Annual members day featuring recent scientific research, plus tastings of NIAB wine

Members-only website and enewsletter, presenting project updates, cool climate viticulture and wine news, challenges and solutions, regenerative viticulture and new technology

Annual technical webinar on a topic requested by members

National and international members-only tours and visits

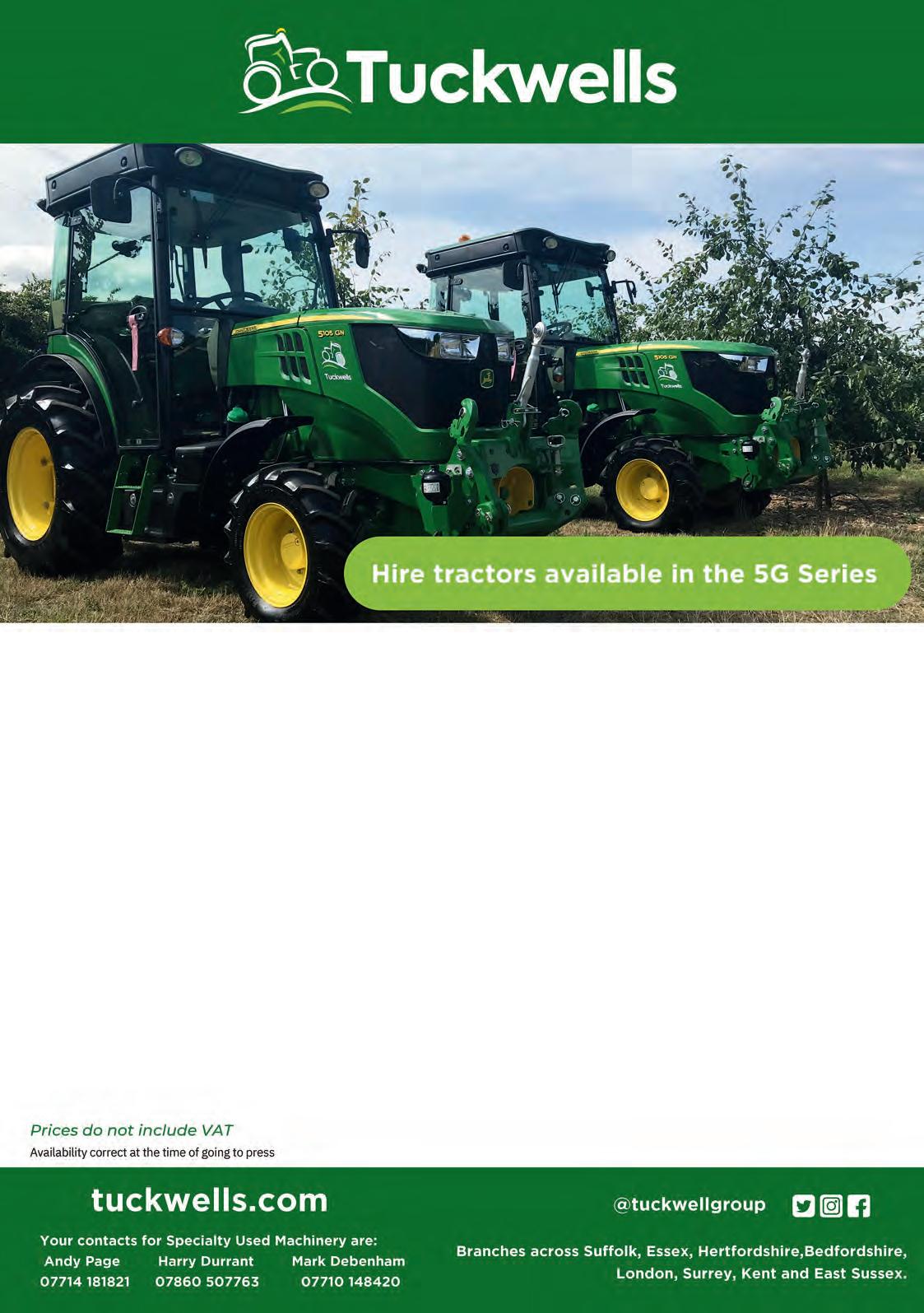

The Fruit & Vine team enjoyed a busy day at Fruit Focus in early July, meeting readers and catching up with clients. You can read more about the event on page 29. Pictured (l-r) are: Marketing executive, Patrick Over; multiplatform journalist, Aleksandra Cupriak; sales executive, William Taylor; Fruit & Vine sales specialist, Samantha Wilson; and sales director, Zohra Mitchell

Editor Rachel Hicks attended the Groundswell Festival, where she chatted with VineWorks business director and head of vineyard services, Chris Buckley (left) and viticulturist Patrick Martin. Read VineWorks' latest advice on cover crops on page 36

Machinery editor Neale Byart headed to fruit grower Hall Hunter Partnership in Wokingham, to see their latest machinery purchases in action. The team have recently started using a Harvy 500 blueberry harvester, as well as an Elifab grading and packing machine – read the full report on page 17. Neale is pictured with Hall Hunter managing director, Jim Floor

News

Products, research and events you need to know about

Special report

The importance of Great British cider and protecting the industry

Special report

Does your vineyard or orchard need a Babydoll?

Machinery

Hall Hunter brings automation to blueberry production

Machinery

NP Seymour event generates "considerable interest"

Grower pro le

Berry grower is adopting new technology to meet ambitious targets

Show review

Latest technology for growers showcased at Fruit Focus 2024

Agronomy

Challenging season poses disease and insect control questions

Special report

Agronomy

Cover cropping in UK vineyards

Agronomy

Planning for a hassle-free harvest in the vineyard

Grower pro le

Little Wold Vineyard is a true family a air

Technical advice

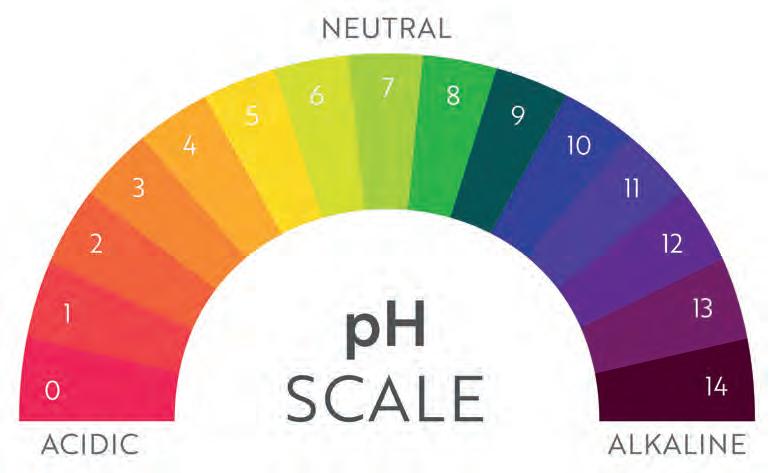

Measuring and managing acidity in wine

Professional advice

Free business advice helps familyrun vineyard to grow sustainably

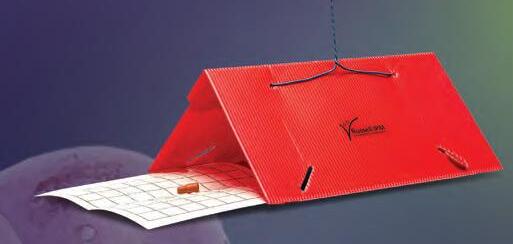

Monitoring codling moth numbers remotely and in real time 06 10 13 17 21 25 29 32 36 39 43 50 54 49 35

Technical advice

52 66 Professional advice

Vineyard branding: From roots to reputation

Boost your winery's business power with software solutions

In the know

Ali Capper discusses what the future holds for British apples and pears

www.fruitandvine.co.uk

Directors

Editorial

Managing director

Julie Goulding julie@fruitandvine.co.uk

Director

Greg Goulding greg@fruitandvine.co.uk

Editor

Rachel Hicks

rachel@fruitandvine.co.uk

Deputy editor

Sarah Kidby hello@fruitandvine.co.uk

Machinery editor Neale Byart

hello@fruitandvine.co.uk

Machinery contributor

David Williams

hello@fruitandvine.co.uk

Multiplatform journalist Aleksandra Cupriak hello@fruitandvine.co.uk

Advertising

Sales director

Zohra Mitchell zohra@fruitandvine.co.uk

Fruit & Vine specialist

Samantha Wilson sam@fruitandvine.co.uk

Senior sales executive

Joanna Blower

hello@fruitandvine.co.uk

Senior sales executive

Jana Moyes

hello@fruitandvine.co.uk

Sales executive

Alex Coe

hello@fruitandvine.co.uk

Sales executive

Rosanna Sweet

hello@fruitandvine.co.uk

Sales executive

William Taylor

hello@fruitandvine.co.uk

Classi ed sales manager

Nicki Procter hello@fruitandvine.co.uk

Marketing

Marketing manager

KM Sharp

hello@fruitandvine.co.uk

Digital marketing executive

Patrick Over hello@fruitandvine.co.uk

Publishing assistant

Kat Morton hello@fruitandvine.co.uk

Design & Production

Production manager

Martyn Smith

hello@fruitandvine.co.uk

As the fresh produce industry, retailers and NGOs continue to explore ways to reduce plastic within fresh produce, British Apples & Pears Limited (BAPL) has published a new report into potential solutions.

