54 minute read

Trade News

SMART’S NEW ALITHERM 400 SYSTEM DELIVERS OUTSTANDING VALUE AND QUALITY

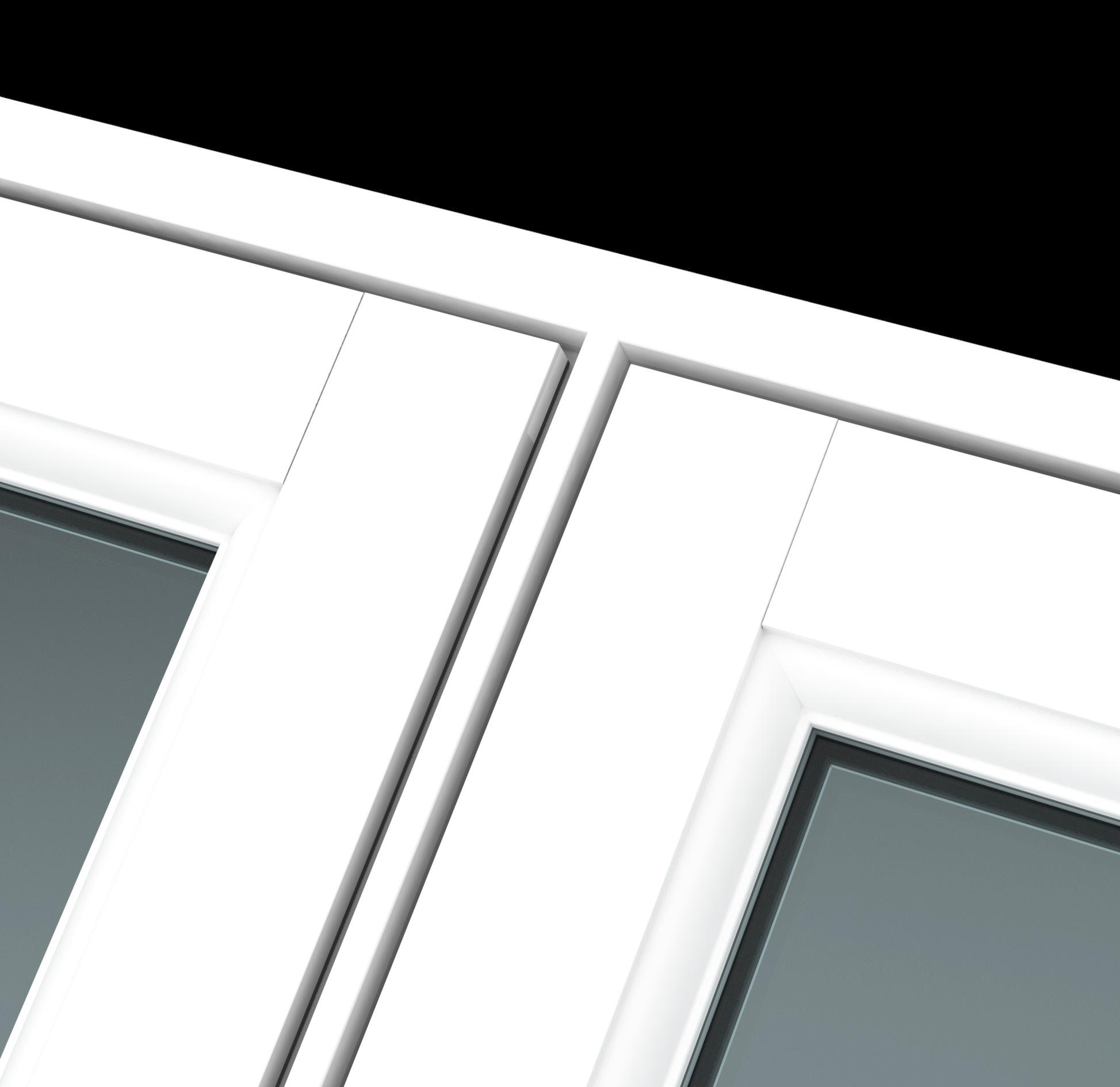

Smart Architectural Aluminium has launched Alitherm 400, the latest addition to its proven Alitherm portfolio of window and door systems.

TUFFX’S INFINITY MARKETING DRIVE HITS THE ROAD

When you’re next on the open road, keep an eye out for TuffX, as the leading safety glass specialist has recently invested in new graphics for its entire vehicle fleet.

As part of a year’s planned programme of investment to promote and grow production of its Infinity rooflight range, TuffX has updated all 44 vehicles in its fleet with the new graphics. TuffX’s Infinity brand includes rooflights, roof lanterns, walk-on and fire-rated walkon glass units, available as either double or triple glazed and in a choice of clear, solar and privacy glass. What’s more, Infinity’s unique ‘drop-in-and-seal’ design makes them super easy and fast to fit straight out of the box, as they require no additional assembly on site. Which means they are as popular with installers as they are with homeowners.

“Our Infinity range of rooflights and walkon glass units, which includes our all-glass frameless-look rooflight, continues to be more popular than ever, and we intend to ensure we remain first choice,” said Paul Higgins, TuffX’s Commercial Director. “We deliver direct to site, in as little as three to four days for our standard sizes, and whether it’s a commercial delivery heading out from our Merseyside base in our 13-tonne truck, or our 7.5-tonne truck making a rural delivery to a homeowner with restricted access, you won't be able to miss us now with our new graphics. “To find out more about why we’re shouting about our Infinity range, and why it’s so popular with installers and homeowners alike, visit www.tuffxglass.co.uk.” Combining outstanding value and quality, with class-leading performance and security, the new Alitherm 400 system offers a range of stylish casement windows and single and double doors. The system has been designed to fully comply with the updated thermal requirements of Part L of the Building Regulations, which are to be introduced in England in June 2022. Developed to suit a wide variety of projects, including both new build and refurbishment, residential and light commercial applications, Alitherm 400 features Smart’s innovative Quick-Glaze Beads with integrated gasket. With the profiles and beads being supplied with the glazing gasket pre-extruded into the profile, the Quick-Glaze Bead significantly reduces fabrication and installation time.

