Editor

Bertha M. bertham@fmdrc-zambia

Sub-Editor

Anthony Kiganda

Contributing Writer

Oscar Nkala, Mfuneko Jack Lindani Mkhize Caroline Thomas Anthony Kiganda Anita Anyango Jeff Kapembwa

Bertha M. bertham@fmdrc-zambia

Oscar Nkala, Mfuneko Jack Lindani Mkhize Caroline Thomas Anthony Kiganda Anita Anyango Jeff Kapembwa

Africa is endowed with vast mineral of resources which if well used could help enhance the continent’s economic fortune.

And with vast untapped mineral resources, Africa represent significant investment opportunities for interested stakeholders around the world.

Culture, protocols key to blast safety on mines

A recent global safety report for mining indicates a gradual but steady improvement in mine safety, with a total recordable injury (TRI) frequency rate at a low 2,90 –down from 5,07 just a decade ago. The Safety Performance benchmarked the progress of its members during 2021 noting that the industry has focused on “operational, cultural and leadership transformation” in reducing fatalities in recent years.

28 www.fmdrc-zambia.com

Sales and Marketing Victor Ndlovu victorn@fmdrc-zambia.com +27 11 044 8986

M. Pikes +260 76 173 0213 mutalek@fmdrc-zambia.com Plot 866A Old Airport Road, Mukubu Natwange, Kitwe, Zambia.

Meshack Ndzendevu Polite Mkhize Gladmore Ndhlovu Leslie Nyembe

Kholwani Dube kholwani@fmdrc-zambia.com

Augustine Ombwa

Arobia Creative Consultancy austin@arobia.co.ke

Circulation/Sales info@fmdrc-zambia.com sales@fmdrc-zambia.com +27 11 044 8986

However, the big question has been whether the continent has been using its resources in a prudent manner. There is a persistent outcry within the continent that African people are being dispossessed of their resources.

African mineral resources should be used transparently and equitably. The ultimate objective is to create wealth for Africans. Wealth creation will contribute to resolving the triple challenges of poverty, inequality and unemployment.

But there is a direct relation between political power and the under-performance or mismanagement of the mining sector. There are various political and social forces that mediate the relationship between mineral resources and development outcomes.

This is true for Africa where political power is the dominant factor that determines how resources are negotiated, extracted, commercialised and how revenues are used.

This is undermining economic progress in Africa. Politics should not be used to punish Africans. Miners should be given mining tenders in an open and transparent manner, pay their taxes and pledge to conserve the environment in which they are operating and this includes communities.

Mailing Times Media (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Mailing Times Media (Pty) Ltd www.fmdrc-zambia.com

www.fmdrc-Zambia.com

Bank of Nevis International Ltd. (BONI) provides private banking and holistic wealth and portfolio management to clients from all over the world. We provide a highly personal service and have a truly global approach. From our base in Nevis we offer clients a global footprint by acting as an independent financial gateway connected to international financial centres and markets in London, New York, Hong Kong, Dubai and Sydney whilst maintaining our traditional gateway to the wider Caribbean, South America and the Continent of Africa. As a result, we are ideally suited to help our clients achieve their global ambitions, safeguard their future, and meet their exacting needs in an increasingly digital and financially inclusive world.

Who are your clients and what do you do for them?

Our clients are from all walks of life and all parts of the world. What they have in common is their ambition. Our

clients in sub-Saharan Africa, like our clients everywhere, want to take their ambitions global. We work closely with them to tailor their financial needs to deliver long-term, high-yield sustainable returns so they can build a lasting legacy for their loved ones. We are proud of our strong repeat client base which is the result of our team’s inclusive and diverse approach at every level. Whatever your story, and wherever you’re headed next, we want to be a part of it.

We are meeting the challenges of today and the future by use of fintech. Through the same, we are increasing our global footprint to provide real-time 24-hour banking experience to a wider and more diverse demographic. Be they in Africa, Asia, Australasia, Middle East, North Americas and South America. Through our subsidiary we realise that second passports are rapidly becoming

essential requirements for high-networth individuals (HNWI). Bank of Nevis International Trust Services Inc. (BONITS) provides Migration Investment clients from all over the world the freedom to live a life without borders with visa-free travel to over 155 countries. Freedom of movement not only opens new, global opportunities but it also serves as an insurance policy in an uncertain world. Combined with BONITS’s trusts and incorporation services and BONI’s wealth and portfolio management, we offer a deeply personal, long-view approach to securing your legacy and protecting your family’s financial future.

A new generation of HNWIs also want to see their money doing good, not just doing well. This is why, in collaboration

with BONITS, we are currently developing new impact investment products that will deliver long-term, highyield sustainable returns and deliver a positive development impact for local communities in developing markets, including improving access to renewable energy. Investing with impact is the future of our sector and we want to lead from the front.

What’s next for BONI? Where is the private banking and wealth management sector headed next? Banking is undergoing unprecedented disruption. New business models are being invented. New currencies are being introduced. New channels to market are being opened. All this makes the present an exciting time for our industry.

Fintech has had a significant impact on global banking and is being used to democratise access to finance, although much work still needs to be done in Africa and elsewhere to reach those that are still unbanked.

BONI is developing new fintech products and services to ensure our clients benefit from immediate access to our platforms anywhere in the world. Our investment in fintech ensures the transfer of money with confidence and security to over 100 countries.

Wealth and Portfolio Management: Supporting Your Global Ambitions Bank of Nevis International Ltd. (BONI) provides high level private banking and holistic wealth management to clients from around the world. We are truly outward looking in our approach and recognise no one size fits all. We work closely with our clients to tailor their individual needs to help them to achieve their global ambitions.

Private banking

Wealth and portfolio management

Bespoke mortgages

School and college fee planning

Multi-currency accounts

FinTech solutions

Real time payment solutions to over 160 destinations

Multi-currency wallets

High return fixed – deposits

Credit cards

Virtual credit cards and more

For more information, please visit www. boniltd.com or email info@boniltd.com

Bank of Nevis International Trust Services Inc. (BONITS), a related business of BONI, helps ambitious people in fast growing economies around the world take their ambitions global. To us, Migration Investment means more than just obtaining a second passport, it includes sustainable investment options to help clients live a life beyond borders and have a positive impact on communities. Secure a lasting legacy for your

family and invest with impact through citizenship to St. Kitts & Nevis:

• Visa-free travel to 156 countries

• US dollar-pegged currency

• A competitive business environment connected to global markets

• A stable political environment

• World-class university education options on island

• Favourable and efficient tax system

For more information, please visit www.bonitsinc.com or email info@bonitsinc.com

www.fmdrc-Zambia.com

of the $121 million cash that Danakali has been left with will be distributed back to shareholders. The remaining cash, about $12 million will be used to identify new projects and potential new alternative growth opportunities.

The Colluli potash project is a low-cost, long-life sulphate of potash (SOP) project under development in Eritrea, Eastern Africa. It has been ranked as world’s most significant and lowest-cost sources of sulphate of potash (SOP), a premium grade fertilizer. It boasts JORC compliant reserve at 1.1 billion tonnes.

Danakali has announced plans to its 50% stake in the Colluli potash project in Eritrea. The Australia’s firm revealed it will sell its stakes to Chinese company Sichuan Road and

Bridge Group in a deal which will be finalized between March and May2023. Danakali has been in partnership with Eritrean National Mining Corporation (ENAMCO) over the mine project. 90%

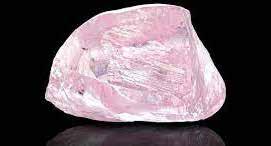

Storm Mountain Diamonds has sold 47.8 carats pink diamond recovered from Kao diamond mine, in Lesotho. The valuable stone which was named the Pink Eternity was exhumed in April, according to the company’s Chief Executive Officer (CEO), Mohale Ralikariki. It’s so far the largest pink diamond recovered at the mine to date and also possibly the largest pink diamond to be mined in Lesotho.

