FF859C Adhered Membrane Adhesive Product Description FF859C Adhered Membrane Adhesive allows you to securely and professionally bond Fatra fleecebacked membranes to a wide range of roof substrates, including tissue-faced insulation and plywood. It meets all the demands for a high-performance PU adhesive, with a quick and simple application system. FF859C Adhesive is ideal for both large-scale fieldwork and detailing.

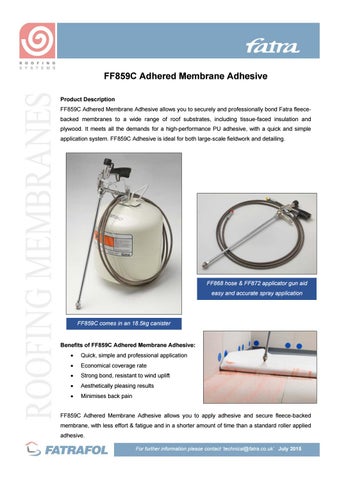

FF868 hose & FF872 applicator gun aid easy and accurate spray application

FF859C comes in an 18.5kg canister

Benefits of FF859C Adhered Membrane Adhesive:

Quick, simple and professional application

Economical coverage rate

Strong bond, resistant to wind uplift

Aesthetically pleasing results

Minimises back pain

FF859C Adhered Membrane Adhesive allows you to apply adhesive and secure fleece-backed membrane, with less effort & fatigue and in a shorter amount of time than a standard roller applied adhesive. For further information please contact ‘technical@fatra.co.uk’ July 2015

Quick, simple and professional application: 4x faster application and faster cure FF859C Adhesive allows you to minimise the time it takes to complete jobs. It is up to four times faster to apply than a standard roller applied PU adhesive due to the spray application system. FF859C Adhesive covers up to one square metre of membrane in as little as 25 seconds, whereas it takes 90 seconds with a standard roller applied PU adhesive. It also cures much more quickly than a standard roller applied PU adhesive; in as little as 60 minutes, in comparison to 90 minutes.

Economical coverage rates: One-way stick, reduced waste Fatra understands that overall ‘onsite cost’ is a key concern, especially given the current economic climate. FF859C Adhesive has been developed with this in mind. It has an economical coverage rate; one canister can cover up to 180m². Minimal adhesive is required to ensure a strong bond because FF859C Adhesive is a one-way stick system (adhesive is applied to insulation only). Wastage is also reduced due to the 3m hose, which allows for professional and precise application.

For further information please contact ‘technical@fatra.co.uk’ July 2015

Strong bond, resistant to wind uplift (BRE): unique PU, weatherproof bond FF859C Adhesive enables you to meet the demands for a high performance ‘PU adhesive in a can’. It is the only PU canister adhesive on the market that will securely bond fleece-backed membrane. FF859C Adhesive gives you all of the benefits of a PU adhesive; weatherproof bond, excellent temperature resistance (-30 to 150°C) and great aging properties, whilst being simple and fast to apply. FF859C Adhesive is also the only fleece-backed membrane adhesive to have passed rigorous and independent testing at BRE for resistance to wind uplift. This will give you peace of mind that the roof you lay is secure and that your reputation is safe.

Exceeds BRE approved wind uplift requirements: FF859C Adhesive significantly exceed independent standards for resistance to wind uplift They have been rigorously and independently tested at BRE premises, using BSI EN 1991-1-4 guidelines, where they achieved a resistance figure of -5500Pa. Typical wind uplift pressure is 1000Pa in London and -2000Pa in Inverness. This gives safety factors of 5.5 for London and 2.75 for Inverness.

Aesthetically pleasing results: non-foaming adhesive, smooth consistent finish Your reputation is not only reliant on ensuring a strong and secure bond, resistant to wind pressure; the quality and aesthetics of the roof are also important. FF859C Adhesive is a non-foaming adhesive, which allows for aesthetically flat lamination of the membrane, without creasing and wrinkling. Its spray application ensures even coverage, further promoting a smooth consistent finish.

