Printed by Walstead Roche

News

Record rainfall impacts 2024 apple harvest 6 10 13 15 21 25 30 33 38 41 42 46 45 37

The latest products, advice and research you need to know about

Special report

Future potential for vertical farming of strawberries

Show preview

The National Fruit Show returns for 2024

Machinery

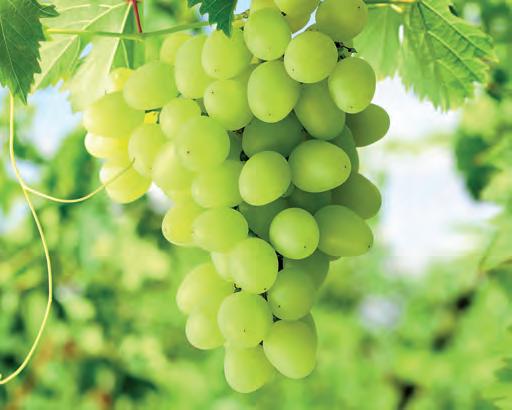

Grape harvester purchase brings automation to Northants vineyard

Machinery

Autonomy and AI: The next big thing in viticulture?

Grower pro le

Iconic jam business blends a rich history with modern techniques

Agronomy

Preparing soft fruit for the winter

Agronomy

Top fruit nutrition: Getting the balance right in turbulent years

Special report

Professional advice

Post-harvest pest and disease management

Agronomy

Pruning for frost protection in vineyards

Technical advice

Sparkling installation for Gusbourne Estate

Special report

New contract winery opens in East Anglia

Grower pro le

Rolling hills, roaming deer and award-winning wines

58 In the know

Estelle Gayout of innocent Drinks discussed the regen ag journey

www.fruitandvine.co.uk

Directors

Editorial

Managing director

Julie Goulding julie@fruitandvine.co.uk

Director

Greg Goulding greg@fruitandvine.co.uk

Editor

Rachel Hicks

rachel@fruitandvine.co.uk

Deputy editor

Sarah Kidby hello@fruitandvine.co.uk

Machinery editor Neale Byart

hello@fruitandvine.co.uk

Machinery contributor

David Williams

hello@fruitandvine.co.uk

Multiplatform journalist Aleksandra Cupriak hello@fruitandvine.co.uk

Advertising

Sales director

Zohra Mitchell zohra@fruitandvine.co.uk

Fruit & Vine specialist

Samantha Wilson sam@fruitandvine.co.uk

Senior sales executive

Joanna Blower

hello@fruitandvine.co.uk

Senior sales executive

Jana Moyes

hello@fruitandvine.co.uk

Sales executive

Alex Coe

hello@fruitandvine.co.uk

Sales executive

Rosanna Sweet

hello@fruitandvine.co.uk

Sales executive

William Taylor

hello@fruitandvine.co.uk

Classi ed sales manager

Nicki Procter

hello@fruitandvine.co.uk

Marketing

Marketing manager

KM Sharp

hello@fruitandvine.co.uk

Digital marketing executive

Patrick Over hello@fruitandvine.co.uk

Publishing assistant

Kat Morton hello@fruitandvine.co.uk

Design & Production

Production manager

Martyn Smith

hello@fruitandvine.co.uk

The visa allocation has been con rmed for the seasonal worker visa route in 2025, but there are calls for long-term certainty.

White Castle Vineyard announced the successful start of its 2024 harvest on 10th October, plus a new winery marking a new chapter in the vineyard’s journey.

For the rst time, Monmouthshirebased White Castle Vineyard has harvested and processed its grapes onsite in its newly established winery using state-of-the-art equipment, paving the way for a future of increased production and enhanced wine quality. This exciting milestone represents the culmination of years of planning and investment in cutting-edge winemaking technology, aimed at improving both the quality and quantity of White Castle’s awardwinning wines.

“We’ve been dreaming of this moment for years, and now it’s nally here,” said Robb Merchant, co-owner of White Castle Vineyard.

“Having the ability to process our grapes where they’re grown, with some of the best equipment in the industry, gives us complete

control over every aspect of the winemaking process. This is a huge leap forward for us, and one that will allow us to o er our customers even more premium, hand-crafted Welsh wines.”

The debut harvest brought together an enthusiastic team of 45 volunteers, including friends, family, and loyal customers who participated through the vineyard’s Adopt-a-Vine program. Together, they hand-harvested three grape varieties – Phoenix, Pinot Noir Précoce, and Rondo – all of which were processed the same day using the vineyard’s new destemmer and press.

Despite challenges caused by the weather, including the threat of frost and a lower-thanaverage yield, White Castle Vineyard remains optimistic.

“We’re incredibly proud of what we’ve accomplished,” said Nicola Merchant, co-owner of the vineyard. “The launch of our winery opens up so many new possibilities for us. Over the coming years, we plan to expand our production and continue creating wines that re ect the passion and dedication we pour into every bottle.”

Currently, White Castle Vineyard has 13,500 vines planted, including the more recent addition of Chardonnay, which promises exciting growth opportunities in the near future.

A total of 43,000 seasonal worker visas will be available for horticulture next year, the government has announced.

Defra said the move will provide certainty and help secure the labour and skills needed to bring high quality British produce, including strawberries, rhubarb and da odils to market.

Food security minister Daniel Zeichner said: “This government recognises that food security is national security, and this can only be achieved by supporting food and farming businesses.

“Con rming the seasonal worker visa allocation for 2025 gives growers and producers certainty, allowing them to plan ahead and secure the labour they need to grow and thrive.”

Whilst the announcement is welcome news, the NFU said it is essential that growers are given the certainty of a long-term scheme.

NFU president Tom Bradshaw said: “For the many horticulture and poultry businesses that produce climate-friendly food and plants for the country, this news will be a relief as they will be able to plan for the year ahead.

“But farming and growing businesses don’t just work on year-to-year production cycles, they plan their business operations years ahead.”

Recent press reports have shown that farmer con dence is at an alltime low and worker availability has been a signi cant barrier to growth.

The Migration Advisory Committee (MAC) recently recommended the importance of the Seasonal Workers Scheme to domestic food security – and the need for a long-term scheme.

Mr Bradshaw urged the government to publish its response to the MAC report as soon as possible.

“We don’t want to see a return to empty supermarket shelves or further years where £22M of crops are left to rot in the elds. [...]

“We have an ambitious industry that wants to drive productivity to support the health and wellbeing of our nation, but action is needed to make this a reality.

“Moving forward we need to see assurances of a long-term SWS and the government’s response to the MAC report,” Mr Bradshaw concluded.

See you at the National Fruit Show on 6 November and at the Vineyard and Winery Show on 20 November. SPECIALISTS IN NEW AND USED FENDT 200 V/F/P TRACTORS AND ESSENTIAL MACHINERY FOR FRUIT AND VINE GROWERS. PLUS SPARE PARTS, SERVICE, REPAIR AND AFTER SALES CARE.

CELEBRATING 50YEARS

The Hutton Institute is renowned for breeding a range of raspberry varieties, including Glen Ample

A ve-year project to tackle the economic issues plaguing the UK’s raspberry growers carried out at The James Hutton Institute has received a £1 million boost.

The Raspberry Economics in Production project has been awarded £1 million in funding from UK Research and

Innovation’s (UKRI) Innovate UK programme to focus on improving the sustainability of raspberry

production in the UK.

The project will focus on developing raspberry varieties that require less water, fertiliser and labour to grow. It responds to recent industry challenges such as rising production and labour costs, and the reduction of available pest and disease control measures.

In the last two years alone, growers’ costs have risen by 25%, while retailer returns indicate a 0% increase. Despite consumers consistently ranking UKgrown fruit quality ahead of imported fruit, purchasing patterns themselves mainly re ect price, with imported fruit costing less and selling more.

Dr Julie Graham, who leads the project at The James Hutton Institute, said that the UK raspberry industry is at a “critical crossroads”.

She added: “While growers face rising costs, competition is increasing from cheaper imports. Add the pressure brought about by climate change, and it paints a bleak picture.

“We’ll utilise cuttingedge genetic technology

Dr Julie Graham, soft fruit geneticist at the James Hutton Institute

to develop varieties more resistant to climate change, which require fewer resources to grow. The project aims to safeguard the future of the industry while also supporting rural economies and the environment.”

Using advanced genetic techniques such as genomics, transcriptomics and phenomics, the project will identify and apply traits in raspberries that make them more cost-e ective to grow and more resilient to changing climates.

