AFTERMARKET SUSTAINABILITY

Understanding reman | 16

Remanufacturing has a history in the auto care sector but its importance to sustainability and benefits to the industry have long been overlooked. Here’s why it’s key to this industry and why it's growing in popularity

What customers prefer | 22

Consumers would rather go to the dealer for vehicle repair and maintenance than an independent shop. Two recent reports explain where the aftermarket is falling short

Brake Rotors and Drums

Brake Pads and Shoes

Brake Calipers

Hub Bearings

CV Axles

Chassis Parts

Complete Strut Assembly

Shock Absorbers

Strut mounts

Radiators

Water Pumps

Steering Pumps and Racks and Pinions

Steering Gears

Starters and Alternators

Batteries

Oil Pans

Fuel Pumps

Wiper Blades

Ignition Parts and Coils

Fuel lines

Exhaust Parts, Universal Converter, and Flex Pipes

Misc Automotive Parts HOTSPOT AUTO PARTS

939 Warden Ave Scarborough ON M1L 4C5 Info@hotspotAutoparts.com | www.hotspotautoparts.com

Jobber News is Canada’s longest-established publication serving the distribution segment of the Canadian automotive aftermarket. It is specifically directed to warehouse distributors, wholesalers, machine shops, and national accounts.

Publisher | Peter Bulmer (585) 653-6768 peter@turnkey.media

Managing Editor | Adam Malik (647) 988-3800 adam@turnkey.media

Associate Editor | Derek Clouthier derek@turnkey.media

Contributing Writer | Greg Aguilera, Zakari Krieger

Creative Director | Samantha Jackson

Video / Audio Engineer | Ashley Mikalauskas, Nicholas Paddison

Sales | Peter Bulmer, (585) 653-6768 peterb@turnkey.media

Delon Rashid, (416) 459-0063 delon@turnkey.media

Circulation | Delon Rashid, (416) 459-0063 delon@turnkey.media

Production | Tracy Stone tracy@turnkey.media

Jobber News is published by Turnkey Media Solutions Inc. All rights reserved. Printed in Canada. The contents of this publication may not be reproduced or transmitted in any form, either in part or full, including photocopying and recording, without the written consent of the copyright owner. Nor may any part of this publication be stored in a retrieval system of any nature without prior consent.

Canada Post Canadian Publications Mail Sales Product Agreement No. 43734062

“Return Postage Guaranteed” Send change of address notices, undeliverable copies and subscription orders to: Circulation Dept., Jobber News, 48 Lumsden Crescent, Whitby, ON, L1R 1G5

Jobber News Magazine (ISSN#0021-7050) is published six times per year by Turnkey Media Solutions Inc., 48 Lumsden Crescent, Whitby, ON, L1R 1G5

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us.

TTHE THREAT TO CANADA'S AFTERMARKET

he average age of vehicles in Canada is significantly lower than that in the United States. Canadian vehicles average10.5 years compared to 12.6 years south of the border. This gap is not merely a statistical curiosity but a big yellow flag for the Canadian aftermarket industry.

This disparity is driven by a substantial outflow of younger vehicles from Canada to the U.S., a trend that poses a significant threat to the future health of the Canadian aftermarket sector.

Over the past few years, the number of vehicles in operation (VIO) in Canada has remained steady at around 26.7 million. We’re keeping about the same number of vehicles on our roads but they’re not reaching an age like that on the other side of the border. Todd Campau, aftermarket practice lead at S&P Global Mobility, delved into this issue during the AIA Canada National Conference this spring. His findings revealed a concerning trend: A pipeline of younger vehicles is exiting Canada, driven by economic factors and demand imbalances across the border.

Combine our weak dollar and a shortage of vehicles in the U.S., Canada is an attractive seller. Hundreds of thousands of vehicles are going across the border each year — we’ve seen at least 50,000 vehicles being exported quarterly.

These vehicles are predominantly younger, Campau pointed out, with the average age dropping from nearly nine years in 2016 to less than seven years today. This trend is alarming for the Canadian aftermarket industry because it means vehicles that would typically enter the prime aftermarket repair age range are being siphoned off to the U.S., depriving the Canadian aftermarket of critical business opportunities.

This situation is compounded by the fact that newly purchased vehicles are the eventual pipeline to the aftermarket — but sales aren’t what they used to be. So part of this reduced pipeline is leaving Canada before they age into the aftermarket sweet spot. Fewer vehicles aging into the 10-plus year category is a concerning trend for the future health of the industry.

For the Canadian aftermarket industry to thrive, it must address this challenge head-on. One strategy is to advocate for policies that restrict the export of younger vehicles. Additionally, independent service providers need to innovate and find ways to attract and retain older vehicles that remain in the country.

Moreover, the industry should focus on educating consumers about the benefits of keeping their vehicles longer and maintaining them properly. Emphasizing the cost savings and environmental benefits of extending the life of their vehicles can help shift consumer behaviour and reduce the allure of dumping their vehicles for a new one, leaving the old one to be exported.

President & Managing Partner | Delon Rashid Head of Sales & Managing Partner | Peter Bulmer

Corporate Office

48 Lumsden Crescent, Whitby, ON, L1R 1G5

0021-7050

The export of younger vehicles from Canada to the U.S. is a significant threat to the Canadian aftermarket. The industry must take this issue seriously and implement strategies to counteract this trend, ensuring a stable and prosperous future for our vital auto care sector.

Adam Malik Managing Editor, Jobber News

We want to hear from you about anything you read in Jobber News magazine. Send your email to adam@turnkey.media

HOW THE BEV LANDSCAPE WILL CHANGE

OK, we’re hearing a lot about the investments but what about the repairs? It’s about time we start publishing the cost of all these batteries and the turnaround times. What is repairable and what is not? When is there going to be certification for those in the aftermarket? The way I see it right now we’re in the Wild Wild West when it comes to EVs. It’s time to make OEMs accountable for the future of these vehicles, not just the production. We need to ask these questions now. The phone calls I’ve made have been very revealing and will make the average consumer think twice about investing in an EV.

Todd Holmes, Holmes and Son Service

BARRIERS SHOP OWNERS FACE IN EV, ADAS PREP

I agree shops need to be prepared for the onslaught of new technology and EVs. We have had three charging stations for over two years and currently service over 30 EVs. However, I disagree on the need for fast charging. The expense will not give a big enough return on investment. We find our actual clients have no problem leaving vehicles to charge. Transient consumers are looking for fast chargers.

Bruce Eccles, Eccles Auto Service

HOW TO KEEP UP WITH CONSUMER CHANGE

There is a severe flip side to this. We tried using an online presence. It generated a lot of no-shows and wasted time. Without a personal contact of some kind for our first interaction, I have no idea if I’m talking to someone I even want to deal with. I took our website down and never looked back. Same with sales tools like tire quote requests through our distributors' search tool. I think I converted 1 quote request out of the hundreds I wasted my time on — and I know it wasn’t because of price. Came to realize later we were getting quote requests from people hundreds of kilometres away. I’m an older millennial, not some old curmudgeon afraid of the interwebs, but I have come to absolutely despise that way of doing business, and my appointment backlog doesn’t seem to be shrinking.

Geoff Walton, Grant Street Garage

Too many people think they can run this industry with never experiencing the front line or failing at doing so. It's great to have all these techniques in place, but the real world is not a fantasy. The automotive industry should be promoting consumers to leave their vehicles for service and repairs, not promoting a quick service lane that one can wait for. The problem is people do not want to give up their freedom of transportation or being inconvenienced without their cars. We have to educate the consumer that these

cars are complicated and there are just too many variables that can jeopardize the timeline of repairs or services being completed.

