With the festive season well behind us and the year speeding by already, we are into the swing of Field Days and have seen the busiest part of peak season for Fencing Contractors.

The awesome summer weather was a long time coming, and I’d say there were a lot of contractors playing catch up.

The Board is a couple of meetings into the year, and we’ve been working on organising the upcoming Best Practice Days, webinars and other events around the country – including our annual conference. More information on these can be found throughout the magazine.

In February, we were humbled to be able to go to the East Coast region to give away gates, gudgeons and insulators. This came about because of our “Help a mate, buy a gate” fundraising campaign and the epic support of FCANZ Partners Gallagher, Beattie Insulators, Farmlands, Stihl and Summit Steel & Wire. The cyclone recovery work in the area is ongoing more than a year later, and every little bit of support really does help.

Industry training has been fairly steady. There are Level 3 and 4 courses currently available for enrolment.

We need to see enrolments coming in for these courses to continue, especially considering the upheaval within government departments, restructures and entities being disbanded. Bums on seats is what will see the continuation of these NZQA backed courses. On that, I am fortunate (sometimes unfortunate) enough to see what goes on behind the scenes to make these courses come together. If you or your staff are completing these courses, please make sure you are doing the work required to enable the tutors and support staff to get the results through.

The reviewed FCANZ Strategic Plan has been finalised after much consultation and many hours of debate. This is now being made widely available (see page 10) and will enlighten many on the direction of the Association.

I’d like to make special mention to our Partners for their ongoing support of the industry, we look forward to working with you throughout the year, especially in

the lead up to the National Fencing Field Day and AGM/Conference in Christchurch. We all really appreciate the effort and input you all have to the Association and members.

Cheers, Phil

Phil Cornelius President

Phil Cornelius President

To raise the profile of fencing as a professional trade, delivering high quality work and adhering to best practice standards.

The month of December is always mad, and there resounds a client viewpoint that the world ends on Christmas Day because they all want you prior to Christmas - this certainly rings true for the lifestyle market.

That being said, the Board got in an early December meeting and - in what seemed like short succession, a mid-January meeting. Being conscious of cost savings, meetings are being held near Auckland Airport, with some of the Board Zooming in.

One of the focuses at the moment is on policy; going through and tidying up existing Association policies and creating policy to fill in the gaps. This is partly in relation to the Board’s governance, Code of Conduct, Complaints, partner policy, etc. The Board manual, including these governance policies, has been

incomplete but is in the process of being finalised for sign-off.

Event planning is another focus, working out locations for Best Practice Days and the logistical details, Field Days involvement, Career Days, Clash of the Colleges, etc. The November 4WD two-dayer was a big hit with those who attended and another one is being planned for the Wairarapa, with the date to be confirmed once we have spoken with the landowners.

With the number of NZQA Level 4 Certificate in Fencing graduates, the push is on for transferring existing Certified Fencers across to Accredited Fencing Contractors and bringing through the new system Certified Level 4s (which is a foreman level status) and Accredited Fencing Contractors (which covers the Principle and Business).

If you’re confused by this, please read the paperwork on the application forms. Yes, this Board is well aware of the name changes over the years and the simple need to get this promoted to outside bodies and work on the credibility of this qualification endorsement.

Currently 2024 does not seem to be firing like we all want it to. Certainly, work is out there, but there’s some real hurt in effect with commodity prices and running costs. The Board has been working hard to reign in the current financial year’s expenses and is working on a realistic 2024- 25 budget that will still work towards delivering the Association’s strategic objectives.

Written by Debbie WhiteOrganising for Conference 2024 is well underway, and once again, the programme looks fantastic. This year we look forward to seeing our FCANZ members and partners in Christchurch, at what has become an annual trip for many people.

Our Business Staples webinar series is now locked in for the year, with some big names lined up to share their knowledge with members. Keep an eye on your emails, and the FCANZ website and Facebook page for confirmed dates and topics.

This year sees the team delivering a number of Best Practice Days around the country. If you haven’t been to one of these before, they are well worth attending if there is one near you. Head to the events section of the website for details of the Best Practice Days, webinars and Conference. www.fcanz.org.nz/events

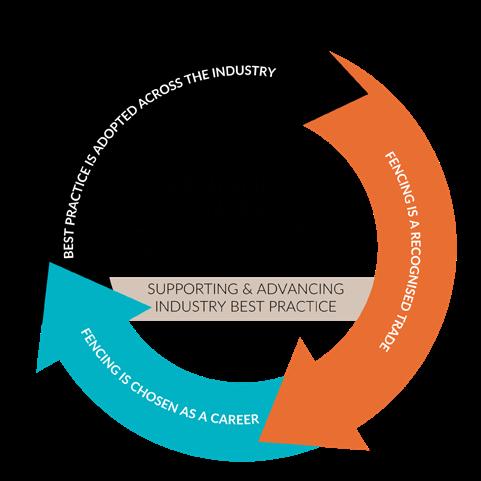

The team have been working hard on squaring away our strategic plan for the next five years. Part of this has resulted in the creation of a new tagline that sums up in simple words exactly what the Association stands for: Supporting & Advancing Industry Best Practice. It is essentially our ‘elevator pitch’. You will start seeing this used across our advertising, replacing ‘Setting Industry Standards’, which had been used previously.

Did you catch FCANZ in the media in the past few months?

The ‘Great Gate Giveaway’ generated quite a bit of media interest and was covered in a number of print publications. FCANZ President Phil had a great chat with Dom from Rural Exchange about the event and why it was so important to the Association to help those impacted by Cyclone Gabrielle more than a year ago. You may have also heard radio adverts for the Join FCANZ campaign. The campaign was delivered across a number of marketing channels, so it will be interesting to complete the analysis and see which has been the most effective.

The newest FCANZ Bronze Partner is well-known to most. Milwaukee Tool offers a full range of power tools, hand tools, accessories and storage solutions designed with professional trades in mind. Based in Auckland, Milwaukee Tool New Zealand is dedicated to catering to the ever-growing demands of the job site and supporting all tradespeople to be the best they can be.

www.milwaukeetool.co.nz

In late February, FCANZ gave away 100 farm gate and gudgeon sets and 10,000 insulators to farmers in the East Coast and Hawke’s Bay who were still dealing with the after-effects of Cyclone Gabrielle.

The Great Gate Giveaway was the culmination of fundraising efforts in the 12 months since the cyclone and was made possible thanks to the support of Association Partners Gallagher, Beattie Insulators, Farmlands, Stihl and Summit Steel & Wire. The equipment retails for more than $35,000 and was distributed at the East Coast Farming Expo held in Wairoa on 21-22 February.

“We are a year on from the cyclone, and some of these farmers are still unable to contain their stock. You can’t farm like that. As an Association, we hope this giveaway helps ease some of the financial and mental strain that these farmers are feeling,” said FCANZ President Phil Cornelius.

Recipients were nominated by FCANZ members based in the area and the local Rural Support Trust co-ordinator to ensure the gates, gudgeons, and insulators made it to those really struggling to get on top of their stock fencing.

Family-owned New Zealand manufacturer Beattie Insulators donated 10,000 insulators to the cause. “We were delighted to be able to work with FCANZ to help these farmers. We know it’s only a small part, but every bit helps,” said Ivan Beattie, one of the second-generation company owners.

The Association also hosted a BBQ on the evening of 21 February for FCANZ members, gate recipients and their families. FCANZ Patron Craig ‘Wiggy’ Wiggins, and creator of the “Lean on a

Gate, Talk to a Mate” movement, was available to talk with people about their concerns for themselves or their friends.

“Some of these farmers are doing it really tough, so it’s never been more important for people to reach out to their mates and check they are ok. It can be hard to start the conversation, but Lean on a Gate has resources and people to help, no matter what you’re dealing with,” said Craig.

The Association plans to be back in the district in early autumn to deliver another two-day re-fencing event, during which time fencers will volunteer their time to reinstate essential fencing.

Originally planned for late 2023, the event had been delayed to allow the ground to dry out – a plan hampered by recurring rain events. “The reality is that the scale of damage in the area means it will be some time before permanent fencing work can be started in many areas,” says Phil. “It makes sense that we come back in autumn and assist with the reinstatement of essential fencing then.” To learn more about Lean on

Enjoy a day out with Fencing Contractors Association NZ and see best practice fencing techniques showcased in practical demonstrations throughout the day.

