NOVEMBER 2022 www.ForConstructionPros.com/Asphalt + CASE STUDY: PAVER PLACED STABILIZED FULL DEPTH RECLAMATION GET THE HIGHEST QUALITY RAP USAGE INDUSTRY EXCLUSIVE: Compare Over More Than Models 75

a well-trained

vital to maintaining

ciency

and its training

of

the sciences and

represent the iggest

in

involved in the

of

plants.

who attend these seminars

y ha ing the

attention of the est

Gencor’s state-of-the-art

uipment

a

in the

step-

GENCOR ADVANCED TRAINING SCHOOL 2023 BE PART OF THE GENCOR EXPERIENCE mpro ing o erall plant production and e ciency are all common concerns for plant owners and operators. Having

technical crew is

plant performance and e

encor

staff

concentration

knowledge and expertise

all

technologies

production

asphalt

Customers

enefit

support and focused

specialists

asphalt industry Using

control simulators and actual e

our experts ta e you

y-step through

comprehensi e intensi e concentrated hands-on training program providing the latest techniques on optimizing production e ciency 2023 DATES •Week 1: January 16 - 19 •Week 2: January 23 - 26 •Week 3: January 30 - February 2 •Week 4: February 6 - 9 REGISTRATION CLASS SIZE IS LIMITED ! o secure your seat please register efore o em er DETAILS etails can e found at www gencor com training or call us at - - ext 5201 N. Orange Blossom Trail Orlando Florida 32810

POSTMASTER:

SUBSCRIPTION

December, with an additional Buyer’s

201 N. Main Street, Fifth Floor, Fort Atkinson, Wisconsin 53538.

offices.

ASPHALT CONTRACTOR, PO Box 3605, Northbrook, Illinois 60065-3605.

only in the USA. The Publisher reserves the

individuals: U.S. $45.00, Canada & Mexico

U.S. bank).

(prepaid only)

4 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt TABLE OF CONTENTS | NOVEMBER 2022 Published and copyrighted 2022 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November,

Guide issue published in August by AC Business Media,

Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry

Please send change of address to

Printed in the U.S.A.

POLICY: Individual subscriptions are available without charge

right to reject nonqualifying subscribers. One-year subscription to nonqualifying

$65.00, and $95.00 all other countries (payable in U.S. funds, drawn on

Single copies available

$10.00 each (U.S., Canada & Mexico), $15.00 each (International). 201 N. Main Street, Fifth Floor Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com www.ForConstructionPros.com/Asphalt Published by AC Business Media. LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS WWW.FORCONSTRUCTIONPROS.COM/ASPHALT CONTRACTOR CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sphalt LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS WWW.FORCONSTRUCTIONPROS.COM/ASPHALT CONTRACTOR CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sphalt LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS WWW.FORCONSTRUCTIONPROS.COM/ASPHALT CONTRACTOR CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS ASPHALT CONTRACTOR LATEST INNOVATIONS FOR ASPHALT PROFESSIONALS A sphalt CONTRACTOR NOVEMBER 2022 Vol. 36, No. 9 TECHNOLOGY MATTERS 10 How Asphalt Simulation Technology Provides Powerful Insights Simulation is an engineering tool for virtually exploring and testing new ideas. By investigating new concepts virtually, engineers can test more ideas faster and at much less cost than physical prototyping. INDUSTRY EXCLUSIVE 16 Asphalt Paver Spec Guide We’ve compiled all the specs into one place so you can compare over 75 models of asphalt pavers, and find the best fit for your crews. PRODUCTION NOTES 24 Optimizing Your Process For Maximum RAP Usage Step-by-step ways to help any asphalt contractor or plant manager take their RAP percentages to the next level. JOBSITE INNOVATIONS 36 If You Build It, They Will Come How Superior Construction crews are taking a unique approach to a massive $135 million project, and creating more traffic volume for Nashville’s busy airport. Paver-Placed Stabilized Full Depth Reclamation indus helps the town of Dartmouth save nearly 10% by using innovative recycling method. | 40 COVER STORY IN EVERY ISSUE 8 Editor’s Perspective 50 Last Exit

The Blaw-Knox University, now in its 58th season, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and hands-on application courses.

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

Blaw-Knox provides improved technical and problemsolving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

Blaw-Knox offers multiple dates to satisfy the demand

popular courses.

BLAW-KNOX UNIVERSITY 2023

for its

5201 N. Orange Blossom Trail Orlando Florida 32810 2023 DATES • Week 1: January 16 - 19 • Week 2: January 23 - 26 • Week 3: January 30 - February 2 • Week 4: February 6 - 9 REGISTRATION CLASS SIZE IS LIMITED ! To secure your seat, please register before November 15, 2022 DETAILS Details can be found at www.blawknox.com/ training

10 Worst Roadways in America

Where does your state rank when it comes to the worst public roadway conditions? A study conducted by the Bureau of Transportation Statistics, utilizing several key metrics, revealed the top 10 worst states when it comes to roadway infrastructure.

Read more at: http://asphalt. com/x2aqms

Podcast: Investigating I-375 and The Legacy of Urban Renewal in Detroit

Millions of dollars in new funding are available

states

one of the most highly touted is the “Reconnecting

Read more at: http://asphalt.com/i7gpgw

What You Missed at Autodesk University

Wirtgen Group and BuildWitt Form New Partnership, Tackle Labor Issues

The steady trend of labor shortages shows no end in the near future. Shrinking

pools, high rates of

and under skilled labor continue to be issues for the entire industry. This new partnership vows to work together on innovative solutions.

Read more at: http://asphalt. com/tu4n9q

Read more at:

more at:

www.ForConstructionPros.com/Asphalt DIGITAL CONNECTION

labor

turn-over,

to

for infrastructure projects,

Communities” pilot program that seeks to undo transportation initiatives that negatively impacted neighborhoods.

Get social with us! Share pictures of what you’re working with over 29,000 other asphalt contractors on our Facebook page: Facebook.com/ Asphalt.Contractor/ 6 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

Autodesk announced new BIM capabilities for its Autodesk Construction Cloud and Tandem products and revealed broad new capabilities for Autodesk Build.

http://asphalt. com/gq2qua How Lightweight Aggregate Improves Asphalt Chip Seal Aggregates made from expanded shale, clay or slate (ESCS) enhance road safety not just when the pavement is placed, but throughout the life span of the product. Read

http://asphalt. com/w26j1n

BUILT TO CONNECT

Single-Source Supplier Advantage

Astec provides a significant advantage as a single-source supplier for the diverse products and services involved in building and maintaining an asphalt mixing plant. Astec liquid AC storage tanks, tank farms, and heating system controls feature high quality construction and unmatched efficiency. We offer a variety of sizes and configurations that can be fully customized. Optimize your asphalt storage tanks and hot oil heaters with the addition of the Recon® mobile monitoring system to receive status updates on a smart phone, tablet or PC.

Scan QR code to see Astec’s full line of Tank Farm Components.

Contributing

Diversifying Can Broaden Labor Pool

The ability to change and be flexible is as important to people and our ways of thinking, as it is to the construction materials utilized on a job site.

It is important that they be strong and durable, while also not so rigid that they crack under pressure. And the ongoing deficits in the labor pool are exactly that type of pressure.

Sometimes it isn’t always clear to see how to go about being more inclusive in hiring or recruitment practices. It might even seem like it won’t be a significant help, but consider the reality that African Americans are 12% of the nation's general workforce, but in construction it’s only half that: 6%.

That’s an indication there is healthy room for employment growth in that demographic. However, some labor statistics reveal potential barriers to entry, not only for African Americans, but for women and other minorities.

According to the U.S. Equal Employment Opportunity Commission (EEOC), 60-90,000 charges are filed annually in regards to the rites of workers belonging to these demographic groups. The past 20 years of records show a steady 32% average of all complaints fall into this category annually.

Recognizing these shortfalls, on May 17, 2022, the EEOC held a hearing on the subject of Mistreatment of Women and People of Color in Construction, and heard from several expert witnesses on the challenges faced by minorities and women who work in the traditionally white and male-dominated construction industry.

Janel Bailey, co-executive director of the Los Angeles Black Workers Center, said, “It isn't mysterious that the EEOC called for a hearing regarding the trades specifically. The current situation didn't fall from the sky. This is the result of exclusive policies that have shaped the cultures of the industries and their unions. The good news is that we can choose to move away from that legacy, and it must be in partnership with Black workers and other workers who have been left out.”

That’s the goal. Working together with the industry as-a-whole to grow our ranks. The pathway forward into the future isn’t to leave things as they are but to make more opportunities for everyone.

This approach takes specific aim at the gap in minority employment as a means to fill open positions. It’s not a one-size-fits-all solution, but it’s a good place to start.

Here is an non-comprehensive list of ways to improve diversity the job site:

• Recognize individual bias - Having and recognizing a personal bias is not a moral failing. It is a structural, systematic failing.

• Develop new company policy - Inclusive standards for hiring and promotion. Ask questions. Hear what your minority employees have to say.

• Assess diversity inventory - Survey of the demographics of your workforce and management teams.

• Eliminate racial wage gaps - On average, black workers make $.76 per dollar of their white counterparts. Resolving this may lead to increased retention and application.

• Inquire up/down the chain - Include minority owned suppliers, contractors, and other business partners.

Brandon Noel bnoel@acbusinessmedia.com

Jessica Lombardo jlombardo@acbusinessmedia.com

Gigi Wood gwood@acbusinessmedia.com

Charles Rathmann

Cindy Rusch crusch@acbusinessmedia.com

April Van Etten

Schwandt aschwandt@acbusinessmedia.com

Sean Dunphy sdunphy@acbusinessmedia.com

Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason Desarle

Brand Director, Construction Sean Dunphy VP, Audience Development Ronda Hughes VP, Operations & IT Nick Raether Content Director Marina Mayer GM, Online & Marketing Services Bethany Chambers Content Director, Marketing Services Jess Lombardo Director, Demand Generation & Education Jim Bagan Director, Enterprise Sales Kay Ross-Baker CIRCULATION & SUBSCRIPTIONS P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915

Fax: (847)-291-4816 circ.pavement@omeda.com

Tadashi Soma

8 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

One possible solution to worker shortages is to expand inclusion efforts

EDITOR’S PERSPECTIVE

Brandon Noel, Editor bNoel@ACBusinessMedia.com 234-600-8983 @ASPHALTCONTRACTOR @ASPHALTCONTRACTOR @ASPHALTCONTRCTR WWW.FORCONSTRUCTIONPROS.COM/ASPHALT Published by AC BUSINESS MEDIA 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com EDITORIAL Editor

Editor

Managing Editor

Technology Editor

crathmann@acbusinessmedia.com AUDIENCE Audience Development Manager Angela Franks PRODUCTION Senior Production Manger

Art Director

ADVERTISING/SALES Brand Director Amy

Brand Director ..............................................................

