12 minute read

ENGINES COMPONENTS

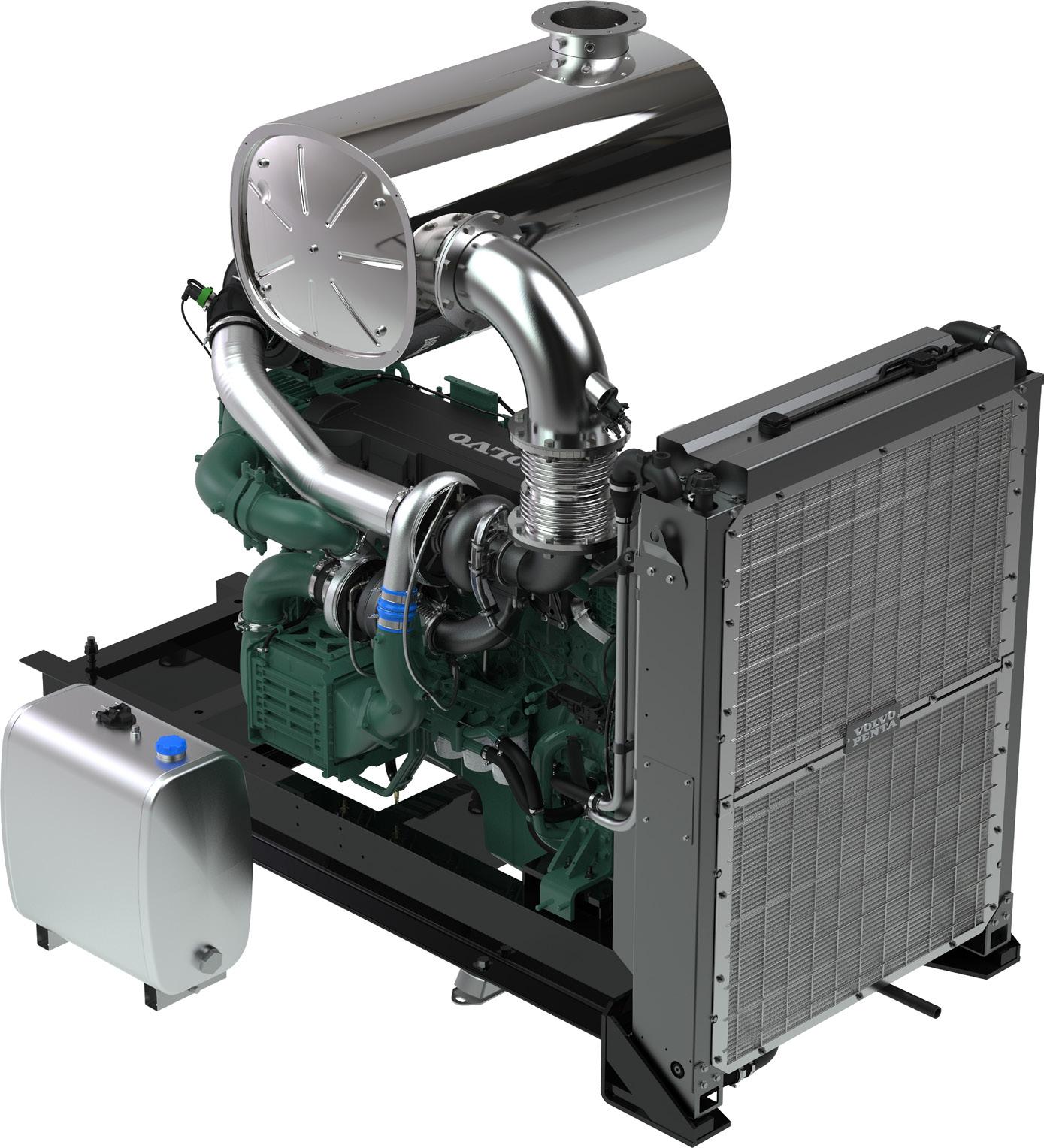

Sponsored by Volvo Penta

Volvo Penta’s Tier 4 Final 16 L industrial power generation engines are designed with efficiency and reliability in mind. Consider these five reasons Volvo Penta should be your power generation engine partner.

Proven Tier 4 Final Platform. With over 100 years of experience, we have a tradition of engineering excellence that’s reflected in the longevity and durability of our industrial engines in the most demanding environments.

Lowest Total Cost of Ownership.

