"I believe a leaf of grass is no less than the journey-work of the stars."

—Walt Whitman

"I believe a leaf of grass is no less than the journey-work of the stars."

—Walt Whitman

Dear Readers,

Welcome to the tech edition, Fat Nug’s last issue of 2024. In my first year as EIC, we have put out five incredible editions, and I couldn’t be more proud of this one.

Cannabis tech is a hot topic: how can we utilize technology to scale operations and become more efficient? How can we use data to make cannabis products more safe? On the other side of the coin, how much can we automate this process until we’ve removed an essential element for success: the human touch?

Your opinion on cannabis tech is likely influenced by your opinion of technology on a larger scale. Whether you love it or loathe it, there is no escaping big tech. And it is this variety of opinions on technology we have endeavored to include in this issue—the good, the bad, and the downright flawed.

Rob Sanchez takes you through the evolution of cannabis software systems on page 12 while Lance Lambert sets his sights on the expansion of cannabis tech and research around the world on page 34. Dustin Hoxworth asks some of the best tech minds in the industry to weigh in on the future of cannabis tech on page 24 while Daniel Crawford

shares his must-have tech rec's for solventless extraction on page 40. And in our quest to remain contrary, Bri Smith weighs in on how Big Tech keeps cannabis down on page 66.

You do not have to love technology to enjoy this issue. Consider this a state of the union, taking the pulse of where the cannabis industry is and where it is going. The more advanced our tech becomes, the more evident it becomes that tech cannot replace everything in our lives.

As Jim Berry says on page 44, if we frame cannabis like nature’s technology, it is quite amazing. The sun, the soil, and the water coming together to work something close to magic—the growth of the cannabis plant.

No matter how far technology takes us down the path (or rather, how far we let it lead us) there is no technology better than the one Mother Nature created tens of thousands of years ago. Cannabis reminds us that we are intricately connected to the land, no matter how many terabytes or data points we use to separate ourselves.

It gives me great pleasure to share with you: THE TECH ISSUE. See you in 2025!

Jessica Reilly-Chevalier EDITOR-IN-CHIEF

Pg. 10 Bud Backstories: The Origins Of Alien Technology Bud Backst ories: Of By Ali Lopez

Pg. 12 Seed-To-Sale: The Software Behind Cannabis Business By Rob Sanchez

Pg. 18 Dirty Hands Clean Hash: A Ganjier Review Of Y.P.F. Cle an #17 Hash Rosin By Shelley Peebles, CG, RDH

Pg. 24 Embracing Technology: The Future Of The Te chnology: Cannabis Industry By Dustin Hoxworth

Pg. 34 International Cannabis Technology Update Inter national By Lance C. Lambert

Pg. 40 Flower To Rosin Oil: Solventless Extraction & The Tech That Makes It Possible By Daniel Crawford

Pg. 44 Homegrown Homeg rown With Jim Berry

Pg. 54 Infused Peppermint Marshmallows Infused By Kelly Kreutzer

Pg. 66 Activism In Analog: How Big Tech Put Cannabis Activism In The Dark Ages By Bri Smith

Dustin Hoxworth: FOUNDER

Jessica Reilly-Chevalier: EDITOR-IN-CHIEF

Daniel Crawford: CHIEF OPERATING OFFICE

Christina Aydt: DESIGNER

Casey Renteria: PROGRAM MANAGER

June Blankin: COORDINATOR

Kyea Mofire: PHOTOGRAPHER

Hollis Doherty: EDITOR

Kelly Kreutzer: NATIONAL SALES MANAGER

Ihave been obsessed with aliens since I don’t know when. Not IF they exist—WHERE they exist. Are they hiding amongst us? Have they already been here and decided to leave? Are they hiding in the ocean? Are they smart enough to stay away from humankind’s foolery? Are they looking for us just as we are looking for them but they don’t have sufficient… alien technology?

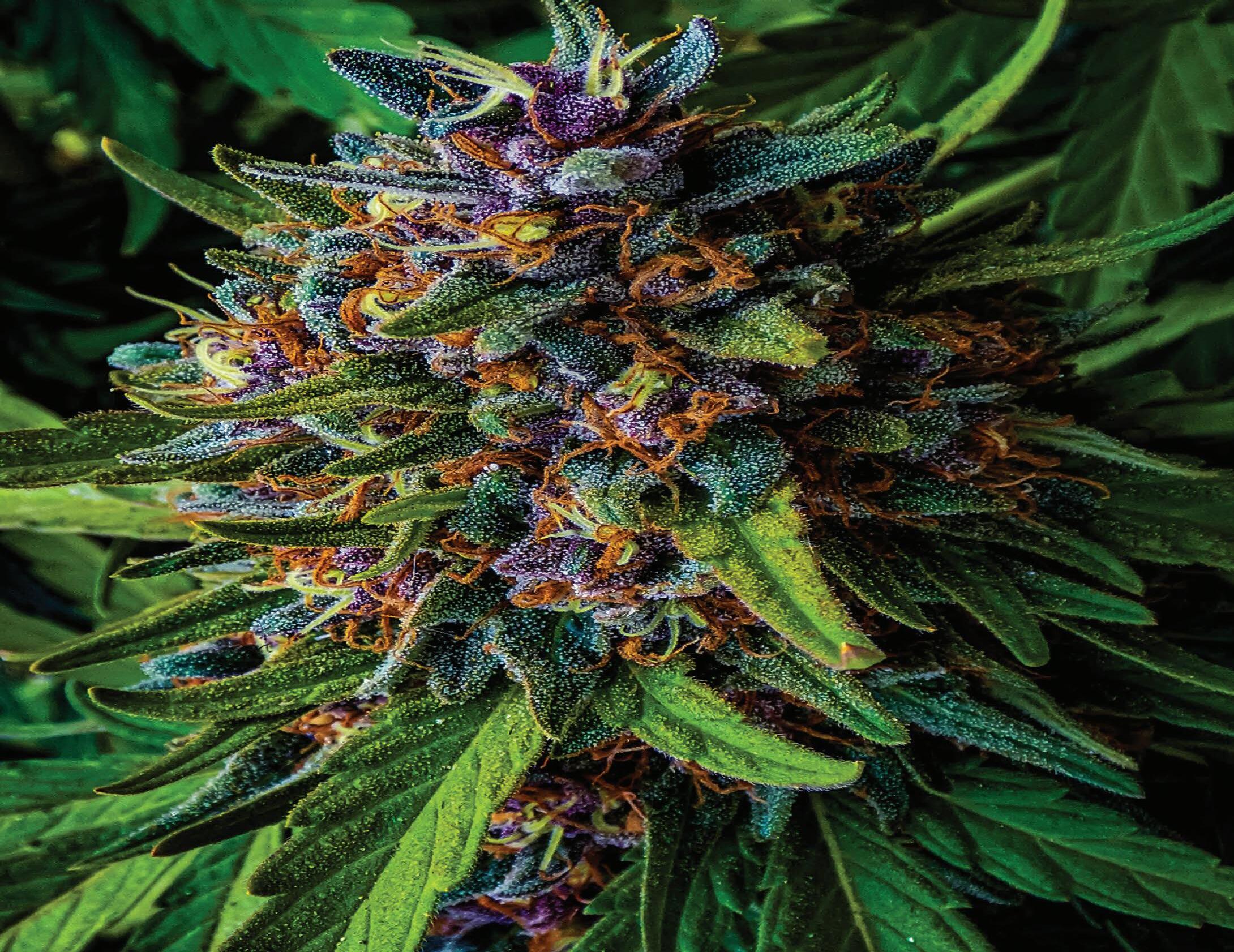

In this series, we dive into the backstories behind the crazy names of cannabis buds. Because I’m fascinated by stories with that otherworldly vibe, I knew I had to set my sights on a strain that goes beyond the basic and chase after something a little more sci-fi. After searching the stars, I landed on a strain that pushed all the right buttons: Alien Technology.

Much like all things extraterrestrial, there’s a lot of uncertainty around the origins of Alien Technology, but I probed the internet for answers. According to the legend, it all started in a small, remote village in Afghanistan. But the strain’s seeds didn’t teleport to the US—supposedly, they were brought back by an American soldier who had been stationed there.

It’s said that this soldier discovered the seeds (along with several others) during his time in the region, where cannabis has a long history of being cultivated for its potent effects. Recognizing the uniqueness of this particular landrace strain, the soldier decided to bring a piece of it back to the States with him.

Once back in the U.S., the seeds ended up in the hands of a well-known breeder in the cannabis community named OBSoul33t.

Obsoul33t, known for cultivating and preserving some of the most potent and unique strains, immediately saw the potential in these Afghan seeds. After experimenting with the genetics, OBSoul33t was able to perfect the strain and introduce the world to Alien Technology, a pure indica that’s become a fan favorite for its strong, long-lasting high.

By Ali Lopez

Like any great alien story, Alien Technology leaves behind a lasting legacy, spreading its celestial vibes through the creation of some seriously popular hybrids. It’s been a key parent strain for fan favorites like Alien Dawg and Alien Kush, both of which carry that same unique genetic profile, but with their own twist. These hybrids have taken the cannabis world by storm, blending the out-of-this-world potency of Alien Technology with other strains to create something new, yet familiar.

But if you're craving the pure experience, uncut and straight from its mysterious Afghan origins, Alien Technology is the strain to go for. It’s the kind of bud that feels like it was dropped straight from the stars, with its frosty, potent flowers and a high that takes you on an intergalactic journey lasting for hours.

Maybe the universe is keeping its secrets about the full story behind this strain for now, but one thing is clear: Alien Technology brings us closer to the cosmos. It’s a reminder that sometimes the best stories are the ones that leave a little to the imagination.

