JANUARY / FEBRUARY 2025

CCS MCLAYS

MEETING CONSUMER EXPECTATIONS FOR TAMPER-EVIDENT FAST-FOOD PACKAGING

BCH ROCHDALE SUCCESS AT HOME AND AWAY MEANS A GREAT YEAR IN STORE FOR BCH

ALS LABORATORIES EVOLUTION NOT REVOLUTION: A NEW ERA BECKONS AT ALS

JANUARY / FEBRUARY 2025

MEETING CONSUMER EXPECTATIONS FOR TAMPER-EVIDENT FAST-FOOD PACKAGING

BCH ROCHDALE SUCCESS AT HOME AND AWAY MEANS A GREAT YEAR IN STORE FOR BCH

ALS LABORATORIES EVOLUTION NOT REVOLUTION: A NEW ERA BECKONS AT ALS

PUBLISHER

Planet Media & Design Ltd

Brooke’s Mill, Huddersfield HD4 7NR

MANAGING DIRECTOR

Jillian Evans

NATIONAL SALES MANAGER

Shazia Hussain

CHIEF EDITOR

David Barnett

SUB-EDITOR

Abigail Wears

CONTACT US:

FACEBOOK @food&drinkmagazine

INSTAGRAM @foodanddrinknews

TWITTER @food_drink_news

CONTRIBUTE info@planet-media.co.uk

ADVERTISING advertising@planet-media.co.uk

EDITORIAL editorial@planet-media.co.uk

MAG SUBSCRIPTIONS subscriptions@planet-media.co.uk

With the start of 2025, we have all been hoping for some good news that will perhaps mean a little more stability for the food and drink sector.

After many years of Covid, spiralling costs, fuel and energy price peaks, conflict across the world affecting prices, it seems there has been something new to weather every couple of months.

For those expecting a calm start to the new year, perhaps that has not quite been the case. The inauguration of Donald Trump as President of the US has created ripples that extend far beyond America’s shores, especially with the recent plans to impose trade tariffs on countries with which the US does business.

However it all pans out, two things are certain: firstly, that nothing can ever be taken for granted and nobody can predict what the next challenges coming over the horizon are.

But the second point is perhaps more important: time and time again the food and drink industry has proved itself capable of rising to meet these challenges, and will continue to do so.

David Barnett

CHIEF EDITOR

Speciality coffee in the UAE is about to experience a revolution. Bluewater, the global innovator in water purification beverage enhancement, is set to debut its groundbreaking Bluewater Café Station at the World of Coffee Expo in Dubai. Following its spectacular UK launch in December 2024–where it won widespread acclaim from speciality coffee shops–this state-ofthe-art brewing solution is now making its way to the Middle East’s coffee capital.

As Dubai enjoys a thriving café scene and a growing appreciation for precision-brewed coffee, Bluewater is proud to welcome visitors to Zabeel Hall 5, Stand G6 at the Dubai World Trade Center, 10-12 February, where they can witness firsthand how the innovative Café Station system elevates barista craftsmanship with extraordinary consistency in every brew.

Recently recognised by The Caterer Magazine as a ‘Best Buy’ for speciality coffee shops in 2024, the Bluewater Cafe Station is redefining the bean-to-cup journey. As a key partner of World of Coffee Dubai, Bluewater is at the forefront of this transformation, delivering a solution that respects tradition while embracing modern innovation.

“The Bluewater Café Station allows baristas to super-power their craft like never before,” says Maximillian Lundin, Coffee Division Manager at Bluewater. “Our solution not only purifies water of all known contaminants, such as PFAS and other harmful chemicals, but also optimally enhances it using our exclusive Liquid Rock® mineral dosing system. This ensures that every cup brewed achieves its fullest

flavour potential, creating an unparalleled sensory experience for coffee lovers.”

At the core of the Café Station’s innovation is its precision water calibration technology, which tailors the mineral composition of water to match the unique profile of each coffee bean. By fine-tuning water chemistry with the help of Bluewater, baristas can unlock and amplify the intricate flavours and aromas of their speciality beans, ensuring a sublime and consistent brew every time. In a further major development for precision coffee brewing, Bluewater and its local UAE partner, NIA –the country’s leading distributor of innovative home appliances – have announced a groundbreaking collaboration with Roasttrip, the UAE distributor of Kees van der Westen espresso machines, who launched the brand in the GCC region many years ago. This partnership marks a significant leap in speciality coffee innovation and will debut the exquisite Spiritello Lever machine, which seamlessly integrates with the Bluewater Café Station.

Visitors at the World of Coffee expo can experience the Café Station’s cutting-edge capabilities firsthand at the Bluewater and

NIA Stand (Z5-G6) throughout the event.

“By infusing water with the perfect balance of minerals, Bluewater’s advanced purification technology enhances the depth, aroma and flavour profile of every cup of coffee, allowing the Spiritello to deliver an unparalleled coffee experience,” says NIA CEO Kamran Khan. “Through the synergy of Roasttrip’s world-class espresso machine craftsmanship and dedication to perfection combined with Bluewater’s pure, mineralenriched water, we are redefining coffee –one perfect cup at a time.”

Don’t miss the opportunity to witness the future of speciality coffee brewing in action.

AUDI AG’s new Vehicle Safety Centre began operations in 2023. With a gross floor area of 33,000 square metres, the new building is located on the new ‘incampus’ premises in Ingolstadt. The heart of the huge building is the Crash Arena, an area spanning over 50 x 50 metres without a single column for support. In order to protect the huge hall from unwanted visitors, it is secured with 22 high-speed doors from EFAFLEX, both at the entrances and in the interior.

“Both within the building and outside it, we have to ensure the security of our prototypes, which is why it is imperative that the doors are intruder-proof and have fast opening and closing speeds”, explains Carina Müller, trained architect and employee in the Physical Infrastructure department at AUDI AG. She has played a leading role in the project, supporting the Vehicle Safety Centre from the planning stage through to realisation and completion. As to her requirements for the EFAFLEX doors, she has already given some of her reasons. For the doors on the outside of the building, they were delivered in the RAL tone of the building envelope, making them fit almost invisibly into the overall look of the large cube.

All doors were designed especially for the project and contain between three and four special features which are not standard. The EFA-SST® Premium variants L, S and ÜS also have excellent thermal insulation between 0.66 and 1.52 W/qmK, depending on the door size. “ We wanted to reduce our primary energy consumption by 10 percent by insulating our building envelopes, so the doors also needed to have a high insulation value”, explains Carina Müller. “In addition, global vehicle testing standards stipulate that tests should generally be carried out between 21 and 23 degrees Celsius. Both the vehicles and the dummies are pre-tempered and pre-configured for the tests in climate chambers. If the room temperature or the ‘ body ’ temperature of the dummies were incorrect, the test would be declared invalid.” And because of the hall’s state-of-the-art equipment, this would incur unnecessary costs: A mobile crash block made of 90 tons of concrete can be placed at various points on the test tracks. The crash arena is crossed by several crash lanes, the longest of which measures 240 metres and allows tests at speeds of up to 120 kilometres per hour. There is also a new type of sled track, which is intended to make the development of belt systems and airbags even more efficient.

