12 minute read

The difference engine

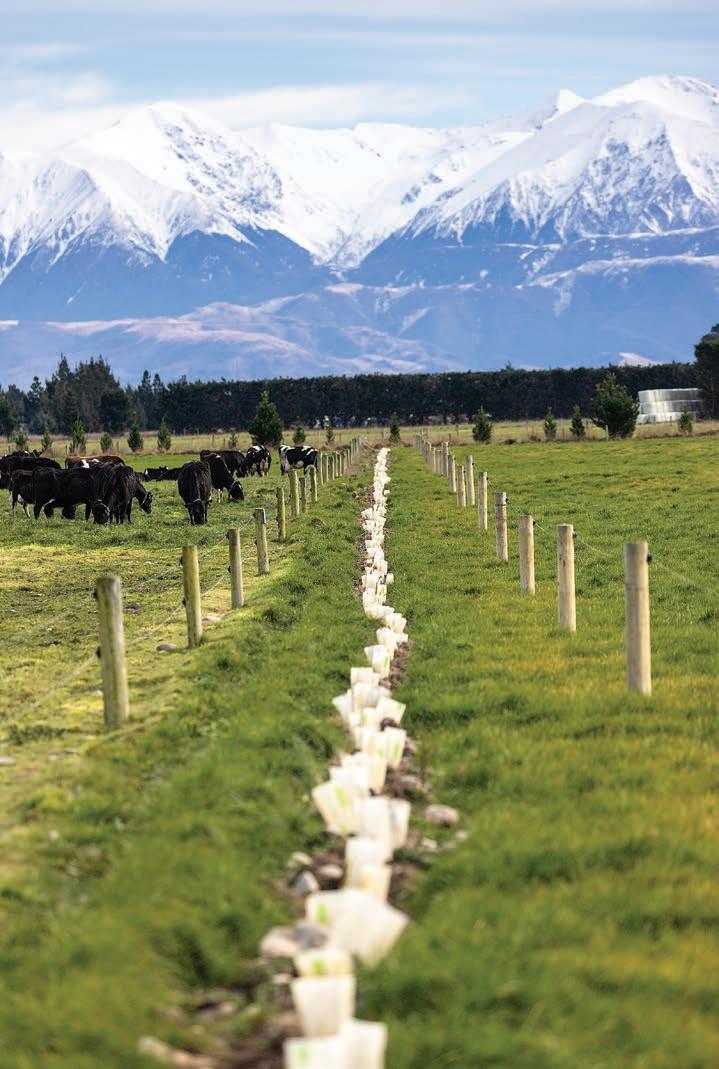

From bale-grazing in winter to boosting oxygen in the irrigator, this North Canterbury ag leader has never met a farm system he couldn’t tweak.

Cameron Henderson had plans for a corporate career rather than one as a dairy farmer but since he chose the land over an office he’s made his mark, both on farm and in the wider community, and was this year named winner of the Fonterra Responsible Dairying Award.

The award recognises dairy farmers who are respected by fellow farmers and their community and demonstrate leadership in their approach to sustainability.

Henderson, who farms near Oxford, North Canterbury, is an innovative farmer but also finds time to be a founder and trustee of the Waimakariri Landcare Trust, a member of the Environment Canterbury regional water committee, and fill various roles on the DairyNZ Dairy Environment Leaders group.

“I find the variety keep me motivated,” Henderson says. “If I was just doing one thing day in day out, it’d drive me nuts. It’s just a matter of balancing everything and most of the time it works.”

Henderson was born into a multi-generational farming family and grew up on the family dairy farm west of Hamilton. There were aspects of dairy farming he liked, mainly the machinery, but he had other career plans.

“I guess I was more academic at school and if you were academic you didn’t even think about going dairy farming. My interest was always in problem-solving and designing things and fixing things and so I went down the engineering path.”

He studied robotic engineering and finance at Auckland University, did some travelling and then worked for Fonterra for three and a half years, starting in HR and then working in the supply chain area, building track-and-trace systems and working on data management.

“It gave me a really good view across the entire company, what it was doing and how it worked,” Henderson says.

But he wasn’t sure the corporate world was where he wanted to be, even though Fonterra paid very well.

