At NFU Mutual, we understand the unique opportunities and challenges that come with diversifying. Whether you’re exploring new ventures or enhancing your current operations, our local experts are here to provide tailored advice and comprehensive insurance solutions, so you can focus on what matters most.

Scan the QR code or search ‘NFU Mutual Farming Diversification’ to discover the latest trends, expert insights, and inspiring real-life success stories.

Editor Katie Jones 07786 856 439 katie.jones@agriconnect.com

Creative Services

Mike Begley

mike.begley@agriconnect.com

Katie Haydock katie.haydock@agriconnect.com

Picture Editor

Marcello Garbagnoli 07815 003 236 marcello.garbagnoli@agriconnect.com

Sales Gemma Thorpe 01772 799 500 gemma.thorpe@agriconnect.com

Account Manager

Mark Jackson 01322 449 624, mark.jackson@agriconnect.com

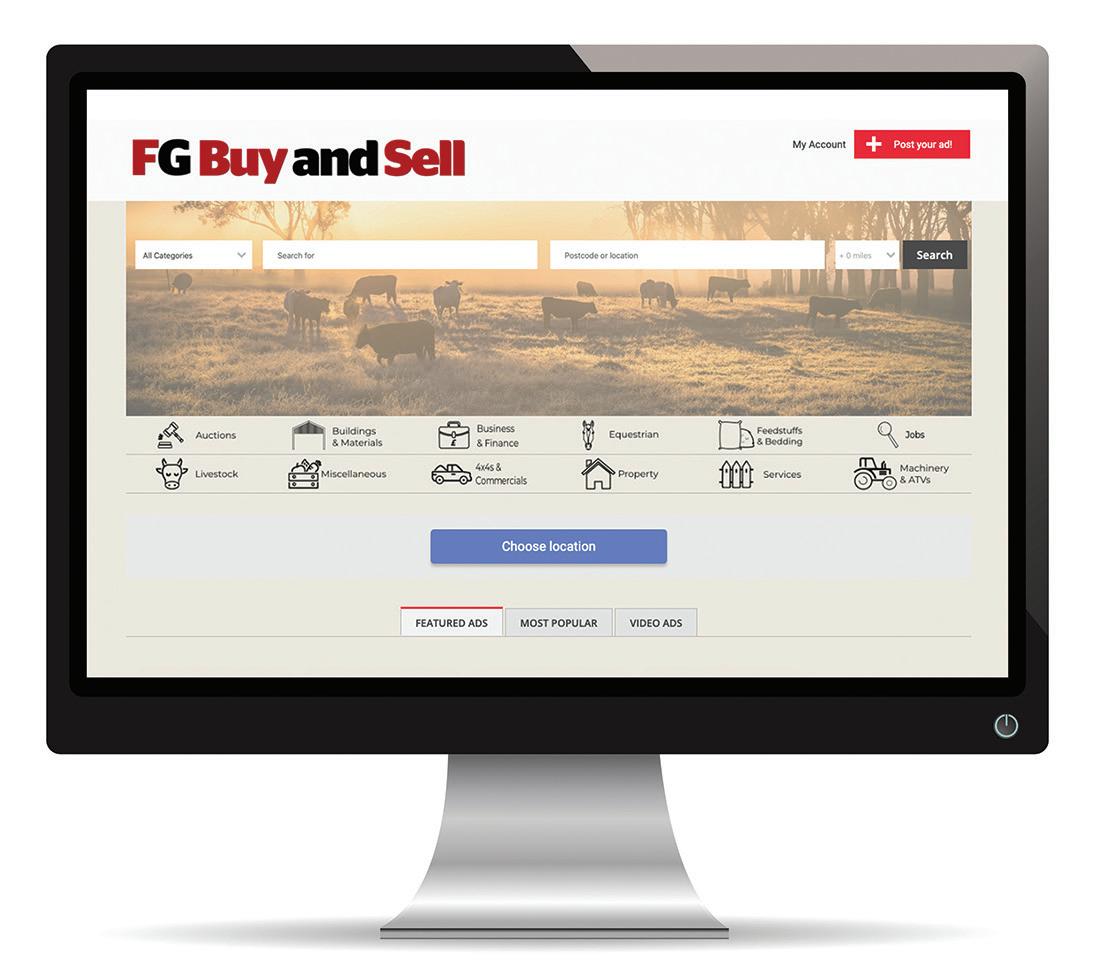

Classified Advertisements 01772 799 400 fgclassified@agriconnect.com

Advertising Production

Justine Sumner 01772 799 437 Fax: 01772 796 747 justine.sumner@agriconnect.com

Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com

Subscription rates: UK £65 a year Europe: £85 World: £95

ISSN 1475-6994

© Farmers Guardian 2024 All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems.

Dairy Farmer, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ

Origination by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ. Printed by Warners Midlands, The Maltings, Manor Lane, Bourne, Lincolnshire, PE10 9PH. No responsibility can be accepted by Dairy Farmer for the opinions expressed by contributors.

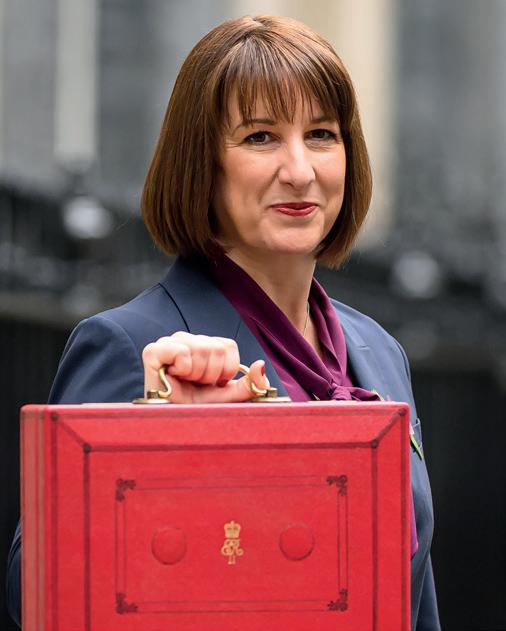

News over recent weeks has been dominated by the fallout from Chancellor Rachel Reeves’ Budget announcement, which has been heralded as one of the biggest changes farming has seen in generations.

Farmers across the country are now looking ahead to a future with a great deal of uncertainty and concern following the announcement that there will be a new Inheritance Tax threshold of £1 million.

So, in this month’s edition, we have spoken to a range of experts to gain their advice on what farmers should be doing now to navigate and mitigate the changes announced in the Budget.

e message continually comes back to the importance of succession planning and gaining as

much advice as possible when it comes to business structures and tax planning.

While this has always been important for our businesses, the changes announced in the Budget make it more important than ever.

Some in the industry have suggested one bene t of the new rules is that those who have not made plans for the next generation will now be compelled to do so.

Elsewhere in this issue, we take a look at technology, in particular that which is found in the parlour, and also consider the best ways to optimise the use of muck and slurry, which is an increasingly valuable product on-farm.

And nally, as this is the last edition of 2024, I would like to wish you and your families a Merry Christmas and a Happy New Year.

Farmers could face Inheritance Tax (IHT) bills that would wipe out their profits every year for 10 years following changes announced in this year’s Budget, an industry body has warned. It comes as Ministers doubled down on their claims the Budget announcements would not affect small farms.

The CLA said its latest modelling counteracted Government claims only ‘wealthy’ landowners would be affected by the swathe of changes which would be applied

to Agricultural Property Relief (APR), IHT and Business Property Relief (BPR).

According to CLA modelling, a typical 80.9-hectare (200-acre) arable farm owned by an individual with an expected annual profit of £27,300 would face an IHT liability of £435,000.

If spread over a period of 10 years, this would require the farm to allocate 159% of its profit each year to cover the tax bill. To meet this payment, successors could be compelled to sell 20% of their land. Similarly, a 101ha (250-acre)

JAlongside the radical shake-up of Agricultural Property Relief as announced in the recent Budget, farmers were also facing a rapid reduction to direct payments over the coming year.

As of 2024, the Basic Payment Scheme was replaced by a system of delinked payments, with funding due to reduce gradually for qualifying landowners until 2027.

Although the phased reduction in the payments had been announced to include 2024, Chancellor Rachel Reeves revealed on November 5 that as of 2025, delinked payments

to farmers would be cut by 76% compared with the 2020 base level, taking a previous £30,000 payment to just £7,200, with no payments above that level.

Ed Barker, head of policy at Agricultural Industries Confederation, said: “Businesses are already starting to work out what this means for the cashflow. [The cut] is clearly going to impact purchases on inputs for the year ahead. We have already had concerned phone calls from farmers on how they are going to manage that and how they will be able to address that for the year ahead.”

arable farm owned between a couple (in the way the Chancellor expected to be possible) with an expected annual pro t of £34,130 would face an IHT liability of £267,000, amounting to 78% of its pro t each year over a decade.

e research debunked gures released by Chancellor Rachel Reeves which said three-quarters of farms would be una ected once combined allowances were taken into account.

Judicaelle Hammond, director of policy and advice at the CLA,

said the introduction of the taxes showed a ‘lack of understanding by Ministers’ regarding farming’s long-term future.

“ e model outcomes are unsustainable and will not promote growth,” she said.

“ is is before we have factored in BPR, Capital Gains Tax, higher employer National Insurance contributions and minimum wage rises.”

A spokesperson for Defra said the

Research from the CLA counteracted Government claims that only ‘wealthy’ landowners would be affected by tax changes.

Government had made a ‘di cult decision’ in the face of ‘crumbling’ public services and a ‘£22 billion scal hole inherited from the previous Government’.

“About 500 claims each year will be impacted and farm-owning couples can pass on up to £3 million without paying any Inheritance Tax – this is a fair and balanced approach,” the spokesperson said.

rFor more on the Autumn Budget, see pages 72-74.

JFarmers attended two mass lobby events in London on November 19 to demonstrate their strength of feeling towards the Chancellor’s changes to Inheritance Tax.