The project is supported by Thomas Thomson Blairgowrie Ltd, Berryplants Ltd, Dole UK Ltd, The Asplins Producer Organisation Ltd, Angus Soft Fruits Ltd, and the Institute’s commercial arm, James Hutton Limited (JHL).

Suffolk-based brewery, Adnams, sadly announced the unexpected passing of its head distiller, John McCarthy.

John, who had been an integral part of the

for more than 20

suddenly on Saturday 12th October at the age of 55. Originally an electrical engineer

for the company, John grew more interested in the world of brewing and distilling and went on to study for, and succeed in, his brewing exams. By 2009, he was chosen to serve

as lead engineer to run the new distillery project.

He became known for his innovative approach and unwavering commitment to quality, and went on to develop over 30 di erent gin recipes in the lab ahead of the distillery’s o cial opening.

The Adnams team said that John was the one who so successfully conceived the recipe for the brewery’s best-selling Copper House Dry Gin, which was released in 2010 and has gone on to achieve countless accolades.

John went on to develop an extensive and varied range of spirits for Adnams, winning many prestigious international awards along the way, including gold medals in the World Whiskies Awards and gold outstanding in the International Wine & Spirits Competition, the company con rmed.

He helped Adnams claim the further accolades of world’s best gin, world’s best vodka and world’s

best vodka producer, as well as England’s best rye whisky.

John achieved his Diploma in Distilling from the Institute of Brewing and Distilling and was a member of The Worshipful Company of Distillers, The Gin Guild and The English Whisky Guild.

Jenny Hanlon, Adnams CEO, said: “We are all so deeply saddened to learn of John’s death. He was a wonderful friend, mentor, colleague – and an incredibly talented and devoted professional too.

“John had time for everybody and anybody – no matter how busy he was. He was one of those special people who really left an impression.

“His expertise and dedication undoubtedly transformed Adnams into a leader in the craft distilling movement. John’s passion for his craft and his belief in the power of community were truly inspiring. He will be deeply missed by all of us.”

The Adnams family extends its heartfelt condolences to John’s family, friends, and all who had the pleasure of knowing him, the company said.

NIAB’s Katia Zacharaki and Dr Mark Else outline why vertical farming of strawberries has not always been a commercial success and explain how NIAB is using this technology to improve the yield potential and performance of strawberry plants propagated using this approach.

There has been a lot of buzz around the concept of “vertical farming,” especially when it involves a particular crop like strawberries. Vertical farming is often perceived as a challenging venture due to its high capital expenditure (CapEx) and operational expenditure (OpEx). Strawberries, being a highvalue crop that is relatively compact, appears to be an excellent candidate for vertical farming. Indeed, over the past decade, several attempts have been made to grow strawberries commercially in indoor vertical farming conditions for their highlyavoured fruits, although these have not always been successful. In fact, some of these attempts resulted in spectacular failures, garnering negative publicity for both the companies and the industry. The general perception might be that strawberries cannot be grown in an indoor environment, that it’s too expensive, that the technology is not quite there yet, or perhaps that the fundamental physiological responses of the crop are not yet understood well enough. While these speculations may hold some truth,

several companies and research institutions have successfully grown strawberries for fruit production in controlled environments for some time now.

One example is NIAB, where researchers have been conducting studies on soft fruits in controlled growth rooms for over 20 years. Other groups could also claim to have been working on strawberry cultivation in vertical farming, or Total Controlled Environment Agriculture (TCEA), the term that scientists prefer to call the practice of growing plants indoors using arti cial light as the sole source of photosynthetic radiation (light).

In addition to research institutions, some commercial companies working on the crop have produced groundbreaking ndings. However, due to the cost and nancial bene ts involved, these results are often not made public.

While some companies have managed to use these ndings for commercial gain, many start-ups have ended up failing, often quite dramatically.

These notable bankruptcies and dissolutions are not caused by any single reason but by a combination of factors. Frequently, the business plans underestimate the unpredictable ‘biological’ responses of plants. Entrepreneurs from elds like engineering or nance often make the mistake of using overly optimistic scenarios as their baseline, leading to nancial di culties even after securing signi cant investments. The issue was not their ability to attract funding, but perhaps that they failed to employ the expertise of horticulturists or plant scientists or to heed their advice. Oftentimes, it seems these plant and crop experts have not been consulted as completely as the technology providers, with the inevitable result that attempts to grow strawberries in TCEA conditions and systems suitable for the production of leafy salads and herbs have failed.

We do believe, however, that this is changing, and that the remaining companies, as well as new entrants in the eld, are now giving biological factors the attention they deserve in their

planning and decision-making processes.

Returning to successful TCEA strawberry ventures, two companies worth mentioning are Agricool (Paris) and Oishii (New York). Agricool was a pioneer, being the rst company globally to grow strawberries in containers and sell them in stores in Paris.

Unfortunately, Agricool faced nancial challenges and discontinued operations in 2022. Oishii, on the other hand, has focused on premium, high-end marketing, selling eight strawberries for $50. It recently raised $134 million in its Series B funding round. Oishii’s success stems from its understanding that growing strawberries in TCEA is signi cantly more expensive than conventional cultivation. The higher costs are mainly due to the higher light intensity and more stringent environmental controls compared to crops like leafy greens, leading to higher energy bills. This means that, currently, a TCEA strawberry company can only be pro table by moving away from the commodity market and positioning its product as a niche, premium o ering. This is how Oishii has achieved its success.

In addition to the fruiting stage, TCEA could also add value in the propagation of strawberry plants, especially given the current state of the supply chain and industry. The principle of vertical farming is based on using multiple and stacked growing layers in order to maximise each square meter of growing space. Propagation is a stage where plants are grown to a relatively short height at high planting densities, which aligns well with the vertical farming model.

In the case of strawberries, imagine propagating plants year-round in indoor vertical farms, producing high-health, pest- and disease-free tray

plants with a greater and more consistent cropping potential, all produced with fewer plant protection products and less waste. Do you think that there is a market for this product? We think there is. The end customer of these high-health, high quality propagules could be the existing soft fruit sector who grow in polytunnels and CEA, and perhaps the new generation of TCEA strawberry growers.

With this unique selling point in mind, NIAB is working on a £1.8m project to develop the infrastructure and methodology for propagating strawberry plants in indoor vertical farming or TCEA. NIAB is collaborating with a number of leading companies in the industry, from commercial soft fruit growers (Clock House Farm and Hugh Lowe Farms), propagators (Blaise Plants and Linton Growing) sensor providers (Delta-T) and substrate (Cocogreen) suppliers, as well as Reading University, while the project is led by Vertical Future.

This three-year project is using TCEA to produce high-health June-bearing and everbearing cultivars. The experiments begin with tissue-cultured plants, which are then raised to become the mother plants.

These mother plants are grown in Vertical Future’s prototype strawberry propagation facility at NIAB East Malling using LED lighting, with the aim of accelerating runner production and generating healthier daughter plants in a more consistent environment. The daughter plants have been planted in coir substrate and moved to a second compartment, where they are currently undergoing ower induction treatments before being exposed to chilling conditions.

The project will compare the marketable yield and fruit quality of these high-health plants with that from commercially-propagated plants from our partner propagators. These comparative trials will take place in three production environments: conventional polytunnels, glasshouses, and TCEA systems. After all, the main clients of our approach will likely be strawberry growers, whether they use polytunnels or glasshouses, until TCEA strawberry cultivation for fruiting becomes more prevalent.

Strawberries appear to be an ideal candidate for

NIAB’s aim has been to accelerate runner production

NIAB’s experiments began with tissue cultured plants

At NIAB, we believe that recent developments in vertical farming when coupled with expert plant sciences can bene t the wider horticultural sector by accelerating speci c parts of the cultivation process, such as propagation, while also enabling a better understanding of the fundamental responses of plants to their environment.

This, in turn, will enable us to ne-tune speci c attributes through judicious tweaking of the growing environment, and to ensure that all resources, including energy, are used most e ciently. This knowledge will allow us to collectively improve commercial cultivation practices in future. In many traditional production systems, marketable yield and quality improvements have reached a plateau, and only through new technologies and methods will we be able to achieve further progress. It is clear to us that TCEA is one of those key innovations.

Taking place on 6th November, the National Fruit Show will follow a new one-day format this year.

Now in its 91st year, the show is a platform for British top and soft fruit, run by growers for growers. After feedback from 2023, this year’s show will be across one day only, located in the Maidstone Exhibition Hall.