Sales Representative ...................................................

|

LIST RENTAL Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com REPRINT SERVICES

(800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com Published and copyrighted 2022 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher. @ASPHALT-CONTRACTOR-MAGAZINE

10106 SMITH ROAD, FORT WAYNE, IN 46809 (260) 672-3004 www.ALmix.com DESIGN, DETAILS, AND DURABILITY. VISIT BOOTH S6816 MARCH 14-18, 2023 | LAS VEGAS, NV Come meet our team and see our asphalt plant equipment first hand.

How Asphalt Simulation Technology Provides Powerful

Astec has been using simulation for decades to solve engineering problems, improve product quality and provide value to its customers.

“Astec’s pioneering use of simulation has contributed to our recognition as a technology leader, not just in our industry but more broadly in the simulation space,” explained Andrew Hobbs, PhD and Head of Simulation & Modeling for Astec.

“Simulation begins with a concept and then a computer assisted design (CAD) model. With a virtual representation of the concept, different simulations are then performed and the results analyzed. Based on the findings, changes to the concept or CAD may be introduced and the process looped through until the design is ready for physical testing.”

The process Hobbs describes is used in new product development (NPD), as well as towards continuous improvement of existing products and customer support.

“We can investigate everything from burner combustion, engine cooling, fans and air filtration using computational fluid dynamics (CFD), rock crushing, mixing, and drying using discrete element method (DEM) and ensure robust structural integrity using finite element analysis (FEA).” Hobbs said.

Here are some of the ways Hobbs and his team use simulation to help Astec bring value to their customers:

INSIGHTS 10 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt TECHNOLOGY MATTERS | BY BRIAN BAKER

Simulation is an engineering tool for virtually exploring and testing new ideas.

By investigating new concepts virtually, engineers can test more ideas faster and at much less cost than traditional prototyping

Computational fluid dynamics (CFD) combustion simulation of an Astec Power Flame burner

Provided by Astec Industries

Particle simulation of the Astec

Barrel

Provided by Astec Industries

particles

3. IMPROVED SUSTAINABILITY

4. GREATER INSIGHT AND UNDERSTANDING

The data from simulation gives a unique window inside equipment. Things that are usually impossible to observe in actual equipment can be “seen” in a new way. This technological advantage gives us a better understanding for how the equipment operates.

1. IMPROVED PRODUCT QUALITY

Quality at Astec is measured in reliability, safety, and robustness. Simulation is used to eliminate potential issues early in the design cycle.

“In a recent NPD project, we ran numerous unique simulations in the design phase and identified several potential failures,” Hobbs said. “By fixing those problems before any steel was cut or welded, we drastically reduced the overall development time as well as reduced the risk of customer downtime and costly rework or warranty repair.”

2. IMPROVED PRODUCT PERFORMANCE TO MAXIMIZE ROI

From crushing rocks to paving roads, Astec customers expect products that will help them run an efficient and successful business.

Simulation is used across Astec’s product line to maximize equipment throughput and improve performance all with an eye on the final product to make sure customers get the best results from the equipment they invest so much of their resources in.

Simulation aids sustainability in a number of ways. On the production end, thermal efficiency in Astec’s mixing equipment means less fuel consumed, less waste and lower emissions. This goes a long way towards the industry's goal of net-zero carbon emissions over the next few decades. But simulation also aids in improving the recycling and reuse of old material. Greater Reclaimed Asphalt Pavement (RAP) capacity in the company’s asphalt plants allows for more recycled asphalt, saving resources and reducing the environmental impact of road construction. Competition for road work projects is at an all-time high, and sometimes the RAP mix and usage is the factor that makes all the difference between getting a job and it going to a competitor.

“To increase RAP usage in a sustainable manner requires thermally efficient mixing equipment,” Hobbs said. “Simulation can help improve equipment design if models can capture the physics relevant to RAP heating at industrial scale. Astec has developed their modeling methods to improve RAP heating and mixing in our equipment.”

“Astec is on the cutting edge of leveraging technologies like AR and VR to gain greater understanding of our equipment functions,” Hobbs said. “This is a great tool for communicating the benefits of Astec technology to customers.”

5. ACCELERATED INNOVATION

Simulation allows for the in-depth investigation of more ideas at a much faster pace than physical prototyping possibly could. Instead of a handful of designs, simulation technologies can work through hundreds of different variations to indentify the optimum results or solutions at an incredibly efficient speed.

“Working on a computer to analyze hundreds of designs allows us to move more quickly to eliminate bad ideas,” said Hobbs. “We like to say, ‘fail early and fail often until you land on a product that works.’”

For more information visit http://asphalt. com/2wp4nr

Particle simulation of the Astec Shuttle Buggy SB-3000 filling a RP-175 paver with particles colored to show lateral mixing.

Provided by Astec Industries

12 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt TECHNOLOGY MATTERS

Double

showing

colored by velocity

• CrackPro® Melter / Applicators • CrackMaster® Sealants • CrackMaster® Mastic • CrackPro® Mastic Machine MASTIC MACHINES HOT POUR MATERIALS Your One-Stop Source for Hot Pour Crack Filling Equipment and Materials. Rental Programs | Zero Down Financing sealmaster.net | 800-395-7325 LOCATIONS NATIONWIDE HOT POUR CRACK FILLING SOLUTIONS. HEATED HOSE MACHINES

A Correction For Outdated Information

Asphalt Contractor regrets publishing details from an old report on density technology

In last month’s issue, we covered technology that can be used to measure asphalt density. We were made aware that some information in the article was from a report that was written several years ago.

As we know, technology in our industry changes rapidly and the information reported in the piece was outdated and therefore inaccurate with today's devices.

The report indicated that concerns were raised about the accuracy of non-nuclear density gauges,but that technology has greatly improved since then.

This table is a copy of the precision data from ASTM D2950 Standard Test Method for Density of Bituminous Concrete in Place by Nuclear Methods and ASTM D7113 Standard Test Method for Density of Bituminous Paving Mixtures in Place by the Electromagnetic Surface Contact Methods. It shows a better range of results in all categories from the non-nuclear gauge.

Both ASTM D7113 and AASHTO T343-12 have detailed and accepted practices for the calibration procedures for a non-nuclear density gauge.

The part of the article written on the non-nuclear density gauge does not make any attempt to highlight some fundamental advantages of this technology over the use of nuclear density gauges. The three used as illustrations are:

• PORATABILITY: a non-nuclear gauge is less than 1/3 the weight of a nuclear gauge making it much more portable.

• QUICK RESULTS: the non-nuclear method produces results in less than 3 seconds in comparison to a nuclear gauge in 60 seconds.

• VIRTUALLY NON DESCRUCTIVE: the non-nuclear density gauge is non-invasive so there for 100% non-destructive.

We apologize for the error as we commit to provide relevant and accurate information to the industry and our readers.

14 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

For an even

at http://www.

on the

needs

VÖGELE

tracked

the

the 8-ft. tracked

advanced technology pavers for North American highway and commercial markets. Now, a new app for smart phones, tablets and PCs helps users understand the intuitive and easy-to-use ErgoPlus 3 operating system via animations and step-by-step videos that provide an easy-to-grasp demonstration of work steps, including setting up the screed, varying pave widths,

1700-3i and wheeled Super 1703-3i, Vögele is marketing

comprehensive

functions. Download at Google Play or Apple store or search Voegele ErgoPlus 3 app.

16 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

With the 10-ft.

Super 2000-3i,

wheeled Super 2003-3i,

Super

four

and

automatic

www.ForConstructionPros.com/10075523 Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) Vögele Super 700i Tracked 74 14' 5" X 4' 7" X 6' 3" 14,330 6 3'7" 6'6" 98 fpm n/a 2.24 mph Vögele Super 1300-3i Tracked 100 16' 3" X 6' 1" X 9' 10" 23,480 11 5'9" 11'1" 98 fpm n/a 2.8 mph Vögele Super 1700-3i Tracked 173 18' 5" X 8' 6" X 9' 8" 40,345 14.3 8' 0" 15'6" 250 fpm n/a 7.5 mph Vögele Super 1703-3i Wheeled 173 19' 7" X 8' 6" X 9' 8" 38,140 14.3 8' 0" 15'6" 250 fpm n/a 12 mph Vögele Super 2000-3i Tracked 250 22' 6" X 9' 10" X 10' 2" 49,935 16.5 10' 0" 19'8" 250 fpm n/a 7.5 mph Vögele Super 2003-3i Wheeled 250 21' 4" X 9' 10" X 10' 2" 46,848 16.5 10' 0" 19'6" 250 fpm n/a 12 mph Vögele Super 2100-3i Tracked 250 22' 4" X 9' 8" X 10' 2" 50,930 15.5 10' 0" 19'6" 82 fpm n/a 2.8 mph Vögele Super 1800-3i SprayJet Tracked 173 20' 7" X 9' 8" X 10' 2" 50,510 14.5 10' 0'' 19'8" 79 fpm n/a 2.8 mph

With so many options available, purchasing a new piece of equipment that meets your needs is not an easy decision. Research is an important first step to help you decide exactly what you’ll want to rent or buy. If you’re in the market for an asphalt paver, these next few pages are your best resource. Here, we’ve compiled the industry’s only Asphalt Paver Spec Guide where you can compare more than 75 models.

easier way, visit the exclusive, interactive and customizable version of this spec guide

forconstructionpros.com/specguide/asphalt-paver to sort and rank models based

specific

and requirements of your crew.