Rob Nurse, Bob Nurse Motors

THE RISK OF NOT DOUBLE CHECKING VEHICLES BEFORE CUSTOMER PICK UP

Most people don’t say anything so you may never know. They just don’t come back. It is very important to have policies and procedures in place and have them followed. Quality checks often catch problems and keep employees following these procedures. Doing all jobs the same way every time prevents mistakes.

Bob Ward, The Auto Guys

We have a hardcopy checklist we give the techs, they initial every checklist item and leave it in the car so customers can see what was done. It helps to show we are thorough, and people often notice that there was no labour charge for those checks, and that goes a long way too. We timed it, even adjusting tire pressure in all four tires, the time spent never exceeded 10 minutes.

Glenn Kroeze, Western Turbo

THE KEY ROLE FOR OLDER TECHS IN AN AI WORLD

All AI will do is train techs not to think. You cannot rely on AI for assistance in the auto service sector. Look how well it worked with autonomous driving vehicles. We need techs who are analytical and thinkers, not ones who will rely on AI. Our education system needs improvement instead of developing AI.

Bob Ward, The Auto Guys

Don’t think AI will just dive in and say replace a part but would guide tech along a diagnostic testing approach. This is already used in scan tools.

Mike, Elite Auto Service

SUPPLIERS SHOULD BRACE FOR GEOPOLITICAL SHAKEUPS

I believe there is a potential problem with relying on foreign countries to supply raw materials. Can they be trusted to fulfill supply contracts? China has control over many of the raw material suppliers so it is a very dangerous area that North American car manufacturers have entered into. Why have they chosen to deal with the world’s largest manufacturing country that could literally control its competition? Is this a sound business decision?.

Bob Ward, The Auto Guys

Scan the QR code for the latest and more in-depth news online.

UNI-SELECT GOES ON ACQUISITION SPREE

QUEBEC-BASED UNI-SELECT has been named a gold partner of the 2024 Grey Cup Festival recently acquired three different jobbers across Canada.

First, in British Columbia in June, Uni-Select expanded its footprint in the province by acquiring Alder Auto Parts, a long-time member. The business has been around since 1978 and currently serves Port Kells and Cloverdale, just outside of Surrey and Aldergrove, near Langley, with 34 staff members. This came about two months after Gilbert Auto Supply was acquired by Uni-Select.

“Joining Uni-Select starts a new and important chapter for us,” said John Feddersen, president of Alder Auto Parts. “We are proud to unite with a company that respects our heritage and shares our values. This partnership will amplify our strengths and continue the legacy we have built in this community.”

Then, Uni-Select announced it added jobbers in Ontario and Quebec. General Auto Parts part of the Toronto community since 1959, was acquired. It caters its automotive aftermarket parts to retail, wholesale and corporate customers. Its 32,000 sq-ft. store is located near Pearson International Airport and is staffed by 27 employees.

“Joining forces with Uni‐Select represents a strategic leap forward,” said Harold Baker, president of General Auto Parts. “The respect and understanding that have characterized our discussions are set to forge a path of sustained growth and innovation.”

In Saint‐Eustache, Québec, long-time member Miron Auto Dépôt was acquired. It has served the community for 50 years.

“We are happy to see our legacy continued by Uni‐Select, a company that stands on similar entrepreneurial foundations,” said Robert Mirron, president of the company. “Choosing Uni‐Select was a natural fit, given our mutual dedication to a customer‐first approach and deep appreciation for our employees.”

“The acquisition of General Auto Parts and Miron Auto Dépôt marks another important step for us in our growth strategy as we continue to expand our store network, further solidifying our footprint in these strategic markets,” said Émilie Gaudet, president and chief operating officer of Uni‐Select. The flurry of moves comes less than a year after LKQ completed its acquisition of Uni-Select.

HOW BIG THE CONCERN OF RIGHT TO REPAIR IS FOR SHOPS

THE VAST MAJORITY of independent repair shops put the right to repair issue at the top of their list of concerns for doing business going forward.

The Auto Care Association — the U.S.-based national body representing several sectors of the automotive aftermarket — released findings from a nationwide survey of repair shops that underscored the hurdles faced by independent repair facilities in servicing vehicles, often compelling them to decline business.

Key findings reveal that 84 per cent of independent repair shops rank access to vehicle repair and maintenance data as their top business concern, outranking issues such as technician recruitment, retention and inflation. Furthermore, 63 per cent of these shops face difficulties in making routine repairs daily or weekly due to data access restrictions. Notably, 51 per cent of shops reported having to send up to five vehicles per month back to dealerships because of these restrictions.

PARTS STORE EVOLVING

THE LANDSCAPE OF AUTO parts stores in the United States experienced notable shifts over the last few years, according to a recent report from Lang Marketing.

From 2017-2023, the mix of jobber stores and retail auto parts stores saw substantial changes, reflecting evolving market dynamics and consumer preferences. In the U.S., the number of jobber stores is dropping; the number of retail auto outlets is on the rise.

Automotive jobbers have struggled to maintain their share of the expanding do-it-yourself (DIY) market, losing nearly

one-fifth of their market share in six years. Additionally, jobbers have faced increasing competition from retail auto parts stores in the commercial market, which has traditionally been a stronghold for jobbers.

The emergence of two-step distribution by traditional warehouses — designed to bypass jobbers to sell directly to commercial accounts and end-users — has further impacted jobber business.

On the other hand, retail auto parts stores have successfully adapted to changes in the marketplace. These stores have maintained a strong presence in the DIY market, despite challenges from e-commerce platforms and other online sellers.

Looking ahead, Lang Marketing anticipates these trends will continue. The decline of jobber stores is expected to persist, while retail auto parts stores are projected to increase both in number and market share in the commercial sector.

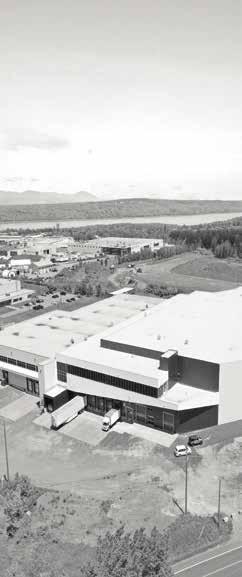

NEW VAST-AUTO WAREHOUSE ANNOUNCED

OAKVILLE, ONTARIO IS THE new home for a Vast-Auto Distribution satellite warehouse.

In an announcement about the expansion, the company said the added facility — west of Toronto and the fifth in Ontario — is part of its “unwavering commitment to customer service through availability and accessibility to quality automotive parts.”

The move is part of the company’s growth strategy, its announcement added. When O’Reilly Automotive announced it had bought Vast-Auto, expansion was pointed out as a key motivator.

“This is a significant milestone and fantastic opportunity for Vast-Auto and will be a catalyst to accelerate our expansion throughout Canada,” president and CEO Mauro Cifelli said in December.

The move also fits in the company’s mission of supporting its customers across Eastern Canada, the announcement noted.

“This expansion not only emphasizes our dedication to meeting the evolving needs of our customers but also reflects our ongoing commitment to driving excellent customer service,” Cifelli said in the announcement about the new Oakville warehouse.

FIRST BRANDS ACQUIRES LUMILEDS BUSINESS

CITING CHANGING MARKET conditions since the merger of Lumileds and Philips, Lumileds announced it has sold its lamps and accessories division to First Brands Group.

The move, Lumileds announced in a press release, allows

Lumileds to focus on its core LED and MicroLED technology, which serves the automotive, general illumination, display and flash markets.