Mr Ralikariki said the development was a significant recovery from the COVID-19 impact, adding that the mine had spent a lot of money operating under undesirable circumstances while striving to meet its targets.

The sale attained is set to benefit the government in terms of royalties paid and the balance will be reserved to sustain the mine’s daily operations. The Kao

mine is located in the Lesotho district of Botha Bothe, and mines the fourth largest kimberlite pipe in Southern Africa and the largest kimberlite pipe in Lesotho over 19.8 ha, with an

Colluli potash project also projects commercialization of kieserite and mag chloride. Other fertilizer products at the site include; gypsum, rock salt and muriate of potash (MOP). It also has access to solar, wind and geothermal energy systems – the East African rift.

indicated and inferred resource base of 12.7-million carats.

The mine has produced a couple of rare coloured gems including blue, top light brown, classic white, yellow, purple, and pink diamonds. The mine has been explored and confirmed to a depth of 500 m, and boasts 18 years of operation left.

Gold Corporation (CSE:ASE | GSE:ASG | FRANKFURT:1A9 | U.S.OTC:ASGOF) (“Asante” or the “Company”) is pleased to announce that the first gold pour at the Bibiani Gold Mine has been completed successfully with process of gravity gold concentrate recovered by the Knelson Concentrator.

Asante acquired the Bibiani Gold Mine in August 2021 and completed its project execution plan that included refurbishment and upgrade of the Process Plant, Tailings Storage Facility and Mine Site Infrastructure.

In September 2021, Asante announced start of the refurbishment process and the Company’s plan to pour gold in Q3 2022.

In early June 2022, Asante announced the start of commissioning and operation of the Bibiani Process Plant. Since July 1, 2022, 24 hour per day operation has proceeded with the Carbon-in-Leach, carbon stripping and elution areas now operating. Hot Commissioning of the Gold Refinery was completed on July 7th. This is the final operating area of the Process Plant to be commissioned. Scale up of production is continuing as planned, including collection of gold on carbon, leading to delivery of

approximately 175,000 oz gold over the next 12 months.

Asante Gold’s CEO, Dave Anthony, stated: “From the outset of our acquisition of the Bibiani Gold Mine, Asante has made a number of commitments to our stakeholders, including the local community, the Government of Ghana and our investors. We are proud that all of the commitments we made in the past 10 months relating to the Bibiani Gold Mine have been met or exceeded, up to this time.

“The quality and timeliness of work completed by the Asante team is testament to their abilities and commitment to delivering results as planned. We recognize and thank our principal project partners, all of which have been Ghanaian companies, including Harlequin International, Rabotec, KPS, Kozah Construction, iConstruction, Emak, Electrowind, FLSmidth – Ghana,

The government of the Democratic Republic of Congo plans to expand its main border post with Zambia in bid to ease truck queues.

Mining trucks have reported this year to be having queues of upto 60km due to increased production and inadequate infrastructure. Congo accounted for 1.8 million tonnes of mined production of the metal last year. However, the turnaround time of trucks has increased substantially taking an extra 45 to 60 days for the products to reach consumption centres in Asia, Europe or North America. This compares to around 15 days in 2019.

The backlog of trucks at Kasumbalesa, a border town and the main exit point for metals exports from Congo, is an example of supply chain disruption that will make it harder to meet future demand for copper, essential for electric vehicles. According to Michel Kibonge Nyekuma, chief of staff for the Minister of Mines increased traffic also affects the long queues of trucks.

However the government is trying to lessen the situation. A construction project for a second Lubumumbashi

Caesar Furnace, Mining Project Processing and Engineering Limited (MPPE), Top Quality Investments Limited, Rand Sandblasting Company, Tesla Electricals, Multigeomatics, Knight Piesold Ghana Limited, Bosch Rexroth (Ghana) and PW International (Gh) Ltd.”

Asante is a gold exploration, development, and operating company with a high-quality portfolio of projects in Ghana. Asante is currently focused on closing the acquisition of the Chirano Gold Mine from Kinross Gold Corporation and developing to production its Bibiani and Kubi Gold mines located on the prolific Bibiani and Ashanti Gold Belts. Asante has an experienced and skilled team of mine finders, builders and operators, with extensive experience in Ghana.

Asante is listed on the Canadian Securities Exchange, the Ghana Stock Exchange and quoted on the Frankfurt Stock Exchange. Asante is also exploring its Keyhole, Fahiakoba and Betenase projects for new discoveries, all adjoining or along strike of major gold mines near the centre of Ghana’s Golden Triangle. Additional information is available on the Company’s website at www.asantegold.com.

- Kasumbalesa road is in the process of being signed and it would take at least 18 months to complete from the date the project is approved.

“More border posts would add “a significant amount of processing capacity, create competition between the different provinces (and) all those customs clearing revenues would improve efficiencies,” said Miners with operations in Congo.

and highlighted by the recent PFS, we can demonstrate a fundamentally robust development case at Ewoyaa, which delivers extensive social and economic benefits to our local communities and the Republic of Ghana,” Atlantic interim CEO Lennard Kolff said.

AtlanticLithium Limited, has submitted a mining licence (ML) application in respect to the extraction of minerals from the proposed Ewoyaa Lithium Mine to the Minerals Commission of Ghana (MinCom), in West Africa. The funded African-focussed lithium exploration and development company targeting to deliver Ghana’s first lithium mine, lodged initial documents in support of its ML application for the Ewoyaa project.

The application will now be assessed by the Ghanaian government as soon

as practicably possible, as part of the approval process ahead of the grant of the ML. The application includes the submission of the recent prefeasibility study (PFS), the results of which were announced in September.

The Ewoyaa lithium project has a compelling case for development at a time of unprecedented lithium demand. [We have] completed extensive exploration and technical programmes, environmental and social studies, economic studies and the valuation of the project. “As evidenced by our work to date

Atlantic Lithium would be working closely with MinCom, Ghana’s Ministry of Lands and Natural Resources, the Environmental Protection Agency, local government authorities, host communities and other regulatory bodies towards the grant of the Ewoyaa ML.

“Our ongoing and planned activities now focus on further derisking the development timelines of the project, rapidly advancing a detailed design and construction phase and ultimately, moving into production whilst continuing to grow our exploration pipeline,” Kolff said.

Limited is set to launch international arbitration against Congolese state mining company Gecamines after Democratic Republic of Congo armed forces occupied two concessions near its Kinsevere copper mine.

MMG Limited is a mid-tier global resources company that mines, explores and develops base metal projects around the world. MMG’s largest shareholder is China Minmetals with 68% According to the firm, armed forces entered its Nambulwa mining lease on Sept. 16 claiming Gecamines had signed a research contract for it. MMG staff were able to return to site and continue work from Sept. 28 but the armed forces remained there.

The Hong Kong-listed firm added that security forces removed MMG staff from its Sokoroshe II mining lease on July 1, again citing two research contracts for the area with third parties signed by Gecamines.

“We intend intends to commence international arbitration in the International Chamber of Commerce in Paris and Geneva. MMG continues to be denied access to Sokoroshe II, which it plans to mine along with Nambulwa as part of an expansion of its Kinsevere operation. We continue to make formal

requests to both Gecamines and the ministry of mines for Gecamines to withdraw the agreements with third parties and remove the armed forces and third parties from the sites,” said majority owned by China MinMetals, said in a statement.

www.fmdrc-Zambia.com

WestAfrica-focused gold miner Centamin is soon to commission solar plant at Sukari gold mine in Egypt. The company, announced that it’s in the final stages of making its Sukari mine in Egypt a solar powerfuelled operation. The firm has already seen a reduction in fuel consumption and energy costs.

The solar plant, which is made up of a 36 MW solar farm and 7.5 MW battery–energy storage system, has been consistently delivering 36 MW DC, converting to 30 MW AC of power, since early September, Centamin said.