And who knows? Maybe one day, when we finally do make contact, we'll have a joint of Alien Technology to break the ice.

By Rob Sanchez

Acommon statement in the cannabis industry is that a year in cannabis is equal to several years in any other industry. The needs of the business and consumers continue to evolve rapidly, along with innovation and regulatory requirements, keeping people on their toes to adjust and adapt.

This is especially true for software. As business requirements change, they need evolving software to support and manage their operations. Cannabis businesses have undergone a digital transformation that I have had a front-row seat to since 2017.

I’ve worked on six cannabis software solutions over the last seven years as a Product Manager. I design new features, demo the software, implement it, and fix issues, while working with internal teams and external customers to polish the product offerings and its workflows. In this article, I’d like to explain a little about cannabis software, what it is, and why it matters while highlighting some of the challenges I’ve seen companies face in the industry.

Cannabis software covers a variety of different business cases, but the software at the heart of things is Seed-toSale. Seed-to-sale software covers the full supply chain of the cannabis industry from cultivation through postharvest processing, manufacturing, distribution, and retail.

This is not new software but an adapted form of an ERP (Enterprise Resource Planning System). ERPs have been used for decades to manage the supply chain and inventory for every other industry from CPGs to construction materials and biomedical devices. ERPs are beasts; they can do it all. Think of ERPS like cathedrals that took generations to complete and perfect. They can be fantastic for business when implemented and managed correctly, but implementation and management can take entire teams of dedicated folks to maintain it—something the cannabis industry rarely has readily available.

To solve this, some traditional ERPs have been customized to work within cannabis by adding cannabis specifics and compliance functionality to run them for the industry.

These are called legacy solutions as they ride on the legacy of the standard ERP they are built on top of. They are great, but they are not cheap—at all.

What I’ve seen rise up throughout the years are SaaS (Software as a Service) solutions that cover one aspect of an ERP, like an app built specifically for cultivation, another for finance and another for distribution and retail. When you have a stack like this, it is known as a Bespoke ERP. Operators pick and choose the right software to build a perfect stack for them; sounds fun, right?

The downside with bespoke ERP solutions is that instead of having one software partner, as you would in a legacy solution, you have multiples—and they don’t always play nicely with one another. Integrations can be costly and require development work and time; they also may have flaws that can make certain combinations of software fall short of reaching the goal. The benefits of a bespoke solution are that the operator chooses who they work with and how they build their stack, and it’s often much cheaper and easier to implement to run a stack vs a legacy system.

There’s not a perfect fit, but budget and operation size mean businesses lean one way or another in their choices. At a certain point in scale, a legacy seed-to-sale solution can be perfect, but for small to medium businesses a bespoke or “stacked” solution tends to be the way to go.

Other things to consider are the support operators receive from businesses and the quality of the software. Quality is key in cannabis products and the software running things in the background. You want to make sure to go with a company that provides the support structure you need; one that is willing to listen to its customers and adapt to make changes to the software quickly. Because of how often regulations and requirements can change in the industry, it’s necessary to know how long it takes your software providers to make changes and to know that they can do it right.

Let me provide an example of what Seed-to-Sale really does. Starting with seeds or clones at the beginning of cultivation, the software can track the cost of all the materials and the locations you have to grow in. It does this while communicating to Metrc or Biotrack, the state compliance systems, at every step of the process.

From here, you’d manage your clones on an order that shows the estimated end date and a list of the tasks necessary to see these clones through their lifecycle. Some apps will allow you to track labor against this and real-time task management, whereas others act more like a schedule for when and where to do things. For example, watering, pruning, culling, up-potting, staking, and harvesting are all actions that could be taken against the plants. The software could and should track all of this while forecasting an end date and totaling up the resources in terms of material costs and labor.

After this, a different order would be created to trim, dry, cure, and process the plant material into various end products we’re all familiar with. Software assists here by tracking recipes, inventory cost, labor, and compliance. Then, it assists in selling said products via distribution and manages your various wholesale customers and sales orders. You can also track and manage purchase orders and know when different items in inventory will run out of stock. Everything rolls up into the financial piece of the seed-to-sale where business decisions can be made based on the estimated and actual costs of operating.

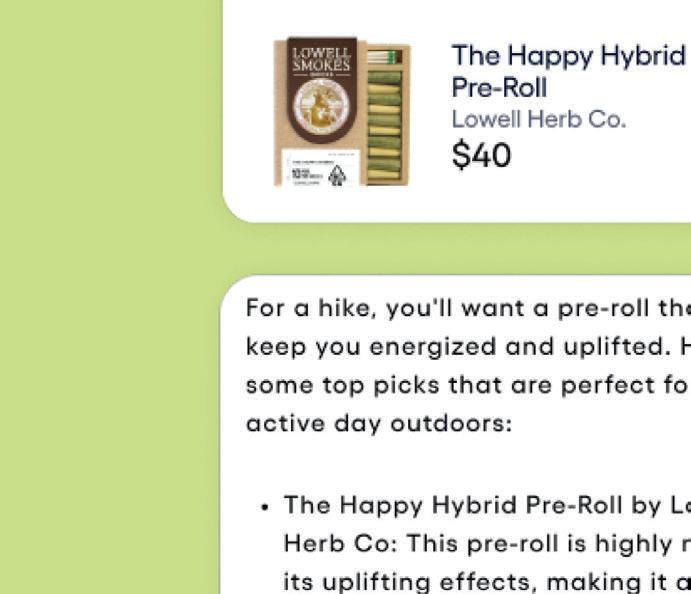

On the retail side, operators have to purchase their inventory, stay compliant, track customer transactions and records like loyalty points, average cart totals, profit margins, and more. Every terminal in a retail operation runs a system to manage their cash drawer, create sales, and help the business stay compliant and avoid overselling. We also see a lot of ancillary software companies providing retail functionality like digital menus, delivery, AI budtenders, and more. Without software, running a cannabis business can be a nightmare and with the wrong software, it can be a very expensive nightmare.

When I originally entered the cannabis industry in 2012 as a cultivator and hash-maker in Denver’s medical days, software was not part of the conversation at all. Operations relied on manual tracking and (in my

case) painter’s tape and sharpie markers paired with strategically placed whiteboards to keep facilities running and on track. While this wasn’t ideal, it did (and does) work for small operations—but requires a lot of time, training, and attention to detail. With one wrong move, you could erase the harvest date or nutrient recipe the business relied on. I saw the inefficiencies of this around cultivation planning and forecasting firsthand. We churned out some wonderful flower and awardwinning products, but it wasn’t scalable or efficient.

Software was quick to rise to the occasion but was far from perfect. Early solutions were cumbersome. They had people responsible for the product who had no love for or experience with cannabis. This led to the demise of more than a few companies along the way. Some applications attempted to jump into cannabis from traditional manufacturing using legacy ERPs. The industry wasn’t exactly ready for this complexity early on, and they ended up causing more problems than they solved. That’s where the bespoke solutions quickly became the way to success.

As cannabis sweeps the nation and picks up speed across the globe, the need for efficient, compliant, and scalable software will increase. The future of cannabis technology involves software companies working hand in hand with their operators and customers to endlessly perfect their solutions. The work is never done.

I operate Apartment 113 to provide product management for cannabis software companies and help operators find and use the right software solutions. I build integrations, new features, teams, and processes to create the best possible products for the industry. A software decision can make or break a company, so it’s important to partner with the right people from the beginning. I’ve seen too many things done incorrectly in the past that have only reaffirmed my dedication to building quality software for the cannabis space.

I can confidently say combining industry knowledge with technical expertise is the way forward for operators and software providers. Know your providers and their leaders to make sure their hearts are in the right place and that they are building something right for the industry, not just their bank accounts.

By Shelley Peebles, CG, RDH

Deep in the mountains of Mendocino County lives a hash maker dedicated to his craft. He is obsessed with providing the cleanest, single-source hash possible. In an ironic twist, he calls himself Dirty Hands, Clean Hash, a name that, on first thought, has you questioning whether or not you should smoke it - which would be a huge misjudgment of quality.

A homesteader at heart, DHCH believes in being a good steward of the earth, and using the nutrients that Mother Nature provides. “I worked on a farm and did everything, making composts from stalks and other things around the property.”

His culinary background plays a crucial role in hash making, providing him with the expertise to manage every outcome and refine his pristine methods. He believes in single-source flower, grown in all organic soil. Never does he use a flushing agent, as the inputs are free from pesticides.

A good friend first introduced me to DHCH when visiting the redwoods of Northern California a few years back. We set up a dab bar, with a large assortment of hash rosin to try. “I can’t wait to see what you think of this one!” he told me excitedly.

Grateful that my friend loves to play dab-tender, I took my first dab as it was prepared. Instantly blowing out a waft of smoke, I asked him, “Why do I taste dryer sheets?” I meant that in a good way of course, and he agreed. “Right?!”

He went on to tell me that he discovered this guy’s hash while exploring the Redwoods of NorCal, and really liked his stuff. I went on to follow his page and discovered that this hash maker also uses flower grown in living soil, all organic, and believes in quality over quantity.

When it comes to craftsmanship, DHCH sticks to small batches with the utmost attention to sourcing organic, single-source strains, down to the very genetics from which the flower comes. For every seventh 1-gram jar he makes, a lucky person will find a terp pearl, most likely made by Ooze Glass, a cult favorite in the hash world. I was lucky enough to get my hands on some of their Y.P.F. #17, or Yellow Passion Fruit, as it’s known. The number 17 is for the 17th phenotype which was a winning pheno from Black Cat Genetics, grown by Palo Verde Appellation in light deps. The flower is fresh-frozen, then hand-washed and pressed by DHCH.