The deal came in at US$238 million and was expected to close by the end of the first half of the year.

AFTERMARKET EMPLOYMENT IS ON THE RISE

EMPLOYMENT LEVELS IN THE auto repair sector are higher than pre-pandemic levels, according to data from DesRosiers Automotive Consultants.

The automotive aftermarket showed robust growth in 2023, with the automotive repair and maintenance sector reaching 121,000 employees by December, surpassing 2019 levels by 4.8 per cent. Similarly, employment in automotive parts and accessories stores came in at about five per cent above pre-pandemic figures.

However, other sectors lagged behind. Motor vehicle manufacturing remained 11 per cent below 2019 levels, while automobile dealers were still slightly short of returning to prepandemic employment numbers.

“The overall employment picture in the automotive space was positive by the end of last year,” commented Andrew King, managing partner at DesRosiers. “With the manufacturing side of the industry transforming, the retail aftermarket led in employment growth.”

DEALER WAIT TIMES INCREASE

DESPITE WAIT TIMES AT dealerships increasing due to parts delays and labour shortages, customer satisfaction increased, according to J.D. Power.

The 2024 U.S. Customer Service Index Study found that the overall service satisfaction score increased by five points to 851 on a 1,000point scale.

“It’s encouraging to see an improvement in service satisfaction but, unfortunately, the capacity and wait time issues have gotten progressively worse since the pandemic and show no immediate signs of easing up,” said Chris Sutton, J.D. Power’s vice president of automotive retail.

He further noted the mixed nature of the results. While service satisfaction has seen an uplift, the issues surrounding capacity and wait times have worsened since the pandemic, with no immediate solutions in sight.

The study further found that appointment wait times are increasing, with mass market vehicle owners waiting an average of 5.2 days and premium vehicle owners waiting 5.4 days.

It also noted that a growing preference for prompt service is

leading more customers to choose aftermarket facilities over dealerships.

PRIVATE LABEL LESS APPEALING

WHILE THERE MAY HAVE been an uptick in consumers choosing private label options for their automotive aftermarket needs, it appears the area is no longer growing.

Nathan Shipley, executive director of industry analysis in automotive at Circana, showed data from the last three years and it all suggested that numbers are flat in this area.

“But there’s not some major shift to private label like I think a lot of us would expect as we have gotten into a little bit tougher economic times this year,” he said at AAPEX 2023 during his session, Aftermarket Outlook 2024.

A low-income consumer was more likely to opt for private labels more often than a higherincome one. Private labels made up 50 per cent of their purchases.

“So [there is a need out there] for branded offerings and not discounting having premium products targeting that higher income consumer,” Shipley said.

Shipley had previously noted that it was the higher-income consumer who was frequenting the aftermarket more often. Retailers, he said, need to account for that when thinking about their product offerings.

REPAIR DEMAND RISES

AS OUTLETS FALL

THE DO-IT-FOR-ME (DIFM) automotive service and repair market has experienced significant shifts over the past decade, with a growing demand for vehicle repairs but a declining number of repair outlets.

According to data from Lang Marketing, while the volume of products installed by automotive technicians increased by more than 25 per cent from 2013 to 2023, the number of repair outlets fell by 10 per cent.

The COVID-19 pandemic had a profound impact on the DIFM market in recent years.

In 2020, the market saw a double-digit decline in light vehicle repairs across the United States, coupled with a sharp reduction in the number of repair outlets. Although the DIFM market regained its product volume over the next three years, the total number of repair outlets did not recover, indicating a lasting effect of the pandemic on service infrastructure.

However, while many repair outlets struggled, repair specialists — outlets focusing on a limited range of vehicle services — showed resilience.

The changing landscape of repair outlets has substantial implications for the automotive aftermarket, Lang noted.

With fewer service stations and garages, there is increased pressure on the remaining outlets to meet the rising demand for repairs. This shift affects the competitive strength of distribution channels supplying the DIFM market and impacts the volume of aftermarket brands and the share of product volume captured by both dealers and independent repair outlets.

DEALERS SAY THEY HAVE TOO MANY ZEVS

THE CANADIAN AUTOMOTIVE market has grappled with a significant lack of new vehicle inventory since early 2021. While these shortages have largely eased and

For customers who want the best in off-road lighting.

Philips Ultinon Drive LED Lightbars and Pod Lights have been engineered to provide brilliant, reliable lighting in the conditions that dedicated on and off-roaders encounter. philips.ca/ultinon-drive

inventory levels are beginning to normalize, the full story is more nuanced.

Specifically, dealers say they have too many zero-emission vehicles and not enough internal combustion engine ones, according to a survey of Canadian Automobile Dealers Association members by DesRosiers Automotive Consultants.

When surveyed about ICE vehicle inventory, 43.1 per cent of dealers reported insufficient inventory. Meanwhile, 32.6 per cent indicated that they had the right amount of inventory, and 24.3 per cent stated that they had too much ICE inventory.

In contrast, 31.4 per cent of dealers reported sufficient ZEV inventory, but a larger group, 44.4 per cent, felt they had too much ZEV inventory. Only 24.3 per cent cited a lack of ZEVs.

“While dealer inventory is not the sole determinant of sales success, the opinions on ZEV and ICE stock levels are certainly revealing,” said Andrew King, managing partner at DesRosiers. “Consumers are increasingly resistant to higherpriced vehicles. As the market focus shifts from early adopters to a more hesitant general public, the road ahead for ZEVs will be challenging.”

MOBILE REPAIR IS OUTPACING DIFM

THE BARRIERS TO MOBILE vehicle repair are coming down and the market is now growing at a much faster pace than the do-it-forme segment, a recent report found.

From 2016-2020, the mobile repair market grew 16 per cent annually — then twice that pace the next two years, reported Lang Marketing.

“Between 2016 and 2022, mobile repair climbed at an annual pace more than ten times faster than the overall DIFM light vehicle market,” it said in its report, Mobile Repair Surges Ten Times DIFM Pace

There used to be three key barriers, ones that were believed would insulate vehicle repair from disruption: The need for hands-on technician diagnosis, required parts at the place of repair and the value of a personal relationship between vehicle owners and repair outlets.

But that’s changed now. Advancing technology and the differing values of younger generations have played roles in significantly altering how consumers decide when and where to have their vehicles repaired.

“The rapid growth of mobile repair has demonstrated that the barriers to auto repair disruption are no longer as formidable as once thought,” Lang’s report said.

Mobile repair, it observed, can perform more than 85 per cent of repairs in one visit to the client, with an expanding range of repairs coming.

VEHICLE OWNERSHIP IMPACTED BY INFLATION

CANADIAN MILLENNIALS ARE increasingly being priced out of car ownership due to inflation, a recent study has revealed. Those being hit hardest are between the ages of 25 and 34, according to the Car Ownership Index from Turo, a peer-to-peer carsharing marketplace. It found that 56 per cent of young millennials are less inclined to purchase or lease vehicles this year — compared to 46 per cent across all age groups.

Last year, the percentage of Canadians reconsidering car ownership

was lower with 39 per cent showing a level of financial caution related to vehicle ownership. The findings indicate a shift in Canadians’ approach to car ownership, exacerbated by financial concerns that have escalated over the past year.

The index pointed to a growing trend of economic conditions affecting Canadians’ decisions on car ownership. Nearly two out of every five (37 per cent) respondents without a vehicle stated that high costs are the primary deterrent — an increase from 32 per cent the previous year.

CONCERNS OVER AUTOMATION SAFEGUARDS

THE INSURANCE INSTITUTE FOR Highway Safety (IIHS) has introduced a new ratings program aimed at driving automakers to integrate more stringent safeguards into their partial driving automation systems.