Cutting-edge mobile high-speed cameras combined with very bright LED lighting systems enable accurate analysis after the tests and support the developers in their work. A dummy laboratory, workshops, offices and component test benches are also located in the building.

The component test benches on the ground floor are additionally protected with EFAFLEX EFA-SST®-S Premium high-speed doors. The vehicles reach this area via a lift. In these chambers, the test objects are measured with millimetre accuracy. In order to bring these doors to the upper floors, along with a door for the building envelope, a heavy lorry crane was needed. The forklifts and lifting platforms were also brought to the upper floors in this way. A special assembly platform had to be built for this purpose, on which all parts and lifting equipment could be placed.

In the logistics area, where the prototypes are transported to the hall, there is a door lock. The two EFA-STT®-S doors are interlocked against each other. This guarantees that no one can see into the hall. Two other doors on the ground floor are included in the smoke extraction concept in the event of a fire. They serve as ventilation openings to let in fresh air. Because of the high security required for prototypes, the doors are additionally secured with a grate in case they need to be opened

EFAFLEX produces high-speed doors for industrial applications. The company, which was founded in 1974, works for clients from industry, trade, food production, and the chemical and pharmaceutical industries, among others. As the only manufacturer in the field of high-speed industrial doors, EFAFLEX is listed in the world market leader index and is therefore one of the top 461 companies in Germany, Austria and Switzerland. The family company employs more than 1,200 people worldwide. With its headquarters in Bruckberg, Bavaria, EFAFLEX is firmly anchored as the largest employer in the region. In addition, the company opens up international markets with 10 subsidiaries on five continents. EFAFLEX generates over 40% of sales abroad.

EFAFLEX Press Contact:

Ms Jasmin Jobst

Tel.: +49 8765 82-525

E-mail: Jasmin.Jobst@efaflex.com Web: www.efaflex.com

Bluewater, a leader in sustainable water purification and beverage solutions, is thrilled to announce an exciting partnership with London’s premium Divertimenti Cookery School! This collaboration aims to raise awareness about the impact of using purified water in the kitchen, showcasing its vital role as a means of hydration and enhancing the quality of the food we prepare and consume.

“Water is often the unsung hero of the kitchen, yet it is absolutely essential to ensuring food is safe and clean to eat, bringing out the full flavour of vegetables, and safeguarding meats are tender and soft,” says Bengt Rittri, founder and CEO of Bluewater, a Swedish water brand with a global footprint. As part of the partnership, Bluewater has installed one of its premium water purification Kitchen Stations –designed for home, work and play – in the iconic Divertimenti cookery school located in London’s exclusive and vibrant Knightsbridge area.

Jules Kane, Cookery School Head (on right with Jo Pratt, Director of Food), comments that water is probably the most overlooked yet essential ingredient in any home or professional kitchen.

“At Divertimenti Cookery School we strive to create an environment where every detail contributes to excellence,” says Jules Kane. “Water is a foundational ingredient in both hydration and cooking, and by having Bluewater as a partner, we’re empowering our clients to better understand the importance of being able to access greattasting, contaminant-free water for

hydrating and food preparation.”

Since being founded in 2013, Bluewater has worked to deliver innovative solutions to consumers and businesses alike that transform municipal tap water into the purest and tastiest water on the planet, free of contaminants, from toxic chemicals and metals to viruses and bacteria. The brand’s products have been recognised with two Fast Company World Changing Ideas Awards, a Kitchen Innovations Award, and an Envisioneering Innovation and Design Award at Berlin’s international IFA trade show for consumer electronics and appliances.

In addition to purifying water using its state-of-the-art proprietary Superior Osmosis™ system, Bluewater has moved to a higher level in its transformation of water with the recent launch in its Kitchen Station of a groundbreaking mineralisation process that allows customers to add a mix of minerals meeting their taste preferences and wellbeing needs. Called Liquid Rock™, the proprietary Bluewater solution uses a unique dosing system to add a unique blend of liquified minerals harvested from Swedish mountain rock, delivering the perfect mix of minerals needed to provide a healthenhancing formula and superior taste.

The mineral solution is delivered via an IoT infuser system steered via a smartphone app that allows users to adjust the mix of minerals according to their taste preferences and wellbeing needs. It is also the world’s only mineral solution that doesn’t cause scaling, thereby avoiding the need to scrub saucepans after boiling eggs, for example.

The synergy between Bluewater’s advanced purification technology and Divertimenti’s renowned culinary expertise promises to create a more immersive and transformative cooking experience.

“This partnership is a perfect blend of innovative technology and culinary passion,” says Jules Kane “Using high-quality purified water that has been remineralised truly makes a difference, and by ensuring all of our clients have access to the great-tasting water in all of our classes we are adding to

our overall experience at the school.”

The collaboration will include engaging Bluewater workshops and cooking classes at Divertimenti, where participants will learn firsthand about the practical benefits of cooking with purified water. It also represents a long-term vision for both Bluewater and Divertimenti to foster a culture of better cooking practices and raise awareness about the importance of water quality in the culinary arts.

Bengt Rittri adds: “We want to educate emerging chefs and home-based foodies about how water quality can significantly enhance the taste, texture and overall enjoyment of food. Together with our partners at Divertimenti, we’re looking to take people on an exciting journey to rediscover the role of purified water and experience the magic it can bring to culinary adventures!” Rittri said.

For more information, please contact:

Divertimenti Cookery School, Jules Kane, Head of the Cookery School

(E) jules@divertimenti.co.uk (T) 0777 3344473

https://www.divertimenti.co.uk/ pages/about-the-cookery-school

New research from Nespresso Professional reveals that sustainability is a critical factor for UK business leaders when choosing coffee suppliers. Despite economic challenges, businesses are increasingly prioritising eco-friendly practices alongside taste and cost.

Of the 2,000 business leaders surveyed, 54% identified environmental sustainability as a key consideration when purchasing coffee, alongside 90% citing taste and 62% cost. In Greater London, respondents were more likely to prioritise sustainability over cost.

The younger generation is leading this shift, with nearly 9 out of 10 Gen Z business owners and decision-makers preferring coffee brands that actively promote sustainability, compared to 7 in 10 overall. Almost 90% of respondents across all age groups said they are willing to adapt their purchasing habits to safeguard the future of coffee, with only 7% unwilling to consider

more sustainable options.