The reduction in exposure to volatile fuel pricing is saving Centamin up to 70,000 litres of diesel per day and averaging a reduction in fuel consumption of 22 million litres per year, according to company. Based on current diesel prices, this means the plant has the potential to provide annual cost savings of $20 million, alongside an expected reduction in Scope 1 greenhouse gas (GHG) emissions of 60,000 tonnes of CO2 equivalent a year, and a subsequent

reduction in volume of diesel trucked to site. Centamin also said it continues to be engaged in talks with the Egyptian government and independent power providers to assess the opportunity to use their power grids at Sukari. The mine is optimally located within Egypt’s Eastern Desert, which has some of the highest levels of solar irradiance globally, averaging over ten hours of sunshine a day throughout the year.

CEO Martin Horgan noted that Egyptian grid power is generated from natural gas and a mix of renewables, such as hydro, solar and wind. This, he said, opens a path for Sukari to further

reduce its GHG emissions.The executive highlighted the potential for further cost savings. Egyptian industrial grid tariffs are significantly cheaper than the cost of power generation using diesel fuel, he noted. “The solar plant and potential to integrate grid power will contribute materially to our environmental stewardship philosophy and our strategic objective of maximizing returns for all stakeholders,” Horgan said in the statement.

Once fully commissioned, expected to happen in the present quarter, the facility will be the largest hybrid solar project at an off–grid mining operation.

government of Zambia has limited the number of mining licences to be acquired by companies. The country’s mines minister Paul Kabuswe made the announcement and said the move aims to curb speculation and promote investment.

Mining firms will now be restricted to five licences and those that need more will have to justify. The restrictions follows suspension of issuance of mining licences in February. The ministry of mines commissioned an audit in response to public complaints about a lack of transparency.

“Initial process audit findings have confirmed our fears that some companies

own too many mining rights, using either a single or multiple companies with the same beneficial owners. We have had a lot of licences being used for speculative purposes and we want to curtail that.

The audit show that some companies own as many as 50 licences. It also found that some were not registered with Zambia’s patents and companies’ registration agency and may not be paying tax. The licensing department, which was expected to re-open on April 11, will resume work on Oct. 19.

Illegal miners would be given 90 days of amnesty to register with the ministry of mines,” said Kabuswe.

The mining landscape in Zambia covers production of multiple mineral raw

materials, including copper, cobalt, gold, nickel, manganese, emeralds, beryllium, myriad gemstones, sulfur, zinc, coal, iron ore, steel, limestone, uranium and other platinum-group metals. Mining has long been a significant primary sector industry and contributor to the Zambian economy by providing export income, royalty payments and employment.

Resources Limited has announced that a ground geophysics (Induced Polarization, or ‘IP’) survey has commenced at the Odienné gold-copper Joint Venture project in Cote D’Ivoire. The Odienné Project is subject to an earn in joint venture agreement with Newmont Ventures Limited (“Newmont”).

The IP survey will cover the core of the 2.2 km long Sceptre East and the high grade Charger Iron Oxide Copper Gold (“IOCG”) targets, and will allow for the prioritization of these targets for a scout drill program expected to commence in December 2022. Results from the IP program are expected to be completed and reported in November 2022.

The current work program is being funded by Newmont as part of an earn-in JV agreement through which Newmont retains the option to earn-in to a minimum 65% interest, from Awalé, in the Odienné project in return for the sole funding of USD 15M in exploration. Awalé is the project manager for the initial 3-year phase.

Company CEO Glen Parsons commented: “We are pleased to announce the continued drive toward exploration success at Odienné with the commencement of this IP program. We are eager to complete this phase of geophysics for the JV to finalise an initial scout drill program at Sceptre and follow up drilling at Charger, both of which are scheduled for the end of Q4.

In recent months Awalé has achieved significant milestones and we are building our exploration pipeline with new targets such as the Lando target (see company news release dated 23rd August 2022) and progressing existing ones such as Sceptre and Charger

toward drilling. The compelling new 4km long Lando target has the same geochemical footprint to the Sceptre and Charger targets. Exploration intensity is increasing as the wet season closes and we look forward to keeping the market informed of our progress”

Background on Sceptre and Charger Based on the regional geological setting of Odienné, the soil/termitaria data from the Sceptre prospect and the initial drill results and newly found gossan from the adjacent Charger prospect, the Company interprets the geological setting of the Odienné district to be comparable to that of other significant IOCG provinces globally. IOCG deposits

are significant contributors to global copper and gold inventories, and the Company considers the Odienné project to contain significant potential for the discovery of the first major IOCG style known in West Africa.

Recent pitting and geological mapping have confirmed the high order geochemical anomalism at Sceptre and mapping at the Charger target has revealed new artisanal pits containing blind gossan outcrops just 100m from previously reported drill intercepts.

The IP program is expected to take three to four weeks to complete with processed data delivered for interpretation, company geologists will then integrate this data with geological and structural surface mapping, geochemistry with the view to plan a scout drilling program to test these targets and determine the nature of mineralization and alteration as well as orientation and 3D geometry of these targets.

The company has now completed soil and termitaria collection at the BBM prospect and interim pXRF results will be reported in the ensuing weeks. At the same time, ICP multielement results including gold and silver are expected to be returned and reported. The company is also receiving training on Newmont proprietary geochemistry data collection (Stream Bulk Leach Extractable gold or ‘BLEG’ and Deep Sensing Geochemistry or ‘DSG’) this month and this expertise will also be implemented on the project in Q4.

The world leader in industrial private LTE networks

Resources Limited has announced that a ground geophysics (Induced Polarization, or ‘IP’) survey has commenced at the Odienné gold-copper Joint Venture project in Cote D’Ivoire. The Odienné Project is subject to an earn in joint venture agreement with Newmont Ventures Limited (“Newmont”).

Aya Gold & Silver Inc. is pleased to report record mine and mill throughput and strong production in Q3-2022 at the Zgounder Silver Mine in the Kingdom of Morocco.

“Our mining operations are performing very well as a result of continued strong execution and measures taken by our team in previous quarters to improve efficiencies and deliver a strong quarter. In what is the driest quarter of the year, we particularly benefited from our optimised water management facilities and measures.

We have started mine development and are maintaining annual cost and production guidance ahead of announcing several expansion-related strategic milestones at Zgounder and an aggressive drill exploration

program, which will unlock value for all stakeholders.” said Benoit La Salle, President & CEO

During the third quarter, record mine and mill throughput of 825 tpd and 803 tpd, respectively, were achieved along with quarterly production of 451,681 oz Ag with a mill feed grade of 232 g/t Ag. A total of 75,907 tonnes (“t”) were mined at a head grade of 216 g/t Ag with underground mine development being a major focus in the quarter. Silver recovery was 84.5% at the flotation plant and 88.9% at the cyanidation plant for an average recovery of 86.2% in the quarter. Mill availabilities of 92.0% for the flotation plant and 95.6% for the cyanidation plant were achieved.

As mine operations are scaling up to reach 2,700 tpd by the end of 2024, management has determined that additional definition drilling is required to ensure predictable grade in stopes. Additional equipment and human resources have been added to meet this objective. Additional inventory on the Run of Mine (“ROM”) pad will help maintain a more consistent grade sent to the mill.

Infrastructure development continues to ramp up and reached 470m in September 2022, close to the 500m monthly objective for 2023-2024. New mine levels were put online and will contribute to ensure mine ramp-up in 2023, as per the mine plan. Underground mine production is expected to accelerate in 2023 to accumulate a stockpile of 200,000t for the new plant commissioning in 2024.

Aya Gold & Silver Inc. is a rapidly growing, Canada-based silver producer with operations in the Kingdom of Morocco. The only TSX-listed pure silver mining company, Aya operates the high-grade Zgounder Silver Mine and is exploring its properties along the prospective South-Atlas Fault, several of which have hosted past-producing mines and historical resources.

Aya’s Moroccan mining assets are complemented by its Tijirit Gold Project in Mauritania, which is being advanced to feasibility. Aya’s management team has been focused on maximising shareholder value by anchoring sustainability at the heart of its operations, governance, and financial growth plans.

required by Section 4.1 (a) within the period provided in such Section according to Sec 12.1 (a) of the Mineral Exploration Regulations, or there is no evidence of the 2% of the approved work budget for the affected licenses that apparently could neither be calculated nor verified for the periods according to Sec 9.3(b) of the Mineral Exploration Regulations; or the companies have not submitted the required Annual Environmental Audited Reports for the affected license(s) during the period under review according to Sec.10.2 of the Mineral Exploration Regulations.