For further information please contact ‘technical@fatra.co.uk’ July 2015

Minimises back pain: reduces bending and stooping due to 3m hose / applicator Back pain is a common complaint of contractors, and it is often caused by bending and stooping to apply roller applied or bead applied adhesives. Such actions can cause labour fatigue, which is not only incredibly uncomfortable and unpleasant for contractors, but it can have a detrimental impact on their performance. Consequently, this can increase the amount of time it takes to complete projects and result in poor quality work. Repetitive bending and stooping can also cause permanent long term back problems. FF859C Adhesive eliminates repetitive bending and stooping because it is applied via a 3m hose / applicator, which allows you to lay membrane quickly and safely. It is also simple to carry onsite due to the handles featured on the outer packaging.

For further information please contact ‘technical@fatra.co.uk’ July 2015

Guidelines for Use: 1. Ensure the insulation board or other roof substrate is dry and clean from grease, dirt and other contaminants before applying adhesive. 2. Set the canister up as described in the ‘Set-Up and Maintenance Guide’. 3. Mark out the area to be bonded, ensure the fleece-backed membrane is cut to size and in position. 4. Protect the edge / seam to be welded in order to prevent it becoming contaminated with adhesive. 5. Remove any overspray from the surface of the membrane with a dry cloth or FF860 Solvent cleaner. 6. Ensure the FF859C canister is spraying correctly and the spray pattern is 300mm wide. Fatra recommends using a test surface prior to application. 7. Secure the FF859C canister in a suitable position and apply to the insulation board. 8. Apply a minimum of two coats of adhesive to the insulation board, ensuring each two metre pass takes a minimum of 10 seconds. 9. Walk backwards ensuring an even coat of adhesive is applied. 10. Allow the solvents to evaporate from the adhesive layer for a minimum of five minutes at 20°C. NB: this time will vary depending on climatic conditions. 11. Roll the fleece-backed membrane into the adhesive layer. 12. Consolidate the bond using a 20kg water-filled roller.

FF859C Adhesive is supplied in a 450mm x 330mm cardboard carry box. Other components required and supplied separately include: applicator (gun and 3m hose), spray tip, solvent cleaner and canister flushing System.

Coverage Each canister can cover up to 180m².

Coverage rates are dependent on a range of variables including temperature, substrate and insulation facings.

For further information please contact ‘technical@fatra.co.uk’ July 2015

Physical Characteristics FF859C Adhered Membrane Canister Adhesive Appearance Open Time

Pink 10 minutes at 20°C

Temperature Resistance

-30 to +150°C

Application Temperature

5 to 30°C

Coverage Rate Storage Cure Time Environmental

Up to 180m² per canister 5 to 30°C 60 minutes at 20°C Solvent / Flammable / Hazardous

Important notes: Open-time and cure-time: All information is provided as a guideline only. Cure time and open time are dependent on a range of variables: temperature, substrate being bonded, method of application and weight of product applied. Fatra highly recommends that testing is conducted prior to application.

Temperature and Timings: All information on temperature and timing represent normal working conditions and is provided as a guideline only. However, please contact Fatra for advice if you wish to operate outside of these parameters.

Disclaimer: Fatra has taken every care to ensure that the information provided in the literature is correct and up to date. However, it is not intended to form any part of a contract or provide a guarantee. Purchasers / intending purchasers should contact Fatra to check whether there have been any changes to the information since publication of the literature. Please refer to the MSDS before using these products.

For further information please contact ‘technical@fatra.co.uk’ July 2015

Set-Up and Maintenance Guide Canister Set-up Guide NB: It is important to set-up your FF859C canister correctly before use to ensure the best possible performance and to avoid leakage or system failure.

