6 minute read

Machinery

3D ALUMINIUM CHOOSES EMMEGI MACHINES AGAIN

For Oxfordshire based 3D Aluminium, investment in the latest, most advanced fabrication machinery is part of its commitment to providing an exceptional service to its commercial clients.

3D is involved in flagship fenestration projects across London and the Home Counties, with a real emphasis on education, healthcare and both the new build and refurbishment sectors. It prides itself on the quality and precision of its windows, doors and curtain walling in Comar, Aluprof, Technal and Wicona profiles and on the efficiency of its operation. It makes sense then for 3D to choose a machinery partner like Emmegi (UK) which can guarantee a continually updated product range, with an emphasis on minimising cutting and machining tolerances and maximising productivity. 3D Aluminium has been an Emmegi (UK) customer since the machinery supplier was established in the UK 10 years ago and has equipped its factory with a comprehensive mix of Emmegi saws and machining centres. Now, 3D has upgraded its original Emmegi Phantomatic T3A 3-axes machining centre to a brand new Phantomatic X4 4-axes model to add to the X4 it already owns, in order to expand capacity and increase its versatility. The fourth axis on the X4 model allows it to machine profile at any angle from 0 to 180°, in comparison with the T3A which can machine from above and from 90º to right and left from the vertical. This gives 3D more flexibility for machining on profile edges and on more complex profile shapes. Alongside the new machining centre, 3D has also invested in a new Emmegi Precision TS2 twin-head electronic saw, complete with a patented profile clamping device which, as the name suggests, achieves extremely precise cuts. Paul Batts, 3D’s Production Manager, says Emmegi’s quality and service meant 3D didn’t need to go anywhere else when it was looking to invest in new machinery. He explained: “We’ve always been impressed with the machines and with the service from the whole team. What’s particularly useful for us is the fact that Emmegi’s range is so broad that we know they will always have a machine available which exactly suits our needs.” More details at: www.emmegi.com and www.3daluminium.co.uk.

D&I WINDOW SOLUTIONS SCALES UP PRODUCTION WITH HAFFNER MURAT MACHINERY

Established domestic fabricator D&I Window Solutions is scaling up its operation with investment in numerous aluminium fabrication machines from industry specialists Haffner Murat. The largescale investment is a result of D&I Window Solutions’ strategic expansion into trade manufacture.

David Saxon, Director of D&I Window Solutions, said: “We’ve seen a considerable increase in demand for aluminium bifolds in recent months and we spotted an opportunity to capitalise on the growth by expanding into the trade market. When it came to investing in the machinery we needed, Haffner Murat was the only choice for us.” David was already in discussions with Matt Thomas, Area Sales Manager at Haffner Murat about replacing some of D&I Window Solutions’ current PVC-U machinery when the decision was made to move into trade aluminium. David explains: “Matt prepared a full machinery package that would enable us to get up to volume quickly and easily. The advice and attention to detail from Matt and his team was invaluable and we appreciated his knowledge, honesty and integrity throughout the buying process.” D&I Window Solutions will be investing in six new machines in total to set up their new trade production: an Adir C Fom Industrie CNC Machining Centre, a Panda Echo 300 Fom Industrie Pneumatic Saw, a Quota Base Fom Industrie 3m Discharge Roller Table, a Porter Fom Industrie 3m Infeed Roller Table, a Crab XL Fom Industrie Corner Crimper & Roller Table and a TT 405 Haffner Murat Double Mitre Saw. All machines deliver superior automation, high quality production and exceptional efficiencies. They will be installed in February 2021, following Covid-19 guidelines throughout. D&I Window Solutions is based in Barnsley, South Yorkshire. Since it was founded in 2010, the company has grown in size and reputation to become one of the go-to fabricators when it comes to windows and doors in the region. With its commitment to exceptional standards – and use of Haffner Murat machines – it seems it is only a matter of time before it gains the same reputation for high-quality trade products too. Haffner Murat was recently crowned joint winners of the Machinery Supplier of the Year at the National Fenestration Awards 2020. The honesty and expertise of the Haffner Murat team and testimonials from people such as David Saxon show why it was such a worthy winner. Tel: 01785 222421 www.haffnermurat.com

MODPLAN INVESTS FOR ITS NEXT STAGE OF GROWTH

Trade fabricator Modplan has just completed a largescale investment in 12 new fabrication machines from Avantek to support its next stage of growth. The machines have been installed across Modplan’s multiple production facilities enabling the company to continue to deliver the outstanding quality and efficiencies that support its customers businesses.

Heidi Sachs, Managing Director of Modplan, said: “There were two reasons for the investment. Firstly, we wanted to update machines that were reaching their end of life and replace them with more technologically advanced models. Secondly, we wanted to expand our operations. Our overall goal was to ensure that we could continue to offer the best in product quality with exceptional manufacturing efficiencies.” The machines include quad welders and corner cleaner, 5 head fully automatic welder, 4 headed fully automatic welders, two-head uni welders, bead saws and corner transom cleaners.

The machinery is part of a wider programme of investment for Newport-based Modplan, which has included setting up a dedicated factory for its popular Flush Sash Windows and an internal Control Hub that gives realtime information on the status of every order in all its manufacturing sites. The investment across the business reflects Modplan’s ongoing commitment to its customers. Heidi commented: “Quite simply, we are nothing without our customers and everything we do is driven by what they need. It’s why we planned the investment and installation meticulously for a seamless integration into the business. We continue to set stringent KPIs across the business and monitor them to ensure they are met. And it’s also why we rolled out the internal Control Hub to maintain our schedules for improved customer communications.”