As I pop open the jar, it has a smooth, waxy appearance. I examine it closely with my loupe—it’s clean. Nothing but glistening tiny trichomes. It resembles light yellow ear wax, and I gather its dry appearance is likely due to storage. I remembered my manners and whipped it until it became a nice, creamy consistency.

The smell takes me back to packets of orange Kool-Aid mix being made after school on a hot sunny day. Hints of lemon and lime zest pop out at me. There’s a sweet and tangy sharpness to it, and the bottom half of my nose starts to tingle. I notice a trace of floral notes from that sweetness, like honeysuckle. The strong adhesive on the end is invigorating. Tropical fruits make it smell exotic, getting me excited to try this one!

It’s a nice, light citrus taste and a clean finish. More lemonlime forward with nectarines. On the exhale, the floral taste of something reminds me of accidentally getting a mouthful of perfume from the 1980s or walking into an old house. I can taste some sort of spice like pepper mixed with a strong glue, like the old school Elmer’s Glue in the brown jars.

This one is noticeably uplifting, with a cerebral stimulation. I sense a lot of tingling in the lower part of my nose. This transitions to soothing and calming effects, as the strain in my shoulders and neck effortlessly melts away. It reminds me of a joyful memory, and I feel it tugging me towards happiness. This is a great way to manage pain and uplift yourself!

DUSTIN HOXWORTH FOUNDER FAT NUGS MAGAZINE

As the cannabis industry matures, businesses face an imperative to evolve in an increasingly competitive market. To thrive, companies must fully accept, embrace, and harness innovative technologies that not only differentiate their offerings but also enhance the quality and consistency of their products.

The rise of AI and advanced cultivation techniques, such as precision agriculture and automated growing systems, is already transforming how cannabis is produced. These technologies enable growers to monitor environmental factors in real time, ensuring optimal conditions for plant health. When done right this can lead to higher yields and a more uniform product, which of course is crucial for meeting the diverse needs of consumers and patients alike.

Other technologies can advance other parts of doing business, leveraging data analytics and CRM tools to increase brand engagement, or AI-driven marketing strategies to personalize customer outreach.

Radical ideas like adopting blockchain technology to overcome banking limitations or even creating robots that can roll the best hash holes can help take the cannabis industry into its maturing phases.

As the future of the cannabis industry hinges on things like descheduling/rescheduling, state lawmakers, tax policy, and more, the industry’s ability to embrace technology will eventually change everything. Those who innovate will not only improve product quality but also forge deeper connections with their customers, ensuring sustainable growth in an ever-evolving landscape. As the industry continues to expand, the integration of technology will be key to unlocking its full potential.

With all of that in mind, I asked some of the industry’s leading technology companies to chime in and tell us how what they’re doing in their respective companies is helping to improve and move the industry forward. Here is what they had to say.

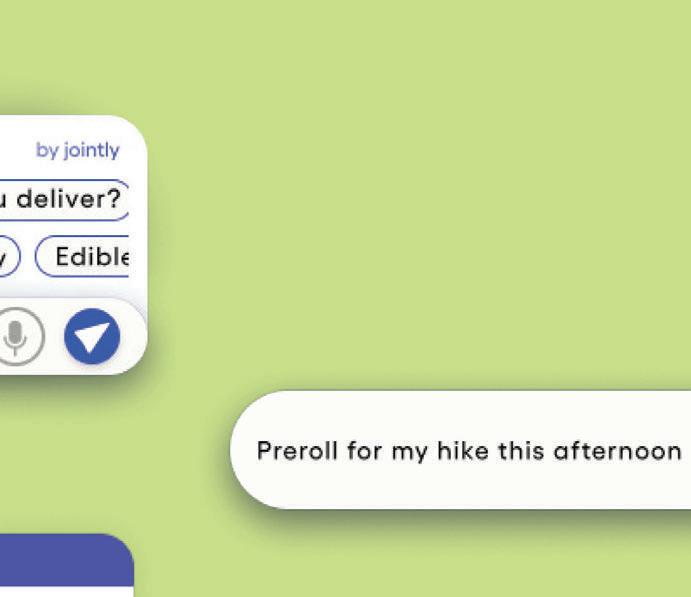

DAVID KOOI CO-FOUNDER & CEO JOINTLY

CAN AI HELP YOU GET A BETTER HIGH?

Turns out, with the right data, it can. At Jointly, our users show that the answer is a resounding yes.

Have you tried asking the popular AI tools—ChatGPT, Google’s Gemimi, or Claude— for advice on cannabis? Sure, they can talk about it, but their advice is based on the random grab bag of info floating around the internet, which, let’s be honest, is… not that great. Have you tried Googling for answers? The internet is filled with the usual baggage: stigma, outdated info, and half-baked myths.

SO, WHAT MAKES JOINTLY’S AI DIFFERENT?

Our AI doesn’t just pull from the same old internet potluck. It’s powered by real-world data from real cannabis users. People like you, who use the Jointly app to track their experiences and discover how to live better with cannabis. We’ve got millions of data points to back it up.

The result? Personalized cannabis recommendations and answers that aren’t based on guesswork. They’re backed by solid data, science, and the collective wisdom of a

community that’s been there, done that. No more wandering the dispensary aisles wondering which product is going to work for you. Now you can know.

Cannabis retailers love Jointly’s AI, too. Budtenders can finally stop feeling like they need a PhD in every strain and product on the shelf. With Jointly’s goal-specific product data, they can confidently recommend what works.

In short, Jointly is about making cannabis better for everyone—whether you’re consuming it, selling it, or recommending it. We’re using tech and data to cut through the noise, so you can get what you deserve from your cannabis experience.

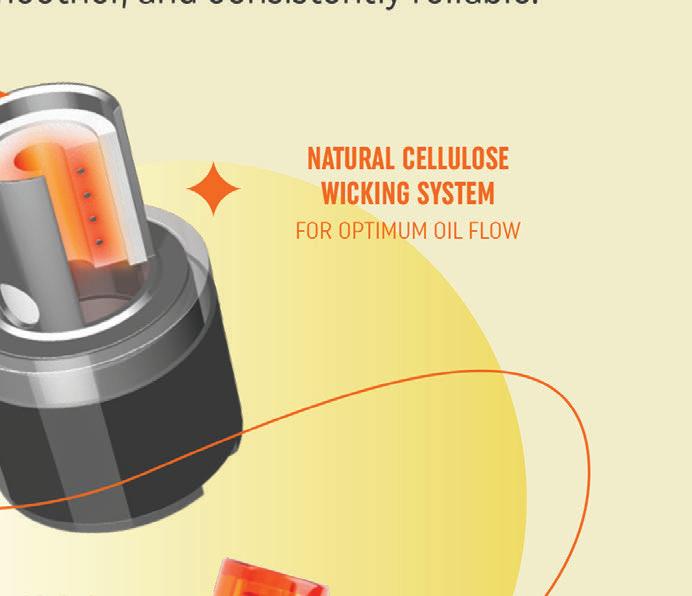

Rich Yost CEO—AIRO

The cannabis industry is at a critical juncture. In the midst of increased regulatory oversight and concerns about vape safety, companies like Airo are responsible for driving the next wave of innovation. It’s not just about creating better products—it’s about addressing real concerns head-on and pushing forward with solutions that consumers can trust.

Recent reports on vape safety have left many consumers questioning what’s inside their devices. We’ve responded by ensuring that our products are built with precision and integrity. Airo’s custom-engineered atomizers and airflow technology are designed to eliminate uneven heating and burnt oil—two major issues that affect both product quality and consumer trust. We take it a step further by prioritizing non-burning technology, reducing health risks, and improving the overall user experience.

Our approach to product development centers around two key pillars: safety and performance. We focus on using the best materials and technology available to produce cleaner, more reliable cannabis vaping. Our goal is to eliminate the guesswork for consumers, so they know they’re getting a product that has been rigorously tested and built to perform consistently from the first puff to the last.

As Airo looks ahead, we’re not just refining what’s already working; we’re thinking about how to shape the future of cannabis consumption. Whether through operational efficiency or breakthroughs in hardware, our commitment to innovation and consumer trust is unwavering. We believe the next generation of cannabis vaping will be built on the foundation of transparency, safety, and technological advancement—and Airo is ready to lead that charge.

ANDREW WATSON

FOUNDER & CEO—HAPPY CABBAGE

Cannabis retailers are facing a major problem: too much product and not enough customers. Right now, there’s an estimated $3 billion worth of overstocked inventory nationwide. This glut of unsold weed is pushing retailers to offer huge discounts just to get rid of it, often selling products at fire-sale prices. Some are even going out of business, owing millions to their suppliers.

Why? Bad inventory planning and relying on outdated systems. In some areas, 20-30% of all sales come from discounted products. This constant price-cutting might seem great (who doesn’t love cheap weed?), but it’s hurting brands and retailers. As prices drop, retailers have to spend more on marketing just to get you in the door, and it all stems from poor inventory management.

So, how do they fix this and how does that impact you? They fix it with better technology. A lot of dispensaries get bogged down by tech that promises to do everything or focuses on pretty reports nobody uses. What they really need is tech that solves the key issues—figuring out what to stock and when, with speed and accuracy. The right system helps stores run smoother without adding more headaches.

JACK GROVER CO-FOUNDER & CEO GROVE BAGS

POTENCY POLITICS: WHAT MAKES ME HIGH?

Nationwide, budtenders agree that using “THC per dollar” as a purchasing metric is flawed. Potency depends on more than just THC; the real magic is in the entourage effect—the synergy between cannabinoids, terpenes, and other compounds that enhances the plant’s effects when they work together.