Fencing Best Practice Days are a great opportunity to learn new skills, see the latest fencing gear and meet likeminded fencing contractors in your region.

Industry Partners, FCANZ Board members, Health & Safety advisors; Tertiary Education providers and Fencing Contractors from across the region.

*Subject to availability

Fencing Contractors, Fencer Generals, Horticulture workers, Farmers and those starting or interested in a career in a fast-growing industry.

Cost (includes lunch)

Non-Members: $40

FCANZ Members: $20

FCANZ Employee Members: $10

Keep an eye on your inbox, FCANZ Facebook and the FCANZ website for when registration opens for each event. Note: Dates and locations are subject to change.

Late last year, the 5-year strategic plan was signed off by the Board. The strategy sets the overall goals for the Association and the framework for developing an action plan to achieve them.

It involved the team stepping back from day-to-day operations and asking where the Association is headed and what its priorities should be. While the plan has some lofty goals, it is also flexible and agile enough to respond to change, allowing current and future Boards to ensure that the Association is always on track to support and advance industry best practice.

Our mission: To raise the profile of fencing as a professional trade, delivering high quality work and adhering to best practice standards.

Vision: FCANZ is acknowledged as the authority within the fencing industry, contributing to a high level of workmanship across diverse fencing sectors through the dissemination of industry knowledge and standards, while encouraging fencing as a career path.

Best practice is adopted across the industry Fencing is chosen as a career Fencing is a recognised trade

Strategic Initiatives:

• Increase the level of professionalism and skills across the industry.

• Encourage implementation of best practice techniques into everyday systems.

• Ensure industry knowledge is shared and expanded upon.

• Model Best Practice within the Association.

Tactics:

1. Finalise and deliver the FCANZ endorsement programme, including the auditing process.

2. Facilitate and support apprenticeship schemes.

3. Uphold and promote Best Practice Standards in the rural fencing sector.

4. Develop and disseminate Best Practice Standards for other fencing sectors.

5. Develop and disseminate industry standards e.g. wire standards.

6. Engage with public sector organisations to encourage adherence to industry standards.

7. Develop and monitor training systems for members that reflect industry best practice.

8. Deliver training and upskilling opportunities at FCANZ events to showcase industry best practice, including Conference, National Fencing Field Day and Best Practice Days.

9. Deliver in-person or online business best practice training on areas such as compliancy, H & S, wellbeing.

10. Develop and maintain Association operational policies such as dispute management, and member disciplinary processes.

11. Provide an industry mediation/ disputes service.

12. Support and promote fencing competitions/NZFC.

• Promote fencing as a career to encourage more people to enter the industry.

• Develop partnerships with schools/ education facilities to support pathway students into the industry.

• Grow Association membership by increasing and promoting tangible membership benefits.

Tactics:

1. Achieve membership growth through education about Association activities and benefits.

2. Expand member benefits and value proposition including networking opportunities to unite industry and support feeling of a united entity, a “go to” place for information.

3. Develop partnerships with training providers and academies.

4. Support the development of a managed apprenticeship program.

5. Develop resource packages for career seekers incl. school leavers, industry career change and immigration.

6. Implement industry promotion and advertising to key influencers (e.g., parents, heads of Agriculture in schools) showcasing diversity of fencing.

7. Become active in gateway programs and find methods for members to participate in these or other work experience offerings.

8. Provide Member support to prepare for work experience students. e.g., guidelines, training.

9. Participate in targeted Trade Days for school students and Trades Academy participants.

10. Develop work experience initiatives with central government agencies such as, MSD, MPI.

11. Provide a job opportunity listing service.

• Demonstrate industry support through the development of mutually beneficial partnerships.

• Increase awareness of Fencing as a skilled trade.

• Develop an understanding of the industry’s advocacy and lobbying needs.

• Ensure stakeholders embrace the value of FCANZ endorsements.

Tactics:

1. Increase depth and breadth of Association partnerships with a robust partnership strategy.

2. Create and support sector/regional subcommittees.

3. Develop Central/Local Government database.

4. Engage with public sector organisations to promote the use of Accredited fencing contractors.

5. Develop the media database & maintain connections/rapport.

6. Conduct annual member surveys to identify trends.

7. Position WIRED content, features and advertising to support fencing as a trade.

8. Improve social media engagement with Partners and members

9. Produce regular e-newsletters which provide value for members and partners.

10. Continue with website development and online resources with UX at front of mind.

11. Ensure that FCANZ events are well attended by partners and members.

12. Utilise Partner communication channels to circulate key FCANZ messaging.

13. Work with a Patron to increase the reach of Association.

14. Build relationships with other trade and Primary Sector organisations.

Fencing Contractors Association NZ (FCANZ) is the industry body supporting the fencing industry of New Zealand.

Established in 2006, FCANZ aims to raise the profile and standards of the fencing industry, growing the market for fencing contractors and others associated with the industry, and ensuring Fencing Contractors Association NZ is the first port of call for those seeking a fencing contractor.

Boost your business by being listed on the FCANZ ‘Find a Fencing Contractor’ directory, helping the public find contractors in their area. Enjoy free promotion through campaigns that attract potential clients to the directory which is visited more than 25,000 times each year!

Receive a new member Welcome Pack which includes a branded cooler bag, hi-viz vest, hat and other merchandise.

Plus, enjoy access to exclusive offers and unparalleled support from FCANZ Partners.

FCANZ’s affiliation with Federated Farmers gives all members a complimentary Federated Farmers membership – worth $499, including access to free legal and employment advice, group purchasing opportunities and much, much more.

All members receive four editions of WIRED magazine per year worth over $80

WIRED is the official quarterly publication of FCANZ, and is New Zealand’s only fencing industry magazine. Each issue contains a host of informative news, business & industry insights, human interest articles and information specific to the fencing industry.

FCANZ members also benefit from:

• Belonging to an Association of like-minded individuals

• Regional fencing Best Practice Days

• Access to free business best practice webinars

• Subsidised Annual Conference tickets

• Use of FCANZ logo to differentiate your business from your competitors

• Creating industry-wide connections through networking opportunities with members and Association partners

• 10% discount on Site Safe membership

• Free job, tool and equipment listings on the FCANZ classifieds web page

• Certified Fencer and Accredited Fencing Contractor industry endorsements to prove your quality

Firstly, let me say THANK YOU FCANZ!

Over the last two years, the generosity shown by FCANZ members towards the Lean on a Gate, Talk to a Mate campaign with over $30,000 donated by the conference charity auctions has allowed the Whatever with Wiggy Charitable Trust to grow significantly. We now have a great website which has so many tips, tools and good pathways to mental and physical wellness and nationwide recognition of what we do and the services we provide. Check out the leanonagate.co.nz website and know that I will always be grateful for your help, and that help has saved lives. FCANZ, again, I say thank you!

To be asked to be your Patron and to facilitate a judging panel for the young fencer awards has also been a highlight. To be associated with this organisation of great people who work hard and are proud of their toil while setting and lifting industry standards can never be taken for granted.

We all face challenges in our lives, which can put us in a position of high anxiety and stress and create a negative space to live in. I hope by writing in here, talking at events and being a part of FCANZ, we can form a relationship where you feel you can be your best, or if not your best, then able to connect with us, check out our website and make the changes necessary to have a strong professional life balanced with a happy and supportive personal life. That’s right, a ‘Work/Life Balance’. You are the most important cog in the wheel, your success depends on being able to perform.

This year, I was asked by Luke Gibson, whom I met at the fencing contest at the National Fieldays, to come to Indiana and be a part of their Fall Fencing Conference. I was nervous about this trip as I know what I know in New Zealand; what we do here makes a difference. But could I go to another country and get results, help people, and ultimately make a difference? Luke was confident, so I packed my bags and flew to Indianapolis, and was driven to Worthington, Indiana. Within a short time, I found myself in deep conversations with fencing contractors and merchants from all over America and two not-bad Englishmen.

Connections and friendships that will last for as long as I’m above ground!

Over the three days of Conference, counting the first night of campfire introductions through to the contests and speakers, we talked a lot of topics. Tony Thornton, who owns Thornton Fence Consulting Group, led the charge, educating people about the business and profit-making part of being a fencer, relationships with staff and clients, and ultimately being successful in life. I’d like to see Tony attend our conference here and speak, there would be something for everyone.