1. Remove the black cap from the canister valve. 2. Attach the braided hose to the canister valve (using the small nut). Tighten with a spanner (see image 1). 3. Attach the other end of the braided hose to the spray gun (using the large nut). Tighten with a spanner (see image 2).

Image 1: Canister with braided hose attached

Image 2: Braided hose and spray gun

Image 3: Attach the spray-tip

Image 4: Valve to adjust spray pattern

4. Using the locking nut provided, attach the spray tip to the end of the spray gun. Carefully tighten the spray tip using a spanner (see image 3). 5. Fully open the valve on the canister. 6. Pull the trigger on the spray gun to apply the adhesive. 7. Adjust the spray pattern by turning the black valve on the spray gun anti-clockwise until you have a spray pattern approximately 300mm in width (see image 4). For further information please contact ‘technical@fatra.co.uk’ July 2015

Maintenance Guide: Maintaining your FF859C Adhered Membrane Adhesive.

1. Once work has been completed, ensure the valve on the canister is turned off (see image 5). This can be done by turning the white valve clockwise until it is fully closed. 2. Turn the spray gun off by turning the black valve clockwise until it is fully closed. 3. Unscrew the spray tip and locking nut from the spray gun. 4. Clean the spray tip and the end of the spray gun with FF860 solvent cleaner using a soft nylon brush to ensure that the aperture is clear (see image 6). This is essential. Failure to clean the spray-tip and the end of the spray gun may result in damage to the aperture and prevent the system from working.

Image 5: Turn off the valve

Image 6: Cleaning the spray tip

Image 7: Spray tip in solvent

5. Place the spray tip and locking nut in a container with a small amount of FF860 solvent cleaner until it is needed again (see image 7). Ensure the container is closed and airtight. 6. The canister and gun will remain usable for one month after opening. If you do not intend to use the system within this time, flush it with the Canister Flushing System.

For further information please contact ‘technical@fatra.co.uk’ July 2015

Canister Flushing System Fatra can supply the easy to use Canister Flushing System, which ensures the canister gun and hose remain free from blockages. It consists of a cleaning aerosol and the canister assembly.

Image 8: Canister assembly

Image 9: Tighten the nut

1. Ensure the valve on the canister is completely turned off before attaching the assembly. Unscrew the hose from the canister valve. 2. Attach the assembly to the valve. Ensure the assembly remains upright whilst you tighten the nut (see image 9). 3. Attach the hose to the assembly. Ensure the assembly remains upright whilst you tighten the hose. 4. Check the tap on the assembly is off before applying the Cleaning Aerosol.

Image 10: Screw cleaning aerosol into the adaptor

Image 11: Turn the tap on

Image 12: Disperse the adhesive

5. Screw the Cleaning Aerosol into the adaptor (see image 10). Turn the tap on the assembly to the ‘on’ position to release the Cleaning Aerosol into the hose (see image 11). 6. Aiming the gun into a waste container, apply pressure to the trigger on the gun to push the Cleaning Aerosol through the hose and gun until the adhesive starts to disperse. Keep pressure on the trigger until the hose and gun are thoroughly cleaned (see image 12).

For further information please contact ‘technical@fatra.co.uk’ July 2015

Emptying and Disposing of Your Canister Safely Guidelines on how to empty and dispose of your FF859C Adhered Membrane Adhesive canister.

1. The FF859C canister contains compressed gas. It should be emptied by carefully opening the valve, which will release any excess adhesive and / or pressure (see image 13). 2. Allow any excess adhesive and / or pressure to fully escape into a suitable container. Leave the valve open. 3. Once the canister is empty, the circular disk can be pierced using a non-ferrous bar / rod. Allow any remaining adhesive to cure. The empty depressurised canister should be disposed / recycled in accordance to site regulations. 4. Information on storing canisters can be found on the following websites: www.bama.co.uk/transport-storage/ and www.hse.gov.uk/pubns/priced/hsg71.pdf

Image 13: Open the valve

For further information please contact ‘technical@fatra.co.uk’ July 2015