November 2024

November 2024

Flexible, reliable and easy to maintain:

Flexible, reliable and easy to maintain:

As a pioneer in agricultural technology, Vogelsang leads the way in environmental friendly spreading equipment. The dribble bar systems combined with the ExaCut distributor give the highest application of liquid manure nutrients.

Highlights from the Bath and West Showground

Pages 64-67

FODDER & FORAGE DAIRY SHOW REPORT

Special focus, including maize and alternative crops

Pages 54-63

As a pioneer in agricultural technology, Vogelsang leads the way in environmental friendly spreading equipment. The dribble bar systems combined with the ExaCut distributor give the highest application of liquid manure nutrients.

Dribble bars are available in working widths of 7.5m right up to 36m and are retrofit-friendly.

For more information visit www.vogelsang.info/en-uk/dribble-bar-systems

Dribble bars are available in working widths of 7.5m right up to 36m and are retrofit-friendly.

For more information visit www.vogelsang.info/en-uk/dribble-bar-systems

VOGELSANG – LEADING IN TECHNOLOGY

Contact us at: 01270 216 600 | sales.uk@vogelsang.info vogelsang.co.uk

VOGELSANG – LEADING IN TECHNOLOGY

Contact us at: 01270 216 600 | sales.uk@vogelsang.info vogelsang.co.uk

ANIMAL HEALTH

Tackling diseases in calves and parasites at housing

Pages 40-52

MILK PRICES

Pages 72-74

At NFU Mutual, we understand the unique opportunities and challenges that come with diversifying. Whether you’re exploring new ventures or enhancing your current operations, our local experts are here to provide tailored advice and comprehensive insurance solutions, so you can focus on what matters most.

Scan the QR code or search ‘NFU Mutual Farming Diversification’ to discover the latest trends, expert insights, and inspiring real-life success stories.

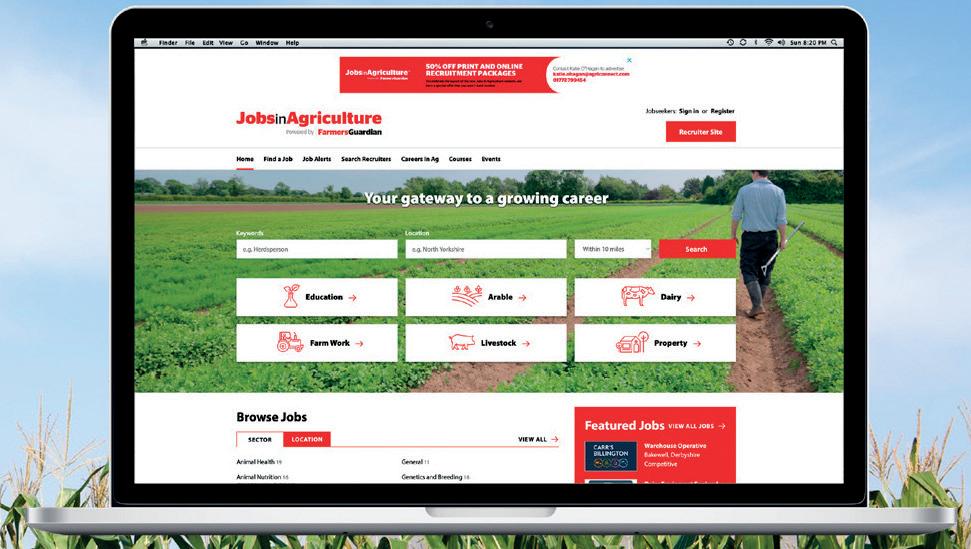

Editor Katie Jones 07786 856 439 katie.jones@agriconnect.com

Creative Services

Mike Begley

mike.begley@agriconnect.com

Katie Haydock katie.haydock@agriconnect.com

Picture Editor

Marcello Garbagnoli 07815 003 236 marcello.garbagnoli@agriconnect.com

Sales Gemma Thorpe 01772 799 500 gemma.thorpe@agriconnect.com

Account Manager

Mark Jackson 01322 449 624, mark.jackson@agriconnect.com

Classified Advertisements 01772 799 400 fgclassified@agriconnect.com

Advertising Production

Justine Sumner 01772 799 437 Fax: 01772 796 747 justine.sumner@agriconnect.com

Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com

Subscription rates: UK £65 a year Europe: £85 World: £95

ISSN 1475-6994

© Farmers Guardian 2024 All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems.

Dairy Farmer, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ

Origination by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ. Printed by Warners Midlands, The Maltings, Manor Lane, Bourne, Lincolnshire, PE10 9PH. No responsibility can be accepted by Dairy Farmer for the opinions expressed by contributors.

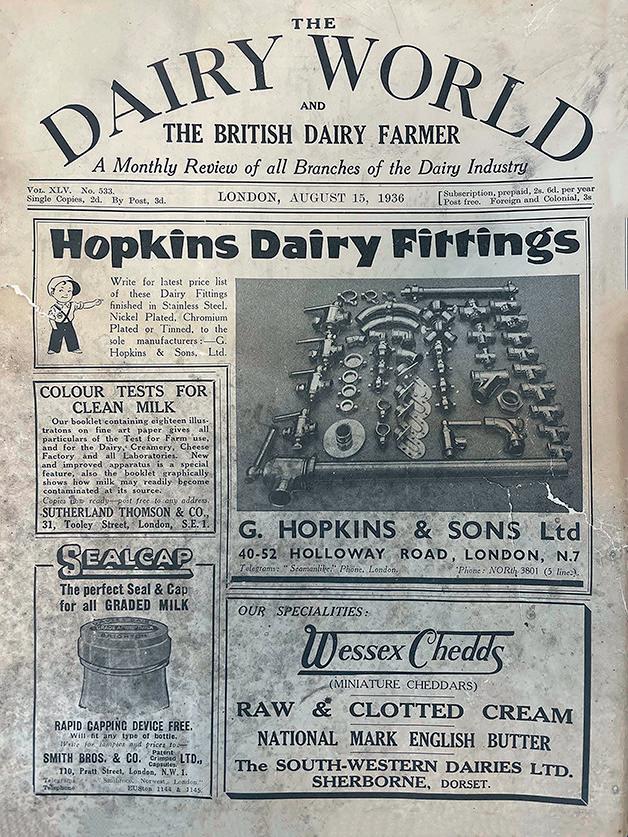

This year marks the 95th anniversary of Dairy Farmer. And to mark this special moment in the history of the magazine, we have taken a look back at dairy farming over the last 95 years and have also asked some of our long-standing farming commentators and contributors to provide their views on how farming has changed for them.

In preparation for this edition, I was able to look back at some of the early copies of the magazine.

ere were some interesting regular features in those early years, including a ‘Vet’s Notebook’, a page dedicated to ‘Books for the Farmer’ and the ‘Diary of a Dairy Farmer’, which provided a very detailed day-by-day account of what that particular dairy farmer had been up to the previous month.

‘Herdsman’s Essays’. Readers were presented with a question, such as ‘how to handle the awkward bull’, and asked to write their response within 250 words. A selection of the best reader essays were published and there was a £5 cheque for the winning entry.

While the look and feel of the magazine will have undoubtedly changed over the last 95 years, the way that the magazine aims to put farmers’ views rst and foremost I hope still rings true.

My favourite feature, however, was the

Some of the issues covered in those early editions are still relevant today, for example, there were articles on the latest equipment, animal health and nutrition, and even farm labour, with one article looking at whether farm sta should be entitled to living accommodation. e make-up of dairy farming in the UK may have changed considerably over the last 95 years, but the ambition to run e cient businesses will always be at the forefront.

Farming Minister Daniel Zeichner sent out a letter to key stakeholders across the dairy sector at the beginning of October, outlining a proposed amendment to the new Fair Dealing Obligations (Milk) Regulations, to address the use of seasonality payment systems and volume bonuses in the dairy sector.

The wording of the letter

prompted concerns from unions over the lack of consultation, with calls for further ‘clarity’ on changes.

The Minister said his officials had informed him of ‘potentially unintended consequences stemming from the tiered pricing’ provisions in the regulations.

While these were designed to ‘protect producers’, they also aimed to preserve flexibility.

Some practices, such as season-

JThe NFU is ‘frustrated at the slow conversion rate’ from initial Sustainable Farming Incentive (SFI) applications being submitted to the agreements offered to farmers.

NFU deputy president David Exwood said while it was ‘encouraging that there were checks and balances to ensure the IT systems were working well’, the sector needed to get to a position where the ‘expression of interest’ process was removed and farmers and growers can expect an agreement offer ‘within weeks’.

Latest SFI figures from Defra as of September 30 showed that just under 13,000 expressions of interest, more than 3,500 applications and

800 agreements had been made.

A recent sentiment survey from Knight Frank’s rural division highlighted less than half of respondents who took part had signed up to SFI, with many farmers harbouring ‘preconceptions’ from past environmental programmes.