The show’s chairman, Nigel Bardsley, commented: “With meticulous planning there will be space for all exhibitors creating a

dynamic, buzzing atmosphere, and a great place for customers to meet and socialise. [...] I look forward to witnessing the positive impact our changes have made to the ongoing success of the showcase of our industry’s innovation and excellence.”

Fruit & Vine spoke to a few of this year’s exhibitors to nd out what visitors can expect to see.

With over 25 years of industry experience, Agricare says it is the primary choice for planting products, pruning and tying equipment. Being the UK main distributor of the renowned Infaco and Bellota brands, the Agricare team know what is needed to keep you going, o ering expert support and service, to ensure that you always have the right options.

The company’s priority is ensuring you have the best and most capable tools for the job at hand, making your work e cient and cost-e ective. With a fully stocked shop to visit and e cient delivery service Agricare says it can supply equipment as quickly as possible to enable you to carry on working.

Visit stand M18 at the show, for Agricare’s

Hortifeeds says it is looking forward to welcoming visitors to stand M47 at the show.

UK launch of the new Infaco AT1000 tying machine, where you can give this revolutionary machine a try for yourself with Agricare’s professional advisors.

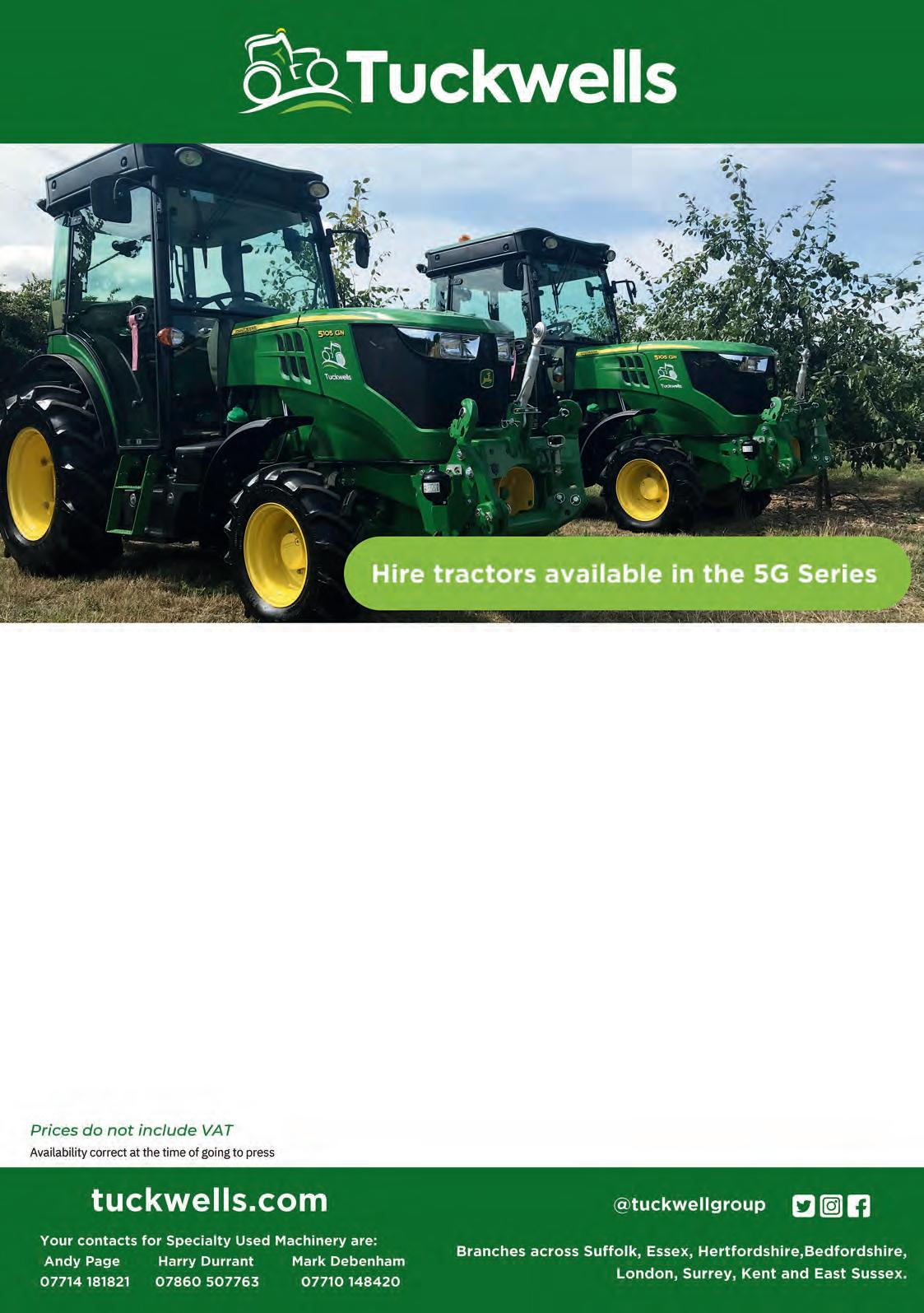

Tuckwells will be attending the National Fruit Show this year. The company’s fruit and vineyard sales and service teams operate primarily from the Stockbury, Kent depot, but all depots are equipped with trained sta to assist customers in selecting machinery and speci cations.

The specialist division o ers a range of products, including John Deere tractors, Kramer handlers, and machinery from Tehnos and Teyme, for which Tuckwells is the UK importer.

John Deere introduced its updated narrow tractor models last autumn. The 5G series ranges from 73–111hp and features widths starting at 1.25m. Customers can choose from V (vineyard), N (narrow), and F (fruit) variants, with cab options of 1.0m and 1.2m wide. These models boast large windows for better visibility, and Cat 4 ltration is available for spraying.

The 5G series also incorporates John Deere’s precision farming technology, with JD Link providing wireless connectivity and telemetry through the Operations Center app. This allows tasks like variable rate application maps to be sent directly to the user and tractor from the farm o ce or agronomist.

Agricare says it is also excited about the addition of the CFMOTO range of UTVs and ATVs to its portfolio, which are proving to be very popular and a useful machine in the fruit and vineyard industries. These will be on the company’s stand at the National Fruit Show.

company will be welcoming Rob Kempster, lead applications scientist at Plant Impact to the stand, who will be happy to discuss the bene ts of calcium mobility product Amētros, available through Hortifeeds. Amētros has been shown to improve Class 1 yield and fruit rmness in a range of fruit crops, so head to the stand and chat with the team about how it can bene t your business.

Hortifeeds will also be highlighting the bene ts seen from regular applications of its complete biostimulant HortiBoost. When used in tank mixes with each round of programmed sprays, HortiBoost

monitoring of location and operating status.”

Andy Page, Tuckwells fruit and vineyard specialist, said: “We have customers operating up to 30 John Deere narrow tractors, all of which can be tracked via smartphone for real-time monitoring of location and operating status.”

hours and contacts owners when maintenance is

Tuckwells' service team keeps track of working hours and contacts owners when maintenance is due, ensuring tractors remain in peak condition.

The company’s ability to keep machines running

The dealer’s customer base ranges from traditional family farms to multinational brands. The company’s ability to keep machines running smoothly, backed by over £1M in parts stock across its depots, is a major attraction. Parts include fastmoving items for John Deere 5G-series tractors, Kramer handlers, and Tehnos and Teyme products.

Tuckwells also employs a team of eight technology specialists who ensure customers maximise performance and e ciency from their machinery investments.

has been shown to improve yield, the fruit quality, and can strengthen plants to combat stress events such as extreme heat and drought. The little and often approach to HortiBoost application is cost e ective and ensures crops are protected from stress, whenever it may occur.

Hortifeeds will also be showcasing its extensive range of fertiliser and biostimulant products at the show, including foliar products to suit all fruit crops and growth stages, and an extensive range of bespoke soluble fertilisers for top and soft fruit.

•

Northampton-based vineyard and contractor, Croxford Wine Estates has just taken delivery of its new Gregoire GT3 trailed grape harvester. Fruit & Vine joined owner William Croxford during his rst harvest with the machine. Neale Byart reports.

Croxford Wine Estates has been running for two years with owner William, who is also director of Nene Valley Winery, following on in his father’s footsteps. Nene Valley Winery is a contract-only business set up alongside Croxford Wine Estates Limited. Croxford Wine Estates operates its own vineyard just up the road from the location of the winery.

The 10ha site had been under vine for around three years and was just coming into commercial productivity when the owner decided to go in a di erent direction.

The vineyard is set on sandy loam over ironstone and is growing Pinot Noir, Chardonnay, Solaris, Pinot Noir Précoce and Bacchus.