Our engine technology is designed to deliver industry-leading fuel economy with minimal maintenance. Our fuel efficiency is up to 5% lower than other powergen engines. This translates into more uptime and lower total cost of ownership.

Reliable Products. You can count on Volvo Penta for thoroughly engineered highperformance solutions that meet your power needs. An important attribute of our engines is unmatched load acceptance, giving you instant access to full power output the second you start the machine.

Easy to Install, Easy to Maintain.

Volvo Penta’s engines are designed to fit easily into virtually any space requirement for mobile gensets or permanent standby installations. Our application engineers are standing by to assist as needed in designing the system that meets your space and load requirements. And our factorytrained dealers have the technical competence, skills, spare parts and diagnostic tools to maximize your productivity and minimize disruptions. Service points on the engine were designed for convenience. They allow for greater accessibility, saving you time and effort on preventative maintenance.

High Power, Low Emissions.

We’re serious about sustainability and protecting the environment. Our Tier 4 Final solution uses a combination of SCR with light EGR aftertreatment. There is no Diesel Particulate Filter (DPF). This means no periodic shutdowns for regeneration.

Contact us today to learn more about how Volvo Penta can reliably meet your power generation requirements and improve your bottom line.

Drain Plugs and Clickers

Femco released the non-drip system, a series of drain plugs and clickers specifically created to rapidly drain and refill oil from vehicles without leaving any residue afterwards. • Uses a single draining system for both draining and refilling and adds value if there is no residue left behind • Ensures a more efficient, safe and productive workplace by eliminating excess oil spills • Features a robust brass construction which suits changing oils and fluids at high temperatures • Available in numerous different sizes and is designed to be used together with the non-drip clicker which is sold separately • Achieves clean and safe workspace by decreasing the distance between the valve opening of the plug and the nozzle opening of the clicker

https://oemoffhighway.com/21648046

Low-Pressure Direct Injection Hydrogen Injectors for HeavyDuty Engines

They ensure stable, precise and leak-free injection for heavy-duty engines. • Two-valve concept ensures that H2 leakage is kept as low as possible • Designed for system pressures of up to 60 bar (870.2 psi) • Typical applications are in the range of 30 bar (435.1 psi) • Covers a wide range of applications • Allows customer-specific screw inserts to interface with the hydrogen connection • Geared towards most common connection types and offers flexibility in engine development • Blow cap also provides flexible handling • Easy to replace • Asymmetrical geometry makes an individual injection angle in the combustion chamber possible ensuring integration into different engines with sometimes widely differing installation situations • Flexible design supports wide range of customer-specific requirements and modular installation—including centrally, laterally and at different angles • Sized and designed to provide a comprehensive injection system which includes system pressure control to provide a fully integrated solution • Meets the transient requirements of the engine