The Alitherm 400 window system is available in fixed, side-hung, top-hung and flush casement options, and has been developed with efficient fabrication and fast and straightforward installation in mind. It also features both flush and chamfered window profiles, with the flush, flat face option suitable for off-set, face-mounted espagnolette locks and the chamfered design, which features a eurogroove, enables in-line espagnolette locking mechanisms to be used.

Available in open-in or open-out and single or double door options, the Alitherm 400 doors perfectly complement the window range, featuring the same stylish lines and the ease of fabrication and installation. They can also be combined with Smart’s Designer Door Panels and the company’s range of standard door furniture (including colour matched lever handles, and the Quantum range of stainless steel hardware), to create elegant and contemporary entrance doors. Smart’s Managing Director, Eddie Robinson said: “Our Alitherm systems have proved to be exceptionally popular in projects across the UK and we’re delighted to now be adding Alitherm 400 as yet another option. Fully compliant with the new Part L requirements, the system is fast and easy to fabricate and install, which together with its elegant lines and outstanding performance provides a solution for architects, developers, fabricators and installers. Along with our new Visofold 1000 Slim bi-fold door, we’re also delighted to be launching more great new products that have been designed, developed and manufactured in Britain.”

Both window and door systems provide excellent weather and thermal performance, as well as the security assurance provided by PAS 24:2016 accreditation. The systems are also available with a wide range of 316 marine grade stainless steel hardware options, which can be painted to order, with the systems and hardware all available in Smart’s extensive range of standard colours. For more details, call the company’s support team on 01934 876 100 or to download the new product datasheets, visit www.smartsystems.co.uk.

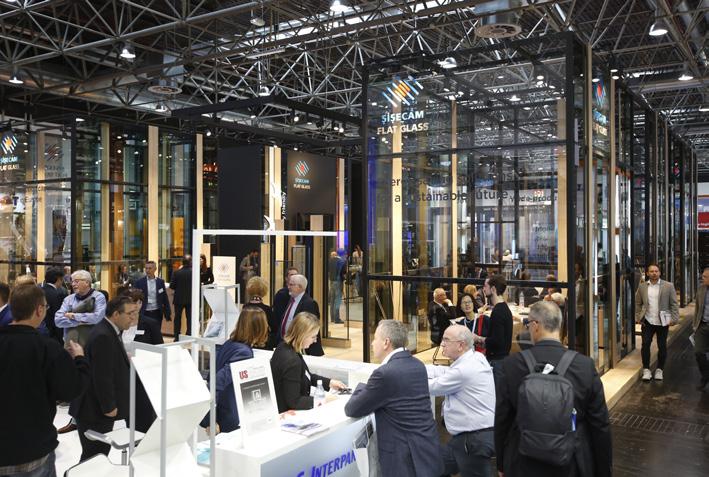

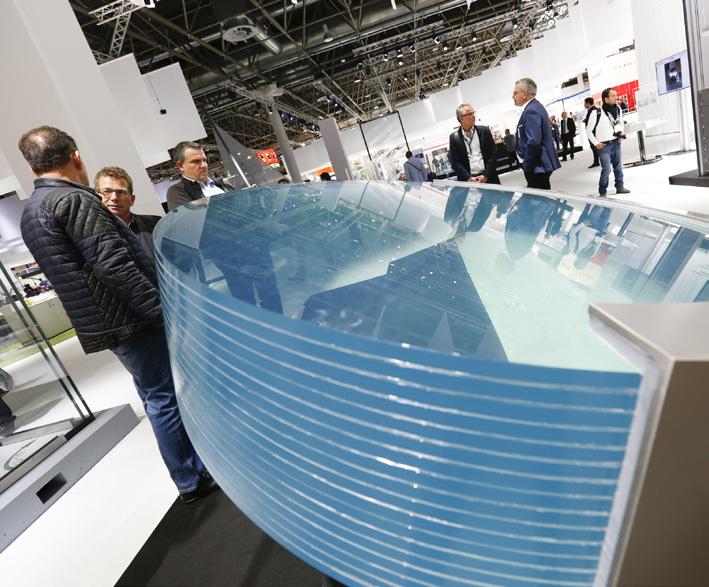

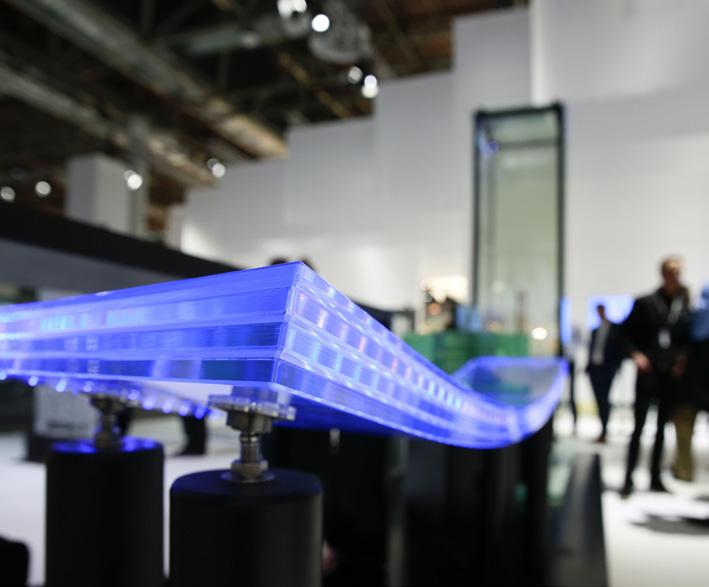

EDGETECH TO TALK AUTOMATION AND SUSTAINABILITY AT FENSTERBAU 2022

Automation, innovation and sustainability will be among the key themes highlighted by Edgetech, a Quanex company, at this year’s Fensterbau Frontale.

