Editor

Bertha M. bertham@fmdrc-zambia

Sub-Editor Anthony Kiganda

Contributing Writer

Oscar Nkala, Mfuneko Jack Lindani Mkhize Caroline Thomas Anthony Kiganda Anita Anyango Jeff Kapembwa

Africa, south of Sahara, is a region endowed with plenty of valuable mineral resources such as metals, oil and diamonds. This region is also the site of several open conflicts that threaten mining activities in the region.

Sales and Marketing

Mining equipment: suppressing the fire risks

As mine workers continue to work long hours across consecutive shifts, heavy duty mining vehicles and machinery – for overground and underground operations – is often required to work 24/7 to meet tight schedules. Operating in the high-risk mining environment, with dust, extended use and prolonged vibration all raising risk of equipment overheating, heavy duty mining vehicles are susceptible to increased fire risk.

COVER STORY: PG 28 www.fmdrc-zambia.com

Victor Ndlovu victorn@fmdrc-zambia.com +27 11 044 8986

M. Pikes +260 76 173 0213 mutalek@fmdrc-zambia.com Plot 866A Old Airport Road, Mukubu Natwange, Kitwe, Zambia.

Advertising Consultants

Meshack Ndzendevu Polite Mkhize Gladmore Ndhlovu Leslie Nyembe

Production Coordinator Kholwani Dube kholwani@fmdrc-zambia.com

Art Director/Layout

Augustine Ombwa Arobia Creative Consultancy austin@arobia.co.ke

Published By Mailing Times Media

Circulation/Sales info@fmdrc-zambia.com sales@fmdrc-zambia.com +27 11 044 8986

Mailing Times Media (Pty)

No wonder geopolitics were ranked second in EY’s -Top 10 business risks and opportunities for mining and metals in 2023. Indeed, without political stability the future of the industry is gloom. According to the BBC’s calculations, coups have been occurring at an average rate of two per year on the continent between 2000 and 2019. Recently, Mali’s president Ibrahim Boubacar Keïta was overthrown, followed a few months later by the dismissal of the transitional government.

A coup d’état took place in Burkina Faso on 30 September 2022, removing Interim President PaulHenri Sandaogo Damiba over his alleged inability to deal with the country’s Islamist insurgency.

The danger of such conflicts especially in countries relying heavily on minerals is enormous. It is difficult to carry out mineral exploration and processing in conflict areas.

And reduced exploration has a direct impact on the whole value chain of the mining industry. The net effects are diminishing earnings not only for the miners but also the countries involved. Africa cannot afford such misfortunes at this time especially when they can be avoided.

www.fmdrc-zambia.com

discoveries from the surface at Mankouke South and Central Mankouke. Roscan continues to strategically expand its drilling program and test the current key targets in West Mali, the most productive greenstone gold belts on the continent.

Aroyalty financing deal has been signed between Roscan Gold and Osisko Gold for the Roscan’s Kandiolé project in Mali.

The two inked a deal to raise C$10m ($7.42m) in gross proceeds. It will also see Osisko retain the option to purchase a second 1% NSR for an additional C$5m at any time on the Kandiolé project.

Osisko has already purchased a 1% net smelter return royalty for C$5m ($3.7m)

for upfront consideration. It will also retain the option to purchase a second 1% NSR for an additional C$5m at any time on the project. Roscan, however, will have the right to oblige Osisko to acquire the additional 1% NSR royalty in case the firm secures a long-term exploitation licence from the Malian Government on the 401.8km² Kandiolé property.

The Kandiole Project consists of exploration properties located in West Mali, hosting two high-grade gold

In a press statement, Roscan said: “Osisko has also been granted a right of first refusal (the “ROFR”) on future royalties and streams related to the property including in relation to the company’s outstanding buyback rights, should the company decide to sell those rights, and royalties on any future properties acquired or claimed by the company that are contiguous or complementary to the property.”

Roscan president and CEO Nana Sangmuah said: “We are very happy to welcome Osisko Gold Royalties, a leading royalty and streaming provider, as a strategic partner while we continue to unlock significant value on the very prospective Kandiolé project, which is strategically located between two of the largest producing gold mines in Africa.”

Caterpillar Inc, has unveiled its first battery electric large mining truck. The prototype 793 rigidframe dump truck performed its first live demonstration on a 4.3-mile course fully loaded.

The prototype truck was built at Caterpillar’s Tucson Proving Ground, located in Green Valley, Arizona. The construction and mining equipment manufacturing giant completed development of the electric truck with support from key mining customers participating in Caterpillar’s Early Learner program. Participants of the program with definitive electrification agreements included BHP, Freeport-McMoRan, Newmont Corporation, Rio Tinto and Teck Resources Limited.

During the demonstration, Caterpillar monitored over 1,100 data channels, gathering 110,000 data points per

second, to validate simulation and engineering modelling capabilities. The battery-electric truck clocked a top speed of 37.3 mph on its 4.3-mile test, similar to the diesel model. It travelled .62 miles up a 10% grade at 7 mph and .62 miles downhill at a 10% grade.

Cat further noted that on the downhill section the truck captured energy “that would normally be lost to heat”

and returned it to the battery. This is a process known as regenerative braking in which energy lost when applying the brakes or taking pressure off the accelerator pedal is captured and used to recharge the battery.

“Upon completing the entire run, the truck maintained enough battery energy to perform additional complete cycles. Our global team came together to develop this battery truck at an accelerated pace to help our customers meet their sustainability commitments. This demonstration is a significant milestone, and we are excited for these trucks to get to work at customers’ sites around the world in the near future,” said t Denise Johnson, Resource Industries Group President.

Aton Resources has been issued a six-month force majeure compensation period at the Abu Marawat Concession in the Eastern Desert of Egypt, under the provisions of the Abu Marawat Concession Agreement.

Interim CEO Tonno Vahk confirmed the report and said the compensation period will be added to the final exploration period of its current exploration license thus allowing completion of maiden mineral resource estimate (“MRE”) at the Rodruin deposit, as well as updating the existing Hamama West MRE.

“We are very pleased to announce that this extra time has been added to the term of the Abu Marawat exploration

licence, primarily to make up for time unavoidably lost during the Covid-19 pandemic. We wish to thank the Egyptian Mineral Resources Authority and the Ministry of Petroleum in Egypt for their continuous support and their assistance in making this happen,” he said.

“We will complete the diamond drilling at Rodruin within the next fortnight,

The LF-10 NEO has a z-link design with the maximum tipping height in its class, of 2.5 m, which is perfect for truck loading all 30 ton trucks in the market.

“The high break out forces, efficient boom and bucket motion times as well as the strong power to weight ratio makes the LF-10 NEO one of the best in class” says Ingo Rath, Product Line Manager Loaders at GHH in Germany. With a length of 9,6 m and width of 2,6 m the LF-10 NEO is very compact and versatile for excellent maneuverability in a midseam underground mining environment.

The standard bucket holds 4,6 m3 or 10 tons at 2500 mm width, making loading and unloading easier and more

cost-effective. “GHH installs the watercooled Mercedes OM936 diesel engine with 240 kW which is the best in the 10 ton loader size class”, says Rath. “The large fuel tank also allows for full shift operation with no worry for refuelling mid shift and losing valuable production time”. Exhaust gas emissions complies with EPA Tier 3 or EU Stage IIIA on the standard machine, while EU Stage V is also optionally available. The low fuel consumption, ease of maintainability and robust design as well as durability and reliability of the product all add to the low operating costs.

The LF-10 NEO has a great operators’ compartment which boasts excellent ergonomics, which is evident through the way the controls have been laid out and the general arrangement within the cabin. There is also a nice, large footbox

where we have now drilled well over double the originally planned number of metres. Work is already well underway on the revision of the Hamama West MRE, following the completion of the RC drilling there at the end of August, and we will start working on the Rodruin maiden MRE immediately on receiving the final assays from the drilling programme in early 2023 {….}.The extra time we have been granted will also allow us to continue our ongoing exploration on the Concession as a whole, and we plan to start drilling several of our highly prospective regional targets during 2023, including Abu Gaharish, Semna and our recent new discovery at West Garida, ” he added.

giving the operator significantly more space and comfort, while the excellent visibility rounds off an already well designed operators’ compartment. In general, the loader now comes standard with useful safety and maintainability features such as the Proximity Detection System (PDS) interface, which allows the integration of third-party equipment. And optional wear sensors on the brakes.