THC may be the main player, but without support from terpenes and other cannabinoids, the experience lacks impact and nuance. Cannabis contains THC, CBD, and over 100 other cannabinoids, plus terpenoids and flavonoids, which combine to create effects greater than the sum of their parts. Two strains with similar THC levels can produce very different effects due to their terpene profiles.

Preserving this complex interplay of compounds is crucial, and that’s where packaging comes in. Some methods keep the flower intact but fail to protect the delicate terpenes that drive the entourage effect. The challenge is ensuring these volatile compounds reach the consumer Intact.

We designed TerpLoc® to maintain flower quality at every stage. While cannabinoid and terpene content are common

The best tech for cannabis shops should fit into their existing operations. It needs to make inventory management, demand forecasting, and supplier relationships easier and more effective, not more complicated. Think of it as the behind-the-scenes engine that ensures your favorite strains and edibles are always in stock without the need for constant discounts.

For you, the impact is higher quality and more consistent availability at fair prices. Dispensaries that get inventory right don’t have to rely on last-minute sales, and everyone benefits. So next time you’re shopping, remember: the tech driving your favorite dispensary plays a big role in your experience.

Keep your expectations high, just like your standards for quality cannabis.

metrics, focusing on overall quality also means addressing gas and moisture regulation, mold prevention, UV protection, and trichome preservation. This ensures a full experience—not just high THC but the rich combination of compounds unique to each strain. TerpLoc® packaging retains up to 37% more terpenes than traditional methods by taking these challenges into account.

You wouldn’t buy meat based solely on fat content and pack it in a shoebox. Don’t shop for cannabis this way either. Next time you’re at a dispensary, ask about terpene profiles and observe how the flower is stored and packaged. Choosing products that preserve the full spectrum of cannabis compounds will lead to a richer, more enjoyable experience.

Nohtal Partansky FOUNDER & CEO SORTING ROBOTICS

ELECTRIFYING CANNABIS: HOW TECHNOLOGY IS ELEVATING YOUR EXPERIENCE

As the Co-Founder & CEO of Sorting Robotics, I’ve had a front-row seat to how technology is reshaping the cannabis industry. When you indulge in a premium cannabis product, you might not consider the myriad of innovative processes behind it ensuring its quality, safety, and consistency.

State-of-the-art automation and robotics are changing the game in production. By incorporating precise dosing systems and advanced packaging solutions, we’re able to eliminate inconsistencies that could affect product integrity. This means that every time you use a cannabis product, it meets the exact standards promised. It’s not merely about boosting efficiency; it’s about raising the bar for what consumers should expect from cannabis.

Pre-rolls are another area where technology is making a significant impact. Traditional hand-rolling methods can lead to variability in quality and experience. With the introduction of automated pre-roll machines, we’re able to produce joints that are consistently packed and precisely measured. This ensures that every pre-roll delivers the intended flavor and potency, providing a reliable experience each time. Technology not only

enhances the consistency but also allows for innovative products like infused pre-rolls or customized blends, expanding the horizons of what consumers can enjoy.

Angela Pih GLOBAL CHIEF MARKETING OFFICER—CCELL

Technology has allowed us to experience the cannabis plant in whole new ways. It’s a driving force shaping the future. From cultivation to consumption, every aspect of cannabis is being transformed by cuttingedge innovations. The true potential of the plant is now being unlocked, allowing cultivators to grow smarter, extractors to process more proficiently, and consumers to experience a more refined, consistent product at the end of the day.

At its essence, the cannabis movement is about the plant. But how we interact with it (and how it interacts with us) is deeply influenced by the technology we use to harness its unique benefits. Advancements in vaporization hardware center around ensuring that this symbiotic relationship between cannabis and tech is as effective and pure as possible for all consumers. From medical patients seeking consistent

dosing and safe relief, to cannabis sommeliers searching to unlock unmatched terpenerich experiences, the importance of delivering cannabis in its most authentic form cannot be overstated. In an era where precision, purity, and safety define successful cannabis brands, technology will continue to shape the overall experience from the core. That said - the future of cannabis is looking cleaner, safer, brighter, and more innovative than ever.

Ultimately, it’s about building trust and offering transparency. You deserve to know that the products you consume are crafted with the utmost care and cutting-edge technology. By staying at the forefront of innovation, we’re not just keeping pace with industry advancements—we’re driving them. This ensures that the future of cannabis is more efficient, sustainable, and centered around delivering the best possible experience to you.

Chris Doucette CO-FOUNDER & CEO—TOKE

What makes the cannabis industry great?

Many things, of course. We could have an entire smoke session discussing the benefits of cannabis and the grassroots initiatives that are slowly changing laws and saving lives. It’s evident in the passion for cultivation, innovation, and making a difference. These contributions stem from the dedication of individuals in unique roles—growers, manufacturers, software developers, dispensaries, and caregivers. Yet, all these efforts culminated for one purpose: the customer.

We find strength in the cannabis movement through our desire to create a tailored and elevated purchasing experience for each type of customer that stands before a budtender. We don’t judge, we engage. Who are they? Do they come for medical purposes, a fun Saturday night, or to relieve life’s stresses? In a world that has become increasingly transactional, automated, and disconnected from human connection, cannabis has demonstrated the fundamental human desire to be acknowledged.

In my decade of working in the industry, and now as CEO and Co-founder of Toke, I’ve witnessed how the customer experience has driven the acceleration of the cannabis revolution. The stereotypes that came from buying off the streets have diminished, and we now see state and federal resistance weakening because of the personalized professional experiences the culture offers.

I am proud to be in a position at Toke to offer point-of-sale software that is committed to the common cultural goal. As cultivators create a variety of strains to meet specific needs, manufacturers develop edibles, pens, and other consumption products to enhance the overall experience, and dispensaries provide comfortable spaces for building connections while shopping.

Dispensaries choose our software to be more effective with their efforts to create a convenient and trusted shopping atmosphere, leveraging our tools that help capture the unique relationships created with each interaction. We strive to be the keepers of their story, educating them on product origins, different types of highs, and ensuring they feel at home with multiple purchasing methods—making customers feel valued at every step of their buying journey.

All together, we are changing how the world perceives cannabis one transaction at a time.

J.D. Garrick MANAGING PARTNER ILLUMINATED EXTRACTORS

WHY HIGH-QUALITY EXTRACTION MATTERS TO CANNABIS CONSUMERS

As the Managing Partner at Illuminated Extractors, I’ve seen firsthand how crucial extraction is in delivering great cannabis products. When you’re enjoying your favorite concentrates, oils, or edibles, what you might not realize is that the quality of extraction directly impacts the safety, potency, and overall experience.

A high-quality extraction process preserves the full profile of cannabinoids and terpenes—giving you the purest, most flavorful experience. Proper equipment and innovation help ensure that no harmful contaminants make their way into your products. It’s not just about getting the most out of the plant; it’s about ensuring what you’re consuming is consistently safe, and clean.

As the cannabis industry grows, it’s important for manufacturers to innovate in ways that reduce their environmental footprint. Cannabis extraction is a power-

intensive process, but by developing more energy-efficient technologies, we’re able to produce high-quality products without the heavy energy costs of traditional methods. This balance of sustainability and efficiency ensures a better experience for consumers while contributing to a greener future.

When you choose a cannabis product, you’re trusting that what’s inside is as good, and safe, as advertised. By focusing on purity and quality with certified equipment for extraction, we ensure that every product processed with our systems lives up to that trust—giving you peace of mind and a premium experience.