The NFU event was held at Church House, Westminster, with 1,800 members registered to attend, and warnings that this was ‘just the start of the fight’.

Farmer and grower members were asked to get in front of their MP, to ‘look them in the eyes and tell them from the heart how the changes to Agricultural Property Relief will affect farming and growing businesses’.

The NFU stressed it was important Ministers understood the industry would ‘not get tired’ and farmers would ‘not go away’ until the changes were ‘overturned’.

Another ‘complimentary’ event was organised by a group of farmers, held on the same day at Richmond Terrace, Whitehall. The organisers asked those attending to bring British produce to make a mass food bank donation.

Plans to introduce new rules rede ning doublecab and king-cab pickups as cars bring an end to an era and remove the once grey area of vehicle class and taxation. Historically, HMRC’s interpretation of law de ned any vehicle with a one-tonne payload or above as a commercial vehicle with the associated VAT entitlements.

HMRC has announced this will change from April 1, and doublecab and king-cab vehicles purchased from this date will be de ned as cars. is could have serious implications for farm businesses that traditionally purchased a double-cab pickup for tax relief against a businesses’ trading pro ts, alongside its farm-focused practicalities.

A grace period will allow any company buying a double-cab or

HMRC has announced that from April 1, doublecab and king-cab pickups will be defined as cars.

king-cab in the interim until April to access the same bene t-in-kind tax rules that currently apply.

JFarming Minister Daniel Zeichner has con rmed the Government will appoint the rst Tenant Farming Commissioner for England as part of its support for a ‘thriving tenant farming sector’.

e Commissioner’s role will be to improve collaboration between tenant farmers, landowners and their advisers; help ensure fairness in the sector by investigating and facilitating solutions to complaints; and play an important leadership and advocacy role for the sector.

e role will promote the standards outlined in the Agricultural

Landlord and Tenant Code of Practice and will work alongside Defra and the Farm Tenancy Forum to ensure a fair, balanced and collaborative relationship between tenant and landowner.

Tenant Farmers Association (TFA) chief executive George Dunn said the appointment would give the Code of Conduct ‘additional and much-needed teeth’.

He said: “With a TFA survey concluding that 30% of tenants felt bullied or harassed by their landlords and 37% by their landlords’ agents, clearly there is some very important work to do south of the border.”

Vehicles must be ordered before April 1, 2025, to retain the commercial entitlement, but in order

to qualify for plant and machinery capital allowances, the unit must be delivered before October 1, 2025.

J e UK’s Competition and Markets Authority (CMA) has approved Arla Foods Ingredients’ acquisition of Volac’s Whey Nutrition business.

It comes a er the two companies signed an acquisition agreement on April 18, 2024.

Luis Cubel, group vice-president and managing director of Arla Foods Ingredients, said he welcomed the decision at a time when demand for high-quality whey ingredients was ‘growing’.

He said: “It means we are a step closer to a signi cant acquisition that would consolidate our position as a leader in the whey nutrition space. We will now move forward

with the formal process necessary to make Volac’s Whey Nutrition business part of Arla Foods Ingredients.

“Once that is complete, we will be able to comment further on the many advantages of bringing together these two major manufacturers of whey ingredients – not just for both companies, but also for our customers and the industry as a whole.”

James Neville, joint owner of Volac, said they had always been con dent that Arla Foods Ingredients had the ‘necessary expertise and values to take its Whey Nutrition business to the next level’.

Dan and his family own and run the 300-hectare (741-acre) Cockhaise Farm, near Haywards Heath, West Sussex. The farm is home to an organic autumn-calving herd of 240 Holstein and Friesian crosses. He also contract farms another organic autumn-calving herd of 220 cows at Bore Place, near Edenbridge, Kent.

“ I

Another year, another calving block comes to an end, filled with a few surprises and challenges, but mainly positive memories.

At home we followed the usual course of the first 85% running without a hitch and then the last 15% dragging on, with the odd issue thrown in.

This year I had a real challenge with the Octoberborn calves, some of which had rotavirus, something I have rarely seen and so was unprepared for, leading to a handful of losses.

As with all tough lessons, we must learn and be more prepared next year, with better pen hygiene and possibly vaccinating later calving cows.

In Kent, Ryan and the students did an amazing job to have zero cow or calf losses through the whole period.

Earlier in the year I had been worried about how a team with such little experience would get on, but they have proved themselves to be hard-working, diligent and, above all, deeply passionate for looking after cows and calves.

The extreme wet weather meant cows were fully housed by October 14, two weeks earlier than planned, as field conditions just wouldn’t allow us to stay out any longer.

I used to farm by certain dates in mind for turnout and housing, but am now having to be much more flexible in how we approach both, with extreme weather now becoming the norm.

With some dry and warm weather over the last 10 days, the grass looks unbelievably good, with a healthy closing cover of 2,500kg of dry matter/hectare, ready for grazing hopefully in the New Year.

Earlier this year I wrote about the measures we were going to take to reduce levels of slurry in the lagoons. With a grant from South East Water we have upgraded all gutters on the farm, with them all now flowing away from lagoons.

Unfortunately, we weren’t able to put the floating cover on due to the constant wet weather. I am hoping that the upcoming inspection from the Environment Agency is understanding of our intent as it assesses whether or not we are working hard enough to ensure compliance.

Recently our discussion group had our first Comparable Farm Profit meeting since pre-Covid-19 days. As a result of the lack of meetings, I feel we have become a bit stagnant in our approach to the business, with little to challenge what we do and how we do it.

In my first 15 years of farming I was lucky enough to travel and see many other farms across the country and could never understand why some other farmers would rarely attend meetings or take part in discussion groups, as this is where I found my inspiration to constantly improve what we do.

Over the last two years I have become that farmer, as margins have tightened and my time has become more limited I have simply stopped learning from others. This has left me feeling a little stale, with my love for the job waning as a result.

Hopefully the resurrection of the discussion group will be the spur to get back out on the road again.

Becky Fenton and husband Paul milk 200 pedigree Holsteins under the Springlebee prefix at Centenary Farm, a Cheshire county council farm. In 2021, they bought a farm in Staffordshire and they plan to farm there once the new dairy set-up has been built.

“ While the discussions were valuable, I didn’t hear much which was truly groundbreaking

As I write this at the beginning of November, we are currently in the midst of doing our maize in Cheshire. Last week we did our maize in Staffordshire and have been getting it off with no trouble.

Unlike last year, we’ve managed to get the cover crop in, using last year’s grass seed. We will welcome this crop come spring, especially after a disappointing fourth cut silage, which didn’t yield as well as expected. We’ve also reseeded 92 acres, all on the Sustainable Farming Incentive improved grassland action.

October saw us move to a new milk buyer. It wasn’t a choice we made lightly, but it’s already proving worthwhile. With our previous milk buyer, we saw a lot of variation in daily samples, but with the new one our samples are consistent.

I’d be intrigued to know how much independent quality control takes place on the dairies themselves. The finger is always quick to point at the producer.

Our new contract is within the cheese sector; we look forward to dealing with them henceforth. The new contract comes with the bonus of cheese discounts.

I recently found myself at a round table event hosted by Tesco’s Sustainable Farming Group, where farmers came together to discuss some of the big issues facing UK agriculture.

We talked a lot about how to make the most of low carbon opportunities, sustainable approaches and the challenges ahead.

While the discussions were valuable, I didn’t hear much which was truly groundbreaking. Soil health remains at the forefront; it’s where most carbon is stored, even on farms with woodland.

Take care of your soil and it will take care of you. Alongside the usual advice of reducing calving age, reducing the age of slaughter, increasing crop yields and educating the consumer (more difficult).

We’re making good progress with the new calf shed, which is nearly finished. We’ve chosen Holm and Laue automatic feeders after a lot of research. They’re not the cheapest option, but they come highly recommended. We have secured funding through the Farming Equipment and Technology Fund grant, which is a huge help.

The shed is 200ft long and after pricing up gates we have decided to make those ourselves to save a couple of thousand pounds.

When it comes to the recent Budget announcement, I don’t know much yet, but I’m hopeful that professionals can identify ways to support farmers through challenges in the future.

I believe we need to communicate better as an industry, sharing knowledge and supporting each other. Farming isn’t a competition.

I had the privilege of attending the British Farming Awards in October. It was a real honour to be part of the event and I’d like to congratulate everyone involved, nominated, shortlisted or winners. Our industry has so much to be proud of. I might have had a bit too much wine though and ended up losing my shoes.

We are lucky to have the best team on the farm and I try to keep them well hydrated and well fed. During one milking I took a brew out to one of them and he told me of his eventful morning. He’d had piles a few weeks earlier; in his sleepy haze he grabbed the wrong tube to brush his teeth. Had me in stitches.

Finally, I recently turned 40, and I was feeling a bit down about it. Talking to our vet I said: “What have I got to be happy about?” He simply replied: “You’re alive.”

A moment of reflection made me appreciate the simple things: I’m healthy, happy and lucky to be doing what I love, surrounded by great people.

Pedigree Dairy Shorthorns are milked alongside commercial Holsteins on Jonny Wyatt’s Norfolk unit, with the two breeds bringing different attributes to the table. Wendy Short reports.

The ‘Twells’ herd of Dairy Shorthorns at Grange Farm, near Norwich, dates back to the 1930s, with Holsteins introduced in 2010, says Jonny Wya , who farms in partnership with his wife Emma and his mother Anne.

Milked twice a day, the 260-cow herd, split 50:50 between the two breeds, has a 305-day average yield of 9,240kg at 4.3% bu erfat and 3.3% protein.

Milk is sold to Arla on a CARE contract, which o ers bonuses for high health and welfare standards.

Performance

Jonny says: “ e Holsteins produce about 25% more milk compared with the Shorthorns on average. However, one of our Shorthorn cows gave 13,093kg over a 305-day lactation period, for example.

“ ere is a general perception that Shorthorns have relatively low yield potential, but with the right genetics and correct management

they can match the performance of other top dairy breeds.