Easy operation, seamless integration Like other GHH vehicles, the articulated LF-10 NEO is designed for underground hardrock mining and can be ordered with many options. Also worth mentioning is the seamless integration with electronic monitoring and digital analytics systems “GHH inSiTE”, which provides for great insight into the machine performance and maintenance requirements and can be tailored to customers specific needs. The LF-10 NEO, with an operating weight of around 28 tons manages up to 32 km/h with four-speed transmission and gradients up to 25%. It tips the 10-ton payload in just 2,6 seconds. The NEO joins the company´s mid-range segment of LHD offering, which is one of the most comprehensive on the market: The range of 18 diesel and electric models with payloads from 1 to 21 tons is a weighty factor in choosing the perfect loader. And by the way, the Germans have the same great selection in dump trucks to complement.

Caracal Gold’s Kenya’s wholly owned subsidiary, Kilimapesa Gold Pty Ltd (KPG) is set to expand its operations at Kilimapesa Gold Mine in Kenya.

The mine is located in a mining friendly jurisdiction in Narok County. The firm has a mining licence with a JORC resource, an established, producing, shallow underground mine and processing plant as well as an extensive prospecting permit. Gold ore is produced on site and exported to international refiners, offering immediate value uplift through revenue generation. Further upside can be seen through plant expansion and reserve and resource upgrade.

The miner’s objective is to expand its operations by undertaking exploratory drilling and open-cast mining at Kilimapesa Hill. The mine intends to use a combination of reverse circulation

drilling, diamond drilling as well as open-pit mining to complement the underground mining currently in place. The company said it is awaiting approval for the expansion from the National Environment Management Authority (Nema).

Caracal acquired 100% ownership of Kilimapesa last year, and the company was listed on the London Stock Exchange in September. Caracal is also

listed on the Frankfurt Stock Exchange & is currently in the process of being listed on the Nairobi Securities Exchange, which will make Caracal the first gold and related minerals miner on the exchange. “We have had great success on this front to date, with production and processing output both increasing, and exploration drilling successfully growing the resource and ultimately the life of mine,” said CEO Robbie McCrae.

Egypt is set to develop its first accredited gold refinery. The country’s Minister of Petroleum and Mineral Resources Tarek alMulla confirmed the report and said the project’s goal is to boost country’s mining sector.

The project will be situated in the Marsa Alam area in the Eastern Desert, with development costs reaching $100 million. According to the Minister, the refinery which will serve the region as a whole will help finalize the value chain for gold production by maximizing the local content.

Mulla further explained that the vision for developing the mining sector aims to increase its contribution to the gross domestic product from about half a percent now to five percent within the next two decades. It will also provide a large number of job opportunities and maximize mining activities by issuing more than two hundred exploration licenses annually.

Egypt has a history of gold-mining stretching back to the pharaohs but now has only one commercial gold mine in operation, Centamin’s Sukari, in the eastern desert region. Sukari contributes up to $900 million a year to the Egyptian economy.

The country in general is home to a wealth of mineral resources including gold, copper, silver, zinc, platinum and

a number of other precious and base metals. These resources all lie beneath Egypt’s Eastern desert and the Sinai Peninsula, both part of a geological setting known as the Arabian-Nubian shield. With an estimated 6.7 million ounces of gold, 48 million tons of tantalite (fourth largest reserves in the world), and 50 million tons of coal, Egypt has the potential to be one of the top mining jurisdictions in the world.

TRX Gold Corporation reported its results for the fourth quarter (“Q4 2022”) and year end August 31, 2022. Financial results will be available on the Company’s website on November 30, 2022.

The TRX Gold team delivered two mill expansions on site at the Buckreef Gold Project. In Q2 2022, Phase 1 of the 1,000 tpd+ mill was commissioned, allowing for an increase in production rates and plant throughput to 360 tonnes per day (“tpd”).

Subsequent to year-end, in September 2022 Buckreef Gold announced successful commissioning of the second phase of the mill expansion to 1,000+ tpd. As a result, since Q2 2022, the production of low-cost, high margin gold ounces has steadily increased each month.

Thanks to TRX Gold’s local employees, contractors, trades people, material suppliers and service providers, the two mill expansions were delivered on time and on budget, at a capital cost of approximately $5.6 million for both phases. Tanzania continues to prove itself as a country that is self-sufficient, dependable and capable. Thanks to these qualities, Buckreef Gold did not experience any slowdowns or cost overruns caused by ongoing global supply chain challenges.

For the year ended August 31, 2022, Buckreef Gold poured 8,874 ounces of gold and sold 8,598 ounces of gold. The Company recognized revenue of $15.1 million, cost of sales of $5.7 million

and cash costs1 of $665 per ounce of gold, generating a strong full year gross profit of $9.4 million, gross profit margin of 62% and Adjusted EBITDA1 of $3.5 million.

For Q4 2022, Buckreef Gold poured 3,619 ounces of gold, a new quarterly production record, exceeding previous production guidance of 750-800 ounces of gold per month. Furthermore, 3,363 ounces of gold were sold, also a new quarterly sales record for the Company, resulting in positive operating cash flow of $2.4 million. Buckreef recognized revenue of $6.0 million in Q4 2022, cost of sales of $1.9 million, and cash costs1 of $560 per ounce of gold, below guidance, generating strong Q4 gross profit of $4.1 million, gross profit margin of 69% and Adjusted EBITDA1 of $2.2 million.

In 2022, the Company drilled over 22,000 meters at Buckreef Gold ($3.7 million) including infill drilling, step-out drilling and grade control drilling. During the year, the Company extended Buckreef Gold’s Main Zone by 300 meters or 30%, to 2.0 kilometers, as a result of its northeast step-out drilling program.

In Q4 2022, an additional drill rig was added to expand the exploration program and, to date, a total of 22 holes representing over 7,592 meters in the

northeast extension of the Buckreef Main Zone, have been completed.

The Company executed an infill drill program at the Main Zone, consisting of 16 drill holes, representing 3,695 meters. Also, during Q4 2022, the Company explored under the South Pit and tested the South Zone extension with 24 drill holes, representing 4,255 meters. Results from both programs are pending. Subsequent to year-end, the Company commenced exploration drilling at the Anfield Zone, where the drill rig is now active with 9 drill holes representing 1,650 meters. Assay results from this program are also pending.

At the end of Q4 2022, TRX Gold had no debt on record, cash of $8.5 million and working capital of $5.4 million after adjusting for liabilities which will only be settled by issuing equity of the Company. During the year, the Company successfully closed three financing transactions providing the Company with additional flexibility and liquidity, if necessary, to help fund acceleration of its growth strategy including: (i) a registered direct offering with a single institutional investor for net proceeds of $6.4 million; (ii) a pre-paid gold purchase agreement with a contract price totaling $5 million with OCIM Metals & Mining SA; and (iii) a purchase agreement with Lincoln Park Capital Fund, LLC (“Lincoln Park”) enabling TRX Gold, in its sole discretion, to sell up to $10 million of its shares to Lincoln Park over a 36-month period.

track with successful development exploration at Russel South (see press releases of March 29th and August 17th) and drilling programs continue at the Grasshopper and Elizabeth deposits as planned.

The Company will continue its near mine development exploration program with planned drilling of approximately 30,000 metres per year for 2022, 2023 and 2024.