The 'BAPL Report into the Current Position of Single-Use Plastic Packaging in the UK Top Fruit Sector' was written by Claire Donovan, a retail expert and experienced food production specialist.

Within the report, Claire points out that currently around 70% of apples and pears are sold in a ow wrapped or bagged format. This format facilitates a range of sizes and counts and allows good visibility of the fruit for customers. As well as ease of transport, packaging also confers protection from a hygiene perspective which, Claire points out, is a concern for customers.

Loose sales account for the remainder of sales, and whilst the results of customer research suggests that they wish to buy more loose fresh produce, WRAP’s recent research suggests that only around 23% of customers actually shop loose apples, as opposed to 76% of bananas being bought loose.

Within the report, Claire explains that unfortunately, for many reasons, UK plastics recycling has not been as successful as hoped. In 2021, 2.5 million tonnes of plastic waste was generated across UK households and just 44% of that was recycled.

The report stresses the urgent need to create a cross-retailer/

industry taskforce to nd solutions for the sector. This is one of seven asks set out in the report that would support future e orts towards minimising plastic pollution.

Another key ask in the report is the need for the UK government to meet its commitment to consistent home/kerbside collection and recycling infrastructure.

“This is a complex, but important area of focus for UK apple and pear growers,” explains Ali Capper, executive chair of BAPL. “We absolutely want to minimise plastic in the production and sale of British apples and pears, but we must fully consider the implications of proposed changes. We need to be especially mindful of keeping food waste to a minimum. We also need to ensure we’re not just moving environmental challenges from one part of the supply chain to another.

“This report is an important contribution to discussions, but most critical is that government, growers, NGOs and retailers come together now to work out the best possible solutions. That way the full implications and bene ts of all approaches can be properly considered.”

You can read the full report on the BAPL website: www. britishapplesandpears.co.uk

Kubota Corporation and French start-up UV Boosting have announced a partnership to jointly promote innovation with sustainable solutions for the viticulture industry.

UV Boosting has developed a patented solution for stimulating a plant’s natural defences, through the use of UV-C light ashes. This allows growers to reduce their reliance on fungicides and minimise damage caused by pathogens and other abiotic stresses such as spring frost or drought. UV Boosting’s UV-C light ash technology is crop agnostic and the existing implement portfolio can be easily extended into other crops.

Kubota plans to tackle global challenges, such as environmental regulations, climate impacts, and labour shortages, by expanding community-focused operations and o ering integrated solutions and technological advancements for customers.

Daria Batukhtina, strategic business development manager at Kubota Innovation Center Europe, commented: “Increasing regulatory restrictions and environmental concerns are enabling a need for alternatives to minimise chemical inputs in speciality crops. This pilot program with several growers and dealers is a part of Kubota’s strategy to create an eco-system which allows innovation to evolve, through partnerships with external businesses

such as AgTech start-ups, agricultural producers, research institutes and universities.”

The pilot programme is taking place in Brescia, Italy, and Anjou, France. The participating dealers will manage and support UV Boosting’s technology, and collate customer feedback. The distribution network already recognises an increasing demand for new environmentally friendly solutions that enables plants to self-protect, through UV light stimulation.

Herve Gerard-Biard, vice president of business development, Kubota Holding Europe BV said: “With this partnership, Kubota is extending its scope into alternative crop protection solutions and accelerating its innovation strategy with the objective of creating new business opportunities.”

According to experts and backed by scienti c evidence, Kubota and UV Boosting say, UV light solutions secure the yield for organic, biodynamic or conventional wine growers. Growers will apply four to seven treatments during the season to evaluate the technology impact on yield results, in addition to the overall e ectiveness on plant health.

the rst time this year, and early yields and quality have been very promising.

Jo Hilditch, chairperson at the Blackcurrant Foundation, commented: “The berries are the biggest I've ever seen, high in sugar and ready to go. However, climate change is a serious issue, and the weather earlier this year made it very di cult and sometimes impossible to get our cuttings in the ground.”

Representing 36 growers across the UK, the Blackcurrant Foundation reports that the nation’s blackcurrant crop is thriving, with an anticipated yield of over 11,600 tonnes this year.

British blackcurrant growers once again faced challenging weather patterns this year. One site in Kent recorded an exceptionally wet winter, with 1,109.6mm of rain by the end of May. The warm winter brought insu cient winter chill for older blackcurrant varieties across most regions except Scotland. However, the groundwork for the 2024 crop was laid in July 2023, when favourable weather allowed

the bushes to produce extension growth, which owered this year and underpins the current harvest. Additionally new climate-resilient varieties like Ben Lui and Ben Macdui are being harvested in quantity for

Berry producer-marketer, BerryWorld says it was delighted to see its growers sweep numerous awards at the prestigious National Cherry & Soft Fruit Show in July.

The award-winning berries were supplied by BerryWorld's esteemed growers: Edward Vinson, Withers Farm, and Tasker Partnership. The growers clinched top honours in several key categories, including:

• Best exhibit of strawberry –Eves Joy – from Edward Vinson

• Best exhibit of raspberry –

BerryWorld Jewel from Edward Vinson

• Best exhibit of everbearer strawberry – Eves Delight 2 from Edward Vinson

• Best supermarket strawberry pack –

1st place: Eves Delight 2 grown by Wye Fruit (Withers Farm)

2nd place: Eves Joy grown by Tasker Partnership

3rd place: Eves Delight 2 grown by Tasker Partnership.

BerryWorld raspberry varieties also scooped further awards:

• Best summer fruiting variety –1st and 2nd place to BerryWorld Jewel and BerryWorld Ruby respectively

• Best UK bred variety – 1st and 3rd place to BerryWorld Jewel and BerryWorld Ruby respectively.

As a sponsor of the event, BerryWorld says it was delighted to discover that winner, Edward Vinson, would be delivering the awardwinning berries to Buckingham Palace for the royal family's enjoyment, underscoring the exceptional quality of the fruit.

Graham Clarkson, breeding director at Edward Vinson and BerryWorld Plus, commented: “These awards validate our breeding

programme's focus on developing varieties that excel in yield,

Simon Hill, senior category buyer at Suntory GB&I, added: “The spring weather was conducive to good growing conditions with plenty of rain, and unlike Europe, we escaped any late frosts, which can damage blossom. Warm weather in late May and early June accelerated the fruit ripening, and we started processing earlier than usual. Recent wet weather has a ected the fruit sugar but has given very good yields and a heavy crop."

Over 90% of British blackcurrants are destined for Ribena, with a small amount nding their way to the supermarket shelves and other products, including frozen formats and other soft and alcoholic drinks.

avour, texture, and shelf life. This recognition drives us to continue innovating.”

This achievement holds particular signi cance as BerryWorld celebrates its 30th anniversary in the berry industry this year.

The company's UK technical director, Stefan Rusev, stated: “These awards are a testament to three decades of dedication to berry innovation and the ongoing commitment by our top-tier growers to deliver superior taste and quality to consumers.”

As part of its growth series releases, WineGB has revealed that there are now 1,030 vineyards in the UK – a 9.2% rise since the last annual report.

This is according to new gures from the Food Standards Agency Wine Team. In addition, last year English and Welsh wine sales grew by 10% compared to 2022.

In 2023, 87 new vineyards were registered bringing the total number to over 1,000 for the rst time. Government data also shows that winery numbers have risen from 209 to 221 and that the total area under vine now stands at 4,209 hectares, representing a growth rate of 123% in 10 years.

Production returns supplied to the Food Standards Agency Wine Team con rmed early estimations in the WineGB Harvest Report that 2023 had been a record year. O cial gures for production in 2023 totalled 161,960.84 hectolitres, the equivalent of 21.6 million bottles, up 77% on 2022.

While last year’s volume growth was signi cant, the UK’s marginal climate will continue to deliver vintage variability with the

production ve-year average up from 10.7 million to 12.4m bottles.

WineGB’s data shows that sales of English and Welsh wine continue to grow sustainably and manageably as new plantings come into production. Sales rose 10% last year to reach 8.8m bottles. Over a ve-year time horizon since 2018, sales have consistently risen.

