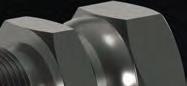

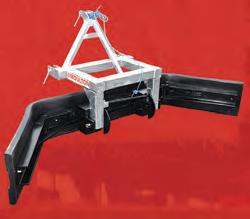

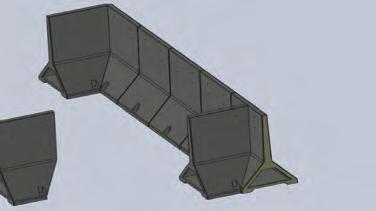

FLEXCARE V 6200 0% Finance available

FLEXCARE row crop cultivators with working widths of 4.70, 6.20 and 9.20 metres

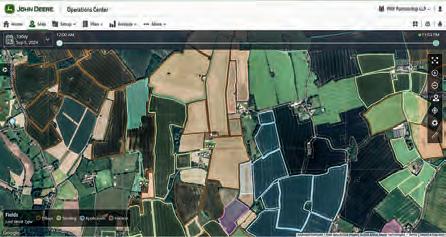

The best working results due to precision settings with optional Section Control

Easy adjustment of hoe elements, weeding blades and all settings without the need for tools

Modular design of hoe elements for di erent crops and row widths between 25 and 160 cm

Integrated hydraulic shift frame for absolute precision

PÖTTINGER Finance available to business users only, subject to terms and conditions. Details upon request. Authorised and regulated by the Financial Conduct Authority only in respect of agreements regulated by the Consumer Credit Act 1974.

Alois POTTINGER UK Ltd, T: 01536 272220, info@pottinger.uk, www.pottinger.uk

With the Farmers Guide team

Machinery editor Neale Byart spent a day with the team at Claydon this month, at the company's Wickhambrook HQ, to see the latest drilling and moling machinery in action.

Pictured (l-r) are Neale Byart, Claydon CEO Je Claydon, and Claydon commercial director, Spencer Claydon. Turn to page 47 to read Neale's in-depth report .

Find out what exciting new products were revealed on page 41.

A man left work one Friday afternoon, and decided to spend the weekend drinking and playing golf with the lads, instead of going home.

When he nally returned home late on the Sunday afternoon, he was confronted by his very angry wife.

After shouting at him for around an hour, she nally asked: “How would you like it if you didn’t see me for two or three days?”

To which the husband replied: “That would be ne with me.”

Monday went by, and he didn’t see his wife.

Tuesday went by, and he didn’t see his wife.

Wednesday came and went, and he still didn’t see her.

Finally on Thursday, the swelling had gone down enough that he could just about see her out of the corner of his eye.

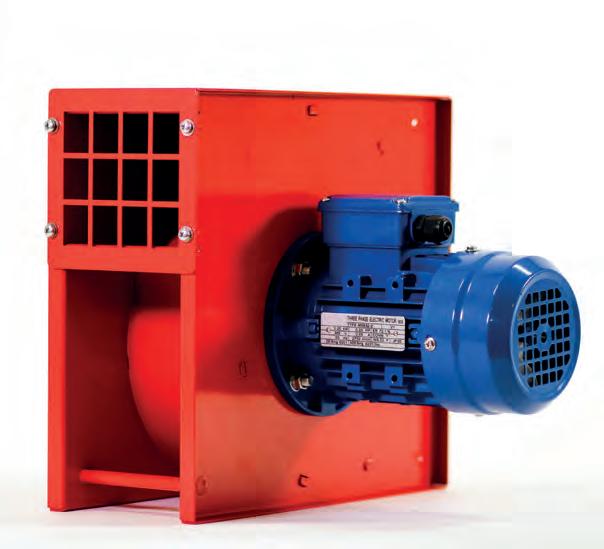

XSplit- the ultimate separation solution

XSplit -

Separating makes slurry handling much easier and significantly reduces the amount of slurry needing to be stored. Vogelsang’s XSplit slurry separator can produce solids of up to 40% dry matter, making liquid slurry much easier to apply during spreading season.

Get in touch to arrange a demo today.

VOGELSANG – LEADING IN TECHNOLOGY

Contact us at: 01270 216 600 | sales.uk@vogelsang.info vogelsang.co.uk

Cover crops protect and enhance the soil when a cash crop is not growing; but they can also boost your pro ts if thought and planning is put into the process, writes Open eld environmental technical advisor, Delyth Gilman.

Cover crops are fast growing plants – often legumes, grasses, brassicas and cereals – that are planted after a cash crop to bring a plethora of environmental bene ts. Aside from the obvious bene ts of improving soil structure, preventing soil erosion, conserving soil moisture

and protecting water quality, they also feed many types of soil organisms and help increase soil organic matter content and the number of earthworms, especially if combined with no-till.

Selecting the right cover crop mixture for your farm requires planning if you want to maximise the potential bene ts. As Gemma King, Open eld fertiliser trader, mentions in her update later, soil testing should be your rst port of call to determine the foundation, not just to bene t your main cash crop but also to determine which cover crop to sow to help make up any shortfall in soil indices. For example, buckwheat can increase phosphate mobility in the soil, legumes x nitrogen and mustard act as a biofumigant as a method of pest control. Incorporating deep rooted varieties into your mix can also help increase soil organisms and organic matter and break down compaction.

A mixture of di erent species will enhance the bene ts to the soil and the environment, but consideration must also be given to the crop rotation for disease and pest carryover into the next cash crop. Legumes can be an issue where there are peas or beans in the rotation; some brassicas can increase clubroot and slug risk in oilseed rape; and some clovers and small grains can increase wireworm risk in potatoes.

Cover cropping enhances the overall resilience of a farming system through reducing the need for synthetic fertiliser and pesticides, making it an important component of sustainable agriculture. The Sustainable Farming Incentive also o ers payments for spring, summer and winter multispecies cover crops, making establishing them even more appealing.

If you’ve recently completed crop removal, now is the perfect time to sample your soil and set the foundations for your next crop, writes Open eld fertiliser trader Gemma King. Soil sampling is a cost-e ective method to gain a comprehensive understanding of your soil’s health, especially after nutrient o take during harvest. It identi es nutrient de ciencies or surpluses, showing current indices and o ering recommendations to correct or maintain them.

A key aspect of soil sampling is assessing soil pH. Recent data shows that nearly 40% of UK arable soils tested in 2023 had below optimal pH levels. Having below optimal soil pH levels would limit nutrient availability, reduce yield, and cause nancial implications. Testing pH helps determine if lime application is needed to correct these issues.

Soil sampling also ne-tunes your fertiliser strategy and complements other tools like grain nutrient analysis, providing a complete picture of soil health. Additionally, it ensures compliance with the Farming Rules for Water and Sustainable Farming Incentive requirements, optimises nutrient management, and boosts yields by maximising nutrient uptake, leading to better overall crop and soil performance. FG

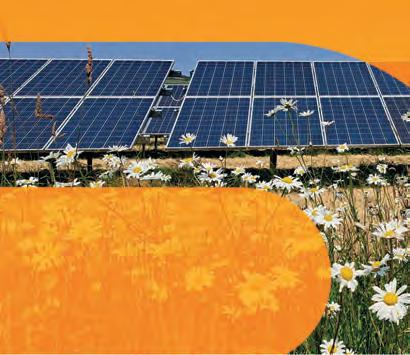

Noventum Power Limited is one of the leading large-scale renewable energy companies in the UK

We

We will work with you, helping you towards developing your land into an income generating asset that can provide additional income streams for your business.

The benefits include:

• Diversifying revenue streams away from farming or other land uses

• Deploying solar power or wind turbines on your available land

• Maintaining agricultural use through sheep grazing when possible

We are looking for sites between 50 acres and 200 acres, ideally close to a nearby grid connection

Land should be relatively flat and Grade 3 or lower

Well screened by hedges and a good distance from residential property

Not in a valued landscape or near historic buildings

We have a team of experienced, highly proficient renewable energy experts. They have an extensive record which encompasses the following:

Land Acquisition

Investment

Construction

Energy Storage

Planning and Permitting Grid Solutions

Power Engineering & Grid Connections

Operation and Maintenance

If

SPONSORED BY Merit Inspection Services

There are two versions of MeritAgCheck available – Essential and Premium. Essential allows for daily checks of commonly used machinery and the ability to monitor defects. Premium starts at £7.90 per month for three users and gives you access to over 2,000 customisable checklists and the ability to add servicing, maintenance or inspections with the capability to link all of this via machine QR codes. MyFuel enables you to take control of your fuel and record usage across your machinery and other assets, identifying valuable trends and supporting you to make data driven decisions.