The world’s leading fenestration trade show, Fensterbau is returning after a four year absence. Thousands of glass and glazing professionals from around the world will gather in Nuremberg, Germany to see cutting-edge technology, meet colleagues from throughout the industry, and discuss the challenges and opportunities the sector’s faced with.

At Edgetech, they’re eager to take part in those discussions, and help shape fenestration’s future, as Head of Marketing Charlotte Hawkes explains. “After an incredibly disruptive and unpredictable few years, our sector still faces many challenges,” Charlotte says. “However, it’s also shown its ability to react and adapt to rapidly changing circumstances.

“In the years to come, we’ll need that same resilience and flexibility to tackle some of the biggest issues facing not just our industry, but society as a whole.

“The climate crisis is one such threat. Meeting hugely ambitious international net zero targets will require sweeping changes to the way we construct and renovate buildings - and the sort of outstanding energy efficiency that Edgetech’s warm-edge products provide. “Another major obstacle restricting growth in the glass and glazing sector is the worsening skills shortage. “In countries like Britain, an ageing population means that thousands of the most experienced construction and manufacturing professionals are set to retire over the next twenty years. “While governments need to be doing much more to encourage and support talented new recruits to enter vital industries, at Edgetech, we believe we’ll see much wider adoption of automation technology. “We’ve experienced surging demand for our automated spacer application lines in recent months, and will be explaining the benefits to visitors to our stand at Fensterbau.”

You’ll find Edgetech at Hall 6, Booth 2-232, where the company’s internationally renowned Super Spacer®, high-performance Super Spacer® T-Spacer™ SG, and other exceptional products will be on display. For more information, please call 02476 639931 or visit www.edgetechig.co.uk.

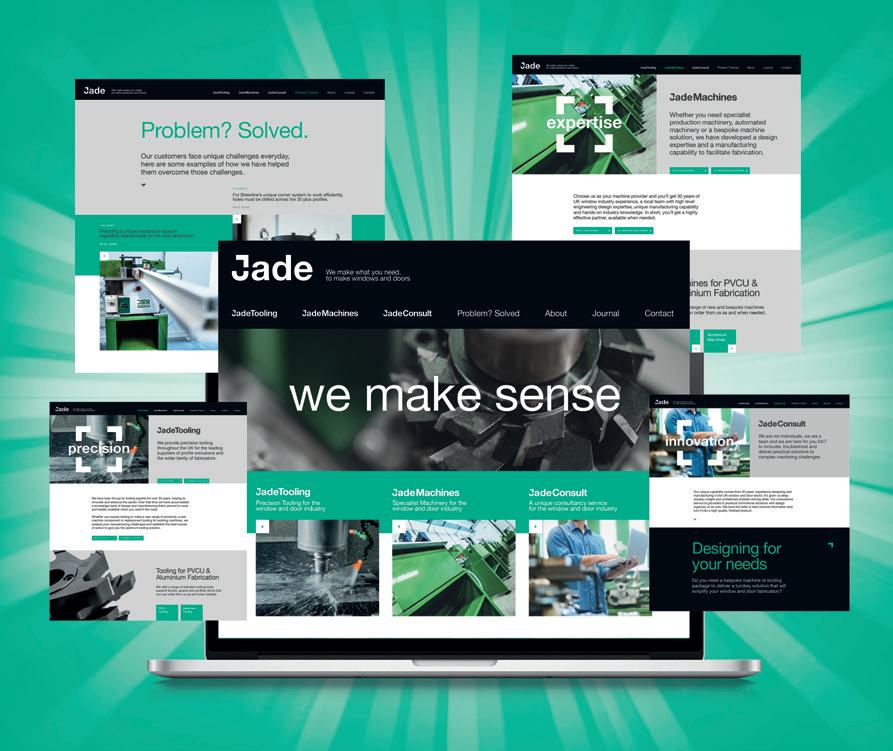

NEW WEBSITE AND REBRAND FOR JADE ENGINEERING

UK Window Industry’s Most Prolific Brand Sharpens Up Image, Shows ‘Hidden’ Talents

Announcements by companies of a new website being launched, or a tweak being made to their logo, are hardly ground-breaking these days. But when a firm that can claim to have its products operating in virtually every one of the potential customers in its sector, it becomes more intriguing. Jade Engineering is the firm in question, having undergone a full redesign of the way the firm presents itself to the world. This includes a new website and fresh, new face for the firm, including a modernised version of the logo that will be found in the factories of vast majority of PVC-U and aluminium window and door fabricators in the UK.

The Jade name and brand are so well known; so why bother now? Jade Engineering is the window and door industry’s most prolific brand but, says the firm’s owners, even Jade’s most ardent clients know little about them beyond their own specific touchpoint. All that is about to change, says Sean Mackey, who with partner Adam Jones has built Jade into the industry’s de facto machine tool supplier over the past 30 years: “Our machine tools are to be found in every PVC-U fabricator and the majority of aluminium frame makers too,” he explained. “But we often hear the phrase ‘I didn’t know you did that’ when we are simply chatting about day-to-day business issues. So we decided to up our game, and take the guesswork out of it,” added Sean. In addition to the products for which they are bestknown, Jade Engineering designs and manufactures a range of standalone, task-specific machines that, in an age of increasingly sophisticated CNC-controlled equipment, are revered for their simple, effective, efficiency: “Our end millers, bead saws and more unusual kit such as the Jade Reverse Butt Cleaner, are inexpensive solutions to problems many fabricators often don’t know they have,” explained Adam. “Our new website will show the whole range, also including videos of some of the machines we supply.” The website is divided into three main groups: Jade Tooling; Jade Machines; and the firm’s fast-growing Jade Consult division. This, says Sean, has been growing spectacularly and is what the website will probably explain the most effectively: “When chatting with customers, they will often mention a production issue that they have been unable to resolve,” said Sean. “We believe there is always a solution, and we will then design, manufacture and install it for the client. This has led to larger and more ambitious projects, now including a number of complete production lines and start-up factory kit outs. It’s very big business and we are the only firm that has the expertise to offer it. Tell us what you want, how much you have to spend and we will design, supply and commission it for you.” In text, superb photography and HD video the new Jade Engineering website explains everything offered by the Coventry-based firm and presents it superbly, including some excellent case-studies contained in the website’s ‘Problem? Solved.’ section.