• Sales of sparkling wine have risen 187% since 2018, from 2.2m bottles to 6.2m in 2023

• Sales of still wine have increased by 117% over the same period, from 1.2m to 2.6m bottles. This growth is even more impressive as it is against the wider trend of falling UK and global wine consumption.

Nicola Bates, CEO of WineGB, said: “This is our year of growth and surpassing the 1,000-vineyard-mark is a real milestone for our industry and cements our position as the UK’s fastest growing agricultural sector.

“We are growing sustainably with our production, and securing a 10% rise in sales, which is all the more remarkable with the wider decline in UK wine consumption.

“As consumers start to feel more con dent with the economy, they will likely have more disposable income to discover our wines in pubs, bars, and restaurants. We expect a wider re-boot that will support our future wines reaching new markets and new drinkers.”

National Association of Cider Makers CEO, Fenella Tyler, highlights the importance of protecting the British cider industry.

Cider apples, unsurprisingly, are grown speci cally for making cider. There are more than 250 varieties grown in the UK and they all have in common features that leave them with only one use: Cider.

Cider apples and cider making are part of Great British culture dating back centuries. The Romans brought apples for alcohol with them 2,000 years ago and cider making was a part of the culture inherited from the Norman invasion over 900 years ago. This is one of our oldest drinks and whilst cider making as an industry has evolved over time, the skill of the cider maker still relies on the traditions developed over centuries.

The cider market in the UK is relatively small. It represents between 5–10% of all alcohol consumed at any point in time, with beer, wines and spirits taking the majority of market share. However, when viewed globally, the UK cider market accounts for more than 30% of global cider consumption.

One major challenge faced by cider makers is scale, as a typical cider maker needs signi cant space to operate. Growing from a small or medium sized business can be challenging when there is a need to access large acreage of apple orchards, space for milling apples, vats to ferment the juice and then mature the cider over time. With a crop that typically harvests over a 12-week period in the autumn, the juice and fermented cider must be stored for use over the next 12 months.

Orchards require long term planning. A cider apple orchard will take around seven years from planting to reach break-even, and nine years to reach full maturity. The trees will then continue cropping well for more than 30 years.

Cider makers therefore o er long-term contracts to encourage farmers to plant orchards, without any guarantee that the market will be buoyant by the time the trees mature. As an example, trees planted in 2002/2003 as the market started to grow, reached maturity just as the market stalled in 2010.

Defra records around 15,500 acres of cider apple trees grown in the UK, and the majority of these are to be found in the west and south-west of England. This is a regionally signi cant crop, but slides down the government priority list when compared to commercially grown crops of national scale.

After Brexit it was hoped that support for farmers would be broadened to include cider apples as a uniquely British approach to cider making and apple growing. Protecting these orchards through a long-term approach to agricultural support is essential for cider making, to ensure that trees thrive during the highs and lows of the cider market.

Excise duty rates are a major catalyst in terms of market success. When duty rates increase, the cider market tends to decline, but a positive approach to excise duty by the government can be the catalyst for market growth. With a new government just in place, cider makers and cider apple growers will be looking for positive signs that the government supports this important British industry. A fair legislative platform for cider can be the springboard for market growth both in the UK and for export, supporting an industry steeped in heritage, and an essential part of the rural economy.

Cider makers and orchards in counties such as Herefordshire, Somerset and Devon bring so much to their local areas. More than 11,500 jobs are created through cider making and the cider market has a category value of over £3 billion. Blossom time and harvesting attract large numbers of tourists, with more than a million people visiting cider makers and orchards across the regions. Orchards are a haven for biodiversity, and after the introduction of best orchard practice for cider apple orchards 25 years ago, the increase in natural features such as ponds, hedgerow and wider margins mean that these orchards support large numbers of pollinating species, birds, amphibians and mammals.

Cider makers have invested in sustainable solutions for many areas of their operations, with examples including reed bed e uent plants and waste-water recycling. Looking to the future, many see opportunities around renewables as large site footprints open up opportunities for solar.

As a centuries-old drink, cider should be celebrated as a great example of British heritage that is recognised and applauded around the world. The importance to rural economies, especially in traditional cider making counties, should be appreciated. Cider making and cider apple growing is a partnership between producers and farmers that is unique to Great Britain and must be protected. With a new government, the time is right for cider to be reevaluated and the support it needs put in place for future generations of cider makers, growers and of course, cider drinkers.

The Tow and Fert is a unique sprayer designed to mix and apply a wide range of nutrients and biostimulants. Our range of equipment gives unparalleled versatility and ease of application for your nutrient management programme.

• Application of fine lime/gypsum powder suspensions, viscous liquids and solutions

• Low pressure suitable for biologicals, compost teas/extracts

• Mixing and application of multiple nutrients in a single pass

• Precise application rates

• Accurate nutrient placement

• Dust free application

The Tow and Fert range comes in 5 sizes with various boom options suited for horticulture and tree crop applications. •

• Unique liquid formulation

• 15.6% increase in grape yield

• Larger, juicer grapes

• Improved Brix levels

The Deutz Fahr 5105D S, pictured with a Voxx Intervine Strimmer.

For more information on the range and to discuss your requiments contact our sales team today.

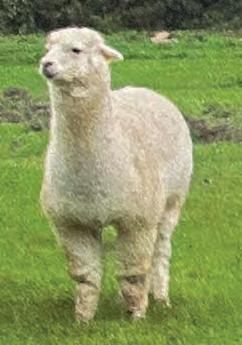

Does your vineyard or orchard need a

Earning its nickname from its ‘teddy bear-like’ appearance, the Babydoll breed dates back to the 1700s, on the South Down hills of Sussex. There were once 100,000 ewes in England but World War I brought about a sharp decline in numbers and the breed was all but extinct by the end of WW2. This was down to demand for larger cuts of meat, which caused a split within the breed – between the original Olde English Babydoll and the larger, ‘leggier’ Southdown. The traditional breed was reintroduced to the UK 20 years ago, but there are still fewer than 200 in the UK, and 400 in the whole of Europe.

Its miniature stature – measuring just 22 inches tall – may have been its undoing as a meat breed, but it makes the Babydoll ideal for vineyards and orchards, as the sheep are too small to reach the fruit.

Sheep o er a number of advantages in vineyards, especially those moving to regenerative practices, including eating weeds and ‘mowing’ between the vines, saving fuel, labour and herbicide use; as well as distributing free fertiliser. However, to prevent them eating the fruit, sheep are often only grazed from post-harvest to the pre-bud stage.

Heidi Bell, of Babydoll Sheep UK, is one of only eight Babydoll breeders in the UK, and keeper of the largest known UK ock – numbering 47 sheep. Keeping them on her own orchard, she says Babydolls are an e cient eco-mower and have an open, trusting nature that makes them easy to handle – with no need for a sheepdog.

One wine producer in New Zealand, meanwhile, has gone so far as to name a wine brand after this quirky breed. Using sheep to keep the vine rows tidy during the colder months is fairly common practice in New Zealand, but Yealands Wine Group, which makes Babydoll wine, believes it was the rst – and only – vineyard to trial grazing Babydolls when the grapes are ripening.

The sheep are used for weed control and to keep the grass short over winter, reducing the number of passes with a tractor, and adding a

Olde English ‘Babydoll’ Southdown sheep are one of the UK’s rarest sheep breeds – but for some vineyards and orchards around the world, they are making a comeback as an ‘ecomower’. Sarah Kidby reports.

dose of natural fertiliser to the mid-rows, which also improves soil quality.

In the warmer months, sheep are moved to the paddocks and cover crops and wild owers are planted between the vines to help manage the vine rows (and reduce mechanical mowing). Wild owers have the added bene t of attracting bene cial insects for extra pest control. Whilst agreeing that Babydolls are easy to handle, the team said they do have a tendency to misbehave and get through the fences, however.

Saving costs and labour

Stephanie Helm runs a 6ha vineyard and winery called The Vintners Daughter in Canberra, Australia, with her husband Ben Osborne. They decided to bring sheep into the vineyard as they wanted to reduce their herbicide use, but specialised mowing equipment was outside their price range. “Babydolls are perfect for vineyards due to their short necks, thick legs, solid body and gentle nature. Their build makes them unlikely to damage the vines, which means they can be used in the vineyard even during the growing season – and they also remove suckers from vine trunks,” Steph explained.

This has allowed them to cut back on fuel and labour costs. “We generally need to have teams of people debudding a few times a year but the sheep have eliminated the need for this labour. They also can work no matter the weather – this was very useful during a few back-to-back wet years where we weren’t able to drive a tractor into the vineyard without getting bogged. They also contribute to improving vineyard soil health by providing natural fertiliser and reducing the need for heavy machinery in the vineyard. This in turn leads to less soil compaction, improved soil fertility and structure, and healthier grapevine growth.”