This concern is well-founded. Currently, 60% of wild coffee species are endangered, and half of the land used to grow coffee today may become unviable by 2050 due to climate change. To address these challenges, Nespresso has prioritised sustainability through its AAA Sustainable Quality™ Program, launched in 2003 in partnership with Rainforest Alliance. The initiative improves harvest quality while protecting the environment and supporting farming

communities.

Sustainability in packaging also matters to businesses, with over 90% of leaders recycling their coffee packaging at least sometimes and nearly half seeking easily recyclable options. Certifications such as BCorp, Fairtrade and Organic are essential for 80% of respondents, particularly in larger companies.

Nick Stevens, Commercial Director B2B at Nespresso Professional, commented: “This research highlights how businesses are embracing sustainability in response to consumer and societal expectations. At Nespresso Professional, we are committed to delivering premium coffee solutions that meet these priorities across workplaces and hospitality venues.”

Nespresso Professional supports these efforts with a free recycling programme for aluminium capsules, ensuring they are repurposed, while coffee grounds are transformed into compost or energy.

New Forest-based 820 Spirits has announced the latest addition to its range of award-winning spirits, ‘Drop of Gin’, a low alcohol gin distillate. Available in a 50ml bottle with a pipette, all you need to do to make a fantastic drink is add two full pipettes of the drop into a glass with a tonic of your choice, which leaves you with a drink that is 0.3%, but still full flavoured. With this small bottle, you will get 34 servings, and once opened, the gin doesn’t go off and doesn’t need to be refrigerated.

Tom Simpson, co-founder and Chief Distiller at 820 Spirits, says: “Sometimes, we all crave the taste of a G&T without the alcohol-whether at a working lunch, as the designated driver, or simply when you want something refreshing but low or no alcohol. At 820 Spirits, we’ve crafted the perfect solution to meet your needs in these moments. A lot of low alcohol products are actually full of chemicals and citric acids, but our low alcohol gin is made in the same way as we make all of our products – all

natural ingredients locally grown in the New Forest where our distillery and gin school are based.

“The low alcohol gin has an initial warmth of juniper expanded with the sweetness of hibiscus and liquorice, and accompanying citrus notes provide a zest to harmonise the eight other botanicals. We have used our in-house process to make the Drop of Gin low alcohol gin so there are no nasties added.”

Perfect for Dry January, a bottle of Drop of Gin is priced at £30 and available now from https://820spirits.com/product/non-alcgin/.

This time last year, research from Alcohol Change UK, the charity behind Dry January® revealed that among UK adults (excluding non-drinkers), 30% of men and 26% of women would like to reduce the amount of alcohol they drink in 2024. In 2024, it is estimated that one in six UK adults (16%) took a break from alcohol in January. This is estimated at 8.5 million people.

In a competitive marketplace, packaging has to efficiently protect food, while attracting customers, but there is an increasing focus on its sustainability credentials. Many claims are made, but Greiner Packaging UK & Ireland asks: “How do you know the CO2e impact of your plastic packaging?”, and goes on to question how you can properly know what percentage of post-consumer waste a pack contains, will it be liable for the UK plastic packaging tax and does it have EU food approval?

“We are convinced that sustainable economic success can only be achieved with innovative strength and ecological and social responsibility,” says Sustainability and Innovation Manager, Rachel Sheldon. “For the last few years, we have been working hard and investing heavily to ensure we are manufacturing the most sustainable packaging solutions, and providing the relevant third-party certifications to back up every claim that we make.”

How do you know the CO2e impact of your plastic packaging?

“Calculating the ‘carbon footprint’ of packaging has become increasingly important, and wherever possible, we have been determined to be able to prove what we have achieved, product by product,” says Rachel Sheldon.

“I am excited to announce that we can now provide Sustainability Passports for most of our plastic packaging products, calculating the cradle to gate CO2e values. The calculation method and underlying model have been reviewed and validated by TÜV Austria and are compliant with ISO14067:2018.”

How do you know the percentage of post-consumer waste in your PET packaging?

“All of our PET packaging is certified for its percentage of post-consumer waste, by Sustainable Certifications Group (SCG), and is compliant with the Sustainably Sourced Certification Scheme.”

SCG’s Sustainability Director, Andy Whyle, said: “SCG’s certification independently

verifies that Greiner’s products are manufactured with 30% or more recycled PET, providing proof of exemption from the UK’s Plastic Packaging Tax. We are collaborating with Greiner and OPRL to promote validated recycled content, facilitating compliance for supply chain actors and helping them avoid HMRC prosecution, whilst accounting for the carbon saved in the recycling process.”

How do you know if your packaging has EU food approval?

“Two years ago, with a UK first – the European Food Safety Authority approved the decontamination process used at our factory in Dungannon, Northern Ireland, to recycle post‐consumer PET into food contact materials, and we are now compliant with EU Regulation 2022/1616,” says Rachel.

“We have also recently invested in the latest flatbed technology to expand our capabilities into the EU food approved rPET tray market.”

“As a business, Greiner Packaging takes a collective industry position and wherever possible, leads through example. We are members of RECOUP, the official RecyClass auditor for rigid plastic packaging in the UK, and we were one of the founding members of the UK Plastics Pact,” Rachel concludes.

“Since Greiner Packaging first introduced its K3® cardboard-plastic innovation in 2007, there has been continuous investment at our UK manufacturing facility. But, alongside investing to create new packaging solutions, there has been a constant focus on improving our environmental sustainability performance and pursuing our goal to achieve a circular economy.”

Greiner Packaging UK & Ireland can now provide Sustainability Passports for most of its plastic packaging products, calculating the cradle to gate CO2e values.

When it comes to what is hidden underground, the BauGrund Süd Gesellschaft für Geothermie GmbH in Bad Wurzach is a sought-after partner. The company offers key technologies in the areas of geothermal energy, ground surveying and water extraction, as well as precision locating technology for the ordnance disposal service. Alongside 300 excellently trained employees, including more than 30 geologists, the latest drilling rigs and technical equipment are used to implement customer orders. Recently, around 30 million euros were also invested in new buildings on company premises. Well-insulated doors from EFAFLEX provide reliable outer seals for the new buildings and keep the heat inside, especially during the cold season.

In the maintenance and service hall, two sturdy punches extend upward from the floor, allowing heavy drilling equipment to be lifted for inspections and repairs. An oversized lifting platform for large vehicles complements the equipment in the hall. Eight EFA-SST-L Basic highspeed doors are installed in the entrances and exits. Because it ’s not just their customers who they keep warm in the winter: their own buildings are also constructed in accordance with the latest specifications.