Agreement offers

A Defra spokesperson said: “We are rolling out the SFI with expressions of interest accepted, agreement offers being made, and over 1,000 agreements in place under SFI 2024.”

Defra added the rollout was being managed to ensure the service was working ‘as expected’.

A proposed amendment to the new Fair Dealing Obligations (Milk) Regulations, to address the use of seasonality payment systems has been outlined.

ality payments, which are based on historic volumes and volume bonuses, are, when used in exclusive agreements, prohibited by the regulations.

But he said he understood these practices as ‘mutually beneficial’ and there was ‘no desire to see them outlawed’.

NFU dairy board chair Paul Tompkins said he believed the letter was prompted by processor concerns.

He said he understood they needed to have processors which provide incentives and disincentives at different times of the year, but

what processors wanted was ‘exclusive’ rights over milk from a farm.

But he questioned why if processors were discounting spring milk as they did not want it, farmers could not market it elsewhere.

With the regulations carrying a statutory duty, any amends will require parliamentary time, with the Minister offering reassurance it would be undertaken in a ‘timely manner’.

However, Mr Tompkins was sceptical, adding parliamentary time ‘slips very easily’ and would

• High density concrete, steel and composite

• Capacities from 400 to 2500kg

• Sizes and add-ons to suit every need

• Long-life rubber coating on selected concrete units

• Integrated tool box designs

• Ultra-high density, space-saving steel weights

only create confusion for the sector. Ulster Farmers Union deputy president John McLenaghan said the union was ‘extremely concerned’, adding there was ‘absolutely no reason’ to limit farmers’ ability to market excess milk to a third party if their primary purchaser was discounting it.

Dairy UK chief executive Dr Judith Bryans welcomed Defra’s decision, adding these practices were ‘mutually beneficial’.

A Defra spokesperson said it was discussing an amendment with the industry and would provide more information in due course.

JAldi has said it will invest £30 million into dairy farming over the next three-and-a-half years through an enhanced partnership with Arla.

The enhanced partnership will run until the middle of 2027 and provide support to enable greater focus on sustainability and animal welfare through Arla’s FarmAhead Customer Partnership.

Through this programme, Aldi will partner in farming projects and innovation which aim to accelerate more sustainable farming practices and decarbonise dairy.

JWelsh researchers have been awarded funding of almost £1.2 million to develop a detector for TB in humans and animals which can report a result in one hour. The technology, which will be simple enough to be operated by any healthcare worker or vet, will be more specific than existing methods.

There is a clear message that the current UK Farm Assurance system ‘needs to change’, according to the NFU’s response to the UK Farm Assurance Review.

NFU president Tom Bradshaw said while the NFU response covers ‘some of the bene ts’ that farm assurance schemes o er, it also explains the ‘inescapable issues’ which must be addressed, including the perceived lack of value for money, the audit burden and the need for individual sectors to have a di erent approach.

AHDB identi ed four principles in its response to the review, which underpinned a scheme that was ‘ t for the future’, including purpose and value, governance, di erentiation and audit process. It said it recognised ‘signi cant visible and tangible change will be needed to win back hearts and minds’.

It shared analysis of some weaknesses, which included a ‘perceived dominance of retailers in the standard-se ing process’ which has resulted in a sense of ‘powerlessness’ among many users, adding there was a perception that with any voluntary bolt-on standard, it would lead to an ‘unnecessary standard creep over time’.

NFU Scotland director of policy Jonnie Hall said the union remained in support of the principles of farm assurance, but its members had made a ‘signi cant number of concerns’ clear.

Mr Hall said the commissioners

must make ‘clear recommendations’, which he said when adopted must ‘improve audit systems, utilise technology, rebuild trust, improve communications and introduce more transparency and accountability’.

Devon farmer and National Sheep Association vice-president Bryan Gri ths, who has

previously called for a ‘root and branch’ review of Red Tractor, said: “I am encouraged that two powerful and in uential ownership bodies have highlighted the shortcomings of Red Tractor and the ball is now in Red Tractor’s court to bring about the change that some of us have called for, for so long.”

In a ‘members ma ers’ newsle er sent to Red Tractor members in September, its interim chair Alistair Mackintosh said ‘it was listening’. He said: “ is is no empty promise. My primary focus as I take up the reins as interim chair is to rebuild relationships with farmers, growers and processors.”

JArla has launched a free milk ATM in London, allowing people to receive fresh milk at the push of a bu on.

It comes as the co-operative launched a nationwide initiative to ensure fresh dairy provision in food charities across the country. is comes a er insights revealed an estimated 450,000 people who rely on these schemes

do not have access to fresh dairy, with charities forced to decline donations due to a lack of storage facilities.

Arla is providing fully stocked and sponsored fridges to charities across the country, starting with the rollout of 100 fridges to FareShare charities.

It comes a er a study commissioned by Arla found that half of

adults could not imagine not having access to milk on a daily basis, with 76% consuming it at least a few times a week.

Meanwhile, 62% were not aware that not all foodbanks have fridges and therefore cannot store fresh dairy products, with 53% of the opinion that everyone should be able to easily get dairy-based foods.

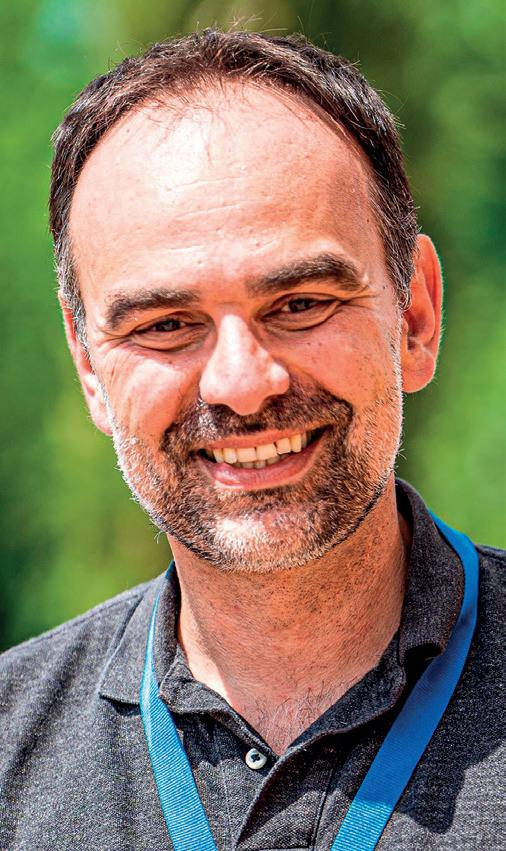

Ben Yates manages Mells Park Estate, Somerset, where he oversees a 400-cow unit and manages the 405-hectare (1,000-acre) estate. Along with his wife and two sons, Ben has his own small herd of pedigree Holsteins under the Wowcow prefix. He joined the Holstein UK Board of Trustees in 2021.

“ As a family, we have been to several local shows where both our boys have enjoyed success in their handling classes

It has been a busy couple of months through our calving period, with 360 calvings in eight weeks. The team has achieved some excellent results, meeting the target of 120 heifer replacements, the British Blue calves have done well averaging over £200/calf at three weeks old at market and a mortality rate below 1.5%.

Random blood protein testing has seen everything achieving the highest grade, so colostrum management has worked fantastically.

The focus now moves to being ready to start serving on November 1. The reliance on Cow Manager will increase as this is the third breeding season with the technology in place. Our knowledge and confidence in the system increases year on year.

In the one dry week we had in September we did our last cut of silage which filled up the pits nicely. The maize is still to come in as I write this.

We have seen great success with our SAM3 herbal leys, which have yielded very similar to our conventional grass leys. As mentioned previously, we direct drilled into a few pastures that were starting to look thin, to try and regenerate them, which look to be coming along quite nicely.

Next season, we will start to run trials on our nitrogen usage to see how low on usage we can go to achieve the same yields.

The summer saw the team prep and lay over 250 cubes of concrete to finish the yards off, which will make a massive difference in the working conditions of everybody and, hopefully, the life expectancy of machinery.

This also led to a restructuring of the yard drains meaning we can very clearly separate clean and dirty yard water, and therefore are not filling our lagoon with excess rainwater.

Holstein UK’s two flagship events took place in September, both with great success. UK Dairy Day celebrated its 10th Anniversary and saw a tremendous National Holstein Show, with a fantastic final lineup in the championship that showcased the quality of Holsteins in the UK.

I thoroughly enjoyed the whole event and the trade stand spaces were full and welcomed plenty of footfall.

There was a real buzz and great optimism within the industry at the show.

The All Breeds All Britain Calf Show took place 10 days later at its new venue, Staffordshire County Showground. For this, HYB clubs and young dairy enthusiasts from all over the UK come together to compete in the handling and calf classes.

It is always a fantastic event where the standard of competition is at its highest, and it is great to see young, like-minded people of different ages work so well together, with the youngest learning from their peers.