With a docile temperament, the sheep haven’t caused any problems with breaking infrastructure like vines, irrigation or trellises, and they seem to have little interest in eating bark. However, Steph advises only using them in established vineyards. Tourism and sta wellbeing have also seen a

boost since the sheep were brought in. “They are very cute and people love seeing them in the vineyard. We know each and every one of them on sight by name, they are very friendly and love a pat – so they’ve been great for our own mental health and happiness too,” she added.

Things to consider

With Babydolls being a rare breed globally, Steph and Ben opted to breed them and their ock has expanded from ve to 50 in four years. Whilst this has brought extra revenue from selling rams and wethers to other studs and vineyards, it’s hard work. For most vineyards, Steph recommends obtaining a ock of wethers to avoid the additional work of breeding. They are also usually particularly docile and friendly.

The only real downside to the Babydolls has been the extra work in terms of husbandry and initial investment in handling infrastructure. “They need daily checks and then all of the usual sheep husbandry tasks – shearing, foot trimming, yearly vaccinations, worm counts and drenches if needed,” Steph said.

Ben Osborne runs The Vintner’s Daughter with Steph Helm

“Vineyard owners will need to ensure they have appropriate infrastructure in place for handling and husbandry, such as sheep yards and races, watering points, mineral blocks and appropriate fencing. Providing some sort of alternative shade or shelter is also important, as vines do not provide adequate protection. Vineyard owners should also plan for supplementary feeding in dry times.”

Additionally, the breed is prone to excessive weight gain, especially the wethers, so you need to keep an eye on this. Getting an expert in for shearing and foot trimming is also advised.

Are you ready for sheep?

Heidi Bell is one of only eight Babydoll breeders in the UK. Image © Babydoll Sheep UK

700 breeding ewes in Kent, recommends yearly vaccinations against clostridial disease, worming according to faecal egg counts and veterinary advice, and blow y protection. Annual shearing will also be needed in early summer, so book a shearer in good time.

The three big health threats for sheep are y strike, gut worms and clostridial disease, Kaz con rmed – but there’s no boilerplate health plan that will suit all farms, as it varies depending on the year, stocking density, location, climate and grazing history. Kaz stressed the importance of having a proactive, rather than reactive relationship with your vet.

the depending on the year, stocking density, stressed the importance of having a proactive,

Kaz Strycharczyk, a partner at Black Sheep Farm Vets, says the rst thing to ask yourself is: do you need to own the sheep? With lots of people looking for land to graze their sheep on, this could be a great way to dip your toe in, without being fully committed.

As many vineyards and orchards will be new to sheep keeping, there are many things to consider...

Infrastructure: Sheep must be registered with Defra and the Animal and Plant Health Agency; and you’ll need to ll in movement records. There are also strict rules on medicines usage. Sharminda Lockwood, of Westpoint Farm Vets, part of the VetPartners group, added that you’ll need sheep hurdles to pen them for routine management (they may need training to come into the pen), water provision, potentially electric fencing and someone to check the sheep daily. Spring and summer grazing provision will be needed when sheep are not in the vineyard, and you’ll need to register with a local farm vet. It’s also a good idea to sign up for a sheep keeping course if you’re a rst-time keeper.

Health and welfare: Sharminda, who keeps

Spending half an hour with them and getting and heartache in the long run,” he added.

Spending half an hour with them and getting a health plan will “save you a lot of money and heartache in the long run,” he added. Copper toxicity: If copper compounds are being used to protect vines from fungal disease, there’s a risk of chronic copper poisoning in sheep. Copper is a ‘Goldilocks’ trace element, in the sense that there’s a narrow range between too much and not enough, Kaz said. Breed is one factor that a ects copper requirements; for example, Texels are better at absorbing copper than Scottish Blackface, so require less to cause poisoning.

A recent study in France suggested overwintering sheep on copper-treated vines is reasonably safe if care is taken to leave time after harvest before introducing sheep and limiting the grazing season, Sharminda said. However, research into this area is ongoing. Any sickness or mortalities while grazing the vines should be investigated, and avoiding mineral buckets and additional feeds containing copper is sensible.

Your local vet can advise on breed selection, and also work out the amount of copper that’s likely being taken up by the sheep and how this relates to their daily requirements, Kaz noted.

Blood tests are also available to determine

Wine Group introduced Babydolls to its vineyards early on, and named its wine after them

copper status.

Breeding: Lambing can be a severe pinch point in terms of expertise and potential complications, so running a non-breeding (‘dry’) ock – e.g. groups of ewes and wethers (castrated males) – is advised. Should you decide to run a breeding ock, it’s worth attending a lambing course and spending time on a local sheep farm at lambing time for experience. Also, consider the additional costs and management practices – sourcing a ram, where to lamb, grazing requirements, and the plan for the young stock males, Sharminda concluded.

Dedicated to the development of innovative and dynamic integrated pest management solutions compatible with biological control agents. The Russell IPM Group provides growers with safe and sustainable tools for accurate and well-timed monitoring, prevention and suppression of pests. Reducing the need for pesticide intervention.

– Typical fruit damage can range from 5-20% in susceptible crops

– Typically achieves 2 generations per year

– Larvae feed beneath the calyx of young fruit, leaving a halo-like scar that can cause packed fruit to be downgraded. Older larvae can bore into mature fruit, causing it to drop

– Can achieve 13 generations per year in favourable conditions

– Female SWD puncture the surface of fruit in order to deposit their eggs. Larvae then hatch and feed on the fleshy pulp within fruits, diminishin

– Capable of 100% crop loss in cherry If left uncontrolled, and over 50% in other susceptible crops

Rare, heritage & modern variety certified organic fruit trees grown in the Welsh Marches

APPLE, PEAR, PLUM, DAMSON, QUINCE, CHERRY AND MEDLAR TREES

Catering for traditional, community & commercial orchards, small holdings and the home garden.

We utilise agroforestry principles for healthy soils, biodiversity, and environmental sustainability, all our trees are Soil Association certified organic.

• Pruning, tuition & courses

• Consultancy & agroforestry design

• Variety & rootstock advice

• Planting and aftercare advice

www.tomtheappleman.co.uk enquiries@tomtheappleman.co.uk

Hall Hunter, one of the leading berry producers in the UK, has a progressive and visionary outlook to fruit production. Machinery editor Neale Byart visited to see the grower's latest machinery in action.

Founded back in 1966 by Mary and Mark Hall on Hearthlands Farm in Wokingham, the company now grows a variety of fruit across four sites in Berkshire and Surrey. The largest of these farms is Tuesley Farm in Surrey – home to Mary and Mark’s son Harry, who now runs Hall Hunter. On this site Hall Hunter grows strawberries, raspberries, blackberries and blueberries, with the latter taking up the most hectarage.

The UK market consumes around 60,000 tonnes of blueberries per year, with around 6,000 tonnes of those grown in the UK. Of these, Hall Hunter will produce around 2,400 tonnes of blueberries in 2024, growing to 4,000 tonnes as the crop matures over the next few years – making them the largest individual grower of blueberries in the country.

The UK market for blueberries is currently growing at around 25% year-on-year as consumers wake up to the fact that not only are they delicious, but they are also considered to be one of the ‘superfoods’ due to their high levels of vitamins,

minerals, bre and antioxidants. The rest of those sold in the UK currently come from Peru, South Africa, Morocco, Portugal, Spain and Eastern Europe.

Until recently, all blueberries at Tuesley farm have been picked by hand, and this tradition is set to continue in the main, for the foreseeable future; but there is a change coming, in the form of the Harvy 500 mechanical blueberry picker from Fine Field Innovative Agri Solutions. However, picking is not the only part of the process that Hall Hunter has looked to streamline through automation. They have also added an automatic grading and packing machine in their packing house and, on the day of Fruit & Vine’s visit, were trialling some autonomous robots to take the berries from the eld to the packing house.

Jim Floor, managing director of Hall Hunter explained: “The Harvy 500 is the only one in the UK. We took delivery last season, but this is really the rst year we have used it in anger.

“There are other similar machines on the

market, as anyone who has watched Clarkson’s Farm will know, but we believe that the Harvy 500 is the best machine available and the guys that designed it are operators of a blueberry farm themselves so, although similar, this one has been speci cally produced with blueberry harvesting in mind.”

Jim points out that developing a machine to pick blueberries is very di cult, speci cally when it comes to matching the dexterity used when picking by hand. Although the machine can work much faster than its human counterparts, the downside is that it will take everything, so you get some unripe berries picked that a hand picker would have left on the plant.