It all means Modplan offers a reassuring level of reliability that its customers appreciate. Modplan’s customer focus is refreshing and is one of the many reasons that it has been in business for nearly 50 years. And despite the Covid-19 pandemic, the company is gearing up for its next phase of growth. Tel: 01495 246844 – www.modplan.co.uk

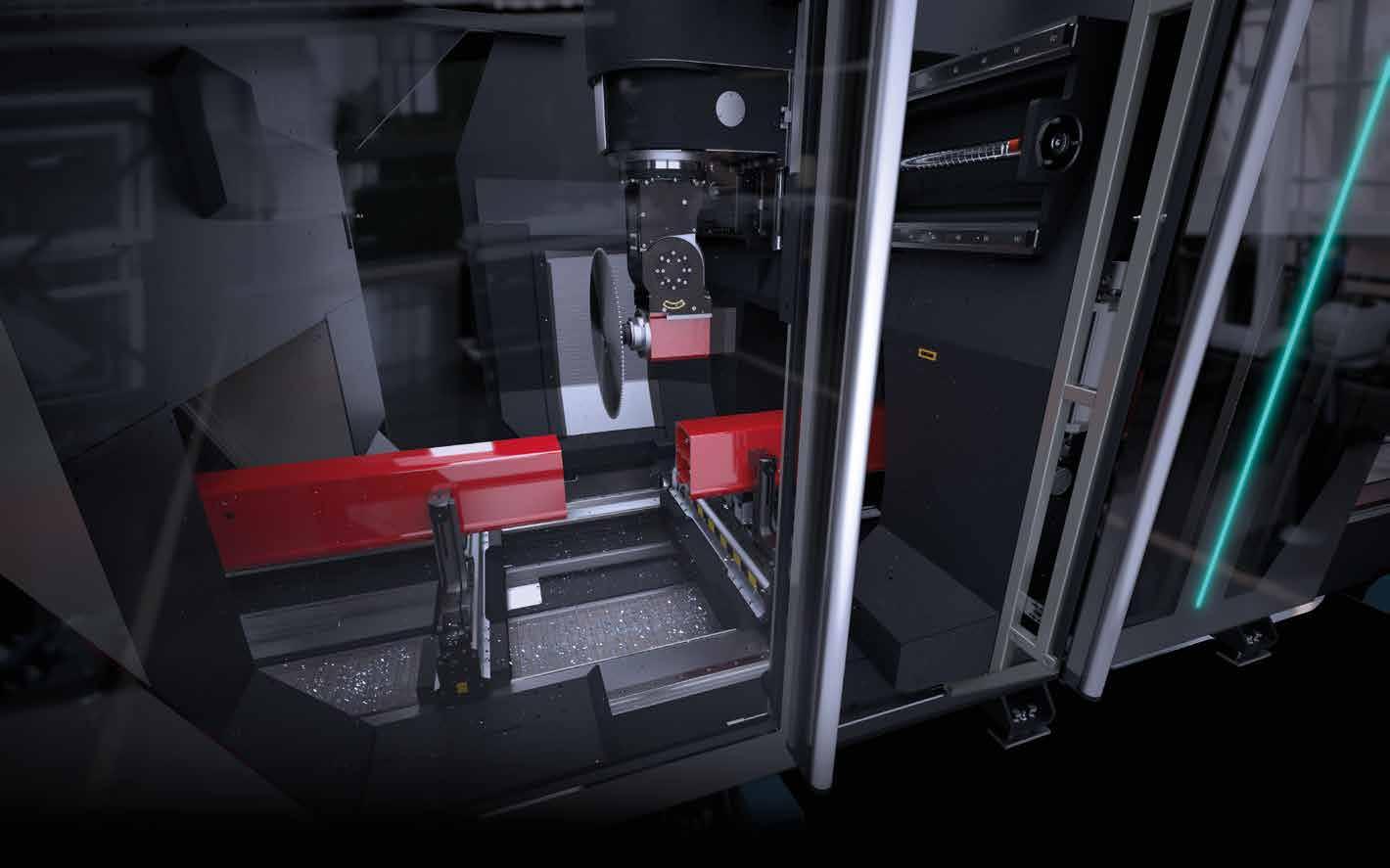

5-AXIS CNC ADVANCED AND AUTOMATED

Emmegi (UK) Limited Unit 14, Spitfire Close, Coventry Business Park CV5 6UR Coventry Tel. +44 2476 676 192 - Fax +44 2476 677 381 www.emmegi.com - info.uk@emmegi.com

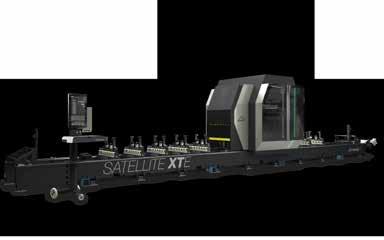

SATELLITE XTE

5-AXIS CNC WITH MOVING GANTRY

CHIP CONVEYOR FOR EASY CLEANING

CUTS AND SEPARATES DIRECTLY FROM THE BAR

24-POSITION TOOL WITH EXCHANGER ARM

COMPACT, SERVO-CONTROLLED CLAMPS

NEW CABIN DESIGN, IMPROVED SAFETY AND VISIBILITY

24IN TOUCHSCREEN WITH USER FRIENDLY NTERFACE