Following a trailer brake test, you can record your trailer brake reports and re-test dates, meaning that you can continually monitor trailer and machinery safety across your site, giving you full con dence in your operations.

Merit Inspection Solutions specialises in trailer brake testing for farms, estates and agri businesses. Its goal is to save lives and reduce the risk of serious injury through ensuring your trailers have safe and e cient brakes that have been thoroughly tested.

Merit o ers a high-quality mobile rolling road for onsite trailer brake testing at the location of your choice. The company says its leading technology provides detailed data and insights on the braking e ciency of each wheel on every axle.

Testing your trailer brakes ensures you can optimise braking performance, fuel e ciency and overall safety, while reducing any dependencies on tractor brakes, saving you money on servicing and maintenance. Merit tests up to 20 trailers in one day and o ers a xed day rate for clients with multiple trailers, or can o er a shared testing day at one location for those interested in running trailer brake testing with neighbours.

For any trailers that fail, many defects can be easily targeted and recti ed on the day. The

Merit Inspection Services shares advice on legal requirements, findings from testing data, and its range of solutions.

company provides you with proactive advice to support you in making your trailers safe and optimising their performance. There may be time to reinspect failed trailers during the same day of testing where remedial work is completed, or Merit can arrange follow-up days to conduct regular retesting as required.

Following each test day, the company provides online and hard copy reports and will arrange the scheduling of further trailer brake testing to meet your business and safety needs, saving you time and money.

The importance of undertaking regular trailer and machinery checks to document compliance and manage defects cannot be overstated. As part of Merit’s trailer brake testing service, customers bene t from access to MeritAgCheck, the UK’s farm machinery app. MeritAgCheck enables you to maintain the safe and e cient operation of all machinery on your farm, estate or agri site through the touch of a button.

You are legally required to test your trailer brakes. The Road Vehicle Regulations, 1986, and the Provision and Use of Work Equipment Regulations (PUWER), 1998, contain provisions requiring tractors and trailers, including braking safety, to be properly maintained and regularly assessed as safe for use. Further, you cannot rely on visual inspections and servicing to determine whether your trailers are safe for the road.

Using data collected from Merit Inspection trailer brake tests up to the end of 2023, a total of 62% of trailers tested were not safe to go above 25mph or 40kph. 16% of the trailers tested were deemed unsafe for use at any speed and couldn’t be used due to the risks associated with brake failure and overall poor braking e ciency. This included brand new trailers. Failed trailers also create a serious strain on tractor brakes which can cost signi cant amounts to replace early. In most cases, trailers that failed required simple remedial work and a same day retest before they could operate safely.

Merit has collected valuable trailer brake test data and insights covering a range of manufacturers and suppliers, and o ers initial advice as part of any trailer brake testing day. Its trained trailer brake test operators work closely with you to ensure that a robust and thorough process is followed during each testing session.

Contact Merit Inspection Solutions directly to book your trailer brake testing or nd out more. Download the MeritAgCheck app by visiting www. meritcheck.co.uk/meritagcheck or call Merit to book a free demo and overview session to explore the app. FG

Kubota (UK) has extended its range of Kubota Care tractor warranty and aftercare packages to include 1,000 hours of servicing with all new M7003 models purchased before 31st December 2024.

This latest promotion,

alongside 0% nance and a ve-year manufacturer’s warranty, contributes to lowering the total cost of ownership for those customers looking to make the change to a Kubota M7003 tractor.

This latest aftercare o er is also available with dealer demonstrator M7003 models and applies to the balance on any servicing up to, and including, the 1,000-hour service.

Kubota Care is an extended warranty scheme that is backed by Kubota, and is not a third-party insurance policy. As such, Kubota Care does not require customers to pay an excess for any warranty claims that may arise.

In addition, any unused Kubota Care warranty is also transferrable with the tractor when supported by full service history from the Kubota dealer network.

David Leaper, technical manager for oilseeds with Agrii, commented on the performance in Agrii trials of NPZ UK variety Vegas which has done consistently well in Agrii trials over the past three years. It was selected into the portfolio because of its good disease resistance and exceptional late season stem health seen in all of the NPZ UK varieties.

“Vegas bene ts from a rapid spring growth habit that helps mitigate the e ects of CSFB larvae that still pose

a huge risk to UK growers especially in earlier sown crops.

“Agrii are also supporting Vegas with an excellent establishment scheme.

“Furthermore, Vegas was a top yielding-variety in AHDB Recommended List trials this year when it was compared, for the rst time, with the best new candidates coming through the RL system.

“NPZ UK’s Maverick is similar to Vegas and bene ts from additional TuYV resistance that has proven popular with growers across

the UK. It has performed exceptionally well in Agrii trials and had highest yields of any variety over the past two years.”

NPZ UK managing director, Chris Guest notes that when it comes to late drilling, variety choice is key: “The prerequisite is to choose hybrid varieties, and all NPZ UK oilseed rapes are hybrids – with both Vegas and Maverick very good in this slot. They are quick to get going with good autumn vigour added to strong spring re-growth.”

Blaney Agri says its Forager X10 and Bale Feeder X6 bale unrollers, designed and manufactured in the UK, are set to revolutionise bale feeding.

The Forager X10 was developed based on the challenges facing farmers. Designed for maximum e ciency, it o ers a one-man, one-tractor operation that feeds out silage in seconds. Its compact design is perfect

for navigating tight spaces, and its ability to feed out both sides ensures that every bale is used to its fullest potential. It e ortlessly handles all bale types (wet, misshapen, or tightly packed). Farmers have reported up to 20% reduction in bale waste.

The Bale Feeder X6 is ideal for those who don’t require all the advanced features of the X10. It’s perfect for feeding

round bales in favourable conditions, o ering a fast, e ective solution.

Visit www.blaneyagri.com or follow #BlaneyCommunity on social media.

Family-owned agricultural machinery manufacturer Claydon Yield-o-Meter Ltd in Su olk has been shortlisted for a British Chamber of Commerce Global Britain Award. These recognise the achievements of businesses which are trading with the world in a successful, innovative way and helping to create a Global Britain.

The company was founded in 1981 by Je Claydon, who with his brother Frank has farmed at Wickhambrook since 1970, to manufacture a revolutionary product which Je had designed. Supported by a £267,400 Growing Business Fund Grant from the New Anglia Local Enterprise Partnership (NALEP), the project has helped the 43-year-old company to meet an exponential increase in orders from UK and overseas customers. These have continued to grow as the business has worked with its expanding dealer and distributor network to develop sales in existing and new markets.

“The role of machine technology will grow signi cantly in the future and Claydon will continue to move forward,” Je Claydon says. “Our latest drills incorporate the ability to place crops, companion crops, fertilisers and crop protection products in one pass to help the farming industry meet the challenges which it will face in the future.”

British Sugar has shared details of the campaign start dates for each of its four factories. The factory beet intake opens on the following dates:

• Bury St Edmunds – 16th September

• Wissington – 16th September

• Newark – 23rd September

• Cantley – 7th October.

Sugar beet growers, hauliers and industry partners have been advised of beet intake times at the factories by email and via British Sugar’s online portal, My British Sugar.

Growers and industry partners can get in touch with their British Sugar agriculture manager or call British Sugar Services if they have any queries, at this stage or as the campaign progresses.

Dan Green, British Sugar’s agriculture director said: “As we look ahead to this year’s campaign, we look forward to working together with growers, harvesters and hauliers. We’d like to wish everyone across the British beet sugar industry all the best for a safe and successful campaign.”

• High street banks unsupportive

• Tenant farmers welcome

Please ring George Bridgman on 07522 731193 or email george.bridgman@abfltd.co.uk or apply on line at www.abfltd.co.uk

A £7.5M combined investment from Origin Fertilisers and the Port of Tyne in a new fertiliser facility will o er improved fertiliser access and supply to customers across the Borders, Northern England and Southern Scotland for the 2024/25 crop year and beyond.

The project on the Port of Tyne site for a dedicated 6,000m2 fertiliser warehouse will allow Origin to produce and store in excess of 100,000 tonnes of product to support farmers and growers across the region, o ering better access to the right crop nutrition.