“That ’s why it was very important to us that the doors are well insulated, because we build using the KfW 50 to KfW 40 standard here, in a very high energy efficiency class for buildings”, explains Georg Beck, quantity surveyor at BauGrund Süd.

As the world’s first manufacturer of industrial doors, EFAFLEX offers thermally separated EFATHERM® insulation laths for the EFA-SST® as standard. Depending on the door size, this allows outstanding thermal insulation values of between 0.66 and 1.52 W/m² K to be achieved. The door leaf for industrial doors is exceptionally robust, durable, airtight and sound-absorbing. The spiral body of the doors is designed to guide the laths of the door leaf entirely without contact, and therefore without wear, and with optimal noise reduction. EFA-SST® can effortlessly perform up to 200,000 opening cycles per year under the most severe industrial conditions.

In addition, the doors are each provided with five double-walled, thermally separated aluminium screen laths. “This increases traffic safety at the doors and brings more daylight into the hall”, explains Georg Beck.

The impermeability of all doors is ensured by low-wear vertical door leaf seals made of plastic. The laths are insulated from one another by rubber lips. A horizontal, foldable profile is inserted between the lintel, door leaf and the door cases, which automatically presses against the door leaf when the door system is closed, thus preventing outside air from mixing with inside air.

The quantity surveyor emphasises the very good cooperation with the EFAFLEX field service and with the installation team. “ We overcame various planning and installation challenges together. EFAFLEX identified and resolved possible problems before work even began.” He points out two EFA-SST-S ECO high-speed doors, which are mounted with a low-header design despite the extensive height of the hall. “Here, for example, we have one of these special situations. During work preparation, we had crane tracks mounted parallel along the outer walls. A spiral body could not be realised due to space constraints. The frames of the doors therefore had to be installed between the steel beams and the outer wall in a complicated manner, allowing the door to be moved over the crane track under the hall ceiling for opening.” EFAFLEX and BauGrund Süd have worked very closely together on all projects. “ The coordination was perfect because we had the same goal in mind.”

EFAFLEX produces high-speed doors for industrial applications. The company, which was founded in 1974, works for clients from industry, trade, food production, and the chemical and pharmaceutical industries, among others. As the only manufacturer in the field of high-speed industrial doors, EFAFLEX is listed in the world market leader index and is therefore one of the top 461 companies in Germany, Austria and Switzerland. The family company employs more than 1,200 people worldwide. With its headquarters in Bruckberg, Bavaria, EFAFLEX is firmly anchored as the largest employer in the region. In addition, the company opens up international markets with 10 subsidiaries on five continents. EFAFLEX generates over 40% of sales abroad.

EFAFLEX Press Contact: Ms Jasmin Jobst Tel.: +49 8765 82-525

E-mail: Jasmin.Jobst@efaflex.com Web: www.efaflex.com

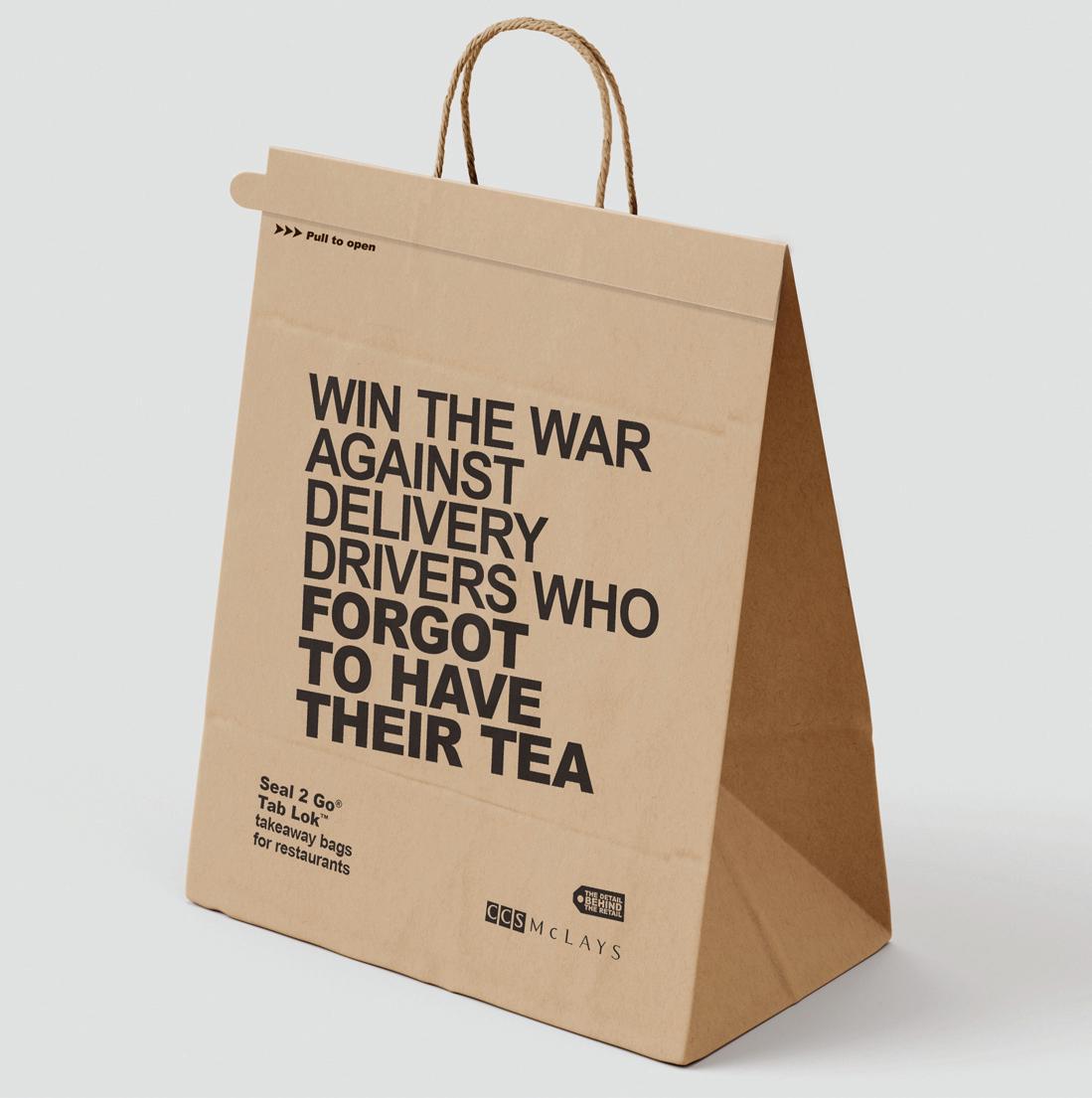

Since the pandemic, there’s been consistent demand for ordering food in, with popular apps such as Deliveroo, JustEat or Uber Eats becoming a part of everyday life.

