INDUSTRIAL CYLINDER VALVES

TABLE OF CONTENTS

PRODUCT RANGE OVERVIEW

INTRODUCTION

P.004

P.009

- Main introduction P.009

- Technology overview P.011 - How to select valves P.015

PRODUCTS

P.017

- Standard valves P.017 - RPV valves | in line P.030 - RPV valves | off line P.037

-Bundle and filling station valves P.042 -Integrated valves P.048 -Refrigerant valves P.050 -Accessories P.055 -Connec tions configurator P.056 -Other configurator P.074 -Dimensions char t P.077

3

4 PRODUCT RANGE OVERVIEW ALL RIGHTS OF CHANGE RESERVED OXYGEN (O 2 ) C100 / C105 / C110 / C115 P. 017 C972 / C973 P. 018 C510 / C515 P. 019 C511 / C516 P. 020 Type of valve Standard Small cone RPV RPV | in line Working pressure C100 / C 105: 200 bar (3000 psi) C110 / C115: 300 bar (4350 psi) 200 bar (3000 psi) 200 bar (3000 psi) 200 bar (3000 psi) Material Brass / Chrome plated Brass / Chrome plated Brass / Chrome plated Brass / Chrome plated Safety C100 / C110: No C105 / C115: Yes C972: No / C973: Yes C510: No / C515: Yes C511: No / C516: Yes Standard Diameter 4 mm 2.5 mm 4 mm 4 mm GAS TYPE C540 / C545 P. 021 C878 / C879 P. 022 C978 P. 023 Type of valve RPV Small cone RPV | in line Small cone RPV | in line Working pressure 300 bar (4350 psi) 200 bar (3000 psi) 200 bar (3000 psi) Material Brass / Chrome plated Brass / Chrome plated Brass / Chrome plated Safety C540: No / C545: Yes No No Standard Diameter 4 mm 2.5 mm 2.5 mm C140 / C141 P. 024 C142 / C143 P. 025 C806 P. 026 Type of valve Line & angled bundle Line & angled bundle Integrated valve Working pressure 300 bar (4350 psi) 300 bar (4350 psi) 200 / 300 bar (2900 / 4350 psi) C2H2: 30 bar (435 psi) Material Brass / Chrome plated Brass / Chrome plated 0 - 10 bar Safety No No 30 m3/h O2 Standard Diameter 10 mm 10 mm 8 mm

NITROUS OXIDE (N 2 O)

C100

Type of valve Standard Small cone RPV | in line

Working pressure C100 / C 105: 200 bar (3000 psi) C110 / C115: 300 bar (4350 psi) 200 bar (3000 psi) 200 bar (3000 psi)

Material Brass / Chrome plated Brass / Chrome plated Brass / Chrome plated

Safety C100 / C110: No C105 / C115: Yes C972: No / C973: Yes

C511: No / C516: Yes

Standard Diameter 4 mm 2.5 mm 4 mm

C510

Type of valve RPV Small cone RPV | in line

Working pressure 200 bar (3000 psi) 200 bar (3000 psi)

Material Brass / Chrome plated Brass / Chrome plated Safety C510: No / C515: Yes No

Standard Diameter 4 mm 2.5 mm

ACETYLENE

(C 2 H 2 )

Type of valve Standard

Working pressure 30 bar (435 psi)

Material Brass / Chrome plated

Safety C400: No / C405: Yes

Standard Diameter 4 mm

/ C105 / C110 / C115 P. 027 C972 / C973 P. 028 C511 / C516 P. 030

C400 / C405 P. 032

/ C515 P. 029 C978 P. 031

5 PRODUCT RANGE OVERVIEW ALL RIGHTS OF CHANGE RESERVED

6 PRODUCT RANGE OVERVIEW ALL RIGHTS OF CHANGE RESERVED

TYPE (continued)

& MIX C042 / C047 P. 033 C200/C205/C210/C215 P. 034 C974 / C975 P. 035 C520 / C525 P. 036

of valve Standard Standard Small cone RPV

pressure 300 bar (4350 psi) C200 / C205: 200 bar (3000 psi) / C210 C215: 300 / 360 bar (4350 / 5220 psi) 200 bar (3000 psi) 200 bar (3000 psi)

Brass / Chrome plated Brass / Chrome plated Brass / Chrome Brass / Chrome plated

C042: No / C047: Yes C200 / C210: No C205 / C215: Yes C974: No / C975: Yes C520: No / C525: Yes

7 mm 4 mm 2.5 mm 4 mm C979 / C980 P. 041 C140 / C141 P. 042 C142 / C143 P. 043

of valve Small cone RPV | in line Line & angled bundle Line & angled bundle

pressure 200 bar (3000 psi) 300 bar (4350 psi) 300 bar (4350 psi)

Brass / Chrome plated Brass / Chrome plated Brass / Chrome plated

No / C980: Yes No No

2.5 mm 10 mm 10 mm

P. 044

of valve Integrated valve

200 / 300 bar (2900 / 4350 psi) C2H2: 30 bar

psi)

bar

1.8

8 mm C521 / C526 P. 037 C530 / C535 P. 038 C560 P. 039 C878 / C879 P. 040

of valve RPV RPV RPV | off line Small cone RPV | in line

pressure 200 bar (3000 psi) 300 bar (4350 psi) 200 bar 200 bar (3000 psi)

Brass / Chrome Brass / Chrome plated Brass / Chrome plated Brass / Chrome plated

No / C526: Yes C530: No / C535: Yes Yes No

4 mm 4 mm 4 mm 2.5 mm

GAS

INERT

Type

Working

Material

Safety

Standard Diameter

Type

Working

Material

Safety C979:

Standard Diameter

C805

Type

Working pressure

(435

Material 0-4

Safety

m3/h (=30l/mn) Standard Diameter

Type

Working

Material

Safety C521:

Standard Diameter

CHLORE (CL )

HELIUM (HE)

HYDROGEN (H

7 PRODUCT RANGE OVERVIEW ALL RIGHTS OF CHANGE RESERVED

C990 P. 045

of valve Specific chlorine applications

pressure 14 bar (203 psi)

Brass / Chemically nickeled

No O-Ring type

4 mm

Type

Working

Material

Safety

Standard Diameter

C979 / C980 P. 047

of valve Small cone RPV | in line

200 bar (3000 psi)

Brass / Chemically nickeled

C979: No / C980: Yes

2.5 mm CARBON DIOXIDE

2 ) C040 / C045 P. 050 C508 P. 051 C560 P. 052 C506 P. 053 C969 P. 054 Type of valve Standard RPV | In line RPV | off line RPV Small cone RPV | in line

pressure 200 bar (3000 psi) 200 bar (3000 psi) 200 bar 200 bar (3000 psi) 200 bar (3000 psi)

Brass / Chrome Brass / Chrome Brass / Chrome plated Brass / Chrome Brass / Chrome

C040: No / C045: Yes Yes Yes Yes Yes

Diameter 8 mm 8 mm 4 mm 6 mm 2.5 mm

2 )

Type

Working pressure

Material

Safety

Standard Diameter

(CO

Working

Material

Safety

Standard

C817 / C818 (balloon valve) P. 046 Type of valve Integrated Inlet pressure 200 / 300 bar (2900 / 4350 psi) Outlet pressure C817: 4.5 bar C818: 3.5 bar Flow C817: 110 l/mn Hé C807: 100 l/mn Hé

AIR C311 P. 048 C300 / C302 P. 049

of valve Breathing Air Valve with manometer Breathing Air Valve

pressure 300 bar (4350 psi) C300: 200 bar (3000 psi) / C302: 300 bar (4350 psi)

Chrome plated Brass CW722R (CZ115) Chrome plated Brass CW722R (CZ115)

3.5 mm 4 mm

BREATHING

Type

Working

Material

Standard Diameter

8 PRODUCT RANGE OVERVIEW ALL RIGHTS OF CHANGE RESERVED ACCESSORIES GUARDS - CAPS UP TO P. 055 40KG PLASTIC UP TO P. 055 60KG PLASTIC UP TO P. 055 150KG STEEL CONNECTORS I, T, L CONNECTORS P. 055 BRASS & STAINLESS STEEL CYLINDER P. 055 CONNECTORS FILLING P. 055 CONNECTORS PLUG WITH FUNCTIONAL ELEMENTS LOW PRESSURE PLUG P. 055

MAIN INTRODUCTION

APPLICATIONS

There are 2 applications :

- Bottle valves (compressed gas)

- Bundles valves

TECHNOLOGY

Main technology used for industrial gas is the O-ring sealing. Purity reached is 4.5 with OR technology (degree of purety: 99,995) but the valves with OR can’t be used for high purity gases, it is suitable for industrial applications:

- Flammables : C2H2, H2, CNG

-O2 : Oxygen, Oxygen Mix

- CO2

- Inert & Mixtures : Ar, He

Technology is divided by pressure:

- 200 bar : Series C100 for ex.

- 300 bar : Series C110 for ex.

- 450 bar : Series C150 with step down system

EXPLANATION FOR C V & K V

Kv is the flow coefficient expressed in metric units. It is defined as the flow rate in cubic meters per hour [m3/h] of water at a temperature of 16º Celsius with a pressure drop across the valve of 1 bar.

Cv is the flow coefficient expressed in imperial units. It is defined as the flow rate in US Gallons per minute [gpm] of water at a temperature of 60º Fahrenheit with a pressure drop across the valve of 1 psi.

Kv = 0.865 • Cv

Cv = 1,156 • Kv

All changes in the internal geometry of a valve will affect the Cv of the valve. Each type of valve has its own Cv.

TEMPERATURE RANGE

The temperature range can evolve from -25° to +65°C

LIFETIME

Valves are guaranteed for a use of 2000 cycles before replacement (ISO 10297).