“We also felt that the time was right to redesign our overall image,” said Sean. “It’s fresher, clearer and better reflects what we are today.” https://jade-eng.co.uk

Shipston-on-Stourbased Holdsworth Windows has joined the Steel Window Association (SWA). Holdsworth Windows offers customers the complete solution when it comes to steel windows and doors - site survey, design, manufacture, repairs, refurbishment, installation, and double glazing.

As well as beautiful domestic and commercial projects, Holdsworth Windows prides itself on being able to work on any job - in their own words “no job is too large or small”! Conservation is also an integral part of the business, from removal right the way through to fitting the newly repaired or refurbished windows and doors. windows, doors and screens for more than 50 years, serving private homeowners and main contractors alike. We’re excited to be members of the Steel Window Association and look forward to the year ahead!” For further information on the Steel Window Association, or if you’re interested in becoming a member, please visit www.steel-window-association.co.uk.

BOMBS AND BORSCHT

PLAYING RUSSIAN ROULETTE ON MY RETURN TO UKRAINE

Just 6 weeks after returning from my first trip to Poland and Ukraine, I was back on a flight out to Poland ready to leave the border behind, and head into Ukraine.

Arriving at Medyka and what once was the village of charity tents, I was shocked to see most of the tents had gone. Walking through at 2am, you once would have been weaving your way through a sea of people. Not now. Nobody. Once you cross the border, you are no longer truly safe - in some respects, literally a game of Russian roulette. Air raid sirens ring out at all times of the day and night. I always knew in the back of my mind there was a chance of being in a place that was targeted, but I don’t think I was truly ever prepared to witness one. Even a few miles away, they’re terrifying. Despite the risks, my incredible journey took me over 1,000 miles throughout North, West and Central Ukraine, delivering aid while meeting and working with so many inspirational people – here’s just a snapshot… I spent a few days with an organisation just a few hundred miles away from Severodonetsk, where the most intense fighting is happening at the moment. Many of the people here have full time jobs and volunteer in the evenings or are refugees themselves from the East. They make up humanitarian aid packs, despite donations become less and less, small first aid kits are assembled for the army, containing lifesaving trauma bandages along with other items. A group of ladies make camouflage nets and ghillie suites from remnants of their military uniforms - they have made 1,300 of these since February. One young girl, no older than 16 or 17, helped her family escape from nearoccupied territories. Her grandparents wouldn’t leave as they didn’t want to abandon their farm animals. She helped more women and children escape, including her own mother. Evading capture herself, her phone was tracked. “They know I am still in Ukraine,” she told me. “Our town is occupied, if I go back to help my grandparents, I’m sure I will be made to leave or I will die. I haven’t spoken to my grandparents in over a month, I don’t even know if they’re still alive.” Another woman, who was one of the last few people to leave Mariupol, told me how they had no food, no water or medicine and, worst of all, they’re not allowed to bury their dead. Not only a complete disrespect for life, but also for death too.

“They have an outbreak of Cholera now,” she said. “I’m not surprised. The dead are piled up by the occupiers and look at the temperature!” It’s currently ranging from 27-35 degrees in Ukraine at the moment. “There are wild dogs around there too. They have no regard for who they are, they tear limbs off without a thought, off people’s loved ones.”

Even liberated towns, such as Bucha, Irpin, and Borodyanka, still have a long way to go to rebuild their lives. No different to the rest of the country, the feelings here are of hope. People still live here and have even returned, and they are trying to get back to some sort of normality. Gas and electricity has been reconnected, some small shops have reopened and a huge clean-up operation has taken place since the occupiers left. While it’s always said that it’s only military targets that get hit, just driving through these areas shows that it’s clearly not the case. They just want to cause as much devastation and terror as possible. A woman tells me, “50 tanks arrived, turned cars on their sides so no one could leave. We tried to hide away from bombs. But it was no good. They came into our homes and took everything, the shop keeper down the road was shot as they took food, cigarettes and alcohol. The dead were left on the streets to remind us, that if we don’t do as they say that will be us. Children saw it all.” I also visited a hospital in central Ukraine that has the capacity to care for around 750 people. At the moment, it's almost full of casualties of this war. I met injured soldiers, some who are lucky to be alive, while others laugh and joke and can’t wait to get back to the front line. Civilians who are just happy to be alive, despite horrific injuries – children and babies with shrapnel wounds, 80% burns and broken bones. The chief doctor stopped on one of the wards and said: “We go no further, the injuries down here are critical.” On the other side of the door were two soldiers who were travelling with six others when their vehicle was hit by artillery – they were the only survivors. They remain in a critical condition with broken bones, deep wounds from shrapnel and burns, requiring significant skin grafts. It was a privilege to be able to present a range of medical supplies to the director of the hospital – all hugely appreciated and purchased thanks to the funds I’ve been able to raise.

The strength and courage of this country is an inspiration, but they feel like the world is starting to forget them. They're not front-page news anymore. I understand not everyone is in a position to be able to donate, host a refugee, or volunteer, but everyone can stop them being forgotten and share their stories. It’s incredible how much this has fallen off the news, and how the news differs here to what I have seen and heard for myself. On a lighter note, it’s been a privilege to spend time here, it’s a beautiful country. I was also incredibly lucky to be hosted by a Ukrainian family - Oksana, her husband and children were so welcoming and gave me an opportunity to experience true Ukrainian life and culture. Little did I know just how much - from walking the streets of Kyiv to being interviewed on live news to having dinner with the Chechen army, it’s been a crazy week and it’s safe to say I’ve fallen in love with Ukraine.