Were they ready to talk Mental Wellbeing? I’m still not sure, but heck, did they ever open up and get involved. To say I was often overwhelmed by the outpouring of gratitude and their investment in what we discussed and workshopped is an understatement. For two days “great people who work hard and are proud of their toil while setting and lifting industry standards” (just like NZ fencers), connected, dug deep, looked for answers and found support. I again had a great appreciation for what I am lucky enough to do, and again humbled to the point of being overwhelmed…

Fencers all around the world are cut from the same cloth, we are a community of international chapters/organisations that I would like to see more collaboration between. Exchange programs for our youth, conferences being attended by international guests and speakers and competitions where everyone is able to be lifted by the best to be their best.

I was awarded the Top Gun award at the conference (literally given a rifle) for ‘delivering the most’ to that event, but what I got back from attending was more than I gave, I’m sure.

When asked by Luke what was my summary of the conference I simply replied, “He tangata, he tangata, he tangata”! The people make the industry, and they are the most important part of the industry. The conference served them well!

Planning is well underway for what is set to be a bumper FCANZ Conference this August.

Resilience and reinvention are not new concepts for Kiwis, especially those who work on the land. In an uncertain economy, outside-the-box thinking can be an invaluable tool for business owners. Many service, retail and hospitality businesses embraced the ‘pivot’ during COVID and succeeded because of it.

Exploring how fencing contractors can visit opportunities that ignore “the box” entirely without stretching themselves too thin or diluting their core business, is what Conference24 is all about.

Open to all current FCANZ members and their partners, the three-day event will once again provide delegates with a chance to have a say in how the Association runs, see the latest and greatest fencing tools and techniques, embrace business-best practice learning and enjoy the unrivalled networking opportunities.

AUGUST

WEDNESDAY 7 AUGUST

National Fencing Field Day (NFFD)

Come along to the 4th annual NFFD to see the latest fencing gear, watch best practice demos, and wrangle a bargain from exhibitors. This year will see the return of the “Show Us Your Toolbox” competition for those who drive to the event.

We’ll also be running another “Ladies Who Lunch” event for the long-suffering partners who aren’t so keen on spending the day in the field.

This year, we’re working on a venue with some wet-weather contingencies, as no one wants a repeat of last year’s icicle fest! Travel to and from the NFFD and entry into the event are complimentary as part of your Conference ticket.

Join us for the ever-popular Mix & Mingle dinner for a chance for a casual catch-up with acquaintances old and new.

This self-pay event will be held at Lone Star Spitfire – a mere 5-minute walk from the hotel.

Today we get down to business. As usual, the day will kick off with an update about what the Board has achieved in the previous 12 months and what is on the plan for the next 12 months. This is followed by the Annual AGM, during which time the Board will be decided, and any Association rule changes will be voted upon.

This year will see four of the seven Board positions up for renewal due to our retirement-by-rotation policy. If being involved in the direction of the Association is something you have been considering, then now is your chance. While the incumbents may look to stand again, this doesn’t stop others from putting their names in the hat. If there are more nominations than positions, it will go to a confidential vote, with the results notified later in the day. Nomination forms and role descriptions will be available on the website from April.

The AGM will be followed by our keynote speaker, who will ensure delegates walk away knowing more than when they arrived. Later in the afternoon will see the Member Feedback Forum, which is when you, as a member, are invited to comment on Association activities and contribute to the forward direction of FCANZ.

Dinner & Bingo

We like to mix things up occasionally, so this year, instead of the usual (extremely competitive) Quiz Night, quiz-master extraordinaire Stephen Caunter will be running a highly entertaining bingo session. Join us for dinner, and then see if the numbers will fall your way for some great prizes!

Note: we are aware that due to the state of the economy, times are tight for many, so there won’t be an impromptu auction this year.

This morning we’ll be visiting some unusual fencing around the region before heading to a delicious lunch at one of our favourite spots. After lunch, you need to get set for an adventure!

We know how you all love a competition, so this year we’ve got something special planned for the afternoon. We’re going to keep it under our hats, but we can confirm that it IS a competitive teams event, and there will be great prizes! Wear gear that is comfortable to walk in and bring your lateral thinking brain. We can confirm that it absolutely does NOT involve fishing.

Gala Dinner & FCANZ Industry Awards

We finish off the day in style at our smartcasual dinner and awards ceremony. This year, we will not only recognise Trainee of the Year and Emerging Talent – Youth nominees and recipients, but we will be adding two more awards to the suite. Full details will be in the June WIRED and in your emails – watch that space for how you can submit a nomination.

Conference24 will be held at the Sudima Christchurch Airport. Located within walking distance from the airport (but with well soundproofed rooms), the Sudima also offers plenty of complimentary parking for those who will be driving.

The team at the Sudima have created a code for FCANZ members to use to secure a discount when they book online or through reception. Bookings for the rooms are now open, so get in quick to secure a great price! The discount expires at the end of June.

Book Online: www.sudimahotels.com

Booking code: FCANZ24

Hotel: Sudima Christchurch Airport

Group Name: Fencing Contractors Association - FCANZ Conference

Confirmation Number: 9877602

Arrival date: anytime between 05-08-2024 and Departure date: 10-08-2024

We’ve opened the portal for ticket purchasing early this year, since you can already book your accommodation.

Early Bird tickets are $390+GST per person and are available until 31 May 2024. From 1 June tickets will be full price at $450+GST per person.

Book your ticket now and lock in the great prices for conference and accommodation. www.fcanz.org.nz/conference24

Learn more about Christchurch at www.christchurch.nz

Best Practice Fencing Techniques | Practical Demonstrations | Competitions Tools, Machinery & Vehicles | Activities for all

Wednesday 7 August 2024

10.00am - 3.00pm

Christchurch

FCANZ Conference delegates – Free

FCANZ members $10

Public: $20 | Students (5-18yrs) $5

Under 5s – Free

• Fencing technique demonstrations and discussions

• Fencing and machinery exhibitions – come along and talk to their reps

• New product releases

• Interactive competitions

• Be in to WIN the Best Ute Toolbox competition!

Christchurch

Christchurch

Fencing Contractors seem to have an affinity with 4WD utes. It’s a well-known fact that a ute is commonly the top-ranked item to be factored into one’s asset business startup.

Indeed, throughout a fencing contractor’s business lifespan, a 4WD ute continues to receive top billing. It doesn’t seem to matter if it’s a pimped out (accessory wise) latest model, or a cherished dependable 1997 model with a few seasoned dings. At least one of our members has owned a Toyota Hilux from new, that went round the clock and ticked over again from zero.

Fencing Contractors often work in amazing locations, and their access to many enviable properties means they could also double as tourist guides with off-road adventures.

Given this combination and having been dragged along with the whole 4WD scene throughout my married life, an opportune conversation with Scott and Anna Heasley, down at the Dunedin Conference in 2022, meant organising a 4WD trip for our members through some of Scott’s client’s properties – most notably the iconic MacDonald Downs – was a no brainer.

Having been in the Lees Valley, I asked about linking this up and ending the trip in Oxford, and Scott saw to that as well. We had options of starting in the

Awatere Valley, Marlborough or perhaps coming down through the Rainbow from Nelson, but it was decided for us when Mike Renner (Renner Fencing) jumped on board, organising a start location from his yard at the start of the Awatere Valley.

Thus were the origins of the FCANZ great 4WD adventure in November 2023; meeting up at Mike and Olivia Renner’s, with a quick look through one of Renner’s yards, up through the Awatere Valley, overnight in Hamner, the next morning down through into MacDonalds Station, out through the Lees valley into Oxford, with dinner at Rangiora. That’s a quick summary, though this misses a number of key elements.

With 17 vehicles attending, the attendees came from as far south as Balclutha and Invercargill, and as far North as Auckland, with Masterton (Tim McKay) and Galatea (Scott Graham) also represented. Along with the usuals, it was nice to see some faces of members who we hadn’t seen before, which was one of the interesting aspects. We also had two partners attending – Brendon Crequer from

Waratah and Ivan Beattie from Beattie Insulators. Following a group photo, the group was tasked with getting to know each other and were told that there would be a name quiz at the end of the trip, which I was determined to win, but I think Georgia Douglass might have taken out those honours.