As a family, we have been to several local shows where both our boys have enjoyed success in their handling classes. The highlight for me has been seeing our homebred heifer, Wowcow Lambda Roza, winning supreme champion at our most local show, Frome Show, and going on to win reserve inter-breed champion heifer at The Dairy Show, at Shepton Mallet.

The rugby season has started in earnest, apart from a delay for my eldest son who broke his arm in the summer, so he’ll have to wait a few more weeks to get back on the field.

Claire Eastham farms with her husband Martyn in Dorset, where they milk 120 spring calving cows. After gaining knowledge and experience working for other businesses, the couple started their own dairy farming journey in 2015 by taking on a share farming agreement before progressing to their current county council farm.

“ For the first time, we had a flyer through the door from another milk buyer looking for suppliers

Compared to last year’s empty rate of 16%, this year’s figure looks to be 5%, with a couple of those as rechecks. We’re hoping it’s right.

All heifers are also in-calf, and we didn’t make the mistakes of last season when we pushed the cows too hard in the wet weather and they’ve held good condition this year.

We also vaccinated for IBR, so if the results are right, this is definitely something which will be worth continuing.

After much concern that we missed the last good weather window, we finally made the last of our bales on October 5, boosting the winter forage stocks.

We have been feeding palm kernel to extend the supplies and it has also given the milk solids a huge boost, with today’s results of 6.37% butterfat and 4.3% protein.

We even went slightly over forecast this month (for the first time ever) and had some additional litres on the AMPE price.

With the milk price increases of late, this will see our average October milk price at about 58ppl – meaning we are very happy with Barber’s, our milk purchaser.

For the first time, we had a flyer through the door from another milk buyer looking for suppliers, which can only be a positive sign for the industry.

Historically, I used to think that dairy and faming as a whole seemed to operate in ‘boom-bust’ cycles of seven years, but these now seem to be much shorter – perhaps on a two- to three-year rotation.

We all need to be aware of this, as having a buffer brings some resilience to the business and minimises the impact of stress after one bad PD session or a wet season.

I feel that over the past three years or so, more and more businesses have worn away this resilience buffer. Some of this is undoubtedly due to things such as Basic Payment

Scheme reductions, but it is also a sign of the more global markets we operate in and how a conflict in the Middle East can affect our operating costs. Something we will all have to pay for on the shelves.

At the South West Dairy Dinner, Richard Clothier was the speaker and spoke about how dairy products have passed the 1,000-year test for human health – a sustainable, healthy whole food, which many of today’s seed oils and processed items will not.

This is something I think the dairy industry should be shouting more about. There is a gap in the market for this to be monetised. Many people in their 20s seem to be ultra-aware of processed foods, and influencers are selling the virtues of whole foods, whole fats and the fact we were so easily sold mistruths in the past around what we eat.

It is looking like the food system might be slowly going full circle. Even the high street is returning – with consumers turning against high postage costs and missed return dates. If we’re lucky we might all have a grocer, a butcher and a baker shop too.

The [cows] must be looked after with attention to detail if they are going to achieve their potential

ANDREW LEGGOTT

Following significant investment in his family’s dairy farm, Andrew Leggott is now focusing on achieving small improvements in efficiency. Wendy Short reports.

The rst robotic milkers were installed at White House Farm, near Northallerton, in 2007.

Back then, Andrew Leggo , who runs the family farm in partnership with his wife Sarah and his parents George and Barbara, purchased three second-hand robots to milk the 150-170 cows that made up the Cocklewood Holstein herd.

Andrew says that at that point the parlour needed replacing, and it was thought that a robotic system would li yields and reduce labour. Since then, there has been further investment into robotic milking.

He says: “By 2019, the farm was at a crossroads and we were looking at herd expansion. is led to the purchase of six new Fullwood Packo M2erlin milking robots.

r113 hectares (280 acres) of land farmed

rA calcium binder has been added to the diet in the runup to calving for the past 18 months to help reduce cases of sub-clinical milk fever/ retained cleansings

“Grant aid was available, but unfortunately my application was unsuccessful. Another installation was added in 2021, and a second went in the following year.”

Cow numbers now stand at 420 and the all-year-round calving herd is milked via eight robotic machines.

rTwo weeks before calving, cows are also given a slowrelease bolus for protection against ketosis

rRumen-protected choline has been another useful measure for improving transition cow health

e herd has a 13,000kg yield average at 4.1% bu erfat and 3.3% protein, with the average number of robot visits standing at 2.9 per cow.

Andrew says the family has ‘no regrets’ about switching to a robotic system, and now his goal is to breed a ‘balanced’ cow via a sire selection programme.

“Our interpretation of a balanced cow is one with plenty of chest width and body depth,” he says.

“A balance between type and production is needed, and the customised index identi es bulls that best suit our system.”

e farm was one of the rst to utilise sexed semen in 2004, and the

ca le are genomically tested, with genomic bulls rst trialled in 2018.

e herd has a pregnancy rate of 34%, with a 50% conception rate and 70% submission.

To aid heat detection, cows are ed with activity-recording pedometers.

Females failing to get in calf a er two services receive Aberdeen-Angus semen, and heifers are calved at 23 months.

“Good results were achieved with sexed semen from the outset,” says Andrew.

“ e initial recommendation was to limit sexed semen to the maiden heifers, but it was extended across the herd as I grew in con dence. It produces 90% female calves.

“When I was in my late teens, the 10-day-old black and white bull calves that I took to the local auction mart were worth £200 apiece.

“Times are very di erent nowadays, but fortunately a local farmer collects the young beef cross heifers and bull calves for rearing. I have asked whether I should use sexed

beef breed semen to produce only bull calves, but the buyer is happy to accept mixed sexed batches.

Genomics

“Genomics o ers a number of advantages, especially in terms of milk constituent levels and general herd health. I believe that it is one of the

keys to the future of dairy farming, as it represents an opportunity for ge ing more for less.”

e original Cockleton herd was established by Andrew’s grandfather, George, in the 1950s. Andrew describes him as ‘forward thinking’ – he started using embryo transfer soon a er its launch, with

the emphasis on establishing a solid foundation through the breeding of high-quality cow families.

Originally comprising British Friesians, the Cocklewood Holsteins pre x was registered in 1989. e farm’s expansion plan has reached its target, which is limited by place numbers in the dry cow and

calf housing. By next spring, young heifers that are not required for breeding will be marketed privately.

Grass and maize silage and rolled wheat form part of the 16-17% protein total mixed ration (TMR) for lactating cows. e mix also includes soya meal and hulls, urea, Prairie Meal, dried distillers’ grains, molasses and minerals.

“My preference is for the cows to receive the bulk of their nutrition through the TMR, because it is better for rumen health,” says Andrew.

“ e feeders in the robots are used to tweak the diet to suit individual requirements. During lactation, the cows’ dung is si ed once a week to check for healthy bre digestion of the TMR. Visible grains or minute pieces of gut lining are two of the triggers that will prompt a review of the diet. Problems are minimal, usually occurring a er a change in silages.”

e unit grows 73 hectares (180 acres) of maize, with earlier varieties used on the more challenging land and mid-season types for more favourable sites.

e crop is usually cut at the end of September/early October.

It has traditionally been followed by a crop of wheat and then sown with a grass seed mix. However, the business has a contract with milk buyer Arla to supply Asda supermarkets, and a ‘greening’ incentive has recently been o ered.

erefore, an Italian ryegrass mix will be sown directly a er this year’s

maize, with the designated elds put back into maize in the spring.

“ e maize crop has recovered well a er the cold, wet spring conditions,” says Andrew.

“I nd that a foliar nitrogen treatment at the row cover stage promotes growth and maturity, alongside the prior applications of slurry and farmyard manure.”

Five cuts of grass silage are taken annually, and a biological additive is used to enhance fermentation.

Andrew says: “It has been a good year for grass growth. e silage leys are down for two years and provide an excellent entry for the wheat.

“High straw prices have a ected the silage-making pa ern, and the time between fourth and h cut has been extended to reduce the nutrient

content for feeding the heifers. is may seem counterproductive, but it is cheaper to o er low-quality silage than to buy in straw. ey would lay down too much fat on ‘rocket fuel’ silage, with a negative e ect on fertility results.”

e herd is screened for Johne’s disease and vaccinated against BVD and IBR, with the calves vaccinated against pneumonia.

“ e calves have been coughing intermi ently and there have been a few cases of pneumonia, despite the vaccination programme. e roof opening is being widened in the calf house and there will be a new air vent tunnel, as well as an extension to the Yorkshire boarding,” says Andrew.

“Calves are not currently weighed, but a weighing machine might be the next purchase.

“It would be a more accurate way

of monitoring progress compared with a visual assessment.”

Assisted by the three full-time and two part time workers, Andrew says he will continue to review the herd management policy.

He says: “We have a good team at present, but it has not been easy to nd sta in the past. at is one of the reasons why I continue to strive for e ciency and to try and cut down on the workload, as well as making the day-to-day routine as pleasant as possible.