www.oemoffhighway.com/21821779

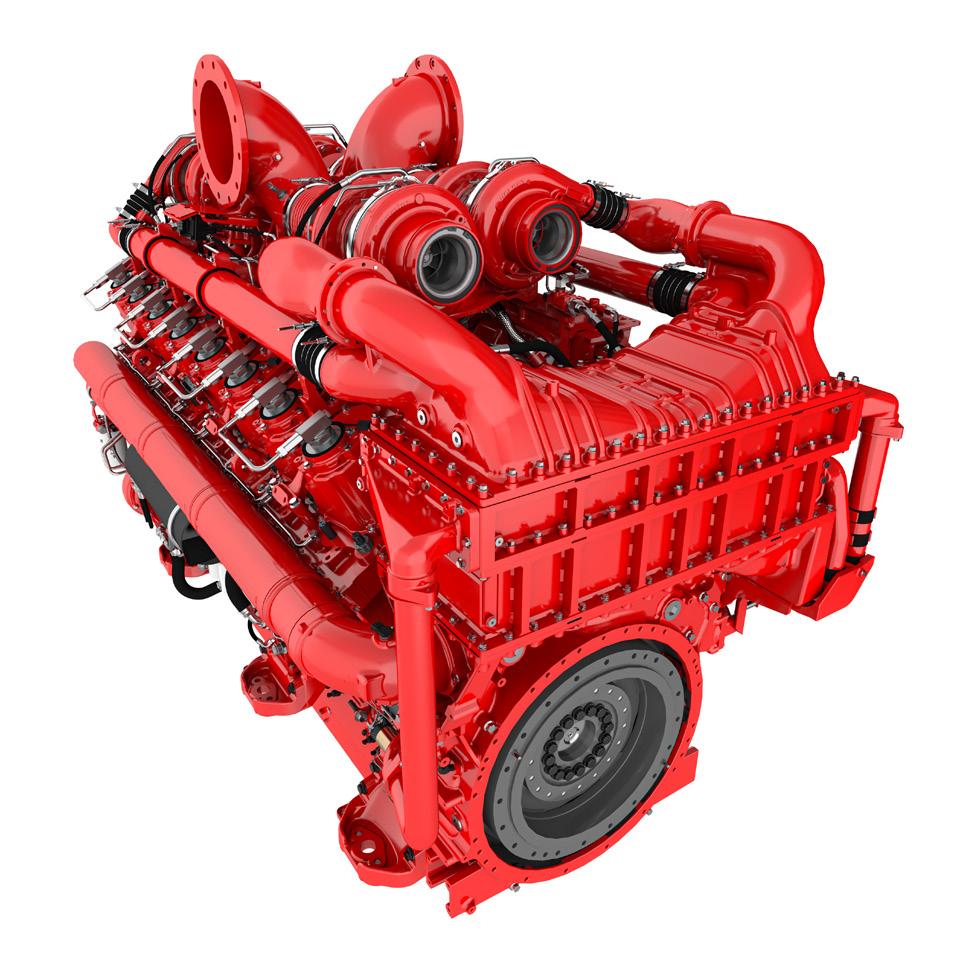

High-Horsepower Engine for Mining Applications

Cummins Inc. introduced the high-horsepower QSK95 engine for mining applications. • Produces up to 4,400 hp (3,281.1 kW) • Offers optimum power-to-weight ratio for 400T haul trucks • Provides 3,800 hp (2,833.7 kW) rating for increased fuel efficiency • Specially designed single-stage turbocharging ensures power at high altitude • Clean-sheet modular design for easy servicing • Delivers average 15% better life to overhaul (LTO) • Available with PrevenTech, Cummins cloud-based software designed for engine health monitoring and remote diagnostics • Features stiffened engine block and V16 cylinder set up which reduces vibration and noise to enhance operator comfort

www.oemoffhighway.com/21521645

Small Displacement Engines

The Kohler Small Displacement (KSD) Series engine family offers a below-19 kW (25 hp) solution that complies with all global emissions standards and fuels. • Compatible with different machine types • Can be easily integrated with more complex electronic systems of ever-evolving machines • Versatile design which allows integration without modifying or redeveloping machine • Allows customized settings for any duty cycle and the ability to exchange data with few physical connections • Features high, low-end torque of 95 Nm (70.1 lb.-ft.) at 1,000 rpm • Peak power output of 18.4 kW (24.7 hp) at 1,800 rpm • Multi-fuel solution enables use with diesel, gasoline and propane • Easily fits into existing telematic solutions • Electronically controlled but as simple to use as mechanical engines • Fuel system allows precise fuel metering and excellent load response • Electronic control allows for integration of CANbus communication, TSC1 control, tailored error messages and remote diagnostics • Enables prognostic, diagnostic, geolocation, remote monitoring and switchability for genset application, and offers a service interval of up to 500 hours, for both oil and fuel filters

www.oemoffhighway.com/21916034

Heavy-Duty Air Cleaners

MANN+HUMMEL introduces the ENTARON HD 2.5 heavy-duty air cleaner, the latest extension to its ENTARON HD range for agriculture and construction machines. • Delivers higher air flow rating and 35% longer life than competing products • Optimized for outdoor power applications like commercial mowers, compact tractors and construction equipment • Two-stage housing contains integrated pre-separator with efficiency of more than 90% • Filter element with composite media features blend of synthetic and cellular fibers while providing optimal efficiency and performance in challenging operating conditions • Patented sealing interface ensures secure sealing in all conditions • Robust outlet design ensures maximum stability in all severe-stress applications • Outlet tube joint strength exceeds 3,000 Newtons, which is twice the strength of competing products • Water and chemical resistant • Cover rotation prevention avoids twisting in case of strong vibrations • Features compact design • EasyLatch bracket system allows quick and easy installation as well as filter servicing without tools • 360-degree rotating elbow outlet and two integrated service ports provide flexible installation