Those companies and licenses affected include but not limited to:

1. No.COMPANYLICENSE #NOTICE

2. 1Mekinel Holdings LtdMEL 7001818TERMINATION

3. 2Pedras Age Mining CompanyMEL 7003319TERMINATION

4. 3EarthSat Engineering Construction Inc.MEL 7003519 MEL7004120TERMINATION

5. 4BSD Mining LtdMEL 7003419TERMINATION

The Government of Liberia through the Ministry of Mines and Energy continues carve out policies and implement existing regulatory frameworks to enhance the mineral sector of Liberia.

• To improve our regulatory oversight, the Ministry has embarked on the following:

• Begun the process of reviewing the existing 2000 Minerals and Mining Laws of Liberia;

• Banned the use of dredges and mercury during gold mining activities on our water bodies;

• Banned the use of heavy earth moving equipment within non-Class B mining license areas;

• Introduction of ASM identification cards;

• Established the Artisanal and Small-scale Mining Sector Working Group (ASMWG)

• Working collaboratively with the FDA and the World Bank through Redd++ on the implementation of Smart Mining techniques during ASM operations;

• Establishment of the Special Mineral Task Forces(SMTF);and

• Issuance of Default Notices and

Termination Notices to some Mineral Exploration license Holders that are not in compliance with the Mineral Exploration Regulations and the licenses they possessed.

The Ministry has issued Termination Notices and Default Notices to fifteen (15) Mineral Exploration license holders. These notices will affect twenty-seven (27) Mineral Exploration Licenses. The affected companies have either not made the requisite filings required by Section 4.1 (a), Sec 12.1 (a) or Sec. 17.1 (c) of the Mineral Exploration Regulations of Liberia. As such, some of these licenses automatically expires at the end of the Initial Term of the Extended Term without requirement of action or notification by the Minister. As the result of these notices, the companies have the right to request hearing to contest the Ministry’s justification for termination according to Sec. 17.2 of the Mineral Exploration Regulations of Liberia.

As for those licenses that were issued Notices of Default, either the companies have not made the requisite filings

6. 5Ya Ni Mining CompanyMEL 9000919TERMINATION

7. 6Equinox Minerals Liberia LtdMEL 7003619TERMINATION

8. 7West Mining Ltd.MEL 7003118TERMINATION

9. 8Tango Mining Inc.MEL 7003018TERMINATION

10. 9SRG LiberiaMEL 7004220TERMINATION

11. 10Yuhem Group Liberia LtdMEL 7004320TERMINATION

12. 11Saffron Gold Liberia LtdMEL 9001320 MEL9001220TERMINATION

13. 12HAMAK MINING COMPANYMEL 7001418 MEL 7002018 MEL 7001618 MEL 7002118TERMINATION

14. 13Afro Anglo American Resources Inc. MEL 7001118 MEL 7001018 MEL 7000918 DEFAULT

15. 14Rhino Gold Liberia LtdMEL 9001420 MEL 9001120 DEFAULT

16. 15MNG Gold Exploration Inc.MEL 2111/16 MEL2111/16 MEL2108/16 MEL 2109/16 MEL2113/16

www.fmdrc-Zambia.com

Gold Corporation is pleased to provide an update and status report for the initiatives the Company has taken at its Bibiani and Chirano Gold Mines in Ghana.

The first gold pour at the Bibiani Gold Mine (“Bibiani”) occurred on July 7, 2022, two months ahead of schedule. All process plant and mine facilities are operating on a 24 hour per day basis, with ~220,000 tonnes of ore treated in September. Asante plans to increase throughput to 250,000 tonnes ore per month by Q1 2023.

Gold production in September was just above 9,300 ounces, 17% above the Company’s start up plan. Mine plan and mine to mill reconciliation for the Walsh satellite pit and Main Pit were on target. The Walsh Pit continues to outperform, relative to our initial planned gold production. The area between the Walsh and Main pits were historically used for tailings storage.

This area has now been partially explored and Measured and Indicated Mineral Resources have increased from 20,000 to more than 100,000 ounces (1.37 MT with Au grade of 2.62 g/t). The drilling program to explore this trend and to support the planned underground mining strategy has been initiated.

The Company’s plan to extend the Bibiani LOM (life of mine) from 8.3 years to +10 years is on track with successful development exploration at Russel South (see press releases of March 29th and August 17th) and drilling programs have commenced at the Grasshopper and Elizabeth deposits. The Company will continue its near mine development exploration program with planned drilling of approximately 30,000 metres per year for 2022, 2023 and 2024.

The Company filed an updated National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43101”) technical report on the Bibiani Gold Mine on September 1, 2022 that incorporates exploration and mine planning results to February 28, 2022 and increased the Measured and Indicated Mineral Resources by 26.4% to 2.29M ounces (31.57 MT with Au grade of 2.24 g/t) and are further classified as 1.95M ounces of Proven and Probable Mineral

Reserves (28.4 MT with Au grade of 2.14 g/t). An updated NI 43-101 technical report to incorporate results of the 2022 exploration program is planned for Q3 2023. We anticipate this report will define additional ounces to the current resource and LOM.

The Chirano Gold Mine (“Chirano”) acquisition was completed on August 10, 2022. This acquisition added Measured and Indicated Mineral Resources of 28.1Mt at 1.26 g/t Au (1.13 Moz) and Inferred Mineral Resources of 6.05Mt at 1.91 g/t (0.37 Moz) to Asante’s gold resource.

An updated NI 43-101 technical report for Chirano was filed by the Company on October 11, 2022. The technical report is based upon information and planning developed by Kinross Gold Corporation, the former owner of Chirano. Asante continues to identify and develop opportunities to add value to this asset. An update to this technical report is planned for Q3 2023 and will incorporate results of the 2022 exploration program and Business Improvement Plan, referenced below.

The Company has initiated a Chirano Transition and Business Improvement Plan to increase Chirano current gold production by 30% and to reduce AISC (all-in sustaining costs) by 10% by 2024 through the following initiatives: Gravity plant design and procurement are well advanced with installation planned for completion at Q2 2023;

Oxygen addition to the CIL (carbon-inleach) process is proceeding and an oxygen plant is planned for installation in Q2 2023; to date, we have increased gold recovery by +3% to 89%. A pebble crusher has been ordered and primary grinding upgrades are planned to be installed in Q2 2023 to increase process plant throughput from 3.2 to 4.0M t/y; Relocation of minor infrastructure and facilities is underway, to provide access to expansion of the Akoti South open pit and to start the second cut at the Sariehu open pit. These initiatives will access lower cost resources;

Studies and associated initiatives are underway to improve the material handling systems to deliver ore to the

Process Plant at lower cost; Initiatives to capture synergies between the Bibiani and Chirano mines have started to yield benefits related to supply of principle consumable materials;

Development of the wide Obra orebody, the lower Tano underground mines and the Mamnao open pit mine have been accelerated, to provide lower cost resources for treatment; and Asante plans to invest minimum of $5M/y in near mine and regional exploration over the next three years with the target to increase Chirano LOM from current 5 to +10 years; exploration of the Aboduabo and Chine targets has been initiated.

The Company has commenced initiatives to capture synergies between its’ Bibiani and Chirano mines, that are situated with their process plants approximately 15 km apart. These initiatives include development of an access road to directly link the process plants and provide access for exploration along the highly mineralized BibianiChirano shear zone. This road will be upgraded to become a mine haul road, so that ore can be treated where most appropriate, based upon availability and mineralogy. Asante continues to develop opportunities to share infrastructure and to realize operational cost reductions.