“ e breeding programme is centred on high-performing Holsteins, and they must be looked a er with a ention to detail in every aspect if they are going to achieve their potential. ere is some small capacity in the robots, but that will be lled through increased yields rather than future herd expansion.”

The sequential use of identical PI3 and RSV antigens in live and killed presentations, called a PRIME-BOOST effect, can optimise the immune response to two of the key viral pathogens associated with bovine respiratory disease (BRD).

References: 1. Philippe-Reversat et al. (2017) Acta Vet BRNO. 86: 325–332 2. Metcalfe et al. (2020) Vet Record Open 7: e000429 3. Ellis et al. (2018) Can Vet J. 59: 1311–1319 ® our farm has the ha iest Cows in the world!

BOVALTO® is the ONLY BRD VACCINE RANGE which provides ALL of these benefits:

Efficacy proven by challenge studies1

A duration of immunity proven by challenge: 12 weeks for BOVALTO Respi Intranasal2

6 months for BOVALTO Respi injectables1

Intranasal efficacy against BRSV and PI3 unaffected by MDAs, providing the optimal start to immune protection against BRD2

Bovalto® Respi Intranasal, nasal spray, lyophilisate and solvent for suspension contains Bovine parainfluenza 3 virus (PI3V), modified live virus, strain Bio 23/A 105.0 – 107.5 TCID50 and Bovine respiratory syncytial virus (BRSV), modified live virus, strain Bio 24/A 104.0 – 106.0 TCID50. Bovalto® Respi 3 Suspension for Injection and Bovalto® Respi 4 Suspension for injection contain inactivated bovine respiratory syncytial virus, strain BIO-24, inactivated bovine parainfluenza 3 virus, strain BIO- 23 and inactivated Mannheimia haemolytica, serotype A1 strain DSM 5283. Bovalto® Respi 4 also contains inactivated bovine viral diarrhoea virus, strain BIO-25. UK:

Enables sequential use of identical PI3 and RSV antigens in different forms for rapid and long-lasting immunity3

POM-V IE: POM (E). Advice should be sought from the prescriber. Further information available in the SPCs or from Boehringer Ingelheim Animal Health UK Ltd, RG12 8YS, UK. UK Tel: 01344 746957, IE Tel: 01 291 3985. Email: vetenquiries@boehringer-ingelheim.com. Bovalto® is a registered trademark of the Boehringer Ingelheim Animal Health France, used under licence. ©2022 Boehringer Ingelheim Animal Health UK Ltd. All rights reserved. Date of preparation: September 2022 BOV-0108-2022. Use Medicines Responsibly.

‘I am confident that we are finally on the right path’

NFU dairy board chair Paul Tompkins farms with his wife Rachael in the Vale of York. Not from a farming background, Paul worked in the financial sector before meeting his wife and joining the family dairy business.

Over the next five weeks, the NFU will be hitting the road to explain how the brand-new legislation governing the sector affects your business. The Fair Dealing Obligations (Milk) Regulations 2024 came into force in July and will change the way our industry works for the better. We want to help you understand the regulations and give you the opportunity to meet the farmers representing you nationally and regionally.

Earlier this year, more than a decade on from the NFU’s SOS Dairy Campaign, and the UK farming unions first calling out unfair practices and abuses of power in the dairy supply chain, the new legislation was laid in Parliament to ensure fair and transparent contracts for all dairy farmers in the UK.

Unfair and unbalanced milk contracts have long been a concern for the dairy sector. You will remember reviews in 2018 and 2020 by the Groceries Code Adjudicator and Defra finding an imbalance of power across the supply chain, believed in part to be caused by milk buyers having the power to set and modify the terms of a contract with often little notification. This led to huge amounts of uncertainty and ambiguity and enabled unfair practices to persist. This undermined those good relationships which do exist between milk buyers and producers and damaged trust across the supply chain.

The new regulations, a commitment set out by former Prime Minister Rishi Sunak at the Farm to Fork Summit last year, will establish transparency and accountability

across the dairy supply chain by stopping contract changes being imposed without agreement. There will also need to be agreed procedures in place to enable farmers to independently verify the calculation and justification of variable prices. Importantly, the regulations also include an enforcement regime, backed up by the ability for the Secretary of State to impose substantial financial penalties in respect of any breaches. While progress has taken far longer than any of us hoped and expected, I am confident that we are finally on the right path to building a stronger, more resilient future for the UK dairy sector.

Notwithstanding the progress that is being made, the NFU believes that representative organisations, such as producer organisations, will continue to play an important role in helping farmers negotiate contracts within the dairy sector.

The new regulations offer processors who make the most from these farmer groups the ability to simplify their negotiations, while offering farmers collective strength and we will continue to support the development of representative structures like these to help improve trust and collaboration across the supply chain.

How will the legislation work, is a question I have been asked a lot over the past few months. There are several areas to consider including price, variation, farmer representation, exclusivity and notice periods:

JPrice: Prices will continue to be market led, but the legislation will introduce greater transparency. For example, if the contract contains a variable price, it can only be moved in reference to the agreed factors set out in the contract. Any change to those factors would have to be negotiated and farmers will have the power to challenge a price through an independent third party if they feel their milk buyer has not followed due process.

JVariation: All variations to the contract must be agreed by both parties. This means milk buyers cannot enforce changes without agreement from the farmer or their representative organisation.

JFarmer representation: Greater contract flexibility will be allowed where farmer-owner structures such as cooperatives and producer organisations, negotiate the terms of a contract on behalf of producers. The flexibility

“ Across the sector, there has been another round of milk price increases, taking some values to their highest since early 2023

allowed under the regulations may also make these structures more a ractive for processors to engage with.

JExclusivity: Non-exclusive contracts must be o ered where the milk contract demands a xed volume of milk.

JNotice periods: e legislation requires milk buyers to provide a minimum of 12 months’ notice if they wish to terminate a contract.

ere are several other areas covered in the regulations too, such as dispute resolution, force majeure, and the introduction of cooling-o periods.

e legislation also includes powers for the newly appointed Agricultural Supply Chain Adjudicator (on behalf of the Secretary of State), to oversee and enforce the code and impose nancial penalties on those in breach.

My predecessor as NFU dairy board chair, Michael Oakes, who was recently acknowledged for his contribution to British dairy farming at the 2024 Cream awards, played a huge part in seeing the regulation of dairy contracts over the line. e work that has gone into this has been incredible and dairy farmers everywhere owe Michael a huge debt of gratitude for being one of the key driving forces.

Across the sector, there has been another round of milk price increases, taking some values to their

highest since early 2023 and over the next few months market signals are that this will continue into the winter. is is encouraging but will need to be sustained to o er any sort of relief following a di cult year.

Talking to many of you over the past few weeks, I know con dence is still low as we contend with a range of issues such as the relentless wet weather, a lack of labour and the ongoing threat of bluetongue. ere are still plenty of opportunities though and as I have said before, the new contracts legislation is our chance to change the way the dairy supply chain operates.

e additional transparency and accountability introduced by these regulations will bene t the whole supply chain and provides additional certainty and con dence to farmers as to the terms under which you sell your milk.

As an NFU, we will continue to work alongside the other UK Farming Unions, with government and the wider supply chain to ensure this new contract legislation delivers not only for UK dairy farmers, but the millions of consumers that enjoy our climate-friendly and nutritious products.

Vaccination, tag testing and biosecurity are identified as key measures to preventing the spread of BVD across UK dairy farms. Katie Fallon reports.