It’s a rapidly expanding industry, with the projected revenue of the UK online food delivery market expected to reach US$63.75bn by 2029 from US$44.76bn in 2024.

In the digital age, customer loyalty is everything and bad news travels fast. Customer experience has become a complex area for fast food brands, comprising not only ease of ordering and speed, but food quality and the last mile of food deliveries – the safe and secure arrival of the order – is critical. More than ever before, in a cost-of-living crisis, consumers expect the food they have paid for to arrive in good condition.

Although the pandemic provided food outlets an opportunity to satisfy customers with speed and convenience, since then in a more competitive market, UK consumers have higher expectations of their remote-based meal experiences. In fact, a recent CCS McLays survey conducted by YouGov revealed widespread dissatisfaction among Brits regarding the hygiene standards of food deliveries, with more than half (55%) expressing concern.

UK consumers are becoming increasingly unforgiving when it comes to poor food delivery experiences. They ’ ll often give food outlets just one chance – if they ’re dissatisfied, they ’ ll quickly switch to

a competitor. Food outlet leaders must get the essentials right for the entire customer journey – from browsing to delivery – to stay onside in a competitive market.

In particular, fast food delivery packaging has become a bone of contention, with one in 10 survey respondents believing a delivery driver may have tasted their food. The bottom line is that almost half of consumers surveyed (49%) are calling for tamperevident packaging that indicates when the meal package has been opened, to keep food safe and secure. This means that food outlet leaders will need to seriously reconsider their packaging provisions.

Across the other side of the world in California, regulations have been in place since 2021 that mandate tamper-evident packaging for all food deliveries. Law AB3336 requires Californian restaurants to keep food safe from tampering and spoiling. It specifically requires restaurant orders delivered by third parties to use packaging that is ‘tamper-evident’.

The tamper-evident packaging industry is predicted to grow to a market value of US$3.8bn in 2032, from US$1.76bn in 2022. With most Brits (86%) believing it is a food outlet s responsibility to protect their delivery food from being tampered with, it may only be a matter of time before new regulations are introduced in the UK.

The consequences of negative customer experiences on food outlet brands and their reputation are significant. According to the CCS McLays survey, almost half (44%) of Brits wouldn t re-order from the same provider after a negative experience. Only 14% of those aged 25-54 would give a food provider another chance, while among over 55s, only 6% are willing to return for one more try.

The power of digital technology also poses a serious risk; 66% say they would complain to the brand directly, 38% would warn friends and 17% would leave a negative review on social media.

The findings also reveal that 84% of UK adults would expect food outlets to use a product that guaranteed their food delivery wasn’t tampered with and arrived in good condition, if such a product was available.

Therefore, providing tamper-evident food delivery bags in the UK is likely to increase brand trust, both for

the food outlet and delivery partner. Packaging food orders in paper bags with a tamper-evident integrated system will offer visible security protection for all – the restaurant, driver and consumer.

Tamper-evident food delivery bags have been recently available in the UK. Featuring an integrated tamper-evident system, the bags come equipped with foldable adhesive closure tabs and tamper-proof score cuts, ensuring an added layer of security that protects food from unauthorised access. For instance, the Seal2Go bag, available from CCS McLays, includes a unique pull tab, requiring a deliberate action to tear it open, which not only reinforces the integrity of the contents but also provides reassurance to customers. Additionally, built-in vent holes allow for proper air circulation, helping to maintain the freshness and quality of the food during transit.

As we head into 2025, brands in the fiercely competitive UK fast food market are looking for innovative ways to stand out and capture greater market share. If making customers happy is their priority, they must assess all touchpoints in the customer journey to make that happen. Improving the final stage – the ‘ last mile’ of delivering orders – can leave a lasting impression that fosters loyalty and keeps customers coming back for more.

Ian Hall, CEO at CCS McLays

Anyone involved in packaging for the food and drink industry will be beating a path to Birmingham in February for the 2025 Packaging Innovations & Empack show.

Held over Wednesday and Thursday, 12 and 13 February, at the NEC Birmingham, the event is set to draw more than 7,000 attendees and hundreds of exhibitors.

The curated educational programme and extensive speaker lineup will tackle the hypothetical and strategic challenges and opportunities facing the supply chain, while exhibitors are coming through with actual solutions designed for the needs of the packaging industry.

For a number of exhibitors, prioritising the removal of unnecessary plastic and replacing it with sustainable alternatives is to be front and centre of their presence at Packaging Innovations & Empack 2025.

Each of these have been developed to deliver sustainable solutions without compromising the look, feel and performance of packaging products.

FiloPack and FiloServe are paperboard alternatives to single-use plastic and LDPE-coated boards for food delivery and foodservice, respectively.

Brought to market by EBB Board, both are food-grade paperboards that are certified PFAS-free and feature a barrier coating designed for water, oil and grease

resistance. FiloServe is designed specifically for foodservice applications like cartons for bakery, confectionery and frozen food, with Kit Values 8 and 11. FiloPack comes with Kit Value 16, making it suited for the serving and delivery of oily and greasy foods. Both FiloPack and FiloServe can be printed for enhanced branding opportunities, can be recycled and are compostable under industrial composting conditions.

Plastic-free shrink collars from Viscose similarly use fibre and wood pulp to replace polymers in a common packaging application. The collars are hand applied and self-shrink without the application of heat, making them suitable for the packaging and protection of temperature-sensitive products.

TerraMoulds are baking moulds produced using grass. Specifically, grass fibre collected from the mowing of golf courses. According to Ecopack, using 40% grass fibre in their construction lowers the product’s impact on the environment and promotes sustainable choices, while maintaining aesthetics and product quality.

Other exhibitors have fully embraced innovative new solutions to meet the challenges and needs of modern

packaging.

STARDIRECT is a proprietary no-label look technology developed by All4Labels. Special inline applicators or rotary applicator modules, developed with partners, provide high-quality labelling, meaning STARDIRECT can be used to decorate glass, plastic and aluminium containers.

By eliminating the use of printing substrates, STARDIRECT allows brand owners to convert their packaging into attractively designed solutions with a lower environmental impact.

Coming at the issue of waste in the label supply chain from another direction is Reflex Group, with its patented Stereo Labels solution. These are the first labels to be printed on both sides of the liner, so cutting liner waste by 50%, and also resulting in a significant reduction in water and electricity usage during liner manufacture.

Stereo Labels also have substantially more labels per reel than their single-sided equivalent, meaning lower transport and handling costs, reduced liner disposal costs and minimised storage requirements.

A commercial first on the market from Facer is a plastic-free blister pack. The all-paper pack remains a heat-seal solution that utilises the same packing processes and machinery of conventional blister packs whilst retaining the benefits of folding carton

packaging. One early adopter has used the solution to increase their market share by nearly 40%.