I’ve already booked to go back in August and continuing to fundraise, to make as big an impact as I can on my next trip – anything you can donate is hugely appreciated, it changes lives and saves lives.

https://www.justgiving.com/ crowdfunding/nikkiinukraine

WINDOWS MAKE WAVES ON HAYLING ISLAND

When Alpine Homes looked to create a high-end housing development with stunning coastal views, Central Windows were called upon to supply and fit a contemporary solution that could stand up to the elements.

Resting in the shadow of its larger sibling the Isle of Wight, Hayling Island is one of the nation’s best kept secrets – a seaside retreat home to over five miles of unspoilt coastline. The close proximity of the cities Portsmouth and Chichester make the island an ideal location for both holidaymakers and new residents alike, which is exactly why Alpine Homes chose it as the location for their latest housing development, Yacht Haven.

Since its foundation, the Hampshire-based company has grown to become one of the most recognisable names in the county, constructing over 200 homes throughout the cities and shores of the South Coast. Its portfolio spans everything from urban high-rise apartments to traditional country homes.

A PLACE BY THE SEA

Yacht Haven would prove to be one of Alpine Homes’ most compelling projects to date – a gated development of six luxury properties with stunning waterside views, including a pontoon for each home to access water-based activities. With the build soon underway, Alpine Homes would call upon locally-based Central Windows to source and fit window frames that would suit such high-end surroundings. Chris Fields, Project Manager at Alpine Homes, said: “The unique demands of the coastal environment meant that we needed profiles that could stand up to the elements. However, it was critical that this did not come at the expense of compromising the modern look and feel of the build. For this reason, we enlisted the help of Central Windows to help us identify the correct product for our needs.”

LET THE SUNSHINE IN

Central Windows would specify REHAU’s TOTAL70 windows and Invisifold doors in anthracite grey on white as the best fit for the build. The tilt-and-turn system’s slender profiles would allow for a larger glass area to let more natural light in, while also ensuring that it would be resistant to any corrosion caused by the coastal environment. Steve Smith, Managing Director at Central Windows, said: “We’ve been specifying REHAU windows for a number of years now, and continue to be impressed by the quality of service and product they offer. The chamfered system provided a contemporary look in keeping with the rest of the property, while also remaining more cost-effective than timber or aluminium alternatives. These solutions also allowed us to easily meet the u-value requirements set out in current building regulations, meaning that the homeowner could benefit from a more energy-efficient property.”

CREATING FOREVER HOMES

Due to their high-performing uPVC polymer, REHAU’s TOTAL70 windows achieve an A+ rating for thermal efficiency – the highest Window Energy Rating (WER) currently possible. Double glazed units would also ensure that the residents of Yacht Haven could access peace and quiet inside of their home whenever it was desired, despite the close proximity of the waterfront. Moreover, as the TOTAL70 range makes use of a unique compound with a smooth gloss finish, the frames were guaranteed not to rot, warp or be in need of painting, even after years in place. Combined with an energy efficiency rating far exceeding current standards – even in light of recent uplifting of these requirements under the Future Homes Standard – Yacht Haven residents can enjoy longlasting, quality frames. Luke Boban, Area Sales Manager at REHAU concluded: “The TOTAL70 range has long proved an ideal fit for residential builds, and Yacht Haven is no exception. The innate qualities of the product made it an ideal fit for the coastal environment, ensuring that the homes would remain energy-efficient and resistant to the elements without compromising on views of the surrounding scenery. We’ve received glowing feedback from all involved with this project, so look forward to working with both Alpine Homes and Central Windows again in future.”

For more information about REHAU’s TOTAL70 system, click https://bit.ly/3QrU7Ko.

YALE SLOTVENTS NOW IN STOCK AT MILA FENSA CELEBRATES 20 YEARS WITH 15 MILLION CERTIFICATES

Ahead of the deadline for the new Building Regs on 15 June, Mila has added the new Yale SlotVent contemporary styled trickle vents to its range, making it easy for customers to comply with the ventilation requirements in Approved Document F.

Alongside the product launch, Mila has created a dedicated new section on its website at https://www.mila.co.uk/slotvents/ to give customers all the information they need on when trickle vents are required and how best to communicate the benefits to homeowners. All three sizes in the SlotVent range – 2500EA, 4000EA and 5000EA - are now in stock at Mila. They can be used on their own or in combination to reach the 4000mm2, 8000mm2, or 1000mm2 targets required for bathrooms, kitchens and habitable rooms in either multi-storey or single-storey dwellings. All of the sizes are available in 10 colours, including anthracite grey, Irish oak, cream and Chartwell green to match with the most popular frame choices, and all have the option of a white internal half to suit most decor.

The new Approved Document F requires that trickle vents must be controllable by the occupant and the SlotVent range is particularly flexible with 30°, 60° and 90° tilt modes to adjust the airflow. Externally, they feature a curved hood for optimum weather sealing, and they can be ordered with a fly screen add-on if required. In high noise areas, or where customers are particularly concerned about draughts, there is a noise reduction version available, which comes with a foam gasket on the internal section. In terms of fitting, Mila is supplying fabricators with all the routing details they need to set up the machines in their factories for the different SlotVent variants, and the vents themselves come with universal pre-fitted clips designed to make fabrication as quick and easy as possible. Richard Gyde, Mila’s Managing Director, commented: “We know that trickle vents aren’t universally popular with either fabricators or homeowners, but they are set to become a statutory requirement for the vast majority of windows from June to prevent excess condensation build up and ensure adequate air flow in our increasingly airtight homes. “By adding the SlotVent range to our product line-up, Mila is giving customers a quality solution, which requires minimal disruption in fabrication and is stylish and unobtrusive enough to convince even the most cynical homeowner that they will benefit from better indoor air quality as a result. “The big benefit of buying from us of course is that trickle vents can simply be added to a customer’s hardware order, and they will also come with all the value-added elements of the Mila service including next day delivery from stock, sales and marketing support, expert technical advice, and independent testing services.” More info, including a downloadable brochure is at: https://www.mila.co.uk/slotvents/

QUICKSLIDE’S DIGITAL INVESTMENTS GET RESULTS

Quickslide’s continued investment in the digital aspects of its business has seen it further increase efficiencies while providing even more consistently high-quality products and services.