9 ALL RIGHTS OF CHANGE RESERVED INTRODUCTION

INTRODUCTION

TECHNOLOGY OVERVIEW

Indutec uses the following main technologies to achieve a proper and reliable gas use from the cylinder:

STANDARD CYLINDER VALVE

- Standard open/close functionalities

- High life c ycle thanks to smart choice of materials

- Safe, long, trouble free life under all service conditions

VALVE WITH INTEGRATED PRESSURE REGULATOR (VIPR)

- Design to save your time: Easy and Ready to use design / valve with in-built regulator, flow meter, contains gauge and outlet pressure connector

- Compac t and lightweight : ideal for small cylinder

- Fully protected by an ergonomic plastic guard

-Filtration system ensures safety against ignition

- Flow meter with orifice plate precision design increase high flow precision and low flow precision

RESIDUAL PRESSURE VALVE (RPV)

- Open/close func tionalities

- Improved safety thanks to RPV technology included (avoid all contamination risks)

- Safe, long, trouble free life under all service conditions

- Exist in off line and in line version

PRODUCT FINDER

INDUTEC Standard valve

C100/C105/C110/C115/C040/C041/C042/C045/C046/C047/C200/C205/C210/C215/C400 C405/C450/C972/C973/C971/C974/C975/C300/C301/C302/C310/C311/C990/ C202/C140 C141/C142/C143/C144/C146

PRODUCT FINDER

INDUTEC VIPR

C805/C806/C807 P. 054 C817/C818 P. 055

PRODUCT FINDER

INDUTEC RPV valve

C511/C516/C508/C560/C521/C526/C978/C969/C979 C980/C878C879/C510/C515/C540/C545/C506 C560/C520/C525/C530/C535 from P. 032 to P.045

10 ALL RIGHTS OF CHANGE RESERVED

TECHNOLOGY OVERVIEW

RPV IN LINE & OFF LINE

WHY RPV?

Under the RPV Expression is gathered a cassette unifying the following 2 qualities:

- Residual pressure function - Non-return function RPV is used due to a physical necessity and not a technical one.

GENERAL FUNCTION

The RPV is used to:

- Keep a residual pressure in the cylinder

Ensure, that at the end of gas extraction, a minimum gas pressure stays in the cylinder (+/- 1 bar for the In-line version and +/- 3 bar for the Off-line version)

- Avoid entering of unwanted (non-wanted) goods/particles

Keeping gas in the cylinder (= over pressurized system) avoids entering fluids, gases and particles and so spoiling the cylinder content quality.

- Allows direct top filling

After checking overpressure (= check content OK) a top filling, weight based makes sense. In case there is no (more) overpressure a contamination can have taken place and a cleaning process is required.

- Impose on having a specific filling tool wild fillers need to create at least their specific tools no misuse of cylinders to i.e. dispose cleaning waste (Horeca domain) and avoiding the extra cost for cleaning an vacuuming. split cylinders for specific applications can now be handled with high process safety.

- Have various pin length(s) for specific fields of application · to unify/differentiate as per standards (rarely explicit definitions given as i.e.EIGA with ISO5145 or the IGV recommendation for the German market)

For Filling: Pin declared for OPEN position

- the pin length open position must explicitly be defined as the standards do not do this. Either our proposal or your clear indication (L = length @ at reference point)

- the pin length closed position is typically assigned in a way so the use of material to be connected is not interfering/limiting

When gas is withdrawn, once the bottle is empty, the bottle is disconnected by the user (client) and then it appears a risk of:

- Dust - Corrosion - Inflammation of par ticles going outside Therefore it is safer to use an RPV valve.

Different phases of operation:

- Valve open: the RPV cassette automatically opens and material according the standard thread can be connected and handle the arriving gas.

- Valve bleed off: the system is designed that no extrusion of O-rings will take place

- Valve filling: in case the filling adapter has no pin, the non-return function makes it a blocked inlet

- in case the filling adapter has a wrong pin length, this can lead to either the risk of overheating as the opening stays very small or damaging the pin and/or cassette when the pin is too long

11 ALL RIGHTS OF CHANGE RESERVED INTRODUCTION

FASTER FILLING

Increase your flow capacity thanks to high Cv value up to 0.7 Bigger stroke of Residual Pressure Device (RPD) piston (up to 7mm)

Improve your productivity

BROAD COMPATIBILITY

Fit to all existing RPV connections and common industrial gases on stroke (Residual Pressure Device (RPD) Displacement up to 7 mm) enhancing to cover all range of pin length Compatible with automatic filling station

Oxygen pressure surge tested at 380 bar

INNOVATIVE DESIGN

Robust & compact patented design up to 315 bar (4000 cycles tested)

Excellent gasket resistance up to 60 blow downs

New handwheel design with integrated rupture safety Easy guard replacement during maintenance thanks to the compact design

12 PRODUCT RANGE OVERVIEW ALL RIGHTS OF CHANGE RESERVED

OPTIMIZED DESIGN

THE NEW RPV GENERATION FLOW

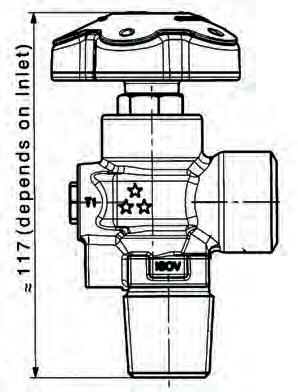

★ Opaque or transparent cap ★ Available in many different colors ★ Customized printed logo on request ★ Stronger assembly cap with handwheel ★ Ergonomic design for comfortable grip Residual Pressure Device / Non Return function Burst disc Handwheel Inlet Dip tube thread Direct gas flow Outlet Plastic cap (Optional) Cv 3.03.54.04.55.05.5 to7.0 0.53 0.54 0.58 0.64 0.73 0.79 0.0 0.2 0.4 0.6 0.8 Stroke (mm)

TECHNOLOGY OVERVIEW

INTEGRATED VALVES

VALVE INLET

- Anti dust tube according to the last amendment of EN ISO 10524-3 Better protection of the valve against contamination and eliminates the risk of ignition in case of accumulation of particles in a filter

- Excess flow device

· Additional saf and optimize normal flow in use

FILLING PORT

- Approved for 300 bar (tested at 360 bar)

- Ac tive and non-active

- Spring in C gases

- O-rings in EPDM

- High leak int degasing hole

- High perf design

- Filling por

- Endurance performance is twice the requirement of the ISO standard (2000 cycles)

PRESSURE GAUGE

- Design fully in ac restrictor to prevent part ejection in case of failure

- Direct drive technology used for the Bourdon tube to reduce consequences of vibration or shocks

- Gauge displa

-Safety relief valve with 3 holes on the glass and tightness evidence sticker

- Ac tive pressure gauge for permanent content visibility

OUTLET PRESSURE:

- Minimum outlet pr downstream equipment

SHUT-OFF VALVE

- 5000 cycles according CGA V9 (under 360 bar)

- None rotating lower spindle to avoid particles generation

- Ver y low torque design to operate the shut-off valve up to 300 bar

- ISO 10297

ALL RIGHTS OF CHANGE RESERVED

TECHNOLOGY OVERVIEW

INTEGRATED VALVES

(continued)

REGULATOR SAFETY RELIEF DEVICE

- Integrated into the regulator design

Quicker reaction - Large contact surface to increase sensitivity and reactivity to overpressure

- No risk to damage the device

- High flow through the device due to the large diameter and large venting holes

PRESSURE REGULATOR

- Piston-type regulator

- Improved safety and reliability

- Direct acting valve (decrease pressure curve) according to ISO 10524-3 and CGA-18

- High compatible materials with Oxygen and Medical applications

RESIDUAL PRESSURE VALVE

- Protection of the cylinder against external contamination

- High endurance performance in terms of leak integrity and functionality

· According standard ISO15996 – 100.000 cycles

· Specific seat design to protect sealing O-ring during operation

- 3 bar residual pressure guaranteed at maximum flow setting

ALL RIGHTS OF CHANGE RESERVED

14 INTRODUCTION

HOW TO SELECT VALVES

BODY MATERIALS

Most Indutec valves are available in brass or chrome plated brass.

Brass is :

The most commonly used material for oxygen applications due to its cost effectiveness, good strength, resistence and low-friction flow properties.

Need more information? One of our material engineers would be happy to discuss the pros and cons of each option to help you choose the best solution.

WORKING PRESSURE

Different models are designed for different working pressure to fit with your applications need. For high pressure (200 - 300 - 450 bar / 2900 - 4350 - 6525 psi) the Indutec valves range covers any requirements. The available options are clearly indicated on each product page.

OUTLET PRESSURE

Especially for VIPR: different models are designed for different outlet pressure to fit with your applications need (working pressure). For low pressure in use (4,5bar/50psi) and accurate flow (from 0-2 to 0-25 Lpm) the Indutec VIPR range covers any requirements.

INLET CONNECTIONS

Specific cylinder valve connections are required for each gas type. The most common connection types are 3/4’’-16 UNF and 25E. Other standards and dimensions are available on request.

OUTLET CONNECTIONS

VIPR:

According to your national standards the Indutec valves range covers any requirements.

Gas Compatibility: make sure the body material is compatible with the gas type you will be using.

Please specify required working pressure when ordering. We can also accommodate special requests.

The available options are clearly indicated on each product page. Please specify required outlet pressure when ordering. We can also accommodate special requests.

Valves:

According to your national standards and according to upstream device to be connected (pressure regulator, flex hose,...) the Ceodeux valves range covers any requirements.