Origin’s managing director, Michael Pater, says the investment is signi cant for the region. “This major investment provides us with a new site in north-east England complementing existing facilities in Silloth, Immingham,

Ayr and Montrose. The facility is located port-side and gives direct access to deep sea vessels, which will be a major improvement to the region in accessing raw materials from further a eld, providing a wider range of product sourcing and competitive pricing. It will allow us to meet the growing need for prescription fertilisers in the area, while simplifying supply and logistics of fertiliser for many customers.”

Completion of the site is planned for early October.

A project which started in late August is aimed at improving management of cabbage stem ea beetles (CSFB) which are the primary cause for the dramatic reduction in the area of UK OSR crops over the last decade.

AHDB has contracted NIAB to monitor migration of the adult insects from August–October and larval invasion from September–October, at sites across England. The information obtained will be made available to farmers

during the 2024–25 growing season – and it may also be used for research.

To monitor adult CSFBs, yellow water traps will be used at ground level and at a height of one metre at seven sites across England. At all locations, a Bayer MagicTrap (new to the UK), which photographs beetles caught in the trap, uses image analysis to identify and count CSFB, and transmits information remotely, will be used as well as the yellow water traps. Weather data will

also be recorded.

At the end of the project, a full dataset will be available, including adult CSFB numbers for each trap, larval scar assessments, weather data, assessment dates, location information and agronomic information such as dates of eld operations (e.g. harvest, cultivations, drilling), pesticide usage, methods of cultivation and information on other CSFB management approaches used in the eld, such as companion crops.

A Derbyshire broiler unit has been launched for sale by Carter Jonas – the third sizeable farm of its type to be sold in the past 12 months.

Dovelowe Farm in Ashbourne is an awardwinning poultry unit capable of housing up to 84,000 birds, with a guide price of £1.1M. “With people travelling across the country for viewings, we expect interest in Dovelowe

Farm to be high,” says Edward Beale, associate partner at Carter Jonas.

“Feedback so far has been that it’s in great condition for its age. The unit comprises four poultry growing sheds along with ancillary buildings for water, power generation and sta welfare facilities. All poultry rearing equipment along with the biomass boilers will be available to the buyer.”

In addition to the productive poultry unit, the site also includes a bungalow and two biomass boilers.

The boilers provide heat for the poultry sheds, generating around £50,000 per year in RHI. There is also the possibility of purchasing two further biomass boilers by separate negotiation.

To view Dovelowe Farm contact Carter Jonas.

Ernest Doe & Sons Ltd has announced the successful acquisition of The Burdens Group Limited’s southern Lincolnshire branches, located in Sutterton and North Kyme. This acquisition was facilitated through the appointed administrators at Begbies Traynor (Central) LLP, following The Burdens Group’s entry into administration.

“We are thrilled to welcome the Sutterton and North Kyme branches into the Ernest Doe family,” said managing director, Angus Doe. “Our focus is on maintaining the strong customer relationships cultivated by The Burdens Group, while introducing the high standards of quality and service that have de ned Ernest Doe & Sons for over 125 years. We look forward to serving the local community and supporting our new customers with the expertise and dedication that our longstanding customers have come to rely on.”

The number of agricultural tractors being registered in the UK remained lower than normal in August. The month typically sees reduced numbers, as farmers are occupied with harvest and related activities. The challenges of the past 12 months, both with the weather and the nancial situation for some farm businesses, meant the decline was bigger than usual this year. At 495 machines, the monthly gure was over 30% lower than for August 2023. It was also less than two-thirds of the average number logged in August over the previous ve years. The total of 7,325 agricultural tractors registered during the year to date was 15% fewer than in the opening eight months of last year and the lowest for four years.

Month: 495 units – 30.7% change (compared with August 2023)

Year to date: 7,325 units – 14.7% change (compared with January–August 2023

The application of microgranular or liquid placement fertilisers close to seed at drilling can help mitigate this lack of mobility and o er signi cant bene ts to early establishment, with far greater uptake e ciency than seedbed applied products – which can be as low as 10%.

“We’re placing a small amount of phosphate right near the seed just to get it o to a start. Once it starts putting down roots itself, these release root exudates, which we know help kick-start nutrient cycling, releasing more phosphate.”

Microgranular fertilisers by their nature are small, but are incredibly e cient, so much less product is required than with seedbed applied products – typically 10–20kg/ha compared with nearer 100kg/ha for TSP in some cases.

“Admittedly, not every farm has the kit to apply placement fertiliser, which is a challenge, but the number is increasing, and growers will de nitely see the bene ts.”

Establishing a strong rooting system is fundamental to the resilience of all crops. Farmers Guide seeks expert advice on how best to achieve this through targeted soil nutrition.

When it comes to autumn nutrition, the starting point, as with so many aspects of crop agronomy, is to fully understand the soils on your farm, says Hutchinsons development manager, Jennie Watson.

“Nutrition and soils are so closely interlinked; we need a thorough understanding of the condition of soils to highlight any limiting factors and show where to focus our attention for nutrition over the season ahead.

“So often we’re talking about making use of nutrition that’s already in the soil, but unfortunately for whatever reason, may not be available to the plant. That can be for various reasons, from the chemistry causing nutrient lock-up, to an imbalance in soil biology, or physical structural issues preventing roots from getting down to where nutrients are. Our focus is on understanding how we can support plants to access that nutrition and make the most of anything else that’s applied.”

Autumn is a good time to assess soils, providing they are warm with su cient moisture, and there are some simple visual tests growers can do themselves. But Ms Watson believes it is worth investing in more detailed analysis of physical, chemical and biological soil properties, such as through the Healthy Soils Gold test or Terramap Gold, to fully understand the complex interactions involved.

The Gold test, for example, includes an assessment of total nutrition in the soil, and what is available to plants, to allow a much more meaningful discussion around nutrition programmes.

“You won’t be able to act on everything that detailed analysis shows in one season, but it could help hone-in and prioritise the points you need to focus on. It all comes back to the principle of ‘measure to manage’. If we aren’t monitoring things, how do we know if we are moving forward or not?”

The cost is generally far outweighed by the potential bene ts from improved nutrient use e ciency, fertiliser savings, and crop output, she adds.

Placement fertiliser benefit

Access to phosphate is a core focus for autumn nutrition, as the nutrient is integral to root development, Ms Watson continues.

Although soil indices can often suggest there is su cient phosphate in soils, there can still be challenges in terms of plant availability given phosphate’s limited mobility and tendency to become complexed (locked-up) by other elements, such as calcium, iron or aluminium.

“Phosphate is so immobile, just putting it on the surface and expecting it to get to where it’s needed, just doesn’t work.”

The bene ts from placement phosphate for kick-starting root development can be further enhanced with the use of phosphite-based biostimulants to build root biomass in the autumn, says Ms Watson.

“Last year we saw some clear bene ts from using phosphites in the autumn to help late-sown plants struggling to root because of the conditions. This year, we could be looking at a di erent scenario of earlier drilling, but there could still be a bene t from building root biomass to support a potentially bigger crop canopy.

“Roots are so fundamental to accessing nutrition and supporting the development of plant biomass throughout the season, there’s a really good case for using phosphites.”

Phosphites are not a plant food in the same way as phosphate, she adds. “Phosphites act as a biostimulant, upregulating plant processes, increasing root growth and associated root exudates, which support the release and uptake of nutrition in the soil.

“There will still be a need to come back in the spring to provide nitrogen and the other nutrition that plants need, but in terms of supporting autumn growth, the focus is very much on kickstarting rooting and nutrient cycling.”

Finally, soil pH is a simple, but fundamental, factor to consider when planning crop nutrition, as it has such a big in uence on the availability of many nutrients.

In acidic soils, for example, aluminium and manganese can become more available, potentially causing toxicity issues, while calcium, phosphorus, and magnesium are less available.

Most growers rectify low pH with lime post-harvest ahead of drilling, sequenced with cultivations to get the lime acting in the top layer of soil rather than waiting for worm activity to take it down.