www.ForConstructionPros.com/Asphalt NOVEMBER 2022 ASPHALT CONTRACTOR 17 BOMAG BOMAG is dedicated to asphalt and compaction. While other companies supply products for multiple segments; dirt work, mining, agriculture, BOMAG expertise is solely dedicated to your work and what’s important to you. You’ll be able to rest easy knowing that the support you get with BOMAG products is laser focused on what is most important to you. www.ForConstructionPros.com/10072222 Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) BOMAG BOMAG BF 200 C-2 Track 74 14' x 4' 3" x 7' 7" 13,228 5 3.6 ft 7.6 ft 95 ft/min n/a 3 mph BOMAG BOMAG BF 300 P-2 Wheel 75 16' 7" x 6' 2" x 9' 2.5" 19,400 10 5.6 ft 16.4 ft 425 ft/min n/a 10 mph BOMAG BOMAG BF 300 C-2 Track 75 16' 7" x 6' 2" x 9' 2.5" 19,400 10 5.6 ft 16.4 ft 66 ft/min n/a 3.2 mph BOMAG BOMAG CR 820T Track 160 20' 8" x 10' 10" x 9' 2" 36,400 10 8 ft20 ft 283 ft/min n/a 9.3 mph BOMAG BOMAG CR 820W Wheel 160 20' 8" x 10' 10" x 9' 11" 34,500 10 8 ft20 ft 427 ft/min n/a 10 mph BOMAG BOMAG CR 1030 T Track 225 20' 10" x 10' 10" x 9' 2" 42,600 14 10 ft 30 ft 246 ft/min n/a 9.8 mph BOMAG BOMAG CR 1030 W Wheel 260 22' 3" x 10' 10" x 9' 11" 38,280 16.7 10 ft 30 ft 313 ft/min n/a 12 mph BOMAG Cedarapdis CR652RX Wheel 260 19' 11" x 10' 4" x 9' 2" 44,100 16.7 10 ft 30 ft 426 ft/min n/a 11.2 mph BOMAG Cedarapdis CR662RM Track 260 19' 11" x 10' 4" x 9' 2" 44,100 16.7 10 ft 30 ft 225 ft/min n/a 9.6 mph Sponsored by For more information visit http://asphalt.com/2ecsre

DYNAPAC NORTH AMERICA

18 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

Whether on compact city streets or vast highway projects, Dynapac offers solutions to meet all of your paving needs. Dynapac pavers are designed with paving quality, innovation, ergonomics and innovative solutions in focus. Built with robust screed designs, top pre-compaction and solutions such as PaveManager, Truck Assist and BPO. www.ForConstructionPros.com/10072810 Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) Dynapac D25T High Speed Rubber Track 173 21 x 8.8 x 10.5 37,950 10 8 20 282 ft/min N/A 9 mph Dynapac D25W High Floatation Wheel Drive 173 21.16 x 9.1 x 9.9 35,750 10 8 20 426 ft/min N/A 10 mph Dynapac D30T High Speed Rubber Track 225 22 x 11 x 9.9 45,200 14 8 30 245 ft/min N/A 10 mph Dynapac D30W High Floatation Wheel Drive 225 23 x 10.8 x 9.9 41,700 16.510 30 305 ft/min N/A 10 mph Dynapac F1250CS Steel Track on Poly Pad 74 14 x 4 x 6 13,000 5.53.8 7.3 90 ft/min N/A 2.5 mph Dynapac F80W Wheel Drive 8 8 x 2.75 x 2 2,300 0.6 2.75 5.5 82 ft/min N/A 3 mph Dynapac FC1300C-II Steel Track on Poly Pad 25 9.75 x 8.5 x 5.75 9,700 68 13 115 ft/min N/A 3 mph Dynapac FC1400C-II Steel Track on Poly Pad 74 11.25 x 8.5 x 5.25 12,500 6.5 8 14 140 ft/min N/A 3 mph Dynapac FC1700C Steel Track on Poly Pad 120 13.75 x 8.5 x 6 18,500 9.5 8 15.5 140 ft/min N/A 3 mph Dynapac SD1800C Steel Track on Poly Pad 73 16.5 x 6 x 9.56 23,000 11.5 6 11.5 82 ft/min N/A 2.5 mph Dynapac SD2500C Steel Track on Poly Pad 173 20.16 x 8.2 x 10.16 40,785 13 8 19.5 N/A 92 ft/min 2.5 mph Dynapac SD2500CS Steel Track on Poly Pad 200 20.16 x 8.2 x 10.16 40,785 13.5 8 19.5 N/A 92 ft/min 2.5 mph Dynapac SD2550C Steel Track on Poly Pad 220 21.74 x 8.2 x 10.17 44,000 16 8 19.5 N/A 92 ft/min 2.5 mph Dynapac SD2550CS Steel Track on Poly Pad 264 21.74 x 8.2 x 10.17 44,000 16 8 19.5 N/A 92 ft/min 2.5 mph Sponsored by

A WIRTGEN GROUP COMPANY Bl vOGELE The Most Innovative Paver Technology! VOGELE SUPER 1700-3i / SUPER 1703-3i VOGELE SUPER 2000-3i / SUPER 2003-3i

ASTEC

Astec has recently rebranded its subsidiary brands to be connected as OneAstec. This rebrand offers a streamlined approach to purchasing highway and commercial pavers more conveniently in one place, with the same training and expert support. The legendary screed technology and design fit both highway and commercial pavers, allowing contractors to achieve greater uptime and exceptional mat quality from driveway projects to large commercial and municipal applications.

www.ForConstructionPros.com/10909995

Manufacturer

No.

Astec RP190e Rubber Tire Paver

Astec RP195e Rubber Track Paver

Astec RP170e Rubber Tire Paver

Astec RP175e Rubber Track Paver

Astec SP100e Rubber Tire Paver

Astec SP200e Rubber Track Paver

Tier 4F, Cummins ® QSB6.7 230 hp 172 kW) @ 1,900 rpm

Tier 4F, Cummins ® QSB6.7 230 hp 172 kW) @ 1,900 rpm

Tier 4F, Cummins ® QSB6.7 174 hp (130 kW) @ 2,200 rpm

Tier 4F, Cummins ® QSB6.7 174 hp (130 kW) @ 2,200 rpm

Tier 4F, Cummins®QSB6.7 173 hp (129 kW) @ 2,200 rpm

4F, Cummins®QSB6.7 230 hp (172kW) @ 1,900 rpm

17'7" x 10'6" x 10' 36,700 13.8 tons 10' 19'6" 0 - 284 fpm (86 m/min.) Not applicable 0 - 12 mph (19 k/hr.)

16'8" x 10'6" x 10'6" 39,220 13.8 tons 10' 19'6" 0 - 215 fpm (66 m/min.) Not applicable 0 - 7.5 mph (12 k/hr.)

16'3" x 10'1" x 10' 29,280 11.5 tons 8' 15'6" 0 - 300 fpm (91 m/min.) Not applicable 0 - 10 mph (16 k/hr.)

15'7" x 10'1" x 10' 32,500 10 tons 8' 15'6" 0 - 200 fpm (60 m/min.) Not applicable 0 - 7 mph (12.8 k/hr.)

16'10" x 11'4"

19'6" 0 - 143 fpm (43.59 m/min.) Not applicable 0 - 7.6 mph (12.23 k/hr.)

19'6" 0 - 168 fpm (51 m/min.) Not applicable 0 - 3.6 mph 5.8 k/hr.)

20 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt Sponsored by

Model

Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph)

x 10'7" 32,360 11 tons 10'

Tier

27' x 11'4" x 10'3" 63,800 11 tons 10'

Astec RP250e Rubber Tire Paver Tier 4F, Cummins®QSB6.7 250 hp (186kW) @ 1,900 rpm 23' 4"x 10'6 x 10'1" 39,500 15.8 tons 10' 19'6" 0-233 fpm (71 m/min) Not applicable 0 - 12 mph (19 k/hr.) Astec CP75 II Track Tier 4F, 74 hp 12'5" x 8'6" x 6'2" 16,950 8 tons 8' 15' 155 fpm Not applicable 255 fpm Astec CP85 Track Tier 4F, 74 hp 13'11" x 8'6" x 6'3" 19,500 8.5 tons 8' 15' 100 fpm Not applicable 200 fpm Astec CP100 II Track Tier 4F, 100 hp 14'6" x 8'6" x 6'8" 22,000 9.5 tons 8' 15' (17' w/ bolt-ons) 155 fpm Not applicable 255 fpm Astec CP130 Track Tier 4F, 130 hp 14'6" x 8'6" x 7'6" 22,500 9.5 tons 8' 15' (17' w/ bolt-ons) 155 fpm Not applicable 325 fpm

22 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt LEEBOY LeeBoy features a broad range of commercial class pavers to meet any contractor’s needs. All the models are simple to operate, maintain and service while offering top mat quality provided by the Legend Screed. www.ForConstructionPros.com/10075155 Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) LeeBoy 1000G Track Drive System 49 9' 6" x 8'6" x 7' 11,000 5.5 up to 13'0-220 fpm 0-220 fpm LeeBoy 5300 Track Drive System 64 15'5" x 4'5" x 7'8" 12,700 7 up to 7' 0-151 fpm 0-239 fpm LeeBoy 6150 Wheeled drive system 74 16'6" x 8'6" x 7'8" 17,550 7 up to 15'0-228 fpm 0-660 fpm LeeBoy7000C Track Drive System 64 11'0" x 8'6" x 7' 13,000 6 up to 13' 0-210 fpm 0-210 fpm LeeBoy 8500D Track Drive System 64 12'9" x 8'6" x 7'10" 15,800 7.5 up to 15' 0-140 fpm 0-240 fpm LeeBoy 8510E Track Drive System 74 13'5" x 8'6" x 8' 17,720 7.5 up to 15' 0-150 fpm 0-300 fpm LeeBoy 8515E Track Drive System 74 13'5" x 8'6" x 8' 17,600 7.5 up to 15' 0-150 fpm 0-300 fpm LeeBoy 8520B Track Drive System 106 14'5" x 8'6" x 8'2" 19,760 9 up to 15' 0-150 fpm 0-300 fpm LeeBoy 8530 Track Drive System 125 15' x 8'6" x 6'8" 22,520 9 up to 15'6" 0-150 fpm 0-300 fpm LeeBoy 8616D Track Drive System 127 16'4" x 8'6" x 6'8" 23,450 9 up to 15'6" 0-125 fpm 0-350 fpm Sponsored by