“ e Shorthorns are slightly more resilient, producing an additional one calf per lifetime on average. Some will have as many as 10 calves and this has a positive impact on overall herd pro tability.

“ e breed also li s the bu erfat percentage in the tank and their beef cross calves have a slightly higher value than the Holstein crosses. e Shorthorn is a robust breed, easy to manage and a very good converter of grass.”

Calving is mainly in autumn, says Jonny. He says: “All the heifers are au-

tumn-calving, but a small percentage of the cows calve all year round because it spreads labour demand and takes the pressure o the youngstock facilities.

“ e primary focus is on winter milk production because of the frequent risk of summer droughts which depress grass yields. e soil on most elds has a high sand content and the area has a low annual rainfall compared with other parts of the country.

“ erefore, we cannot a ord to rely on grazed grass for milk production and it is used primarily for the dry cows. e main calving period starts in September and

nishes in January, and the grazing season usually runs from April until September.”

While the Shorthorn bulls used via arti cial insemination (AI) are registered, the bloodlines of some of the home-bred sires also contain some Holstein genetics.

Pedigree females are shown on occasion, and one of the top achievements was when Twells Susie 69 won the breed championship at the 2019 Dairy Event.

Jonny says: “Predominantly, sexed semen is used on the Holsteins, while the Shorthorns receive a mixture of sexed semen from our own bulls and conventional semen.

“ ere are no females by sexed semen in the milking herd at present, although there will be some coming through soon.

“ e Holsteins are genomically tested, but it is not an option for the Shorthorn due to low breed numbers. e lower end will be given beef breed semen via DIY AI.”

Twells bloodlines have been exported worldwide.

“One of our home-bred Shorthorn bulls, Twells Tornado, has performed particularly well in the herd and his straws have proved popular with other breeders. He is by Cotonhall Ambrose and out of our show cow, Susie,” says Jonny.

“ e two breeds are not usually crossed, because there is enough high-quality Shorthorn semen available on the market to allow us to carry on making genetic progress in the pedigree herd.

“ e type of Shorthorn we like to breed has plenty of width

A further 101ha (250 acres) of and strength in its conformation. Despite being shorter in stature than the Holstein, it tends to be a fairly heavy animal, weighing about 600-700kg.”

e family farm spans 303 hectares (750 acres), which is used to grow irrigated vegetables and sugar beet as well as grass.

rented land grows grass and maize, some of which is added to slurry and sugar beet pulp to power the on-site anaerobic digester plant. Two new cubicle sheds

were built in 2023 to replace the loose housing.

“It has halved the incidence of mastitis from 37 cases per 100 on straw to 18 cases, and numbers are still falling,” says Jonny, who is assisted by herd manager Andrew Smith.

Jonny says: “Having two sheds is convenient, as it allows the herd to be split into high and low-yielding groups.

“ e dairy unit now has a workable infrastructure, and the most recent development is an automated feed pusher, which has li ed

feed intakes by 10%, with a yield increase of 1.5 litres/cow in the rst few months. e next project under consideration is a new calf unit, to replace the old building.”

e business is working towards a number of environmental goals as part of the milk contract requirements and to bolster business sustainability, while cow welfare is also high on the agenda.

“ e generation of our own electricity improves the farm’s credentials,” says Jonny.

“Some 75% of the parlour chemical usage has been replaced with a biocide product which is just as e ective, and a goal has been set to plant 1,000 trees in 1,000 days.

“ e most recent carbon audit showed a gure of 1.19 kg of CO2e per kg of fat and protein corrected milk. We are always striving towards improvement.

“ e building is ed with brushes and the cubicles were picked with regard for cow comfort, with top-quality ma resses topped with chopped straw. Rubber ma ing has been laid wherever the cows stand for any length of time, including the feed passages and the concrete around the water troughs.”

e cows are vaccinated against IBR and leptospirosis and given a mastitis vaccine, he adds.

e farm is in a high-risk area for the BTV-3 bluetongue virus and the herd is on the waiting list to receive the latest vaccine.

e dairy business looks very di erent today, compared with a decade ago, he comments.

“In 2010, it became clear that a decision would have to be made about whether or not to stay in dairying. Running 100-120 cows was becoming unviable, the eightpoint rotary parlour was in dire need of replacement and the loose housing was 50 years old.

“We decided to carry on, partly because of our commitment to the pedigree Dairy Shorthorns

rThe business, which trades as Pearn Wyatt and Son, also runs a fleet of haulage wagons (Pearn Wyatt Transport), specialising in agricultural produce

rThe winter diet comprises maize and grass silage at a 60:40 ratio, plus a protein blend, soya hulls, brewers’ grains and minerals

rThe same ration is also used to buffer grazing shortfalls and is offered at the feed fence for a couple of hours after each milking

and a new 18:36 swingover parlour was installed in 2012. e AD plant was built in 2014 and it has been a bonus, supplying all the farm’s electricity and producing an income from sales to the National Grid.

“ e digestate is spread either by tanker or through an umbilical system. It has cut the purchased fertiliser bill by about 35% and it also acts as a soil conditioner. Yet another bene t is that it utilises some of the slurry, so storage and spreading times are no longer an issue.

“Probably our biggest concern is continuing to nd the right sta . ere are too few young people coming into the industry and it is a concern for the future,” says Jonny.

CRYPTOSPORIDIOSIS

COCCIDIOSIS

ROTAVIRUS, CORONAVIRUS, E. COLI

SALMONELLOSIS

In the event of a Cryptosporidium parvum outbreak Halocur® can help. Contact us to find out how we can help protect the long-term productivity of your herd or visit www.msd-animal-health-hub.co.uk

Reference: 1. APHA 2012-2019 Neonatal, Prewean, Postwean calf groups. https://www.gov.uk/government/statistics/veterinary-investigation-diagnosis-analysis-vida-report-2012 Bovilis Cryptium® contains inactivated Cryptosporidium parvum Gp40. POM-V. Bovilis® Rotavec® Corona contains inactivated rotavirus, coronavirus and E. coli strain CN7985, serotype O101:K99:F41. POM-VPS. Vecoxan® contains 2.5mg/ml diclazuril. POM-VPS. Bovilis® Bovivac® S contains inactivated cells of Salmonella dublin, strain S342/70 and Salmonella typhimurium, strain S341/70. POM-V Halocur® contains 0.5mg/ml halofuginone lactate in an aqueous excipient. POM-V Further information is available from the respective SPC, datasheet or package leaflets. MSD Animal Health UK Limited. Registered office Walton Manor, Walton, Milton Keynes MK7 7AJ, UK. Registered in England & Wales no. 946942. Advice should be sought from the medicine prescriber. Prescription decisions are for the person issuing the prescription alone. Use Medicines Responsibly. Copyright © 2024 Merck & Co., Inc., Rahway, NJ, USA and its affiliates. All rights reserved. UK-VCN-240900001

‘I think there will be a

Philip Kirkpatrick is a director at Old Mill, one of the leading specialist farm accountants, which employs more than 300 staff at offices in Yeovil, Wells, Exeter and Chippenham, and look after over 1,200 farmers.

Farmers and rural businesses are rightly up in arms following the Budget, in which valuable Inheritance Tax (IHT) reliefs for agricultural and business assets were decimated. But there are practical steps which people can take to try and mitigate the effect of the changes.

There is no getting away from the fact that these are huge changes, which are going to cause a lot of heartache.

The important thing is not to panic. Take stock, ensure your accountant has a thorough understanding of asset values and ownership, and make a plan.

The headline change is that agricultural and businesses assets will only qualify for 100% relief up to a cap of £1 million per person (over and above the nil-rate band, which is tax-free up to £325,000 per person, or up to £500,000 where eligible for the residence nil-rate band as well).

Above the £1m cap, relief on eligible assets will apply at a rate of 50%, meaning effectively IHT will be levied at 20%.

So, for an individual owning a farm worth £3m, attracting a nil-rate band of £325,000, the first £325,000 is tax-free, the next £1m qualifies for Agricultural Property Relief (APR) or Business Property Relief (BPR) at 100%, so remains tax-free. The remaining £1.675m incurs a tax bill of £335,000.

It is important to remember that the £1m eligible for APR/BPR is not just land – it is all the working assets, including livestock and machinery. So that can very quickly be taken up. However, the cost of any loans or mortgages secured against the property could be deductible.

The changes only take effect for deaths after April 5, 2026, so any inheritance triggered by death before that date will be subject to the existing, unlimited APR/BPR rules. However, even then, check the reliefs available; do not take them for granted.

Those whose estates will be subject to large tax bills on death will have to decide what to do about it; either spread the ownership of assets among family members to maximise the reliefs available, sell land to fund the tax bill, or borrow money to pay the tax bill.

Borrowing money to service that debt will put a considerable strain on a farm business. I think there will be a lot more land coming to the market. The most sensible option to mitigate tax bills is to spread assets around the family. The £1m APR/BPR allowance does not pass automatically to a spouse, so the first thing is to ensure that both spouses are making the most of their allowances.

“ I envisage considerable uncertainty for tenant farmers and the overall land market

You can pass assets onto a spouse without any tax being incurred.

Landowners can also pass assets on free of IHT, provided they survive seven years from the date of the gi . For any gi s made before the day of the Budget (October 30), there is no cap on the value or tax-free element of the gi .

But gi s made from October 30 onwards will count towards the £1m cap – should the landowner die within seven years, the gi falls within that cap. If they survive more than seven years, the gi should fall outside the scope of IHT.

ese changes are going to encourage people to hand on assets much earlier in life, which probably is not a bad thing for the industry.

However, how the Government has chosen to do this is going to hurt some families – particularly those su ering unexpected deaths. And early inheritance will not suit everyone – each family and business situation is di erent, and the day-to-day implications must be considered, not just the tax bene ts.

One option which is likely to see signi cant uptake is life insurance, to cover the potential cost of IHT bills. If you are making gi s and are concerned you could die within the seven-year window, you might take out insurance to cover the potential tax, just for that period; it could be an a ordable solution.