•

Asante Gold Corporation (CSE:ASE

| GSE:ASG | FRANKFURT:1A9| U.S.OTC:ASGOF) is pleased to announce that the Bibiani Gold Mine (“Bibiani”) ramp up remains on track and commercial production has been established with three months of consistent production since the first gold pour was completed in early July 2022. Operational highlights include:

• The first gold pour at Bibiani was completed July 7, 2022, two months ahead of schedule. Metallurgical performance and gold production is on track with the ramp up schedule.

• All process plant and mine facilities have been operating on a 24 hour per day basis from late June, with ~220,000 tonnes in September and~206,000 tonnes in October.

Asante plans to increase throughput to 250,000 tonnes ore per month by Q1 2023.

• Gold production in September was above 9,300 ounces, 17% above the Company’s start up plan. October production was 9,910 ounces, 15% above plan. Gold production will continue to ramp up to ~20,000 oz per month by early 2023.

• The Walsh Pit continues to outperform relative to our initial planned gold production. As this pit has been developed, the grade control drilling program has been a key component to development of this trend.

• The Company’s plan to extend the Bibiani open pit Life of Mine (LOM) from 8.3 years to +10 years is on

Black Rock Mining Limited is set to supply power to Mahenge Graphite Project in Tanzania. The firm inked a non-binding Memorandum of Understanding (MoU) with Tanzania Electric Supply Company Limited (TANESCO) for the energy supply.

The MoU will see a 220kV transmission line constructed to support dependable, renewable, and low-cost grid power. The Mahenge Graphite Project’s enhanced Definitive Feasibility Study (eDFS) considered grid power connectivity to support the Company’s goal of a highly differentiated and sustainable operation. The two associated will implement the project’s design, financing, construction, commissioning, and operation. The

line will also supply power to nearby settlements, including the Ulanga District. It will run from Ifakara and extending to the Mahenge substation for a distribution network inside Ulanga District. A 33kV feeder distribution network will be built from the Mahenge substation to the Mahenge graphite project site.

Tanzania’s grid power output is currently 40 per cent hydropower and 60 per cent natural gas, with the share of hydroelectricity expected to increase. As a result, graphite from Mahenge is expected to have an extremely low carbon intensity compared to peers and one of the world’s lowest carbon footprints of any graphite project. Access

The Bibiani orebodies typically dip near-vertical and are open at depth. Bibiani has initiated an underground mine planning study to define development of an underground mine operation that will access mineralized deposits below the Main Pit and the satellite pits. Asante anticipates the underground mine program initiative will increase annual gold production significantly and proceed from 2025 and extend mine life beyond the period of open pit mining.

Dave Anthony, President and CEO stated, “We are very pleased with the progress that has been achieved at Bibiani. Over the past 12 months the Bibiani Mine Team has established a track record of over achievement and we look forward to increasing the value of this asset. As we gather momentum at the Bibiani Mine, and advance with exploration activities and production improvement initiatives, we look forward to providing further updates.”

to a clean, low-cost energy supply will also help Project economics by providing a sustained, low-cost base that drives a higher-margin operation.

“Grid power would provide a huge multiplier effect for the Mahenge Graphite Project by providing low-cost sustainable power, which should lock Black Rock in the bottom quartile of the cost curve; low carbon, which will differentiate its product in crucial consumer markets; and reliable power for the Ulanga and Mahenge areas, driving the win-win relationship developed under the government’s Framework Agreement and ratified by the Special Mining Licence. Critically, as we navigate the debt and equity finance process, investors should look at this outcome and gain confidence that Black Rock and Faru are focused on our long-term plan to deliver a world-class, sustainable and responsible graphite project at Mahenge,” Black Rock CEO John de Vries.

The high academic standard at Wits University’s School of Mining Engineering has once again been confirmed by its recent accreditation by the Engineering Council of South Africa (ECSA).

The ECSA accreditation is required every five years, and this cycle will see the School through to 2027, said Head of School Professor Cuthbert Musingwini. This follows a lengthy period of selfevaluation to document activities and processes, after which the ECSA accreditation team visits the School to confirm this evaluation.

During their visit, the ECSA team examines every aspect of the School’s self-evaluation report. It conducts interviews with staff, students, recent graduates, and senior industry representatives and inspects both documentation and facilities to ensure compliance. Laboratory and teaching facilities are inspected and checked

for proper functioning, ensuring that all resources are effectively used.

The ECSA stamp of approval is vital to the careers of Wits Mining graduates, as it permits them to register with ECSA as candidate engineers before they achieve professional engineers status later in their careers. Also, it allows Wits Mining graduates to have their qualifications internationally recognised by employers and universities in other countries

that are signatories to the Washington Accord.

“Being accredited by ECSA therefore puts our graduates at an advantage when they enter the local or global workplace, and when they study further,” said Professor Musingwini. “Accreditation assures the marketplace and academia of our world-class standards of teaching and research.”

The School offers one of the leading mining engineering programmes internationally, and boasts having one of the largest mining engineering programmes in the English-speaking world.

“Student numbers remain high in both undergraduate and postgraduate streams,” he said, “with a significant proportion of the student body coming from countries outside South Africa.”

Epiroc pioneers a battery-electric underground mine truck prototype made from fossil-free steel in line with the company’s vision to produce the world’s greenest machines. This partnership with Swedish steelmaker SSAB accelerates the journey towards reduced carbon-dioxide emissions, ultimately helping mining companies reach their climate goals.

In partnership with steel manufacturer SSAB, we now prototype an underground mine truck with a dump box made of fossil-free steel, the batteryelectric Minetruck MT42. The result is a 10-tonne reduction of CO2 emissions per manufactured dump box, the equivalent of taking five gasoline cars out of service for an entire year.

The partnership will help us accelerate the journey to create a more sustainable future, deliver the world’s greenest machines, and support our customers. “Our innovation agenda goes hand in hand with our customers’ sustainability agenda,” says Sami Niiranen, President of Epiroc’s Underground division. “In the shift to a new, low-carbon economy, our products and services will be a key contributor for our customers to meet their climate goals.”

SSAB aims to deliver fossil-free steel to the market in commercial scale during

2026, and delivered the first steel made of hydrogen-reduced iron in 2021. SSAB works with iron ore producer LKAB and energy company Vattenfall in Sweden as part of the HYBRIT initiative to develop a value chain for fossil-free iron- and steel production, replacing coking coal traditionally needed for iron ore-based steelmaking, with fossil-free electricity and hydrogen. This process virtually eliminates carbon dioxide-emissions in steel production.

“The development of new technologies is essential to enable the transition to a low-carbon economy,” says Johnny

Sjöström, head of SSAB Special Steels. “Our fossil-free steel immediately reduces the carbon footprint to near zero without compromising the high quality and properties you would expect from SSAB steels. It is the same steel, just without the negative environmental impact.”

The Minetruck MT42 Battery is a breakthrough for our sustainable innovation. It is a significant step in our company’s ambition to produce cutting-edge, environmentally smart mining equipment. It is emissionsfree in operation, generating a strong positive impact on the climate as well as on operators’ work environment and productivity. “We all play a part in creating a more sustainable future”, says Camilla Goldbeck-Löwe, Vice President Corporate Responsibility at Epiroc. “Our partnership with SSAB has enabled us to present the world’s first underground mine truck made using fossil-free steel.”

Metso Outotec has signed an agreement with Kyzyl Aray Copper, a subsidiary of Caravan Resources, for the supply of copper solvent extraction and electrowinning technology for a plant to be built in the Karagandy region of the Republic of Kazakhstan.

The order of approximately EUR 35 million has been booked in the Minerals segment’s fourth-quarter order intake. The Metso Outotec technology package delivery includes the modular VSF®X solvent extraction plant and the main process equipment for the electrowinning plant.

“We are looking forward to working with Kyzyl Aray Copper on this project. The energy-efficient VSF®X solvent extraction plant, which is part of our Planet Positive product range, reduces emissions and is safe to operate.

The Kyzyl Aray Copper project will become an important new reference for Metso Outotec in the growing Kazakhstan copper market as a supplier of a complete production plant that uses solvent extraction and electrowinning technology for copper recovery,” says Mikko Rantaharju, Vice President, Hydrometallurgy, at Metso Outotec.