Record

Drum

Eco

dynapac.us | 800-651-0033 Designed to perform, Built to last Follow Dynapac North America Provide high-quality compaction in areas where vibration needs to be reduced with oscillation technology; bridge decks and joints, near foundations and concrete structures and better performance on thin asphalt layers. Industry’s best warranty for oscillation drum shell – 7 years / 7,500 hr pro-rated warranty Large water tank to prevent more stops for refilling Full seat rotation with electronic steering to improve comfort an ergonomics

shell is made of highly wear resistant Hardox® steel, ensuring many hours of trouble free running

Mode and automatic idling saves up to 15% fuel while lowering noise level Easy to change timing belt — only 2 working hours needed

number of passes, potion, temperature and compaction value in real time with Dyn@Lyzer

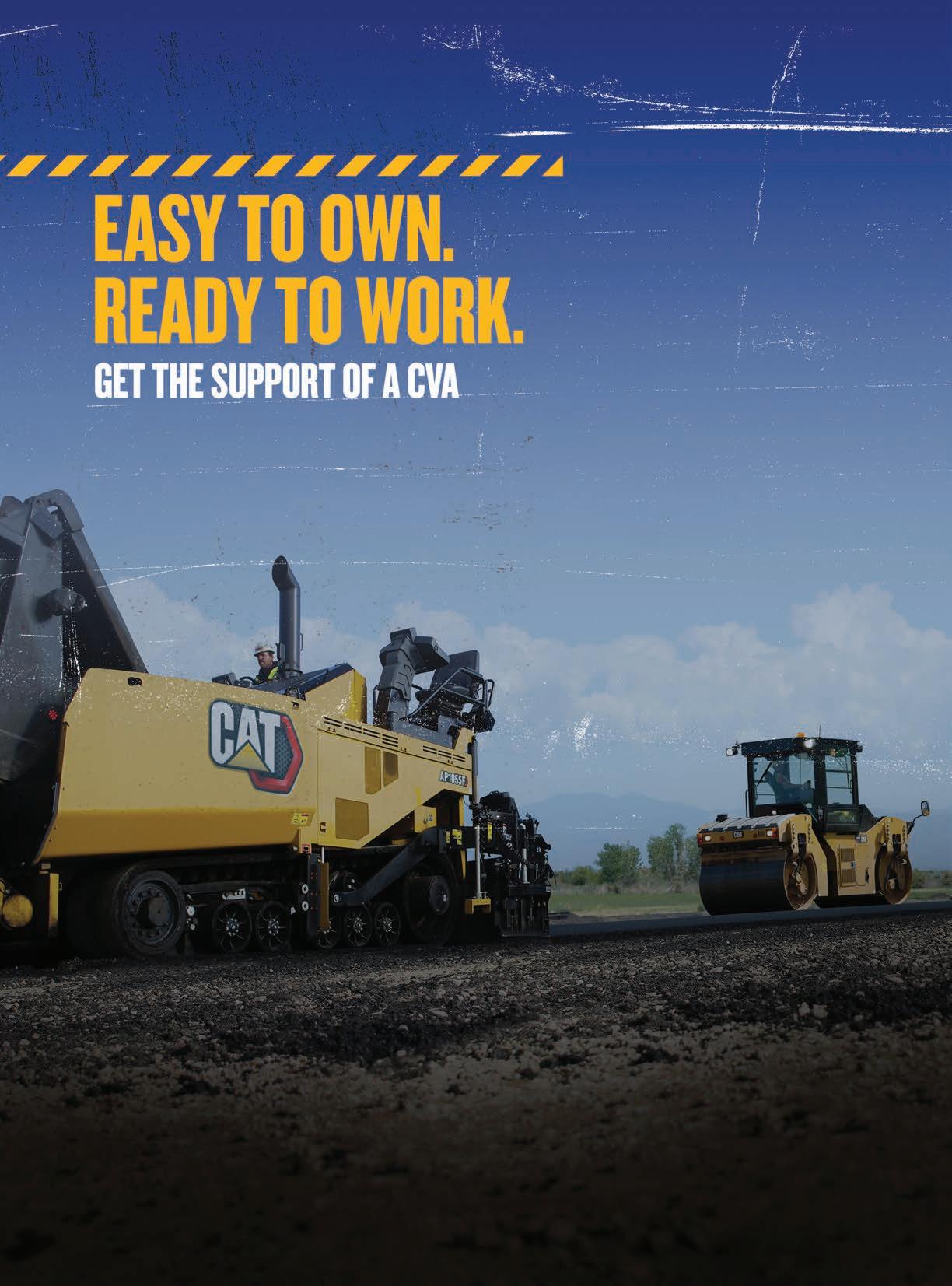

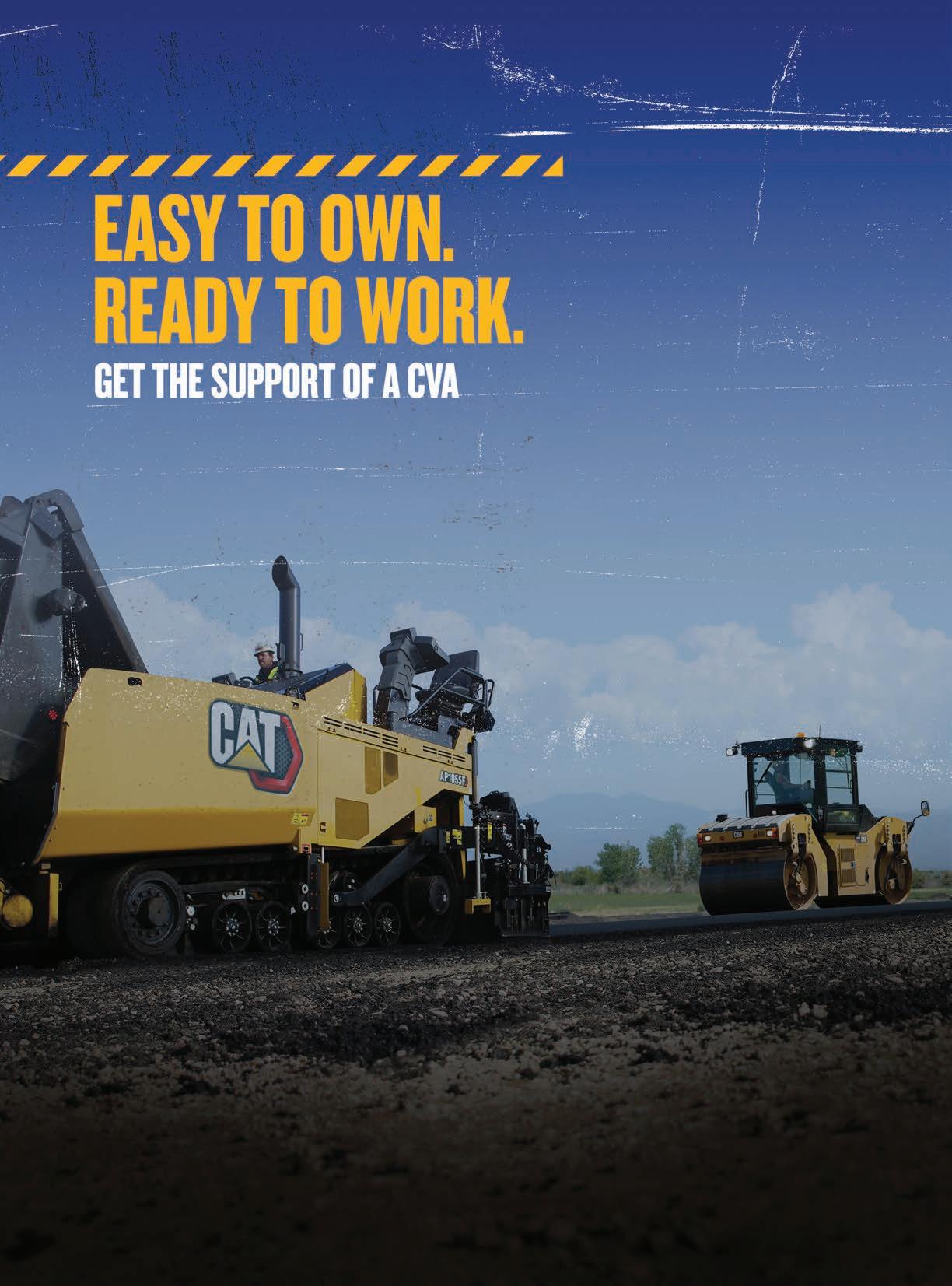

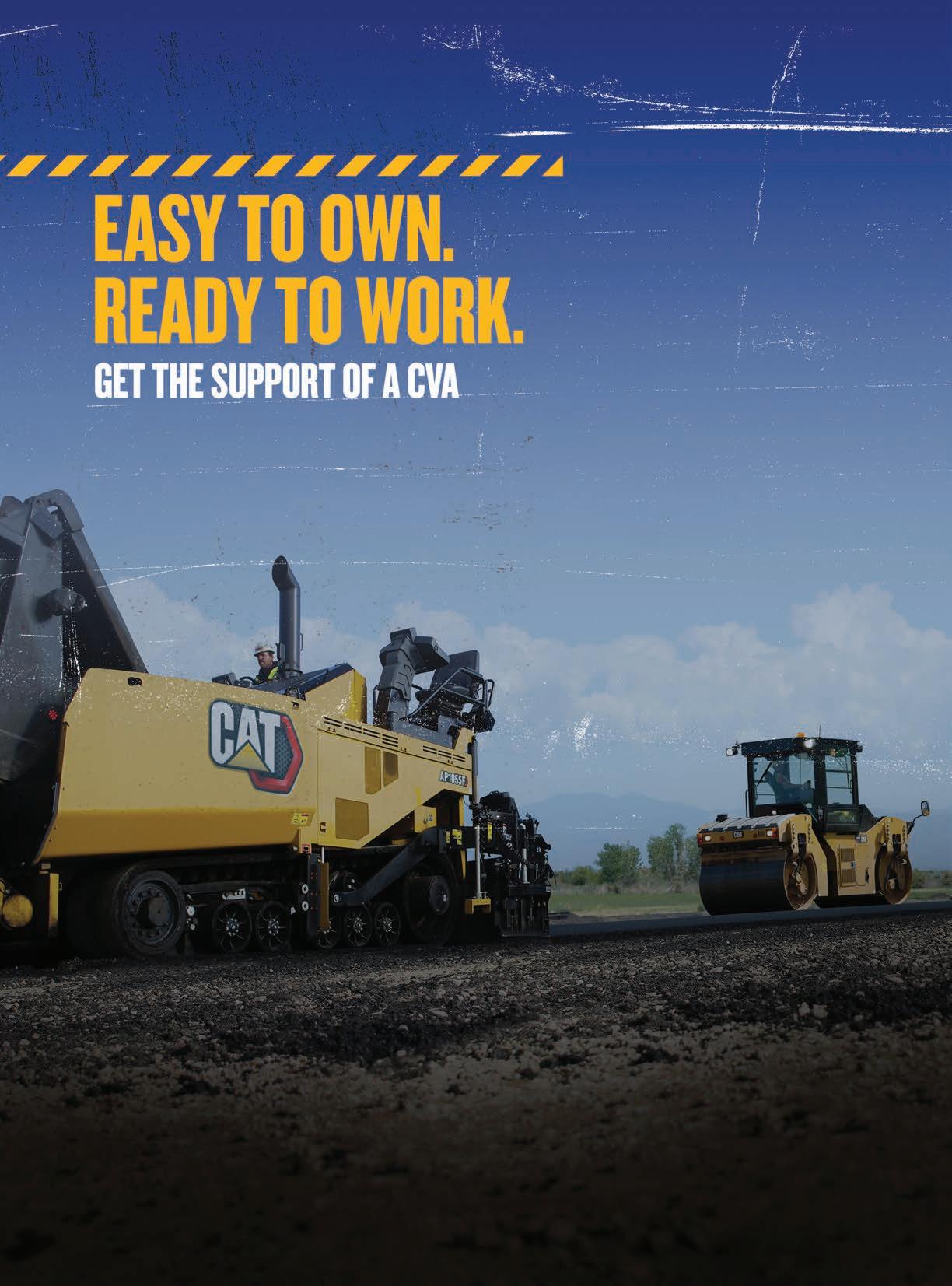

CATERPILLAR INC.

Whether paving pathways or interstates, meeting performance targets is the expectation of all contractors. With a complete line of paver/screed combinations, Caterpillar makes it easier for contractors to deliver on their promises. And with cleaner burning, more fuel-efficient engines, great parts and service support, application expertise, and outstanding training solutions, Cat dealers provide a one-stop-shop that helps paving contractors meet the needs of their customers.

www.ForConstructionPros.com/10075307

Cat AP300F Wheel 74.8 16.08'

Cat AP355F Track 74.8 16.08'

Cat AP400Wheel 120 18.1'

6.17'

6.17'

8.5'

Cat AP455 Track 120 18.1' x 8.5'

8.67' 18,078 9.75.75' 11.17' 200 fpm 82 fpm 10 mph

8.67' 19,246 9.75.75' 11.17' 210 fpm 82 fpm7 mph

8.6' 29,800 8' 19.5' 200 fpm 10 mph

8.3' 33,448 8' 15.5' 200 fpm 7 mph

Cat AP500 Wheel 148 18.5 x 8.5' x 8.6' 31,772 8' 19.5' 200 fpm 10 mph

Cat AP500F Wheel 142 20.33' x 9.08' x 9.58' 36,71515.9 8.33' 16.33' 250 fpm 82 fpm 10 mph

Cat AP555 Track 148 18.5 x 8.5' x 8.3' 33,448 8' 20.5' 200 fpm 7 mph

Cat AP555F Track 142 20.5' x 9.08' x 9.58' 38,125 15.9 8.33' 16.33' 210 fpm 82 fpm7 mph

Cat AP600 Wheel 173 20.9' x 9.8' x 9.9' 36,716 8' 20.5' 250 fpm 10 mph

Cat AP600F Wheel 173 22.08' x 9.08' x 9.83' 38,217 18.1 8.33' 16.33' 250 fpm 82 fpm 10 mph

Cat AP655 Track 173 20.9' x 9.8' x 9.7' 40,560 8' 20.5' 210 fpm 9 mph

Cat AP655F Track 173 22.08' x 9.08' x 9.58' 44,347 18.1 8.33' 16.33' 210 fpm 82 fpm9 mph

Cat AP1000 Wheel 225 20.9' x 11.9' 9.8' 42,620 10' 25.5' 250 fpm 12 mph

Cat AP1000F Wheel 225 22.08' x 10.5' x 9.83' 44,811 20.7 9.83' 19.5' 250 fpm 82 fpm 12 mph

Cat AP1055 Track 225 21.9' 9.8' x 9.7' 45,087 9.8' 25' 210 fpm 9 mph

Cat AP1055F Track 225 22' x 10.5' x 9.42' 47,544 20.7 9.83' 19.5' 210 fpm 82 fpm9 mph

BLAW KNOX

The new PF series of Blaw-Knox pavers marry proven technology with the latest in advanced design features. Simple controls and easy maitenance make the PF Series of Blaw-Knox pavers the ideal partner for veteran and next generation road crews alike. Available in 5 different models, with multiple screed options, the new PF series packs plenty of horsepower with Tier 4 final engines, that increase fuel efficiency and reduce emissions. With over a century of innovation to its credit, Blaw-Knox pavers have earned a reputation for quality, durability and performance unmatched in the industry. Today, with its new and improved highway-class designs, Blaw-Knox continues to deliver on its promise with all the performance features you’ve come to expect from an industry leader