“This is where our new grading machine comes in, as it takes a harvested crate of blueberries, including any unripe berries and the odd leaf, and picks out just those fruits that are in good condition and ready for the market,” Jim said.

“The machine uses a colour monitor to remove the unripe fruit, and a camera that can detect damaged berries with a high degree of accuracy.

“The unripe or damaged berries are rejected, while the approved fruit then goes on to be weighed and packed into a punnet. We probably lose around 10% of the total fruit yield due to being picked when unripe, along with other losses, but with a picking rate of around 500kg an hour, compared to a typical 10kg per hour for the average hand picker, the Harvy 500 is doing the work of around 50 people; so, despite the initial high outlay, the sums do add up.”

On the day of Fruit & Vine’s visit, the machine was in action just up the road at Binton Farm – a new venue for Hall Hunter which is rented and used mainly for blueberries, but which also houses their raspberry nursery.

It has very sandy soil and has been in development since last autumn. Here, there are a mixture of some new beds, which are ready for planting in the autumn, and other elds with plants ranging from one to four years old, transplanted from Tuesley Farm.

One eld has been planted with a variety of

blueberry that has been speci cally developed and grown for machine harvesting, although they won’t be producing fruit in harvestable numbers for two or three years. These plants, a variety called FC 1164, grow in such a way that makes them particularly suitable for machine harvesting. Most importantly, all the berries mature at the same time, so that it only needs harvesting once when all the berries should be ripe, reducing wastage. They also retain the berries on the plant better, to reduce shedding losses, and they have a growth habit which is more upright, allowing the machine to operate tightly against the stem.

There is a signi cant investment in plants, but each should have a lifespan of around 15 years.

To demonstrate the Harvy 500, Hall Hunter were harvesting on standard blueberry plants, which would normally be hand-picked. Despite this, the machine did a very impressive job. The ‘brushes’ rotate and move up and down as the machine moves along the row, replicating the actions of a hand picker.

The machine is loaded with empty crates on both sides, which are automatically rotated as they ll, starting with stacks of empty crates on each side of the machine and nishing with full crates in the same position.

When full, it provides a maximum capacity of 1,000kg. The machine can operate completely unattended for short periods, with probes determining the position of the plants, although it would normally be sta ed by two people.

During these early days, while there is still a little ne tuning to be done, Hall Hunter is using a team of four, with two following up behind hand-picking any berries that were missed.

There was also a certain number of berries lost to the ground and a number of unripe berries, together with a little bit of foliage, ending up in the trays, despite the air stream system that is designed to remove leaves and twigs just before they enter the trays. These are all things that will gradually be improved upon with slight modi cations to the machine, and the development of the crops speci cally designed for machine harvesting. Even so it was an impressive sight watching the machine

at work and seeing how quickly the trays were lling. There is a computer on board that ensures that the four wheels are continuously at the right height, and it is self-levelling, so the machine remains perfectly vertical, regardless of the surface. At the same time, the load-bearing capacity per wheel is measured and regulated, so there are no unwanted forces on the frame and the traction is always perfect. An onboard internet connection allows the machine’s current status – such as harvesting data, e.g. kg per hour, kg per bush and kg per row, as well as the position of the machine in the eld – to be monitored from, and reported to, the machine’s HQ.

After completing the harvesting of one row, a set of four wheels drop down to allow the machine to move sideways to the next row before being retracted and o it goes again.

The whole thing is controlled remotely from a wireless control box by one of the operators and is powered by Li-Ion batteries that run two energye cient electric motors. The batteries are charged from a large array of solar panels on the top, providing quiet, emission-free running.

On cloudy days, a small internal combustion engine generator provides additional power to keep the machine running, should the batteries run low. Of course, unlike manual pickers, the machine could operate 24/7, if required and can work at speeds ranging from 100 metres per hour up to 700 metres per hour.

Despite the initial investment cost, and the fact that even with the re nements Jim is hoping to see there will still be a greater loss of berries on the ground and a higher number of unripe berries picked than with hand picking, the savings in labour costs will be so huge that Jim would like to see four or ve of the machines roaming the farm.

On the day of F&V’s visit, a new kind of automation was being trialled and demonstrated. The Fox Robotics Hugo RT is an autonomous mobile robot designed speci cally for the purpose of transporting soft fruit.

The Hugo RT can be programmed to

independently travel between the eld and the fruit storage, sorting or packing area using pre-programmed mapping data. It can carry up to 200kg of fruit and tow a trailer behind of up to 500kg. It uses GPS for location planning, and cameras and collision sensors to avoid obstacles.

Its location can be monitored using an app so, with perhaps a eet of them running backwards and forwards, the Harvy 500 operators can see where they are and be ready for o oading empty crates and reloading full ones, keeping the Harvy running almost continuously. The Hugo is powered by two rechargeable batteries and has a top speed of up to 10kph. The RT in its name stands for rough terrain, so it should have no trouble dealing with the typical lumps and bumps found on farm tracks and between the rows of fruit.

Once the berries are delivered from the eld to the packing area, another new autonomous machine is used to grade them and remove those that are unripe or damaged.

The Elifab is a blueberry grading and packing machine that utilises AI technology to sort through the crop at a high rate. The rst stage removes the green unripe berries and any that are obviously damaged. Then a second stage removes any ‘B’ grade fruit that does not meet the requirements for Hall Hunter’s premium customers.

The best berries are then passed into hoppers where the exact required weight is measured before they drop into punnets below. These are then passed through a process that places a cellophane lid on the punnet before they go through a nal check to ensure the weight is correct.

Any found to be underweight are quickly rejected before the punnets that pass get delivered to a nal packing station to be stacked and crated up ready for collection and delivery to the supermarkets. It is really only this nal stage, and the loading of the full crates at the beginning, that requires any human input beyond a skeleton sta for monitoring processes as the berries go through the process.

As already mentioned, Hall Hunter is a visionary grower – but it’s not just through the use of autonomous machines. Elsewhere on the farms, huge investment has been made in a heating system for the polytunnels.

When Hall Hunter took over Tuesley Farm they installed a system that takes residual heat from an on-site 150 million litre reservoir using heat exchangers, as found in ground source or air source heating systems.

The heat is used to warm water that is then pumped via pipework into the polytunnels, where they grow 26ha of strawberries in heated conditions. Despite the fact that in the depths of winter the surface of the reservoir can be frozen over, they can still extract 4-5°C out of the water deep at the bottom using equipment housed in specially-built machine rooms.

The 4–5°C taken from the water is increased via the pump system to 45°C, creating a signi cant rise in temperature beyond the 5°C taken.

Each one of these machine rooms represent a multi-million pound investment, and they have one at each of their three farms; but the payback is that they give a reduction in heating costs and allow the farms to produce early and late fruit for premium markets. In the summer, the reservoirs, which are naturally fed and lled, are used for irrigation.

With demands for less chemicals and more organic methods in farming generally, Hall Hunter has planted the unfarmed areas of the farm, around the perimeters of the poly tunnels for example, with plants and owers speci cally chosen to attract wildlife that help naturally keep pests under control.

Hall Hunter also houses ve million bees, both honey and bumble, to help with pollination, particularly of the blueberries. A bene cial bi-product of this, in addition to the increased pollination and crop sizes, is that the company can o er its own-branded honey.

The company is proud not only of its traditions and heritage, but of also consistently working to implement new technologies to execute the best and most e cient harvests possible.

In late July, the NP Seymour team hosted a two-day event where customers could see some of the latest equipment in operation. Neale Byart attended on day two, which highlighted the vineyard machinery available.

NP Seymour, the fruit and viticulture machinery specialist, has been serving fruit and vine growers since 1974. The company hosted its annual two-day event recently, which was held on the family-run fruit farm and vineyards of JL Baxter and Sons in Hunton, Kent.

The event is split, with day one dedicated to machinery for the fruit growing sector, and the second day given over to demonstrating equipment for the viticulture market. Fruit & Vine attended on day two and spent a day among the established vines in the rolling Kent landscape.

The team from NP Seymour were bolstered by representatives from the various companies whose equipment was on display. Amongst these were specialists from Fendt, suppliers of the ve di erent tractor models used on the day, Braun Maschinenbau, the OCLL company, Perfect Van Wamel, Airjet, ERO GmbH and BMV-Italy. As well as the machinery, visitors had an opportunity to see a range of weather and plant health equipment from Metos UK.

“We were so pleased to see growers travel from across England and Wales to view the machinery we o er,” explained NP Seymour sales and marketing director, Claire Seymour. “There is always considerable interest in the Fendt specialist tractors, of which we’ve been a dealer now for 40 years. In similar fashion to last year’s event most visitors mainly wanted to see and compare the mechanical weed control solutions we have from Braun and the various canopy management tools on o er. As labour for hand stripping is still expensive to source, more people are investing in defoliators

and trimmers. We were delighted to be supported by representatives from our suppliers who gave further insight into the current machines on the market and new technology being developed.”