“I looked at the executives who were 10-15 years further ahead than me and they were working really hard, being paid exceptionally well and travelling all over the world and there were some parts of that that were quite attractive, but it just didn’t fit with what I saw in my future.”

He’d studied entrepreneurship at university and really wanted to be in his own business. After working for Fonterra he realised one of his best options was to go dairy farming.

“In many ways it’s an exceptionally easy business model to step into to because you’re not competing with the 12,000 other farmers in

Continued page 10

Farm Facts

• Farm owners: Henderson Farms Trust (Cameron and Sarah Henderson)

• Contract milkers: Overend Meadows (Steve and Kate Overend)

• Location: Burnt Hill, North Canterbury

• Farm size: 238ha (221eff)

• Production: 2022-23: 341,000kg MS

• Production target: 2023-24: 370,000kg MS

WHAT TIME IS IT? IT’S

JCB

JCB SERIES III IT’S JCB SERIES III TIME.

SERIES III TIME.

IF YOU CAN IMAGINE IT, A JCB SERIES III CAN LIFT IT.

IF YOU CAN IMAGINE IT, A JCB SERIES III CAN LIFT IT.

Some farmers think a telehandler is for the big farms or best suited to European or North American operations. But you’ll be surprised to know that telehandlers are the fastest growing on-farm utility category in the New Zealand market. You’ll also be surprised by what you can do with a LOADALL and how much it improves productivity on all types of farms. You won’t however be surprised to know that the JCB SERIES III is the world’s No.1 LOADALL.

Some farmers think a telehandler is for the big farms or best suited to European or North American operations. But you’ll be surprised to know that telehandlers are the fastest growing on-farm utility category in the New Zealand market. You’ll also be surprised by what you can do with a LOADALL and how much it improves productivity on all types of farms. You won’t however be surprised to know that the JCB SERIES III is the world’s No.1 LOADALL.

You’ll wonder how you farmed without it!

You’ll wonder how you farmed without it!

JCBAGRICULTURE.CO.NZ

JCBAGRICULTURE.CO.NZ the country – everyone shares their information, you can learn a lot from of what other people are doing and put it together to create a successful business

“And, arguably, you’re only running half a business because you don’t do sales and marketing and manufacturing, someone else takes care of that.”

Having made the decision to go dairy farming, Henderson looked around and decided the best opportunities were in Canterbury.

“Down here they were about five years into the dairy boom so I thought, ‘I’ve got some family experience to back me up, plenty of advisers, so let’s give it a go.’”

He moved south in 2009, taking a dairy assistant’s job with Steve and Sharon Schmack in Mid Canterbury. When they moved to Mayfield to convert their parents’ drystock farm, he went with them as 2IC.

“That was a really good learning curve, coming in early in the conversion process and seeing how it worked.”

In 2011, with the support of his family, he bought a 190ha block at Burnt Hill, near Oxford, land that had previously been used for sheep farming and cropping.

“Since I started, I knew I wanted to own my own block of land and do my own thing so from the day I arrived in Canterbury I was looking for blocks of land and putting the numbers together and doing a bit of modelling on water requirements and what a business model might look like, and this came up.

“It was very fringe dairy territory at the time, it didn’t have infrastructure on it, and it had been leased out for nine years. It’s windy here and the soils are light so there are a number of things that probably aren’t perfect about it but that made it quite a good deal when I came to buy it. It scared a lot of people off,” Henderson says.

There were three wells on the farm, albeit undeveloped, and not much else – no power, no water, no housing and no sheds.

“If I knew how much work I was taking on, I would never have done it, but ignorance was probably quite useful back then. We converted the farm on a shoestring budget and borrowed half the money from the bank and half from the family.” There was only enough money for one house, which was shifted out from Christchurch following the earthquakes.

“I had one staff member living here and I was renting a house down the road and living with another staff member for three years. I was still single, and I was hiring single people on purpose because we were very short of space, but it worked quite well.”

Since then, the farm has grown to 238ha plus a nearby 200ha support block, leased from renowned golfer Sir Bob Charles. Contract milkers Steve and Kate Overend now milk the 750 Kiwi-cross cows on Henderson’s farm.

