers, agreed and suggested regenerative cheesemaking should not be about a brand or a sticker, rather it should be a ‘process, a force for good’.

We are noticing a range of different plants growing in our swards

JONNY CRICKMORE

The theme for this year’s Gold Cup Open Day, hosted by the 2020 winners – the Torrance family, Albyns Farm, Essex – was ‘the road to net zero’. Sarah Alderton finds out more.

The Torrances are milking 685 cows with just over 500 followers and are breeding for lifetime production and feed e ciency. ey are yielding 13,100 litres on three times a day milking with 58 100-tonne cows in the herd.

All heifers are genomically tested at birth and anything with a Pro table Lifetime Index (£PLI) under 485 is served straight to beef. eir top £PLI animal currently stands at 811.

eir breeding outlook changed in the late 2000s when they joined a discussion group and switched to breeding smaller, more functional cows which were easier to maintain. eir continual selection of £PLI for the last eight years instead of the Holstein Index has resulted in longer living, healthier animals, explained Liam Healy, GB genetic service manager for Genus.

At the same time, the family also invested in a sand-based 360-cow shed and slurry system, which was replicated two years later with a dry-cow shed, eradicating the need for antibiotic dry cow therapy.

ey have not used intramammary antibiotics in 24 months, opting only for teat sealants at drying o . eir success lies with breeding a herd ranked in the top 1% on £PLI managed in a system that allows cows to exhibit their genetic potential.

Speaking at the open day, Christine Pedersen from e Dairy Group, said: “ e things that make a pro table herd are the things that also help reduce emissions.

“John is breeding a herd in the top 1% on £PLI and health, welfare and fertility go hand in hand.

“He is achieving a pregnancy rate of 29%, which shows you can have high-performing cows and good fertility.”

Ms Pedersen explained how, unlike many milk producers, Mr

Torrance had moved away from targeting milk from forage, with only 30% of the milking cow ration made up of grass.

She explained: “When John looked at the opportunity costs for growing grass compared to wheat, forage was expensive. Instead, he uses multiple co-products, which in turn, is also helping reduce his carbon footprint.”

Milking cows are fed a maintenance (M) +45 litre ration total mix ration and later in lactation move onto a M+40 litre ration and M +35 litre ration. Maize makes up the majority of the ration (21-22kg a head a day), with three co-products also included – brewer’s grains (5-10kg/head/day), potato chips (4.5-7kg/head/day) and citrus pulp (4-6.5kg/head/day).

Straights are also included. e target is to aim for a dry ma er intake of 26kg/head/day containing 16% protein.

Co-product feeding helps reduce the carbon footprint of the farm, which currently stands at less than 900g of CO2 equivalent per kg of fat and protein corrected milk produced.

Emily Keep, UK head nutritionist at Duynie UK, said co-products o ered a solution to reduce feed

costs and carbon footprint and remove soya from the diet.

“Co-products replace crops grown on land with products harvested from the surplus in the human food chain. is reduces the land required per kg of milk and meat in any livestock enterprise.

“You can not get net zero without addressing feed carbon. Co-products are virtually all very low carbon plant-based products, as the primary product used in the human food chain takes responsibility for the carbon.

“John is using co-products to reduce his reliance on wheat; on top of that, they are highly palatable and nutritious, so help drive intakes.”

Ge ing cows eating and digesting their food relies on well thought-out accommodation in this housed herd. Ideally, cows should eat or lie down for more than 20 hours a day.