This vineyard forms the basis of Croxford Wine Estates while the winery, which William runs in conjunction with his business partner Dennis Hall of Patch Lodge Estate, is sited on land owned by William’s in-laws and covers just under 500m2.

The contracting side of the business which is owned and operated by William o ers a range of vineyard management services available to other vineyards. At the same time, Nene Valley

Winery, with its state-of-the-art equipment, is large enough to not only process the grapes from William’s own vineyard, but also to support other vineyards who don’t have their own facilities.

The winery has initial capacity for production of 250,000 bottles annually, with future increases planned.

A new vineyard and winery

“This is the second year of wine production from our own vineyard. The rst year we had to use

William Croxford, owner of Croxford Wine Estates and director of Nene Valley Winery

William says the harvester removes the destemmer from the operation to deliver a better quality fruit, more akin to a handpicked result

another winery as we didn’t have the facilities set up, but this year we have everything in place to not just process our own grapes, and that of my business partner who also has his own vineyard, but also to work with other small growers who don’t have their own winery facility.

“The winery currently has a processing capacity of 103,000 litres, with plans to increase this to 200,000 litres for next year, together with a planned purpose-built barn to deal with all the handling and storage.”

Inside the winery, William has installed 36 individually heated and cooled Letina fermentation tanks, and the incoming grapes are o oaded from a tipping trailer into a Zambelli elevator that delivers the grapes into a Bucher Origin press. He also has a Zambelli de-stemmer and crusher so that when it comes to contract wine production, they can take either machine-harvested or hand-picked grapes.

“Our tanks are all heated from a jacket on the base to deliver a more consistent and level heat to the contents, and when it comes to the fermentation process, we are very much customerled in terms of speed and processes.

“We like to involve the customer as much as possible, as the process of making wine is a very personal thing. On that basis we use a software system called Innovint, which allows us to manage the wine much better and allows the growers to access information about their grapes and wine throughout the process.

“From our own vineyards we are on track to produce around 50,000 bottles from this year’s harvest, with a target of around 70,000 next year.”

William admits the winery was a large investment, but says: “We wanted to do it in the best way with the highest quality equipment. Yes, we could have done it cheaper by buying used items, but we wanted to get it right rst time. We used Core Equipment to do the full install as a turn-key project.”

Current machinery and future plans

Contract services, including mechanical harvesting, are available to growers nationwide.

“Our machinery consists of a Friuli drift recovery sprayer, which has reduced our sprays this year by 60%, a Provitis de-leafer, a Provitis

trimmer, an under-vine fertiliser spreader and an Orizzonti under vine strimmer. Plus, we are currently building an under-vine herbicide sprayer to be mounted on a Polaris Ranger with a 300-litre tank, which will also be useful for spraying fungicide in smaller vineyards, where our tractors might not t, when combining it with an air assist boom,” says William.

“We are really looking to be able to o er all the services that any vineyard, large or small, might need. We have our own haulage to help keep transport costs down by putting, say, a trimmer and de-leafer on the same transport to carry out both jobs on one vineyard, or work on two vineyards in the same area. If we can keep the transport costs down, we can o er a more a ordable service.”

Discussing his second ever harvest from the estate, William explained that it hasn’t all been smooth sailing. “We are behind with the harvest this year due to weather, with some early frost damage, and we have su ered quite badly with losses to birds, with an estimated 60% of yield potential –around eight tonnes of fruit, or the equivalent of 6,500 bottles – lost to the pigeons. We are going to have to net in future years, which is another big cost, as we have around 36km of vines.

“Luckily, we don’t have too many issues with

deer and badgers, so it’s just the birds we must stop. We are looking to expand the vineyard using land adjacent to the winery, and also on some of the south facing elds opposite; but we need to keep an eye on the market, which is certainly growing for UK produced wine, including export, and we need to expand as the demand increases. Currently, we tend to focus on supplying our wines to local pubs and restaurants, although we have future plans to sell direct to customers via cellar door by building a new tasting room with views over Pitsford Water.”

Machine harvesting comes to Croxford

“Last year our entire harvest was hand-picked, but suitable seasonal labour seems to be getting harder to nd. Then there is the cost. Realistically we would need around 40 pickers working an eight-hour day for around 10 days to harvest our current crop. That equates to a sta bill of around £50,000. With costs like this, it is very di cult not to pass it on to the end consumer and, with so many people buying wine on price, we have to do whatever we can to keep our overheads, and therefore the price of our wine, down. This was really the driving force behind us looking for a harvesting machine.”

William already had a relationship with Kentbased specialist fruit and vineyard machinery dealer, Kirkland UK, having purchased other equipment from them previously. So, when it came time to look for a grape harvesting machine, he was more than happy to put the business their way after considering various options. “We looked at New Holland, Pellenc and Gregoire and, after travelling to France to trial one, I felt that the Gregoire was the best option for our specific needs.

“Each brand has its strengths and weaknesses, and pricewise they were all very similar, but for me I felt that the Gregoire handled the fruit more gently. It also removes the de-stemmer from the operation to deliver a better quality fruit, more akin to a handpicked result.

“It is a fairly simple machine to use, and I genuinely feel it is a game-changer for the UK vineyard industry. I was also impressed to see that Gregoire has machines still out working in vineyards that are 40 years old. I doubt we will be keeping it that long, but it’s good to know that the quality and longevity is there. Kirkland is a great company to deal with – they really understand the machine and offer lots of support and parts backup, so that any issues with the machine can be dealt with quickly.”

The machine William purchased was the GT3 trailed harvester, and Croxford’s is the first of these models to be delivered to the UK. Its features include auto height management and obstacle detection, auto tilt correction up to 700mm, auto row centring, vacuum system for harvest cleaning, and Isobus compatibility with an 8.4in display and multi-function joystick.

An Easy Clean De-Stemmer can be activated and deactivated from the touch of a button, plus the harvester offers the ability to change the pressure on the catching system, making it adaptable for old and young vines.

It also comes with its own independent 70-litre hydraulic unit fitted on the three-point linkage and powered by a PTO. This allows the GT3 to be completely independent from the tractor’s hydraulics. The GT3, which can work on vineyards with a width of 1.5m upwards, is brand new to Croxford for this year’s harvest and, on the day of Fruit & Vine’s visit, was being used for the first time so still required some fine tuning to get it working just right on the Croxford Wine Estate vines.

William, who has been working on harvesters of all types since he was 16, seemed to have an instinct for how to get the best out of it, and after a couple of test runs, where it wasn’t quite working as expected, he put his head together with the Kirkland reps, who had accompanied the harvester on its delivery to assist in getting it up and running.

By adding an extra pair of bars to increase the working height of the fruit shaker unit, and changing the speed and vigour of the shaking motion, the harvester began to work exactly as required and it was doing an impressive job.

After a single pass the vines were stripped of all but the smallest unripe fruit. The produce was reasonably clean, with just a few stray leaves and vine stems finding their way into the hoppers; but a few more minor adjustments on the machine should improve this further. At the end of the work, the machine can be cleaned using an integrated washing line, whereby a single low-level hose connection provides cleaning water right up to the top platform. Grease points are all easily accessed, and an automatic greasing system is available as an option.

The steering drawbar makes lining the

up much easier

The GT3 features 14 adjustable shakers, enabling you to modulate the picking intensity

Croxford’s purpose-built winery is state of the art and available for contract winemaking

William admits the winery was a large investment, but says: “We wanted to do it in the best way with the highest quality equipment”

The GT3 can harvest at a rate of 1ha/hour, meaning in theory it could do the whole Croxford Estate harvest in one day. “This obviously gives us so much more exibility to work around weather windows and we can use it for our contracting business too, meaning payback could be in as little as two years. Not only can we reduce our own harvest down from 10 days to one, but instead of 40 sta I could actually do the whole harvest on my own, if needed.”

In the vineyard, the steering drawbar makes lining up the machine over the vine much simpler, and it also means that it is easier to manage and

Once set up properly, fruit removal was e cient

more manoeuvrable in the headlands, which makes it perfect for vineyards with little space.

The GT3 comes with two 2,000 litre fruit hoppers, although Gregoire also o ers a narrower, twin 1,600 litre option, and once the harvester is full it is simply a matter of positioning the trailer behind it and tipping the fruit bins, together or independently, using a remote control.

The machine comes with a tipping height of 3m, allowing even taller trailers to be used. William has opted for a slightly oversized specialist Sthik fruit trailer that comes with a liquid take-o point underneath. The process of emptying the harvester takes no more than ve minutes or so, and that includes moving the trailer for each receiver, if necessary.