ALL RIGHTS OF CHANGE RESERVED 15

INTRODUCTION

HOW TO SELECT VALVES (continued)

SELECTING THE RIGHT VALVE

To choose the right valve solution for your application and get the best results, you should identify the following technical parameters:

TECHNICAL PARAMETER EXAMPLES

Product type

Material type

Gas type

Type of source

Sealing technology

HP valves (High pressure), RPV (Residual Pressure Valves), VIPR (Valves with Integrated Pressure Regulator)

Raw brass, chrome plated brass, high tensile brass, nickel plated brass, aluminium silicone bronze (ASB), stainless steel

O2, N2O, inert, mixture (or inert & mixtures), flammable, C2H2, Cl2, SO2

Compressed gas cylinder, liquid gas tank,...

O'ring, packed valve, diaphragm & tied diaphragm

Handwheel type Manual, key operated, lost motion, hanwheel 5 lobes (EU) or H.8 lobes (US)

Working pressure bar or psi

Inlet connection

Outlet connection

According to standards and type (EN ISO11363...) / or Marking

According to standards and type (ISO5145 nrx,... NF type x, CGA xxx,) / or Marking

Dip tube Required or not required? If required, which size

PIN (for RPV valves) lenght

Gauges (option)

PIN length and point of reference

Pressure range

Safety type Without; burst disc x bar, fuse metal x °C; burst disc + fuse metal

Product applicable standards Valves:

EN ISO 10297 for gas cylinders-cylinder valves

EN ISO 2503 for breathing systems

EN ISO 15996 for gas cylinders-residual pressure valves (RPV)

EN ISO 13341 for gas cylinders-fitting of valves to gas cylinders

EN ISO 22435 for gas cylinders-cylinders valves with integrated pressure regulators (VIPR)

Outlets:

ISO 5145 for cylinder valve outlets for gases and gas mixtures

EN ISO 12209 gas cylinders-outlet connections for gas cylinder valves for compressed breathable air.

Other outlet type: DIN477-1, DIN477-5, BS341-3, CGA-V1, NF-650, NEN 3268, BQ-E5.15 NORMA 3, UNI...

Certification

PI marking, ISO V, ISO VB (for bundle)

16 ALL RIGHTS OF CHANGE RESERVED INTRODUCTION

22 ALL RIGHTS OF CHANGE RESERVED C971 | SMALL CONE VALVES FOR CO2 STANDARD VALVES PRODUCT CONFIGURATOR SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C971190 L A5 17E 6 M1 CO2 With 1 Burst disc 190 bar 190 Brass L Small aluminium A5 17E EN ISO 11116 17E DIN 477-1 Nr.6 6 Without CO Burst disc 250 bar 250 Chrome plated brass CL Painted handwheel B Others list P.XXOthers list P.XX M8x0,75 M0 Gas list P.XX Others list P.XX Handwheel with logo cap C Others list P.XX Key operated Square 7.8 D Key operated 5.9 x dia 9.3 E Small Plastic Black P SPECIFICATIONS -CO and CO Mix - O-ring seal type - Orifice diameter 2,5 mm - 200 bar - Integrated safety KEY FEATURES Compact high pressure brass cylinder valve for CO and CO mixtures service and for small sized cylinders Permanent gas tight seal π marking according TPED directive Tested according EN ISO10297 and CGA V9 standards OPTIONS Key operation Plastic hand wheel Cap with customer’s logo Coloured hand wheel Chrome plating Parallel inlet thread Thread for dip tube connection Dip tube Filter Teflon tape Working pressure pmax. 200 bar 3000 psi Gas type CO Seat orifice size 2,5 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10 mbarl/sec Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70) Cv 0,2 Safety C041: No C046: Yes Temperature range -4°C / -25°C up to +65°C Each product page is designed to provide you the essential technical information at a glance :

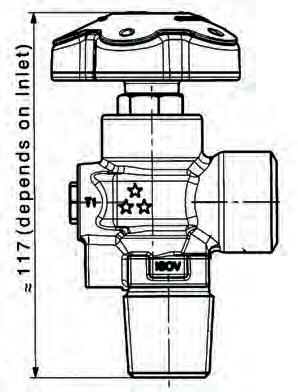

- O-ring seal type - Orifice diameter 4 mm - 200 bar/300 bar - Safety on request

KEY FEATURES

- High pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service

- Permanent gas tight seal - π marking according TPED directive

- Tested according EN ISO 10297

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel

- Chrome plating

- Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device - Filter - Teflon tape

Working pressure pmax. 200-300 bar / 3000-4500psi Gas type O2, N2O Seat orifice size 4 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass In-

C100/C110: No C105/C115: Yes

range -20°C up to +65°C

17 ALL RIGHTS OF CHANGE RESERVED OXYGEN (O2)

C100 / C105 / C110 / C115 | STANDARD VALVES

TITRE - Xxxxxxxxxxx - Oxygen, nitrous oxide and mix ture

C100 - C110 without safety C105 - C115 with safety SPECIFICATIONS

Temperature

PRODUCT CONFIGURATOR Working Pressure SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C1 000 L A 25E 9 M1 O2 200 bar 0 Without 0 Without 0 Brass L Handwheel - standard A 25E EN ISO 11363 25E DIN 477-1 Nr.9 9 Without 0 O2 300 bar 1 With 5 Burst disc 3360 psi CG1 P33 Chrome plated brass CL Painted handwheel B 3/4”-14 NGT CGA V-1 12N CGA 540 58 M10x0,75 M1 N2O Burst disc 3775 psi CG1 P37 Handwheel with logo cap C 3/4”-14 NGT(+24) CGA V-1 12N24 ISO 5145 Nr.32 (300 bar) 245 1/4” - 18NPT N3 Gas list P.91 Burst disc 4000 psi CG1 P40 Key operated Square 7.8 D Others list P.68BS 341-3 Nr.3 (300 bar) 44 G1/8” (ISO 228/1) G1 Burst disc 7500 psi CG1 P75 Key operated 5.9 x dia 9.3 E Others list P.70Others list P.90 Burst disc 10000 psi CG1 P10 Burst disc 270 bar 270 Burst disc 380 bar 380 Others list P.90

and outlet connections in accordance with all country standards (details p.70) Cv 0,3 Safety

FEATURES

18 ALL RIGHTS OF CHANGE RESERVED OXYGEN (O2) C972 / C973 | SMALL CONE VALVES SPECIFICATIONS PRODUCT CONFIGURATOR SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C972 0 L AS 17E 9 M1 O2 Without 2 Without 0 Brass L Small aluminium AS 17E EN ISO 11116 17E DIN 477-1 Nr.9 9 Without 0 O2 With 3 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P DIN 477-1 Nr.12 12 M8x0,75 M0 N2O Burst disc 250 bar 250 Handwheel with logo cap C Others list P.68Others list P.78Others list P.90Gas list P.91 Others list P.90 Key operated Square 7.8 D Key

5.9

dia 9.3 E Small

P Lost

LM

operated

x

Plastic Black

Motion

-

200

Seat

internal 10-3

external 10-3

In- and outlet connections in accordance with all country standards (details p.70) Cv

Safety

Temperature

+65°C

KEY

- Compac t high pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service and for small sized cylinders - Permanent gas tight seal - π marking according TPED directive - Tested according EN ISO 10297 - Adiabatic compression tested to avoid oxygen ignitions OPTIONS - Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

Oxygen and nitrous oxide - O-ring seal type - Orifice diameter 2,5 mm - 200 bar - Safety on request Working pressure pmax.

bar / 3000 psi Gas type O2, N2O

orifice size 2,5 mm Helium leak rate at pmax.

mbarl/sec

mbarl/sec Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

0,2

C972: No C973: Yes

range -20°C up to

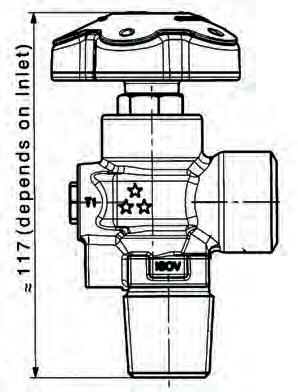

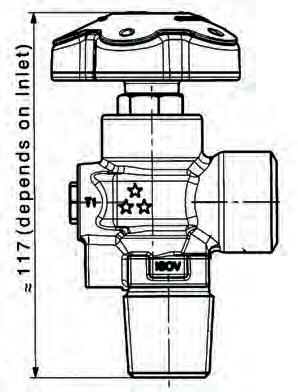

- Oxygen and nitrous oxide

- O-ring seal type

- Orifice diameter 4 mm

- 200 bar

- Safety on request

- RPV included

KEY FEATURES

- High pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service - Permanent gas tight seal - Specific filling adaptor required - Residual pressure valve execution - π marking according TPED directive -Tested according EN ISO 10297 and ISO15996 standards

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device

- Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi Gas type O2, N2O

Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv Up to 0,7 Safety C510 : No C515 : Yes

Temperature range -20°C up to +65°C

19 ALL RIGHTS OF CHANGE RESERVED C510 / C515 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Gas type SafetySafety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C5 100L A25E4411.72OO2 O2 / N2O 1 Without 0 Without 0 Brass L Handwheel - standard A 3/4”-14 NGT CGA V-1 12N BS 341-3 Nr.3 44 4,6 4.6 Front Sealing F Without 0 O2 With 5 Burst disc 216 bar 216 Chrome plated brass CL Handwheel with logo cap C 25E EN ISO 11363 25E NF E29650 Type F 38 11,7 11.7 ø 10 1 M10x0,75 M1 N2O Burst disc 250 bar 250 Others list P.68UNI 11144 No. 9 267 15 15 ø 14 2 M10x1 M2 Gas list

Burst disc 3360 psi CG1 P33 CGA 540 58 Others list

Other:

0

-

N3

P.91

P.92

to be mentioned

1/4”