Becker Mining South Africa (Pty) Ltd has recently launched the new range of Kito RX wire rope hoists in Southern and Sub-Saharan Africa and has sold its first unit to a processing plant in Rustenburg area.

“This 10 Ton 525V with 25m lift Kito RX wire rope hoist will be supplied by Tech North - our distributor in the Rustenburg region, to a processing plant in the platinum area, for use in maintenance procedures and the installation of new

equipment in the plant,” explains Rick Jacobs, Senior General Manager (SGM) for consumables, Becker Mining South Africa. “The addition of wire rope hoists is an important addition to our extensive range of Kito lifting equipment, which includes manual and electric chain hoists and lever hoists.

“Our new Kito RX wire rope hoists have been developed with a robust design and advanced technology, for dependable operation and extended service life in tough conditions. These flexible hoists are adaptable for use in conjunction with existing cranes and machinery and all components are easily accessible for ease of maintenance.

“RX wire rope hoists are suitable for the use in many industrial applications, including production plants, plant engineering, production lines and workshops, as well as ship building and maintenance.”

The Kito RX range, with lifting capacities between 1 000 kg and 50 000 kg, is available in units with two or four rope strands, reeving 2/1, 4/1 and 4/2. These

hoists have lifting speeds from 1.5 m/ min to 12m/min, with the option of singlespeed, two-speed, and frequencycontrol.

Features include 380 - 440V / 5060Hz / 3 phases, Insulation Class: IP 55 (standard) or IP 66 (optional) and a control voltage of 42 V, 110 V, 24 V, 48 V or 230 V (optional). These hoists are powered by a three-phase asynchronous motor or the option of a sliding anchor motor. A planetary gearbox ensures optimum power transmission between the hoist motor and rope drum.

For enhanced safety, an electromagnetic disc brake acts directly on the rotor shaft for effective braking force. Electronic overload protection, with two adjustable levels, offers protection to the hoist and all its components from overloading (Performance Level C). There is also integrated overheating protection for the motor.

A notable design feature includes the rope guide that consists of two partsthe guide ring and tension spring. The tension spring ensures that the rope lies correctly in the drum groove, whilst the guide ring always maintains the rope in the correct position, preventing it from coming off the drum groove. By moving the guide ring along the drum, limit switches are activated for the highest and lowest hook positions.

The double-girder trolley is equipped with double-flange wheels, all with high quality ball bearings. This construction, where driven wheels are connected directly to the self-braking gear motor, ensures efficient power transmission between the running wheels and the trolley rail. This design also ensures extended service life, reduced wear and low maintenance requirements.

Trolley construction comprises a standard headroom monorail design that enables the hoist to operate directly under and parallel with, the crane or runway beam. The hoist is directly connected to the trolley and all components are easily accessible for ease of maintenance.

Hoists available in this range include a foot mounted hoist without a trolley, designed for lifting capacities from 1 000 kg to 50 000 kg and a hoist with a standard headroom monorail trolley, for

capacities from 1,000 kg to 32,000 kg. Double girder trolleys are suitable for capacities from 1,000 kg up to 32,000 kg, either supported or suspended, version S2-S4.

Units are available only in supported execution, for capacities from 20,000 kg up to 25,000 kg two rope falls, and for capacities from 40 000 kg to 50 000 kg, four rope falls. Units are also supplied as a double hoist, with capacities up to 100 000 kg. The low headroom monorail hoist trolley is designed for capacities from 1 000 kg to 16 000 kg.

There are many options available to suit specific application requirements. These include radio remote control, customised painting and festoon cable systems. User can also choose load spectrum monitoring and synchronisation, load display, summation and measurement, as well as anti-sway control.

Becker Mining also supplies a full range of Kito accessories, designed to enhance performance of Kito hoists. These components include universal trolleys, available in plain or handgeared configurations, to provide smooth, precise and easy traversing and positioning.

Modern society is heavily reliant on metals and minerals and the demand is growing, driven by a combination of global trends. The rising urbanization and higher living standards are pushing up the requirements of construction materials, as well as the minerals used in the electronics and appliances that are part of our daily life. The pursuit of the United Nations’ Sustainable Development Goals (SDG) and the move away from fossil fuels are also driving a significant increase in the demand for the metals and minerals required by low carbon technologies – from Rare Earth Elements for wind turbines and quartz for solar panels to lithium for battery electric vehicles and copper for renewable energy systems. Even in agriculture there is an increasing need for minerals, such as the phosphates in the fertilizers used to produce crops to feed our planet’s growing population.

We are facing the challenge of meeting an unprecedented demand for metals and minerals, which are finite and scarce resources. Recycling rates for materials critical to the energy transition, such as Rare Earth Elements, lithium and graphite, are low and not expected to rise significantly for some time. Even then, recycling alone will be unable to meet the increasing demand, and mining will continue to play the key role in supplying necessary primary resources. It is becoming increasingly important to mine efficiently and sustainably using modern technologies such as sensorbased sorting.

In October 2022, the European Parliament and Council have provisionally agreed that all new vehicles registered in Europe must be zero emission by 2035. This agreement

is set to accelerate the adoption of electric cars: according to the European Automobile Manufacturers’ Association, in 2021, 20% of new cars sold in the EU were plug-in and by 2030 this set is expected to rise to 60%. Legislative actions such as this across the world will drive a fast growth in the demand for electric cars, which will require high volumes of lithium for their batteries.

The current production rates of lithium will soon be insufficient to meet this demand. In fact, according to the Benchmark Mineral Intelligence, it will require 78 mines by 2035 (the calculation includes projected volumes of recycled lithium) – this is around six times more production than today. It is essential that mining and processing this element is as sustainable as possible.

Sensor-based sorting technology can significantly contribute to reducing the

environmental footprint of lithium mining and processing in different ways. On the one hand, it is able to selectively reject waste and low-grade ore upstream of processing. This means that less material is processed, resulting in significantly lower usage of energy, water and chemicals. A complementary environmental advantage of this technology is the reduction of wet tailings.

On the other hand, sensor-based sorting technology addresses effectively the challenge of basalt contamination, typical of lithium mines. Due to its high density – similar to that of spodumene – this high-iron, barren material is also concentrated by Dense Media Separation, contaminating the final product. With sensor-based ore sorting technology, it is possible to sort out the basalt and as a consequence to unlock value from existing stockpiles of contaminated materials, achieving a high-purity product.

This was the case at the Galaxy Resources Mt Cattlin mine in Western Australia, which had been stockpiling basalt contaminated material since 2016, while it searched for an effective solution. In 2021 it installed a TOMRA PRO Secondary Laser sorter, and in 9 to 12 months it processed the best part of the 1.2 million tons of stockpiled material, consistently achieving high purity with less than 4% basalt. As Matthew Bateman, Principal Metallurgist at Galaxy Resources said, “with the TOMRA sorter, we are using far more contaminated ore than we would previously have processed.”

Another excellent example of how sensor-based sorting can make a difference is in processing phosphates, recovering the valuable nutrient efficiently and more sustainably. The sorting plant at Wa’ad Al Shamal in Saudi Arabia, with a capacity of around 1900 t/h, is the perfect demonstration of this technology’s potential.

The run-of-mine material contains significant amounts of unwanted flintstone, or chert, which has to be removed before the phosphates are fed downstream for refinement processes. TOMRA’s X-Ray Transmission sorters remove flintstones from the phosphate to reduce silicon content, so that the downstream process can be significantly downsized. This results in much lower consumption of energy, water (as much as 45% less), and flotation reagents. In addition, TOMRA’s sensor-based sorters are able to process larger grain sizes, extract value from materials which

are often discarded as waste when using traditional sorting solutions such as Dense Media Separation.

To achieve the Paris Agreement goal, countries around the world need to reduce their greenhouse gas emissions to ‘net zero’ by around 2050. This means that every sector must reduce the amount of carbon it puts into the atmosphere. For this to happen, legislation has a critical role to play in addressing market flaws, pushing for environmental compliance, drive investments and create favourable conditions for businesses to invest, and foster alignment of all stakeholders.