We drove in convoy up the Awatere Valley Road with Mike and Terry Renner in the lead and John and Carol Noakes as tailend Charlies. When you’re driving through an area as scenic as the Molesworth, there’s often a question as to the history of the area and what goes on in terms of farming, etc. That’s one of the reasons this trip was so interesting, stopping off and having morning tea in the Upcot Station shearing quarters (thank you Friends of Seddon School, who supplied morning tea and lunch), then looking through the shearing shed (Upcot supplies merino wool to Icebreaker). Next, we walked across over to the old saleyards for the district, which Terry Renner helped to build in 1986 and used to hold 7,600 sheep. They ceased using the yards when foot and mouth entered the area.

Upcot Station’s Bill Stevenson met us further up the road, the third generation of stewardship of the Station, with one of Bill’s daughters, Louise, taking on the running of it. Bill’s talk was an interesting insight into the station’s running, stock numbers and breeding, and the challenges and success of the calicivirus in controlling rabbits in that area. Upcot has a horse breeding program with some very nice horses leaning over the fence begging for a new home (some were for sale).

On the Upcot saddle (1,200 metres above sea level), we stopped to look at the views, and naturally running along the saddle was a Waratah brand fence, complete with Jio Star posts and wire. Brendon gave a talk about Waratah’s

performance in high country such as this. Ivan Beattie also talked about his insulator products, again with their suitability for high country fencing.

At Molesworth Station, we stopped for lunch at the Cobb Cottage, which was precluded by an interesting talk from Jim Ward, who manages Molesworth as a productive 182,000 hectare farming and recreational unit. Molesworth is 60 kilometres in length and about the same in width. Jim talked about a concentrated effort towards lessening stock numbers, changing farming practices and improving economic returns in doing so, while balancing farming with recreational usage and sustainability. Horses are still widely used on Molesworth, and as we drove

along, we saw numerous loading banks where the horses were trucked along to mustering points for offloading. Three of the shepherds were involved in the talks, and it was interesting to hear how they coped with the isolation. The future of Jim’s farm lease is in jeopardy given DOC’s purchase of the land from Landcorp, with a review being undertaken as to the future of managing the land, which, from listening to Jim’s knowledge and passion for putting the land first, was incomprehensible. After a quick drive around the Molesworth infrastructure, we were on our way towards Hamner, with the amazing scenery becoming tarnished with wilding pines. There was evidence of some attempts to control them, but it’s a huge problem.

FCANZ Administration Manager Jeanette Miller had organised the motel and a buffet dinner. Some beers amongst a tailgate meeting, aka standing at the back of the ute in the motel car park with a beer in your hand, helped dull the pain of overly expensive drinks at the bar, but the accommodation was very nice, and dinner was tasty. We woke up to a moister day with fresh snow on the mountain tops and predicted rain, which was a shame as Scott and Anna, our Day 2 leaders, had a good offroad route organised once we got into MacDonald Downs (11,333 hectares).

On the way in, we stopped at Waikari Kitchen in Waikari to pick up a prepackaged morning tea and lunch (recommendation – stop there, never drive past if open), and then we pulled up at the beautiful MacDonald Downs homestead and gardens for a hugely entertaining talk by Bill Paterson, and a look over the Station’s maps and historical photos.

Moving along, we started towards an excursion up over saddle, but

was latched from the inside. One can only imagine the robust debate that followed, as to whether to climb up through the dunny hole and who was going to do that, to be able to unlatch the door.

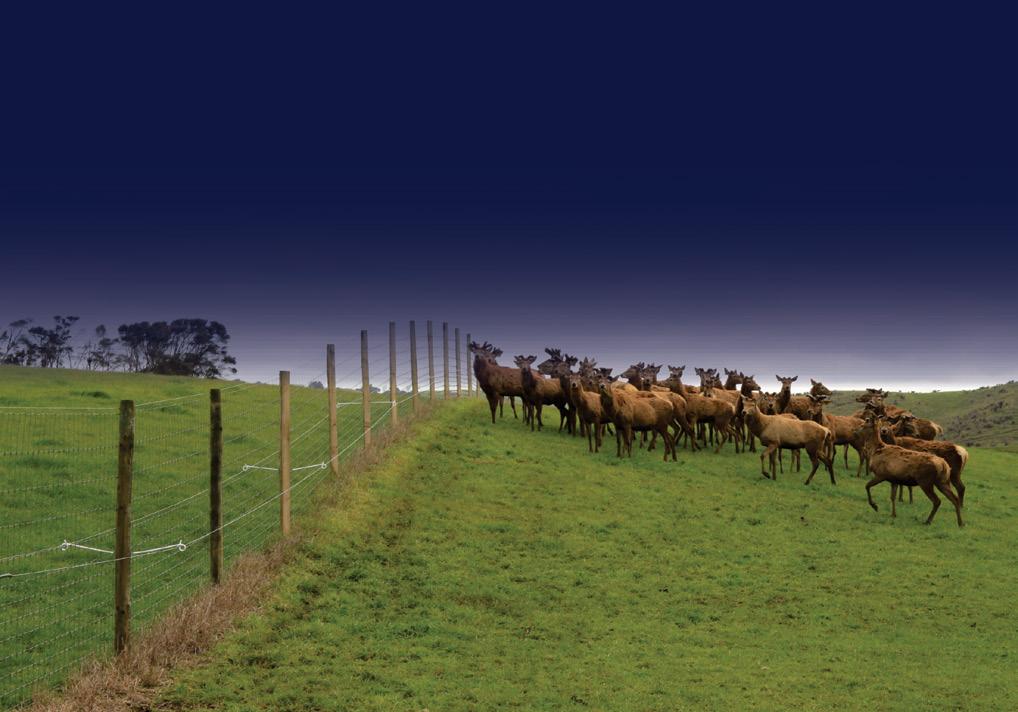

Onward and upward, then descending, we drove, entering the Lees Valley, stopping at Wharfdale Station. Along the way, we saw a good deer fencing job, which member George Williams had been a contractor on. On hitting the main road at Oxford, a few headed off, but the majority of us had dinner at the Plough Hotel in Rangiora, with thankfully cheaper drinks.

The trip was well organised by Mike and Terry Renner, Scott and Anna Heasley and

unfortunately, the wet combined with long grass wasn’t feasible for several of the vehicles, along with not wanting to leave damage, so we turned around and made towards a picturesque batch of bush alongside a river for a combined morning tea/lunch. A light drizzle came across, but it was hardly noticed as we all grouped together and talked about all sorts.

Scott had gone beyond the call of duty, or should that be the call of nature, by installing a long drop for the ladies. Given that we were miles from anywhere, this was a feat involving a digger, a 44-gallon drum, an outhouse, a dunny seat, and a No 8 wire solution for a toilet roll holder. Apparently Scott realised, as the outhouse was being lowered into position, that it

Two things stood out on this trip. One: what a nice bunch of people were on the trip and how well everyone mingled. Two: the calibre of Bill Stevenson, Jim Ward, Bill Paterson and their families, past and present. If High Country farming is in the hands of these types of people who are proud of their heritage and contributions, their commitment to sustainability and improvement, then high country farming in New Zealand remains a strength in the future of farming.

Such was the enjoyment of the trip that an across-Station off roader on/near the Wairarapa coastline is in the early stages of planning. The timing will be confirmed after the landowners and route have been established.

Article written by Debbie White

Introducing the newest business tool from STIHL: STIHL Commercial Online. You can now shop online for your business while continuing to use your local STIHL SHOP’s expert knowledge and services. STIHL Commercial Online is a tool to keep you and your team working.

One of the benefits is the 1 hour Click and Collect service through STIHL SHOP; by choosing your local store, you can see if they have the machine or accessory available for you in store at that moment, with our live-updating stock levels. Once you have ordered, it will be prepped by the experts at the STIHL SHOP for you.

If your local STIHL SHOP does not have your selected item in stock, you can buy online and have it delivered to you. Organise your product to come to your

home or office so you don’t have to send the apprentice off-site during the day to pick it up. Save your valuable work hours and get exactly what you need with free delivery on your order.

Through STIHL Commercial Online, you can link your month-end-type account that you have with your local STIHL SHOP and purchase machines and accessories as you need them. Or use card payments for your purchases. Set up multiple authorised users through work email addresses linked to your account with different levels of purchasing power! Having a month-end-type account is at the discretion of individual STIHL SHOPs.