It has not gotten off to a great start for automakers. The first evaluation of 14 systems yielded predominantly disappointing results: Only one system received an “acceptable” rating, two were deemed “marginal,” and the majority, 11 systems, were classified as “poor.”

The group measured BMW, Ford, General Motors, Genesis, Lexus, Mercedes-Benz, Nissan, Tesla and Volvo.

“Most of them don’t include adequate measures to prevent misuse and keep drivers from losing focus on what’s happening on the road,” observed David Harkey, IIHS president.

The Lexus LS’s Teammate system stood out as the sole system meriting an acceptable rating, a stark contrast to the poor ratings attributed to popular models such as the Ford Mustang Mach-E and Tesla Model 3.

“Some drivers may feel that partial automation makes long drives easier, but there is little evidence it makes driving safer,” Harkey said. “As many high-profile crashes have illustrated, it can introduce new risks when systems lack the appropriate safeguards.”

The overarching message: Vehicles with partial automation require active human oversight, countering any misleading implications by automaker marketing.

NAMES IN THE NEWS

Sean Lannoo has joined Dill Air Controls as technical training manager. He was previously with Continental and its VDO brand

Continental named Stefan Feder as its head of automotive aftermarket and OE service for North America. He has been with the company since 2004.

Holley Performance Brands announced Jordon Musser as its senior vice-president of safety and electronics product categories.

Nick Tufo has been promoted to regional sales manager –east region at KYB Americas. He was previously a territory sales manager.

Denton Lewis has been promoted to category manager by the Aftermarket Auto Parts Alliance. He will work with new and existing channel partners.

WHAT’S PUSHING TECHS OUT OF THE INDUSTRY?

A RECENT STUDY CONDUCTED by Wrenchway has shed light on a concerning trend within the automotive repair sector: Nearly half of the world’s mechanics are considering abandoning their profession.

The primary catalyst for this professional discontent stems from issues related to compensation, pushing workers to their limits.

As the technological advances continue in the field, technicians are facing escalating pressures. The evolution of vehicles, increasingly equipped with advanced technologies, has significantly heightened the demands placed on techs.

The Wrenchway study identified that, beyond salary grievances, the major sources of tech dissatisfaction lie in the strenuous physical and mental requirements of the job. These pressures are compounded by the substantial costs associated with tools, inadequate management, a lack of respect within the industry and insufficient benefits.

A notable point of contention within the sector is the preference for compensation structures. A majority of surveyed technicians (65 per cent) voiced a preference for an hourly pay system or a combination of hourly wages supplemented by production bonuses, over the traditional flat-rate compensation model.

The burden of expensive tools and training, typically shouldered by the mechanics, further exacerbates the issue.

Stats that put the North American automotive aftermarket into perspective

129,034

The Vancouver International Auto Show set a new attendance record for its five-day event, the first after a four-year hiatus. It set a single day attendance record of 39,823 guests

2017

ADAS work that is sourced out to dealers because aftermarket repair shops can’t do the work. Collision shops outsourced US $177 million worth of ADAS calibration work.

58%

Kilometres travelled in Q4 2023 were down significantly from the same time the year before. Last year’s middle quarters also saw a reduction from 2022.

16,618 km

Traditional internal combustion engine vehicles in Canada travelled fewer kilometres than battery electric vehicles.

S&P Global Mobility

The number of parts and accessories wholesalers dropped 3.1% from 2022 to 2023 but the number of retailers grew 0.9% to

$70,000

The top-end total cost for a shop that wants to be able to perform ADAS recalibrations. Most shop owners estimated costs maxing out at $55,000.

top of mind as the biggest concern for U.S. shop owners, ahead of

DesRosiers Automotive Consultants

Vancouver International Auto Show

On the Road

April 24, 2024

Toronto, Ontario

Automotive aftermarket professionals from across Canada gathered in Toronto to hear from some of North America’s top experts who shared knowledge and insights. Speakers took the stage either during the main or breakout sessions, analyzing how the industry is moving, how auto care professionals can take on change and more. Attendees heard from AIA Canada leadership as well as Todd Campau from S&G Global Mobility, Stacey Miller from Auto Care Association and others. During lunch, Bill Hay was recognized with the Distinguished Service Award and Patrick Verriet received the YPA Committee’s Young Leader of the Year Award.

AIA Canada National Conference

THE ENTREPRENEURIAL JOBBER

Rather than relying on your established customers, look for some diamonds by working with upand-coming shops. Here are some tips on growing your business // By Zakari Krieger

In the competitive realm of the automotive aftermarket, the role of an entrepreneurial jobber is multifaceted, requiring a delicate balance between catering to core clients and strategically expanding the customer base.

Whether you own a single auto parts jobber location or manage a network of stores, success hinges on understanding the market dynamics and effectively prospecting new clients while nurturing enduring relationships.

In the pursuit of growth and diversifying your customer base to

manage risk, it is crucial to identify potential clients who align with your business values and objectives. Look for characteristics such as growth potential, compatibility with your product offerings and a willingness to collaborate for mutual benefit.

Many jobbers look to land business from the most established shops in their market. But there is also opportunity in working with emerging shops and working as a partner with them to build their business through coaching, technology, branding and overall shop experience to help that location grow and expand into the next

QUALITY THE PROS COUNT ON.

top professional automotive shop in their trading area.

Recent data suggest that the number of automotive shops in Canada has shrunk over the last two years — by close to 20 per cent — due to the impacts of rising interest rates, cost inflation driving up wages, rents and business services and increasing parts costs squeezing the price thresholds shops can charge to consumers.

In this environment, it has become ever more challenging in a trading area to think outside the box. It is increasingly difficult to develop effective strategies to grow sustainably and efficiently to avoid the desperation of selling into customers that do not align with the business' values or using short-term programs to win business with unsustainable pricing methods. And other short-term strategies can drag a jobber down.

In addition to targeting mainstream markets, exploring niche segments within the automotive industry can be fruitful. Whether it's catering to performance enthusiasts, light industrial & fleet segments, import or EV specialists, tailoring your marketing efforts and product offerings to meet their specific needs can unlock new avenues for growth.

Our parts business was successful in having various facets to the business where we were able to diversify our revenue streams. At one point, we serviced the traditional ASPs, import specialists, light industrial and fleet, paint and body and tools and equipment sectors. Many jobbers are habitual in servicing a core area of the aftermarket, but diversifying product segments as well as sectors can be an effective way to drive diversification.

Looking back at some time periods when the traditional repair business had slowed, our business was diverse and was supported by recurring revenue from industrial, fleet clients and paint and body contracts we held.

Furthermore, offering value-added services can set your business apart from the competition. Whether it's providing technical support, product customization, flexible payment options or going the extra mile to enhance the customer experience can foster loyalty and differentiate your brand.

Additionally, staying agile and adaptable in response to evolving market needs and consumer preferences is crucial. By

continuously monitoring key performance indicators (KPIs) and soliciting feedback from clients and employees, you can identify areas for improvement and innovation, positioning your business for sustained success.

Successfully managing a jobber business requires a holistic approach that balances the needs of core clients with an emphasis on diversifying the customer base. By understanding market dynamics, prospecting new clients strategically and nurturing enduring relationships based on trust, communication and quality, you can navigate the complexities of the industry landscape and position your business for sustainable growth and resilience.

Continental door system components come ready-toinstall, right out of the box. We offer window lifts, motors, and assemblies as well as door lock actuators. Made in ISO Certified facilities, they provide exact OE fit, function, and performance for simplified installation and no comebacks.