A 104hp Fendt 210V was equipped with a Braun double over-row stem cleaner on the front and an Alpha 2000 mower on the rear, featuring dual nger weeders.

Explaining how the stem cleaner tackles the quadruple issues of labour costs, fuel expense, weather and lack of time by cleaning stems on both sides, two rows at a time, Braun representative Cristina Castagnotto went on to say that further savings in time and fuel costs can be made by adding a mower, to keep the alleyways trimmed, and in turn this can be combined with additional accessories such as the nger weeder, as tted on the day, that removes weeds right up to the plant stem while at the same time levelling the under-vine soil. Other tools, such

interest”

as rotary tillers, can also be simply added by undoing just 2 or 3 bolts and the working width of these tools is easily adjusted. The Alpha 2000 is available in various models with working widths from 1.1–2.50m and each model having adjustment capability of between 300mm and 550mm. The nger weeders are available in two di erent sizes, 540mm and 700mm – and in two di erent levels of material hardness.

Peter Knight from Bury Turfcare designed and built the Airjet ground aerator originally to relieve waterlogged ground on sports facilities such as football pitches and golf courses. It consists of a 25mm diameter metal tine, with four holes in the sides. The tine is pushed into the ground, up to half a meter, using hydraulics and air from a compressor is injected into the ground.

The air can be set to inject numerous times and for varying periods, and will inject on both the in and the out stroke of the tine to inject lots of air to relieve compaction. Originally a single tine machine, the latest version, as demonstrated at the event, has a twin tine set-up allowing it to inject air into the soil near the vine roots on both sides of the alleyway at the same time. The system has quite a heavy air demand, so works best with a towed compressor that can deliver the high volumes

required. The spacing of the injections, and the quantity of air injected, all depends on how bad the compaction is, but typically in a vineyard type environment it would inject around every one to two meters. On the day, the Airjet was being pulled by a Fendt 207F producing 79hp.

Available in ‘L’ or ‘over the row’ versions, all with single or double sided variants, the ERO Elite trimmer uses 350mm stainless steel blades with either four, ve or six blades on the vertical cutting beam, and either three or four blades on the horizontal cutting bar depending upon the model. Cutting length ranges from 1,000mm up to 1,950mm. The range promises easy set up and comes with a ‘comfort’ joystick for smooth, light-touch action. Each trimmer comes with a double acting lift mast on which other ERO products can be mounted. The model demonstrated was an ‘L’ double sided trimmer attached to a Fendt 210V tractor.

The VITIpulse Combi, attached to a 114hp Fendt 211V, uses a dual system to remove leaves from the lower part of the vine, exposing the developing

grapes for better spray access and reducing the risk of mould and disease. It uses the two universally accepted methods of defoliating vines – the sucking and plucking method and the air blast concept – combined into a single unit.

Available in a double version to work both sides at once, or a single side version for smaller vineyards or those in hot climates where only the shady side of the vine is worked at any one time, the dual system delivers deeper penetration into the canopy than hand plucking delivers, at a speed that is faster than air blasting alone. Air blasting alone can also cause damage to the grapes with leaf fragments cutting into the fruit. By sucking and plucking rst, damage is much reduced and the window during which air blasting can be used is much greater. It is also claimed that this system is less damaging to the fruit than even hand plucking. The results seen on the day were impressive, with excellent foliage removal and little to no damage to the grapes.

This single sided trimmer has rotating knives, that are claimed to require less maintenance than reciprocating saws, provide less vibration and are less prone to jamming, with either three or four on the vertical cutting bar, one or two on the top horizontal bar and an optional bottom knife. The horizontal bar can be operated vertically to increase the overall length of the vertical bar, if required. Three electrically operated hydraulic rams o er various adjustment options in sidewards, upwards and tilting orientations. The BMV E600 is lightweight, but strongly built and only requires a tractor with between 40 and 60hp to operate. On the day it was mounted on a Fendt 207F with 79HP.

NP Seymour o ers a range of spraying machines with the OCLL APUS 5 being the entry level model. This simple tractor-mounted directional air blast sprayer o ers an economical solution for both horizontal and vertical spraying. Designed

speci cally for compact spaces, tight headlands or sloping ground, the APUS 5 is available with a plastic tank of 300, 400, 500 or 600-litre capacity and two di erent pump sizes depending on tank capacity. The sprayer comes with a two-speed and neutral transmission and a bypass valve to wash the system without diluting the mixture.

David Whato from Metos UK was present on the day demonstrating a couple of products from the weather and frost monitoring range, as well as a new hand-held device for monitoring vine health.

The 3.3 weather station provides rain, temperature, humidity, solar radiation, wind speed and wind direction which, when used in combination with the Metos software and built-in modem, can provide disease monitoring and frost alert functions. For simple, more localised weather monitoring, there was the nMetos Frost – a small standalone unit that crucially uses a wet and dry bulb sensor for more accurate frost detection.

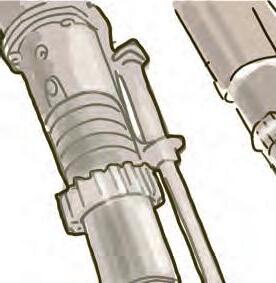

The Dualex is a device for monitoring crop health by simply clipping the unit across the vine leaf. Designed primarily for the viticulture market the Dualex measures nitrogen balance index, chlorophyll, avonoids and anthocyanins which, among other things, tells the story of the uptake of nutrients over time. A built in GPS will record and output data at the end of the day to avoid making notes and speed up the process of taking measurements.

SPECIALISTS IN NEW AND USED FENDT 200 V/F/P TRACTORS AND ESSENTIAL MACHINERY FOR FRUIT AND VINE GROWERS. PLUS SPARE PARTS, SERVICE, REPAIR AND AFTER SALES CARE.

The Summer Berry Company, which produces 7,000 tonnes of fruit in the UK a year, has adopted robotics and green energy solutions to help it meet its sustainability goals – and it’s got big expansion plans in the next few years. Sarah Kidby reports.

Sustainability and decarbonisation are key watchwords for The Summer Berry Company (TSBC), which has invested in various new technologies including a green energy solution to extend the strawberry season, and using robots

for various farm tasks. The business has farms in both the UK and Portugal – with its UK fruit predominantly going to major retailers such as Tesco, M&S, Waitrose, ASDA, Ocado, and Aldi. Around 4–5% of its total sales this year will be to

international markets – Germany, the Middle East and Japan – but this gure is set to rise next year. TSBC grows over 6,000 tonnes of strawberries, 750 tonnes of blueberries and a small amount of blackberries in the UK each year. It is not producing raspberries in the UK in 2024, but o ers year-round supply of raspberries in Portugal. As part of its sustainability strategy, tackling waste fruit is an important focus, and something its environmental, social and governance (ESG) manager is actively working on. It has a partnership with Chichester Food and

Sustainability is a key focus for TSBC

Nitrogen- xing clover is planted between rows

Labour is sourced directly and via Seasonal Workers Pilot Scheme Operators, on a sixmonth visa

Drink Company, which preserves surplus fruit and turns it into high quality, intensely avoured new products, giving fruit waste a second life.

The business also has an open-door policy to local schools, universities, associations, community groups, etc – all they need to do is get in touch to schedule their visit.

TSBC’s farms date back to the 1960s and are grounded in traditional British farm life. After being acquired by Cibus Fund, a private equity investment fund with headquarters in London, TSBC was formed in 2019 and its current CEO David Sanclement joined in 2020. He began his career in Spain, his home country, before moving to Belgium and Germany, then settling in the UK. His long career in the fresh produce industry includes operations and nance roles for global fruit producers, which has taken him around Europe.

Flavour, aesthetic appearance and shelf-life are the critical attributes for TSBC’s variety selection. “We know that it is these characteristics that make our berries so enjoyable and keep consumers coming back for more,” David explains. “But it is also vital that these characteristics align with the agronomic parameters of yield, harvest speeds and disease tolerances. This enables The Summer Berry Company to achieve its critical objective of growing berries sustainably, ensuring our customers get a product which not only tastes fantastic but is also grown responsibly.”

TSBC recently scooped two Superior Taste awards for its Fandango strawberry and Amalia Rossa raspberry varieties. The judging panel is composed of more than 200 professional taste experts, with a focus on avour, appearance, texture, and aroma. Fandango is a top tier strawberry variety created by Fresh Forward, an expert breeder based in The Netherlands; Amalia Rossa is a premium raspberry variety created by the experienced Italian breeder BerryTech. The Summer Berry Company holds the exclusive rights to sell Amalia Rossa grown in Portugal to British and Irish retailers. With an annual production of more than 1,500 tonnes, it also sells Amalia Rossa grown in Portugal to European markets and the Middle East.