“The dairy farm’s fairly settled now and we’re getting to the point now where we’re tinkering more than anything else.”

What Henderson calls tinkering might be considered big changes by other farmers but he’s always looking for better ways, ones that are both economically and environmentally sustainable, to run the farming business.

He’s rethinking how he uses the 200ha support block, which for the past few years has wintered his cows plus a neighbour’s herd, a total of 1700 cows.

“We know how to grow winter feed and feed cows and that’s provided some winter cashflow to provide us a very flat income curve through the year and we don’t get the big peaks and troughs.

Continued page 12

“The October-November retro payments from the dairy farm tend to go into growing the crops down the road and the wintering money comes through in winter, which subsidises our dairy farm when the milk cheque isn’t coming in.”

They also grew small seed crops and barley on the block, so the operation had become quite complicated and relied on experienced manager Pete McPherson to keep it ticking over. When McPherson left farming to become a fire-fighter, Henderson decided the system had to be simplified. That coincided with his growing doubts about relying on fodder beet to winter his cows, doubts that were amplified when data from recently fitted Allflex collars came through in real time.

“We were feeding fodder beet with a little bit of grass silage and finding, like a lot of people are, that that’s not really doing us much service. We’re getting fat cows out of it but we’re getting a high empty rate and a lot of mysterious deaths.”

The collars revealed repeated drops in rumination, which Henderson attributes to acidosis brought on by giving cows exactly the same ration of high-sugar fodder beet each day.

“It could be anything from having a wet day so the cows make a real mess of the fodder beet and don’t really eat much and then over the next few days it all dries out, so they eat their next allocation plus back-graze and then you get a sudden spike in acidosis and the rumination drops away,” he surmises.

He adds that even with yield testing, some paddocks have lighter or heavier cropping patches that mean some cows get more fodder beet than is good for them.

“Most of the acidosis is subclinical and not obvious to the eye so in the past, before collars, it could have been happening all the time and we just wouldn’t have noticed it.”

Acidosis can burn the cow’s rumen and while it can be treated if caught early enough, it can slowly kill them.

“She can’t absorb energy from the feed, so they’ll just go downhill, get skinny and die. That quite often manifests itself after winter so you’ll think you’ve got through winter, the cow will calve so she’s under stress and in energy deficit anyway, then you’ve got acidosis on top of that.

“We were finding was we had fat cows that would calve and we might lose 5% of them and we just couldn’t figure out what was going on.”

Like other Canterbury farmers, Henderson had believed fodder beet was the best wintering option available. Although relatively expensive to grow compared to kale, it offered twice the return per hectare.

But it’s tricky to feed and if you get it wrong, like taking the cows off the diet for more than about 24 hours at a time, the results can be disastrous because of acidosis.

“We had a big storm two years ago so we shifted them off into protection because the storm had lasted so long, and they had three days of silage and hay. We transitioned them back on to the fodder beet but got it wrong and immediately lost a number of them.”

As well as the concerns it raises for stock health, the damage to soils and to the wider environment from wintering cattle on crops just isn’t sustainable long term, Henderson believes.

“There were days during a weather event recently when I walked over Lytham [the support block] and said, ‘This just isn’t good enough. We’re doing farming to best practice but they are still living in mud.’

“The soil structure’s just completely gone and I think there’s only so long you can get away with that before you see the farm go downhill. You’ve got cows pugging right through the topsoil to the stones so the topsoil’s getting absolutely buggered. It’s just not good for the farm.”

The solution for Henderson is to ditch wintering his cows on crop altogether and he’s leased 60ha of dryland adjoining the dairy farm where he plans to bale-graze through winter, a practice quite rare in Canterbury but popular in Southland.

“We’re still working through the best way to do it. The current plan is we’ll have some round hay bales and some individually wrapped silage bales laid out pre-winter and one day a week going out and opening the bales a week ahead and then just shifting the fence every day.”

The herd will move much faster than on fodder beet, with the 750-cow herd expected to use about .8ha a day. Henderson’s looking forward to life with less of the mud that goes in hand with feeding crop.