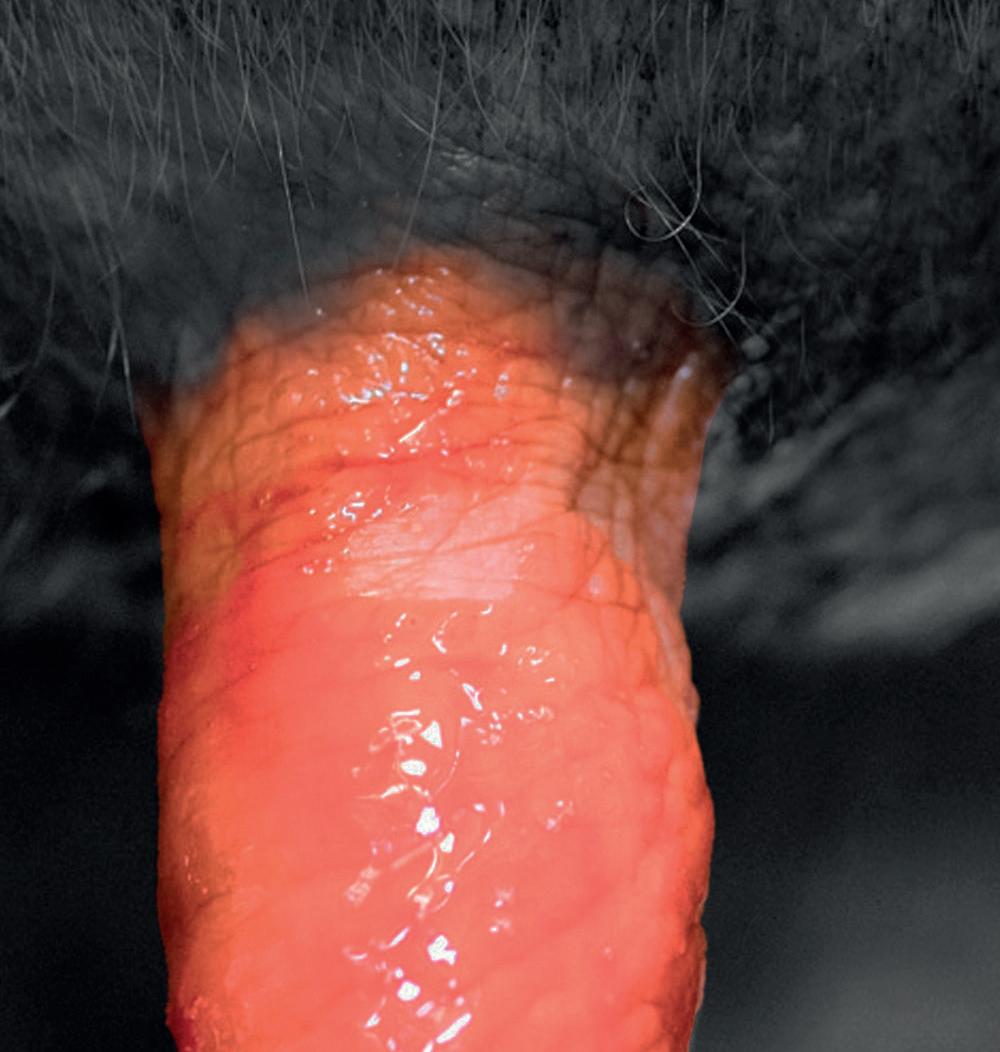

One of the biggest diseases facing the UK cattle industry, infecting at least 27% of dairy herds in Wales, is BVD. A highly contagious viral disease transmitted from one bovine animal to another, vets David Staak and Sara Melo, of the Carmarthenshire-based vet practice Dyfed Vets, say the disease can have significant impacts on both youngstock and the milking herd. While buying-in infected cattle and mating with infected bulls can both be sources of infection, Mr Staak says infections are common among in-calf cows. He says cows are often infected with the disease during the first trimester of pregnancy, resulting in the disease being transmitted to the unborn calf in the womb.

The calf is then born as a persistently infected animal (PI), which will go onto shed a huge amount of virus into the environment and will usually not perform very well.

Ms Melo says PIs will go on to transmit the disease to other cattle in the herd and negatively affect the immunity of a group of calves around them.

She says: “Other calves will become infected with the virus for a short period of time, but they will not become PIs. It will lower their immune system and make them susceptible to other diseases, such as scour and pneumonia.”

While these calves will be transiently infected rather than permanently infected, the infection will usually occur while calves are still growing and are vulnerable to disease.

A lot of farmers tag test calves, and it is a good way of trying to eradicate BVD, because we know a PI will give birth to a PI again

DAVID STAAK

Therefore, significantly impacting their growth and performance.

Mr Staak says: “It is not always obvious which calves are PIs.

“Sometimes after a few months it can become obvious, but you could have PIs that carry on in the herd and you would never know.”

Indicators that calves might be infected with BVD include increased cases of pneumonia and scour, or calves not thriving.

Mr Staak says: “Sometimes you do go to a farm and see a calf that is a PI. It will look miserable with poor growth and condition and runny eyes.”

For herds with calves which are showing these symptoms, Mr Staak advises blood testing yearling animals between nine and 18 months of age, to see if a BVD infection is present.

He says: “Do not test calves younger than nine months as they could still have maternal antibodies in their system.”

When looking at BVD infections in adult cows, Ms Melo says if a PI cow makes it to the milking herd and gets in calf, its future offspring will also be born as a PI.

And while PI cows will go on to shed the virus into the environment infecting other cows, those cows will not become PIs and will only experience transient infection.

Mr Staak says: “It depends

on the stage of gestation, but in-calf cows infected with BVD will either give birth to a PI if infected early on in the pregnancy or will potentially abort their calf if infected later on in pregnancy.”

Adult cows infected with BVD will experience reduced production, poor fertility and increased susceptibility to other diseases such as IBR, leptospirosis, mastitis and mycoplasma.

To understand the level of exposure within a herd and determine antibody levels, Mr Staak advises carrying out a bulk milk test.

He says: “When testing for antibodies we are not looking for a PI, but we are looking to see if animals have been exposed to a PI. These animals will not be persistently infected themselves, but indicate that there could be a PI within the herd.”

Following this, Mr Staak says farms will need to carry out a ‘PI hunt’ to identify the PIs within the herd.

He says: “It might only be one animal, or it could be two or three. You can try and identify the infected animal by pool

For herds with calves showing BVD symptoms, youngstock should be blood tested to see if a BVD infection is present.

blood sampling in youngstock, testing milk from cows and pooling samples together to whi le it down into smaller groups and eventually identify the PI.”

Tag testing calves for BVD is also an e ective method of identifying PI calves to help eradicate the disease on-farm.

Mr Staak says: “A lot of farmers do this now, and it is a very good way of trying to eradicate BVD, because we know a PI will give birth to a PI again.”

Ms Melow advises tag testing alongside vaccinating the herd. She says: “You are protecting the herd initially by vaccinating, then by tag and testing you are eliminating any new animals coming through.”

Although vaccination will not cure the PI ca le, it will protect the rest of the herd, alongside blood testing the dams of any new PIs identi ed through tag testing.

Mr Staak says calves can be vaccinated from around three months of age, but advises vaccinating bulling heifers before

rBiosecurity - only buy from BVD-free farms

rMonitoring – blood test five yearling animals annually

rTag and test calves

rVaccination

rPI hunt - identify and cull

going mating, as well as vaccinating in-calf heifers and cows annually.

He says: “Vaccination and tag testing are key to prevention.

“If you suspect you have a problem, I advise blood testing ve yearling animals in each management group each year to identify if there is exposure to the virus.”

Ms Melo says the sourcing of ca le is also important when buying-in replacements and advises sourcing ca le from farms which are BVD-free.

She says: “Biosecurity is critical because you could have a herd that is BVD-free, but you buy-in one PI and it could be a disaster for the herd.”

By providing class-leading levels of heat detection accuracy and clear guidance on when individual cows and heifers should be inseminated, the SenseHub Dairy herd monitoring system from MSD Animal Health enables herd managers to optimise their herd’s fertility performance.

SenseHub Dairy uses electronic neck collars and/or eartags to constantly monitor the subtle behavioural and activity patterns associated with the various stages of the fertility cycle of maiden heifers and cows.

In doing so, it accurately and reliably detects 95% of heats, including silent and weak heats.

Whenever a heat event or potential problem with the ensuing gestation is detected, the SenseHub app automatically sends an alert to key members of staff so an informed breeding decision or medical intervention can be made as quickly as possible.

The SenseHub app also highlights the optimum time for insemination to take place, with separate guidance provided to maximise conception rates from sexed or conventional semen.

This unrivalled heat detection accuracy, along with SenseHub’s ability to filter out any false heats, eliminates the guesswork from artificial insemination

(AI) timing and contributes to improvements in first service conception success and subsequent pregnancy rates.

It also eliminates the need for staff to make visual observations to spot bulling cows and heifers, and reduces AI and semen costs.

SenseHub’s clear and simple to understand charts and graphs can be shared easily and quickly with third party consultants – such as the farm’s vet or nutritionist – so any problems can be diagnosed and treated as soon as possible. This not only reduces unforeseen fertility costs, but also helps to fast-track the herd’s genetic improvements by shortening the calving interval and reducing the number of open days.

The SenseHub system can also detect anoestrus cows, cystic cows and suspected abortions and can be used to monitor the health and well-being of cows during the transition period.

Calf rearers should look at all areas of calf management and disease prevention to help control problems with cryptosporidiosis in calf sheds. Katie Jones reports.

With calf cryptosporidiosis the most common cause of infectious scours in the UK, it is important that calf rearers are looking at all the ways they can control this issue on-farm.

And to help achieve this, a five-step action plan has been released alongside a new vaccine.

The action plan, which was developed by MSD in conjunction with Moredun, looks at five areas: diagnosis, colostrum, environment and management, prevention, and treatment.

Speaking during a recent press briefing, Dr Kat Baxter-Smith of MSD Animal Health said that the tool would allow farmers and their vets to explore, record and score performance across these five key control areas.

She said: “For each of the areas, there are a series of questions which farmers can answer and

rCaused by the protozoan parasite cryptosporidium parvum, and is now the most common cause of infectious scour in the UK

rCauses intermittent scour, loss of appetite, dehydration and weakness

rOnly five oocytes are needed to cause infection, but millions of oocytes are excreted for seven to 10 days at the peak of shedding

rThe disease is widespread and found on more than 90%

It is vital we use diagnostics to identify the likely cause or causes of scouring

score themselves on. The scores are added up at the end, and the results will help highlight the areas where focus is needed.”