This commitment to on-going digital improvement has driven up the quality of both production and customer service, as Managing Director Ben Weber explained: “Everything we do at Quickslide is focused on how we can improve our products and services so that, ultimately, our trade partners can improve theirs. From large overhauls to smaller continuous tweaks and improvements, we’re always looking for ways to increase efficiencies, quality, and sales.” Systems Development Manager James McArthur completely redesigned Quickslide’s VS production line, with a fully optimised system tailored specifically to suit the business’s unique requirements. “The system has been developed using the latest EvoNET management tool from fenestration industry software specialist Business Micros, that we use across the business to give us greater visibility and control,” said Ben. “James has along with our in-house team of developers produced a system that syncs with the core BM system for use on the VS production line, to drive lean manufacturing. As a result, we’ve seen a dramatic drop in post-delivery remedials. “We have always been proud of our quality and our emphasis on ‘right first time’, but we never rest on our laurels and will always strive for perfection. Because fewer site visits also mean our Service Engineers’ time is freed up to focus on actively helping grow our business and that of our trade partners instead.” The digital investment and improvements in production run alongside Quickslide’s web developments. The new website, which focused on completely reworking the back-end without compromising the familiar front-end, has been a huge step forward in driving organic growth. Ben explained: “With our new website our trade partners will soon be able to gain access to a dashboard system where leads can be effectively managed – in effect, it’ll function as a complimentary CRM system for our partners. Meanwhile, investments in clever lead generation tools will enable us to grow with our partners, while we continue to invest in SEO to drive the right kind of customers with the right kind of requirements to our site. “At Quickslide we pride ourselves on focusing on all aspects of our business to continually bring improvements to our products, services and ultimately to the trade our partners do. It's great to see this latest investment in our digital capabilities for both our products and services making such a difference to our business and that of our partners.” www.quickslide.co.uk

FENSA is proud to be celebrating its 20th anniversary with 15 million certificates now issued by the government-authorised scheme that monitors building regulation compliance for windows and doors.

Lis Clarke, Operations Director of FENSA says: “FENSA was established in 2002 as the first Competent Person Scheme for the window and door installation industry to improve installations, professionalise installers and protect homeowners. We believe we are now the most widely recognised competent person scheme having issued 15 million certificates. “We celebrated this significant milestone at the FIT Show and believe with so many homes already covered by our scheme, FENSA Approved Installers will be able to maximise on our longevity in their own marketing. Installers are already proud to display the FENSA brand, but this landmark gives us all a new angle to promote the benefits of the scheme.

“We have moved premises twice in our 20-year history in 2009 and 2016, to allow us to continually grow our team and stay ahead of the increasing popularity of FENSA. 2019 saw our first TV appearance to further support the FENSA community by educating homeowners to the benefits of having their installations registered by FENSA.

“As the drive for energy efficient products increases, the importance of proving compliance with all the most up to date Building Regulations will only become more important. The passionate team at FENSA are committed to supporting the industry through these changes and any new challenges we must face in the next 20 years and beyond!”

GLASSTEC IS THE PLACE TO BE WHEN IT COMES TO INNOVATIONS AND TO STAY AHEAD OF THE COMPETITION

In the International Year of Glass, the glass industry will celebrate a long-awaited reunion in Düsseldorf, Germany from 20 to 23 September 2022. The sector had to wait four years to once again experience the wide range of exhibitors on the topics of glass production/manufacturing technology, glass processing and finishing, for numerous glass products and applications as well as a unique and extensive supporting programme from industry and science.

MEGATRENDS POINT TO FUTURE CHALLENGES

On the basis of in-depth conversations with experts from all stages of the value chain, five global trend themes were identified. They are considered essential for the future development of the glass industry as well as for our society as a whole. These are: • Climate (emission reduction and renewable energies) • Urbanisation (future-proof architecture with glass) • Value (sustainable value chain) • Resources (efficient and sustainable use of resources) and • Wellbeing (improved quality of life through glass)

NEXT IN GLASS – GLASS TECHNOLOGY LIVE: THE INNOVATIONS SHOW WITH AN OUTLOOK ON FUTURE GLASS APPLICATIONS

The special show glass technology live (gtl) will be organised by the university network of the four Technical Universities of Darmstadt, Delft, Dortmund and Dresden. Students from a wide range of disciplines and the industry will again amaze visitors and fuel discussions with their mock-ups and innovative glass structures. Exclusive insights into the work of the glass technology live organizers are provided by a series of gtl video interviews, made available on the glass technology live-Website.

THINK TANK: GLASSTEC CONFERENCE AND CALL FOR PAPERS

The glasstec conference combines industry know-how from theory and practice in the context of the five trend themes. Every day, glasstec 2022 visitors can find out about the current developments and trends in the sessions on Glass Production, Processing Technology and Products. Also forming an integral part of the line-up of supporting program, is the international Architecture Congress. This year it will be held once again in cooperation with the Chamber of Architects North Rhine-Westphalia on the Thursday of the trade fair (22 September, CCD Ost) under the heading: “Foresight. Future-Proof Architecture with Glass”.