Flowers Hydration Pot has been developed by The Sherwood Group at the request of flower delivery service Bunches, to replace plastic pots used for flower hydration during delivery with a sustainable alternative.

The result of this project has been the creation of a cardboard pot made using the packaging company ’ s Puracoat solution developed for direct food contact applications. With Kit Value 12 and being recyclable and biodegradable, Puracoat provided the perfect solution for Bunches’ needs by ensuring structural integrity and leak prevention while championing environmental responsibility. Integration of the Puracoat sustainable barrier coating directly allowed the elimination of plastic pots, allowing Bunches to save 5.4 tonnes of plastic annually and setting a new standard for sustainable practices in the floral industry.

With these solutions and more already developed and ready for you to use, it s clear to see that the answer to tomorrow s packaging challenges are available today. At Packaging Innovations & Empack 2025, you can experience them all.

For more information go to packagingbirmingham.com

It’s a new era at ALS Laboratories as long-standing Sales and Marketing Director, Nigel Richards, retires after more than 15 years in the role.

Nigel will be handing over the reins to Angela Turner, who will handle sales and marketing for the food business side of ALS, which offers a comprehensive range of testing capabilities from its six UK laboratories in Carlisle, Chatteris, Rotherham, Shrewsbury, Sittingbourne and Trowbridge.

Before Nigel gets to grips with improving his golf game in his retirement, Food and Drink News caught up with him to talk about the achievements of the company in recent years.

Although this is going to be a period of change for ALS, I think the overall story is very much one of continuity,” says Nigel. “I’ve worked with Angela since 2010 and she s been closely involved with all our clients, so it s very much a case of evolution rather than revolution.”

Nigel said 2024 has been a year of real progress for ALS, with strong sales growth and a record Net Promoter Score (NPS). He says: “We can never forget that as a service provider our primary aim is to deliver good service. If you falter in this mission, it can have a direct impact on your sales as clients will vote with their feet. I’m pleased to say that we’ve finished the year on a high note, receiving ‘Highly Commended’ recognition at the annual Society of Food Hygiene and Technology awards that took place in November.

“One of those was in the ‘Company of the year for over 10 employees’ category; the other one coming in the trainer of the year ’ category where Keith Watkins, ALS Technical Specialist, achieved recognition. Keith has also decided to retire so there is a little bit of the

‘out with the old and in with the new ’ and a changing of the guard.

Nigel is keen to get the message across that the success of ALS is always down to teamwork. He outlines some of the key themes that have underpinned the company s growth and performance over the last year.

Nigel says: “Let’s start with some of the commercial decisions that we’ve taken because we have had to be very robust in some that we ve made over the past 18 months in order to protect the financial foundations of the business. “You can look back to 2020 and the postCovid period when many businesses were significantly impacted and then you remember the latter end of 2022 when inflation started to rise steeply. This trend continued into 2023 when it was accompanied by a 10% increase in the National Living Wage, so suddenly, you ve got a series of severe cost pressures that are undermining your business.

“In order to counter this impact, we had to review our pricing structure. Whilst we know that this is never welcomed by our clients we always try to engage with our clients and work with them to deliver mutually agreeable outcomes.

“The sales and client service teams work hard to listen to our clients and to work in a transparent and fair way which reflects our core values. One of the core values within our business is that of being honest and I think that is one of the things that clients appreciate most about ALS.

“With the National Living Wage and Employers

National Insurance set to rise in 2025 it is inevitable that we will have to embark on a further round of negotiations with clients but hopefully we can continue to work together and maintain our excellent relationships.”

‘Client-centricity ’ is an integral part of ALS’s philosophy and is reinforced by their dedicated Client Service Team based in Chatteris who are on hand to provide help and support whenever needed. Nigel says: “In an age of AI and automation we are proud to have a great team of real people behind the phones who genuinely care about helping our clients. Indeed, despite the challenges we experienced in 2023 we finished the latest financial year with our highest ever NPS score of 65% which is a great achievement. In addition, we regularly receive a steady stream of unsolicited praise from clients which helps to reassure us that we are on the right track.”

As well as the successes in customer relations and financial growth, ALS is also committed to building a greener business as well as an economically successful one.

Nigel says: “We are a global organisation and climate change is a company-wide risk for us, as it is for everyone. We are working hard to manage our exposure to those physical and transitional impacts in accordance with our risk management plan. “We are committed to achieving net zero carbon emissions by 2050 across Scope 1, 2 and 3, and to reducing our Scope 1 and 2 emissions by 78% by 2030.”

One of the ways in which ALS is working towards these targets is by installing solar panels on the roofs of some of their laboratories. This is already showing huge benefits as they have generated over 100 kWh of electricity at Shrewsbury and Rotherham, as well as contributing to a significant drop in emissions.

In addition, the company has been assessing the suitability of Hydro-treated Vegetable Oil (HVO) by testing it as fuel in some of their refrigerated sample collection vans. Nigel says, This is fuel which is compatible with, and manufacturer approved with several of our vehicles. It is made from renewable items, doesn’t contain any palm oil sources, is free from fossil fuels and reduces greenhouse gas net emissions by up to 90% compared to standard diesel.

“We have committed to take 24,000 litres over a sixmonth trial which will reduce our diesel consumption significantly. We have also purchased our own 10,000 litre tank to increase the use of this alternative fuel.”

What really makes ALS tick is people. Nigel says: “We are very much a people-focused business and in the last year we have launched further initiatives all designed to build a happier and more productive workforce. Staff retention is the key so we’ve been looking at some of the policies that have a bearing on home life. We recognise that times have changed now that there is a kind of drive towards flexible working,

the shape of a modern family has changed.

People have different pressures in their life and we re trying to be adaptive and flexible as a business by revising our policies to reflect these changes. “We’ve also spent the year rolling out some coaching sessions to those in new leadership roles as we are an organisation that always tries to cultivate its own leaders from within. “Our aim is to give staff the opportunity to build long and rewarding careers with the business and to encourage enterprise and aspiration.

“We’re also doing whatever we can to support staff affected by mental health issues in the workplace. We have partnered with Mental Health First Aid England and so far helped over 30 staff members become qualified as mental health first aiders so that they ’ re ready to give assistance to all our staff across the UK.” This team supports staff both inside and outside the workplace and organises social events, including hikes at the weekend and painting classes. “It builds a sense of community and enjoyment,” says Nigel. “The fact that we ve got so many individual initiatives that have just been started voluntarily by individuals that have a real genuine interest in people’s wellbeing is wonderful.”