18NPT

Others list P.90 Others list P.84 Others list P.90

OXYGEN (O2)

- Oxygen and nitrous oxide

- O-ring seal type

- Orifice diameter 4 mm

- 200 bar

- Safety on request

- RPV included

KEY FEATURES

- High pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service

- Permanent gas tight seal

- Specific filling adaptor required

- Residual pressure valve inline execution

- π marking according TPED directive

-Tested according EN ISO 10297 and ISO15996 standards

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel

- Chrome plating

- Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type O2, NO2

Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,3 Safety C511 : No C516 : Yes

Temperature range -20°C up to +65°C

R

20 ALL RIGHTS OF CHANGE RESERVED C511 / C516 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Gas type SafetySafety Set Up Body Material ActuationInletOutlet PIN Length Reference Point Dip tubeGas C511 0 LA25E97.5F M1 CO2 O2 (Medical) /N2O 1 Without 1 Without 0 Brass L Handwheel - standard A 25E EN ISO 11363 25E DIN 4771 Nr.9 9 7 7 Front Sealing F Without 0 O2 (Medical) With 6 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B 17E EN ISO 11116 17E DIN 4771 Nr.6 6 7,5 7.5 ø 10 1 M10x 0,75 M1 N2O Burst disc 225 bar 225 Handwheel with logo cap C 3/4”-14 NGT CGA V-1 12N Others list P.82 10,5 10.5 ø 14 2 M12x1 M6 Gas list P.91 Burst disc 250 bar 250 Key operated Square 7.8 D Option: Filter (Tamis) TAM Others list P.92 Other: to be men-

O 1/4” -

N3 Burst disc 270 bar 270 Key operated 5.9 x dia 9.3 E Others list P.68 Others list

Others list P.90 Single

S

tioned

18NPT

P.90

Central Alu Handwheel

Small Plastic Black P Small Plastic Red / Blue

OXYGEN (O2)

High pressure brass cylinder valve for oxygen service

Permanent gas tight seal

Specific filling adaptor required

Residual pressure valve execution - π marking according TPED directive -Tested according EN ISO 10297 and ISO15996 standards - Adiabatic compression tested to avoid oxygen

OPTIONS

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi 300 bar / 4500 psi Gas type O2 Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

- Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

Cv up to 0,7 Safety C540 : No C545 : Yes Temperature range -20°C up to +65°C

21 ALL RIGHTS OF CHANGE RESERVED C540 / C545 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Working Pressure SafetySafety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C5400L A25E24581 M1 O2 300 bar (O2) 4 Without 0 Without 0 Brass L Handwheel - standard A 3/4”-14 NGT CGA V-1 12N ISO 5145 Nr.32 245 8 8 Front Sealing F Without 0 O2 With 5 Burst disc 216 bar 216 Chrome plated brass CL Handwheel with logo cap C 25E EN ISO 11363 25E Others list P.84 Others list P.92 ø 10 1 M10 x0,75 M1 Gas list P.91 Burst disc 450 bar 450 Others list P.68 ø 14 2 Others

Others list P.90 Other:

-

list P.90

to be mentioned O KEY FEATURES

-

-

-

ignitions

- Oxygen - O-ring seal type - Orifice diameter 4 mm - 300 bar - Safety on request - RPV included

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70) OXYGEN (O2)

TITRE

- Xxxxxxxxxxx - Oxygen and nitrous oxide - O-ring seal type

- Orifice diameter 2,5 mm - 200 bar - RPV and manometer included

KEY

FEATURES

- Compac t high pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service and for small sized cylinders

Specific filling adaptor required - Residual pressure valve inline execution ed according EN ISO 10297 and ISO15996 standards tic compression tested to avoid oxygen

OPTIONS

- Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi Gas type O2, N2O

Seat orifice size 2,5 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Cv 0,2 Safety C878 : No C879 : Yes Temperature range -20°C up to +65°C

22 ALL RIGHTS OF CHANGE RESERVED C878 / C879 | SMALL CONE RPV VALVES WITH INTEGRATED MANOMETER PRODUCT CONFIGURATOR Safety Gas type Safety Set Up Body Material ActuationInletOutlet PIN Length Reference Point Dip tubeGas C8780L A 17E97.5F M1 O2 Without 7 O2 8 Without 0 Brass L Handwheel - standard A 17E EN ISO 11116 17E DIN 4771 Nr.9 9 7 7 Front Sealing F Without 0 O2 Inert 9 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P DIN 4771 Nr.10 10 7,5 7.5 ø 10 1 M10 x0,75 M1 N2O Burst disc 250 bar 250 Handwheel with logo cap C Others list P.68Others list P.82 Others list P.92 ø 14 2 Others list P.90 Inert & Mix (IM) Burst disc 270 bar 270 Key operated Square 7.8 D Other: to

mentioned O Gas list

Others list P.90 Key operated 5.9 x dia 9.3 E

be

P.91

-

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70) OXYGEN (O2)

- Oxygen and nitrous oxide

- O-ring seal type

- Orifice diameter 2,5 mm

- 200 bar

- Safety on request

- RPV included

KEY FEATURES

- Compac t high pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service and for small sized cylinders

- Specific filling adaptor required

- Residual pressure valve inline execution

- Permanent gas tight seal

- π marking according TPED directive

-Tested according EN ISO 10297 and ISO15996 standards

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Cap with c ustomer’s logo - Coloured hand wheel

- Chrome plating - Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 30 bar / 450 psi 200 bar / 3000 psi

Gas type O2, N2O

Seat orifice size 2,5 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,2

Temperature range -20°C up to +65°C

23 ALL RIGHTS OF CHANGE RESERVED C978 | SMALL CONE RPV VALVES PRODUCT CONFIGURATOR Safety Gas type Safety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C9780 L AS 17E 9 7.5F M1 O2 Without 7 O2 / N2O 8 Without 0 Brass L Small Aluminium AS 17E EN ISO 11116 17E DIN 4771 Nr.9 9 7 7 Front Sealing F Without 0 O2 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P Others list P78 7,5 7.5 ø 10 1 M8x 0,75 M0 N2O Burst disc 250 bar 250 Handwheel with logo cap C Option: Filter

TAM Others list P.92 ø 14 2 M10 x0,75 M1 Gas list P.91 Others list P.90 Others list P.68

O Others list

(Tamis)

Other: to be mentioned

P.90

OXYGEN (O2)

SPECIFICATIONS

24 ALL RIGHTS OF CHANGE RESERVED C140 / C141 | LINE BUNDLE VALVES PRODUCT CONFIGURATOR Gas Type Body Material Actuation Inlet OutletDip tubeGas C140 L A G3 G3 0O2 O2 0 Brass L Handwheel - standard A G3/4" + inner machining G3 G3/4" + inner machining G3 Without 0 O2 Inert & Mix 1 1/4"-18NPT FEM 463 1/4"-18NPT FEM 463 Others list P.90Inert & Mixtures (IM) ISO 5145 Nr.32 245 ISO 5145 Nr.32 245 Flammable & Mix (F) Others list P.69 Others list P.86 Gas list P.91 KEY

-

-

-

-

FEATURES

High pressure brass bundle valve for Oxygen, Inert, Inert mixtures and flammable gas service

Permanent gas tight seal

π marking according TPED directive

Tested according EN ISO 10297 - Adiabatic compression tested to avoid oxygen ignitions OPTIONS - O2, Inert and Inert Mix - O-ring seal type - Orifice diameter 10 mm - 300 bar

Cv 2 Safety C140 : No C141 : Yes Temperature range -20°C up

OXYGEN (O2)

Working pressure pmax. 300 bar / 4500 psi Gas type O2, Inert Seat orifice size 10 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec Material hand: wheel aluminium seat: PCTFE O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70)

to +65°C

- O2, Inert and Inert Mix

- O-ring seal type

- Orifice diameter 10 mm - 300 bar

- Safety on request

KEY FEATURES - High pressure brass bundle valve for Oxygen, Inert, Inert mixtures and flammable gas service - Permanent gas tight seal - π marking according TPED directive - Tested according EN ISO 10297 - Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

SPECIFICATIONS

Working pressure pmax. 300 bar / 4500 psi Gas type O2, Inert Seat orifice size 10 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

EPDM

25 ALL RIGHTS OF CHANGE RESERVED PRODUCT CONFIGURATOR Gas Type Body Material Actuation Inlet OutletDip tubeGas C142 L A G3 G3 0 H2 Inert & Mix 2 Brass L Handwheel - standard A 25E EN ISO 11363 25E G3/4" + inner machining G3 Without 0 O2 O2 3 3/4"-14 NGT / CGA V-1 12N 1/4"-18NPT FEM 463 Others list P.90 Inert & Mixtures (IM) G3/4" + inner machining G3 Others list P.86 Flammable & Mix

Others

H2 Gas list

C142 / C143 | ANGLED BUNDLE VALVES

(F)

list P.69

P.91

OXYGEN (O2)

Material hand: wheel aluminium seat: PCTFE O-rings:

body: brass In- and outlet connections in accordance with all country standards (details p.70) Cv 1,0 Temperature range -20°C up to +65°C

KEY FEATURES

APPLICATIONS

TITRE

- Xxxxxxxxxxx - O2, C2h2, Inert and Inert Mix, flammable

- O-ring seal type

- 200 bar / 300 bar inlet pressure

- 0-4 bar outlet pressure

- Flow: 1,8-30Nm3/h (acc. gas type)

- Safety on request

- Brass valve with integrated pressure regulator for Oxygen, Acetylene, Inert, Inert mixtures and flammable gas service (including forming gas)