Collaboration will be key in all industries, and TOMRA is actively seeking opportunities to build partnerships with the big mining houses and other stakeholders across the mining supply chain. This is the path to achieving a circular economy where mining will play a vital role by supplying the minerals needed for the energy transition and the new low carbon technologies. Collaboration will enable the mining industry to operate sustainably, maximizing the opportunities to reduce its environmental footprint.

TOMRA Mining is already actively contributing to green mining with its sensor-based sorting technologies, enabling mines to maximize the efficiency of their operations, minimize the use of energy and other inputs, and reduce waste as much as possible. Today there are around 190 TOMRA sorters in operation across the world, delivering a reduction in CO2 emissions of 168,945 metric tonnes per year.

Subsoil Technologies delivered its flagship underground communication network from Australia based Northern Lights Technologies’ (NLT) to Al Masane Al Kobra Mining Company (AMAK Mining) in Saudi Arabia. The solution delivered to AMAK Mining includes a 1Gbps Wi-Fi network, real time positioning system for people and equipment with evacuation system and rugged mine phones for workers. This will be the first N-Connex network installed in the Middle East by Subsoil Technologies and the 35th installation of its kind globally. Notable installations of the N-Connex network in the Africa, Middle East territory include Ekapa Mining (formerly Kimberely Diamond Mines) in South Africa,

completed in 2021 and Managem Mining’s CMG Draa Sfar slated for delivery before the end of 2022.

“The communication system from Subsoil technologies will help AMAK to enhance worker safety and efficiency through improved communication. This network gives us the ability to consider further smart mining solutions such as ventilation on demand and production monitoring, which we intend on implementing in the near future”, says Sinan Burak, AMAK’s mine manager. Tendayi Mwayi, sales director at Subsoil Technologies had this to say “we selected the N-Connex network for AMAK because it is a modular, plug and play solution built for harsh operating

environments typical of highly remote mines such as AMAK. The network is flexible and easily scalable to cater to the demands of both mechanized and conventional rail and track mines.”

Subsoil Technologies is a reseller and implementation partner of NLT and other global technology companies including Huawei, Nokia, Centero, CGG and Groundhog Apps in the Africa and Middle East territory. Subsoil’s goal is to help mines in Africa and the Middle East to get meaningful value from wireless connectivity and smart mining solutions. Subsoil Technologies also offers private LTE and Wireless mesh networks, geotechnical monitoring services and operations management software.

Focusing on the ways Africa can optimise the opportunity to increase the supply of green metals for global energy demands while creating meaningful value for communities will be the emphasis of Investing in African Mining Indaba 2023 (https://www. MiningIndaba.com) which takes place at the CTICC, Cape Town, 6 - 9 February 2023. Green Metals Day, supported by keynote sponsor JOGMEC, will cover the impact of COP27 outcomes on green metal demand and supply; battery metals and carbon neutrality; green metals outlooks; Africa’s hydrogen potential; as well as ways to build domestic manufacturing industries as part of mineral value addition.

African mining and metals are critical to tackling the global climate emergency. Home to 30% of the world’s mineral deposits, including the critical minerals needed in green technologies and renewable energy, the continent is positioning itself to benefit from the green energy transition.

Simon Ford, Portfolio Director for Investing in African Mining Indaba, said “Mining Indaba provides the perfect platform to explore the balance between opportunity and value creation, particularly in the African context where the social licence to operate is as fundamental to success as the commodity being produced.”

A Minerals for Climate Action report released by the World Bank in mid2022 estimates that demand for green metals could increase five-fold by 2050 to meet the growing demand for clean energy technologies. This massive boost in demand for minerals and metals will mean that mineral-rich developing countries, like those in Africa, can drive a net-zero future. “Attracting a share of the investment to low and middle-income countries could contribute to economic growth, jobs and local development,” the bank stated.

“Mining Indaba 2023 theme is ‘Unlocking African Mining Investment: Stability, Security, and Supply’, which explores African mining’s opportunities to tap into the global rush for the raw materials needed to ensure a cleaner future, while

at the same time considering responsible sourcing and sustained, ethical supplies

This view is supported by the International Council of Metals and Mining (ICMM), a foundational partner to Mining Indaba. ICMM President & CEO, Rohitesh Dhawan notes that “Critical minerals are the backbone of the energy transition, but how we source and produce them is just as important as how much we need,”

Supporting the Paris Peace Forum’s call for responsible sourcing and production of critical minerals, the ICMM warned that we are walking on a tightrope between an exponential increase in demand for these minerals, rising geopolitical tensions and urgent action on global issues such as climate change.

Simply put, the ‘green’ version of almost anything means the use of more metals but the ICMM doesn’t see this as a license for industry to mine them at all costs, added Dhawan.

African mining and metals are critical to tackling the global climate emergency

More mining companies are making bold commitments to decarbonize their operations to reduce business risk and help combat climate change.

The International Council on Mining and Metals (ICMM), which represents 28 mining companies and 35 commodity associations worldwide, recently committed to a scope 1 and 2 net greenhouse gas emissions target by 2050 or earlier, in line with the ambitions of the Paris Agreement.

As suppliers of metals and minerals essential to decarbonization and sustainable development, the industry has a responsibility to minimize its environmental footprint - and it is acting. While the speed and depth of decarbonization initiatives vary across the industry, many mining companies are taking immediate action, investing in areas such as renewable energy and electrification, and improving governance to align with global climate risk reporting standards.

Mining companies are under increasing pressure from various stakeholders to

reduce emissions and address climate risks, which can have a negative financial impact on the company. Financial risk comes from the physical effects of climate change, such as extreme weather events, and the risks of transitioning to a low-carbon economy.

Challenges of Mining Decarbonization in mining depends largely on electrification and renewable energy. In some ways, it is easier to imagine how mining can become carbonfree than other sectors. That doesn’t mean it will be easy.

Investors are putting strong pressure on large multinational players in the mining sector, particularly in relation to operational emissions. The rapidly declining cost of renewable energy has made it easier for them to respond. For example, BHP has signed a deal to develop new solar and wind farms in the Australian state of Queensland, which will allow them to run their coal operation in the region on solar power. They hope this will help them reduce their indirect emissions in the country by 20% over five years. BHP is also moving toward green copper by signing renewable energy

contracts that will allow its Escondida and Spence copper mines in Chile to switch to 100% renewables, replacing imported LNG. It has also committed to eliminate groundwater use in Chile by 2030, invest in desalination plants.

With a patchwork of different national and local policies to navigate, many mining companies are designing their decarbonization strategies based on the strictest common denominator and then applying these tactics globally across their organizations. While mining and metals companies hope to price carbon and increase regulation, these are not the main drivers at the moment. Instead, investors and markets are ahead of where governments are, as evidenced by the growing number of companies signaling their decarbonization ambitions.

The supply chain pull is also generally stronger in mining than in other sectors. For example, battery manufacturers are starting to look for carbon-neutral lithium and nickel, while automakers are starting to ask for green steel and aluminum. Market demands like these could become the biggest driver of all. If customers start demanding green products, mining

companies must offer them to stay in the game.

What are the factors that can provide CO2 reduction in mining?

Cots – energy is a substantial and growing proportion of a miner’s cost, accounting for about one-third of the total cost base of mining companies. Most miners anticipate the introduction of a carbon price, which will increase the cost of diesel power.

Consumers – the COVID-19 pandemic has radically changed the sustainability mindset of consumers, with global markets becoming increasingly consumer-driven, social expectations are rising and participants at all stages of the value chain will have higher expectations of them to reduce carbon emissions.

Capital providers – pressure is increasingly being applied by capital providers to meet decarbonization targets in order to access financing for mining projects.

Cots – energy is a substantial and growing proportion of a miner’s cost, accounting for about one-third of the total cost base of mining companies. Most miners anticipate the introduction of a carbon price, which will increase the cost of diesel power.