The first area is diagnosis, and Dr Baxter-Smith said accurate diagnosis was the first step towards better disease control of any cause of infectious scour on-farm.

She said: “It is vital we use diagnostics to identify the likely cause or causes of scouring. Calf-side testing is a rapid option to help identify whether the most common scour-causing pathogens

of GB farms, and is shed by adult cattle as well as calves

rThe condition is mostly seen in calves seven to 14 days of age, but can strike anytime and is prevalent throughout the year

rIt is a zoonotic disease. There are 3,000-6,000 UK lab-confirmed cases a year, but this is likely to be much higher. A significant number of these cases can be linked to contact with animals and to farms which open their doors to the public

including cryptosporidium parvum, rotavirus, coronavirus or E.coli, are involved. Further lab testing could be required if it is suspected there might be other causes, such as coccidia and salmonella.”

The next area is colostrum and Dr Katie Denholm, an academic clinician at the University of Glasgow Veterinary School, reminded farmers about the importance of the ‘five Qs’: quality, quantity, quickly, quietly and quantify.

She said: “If calves fail to ingest an adequate quantity of quality colostrum, there will be huge implications for the calf. These calves will not grow as they should, they will

not conceive as well or produce as much milk.”

And she added that recent studies suggested there were benefits from feeding high-quality colostrum for longer. A recent survey of 248 farms across England, Wales, Scotland and Ireland found that three quarters of respondents said that if it was shown that feeding colostrum beyond day one was beneficial, they would do it.

Dr Denholm said potential benefits of feeding colostrum for longer included increasing calf serum immunoglobulin concentrations, reduced antimicrobial use, increased immune protection for specific dam vaccinated pathogens, the promotion of sound intestinal villi development, reduced calfhood morbidity and mortality, and the improvement of reproductive and lactation outcomes in later life.

She added that while there could be barriers to adopting this approach, there were a number of ways to supplement colostrum feeding – for example, adding two or three large ice cubes of frozen first milking colostrum into milk replacer feeds or adding 40-70g of a colostrum replacer to milk replacer.

“This liquid gold also contains immune modulators such as oligosaccharides, valuable enzymes, lactoferrin, cytokines, hormones, vitamins, and minerals – all of which are important for long-term gut health, function and development,” she said.

She also said the benefits of feeding transition milk (the milk from milkings two to six) should not be overlooked, and suggested feeding this transition milk for the

rst three to ve days or mixing transition milk into pasteurised milk.

She said: “Transition milk contains a greater concentration of bioactive compounds compared with whole milk.”

e third area on the ve-step action plan is environment and management, and Dr Baxter-Smith said farmers traditionally did not score well in this area. Issues within this area could include the mixing of di erent age groups of calves, poor hygiene around the cleaning of equipment and not replacing straw bedding o en enough.

e fourth area is prevention,

and this is where MSD’s new vaccine, Bovilis Cryptium, comes in. is is the rst ca le vaccination against crypto parvum, with pregnant heifers and cows receiving the vaccination in late pregnancy to provide protection for calves from birth at the start of colostrum feeding.

rInfection with the parasite causes blunting of the intestinal villi, reducing capacity for nutrient and water absorption. This has a significant impact on a calf’s future productivity

rIn a recent UK study, cryptosporidiosis in the first

Dr Baxter-Smith said: “ e protection of calves depends on adequate ingestion of colostrum and transition milk from vaccinated cows. It is recommended that all calves are fed colostrum and transition milk during the rst ve days of life. At least three litres of colostrum should be fed within the rst six hours a er birth.”

16 days of life significantly reduced weight gain over a six-month period, with severedisease calves weighing 34kg less on average than low-disease calves. This equated to a £161 reduction in the calf sale price

e nal area is treatment, and Dr Baxter-Smith said that even if all of the other steps were done well, there could still be calves that required treatment.

She said: “Calves with diarrhoea are o en dehydrated. erefore, oral rehydration therapy should start as soon as scour is observed and continue for at least 48-72 hours.”

Former UK sheep shearer, Will Hinton and his partner Kali Rangiawh have recently been named as New Zealand’s share farmers of the year. Chris McCullough reports.

Having spent most of his time travelling the world shearing sheep, UK-born Will Hinton has changed farming direction and is now milking cows on a share farming basis in New Zealand.

Will, who farms with his partner Kali Rangiawha, hails from Wiltshire where he grew up following the sheep shearing trail before travelling Down Under to perfect his cra .

It was while on this quest in 2017 he met New Zealander Kali, who had accrued a wealth of dairy experience. Before long their children, Rylan 6, Billy 3, and Blake 1, were born and roots were put down.

For the past 15 months the couple have been contract milking 350 cows on a 113-hectare (280acre) farm located near Fielding, in the Manawatu District on the North Island.

e couple have recently won the 2024 New Zealand share farmer of the year award.

Will says: “With several years of dairy experience, Kali was the key driver behind our contract milking business that we started four years ago.

“ e farm we are on now is owned by Tim and Victoria Gorton. is is their rst year owning a dairy farm so they have employed us to run it for them, while leaning on us for our experience.

“We milk 350 cross-bred cows twice a day through a Waikato milking system 54-unit rotary parlour.”

Kali also works as an AI technician for LIC and likes to run a tight spring calving system to match the grass growth on the farm.

She says: “Compact calving is very popular over here, run to match grass growth. We calve the cows from mid-July through to the end of September, with the majority calving in the rst six weeks.

“ ree major breeding traits that we are concentrating on include Breeding Worth, Production Worth and Lactation Worth.

“Breeding Worth is the genetic potential for pro table o spring as well as feed e ciency.

“Production Worth is the cow’s lifelong pro t-making ability. Our top PW cows receive sexed semen

and the bo om tier receives beef semen.

“And lastly, Lactation Worth reects on how pro table and e cient a cow has been within the current lactation.”

Will and Kali run the cows as a single herd grazing outdoors all year round. e mating season is kept at about 10 weeks, six weeks for AI and four weeks using a bull.

Operating a share farming model means costs have to be monitored carefully and this includes labour use.

Will says: “We run the farm ourselves, but this season we are employing someone so we can start training them up before we take our next step up in the industry of owning a herd.”

Will achieves 14 tonnes of grass per hectare, a total of 1,580 tonnes dry ma er, which accounts for 81% of the cows diet.

He also feeds a blend and uses 100 tonnes of maize as a transitioning tool in early spring, and as a condition builder late lactation.

He says: “We also grow summer crops, such as chicory, to complement the drop in metabolisable energy and crude protein in pasture, which helps us hold production levels.

“I am very passionate about feeding and the transition phase is crucial.

“It is very challenging here as pasture is a huge part of the cows diet and therefore it is hard to achieve a low DCAD [dietary cation-anion

rMilking takes 1.5 hours in the morning and one hour in the afternoon

rOver the past year, a record production of 443kg milk solids per cow has been achieved

rMilk is sold to Open Country and the price is about NZ$8.40 (£3.96) per kg of milk solids

di erence]. e DCAD is a particularly important measure used when formulating diets for dry, transition and lactating dairy cows.

“In the future, I would like some technology that tells me how well each cow is transitioning, as it would let me pick up subclinical cows a lot quicker.”

Will and Kali’s ve-year goal was to own 200 cows themselves, a target that could have been reached this year, but was pushed forward to

The herd is run as a single unit, achieving a record production this year of 443kg milk solids per cow.

ensure a good work life balance with three young children in the family.

Will says: “Our target has now changed to around 600 cows which we hope to purchase early in 2025.

“In the next ve years we would like to increase this to 1,000 cows and own a farm by 2034.

“It was amazing that we won the national share farmers of the year award, which is the top tier of the New Zealand dairy awards. is is a lifetime achievement for us and will

Scan the QR code to watch the Glycolac video

de nitely help us with some amazing opportunities going forward.”

And looking into the future, Will said there will be some tough challenges ahead.

He says: “I think the progression ladder is ge ing a lot harder in New Zealand. Farm ownership used to have a clear trajectory, but with in ation of farm working expenses, high interest rates and average milk prices, these all seem to be moving the goalposts further away.

“I think global environmental regulations will be more challenging, but I feel this is an exciting challenge. We need to reduce our carbon footprint per kg of milk solids.

“We are at the forefront of the lowest carbon footprint per litre of milk in the world, but we need to maintain this. By improving the bottom 25% of our herds and breeding more resilient cows, we can then slowly reduce our stocking rate.”

Methane emissions from dairy farms may be higher than thought, but conversion to biogas could reduce emissions and save more than £400 million a year in fuel costs. Dairy Farmer reports.