Make your admin easier - each purchase made through your account can be tracked against projects with a purchase order field.

To get signed up today, contact your local STIHL SHOP and request online shopping for your business account. If you are a company and don’t have a business account yet, you can get signed up to

both at the same time. Enquire through your preferred STIHL SHOP or online at STIHLSHOP.co.nz www.stihlshop.co.nz/ business_account/create

Article supplied by:

Article supplied by:

reputations— there’s no comparison

Our truly best-in-class Stockade post staples are now going to be proudly manufactured in New Zealand. Still the same superior staples delivering a consistent stronger, longer hold on the fence line — and designed to last the lifetime of a fence so fencing contractors only return to admire their endurance.

Same superior staples, made in New Zealand

Plain and barbed, post and batten… our whole staple range will be New Zealand-made

There’s no comparison: divergent point profile and ultra heavy 90% zinc:10% aluminium coating for durability.

New look packaging for Stockade’s 4mm barbed impulse and pneumatic post fencing staples is making its way onto store shelves and will soon be loaded into ute trays around New Zealand.

A fresh look: modern, clean, and dynamic

From the outside, fencing contractors will see the difference. Inside the new packaging, it is the same truly superior quality staple — with one key change: all Stockade 50mm staples, compatible with ST400i and ST400 power staplers, are now proudly made in New Zealand.

Manufactured from pre-galvanized wire, with a heavy coat at 240g/m3 of zinc alloy at a ratio of 90% zinc: 10% aluminium, Stockade staples are extremely durable. Many other staples across the market use a 95:5 zinc aluminium ratio, which offers a lower durability than the 90:10 coating.

Graeme Young, Stockade engineer, says the move to manufacture all Stockade staples in New Zealand is a very satisfying one. “We have the full circle, R&D and production, right to the fence posts, happening right here in New Zealand.

To know our staples are contributing to New Zealand’s local manufacturing and supporting our business and communities is a real bonus.”

The zinc-heavy alloy used on Stockade staples, with twice the amount of zinc than other manufactured staples, makes a big difference when it comes to standing up against heat extremes, moisture, timber tanalising agents and other factors on the New Zealand fence line.

“With the 90:10 zinc to aluminium mix, Stockade staples provide a best-in-class defence against corrosion and, alongside the high tensile and yield strength, they are made to last for the life of the fence.”

“Other design features include Stockade staples’ divergent point profile and waterproof collation tape,” he says. “The divergent point profile forces the staple legs to spread apart as each staple is driven into timber. In turn, its additional holding power ensures a formidable grip

and the withdrawal force required to remove the staple is markedly increased.”

The staple crown is formed specially to grip common New Zealand fencing wire sizes, especially when fixed on an angle. The diameter of the staple’s eye was specifically designed to reduce the occurrence of wire chattering in winds, placing the staple on an angle also helps.

Each Stockade staple is designed to work in tandem with the driver blade of Stockade power staplers minimising any possible damage to the staple crown’s zinc alloy protective coating on delivery to maintain the high structural integrity of the staple.

A truly superior staple and premium cordless tool development go handin-hand for Stockade. They are the two components of its total system for superior, consistent results on the fence line. All Stockade staples, in the new packaging, are being locally produced in New Zealand.

“ With the 90:10 zinc to aluminium mix, Stockade staples provide a best-inclass defence against corrosion and, alongside the high tensile and yield strength, they are made to last for the life of the fence

New Zealand has always been home to the research and development of Stockade staples.

Graeme Young is one of the engineers at the forefront of Stockade’s post and batten staples development in New Zealand over the last two decades. He says it’s great to see the Stockade staples manufactured here too.

What is the perfect staple?

One which holds firm for the lifetime of the fence or trellis system. Holding power is the whole purpose of a staple, so the staple needs to be uncompromising from both a corrosion and a withdrawal standpoint. Also, it needs to stand up to the environment. It has to tolerate temperature extremes, animal movement, stock pressure for the life of the fence, and heavy rainfall, water run off or crop loads.

Two decades ago, what was your big vision?

We were after that perfect staple for farming, contracting, horticulture and viticulture systems. Fortunately, New Zealand provided us with the ideal rugged testing ground to develop a truly superior staple.

How did you create the superior staple?

Creating the perfect staple was a considered and rigorous process – and clever engineering. We talked extensively to farmers and contractors about staples. It started from there. We talked about their issues with staples chipping, rusting out, and their holding power. Then, we set out to find ways to improve the staple performance. Over the years, we have designed and trialled a number of iterations, different coatings, and leg designs.

What were you after?

Ultimately, we were in pursuit of increased durability. In New Zealand, most new fences are built using medium or heavy galvanised wire with a standard zinc/aluminum coating. All in all, this means many staples on the market start to rust well before the fence wire… and every farmer would expect their fence to stand up for at least 30 years, so should their staple.

What did you need to consider?

To be best-in-class, we wanted to make sure our staple has the right coating, right tensile strength, right depth of drive, no damage to the staple crown when it is driven in, and specially shaped driver blades. All those things need to be correct.

How did you go with your pursuit of durability?

We created a heavier coat containing 90% zinc and 10% aluminium. This ensures superior corrosion resistance over standard hot-dipped galvanised staples — and a stronger, longer hold. Our Stockade staples have six times the corrosion protection compared to standard zinc galvanising.

What’s one thing more people should know about staples?

Not all staples are created equal! When you want a staple to hold the strain and last the distance, look for consistent quality and strength.

What are your thoughts about Stockade staple manufacture in New Zealand?

When stock walk through a fence that has failed, it is annoying and costly. The value of a good fence is priceless – so creating a product that offers real long-life performance in the field and allows farmers and fencing contractors to get on with the job is extremely satisfying. Having the staples manufactured locally is really the icing on the cake. It’s a win-win situation for Stockade and the industry.

While kids’ safety is the end game for school and pool fencing, there’s a lot more to it than whipping up an impenetrable barrier.

In the last year, Mike Renner from Renner Fencing has put in fencing for three schools and two pools around Marlborough’s Awatere Valley. The jobs have taken technical attention, relationship nous and a good grasp of contemporary design.

“Pools are never easy,” says Mike. “It pays to do your research ahead of time. Getting in and knowing the rules helps a lot when quoting. Rules and regulations can differ across council areas, and a client might want a certain thing but that might not meet the criteria.”

Fencing contractors can usually find rules and regulations for pool fencing online on the local council’s website.

Pool covers are a case in point. Popular in recent years for keeping debris out and keeping warmth in, covers are often also used for stopping children from falling in unsupervised. Now, in Marlborough, they are no longer approved under the local council regulations and fences must go up around the pool.

Mike says many residential pools are close to the house, which has implications for doorways.

“Doors must lock: sliding doors cannot open more than one metre. There might be trees, shrubs and other bits and pieces around for shade. If any kid can climb up and over, then that tree has to come out. Fence height needs to be 1.2m, at a minimum, and either solid or

vertical slats no more than 100mm apart with horizontals 900mm so kids have nowhere to put their little feet to climb.”

The visual appeal of pool fencing has a large bearing on what clients end up running with. Clients look to Mike for ideas around what will look good and allow them to make the most of their scenic views. He usually follows the process of finding out what the client wants first, has a frank discussion on what won’t work, then offers ideas.

“ It pays to do your research ahead of time. Getting in and knowing the rules helps a lot when quoting

“Some clients have done their research in the beginning,” he says. “A select few come armed with a clear idea of what they want, but most will want your input first. A handful of brochures with pool fencing designs is very useful. You can add your touch, and the client can add theirs.”

“Some more expensive fence materials, like glass, are popular first choices, but it can come down to budget. Then, there’s weather patterns — where the sun comes up, where the prevailing winds are. These impact what you put in. There’s all that to tack on too.”

Schools – there’s a lot to discuss

In comparison to pool fencing, design input for a school fence is minimal. Unsurprisingly, fence design parameters are laid out as part of the Ministry of Education tender process. Most school fences are 1.8m high. Mike says this is the standard for a school which may have a child who the Ministry considers a “runner”. School fences have the same principles as the pool fences – they should not be climbable, to keep children in and safe when unsupervised.