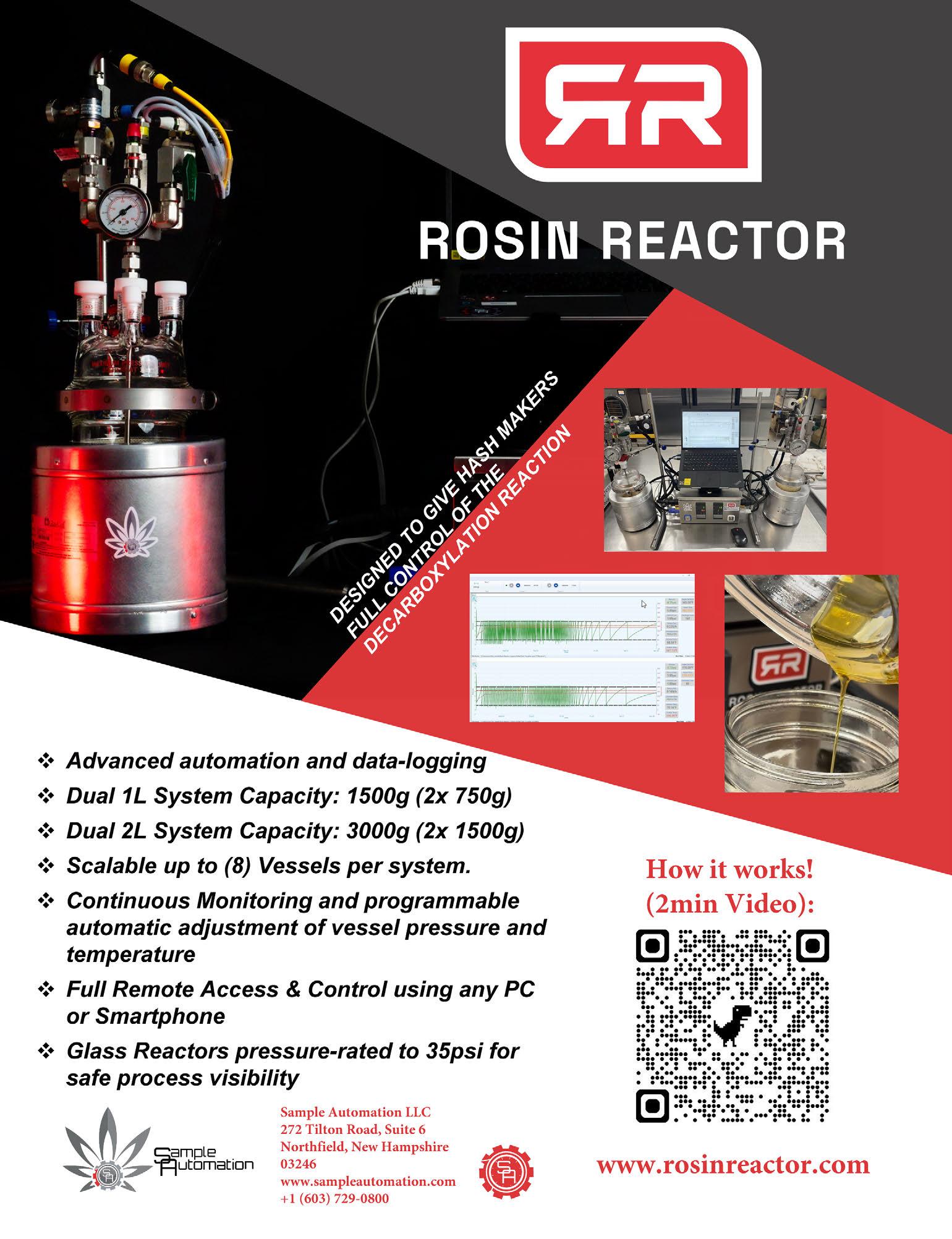

Corey Crosser CANNABIS R&D, SALES SAMPLE AUTOMATION

The human desire to explore and improve our connection with cannabis is the precursor to developing effective technologies for the industry. When adding automation to any cannabis manufacturing process, it is critical to first understand and appreciate why traditional craft processing methods work, to ensure product quality is never lost or sacrificed.

Legacy operators in backyard farms and basements deserve significant credit for discoveries and advancements in cultivation, processing, and extraction methods. Growers and extractors routinely designed and fabricated their own solutions, repurposed equipment from other industries, or used whatever was available: trash cans or washing machines for making water hash, hair straighteners or homemade presses for rosin. If the product was top shelf, the method didn’t matter. Everyone working with cannabis long enough has their own catalog of D-I-Y "tech" that does (and does not!) work.

For the last 5 years, I have partnered with Sample Automation to develop equipment specific to cannabis milling and concentrate post-processing, tackling challenges encountered firsthand as an Extraction and Lab Operations Manager. These passion projects include the first fully automated Diamond Miner and the Rosin Reactor. Both systems were designed with the same purpose: to track and automatically control/reproduce the parameters of ideal “jar tech” (heating a mason jar in an oven during concentrate processing). While “jar tech” is effective for creating high-quality end products, mason jars are not rated for oven heat (or pressure) so their use is not allowed in any highlyregulated production facilities.

We wanted to give lab managers and operators better, compliant options with full control over their jar tech recipes. Not only is the reaction data displayed live, but they can check in and make changes using a smartphone from anywhere, at any time. No more wondering if someone left an oven on, or watching bubbles in a jar and guessing if the decarboxylation reaction is complete!

"There are more things in heaven and earth, Horatio, than are dreamt of in your philosophy."

—Hamlet

By Lance C. Lambert

Cannabis legalization has been a global movement for years now. Countries like Uruguay and Canada garnered international attention in the early teens due to being the first adult-use, aka ‘recreational’ markets to legalize.

Many are unaware that Canada was also the first country to legalize medical cannabis back in 2001, just five years after my home state of California fully legalized medical use. This was also the same time several countries were decriminalizing cannabis as well, including Luxembourg and Portugal. But surprisingly, even Russia decriminalized cannabis in 2004—a shocker for those working in the industry today.

In total, over 53 countries have now legalized medical and/or adult-use as of today. And with legalization comes an evolution in how the plant is produced, processed, and consumed. We all agree that when it comes to benefits and abilities, this plant is still very much an enigma. But when it comes to working with that plant from seed to smoke, technology has come leaps and bounds, compared to those heavy prohibition years around the world.

The United States can take a good amount of credit for the culture and craft of cannabis today. The same can be said for many of the technological innovations the plant has seen in this century. Bringing technology into the grow is a great example of this evolution.

Those of us who grow have traditionally depended on simple means in which we monitor the most basic things like transpiration pull (how the plant absorbs water from the soil), the pH, or even ambient temperature. Now there are sensors that measure everything from soil

moisture content to ambient relative humidity in the grow environment. The same goes for environmental gases like CO2 and oxygen. These sensors take the guesswork out of the precious balancing act a grower embraces to optimize production quality, and output.

Even how the plants are watered has seen an evolution. I remember seeing my first fertigation system back in the mid-teens—I was blown away by the amount of automation. Having such a system integrated into a commercial grow saves the cultivation team hundreds of hours per year, giving them more time to manually optimize the crop in other ways.

The number of ways that growers treat, cure, and store their flower post-harvest has also increased dramatically, especially in the last decade. While as a humble full-term, outdoor home grower I’ve kept most things simple and traditional, many commercial cultivators have spent millions on methods to help them achieve consistency, potency, and quality at true scale. Some of these technologies have proven more effective than others, while some still struggle to fully explore the comprehensive, long-term effects they sincerely have on cannabis.

As legalization further scales internationally and new tech comes into play, research to better understand cannabis and its preservation is also increasing. That being said, many of the results of that research fail to make its way down to the growers themselves. This is why the company I work for is constantly monitoring ongoing studies, from Iowa to Italy. Why? This new information helps us source data to develop better solutions for our clients. These studies also uncover how effective (or in some cases ineffective) new technology can be when it comes to creating a better finished product for the consumer.

During my travels, I’ve come across many unique individuals who turned me on to regional studies. Often these studies dig into ideologies and respective tech that seem too good to be true.

Case in point, one study took a close look into different practices around drying and curing. This study can be found in the May 2024 edition of Analytical and Bioanalytical Chemistry. Italian researchers looked at the influence of drying and storage conditions on cannabis—specifically at their impact on cannabinoids and volatile compounds, like terpenes. As a part of their conclusions, they found that freeze-drying flower resulted in decent preservation of cannabinoids, but a loss of other compounds.

While freeze-drying might seem like an attractive option to growers who want to get their flower to market faster, sacrificing your finished product’s unique aromas and terpenes is a recognized and tested trade-off that most aren’t willing to make, especially if a grower is heavily focused on the quality and integrity of their harvest.

Another group brought into question the stability of cannabis oils. A 2023 conference paper from academics in North Macedonia, Davkova et. al., looked at the longterm storage and stability of cannabis oil, and how it might impact the effectiveness and regulation of medicinal products.

Notably, they found that after 12 months of storage, CBD levels decreased while THC levels increased.

We know CBD and THC are just two of a myriad of cannabinoids found in this amazing plant and its extracted oil. These findings support the researchers’ recommendation that “potency retesting is requested after a prolonged period of time, and care should be taken when comparing sample concentrations.” Because potency matters, especially for medical patients.

The same group is now looking into technology to properly maintain the quality, potency and consistency of oil postprocessing, something that wasn’t taken into account as little as ten years ago in this industry. A simple thing to resolve, once the issue was identified.

While some methodologies and/or solutions have been identified as flawed, others are taking off exponentially. Lighting is an excellent example of this.

Similar to what we’ve seen stateside, LED lighting for indoor/ mixed-light grows have evolved in recent years. This is extremely important for growers in markets that have limited resources when it comes to electricity. Spain would be an excellent example of this. Being a constrained and often pricey resource, LED has made a huge impact for those who are forced to grow indoors, versus harnessing Mother Nature by growing under the sun.

Another big shift I saw evolve in recent years, specifically in larger consumer-friendly markets like Barcelona and Amsterdam, is how the end product is consumed. Just a handful of years ago, your options for consumption were primarily whole flower or hash… now you will find a plethora of concentrates, and all the modern tools to consume them. Many have retired their blow torches and glass rigs for clean, simple handheld units. These aren’t just more efficient - they help avoid the hard drug stigma many endure when utilizing old-school concentrate consumption methods, because nothing looks right being lit with big blue blow torches.

The evolution of technology on the international stage continues. Especially as adult-use markets continue to come online, like Luxembourg, Malta, and more recently Germany, we see the technology follow closely behind. And this is a big advantage over those that continue to embrace the ‘that’s the way we’ve always done it’ mentality, more commonly found in the U.S.

Whether it’s using a passive atmospheric modification to auto cure your bud like TerpLoc, or grabbing a futuristic handheld device for consuming concentrates like a Peak Pro, or swapping out HPS lights for some Fohse lights, technology plays as major a role on the international stage just as much as it does back home here in the states.

The pictures are from indoor, mixed-light/greenhouse operations from Thailand, Malta, Holland, and Southern California.

By Daniel Crawford

The evolution of cannabis concentrates has come a long way in a relatively short amount of time. For most of the history between humans and cannabis, there was one basic form of cannabis concentrate: hashish. Hashish is made by the gathering of resinous trichomes from female cannabis plants either from dry sifting kief or collecting the resins from freshly harvested plants on the hands of the farmers who grew it.

Today you can find a plethora of different concentrated form factors at your local dispensary. From shatters to butters, sugar to sauce, diamonds, distillate, RSO, and everything in between, the choices can be overwhelming. For me, the biggest differentiating factor is the answer to this question: how is it made?

As a connoisseur of quality, especially when it comes to my cannabis products, the answer to the question I am seeking is, “It’s made using solventless extraction.” With a patchwork of inconsistent regulations written by uneducated politicians coupled with unscrupulous laboratories and businesses trying to make a quick buck, I don’t want to risk my health by smoking petrochemicals or products made by using them.