Nigel adds that the company is committed to fostering an inclusive environment, creating a greater sense of belonging for all staff. They have got an employee-run network called ‘RISE’ which is sponsored by the company and seeks to promote gender equality across the organisation. Nigel says: “We’re very proud of our record of having a strong gender balance and have got many women in the business that occupy senior roles across many areas of the business.”

As well as creating the most inclusive workplace they

can, ALS has one eye on the workforce of the future. Nigel says: Since 2022 we ve collaborated with Anglia Ruskin University and supported their 1st year biomedical science and microbiology students in creating what we call a life brief as part of their introduction to science and business connectivity.

As part of their course we have two General Managers who have presented to students, connecting our purpose with their everyday lives in terms of food safety. It s about understanding what ALS does, what is our core purpose, why we exist and ultimately it is about providing food safety for individuals (consumers) and for organisations alike.

We have had approximately 100 students so far preparing an abstract on an emerging pathogen or virus including any potential novel methods for detection and the projects required extensive research skills on their part. They were then reviewed by ALS in partnership with the university lecturers which has helped to reinforce the bond between the world of work, the world of industry and the world of academia.

Ultimately the hope is that by having this collaboration it gives students a better insight into what we do as an organisation and it’s going to encourage more students to ultimately pursue a career in science.”

ALS has also partnered with the University of Chester and some of the students there have participated in 150-hour work-based learning programmes at the Shrewsbury lab, acquiring skills through a hands-on process.

ALS has always prided itself on being a one-stop shop of testing services and in the past year they have seen even further advances in this area. Nigel explains: Recent trends in terms of detection have increased sugar toxin-producing E.coli, or STEC, so in response to

WE ARE PROUD OF OUR ASSOCIATION WITH ALS GROUP. THEY HAVE SUCCESSFULLY TESTED OVER 75 MILLION FOOD SAMPLES IN THE PAST 25 YEARS USING OUR BAGS AND STRAWS.

this trend we’ve now got a specialist microbiology team based at Rotherham who have been developing methods to aid testing for this illness. Back in September we received UKAS accreditation for the most comprehensive STEC PCR testing in the market today, showcasing what is called Top 8 testing as a routine surveillance and in response to immediate issues with fast turnarounds. In conjunction with that our Head of Specialist Microbiology has been hosting a series of webinars for clients on the issue of STEC testing and to explain about the organism and how and why it should be tested for.”

By anyone’s standards, it’s been a busy year. Nigel has said that leaving it all behind will be very difficult, but he knows that he leaves his company in good hands.

He reflects: “I’ve worked in the food industry since 1986 and have been privileged and proud to be part of ALS for the last chapter of my career. For the last 15½ years I ve worked with some exceptional colleagues. I’m very pleased to be handing it over to Angela because she deserves this opportunity and has a great deal of experience. I m looking forward to watching the continued progress of ALS under Angela’s leadership and know that it is in safe hands.

“As one of the leaders in this industry, clients rely on ALS to provide testing with integrity and it is vital for us to continue to evolve as an organisation. We have worked hard to build a sustainable business that keeps pace with changing trends and is committed to investing in its staff and in its sites. In short, there is certainly much more to come from us in 2025!”

BCH, the Rochdale-based specialist in bespoke food and confectionery processing systems, is entering 2025 with a strong order book and a positive outlook. Recent high-profile international contracts, coupled with several deals nearing completion in the UK, have positioned the company for continued success.

We ve had a very good 2024, and we re very excited about 2025,” says Stuart Grogan, Operations Director at BCH. “The order book is looking extremely robust, which is a very good position to be in.

BCH provides a comprehensive range of solutions, from standalone machines to complete turnkey process lines for a large range of confectionery products, including 100% fruit products, caramels, syrups, jams and preserves. The company also provides advanced cooking, mixing and cooling technology for the production of chilled and frozen meals, sauces, dips, and sweet and savoury fillings.

The extensive range of skills, machinery and workshops, enable BCH to undertake bespoke and tailor-made equipment to be built within strict completion deadlines. A total in-house service is offered, which incorporates the most up-to-date modern process and control technology available.

Recent months have seen a significant increase in demand for BCH s equipment in the condiments, dips and dressings sector. “We have completed several large

projects in the last year, due to an increase in demand for our equipment in this sector. says Stuart.

2024 has been a year of significant international growth for BCH. Notable achievements include a major contract for airline catering with a leading international carrier in the Middle East and a high-spec system delivered to North America. The company has also secured projects in South Africa, Australia, New Zealand, Egypt, Scandinavia, Spain and Turkey.

In Asia, BCH has successfully completed a large-scale hospital food production facility in Hong Kong. The company is also actively expanding its presence in the Indian market, a significant growth area.

“While cost drivers are significant in India, many reputable manufacturers still prefer to invest in European equipment,” explains Stuart. “We are actively engaging with our agents in India and making concerted efforts to break into this market.”

This global expansion is driven by the move towards more convenience foods in these markets.

“Many of these countries are transitioning towards more convenient eating habits, says Stuart. While home-cooked meals are still prevalent, growing affluence means people have that free money to spend on convenience food. While chilled food distribution might be challenging in some regions, the demand for ready-to-eat products is on the rise.”

Concentrating on Europe, BCH will be exhibiting at Prosweets 2025 in Cologne, Germany, at the Koelnmesse, from 2 – 5 February 2025. You can visit the BCH team in Hall 10.1, Stand A38/B39, where the company will showcase its confectionery processing range, tailored for a wide range of confections including liquorice and caramel.

ProSweets attendees will have the opportunity to see BCH s DMS 6 – Six Colour and Six Flavour Dynamic Mixing System. This cutting-edge technology, seamlessly integrates with BCH’s latest extrusion equipment, and delivers superior product quality, improved energy efficiency and enhanced food safety standards.

Looking ahead to 2025, this could also be the year that BCH expands its site to accommodate the increased demand in its products. The company is going through the planning process to start construction on an extension of BCH s manufacturing facilities.

“This year marks our 190th anniversary,” says Stuart. “International business has always been at the heart of what we do. Our continued investment in marketing, trade show participation, and expanding our global agent network has been a key driver to our more recent success.”

The company currently employs 95 people and is on track to reach the 100-employee milestone.

“Reaching 100 employees is a significant milestone for us,” says Stuart. “We don’t want to just get there for the sake of it, but it seems we re heading in that direction.

BCH places a strong emphasis on retaining its skilled workforce and nurturing the next generation of talent.

The emphasis remains strongly on both staff retention and training the next-generation workforce.

“We typically hire three or four apprentices each year, ” explains Stuart. “This is particularly important to me, as I began my career here as an apprentice. Staff training is essential for our business to ensure we are at pace with the latest technological advancements. Given the diversity of our product portfolio, employee training can be extensive, requiring significant time and

investment. This further supports the importance of retaining staff.