A full-year crop planning is an increasingly critical element to the business, David adds. “We strive to take advantage of our geographical location for our eld crops and our glasshouse production is timed to come on both shoulders of the main UK season. It’s also important to take into account the availability of labour and to ensure our volume pro ling throughout the year does not exceed our labour capacity.”

There are six primary tasks the production team focus heavily on throughout each year. Firstly,

ensuring the correct types of plants and varieties are planted at the correct time of year, in the most suitable locations. Secondly, ensuring all plants are grown optimally at all times, and that the climate conditions are adjusted to suit the time of the year, the stage of growth and the current market situation.

Limiting the impact of pest and disease through varietal selection and timing is also key, as well as: climate control; timely crop management plans; robust monitoring, prediction and identi cation strategies and a clear IPM strategy.

Another priority is precision irrigation and fertigation strategies, ensuring the crops have exactly what they need when they need it, at all stages of their life cycle. And nally, maximising fruit quality, avour and timing; and timely harvesting to ensure the fruit is at its absolute best when it reaches the customer.

Powdery mildew is a key issue for the farms’ strawberries and UVC treatment is used for the most susceptible varieties. They also use a timed pesticide treatment programme in addition to regular and timely crop management. Active climate monitoring and control forms part of the strategy. And for pests, they implement rigorous and timely IPM strategies including regular preventative bio-control applications as well as spot curative treatments. Two bio-applicator machines have been out in the elds this year for timely applications and reduced labour requirement.

The farms do a lot of their agronomy practices in house, ranging from fertigation recipes and spray programmes to prediction modelling and ower mapping. “We strongly believe in investing in our growers and production sta , equipping them with the knowledge and experience to manage the day-to-day complexities and

challenges that come with soft fruit farming,” David comments. TSBC also utilises external agronomy services, which provide valuable insights and learning.

For pollination, the farms use a local beekeeper who provides around 150 honeybee hives, each containing about 10,000 bees – and they are introducing native bumblebees throughout the crops as part of TSBC’s biodiversity push.

Weather resilience

As is the case for all growers, the increasingly unpredictable weather creates another set of issues to be managed. “The lack of light this year has been particularly disruptive to our crops and has made pro ling and timing a challenge,” David comments. “Changeable weather conditions year on year make it di cult to really track historical crop speci c performance and to fully understand the incremental gains that we strive to achieve. It’s the same for all areas of horticulture and agriculture and we must remain resilient to the challenges that the weather brings.”

Meanwhile, frost risk is a critical area for the farms’ blueberry crops, due to the very short timeframe for the open owers to be pollinated. “Sprinkler systems are used to cover the owers and bushes with ice – the ice encasement shields the owers from harsher temperatures and the freezing process itself, then releases latent heat which creates a ‘warmer’ microclimate around the ower, preventing frost damage,” David explains. Other crops are planted in sealed tunnels and covered with single/double layers of eece and mulch during frost events. Crops are normally covered during the day of a predicted frost to trap warmer air and residual heat within the crop. Speci c biostimulants are also applied to the crop prior to a frost. “Some products enhance the plants’ natural defence mechanisms to resist frosting damage, whilst others create a

semi-permeable elastic membrane around the plants, providing a physical protective barrier,” he continues.

Whilst labour is a key issue for many growers, TSBC sources its labour directly – these are returnees who have EUSS settled and pre-settled status – and via Seasonal Workers Pilot Scheme Operators which is on a six-month visa. “We have established good working relationships over the years with the Pilot Scheme Operators and have enough labour to pick and pack our crops and complete any other jobs,” David says. “Our strategy is to rehire each year and we have a success rate between 50–65%.”

They also recruit new workers every year and have a training programme for both new workers and returnees, according to their speci c needs. The peak season tends to be from May until September, but there are shoulder seasons in the glasshouse before and after that.

The business also currently has 75 permanent employees working from the UK.

Nearly 100% of the company’s fruit is packaged on site, the only exception being where some customers prefer to pack themselves. “Because of our signi cant packing capacity (1.5M units per week), we are also exploring the possibility of packing for third-party companies during the winter months, when the amount of fruit we produce is lower,” David adds.

Additionally, all the farms’ machinery is bought new – including its tractors, forklifts, and a blueberry grader, to name a few examples.

Among a number of new technologies adopted by TSBC, it has developed a green energy solution (GES) in the glasshouse which will allow it to produce British strawberries all year round, starting this winter. The move will reduce overall spend on energy by around 40%, cut CO2 emissions by 20%, and allow the site to provide extensive additional lighting to the crop in winter.

Additionally, it has partnerships with Tortuga Agtech and Saga Robotics, which has seen the business incorporate robots onto the farms. They do jobs such as harvesting strawberries, providing forecasting on yields and plant health, as well as providing support to its agronomists in ghting pests via UV light application.

“We have a growth plan to increase the production in our current farms in the UK and Portugal but also expand our business to other geographies,” David shares.

Glasshouse production in the UK will increase by 40% until 2028, and in Portugal, its raspberry production will be expanded by working with associated growers, to best serve the markets. There are also expansion plans in South Africa and Morocco, which should be completed by 2025.

“This diversi cation of geographies will allow us to support our strategy of year-round direct supply of premium genetics to premium retailers,” David explains.

And nally, one of the company’s main focuses for the future is further developing its sustainability programme and achieving decarbonisation by 2030.

Farm owner/manager: Chief executive o cer, David Sanclement

Location: Three farms in the south of England, near Chichester, West Sussex, and farms in Portugal

Total size in ha: UK: 156ha of glasshouse and outdoor crops

Fruits grown: Strawberries, blueberries, blackberries, raspberries

Varieties grown (excluding trials):

Strawberries: Karima, Ania, Murano, Favori, Malling Centenary, Fandango, Parlando

Blueberries: Duke, Valor, Top Shelf Blackberries: Sweet Royalla

Around 100 exhibitors and thousands of visitors had a chance to meet, talk about the latest innovations and exchange ideas during Fruit Focus 2024. Multiplatform journalist, Aleksandra Cupriak, attended the event.

The Fruit Focus 2024 event took place at NIAB’s East Malling site on 10th July, featuring exhibitors from around the country and beyond.

During a number of seminars, participants learned about subjects including innovative strawberry cultivation and marketing through breeding, getting crop protection right for the future, and AI vine monitoring solutions.

NP Seymour has specialised in tractors and machinery for fruit and vine growers for over 40 years, and prides itself on ensuring the correct and most suitable equipment is supplied. The range includes tractors, sprayers, mowers, trimmers and defoliators, weeding machinery, frost protection equipment, weather and also winery equipment.

At the event, NP Seymour sales professional, Tim Sillence said that the Fendt 207V Vario Gen3 is currently one of the company’s highlights and receiving a lot of interest.

Speakers covered technical topics including breeding, pollination, integrated pest management, biological control and drone spraying.

During this year’s event, the attendees had a chance to talk to the exhibitors, take part in a range of NFU Fruit Forum seminars and join NIAB research tours.

Hortifeeds was chatting to visitors about its latest foliar spray, Amētros. The company’s regional sales manager, Ben Dalton, said: “Amētros optimises calcium mobility for improved quality and shelf life in all types of soft and top fruit. It can also be used to correct calcium disorders in other crops, such as tip burn in lettuce.”

Mr Dalton added that fruit growers currently face many challenges, with the biggest one being the weather conditions.

“The beginning of this year was cold and wet; it’s been quite a mild summer as well, with really low light levels, which is not good for fruits, particularly strawberries as well as vines. Yields are likely to be down this year due to the environmental conditions,” he added.

Rootwave recently launced its rst product into the UK market – its electrical deweeding technology that can be used in vineyards and fruit plantations. Head of sales and marketing, Tom Archer, explained that the RootWave robot kills weeds using electricity to ‘boil’ the roots, giving better weed control at a lower cost than chemical herbicides while protecting soil health and helping nature restore its soils, water and biodiversity. Rootwave has recently teamed up with mechanical weeding specialist, Garford to distribute its new machinery.

It was a very successful show for Russell IPM, Russell BioSolutions and Russell IOT. The Russell IPM Group said they had the pleasure of exhibiting their extensive range of specialist traps and lures, novel trapping systems and adjuvants – as well as a leading range of biological fermentation and formulation products including biostimulants, biofertilisers and biopesticides. Scienti c o cer (entomologist), Rachel Turner, commented: “We were particularly excited to showcase and provide talks on our new mobile phone application and software suite powered by arti cial intelligence (AI) systems named TruePest. This innovative tool is designed for the monitoring and identi cation of key economically important insect pests, such as the spotted wing drosophila (Drosophila suzukii) on sticky boards. We received fantastic feedback from growers and distributors, made new connections and discussed our solutions to growers requiring guidance. Thank you to everyone who visited our stand.” Pictured (l-r) are: Group marketing coordinator, Araixchel Garcia Fernandez; technical director, Dr Rihem Moujahed; technical sales manager, Andy Russell; scienti c o cer (entomologist), Rachel Turner; entomology technician, James Pybis; and head of AI, Dr Dhurgham Al-karawi.