- Separated filling port

- Outlet: thread or quick connector type

- If non-return valve on filling part, specific filling adaptor recommended

- Outlet pressure / flow ajustable

- Permanent gas tight seal

- π marking according TPED directive

- Tested according EN ISO 22435 and CGA V9 standards

- Ox yacetylene cutting and welding

- Elec trical welding: TIG MIG MAG

- Potentially usable on laser applications

SPECIFICATIONS

Working pressure pmax. 300 bar / 4500 psi

Gas type O2, C2H2, Inert &mix, flammable Seat orifice size acc. to the type of gas

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Flow 1,8-30Nm3/h

Temperature range -20°C up to +65°C

Flammable & Mix(F)

Forming Gas (Flammable) (F) Gas list P.91

26 ALL RIGHTS OF CHANGE RESERVED C806 | VALVE WITH INTEGRATED PRESSURE REGULATOR PRODUCT CONFIGURATOR Gas Type Working Pressure Safety Safety Set Up Body Material ActuationInletOutlet Max Flow range Dip tubeGaugesGuardsGas C80 50 PR 4L OC 25E2391.801- IM Inert& Mix 5 30 bar (C2H2) 3 Pressure Regulator PR 0 - 4 bar 4 Brass L Open-Close OC 25E EN ISO 11363 25E ISO 5145 Nr.30 239 1.8 m³/h (=30l/ mn) 1.8 Without 0 With Gauge (std) 1 Without - Inert & Mixture (IM) O2 6 200 bar 0 0 - 1,5 bar 1.5 Chrome plated brass CL Painted handwheel B 28E EN ISO 11116 28E ISO 5145 Nr.32 245 3 m³/h (C2H2) 3 Others list P.90 Plastic Guard > 40kg G1 O2 C2H2 7 300 bar 1 0 - 10 bar 10 Handwheel with logo cap C Others list P.69 ISO 5145 Nr.42 509 30 m³/h (O2) 30 Plastic Guard >

G2 C2H2 Others list P.XX Steel

G3

60kg

Guard > 150kg

OXYGEN (O2)

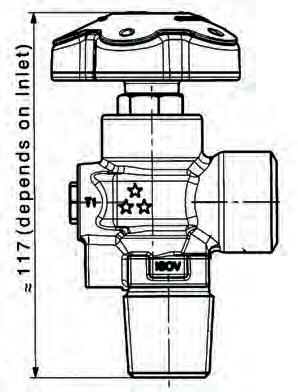

TITRE - Xxxxxxxxxxx - Oxygen, nitrous oxide and mix ture

- O-ring seal type

- Orifice diameter 4 mm

- 200 bar/300 bar

- Safety on request

KEY FEATURES

- High pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service

- Permanent gas tight seal

- π marking according TPED directive

- Tested according EN ISO 10297

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel

- Chrome plating

- Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device

- Filter - Teflon tape

C100 - C110 without safety C105 - C115 with safety SPECIFICATIONS

Working pressure pmax. 200-300 bar / 3000-4500psi

Gas type O2, N2O

Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass

Cv 0,3 Safety C100/C110: No C105/C115: Yes

Temperature range -20°C up to +65°C

27 ALL RIGHTS OF CHANGE RESERVED NITROUS OXIDE (N2O)

C100 / C105 / C110 / C115 | STANDARD VALVES

In- and outlet connections in accordance with all country standards (details p.70) PRODUCT CONFIGURATOR Working Pressure SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C1 000 L A 25E 9 M1 O2 200 bar 0 Without 0 Without 0 Brass L Handwheel - standard A 25E EN ISO 11363 25E DIN 477-1 Nr.9 9 Without 0 O2 300 bar 1 With 5 Burst disc 3360 psi CG1 P33 Chrome plated brass CL Painted handwheel B 3/4”-14 NGT CGA V-1 12N CGA 540 58 M10x0,75 M1 N2O Burst disc 3775 psi CG1 P37 Handwheel with logo cap C 3/4”-14 NGT(+24) CGA V-1 12N24 ISO 5145 Nr.32 (300 bar) 245 1/4” - 18NPT N3 Gas list P.91 Burst disc 4000 psi CG1 P40 Key operated Square 7.8 D Others list P.68BS 341-3 Nr.3 (300 bar) 44 G1/8” (ISO 228/1) G1 Burst disc 7500 psi CG1 P75 Key operated 5.9 x dia 9.3 E Others list P.70Others list P.90 Burst disc 10000 psi CG1 P10 Burst disc 270 bar 270 Burst disc 380 bar 380 Others list P.90

28 ALL RIGHTS OF CHANGE RESERVED NITROUS OXIDE (N2O) C972 / C973 | SMALL CONE VALVES SPECIFICATIONS PRODUCT CONFIGURATOR SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C972 0 L AS 17E 9 M1 O2 Without 2 Without 0 Brass L Small aluminium AS 17E EN ISO 11116 17E DIN 477-1 Nr.9 9 Without 0 O2 With 3 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P DIN 477-1 Nr.12 12 M8x0,75 M0 N2O Burst disc 250 bar 250 Handwheel with logo cap C Others list P.68Others list P.78Others list P.90Gas list P.91 Others list P.90 Key operated Square 7.8 D Key operated 5.9 x dia 9.3 E Small

P Lost

LM

-

pmax. 200 bar / 3000

Gas

Seat

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec Material

seat:

O-rings:

In- and outlet connections in accordance with all country standards (details p.70) Cv

Safety

Yes Temperature range -20°C up to +65°C

Plastic Black

Motion

KEY FEATURES - Compac t high pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service and for small sized cylinders - Permanent gas tight seal - π marking according TPED directive - Tested according EN ISO 10297 - Adiabatic compression tested to avoid oxygen ignitions OPTIONS - Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

Oxygen and nitrous oxide - O-ring seal type - Orifice diameter 2,5 mm - 200 bar - Safety on request Working pressure

psi

type O2, N2O

orifice size 2,5 mm

hand: wheel aluminium

PA 6.6

EPDM body: brass

0,2

C972: No C973:

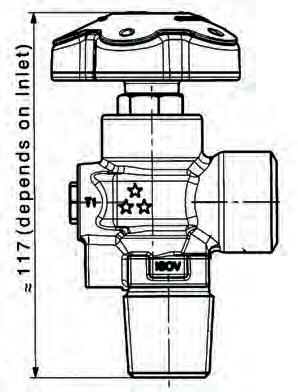

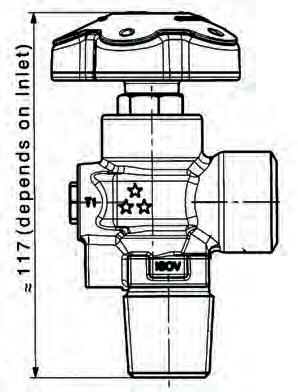

- Oxygen and nitrous oxide

- O-ring seal type

- Orifice diameter 4 mm

- 200 bar

- Safety on request

- RPV included

KEY FEATURES

- High pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service - Permanent gas tight seal - Specific filling adaptor required - Residual pressure valve execution - π marking according TPED directive -Tested according EN ISO 10297 and ISO15996 standards

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type O2, N2O

Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv up to 0,7

Safety C510 : No C515 : Yes

Temperature range -20°C up to +65°C

29 ALL RIGHTS OF CHANGE RESERVED C510 / C515 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Gas type SafetySafety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C5 100LA25E4411.72OO2 O2 / N2O 1 Without 0 Without 0 Brass L Handwheel - standard A 3/4”-14 NGT CGA V-1 12N BS 341-3 Nr.3 44 4,6 4.6 Front Sealing F Without 0 O2 With 5 Burst disc 216 bar 216 Chrome plated brass CL Handwheel with logo cap C 25E EN ISO 11363 25E NF E29650 Type F 38 11,7 11.7 ø 10 1 M10x0,75 M1 N2O Burst disc 250 bar 250 Others list P.68UNI 11144 No. 9 267 15 15 ø 14 2 M10x1 M2 Gas list

Burst disc 3360 psi CG1 P33 CGA 540 58 Others list

Other:

0

-

N3

list

P.91

P.92

to be mentioned

1/4”

18NPT

Others

P.90 Others list P.84 Others list P.90

NITROUS OXIDE (N2O)

- Oxygen and nitrous oxide

- O-ring seal type

- Orifice diameter 4 mm

- 200 bar

- Safety on request

- RPV included

KEY FEATURES

- High pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service

- Permanent gas tight seal

- Specific filling adaptor required

- Residual pressure valve inline execution

- π marking according TPED directive

-Tested according EN ISO 10297 and ISO15996 standards

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel - Chrome plating

- Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type O2, NO2

Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,3 Safety C511 : No C516 : Yes

Temperature range -20°C up to +65°C

Small Plastic Black P

Small Plastic Red / Blue R

ALL RIGHTS OF CHANGE RESERVED 30 NITROUS OXIDE (N2O) C511 / C516 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Gas type SafetySafety Set Up Body Material ActuationInletOutlet PIN Length Reference Point Dip tubeGas C511 0 LA25E97.5F M1 CO2 O2 (Medical) /N2O 1 Without 1 Without 0 Brass L Handwheel - standard A 25E EN ISO 11363 25E DIN 4771 Nr.9 9 7 7 Front Sealing F Without 0 O2 (Medical) With 6 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B 17E EN ISO 11116 17E DIN 4771 Nr.6 6 7,5 7.5 ø 10 1 M10x 0,75 M1 N2O Burst disc 225 bar 225 Handwheel with logo cap C 3/4”-14 NGT CGA V-1 12N Others list P.82 10,5 10.5 ø 14 2 M12x1 M6 Gas list P.91 Burst disc 250 bar 250 Key operated Square 7.8 D Option: Filter (Tamis) TAM Others list P.92 Other: to be men-

O 1/4”18NPT N3 Burst disc 270 bar 270 Key operated 5.9 x dia 9.3 E Others list P.68 Others list