“Getting on with the Ministry of Education project manager as well as the principal is the key to managing school fence jobs,” says Mike. “There is a lot to discuss, then we devise a plan that is best for everyone. Spotting risks, raising them,

keeping open communication, providing alternatives keeps school projects on track, and we do everything there is to help them achieve what is to be achieved.”

“With schools, when putting fences on boundaries, you need to deal with neighbouring residential properties, roads and reserves, and footpaths. It can open a can of worms. Getting the boundary surveyed before you start is ideal, if the Ministry doesn’t have a current survey in their tender already, it is the way to go.”

Once Mike knows where the boundary sits, it’s a case of working out whether the new fence can run along or whether it might need to deviate from the legal boundary – and following through with subsequent discussions with various people and organisations impacted.

“For one job we are doing, the boundary is out on the footpath. Obviously, the council wasn’t too keen to rebuild the path.”

Trees are an issue too. Some are valued for their shade. Schools might want to keep them, so Mike looks at moving the boundary fencing around them.

Mike’s local school, Seddon School, was the first combined school-andpool fence job. The land was raised up along the boundary line, so the fence moved inside the boundary to reduce the work for the caretaker to maintain this uneven ground. First, the decision to vary the boundary fence was made by the principal, then passed by the Ministry.

School fence designs in Marlborough fall into two categories depending on the shared boundaries. All residential properties are solid fences; the rest, like main entrance road reserves and council boundaries, are see-through panel fencing. Mike uses standard paling, iron and Smartwall for the solid fences and powder-coated steel or aluminium panels. Almost all posts are augered and concreted in.

“Another vital task is to find out about services. Most schools are land mines! There is a lot going on under the surface. Contact your local power supplier for locations and Before You Dig for phone and fibre. Councils can help with water and wastewater pipes, but, often, the best information is from local knowledge like the caretaker.”

“The right tools and machinery to do the job are up there in my mind. We use hand augers or, even better, a small digger to auger the holes. String lines, levels, and good battery tools are key. A dumpy level to get the fence heights correct and level is useful.”

“It is always easy if you are working with flat and level ground, but in most cases, you will have to deal with sloping ground. Solid fences can be run with the ground on a sloping level, but you can’t do that with panel fencing. Either you need to use racking panels on steep slopes or stage the fence by lowering or raising each bay or every second, for example, in the same amount.”

Mike enjoys going the extra mile with school fence work.

“At Seddon, my local school, I wanted to do whatever I could for the school because they have helped me along the way. We had pulled down the old fence, so I had a skip for us. While we were there, we chucked in another skip, for nothing, for the school to do a tidy up. Little things like that, going that little bit further, helps them out along the way.”

Article written by Megan Fowlie

“ Crafted from hot-dip galvanised solid steel and expertly powder-coated, this pool fence not only meets the highest safety standards but also adds a touch of sophistication to its surroundings

Otago Engineering has been a trusted business in Dunedin for over 65 years, previously called A. J Grant after the previous owner, Alex Grant. The business began in a backyard garage, building roof racks and gates from recycled conduit pipes. Sons Allan and Bruce took over from their father in 1976.

During that time, A. J Grant introduced IRONGEAR as a major facet of the business. IRONGEAR included wrought iron products, gates, elegant balustrades, fencing, ornate staircases, and specialised in swinging and sliding security gates. You can still see some of the beautiful wrought iron fences and security gates produced decades ago by A. J Grant and Brett St John around Dunedin as IRONGEAR produced work for the likes of Port Otago, Milton Prison, the University of Otago and the Dunedin Chinese Gardens. Long-time employee, Brett St John spent his life honing his craft and would forge intricate pieces manually. To this day, Otago Engineering continues to have a forge and can complete historical fence pieces using traditional techniques.

Andrew and his sister Lauren took the helm of A. J Grant in 2019, rebranding to Otago Engineering. Andrew began his engineering apprenticeship with A.J Grant in 2007. After qualifying as an engineer, Andrew embarked on his overseas experience, returning to A.J Grant in 2015 to take on a managerial role. As Bruce and Allan looked to retire, Andrew and his sister, Lauren, decided to take on the business.

With over 65 years as an engineering business in Dunedin, it was their aim to continue, expand and further improve: supplying and installing a wide range of steel and iron products, including gates, automatic gates, fencing, balustrade, handrails, clothesline, spiral staircases and playgrounds throughout the country with their main focus being on the Otago region including Alexandra, Clyde, Queenstown, Cromwell and Wanaka.

Andrew brings over a decade of experience from New Zealand and Australia as an engineer to Otago Engineering, and Lauren comes from a background in graphic design and administration. Together, their focus is on bringing quality and creativity to every

project they complete, helping businesses throughout Dunedin and New Zealand with steelwork and wrought iron pieces.

One such project completed in the heart of Queenstown at the end of 2023 has once again allowed Otago Engineering to showcase its prowess in design, fabrication, and installation with the completion of a meticulously crafted pool fence featuring two pedestrian gates. The project, from inception to installation, exemplifies Otago Engineering’s commitment to excellence and innovation in engineering solutions. Crafted from hot-dip galvanised solid steel and expertly powder-coated, this pool fence not only meets the highest safety standards but also adds a touch of sophistication to its surroundings.

Otago Engineering’s design team took on the challenge of creating a pool fence that not only adhered to safety regulations but also seamlessly blended with the natural beauty of Queenstown. The decision to use hot-dip galvanised solid steel not only ensured the durability of the fence but also provided an aesthetically pleasing finish. To enhance both the longevity and visual appeal of the pool fence, Otago Engineering employed a high-quality powder-coating process. This meticulous application not only protects the steel from corrosion but also allows for the seamless integration of the fence with its surroundings. The colour choice of matt black was selected

to complement the natural elements of the Queenstown environment, ensuring the fence becomes a harmonious part of the landscape and surrounding buildings. The initial challenge of this project was in the drawing and manufacturing stage: because of the inconsistent curve of the fence, the initial measure had to be extremely precise as each angle and slope had its own radius. It was due to Otago Engineering’s extremely talented CAD drawer and fabricators that they had the ability to create such a challenging project. One of the notable features of this project was the absence of a top rail, a unique design choice that posed its own set of challenges. Otago Engineering, known for its innovative solutions, successfully

overcame these challenges, creating a fence that is not only structurally sound but also visually appealing. The installation of a pool fence becomes particularly challenging when dealing with uneven terrain, such as the uneven stone finish of the ground in this Queenstown project. Otago Engineering’s installation team, equipped with experience and expertise, tackled this challenge head-on. Precision and attention to detail were paramount in ensuring the fence maintained its straight lines and uniform height, all while adapting seamlessly to the natural contours of the stone-laden landscape.

Otago Engineering’s successful completion of the pool fence with pedestrian gates for Queenstown’s Relaxaway Holiday Homes Alpine Cottage, stands as a testament to the company’s dedication to excellence in every aspect of engineering. From the initial design phase to the fabrication and installation, Otago Engineering has demonstrated its ability to overcome challenges and deliver a product that not only meets safety standards but also enhances the aesthetic appeal of its surroundings. Visitors to Relaxaway Holiday Homes Alpine Cottage can gaze upon this masterfully crafted pool fence, witnessing not just a safety barrier – but a work of art. Otago Engineering continues to raise the bar in engineering solutions, creating structures that not only serve their practical purpose but also contribute to the visual tapestry of the businesses and communities they serve.

Article written by Lauren Callander

In March 2023, Agri-Fencing Taranaki was asked to look at a boundary fence for the Te Kura Kaupapa Māori o Te Pi’ipi’inga Kākano Mai I Rangiātea in New Plymouth. After meeting with the Property portfolio manager on the school board, we had a look at the boundary section of the fence.

The design brief was a bit different from our usual projects, that’s for sure! It had to be 1.8m high for the first section of the fence line, then the height could be dropped down to 1.5m. The height had to deter kids from ages 3 up to 12 from climbing or pushing through. It also had to stop tennis balls and such from running down the hill into the neighbouring property. There was an existing chain-link fence along the playing field, which we initially thought could be continued, but

we agreed it would give the fence line a bit of an industrial look, so we went for something with cleaner lines. This was certainly a bit different from our usual requests around stock management!

After exploring some options on a few fence designs, we came up with the idea of using equine netting at 1.5m height and using plain 2.5mm HT wire at 100mm spacings to achieve the requested 1.8m height for the first part of the fence line.