The morning sessions of the glasstec conference agenda at a glance: • Tuesday, 20 September: glass processing and finishing

New processing options and technologies

• Wednesday, 21 September: glass production I

Decarbonisation – new energy systems and transition to renewable energy sources

• Thursday, 22 September: glass products and applications

New glass products and recyclability of glass

• Friday, 23 September: glass production II

Alternative resources and recycling of container and flat glass Each afternoon will feature additional lectures in the glasstec conference area. These will be offered by universities and scientific institutions on the topic of façade and metal construction, by the VDMA on the topic of machine communication and by EuroWindoor on energy efficiency and the use of natural daylight. Details on the supporting will be available here in the future: www.glasstec-online.com/en/ Program/Overview

www.glasstec-online.com

CRAFTS CENTER AND WORLDSKILLS GERMANY @ GLASSTEC

The wide range of exhibitors and products at glasstec provides craftspeople with a comprehensive overview of the latest glass products and tools as well as mounting and lifting aids. For the third consecutive time, the special Crafts LIVE show will present among others the top innovations for the glass processing trade in practical application. This year, the area is themed around the World Cup of Trades. At the ‘WorldSkills Germany @ glasstec’ young glaziers from all over Germany will compete in this qualifying competition to secure their starting place for ‘EuroSkills 2023’.

GLASSTEC START-UP ZONE 2022 – THE NETWORKING PLATFORM FOR YOUNG, INNOVATIVE COMPANIES

At glasstec you encounter the top decisionmakers from the glass industry and experts from business, research and politics. This is why the START-UP ZONE provides innovative young companies with an ideal platform for making new contacts and networking. National and international start-ups now have the opportunity to secure a place in the START-UP ZONE. This exhibition opportunity targets companies that have been on the market for less than 5 years, have less than EUR 10 million in annual sales or total assets and have fewer than 20 employees.

A RESURGENCE LIKE NO OTHER

Pearl Windows has become one of the most widely renowned PVCu window and door fabricators in the industry. This exceptional reputation is all thanks to its forward-thinking nature, highquality products and its commitment to go above and beyond for customers. One of the early adopters of the Liniar system, Pearl Windows has always been on the front foot for fabricating new products from Liniar’s Design and Development department.

Resurgence, launched in 2019 was the UK’s first PVCu double-rebated flush sash system – and Pearl Windows was one of the first fabricators to grab the opportunity to manufacture this revolutionary product. “Resurgence is a beautifully designed product. With the additional superb manufacturing finish which is provided by our Timberweld® machinery, it’s easily the most attractive window available on the market today,” comments Pearl Windows’ Managing Director Jeff Walsh.

EXCELLENCE IN MANUFACTURING

With an efficient manufacturing process set up and in place, Pearl Windows were one of the first to have Resurgence fully tested by a third party and to achieve Secured by Design status. “We’re proud to say that we believe we were the first Liniar fabricator to achieve Secured by Design accreditation for Resurgence,” Jeff states. “We followed the same stringent testing as we did with the original Liniar casement window, which has given us a pass first time. This was all possible because of Liniar’s high-quality design, enabling us to manufacture a fullsize window for testing using the high specification recommended by Liniar’s Design and Development team.”

RELIABLE, HIGH-QUALITY PRODUCTS

Pearl Windows boasts circa 4000 units per week, across it’s three cutting edge facilities in Westhoughton, Bolton, delivering products to installers, trade outlets, building sites and businesses throughout the country. “We offer the full range of Liniar windows, doors and conservatory roofs, and for us, Liniar’s products are the best there are on the market. They tick all the boxes when it comes to quality, energy efficiency and security. On top of that, Liniar is a company which is both socially and environmentally conscious, something that is close to our hearts,” comments Jeff. “Everyone here at Pearl Windows has Liniar products installed in our homes and it’s what we recommend to our families and friends when they are looking to replace one of their fenestration products.”

ACHIEVING QUALITY RESULTS

Resurgence is available in a wide range of solid colour and woodgrain foiled finishes. With four fabrication options, including the highly recommended Timberweld® solution, this product fits well within both modern and character properties.

For installation companies looking for reliable supply of the new Resurgence system, backed up by exceptional customer service, Pearl Windows is an excellent choice. Learn more about the products and services the company offers by visiting https://www.pearlwindows.co.uk/.

Window Systems LTD

20TH ANNIVERSARY

FOR MERCURY GLAZING

July 2022 marks the 20th year in business for specialist trade fabricator Mercury Glazing Supplies. Directors and Co-founders Steve Cross and Martin Halford, take a look back at their journey that has made them the go-to fabricator for vertical sliding sash windows and cuttingedge aluminium products.

AHEAD OF THE CURVE

When we came to market in 2002 as one of the first manufacturers of the Spectus Vertical Sliding window, we set out a clear business focus to deliver a viable alternative to timber sash windows. It’s fair to say the industry has come a long way since those early days, and our vertical slider remains the product most considered and accepted by planners and conservation officers due to its exceptional traditional styling that perfectly replicates its timber counterparts.

What is interesting to note is the shift in demand for the sliding sash window in today’s modern homes, as the windows high-end characteristics mean they are more relevant than ever before.

The broader appeal of the sliding sash window across modern properties is encouraging. Consumers and building contractors are now seeking traditional styling combined with modern-day thermal performance and an expansive colour palette. And while we are still seeing sliding sash window demand for heritage hues such as Cream and Chartwell Green, we have witnessed an industry shift for moderncontemporary colours such as Anthracite Grey or Black. As a business, Mercury has remained steadfast to the quality of our products and continues to meet our customers’ needs across all market sectors. To broaden our appeal and stay ahead of the curve, we expanded the business in 2008 and began manufacturing a range of cutting-edge aluminium products ahead of the market boom. Once again, it was a shrewd business move and one that allowed us to capitalise on the aluminium upturn across all market sectors.

As we celebrate this milestone year, the business has been through a lot in that time, but the past couple of years have easily been the most eventful.