“If you get 100mm of rain you’ll make quite a mess in that break and you might lose two out of 16 paddocks that you need to regrass, but because it’s on non-cultivated ground on pasture with a permanent root system, that helps drain the water away and we hopefully won’t have anywhere near as much mud or soil erosion.”

Continued page 14

According to regulations, Henderson says, bale-grazing isn’t wintering so he won’t need a consent. “It should be better environmentally because you’ve got the living root in the soil that should continue to use the nitrogen through the winter.”

He’s expecting big gains in animal health but accepts it won’t be as economic as feeding fodder beet or kale.

“You have to take a more holistic view of the numbers. If we can improve our in-calf rates and our cow wastage and grow better crops so we’re not destroying our soils – and it’s hard to put a number on that – my hope is it balances out the straight economic loss of spending a bit more to make it happen.”

Henderson recognises that by putting an end to wintering on crop, he’s moving away from what is currently deemed good practice, but trying something different is in his nature. He’s also decided to ditch another recommended practice, using sexed semen, because he reckons he’s just not getting acceptable results. this to be the fastest way to improve his herd’s genetics. Because sexed semen needs to be used fresh, CIDRs were used so the heifers could all be inseminated on the same day – but despite that achieved only a 35% conception rate, not the 75% he’d hoped for.

This year he’s going back to standard, high genetic worth semen. “We’ll need to breed more of our cows and we’ll end up with a lot more bulls so we have to accept a lower overall genetic gain.

“We’re trying to follow the best practices with sexed semen and use it on the heifers because they’re they absolute best genetics we’ve got, but we’ve been hurt too much by the results.”

Another change Henderson has made is fertigation, adding liquid urea to the irrigation water, to be delivered by the three centre pivots on the farm instead of applying it in solid form. He believes clover will start to thrive again under the lower rate and will contribute to overall N levels.

After being decimated by clover root weevil for years, the natural nitrogen fixer is now bouncing back but Henderson reckons that process is being slowed because clover doesn’t do well when too much urea is applied.

“We got addicted to putting on 250-300 units of N and got scared of what would happen if we pulled it out and kind of forgot to learn how to farm with clover in the system,” he says.

“My theory is by putting on a little and often, three to four units a week, rather than dumping on 40 units once a month, the nitrogen is at a steady level that should benefit the ryegrass and clover.” and still maintaining our production so that’s a good enough result for me.”

There are also some potentially large changes in store to the way he irrigates, thanks to a Sustainable Food and Fibre Futures trial project to be undertaken on the farm, replacing the sprinklers on a centre pivot with dripper lines that will drag across the ground surface and to deliver the water more directly to pasture.

Talking about the technology as a nor’wester blows hard, Henderson is enthusiastic about the potential of dripper lines over sprinklers.

“On a day like this, 10% of the water may hit the ground if you’re lucky and with an El Niño year ahead, you might have a week of blowing like this and you go backwards in soil moisture really quickly, so we should see some advantages in water use.”

And it won’t be ordinary water either. The company behind the project, Nanobubble Agritech, will use technology developed for hydroponics to boost the amount of oxygen in the water.

“The technology was developed for hydroponics to inject pure oxygen bubbles into the water which then feeds the roots, and they get exponentially greater growth because the roots are healthier. These guys have developed the same technology for a pivot to irrigate your water into the ground that will hopefully give similar benefits for pasture.”

“We’ve used sexed semen for the last two years but the conception rate was fairly poor,” he says.

He’d been using sexed semen for his heifers, believing

Since installing fertigation, he’s dropped nitrogen from 220 units to 130 units and is now well within the allowable limits.

“We’ve been applying only 60% of what we were applying

Henderson’s farm is one of two in Canterbury where the technology’s being trialled and he’s crossing his fingers it may deliver the 20-30% extra grass growth shown in earlier trials.

“It’s a commercial technology they’re looking at developing and we’re just one of the commercial trial farms to give it go.”

While he tries to be hands- off on the farm’s day-to-day operations, Henderson finds there’s plenty to keep him busy there, especially when he combines that with his off-farm roles, which more recently have included director for Ballance Agri-

Nutrients and trustee on local lines company MainPower Trust.

“I’ve set up a portico office