The success of BCH is perhaps even more remarkable considering the recent challenges faced by the food and drink industry, including social, financial and global crises.

“The disruptions in the supply chain, caused by various factors, have prompted us to significantly enhance our in-house capabilities, stated Stuart Grogan last year. “This includes the installation of four new Computerised Numerical Control (CNC) machines – fully automated systems that allow us even more control over our manufacturing processes.

“The systems we have implemented provide us with a greater degree of protection, as we are doing more in-house, explains Stuart. By increasing our in-house production capabilities, we instil confidence in both ourselves and our clients regarding our ability to deliver our turnkey projects.”

It shows just how far BCH has come since becoming established in 1835 by three Victorian entrepreneurs: William Brierley, Luke Collier and Thomas Hartley. While the world has changed, and technology has advanced far beyond their imagination, the guiding principles of the companies they founded remain in place at BCH today.

With nearly two centuries of experience, BCH offers a comprehensive range of services.

Established in 2000, BCH’s Innovation Centre assists worldwide customers with meeting the many challenges faced in the fast-changing food and confectionery industries. The centre houses a range of

equipment for mixing, cooking, cooling, forming, enrobing, extruding and cutting technologies.

By investing in engineering technology, process knowledge, skilled engineers and food technologists, BCH have created a technical centre of food expertise.

BCH uses the latest PLC and SCADA software systems to deliver the best automated systems. Working in close conjunction with customers, BCH has developed the FlexiChef software for use with a wide range of their machinery. This software offers consistency and flexibility in your production needs.

BCH are experts in highly specialised fabrication, pressure vessels and pipework for food, confectionery, nuclear, pharmaceutical, aerospace and other allied industries.

BCH’s in-house design and project management team work closely with customers to ensure each machine meets specific requirements. From developing tailored process solutions aligned with specifications to overseeing the entire project from handover through to installation, ensuring the project is to specification, within budget and delivered promptly.

BCH is committed to providing customers with a world-class after-sales service. As part of the BCH service support, a range of replacement parts is offered for both new and existing plants and equipment. Service support packages are also provided to meet individual customer requirements. www.bchltd.com

Tel: 01706 852122

In many people’s minds, the Covid pandemic is now, thankfully, a distant memory. But the effects of the global situation, especially the lockdowns, have had long-term effects.

In fact, it s only now that many businesses in the food and drink sector are getting back on an even footing.

One of those is Woods Foodservice, based in Uxbridge, one of the country s leading wholesale catering food suppliers.

“As we get to the end of the financial year and look ahead to the start of the next one, we can say for the first time since the Covid lockdowns we are back where we should be in every single aspect of the business, financially, structurally and operationally,” says the company ’s Managing Director, Darren Labbett.

And now that they are in the right position, it s exciting times ahead for the company as it has lots of exciting plans with regards to our product ranges and services”

One thing the company was adamant it had to do during Covid was keep operating. It is, says Darren, a company built on service, and that reputation had to be maintained, even during an unprecedented international crisis.

Slimming down to an emergency staff of just 25, Woods Foodservice tried to maintain its service to its clients who were still operating, and also fill the gap left by other companies that closed down completely or, sadly, fell by the wayside as viable businesses.

Darren says: “We were firefighting during Covid, and had to pivot the business to other areas, such as direct delivery to homes. And that firefighting continued for long after the lockdowns.”

One perhaps unexpected effect that the company ’ s

dogged determination to keep operating through Covid had was that when the worst of it was over, the extra clients they had picked up wanted to stay with them.

Darren says: Our biggest challenge coming out of the lockdowns was that we had taken on a lot of customers from competitors who closed down completely or operated on a part-time basis, and after it was over they wanted to stay with us, so that was a challenge we had to cope with.

“Our business is built on very high levels of service, and it’s vital to us that we maintain that, so we had to ensure we could look after existing customers and the new customers who wanted to stay with us, whilst at the same time keeping the high standards we are famous for.”

Now that the firefighting phase is over, Woods Foodservice can start to look at the things they had planned to be doing over the past few years, but circumstances put on hold.

For obvious reasons, not a lot of innovation could happen over the past few years, but now we can really focus on developing new products and services, and focus on the commercial side of the business.”

Staffing levels are back up to 128 — more than 100 more than they were during the lockdowns — and there are plans to expand beyond the existing hubs of Manchester, Bristol and Birmingham to truly make the company a nationwide concern. They also have their eye on acquiring new businesses as part of the expansion plans ahead of the company.

As well as commercial considerations, Woods Foodservice is also pressing ahead with its sustainability

ambitions, having recently taken delivery of 12 electric trucks.

These state-of-the-art vans will feature bodies made from recycled materials and will be equipped with solar panels on the roof, reducing the energy required for electric charging.

Each vehicle will offer multi-temperature storage, including chilled, ambient and frozen compartments, enhancing delivery capabilities while minimising environmental impact.

By the end of the financial year 2025, the company plans to replace their entire Euro 6 fleet with electric vehicles, and seven lorries will be added to the fleet in the early part of the year.

One of the biggest innovations has been the development of new software and a new ordering system, based around an easy-to-use app.

The Woods Foodservice Mobile App is described as the ultimate tool for chefs and restaurants, designed to revolutionise how chefs and restaurant managers work. Whether venues are looking to streamline food ordering, discover premium ingredients or manage their account on the go, the app is packed with features to make foodservice operations more efficient and seamless.

It allows customers to browse the company ’s vast product catalogue, check real-time stock levels and place orders instantly from a mobile device. The app ensures customers never run out of essential kitchen supplies, while offering easy access to premium products from top suppliers, so they can keep your menu fresh and exciting.

For more than 40 years, Woods Foodservice has been at the top of their game and maintaining the highest quality service to their customers, which includes sourcing the perfect and freshest ingredients. Their vast network of trusted suppliers spans the globe, enabling them to source an unparalleled variety

of products. From local artisanal producers to international distributors, they have cultivated relationships with vendors who share their commitment to quality and sustainability.

They say: Quality is at the heart of everything we do at Woods Foodservice. We rigorously vet our suppliers to ensure that every product meets our high standards. Our team conducts thorough quality checks, from the initial selection process through to delivery, guaranteeing that you receive products that are fresh, safe and of the highest calibre.”

And sustainability and ethical sourcing is a big part of the current operation: We recognise the importance of sustainability and ethical practices in today ’s food industry. That’s why we prioritise sourcing from suppliers who adhere to environmentally friendly and socially responsible practices. By choosing Woods Foodservice, you are supporting a supply chain that values the wellbeing of our planet and its people.”

This really is exciting times for the company, says Darren. We have some huge plans for the future and it is great to finally be able to put them into action.”

www.woodsfoodservice.co.uk