However, Ms Watson says it is possible to still apply lime after drilling through to the spring, up to the point where any bene ts are outweighed by risks of damaging the growing crop. “Knowing your pH is crucial for optimising nutrition,” she concludes. FG

With over 18,000 diferent grades, our sites can meet all your prescription needs by matching fertiliser to soil and crop requirement.

l No excess nutrient =

l No defciency = l No compromise = saves money and protects the environment improves yield and soil fertility exact match to your soil sample results and crop need

Talk to us about prescription nutrition t: 03333 239 230 e: enquiries@originfertilisers.co.uk www.originfertilisers.co.uk

A detailed soil analysis can help growers make informed decisions about nutrition plans next season, and undertaking this before committing to fertiliser purchases should be a top priority.

That’s the view of Toby Ward, nutrition agronomist at Origin Fertilisers, who says using insight gained from detailed soil data can help guide prescription nutrition requirements and build a solid plan for next spring and beyond.

He comments: “We can only recommend prescription nutrition by understanding where de ciencies lie in the soil. Just applying the same fertiliser as before isn’t going to improve the nutrient synergy and increase yield or quality, with these factors always limited by the most de cient nutrient.

“A broad-spectrum soil analysis, rather than just analysis of the main nutrients, will provide the required information to build a comprehensive nutrient programme.”

A detailed soil nutrient breakdown can also be used alongside other tests to assess where nutrition is required for future seasons. Toby says a grain nutrient analysis can inform where the largest nutrient o takes have occurred.

“Soil analysis tells us what we think is going to happen, leaf analysis is a live account of how the crop is accessing the nutrients and if there is anything that needs changing during the season, while a nal grain nutrient analysis enables us to accurately determine the speci c nutrient o -take from the crop.”

With these three data sets, growers can assess if their current fertiliser

plans are accounting for nutrient de ciencies or, if matching the data to the nutrition, can provide the crops with everything they require. Origin’s Nutri-Match service can blend up to 14 di erent nutrients into speci c formulations to create bespoke blends based on requirements.

Toby says this is becoming a popular option for growers looking at crop nutrition in greater detail.

“If growers have the data, then why wouldn’t they maximise it and address the issues through prescription nutrition? Blended fertilisers allow growers more options to address soil nutrition requirements, providing the crop with everything it requires to improve yield and quality.”

Additional micronutrients can help create a balance within the soil pro le. This will enable farmers to be proactive, rather than reactive, during the growing season by identifying de cient micronutrients at the beginning of the year and applying them in time for the crop to use.

“A crop that’s de cient in a micronutrient, such as copper or molybdenum, can mean that valuable yield potential has been lost before it emerges. Providing a curative measure at the start of the season to feed the ‘hidden hunger’ gap, rather than waiting for the crop to show a de ciency, means the yield potential won’t be limited and soil health will be improved,” concludes Toby. FG

Increase Nitrogen & Phosphate uptake by 30% over the Autumn period.

+ Key nutrients boost root establishment

+ Reduce nutrient losses over winter

+ Increase yield, quality & profts

+ Apply at planting as a standalone product

+ Incorporate as a blend with your usual autumn regime Polysulphate is organically approved by

ICL has reduced the carbon footprint of its naturally occurring Polysulphate multi-nutrient fertiliser by around 90% in the last five years.

This is as a result of production e ciency improvements and infrastructure changes at ICL’s Boulby Mine in North Yorkshire. Polysulphate is already recognised as a low carbon fertiliser, but the latest reduction to 0.0029kg CO2e per kg of product reduces this gure to almost zero and o ers even greater opportunities for farmers and the wider supply chain to decarbonise agriculture, says Richard Ward.

“This reduction demonstrates ICL’s ongoing commitment to playing a key role in a food and farming industry that is increasingly focused on meeting sustainability and carbon targets.

“Traditionally manufactured sulphur fertilisers, now all imported into the UK and combining both nitrogen and sulphur, are increasingly under the spotlight as major carbon contributors in the food supply chain.

“But with UK produced Polysulphate containing no nitrogen, far more accurate management of

both N and S can be achieved which, along with the product’s exceptionally low carbon footprint and other e ciency gains, allows much more sustainable production.

“In fact, a recent paper by Prof. David Powlson, Emeritus scientist at Rothamsted Research, concluded that if all the UK’s ammonium sulphate was replaced with Polysulphate, the ammonia emissions associated with sulphur fertiliser applications would be cut by over 90%.”

Global crop trials conclude that Polysulphate also delivers economic gains for farmers by improving crop yield and quality due to its high e ciency, Richard Ward explains.

“The growing number of farmers using Polysulphate already appreciate the nutritional bene ts of the product (48% SO3, 14% K2O, 17% CaO and 6% MgO) help drive nitrogen use e ciency (NUE) in crops, from

both mineral nitrogen fertilisers or organic sources.

“Furthermore, its prolonged release characteristics also help reduce potential losses of valuable nutrients into water and air, improving both the e ciency with which plants take these up and reducing possible environmental issues.”

Trials have shown these e ciency improvements translate into sizeable economic gains for growers, he points out. “We’ve seen average yield increases of 10–11% on grassland and arable crops alongside better establishment and root development. Oilseed rape and other brassica crops have shown average yield improvements of 12–15% with this rising to 35–40% on sulphur de cient soils.

“In potato and other vegetable crops, average yield gains of 12–15% and signi cant quality bene ts have been reported.

“The bene ts of Polysulphate are already being recognised by many growers, agricultural advisers and the wider food supply chain, with thousands of farmers now using the product. In fact, ICL Boulby set a new record of one million tonnes of Polysulphate produced in 2023 for distribution worldwide.”

According to ICL UK VP and general manager Grahame Wallace, the reduction in carbon footprint of Polysulphate is the result of an ongoing program of energy improvements at ICL’s Boulby Mine.

“The recent achievement of ISO 50001 accreditation for the site recognises that the site has established a comprehensive structure for energy management with the focus on continual improvement,” he points out.

“Since the last carbon footprint calculation in 2019 we have introduced numerous changes including changing

to fully renewable electricity in 2023 and removal of the combined heat and power plants (CHP).

“We’ve also made considerable strides forward in reducing our use of diesel and introduced a range of e ciency improvements across the site and our operational processes.

“Virtually all areas of the business having risen to the challenge of identifying ways in which our carbon footprint could be improved.

“It is, however, very much an ongoing process. The recent carbon footprint evaluation has brought new vigour to the team by highlighting the success of what we have achieved whilst also providing focus on areas of improvement that we will be targeting in 2024. These include replacement of air compressors across the site to provide a more energy e cient supply of compressed air.

“It doesn’t end there as there are numerous projects under consideration that will drive the carbon footprint of Polysulphate down even further with the ultimate aspiration of achieving net zero!”

An autumn application of Polysulphate to supplement conventional spring timings can increase wheat yields by 0.3t/ha trials suggest.

Better nutrient utilisation e ciency and increased root development are the main reasons behind the highly cost-e ective bene ts, says ICL agronomist Scott Garnett.

“Previous trials have shown a 5–8% increase in yields from spring-applied Polysulphate by itself, with three years of trials showing an average yield of 10.49t/ha. But when this was preceded by an autumn application of Polysulphate, an average yield of 10.79t/ha was seen alongside signi cant environmental bene ts.” FG

We’ve kept your fields clean and our boots muddy since 1962.

To find out more visit our website uk.gowanco.com

Integrating biosolutions into conventional agronomy programmes can boost both disease control and crop margins, latest Agrii trials are suggesting.

While in some cases, biosolutions by themselves have o ered the same control as moderate fungicide approaches, integrating them into reduced programmes has produced the same results as full-strength conventional treatments.

“It’s time to take biosolutions seriously,” says Agrii technical manager, Jodie Littleford. “For a start, there are fewer new active ingredients coming to market and all are facing tougher regulatory hurdles.

“Then there’s the fact that across the food supply chain, pressure is growing for greater sustainability and lower carbon footprints of production, with reductions in synthetic inputs seen as a key element of this.

“But we know biological solutions don’t perform in the same way as traditional chemistry, so it’s critical we understand how we can best target their use and support them appropriately in integrated strategies.”

“With changing climatic conditions, there’s an even greater need to focus on crop resilience and stress mitigation and evaluate where biosolutions can contribute to these.”

In challenging conditions and high disease pressure situations, some approaches in particular have stood out from the others, she says.

“Products related to building crop resilience, like elicitors boosting the plants’ hyper sensitive response, have shown particularly positive results, especially when used alongside the right supportive elements.

“Generally, these products work best when they are applied ahead of disease, like a u vaccine administered before the illness takes hold. We are essentially giving the plant everything it needs to better prepare and initiate an immune response for when the pathogen does eventually arrive.”