How mining companies can align their actions to meet the industry’s carbon reduction goals.

Mining companies should ensure that their carbon reduction policies are aligned with industry standards from an ecosystem perspective. This is vital to avoid greenwashing, which occurs when companies claim to be dedicated to carbon reduction for the sake of their reputation, but fail to back up their claims with action.

This alignment is necessary to provide consistent reporting methodologies. Maintaining a social license to operate is crucial for many mining companies. This even affects the company’s employees.

As a result, large multinational corporations are increasingly looking to be at the forefront of environmental challenges to recruit the best talent.

In which areas should the company focus its efforts?

The areas that require decarbonization in mining vary among the different elements that contribute to the success of a mining operation from pit to port.

Decarbonization in mining is required in the following areas:

• Transport;

• Mineral processing;

• Diesel Trucks;

• Supply chain;

• Mineral exploitation;

• Electricity supply;

• Transportation of goods.

Green technology in mining refers to equipment that reduces carbon emissions and mitigates negative environmental effects. Green mining is now a crosscutting concept for the entire industry, where the global mining scenario is already adapting it to its entire process chain.

Green mining alludes to sustainability and the care of each process, such as efficiency in resource extraction, production with less environmental impact, and care for the surrounding communities, among other points. Through this new form of mining, it is expected that the practices within the industries will be optimized and improved to make each process more efficient and conscious.

How can ABC Dust help mines decarbonize their process?

ABCDust is a company focused on developing green technology for smart dust control and soil stabilization. ABCDust’s sustainable solutions help mining companies reduce their C02 emissions:

• Reducing the water used for dust control by 90%, which translates into fewer hours of water transport and energy consumption to move and process water;

• Improving road rolling resistance with our soil stabilization and dust control solutions. Rolling resistance is the energy lost through drag and friction of a tire rolling over a surface. A 10% reduction in rolling resistance would improve fuel economy by approximately 3% to 5% for light and heavy-duty vehicles and improve the life cycle of your tires by up to 5%. Open-pit mines use haul trucks that use an average of 50 liters of diesel fuel per hour. Large mines have a fleet of 70 to 150 haul trucks that operate 24/7/365. This can add up to 300,000 liters of C02 diesel consumption reduction per year, plus

the fuel savings alone;

• Increasing the life of mining roads by reducing the frequency of grading and maintenance required. Also, reducing the need to use aggregates to improve road properties;

• Increasing the life of tires and haul trucks. A better, dust-free road uses fewer tires and extends the life of haul truck suspension systems and filters.

ABCDust - Smart dust control and soil stabilization

DMS dust suppression solutions and high-performance soil stabilizers are created by the following combination:

• DMS® solutions for high performance dust suppression;

• Soil stabilizers with electronically controlled wetting equipment;

• Georeferenced road dust and friction monitoring systems;

• Georeferenced road roughness monitoring systems.

As a result, a completely new dust suppression technology was created and a patent application was generated. Our products are delivered precisely when and where they are needed, resulting in increased productivity, longterm sustainability, and safety. Dust suppression, better soil stabilization, water conservation, shorter braking distances and low maintenance costs are all characteristics of DMS products.

The following DMS® solutions are available for dust reduction:

• DMS-DS: Dust control on mining roads. DMS-DS® dust suppressor is suitable for haul roads and high altitudes, and can withstand up to 600 tons of loading;

• DMS-EB: DMS-EB® is a clean solution that traps particles and improves road and soil stability;

• DMS-DS 80: It is a low-cost dust suppressant and soil stabilizer that is also chloride-free and environmentally harmless. It is successful in a variety of soils, although silty and low water-retention soils produce higher yields;

• DMS-TDS: This is a non-ionic dust suppressant designed for continuous lines of conveyor belts on loading fronts, crusher chutes and/ or high frequency material conveying systems.

By using ABCDust solutions and

services, you can achieve 95-99% dust reduction, thus saving lives, improving the environment, saving money, and ensuring your operational continuity and social license. Please feel free to contact us for more information.

We use soil stabilization solutions to improve many types of roads and sites in different industries such as mining, forestry and construction in Canada, Chile, Peru, Colombia and Brazil. Our solutions strengthen the soil and enable it to withstand more pressure and capacity from heavy vehicles, thus improving the logistics of the sites.

We offer a wide range of products (enzymes, polymers, synthetic oils and asphalt emulsions) that have been formulated to meet different road needs and reduce the need for aggregates and road maintenance. Our selection of products for soil stabilization is very economical, environmentally safe, and non-toxic.

Here are some of our solutions for soil stabilization:

• DMS-DS® 100 is specially designed for soil stabilization and dust control of industrial roads, haul roads and tightly compacted surfaces, improving their overall strength and the binding of road materials;

• EZISS PRO® is a natural liquid soil stabilization enzyme, which improves the properties of native/ local soils;

• CHEM-STAB® is a sulfonated

(ionic) chemical based soil stabilizer, formulated with ionizing complexes associated with ion exchange elements;

• SOILCELLS® are high density polyethylene panels used for soil containment. The three-dimensional structure of the cells allows the granular material to be confined and thus avoid any displacement caused by erosion or static or dynamic loads. This versatile material can be used for slope retention, soil reinforcement, road infrastructure and as a retaining wall.

Due to the nature of the comminution and classification processes, the blasting, transporting, crushing and milling of ores makes them major contributors of dust emissions into the air. Workers, the environment and nearby wildlife are all affected.

ABCDust provides a dust monitoring service to its clients that employs the EPA’s PM10-2.5 near reference measurement technology to provide a consistent assessment of dust levels in a variety of environmental circumstances and production levels (Ton/hr). To assess PM10-2.5 dust levels emitted from operations, we employ dust management methods.

Here are some of the features of our dust monitoring solution:

• For PM 10, 5, 4, 2.5, and 1 particle, multi-channel dust levels up to 4,000 mg/m3 are continuously monitored;

• Gravimetric samples are used to describe and quantify mg/m3 dust emissions;

• Modeling of dust emissions using a variety of parameters (winds, humidity, production, material type, etc.);

• Solutions for dust control are suggested (maintenance, dry mist, fine mist, dust collectors, additives, etc.);

• Before and after implementation, improvement options are reviewed;

• Report on emissions both before and after implementation of the measure.

Global decarbonization depends largely on the sustainable mining of minerals and raw materials. A thriving and healthy mining industry is critical to the global economy and supports the innovation needed to mitigate global warming, protect the environment, and develop the circular economy.

Focusing its efforts on the areas of greatest impact by aligning with clean technology and green technology applications is the first major step towards the goal of decarbonization in the industry.

Regardless of the paths taken by mining companies to lower carbon emissions, achieving the reduction targets under the Paris Agreement and meeting the expectations of a more environmentally conscious population are key to the longterm viability of the industry.

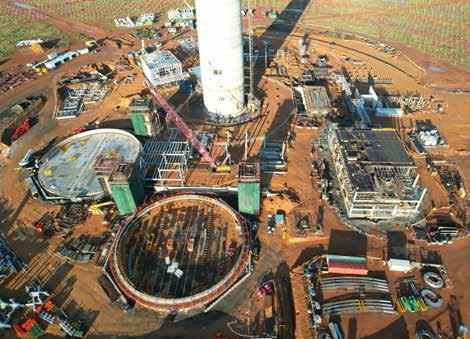

The phased restart of Boss Mining will commence with the processing of the historically mined Kiwana fines at its Luita concession, paving the way for further development

Eurasian Resources Group (ERG) and its joint-venture partner, La Générale des Carrières et des Mines (Gécamines), celebrated the kick-off of the restart of operations at Boss Mining with a ceremony held at its concession on 23 November 2022.

Boss Mining, located in the Lualaba and Haut-Katanga provinces of the Democratic Republic of the Congo (DRC), has a long history of copper and cobalt production from significant openpit resources. Boss Mining was placed into care and maintenance early 2019 to allow for ERG and Gécamines to assess different investments paths and conduct further studies to improve Operations’ economics and sustainability.