Zakari Krieger is the Fix Network, Canadian vice president of Prime CarCare, responsible for the Canadian retail business, encompassing the Speedy Auto Service and Novus Auto Glass business lines

CHANGING THE PERCEPTION

Remanufacturing and attracting new talent two keys to continued sustainability in the automotive aftermarket sector // By

Derek Clouthier

Within the automotive aftermarket, there are several misconceptions about sustainability. While some may dismiss sustainability as an industry buzzword or an effort replaced by profits or customer demand, nothing is further from the truth.

In fact, finding new ways to be sustainable for environmental stewardship, the betterment of the business and a growing number of customers looking for companies that embrace these practices has never been more prominent in the auto care industry than it is now.

“The automotive and commercial vehicle aftermarket has a long history of helping society meet its need for transportation,” said John Chalifoux, chief sustainability officer and Chief operating officer of aftermarket suppliers for the Motor and Equipment Manufacturers Association (MEMA). “With today’s increased focus on sustainability, more can be done to show the strides our industry is taking to do the right thing — now and for generations to come.”

And more is being done. Launched just last year, MEMA was formed to meet the needs of its members given the rise in the importance of sustainability and ESG — environmental, social and governance. It focuses on education, advocacy and problem-solving.

“The centre offers education and peer-sharing programming for members. With the help of our affiliate members, we initiated Sustainability Hour — virtual one-hour sessions that focus on a specific topic or point of view,” Chalifoux explained. “Currently, we are hosting one session per month. We also offer sustainability workshops, where members can roll up their sleeves and spend time learning and sharing on topics related to compliance, value creation and building advantage.”

Learning and sharing this knowledge is key, Chalifoux said, to shedding a perception of the automotive aftermarket industry that does not always match reality.

One key challenge is helping the market understand that the quality of a remanufactured product is as good as new.

“Sustainability is about being responsible to people, the planet and your business. Every aftermarket company has an opportunity to identify what they’re good at and establish a business case for sustainability,” he said. “Show what your company or shop is doing to make a difference for the environment and the people you serve. Highlight everything from battery and oil recycling and reduced energy usage to water conservation and thoughtful community programs.”

One of the biggest challenges in the automotive aftermarket industry and an area that increases the industry’s sustainability revolves around remanufactured products.

“One key challenge is helping the market understand that the quality of a remanufactured product is as good as new,” said Ben Smart, vice-president of the North America region with ZF Aftermarket. “There is a lingering perception that remanufactured products are lower quality because their core is a used part. In reality, the castings and other materials on a remanufactured part are generally better quality than those of today’s reverseengineered products.”

Smart adds that the other benefit of a remanufactured product is its sustainability. At ZF Aftermarket, products are not thrown away after a single use but are instead shared, repaired, refurbished, reused and recycled.

“This approach not only reduces resource consumption, emissions and waste, but also lowers material costs,” Smart said. “It makes it possible for products to have multiple lifecycles and offers significant time, material and cost savings when compared to creating a replacement product completely from scratch.”

Through its North American reman operations, ZF Aftermarket has reduced its CO2 emissions by an estimated 8,874 tonnes, lowered energy use by 12.3 million kWh and salvaged 2,823 tonnes of material.

In addition to creating superior products and keeping the automotive aftermarket supply chain stocked with quality parts, remanufacturing also reduces the need for new materials.

“Just as we have learned to use recycled paper products, we should apply the same principles to parts,” Houman Kashanipour, CEO and president of Alliant Power, a diesel engine parts, service and repair company explained. “The extraction of materials from the earth at our current rate is unsustainable. The fresh water required to process new materials is becoming increasingly scarce, making it crucial to rebuild and reuse older products.”

Quality products, whether new or remanufactured, help the industry reach sustainability goals.

“High-quality products reduce the need for new ones, conserving energy and natural resources,” Kashanipour added. “The costs and resources required to build new products are not well understood, presenting an opportunity to highlight the benefits of sustainable practices.”

South of the border, the U.S. International Trade Commission and MEMA are aligned when it comes to

Investing more in technologies that help us reclaim and upgrade products, rather than constantly building new ones, is essential.

the definition of remanufacturing — an industrial process that restores end-of-life goods to original working conditions or better.

“That leads to remanufactured products that are indistinguishable from new products in terms of quality, performance, appearance, functionality and warranty and, in some cases, they are better than new products,” Chalifoux said.

It’s also important, however, that companies are transparent about the products they remanufacture.

“One problem is the term ‘remanufactured’ can be misused by companies and individuals to refer to products that are not truly remanufactured,” Chalifoux said. “In addition to knowing the source of remanufactured goods, customers can also rely on an industry certification. MEMA and its members are behind a quality process certification named Manufactured Again, which holds remanufacturers to the same international quality standards as new manufacturers.”

Wants and needs of customers

More than ever, customers in the automotive aftermarket sector are looking at the sustainability of the companies they do business with and getting that message out is important for future success.

“When it comes to ESG data, think of five action verbs: Collect, analyze, validate, report and communicate,” Chalifoux said. “Validate and communicate are so important; make sure you tell your true story.”

Smart is not shy when it comes to getting his company’s message out on its sustainability efforts, both to its customers and employees. In addition to embracing such elements as employee development and diversity, safety, human rights and responsible corporate behaviour, ZF Aftermarket has helped its customers through the transition from being defined by the internal combustion engine to one more defined by CASES — connected, automated, sustainable, electrified and shared.

“We’re making it clear that ZF Aftermarket’s goal is to be the green and sustainable aftermarket leader. ZF has committed to being carbon-neutral across all emission categories by 2040, 10 years ahead of what is required by the Paris Climate Agreement,” he said. “A significant part of

meeting our climate goals will be achieved by powering our manufacturing sites and offices with more ‘green electricity’ from renewable sources.”

Smart’s goal is for ZF to switch completely to green electricity by 2030 and to reach 40 per cent next year.

Overcoming challenges

In addition to the perception of remanufactured products, Smart says some of the hurdles when it comes to increasing sustainability in the automotive aftermarket include building strong relationships, embracing digitization and attracting new talent.

“Ten or 15 years ago, workshops competed with each other for the best mechanics. Today, they must compete with many different types of industries for the best software and data analytics experts,” he said, adding that Gen Z is a digital-first generation of workers. “They’re tech-savvy and eco-conscious, but these potential employees are often unfamiliar with the aftermarket and its broad field of activities. They often don’t realize the profound ways vehicle maintenance has changed; what used to be managed with a wrench and oil is now proactively handled through software and electronics.”

Kashanipour agreed, saying the need for a skilled workforce capable of performing increasingly technical and complicated repairs is vital for continued sustainability in the sector.

“Collaboration between OEMs and the aftermarket is essential to provide access to the information required for repairs,” he said, “which is why the ‘right to repair’ is so critical and a must.”

For those in the automotive aftermarket, sustainability is not a simple buzzword; it’s a way to streamline operations, improve their bottom line, create a quality workplace, improve customer relations and, ultimately, minimize their environmental impact.

But, as Kashanipour points out, the industry needs to continue to advocate for sustainable practices and people need to be aware of what businesses are doing for the momentum to keep rolling.

“Investing more in technologies that help us reclaim and upgrade products, rather than constantly building new ones, is essential,” he said. “Remanufacturing is green and sustainable and we must emphasize its importance and benefits.”

DAYCO: DRIVING SUCCESS WITH INNOVATIVE AFTERMARKET SOLUTIONS

AT DAYCO, IT’S NOT just about providing a quality aftermarket product; it’s about helping customers offer and install that product with best-in-class service and experienced technicians.