Programmed approaches

Agrii’s approach is to focus on a wide range of biological products to validate their bene t in the rst instance before they are then looked at as part of programmed approaches, she explains.

“We can then stack these bene ts in a variety of ways so we can evaluate di erent strategies to realise their full potential with regard to plant health, resilience, disease suppression, yield, and ultimately, gross margins.

“Weather conditions over the last two seasons have highlighted just how di cult future disease control might be, but they have also provided vital insights into the promise biosolutions hold.

upregulating photosynthesis which in turn provides the plant with more energy and resources to thrive.”

Hence their e ectiveness does largely depend on when disease starts cycling in the crop, she points out.

“This isn’t necessarily a new concept when we think about current practices around protective applications of fungicides to get the best e cacy. Even now, if you’re in a situation where you’re having to re ght, then you’re far too late!

Marcus Palmer of MJP Supplies is giving 10 Farmers Guide readers the chance to use Algifol for a season free of charge.

Algifol is a concentrated brown algae gathered from the North Atlantic, dried and re ned to maximise its wealth of trace elements, vitamins, enzymes, amino acids, carbohydrates, polyuronides and growth-regulating plant hormones.

Marcus’ customers predominantly apply Algifol to cereals, potatoes, peas and sugar beet to improve yields and root establishment as well as increase resistance to stress caused by extreme weather conditions, such as droughts and prolonged heavy rainfall. Neomed Pharma says Algifol is also a natural nitrogen source due to the high presence of amino acids and peptides. This makes Algifol

The Agrii programme trials to date have basically adopted three levels of approach when it comes to biological products – a full biological approach, a 50% reduction in synthetic inputs and then a fully integrated approach supported with a good fungicide programme, she explains.

“These have then all been tested alongside more traditional approaches using di erent levels of fungicide input, with a range of very encouraging responses seen.

“Where we use biosolutions earlier on in the programme and before disease levels escalate, for example, we see a sustained reduction in septoria levels right through the season, even compared to full four spray fungicide programmes.

“In terms of yield and margin, all three approaches have generally been equivalent, if not better, than our standard fungicide programmes which indicates just how much biosolutions can contribute to crop performance success.”

“We’ve also seen encouraging trends resulting from the use of amino acids. These building blocks are utilised across a number of biochemical functions including protein synthesis, stress reduction and modulating stomatal opening.

“Biostimulation of these processes can enhance growth, nutrient cycling, help crops combat disease and improve productivity.”

Growth promoting compounds like PGA (pyroglutamic acid) and phosphite have also impressed.

“These enhance nutrient utilisation and e ciency, which improves rooting as well as

ideal for combined use with reduced amounts of N fertiliser. When used with a reduced amount of fertiliser, Algifol naturally improves the nitrogen use e ciency of the crop, producing a better yield and reducing the use of costly fertilisers.

“We have previously worked with the PGRO, and its eld trials on combining peas proved that the use of Algifol increases yields and reduces foot rot infection. We’ve also worked with agronomists to establish eld trials and show how using Algifol can increase yields and quality. Now, we’d like to extend this and work directly with farmers and show just how e ective Algifol can be,” says Marcus.

Readers wanting to participate in the project or requiring further information should visit www.mjpsupplies.co.uk FG

While all the trials to date have been eldbased, new developments at Agrii’s Throws Farm in Essex will allow the mode of action and integration of biosolutions to be looked at in much more detail, Jodie adds.

“The construction of a large environmentcontrolled glasshouse will allow us to remove much of the ‘noise’, such as weather, variable growing conditions and pests, from future trials. That is simply impossible to do in the eld.

“This means we can focus speci cally on what the biosolutions are actually doing and manage things like spray timings and crop nutrition much better.” FG

✓

✓

✓

As agricultural machines begin transporting root crops, industry groups have come together for a new campaign to ensure trailer safety.

The Tilly Pass has been working with other industry experts to create a safety group, ‘Root to Success’, to talk about the importance of root crop carting. Together they have created a trusted source of shared information covering all aspects of safe towing, giving farmers and contractors a clear understanding of essential requirements for operators and users to develop an up-to-date on-farm ‘safety portfolio’.

Members of the group shared some advice on safely transporting root crops this season.

Risk assessment: As our workplace changes with the seasons, it’s essential that new hazards are assessed. This could not be more relevant than at the start of the root crop season. Making a risk assessment around this or

indeed any hazard is an essential part of everyday agriculture, and the person making and sharing these must have the appropriate quali cations, knowledge and experience. This should then be part of every business’ safety portfolio.

The Health and Safety Executive for Northern Ireland said a safety portfolio is an essential part of farming in a professional and responsible way, for all farms, whatever the size.

Maintenance: Inspections and record keeping are required to meet the Provision and Use of Work Equipment Regs 1992 (PUWER) regulation 6 along with the new British Standard 14200/2023. The Tilly Pass Scheme is an accessible way of meeting these requirements with on farm inspection, service and central

trailer database; these documents can then be added to your safety portfolio.

Manufacturers’ daily checks: These should always be accessed, used and recorded – download the free safety app Head to Tow at tillypass.co.uk

Knowing your machine: Angus Western, managing director at Richard Western, advises: “You understand the capacity of the trailer you’re towing when you know the actual capacity of the wheel equipment. For professional farmers and contractors requiring a otation tyre, 26.5 rims would be the minimum.”

Load security: The DVSA published the revised version of the load security guidance in July 2023 with the requirement to sheet loose loads. This seems to have caused some issues, a load security spokesperson said. The requirement to do this was in the previous DFT code of practice, but DVSA made it more explicit in the update, due to some high-pro le incidents where people had lost their lives due to loads bouncing o the back of trailers.

“The fundamental requirement to sheet loose loads has not changed since a loose load does present a danger to other road users if the load is not restrained in some way.

“The only concession we will be making will be in circumstances when the load is assessed (by the user) to be sat su ciently low enough in the trailer, to the extent that it is secured by the structure of the vehicle, i.e. the vehicle’s sides, front and rear without the need to cover the load.”

DVSA said its examiners will continue to take action when they assess that the load, and the way it is secured (or not) presents a danger to other road users, irrespective of what a driver/operator risk assessment states.

General advice: Su olk Police stressed the importance of having a good understanding of the weights and speeds of your combination, good visibility around the vehicle, displaying a number plate, working lights and the appropriate use of an amber ashing beacon.

“Trailer weights are set at 18.29 tonnes with a tractor not exceeding 12.71 tonnes; this makes a combination of 31 tonnes train weight. A tractor and trailer should not tow faster than 25mph/40kph. [...] Trailers should be sheeted if fully loaded or su cient ullage so the load cannot fall. Items such as sugar beet can cause damage to vehicles or collisions from drivers swerving to avoid when falling o trailers,” a spokesperson said.

Cymru Farm Safety added that it’s important to remember to check the vehicle and trailer condition before use, from ATV to a larger tractor and trailer. All loads must be secured, from bales to feed.

The Farm Safety Foundation recently launched its new Little Book of Farm Safety (available on www. yellowwellies.org) which includes a special chapter on transport. Issues covered include trailer safety and trailer brakes. Given that moving vehicles have been the cause of an average of seven deaths every year on farms over the past ve years (HSE), trailers and their brakes should never be overlooked and must be given the same level of attention as the tractor itself.

Cymru Farm Safety concluded by saying: “Towing safely is everybody’s responsibility to ensure the safety of all road users. Dewch i ni gyd gwenud gwahaniaeth (let us all make a di erence).” FG

Further information:

• https://www.hseni.gov.uk/topic/ workplace-transport

• https://bit.ly/4eg8Gf0

Maximize your beet harvest with the Richard Western Beet Wellington trailer. Featuring advanced larger wheels and reduced operating pressure, this trailer ensures smoother towing, minimizes soil compaction, and reduces field damage—helping you harvest more efficiently this season.

2024 has favoured slugs, so control measures are of particular importance this autumn.

Encouraging natural predators such as ground beetles, birds, hedgehogs and frogs can be a a key part of an IPM strategy for managing slug populations. Field margins and beetle banks provide ideal habitats for predatory insects and carabids, while providing bird boxes, winter feeding areas, trees and hedgerows will improve overall farmland biodiversity.