Others list P.90 Single

tioned

P.90

Central Alu Handwheel S

- Oxygen and nitrous oxide

- O-ring seal type

- Orifice diameter 2,5 mm

- 200 bar

- Safety on request

- RPV included

KEY FEATURES

- Compac t high pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service and for small sized cylinders

- Specific filling adaptor required

- Residual pressure valve inline execution

- Permanent gas tight seal

- π marking according TPED directive

-Tested according EN ISO 10297 and ISO15996 standards

- Adiabatic compression tested to avoid oxygen ignitions

OPTIONS

- Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread

- Thread for dip tube connection

- Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 30 bar / 450 psi 200 bar / 3000 psi

Gas type O2, N2O

Seat orifice size 2,5 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,2

Temperature range -20°C up to +65°C

be

ALL RIGHTS OF CHANGE RESERVED NITROUS OXIDE (N2O) C978 | SMALL CONE RPV VALVES PRODUCT CONFIGURATOR Safety Gas type Safety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C9780 L AS 17E 9 7.5F M1 O2 Without 7 O2 / N2O 8 Without 0 Brass L Small Aluminium AS 17E EN ISO 11116 17E DIN 4771 Nr.9 9 7 7 Front Sealing F Without 0 O2 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P Others list P78 7,5 7.5 ø 10 1 M8x 0,75 M0 N2O Burst disc 250 bar 250 Handwheel with logo cap C Option: Filter

TAM Others list

ø 14 2 M10 x0,75 M1 Gas list P.91

list P.90

(Tamis)

P.92

Others

Others list P.68 Other: to

mentioned O Others list P.90

31

ALL RIGHTS OF CHANGE RESERVED 32 ACETYLENE (C2H2) C400 / C405 | STANDARD VALVES SPECIFICATIONS PRODUCT CONFIGURATOR Working Pressure SafetySafety Set UpBody MaterialActuationInlet OutletFilterGas C0400 0 L A 28E 122G5 C2H2 30 bar 0 Without 0 Without 0 Brass L Handwheel - standard outlet A 25E EN ISO 11363 25E BS 341-3 Nr.2 & 4 122 For Filter C2H2 G5 C2H2 With 5 Fusible metal 212°F(100°C) CG3 2F Chrome plated brass CL Painted handwheel B 28E EN ISO 11116 28E M28x1,5-LH 266 Gas list P.91 BD & FM 165° F CG4 BF4 Handwheel with logo cap C 3/4”-14 NGT / CGA V-1 12N CGA 510 50 Others list P.90 Key operated Square 7.8 D Others list P.68Others list P.70 Key operated 5.9 x dia 9.3 E Aluminium

O

-

brass

service -

gas

seal -

-

-

OPTIONS -

-

-

-

-

-

-

seal type -

mm -

-

Working pressure pmax. 30 bar / 450 psi Gas type C2H2 Seat

size 4 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

aluminium seat:

+ PA12 O-rings:

In- and outlet connections in accordance with all country standards (details p.70) Cv 0,3 Safety

No

Yes Temperature range -20°C up to +65°C

Oval (Yoke)

KEY FEATURES

High pressure

cylinder valve for Acetylene

Permanent

tight

π marking according TPED directive

Tested according EN ISO 10297

Filter SIEVE included

Key operation - Cap with c ustomer’s logo

Coloured hand wheel

Chrome plating

Parallel inlet thread

Burst disc safety device - Filter - Teflon tape

Acetylene

O-ring

Orifice diameter 4

30 bar

Safety on request

orifice

Material hand: wheel

peak

EPDM body: brass filter: SIEVE

C400:

C405:

- O-ring seal type

- Orifice diameter 7 mm - 300 bar

- Safety on request

KEY FEATURES

- High pressure brass cylinder valve Y type for Inert, Inert mixtures and flammable gas service

- Dual por t design to withdraw liquid and/or vapour

- Permanent gas tight seal

- π marking according TPED directive

- Tested according EN ISO 10297 and CGA V9 standards

OPTIONS

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel

- Chrome plating

- Parallel inlet thread

- Thread for dip tube connection

- Dip tube - Filter - Teflon tape

- Single outlet possible

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi 300 bar / 4500 psi

Gas type Inert

Seat orifice size 7 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,5

Safety C042: No C047: Yes

Temperature range -20°C up to +65°C

Small Plastic Black P

Small Plastic Red/Blue R

Others list P.90

ALL RIGHTS OF CHANGE RESERVED PRODUCT CONFIGURATOR SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C042 0L S 25E 6 M1 IM Without (300 bar) 2 Without 0 Brass L Single central alu handwheel S 25E EN ISO 11363 25E DIN 477-1 Nr.6 6 Without 0 Inert & Mixtures (IM) With (300 bar) 7 Burst disc 250 bar 250 Chrome plated brass CL Handwheel - standard A 3/4”-14 NGT CGA V-1 12N UNI 11144 No.2 120 M10x0,75 M1 Flammable (F) Burst disc 4350 psi CG1 P43 Painted handwheel B M 30 x 2 - 30P EN ISO 15245-1 30P Others list P.761/4” - 18NPT N3 Gas list P.91 Burst disc 450 bar 450 Handwheel with logo cap C Others list P.69 G1/4” - 1/4”BSP G6 Others list P.90 Key

D Others list P.90

E

operated Square 7.8

Key operated 5.9 x dia 9.3

Medium Size Alu M

C042

/ C047 | STANDARD VALVES Y TYPE - Inert and Inert Mix

INERT & MIX 33

KEY FEATURES

OPTIONS

TITRE

- O-ring seal type

- Xxxxxxxxxxx - Inert and Inert Mix

- Orifice diameter 4 mm - 200 bar / 300 bar

- Safety on request

High pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service - Permanent gas tight seal - π marking according TPED directive - Tested according EN ISO 10297 and CGA V9 standards

- Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

Working pressure pmax. 200 bar / 3000 psi 300 bar / 4500 psi

Gas type Inert Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Cv 0,3 Safety C200 / C210 : No C205 / C215 : Yes Temperature range -20°C up to +65°C

ALL RIGHTS OF CHANGE RESERVED INERT & MIX C200 / C205 / C210 / C215 | STANDARD VALVES SPECIFICATIONS PRODUCT CONFIGURATOR Working Pressure SafetySafety Set UpBody MaterialActuationInlet OutletDip tubeGas C2 00 0 L A 25E 44 M1IM 200 bar 0 Without 0 Without 0 Brass L Handwheel - standard A 25E EN ISO 11363 25E BS 341-3 Nr.3 44 Without 0 Flammable (F) & Mix 300 bar 1 With 5 Burst disc 405 bar 405 Chrome plated brass CL Painted handwheel B 3/4”-14 NGT CGA V-1 12N CGA 350 68 M10x0,75 M1 Inert & Mixtures (IM) Burst disc 3360 psi CG1 P33 Handwheel with logo cap C Other list P.68ISO 5145 Nr.30 239 1/4” - 18NPT N3 Other list P.91 Burst disc 4000 psi CG1 P40 Key operated Square 7.8 D ISO 5145 Nr.38 238 G1/8” (ISO 228/1) G1 Burst disc 5220 psi CG1 P52 Key

5.9

dia 9.3 E Other list P.70Others list

Burst

7500

CG1 P75 Burst disc 10000

CG1 P10

operated

x

P.90

disc

psi

psi

Others list P.90

-

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM, NBR body: brass In- and outlet connections in accordance with all country standards (details p.70) 34

- Inert, Inert Mix and Flammable gas - O-ring seal type - Orifice diameter 2,5 mm - 200 bar - Integrated safety

KEY FEATURES

- Compac t high pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service and for small sized cylinders - Permanent gas tight seal - π marking according TPED directive - Tested according EN ISO 10297 standards

OPTIONS - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Dip tube - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi Gas type Inert Seat orifice size 2,5 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70)

0,2 Safety C974 : No C975 : Yes Temperature range -20°C up to +65°C

ALL RIGHTS OF CHANGE RESERVED C974 / C975 | SMALL CONE VALVES PRODUCT CONFIGURATOR SafetySafety Set UpBody MaterialActuation Inlet OutletDip tubeGas C974 0 L AS 17E 6 M1 IM Without 4 Without 0 Brass L Small aluminium AS 17E EN ISO 11116 17E DIN 477-1 Nr.6 6 Without 0 Inert & Mix (IM) With 5 Burst disc 228 bar 228 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P DIN 477-1 Nr.12 12 M8x0,75 M0 Flammable (F) & Mix Burst disc 270 bar 270 Handwheel with logo cap C Others list P.68Others list P.78Others list P.90 Gas list P.91 Others list P.90 Key

D Key

E

P

LM

operated Square 7.8

operated 5.9 x dia 9.3

Small plastic black

Lost motion

INERT & MIX 35

Cv

OPTIONS

TITRE

- Xxxxxxxxxxx - Inert, Inert Mix and

Flammable gas

- O-ring seal type

- Orifice diameter 4 mm - 200 bar

- Safety on request - RPV included

- High pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service - Permanent gas tight seal - Specific filling adaptor required - Residual pressure valve inline execution - π marking according TPED directive - Tested according EN ISO 10297

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type Inert & flammable Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,3