www.oemoffhighway.com/22005490

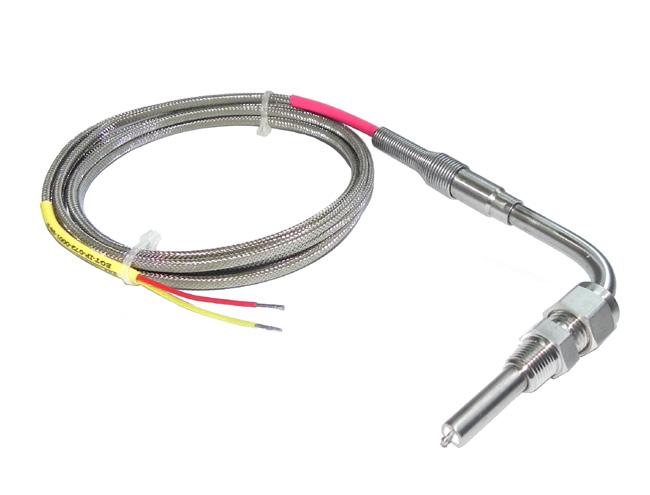

Exhaust Gas Temperature Probes

The Sensor Connection, a division of Harold G. Schaevitz Industries LLC, expanded its line of temperature sensors with the addition of the EGT-IP exhaust gas temperature probes. • Survives extreme vibration and heat up to 2,300°F (1,300°C) • Fits most internal combustion engine exhaust systems from approximately 0.750 in. (1.9 cm) diameter up to about 4 in. (10.2 cm) diameter with nominal installation modifications • Features 0.250 in. (0.64 cm) diameter with a 90-degree bend to accommodate tight mounting locations • Adjustable (316

Stainless Steel) 1/8 in. (0.03175 cm) NPT compression fitting adapter is included • Cable lead length is 6 ft. (1.8 m) or 12 ft. (3.6 m) and is over-braided in stainless steel for heavy-duty abrasion resistance • Signal wires are FEP insulated • Delivers high temperature measurements reliably and consistently • Can be used for many different applications, including off-road vehicle and equipment applications • Probe diameter measures 1/4 in. (0.64 cm) • Features an exposed tip sensing junction (fast response) • Response time constant of 150 ms

www.oemoffhighway.com/21952772

Natural Gas Engines

Peterbilt Motors Company announced the availability of the Cummins B6.7N natural gas engine in its new medium-duty Models 536 and 537.

Peterbilt’s Model 536 includes the B6.7N engine, with 200 to 240 hp and 520 to 560 pound-feet of torque available while emitting 50% lower NOx emissions than current Environmental Protection Agency (EPA) standards. The non-CDL Class 6 Model 536 is with a low cab entry height, visibility, low NVH and room for three people within the 2.1-meter-wide cab. Critical information is relayed to drivers through a 7-inch digital display located in the instrument cluster, and it features a digital card system fully integrated with the latest Peterbilt safety systems.

Medium-duty trucks can be configured with the just introduced B6.7N and the L9N featuring 300 to 320 hp and 860 to 1,000 pound-feet of torque. Heavy-duty trucks including the Model 520, Model 567 and Model 579 can be outfitted with the ISX12N featuring 400 hp and 1,450 poundfeet of torque.

www.oemoffhighway.com/22144638

Jake Brake Improves Engine and Fuel Consumption

Jacobs Vehicle Systems, a manufacturer of engine retarding and valve actuation systems for the commercial vehicle industry, upgraded the company’s engine brake on model-year 2021 PACCAR MX-11 heavy-duty diesel engines. The electronically controlled engine brake now includes a new high-flow solenoid to facilitate faster, smoother gear shifting, resulting in simplified and smoother vehicle operation, as well as fuel consumption improvements.

Jacobs’ newest engine brake is manufactured at the company’s headquarters in Bloomfield, Connecticut, and delivered to PACCAR engine plants in Columbus, Mississippi; the DAF engine plant in Eindhoven, the Netherlands; and Ponta Grossa, Brazil

www.oemoffhighway.com/22159146

The power behind it all.™

3C 8.8 - 17.8 kW .99L - 1.6L 4L 30 - 49 kW 2.2L 4J 52 - 84 kW 3.0L 4H 129 - 140 kW 5.2L 6H 130 - 210 kW 7.8L

6U 170 - 270 kW 9.8L 6W 250 - 382 kW 15.7L

4HV1

Natural Gas / Propane

NG 78.4 HP (58.5 kW) @ 1800 RPM 79.8 HP (59.5 kW) @ 2200 RPM 4.6 L LP 82.5 HP (61.5 kW) @ 1800 RPM 56.3 HP (41.9 kW) @ 2200 RPM 4.6 L