Defra o ers the following advice for creating and maintaining beetle banks:

• Beetle banks are most e ective in elds over 20ha. Make the bank across the middle of the eld so invertebrates can spread out from the bank across the whole eld during the summer. In larger elds of 30–50ha, build 3–4 banks

spaced evenly across the eld

• If you’ll also use your beetle bank to control run-o and soil erosion, make it across the contour of the slope. Make sure the bank does not divert water which may cause problems somewhere else

• Make the bank during your normal cultivations in spring or autumn. It’s easiest to make the bank in the same direction as you cultivate

• Plough in opposite directions to make a raised bank at least 40cm above the normal level of the eld, and 3–5m wide

• Leave a gap at both ends of the bank where it meets the eld boundary or margin so that you can easily get machinery in and out

• You might need to spray with herbicide before sowing if weeds are present

• Sow a seed mix with 3–4 tussocky grass species plus 2–3 ner grasses and owers. Choose species suitable for your soil type and sow at the rate recommended by your seed supplier. In most cases a rate of around 20kg/ha should be suitable

• Broadcast (scatter) seed in a way

that will not damage the bank. You may be able to adapt existing equipment. You can use a fertiliser spreader driven alongside the bank, to broadcast seed on each side; use a slug pellet applicator towed along the bank by a quad; or broadcast by hand

• If you plan to sow in autumn, sow as early as possible into a warm, moist seedbed before poor weather sets in. If frost or prolonged wet weather is expected, leave sowing until the following spring

• A beetle bank takes about 2–3 years to establish. Check the bank regularly to make sure weeds don’t take over

• Cut several times in the rst summer to help grasses grow thickly. It’ll be hard for weeds to grow once grasses establish

• Birds, nests and eggs are protected by law. You must check the bank before cutting. If you see signs of nesting birds, delay cutting until birds edge

• After the rst year, do not cut the whole bank in one go. This will help protect populations of insects and other wildlife. FG

To ensure slug pellets are applied accurately and to achieve the optimum number of baiting points (40–50 pellets per m2), all spreading equipment should be calibrated in accordance with the machinery manufacturer’s recommendations to ensure they are producing an even and accurate spreading pattern.

In addition to regular calibration checks (prior to the start of the spreading season and before each subsequent application), all pellet spreading equipment should also be tested to the required standard to ensure it can spread the desired product over the declared working width in an even and uniform pattern: in order to comply with the NSTS (National Sprayer Testing Scheme) Sustainable Use Directive, all pesticide application equipment over ve years old should be tested every six years. If equipment is less than ve years old it needs to be tested by its fth anniversary, and then every six years thereafter.

The NSTS test includes

1. An inspection of the spreader prior to a tray test

2. A tray test to con rm working width and evenness of spread

3. An electronic report of the rest results.

As well as ensuring spreading equipment is correctly calibrated and tested, care should also be taken to ensure that it is positioned at an appropriate height for the machine on which it is mounted (usually 110cm for quad-mounted applicators).

Forward operating speed and aperture settings should also be considered to ensure pellets are applied at the correct rate, with the best practice considered to be a forward speed of no more than 12kph.

For more info about pesticide applicator calibration or to get your machine tested, go to www.nsts.org. uk or visit https://ahdb.org.uk/slugs to learn about integrated slug control. FG

Gusto Iron is a ready-to-use, pelleted bait containing 2.94% w/w anhydrous ferric phosphate. It is approved for use in a range of agricultural and horticultural crops and o ers the following key

bene ts:

A durable, persistent and palatable slug pellet for the control of all UK slug species

Rainproof and with impressive mould resistance

Excellent colour retention for easy detection

Uniform pellet size and density for accurate spreading to wide working widths

Optimum baiting points of 45 pellets per m2 when applied at a eld rate of 5kg/ha.

Late drilling poses unique challenges for wheat crops as soils cool down and become wetter, requiring careful management to ensure proper establishment, advises Ron Granger, technical manager for Limagrain Field Seeds UK.

Delayed or late drilling of winter wheat considered to be from mid-October onwards is now common practice particularly for black-grass management, in a second wheat situation and for those who are drilling wheat after sugar beet or potatoes.

Ron Granger points out that although most of the varieties on the AHDB Recommended List can be drilled in this later slot, it is important to make a distinction by choosing varieties that will cope well, rather than be challenged by the situation.

“Characteristics of wheats that suit this slot are strong tillering and vigorous, combined with good rooting attributes and a semi-prostrate growth habit in the winter. Get it wrong, and you could be facing substantial yield penalties – which are totally avoidable,” he explains.

“Crops drilled later will not have been in the ground as long as those drilled earlier in the autumn, so the chosen variety needs to be robust with a good tillering ability and quicker out of the blocks in the spring, once growing conditions are favourable.”

Mr Granger points out that this is especially important where there is black-grass as the variety needs to compete with the rapid growth of the black-grass rather than sit and tiller at to the ground where it will eventually be smothered.

In good conditions, target a seed rate of 375-400 seeds/m2 for the end of October increasing to 400–475 seeds/m2 at later drill dates, or in a black-grass or poor seedbed situation.

For these reasons Mr Granger recommends the old favourite LG Skyscraper, LG Redwald, and new variety from the LG Field Seeds portfolio, LG Beowulf for late drilling.

“We have seen very good results from LG Skyscraper both in trials and more importantly on farm over several years now delivering high yield potential and a good consistency of performance in this testing situation.

“Data from several seasons of work also suggests that taller wheats, such as LG Skyscraper are at an advantage in the later drilling scenario as larger plant canopies also play an important role in keeping black-grass ear numbers and seed return to the minimum,” he says.

“On this basis LG Redwald suits this late drilling situation very well – it’s a bit of a beast in the fact that it has a semi-erect plant type combined with a strong tillering ability and large biomass potential – it does de nitely give blackgrass a run for its money!”

Mr Granger believes one of the single most important factors in getting a late drilled crop o to a good start is using the correct seed rate.

“However, seed rates after the end of October are di cult to quantify, speci cally as they will be more determined by the seasonal weather and seedbed preparation at the time of drilling. To compensate for the impact on tillering, as a result of cooler temperatures and shorter days, seed rates need to be increased the later into the season the crop is drilled.”

Some varieties di er, he adds, citing the example, where LG Redwald appears to cope at lower seed rates due to its excellent tillering ability, inherited from its parent LG Sundance.

“LG Redwald has performed very well in the later drilling situation and has the ability to cope with less than favourable seed beds often encountered on the wetter, stickier soil types when drilling has been hampered.”

Mr Granger goes on to say that recently recommended high yielding hard feed wheat LG Beowulf, not only sits as the highest yielding variety, but also has the highest yield potential for drilling after the 1st November on the current AHDB Recommended List.

“LG Beowulf also o ers one of the best agronomic pro les available, with sti straw, good disease resistance, WOBM resistance, combined with a high speci c weight – all attributes for providing growers a security for on farm performance in this drilling position.”

He notes that later drilled varieties often have the advantage of requiring lower inputs and may not require an earlier autumn herbicide, but advises using an e ective seed treatment for either root disease or slug and insect control especially in known high-risk situations.

“Also look at varieties with a good disease resistance pro le, certainly against mildew, as this can be problematic on some soil types in the late drilled situation.”

Mr Granger also advises monitoring crops for yellow rust if winter conditions are mild particularly at the juvenile plant stage –even those that are listed as tolerant varieties. even those as tolerant FG

RGT Grouse key points:

• BYDV resistant

• OWBM resistant

• High yielding hard feed wheat

• Suits early sowing when BYDV risk highest

• Good tillering and tiller retention

• Very good lodging resistance

• Good spec weight

• Suits all soil types.

(prothioconazole and tebuconazole) at 0.6-litres/ha. At T2 Miravis Plus (pydi umetofen) at 1.5-litres/ha plus Era (prothioconazole) at 0.5-litres/ha were used. This was followed at T3 by Tebbit (tebuconazole) at 0.5-litres/ ha, Flyer (pyraclostrobin) at 0.4-litres/ ha and Ecana (prothioconazole) at 0.5-litres/ha.

The Grouse stood very well and stayed clean and Michael will increase the area down to the variety this autumn.

After a five-year battle against barley yellow dwarf virus, Michael Gooderham believes he has found a permanent solution by employing genetics rather than unreliable insecticide sprays to control the disease in wheat.