There is huge potential to turn emissions from slurry stores into a renewable energy source, according to new research conducted by the University of East Anglia (UEA).

e research also found that methane emissions from slurry stores on dairy farms may be up to ve times greater than o cial statistics suggest, but if captured and turned into biogas, emi ed methane could be worth more than £400 million a year to the dairy sector in saved fuel costs, or around £52,500 for an average-sized dairy farm.

Capture technology already exists, and if rolled out across the EU dairy herd, the conversion of methane to biofuel could reduce emissions equivalent to an estimated 5.8% of the remaining global temperature rise budget, if the temperature was to be kept to 1.5degC of warming.

Conducted by the UEA and the International Fugitive Emissions Abatement Association (IFEAA), the research is based on measurements from two dairy farms in Cornwall.

Together with a growing body of international eld research, it suggests that the ‘Tier 2’ calculations used by countries to report their emissions annually to the Intergovernmental Panel on Climate Change (IPCC) may not be robust.

Current National Inventories of greenhouse gas (GHG) emissions report that enteric emissions –those coming directly from animals’ digestive systems – are three to nine times greater than those from manure management, including

The conversion of methane to biofuel could reduce emissions equivalent to an estimated 5.8% of the remaining global temperature rise budget.

the storing and spreading of slurry and manure.

However, the ndings, reported in the journal Environmental Research: Food Systems and an IFEAA Net Zero Methane Hub white paper, suggest the balance between enteric emissions and those from manure management could be much closer to 50:50.

e authors also call for greater focus from researchers and political leaders on emissions from manure management.

Prof Neil Ward, of the Tyndall Centre for Climate Change Research at UEA, says: “ e standard international methodology looks to be underestimating methane emissions from slurry storage.

“Fortunately, we have the technology to turn this problem into a business opportunity for farmers who can reduce energy bills and become energy independent if they capture and make use of methane as a fuel.

“If emissions from manure management are being signi cantly

under-estimated, this not only means that o cial estimates are inaccurate, but also that priorities around mitigation options might be being distorted.

“ is research therefore represents an urgent call for action and further work to be er understand methane emissions from manure management.”

e researchers analysed measurements of slurry lagoon emissions from the two farms during 2022 and 2023. e lagoons were covered with airtight covers and the methane captured.

ey found slurry lagoons produce far more methane than suggested by o cial estimates, such as those based on methods developed by the IPCC.

Actual emissions from the farms were 145kg per cow per year and 198kg/cow/year, respectively.

is is four to ve times higher than the existing o cial gure of 38kg/cow reported in the UK’s National Inventory.

e resulting recommendations

for Government include research and development priorities, increasing grants for slurry covers and extending such nancial support to associated gas processing equipment.

e researchers also suggest simplifying planning and permi ing processes, and tax breaks for supply chain investment in methane recovery and use, such as investments by milk processors in supplier farms.

George Eustice, former Secretary of State for Environment, Food and Rural A airs and chair of IFEAA, said: “Methane is a potent but shortlived GHG and reducing emissions is critical to the pathway to net zero and limiting global temperature rises to 1.5degC.

“ e bad news is that emissions from agriculture are higher than previously thought, but the good news is that this methane is easily captured and used as an alternative to fossil fuels, creating an additional income stream for farms.”

Do you make maximum use of your robot

Using ForFarmers OptiRobot our Dairy and Robot Specialists are able to assess whether the interaction between robot settings, nutrition and health is optimal. It often turns out that small changes can make a big difference; Our Robot Specialists can help highlight areas where you can improve with the unique ForFarmers OptiRobot which provides:

9 Greater insight

9 More opportunities

9 Increased returns

For more information speak to your local ForFarmers Robotic Specialist or visit >

0330 678 0982

info.uk@forfarmers.eu

www.forfarmers.co.uk @ForFarmersUK

UK dairy has taken centre stage, with more than 40 international buyers and 60 British and Northern Irish businesses taking part in a major event aimed at boosting exports worldwide. Dairy Farmer reports.

Buyers from Asia, the Americas, the Middle East, Europe and North Africa headed to the UK for the Government’s Dairy Showcase, delivered in partnership with AHDB, with cross-industry support.

e week-long series of events showcased the best of the UK dairy sector, building overseas buyers’ understanding of the high standards of British farms and dairy production, such as cheese, bu er, yoghurt, cream, milk powders and infant formula.

e event included tours to dairy farms and processors in Somerset, Gloucestershire, Shropshire and Lancashire for delegates to gain rst-hand experience of the farm-tofork story of British dairy produce.

e week culminated with a Department for Business and Trade (DBT)-led ‘Meet the Buyer’ event and gala reception in Hertfordshire, which provided a platform for buyers to meet export businesses, with more than 320 business meetings taking place.

UK Dairy Export Showcase was developed in consultation with the Dairy Export Taskforce and industry as part of a programme which helps to progress the export capability of UK businesses and champions high-quality UK dairy products on the global stage.

e taskforce represents industry and is supported by industry bodies, such as AHDB, the NFU and Dairy UK, as well as Government departments DBT and Defra.

Exports Minister Gareth omas

said: “ e UK dairy industry is among the best in the world, exporting £2 billion of goods to more than 130 countries last year.

Capabilities

“We are backing our dairy producers – many of whom are SMEs – so they can increase their exporting capabilities, use trade agreements to access new routes to market, and continue to thrive and grow our economy.”

Farming and Food Minister Daniel Zeichner said it was great to see UK dairy products take centre stage at the Dairy Showcase.

He said: “We have introduced new rules to improve fairness in the dairy supply chain and are seeking a new veterinary agreement with the European Union to tear down unnecessary barriers to trade.

“ is is part of our new deal for farmers to boost food security, restore nature and support rural economic growth.”

Graham Wilkinson, AHDB chief executive, said the showcase provided the perfect platform to highlight the UK’s world-leading products and high production standards.

He said: “It complemented

AHDB’s extensive international market development activity, including inward and outward trade missions and participation in trade shows around the world.”

NFU dairy board chair Paul Tompkins said it was important the sector was recognised for its ambition and innovation.

He said: “We have previously exported more than £2bn worth of dairy products annually to more than 135 countries and have the potential to continue to increase that value within the next decade.

“However, boosting exports requires commitment and resource from Government, working in partnership with industry, to reduce trade barriers, help create market opportunities and enable growth.

“UK Dairy Export Showcase has been an exciting opportunity for the British dairy sector to stand out, reinforcing our reputation as world leaders in the dairy market and o ering a great platform to demonstrate our global credentials as producers of sustainable, climate-friendly dairy products.”

Dairy Farmer is celebrating its 95th anniversary this year, so we take a look at how the industry has changed and ask some of our regular writers to give their views on dairy farming.

When Dairy Farmer rst launched in 1929, the UK was struggling with low economic growth and recession.

Around this time, total ca le numbers on UK farms were around the eight million mark. From this point on, there was a consistent upward trend, with numbers standing at 15.2m in the mid-1970s.

At that point, the number of ca le began to fall, with much of this associated with BSE and foot-

and-mouth disease, which magnied the downward trend.

Much of the underlying decline in numbers since the 1980s has been in the dairy herd as a result of restrictions on milk production from milk quotas around this time. e latest Defra gures (for December 2023) show that the number of ca le and calves in the UK stands at just under 9.6m animals. And of these, 2.65m head are dairy cows.

According to AHDB’s latest survey of major milk buyers, it was estimated there were 7,130 dairy

producers in Great Britain as of April 2024.

In 2020, there were an estimated

8,300 producers in Great Britain, with an average volume per producer of 1.55m litres a year.

JI started writing Cowmen Comment in DF in 2009, alternating with the late Ian Potter. It was a task I thoroughly enjoyed, and writing about the last month’s farm experiences for so many years gave me a very good record of the happenings on our farm.

On the pedigree side, I tried to keep a medium-sized cow with good fore udder, feet and legs, with longevity and milk quality. We now have many heifers which are three generations of Excellent.

Looking back, the most dominant theme in my articles was the challenges of the weather, particularly flooding. Another irritant was escaping cattle – we have adventurous youngstock.

Since then, technology has moved on apace, with sexed semen and DNA profiling; robotic milking is no longer novel. Grazing herds persist, but more cows are kept inside full-time, with robots pushing up feed and removing the resultant manure, which often ends up in a biodigester.

We also suffered more than our fair share of inspections, but nowadays most farms are routinely assessed and often found wanting. Controls and investment needed for manure management are an expensive minefield. Under the eyes of supermarket buyers, inspections can be demanding and the stress affects mental health.

Over the years, our farm moved forwards and my articles told of a new milking parlour, with a 20:20 Herringbone replacing the antique 8:8, herd size increasing with new cubicles for 150 cows, together with roofing feed areas and new trackways throughout the farm.

We changed from all year round calving to spring and autumn, but always with an emphasis on grazing.

We can look forward to many more robots on the farm, some with artificial intelligence, driving tractors, maybe milking the cows and hopefully cleaning the farmhouse. Would a robot like to do my farm records?