As the harvester also acts as a de-stemmer, the trailer can then be tipped straight into the fruit elevator and onto the press. William is planning to add a fruit-receiving hopper so that he can o er a full service from eld-to-press to those vineyards with their own winery.

“We like to work closely with other producers within this industry, which is still quite small in the UK, and I feel that it is bene cial to help each other out, as you never know when you might need help in return. With the investment in our winery and machines, we can o er competitively priced, full-service contracting to those that need it.”

Two Companies. One Mission. Delivering a complete suite of services for all your vineyard needs.

Whether you’re starting your vineyard journey or looking to enhance your production, Croxford Wine Estates and Nene Valley Winery offer a seamless partnership to meet all your vineyard needs. Together, we provide a full suite of services that guarantee success from vine to wine.

Vineyard establishment

Vineyard management

Under-vine herbicide spraying / grass strimming

Machine harvesting Winemaking, bottling, disgorging

Storage and distribution

info@croxfordwineestates.co.uk

www.croxfordwineestates.co.uk

www.nenevalleywinery.co.uk info@nenevalleywinery.co.uk

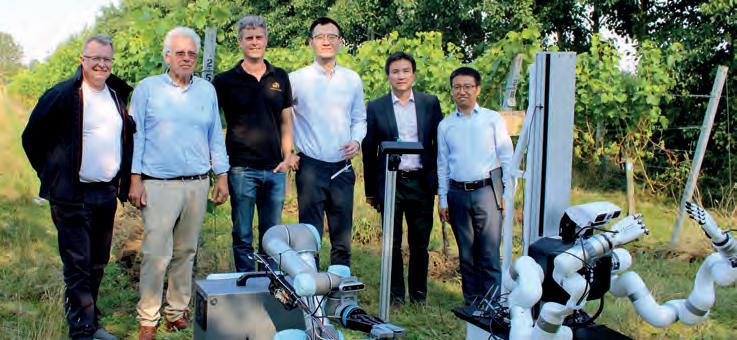

Fruit & Vine was invited to a vineyard in North Essex to hear from a collaboration who are working together to bring robotics and arti cial intelligence to vineyards. Neale Byart reports.

Automation and autonomy are slowly working their way into viticulture, and the next level could just be robotics powered by arti cial intelligence, according to the combined bright minds of Extend Robotics and the Queen Mary University of London. These two establishments have teamed up with Sa ron Grange Vineyard in north Essex and are working on a three-year plan to bring robots with AI to the vines of Sa ron Walden and beyond. The project is funded by Defra’s Farming Futures Automation and Robotics Competition, and Innovate UK.

The vineyard

Sa ron Grange Vineyard produces premium quality English sparkling wines in Sa ron Walden, Essex. They take great pride in marrying traditional viticulture techniques with the very latest technological advances to signi cantly impact growth and productivity.

Owner Paul Edwards began planting it in 2008, with the most recent vines going into the ground this summer and more planned for next year. Of the

16 hectares available, 9ha are currently under vine.

The chalk seam upon which Sa ron Grange sits is the very same one that runs through the south of England and onto the renowned wine regions of northern France.

The logo for the vineyard features a woolly mammoth – a curious choice of mascot, you might think. In fact, the reason it appears on the company branding is that the remains of a woolly mammoth (tusk and teeth) have been found on land at the edge of the vineyard. “To us, the mammoth represents strength, opportunity, adaptability and durability. Their presence on our land for tens of thousands of years is a reminder of the will needed to survive during dramatic climate and geological change,” Paul told Fruit & Vine. Explaining why he decided to get involved in this research project, Paul continued: “We expect the vines to last at least 25 years in the ground, giving us plenty of cause to invest in making it an e cient process.

produced from the 2023 harvest and we have planted more vines to allow us to produce 50–60,000 bottles in the coming years.

“This growth is going to mean a signi cant increase in labour and the costs that are associated with that. We are on track to grow more vines, produce more wine and increase sales and we need to look at how we can drive the business forward, expand and take advantage of new technology to help that.

“As the number of bottles produced increases, the costs do too; which is why I am so happy to be a part of this project to bring robotics and AI into the industry and we are working hard to share every bit of intellectual property needed to make this successful, as well as understanding what changes we need to make in the vineyard to encompass this. In that regard we have put half a eld aside so that we can grow grapes in a slightly di erent way if needed. I’m really excited about the prospects of the next couple of years and working with the teams from Extend Robotics and Queen Mary University of London.”

Extend Robotics is a UK-based start-

“At Sa ron Grange we can now sustain the with

“At Sa ron Grange we can now sustain the growth year-on-year with around 30,000 bottles

up specialising in virtual realitybased teleoperation systems for remote manipulation of robots.

The team’s expertise in precision giving us plenty of cause to invest in making it

manipulation and perception systems are essential to developing modular robotic hardware systems with human equivalent manipulation robotic arms and cameras. Azmat Hossain from Extend Robotics told Fruit & Vine: “We are a robotics company, but also a software developer. We believe that robots are not just hardware or machines, they need to have intelligence and be trained, and this is what we are working on. We are revolutionising the control of robotic systems by building a fully immersive, intuitive and accurate human/robot interface.

“The technology is a ordable and easy to integrate and allows operators to intuitively operate robots using immersive gesture control in real time and from anywhere in the world.

“We work with many partners across di erent industries with an aim to have robots working sideby-side with humans. We are dreamers, innovators and a disruptive group looking at the challenge of building something quite extraordinary, something that can really provide value to the industry and our partners, not just for the UK, but for the world.”

Chang Liu, the CEO of Extend Robotics, added: “We are o ering a virtual reality interface that could be used for delivering automation into future farming – in this case viticulture, which is one of the more di cult agriculture-related uses for this technology. The objective for this project is rstly to be able to monitor the vine growth and plant health to help improve the quality of the wine, but also to develop the virtual reality interface to deliver precision harvesting and pruning as well as promote automation in real world farming.

“Of course, we must combine this with the t-for-purpose custom hardware that can make this all happen. Queen Mary University’s team is working on the monitoring and the hardware development while we are primarily focused on the software side. Delivering automation in the eld is a di cult technical challenge with so many complexities and variabilities but we are looking to develop a robot that almost anyone can use. It is very intuitive and using a VR headset you can use gestures to remotely operate the robot, and you can see things in 3D. As the robots are used, single robot to single operator initially, data can be collected, and this data can then be used to ‘teach’ the robots and drive the automation forwards so that AI can start to automate things

further. This will lead to ‘ eet’ operations whereby a single operator can oversee many robots, while keeping the human in the loop. As it is all cloudbased, you could have farmers on the other side of the world operating a eet of robots on this side meaning seasonal workers could work year-round on di erent continents from their home base, or picking could be carried out round the clock, eliminating local labour shortages.”

The university is bringing its expertise in remote sensing and image spectral analysis to the project, which is critical to its success. Professor Lei Su explained more about its involvement.

“My team is working on instrumentation, particularly AI integrated spectral analysis. If we placed a glass of red wine and a glass of orange juice in front of a person, they could easily tell the di erence. This is our brain carrying out spectral analysis with our eyes being able to see di erent colours in the visible light range.

“If we were to place a glass of water and a glass of ethanol in front of a human, they look identical as they are both clear liquids. What we are working on with AI spectral analysis is a system that can look further than the visible light range at both ends, in both the infrared and ultraviolet ranges and beyond. Using AI spectral analysis, the two clear uids can be clearly identi ed as either water or ethanol due to their di erent wave lengths. This precise technology can be used on the grapes to help ensure that they are harvested at exactly the right time to ensure the very best quality wine. It can also be used on the leaves of the vine to look for disease”.

Dr Ketao Zhang, senior lecturer of robotics at the university, further explained that the aim of the project is to combine robotics and AI to nd the solutions to the challenges faced. “Mechanically we have the wheels to allow the robots to move around the farm, we have the robotic arms to pick and cut the grapes from the vine, but they lack the human touch to select the right amount of pressure required to pick them without damage. We have sensors, of course, but we are also focusing on an electronic skin that provides an arti cial touch to allow the robot to ‘feel’ the pressure being exerted. What we have here today is a concept and we hope to have the rst commercial prototype ready in around two years.”

The team provided a demonstration of how an operator wearing o -the-shelf VR goggles could manipulate the robot using gestures – the fruit of a year’s worth of development. The robot approached a vine, extended the arm towards a bunch of mock grapes, which the arm grabbed, cut and removed – and all done by an operator wearing VR goggles. He may have only been a couple of metres away, but the point is that he could just as easily have been on the other side of the world.