Much of the arable land Michael and son Darren rent at Red House Farm near Eye borders large blocks of woodland and grass, and every eld has a grass margin around it, all of which creates sheltered habitat for aphid vectors of BYDV.

“After the demise of Redigo Deter, we really struggled with the disease, so we’ve been under pressure to get everything sprayed,” says Michael. “We saw RGT Grouse advertised as a resistant variety and, after doing our own research, decided to try some last autumn. It has paid o big time.”

Other varieties on the farm received one insecticide spray last autumn, but a second application had to be shelved after more than 100mm of rain fell in late October.

“By late spring, BYDV was evident in the other varieties, particularly in our second wheat which su ered badly,” says Michael.

Gleam made up the bulk of second wheat, along with 14ha of RGT Grouse, both drilled in early October.

The Gleam produced 8.4t/ha. “It was a very disappointing start to our wheat harvest,” says Michael.

“However, I was more than pleasantly surprised with the Grouse, which yielded 10.3t/ha at 15% moisture.”

While the di erence was not entirely down to BYDV – the Gleam had poorer headlands after the very heavy rain – there was very visible BYDV in that variety. “I could see it clearly when spraying at T2 – the ag leaves were discoloured and going purple in places.”

RGT Grouse was also grown as a rst wheat after beans and averaged 10.8t/ha at 76kg/hl speci c weight across 51ha. The yield just edged Dawsum after sugar beet, which

missed the main aphid migration.

The rst wheat Grouse was drilled in the last week of September at 160kg/ha after a pass with a disc/tine cultivator. It emerged quickly and, while not particularly thick, it grew away well in the spring and retained its tillers, which lled well.

Belcocel (chlormequat) at 1-litre/ha and Canopy growth regulator (0.5-litres/ha) was applied at T1 but no more PGR was deemed necessary as the crop only received 200kg/ha of nitrogen after beans.

T1 fungicides consisted of Vimoy (iso ucypram) at 1.33-litres/ha and Kestrel

“We no longer have to worry about BYDV wherever we grow Grouse. I’m very glad we did our own research – we went to various open day trials but we felt Grouse and Gold nch, RAGT’s other BYDV resistant variety, were overlooked.

“We even had a job to convince our agronomist that this was possibly the way to go, but he seems pretty impressed with the result too.

“The variety has done very well as a rst and second wheat and we’ve put it into the IPM 4 insecticide-free crop option under SFI, which earns an additional £45/ha. It certainly looks to be a good t for our farm.” FG

The high-yielding winter wheat has smashed the five-year farm average, despite a challenging growing season.

Despite a double whammy of tough autumn establishment conditions and high septoria disease pressure, Lincolnshire farmer Alex Jasinski was delighted with a first-time crop of Bamford that produced an average yield of 11.66t/ha with overall bushel weights of 79kg/hl.

Ingoldsby-based Alex, who grows 400ha of arable crops on a mix of soils ranging from heavy blue clay to limestone brash soils, drilled 22.5ha of Bamford on 2nd October last year alongside two other winter wheats, successfully overcoming atrocious wet autumn weather.

Alex says: “It was certainly a tough start to the season. I recall just about managing to get our pre-emergence spray on two days after we drilled the Bamford, before the never-ending rain came again. Although we farm predominantly on free-draining limestone brash soil, the moisture levels were so excessive that I was seriously concerned over the amount of rain the new crops were taking.

“Nevertheless, the Bamford survived, getting away pretty well in fields where our overall blackgrass burden is not too bad. There were no hard frosts that winter and it progressed well through its early growth stages. Two splits of liquid N were applied – the first on 1st March, with a second split applied during the second week of April. In total we applied 225kg/ha.

“On fungicides we applied the same amount of chemical as our traditional four-spray program, but decided to add in a T1.5 spray on 13th May, bridging what would have been a long five-week gap between our T1 and T2 sprays, in what proved to be a very high disease pressure spring for both septoria and yellow rust in our area. Despite the disease challenges, the Bamford crop remained remarkably clean all the way through to harvest.

“Harvesting from 14th August, average yields for the Bamford crop were 11.66t/ha – miles ahead of our five-year farm average of 9.75t/ha for winter wheats. Add to this an excellent specific weight of 79kg/hl,

combined with early grain samples showing an impressively large grain, and you have a high-yielding variety with the potential for a small biscuit premium.

“It’s certainly been our most impressive winter wheat, and we’ll be increasing our drilled area to 50ha this autumn,” concludes Alex. FG

ANTHEM® 400g/L pendimethalin is a long lasting reliable broad spectrum residual herbicide providing a foundation in control programmes targeted at tough grass and broadleaved weeds.

ANTHEM HURRICANE provide exibility to build your bespoke cereal herbicide programme.

HURRICANE 500g/L di ufenican is a residual herbicide targeting a wide

One Dundee farmer is using an on-farm trial to get a detailed insight on improving the nutritive value of pulse crops across his rotation.

British On-Farm Innovation Network (BOFIN) founder and creator Tom Allen-Stevens visited Dundee farmer Diarmid Baird recently to nd out how the organic farm is looking to get more from growing pulses.

“I’ve been farming for 20 years, but only really been thinking about how I do it for three,” Diarmid explains.

He farms in partnership with his brothers, Euan and Dougal, and their parents at Scotston Farm near Dundee. The 485ha business is now fully organic – a conversion that’s progressed since 1988.

Diarmid is looking to get more from growing pulses on his farm. These slot into a rotation that include the clover-rich fertility-building leys, and an array of cereals grown mainly for the 4,500 laying hens, which complement the arable enterprise. A small beef herd completes the system.

Pulse-based combinations

Diarmid has been trialling a number of pulse-based cropping options and combinations. Sections of one eld transition from monocrop

spring beans to beans with peas and then with spring wheat. Then there’s monocrop spring wheat, an area where the crop has been intercropped with peas, and nally, peas on their own.

This has all been undersown with a mix of three clovers.

The eld has been entered as his trial eld for the NCS Project– a fouryear, £5.9M Defra-funded research project led by PGRO, with 17 industry partners. Diarmid is one of 10 Pulse Pioneers – who are farmers paid to carry out on-farm trials by BOFIN, one of the partners in the project.

He’s been keeping a close eye on the crop, submitting two areas as entries into the ADAS Pea & Bean YEN (Yield Enhancement Network). This will give him a detailed analysis, not just of the yield of his trial plots but also a host of leaf-tissue, grain-content and soil-related data.

biology that matters. That goes as much for the combinations of the crops we’re growing as it does for the muck we apply. We’re looking for the data we can gather to inform how legumes interact with cereals, the e ect on the soil, and the consequence for the following crop.”

“It’s the understanding of the with rye and with triticale.

value of the crop itself. Another eld and another trial, this time of beans intercropped with wheat,

“We’ve increased our laying

ration with peas and beans.

“We’re adding 15% each of peas and beans because at 20% protein, that’s not as high as soya. We’ve reduced the amount of cereals, and hopefully the intercropping will boost the protein content of these, although I know they’ll be a pain to harvest.”

His focus before harvest has been getting the nutrients into the grain.

That’s where the detailed analysis of the trials comes in, provided through his involvement as a Pulse Pioneer. The monitoring started o in early spring with a soil mineral nitrogen test, which also provided standard P, K and Mg analysis. Joining the YEN provided a protocol with simple instructions for sampling and monitoring the crop through the season at key points. FG

ock of organic free-range hens from 1,500 to 4,500, and used to buy in the entire ration. Now we’re looking to supply more of their feed from homegrown grains, and it’s the protein content that’s a key constituent,” Diarmid explains.

That poses a problem for his organic system. “Getting protein into the grain is easy if you’re using bagged nitrogen fertiliser, but a lot more tricky if you rely on muck and fertilitybuilding leys.”

He’s now switching away from soya, replacing the 15% inclusion in the

BOFIN is looking to double the number of farmers paid to carry out onfarm trials for the 2025 harvest.

“We currently have 10 farmers who form our rotational platform at the heart of the NCS Project,” explains Tom Allen-Stevens. “Within their pea or bean crop, or in a eld nearby, they have a comparison area which isn’t in a pulse crop. They’ll be monitoring these elds next year to assess the e ect of the pulse crop within the rotation.”

Alongside these elds, the plan is to add at least another 10 sites cropped with peas or beans with the same comparison area of a nonpulse crop within them. “We plan to work rst with our existing Pulse Pioneers, to develop their trials and support their plans to understand more about maximising returns across the rotation from their peas or beans,” he continues.