Milk price is still everfluctuating and often does not cover costs, with the result that many more farmers are leaving the industry. When I was writing for DF, climate change was being left to scientists. In the last few years, it has suddenly become a mainstream concern, with farmers in the forefront.

At first, they were blamed for everything, but at least now it is recognised that they can be a big part of the solution.

Ploughs have been sold, or covered up in sheds, direct drills

Now, the average volume per producer is around the 1.7m litres mark.

and dairy farmer from Wiltshire

are popular, and the state of the soil is now of key importance.

For ourselves, we have found we have good stocks of carbon, but even more flooding.

However, some things never change – muddy and straw-filled wellington boots can still be seen racing through the kitchen with the comment: “Can’t stop – it’s an emergency!”

JIt has been a while since I last had chance to write for Dairy Farmer, but it will soon be 25 years since I first entered a competition, run by former editor Rachel Porter, to be the ‘next Roger Evans’.

I have been a lifelong fan of Roger, and like many of you I expect, when DF arrives, I go straight to the back and read what Roger has to say.

I ended up winning the opportunity to write in the magazine, and that competition has without doubt changed the direction of my career. I am, however, still not even close to being ‘the next Roger Evans’.

In my first column, I started to talk about robotic milking, which seemed to capture the interest of many readers. Saying that, even looking at robots back in the early 2000s was at the time a bold statement.

Around the same time, the first big issue I had chance to

comment on was the foot-andmouth outbreak in 2001. Knowing what to say at the time was hard. It was a horrible time and is best forgotten, but during this period we were also busy fitting two robots and converting over to robotic milking.

Dad had always been keen on technology and we had an early computerised milking parlour which was installed in 1980. The ‘old’ parlour was still ahead of many when it was taken out in 2001.

But by the time I left Askham Bryan College, the parlour was

not physically big enough for the larger Holstein cows we had. So it was time for change and once Dad had seen a robot working he was convinced, telling me that the robot was ‘just an out-of-parlour feeder with a milking arm on it’.

This was still the early days of robotic milking in the UK. There was a lot of scepticism and undoubtedly there were some who wanted to see it fail.

I knew it was working for us and the flexibility that it brought to us allowed me time away from the farm and to develop a business, which would help others do the same thing we had.

My first 10 years of selling robotic milking systems were actually the easy years looking back, as the competition was really just conventional milking parlours versus a robot.

Continues over the page...

Nowadays, every milking parlour company has a robot and I wouldn’t like to be trying to sell one colour against another with companies trying to ‘outdo’ each other with a higher level of complexity, a gadget or add-on.

Robot manufacturers might want to take heed of what my dad said in 2000, that they are ‘just an out-of-parlour feeder with a milking arm’.

The milking robots of today have become way more complicated than they ever need to be, and there is a market for a simple robot to milk cows, but that is another story.

From a personal point of view the herd at Hunters Hill was sold in 2017 and the buildings now are mostly redeveloped. The land is all mostly arable,

which we package and sell as game and wild bird feed.

I have just 20 cows now, sucklers which we take the calves though to finishing.

The silage pits are now grain stores, the cubicles are mostly self-storage units, and the oldest buildings now form a rural office block for letting.

I still sell robotic milking units but mostly used machines which ironically some of which

JWhen I started out farming, the plan was to buy 30 cows. I can’t remember anyone running any budgets and 30 cows was enough. A farming periodical had just run an article where someone could make a living if they had 20 cows and 200 hens on deep litter. They had to keep things simple – all they needed was a tractor, a mower and a buck rake.

You could buy these big buck rakes you reversed into two swaths and when it was full you took it back to the clamp. Ironically, I made my first silage like this. It took me two weeks to do 14 acres. I was on my own with the milking to do as well.

This farm hadn’t sold milk before, so I had to keep the inspectors on-side because there was a grant for almost everything you did. My dairy inspector was a formidable lady in her 50s. She was very concerned about our water in our garden. Our best water was in a well in our garden. I chucked a bucket full of hypochlorite in there the day before she took a sample. She was very keen to know where all our drains ran and one day our wanderings took us up to a fence. I suggested that we return to the gate, but she insisted on climbing over. She got her knickers caught

on the barbed wire and made me unhook her.

I wanted a 3:6 abreast parlour, but she tried to talk me in to a 4:8 herringbone. I said I wanted 30 cows, but what I really wanted was 100. I got there after about two years: 100 cows on 80 acres.

I got there because I fed lots of barley straw and cake in winter. By now I had a bulk tank and the tank was full (200 gallons) and I was putting seven churns (70 gallons) on the communal churn stand in the village.

There were three others using that stand, but my seven churns were more than theirs altogether. That’s how it worked in those days; if you produced it, the Milk Marketing Board had to buy it and do something with it.

Lots of things happened beyond my control that set me back. Going brucellosis-free decimated my herd and took me back towards my original 30 cows.

When milk quotas arrived in 1984, I was selling 650,000 litres, but was given a quota of 300,000 litres. I was advised not to appeal as it might be reduced even further. I would appeal now.

Now we have TB chipping away at our industry. The irritating thing is that when I was at school we were getting on top of TB

and, all those years later, we are in a worse place.

All of that is down to politicians, who over the years have made bad decisions. It’s politicians like them who are telling us how to run the countryside now.

There used to be a feature in DF called ‘Cowmen Comment’. About six farmers would write a contribution every month.

One of the regular writers stepped down and the readers were to elect a replacement.

I decided to enter; there were about 30 of us. I won easily, I had six votes; one of those votes was mine and one was my mother’s.

The editor came out to see me and I was away. It was to be life-changing for me. In those early days we had to send our contributions in by post and fax was a big step forward, whereas now it’s email and much easier.

One day, in 2000, they phoned up to say that we had to go to a big dinner in London. I said

I am selling to the second and even third owner.

Bizarrely, small portable milking machines have become a major business for us, which we fell into by accident but now have a strong brand of ‘Gibson’ milking machines selling to hobby farmers, smallholders and city back garden house cow owners right across Europe. I didn’t like going to London and that I certainly wouldn’t go just for a dinner.

They phoned again in 10 minutes to say that, unbeknown to me, they had entered me in a competition, I had made it to the last six, DF had booked a table and I had to go.

The whole magazine industry would be there, the dinner was in the Grosvenor Hotel and it would be attended by 1,500 people.

The morning of the dinner, the phone was hot. They said to me: “You do know that it’s black tie tonight.” I replied ‘yes’ and 10 minutes later they were back on the phone asking if I knew what black tie meant.

Just to teach them a lesson I convinced them that I didn’t have any black shoes and one of the editors brought her husband’s black shoes to London.

I was entered in the Columnist of the Year category, I can remember that also in the final six were two doctors who wrote in The Lancet.

To cut a long story a bit shorter, the dairy farmer won and we had too much to drink on our table. Jonathon Ross was compere for the evening and he has trouble saying the letter ‘r’, they come out as a ‘w’. He said: “Well done Woger.”

A complete business restructure saved Mossgiel Farm from certain closure, and farm owner Bryce Cunningham is now on a mission to show that big is not always best. Chris McCullough reports.

Sco ish dairy farmer

Bryce Cunningham was forced to make radical changes to the business plan at the family-owned Mossgiel Farm, Aryshire, in 2015, as it was losing cash and on the brink of collapse.

Bryce and his wife Ashlea married in 2021, they share four children aged from four to 11 years old and together they run Mossgiel Farm. e farm was originally established in 1948 by Bryce’s grandfather with just 20 cows. By 2015, the herd had expanded to 150 cows, but it was a year that was set to test Bryce’s resilience.

“Dad was diagnosed with terminal cancer, so I Ie my job as

a mechanic at Mercedes and came home to take over the farm,” says Bryce.

“Both my father and grandfather died the next year, and if that was not bad enough, the milk price crashed. We ended up with milk at 9ppl and subsequently the farm lost £150,000 in my rst year of farming. is then prompted the bank to basically pull out. I knew radical changes had to be made in order to survive.”

It was then that Bryce decided to return to more a traditional way of dairy farming similar to how it was in his grandfather’s time, with less cows and selling milk direct to consumers.

With that bold decision also came the management change to switch

to organic farming, which opened up a new market for milk at premium prices.

Now Bryce wants to challenge the status quo of dairy farming by proving big herds are not the only way to make money from milk.

Today, the herd has 45 Ayrshire cows in total, but Bryce also buys in milk from ve other organic farmers to produce milk and other products in the farm’s processing plant, which are then delivered all over Scotland.

“Most of the milk we sell comes from those ve other farmers,” says Bryce.

“ ey are part of the Organic Herd Co-operative and we buy the milk from there, then process it all at our dairy based on-farm.

“From there, it is delivered all over Scotland to a portfolio of customers including the City of Glasgow College and 100 schools in East Ayrshire, as well as cafes, restaurants and doorstep deliveries to people’s homes. If we have too much liquid milk at any point then that surplus is made into cheese and sold under the organic brand.

“We sell 33,000-38,000 litres per