The prototype obviously needs re nement and further development to realise the potential, but what is in no doubt is the skill and the enthusiasm displayed by the teams from the university and the robotics company, and there can be little doubt that by the time they reach the end of their three year plan, if the progress made in the rst 12 months is anything to go by, there could be a robot in a eld in Essex, operated by a picker anywhere in the world, well before the decade is out.

Wilkin & Sons is world-renowned for its jams, produced in Tiptree, Essex for over 130 years – with its Little Scarlet strawberry jam even nding favour with 007. Sarah Kidby visited the farms and factory to learn more about its enterprise.

The Wilkin family have been farming at Tiptree for nearly 300 years, moving gradually from arable to fruit growing in the 1860s, and beginning jam production in the 1880s. According to farm manager Andrey Ivanov, who has worked for the business since 2002, the fruit was once sent to Kelvedon railway station by horse and cart, then on to London, before jam production was brought in-house. Now, Wilkin & Sons is made up of three farms spanning 263ha, as well as an on-site jam factory, pudding room, storage facility, and packhouse, with an o site patisserie and pudding company, and an estate of quintessentially English tea rooms throughout East Anglia.

Trees with special importance

The business blends its rich history – which saw the Wilkins grow everything from rare Little Scarlet strawberries, to medlars and quinces, all of which are still grown on the farm today – with modern-day technologies and growing practices, which help to secure its future in an increasingly challenging climate.

The farm’s 12 established King James mulberry

trees are over 100 years old, and another 12 have been planted which will not produce any signi cant volume for 20–25 years. Meanwhile, its oldest damsons were planted 84 years ago, the same year that Peter Wilkin, great grandson of founder Arthur Charles Wilkin, was born. Today, the farm continues to grow a wide variety of fruits alongside strawberries, which are its main crop – including Morello cherries, greengages, crab apples and plums, among others. The farm’s more unusual fruits and minor crops are made into its jams, conserves, jellies, condiments and other products, which are sold in the UK and exported to around 60 countries. And whilst the farm has grown many di erent minor crops over the years, such as blackcurrants and redcurrants, many of these haven’t been replanted, and economies of scale mean strawberries are now its main focus.

Despite being known predominantly for its jam, which rst received a Royal Warrant in 1911, Tiptree began growing 1ha of strawberries for the

fresh market in 2002, which has since expanded to 26ha. Currently the fruit goes into Sainsbury’s –and Tiptree has its own packhouse on site.

“The agriculture and horticulture sectors are very tight at the moment,” Andrey noted. “Margins (where they still exist) are miniscule, so we have to look at economies of scale and we only manage to achieve that with our strawberries. Some of the smaller growers are disappearing one by one and we don’t want to do that, so we’ve concentrated over the past 10 years on strawberry production and the fresh fruit market mostly. And all the excess fruit goes to jamming – we are very fortunate to have that.”

Tiptree is thought to be the only commercial grower of Little Scarlet strawberries in the world

The farm grows a wide variety of fruits alongside strawberries – including Morello cherries, greengages, crab apples and plums

They now produce around 1,500 tonnes of fresh fruit per year, and 500 tonnes for jam. Their strawberry varieties this year are Malling centenary, Prize, Aurora Karima and Favori – and every year they trial 3–5 varieties in larger numbers and 5–6 varieties on a smaller scale, usually starting with 50–60 plants. Within the main varieties, they also utilise three di erent planting types: bare root, mini tray plants and green plants, to o er a at pro le of fruit seven days a week throughout the season, whilst avoiding large peaks.

Not all varieties are available to Tiptree farms and they have to work with their customers on varietal selection. Important attributes are: aesthetic, shelf life, sugar levels and avour, but choosing varieties can be very di cult, as no single variety o ers absolutely everything, Andrey said.

Tiptree believes it is the only commercial grower of Little Scarlet strawberries – and its jam gets a mention in the James Bond novel From Russia with Love. The variety was imported by the Wilkins from Virginia, USA, in the early 1900s and has been grown at Tiptree ever since. Little Scarlets are signi cantly smaller than traditional fresh strawberries, with an intense avour akin to that of a wild berry – and it’s a highly valued crop for the farm. Lacking the size or shelf life for the fresh market, it is grown solely for Tiptree’s Little Scarlet jam. Traditionally a June bearer, it has to be picked, washed and processed within 24 hours.

It was previously grown on the ground, but is now in raised beds to avoid pests and disease (particularly slugs), but unlike the rest of the farm’s

strawberries, it is not grown under polytunnels – for now. The variety is actually less troubled by pests and disease than the farm’s other varieties, but being uncovered, weather is an issue. They tend to have an o year every 3–4 years, Andrey said, and incessant wet weather and reduced pollination this year has hit the crop particularly hard. Yields are expected to be down at least 50%. As a result, next year they will trial around 2ha of Little Scarlets under polytunnels, but being such a rare variety, it’s not known how changing its microclimate will a ect the crop. There’s a concern that other fungal diseases may crop up or that the reduced light transmission could a ect plant growth.

The farm’s fruit crops and cover crops in general have su ered this year due to the unseasonable weather – the quinces have had rust on the leaves, though some trees have fared better than others, but the rest of the strawberry varieties were catching up at the time of our visit.

Being located in the driest part of the driest county in the UK, water is a key challenge for the farm. In 2022, they had just 511mm of rainfall which Andrey noted is comparable to a desert country. Last year, it was 912mm, which is still far below the UK average of 1,380mm. And with clay soil, no rivers nearby and very few streams, which generally dry up in summer anyway, there is no underground water to abstract, so rainwater harvesting is their main source of water.

Adopting new technologies has also been important in making the best use of their water. Up until 2002, their production methods were very traditional, with fruit grown in open elds, but now all strawberries apart from the Little Scarlets are grown in tabletop systems under polytunnels, in coir substrate. Sensor technology is used to provide irrigation only when the plant needs it.

The farm has seven reservoirs across its farms, and water is harvested from all of its structures, including greenhouses, polytunnels and its ‘New Growing System’. A treatment plant also allows them to reuse waste water from the factory for irrigation, and prevents any bacteria or fungal diseases from the eld being spread to the whole farm. The central pumping station is at the heart of the Tiptree estate – connecting the farm’s reservoirs and irrigating its crops.

“We needed to do a lot of work on water, and now I can say we are water resilient,” Andrey said. Thanks to their harvesting of water and precise irrigation, as long as they have 650mm rain a year, they are self-su cient.

“We’ve done this because we had no other choice, but we’re very proud of it because now the next challenge for everyone will be water –a lot of farmers are struggling,” Andrey added.

back

The farm has two independent agronomists who visit the farm on alternate weeks. As a conventional grower, sprays are used according to the weather and need of the crop, but they have been using biological controls for the past ve years, which are working very well, and pest monitoring traps are also used. Insecticides have been reduced by 95–100% as a result, but Andrey stressed that it’s dependent on pest pressure and if they could not establish biological control, they would have to spray.

As a conventional grower, sprays are used according to the weather and crop need, but they have been using biological controls too which are working very well

Fungicides, on the other hand, are more di cult to reduce and each year is di erent – botrytis spores are in the environment so if the conditions are right, with wet weather and humidity over 60–70%, it will start to cause problems. The same is true for powdery mildew, which is their biggest disease pressure for the strawberries. They are trialling UV-C treatments over the next two years and this has already reduced their fungicide use by 50%. While consumers are often concerned about spraying, Andrey said UK regulations are strict and the demand for British food from countries such as China shows that the Union Jack carries a promise of safety and quality.

In 2015, Tiptree became the rst grower in the UK to introduce its ‘New Growing System’ (NGS) – a covered oscillating structure rst seen in Spain that allows them to mechanically move layers of strawberries up and down at the touch of a button, with fully integrated climate control. Vents on the top and sides automatically open when temperatures rise. Often referred to as the ‘Tiptree vertical system’ by visitors to the farm, it’s not actually vertical – during the growing stage the layers of strawberries are grown together, and they can be moved up and down to allow pickers to interact with the fruit, creating a better environment for workers.