24 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimen sions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Trav el Speed (mph)

x

x

x

x

X

x

x

www.ForConstructionPros.com/10073090 Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) 0-242 n/a 8.5 0-195 n/a 8.4 0-224 n/a 9 0-240 n/a 11 0-297 n/a 12 Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum 37,100 11 8' 18' 41,350 12 8' 18' 50,050 13 10' 26' 39,200 12 8' 18' 47,369 13 10' 26' Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Blaw-Knox PF-4410B Rubber Track 154 17'-10" x 9' x 8'-10" Blaw-Knox PF-5110B Rubber Track 173 21'-9" x 8'3" x 9'-11" Blaw-Knox PF-7110B Rubber Track 235 22'-6" x 10'-2" x 10' Blaw-Knox PF-5170B Wheeled 173 21'-9" x 8'3" x 9'-11" Blaw-Knox PF-7170B Wheeled 235 22'-6" x 10'-3" x 10'

www.ForConstructionPros.com/Asphalt NOVEMBER 2022 ASPHALT CONTRACTOR 25 Sponsored by WEILER Engineered and built to exceed the demands of commercial paving, Weiler pavers incorporate proven designs with new innovations to provide performance, reliability and outstanding mat quality. Weiler offers six pavers to meet contractor’s needs in a wide range of applications. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America. www.ForConstructionPros.com/10075409 Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) Weiler P395 Steel Track w/ Poly Pads 120 hp 15'4" x 8'6" x 8'4" 24,000 lb 11 ton 7'8" 17'4" 150 fpm 250 fpm Weiler P385C Steel Track w/ Poly Pads 120 hp 14'5" x 8'5" x 6'4" 22,000 lb 9 tons 8' 15'8" 150 fpm 350 fpm Weiler P285 Steel Track w/ Poly Pads 74 hp 13' x 8'2" x 6'4" 18,000 lb 9 tons 7'8" 15' 150 fpm 300 fpm Weiler P265 Steel Track w/ Poly Pads 74 hp 12'7" x 8'2" x 5'10" 16,200 lb 7 tons 7'8" 14'4" 150 fpm 250 fpm Weiler P195 Steel Track w/ Poly Pads 67 hp15' x 4'7" x 5'9" 13,000 lb 7 tons 3'10" 7' std (9' w/ bolt on ext) 233 fpm 350 fpm Weiler P65 Steel Track 49 hp9' 9" x 8'2" x 5' 10" 12,600 lb 6 tons 7'8" 13' 180 fpm 300 fpm

THE POWER

Donnie & T.J. Reed, Madison Asphalt

Join Us In Booth S5467

TO CHOOSE With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs. “ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.” T.J. Reed, Madison Asphalt Madison County, NC 260-637-5729 admasphaltplants.com Plants available from 60-425 TPH

28 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt Manufacturer Model No. Undercarriage Type Engine HP (net) Shipping Dimensions (LxWxH) (ft.) Max Operating Weight (lbs.) Hopper Capacity (tons) S TANDARD PAVING W IDTH (FT) Minimum Maximum Max Paving Speed (Vibratory Screed) Max Paving Speed (Tamper Bar Screed) Max Travel Speed (mph) Mauldin 650 Tire/Track 24hp 9'10"x7'6"x5'8" 9,700 6 8ft 13' 0-115 FPM n/a 3.2 MPH Mauldin 1560 Track 74hp 11'4"x8'6"x5'4" 12,500 6.5 8ft 14' 0-140 FPM n/a 3.5 MPH Mauldin 1860B Track 110hp 13'9" x 8'6" x 5'11" 19,500 9.5 8ft 15'6" 0-140 FPM n/a 3.5 MPH Mauldin 1360 Track 74hp 14' x 3'11" x 6'8" 12,800 6 3'11 7'10' 0-90 FPM n/a 2 MPH MAULDIN PAVING PRODUCTS Mauldin Paving Product’s line of commercial pavers ensure superior performance due to 3 strategic approaches to design. Proven productivity, screed design and a commitment to quality are the key elements that sets a Mauldin Paver apart. Mauldin Pavers have been trusted for decades by contractors to produce lasting results. www.ForConstructionPros.com/10075446 Sponsored by

Get the most from your new Cat® paving machine with a hassle-free ownership and maintenance plan. We’re o ering special deals that make it easy to add a Customer Value Agreement now.