Benedikt Sobotka, Chief Executive Officer at ERG, said: “We are not only celebrating the return to production at this time, but also our long-standing partnership with Gécamines and its professional team, without whom this restart would not have been possible. ERG believes that collaboration is the key to building a better future.”

Recognising that mining plays a vital role in the social and economic upliftment of its host communities, ERG aims to develop and scale operations at Boss Mining in a sustainable way to allow for positive, longer-term social, environmental and economic outcomes.

“We are proud that this phase of the restart will create around 750 jobs for

DRC citizens, primarily recruited from the surrounding communities, ensuring that direct members of our communities are the primary beneficiaries of Boss Mining’s activities,” added Sobotka.

Provincial Minister of Interior and Security of the Lualaba Province, Mr. Kapenda Wa Kapenda Déodat, commented: “As a government, we can only rejoice once again because the restarting of an operation means not only the creation of jobs for our population, but also that the tax revenue of the province will increase. And every time there is production, we know that there is a small amount that goes into the government’s tax coffer that helps us develop other sectors of our society.”

The phased restart will concentrate on processing historically mined fines over the next 16 months to produce copper cathodes and cobalt hydroxide. The operation will ramp up over the coming months to its full capacity producing, on average, 1,800t of copper cathode and 300t of cobalt hydroxide a month, by March 2023.

“The current restart is only the beginning of our journey, and will provide financing for further potential development, exploration and other mining-related activities at Boss Mining. I am convinced that the revival of Boss Mining’s activities will allow for the creation of important number of new jobs in the future and the union of countless families from the surrounding communities and the

four corners of the country,” said Chief Executive Officer of Gécamines, Mr. Ntambwe Ngoy Kabongo.

Boss Mining is also currently renewing its five-year ESIA commitments and formalising its Cahier de Charges. Restarting the production will allow Boss Mining to update its commitments and social contribution, in turn supporting the action programme of the DRC President, His Excellency Mr. Félix Antoine Tshisekedi Tshilombo, which aims to improve social conditions through housing, health, education and employment.

“It is important for us to transmit to you the message of encouragement of his Excellency the Governor of Haut Katanga, Mr. Jacques Kyabula Katwe, who sees this restarting of Boss Mining as a vital sign of life returning to the territory of Lubudi and the economic life of our province, Haut Katanga. ERG and Gécamines have our full support for the relaunch of this giant amongst the mines,” assured Provincial Minister of Mines and Hydrocarbons, Mr. Georges Mawine Kaindu.

Drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs. Drilling fluids are also used for much simpler boreholes, such as water wells.

According to the BIS Research analysis, the global drilling fluids market was estimated to be at $6.1 billion in 2021, and it is expected to grow at a CAGR of 7.8% and reach $12.6 billion by 2031. Along with the increasing onshore drilling activities, offshore drilling activities are also expected to increase significantly due to the rise in energy demand, which will lead to further growth in the global drilling fluids market.

The main functions of drilling fluids include providing hydrostatic pressure to prevent formation fluids from entering into the well bore, keeping the drill bit cool and clean during drilling, carrying out drill cuttings, and suspending the drill cuttings while drilling is paused and when the drilling assembly is brought in and out of the hole. The drilling fluid used for a particular job is selected to avoid formation damage and to limit corrosion.

Common drilling fluids are water, bentonite mud, cutting oil, and polymers (both water-based and mud-based).

Water-based drilling fluids are the most commonly used of the mud systems. They are generally less expensive and less difficult to maintain than oil muds, and in some special types of systems, they are almost as shale inhibitive.

Bentonite on the other hand is used in drilling fluids. The bentonite in the flush fluid lubricates and cools the cutting tools whilst protecting against corrosion. As the drilling fluid generates hydrostatic pressure in the borehole, it hinders fluid and gas penetration.

Cutting oil is designed to maximise the life of cutting and drilling equipment; working under extreme pressure, improving performance and extending the life of tools. Cutting oil improves machine finish,

lubricates to reduce tip welding and prevents pitting and metal seizures.

Drilling polymers on the other hand have high molecular weight fluid with the ability to control the well’s fluid loss and to increase the viscosity. There are over four variants of this chemical which can include polyacrylate, Snergistic polymer, polyglycol, XCD polymer or partly hydrolyzed polyacrylamide.

When choosing a drilling fluid, several factors are considered. For example temperature, well type, environmental impact and overall Fluids Performance.

When drilling in places with high temperature, the effectiveness of chemical additives is generally reduced and can lead to changes in viscosity and fluid loss. Drilling fluids which can resist to such environment can be used like the oil based mud systems.

Understanding a well type is crucial to determine the drilling fluid to use. In exploratory drilling for instance, the information about the region are not enough to design mud properties. The designed mud system has to contribute in obtaining the geological information easily and safely. The mud composition has to allow for quick change in case of unexpected changes or problems.

Environmental issues are still the important considerations when planning and implementing for the drilling fluid. For example, in offshore operations, synthetic or mineral oil based systems are used rather than diesel oil based system.

Drilling fluid technology is constantly evolving because of the escalating demand brought on by more demanding environmental factors such as high temperature and pressure, tight gas and shale gas reservoirs, as well as rising technical standards such as increased lubricity requirements in air drilling and tightening regulations on oilbased systems due to environmental remediation.

Researchers at Curtin University in Australia for instance have developed new technology for the rapid cleaning and re-use of drilling fluids, paving the way toward more efficient and environmentallyfriendly mineral exploration.

Supported by the Minerals Research Institute of Western Australia (MRIWA) and the Deep Exploration Technology CRC, Dr Masood Mostofi and his research team at the Western Australian School of Mines: Minerals, Energy and Chemical Engineering (WASM: MECE) at Curtin University developed the new technology as part of their ongoing research toward automating fluid monitoring and handling in the drilling industry.

Drillers exploring deep beneath the surface for mineral deposits need specialised fluids to lubricate and cool the active drill head, and that won’t leak away through cracks and porous rocks around the drill site.

“New Coiled Tubing drilling technology being developed for mineral exploration needs much higher volumes of these special fluids than conventional drilling,” said Dr Mostofi.

“We have developed a system that can meet these fluid needs in remote locations where geologists might explore for new mineral deposits, and reduces the risk of releasing fluids that might affect the local environment.

The drilling fluid eliminates the use of hydrocarbons. Also developed is a method of keeping boreholes stable and rapidly separating rock chips and solid materials from the fluid as it returns to the surface.

And as environmental conservation takes centre stage, such innovation that have minimum negative impact on the environment are likely to become commonplace going into the future.

The phased restart of Boss Mining will commence with the processing of the historically mined Kiwana fines at its Luita concession, paving the way for further development

The United Nations’ annual COP27 climate change conference is already well underway in Egypt and the topic of developing and deploying lowcarbon technologies, which are critical for the world to achieve its net-zero targets, is high on the agenda. Because the deployment of low-carbon technologies relies heavily on minerals, the mining sector is critical in the fight against climate change.

Africa, a continent rich in minerals, will play a leading role in the supply of key minerals such as copper, cobalt and platinum group metals. These minerals are critical for renewable energy, hydrogen, and battery energy storage technologies – all of which are required for the clean energy transition. However, this must be addressed against the backdrop of Africa’s climate vulnerability and climate adaptation needs.

By doing its part in prioritising lowcarbon investments and partnerships on the continent and building agency and capability, Kamoa Copper plans to become the first net-zero operational carbon emitter among the world’s top-tier copper producers. We believe that mining companies can be the champions of global decarbonisation, not just in reducing their operational carbon emissions and producing lower carbon minerals and metals, but also in producing the critical raw materials needed to facilitate the global clean energy transition.

In May 2021, Kamoa Copper pledged to achieve net-zero Scope 1 and Scope 2

emissions at its Kamoa Copper Mining Complex in the Democratic Republic of Congo – a commitment that supports the 2015 Paris Agreement on climate change, which aims to sharply cut carbon emissions to reduce the threat of climate change.