Operationsrelated to the extraction of mineral ore such as blasting, transportation, grinding, and crushing can release large amounts of dust into the atmosphere. This is particularly true in a crusher plant where the demolition of stones, an operation that generates vast amounts of dust, is a daily procedure.

Metso Outotec is introducing yet another innovative plant concept, Flotation Plant Units, to its unique minerals processing portfolio. The solution provides unparalleled metallurgical performance by seamlessly integrating functional design with a comprehensive scope, leading to high operational reliability and a fast return on investment. Compared to the traditional delivery, Flotation Plant Units result in the earliest time-tovolume.

“In flotation, changing ore types can cause recovery losses, and poorly integrated plant equipment leads to underperformance. Maximizing overall performance and reliability requires indepth understanding of the complex flotation circuit sizing. All these concerns have been taken into consideration in the design of the Metso Outotec modularized Flotation Plant Units to provide unmatched results.

The plant units feature industry-leading technologies, which also include several Planet Positive solutions. The units consist of state-of-the-art flotation equipment, conditioners, froth handling systems, as well as automation and sophisticated services,” explains Tatu Miettinen, Product Manager, Flotation Islands at Metso Outotec.

Metso Outotec Flotation Plant Units offer unique benefits

• Integrates flotation circuit testing, piloting, and modeling capabilities from in-house test centers and modeling software into unrivalled flotation circuit design capabilities

• One-stop-shop from testing to full plant delivery

• Froth handling is designed for a high operational window, allowing for flexibility in circuit operation

• High emphasis on accessibility

• Maximized maintainability and froth visibility thanks to optimal pipe and cable routing, which keeps the top of the cells clear

• Safe, easy and representative process sampling

• Option to vary flotation circuit configuration online

More information on the Flotation Plant Units is available on our website.

Metso Outotec has one of the widest portfolios of flotation solutions on the

market. The company’s extensive experience in process plant design combined with its installed base of over 15,000 flotation equipment installations around the world enables Metso Outotec to design and deliver complete optimized flotation circuits catering to all types of applications and ores. The company’s comprehensive service portfolio extends from spares and wears to advanced life cycle services and is backed by a global network of industry-leading service expertise. The wide variety of upgrades enables the restoration of outdated existing technology for optimized flotation performance and the achievement of sustainability targets.

The Flotation Plant Units are Metso Outotec’s fourth complete plant unit launch for concentrator plants. The previous launches include Stirred Mill Plant Units and Horizontal Mill Plant Units and Filtration Plant Units.

Outotec has signed a 3-year Life Cycle Services contract with one of the biggest platinum producers in the world. With LCS, the customer’s critical assets will achieve enhanced availability and higher production. The performancebased agreement provides among all a Reliability Centered Maintenance application that focuses on preventive maintenance, which will improve machine life.

The value of the order is approximately EUR 16 million and it covers 12 filters across 5 customer sites. The first part of the contract has been booked in Minerals’ third-quarter orders received.

“We are very pleased to have been chosen as the key supplier of filter services for our customer’s sites.

Our service approach will improve the safety, overall filter reliability, and performance in line with customer’s throughput targets,” says Vivian

Pillay, Director, Global Key Account Management in Metso Outotec.

Extensive Life Cycle Services offering and comprehensive filtration portfolio Metso Outotec’s Life Cycle Services offering covers the entire after-market portfolio, including process support and optimization, sustainable wears, spares, and service solutions. Core service elements in the LCS packages for filters are spare parts, repairs, maintenance, reliability, connected equipment, and process optimization. Discover more about Life Cycle Services for Filters on our web pages.

Metso Outotec has the most comprehensive filtration portfolio on the market with 15 different filter types available for hundreds of applications. Metso Outotec has performed over 14,000 filtration tests and has delivered over 5,000 filters around the world.

www.fmdrc-Zambia.com

Lifting applications place special demands on the installation space for drives. With MAXXDRIVE® XD, NORD DRIVESYSTEMS has now developed an industrial gear unit with increased centre distance that is ideally suited to the U-shaped configuration of drive, motor and cable drum.

With the new MAXXDRIVE® XD industrial gear units the drive specialist from Northern Germany is closing a gap in its portfolio. “We can now offer our customers the complete package of running gear and lifting gear drives for cranes from a single source”, said Jörg Niermann, Head of Marketing at NORD.

As for all NORD gear units, the proven principle of robust one-piece UNICASE housing will be applied. During development, the MAXXDRIVE® XD’s housing was specially designed for lifting applications and optimised for downward loads. The elongated arrangement of gear stages also enables a mechanical tailor-made dimensioning of the gear unit with sufficient centre distance – thereby avoiding an otherwise all too common overdimensioning.

Standardisation and reduction of variants NORD currently offers the new

MAXXDRIVE® XD in five sizes with centre distances between 509 and 963 millimetres.

Also, in versions with three or four gear stages. Housing dimensions and centre distance are identical for the threeand four-axle versions. This enables customers to standardise and reduce versions when construction their cranes. Thanks to the three and four stage version, MAXXDRIVE® XD covers very wide speed range with a maximum nominal gear ratio of i=355. The constant torque across the whole speed ratio guarantees a high efficiency while in use. “We are delighted that we are now able to also offer complete drive solutions in an economic and tailor-made manner with our proven NORD quality standards”, said Niermann.

For the MAXXDRIVE® XD’s components, NORD is using tried and tested standard

parts from our proven range of industrial gear units. This offers customers a wide choice of options and guarantees short delivery time. Additionally, housing is also available with an inspection cover, enabling a visual check of internal components without having to remove the gear unit. It is available in grey cast iron (GJL) or nodular cast iron (GJS).

MAXXDRIVE® XD is suitable for use in lifting equipment in all kinds of cranes: From port and container 1/2 cranes to overhead and gantry cranes but also for container and high bay coil storage. This makes it relevant for a wide range of industries, not just for ports, logistics and shipyards but also for metal, chemical and paper industry as well as mining and bulk goods transshipment.

Our new long-hole production drill rig for medium to large-sized drifts, Simba E70 S, offers more than cutting-edge automation features and excellent drilling quality. It also provides Epiroc’s optimization method; a step-by-step program that continuously improves how the machine is utilized in the mining process.

What makes Simba E70 S the next obvious step in production drilling is not its automated features alone. It is also the ability to track and evaluate its performance, then optimize accordingly.

This is made possible by production reporting; the first step in Epiroc’s optimization program. “Our new Simba E70 S delivers greater value to our customers’ operations through improved productivity, with zero compromise on quality”, says Sarah Hoffman, Vice President Sales and Marketing at Underground division.

The Simba E70 S is part of Epiroc’s Smart series and can also be delivered with the optional battery-electric driveline for reduced environmental impact and healthier underground conditions.

The real value is created while the machine is producing meters. That is why the ability to track effectiveness and utilization – if Simba E70 S drills and produces meters when active – is one of its main advantages.

“The connected Simba E70 S provides us with performance and quality data, so we can take the first step towards providing tailored process management to our customers”, says Mikael Larslin, Global Product Manager Production Drilling at Underground division.

“After tracking effectiveness and utilization, we compare the result to global benchmarks. In that way, we can easily analyze if the machine is being used in the most optimal way or if there is room for improvements”, says Olav Kvist,

Global Portfolio Manager Production Drilling at Underground division.

“Increased utilization is the main goal. By guiding customers through a structured step-by-step optimization program, we can increase their efficiency and profits over time. Change management based on data and reports is the real customer value”, Olav Kvist says.

While the optimization journey progresses, the operator’s role changes as well. “As the process becomes more automated, the operator goes from running the Simba E70 S to supporting it when running in automated mode, upskilling and making them more of a process operator”, says Mikael Larslin.

“All in all, it is the obvious next step in production drilling”, says Olav Kvist.

www.fmdrc-Zambia.com

Eurasian Resources Group (“ERG” or “The Group”), a leading diversified natural resources group headquartered in Luxembourg, announces that the Responsible Minerals Initiative (“RMI”) has confirmed that the cobalt and copper produced by ERG’s Metalkol RTR is compliant with the RMI’s Responsible Sourcing requirements. This follows an independent assessment as part of RMI’s flagship programme, the Responsible Mineral Assurance Process (“RMAP”).