Visit cat.com/paving to see all eligible asphalt pavers, soil compactors and utility compactors. Save time and money with this deal.*

*O er valid from October 1, 2022 through December 31, 2022 on select Cat® utility compactors sold by participating Cat dealers to customers in the USA or Canada. Purchase must occur during o er period. O er subject to machine availability. The $500 o er is to be used toward a Cat® Customer Value Agreement (CVA) that includes maintenance parts kits; S∙O∙S scheduled maintenance and a minimum of 12 mo Cat® Daily connectivity. The kit contains one set of parts for regular planned maintenance under normal operating conditions. In some severe applications where maintenance parts need to be replaced more frequently, additional parts will be at customer’s expense. O er excludes additional maintenance parts, dealer labor, wear parts, and fluids. O er only available at participating Cat Dealers. O er may change without prior notice and cannot be combined with any other o ers. Additional terms and conditions may apply. Contact your Cat dealer for details.

*O er valid from June 1 – December 31, 2022 on eligible new Cat Large Asphalt Pavers sold with a CVA Contract. O er is available to customers in the USA and Canada only and can be combined with local RSA support. O er subject to machine availability. Final machine prices are subject to change. O er may change without prior notice and additional terms and conditions may apply. The P+H+T EPP is provided through Cat Financial for use at participating Cat dealers.

*O er valid from Oct 1, 2022 through Dec 31, 2022 on select new Cat® machines sold by participating Cat dealers to customers in the USA or Canada. Purchase must occur during o er period. O er subject to machine availability and credit approval by Cat Financial. Not all customers will qualify. The o ered Cat® Customer Value Agreement (CVA) includes 6 maintenance parts kits; S∙O∙SSM; and 36 month Vision Link™ Daily. The maintenance parts cover the first 3,000 hours^ (estimated 3 years) of machine utilization. The kit contains one set of parts for regular planned maintenance under normal operating conditions. In some severe applications where maintenance parts need to be replaced more frequently, additional parts will be at customer’s expense. O er excludes additional maintenance parts, dealer labor, wear parts, and fluids. O er also includes a 36 month/5000 hour (whichever occurs first) Powertrain, Hydraulics and Technology Equipment Protection Plan (EPP). In some areas, EPP might be sold separately from the CVA. O er may change without prior notice and cannot be combined with any other o ers. Additional terms and conditions may apply. Contact your Cat dealer for details.

© 2022 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

THE PROCESS Secrets to Maximize Reclaimed Asphalt Pavement

The usage of reclaimed asphalt pavement (RAP) is more important than ever for the roadbuilding industry. There are two main factors driving its increased importance. The first is the current direction of state and federal policy. The current congress in Washington worked hard to pass new pieces of legislation, the Infrastructure Investment and Jobs Act (IIJA) which was passed into law in November of 2021, and the more recent Inflation Reduction Act (IRA).

These laws, working in tandem, allocate billions in new funds for infrastructure, but they incentivize projects and contractors who incorporate greener and more sustainable options. Bids that

utilize, or companies that invest, in ecologically friendly technologies, practices and materials will see the greatest amount of return from these policies.

The other factor elevating RAP's importance is similar to what drove its initial growth in the 1970s era market. At that time it was a national oil crisis and imports embargo that suddenly highlighted how important RAP could be, and now, one could say that it’s a crisis of materials in general. All materials. The critical impacts on the supply chain are well documented and discussed at this point. At all levels of industry and construction, the costs and the availability of vital resources are influencing just about every corner of the post-pandemic market.

According to the Federal Highway Administration, an estimated 45 million tons of RAP are produced annually, though that number is based on incomplete data. From the FHWA website, "It has been estimated that as much as 36 million tons, or 80 to 85 percent of the excess asphalt concrete presently generated, is used either as a portion of recycled hot mix asphalt, in cold mixes, or as aggregate in granular or stabilized base materials. Some of the RAP that is not recycled during the same construction season that it is generated in, is stockpiled and is eventually reused at a later time."

Needless to say, the contractors who have the best handle on their RAP

Provided by Ammann

PRODUCTION NOTES | BY BRANDON NOEL

30 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

Step-by-step tools to help take your RAP to the next level

Engineered Innovation.

From innovative designs to Caterpillar dealer service and support, Weiler is paving the way to successfor contractors across North America. Weiler’s material transfer vehicles, commercial pavers, road wideners,windrow

and front mount screedsare

with

is

at

rock drills, tack

while reducing

costs.

dealers throughout North America.

weilerproducts.com

elevators, static split-drum compactors, soil stabilizers,

distributors

engineered

innovative features to increase productivity

operating

Weiler equipment

sold and serviced exclusively

Caterpillar

systems will have a higher likelihood of greater financial success in the coming years, because it is safe to assume that current trends will continue on this path, rather than moving in the opposite direction. While there are a number of possible manufacturers that offer RAP solutions for contractors at varying scales, Ammann and their engineers offer a lot to contractors looking to make the most of their operations with the implementation of their high recycling technology (HRT).

Their HRT is a combination of their RAP preparation methods combined with specific control systems, which can achieve extremely high percentages of RAP in an asphalt mix.

LET’S TALK ABOUT THE BENEFITS

Maybe you're like me, I'm still fairly green in this industry, still learning a lot every day from each new conversation I have with knowledgeable experts. Maybe you know a little bit about RAP, or maybe it hasn’t been a huge focal point for your business or operation.

Great! The next paragraphs are for you and me, because I knew that RAP was beneficial, but I didn't have a clear understanding how it was directly affecting the bottom line.

If, however, you're not like me and you already know this stuff like the back of your hand, skip down to the next header, where we start digging into the ways to improve your RAP process

to get the most out of it. That is going to be where you might find some new relevant information. If you're still with me, though, let's take a look.

Reduced Resource Consumption

Easily the most obvious benefit to the contractor incorporating more RAP into their mix, is the reduced need for fresh or virgin liquid binder (bitumen) and new aggregates. Plain and simple, being able to reuse the removed pieces of road is going to reduce the costs on your bottom line.

Speaking with Carlos Machado, Business Development Manager for Ammann, he said, "It starts with a cost saving for the customer, to address material shortage or continue operating with some price peaks in the needed materials to produce asphalt. However, it is also becoming a point of how to

handle environmental solutions in the asphalt industry."

Why does it become a matter of handling environmental solutions? The answer is in the outcomes. If you want to get more out of your RAP, you have to put more careful and specific work into the whole process. Proper mix gradation, avoiding the damage to bitumen in the recycling, improving RAP quality screening, sorting and storage. These are all factors that play a part in maximizing the reintroduction of used materials into new mixes.

To get the highest cost savings, you are going to need to examine every part of your current methadology:

• Removal from road

•

Sourcing

•

•

•

Provided by Ammann

Provided by Ammann

32 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt PRODUCTION NOTES

Careful

Sorting / Screening

Effective Receiving Inspection

Initial Type Testing

A decidedly human touch to plant automation.

Designed around real people.

“The plant control system that MINDS designed for us has worked very well. The graphics depict the plant almost identically as built and are very easy to follow from the control room. Each value is shown with its position indicated by colours that make identifying issues, such as a stuck valve, extremely easy. The materials that we have produced with the system have been very consistent from the fi rst production run.”

Allen Hendricks, Vise President, Asphalt Divisions Manager Blythe Construction, Inc.

For the past 25 years, MINDS has built a reputation for user-friendly, advanced, customizable plant automation control systems. As of April 2022, we became part of the Astec family to add to their Rock to Road solution for asphalt road building. MINDS provides award-winning desktop software, mobile apps, and hardware for many applications:

Drums, Batches, Combo/hybrid hot mix plants, Emulsion plants, Liquid Terminals.

Silo load-out, Ticketing, and Cloud-based data management for the Rock to Road industry.

Better data. Increased control. Higher profi ts.

SALES INQUIRIES: 866-971-2980 contact@mindsusa.com mindsusa.com

• Storage

• Mix Process

To skip over and neglect any one of these steps, will negatively affect the end result. Each one of them has an impact on the others, for instance: If you don't properly screen your RAP, the ability to incorporate and control your final mix effectively will be reduced. Likewise, if you analyze your aggregates properly, but your asphalt plant can't control the recycling process well enough, the mix quality will suffer.

Machado said, "The requirements for high rates of RAP are not only dependent on the asphalt plant itself. It is all about a combination of state-of-the-art machinery, with handling correctly the preparation processes. When you have higher RAP percentages, the Contractors must have a much higher control of the RAP they reclaim and process." Let's look at what Ammann generally recommends when it comes to this higher level of control.

HIGH GRADE AGGREGATE Removal

The very first step towards a better RAP percentage, and a higher rate of recycling, is the removal process. Carlos Machado explained that an important part of this step is, "Never mix the top layer with the bottom layers of your road, because in each layer, you have different types of aggregates." For many years RAP was handled in

such a way, that would lead realistically only to a Down-Cycle, meaning re-use of a material for an inferior purpose (like stocked in piles with no direct use or placed in landfills, for example).

Ammann wants to help contractors find ways of achieving a True Recycling use, which is when a reclaimed material is reused for the original purpose – use back into the new mix. That's part of what makes this different, because undefined RAP can have uses inside the production chain, but not at the higher level usage in the asphalt plants.

Sorting

Once the road has been removed in layers, and is transported in trucks to the plant for processing, the next step in the process is to properly screen the RAP into a number of piles (ideally 2 to 3 sizes of RAP material), and, as Machado puts it, "The contractor must know as much as possible about their RAP, including the gradation of the material, the filler and bitumen content, and which type of bitumen is present in the RAP to select the right complementary additives. When you really know these aspects of the RAP, combined with the Ammann High Recycling Technology, then you are one step ahead to reach high levels of RAP usage and save asphalt production costs."

Storage

I'm sure everyone has seen vague piles of RAP sitting out, exposed to the environmental elements, unprotected and for who knows how long. This can be one of the easiest places where contractor's experience a drop in aggregate quality. In addition to not allowing the materials to get mixed together, properly covering the RAP Stockpiles is an effective way to reduce moisture. Ammann supports their customers in finding better storage solutions with their on-site asphalt process engineers.