When restructuring asset ownership, it is also important to consider Capital Gains Tax (CGT) implications.

While gi s to spouses are tax-free, other gi s are liable to CGT, at 18% (basic rate taxpayers)

There is no getting away from the fact that the Budget brought about huge changes, says Philip Kirkpatrick.

or 24% (higher rate taxpayers). Holdover relief is one option, to defer the tax liability, and if it is the donor’s main house, principal private residence relief can be available.

If it is a more comprehensive business restructure or sale, business asset disposal relief (BADR), formerly Entrepreneur’s Relief, may apply on gains up to £1m per person. Currently levied at 10% tax, BADR will increase to 14% from April 2025 and 18% from April 2026.

In terms of the wider e ects of these changes, I envisage considerable uncertainty for tenant farmers and the overall land market.

Landlords le ing land only qualify for the £1m APR/BPR allowance, so on death we could see parts of estates sold o to pay the tax.

And the investment case for non-farmers to buy land has got worse. is may end up being a positive for the industry. However, it will certainly cause some upheaval over the next few years.

Pension funds – pending a consultation – are also expected to fall within the estate from April 2027, and will therefore be subject to tax on death.

And those who are looking at passing assets down to the next generation will need to consider what assets they retain for their own nancial security over the course of their life.

Every business and situation is di erent. But what is critical now is not to bury your head in the sand. Take stock, work with your accountant and trusted professionals, and do not rely on any tax planning or wills which have been done in the past without checking it still stacks up.

ere is no substitute for careful planning for the future, now more than ever.

Oen caused by changes in nutrition, but also the result of bacterial or viral infections, diarrhoea or scour in adult dairy ca le can result in reduced milk production and poor fertility.

A ecting herds all year round, scour is more common during the winter months following the housing of ca le and changes to diet and nutrition. And with this year’s silage analysis proving variable, ca le could be at an increased risk of scouring this winter, as balancing diets continues to be a challenge for some.

Jim McKinstry, vet and director at the Lancashire-based Farm Gate Vets practice, says in most cases scour is the result of nutrition, however, it can be caused by a salmonella infection or winter dysentery.

Relatively uncommon in the UK’s dairy herds today, winter dysentery is a highly infectious viral disease which causes explosive scour among adult ca le.

Mr McKinstry says the disease was more common in previous years, when there were more grazing herds.

He says: “Cows would come inside for winter and within a month you would see perfuse scour.

“It was so explosive as cows were out at grass then would come inside and mix, and infection would spread quickly throughout the shed.”

While di cult to diagnose, winter dysentery can still be a cause of scour in adult ca le,

Ensuring you feed adequate fibre and do not overcrowd sheds are two ways to minimise scour in the herd.

Variable silage quality and nutrition challenges could be a driver of scour among milking herds this winter. Katie Fallon reports.

however, changes to nutrition are likely to be the most common cause.

Mr McKinstry says: “Winter dysentery is still a di erential, but it would be further down the list.

In my experience, it is usually nutritional issues which cause cows to scour

JIM McKINSTRY

“It is not the easiest thing to diagnose and if it is that then cows will just get over it.

“You need to ask if it is a scouring cow or if is it a change in faeces which have become looser. In my experience, it is usually nutritional issues which can cause cows to scour rather than something infectious.”

Mr McKinstry says diets will be di cult to manage this winter due to silage variability and be er milk prices.

He says: “I think a big problem we are going to have this year is that milk price is decent, feed price is lower and with the silage not being as good, the danger is people push the cows hard on the concentrates

and we will run into more nutritional problems and potentially more scour.”

He advises farmers to be conscious of including enough bre in milking rations to reduce the risk of scouring cows.

He says: “I always say to farmers; remember they are ruminants not pigs. They need some fibre in the diet.”

When diagnosing scour, Mr McKinstry advises looking at how many cows are a ected and the impacts to milk yield.

He says: “If cows are looking o , have loose dung and a drop in milk yield, I would advise farmers to have a chat with their vet.”

He says investigating the cause of scour is important to identify

diseases such as salmonella, which can start to appear during winter as ca le are housed. He advises taking faeces samples, as the quickest and easiest way to diagnose scouring cows and check for salmonella.

Mr McKinstry advises all causes of scouring will likely cause impacts to milk production and fertility.

He says: “Anything that causes a decreased transit time means you are making good slurry, but not good milk.”

“And anything that drops production and decreases energy utilisation is de nitely going to have impacts on fertility.

“Plus, if you have got salmonella that can cause abortions and embryonic death.”

When treating scour, Mr McKinstry advises supportive therapy, ge ing uids into ca le to help with dehydration and se ling the rumen, as well as a course of non-steroidal anti-in ammatories.

In the case of salmonella, he advises farmers diagnose what type of salmonella is infecting

the herd, then speak with their farm vet to decide next steps.

In most cases antibiotic treatment may be required alongside vaccination but is important to nd out what strain is at play.

With nutrition one of the main causes of scour, Mr McKinstry advises ensuring milking rations are balanced as a way of preventing scours.

“Make sure you have got a well-balanced diet that has not got too much concentrate in it. Remember short cut, multi cut systems feed like a concentrate not a forage.”

Mr McKinstry also advises ensuring there are no other concurrent diseases among the herd, including IBR and BVD as these can also cause issues with scouring in the herd.

He advises farmers to also be mindful of overcrowding in sheds, to prevent infection spread.

He says: “Every building has got a number of litres and once you pile too many cows in, you are not going to get more litres just more problems.”

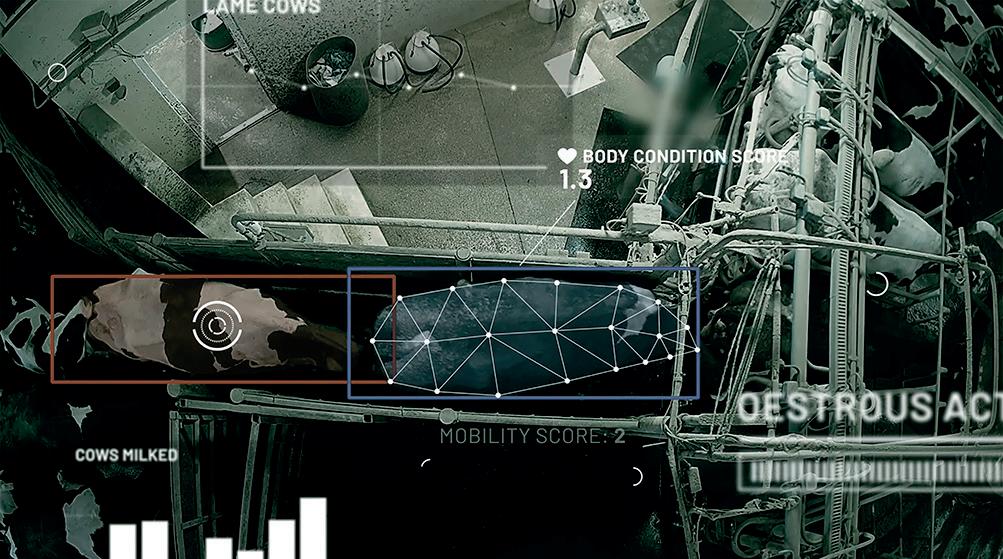

In addition to monitoring the subtle behavioural and activity patterns associated with the various stages of the fertility cycle and health parameters of dairy cows, heifers and calves, the electronic neck collars and eartags used by SenseHub Dairy can also act as ID tags for compatible milking parlours and automatic shedding gates.

When paired with a SenseHub sorting gate, the data collected by SenseHub Dairy automatically segregates cows for artificial insemination (AI), or those which are showing suspected signs of ill health and are in need of additional attention or veterinary intervention.

Automating the drafting process reduces the requirement for skilled labour and eliminates the need to visually identify each cow as she passes through the parlour. It also removes the need for staff to leave the milking parlour to physically segregate animals – a process which can be time-consuming, dangerous and stressful for staff and animals.

Automatic drafting also eliminates the scope for human error, thereby ensuring every animal is presented for insemination or treatment at the optimum time.

The SenseHub smartphone app can also be used to remotely hand-pick or pre-select any additional animals

which need to be segregated from the herd for inspection, treatment or routine management purposes.

SenseHub Dairy also sends text alerts to highlight potential health issues, often before any clinical symptoms have been seen.

This early intervention, coupled with the ability to segregate affected animals quickly and safely, enables herd managers and farm vets to instigate remedial measures before the underlying problem has a significant impact on the animal’s health, performance or future fertility.

Connecting to a SenseHub sorting gate enhances day-to-day operations by:

● Accurately segregating animals based on heat events or health alerts

● Presenting animals for artificial insemination or treatment at the optimum time

● Reducing labour inputs and improving work rate efficiency

● Removing stress on cows and staff

● Minimising disruption to cow flow

Pasteurisation is increasingly being used on farms to help calves get off to a good start. Wendy Short looks at the recommendations around pasteurising calf colostrum and milk.

Calf colostrum and milk pasteurisation plays an important role in ge ing calves o to a good start, says livestock research consultant Jamie Robertson.

e process greatly reduces bacterial load, boosting immunity and minimising disease risk.

General calf husbandry has made signi cant progress over the past decade, but there is still room for improvement, says Mr Robertson, of Livestock Management Systems.

He says that investment in calf colostrum pasteurisation will pay dividends, in terms of future herd performance.

“Pasteurisation can remove from colostrum many of the pathogens that restrict the

absorption of the immunoglobulins which give the calf immunity,” says Mr Robertson.

“Many colostrum handling systems have been modernised, but there are still opportunities for raising standards when feeding youngstock.

“One recent study, which tested more than 4,500 calves, found that about 30% showed signs of ine ective colostrum transfer.

“ is is a worrying statistic. It indicates that while colostrum is being given to calves at the correct time, volume and temperature, the problem could lie in the handling process, with bacteria allowed to multiply within the system.

“ is will hugely reduce the passive transfer of immunity from cow to calf which is vital for the

calf’s future health. Pasteurisation can help to remedy the issue.”