In August 2022, the RMI confirmed that Metalkol RTR was conformant with the Assessment Standard for Cobalt Due Diligence Standard (2018) and Joint Due Diligence Standard for Copper, Lead, Nickel and Zinc (2021). The comprehensive assessment consisted of a number of elements including the collection and review of objective evidence such as interviews with employees and the senior management, documentation, a facility walk-through, and other observations. All of this demonstrated that Metalkol RTR’s due diligence management system conforms in all aspects to the requirements of the RMI’s standards.

Benedikt Sobotka, CEO of ERG, said, “Metalkol RTR and ERG as a whole not only support the transition to a greener economy through our supply of key metals, such as copper and cobalt, but also set an example to the industry through our commitment to responsible

sourcing. Confirmation of this by the RMI is just another reason that the companies buying our cobalt and copper, and consumers who purchase products that contain them, can be confident that they have been produced in line with global responsible sourcing standards. I would like to congratulate the Metalkol RTR team for this latest achievement, and thank them for their hard work in the lead up to it.”

Gillian Davidson, Sustainability Advisor to ERG’s CEO, said, “Metalkol RTR has established itself as a worldleading supplier of responsibly sourced cobalt and copper, thanks to the rigorous management systems and procedures the Group has in place to ensure it operates in accordance with international standards and conducts its business in a responsible manner. The announcement that the cobalt and copper produced at Metalkol RTR are compliant with the RMI’s Responsible

Sourcing requirements is testament to this, and Metalkol RTR is well-placed to continue supplying responsibly produced materials to meet the demands of the clean energy transition.”

The RMI is one of the most utilised and respected sources for companies from a range of industries addressing responsible sourcing issues in their supply chains. The aim of the RMAP is to help companies make informed choices about responsibly sourced minerals in their supply chain, and show that their standards have been developed to meet the requirements of the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, the Regulation (EU) 2017/821 of the European Parliament and the US Dodd-Frank Wall Street Reform and Consumer Protection Act.

BLT WORLD’s new ScrapeTec SureSupport system protects and prevents falling material from damaging the conveyor belt and significantly improves the overall belt load.

BLTWORLD – specialists in bulk materials handling – has launched ScrapeTec’s new SureSupport conveyor system, that has been developed to improve material takeup and maximise the efficiency of skirting and sealing. This is achieved by correcting belt tracking, providing an effective seal at the transfer points, preventing material spillage and enhancing dust control.

“The newly designed SureSupport system delivers support and stability to the belt at transfer points, which increases the effectiveness of side sealing, enhances dust suppression and minimises material spillage,” explains Ken Mouritzen, Managing Director, BLT WORLD. “In conventional conveyors, the force of falling bulk materials causes a high belt load in the transfer area, resulting in belt degradation and increased material, energy and

maintenance costs. To compensate for the belt load and to maintain efficient sealing within the transfer area, the idler density can be increased in the feed area. Although this measure may improve efficiency, it does not fully eliminate belt damage.”

The SureSupport system efficiently reinforces the belt and prevents belt sag at the infeed, which is normally caused by the impact energy of falling materials being conveyed. Specially-designed sliding rails prevent belt damage and tightness of the transfer is increased with the use of a combination skirting and sealing system that ensures even belt tracking.

SureSupport operates in conjunction with ScrapeTec’s AirScrape side seal, providing a high performance, dust free and contactless skirting solution, with reduced material spillage. A smooth

straight and flat belt surface keeps the AirScrape lamellas continuously in the correct position, with no physical belt contact. Other advantages of this system include quick and simple installation, as well as reduced maintenance time and costs.

Scrapetec’s advanced conveyor belt systems - which meet stringent quality, safety and environmental standardsare available directly from BLT WORLD, which provides an assessment and solutions service to customers in diverse sectors, for planning and implementing projects. A technical advisory and support service enhances performance of every system.

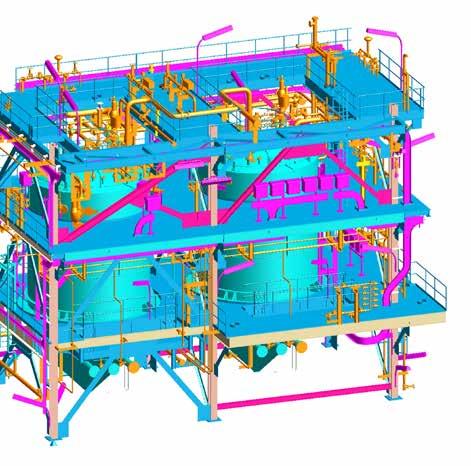

Modularisation has taken centre stage as a highly efficient, productive, cost effective and safe solution for constructing green and brown field plants worldwide. This strategy allows for the off-site construction of modules in open, nonhazardous environments, which are then transported as complete structures via ship and road to the final plant site.

With extensive global engineering capabilities, professional know-how and experience in the construction of modules, thyssenkrupp Uhde has delivered many successful modularisation solutions for a wide range of industries, from petrochemical to mining, around the world. The South African office was responsible for all engineering and design work as well as project management of modules that were required as part of the expansion/ upgrade of two local refineries and a fertilizer plant.

“Modularisation is suitable for virtually any industry and application. We are seeing more and more customers making real estate available to thyssenkrupp Uhde for off-site modular build,” notes Mira Krid, Manager Civil & Structural at thyssenkrupp Uhde.

However, in order to get the full cost benefits, Mira advises that it is critical that the customer’s decision to go modular is made at an early stage of the project, ideally at the front end during conceptual design. Proper front end investment, conducting of the essential cost and benefits analyses and scoping the most effective and affordable strategies will ensure far less escalation at the back end.

“When one of our customers made a late decision to change from ‘stick built’ to modular, we were required to do great deal of engineering and design rework with subsequent cost implications.”

Mira explains that structural engineering for modular construction requires more effort at the design stage compared to the design of a ‘stick built’ structure. “For example, lifting and transport methods have to be decided upfront so that factors such as dimensional restrictions, with input from transportation and rigging contractors, are taken into account during 3D modelling. So the fact that we could still show a cost benefit to the customer after adapting the ‘stick built’ to an off-site modular build illustrates thyssenkrupp’s competency as well as the tremendous value of modularisation.”

On-site construction can be hampered by physical and environmental restrictions resulting in costly delays, reduced productivity and increased risk to personnel safety. Space limitations can impede contractor access forcing on-site building to be done in phases; the structural team has to wait for civils before building structures to the point where they can supply a certificate of

www.fmdrc-Zambia.com

compliance to enable mechanical to start loading equipment. Environmental factors to consider can include anything from harmful emissions to extreme temperatures.

By contrast, the building of modules offsite in an open, easy-to-access area and in a non-hazardous environment facilitates efficient, productive and safe work. “We can, for example, build scaffolding around the module without restricting people working on the inside,” says Ranka Sofijanic, Manager Plant Layout and Piping at thyssenkrupp Uhde.

“Civil, structural and mechanical teams can work in tandem, installing all disciplines in the module, leaving only a few functions such as interconnectivity work once the module has been lifted into its final on-site position. We have an interface file for each module showing us exactly where to build every grid and pipe point, cable end and rack, etc. that has to link to neighbouring modules or structures on the plant.” Leaving only minimal on site work, especially in a hazardous environment, is a massive advantage of off-site construction.

Plant sites where there are deadly emissions or high noise levels, place personnel at extremely high risk. The essential wearing of Personal Protection Equipment restricts movement and slows down productivity. Flammable environments also pose a danger as welding sparks may ignite fuel/gas systems.

A good example of how modularisation can offer an ideal solution where temperature extremes make on-site construction virtually impossible is the successful off-site modular construction of a diamond mine in a sub-zero region in Canada. In addition to putting personnel in great danger, the icy conditions would have severely restricted outside work with subsequent costly delays.