THE RIGHT MIX METHOD

Some like it hot...

One of the real challenges with RAP is the heating of the materials. In order for the RAP to be re-used, it has to be warmed up, but the speed at which that happens makes all the difference.

Adding recycling in a single drum, where the RAP is directly heated and mixed with virgin aggregates, can only reach limited levels of RAP percentage in the new mix. In this situation, it is common that the heating process is too quick and the quality of the bitumen together with its properties is permanently damaged through oxidation. Also, the bitumen becomes sticky and hard to handle inside a common dryer.

Warm recycling, in a dedicated RAP drum, can be a more effective way to

Provided by Ammann

PRODUCTION NOTES 34 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt

get the RAP up to temperature gradually. But what about the highest levels and how does Ammann work with its customers to help them get there? According to Machado, "Ammann offers 4 ways to add RAP in the mix, which can be combined in different forms for both batch and continuous plants."

These are the following specs and methods they achieve with the HRT:

• Up to 30% RAP: Cold recycled material is added directly in the twin-shaft mixer. Each core component does its function with maximum efficiency. No RAP in dryer ensures less maintenance and prevents sticking, while the external mixer ensures the proper coating and dwell time.

• Up to 40% RAP: Cold recycled added in the middle collar up to 40% with possibility to further percentage added directly in the mixer. The special inner dryer parts ensure high temperature transfer to RAP and prevents sticking with correct flow of material. Fresh additional bitumen is added only in the twin-shaft mixer to ensure proper new HMA/WMA coating.

• Up to 60% RAP: RAP is warmed in a dedicated dryer which ensures smooth transfer of temperature to RAPtarget is to have a smooth increase of temperature to avoid bitumen properties losses.

• Up to 100% RAP: RAP is warmed in a dedicated dryer which ensures the RAP reaches the final needed temperature for a hot mix asphalt. In this solution, there is no need for secondary heat sources, like overheating aggregates.

The RAH100 eliminates that concern. It consists of two connected sections. One is a hot gas generator, and the other is a counterflow dryer. Clients can choose the RAP percentage they want to run their plant, either 70%, 80%, or 90%. It will depend on job needs and authorization from their customers – Authorities, DOTs, etc.

THE UPPER LIMIT

Another benefit to the Ammann technologies is that their engineers understand that not every contractor is looking for the same thing. You may not be interested or ready for a process that produces near 100% RAP mixtures, maybe you need variety and flexibility. Ammann's HRT systems can be retrofitted and adapted onto standard type plants. If and when that time comes, Ammann says that it is committed to customer support, and offers training and education for operators to get the most use out of their plants and their as1 Control Systems.

These systems include a dynamic RAP addition control where the operator can continuously change the RAP Ratio during the mix process with a slider, and the PIP system that allows operators and equipment managers to have plant information and performance topics directly sent to their smart mobile device with updated information on production, energy consumption, fuel consumption, RAP usage, and more.

But what is the actual applicable reality of 100% or near to 100% RAP mixtures that uses very limited amounts of virgin

aggregates, additives and fresh bitumen?

Machado said, "This technology has been evolving, and it currently allows us to go up very close to the 100%. It all depends on the customer needs, the norms they must follow and their preparation with support of our equipment. We have several cases of High Recycling Technology applied in the field." Not surprisingly, it has more to do with meeting the specific needs and tolerances of every job, treating them on a case-by-case basis. "The 100% RAP mix is theoretically possible. But the customer's mix will always have a certain tolerance and some proportion of fresh material will be required to adjust into those limits. The plant operators will likely need to add some fresh components to compensate and be within their tolerance, but the technology exists to produce at high RAP addition rates and if handled in the proper way, the contractors can get the most out of their recycled materials".

For more information visit http://asphalt.com/2wp4nr

Provided by Ammann www.ForConstructionPros.com/Asphalt NOVEMBER 2022 ASPHALT CONTRACTOR 35

IF YOU BUILD IT, THEY WILL COME

Superior Construction’s unique approach on a $135 million project, creates more volume for Nashville’s busy airport

The Nashville International Airport (BNA) is one of the busiest in the country, and in 2021, the city was ranked1 fastest growing in the United States, economically. This boom in financial growth has lots of collateral impacts, both directly and indirectly. The original roadways leading into the airport, first constructed in the 1980s, are, and have been for some time, no longer capable of sustaining and adequately serving the traffic demands it now faces.

This, in part, lead to the I-40/Donelson Pike relocation project.

The airport's current loop road currently services the constant stream of arrivals and departures heading into

the main terminal entrance. This is also the access used by taxis and rideshare services, so, it isn't difficult to see why it has become so congested. The new Donelson Pike relocation project — spearheaded by Superior Construction and the Tennessee Department of Transportation (TDOT) — is designed to realign the Donelson Pike interchange to the east. This allows the Metropolitan Nashville Airport Authority (MNAA) to relocate BNA's loop road to provide a badly needed increase to the airport's circulation capacity, as well as added real estate for more car parking.

BIG RELOCATIONS, UNIQUE DESIGNS

To achieve this, Superior crews broke ground in July on the relocation of the Donelson Pike interchange at Interstate 40 southeast of downtown Nashville. The plan is to update the junction to a diverging diamond interchange (DDI) design.

The DDI is a subset of diamond interchange in which the opposing directions

of travel on the non-freeway road cross each other on either side of the interchange so that traffic crossing the freeway on the overpass or underpass is operating on the opposite driving side from that which is customary for the jurisdiction2.

There are many advantages to this unique type of solution:

• Two-phase signals with short cycle lengths, significantly reducing delay

• Reduced horizontal curvature reduces the risk of off-road crashes

• Increases the capacity of turning movements to and from ramps

• Potentially reduces the number of lanes on the crossroad, minimizing space consumption

• Reduces the number of conflict points, thus theoretically improving safety

• Increases the capacity of an existing overpass or underpass by removing the need for turn lanes

• Costs significantly less than a normal interchange

This isn’t Superior’s first DDI. "We will leverage our experience on other

Photos

Provided by Superior Construction

36 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt JOBSITE INNOVATIONS | BY BRANDON NOEL

similar projects, including the I-75/SR 56 DDI in Tampa to complete this important project," said Pete Kelley, Chief Operating Officer, Superior Construction. "This traffic design has proven effective and convenient in those communities. Commuters, visitors and residents in this active Nashville area can look forward to the same."

Despite being used in France since the 1970s, DDIs only started gaining more attention in the United States within the last two decades. The first of its kind was constructed in 2009 in Springfield, Missouri, at the junction between I-44 and Missouri Route 13. However, as of November 2020, there are now 135 DDIs open across the country--a real boom of growth in just eleven years’ time.

However, despite its advantages and benefits, there can be some documented/situational drawbacks from using the DDI design in certain cases, such as:

• Potential confusion for drivers who are unfamiliar with the configuration

• Pedestrian access requires at least four crosswalks

• Free-flowing traffic in both directions on the non-freeway road is impossible, as the signals cannot be green at both intersections for both directions simultaneously

• Highway bus stops are appropriately sited outside the interchange

• Allowing exiting traffic to re-enter the through road in the same direction requires leaving the interchange on the local road and turning around

MANAGING THE FLOW

According to Jeff Anderson, Tennessee Division Manager for Superior Construction, the project will greatly benefit the growing area., "Reconstructing this interchange will increase capacity, correct geometric deficiencies, and improve its overall operation, providing efficient access to the airport, I-40 and other nearby businesses,” said Anderson. “The airport exceeded the capacity of its original

one-mile loop. Now that road will be expanded into a two-mile loop, effectively doubling the circulation capacity to the terminal and parking areas.”

TIPPING THE SCALES

Without a doubt, a job of this size not only requires a huge amount of materials to be transported to the job site for construction, but there is also a massive earth-moving component of the project. Superior plans to blast almost a halfmillion cubic yards of rock, and will require another million cubic yards of embankment and rock in order to build the new roadway to the proper elevation to cross over I-40

COORDINATING TWO JOBS

The interchange relocation is only one aspect of the two projects. Additional

paving and expansion work on airport property is eventually needed to connect BNA to the TDOT roadway updates.

"Regardless of who builds the other project, our team would construct the majority of our interchange and have it fully open for traffic first,” said Anderson. “Once the work on airport property is completed, everything will be connected together."

The entire project is scheduled for completion by September 2027.

For more information visit http://asphalt.com/ mjw7dn

FOOTNOTES:

1. www.stessa.com/blog/cities-with-mosteconomic-growth

2. en.wikipedia.org/wiki/Diverging_diamond_ interchange

38 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt JOBSITE INNOVATIONS

Photos Provided by Superior Construction

40 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt | What is Paver-Placed Stabilized Full Depth Reclamation & How Can It Help Preserve Our ROADWAYS?

indus helps the Town of Dartmouth save nearly 10% by using innovative recycling method on a local road

As an industry, we are constantly tasked with doing more with less. Pave more roads with less money. Recycle more materials in less time. Do more work with less people.

Luckily, we are also no stranger to finding innovative ways to do all-of-the-above, and a new kind of pavement preservation method has emerged to help.

Paver-Placed, Stabilized Full Depth Reclamation, or SFDR, is a roadway rehabilitation process for poor to very poor condition roads (PCI’s typically below 50). The process involves pulverizing the heavily distressed existing pavement and blending it with some of the underlying granular materials. During the blending process, new foamed liquid asphalt and portland cement are added as strengthening agents. This blended and stabilized material is then paved back onto the road in one thick lift, thereby reducing

construction time and the inconvenience to residents and motorists.

indus, a Northeast paving company specializing in pavement preservation, heard about SFDR last year and knew they had to learn more about it to start offering it to their customers.

“We are constantly looking for ways to help our road owner agency clients improve and optimize their pavement management programs, and with this year’s introduction of the SFDR treatment, we now offer a cost-effective solution at every point, up and down the asphalt deterioration curve,” Dan Patenaude, P.E., and strategic advisor at indus says. “Prior to 2017, our solutions were limited to the top half of the curve with preservation treatments such as crack sealing, fog sealing & rejuvenation, microsurfacing and cape seals.”

www.ForConstructionPros.com/Asphalt NOVEMBER 2022 ASPHALT CONTRACTOR 41

Paver-Placed, Stabilized Full Depth Reclamation, or SFDR, is a roadway rehabilitation process for poor to very poor condition roads.