“ This was certainly a bit different from our usual requests around stock management!

Our fence proposal was accepted by the board, then it was a matter of scheduling the work over the school holidays, which at that point were just over a week away… challenge accepted! We scheduled a utilities detection service to make sure the fence line was clear of any underground services, then commenced with some ground prep and building of a small retaining wall to level the fence line and prevent dips. Another challenge included an undulating pump track which made for some interesting tractor balancing.

The result with the use of equine netting and plain wires provided a very tidy, robust fence, safe enough to keep the kids in. This was an enjoyable job and something different, with a good sense of achievement being able to contribute to keeping our tamariki safe at school.

Article written by Jeff Rawson

“Shall we tender for this GETS job for a school fence, Shaun?” asked our project manager, Jimmy.

Shaun, owner/operator of Davies Fencing and Construction, and my husband, doesn’t usually work on schools. He started out doing rural jobs in Whakatane fourteen years ago, and loved yarning to farmers and building relationships. Then he moved our family to Tauranga, grew the business to eleven guys, two office managers; Jimmy and Rochelle, bought a lifestyle property and an acre or so of land became storage for materials, machinery and a huge eye-sore of a burn pile (which I had earmarked for sunflowers, but ho-hum).

Shaun still loves rural fencing, but he quickly worked out that it’s a good idea not to put all his eggs in one basket, so he branched out into residential (highend) fencing and civil works (engineered retaining walls, lakes, boardwalks, stairs on bush tracks, bollards, decks, concrete works, skateparks, dog parks).

Shaun, being a Yes Man, replied, “Yep,” to Jimmy, then asked for all the details.

“It’s for Bellevue Primary School in Tauranga. They have a handful of kids who keep escaping, and they need a ‘better’ fence to keep them in.”

“A handful of kids?” questioned Shaun, “A $120k job for a handful of kids? I hope we get to meet the lucky ducks. Tell me the specs?”

“Ok,” said Jimmy, “It’s 260 metres and will also need about eight gates.”

“Great!” said Shaun, “I’ll give Ellie at Edgesmith a call, she’s awesome to deal with. When does it have to be done?”

“The two-week school holiday in October.”

“Sweet, we can fit that in.”

Jimmy and Rochelle worked on the tender together and submitted it. They chose a 1.5m high balustrade style panel fencing because of its strength and durability. They knew it was going to get a punishing from balls and the like at a primary school.

“ Shaun still loves rural fencing, but he quickly worked out that it’s a good idea not to put all his eggs in one basket, so he branched out into residential (high-end) fencing and civil works

They must’ve done a superb job of the tender because we got it.

On the first Saturday of the school holidays, we had another contractor come in and install about 100 metres of security fencing on a portion of the school perimeter so that on the Monday, the guys could start.

They began by stripping out the old fence. One guy on the digger, two guys doing the hard yards. It was a mishmash of wire, bits of tin, some palings, all bordering house properties. There was overgrown grass and shrubbery mixed in amongst it.

The following day, another three guys joined them. They followed behind the first crew and installed the new fence. When they had done about 100 metres, they moved the security fence along. The whole job itself was pretty simple to install, even when the new fence had to be built

on a section of retaining wall due to the height/fall restrictions.

The challenges arose when it came to the gates. The school had a rough idea of where the gates were to be installed, but they hadn’t confirmed. The issue was to do with emergency services access. The main access at the front of the school couldn’t reach the back classrooms, and they wanted another access down the back of the school but it hadn’t been built yet. The gates had to be custom-made to fit, so they couldn’t be ordered until decisions were made on the access, and the new fence was up.

A few weeks later, once we had the gates in our hot little hands, two guys returned to the school to install them. They were tricky to hang due to the undulating ground, but our guys did an epic job. This time, school was open, and they had numerous inquisitive kids come and ask a million questions. The guys wondered if any of them were the kids that the fence was built for, but they never did find out.

Article written by Angelena Davies

Fencing Solutions Waikato Ltd (FSW Ltd) have been involved with many pool, school and park fencing projects, having been the contractor to Waikato Kindergarten Association, Central Kids, and many private Early Childhood Education (ECE) centres for their fence and gate needs.

Timing always poses a challenge – ideally, being able to get work done in their holiday period. If we have to work when kindergarten is in, then the next challenge is answering all the questions from the 4-year-old onlookers from behind a temporary fence. Fielding questions like ‘What are you doing?’.

The requirements for ECE fencing and gates are as much to keep the public out as it is to keep the children in. It is unbelievable the number of instances of vandalism or theft from such an organisation. The focus first is on function: fences now are generally 1.8m high with a maximum gap between vertical rods of less than 90mm, flat top panel and commercial grade. Gates have heavy-duty self-closing hinges and in all cases, a pulltop latch that is lockable. In some cases we have installed a two-step unlock process with an additional magnetic slide pull latch. All of our fencing materials are sourced from Modern Fence Supplies in Hamilton.

Pool fencing is also one of the many services offered by FSW Ltd, working alongside pool companies who are installing a pool. It is often a step-by-step process where the pool builders will do all their ground works and surrounds. The pool needs to be fenced as soon as it has more than 400mm of water in it, in

accordance with the Building Act 2004, the legislation that governs pool fencing requirements in New Zealand.

The Buildings Act 2004 requires all residential pools and small heated pools with a maximum depth of 400mm or more require a physical barrier that restricts access to the pool by unsupervised children under five years of age .

A temporary fence is installed at this stage to keep the work area safe and away from inquisitive children. We will install a fence with a panel that has a NZSA approved PS1. For commercial sites, we are required to submit a PS3, which is a producer statement to warrant that the work completed is as planned and follows any engineered standards.

Glass fencing is another option that can either be bolted down with spigotts or aluminium posts. Glass pool gates are required by the Act to self-close and selflatch. The Act also requires mandatory inspections every three years to ensure compliance with the regulations .

The Building Performance website provides a comprehensive guide for pool owners to understand the pool fencing requirements of the Building Act 2004 (the ‘Act’). The guide includes information on why pool fencing is important, the types of pools that require a barrier, the

requirements for pool fencing, safety covers for small heated pools, applying for a building consent, and more.

Gates need to follow the rule of being at least 1200mm high, swinging away from the pool on self-closing hinges, and the pool latch needs to be self-latching. Over time, the springs in the self-closing hinges will soften. An easy self-check on gates is whether they can self-close from a distance of 100mm.

In the case of a glass gate, the opening latch must only be accessible from the inside and be 300mm lower than the top of the gate.

Another part of the Act that can be overlooked is that any climbable object must be at least 1200mm away from the outside of the fence and 300mm from the inside of the fence.

It is likely that local councils will require that the pool fencing be a part of the building consent. These plans will be approved by the council, and when the pool is complete, the fence will be signed off.

We get a number of enquiries from pool owners who have been notified that either their fence has failed an inspection or there is an inspection due. It is the responsibility of the pool owner that their fence passes the compliance test at any time.

Article written by Todd Sherburd

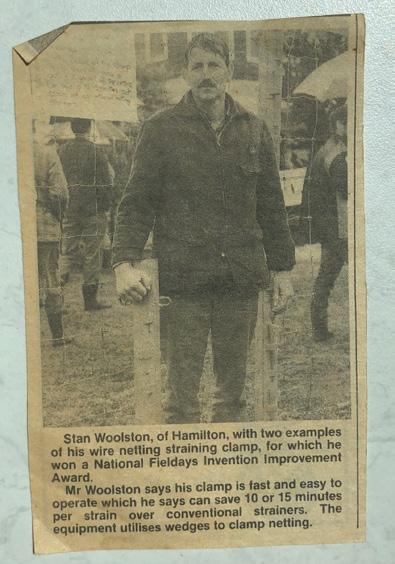

Stan comes from a very fencing-orientated family. His brother was a full-time fencing tutor at the now closed down Flock House Farm Training Institute. His nephew Trevor was a twice Golden Pliers Champion and Silver Spades Champion.

Stan was a familiar sight at the National Fieldays competitions every year for many years and has tucked a few finals under his belt.

In those earlier years of competitions, many tools and methods were developed, which happens in most facets of any type of competition.

Ingenuity really paid off. It’s likely that an exasperated “there’s got to be an easier way than this” led to the birth of many an invention.