There seems to be a never-ending supply of similarly described products and terminology when speaking about cannabis concentrates. Here’s a quick refresher.

RESIN: Concentrates made from hydrocarbon extraction, typically referred to as BHO (butane hash oil), use butane and or propane to dissolve cannabinoids and are generally referred to as resin.

HASH: Solventless extraction uses only ice and water to separate trichome heads from cannabis flowers and creates the purest forms of concentrate, known as hash, which can be further processed into rosin.

When you use freshly harvested flowers that are immediately frozen (as opposed to cured/dried flower) and then use solventless extraction, the end product is referred to as Live Rosin. The same is true for BHO or hydrocarbon extraction processes which use fresh frozen flower to create Live Resin.

There are other forms of extraction to make cannabis concentrates, mainly CO2 and ethanol. In this piece, I will be focused on describing the tools and processes required to turn fresh frozen flower into oil at scale without the use of solvents to create, perhaps, the ultimate experience of cannabis concentrate consumption.

Cannabis plants are inspected for ripeness based on the development and color of trichome heads (the glandular structures containing the plant’s cannabinoids, and terpenes.) Quality trichome heads are bulbous in structure and milky and clear, the color preferred for washing and making hash. This is unlike harvesting cannabis for curing and smoking, which requires a larger percentage of ambercolored trichome heads.

Experienced hash makers are key in determining peak ripeness and guiding the team to which cultivars are best for washing and making hash. Once selected, plants are harvested, the buds removed from the stems and flashfrozen to seal in their flavorful terpy goodness.

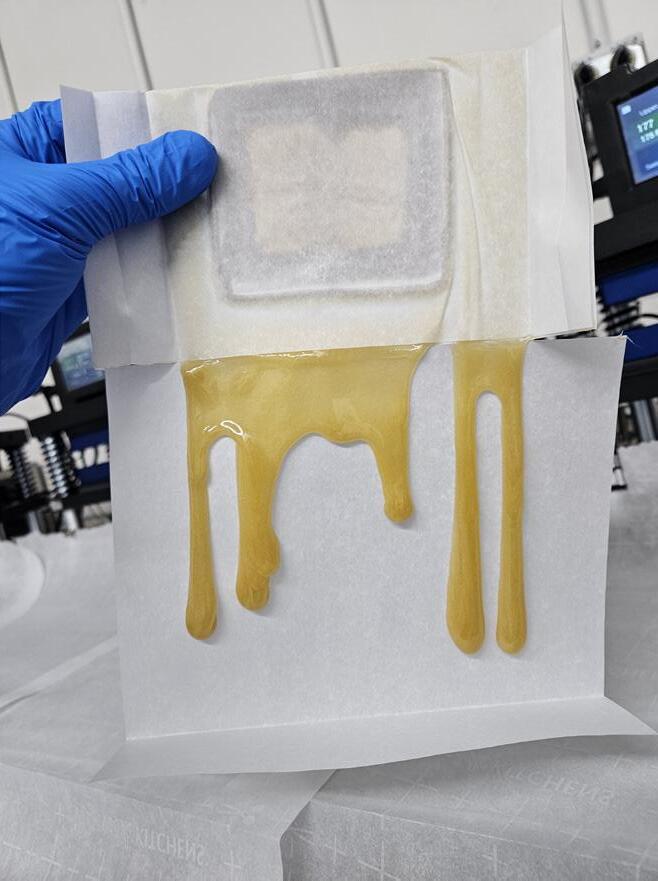

Frozen buds are washed using ice and cold water to agitate and remove the trichome heads from the plant material. This slurry of water and trichomes are then filtered through a series of mesh bags, or sieves, creating bubble hash. Excess moisture is removed and the remaining hash, graded by size, is processed further with heat and pressure to become rosin.

The final step in turning the Live Rosin into oil is to decarb the rosin using heat and pressure. This step in the hash-making process traditionally requires a skilled hash maker or chemist to transform the rosin into oil without degrading the oil by overheating, causing a loss in terpenes.

From here, the finished Live Rosin Oil can be used in edible production, filled into carts or all-in-one vaporizing devices, infused into premium prerolls, or dabbed.

These are my personal recommendations based on my experience scaling up commercial solventless extraction operations in multiple adult-use markets.

If you want quality rosin, the highest-grade freshly frozen flower is absolutely necessary. Without access to this, creating quality rosin is out of the question. You can use high-quality freshly cured flower, but the quality and your ROI will be diminished.

The solventless extraction lab should not be treated as a garbage disposal for poor cultivation practices, under performing cultivars, or a place to send your subpar and unsellable flower. Knowledgeable and experienced hash makers should be able to recommend proper genetics that will wash well for yield and flavor profile.

The size of your extraction system is dependent on the amount of product you will be processing. Keep in mind your projected growth and market expansions, as well as what your local market demands. All Hashatron commercial series washers utilize a triple-wall glucose chilled and insulated main wash vessel with 100% duty cycle servo motor to drive their modular removable stainless steel wash basket. This eliminates the need for nylon wash bags or cleaning out the agitation vessel. No more shoveling ice and soggy buds!

There are similar systems to the Hashatron, but nothing beats their customer service. Hashatron’s CEO, John Digertt, and team are available nearly around the clock to answer any questions and make sure you are operating at your full potential.

The freeze dryer is another necessary workhorse in the solventless extraction lab. Without a freeze dryer, there is no bubble hash and there is no rosin. Since the freeze dryer is usually the bottleneck in the extraction lab, ensuring it’s functioning in top shape is another must. Learning to repair and maintain this piece of equipment will make or break your lab. Harvest Right freeze dryers are designed to handle resinous materials, unlike some more inexpensive home freeze dryers which were designed for food.

Lowtemp has some really high-quality presses on the market. When scaling solventless operations, consider their V2 Medusa Press to increase output while maintaining consistency. Depending on production needs, you can link two to five 4x7 Lowtemp presses together for a single operator to be able to press an easy 500g of sift per squish. This system keeps the small batch quality that the Lowtemp V2 system is known for but is perfect for scaling up production to almost any level.

If you have ever worked in a cannabis post-processing lab, you’ll empathize with this: there are many different components at play that contribute to the final form factor of the concentrate you are working with. Eliminating as many variables as possible is the simplest path to consistent, quality products and processes.

The Rosin Reactor and the Crown Smart Vessel from Sample Automation are able to use data (imagine that!) to take the guessing out of creating valueadded products like rosin jam, diamonds, sugars, and sauces. Creator Corey Crosser, a veteran of the California Prop. 215 medical era who transitioned to the adult-use market in 2017, understands a thing or two about quality. I had the privilege of working with him in Nevada, circa 2019-2021.

Frustrated with guessing and inconsistencies, Corey used his engineering background to create a tool that decarbs your precious concentrates into an oil that isn’t overcooked and won’t crash out in your carts, creating a wonderful customer experience.

When turning cannabis flower into oil, there are a million ways to skin a cat. These are my recommendations based on personal experience scaling and managing an awardwinning solventless lab in the Arizona market.

These suggestions may not fit every operation, be practical in every specific market, and may not fit your budget. Contact your local hash maker for further guidance.

Hey there, home growers! Welcome back to my basement. This issue is a challenge for me. See, I am a tech geek to the core. If I were to start writing about the technology available to you as a home grower, and the gear that I’ve demoed in my garden, I could fill this whole edition!

But I am going to set all of that aside. Why? Well, because we have some unfinished business.

In the last edition, I got us neck deep into our own little pheno hunt and left you hanging! It was just too big of a subject to tackle in one issue. If you’re asking, “what’s a pheno hunt?” do yourself a favor and hit pause on this article, while you log into FMN and read part one in the Flower Edition.

Everyone ready? Great!

From a cultivator’s perspective, we’re going to dig into something that is rather low-tech. (It’s also something that won’t set you back an arm and a leg.) But if we were to frame it as “nature’s technology,” then it really is quite amazing. That miracle is cloning.

Whether it’s tomatoes, leeks, or lettuce, we as cultivators are capable of asexually reproducing a wide variety of plants. I am currently pheno hunting and cloning African daisies in my garden.

But today, we are going to focus on our favorite plant, cannabis sativa. Just understand that the process is similar for most species. With a little precision, a mind towards cleanliness, and the right

environment, we can cut a small branch from a healthy “mother” plant and begin the life cycle again, creating an entirely new plant from that branch, essentially an exact copy of that mother plant.

If you’re in the middle of a pheno hunt and you have a few female plants that you’re ready to transition into the flower cycle, now is the time to clone each of those females. You will care for and continue to vegetate those new plants while the mothers finish their flower cycle. You may find yourself pruning those little clones because they’ve gotten too large while you wait for their mothers to finish up. I’ve even cloned a clone to start the process over while I waited!

Or, maybe you’ve already found a phenotype that you like and you just want to grow more of it. Clone it, baby. Make a few. Make a dozen! Virtually every shoot on that mother plant could be a new plant if you want it to be.

But as part of a pheno hunt, you really only need one. You are just looking to preserve the genetics until you are able to decide whether or not it’s a keeper. You also don’t want to cut too many branches off of a plant that you are about to flower.

If done properly, cloning can have a near 100% success rate. Regardless, I always take a few cuttings of each variety to give myself a little insurance, in case I run into problems. Cloning doesn’t take much time or many resources, and it’s easy to just discard the extra clones that you don’t need.

There are two methods of cloning that are available to the average home grower. One uses simple propagation trays, putting the cuttings in starter cubes that typically are made of peat or rockwool. The other method is using an aeroponic cloner. I prefer aeroponics. But today, we’re going to learn to start with cubes. It’s how I first learned to clone and it is by far the preferred method, both commercially and in home grows.