The company first learned of the paver-placed SFDR process while attending the Asphalt Recycling & Reclaiming Association (ARRA) semi-annual meeting in Charleston, SC, October 2021. Presentations by Wirtgen America, the South Carolina Department of Transportation (SCDOT) and their paver-placed SFDR contractor (King Asphalt) inspired the company to learn more.

“The week following that conference, we sent a small contingent including one of our owners, the QC Manager, and two recycling Superintendents down to visit a paver-placed SFDR project King Asphalt was in the process of completing for SCDOT,” Patenaude says. “They returned from that job

confident in our crew’s ability to perform the same type operation.”

SFDR VS. FDR

Many companies who specialize in pavement rehabilitation are familiar with Full-Depth Reclamation (FDR). Traditional FDR is not paver-placed, and instead the pulverized and blended materials are typically windrowed behind the reclaimer where they then need to be bladed and shaped with a motor grader before compaction.

Paver-placement on the other hand, eliminates the need for the grader which helps to reduce mix segregation and minimize the impact of construction on motorists and abutting property owners.

“Most FDR in this region is not stabilized and agencies rely on thicker lifts of hot mix asphalt (HMA) on top of the recycled layer to meet the traffic load requirements for a particular roadway,” Patenaude says. “The structural layer coefficient of these unstabilized materials is about 0.14 per inch of thickness depending primarily on the quality of the subbase granulars and the proportioning of pulverized HMA with those granulars. The structural coefficient for the stabilized FDR is more than twice that at around 0.30 per inch.” indus was familiar with the FDR and other preservation methods and knew they could provide SFDR with some additional training and support.

“With Wirtgen’s outstanding support, we added cold in-place recycling

(CIR) to our service offerings in late 2017,” Patenaude says. “And with the 2021 upgrade of our Wirtgen recycler to their newest model, we are now able to offer the SFDR treatment which provides a competitively priced and less disruptive solution for communities’ poorest condition roads.”

The newest Wirtgen W 380 CRi cold recycler has 100 additional horsepower, and redesigned front and rear door and side plates which allow for cuts up to 12-in. deep.

“Currently, we are only considering recycling projects up to 8-in. deep, and if we eventually decide to go deeper, we will need to upgrade at least one of our rollers to insure adequate compaction,” Patenaude says.

Since much of the SFDR process is substantially similar to the CIR process the company has been doing for five years, not much additional training was required. Patenaude says the only major differences with SFDR from CIR are:

• The mix design sampling is more extensive and complex because it includes a properly proportioned amount of the underlying granulars (CIR only recycles the pavement and none of the unbound material below it).

• The compaction effort is more intensive given the greater lift thicknesses (CIR is typically done 3-in. to 5-in. deep, whereas the SFDR layers usually range from 6-in. to 12-in. deep).

42 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt PRESERVATION UPDATE

Paver-placement eliminates the need for a grader, which helps to reduce mix segregation and minimize the impact of construction on motorists and abutting property owners.

*Part 1. "Section 179 Expensing" Write Off 100% of Trailer/Equipment Expense up to $1,080,000 You're a "click" away from getting all the information you need from our nearest dealer. Simple, Fast... Guaranteed! *Please consult your tax adviser SAVE TAX $$$ 20XPT • CAPACITY: 40,000 lbs. ANNIVERSARY 1946-2023 7th 7 77 >> EagerBeaverTrailers.co m For a quote on any model, please call 800-257-8163

PUTTING SFDR TO THE TEST

This summer, indus put SFDR to the test for the first time on Woodcock Road in the Town of Dartmouth, MA. The roadway is about 4,000 feet long, a little less than one mile.

"This was a very old county road that hasn't been paved since 2007," Paul Pacheco, Dartmouth DPW Superintendent of Services & Infrastructure says. "The route was heavily decayed as it is a major cut off with major trucking activity. It received an enormous amount of traffic and weight and we needed a strong repair to bring the road back to good condition and withstand future activity."

The Town of Dartmouth has been working with indus for the past 10 years, finding innovative ways to save money on their road projects and turned to them again for Woodcock Road.

44 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt PRESERVATION UPDATE

December 7-9, 2022 Relocated to Sandpearl Resort, Clearwater Beach, FL REGISTER NOW FOR THE PREMIER EDUCATIONAL CONFERENCE AND NETWORKING PROGRAM FOR CONSTRUCTION BUSINESS OWNERS AND HIGH-LEVEL MANAGERS FOR MORE INFORMATION, VISIT: WWW.IGNITECONSTRUCTIONSUMMIT.COM From the producers of: Scan Me!

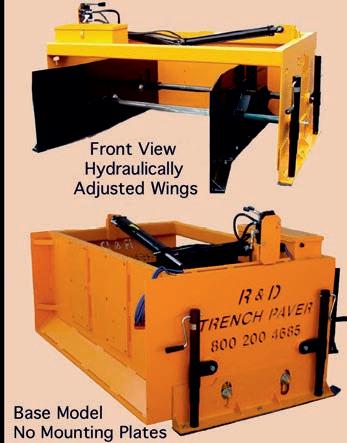

The SFDR set up consists of a water tanker connected in tandem with a liquid asphalt tanker and the recycler which conveys the blended and stabilized material back to the hopper of the paver. Behind the paver is a dual-drum roller, a vibratory pneumatic roller and a technician with a nuclear density testing gauge. indus

"We have been partnering with indus the last few years completing CIR in our area and achieving 60-70% cost savings," Pacheco says. "They use new technologies and they invest the money in the equipment and procedures they know will help us get the best road we can for the money, as well as last the longest."

Patenaude agrees.

“Our municipalities here in the northeast are relatively small compared

with towns and counties out west, and their budgets are small, as well, so most of our recycling projects are in the 1 to 2 miles long range,” Patenaude adds.

“The Town of Dartmouth chose PaverPlaced SFDR for this project over conventional, unstabilized FDR primarily because of the reduced inconvenience the paver placement process provided to their residents. Other benefits that helped convince them to give this new

process a try were that it cost slightly less than their conventional unstabilized FDR option, is likely to be longer lasting because of the strengthened base layer, and was more environmentally friendly with lower greenhouse gas emissions.”

indus pre-milled about 4-ft. wide and 8-in. deep on both outside edges of the road to remove materials and make room for the expanded, recycled material plus the new HMA wear course without raising the elevation of the road. Following the pre-mill, they drop-spread about 8 pounds of portland cement stabilizer additive per square yard, per the mix design.

Next, the SFDR recycling train followed. This set-up consists of a water tanker in tandem with a liquid asphalt tanker, and the recycler which conveys the blended, stabilized material back to the hopper of the paver. Behind the paver is a dual-drum roller, a vibratory pneumatic roller and a technician with a nuclear density testing gauge.

“Once densities are achieved, we then apply an asphaltic fog seal before reopening to traffic within a few hours of starting the recycling on a section of road,” Patenaude says. “The fog seal protects the recycled layer from water intrusion until the HMA wearing course is applied and protects it from traffic picking the fines out of the mat.”

The recycling portion performed by indus was completed in two days (one day for each lane keeping the opposite lane open for alternating oneway traffic), and one day for the HMA paving of the 1-½-in. wear course. indus

46 ASPHALT CONTRACTOR NOVEMBER 2022 www.ForConstructionPros.com/Asphalt PRESERVATION UPDATE

CLASSIFIEDS www.ForConstructionPros.com/Asphalt NOVEMBER 2022 ASPHALT CONTRACTOR 47 CALIBRATEYOUR LIQUIDASPHALTINA QUICK,SAFE,COST EFFECTIVEMANNER WITHOURNEW CALIBRATIONTANK. THISINNOVATIVE SYSTEMELIMINATES THECOSTLY,TIME CONSUMING,AND UNSAFEPROCEDURES NORMALLY ASSOCIATEDWITH LIQUIDASPHALT CALIBRATION.OUR 1,000GALLONTANKS AREOFFEREDINBOTH STATIONARYAND PORTABLE ARRANGEMENTS. INSTOCKTODAY! $15,500 CONTACTUSSALES@RELIABLEASPHALT.COM866.647.1782 STARTINGAT ACCALIBRATIONTANK A A C C C C A A L L I I B B R R A A T T I I O O N N T T A A N N K K

The recycling portion, performed by indus, was completed in two days (one day for each lane keeping the opposite lane open for alternating one-way traffic), and one day for the HMA paving of the 1-1/2 in. wear course.

The mix design (performed by American Engineering Testing in St. Paul, MN) called for the addition of 2.2% foamed asphalt PG binder plus 1% portland cement by weight of the blended RAP and subbase granular materials. For this project, that worked out to 15,429 gallons of PG binder and 32.65 tons of portland cement. After pre-milling to remove material, indus cut about 8-in. deep and then paved the stabilized materials back at an average thickness of 7-in.

Less than two weeks after the completion of recycling, the Town of Dartmouth’s HMA paving contractor (P.J. Keating, a CRH company) installed a 1.5-in. thick 9.5mm Superpave mix as the wearing course. 988.09 tons of the Superpave HMA mix was applied.

To make the most of their SFDR efforts, indus hired an independent testing company (Infrasense from Woburn, MA) to collect some falling weight deflectomer (FWD) and ground penetrating radar (GPR) data to help confirm what they built.

“We learned from their investigation that our average structural coefficient was 0.28 per inch less than 2 weeks after recycling and just before the HMA paving of the wearing course,” Patenaude says. “Understanding that

the foamed asphalt stabilized layer will gain strength over time (one study by VDOT determined a 25% to 50% strength gain after 2 years), we and our client are both pleased with the results.”

In all, the paver-placement SFDR methodology can cut the recycling time by about half. And although pricing is extremely volatile in our industry this year, it appears the cost savings is about 5% to 10% with SFDR. The extra money invested in the stabilizer additives is less than the savings achieved by being able to use a reduced thickness of HMA on top of the recycled layer.

"We are very happy with the results of this project," Pacheco says. "It's sometimes scary being the first to try