Technologically

4H Series Open GenSet Power Units

The Isuzu open GenSet Power Units are Tier 4 Certified. The 4H Series—5.2 liters, 4 cylinders, 127.5 kW (171 hp) at 1,800 rpm—can save time, money and resources because they are pretested and are more than 90% validated, for generator- and alternator-end manufacturers. These units help put standby power solutions into customers’ hands faster for multiple generator applications. The Isuzu Tier 4 Certified, 4J Series—3.0 liters, 4 cylinders, 70.8 kW (95 hp) at 1,800 rpm— and the new 4H Series open GenSet Power Units provide the same workmanship that Isuzu is known for.

They are eco-friendly and durable. They also provide quiet operation and low noise, vibration and harshness performance. These engines come with a 5-year/5000-hour warranty. They are designed with selective catalytic reduction over-the-flywheel and built with common components for multiple configuration options, including adjustable skid base cross members for bolt-on flexibility.

www.oemoffhighway.com/22223355

Vanguard 400 EFI/ETC Single-Cylinder Engine

The Vanguard 400 EFI/ETC horizontal shaft commercial gasoline engine has an electronic fuel injection (EFI) system that provides better fuel efficiency, improved performance and quick load acceptance.

The engine also offers easy, all-weather choke-less starting. The addition of the electronic throttle control (ETC) system means operators can count on smooth and consistent power.

The 400 EFI/ETC features battery-free starting. Like its carbureted predecessors, the engine includes a fully integrated cyclonic air cleaner with advanced AutoShed technology.

The single-cylinder Vanguard 400 EFI/ETC 14.0 Gross hp* engine will be available for purchase in summer 2022. It comes with a three-year commercial limited warranty** plus one warranty bonus year when registered. *All power levels are stated as gross horsepower at 3,600 rpm per SAE J1940. | **See vanguardpower.com for warranty details. Offer not valid in CA or QC.

www.oemoffhighway.com/22223369

There are over 28 million reliable, eco-friendly, durable and technologically advanced Isuzu engines worldwide. Our Tier 4 and Stage V engines and power units are clean, quiet and fuel-efficient - meeting critical requirements in agricultural, construction, forestry and rental markets. Contact your local Isuzu Distributor to experience technologically advanced power today! Ask about our new gen-set ready power units! www.IsuzuEngines.com

4LE2X P/U Tier 4 Final Power Unit

New 4JJ1X Genset Ready Tier 4 Final Power Unit

4HK1X P/U

Tier 4 Final Power Unit

4HV1 DUAL-FUEL P/U

Natural Gas / Propane Tier 4 Final Power Unit

Advanced

FPT Industrial NEF Engines

FPT Industrial announced the E-Series crawler excavators from CASE Construction Equipment to be powered by the FPT’s Stage V NEF engines.

These excavators include 13- to 30-metric-ton models: CX130E, CX160E, CX180E, CX210E, CX240E, CX250E and CX300E. The models offer controllability, reliability, operator comfort, efficiency, productivity and lower total cost of ownership and are all powered by FPT Industrial’s NEF engines.

With the E-Series, CASE completes its Stage V offering. The NEF engines powering the new E-Series include EGR-free architecture, while the FPT-patented HI-eSCR2 after-treatment system results in low operating costs.

Both NEF engines and the HI-eSCR2 system for Stage V compliance are offered in a compact and lightweight package to facilitate installation on the vehicle and offer a range of after-treatment layouts.

www.oemoffhighway.com/22093799

High-Horsepower JD18 Engine

Building on the JD14 engine design from John Deere, the JD18 engine was engineered with flexibility, serviceability and durability in mind. The JD18 extends the rated power range, now 522 kW to 676 kW (700 to 907 hp). The engine features a rear gear train, which produces direct power and options up to two rear aux drives for a total of 902 Nm (665 lb-ft) max torque providing quiet operation.

The JD18 features new combustion technology, which allows John Deere to offer its extended power range without aftertreatment. Without the need for diesel exhaust fluid, users have one less fluid to manage. The high-pressure, common-rail fuel system allows the engine to deliver optimized fluid consumption. Other key features include: • Uptime focused controls • Durability • Serviceability and repairability • Fluid management • Reliable innovation

www.oemoffhighway.com/22223365

For more information about engines, visit the website.

www.oemoffhighway. com/engines