Safety C041: No C046: Yes

Temperature range -20°C up to +65°C

36 ALL RIGHTS OF CHANGE RESERVED C521 / C526 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Gas type SafetySafety Set Up Body Material ActuationInletOutlet PIN Length Reference Point Dip tubeGas C5210LA 25E67.5F M1 IM Inert & Mix /Flammable 2 Without 1 Without 0 Brass L Handwheel - standard A 25E EN ISO 11363 25E DIN 477-1 Nr.6 6 7 7 Front Sealing F Without 0 Inert & Mixtures (IM) With 6 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B 17E EN ISO 11116 17E Others list P.82 7,5 7.5 ø 10 1 M10x 0,75 M1 Flammable & Mix(F) Burst disc 225 bar 225 Handwheel with logo cap C 3/4”-14 NGT CGA V-1 12N 10,5 10.5 ø 14 2 M12x1 M6 Gas list P.91 Burst disc 250 bar 250 Key operated Square 7.8 D Option: Filter (Tamis) TAM Others list P.92 Other: to be mentioned O 1/4”18NPT N3 Burst disc 270 bar 270 Key operated 5.9 x dia 9.3 E Others list P.68 Others list P.90 Others list P.90 Single Central Alu Handwheel S Small Plastic

P Small Plastic Red / Blue R

Black

KEY FEATURES

INERT & MIX

KEY

FEATURES

TITRE

- Xxxxxxxxxxx - Inert, Inert Mix and Flammable gas

- O-ring seal type

- Orifice diameter 4 mm - 200 bar

- Safety on request - RPV included

High pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service - Permanent gas tight seal

Specific filling adaptor required

Residual pressure valve execution - π marking according TPED directive -Tested according EN ISO 10297 and ISO15996 standards

OPTIONS

- Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type Inert & flammable Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM / NBR / PU (acc. to application) body: brass In- and outlet connections in accordance with all country standards (details p.70)

Cv up to 0,7

Safety C520: No C525: Yes

Temperature range -20°C up to +65°C

ALL RIGHTS OF CHANGE RESERVED 37 C520 / C525 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Gas type SafetySafety Set Up Body Material ActuationInletOutlet PIN Length Reference Point Dip tubeGas C5 200L A 25E615F0 IM Flammable & Mix 2 Without 0 Without 0 Brass L Handwheel - standard A 3/4”-14 NGT CGA V-1 12N DIN 477-1 Nr.6 6 6,1 6.1 Front Sealing F Without 0 Inert & Mixtures (IM) With 5 Burst disc 216 bar 216 Chrome plated brass CL Handwheel with logo cap C 25E EN ISO 11363 25E NF E29-650 Type C 40 11,7 11.7 ø 10 1 M10x0,75 M1 Flammable & Mix(F) Burst disc 250 bar 250 Others list P.68CGA 580 65 15 15 ø 14 2 M10x1 M2 Gas list

Burst disc 3360 psi CG1 P33 Others list P.84 22,5 22.5 Other O

-

N3 Others list P.90 Others list

Others

P.91

1/4”

18NPT

P.92

list P.90

-

-

-

INERT & MIX

TITRE - Xxxxxxxxxxx - Inert, Inert Mix and Flammable gas - O-ring seal type - Orifice diameter 4 mm - 300 bar - Safety on request - RPV included

KEY FEATURES

OPTIONS

High pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service

Permanent gas tight seal

Specific filling adaptor required

Residual pressure valve offline execution - π marking according TPED directive -R emove offline -Tested according EN ISO 10297 and ISO15996 standards

- Key operation - Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Burst disc safety device - Filter - Teflon tape SPECIFICATIONS

Cv up to 0,7 Safety C530 : No C535 : Yes Temperature range -20°C up to +65°C INERT & MIX

38 ALL RIGHTS OF CHANGE RESERVED C530 / C535 | STANDARD RPV VALVES PRODUCT CONFIGURATOR Working Pressure SafetySafety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C5300L A25E23981 M1 IM 300 bar (Inert & Mix) 3 Without 0 Without 0 Brass L Handwheel - standard A 3/4”-14 NGT CGA V-1 12N ISO 5145 Nr.30 239 8 8 Front Sealing F Without 0 Inert & Mix(IM) With 5 Burst disc 216 bar 216 Chrome plated brass CL Handwheel with logo cap C 25E EN ISO 11363 25E Others list P.84 Others list P.92 ø 10 1 M10 x0,75 M1 Flammable &

Burst disc 450 bar 450 Others list P.68 ø 14 2 Others list

Gas

Others list P.90 Other:

Mix(F)

P.05

list P.91

O

-

-

-

-

Working pressure pmax. 200 bar / 3000 psi 300 bar / 4500 psi Gas type Inert & flammable Seat orifice size 4 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70)

KEY

FEATURES

OPTIONS

TITRE

- Xxxxxxxxxxx

- Inert, Inert Mix and Flammable gas

- O-ring seal type

- Orifice diameter 4 mm - 200 bar

- Safety on request - Y valve with RPV included

High pressure brass cylinder valve Y type for Inert, Inert mixtures and flammable gas service

- Permanent gas tight seal - Specific filling adaptor required - Residual pressure valve offline execution cording TPED directive ed according EN ISO 10297 and ISO15996 standards

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel

- Chrome plating

- Parallel inlet thread - Thread for dip tube connection

- Burst disc safety device - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type Inert & flammable Seat orifice size 4 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6

O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,3 Safety Yes

Temperature range -20°C up to +65°C

39 ALL RIGHTS OF CHANGE RESERVED C560 | STANDARD RPV VALVES Y TYPE PRODUCT CONFIGURATOR Working Pressure Gas type SafetySafety Set UpBody MaterialActuationInletOutlet PIN Length Reference Point Dip tubeGas C5 608190LA25E4020.5F M1 CO2 200 bar (Y Valve) 6 CO2 0 With (for CO2) 8 Burst disc 190 bar 190 Brass L Handwheel - standard A 3/4”-14 NGT CGA V-1 12N NF E29-650 Type C 40 15 15 Front Sealing F Without 0 CO2 Burst disc 225 bar 225 Chrome plated brass CL Painted handwheel B 25E EN ISO 11363 25E ISO 5145 Nr.17 317 20,5 20.5 ø 10 1 M8x0,75 M0 Gas list P.91 Burst disc 250 bar 250 Handwheel with logo cap C Others list P.68DIN 4771 Nr.6 6 Others list P.92 ø 14 2 M10x0,75 M1 Burst disc 3000 psi CG1 P30 Key operated Square 7.8 D Others list P.82 Other: to be mentioned O 1/4" -

N3 Others list P.90 Key operated 5.9 x dia 9.3 E

list

Single

S

P

R

18NPT

Others

P.90

Central Alu Handwheel

Small Plastic Black

Small Plastic Red / Blue

-

INERT & MIX

TITRE

- Xxxxxxxxxxx - Oxygen and nitrous oxide - O-ring seal type

- Orifice diameter 2,5 mm - 200 bar - RPV and manometer included

KEY

FEATURES

- Compac t high pressure brass cylinder valve for oxygen and oxygen mixtures (>20% O2) service and for small sized cylinders

Specific filling adaptor required - Residual pressure valve inline execution ed according EN ISO 10297 and ISO15996 standards tic compression tested to avoid oxygen

OPTIONS

- Cap with c ustomer’s logo - Coloured hand wheel - Chrome plating - Parallel inlet thread - Thread for dip tube connection - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi Gas type O2, N2O

Seat orifice size 2,5 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Cv 0,2 Safety C878 : No C879 : Yes Temperature range -20°C up to +65°C

40 ALL RIGHTS OF CHANGE RESERVED C878 / C879 | SMALL CONE RPV VALVES WITH INTEGRATED MANOMETER PRODUCT CONFIGURATOR Safety Gas type Safety Set Up Body Material ActuationInletOutlet PIN Length Reference Point Dip tubeGas C8780L A 17E97.5F M1 O2 Without 7 O2 8 Without 0 Brass L Handwheel - standard A 17E EN ISO 11116 17E DIN 4771 Nr.9 9 7 7 Front Sealing F Without 0 O2 Inert 9 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P DIN 4771 Nr.10 10 7,5 7.5 ø 10 1 M10 x0,75 M1 N2O Burst disc 250 bar 250 Handwheel with logo cap C Others list P.68Others list P.82 Others list P.92 ø 14 2 Others list P.90 Inert & Mix (IM) Burst disc 270 bar 270 Key operated Square 7.8 D Other: to

mentioned O Gas list

Others list P.90 Key operated 5.9 x dia 9.3 E

be

P.91

-

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70) INERT & MIX

- Inert, Inert Mix and Flammable - O-ring seal type - Orifice diameter 2,5 mm - 200 bar

- Integrated safety

KEY FEATURES

- Compac t high pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service and for small sized cylinders

- Specific filling adaptor required

- Residual pressure valve inline execution

- Permanent gas tight seal

- π marking according TPED directive

- Tested according EN ISO 10297 and EN ISO15996 standards

OPTIONS

- Key operation - Cap with c ustomer’s logo

- Coloured hand wheel

- Chrome plating

- Parallel inlet thread

- Thread for dip tube connection

- Dip tube - Filter - Teflon tape

SPECIFICATIONS

Working pressure pmax. 200 bar / 3000 psi

Gas type Inert & flammable Seat orifice size 2,5 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Cv 0,2

Safety C979 : No C980 : Yes

Temperature range -20°C up to +65°C

P.90

list P.91

41 ALL RIGHTS OF CHANGE RESERVED C979 / C980 | SMALL CONE RPV VALVES PRODUCT CONFIGURATOR Safety Gas type Safety Set UpBody MaterialActuationInletOutletPIN Length Reference Point Dip tubeGas C9 790L AS 17E67.5FO IM Without 7 Inert & Mix 9 Without 0 Brass L Small Aluminium AS 17E EN ISO 11116 17E DIN 4771 Nr.6 6 7 7 Front Sealing F Without 0 Inert & Mix (IM) With 8 H2 0 Burst disc 190 bar 190 Chrome plated brass CL Painted handwheel B M 18 x 1,5 - 18P EN ISO 15245-1 18P DIN 4771 Nr.9 9 7,5 7.5 ø 10 1 M8x 0,75 M0 Flammable (IF) & Mix Burst disc 250 bar 250 Handwheel with logo cap C Option: Filter