For Stan Woolston of Cambridge, it also led to an Award of Merit, $100 and a hand-painted ceramic plate.

Stan was one of 53 who entered the inventors’ section at the Fieldays in the 1970s and his wire tension gauge was one of 10 to win the Award of Merit. The award is given to “proven farm equipment” inventions which have been on the market for up to 12 months, and the inventor must have sold some of the items.

Although a berry grower for four years, Mr Woolston was formerly a fencer and had often entered the fencing competitions at the Fieldays. In three separate years he fenced his way to the finals.

One of the most difficult aspects of competition fencing, Mr Woolston said, was getting the tension on the wires accurate. “Most people use a spring balance scale to check the tension,” he said, “but it’s very fiddly and there is a lot of human error.”

“I thought there must be a better way than that...” So, he set out to find it.

His first wire tension gauge came off the drawing board, and he put it to the test in the fencing competition at the Fieldays. His score for wires in the doubles was a perfect 10 out of 10, top marks. A friend from Putaruru, Colin Meredith, used the gauge in the same competition and scored almost top marks for his wires.

“It’s very simple and it has so few working parts. It’s accurate enough to be really effective. It really is so simple that anyone could get their tensions all right”.

The gauge is operated by passing the wire over a spring, which in turn activates a needle pointer. The amount of tension registers on the marked scale.

Stan holds a patent on his invention and more than one company showed an

interest in marketing it. “It has quite a potential I feel” Stan said, way back then.

In the late 1970s, Stan got sick of fiddling with a lump of wood and spring balance, so (drum roll please), the Woolston Wire Tension Gauge was birthed. He sold the rights to Franklin Machinery (now Gallagher), and the tool has moved since then and is now part of the Strainrite product range. It has changed very little since its conception.

I can quite confidently say that this invention of Stan’s is now part of almost every fencer’s kit, both here and overseas.

Good on you Stan – you’re a legend.

Article written by Nick Liefting

Name

Emile De GreeuwCourse

Certificate in Fencing (Level 4)

“ It focuses less on the fencing skills and more on running your business, bettering your brand as a professional, which is key

RETAIL

“I cross-credited my prior training and industry experience to be recognised for the Certificate in Fencing (Level 3). Then I applied for the Level 4 course,” explains Emile De Greeuw.

Emile is undertaking the Certificate in Fencing (Level 4) through NorthTec | Te Pūkenga, which is run nationwide.

“I enrolled because I wanted recognised qualifications, and fencing is an industry that is lacking a bit of recognition in that regard. Qualifications are somewhat of a new thing in the industry.”

Emile runs his own fencing business and often has people working under him whom he helps develop in the fencing industry.

“There’s a lot you need to be aware of when it comes to working with clients and companies. Things like liability insurance, progress reports, cultural reports, there’s a lot that comes into it. The course teaches you best practices and industry standards. It focuses less on the fencing skills and more on running your business, bettering your brand as a professional, which is key.

“I would recommend the course to established crews or people that are in their second or third year of business. There’s a range of reasonably experienced modules that you need to cover so it’s more achievable and relatable for those who have been in it for a bit.

“The qualification is all online which suits me as it doesn’t affect my day-to-day running of the business. I can get online at 7 o’clock which suits me and my family as the kids are normally in bed around that time.”

“There’s a lot of support from the tutor and the other students so it’s been easy enough to manage and it’s well worth it.”

https://www.northtec.ac.nz/programmes/ new-zealand-certificate-in-fencinglevel-4

COMMITTEE MEMBERS 2023/24

PRESIDENT: Tim Garrick

VICE-PRESIDENT: Owen Petersen

SECRETARY/TREASURER: Leanne Stanger

CHIEF JUDGE: Owen Petersen

COMMITTEE Debbie White, Shane Bouskill, Joelene Bouskill, Wayne Newdick, Paul Van Beers, Nick Liefting, Matt Jones, Mark Lambert, Tim Stafford, Mike

Cory

I have been coordinating the Certificate in Fencing Level 3 and 4 courses for NorthTec for the last couple of years. As most of you know, the courses were reviewed and reinstated in 2018 in their current format.

In 2018 we saw 11 students go through the Level 3 course. COVID hindered several courses through 2020/2021, but we still had good numbers in 2022, and roughly 70 across the country went through the training in 2023. In Level 4 (which launched again last year) we have seen one course of 12 complete and the mid-year intake of 13 is near completion with similarly good results.

The feedback on Level 4 has been excellent and the tutor David Horner is a great asset to the industry, in that he understands how contractors think. Together we try and align the timings

of the courses to what will work around people’s staff and businesses. This is also the same for Level 3, the tutors across the country are an asset to the industry.

In the last 12 months, I have been working with the online development team to integrate the Level 4 learning into an online system that will help aid and give the learner confidence that what they are doing is correct. This has been a huge undertaking, and it has led the way behind the scenes for other industries.

The fencing industry has lacked a form of continued recognised training. Yes, the Association has had its eggs in

this basket for a very long time, but the implementation and execution of those things has never continually lined up.

When I was in the rural banking industry, I inherently saw the very people fencers work for, downgrading the trade as if anyone could do it. Comments like “It’s just fencing, we’ll do it ourselves”. It used to annoy me, because they would be better sticking to their knitting and sorting their feed and cashflow budgets, than fencing for three months on a job that could be done in two weeks by a professional.

The industry needs to be recognised as a trade by not only the people in it, but

by any member of the public. Sure, within the industry, we can tell who is a good fencer and who is a rubbish one, just by looking at their work (and sometimes just by talking to them). I can’t fence to save my life, but I sure know what a good one looks like now after travelling the country looking at fences for days. This is what we want to get out to the general public, so they can make informed decisions and know that the contractors they are hiring have invested in training and business acumen. Not someone who bought a tractor and rammer and decides they’re a fencer. In shearing if you shear the skin of a sheep, ya mate next door kicks you up the jacksie and you get a tune up. Out in the back of beyond sometimes nobody sees a terrible fencing job until it falls apart and the neighbours have a stoush about stock getting out, or on a residential/lifestyle block the client wakes up every day to look out at their fence, with twisting rails or gaps in their palings the dog and cat can fit through. This is why the training and FCANZ Pathway go hand in hand.

Sure, some contractors and staff can complete these courses with their eyes closed. Do they?? No!! The tutors and I find ourselves dragging people along to get their work done before the end of the courses. There are students that are so diligent and have awesome time management, are great fencers and are the ones to showcase the industry. There are employers putting their staff through the course and I see the dedication and diligence they have in their businesses

regarding training and health and safety - these are the companies we want showcasing the industry.

The courses are numbers-driven, bums on seats. Each fully enrolled student creates a funding mechanism that allows a course to be viable and enables us to pay for tutors and materials. The fee attributed to the learner from TEC is only generated once fully enrolled and attending. Attendance is a key factor. Each week, NorthTec are noting attendance; attendance to Zoom sessions, block courses, etc. If the attendance isn’t tracked, funding is

queried. If someone doesn’t attend, their funding is pulled.

If we don’t have enrolments, we have no funds to keep them going. There is only so much I can do. If the industry (THAT’S YOU, READING THIS) wants to be recognised and have NZQA backing, this is the only opportunity to maintain that. This is as close to an Apprenticeship as we will get at this stage, given the changes in the Tertiary sector with the new government and the changes to skills standards. We are setting things up in the way we provide these courses to hopefully align with an Apprenticeship when the time comes.

“ If the industry doesn’t use it, they’ll lose it

Justin Tilly NorthTec | Te Pūkenga Pathways Manager

If you’re wanting training and to align this industry with other recognised trades like building and plumbing, get on board and get training. Otherwise, it will be lost, more than likely never to return.

P

In our eighth instalment of our retaining walls feature, Nick Liefting takes us through the complexities of Tie Back walls.

Well, it is just that, the poles or wall face is tied back to some form of anchor.

A lot, or should I say most of you reading this article, have done tie backs in a fencing or horticulture application, which is usually the result of having nowhere to install a stay/strut.

The reasons for a retaining wall tie back are a bit different. The main reasons are:

• A high surcharge (the vertical pressure applied to the ground surface in the vicinity of a retaining wall) and ground bearing not at the preferred kilopascal (kPa)

• Severe toe slope and high surcharge, e.g. dwelling