The answer was to construct the entire mining plant in modules off-site, in fact, in another country altogether. Once completed, the modules, some weighing up to 580t, were shipped to their final destination. As the off-site construction was completed in Saudi Arabia where temperatures exceed 50°C, a great deal of engineering was required to ensure optimum functionality at the final subzero site. Despite this, the efficiencies

of modularisation still outweighed the transport logistics as well as the costs that on-site construction would have posed.

thyssenkrupp Uhde is perfectly positioned to provide customers with best-in-class modularisation solutions, drawing from its holistic in-house capabilities that include state-of-theart, customised software programmes, laser scanning, 3D design, integrated engineering and checking tools and Quality Control. Ranka unpacks some of these competencies:

“Our Integrated Piping Programme (IRP/ERM) system is designed for processing and controlling piping information from P&IDs to construction/ commissioning and provides maximum quality assurance. We also use E3D which is a customised multi-user and multi-discipline 3D intelligent modelling design software package. Multidisciplinary design is executed in-house in accordance with Standard Working

Steps and Modularisation Design Method produced for a specific project.” The modules go through the full rigorous inspection and are Quality Controlled on the piece of real estate on which they are built.

These capabilities enable thyssenkrupp Uhde to construct modules, varying in size and complexity, from equipment skids and pipe rack modules to complete process buildings, on a significant scale to meet customers’ individual requirements. thyssenkrupp’s expertise also extends to skid-mounted modular solutions, the Tanzanian chlorine plant being a good example. The company is able to design fit-for-purpose modules that can be containerised in 20 or 40ft containers. “We fully customise the modules so no two structures are alike; we build what the customer wants,” conclude Ranka and Mira.

thyssenkrupp Uhde has delivered many successful modularisation solutions for a wide range of industries around the globe

In the journey towards decarbonisation, the South African mining sector is taking its first steps toward renewable self-generation; what will need to follow is a more systematic and integrated approach that addresses the whole mining supply chain.

This was one of the messages from Professor Michael Solomon, in a webinar for the Southern African Institute of Mining and Metallurgy (SAIMM) on ‘Decarbonizing the Mining Sector by 2040’. Professor Solomon is the chair of the SAIMM’s Environmental, Social, Governance and Sustainability (ESGS) committee, and an adjunct professor at the University of Cape Town.

“Decarbonization is often simplistically interpreted as being about renewable energy and the use of fossil fuels,” he said, “but it is far more complex than that.”

He noted that many of the mines’ renewable energy projects were driven by sheer economics, given the rising cost of grid electricity. Ashleigh Maritz, principal environmental scientist at SRK Consulting, was in the webinar and concurred that mines need to look holistically at their operations and value chains.

“There are many opportunities within the mining value chain, including partnering with suppliers, to build a more farreaching decarbonisation strategy,” said Maritz. “The hydrogen economy is also likely to play an important role.”

In the manufacturing of each ton of hydrogen, some eight tons of oxygen were produced – which could be used for other purposes. The topic of synthetic diesel was also raised; while it is currently more costly to produce synthetic diesel

than sourcing fossil fuel diesel, the impact of carbon tax may change this equation. “Professor Solomon also highlighted that decarbonisation strategies must contribute to a just energy transition, by empowering and equipping vulnerable communities for the future,” she said.

Also in the webinar was Marcin Wertz, partner and principal mining engineer at SRK Consulting, who picked up on the need for a broader approach than just onmine initiatives.

“When considering opportunities to pursue a decarbonisation agenda, it is also worth looking beyond the mine’s boundaries to the communities,” said Wertz. He highlighted the different modalities for decarbonisation mentioned in the webinar. In addition to the key step of mines going off the grid, other avenues included electric mobility and hydrogenpowered heavy mining equipment.

“There are also opportunities in the circular economy, green explosives and waste-to-energy,” he said.

Exciting developments are afoot from mines who are planning to generate their own renewable energy, according to Professor Solomon. He said 29 mining companies were undertaking 89 energy projects which promised to generate 6.5

GW of solar, wind and biomass energy, as well as battery storage.

SRK partner and principal consultant Andrew van Zyl argued that there were considerable spin-off benefits from the introduction of renewable energy technology in mining areas – many of which were rural and remote.

“All along the route that this equipment

takes to a mine, there is now a channel being created for other stakeholders such as communities to embrace this technology,” said Van Zyl, who is also a member of the SAIMM ESGS committee.

“It should be remembered that South Africa faces the pressure not only to decarbonise, but to generate steadily more energy than is currently available.”

recognises the need to make the workplace more inviting for women, not just by moving away from a “male-only” culture, but by using innovation to create new opportunities in rewarding, highly paid and long-term careers.

However, Ms. Savio says the trend within the industry is positive, and applauds the fact that IMARC 2022 is taking a strong focus on the development of female leadership in the sector, and will feature record numbers of female delegates, speakers, and panellists.

Closingthe gender gap in mining is not only a matter of equity, it also makes business sense, according to five Australian experts who will be addressing the International Mining and Resources Conference (IMARC) in Sydney in November.

As a whole, the mining industry is trying to address the under-representation of women in mining. Statistics highlighted by WIMnet (Women in Mining) NSW shows that women only make up less than 20% of the mining workforce. Unfortunately, at an executive level it gets worse with only 6.7% of mining CEOs being female, compared to the national average of 19.4%.

IMARC will shine a light on the incredible contribution women bring to the mining industry, hosting a Gala Dinner with a full female panel at the three-day event that will feature 111 female speakers.

Reflecting on the gender transformation sweeping the industry, Chair of WIMnet NSW Lucy McClean believes opening the door to more women represents an enormous opportunity for the industry to capitialise on the proven benefits of a diverse and inclusive workforce.

“The statistics are very clear, and they tell us that workplace diversity creates more inclusive supporting work environments, enhances teamwork, makes us more effective in-service delivery as well as increasing productivity,” she says.

MinterEllison Partner and Head of

Perth’s Workplace Law team Kathy Reid says: “We need to increase the presence of women in mining, but the industry is facing significant challenges and there’s not one easy answer. Improving mining for women will require significant and consistent cultural shifts across the industry but getting there will be difficult.”

Ms. Reid refers to this issue as the chicken and the egg conundrum. “You can’t really make women feel more comfortable in the mining industry until you’ve got greater numbers, but you can’t get greater numbers unless you make them feel more comfortable.”

METS Ignited General Manager Kylah Morrison agrees some great strides have been made to make mining more appealing to women, highlighting the power of leveraging tech and innovation.

“Equipment manufacturers are leading the way by breaking down barriers to entry, from simple things like hi-vis gear that is made for women, to major capital investments in heavy equipment.

“Rather than the traditional burly bloke on the frontline, maybe it’s a remotely managed machine, which adds even more to the potential inclusiveness of mining.“

“Inclusivity is important and that’s where innovation and technology is really exciting because it does make it more of an even playing field.”

AusIMM Independent Consultant Giulia Savio says it is clear the mining industry

“We’re not there yet. To have true diversity and to realise the value of that diversity, you need inclusivity. In order to improve the industry, leaders need to look at making the sector more friendly and inviting for all. This might mean greater diversity in teams, equipment that can be used by someone with a disability, or more opportunities for flexibility in office based or site-based roles,” say Ms. Savio

Agnico Eagle Vice President of Corporate Affairs in Australia John Landmark echoes this sentiment, outlining the need to tap into a far broader spectrum of talent to shift the idea of the industry being male dominated to being an industry that is in touch with society’s expectations. “We’ve got to change this, and we’ve got to get this right. We must make the workplace more attractive for women and society as a whole.”

“I am so excited that these challenges are such a major focus at IMARC and gives us an opportunity to improve the industry for everyone. The ideal workplace is where everyone can be themselves and contribute to the team environment – people of all diverse backgrounds and makeups. “

“Frankly, if you make the industry more attractive to women, you improve the industry for all.”

