2 minute read

Future Technologies

by Lori Ditoro

The hybrid truck concept

ROLLS-ROYCE

While this issue presents current technologies, looking forward is always important. Two future technologies from mtu and SuperTurbo Technologies are featured..

Hybrid Technology for Net-Zero Carbon Mining Operations

During MINExpo 2021, Rolls-Royce Power Solutions displayed a new mtu concept for a hybrid haul truck that could help cut carbon dioxide (CO2) emissions by as much as 30%. This planned technology is based on existing mtu products and technologies:

• A 12-V 2000 mining engine • An mtu EnergyPack battery system

Scott Woodruff, former head of Rolls-Royce’s global mining business and current VP, oil and gas, said, “Our environment is a critical topic for the mining industry. Mining companies are leading change and holding themselves accountable with ambitious, responsible targets to reduce emissions. We will use MINExpo to discuss with the industry how we can help them reach these targets and achieve net zero emissions.”

Rolls-Royce has a plan with sequential steps for the mining industry: from existing Tier 4 technology to sustainable fuels and new technologies, such as fuel cells and hydrogen combustion engines.

The mtu team considers the hybrid haul truck concept evolutionary. Alexander Richter, Rolls-Royce mining application engineer and the mastermind behind the concept, said, “We envision equipping haul trucks with a combination of mtu diesel engines and batteries; our mtu EnergyPacks. The batteries are recharged by recuperating braking energy when going downhill. This stored energy ... provides power to the loaded truck when going uphill. This allows us to replace the existing engine with a downsized one, leading to huge fuel savings and a meaningful reduction in CO2 emissions.”

Rolls-Royce has simulated operations with a haul truck whose mtu 16-V 4000 engine with an output of 1,865 KW is replaced by a 16-V 2000 engine, with an output of 1,163 KW, leading to a CO2 emission reduction of 20% to 30%, depending on the topographic profile—with identical performance to the conventional version of the truck.

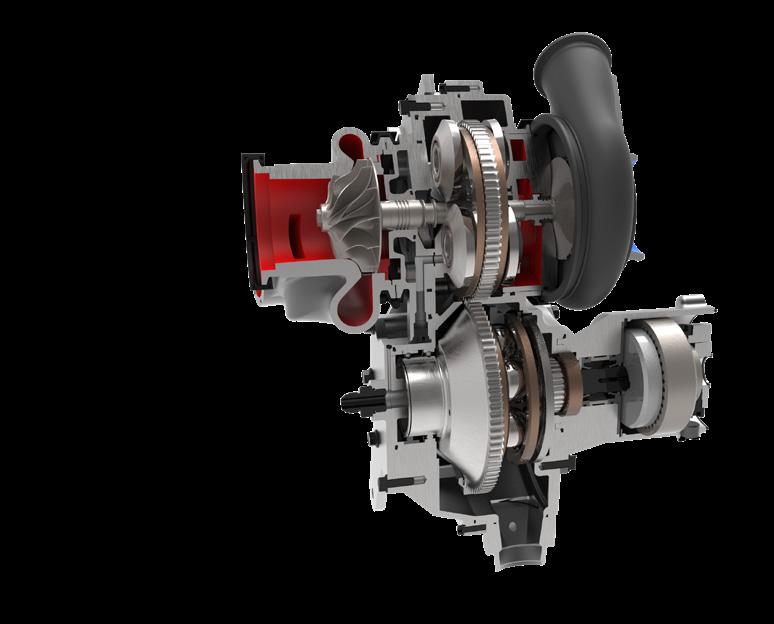

Intelligent Super Turbocharger

The SuperTurbo three-in-one technology from SuperTurbo Technologies combines three technologies:

• Superchargers • Turbochargers • Turbo-compounders Designed for Class 4 through Class 8 trucks and heavy-duty mobile equipment, this technology, currently undergoing the design validation process (DVP), is slated to enter pilot production programs sometime during 2023 or 2024.

The SuperTurbo is a mechanically driven turbocharger that exchanges power to and from The SuperTurbo the crankshaft. According to Tom Waldron, executive vice president of SuperTurbo Technologies, “The SuperTurbo gives an engine the exact amount of air it wants wherever and whenever it wants it.”

Unlike traditional turbochargers that exchange exhaust energy for compressor power, the SuperTurbo adds and subtracts power from the engine.

According to Waldron, this new technology will give OEMs something they have not had before, precise air control. Control of fuel injection has been available to engineers. Now, “they can precisely control and calibrate the air as well.”|