Colostrum pasteurisation can, however, reduce the level of valuable immunoglobulins that protect the calf against disease by about 10%, although the gure can be higher if the heat se ings exceed the recommended temperature, he says.

“ e overall e ect of pasteurisation is positive, but this minor e ect on immunoglobulin levels underlines the advice that it is only worth pasteurising good quality colostrum.

“ e target benchmark is 60g-plus per litre of immunoglobulin G, measured on a colostrum refractometer.”

Pasteurisation has some

limits, when it comes to disease prevention, he adds.

“Pasteurisation will tackle many harmful pathogens, including many of those responsible for causing diarrhoea and respiratory infections,” he says.

“However, it will not control Johne’s disease. Another exception is staphylococcus aureus, one of the mastitis pathogens.

“High-temperature, shorttime machines may control mycobacterium paratuberculosis, plus the salmonella enterica and mycoplasma species, but these units come with complications and are outside the scope of general recommendations.

“Nevertheless, the overall bene ts of standard pasteurisation outweigh its limitations and it is worth investing in a machine.”

Pasteurisation machines,

which can operate on an automatic timer, are available in various sizes from 30 litres upward, and there are milk dispenser carts on the market which also have pasteurisation capability. It will take about 75 minutes to pasteurise fresh colostrum or milk, with a gure of two-and-ahalf hours for frozen liquid.

Electricity usage must be factored in, and Mr Robertson suggests an estimated running cost of 2p per litre.

e machines can be operated in conjunction with single-use plastic storage bags, with some designs having a reusable feeding a achment.

e stored liquid can be frozen and transferred directly into the machine, using the defrost and heat se ing.

“ e machines must be thoroughly cleaned on a regular basis. is involves labour hours, but in most cases it will take less time, compared with manual systems for calf colostrum handling,” says Mr Robertson.

Once the investment has been made in pasteurisation, the equipment can also be used to treat whole milk, he adds.

He is an advocate of feeding pasteurised waste milk to beef cross and male calves.

He says: “In my opinion, whole milk should always be pasteurised for calves. e industry has focused on colostrum produced immediately a er

JAMIE ROBERTSON

the calf’s birth, but the passive immunity does not have a clearly de ned cut-o point.

“Milk will retain some immunity value for up to four days a er parturition, so it could be argued that there are bene ts in delaying the feeding of powdered milk for the rst few days of life. It will depend on having a system which is set up to follow the practice.

“Waste milk feeding is a controversial subject, but margins are tight and while pasteurisation o ers no protection against antibiotic residues, it provides an economically sound solution for treating a product that would otherwise be discarded.

“It is not recommended that waste milk is fed to very young calves, as their intestines are particularly vulnerable to toxins.”

Colostrum pasteurisation is an important piece of the jigsaw in rearing heifers for maximum performance from day one.

“Bacteria thrive in milk and their numbers can double every hour if a bucket is le overnight for feeding the following morning.

“A high standard of cleanliness is essential when handling feeding equipment; there is no point in thoroughly washing calf buckets and then leaving them to dry on the oor, for example.

“A dedicated ‘calf kitchen’ will make it easier to set up a routine for everyone to follow and a pasteurisation machine makes a very useful addition to the system,” says Mr Robertson.

Safely navigate to a successful maize crop, whatever the challenge. Choose Skipper for top starch yields from a very early harvest.

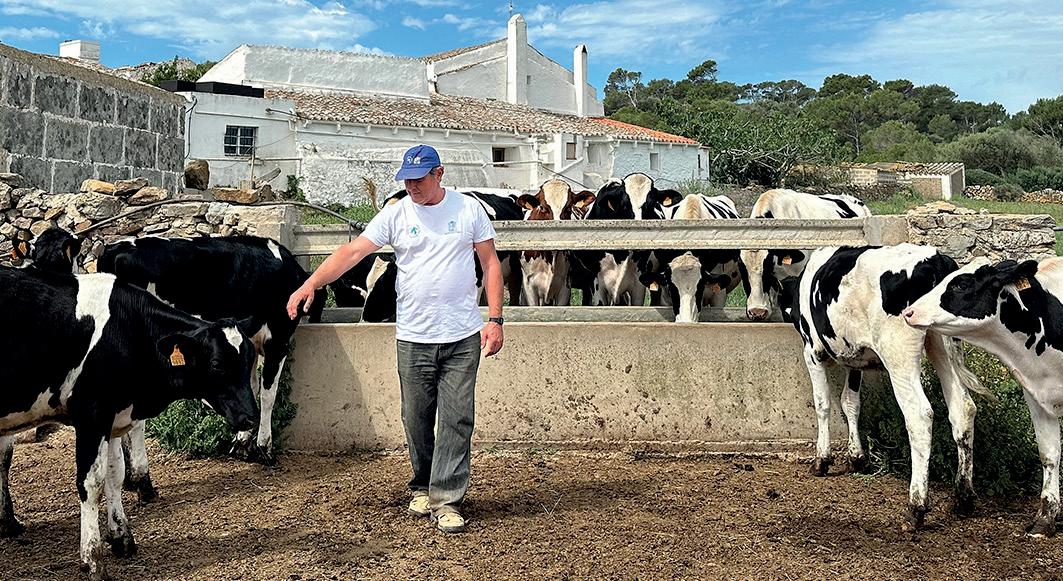

The dairy industry in Menorca is characterised by extensive systems, with a focus on getting the right genetics to facilitate good grazing attributes. Chris McCullough reports.

With a population of just 100,000, plus an in ux of seasonal tourists, Menorca is blessed with endless sandy beaches, an enviable climate and a thriving dairy sector.

In fact, Menorca is home to the highest number of dairy farms on any of the Balearic Islands, and has just over 8,000 dairy cows, producing milk to make the island’s famous cheeses.

Dairy farming on Menorca a racts a slower pace of life, but its farmers do face some nancial challenges when it comes to importing and exporting.

For the past 19 years, Joan Coll Alles has been running Binialcala Farm, situated in the municipality of Es Mercadal.

Dating back 150 years, his farm extends to 86 hectares (212 acres), plus another 60ha (148 acres) rented from a neighbouring farmer. ere is an additional 40ha (99 acres) rented to rear youngstock.

e farm operates through a ‘d’amitges,’ a legal system administered by the Menorcan Rural Society, where both parties sign a contract to operate the farm in close collaboration.

e contract outlines the duration the agreement will run for, which has to be a minimum

of one year. It also details the breakdown for pro ts and losses, the amount or endowment contributed by the owner of the property, and also the contributions that each of the parties has to make.

e contract is a safeguard to ensure succession because

when farmers like Joan, with no children interested to farm, retire, there will be another young farmer ready to take the farm over.

Joan says: “At Binialcala Farm we have 60 Friesian cows that are milked twice daily. Menorca has an average of 50 cows per farm, and has always been characterised by extensive livestock farming. However, by law there can be no more than one cow per hectare.

“We milk the cows at 7am and again at 7pm and on average they give between 28 and 30 litres of milk daily.

A vet visits Joan’s farm every three weeks to PD cows and when it comes to breeding

Joan says he is looking for longevity, and robustness.

Cows are arti cally inseminated using Canadian and American genetics.

Joan supplies his milk to the Coinga Cooperative and the current milk price is about 46 euro cents per litre (38ppl).

Cows receive a bu er feed of silage, with ryegrass and barley.

Joan says: “Our concentrate feed is 50% corn, with vitamins, barley, carob, soyabeans, beets and co on that we produce ourselves. A nutritionist guides us on the correct rations for the cows. I buy in feed two times a month.”

Joan likes to invest in technology to make the job easier, as he does most of the work on the farm himself, assisted by a part-time apprentice.

He says: “We are always making improvements, and recently installed a slurry scraping system.

“ e refrigeration tank has also been renovated to incorporate a new washing system, and I also managed to upgrade the tractor and cultivator.”

Joan says the main problems associated with dairying on Menorca is the higher costs of raw materials, including higher import transport costs.

He admits that he has li le

rCows are milked in a 6/12 milking parlour with electronic meters and automatic cluster removers

rAverage lactation is 305 days

rAverage yield is 10,800 litres at 3.8% butterfat and 3.2% protein

time le before retiring age, but is determined to continue working and maintaining the farm for as long as he can.

“It is a way of life on this island but it sure involves a lot of hard work,” he says.

“Saxon’s improved vigour meant it was greener at harvest and it out-performed our other varieties.”