Scope 1 emissions are classified as direct greenhouse gas emissions from company-owned and controlled resources, for example from vehicles, equipment, and machinery, while Scope 2 emissions are indirect greenhouse gas emissions, usually from the generation of purchased energy. The Company’s Scope 3 greenhouse emissions are currently calculated from its land and airrelated travel and cover the travel across the operations as well as from our head offices.

Kamoa is already making progress on achieving its net-zero goals. The Company’s mining operations and its Phase 1 and 2 concentrator plants are currently being powered by clean, renewable hydro-generated electricity from the refurbished Mwadingusha hydropower plant. Following the successful upgrade of Turbine #5 at the Inga II hydropower plant, which is currently under way, these two hydropower plants will provide Kamoa Copper access to a combined estimated 256 MW of clean, renewable electricity for Phase 3, the smelter and future expansions, while also benefitting local communities. Meanwhile, the Company has also recently taken delivery of several key pieces of stateof-the-art mining equipment powered by

electric batteries or hydrogen fuel cells, supplied by Swedish original-equipment manufacturer Epiroc. This includes the Minetruck MT65 haulers, the world’s highest payload underground truck in the field, as well as Scooptram ST18 loaders and Boomer 282 face drilling rigs.

In 2021, Kamoa’s Scope 1 emissions were 17,634 tCO2e, while its Scope 2 emissions were zero, thanks to its use of 100% renewable electricity usage. The Company’s Scope 3 emissions (currently calculated on the Company’s land and air travel) totalled 2,091 tCO2e. “Once we achieve net-zero Scope 1 and 2 emissions, we will turn our focus on achieving net-zero total emissions at the Kamoa Copper Mining Complex, which will include Scope 3 emissions and become an industry leader in the fight against climate change,” says Ivanhoe Mines Founder & Co-Chairperson Robert Friedland.

A 2020 independent audit of Kamoa’s greenhouse gas intensity metrics performed by consulting engineering and project implementation firm Hatch, confirmed that the Kamoa will be among the world’s lowest greenhouse gas emitters per unit of copper produced. Copper is an irreplaceable element required in the manufacture of advanced decarbonisation technology including electric vehicles, wind turbines, and solar panels.

A laser diffraction particle size analyzer uses multiple light detectors, with more detector elements extending sensitivity and size limits. The time needed to measure particle sizes varies by instrument, ranging from 2 seconds to 10 minutes per sample. The light source used by a laser particle size analyzer also affects particle size measuring limits; shorter wavelength violet and UV lasers are better suited to measure submicronsized particles than red lasers.

Laser diffraction particle size analyzers are used to measure the sizes of particles in a material. Particle size is calculated by measuring the angle of light scattered by the particles as they pass through a laser beam. Laser diffraction analyzers are used in many applications, including manufacturing, quality control and product development. Because this technique can continuously measure particle sizes across a wide range, from 10 nm to 3 mm, laser diffraction particle size analyzers are often used in industrial settings.

AParticle Size Distribution Analysis helps determine information about the size and range of particles representative of a given material. This analysis can be performed using a variety of techniques; the most suitable will be determined based on the sample properties and question at hand.

Sieve analysis still is the traditional and most commonly used method for particle size determination. A sieve stack consists of several sieves with increasing aperture size stacked upon each other and the sample is placed on the uppermost sieve. The most common sources of errors are overloading of the sieves, old, worn or damaged sieves or errors in data transfer. It should also be taken into account that the aperture sizes of new standard-compliant sieves are also

subject to certain tolerances. In modern processes, automated online particle size measurement is being embraced more and more by the mineral processing industry because of the distinct advantages it offers over manual offline measurement and the cost efficiencies it is able to deliver.

One advantage of automated on-line particle size measurement is that it provides a continuous stream of data, which allows for smaller changes to be made more often, thereby reducing wastage during reaction time, allowing problems to be rectified before they can escalate further and optimising operational flow. Where the ore being extracted is of particularly high value such as gold, these cost efficiencies can be significant.

Most studies have confirmed that return of investment for on-line laser diffraction occurs anywhere between six months and a year following installation. The biggest reason for this is that there is much less reliance on manpower; manual analysis methods generally necessitate highly-skilled individuals to be working around the clock, while on-line systems only require occasional intervention from a semi-skilled worker, lowering costs in terms of both time and expertise. These lowered man hours have the added benefit of minimising the risk of hazard material exposure.

Image analysis involves processing an image into fundamental components to extract meaningful information. Upon completion of the measurement, results are available on a variety of size, shape, and intensity parameters, such as

Circular Area Diameter, Length/Width, Aspect Ratio, Circularity, Convexity, and Opacity/Transparency along with several others depending on the instrument manufacturer.

Using static imaging, the particulate is dispersed onto a stage where it remains fixed during analysis. Static imaging systems offer versatility in that various sample states can be analyzed: dry powders, liquid suspensions, particulate captured on filters, in addition to creams and lotions. These systems also have the ability to reanalyze the same particles more than once, allowing for more indepth investigation

Ultrasonic attenuation has been applied in wet mineral processes since the 1970s. Because ultrasonic particle size measurement is sensitive to air bubbles, the sample has to be deaerated before measurement. Recently, ultrasonics has been combined with gamma-ray transmission and sound velocity measurement for more accurate solids content compensation (Coghill et al, 2002). The sample volume measured can be relatively large, which is an advantage of this technology. However, the major limitations in mineral processing operations are its sensitivity

to air entrainment, flaky particles, solids content and slurry viscosity changes.

Companies are increasingly adopting on-line methods especially due to their efficiency and ability to detect a problem early enough to act. With off-line particle size measurement, problems can go undetected for hours, but with on-line methods such as laser diffraction, there is constant monitoring of the process and upsets can be detected as they occur.

Again, while with off-line particle size analysis requires the analyst to wait until several samples have been taken and analysed before they can see the outcomes of their changes. With an online particle size analyser, however, this process is much quicker. Assessing new operating scenarios requires nothing more than a new steady state to be established, meaning the changes can be evaluated in minutes.

Smart. Accurate. Reliable. Boost productivity. Increase yield. Scan this QR code to visit the RTI website and download an AllScan® brochure

The AllScan® n-Gen elemental analyser is your high-speed ore sorting solution. AllScan gives you full control over stockpile grade, increasing production and yield and delivering higher grade, cleaner outputs.

The Global Battery Alliance (“GBA”), a multi-stakeholder organisation to establish a sustainable battery value chain, today launched its Human Rights Index and Child Labour Index for the Battery Passport, ahead of Human Rights Day on 10th December. The indices are the world’s first frameworks to measure and score the efforts of any company or product specific to the battery value chain towards supporting the elimination of child labour and respecting human rights.

The indices were developed by the GBA’s Human Rights and Child Labour working group, led by Levin Sources and including Tesla, UNICEF, Volkswagen, Eurasian Resources Group, Responsible Mica Initiative, and the Cobalt Institute, among other members.

Child labour and human rights violations are a critical and growing issue in the battery supply chain, particularly as demand for batteries continues to increase to achieve the green transition. To address this, the GBA’s indices will incorporate and go beyond existing international standards and frameworks, including guidance from the United Nations, OECD, International Labour Organization and UNICEF. They will enable all reporting companies to more comprehensively assess their performance and that of their products according to more than 100 indicators across their operations, business relationships, and supply chains. To reduce the burden for reporting entities, the indicators include indicative standard equivalency assessments for commonly used responsible mining and sourcing standards.

Alongside the recently published Greenhouse Gas Rulebook to calculate the battery carbon footprint, the Human Rights Index and Child Labour Index will serve as key performance indicators for the GBA’s Battery Passport – a transparency framework integrating technical data, with provenance data and sustainability performance at the product level of the individual battery. In the long term, the GBA will issue a battery quality seal based on data benchmarking to provide consumers with trusted data on a battery’s characteristics, provenance