A global leader in the research, design, manufacturing and distribution of high-quality belts, front end drive system components, hoses and tools for automotive, heavy-duty, powersports and industrial applications, Dayco delivers products and services that move the world forward. Driving that movement is the company’s ongoing commitment to customer service, creating technical content and advice materials to make the installation and maintenance of its aftermarket products simple and understandable.

“Dayco wins when our customers win, so our focus is to give our customers the tools to best sell and install our products,” says Jerry Reeves, manager of product management. “Whether it is our AutoPartIQ inventory assessment software that recommends which parts a new store should stock based on geographic area, our video on servicing snowmobile clutches to improve belt life, or one of our step-by-step instructional videos for the installation of timing chain kits, our content is consciously produced with the customer in mind.”

CONTENT THAT MAKES A DIFFERENCE

Dayco offers a wide range of content that helps its

From left to right: Jay Buckley, Jon Crawford and Jerry Reeves

customers install and maintain the products it designs and manufactures. Whether it’s FAQs or technical articles for those who prefer written information, or how-to videos for audio and visual assistance, Dayco keeps both DIYers and experienced technicians in mind when creating its how-to content.

“Our products are installed by DIYers or technicians with a wide array of technical skills, so we cater the content for the complexity level of the job,” says Reeves. “We have had great feedback with our recent effort to educate shops on how to measure belt wear to help ensure their customers do not experience an unexpected belt failure, while at the same time offering revenue opportunities for the shop.”

This educational effort combines Dayco’s aWEARness gauge belt tool (which allows technicians to pinpoint wear on EPDM belts by measuring specific characteristics), an instructional video and samples of new and worn belts so customers can see the difference between the two. The company also released a recent video guide on the common mistakes that can occur when installing water pumps based on real-world situations Dayco technicians have encountered. For its most complicated product line—timing chains—customers receive step-by-step instructions with several of the most popular applications, including video tutorials.

“When discussing content, it’s easy to overlook our comprehensive installation instructions included with all of our timing kits for chains and belts,” highlights Reeves. “These are accessed with a QR code on the box and are kit-specific instructions for that engine.”

EXPERIENCE AND KNOW-HOW

Dayco’s engineering, product development, manufacturing and customer tech support are handled by experienced, real-world engineers and automotive technicians.

Dayco’s technical centres includes laboratories for material science, dyno (durability testing), environmental and prototype, as well as product-specific testing required by OEMs and the industry.

“This level of engineering and validation testing ensures the customer is getting a product that was designed, validated and manufactured with the same processes as the OEM product their

vehicle was manufactured with,” says Reeves.

Once the product is available to customers, Dayco’s team of technicians play the critical role of developing instructional content to ensure it is understood and installed properly.

“We take the feedback received from our tech line, warranty team and decades in the industry to refine both our product offering and the supporting how-to material,” says Reeves.

And, as Reeves points out, understanding the importance of not only replacing a part that has failed, but all of its accompanying components, is vital for avoiding future downtime.

“It’s not uncommon for a repair facility or DIYer to replace a worn belt, only to have the belt fail in a very short time. The cause of this premature failure is usually due to the fact that other components in the system are also worn,” he says. “The belt tensioner and idler pulleys are critical to optimum belt performance and life.”

Reeves says this systems approach to aftermarket care applies to all its market segments.

“We’ve recently launched new front-end accessory drive kits for both the light-duty and heavy-duty markets, and are working to educate our shop customers and distributors on the benefits of systems maintenance,” he says.

PASSION AND ENTHUSIASM

With two decades of program management and product launch experience, a mechanical engineering degree, certifications in front-end, suspension, steering systems, engine tune-up, repair and performance and braking systems, it’s no surprise Dayco’s team of technicians has thrived under Reeves’ leadership.

“When building a team in the automotive aftermarket, I always look for team members that share my passion and enthusiasm for this market,” says Reeves. “If your hobbies and career overlap, there is so much extra energy, care and excitement for what you do.”

That energy was on full display with Dayco’s creation of a two-piece tensioner for DD13/DD15 heavy-duty engines.

“The OEM tensioner is very difficult and time-consuming to install. So we went to work, knowing we could find a way to address this problem,” says Reeves. “We used our tech team to optimize the design for rapid installation, and the end result was a two-piece tensioner that is easier to get into the proper location, so the belts can also be placed with limited hassle, taking the installation time from hours to minutes.”

It's this kind of innovation that has made Dayco continue to live up to its tagline: Move Forward. Always. With a Canadian location in Milton, Ont. global headquarters in Birmingham, Mich., Dayco also has four distribution centres in Canada, three in the U.S., a manufacturing plant in Mexico, as well as a tech centre in Roseville, Mich.

Visit na.daycoaftermarket.com for more information, and find Dayco products in more than 40 locations in 22 countries, which are supported by over 3,600 associates.

Hassan Mourad

CONSUMERS PREFERENCES

A pair of recent industry reports found consumers have more love for the dealer when in need of vehicle repair. Here’s how they perceive the aftermarket // By Adam Mailk

Dealers are outranking the independent aftermarket in the eyes of consumers, two recent reports have found.

Automotive service providers fell short in several key areas, reflecting significant trends and preferences in the industry. The “Dealership versus Independent: How Canadian Vehicle Owners Choose a Service Provider” report from the Automotive Industries Association of Canada explored the factors influencing Canadian vehicle owners' choices for maintenance and repair services, highlighting the evolving landscape of consumer perceptions.

It found most Canadians (37 per cent) believe dealers outperform the aftermarket when servicing vehicles, while one-third believe the reverse. The remaining 30 per cent see both as the same. The study, the latest in the Consumer Behaviour Series reports from AIA Canada, compared several specific areas where dealerships and independent automotive service providers differ significantly in consumer perception.

Some notable comparisons were:

Helpful Service Advisor: Dealerships 37% vs. ASPs 23%

Proactive Notifications: Dealerships 46% vs. ASPs 18%

Technical Competence: Dealerships 36% vs. ASPs 20%

Quality of Work: Dealerships 33% vs. ASPs 24%

Value for Money: ASPs 58% vs. Dealerships 20%

Being Trustworthy: ASPs 36% vs. Dealerships 28%

The report, available in full and for free to AIA Canada members, offered some advice. For example, if ASPs aim to build greater trust with consumers, they should focus on consistency in matching

technicians with customer vehicles. Two-thirds of respondents said they would trust their service centre more if the same technician always worked on their vehicle.

Similarly, the same number of respondents indicated they would trust more if more time were spent explaining the impact of maintenance and repair, while 64 per cent would appreciate more help in planning for short-, medium- and long-term maintenance and repair.

About half (51 per cent) would be more trustful of shops if they sent videos and other explainers for the scope and importance of maintenance and repair.

The report further dove into where Canadians go for maintenance and repair, the reasons they choose a shop, how they find a new service provider and their perceptions of the independent aftermarket versus dealers. To increase trust and loyalty, the report emphasizes that ASPs must focus on building trust and providing quality customer service. Transparency, trust and quality service ensure repeat business, even if the price initially attracts customers. Satisfied customers can become strong advocates for ASPs, generating positive word-of-mouth and online reviews.

In parallel, a recent Lang Marketing Aftermarket iReport revealed significant changes in consumer perceptions of service stations and garages versus dealers from 2018 to 2023, with notable shifts across key factors such as convenience, technical repair capacity and price.