Nigel Harper, Cheshire

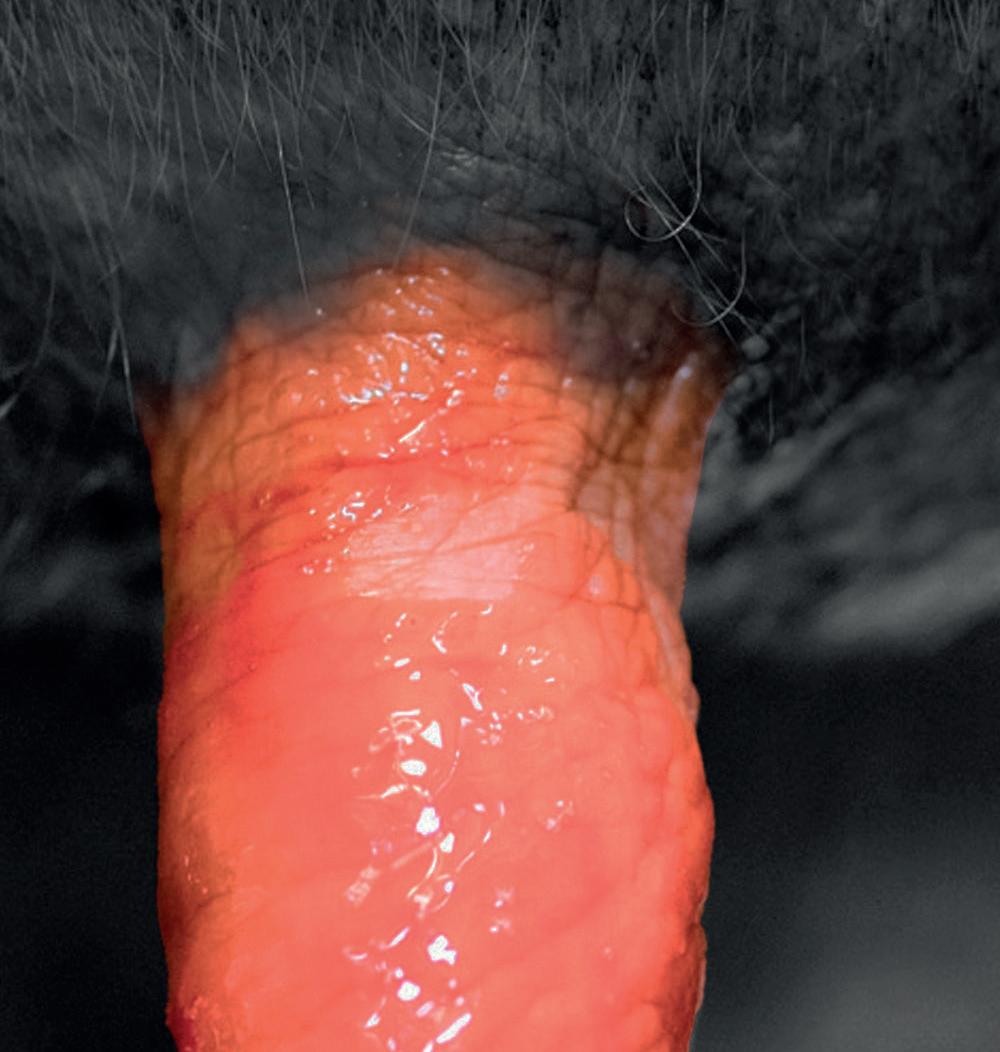

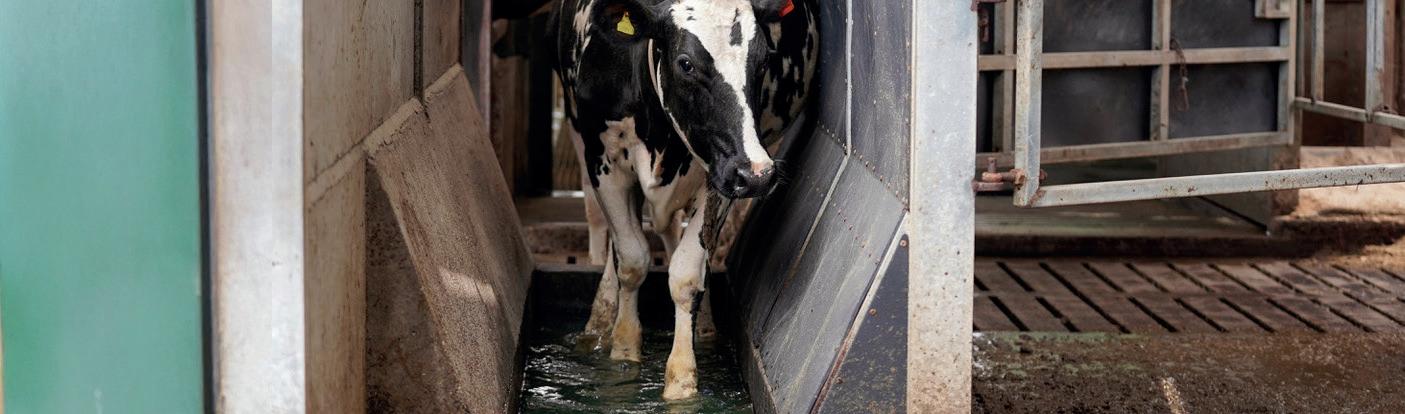

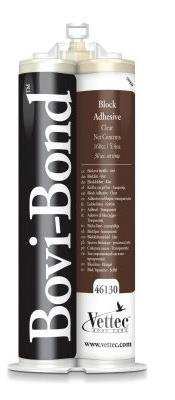

One of the main causes of mobility challenges in dairy cows, white line disease can impact milk yields and lead to an increased risk of culling.

And with evidence to suggest cows su ering from white line disease will exit the herd a year earlier than if they had not, management and prevention is key to cow health and herd productivity.

Foot health consultant at Herd Health Consultancy, Dr James Wilson, says the disease a ects both housed herds and grazing herds, however, it is typically more common in grazing herds.

He says this is largely due to cows travelling longer distances to access grazing pastures, resulting in more wear to the hoof, and an increased risk of shearing forces.

However, the disease can also be seen in housed herds with poor quality concrete ooring, particularly in high-tra c areas, resulting in increased shearing forces, and inappropriate horn wear leading to a greater risk of white line disease.

Dr Wilson says: “ in soles are a big risk factor and one which gets underplayed a lot.”

He also advises poor cow ow as another risk factor, with dead ends in yards and heifers mixed with larger bully cows o en resulting in ‘scrabbling’ on concrete.

He advises looking at cow handling and ow and nding the pinch points in housed environments.

With early treatment and diagnosis key to managing white line disease on-farm, Dr Wilson advises using sensitive mobility scoring to detect the early stages, such as bruising.

He says: “My main detection method is to look at how a cow is walking. She should be sinking her dewclaws to the oor symmetrically on the back feet, as that is where we see most white line disease. If she is not, I would check her in the trimming chute.”

Dr Wilson says that farms should be mobility scoring

A focus on cow flow and suitable concrete flooring in high-traffic areas can help reduce the risk of white line disease. Katie Fallon reports.

cows on at least a monthly basis if not fortnightly.

He says: “Many farms are scoring for quality assurance and not making used of this information for action lists of cows to be checked.”

However, he says the farms which will gain the most bene t from mobility scoring are ones which are scoring on a fortnightly basis, which has evidence to show improved cure rates and reduced recurrences. is is best implemented in

tandem with individual inspections of the animal in the trimming chute.

When completing a mobility score, Dr Wilson says he is looking for shoulder muscle tension and head nodding as signs of lameness in the front feet.

He says: “If you drew straight lines across the cow, could you spot a di erence in symmetry? Could you pick a leg that you would want to check and if the answer is yes, you should check her.”

“Let’s move away from focusing

only on ‘lame cows’, although they still need treatment, and focus on cows that would bene t from inspection.”

When treating white line disease, Dr Wilson says lesions might not always be obvious upon inspection, therefore he advises using hoof testers to identify lesions before removing more horn. It is common for some white line separation to take

Receive a pair of overalls with all orders over 200 L

Synofilm GL is a Post-Milking Teat Dip Based on Lactic Acid and Glycolic By Neogen

place without any challenge to mobility, which is perfectly normal.

“If we ag a cow on a mobility score and start digging away, or using search cuts, we can cause more damage than good.

“I use a combination of hoof testers and sensitive scoring to get to the bo om of problems.

“We inspect a foot to trim it rather than trim it to inspect it.”

Dr Wilson advises applying pressure with hoof testers on an area of the hoof where there is a suspected problem.

He says: “I look for three consecutive withdrawal responses, which tells me there is a problem that I can investigate and treat.

“I then tend to test the other claw in the same way and if I do not get a response I will put a block on it.”

Once lesions have been identied, Dr Wilson says a treatment protocol of sensitive trimming, applying an orthopaedic block and a course of non-steroidal anti-in ammatory drugs for three days, has a strong evidence base.

He says: “Studies have shown applying orthopaedic blocks can promote a return to good mobility by more than 30%, when used in combination with an anti-in ammatory drug.

“I would always advocate three days of non-steroidal anti-in ammatory drugs as part of a lameness treatment, as we can pre y much halve the risk of them being culled

over three years, when we are working with heifers.”

Dr Wilson says some white line lesions are incredibly di cult to treat, especially when complicated with digital dermatitis infections and can require surgical treatment with veterinary assistance.

“We can get cows walking really well through this approach, but it is not for everyone as it is a higher value intervention, but for higher value cows and in-calf cows I think it is a no-brainer.”

Dr Wilson says re-checking feet following the treatment of white line disease is an important part of treatment protocols and one which is o en forgo en.

He advises checking cows feet four to six weeks a er treatment and a two week re-check

for cows which have had surgical intervention.

Dr Wilson says he also tends to avoid bandaging lesions with the exception of surgical treatments or cows which are going onto straw yards.

He says: “ e risk is what goes underneath the bandage and how long that bandage is going to stay on. For me one bandage staying on too long is one too many.”

If bandages are applied, Dr Wilson advises changing them every 48 hours or using dissolvable bandages.

With poor concrete ooring one of the biggest risk factors for cows developing white line disease, Dr Wilson advises using a diamond cut concrete ooring to prevent slips and wear to cows’ feet, with mini grooving recommended in high turning and high-tra c areas.

He also advises farmers to think about cow ow and cow handling, with the use of dogs to move cows and backing gates also big risk factors.

He says: “Every time you hear scrabbling on concrete you are creating white line disease.”

Managing and reducing debris on trackways is another way to prevent cows from developing white line disease, as well as ensuring the camber of tracks is correct so there are no puddles or si ing water.

“Contemplate having multiple

rFocus on walking surfaces and cow flow – avoid slippages where possible

rTreatment follows trim, block and anti-inflammatory

rAlways better outcomes from earlier stage disease

rTrim sympathetically to the hoof – always preserve sole thickness

entrances and exits to elds to avoid poaching and debris being brought onto the track.”

Dr Wilson advises installing cow tracks with either arti cial grass or oolitic limestone top dressing to create a non-slip and even surface. He says the width of tracks is also important and is another opportunity to improve cow ow by giving the cows more space to move.

He adds: “Including biotin in rations can also help prevent white line disease and studies have shown the inclusion of 20mg of biotin per head per day in the dry period and during lactation can substantially reduce the risk of white line disease.”