IMARC is the most significant in-person gathering of Australian and international mining and resources representatives in almost three years and is a key forum to addressing the most challenging issues facing the industry. The conference will be held 2-4 November at the Sydney International Convention Centre and will feature over 450 speakers across six concurrent conferences covering the energy transition, rising costs, skills shortages, diversity within the resources sector and more.

www.fmdrc-Zambia.com

Atwo-year graduate programme has been launched by Omnia-group company BME to address youth unemployment and skills shortages in an evolving mining industry.

The programme targets various disciplines in engineering and science – including mining, chemistry, and microbiology, as well as skills in the fields of safety, health, environment and quality assurance. This is part of the commitment by BME’s leadership to support skills development and the growth of young people within the mining industry. The initiative is also instrumental in attracting and retaining talent for the company.

Announcing the initiative, BME managing director Ralf Hennecke said that many businesses in industry require work experience, and graduates are often overlooked as they do not have the necessary skills or the understanding of the work environment to fill the role.

“Coupled to this, some graduates consider the work environment to be daunting,” said Hennecke. “We therefore believe our role will be to ensure that each graduate on our programme is provided with the opportunity to grow and develop and reach their full potential. It is vital that we invest in skills development of the next generation of people who will drive the mining industry in the future.”

BME has recruited 19 graduates and placed them at various underground and surface mining sites where the company is currently active. Some graduates have also been placed at BME’s Losberg emulsion plant and its AXXIS™ initiation system plant.

“In a country like South Africa, it is crucial to train graduates without prior work experience, and this is what BME aims to do,” said BME human resources manager Tebogo Seakamela. “Skills development, and bringing new entrants into the sector, is critical in growing our economy and the mining sector, which is still one of the largest contributors to the country’s gross domestic product.”

She noted that BME prioritises the nurturing and development of young talent, highlighting that these graduates gain immeasurable knowledge and understanding of the real world of work while on our programme, ultimately preparing them for the workplace. “Due to their resilience, agility and bold characters, our graduates have remained committed to the programme,” she said.

As a trend in the market, most locally trained graduates are also recruited into other countries after having completed a graduate programme – including those around Africa. “This is commendable and a testament to the calibre of our South African mining graduates,” she said.

She highlighted that while the graduates were from various universities across the country, the majority were from Wits Mining Institute at the University of the Witwatersrand in Johannesburg.

BME remains optimistic about the South African mining industry, and the prospects for the rest of the continent.

“Locally, the Northern Cape is booming, while the rest of Africa, and other key BME markets – such as Indonesia, Latin America, Australia and the US and Canada, continue to grow,” said Seakamela. “These African and international markets are vastly different to South Africa and, in some instances,

considered challenging. We believe this programme works together with BME’s continuing expansion strategy of taking our African expertise to the rest of the world and will offer these graduates the opportunity to benefit from exposure to these markets and the global mining industry.”

The industry is also evolving in terms of minerals extraction, she said, noting that with the introduction of automated and artificial intelligence-based mining, the graduates will get first-hand experience of these technologies being used in the workplace.

We are building the skills for the future, as well as ensuring that we cultivate a learning culture that encourages and enables critical thinking and innovation,” she noted. “At the same time, these graduates are offered diverse career path options.

Mampe Mogale, a mining engineering graduate currently based at a mining operation in the Northern Cape, noted that BME held a two-day induction for all its interns across various disciplines at the beginning of October.

“The aim was to familiarise us with the company structure, various disciplines, and the people responsible for certain roles within the organisation,” said Mogale. Clement Marilela, a mechanical engineering graduate, explained that BME made his transition into BME as smooth as possible, informing the graduates about the organisation, while helping them realise the “incredible opportunity” they have been offered.

“It was great to be given the chance to interact with and learn from some of the organisations’ leaders as they shared their expertise and passion for the business,” said Marilela. “BME is proud to play its part in cultivating the future workforce, preparing them for the field of work,” concluded Hennecke. “South African graduates are talented and, with on-site experience, can be gainfully employed.”

Arecent global safety report for mining indicates a gradual but steady improvement in mine safety, with a total recordable injury (TRI) frequency rate at a low 2,90 – down from 5,07 just a decade ago.

The Safety Performance Report by the International Council on Mining and Metals (ICMM) benchmarked the progress of its members during 2021. The ICMM noted that the industry has focused on “operational, cultural and leadership transformation” in reducing fatalities in recent years.

Blasting solutions specialist BME has concurred that a growing safety culture is a major factor behind positive safety trends in mining, as well as uncompromising compliance with strict safety protocols. According to Ramesh Dhoorgapersadh, General Manager for Safety, Health, Environment, Risk and Quality (SHERQ) at the JSE-listed Omnia Group company, safety must be ingrained into every activity, in line with recognised standards and procedures.

“The blasting philosophy of BME is expressed through our innovative

products and leading initiation technologies,” said Dhoorgapersadh. “This also means aligning our policies with customer’s own safety protocols and broader regulatory requirements.” This includes careful adherence to the regulated distances between communities and blasting sites. He highlighted that internationally accepted standards are stringently applied to ensure the safety of communities adjacent to mining areas. These protocols address any possible hazards from blasting such as ground vibration, airborne dust or flyrock.

Tinus Brits, BME’s Global Product Manager – AXXIS™, explained that electronic detonation systems play an important role in achieving safe blasting.

They allow detonators to be accurately initiated within milliseconds of each other, staggering the energy release rather than having five or six holes detonating at the same time. Reducing the charge mass per delay thereby reduces the resulting vibration.

“We design our electronic detonators in such a way that key blast impacts are both measurable and predictable,” said Brits. “With our integrated blast planning software, mines can simulate each blast before it is implemented – so that they can predict aspects like ground vibration to ensure it will be within the required parameters.”

He emphasised that mines apply worldclass standards in this regard, such as the

United States Bureau of Mining (USBM) blast-induced ground vibration criteria. These include the requirement that any blasting in the vicinity of communities, structures houses, roads or other receptors requires a minimum safety radius. Where BME conducts blasts on behalf of customers, therefore, it applies a blasting radius of one kilometre away from any persons or communities, and 500 metres from any material that might be negatively affected.

“For every blast, seismographs are then used to measure the resulting ground vibration and air blast,” he said. “This confirms that the blast did indeed achieve the simulated design parameters, to fall within the regulated limits.”

These vibration reports can confirm that a mine’s blast was fully compliant with relevant standards or regulations, should there be a need for a mine inspector to investigate any blast-related incident.

While a range of safety protocols may be in place to comply with regulations, Dhoorgapersadh noted that human behaviour was still the cause of incidents that could be avoided. This required that mines and their suppliers continue to foster a culture of safety that brings behaviour into line with systems.

“BME’s Safety for Life brand, for instance, priorities the safety of employees, communities and the environment,” he said. “By ingraining a safety culture, we can apply and embed our safety learnings wherever we operate.”

As a result, BME can boast a recorded case rate (RCR) of just 0,15% - a worldclass rating that places it among South Africa’s best safety performers, and a leader in its industry segment. BME has also been recognised at the Chemical and Allied Industries Association (CAIA) Awards for its safety, health and environment (SHE) performance.

Silica in suspension is a chemical component generated in various processes such as mining, metallurgy, and construction.

Silica in suspension can travel long distances and impact the health of surrounding communities with chronic and degenerative pulmonary and cardiovascular diseases.

Workers and communities exposed to silica on a daily basis should be protected through preventive monitoring and control actions to prevent serious diseases.

Next, we will discuss what silica is, the types of silica, the silicosis eradication plan and innovative technologies for realtime silica monitoring and control.

Silica, represented by the chemical formula SiO2 (silicon dioxide), is the second most abundant mineral in the earth’s crust, as it is found in the form of sand, rocks and minerals. This mineral can be found in crystalline forms such as quartz, tridymite, cristobalite and tripoli, or in amorphous forms such as silica gel or colloidal silica.

Crystalline silica is an aggregate of small crystals, due to the well-defined structural arrangement between the oxygen and silicon atoms. It is most common forms are quartz, cristobalite and tridymite, and quartz is responsible for more than 99% of occupational exposures.