Convenience of repair

Service stations and garages have historically received high consumer ratings for convenience due to their widespread locations. However,

the COVID-19 pandemic severely impacted the number of outlets available, leading to a significant decline in their numbers. This reduction has decreased the perceived convenience of using service stations and garages for many consumers.

Technical repair capacity

Dealers are perceived to have superior technical repair capacity compared to service stations and garages. This perception is particularly strong among owners of foreign nameplate vehicles and newer models. Consumers believe dealers possess greater technical expertise, especially for complex repairs, which has widened the perceived gap in technical repair capacity between dealers and service stations and garages.

Low price

Consumers continue to see service stations and garages as offering lower prices for repairs compared to dealers. This perception is the most pronounced among the four factors measured. However, dealers have been making efforts to become more price competitive, particularly for routine repair jobs like oil changes and brake work. By offering aftermarket brands for older vehicles, dealers have narrowed the price gap, making them more appealing to cost-conscious consumers.

Fairness of price

Service stations and garages are still viewed as offering fairer prices than dealers. This perception is less pronounced among consumers with foreign nameplates and newer vehicles. Nevertheless, dealers are working to improve their image by

emphasizing convenience and technical expertise, which helps position their pricing as fairer in the eyes of consumers.

Changing perceptions and market impact

Over the past five years, consumer perceptions of service stations and garages and dealers have evolved, influenced by external factors like COVID-19 and strategic actions by dealers. Dealers have enhanced their services by introducing quick lube services, quick-service lanes, and extended business hours, aiming to improve convenience and capture a larger share of the do-it-for-me (DIFM) market.

These efforts appear to be paying off. Consumers now perceive dealer repairs as more convenient, lower-priced and fairer than they did five years ago. Meanwhile, the perceived technical gap between dealers and service stations and garages has grown, reinforcing dealers’ advantages in complex repairs.

As a result, Lang Marketing reported, dealers have significantly increased their share of the DIFM market between 2018 and 2023, while service stations and garages have seen a decline. With many dealers focusing on expanding their service bay business, this trend is expected to continue, leading to a greater share of total DIFM volume being captured by dealers and a reduction in the share held by independent outlets.

Both reports underscored the shifting dynamics in consumer preferences and perceptions within the automotive service industry. Dealers are making significant strides in improving convenience, technical expertise and competitive pricing, which are resonating with consumers. Meanwhile, ASPs need to focus on building trust and providing quality service to retain customers and remain competitive in an evolving market.

On the Road

Worldpac Supplier & Training Expo

April 24-28, 2024

Nashville, Tennessee

With nearly 400 hundred classes, a two-day expo, an emotional keynote and country-music send-off, the Worldpac Supplier & Training Expo has something for all of the 3,355 people who made the trip to Nashville. Training at the Gaylord Opryland Resort and Convention Center ranged from business management to technical, offering shop owners, service advisors and technicians the ability to get what they needed to enhance their careers and business. Celebration Night featured a performance by Big Little Town at the Country Music Hall of Fame and Walk of Fame Park.

See the event reel on Instagram

Carolyn Coquillette, Earthling Automotive

Bob Cushing, Worldpac, and Marcus Luttrell, retired navy Seal

Worldpac instructor Luke Murray leads a training class

Michelle Rozen speaks during the women’s luncheon

ANALYZING CANADA’S LOW AVERAGE VEHICLE AGE

Vehicles in the U.S. are more than two years older, on average. An expert looks into why and finds there could be long-term risk to the automotive aftermarket // By Adam Malik

The average age of vehicles in Canada is more than two years lower than American vehicles. Why is there such a gap between two nations so closely linked? It’s all thanks to a pipeline of younger vehicles exiting Canada and heading to the U.S.

Canada’s average vehicle age is 10.5 years in 2024, up from 9.7 in 2020. In the U.S., it’s more than two years higher at 12.6 years, up from 11.9 in 2020. During this year’s AIA Canada National Conference in Toronto, Todd Campau, aftermarket practice lead at S&P Global Mobility, explained why there’s been such a gap between the two countries.

He noted that the number of vehicles in operation (VIO) in Canada is steady at 26.7 million; in 2022, Stats Canada reported 26.3 million VIO. The data left him curious. So he investigated why vehicle age wasn’t the same or closer for both sides of the border.

During the session, The Impact of the Evolving Vehicle Fleet on Vehicles in Operation and Vehicle Kilometres Travelled, Campau explained what he found. He said there’s some correlation between the Canadian dollar and vehicle exports to the U.S. When the dollar is low, it’s cheaper for Americans to import vehicles — and that’s been the case for several years.

“And one of the things that is definitely impacting your fleet are exports going into the U.S.,” he explained.

He checked out federal databases, which showed what was taking place.

In particular, the third quarter of 2020 and second quarter of

2022 each saw about 180,000 vehicles shipped from Canada south of the border. That wasn’t tied to the exchange rate, however — it was because there was a dearth of vehicles in the U.S. marketplace and eyes turned to Canada to fill the gap.

Since that later date, quarterly exports to the U.S. have been around at least 50,000 vehicles.

“There’s been a stronger dollar, there’s the high demand for vehicles in the U.S. And so importers in the U.S. have been very successful grabbing vehicles here and selling them there for profit,” Campau observed.

Furthermore, the vehicles crossing the border have been on the younger side of the spectrum, meaning U.S. importers are specifically targeting low-age cars and light trucks.

Back in 2016, the average age of a vehicle going to the U.S. was approaching nine years old. Today, they’re no more than seven on average. That has Campau concerned about the Canadian aftermarket.

“For me, that’s one of the big yellow flags for the market here,” he said.

If older vehicles nearing end-of-life are the ones being exported, that’s one thing. But vehicles just entering the aftermarket sweet spot being shipped down south creates a problem in the Canadian market.

“That’s taking real aftermarket opportunity away because that’s right in that sweet spot of aftermarket repair,” Campau explained. “So this is something that I think is very important for the marketplace to be sensitive of.”

A STRONGER PARTNERSHIP

By better understanding the challenges of your shop partners — and maximizing your time with them — you can be a better jobber to them // By

Greg Aguilera

I’m used to sharing insights with the independent repair shop community but I want to offer parts suppliers across Canada a deeper look into the world of independent shops. Understanding the origins and mindset of these shops can unlock opportunities for stronger partnerships and business growth. These insights are not just theoretical but stem from real-world experiences and interactions with shop owners and technicians. By delving into their day-to-day challenges and aspirations, we can foster a more collaborative and supportive industry environment.

The

mindset

Independent repair shops face numerous external pressures. They frequently voice frustrations about inaccessible information, rising tool costs, public parts sales and uncooperative dealers. While these

challenges are significant, they reflect the changing landscape of the industry rather than insurmountable obstacles. It's often easier for repair shops to blame external factors than to make internal changes, partly because there are few platforms for them to vent constructively.

As you read this, you might recognize some of your customers in these descriptions.

So, how can we move forward? The answer lies in balancing transactional needs with building strong relationships.

Practical tips for parts suppliers

Tip 1: Simplify returns and order policies

A simple, easy-to-understand returns and order policy can make a huge difference. Provide clear signage and parts bins for drop-offs and returns at the shop. This common understanding streamlines the

The Mini-Ductor Venom HP is the highest powered Mini-Ductor at 1800 watts. This handheld induction heater generates high-frequency magnetic fields to produce a flameless heat that releases ferrous metal from rust, corrosion and thread lock compounds. Do it Better - Do it Faster - Do it Safer - Do it Greener!

Seized Lugnuts > Fuel Tank Straps > Exhaust Manifold Bolts

process, making it slick and painless for both your team and theirs.