Dr Wilson also advises that functional trimming of cow’s feet has a role to play in reducing the risk of the disease, with preserving sole thickness and the wall horn crucial.

®

Farming is not just a job – it’s a way of life and is often an incredibly rewarding profession, but it can also prove incredibly challenging at times.

95% of farmers aged 40 and under believe that poor mental health is the biggest hidden problem faced by farmers today

1 in 4 people in the UK experience poor mental health at some stage in their lives

98 % of farmers believe that promoting good mental health is crucial in the battle to keep farmers safe and save lives

Remember, you’re not alone – find help here

If you, or someone you care about, needs help, then don’t hesitate to contact the organisations below for practical advice, guidance and support:

The Farming Community Network

A network of volunteers from the farming community and rural churches providing pastoral and practical support to help people find a positive way through their problems. fcn.org.uk / 03000 111 999

The DPJ Foundation

Spreading awareness in the agricultural sector by offering training on poor mental health and its impact. thedpjfoundation.co.uk / 0800 587 4262

Mind

Provides advice and support to empower anyone experiencing a mental health problem. They campaign to improve services, raise awareness and promote understanding. mind.org.uk / 0300 123 3393

Yellow Wellies

Helps to raise awareness of farm safety among young farmers with their Mind Your Head campaign and provides links to helpful resources. yellowwellies.org / Farm_Safety_Foundation@nfumutual.co.uk

RABI: The Royal Agricultural Benevolent Institution

Provides financial support for farmers in times of crisis such as illness, bereavement or events beyond their control. rabi.org.uk / 0808 281 9490

YANA: You Are Not Alone

Provides unique support and advice for the wide farming community from sympathetic GPs and counsellors. yanahelp.org / 0300 323 0400

The results of the first 750 maize silages analysed by Trouw Nutrition GB this year clearly demonstrate the effect of the growing season on feed quality. Dairy Farmer reports.

While many good maize feeds have been made, there is greater variability than usual, indicating that careful balancing will be required.

Nacia Bonnick, ruminant technical adviser at Trouw Nutrition, says later drilling of some crops, combined with the cooler summer, increased the risk of a higher proportion of immature crops being harvested, or of delayed harvest.

She says: “ e growing season has clearly impacted on many crops and while the average analysis is similar to recent years, we are seeing a greater proportion of poorer analysis, indicating some feeding challenges.”

e average dry ma er (DM) of feeds sampled is down 3% compared to 2023 at 30.7%, with a picture of fewer, drier silages.

Ms Bonnick says typically maize silages average 33-34% and this year’s reduced level indicates

younger, less mature crops have been harvested. e lower DM will clearly have an impact on inclusion rates in diets and management of forage stocks over winter.

Average metabolisable energy and crude protein contents are virtually unchanged. However, while average starch levels are marginally improved at 28.4%, Ms Bonnick says that the range of data shows we are not seeing as many high starch crops compared to last year, which is another indication of immature crops.

She says: “Starch degradability is slightly higher, which combined with higher fermentable carbohydrates, results in a higher acid load than in 2023. Since starch degradability increases with time in the clamp, crops will need regular monitoring to allow steps to be taken to mitigate any acidosis risk.”

e trend in increasing neutral detergent bre (NDF) contents seen over the last three years has

Maize silage analysis 2022-2024

continued, with NDF in the DM increasing by 2.1%.

However, lignin levels have reduced, re ected in slightly higher energy content shown by an increase in dynamic net energy, the energy actually available to the cow for milk production.

By accounting for the higher propionate yield from the increased fermentable carbohydrates in this year’s maize, producers will have the ability to utilise more of the energy coming from maize silage.

Mr Bonnick says: “When including maize in diets this winter, the key will be to avoid overloading the rumen with starch to minimise the acidosis risk.

“ e increased energy availability may allow cost savings, especially as starch degradability increases.

“Regularly reviewing rations will allow this opportunity to be realised.

“Most importantly, make sure to get clamps analysed at least monthly so you know the actual quality of maize being fed and watch for signs of mould on the clamp, as many crops will be at increased risk of mycotoxins this winter.

Source: Trouw Nutrition GB

“Feeding a mycotoxin binder, such as Selko Toxo, as standard practice in diets containing maize silage will help minimise the risk.”

What zero treatment and zero calf losses looks like on-farm

on a day-to-day basis was discussed by Dr Jodi Wallace, of Ormstown Veterinary Hospital, Quebec, Canada, at the Total Dairy Conference held in Stratford-upon-Avon.

Dr Wallace, a guest of Boehringer Ingelheim Animal Health, spoke jointly with vet adviser Dr Becca Cavill.

Dr Cavill is working with vets and farmers up and down the country on the Optimax project, a targeted plan to examine and improve all aspects of neonatal calf health management on individual farms.

This project delivers performance benefits, and has been designed

JDr Jodi Wallace explained why colostrum was at the heart of successful calf production and helps any system work towards a zero zero approach. She said: “Calves are born without a functioning immune system, so feeding colostrum allows antibodies to be transferred into their blood system.

Is zero treatment and zero calf losses achievable and realistic, and if so how do farmers go about setting it as a target? Dairy Farmer reports.

to make all the processes involved easier and more efficient for those undertaking them.

As a dairy producer and vet, Dr Wallace is ideally placed to spot

“These antibodies serve to defend against disease until the calf’s own immune system develops, and the process is called achieving passive transfer [PT].

“Research has shown that calves which receive adequate colostrum have PT of antibodies and have higher average daily gains, improved health pre- and post-weaning, as well as higher

and understand the challenges being faced on a daily basis for anyone working with calves.

She said ‘zero zero’ calf care (no treatment and no losses) was achievable, but ‘will not happen overnight’.

She added: “It takes a team of

milk production in their first lactation than calves which did not receive enough colostrum.”

Dr Wallace said that every farm should be equipped to measure colostrum quality, most commonly with a Brix refractometer. And once tested, only excellent quality colostrum,

ARE CALVES GETTING ENOUGH CLEAN MILK TO DRINK?

rCalves should double their birth weight by 60 days. They should be fed up to 20% of their body weight in milk. Consider feeding three times per day or offering freechoice milk. The cleanliness of feeding utensils (buckets, bottles and nipples) is also key for healthy calves.

DO THEY HAVE ACCESS TO FREE-CHOICE WATER AND STARTER?

rResearch has shown that calves which have free-choice

water versus no water have a 45% increase in starter intake and a 60% in weight gain in the first four weeks of life. Starter intake is important because it increases rumen development.

ARE YOU CALVES PROTECTED AGAINST DIARRHOEA AND PNEUMONIA WITH SPECIFIC VACCINATION PROTOCOLS?

rVaccines help protect against infection and disease and establish immunity in the young calf.

ARE YOU FOCUSING ENOUGH ON YOUR TRANSITION COWS?

rDid you know that dry cows get easily stressed? The issue with stress is the release of adrenaline, cortisol and other hormones.

These hormones are needed for the fight or flight response, but can also cause oxidative damage to the cells. This means they slow down and impair immune system function. If the immune function of the dry cow is impaired too long, there are many detrimental consequences. These include reduced dry mater intake, increased rate of stillbirths, and other metabolic

dedicated caregivers and professionals who care and consistently do the basics right. The starting point is to understand the ‘why’ of each of the daily calf tasks and then set out a protocol around these to get closer to zero zero.”

greater than 24% Brix, should be fed.

She also said that many farms consistently average 28-30% Brix measurements for colostrum quality and that if it is routinely difficult to attain values over 24%, re-evaluating transition cow ration and management is a good starting point.

diseases, such as retained placentas, milk fever and ketosis.

Not to mention a reduction in total lactation milk production and increased risk of lameness, mastitis and days open. Stress is not a good thing.

IS THERE ALWAYS FRESH, CLEAN, DRAFT-FREE AIR FOR YOUR CALVES TO BREATHE?

rPneumonia has serious economic impacts now and for the future of that calf. It can negatively impact growth, reproductive performance, milk production and longevity.

Dr Jodi Wallace said calf treatment and mortality had been regarded as being ‘normal’ because it was what farmers were accustomed to seeing.

Dr Wallace challenged delegates to think about what was ‘normal’. She said: “Calf treatment and mortality is not normal on-farm.

“It is only ‘normal’ because it was what we are accustomed to seeing.

“When abnormal becomes normal, that is a problem. The industry standard is to have less than 5% mortality and 25% treatment rates in preweaned calves. This is abnormal. Strive to better than current standards.”

She reminded conference a endees that the calf was born in good health and that was only as a result of challenge in the environment

that they succumb to either of the most commonly seen diseases – scour and pneumonia.

She said: “At the end of the day, diarrhoea and pneumonia are not the calf’s fault. ey will most likely occur as a result of some failure on our side.

“Yes, medication can help, but not in place of digging deeper to understand the problem and preventing it in the rst place.”

e Optimax approach, as described by Dr Cavill, is an

on-farm exercise with a trained vet and the whole farm team.

e vet will lead a walk around the farm looking at important areas, such as calving pens, colostrum management, calf housing and feeding equipment, to end up with a sound understanding of what is working well, what is working less well and possible solutions.

A proactive plan with a timeline to help move from A to B is then put in place, with regular reviews built in to check progress. Dr Wallace said it was not good enough to say ‘I have always done it that way’.

She said: “Raising calves can be the most rewarding and most frustrating aspect of the dairy farm.

“ ere is a considerable amount of e ort and cost invested in the rst day of life and in the next two years to get her to the milking herd.

“Nobody likes to have sick calves on-farm. It is time-consuming, costly, emotionally draining and stressful. e closer we can get to zero zero, the more enjoyable and more pro table calf raising can be.”

This year’s World Dairy Summit was held in Paris where the main theme was sustainability. Katie Jones takes a look at some of the information that was shared relating to production.

While the production of cows’ milk in France has declined by about 8% since 2015, it is the opposite for the milking goat and sheep sectors, which have increased by 12% and 11% respectively.