“We’re also looking for up to 10 new recruits. They will be paid to carry out monitoring and evaluation of an on-farm trial in a pulse crop and to join the discussion, share their experiences and explore how to get the best from it.”

carry out monitoring and evaluation of an on-farm trial in a pulse crop

peas or beans within your 2024/25 cropping plan and agree to monitor it into the same crop as the rest of the eld, such as into wheat.

To qualify as a Pulse Pioneer, you must include at least one eld of peas or beans within your 2024/25 cropping plan and agree to monitor it through the ADAS Pea or Bean YEN. Within this, there should be an area with a non-pulse crop, such as oats, that in the following year will come into the same crop as the rest of the eld, such as into wheat.

For more information, go to www.ncsproject.co.uk. FG

NPZ UK points out the proven value of combining peas in the rotation.

“This year’s harvest results for combining peas show excellent performance and contradict the negative press they have often su ered from over the past few seasons and the fact that they are under the pressure from some of the SFI options,” says Michael Shuldham, pulse product manager at NPZ UK.

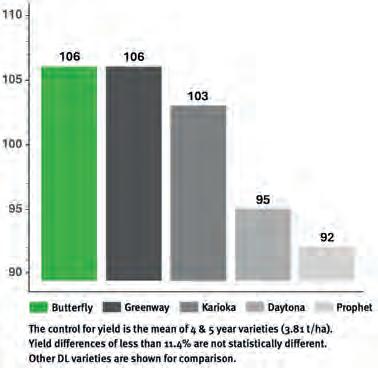

Mike Burdass of Barnwell Manor Estate near Peterborough grew 125ha of Butter y for ADM Agriculture. He commented that the variety, which is close on the heels of NPZ UK’s Carrington, is a high performing variety underlining the strong PGRO Descriptive List results where it shows good downy mildew resistance (6), earliest equal maturity (7), high standing power (7) and, as with all NPZ UK combining peas, resistance to pea wilt.

“It looked good all year and ticked all the boxes for us. Butter y held up well against disease and stood well, even though it was taller than the other green pea variety we grew this season. At harvest it produced a large sample with a yield of around 4.7t/ha.

“All-in-all, Butter y performed just as we expected and was a good variety for us.”

Dave Cooper, head of seed, ADM Agriculture commented:

“Butter y is well placed to become the benchmark for green peas in 2025 and beyond, based on its colour, shape, size, and yield.”

Mr Shuldham notes that the very healthy gross margin opportunity on peas at 4.7mt means that they could t the micronising or lucrative human

consumption markets and be competitive with a good rst wheat – this is in addition to

reduced nitrogen the following

consumption markets and be competitive with a good rst wheat – this is in addition to the improved soil quality and well-known reduced nitrogen requirement for the following wheat.

“It’s a win-win for all involved. Pulse crops are so important for our future, hence it’s fantastic we can utilise these new genetics to really support the whole supply chain.

“Carrington and Butter y are the current leading green peas for growers with impressive agronomics and market performance that has achieved very good on farm results for growers.

“They are two options from the strong NPZ UK pulse portfolio, and we will continue to do our part in developing the UK pulse crop with our current and future candidate varieties,” he adds. FG

The pre-em spray has been the mainstay of weed control in wheat. But with a large wheat area forecast and high seed return, e ective control will be more important than ever this year.

“Make sure timing and conditions are right for success at pre-em,” says Jamie Oakley at Bayer. “Aim to apply within 48 hours of drilling; if the gap gets to several days or even a week, e cacy will be compromised.”

Soil conditions also in uence e cacy –a good quality seedbed is the rst priority and then moisture is needed. “Moisture allows soil mobile herbicides like ufenacet to reach the weed germination zone in the soil. Any compaction or other soil damage can create barriers that can block the movement of herbicides.”

Mr Oakley emphasises that very heavy rainfall just after the pre-em application is the biggest danger. It can wash herbicides through the soil, potentially reaching germinating wheat seed or out of the soil altogether. Lighter soils are particularly at risk.

“Be careful with a larger stack at pre-em, we saw some pretty signi cant crop e ects last season where herbicides got washed through the soil. First of all, pay close attention to the forecast to avoid heavy rain.

herbicides, which could also help prolong earlier drilled crops especially, maintain

“Secondly think about sequencing herbicides, which could also help prolong the longevity of the programme. For earlier drilled crops especially, maintain good protection throughout October with a two-spray programme because that is when we expect peak weed germination.”

He urges farmers no to rush the application as excessive speed can cause turbulence and drift which means inconsistent coverage causing patches of weeds.

Advising farmers in the Highlands of Scotland, Agrii agronomist John Mason uses the pre-em timing as the foundation for annual meadow-grass and brome control in winter wheat crops.

“Pre-emergence is the best opportunity to control weeds. Once they are up and in the crop, it is much more di cult to do anything about them.”

Spring barley for malting is the most important cereal in the rotation followed by winter wheat. Potatoes and carrots are also important crops in the Black Isle region just to the north of Inverness.

“Not everyone grows

“Not everyone grows winter wheat – I’d say it tends to be the larger operations, and most of it goes to Whyte and Mackay for distilling. Annual meadow-grass is widespread whereas brome tends to encroach onto the headlands from margins or sometimes in the straw used for carrot growing.”

E ective weed control is important because any green material in the crop can slow down harvest and increase drying costs which are already a signi cant burden in this part of the world.

Typical wheat drilling date is from late September into the second week of October. Soils are quite light and free draining so there

are not the same concerns over drilling as on heavier wheat land. Added to that, ploughing is still widely used to prepare the ground.

“Some farmers are doing an upgraded pre-em programme on the headland to prevent brome getting worse. One farmer I advise used Octavian Met (metribuzin + ufenacet + di ufenican) in autumn followed by Incelo (mesosulfuron + iodosulfuron) to target brome on headlands, he was very happy with the result.

“Even in lower pressure situations, one litre of Octavian Met at pre-em has been a great addition to the programme. It is a three-pronged attack and has good broad-leaf weed activity as well.

“Timing is important, the aim is to always apply the pre-em within 3–4 days to get the best result; drill, possibly roll then spray. As it’s mainly lighter land, we have to be mindful of rainfall and the potential for crop e ects, so we use an adjuvant to improve herbicide retention in the soil.

“We sometimes still see transient e ects, but this is better than a eld of weeds.” FG

The investment made by KWS in its F1 PollenPlus hybrids allows for high ergot tolerance which, in combination with robust overall performance, bene ts both farmers and end users, KWS UK technical manager for hybrid crops, Rory Hannam, points out.

“With yields of 10–13t/ha commonplace many growers nd that hybrid rye outperforms wheat and barley as a second or third cereal.

“Harvested earlier than wheat, it ticks many boxes in terms of exibility in the rotation. Hybrid rye will slot into most cropping plans and because it ts the requirements of grain and AD markets so well, demand from farms all over the UK, including in the North of England and Scotland, is increasing.

“Hybrid rye can help to mitigate risk in situations where, for example, growing oilseed rape is becoming increasingly challenging or it is di cult to produce wheat and barley economically because of inconsistent yields.

“With extremes of weather becoming more frequent, characterised by extremely wet winters followed by dry, hot conditions in spring and summer, hybrid rye holds signi cant appeal.

“Having another cropping option is very welcome, particularly on free draining, acidic or sandy soils which have a much higher risk of soil moisture de cit and consequently where yields and income are threatened.

“As a result, growers who have traditionally grown rye for years because it tted their rotation are being joined by those wanting an alternative to the mainstream options.”

One of the most drought-tolerant crops available, hybrid rye is well suited to lighter, drier, droughtprone soils, particularly in areas of low rainfall, but it can also be grown on heavier land with many farming businesses in that situation now

considering the crop, he adds.

“Hybrid rye provides a mini break from diseases which may thrive in that situation and has an ultralow take-all carryover,” explains Mr Hannam.

“The crop’s extensive, deep rooting system copes well with dry conditions while its aggressive growth habit means that it moves through stem elongation faster than any other cereal, providing intense competition against black-grass.

“Requiring less agrochemical inputs than other cereals, hybrid rye utilises nitrogen and phosphorus very e ciently without compromising yields, has a 25–33% lower water requirement than wheat and will thrive in conditions where wheat and even barley may struggle.”