Tip 2: Consistency is key

Feedback from repair shops often highlights the inconsistency of reps’ visits.

Typically, a visit goes something like this: "Hey John, how’s it going? Any returns or problems for me? Bye!" This doesn’t build a relationship.

Establish a solid schedule for your reps and hold them accountable for growing the business. Equip them with tools to add value during their visits.

Tip 3: Address stock issues

Help independent repair shops manage their stock better. Report on stock turnover for their most-used items and discuss this during regular rep visits. This educates your customers about parts business dynamics and separates consumables from other items, allowing for focused conversations about bulk versus individual purchases.

Tip 4: Consider consignment

Consignment can be a game-changer for top-performing stores. By consigning their top lines to the store and having reps check and restock during visits, you not only ensure they have what they need but also give your reps a chance to manage obsolete or unused stock. This frees up capital for the shops and strengthens your relationship with them.

Building relationships

Independent repair shops want more parts in stock and faster delivery. Meanwhile, parts suppliers aim to build relationships. These goals may seem at odds, but they can be harmonized. By addressing

practical needs efficiently, you lay the groundwork for stronger, more collaborative relationships.

Consistency, clear communication and proactive problem-solving are key. Understand your customers’ challenges and provide solutions that make their lives easier. This approach not only boosts their business but also strengthens your standing as a reliable partner.

Conclusion

The world of independent repair shops is filled with passionate, hardworking individuals who face unique challenges. By understanding their origins and mindset, parts suppliers can develop strategies that address their practical needs while building lasting relationships. Simplifying returns, maintaining consistency, managing stock effectively and considering consignment are just a few ways to bridge the gap.

Ultimately, the success of your partnership with your repair shop hinges on your ability to balance transactional efficiency with relationship-building. Embrace this dual approach, and you’ll not only meet their immediate needs but also foster loyalty and mutual growth.

Please write and comment on this article if it resonates with you. Your feedback is invaluable in continuing this important conversation.

Greg Aguilera

BAYWATCH

LED WORK LIGHTS

TAKE A LOOK AT THE NEWEST PRODUCTS

A new line of Philips Xperion 3000 LED work lights is available. The Xperion 3000 Pen eco is powered by three AAA batteries. The “Pillar” is a hand-held work light. The Xperion 3000 “Slim” is a hand-held light. The Xperion 3000 “Zoom” resembles a flashlight but features a tilting light. The Xperion 3000 “Line” is an inspection light. The Xperion 3000 “Pocket” is a palm-sized lamp with two output modes. The Xperion 3000 “Headlamp” is a wearable headband work light with two light sources and three output modes. The Xperion 3000 “Flood” is a projector work light with three output modes. It can also be used as a power bank to run other devices. The Xperion 3000 “Penlight” is handy spotlight for tight spaces. www.lumileds.com

PRODUCT LINE EXPANSION

Dayco is introducing 140 part numbers in the coming months and making a strategic effort to have specific top-selling parts guaranteed in stock. The ‘Top Movers’ project will ensure that Dayco’s top high volume part numbers are always in stock for distributors. The operations team is enhancing our warehouse management system by creating a new safety stock policy as well as consolidating different orders to the same shipment, reducing complexity, costs and order cycle times. The 140 new part numbers will launch in Q1 2024.

www.dayco.com

AUXILIARY POWER BATTERIES

EnerSys is now offering customers the first-ever Thin Plate Pure Lead (TPPL) Absorbed Glass Mat (AGM) power solution for automotive auxiliary applications with the Odyssey ODS-AGM14 battery. The batteries are engineered to provide long-lasting power for automotive auxiliary applications. The battery’s TPPL design allows these cars to run anything from lighting and navigation to the latest state-of-the-art stereo systems without running the vehicle’s motor. The ODYSSEY® ODS-AGM14 battery also features a vent port that’s designed to seamlessly fit factory specifications for the vehicle’s existing vent system. www.enersys.com

INVENTORY ASSESSMENT TOOL

Dayco is rolling out its inventory assessment tool across the U.S. and Canada called AutoPartIQ to help customers analyze their existing Dayco-specific inventory to identify possible gaps in coverage, new opportunities or unproductive inventory that could be shifted to another location. The tool provides coverage reviews for 35 CMAs in Canada. The tool is capable of analyzing Dayco’s entire light vehicle product portfolio and all light vehicle and industrial product lines in Canada (16,000 part numbers). It’s a new value-add resource for Dayco retailers, distributors or jobbers that can provide national, regional or hyper-targeted data reports. www.dayco.com

WHEEL BALANCER

The new Hofmann Armored Series 2400P wheel balancer has been introduced. It features an ergonomic design and a compact framework that ensures maximum capability without occupying excessive space. The high-resolution touchscreen display and intuitive interface helps users navigate the balancer. In addition, the enhanced web connectivity provided through an innovative app allows shops to tap into real time updates, job reports and training videos. www.hofmann-equipment.com

BLUETOOTH TPMS

The new Dill Bluetooth Aftermarket Tire Pressure Monitoring System is a retrofit TPMS system made using OE components. The system uses sensors that mount inside the tire for the safest and most accurate way to measure tire pressure and internal tire temperature. Users have the option to purchase either valve-mounted or band-mounted kits for fouror six-wheel applications. Additional sensors can be purchased for larger applications — custom configurations in the app can accommodate up to 38 sensors. The display screen is your own smartphone or tablet. www.dillvalves.com

UNDERCAR PARTS ADDITIONS

Mevotech announced 138 new part numbers. The release included series repair solutions from Mevotech’s top-tier TTX and Supreme lines. Highlights include the TTX Front L/R Upper Control Arm for 2019-2022 Ford Rangers, TTX Front L/R Lower Control Arm for 2020-2023 Ford Escape and 2021-2023 Ford Bronco Sport models, TTX Front Lower Ball Joint for 2019-2023 the Chevrolet Silverado 1500 and 2019-2023 GMC Sierra 1500 and the TTX Tie Rod End Assembly for 2015-2022 RAM 2500s and 2014-202 RAM 3500s. www.mevotech.com

CONICAL VALVE SPRING

Elgin Industries has introduced premium Elgin Pro-Stock conical valve springs engineered for General Motors LS Series and Chrysler Hemi performance engines. The new springs (#RV-107228Q16) feature a next-generation conical design for superior performance and durability while accommodating the peak valvetrain RPMs associated with high-performance camshafts. With a progressively narrower diameter from bottom to top, each coil of a conical spring has its own frequency, dramatically reducing load, increasing the spring’s peak RPM capabilities and enabling customers to use a more aggressive camshaft.

www.elginind.com

MORE SPEED MORE SELECTION MORE SUPPORT

» The easiest and fastest online ordering experience

» Orders ready in 20 minutes

» Same-day shipping even during peak seasons

» An ever-growing selection

» A dedicated account manager who knows you

CERAMIC BRAKE PADS

SMARTLY COATED ROTORS

SEMI-METALLIC BRAKE PADS

CERAMIC BRAKE PADS

NEW NO CORE CALIPERS

OE BRAKE ROTORS

HUB & WHEEL BEARINGS

SUSPENSION & STEERING

PREMIUM BRAKE PADS 100% MADE IN CANADA

SPORT PERFORMANCE BRAKE ROTORS

SEMI-METALLIC BRAKE PADS

AIR, CABIN & OIL FILTERS

FUEL PUMPS & MODULE ASSEMBLIES SHOCK ABSORBERS

STRUT MOUNTS & ASSEMBLIES

HEADLIGHT KITS & WORKLIGHTS

SUSPENSION & STEERING

SENSORS & COILS

TOOLS WIPERS