By Impact Hub Lisbon & Sonia Ferreira

2023

Logistics

Acknowledgements

This toolkit was drafted thanks to the financial support of the European Innovation Council and Small and Medium Enterprises Executive Agency (EISMEA) COSME Programme, under the Call for proposals COS-CIRCFASH-2019-3-02.

We would like to acknowledge the contribution we received from:

• The consortium of the project

• Fashion Revolution

All other stakeholders we have engaged with in the drafting process

• The Fair Trade Movement

• The participants in the project’s Policy Dialogues we held in Berlin and Athens in 2022

• All other stakeholders we have engaged with in the drafting process

• Section 1: What is Fair Trade? • Section 2: Case studies • Section 3: Reflection exercises • Section 4: Worksheets, tools and templates Index 4 8 10 12 SMALL BU T PERF E C T 4 8 11 12 13 Background information and inspiration Case study Goals and potential shifts Reflection exercise Worksheets, tools and templates

Section 1: Background information and inspiration

Logistics 4

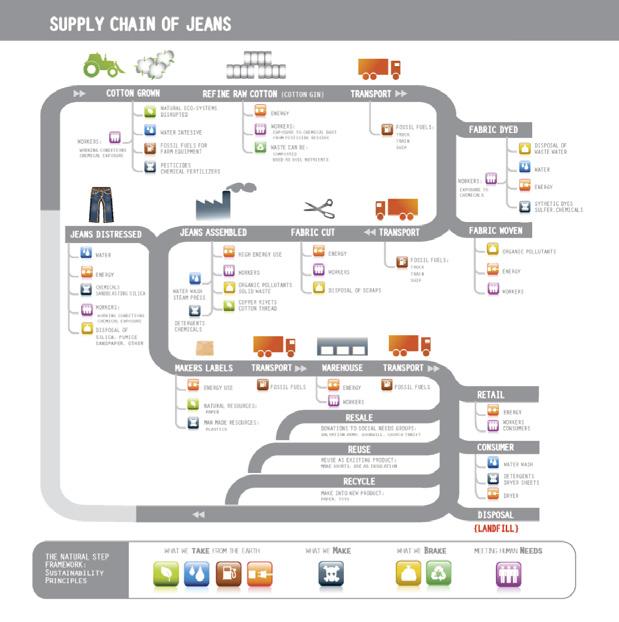

Logistics refers to the process and coordination of products, raw materials, and services across the supply chain. From manufacturing and production to distribution, fulfillment, and final delivery to customers and end users, logistics is a critical and essential component of a successful supply chain.

and delivered. Sustainability and circularity have become increasingly important when designing supply chain networks, allowing brands to try to build different scenarios to include new raw materials, business models or access to market to offer more sustainable solutions.

a.Logistics refers to the process and coordination of products, raw materials, and services across the supply chain. From manufacturing and production to distribution, fulfillment, and final delivery to customers and end users, logistics is a critical and essential component of a successful supply chain.

Logistics design, operations and performance have a significant impact on companies’ commercial and financial results, with companies’ logistics traditionally set up to focus on one of three main drivers: cost, speed or quality. These drivers do not consider the environmental or social impact of how and where materials are sourced or how a garment is made and delivered. Sustainability and circularity have become increasingly important when designing supply chain networks, allowing brands to try to build

Logistics design, operations and performance have a significant impact on companies’ commercial and financial results, with companies’ logistics traditionally set up to focus on one of three main drivers: cost, speed or quality. These drivers do not consider the environmental or social impact of how and where materials are sourced or how a garment is made

The main difficulty in choosing the most sustainable choice is considering the different variables involved and understanding the additional costs involved in bringing it to life, including the logistics costs, to decide on the solutions that can be presented to the right type of consumers who will recognise the value of the product and will be willing to pay for it.

in bringing it to life, including the logistics costs, to decide on the solutions that can be presented to the right type of consumers who will recognise the value of the product and will be willing to pay for it.

BACKGR OU ND IN FO RM AT ION & INS PIRAT IO N

Logist ics 5 Logistics 5

Source: www.vecteezy.com

oms clearance), account for around 30% of the cost of the product, the possibility of an even higher percentage, depending on the model and how linked it is to demand information and consumer behavio

On average, logistics costs (all of the expenses incurred moving product — from sourcing raw materials to delivering customer orders and every step in between, as for example transportation, warehouse costs or customs clearance), account for around 30% of the cost of the product, with the possibility of an even higher percentage, depending on the model used and how linked it is to demand information and consumer behavior. Supply chain networks may be cost efficient or fast to deliver products to market but if they are supplying

products that are not aligned to what clients are interested in buying, it can destroy the company’s business model. High inventory costs and potential markdowns due to excess stock have a significant financial impact, and present a big sustainability issue, so it is extremely important to know your customers well and adjust the logistics setup to the best value proposition to your target market.

market but if they are supplying products that are not aligned to what s are interested in buying, it can destroy the company’s business model. nventory costs and potential markdowns due to excess stock hav significant financial impact, and present a big sustainability issue, so it xtremely important to know your customers well and adjust the logisti setup to the best value proposition to your target market. omer segments they target, as per below:

Supply chains can be split into different types, considering the type of customer segments they target, as per below:

Logistics 6

Source: sciencedirect.com

There are no right or wrong answers in logistics, only more efficient or less efficient choices, at any given time, depending on the product, target market/customers and strategy, but as these variables evolve over time, so should your logistics analysis.