WolkyTolky showcased its drain monitoring system, which gives growers more insight on the ow of incoming water and the outgoing drain that has owed through substrate. The company’s director, Luc Verkoelen, said: “This allows us to detect an irrigation cycle and calculate the drain. In cases of too little incoming water, too little drain or too late drain in the morning, the system can give alarms so you can act quickly.

“This technology allows a plant to grow much more consistently, increasing the yield per plant. Thanks to our technology, growers can make better decisions.”

The Omex team showcased the company’s range of new products, including Kelpak, which promotes positive plant health, quality and yield. Dr Neil Holmes and Andrew Zengerink said: “Kelpak contains kelp, which is a sustainably harvested seaweed from South Africa.

“Our combination of products with Kelpak and nutritional products of organic range is really impressive.

“Our products receive very positive feedback from our customers. They appreciate our sustainable approach. They also know that we have the right raw materials, and we get them approved by the right bodies. This means they get good improvement of yields on their farms, and of course they are happy about that.”

Fox Robotics brought to Fruit Focus its autonomous robot for farming and soft fruit logistics – Hugo RT. Fox Robotics’ CEO, Gary Livingstone, said that the robot allows growers to be more productive at transporting the harvest from the picking area back to a common collection point or to the packing house. He added: “The more crops you need to pick, the bigger the bene t is, because you've got more pickers picking the fruits without wasting time transporting them. Our clients are very keen to try this technology on their farms. We’re very happy to be here today. It’s important for farmers to be able to see the products in operation.” Hugo RT is currently used in on-farm trials.

Director Mike Hutchinson said that Hutchinsons and its sister company Produce Packaging were showcasing their latest technologies.

Hutchinsons was demonstrating its new software extension, Omnia EasyPlan, at the event. Mike commented: “EasyPlan is a recommendation system that has been designed to be much more user-friendly for fresh produce growers. Its soil mapping system gives them a far more detailed analysis of soil condition and nutrient levels than any other system on the market.” Produce Packaging displayed its latest top-sealable carton board for soft fruit and salads, which is set to be launched in one of the UK supermarkets very soon.

Mild, wet conditions have been favourable to disease in soft fruits throughout 2024, requiring proactive control.

It’s been a challenging season all round for growers. The wettest autumn and winter period on record preceded a di cult spring with belowaverage temperatures and poor sunlight levels hampering growth.

Strawberry growers especially were a ected by these less than favourable conditions with crops typically ripening about 10–12 days later than planned. This helped keep prices rm, which was good news for some, but for those with contracts to honour, making good on the volume shortfall proved expensive.

The mild conditions have also been favourable to disease, although in practice there is always a disease of one form or another that does well whatever the season.

“This year, the main focus of strawberry growers has been powdery mildew, especially in the more susceptible varieties,” says Selchuk Kurtev, better known as ‘Semo’, independent consultant at Zest – Sustainable ICM.

“Botrytis cinerea is present, albeit at lower levels despite the favourable conditions,” he adds.

That both botrytis and powdery mildew have not been a problem for growers, perhaps owes much to the proactive nature of disease control programmes employed by growers and the range of fungicides with good e cacy.

For botrytis, Serenade ASO (Bacillus

amyloliquefaciens QST 713) remains highly e ective and is often used in combination with Teldor (fenhexamid) as part of an integrated programme while Sonata (Bacillus pumilus QST 2808) is a cornerstone of powdery mildew control.

reliance on conventional fungicides. There have been successes with powdery mildew and there is anecdotal evidence that it is useful in reducing the incidence of botrytis and certain soft rots.

“What is unclear, however, is whether the use of UV light as part of an IPM programme for pathogen control interferes with bacillus-based products,” Semo says.

“We need research that considers the e ect of UV light on biofungicides and their ability to control disease. We are also seeing the introduction of non-crop protection products claiming incidental control of disease but with the demise of AHDB Horticulture the industry has lost the resources needed to test the validity of these claims,” he adds.

Another crop production di culty speci c to the 2024 season is the lack of crop uniformity caused by the prevalence of crown rot (Phytophthora cactorum) and red core (Phytophthora fragariae).

“We have seen more crown rot and red core than in previous years, especially in the more susceptible types with Malling Centenary being the variety most widely a ected. E orts to control crown rot have been made more di cult by the decline in e cacy of the CAA fungicide, dimethomorph. The need for new fungicides remains as pressing as ever,” Semo explains.

Positive insect control lessons

With the onset of summer and warmer temperatures, spider mite populations have emerged. For aphids, growers have enjoyed more success despite the threat of rst ights being up to three weeks earlier than the average over the last 30 years.

E orts to achieve control of aphids have, in the main, been reasonably successful with many growers seeing near season-long control from a single application of Batavia (spirotetramat).

The performance of conventional insecticides contrasts that seen with biologicals. As a crop, strawberries follow a detailed integrated pest management programme with a heavy reliance on parasitic wasps and predatory mites.

Semo

We have seen more crown rot and red core (in 2024) than in previous years.

– independent consultant of ZestSustainable ICM

Sonata is especially favoured during cropping for its strong eradicant activity where it ts neatly alongside the contact conventional products.

“It is to the credit of growers that we see such quality produce with so few, if any, exceedances of the maximum residue limits,” Semo says.

UV light research needed

The use of ultraviolet light for pathogen control has created opportunities to further reduce

The poor sunlight levels and cool temperatures of spring, however, meant that attempts to establish colonies of the predatory mite Phytoseiulus persimilis, for red spider mite control fell short of expectations. Fortunately, the spring conditions meant that Western ower thrips (Frankliniella occidentalis) populations have remained at low levels.

“Numbers began to build around mid-June with growers proactively applying Neoseiulus (Amblyseius) cucumeris at regular intervals over a four- to six-week period to manage populations depending on levels,” Semo says.

For raspberry growers where the large raspberry aphid (Amphorophora idaei) and small raspberry aphid (Aphis ideai) are a threat, the feeding blocker, onicamid remains an e ective form of control.

“Where spider mite is a concern, which is especially the case in large canopy cultivars or more susceptible varieties and organic crops, then biological controls often perform well. Unfortunately, this has not been the case this season as the unfavourable start to the summer hampered the establishment of P. persimilis

“As with strawberry crops, crown rot is a threat as is cane blight on raspberries (Leptosphaeria coniothyrium) and we have already seen a greater incidence of these diseases than is the case in a typical year,” he says.

The need to tackle several species of insect pest at once has highlighted some of the crop protection challenges facing growers. Achieving the desired control without negatively a ecting populations of bene cials has resulted in greater use of contact insecticides with a physical mode of action, such as Flipper (fatty acids C7-C20).

“Flipper has been useful this year, especially for spider mite control in conventional strawberry crops and also aphid control in over-wintered 60-day crops or over-wintered everbearer,” Semo notes.

Since its introduction in 2019, Bayer has gone to great lengths to highlight that the e ective integration of Flipper relies on proper application. First among these is achieving good coverage of the target pest.

“In modern varieties with dense canopies and vegetative growth this can be challenge, but with the correct water volume, typically 1,400–1,500 litres per ha, and the inclusion of the nonacidifying water conditioner, X-Fusion to support spreadability and adhesion, it has delivered good control,” Richard Phillips, Bayer campaign manager for roots and horticulture crops, says.

The second principle supporting performance is application timing. This applies to population size, its morphological state and the growth stage of the crop.

“All forms of biological crop protection products have been shown to work best when application is

made before pest numbers begin to build and not at a level typically associated with the timing of a conventional product,” Richard adds.

“The physiological stage of the pest is also important. It should be after active feeding when the pest can be expected to have a soft cuticle,” he adds.

Flipper, as with contact-acting insecticides in general, is best applied when the pest is stationary and not actively circulating within the crop. It has been found that conditions at application – high light levels, high temperatures, high evapotranspiration rates – can negatively in uence e cacy. For this reason, it is best to avoid making applications after 9am and, ideally, when temperatures are 15–18ºC.

The nal tenet of good performance is inclusion rate and water quality. Flipper should be applied at a minimum inclusion rate of 1% and mixed with X-Fusion, even with rainwater, as it has been found to support e cacy through improved coverage across the plant surface and the pest.