TAM Others list P.78 Others list P.92 ø 14 2 M10 x0,75 M1 H2 Others list P.90 Others list P.68

O

(Tamis)

Other: to be mentioned

Others list

Gas

INERT & MIX

- O-ring seal type

- Orifice diameter 10 mm - 300 bar

- High pressure brass bundle valve for Oxygen, Inert, Inert mixtures and flammable gas service

Permanent gas tight seal

π marking according TPED directive - Tested according EN ISO 10297 - Adiabatic compression tested to avoid oxygen ignitions

SPECIFICATIONS

Working pressure pmax. 300 bar / 4500 psi Gas type O2, Inert Seat orifice size 10 mm

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PCTFE O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70)

42 ALL RIGHTS OF CHANGE RESERVED C140 / C141 | LINE BUNDLE VALVES PRODUCT CONFIGURATOR Gas Type Body Material Actuation Inlet OutletDip tubeGas C140 L A G3 G3 0O2 O2 0 Brass L Handwheel - standard A G3/4" + inner machining G3 G3/4" + inner machining G3 Without 0 O2 Inert & Mix 1 1/4"-18NPT FEM 463 1/4"-18NPT FEM 463 Others list P.90Inert & Mixtures (IM) C2H2 6 ISO 5145 Nr.32 245 ISO 5145 Nr.32 245 Flammable &

(F) Others list P.69 Others list P.86 Gas list

Mix

P.91 KEY FEATURES

-

-

OPTIONS - O2, Inert and Inert Mix

INERT & MIX

Cv 1,0 Temperature range -20°C up to +65°C

SPECIFICATIONS

43 ALL RIGHTS OF CHANGE RESERVED PRODUCT CONFIGURATOR Gas Type Body Material Actuation Inlet OutletDip tubeGas C142 L A G3 G3 0 H2 Inert & Mix 2 Brass L Handwheel - standard A 25E EN ISO 11363 25E G3/4" + inner machining G3 Without 0 O2 O2 3 3/4"-14 NGT CGA V-1 12N 1/4"-18NPT FEM 463 Others list P.90 Inert & Mixtures (IM) G3/4" + inner machining G3 Others list P.86 Flammable & Mix (F) Others list P.69 H2 Gas list

C142 / C143 | ANGLED BUNDLE VALVES

P.91

KEY FEATURES - High pressure brass bundle valve for Oxygen, Inert, Inert mixtures and flammable gas service - Permanent gas tight seal - π marking according TPED directive - Tested according EN ISO 10297 - Adiabatic compression tested to avoid oxygen ignitions OPTIONS - O2, Inert and Inert Mix - O-ring seal type - Orifice diameter 10 mm - 300 bar - Safety on request

Cv

Safety

Temperature

INERT & MIX

Working pressure pmax. 300 bar / 4500 psi Gas type O2, Inert Seat orifice size 10 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec Material hand: wheel aluminium seat: PCTFE O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70)

1,0

C142: No C143: Yes

range -20°C up to +65°C

KEY FEATURES

APPLICATIONS

TITRE

- Xxxxxxxxxxx

- O2, C2h2, Inert and Inert Mix, flammable

- O-ring seal type

- 200 bar / 300 bar inlet pressure

- 0-4 bar outlet pressure

- Flow: 1,8-30Nm3/h (acc. gas type)

- Safety on request

- Brass valve with integrated pressure regulator for Oxygen, Acetylene, Inert, Inert mixtures and flammable gas service (including forming gas)

- Separated filling port

- Outlet: thread or quick connector type

- If non-return valve on filling part, specific filling adaptor recommended

- Outlet pressure / flow ajustable

- Permanent gas tight seal

- π marking according TPED directive

- Tested according EN ISO 22435

- Ox yacetylene cutting and welding

- Elec trical welding: TIG MIG MAG

- Potentially usable on laser applications

SPECIFICATIONS

Working pressure pmax. 300 bar / 4500 psi

Gas type O2, C2H2, Inert &mix, flammable Seat orifice size Acc. to the type of gas

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass

In- and outlet connections in accordance with all country standards (details p.70)

Flow 1,8-30Nm3/h

Temperature range -20°C up to +65°C

Flammable & Mix(F)

Forming Gas (Flammable) (F) Gas list P.91

44 ALL RIGHTS OF CHANGE RESERVED INERT & MIX C805 | VALVE WITH INTEGRATED PRESSURE REGULATOR PRODUCT CONFIGURATOR Gas Type Working Pressure Safety Safety Set Up Body Material ActuationInletOutlet Max Flow range Dip tubeGaugesGuardsGas C80 50 PR 4L OC 25E2391.801- IM Inert& Mix 5 30 bar (C2H2) 3 Pressure Regulator PR 0 - 4 bar 4 Brass L Open-Close OC 25E EN ISO 11363 25E ISO 5145 Nr.30 239 1.8 m³/h (=30l/ mn) 1.8 Without 0 With Gauge (std) 1 Without - Inert & Mixture (IM) O2 6 200 bar 0 0 - 1,5 bar 1.5 Chrome plated brass CL Painted handwheel B 28E EN ISO 11116 28E ISO 5145 Nr.32 245 3 m³/h (C2H2) 3 Others list P.90 Plastic Guard > 40kg G1 O2 C2H2 7 300 bar 1 0 - 10 bar 10 Handwheel with logo cap C Others list P.69 ISO 5145 Nr.42 509 30 m³/h (O2) 30 Plastic Guard >

G2 C2H2 Others list P.XX Steel

G3

60kg

Guard > 150kg

45 ALL RIGHTS OF CHANGE RESERVED CHLORE (CL2) C990 | SPECIFIC CHLORINE APPLICATIONS KEY FEATURES - High pressure brass cylinder valve for Chlorine and Sulfure dioxyde gas service - Fully chemic ally nickel plated - Lower spindel in stainless steel - Special handwheel design to prohibit access on gland nut π marking according TPED OPTIONS - Parallel inlet thread - Filter - Sealing nut with chain PRODUCT CONFIGURATOR SafetySafety Set UpBody Material Actuation Inlet OutletDip tubeGas C9900 NL A 25E 8 M1 CL2 Without 0 Without 0 Nickel plated brass NL Handwheel - standard A 25E EN ISO 11363 25E DIN 477-1 Nr.8 8 Without 0 CL2 (Chlorine) With 5 Fusible metal 165°F (75°C) CG2 1F Painted handwheel B 3/4”-14 NGT CGA V-1 12N W1” 407 M10x0,75 M1 SO2 Others list P.90 Handwheel with logo cap C Others list P.68Others list P.70Others list P.90Gas list P.91 Key operated Square 7.8 D Key operated 5.9 x dia 9.3 E - Chlorine and sulfure dioxyde - O-ring seal type - Orifice diameter 4 mm - 200 bar - Safety on request Working pressure pmax. 14 bar / 200 psi 200 bar / 3000 psi Gas type CL2 Seat orifice size 4 mm Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec Material O-rings: viton, PVDF body: brass spindle: stainless steel In- and outlet connections in accordance with all country standards (details p.70) Cv 0,3 Temperature range -20°C up to +65°C SPECIFICATIONS

SPECIFICATIONS

Working pressure pmax. 300 bar / 4500 psi Gas type He

Helium leak rate at pmax. internal 10-3 mbarl/sec external 10-3 mbarl/sec

Material hand: wheel aluminium seat: PA 6.6 O-rings: EPDM body: brass In- and outlet connections in accordance with all country standards (details p.70)

Flow 100-110l/mn Temperature range -20°C up to +65°C

46 ALL RIGHTS OF CHANGE RESERVED HELIUM (He) C817 / C818 | VALVE WITH INTEGRATED PRESSURE REGULATOR - BALLOON VALVES PRODUCT CONFIGURATOR Working Pressure Pressure Regulator Safety Set Up Body Material ActuationInletOutletMax Flow rangeDip tubeGaugesGuardsGas C81 7 PR 3-5 CLOC 25E239110O1-He 200 bar 8 Pressure regulator PR Preadjusted P. 3 - 5 bar 3-5 Brass L Open- Close OC 25E EN ISO 11363 25E ISO 5145 Nr.30 239 100 l/mn 100 Without O Without 0 Without - He 300 bar 7 Chrome plated brass CL Painted handwheel B Others list P.69 Others list P.XX 110 l/mn 110 Others list P.05 With Gauge (std) 1 Plastic Guard > 40kg G1 Gas list P.91 Handwheel with logo cap C 180 l/mn (limited at 161 l/mn) 180 Plastic Guard > 60kg G2 Steel Guard > 150kg G3

-

-

-

-

-

-

-

Ox

-

KEY FEATURES

Brass valve with integrated pressure regulator for Helium service

Separated filling port

Specific outlet nozzle

If non-return valve on filling part, specific filling adaptor recommended

Fixed outlet pressure and flow

Permanent gas tight seal

π marking according TPED directive - Tested according EN ISO 10297 and CGA V9 standards APPLICATIONS -

yacetylene cutting and welding

Elec trical welding: TIG MIG MAG - Potentially usable on laser applications

TITRE - Xxxxxxxxxxx - He - O-ring seal type - 200 bar / 300 bar inlet pressure - 3,5-4,5 bar outlet pressure - Flow: 100-110l/mn - Safety on request

KEY FEATURES

- Compac t high pressure brass cylinder valve for Inert, Inert mixtures and flammable gas service and for small sized cylinders

- Specific filling adaptor required

- Residual pressure valve inline execution

- Permanent gas tight seal - π marking according TPED directive