France is still the second player in the EU for cow milk (16% of European volume) and is now the fourth largest producer in the EU for sheep milk (14% of global volume), and is the biggest producer of goat milk (30% of global volume).

However, there are some regional variations, said Benoit Rouyer, an economist at CNIEL, which is the French organisation responsible for sharing tools, standards and promoting milk and dairy products.

Speaking at a press brie ng, Mr Rouyer said: “Cow milk is produced in almost every French region, with a high concentration in

the west. Sheep milk production is highly concentrated in Occitanie, which accounts for three-quarters of the national production and includes the famous area where Roquefort is produced.

“And goat milk is mostly produced in the western and central parts of the country.”

Mr Rouyer said milk production in France is still largely based on traditional family-run farms.

He said: “Among the 46,000 dairy farms producing cows’ milk in France, there are none that have more than 1,000 cows.

“A typical French dairy farm has 110 hectares and 70 cows producing about 500,000 litres of milk per year, with two people working on it.”

Protected Designation of Origin (PDO) dairy products are an important feature in the French dairy sector and are present in almost

JWorld milk production for all species has been growing continuously for more than 30 years despite the global challenges, said Jean-Marc Chaumet, of CNIEL.

Quoting figures from the International Dairy Federation’s World Dairy Situation report 2024, Mr Chaumet said recent figures show that in 2022 there was a slow growth of milk production of all species because of extremely high production costs and limited consumption.

He said: “In 2023, we saw a rebound by 2.1%, which is in line within the medium-term growth rate. And it reached a volume of 964 million tonnes, setting a new record.”

And he said that cows’ milk accounts for more than 80% of the total global milk production.

The second species is buffalo, which is growing at twice the rate of cow milk production.

He added the increase in global production was being

PDO products account for 12% of cow milk production in France.

every region of the country (for more on this see p32-34).

France has 51 PDO dairy products, including 46 cheeses mostly made from raw milk, three bu ers and two creams.

Milk manufactured for PDO dairy products accounts for 12% of cow milk production, 14% of goat

‘propped up’ by production in Asia and Africa.

He said: “It appears clearly that there is an increasing gap between the growth of the traditional milk producing and exporting regions and the emerging dairy countries/ regions, which strive to achieve self-sufficiency and also reduce reliance on imports.”

He added that US and EU production had been levelling off for the past two years, due mainly to skyrocketing costs and adverse weather.

milk production and 36% of sheep milk production.

Mr Rouyer said: “PDO products play a growing role in the dairy industry.

“ is is notably the case for cow milk and, even though milk production has been decreasing over the past few years, the volume of milk intake dedicated to PDO products has grown to almost three billion litres per year.”

rPer capita, consumption of liquid milk is 52 litres per year, which is far below countries such as USA, India and Australia, but consumption of butter (8.2kg) and cheeses (27.4kg) are extremely high on a global scale

rAlmost 40% of milk produced in France is exported and imports represent one-third of the domestic consumption

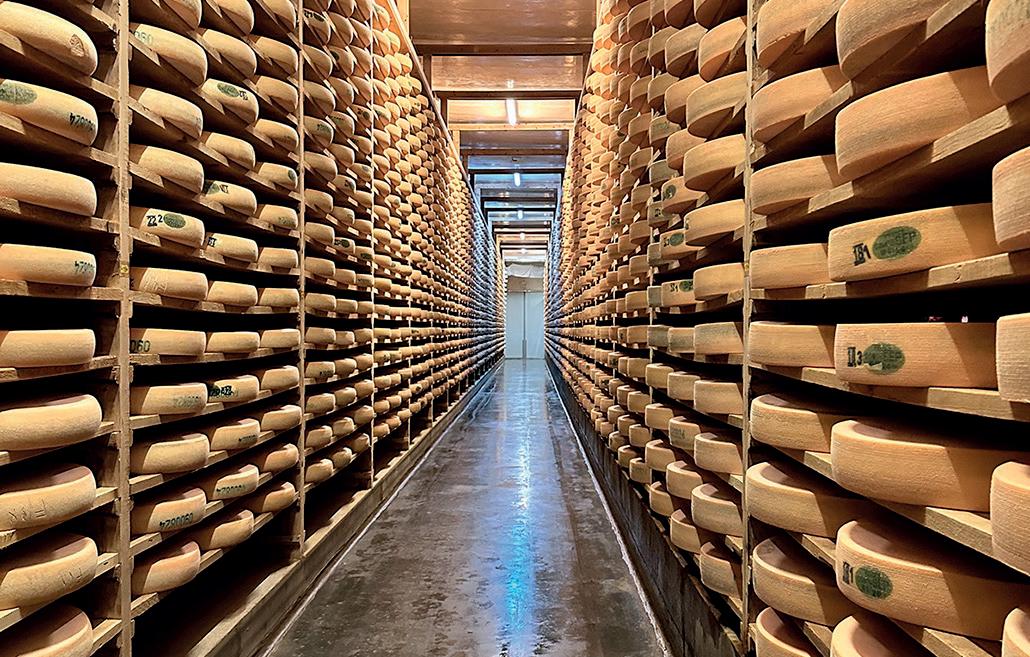

France has more Protected Designation of Origin cheeses than any other European country, but what does this mean for the farmers supplying the milk? Katie Jones finds out more.

The Jura Massif region in Eastern France is home to the Comte cheese, which is one of 46 cheeses produced in the country, which have a Protected Designation of Origin (PDO).

Some 70,000 tonnes of Comte cheese is produced by about 2,500 farmers in the region, with the cheese sold across the world.

e farmers come together in a unique way to help produce this cheese to an exacting set of rules and regulations, while also seeing a nancial incentive to producing this milk.

e origins of Comte cheese can be traced back to more than 1,000 years ago, when farmers in the region began to follow a process adopted by producers in nearby Switzerland who were pooling their excess milk in order to produce cheese for consumption during the long winter months.

Back then, groups of 20 to 50 farmers, each with a handful of milking cows, would pool any milk not immediately consumed to make large wheels of cheese that would mature over several months.

e cheese was made at the village ‘fruitiere’, which loosely trans-

rCows stay in the herd for an average of six lactations

rMilk is collected every day and transported to the local fruitiere where it is made into Comte cheese

rThe farm is not organic, but uses a number of homeopathic techniques

lated means a cheesemaking facility.

e term gets its meaning from milk producers coming together in a desire to be ‘fruitful’ and produce large quantities of cheese.

ese fruitieres are co-operative in their structure, with the group of milk producers involved employing a cheesemaker and working together to make decisions about the way the business is run.

As farms became bigger over the years, these fruitieres began to amalgamate and now there are about 140 in the Jura region.

e farmers supplying milk to make this cheese are involved in every aspect of the process and will o en visit the fruitieres and cheese maturing plants.

One such farmer is Marie Roy, who farms in a ‘gaec’ or partnership with Mickael Pelletier, at Sauget Farm, in Vevy in the north of the Jura region. Brought up on her

family’s farm in Chevigny in the North Jura, Marie went on to spend 10 years in Ireland running a large farm and two years in New Zealand where she was a farm manager until 2009.

On returning to France, she took on a farm in Vevy, but a er a re in 2018, she decided to go into partnership with Mickael and the new farm steading at Sauget was built.

e farm is now home to 100 Montbeliarde cows, which supports the two of them in the farming partnership and also allows them to employ one full-time and one parttime member of sta .

Marie says: “It is possible to make a full income for one person on 30 cows.”

And this is thanks to the milk price farmers in the region receive for the milk which goes into Comte cheese.

Marie says: “ is is a high value product, so it means that we are paid €729/tonne of milk, which is about €200/t above the average price paid to French farmers.”

However, there is a strict set of rules that farmers supplying milk for Comte cheese must adhere to.

Firstly, Comte cheese can only be made with milk produced by Montbeliarde and French Simmental cows. Cross-breeding is not allowed.

Marie’s cows produce an average of 6,500 litres a year at 3.3% protein and 3.8% fat.

e other rules are around feeding and management.

Farmers adhere to a stocking rate of at least one hectare per cow – 1.3ha/cow (3.2 acres/cow) in Marie’s case – and milking animals can be housed for a maximum of 75 days a year.

Marie, who spent time working with grazing herds while in New

Cows graze from late January to early December and are fed only hay while housed.

Zealand and Ireland, is fully commi ed to this system, with cows rotationally grazing around 42 paddocks. Cows are moved every 24 hours.

She adds: “Our farm is 240ha, of which 80ha is grass and 80% of this is within a mile of the farm buildings.

“We grow grass containing seven di erent species including ryegrass, white clover, bluegrass, cocksfoot, Timothy, trefoil and bird’s-foot trefoil.”

As well as adhering to the principles of Comte cheese production, Marie says this is also good for the sustainability of the business.

“We want to reduce our carbon

footprint and be as economically e cient as possible. Grazing grass is a great way of helping us to achieve this. Grass is the most e cient feed stu that we have,” she says.

Cows will usually graze from late January until early December and, while housed, only hay can be fed.

e feeding of silage is prohibited as it is thought to adversely a ect the quality of the milk.

e region is famed for its continental weather, with mild and dry summers. Marie says that Sauget is located on the rst plateau of the Jura mountains, which is about 550 metres above sea level.

“In the summer we can see highs

of 30-35degC for six to eight weeks of the year, but the dry spells seem to be ge ing longer each year.

“ e soils are very light and our soils are only about 7cm in depth. A er that, it is just rock.”

e feeding of concentrates is limited to 1.8 tonnes per cow per year and any feed bought in must be locally-sourced and genetically modi ed organism (GMO) free.

Hay can be bought in, but again has to be locally-sourced.

Another stipulation of Comte cheese is that robotic milking is not allowed.

Marie says: “We believe that we should farm using our senses; we want to see and touch the cows and we do not think you can have this connection to the cows when milking via a robot.”

e focus on reducing the farm’s carbon footprint does not stop at grazing and Marie says she is working hard to reduce age at rst

How can Kersia help to protect teat skin condition?

calving, so that the farm has to carry fewer replacement heifers.