The development wasn’t cheap, but the

rewards for the business have made it a no brainer. It allows them to crop 100% of the production area and increase plant density, unlike in a conventional system where you can only crop every second row. Traditional growing in open fields allowed them to plant 30,000 strawberry plants per hectare, while tabletops extended this to 55,000/ha. But with the new system, they can plant 200,000/ha – though Andrey says the optimum number is 100,000. Insufficient light levels in the UK meant the plants were too vegetative and fruit yields too low with both 200,000 and 150,000 plant/ha. Yields have increased 50% with the NGS, and their carbon footprint has reduced threefold, compared to tabletop systems. They can also start the season earlier and finish later without artificial heating and lighting, and a much more tightly controlled climate means zero insecticides and herbicides. While fungicides are still used, it’s hoped the UV-C treatments will eliminate this too, so they can claim to be residue free.

Following a carbon study, they are now planning a similar 4ha structure closer to the factory which will collect heat from the chimneys and boilers to use for growing – this will extend the season for another 6–8 weeks. Light levels will prevent them growing too early, but beginning in April and continuing until November is sufficient, Andrey said.

Being a business with a farm, rather than purely a farm, gives Tiptree an advantage when it comes to new developments such as these, he acknowledged – they have access to engineers, accountancy, HR etc, whereas for many growers, all these tasks fall to the farm owner.

The business has taken pains to save energy and improve its carbon footprint – carbon calculations are now in their fourth year, which has been a huge undertaking, Andrey said. They have also carried out field scans to identify retained and active carbon to better understand their soils, and will plan methods of putting carbon back into the soil over the next two years. Following these calculations they decided to ‘inset’ – rather than offset – their carbon footprint, i.e. making changes to their own site rather than buying woodland for example, though this will be much more time consuming and costly. As a farming enterprise, Tiptree is now in carbon credit, but as a company, Wilkin & Sons is a long way from this goal due to the energy intensive nature of jam production, particularly the glass jars.

A former arable field has been put into solar panels and another, opposite the strawberry polytunnels, is in regenerative agriculture. Tiptree is in Countryside Stewardship Mid Tier and farms to LEAF (Linking the Environment and Farming) standards, adding biodiversity corners and edges wherever they can, including owl boxes on site and leaving hedges and grass uncut as much as possible to increase biodiversity. Subsequently, the farm has become a haven for hares, pheasants, partridges and muntjacs, among other wild species. This has the added benefit of attracting natural beneficials to combat pests. Providing habitats for pests has also been successful in keeping them away from the fruit crop, Andrey explained.

The crop type planted in each field is changed every two years to maintain vigour and yields, but

Farm manager: Andrey Ivanov

Location: Tiptree, Essex

Fruit growing area: 263ha across all three farms

Fruits grown: 30ha strawberries, and 25ha in rhubarb, raspberries, cherries, apples, greengages, Victoria plums, damsons, mulberries, quinces and medlars

Soil type: Silty clay

After cooking to release the liquor, blood oranges are pulled open by hand to check for pips before being made into marmalade

noting the current buzz around regen ag, Andrey said farmers have been using these techniques for generations.

“It’s inevitable that you cannot put the same crop on the same eld year on year, so to have that success you have to recharge the soil with di erent crops – whatever you choose, wild- owers etc, depends on what you need for your soil. We have been doing this for generations and generations, it’s not something new really but that’s the new modern word that gets everyone excited.”

He added: “Now we’ve got much more modern methods of assessing the soils to decide what to do to get everything back up to scratch.”

The farm does regular soil health tests and eld scanning to understand the nutrient content and health of the soil, sending leaf, soil and water samples every 2–3 weeks and adjusting as needed. Each eld has sensors that constantly measure inputs such as moisture, pH, and electrical conductivity, which is connected to a system in the pumphouse, automatically giving the plants exactly what they need.

Tiptree has 13 permanent members of sta and all other labour for the farms is sourced through the Seasonal Agricultural Worker Scheme (SAWS) – in fact, Wilkin & Sons was the second registered user of the original scheme when it rst opened in the 1950s. It closed in 2014 but reopened as SAWS after Brexit. Whilst the farm has no problem nding su cient labour in terms of numbers, getting skilled, experienced pickers is an issue, as many of the workers are new to the scheme.

Seasonal workers live in the on-site farm

camp, which includes furnished caravans and a recreation and catering facility, plus a laundry, drying room and meeting hall. The farm has around 20–30 workers on site from February each year when the polytunnels are put up, but once harvest gets started, numbers can run into the hundreds at peak times. Harvest begins each year with the Timperley Early rhubarb in April, followed by cherries in June, mulberries in July, greengages in August, damsons in September, quinces in October, medlars – a Mediterranean fruit with a savoury avour – in November and apples from August to September. Meanwhile, strawberries are harvested from May to October.

There are more than 150 workers in the factory year-round, many of whom are friends and family of the permanent sta , who help out during the holidays – and they also have workers on zerohour contracts, explained factory supervisor Tracy Warren, who manages the pudding room and marmalade making.

When it comes to jam production, everything is made to order. While they used to cook from fresh, with orders getting larger they now individually quick freeze (IQF) fruit after picking. Again, they have their own storage facility, which was built in 2012. Being as self-su cient as possible in farm-grown fruits is important to Tiptree. They are often asked if the fruit used for the Tiptree products is grown on the Tiptree farms, and whilst they try to ensure that this is the case for the fruits they can grow on the farm, some is bought in to meet demand or, for fruits such as the Seville oranges used for marmalade and vine fruits for Christmas puddings.

Tiptree produces around 500 tonnes of jam every year

Tiptree produces its own Christmas pudding varieties and Cole's nut-free puddings

The fruit begins its journey in the factory by being put through a conveyor belt, allowing sta to check it and remove any stones in plums or cherries. before it’s weighed, washed and processed. The factory also has a destoner machine for the Morello cherries. For the marmalade, oranges are cooked for three hours and left overnight to release the liquor; they are then pulled apart by hand to check for pips and the pulp and juice are removed, before being added back into the nal product with the cut peel. Every part of the orange is used apart from the pips, Tracy said.

Also produced on-site is the company’s wide array of other products – from curds and sweet spreads, to fruit jellies, chutneys, relishes and sauces, among many others. Additionally, Tiptree produces English spirits and liqueurs.

The on-site pudding room, meanwhile, is where its range of Christmas puddings are created, including Tiptree’s own brand varieties and Cole’s nut-free puddings, which became part of Wilkin & Sons in 2010. The fruits are pre-weighed 24 hours before use, soaked in the alcohol and hand weighed again before being put into basins and into the cooker, which has internal probes to check the temperature. After overnight cooling they are packed, again by hand and checked on a sample table to ensure quality.

Tiptree is always looking ahead, and next on the horizon the business is looking to add nut butters to its extensive product list. By the end of this year, there will also be an announcement on its Royal Warrant, with hopes this will be renewed by King Charles. Finally, on the farm side, Tiptree is looking to trial robots to aid early disease detection in its crops.

As

the cropping season for soft fruit draws to an end, the focus switches to protecting crops over the winter months to give

them the best possible start next spring.

The trend in recent years of milder, wetter, winters poses some speci c challenges for soft fruit crops, from the increased risk of pests and diseases, to the lack of winter cold necessary for vernalisation and renewed vigour in the spring.

Once the polythene comes down, crops are inevitably at the mercy of whatever the winter weather brings; but there are things growers can do to help mitigate some of the risks, says Hutchinsons agronomist, Andrew Taylor.

Watch for aphids

Mild winters, such as 2023/24, can favour the build up of aphid populations, and this year that risk has been compounded by the fact that numbers of natural predators (e.g. wasps) have generally been much lower due to a cool, wet spring.

“The natural predator population has still appeared, but not in the numbers we’d usually expect,” Andrew says. “Now is an ideal time to inspect crops for overwintering aphids, and treat if required.”

Five species of aphid are commonly found on strawberries in the UK, including the strawberry aphid (Chaetosiphon fragaefolii) and the shallot aphid (Myzus ascalonicus).

The latter can migrate into strawberries over winter, as the crop acts as a winter host. “It is worth looking out for shallot aphid, especially – but not exclusively – in areas where a lot of onion or other host crops are grown.

“You tend to see the evidence of shallot aphid in the spring, when a ected plants become stunted and are slow to grow away. This is due to the toxic saliva the aphid injected into the plant.”

In terms of control options in the autumn, Andrew says biological products will become less e ective as temperatures decrease, so where

aphid treatment is required, the main option is lambda-cyhalothrin. Prioritise crops where there is a history of shallot aphid, or those in close proximity to other host species in the local area, he says.

Caution should be exercised where biological controls, such as Amblyseius cucumeris, have already been employed earlier in the season to tackle tarsonemid mite (Phytodromus pallidus), he warns. “Generally, I’d be reluctant to go chasing aphids in that situation, because you want to give the biological control as long as possible to feed on the tarsonemid, which is probably more damaging overall than shallot aphid.”