You will need a few items to get started:

• Propagation tray with a humidity dome

• Starter cubes

• Small packet of rooting hormones

• Razor blade or scalpel

• Possibly two pH adjustment solutions (one to raise the pH and one to lower it)

Start by soaking the cubes in water. I recommend a light nutrient solution. There are solutions specifically designed for cloning, but you can use any nutrient line. I have used a traditional flowering fertilizer as they are higher in phosphorus, something the cutting will use to create new roots. The challenge with any nutrient is ensuring that it is not only the right concentration but also the right pH for cloning.

If there is any “tech” that I would recommend in this issue, it’s a pH meter and an EC meter. The pH meter will measure how acidic a solution is. The EC (or electrical conductivity) meter, ultimately measures the total amount of dissolved fertilizers in a solution, or its concentration. Too low and the plant will be

malnourished. Too high, and the plant won’t be able to effectively move nutrients and water efficiently enough to meet the demands of photosynthesis. Ultimately, the plant will suffer in similar ways.

If these tools are out of your budget for now, just start with water. But if you can afford to add them to your toolbox, do it. These meters will prove invaluable in your garden.

All nutrients are absorbed optimally by the plant at a specific pH and it’s a bit different for each nutrient. If the pH of the solution is too high or too low, the plant will not be able to uptake that nutrient, which is called lockout.

A good general target for that pH is 5.8–6.0. At that pH, the plant will be able to uptake all of the necessary nutrients efficiently enough. For cloning, I aim for a lower pH, in the 5.5–5.7 range. This pH is less than optimal for nutrient uptake, but the more acidic solution will help prevent the growth of bacteria in your media, giving your cuttings a better chance of success.

The EC of the solution is not as critical, but I generally like it to read 1.2–1.4. Some EC meters will use this reading to calculate parts per million (or ppm) for you. The corresponding ppm would be 600-700.

After the nutrients have been added to meet that EC, check the pH. You will then use the pH adjustment solutions to adjust the pH accordingly. Use it very sparingly and add more if needed. It is usually fairly concentrated and you can overcompensate easily.

Whether you’ve soaked your cubes in nutrients or water, squeeze most of the solution out of the cube and place them in the propagation tray. If they are too wet, your clones are more likely

to rot than root. I like to use a checkerboard pattern, only using every other space in order to give the cuttings room to breathe.

Now it’s time to take your cuts. I prefer to take more vigorous cuttings from near the top of the plant, but if they are mothers about to go into flower, I’ll take cuts from the bottom.

I only need those cuttings to be a few inches long, but I will follow it back to where it started and prune it from the plant there. Then I will cut the small cutting to the appropriate length, making a clean 45-degree cut to the stalk, preferably right below an internode, or the point along the stalk where the plant begins new lateral growth.

After I cut it to length, I will tightly prune away any vegetation, leaving just a small cluster of leaves at the top, four to six leaves at the most. I use the scalpel very carefully to shave away about an inch of the outer epidermis of the stalk, just above the 45-degree cut I made earlier. Removing the epidermis from all sides is not necessary—I usually shave about halfway around the stem.

This is a delicate procedure, as you want to shave off the skin without cutting into the inner pith of the stem. It may take a bit of practice. If you’re having trouble, try using the dull side of the blade to rough up the epidermis, rather than shaving it.

At this point, have your rooting hormone ready and dip each cutting into the hormone solution. It doesn’t take much.

Now the cuttings are ready to be pushed an inch or two into each cube. And that’s it!

From here, it’s important to keep the area clean and keep the cuttings at the proper temperature and humidity. Consistency is the key to success. I would aim to keep the temperature in the mid-seventies. The proper humidity for that temperature is 6570%. A humidity dome on your propagation tray will help you maintain that—just take it off occasionally to allow for some fresh air exchange and to help prevent the humidity from being too high. Most domes also come with vents that you can adjust to help regulate this.

Place the tray under your light. Clones will require far less light to get started than flowering or even vegetating plants, so either dim your light down to probably 10–15% of its total output or raise it at least four or five feet above the humidity dome.

And that’s it! Keep the cubes moist, but not wet. Look for fungus growing on the cubes. If so, they’re too wet. If your cuttings are wilting, the cubes are too dry. Do your best to maintain that temperature and humidity. And most of all, be patient and leave them alone.

Within about two weeks, if all goes well, you’ll see them start to vegetate again and new roots will be growing out of the cubes. At this point, they are ready to transplant. Keep the new substrate moist and slowly increase the light levels while decreasing the humidity to 55–60%.

And congratulations! That’s all there is to a pheno hunt. Other than the harvesting, drying, and curing! And sampling, of course! We’ll talk about harvesting, drying, and curing in an issue to come.

Photos by Jim Berry

"Things are as they are. Looking out into it the universe at night, we make no comparisons between right and wrong stars, nor between well and badly arranged constellations."

—Alan Watts

"Out beyond ideas of wrongdoing and rightdoing, there is a field. I will meet you there."

—Rumi

"Do I contradict myself? Very well, then I contradict myself, I am large, I contain multitudes."

—Walt Whitman

By Kelly Kreutzer

Winter is upon us! During my first year in Chicago, I discovered a confectionery restaurant that offered an incredible variety of homemade marshmallows. Honestly, homemade marshmallows are far superior to storebought ones! Alongside these delightful treats, the restaurant served an array of hot chocolate options to pair with them. I was immediately inspired to recreate this experience by making my own infused peppermint marshmallows to enjoy in hot cocoa. Let’s get started!

3 packets of unflavored gelatin

1 cup of cold water

2 cups of granulated sugar

⅔ cup of light corn syrup

¼ teaspoon of salt

2 teaspoons of vanilla extract

2 teaspoons of peppermint extract

¼ cup of cornstarch

¼ cup of powdered sugar

1 syringe of Rick Simpson Oil (RSO) (Fullspectrum extractions work best for this recipe.)

Optional: Edible shimmer dust/glitter—I love using Fancy Sprinkles and recommend their products to elevate your creations.

Before you begin, it’s essential to prepare everything in advance. Remember, mise en place is critical, especially when infusing.

• Prepare the pan: Lightly grease a 9x13 inch pan with non-stick spray, then line the bottom and sides with parchment paper. The spray will help the parchment adhere nicely.

• Mix dry ingredients. In a bowl, combine the cornstarch and powdered sugar.

• Coat the pan. Lightly grease the prepared pan again and evenly coat it with the cornstarch mixture. Set aside any excess cornstarch.

• Prepare the RSO: Place your RSO syringe in a cup of hot water to loosen the oil, allowing it to flow smoothly without clogging.

• Mix gelatin. In the bowl of a stand mixer, combine the gelatin with ½ cup of cold water and let it sit.

• Cook the sugar mixture. In a small saucepan, combine the remaining ½ cup of water, sugar, corn syrup, and salt. Heat over medium-high heat, covered, for about 3-4 minutes. Once warmed, uncover, attach a candy thermometer, and continue cooking until the mixture reaches 240°F.

• Add RSO. Carefully add your RSO to the hot mixture; it’s extremely hot.

• Combine mixtures. Begin mixing the gelatin mixture on low speed and gradually pour in the hot sugar blend. Once incorporated, increase the speed to high and whisk until the mixture is thick and slightly warm, about 12-15 minutes.

• Add flavors. Incorporate the vanilla and peppermint extracts and whisk for an additional minute.

• Pour mixture. Pour the marshmallow fluff into the prepared pan. Use a greased spoon to spread it into an even layer.

• Dust the top. Lightly dust the top with the remaining cornstarch mixture. Allow it to sit uncovered for at least 4 hours or overnight. For best results, I recommend having the marshmallows sit overnight for a nicely set marshmallow.

• Cut marshmallows. Once set, turn the marshmallows onto a cutting board and cut them into 1-inch cubes (a pizza cutter or food scissors dusted with powdered sugar works well.)

• Optional: Add shimmer. I recommend dusting with edible shimmer dust or glitter for an extra edible experience. These infused peppermint marshmallows taste wonderful in hot cocoa or on a skewer with the help of a dab torch.

“The cosmos is within us. We are made of star-stuff. We are a way for the universe to know itself.”

Carl Sagan

"The ultimate goal of farming is not the growing of crops, but the cultivation and perfection of human beings."