Exercise

Rank your supply chain main drivers: cost, speed or quality (considering supply sustainability practices in regards to the environmental and human impact of their products’ journey from raw materials sourcing to production, storage, delivery and every transportation link in between already included in the model)

Is your customer aligned with these drivers? What do they value most?

How do you plan to keep informed of your customers needs and buying behaviors to avoid excess inventory and product?

Logistics 7

Section 2: Case

Goals and potential shifts

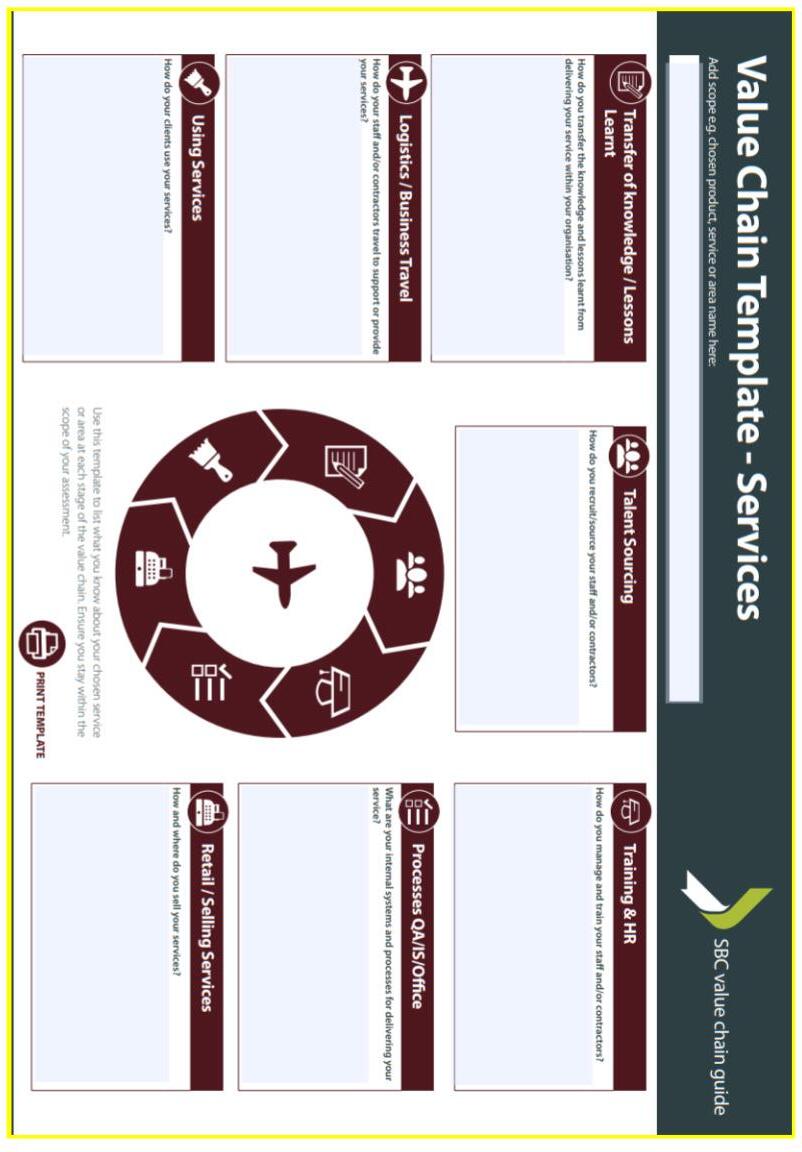

More than focusing on the importance of logistics in your business, it is important to understand what you want to achieve, what are the different echelons in the value chain you belong to and how you can look to logistics as a tool to test new ways to approach your client/suppliers or optimize your capital flows, by using inventory in different ways (push or pull models: ). A pull system initiates production as a reaction to present

demand, while a push system initiates production in anticipation of future demand. In a pull system, production is triggered by actual demands for finished products, while in a push system, production is initiated independently of demands. Look at trends in the industry, even with different products/services, that can give you ideas for new ways of organizing your logistics flows –and test different approaches.

See links in section 5 for more.

Section

Logistics 11

3:

Reflection exercise

Logistics network design depends on what your main focus/differentiator is (considering that sustainability is already included regardless as the differentiator):

1. Speed

2. Cost

3. Service/Product

Analyze which of these variables are more important in your business, considering the sustainability driver that is part of your value proposition and how much you are willing to compromise on or adjust the other variables. Test different scenarios to see the impact of your decisions, for example:

You sell mostly online, so you focus on speed. What if you would have a pop-up store and focus on cost, what would be the impact of that decision in your margin? And in your customers?

You focus on a high quality product and do not compete on cost. What would allow customers to have a lower cost version of your product? Can you differentiate on distribution or other variables related to logistics?

Besides deciding on your key differentiator, it is important to identify what your key challenges are. List the three items that can have the highest probability of negatively impacting your business and why. Think if logistics can support these challenges in any way, as a growth support function instead of a cost.

Exercise Section 4:

Logistics 12