During the winter months, aphid treatment is unlikely to be necessary, but once into February and crops start to be protected again, that is when they should be inspected closely for signs of overwintered aphids, and targeted treatments applied where necessary, he says.

Vine weevil is a big threat, that can be devastating if left uncontrolled, so you don’t want it in crops.

Andrew Taylor, Hutchinsons

One potentially devastating pest in ne-rooted blackcurrants, is vine weevil, and growers are urged to check crops for any signs of activity and treat where necessary before winter.

Identifying the pest can sometimes be tricky, with adult feeding damage, or early senescence in the autumn, being the main indicators. Risk is often greatest in elds with a history of soft fruit growing, but it can also be introduced in new plant material, Andrew says. “It’s also worth noting that adults can easily move 100m or more, so the pest can migrate between elds.”

Some of the more vigorous strawberry varieties are less prone to vine weevil damage than others, he says. Florence and Symphony, for example, are both very vigorous plants that may tolerate a population of vine weevil by outgrowing the damage. In contrast, other varieties like Malling Centenary or Elsanta are less vigorous and would not survive as well. “Either way, vine weevil is a big threat, that can be devastating if left uncontrolled, so you don’t want it in crops.”

In blueberries, vine weevil often target the area around the neck of the plant where sawdust or bark mulch has been applied and new roots form. “Before you know it, the feeding larvae will girdle the outer bark of the bush, and then you just don’t get any production or new growth. There is zero tolerance for vine weevil in blueberries.”

To manage vine weevil risk, Andrew recommends the nematode-based biological control, Nemasys L, applied around the neck of the plant to prevent vine weevil larvae from feeding and causing further damage.

“Vine weevil control with nematodes is dependent on compost temperature though. Once it drops below 7ºC, it is probably getting too late. Products work by the nematode entering the

vine weevil larva and releasing a bacteria which then stops it feeding; that bacteria generally doesn’t work very well below 7ºC.

“Some growers will apply it [Nemasys L] through irrigation systems, but personally, I like to see it applied directly around the neck of the plant using a hand lance because the nematode doesn’t travel very far from the point of application. It does require extra resources to do it this way, but that is money well spent as you just can’t a ord to have a vine weevil population raging in your blueberries. The better you do the job, the better the control is.”

With most strawberries grown in bags or troughs on tabletops, Andrew recommends placing these on the ground over winter and covering with eece to help protect against any potential frost damage.

“Last year, many growers would’ve probably got away with leaving strawberries on tabletops as there was virtually no frost over the winter; but if we do get periods of sub-zero weather in January or February, this can result in quite a lot of crown damage. Generally, strawberries survive a lot better on the ground than up in the air.”

Once strawberries have been moved, tabletop irrigation systems should be drained of water to reduce the risk of pipe damage during freezing conditions.

Autumn pruning of most raspberries should have been done by now, with the exception of late-cropping varieties, and canes tied in to reduce the risk of wind damage over winter. Andrew

says there may be a need for some secondary spawn control post-pruning, and the main option for this in ground or pot-grown raspberries, is carfentrazone-ethyl.

In strawberries, if crops have been a ected by phytophthora crown rot late in the season, growers could consider treating it with dimethomorph, but only while there is still vegetative growth, he continues. “Once growth reduces, the active is not transported through the crop as e ectively.”

He also reminds growers to adhere to the limit on the total amount of dimethomorph that can be used per hectare each year.

“There are some biological products being used for phytophthora control in glasshouses that look quite promising, but at present they aren’t registered for use outside of permanent structures. I’m hopeful that if manufacturers can see there is some potential, then we might be able to get extended usage of these products in future.”

Looking ahead, Andrew notes that careful irrigation management during the spring establishment period is critical to disease control, as too much water can increase risk. “One thing we can’t regulate is the amount of moisture we get over the winter. If we do get prolonged periods of rainfall, then in some cases you can see disease levels increase. There’s not a great deal you can do about it in the winter; it’s only when growth restarts in the spring that you nd disease levels are higher than when you put crops to bed in the autumn.

“We need some cold units over the winter ideally – that’s what makes a good plant in the

spring. They get vernalised with the cold and have a bit more vigour to them when growth resumes.”

Finally, slug populations have been very high this year – largely a legacy of the very mild, wet winter in 2023/24. This risk has carried through to the autumn, so should be managed with targeted pellet applications before winter, to reduce the background slug risk going into next spring, Andrew says.

The HOTBOX HEATWAVE is a made-to-measure bench heating system which encourages germination, propagation and growth by delivering constant, uniform heat to the base of seed trays and plant pots

OPTIMUM GROWING TEMPERATURE FROM 6 to 38°C

Precise thermostatic control

EASY TO INSTALL

Just plug in and plant up ENERGY EFFICIENT

Inexpensive to run DURABLE CONSTRUCTION

Reliability built-in

IDEAL FOR ALL GROWING BUSINESSES

Protection from frost damage

Firmer fruit with more crunch

Reduces cracking, rots and skin disorders

Extends shelf-life

Zero-residue

✓

✓

✓

After a year of unusually heavy rainfall, keeping a close eye on top fruit nutrition will be particularly important – Agrii agronomists shared their expertise during a recent podcast. Sarah Kidby reports.

In years with turbulent weather, such as that seen over the past year with very heavy rainfall throughout the winter months, much of the nutrition put into top fruit trees the previous year may have been washed away or not be plant available, explained fruit agronomist Matt Greep. “The level of investment we make in year one isn’t always returned in years two and three. We need to continually assess it, look at the situation in that cropping year and see if we need to make any adjustments,” he added.

Ryan Williams, another agronomist at Agrii who works with apples, pears, cherries and plums, as well as soft fruit and vines, noted that when plants are not given the correct nutrition, they will be far more susceptible to pests and disease, and less likely to withstand the turbulent weather conditions. In some cases, this leads to the death of the plant, and huge expense for the grower in removing and replanting it.

With some top fruit trees in the ground for as long as 30 years, for example in cider production, growers are always thinking ahead and what we do in the present year is laying the groundwork for next year’s fruit, added agronomist Emma Smith.

The key macronutrients required for most fruit crops are nitrogen, potassium, phosphorous and calcium – and the latter is particularly important for cell division, quality and strength, especially for apples and pears, Mr Greep said. Soft fruit shares these requirements and may need additional

nutrients, whilst for vine crops magnesium, iron and manganese can all be essential to the quality of the crop.

Meanwhile boron and zinc are two of the main micronutrients for top fruit crops during and just before the owering period, Ryan continued. This helps to strengthen the pollen tubes for healthy ful lling owers, which will eventually bear the crop. Additionally, post-harvest storage disorders can be seen in fruit, causing problems in the packing process if plants are de cient in these nutrients.

Moving onto post-harvest nutrition, he emphasised the importance of giving the crop su cient nutrients going through to the dormant winter period to ensure owers are strong and healthy during the rst stage of growing in March and April. Prior to the owering period the tree does not use any nutrition from the soil but purely relies on its carbohydrate reserves.

Crop nutrition is also particularly key in UK crops such as strawberries which are now grown almost exclusively in coir in the UK, Matt added. As coir doesn’t carry any nutritional value, the crop must be fertigated with the right balance of essential nutrients for the plant’s growing stage, to prevent it going into a vegetative state.

When it comes to knowing which crops to give which nutrients, and at what time, the Nutrient Management Guide (RB209) – section 7 for fruit crops and vines – provides a database of knowledge. Agrii agronomists carry out crop walks and monitoring every 10–14 days throughout the

growing season, including visual assessments of the colour and productivity of the leaf and overall plant. Soil and tissue analysis, and when the time comes, fruitlet analysis, will highlight if the tree is out of balance, Ryan explained. Tissue analysis is generally carried out twice per season, once after blossoming and again around harvest time. Nutritional de ciencies can be spotted by eye so if anything stands out halfway through the season then it's always advisable to take a sample then as well, Emma added.

Role of biostimulants

Over 50% of Agrii’s R&D trials each year are speci cally around biostimulants, according to Matt, and the company is actively trying to develop this sector of the market – which is still quite unknown and relatively new. Biostimulants not only stimulate the plant’s defences, they can also boost nutrient use e ciency and pest control, and improve availability of nutrients within the soil.

Giving an example of a product used by Agrii, Ryan said ProAct e ectively primes the plant and can assist with the uptake of calcium. It’s applied 2–3 times a year in top fruit, around blossom time and petal fall, and