By Bri Smith

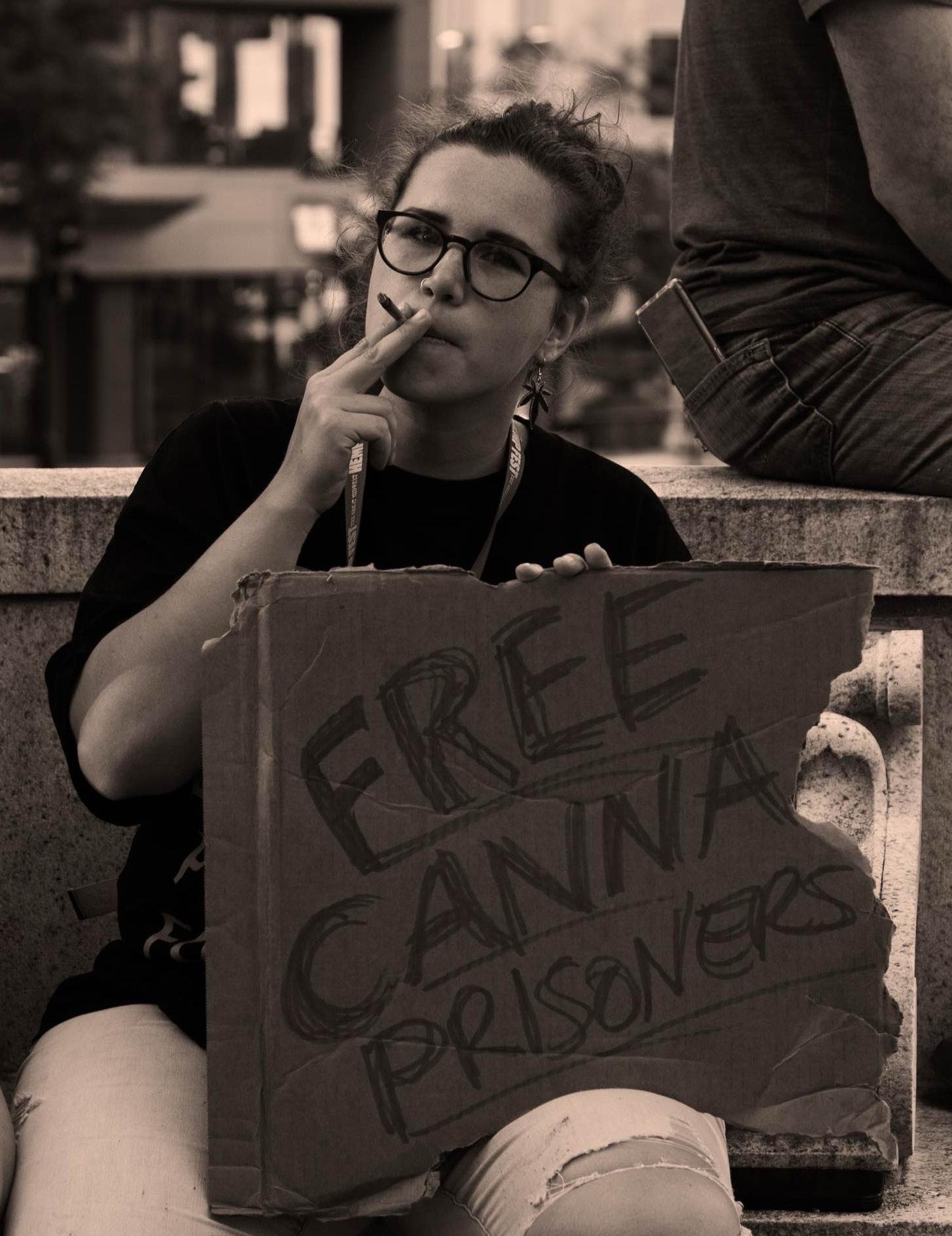

It was 1968, and Pigasus, a nearly 150-lb pig, was being paraded into Chicago as the Youth International Party’s nominee for President of the United States.

A few hundred people attended the charade in the park, many sparking up in protest of federal cannabis prohibition just outside the Democratic National Convention. As Pigasus was brought onstage, and his nomination acceptance speech read aloud by one of the Yippie founders, Jerry Rubin, they would be abruptly interrupted by police with seemingly no sense of humor.

Pigasus. Arrested. Along with his Yippie troupe. Their charges; disorderly conduct, disturbing the peace, and “bringing a pig into Chicago”. Something about an old Chicago law banning livestock in the city. The Yippie crew argued that the Democratic party was doing the same thing. Sick burn.

This young group of up-to-no-good hooligans likely wouldn’t have hit the radar of the political elites or the general public had they been politely holding signs on a street corner. And today, they surely wouldn’t be noticed if they were merely keyboard warriors, re-sharing angry political posts on Instagram and X. This little drama won Pigasus and his faithful brethren a highly publicized trial complete with air time from CBS, NBC, ABC, the Washington Post, the New York Times, and a slew of other major U.S. news outlets.

It was this sort of in-the-flesh theatrical political activism of the Youth International Party that drew the attention of the masses, attracted mainstream media coverage, and ultimately delivered a message to politicians that the younger generation wasn’t putting up with the absurdity of the political climate.

While this stunt occurred fifty-six years ago, the state of American affairs feels eerily unchanged. A self-serving group of politicians morally blinded by corruption and greed, carrying out a barbaric genocide with taxpayer dollars, abandoning the needs of the American people, all while maintaining a racist law prohibiting cannabis at the federal level. And while we still have brave young people speaking out today, there’s one thing that could be stealing its impact. Technology.

It’s 2004, and Zuckerberg has just launched Facebook, a student directory for Harvard Students. The success of that first year led to the expansion of access to students at high schools and other colleges the next year, and then to the general public in 2006. At the time, no one could have predicted what it would be today—a mega-corporation (Meta) that owns Facebook, Instagram, and WhatsApp—with a total of 3.59 billion users across these platforms. With the emergence of cell phones and complex algorithms that feed addictive behaviors, these platforms have nearly constant access to our attention.

This bizarre digital world is filled with messages and imagery ranging from make-up tutorials and cooking recipes to the latest product launch and humans being mercilessly burned in the rubble of their makeshift tent city. Social media provides everyday people, large corporations, brands, celebrities, and murderous soldiers the platform to deliver their unique messages. But one major multibillion dollar industry and its consumers are being left out—or should I say unconstitutionally silenced.

Big tech, like Meta, has been under scrutiny by the federal government and local officials to do more to censor “drug-related” content. And for all intents and purposes, they have obliged. Like clockwork, every few months, Instagram cracks down on cannabis accounts, deleting profiles, shadow-banning accounts, and putting algorithmic mechanisms in place to reduce visibility, reach, and engagement. Instagram’s official “marijuana” policy states:

“Instagram doesn’t allow people or organizations to use the platform to advertise or sell marijuana, regardless of the seller’s

state or country. Our policy prohibits any marijuana seller, including dispensaries, from promoting their business by providing contact information like phone numbers, email addresses, street addresses…”

However, many accounts—small and large—have been affected for merely posting educational, activist, or cultural content as it relates to cannabis. Even though nearly half of America’s 50 states have legalized cannabis, and the Federal Farm Bill made way for low-dose THC products across the U.S. by excluding hemp from the definition of marijuana, big tech still suppresses cannabis and hemp brands at every step of the way.

Want to diversify your marketing tactics by tapping into digital ads? Google will shut it down faster than you can yell Bing. Looking to reach your customers through email? Watch out for the mail monkey that will swiftly disable your account. Want payment processing or e-commerce on your website? Square, Shopify, and WooCommerce have a rep for cutting ties. Need a bank account to pay overhead costs and to operate as a legitimate business? Good luck with most FDI-Insured banks. And let’s not forget to mention the very real suppression of creative content across nearly all mainstream social platforms.

It’s been a growing issue, but it seems there’s no end in sight. This suppression isn’t simply a financial inconvenience to growers and dispensaries. It impacts nearly everyone in the cannabis industry, whether plant-touching or ancillary. It impacts the ability to reach ideal customers and patients, thwarts efforts to educate, silences activists trying to raise awareness, hurts small artisan growers, prevents progress in the opioid epidemic, and effectively abandons the most vulnerable communities impacted by the war on drugs.

So what’s the solution? All the major tech brands will likely continue to suppress cannabis content. My conclusion… let’s bring out the pig.

I feel it's nearing time we all but abandon the infinite scroll on these platforms for good, old-fashioned offline meet-ups. We’ve grown complacent in our approach to asserting our rights by thinking we do so with the flick of a thumb. In reality, it’s the in-person, show-up-with-your-body, bring-apig sort of energy we need to really make change.

It’s the mockingly absurd, yet legal, protests; the nomination of Pigasus, political pie-throwing, and public smoke-ins (one of which inspired the Gastown Riots) that garner the attention we need to move the needle.

In fact, it was the story of the late Great Midwest Marijuana Harvest Protest co-creator and fellow Yippie, Ben Masel, smoking a full joint in the voting booth as a protest that lit a flame under my ass to show up in the Wisconsin cannabis activism movement. It was his constant and intentional guerilla street activism and incessant prodding of our First Amendment rights that earned him the moniker “hellraising rabble-rouser.”

And yet, each year on 4/20, the city of Madison celebrates the notorious cannabis holiday with its own local holiday, “Ben Masel Day.” This holiday is both an ode to an incredible man and simultaneously a slap in the face of his lifelong pursuit of liberty and justice for all Wisconsinites, knowing cannabis remains illegal after all these years.

Don’t misunderstand my desire to bring back Yippie antics for that being enough for change. It won’t be enough. Our system is deeply flawed, and the only way to truly enact change is to strip money and corruption from politics, starve the billionaire class of its unregulated price gouging and blood money, and dismantle decades of deeply racist systemic advantages from the inside out.

Meanwhile, social media likely won’t go anywhere, and we will continue to be trapped in the confines of their unfair jurisdiction over the online dissemination of cannabis creativity and information. We can try to utilize it as best we can, but ultimately without collective pressure and action, or federal law change, there won’t be much movement. Some are ready to abandon these platforms, and I share the sentiment.

Ultimately, it’s still the showing up that counts the most. It’s committing to the action—whether it's boycotting Amazon and Walmart, participating in your local hearing regarding cannabis laws, purchasing your favorite grassroots magazine, or rallying with local orgs to support community initiatives, it’s the showing up that will set us on a path to freedom.

So, I’ll say to you what the great Yippie Manifesto once said to their fellow peace-loving humans and yippies:

“Come all you rebels, youth spirits, rock minstrels, truth seekers, peacock freaks, poets, barricade jumpers, dancers, lovers, and artists... We are there! There are 500,000 of us dancing in the streets, throbbing with amplifiers and harmony... celebrating the birth of FREE AMERICA in our own time.”

It’s time to show up in real life, with our voice, with our community, with the mission as our sole driver. If it hasn’t yet been made clear, it would be fair to consider this my revival of whatever is left of the Youth International Party. Absurdity, meet absurdity. I hope you’ll join me.