THE HIGHS WE’VE CELEBRATED

Despite everything, the business has had an incredible two years of growth. Sales of our aluminium products saw a ten-fold increase along with a step-change in demand for our PVC-U vertical sliders.

Feature-rich products are here to stay. Since day one, they’ve been our bread-and-butter and we’ve certainly reaped the rewards of the recent market boom. Whether it’s PVC-U or aluminium we’re experienced

in offering specialist product solutions that help deliver the aspirational projects that homeowners demand and commercial and new build markets must deliver. Put simply, it helps to make us a very attractive fabrication partner. We’ve also invested in the future of the business. We recently opened a new dedicated aluminium manufacturing centre at our headquarters in Gloucester. It means we now have dedicated facilities for both our PVC-U and aluminium production. As part of the expansion, we made a sixfigure investment in automated machinery to ensure they quality is second-to-none across the board. We’ve also taken on new seniorlevel members of staff too and the Mercury family is now 60-strong and growing.

If you want specialist, feature-rich products, we’re the company you need, whether you work in trade, commercial or residential markets. And the depth and breadth of our portfolio is purposely designed to suit all applications. Our Smart Visofold Bifold series of doors has all the design, thermal efficiency and security benefits you would expect from a highly established product. Add in impressive opening apertures and low threshold options and you have a package that’s hard to beat.

Our Cortizo Aluminium Bifolding Door has up to seven leaves each way (14 in total), comes in a wealth of options and has all the durability and reliability bifold doors need. It offers an exciting solution for timesensitive or budget-conscious projects too. Our Visoglide Plus Aluminium Patio Door offers contemporary styling, robust performance and superior thermal performance. And with the ability to accommodate larger apertures, it delivers on consumer trends for wide glass expanses too. Our Alitherm 300 Aluminium Window combines modern energy-efficient technology with the elegant and understated style of a traditional casement window. Our Alitherm Heritage 47 Aluminium Window has been engineered specifically to replace existing steel and Crittall windows without compromising on modern-day performance. Our aluminium sash windows have been engineered to combine the traditional aesthetics of classic British architecture with modern convenience.

Alongside these, we offer aluminium doors and windows for commercial projects as well as aluminium lantern lights and rooflights and Smarts aluminium designer doors. And with new aluminium products due to be launched soon, the Mercury portfolio of specialist products continues to grow. We also remain one of the UK’s largest fabricators of the PVC-U Spectus Vertical Slider. We offer both welded and mechanical jointed options, delivering the best in Vertical Slider choice.

FOCUSING ON THE FUTURE

We’re in the middle of a four-year plan for growth. We are laser-focused on achieving that while continuing to maintain the customer service levels, turnaround times and quality that we’ve built our name on. We are incredibly proud to have reached this milestone year and its humbling to see just how far we have come. Twenty years ago, we were a company of three people manufacturing one product – the Spectus PVC-U Vertical Slider. Today, we are a multi-million-pound turnover company of 60 people manufacturing a comprehensive range of specialist feature-rich products in both PVC-U and aluminium.

It has been quite a journey but one we couldn’t have done without the support of our customers or our talented team. We’re now looking forward to seeing what the next 20 years bring for Mercury as we continue on our growth trajectory.

For more information visit www.mercuryglazing.co.uk or email sales@mercuryglazing.co.uk.

REYNAERS SHORTLISTED FOR SIX CATEGORIES IN THE NFAS

Reynaers Aluminium has been shortlisted as a finalist in six categories of the National Fenestration Awards (NFAs) following nominations and votes by industry peers.

The premium aluminium supplier is finalist in the following categories: Aluminium Systems Company of the Year, Bi-Folding Door Manufacturer of the Year, Tom Cahill in the Business Development Manager/Sales Executive of The Year, Richard Hall in the Director of the Year, New Product 2022 for the Reynaers SP 68 sliding door system and Systems Company of The Year. This is the 10th year of the awards and organisers were thrilled to receive a record number of nominations from those working in the UK fenestration industry. Samantha Hill, Head of Marketing at Reynaers, said: “We’re delighted to have been nominated as finalists in so many categories. It’s a credit to the whole team here that we’ve been nominated by our peers and colleagues within the industry. “The dedicated teams at Reynaers take pride in supporting not only our customers, but all stakeholders through design and specification, fabrication and installation of our products and services. “Most recently we’ve done so by ensuring our customers are fully aware of what the forthcoming changes to Part L of the Building Regulations mean in relation to our products. As a global business with continual investment in product development, our customers can be assured that they have access to a wide range of fully compliant products and systems. “Reynaers will remain at the forefront with innovative systems designed with future requirements in mind. This year we launched the SlimPatio 68 and will be launching additions to the SlimLine 68 window system range, whilst last year we updated our CF 68 bifolding product to offer both better performance and increased customer choice.

“It’s also fantastic to see Richard Hall and Tom Cahill being selected as finalists for individual awards. They are excellent role models who embody our values of being caring, daring, passionate and united, and we wish them, and all the people and businesses shortlisted, the very best of luck on the awards evening.” You can vote for the winners of the National Fenestration Awards here - https://www.fenestrationawards.co.uk/vote/ - and votes close on October 7th. The winners will be announced at the awards evening on November 5th. For further information about Reynaers visit www.reynaers.co.uk.

ROCKDOOR DEBUT A HUGE SUCCESS

Rockdoor, the Original Composite Door, was overwhelmed with support for their debut appearance at the FIT Show 2022.

Rockdoor was delighted to come away from their three-day stint at the FIT show in Birmingham, with lots of new leads, debuting as one of the most popular stands at the show.

Beaming with an eye-catching design from floor to ceiling, the stand was positioned superbly in the centre of the exhibition hall, filled with 12 unique and bespoke doors and complete with several expert staff on hand to talk all things Rockdoor. The response was so big that Rockdoor is already following up with lots of new customers wanting to become Trusted Installers around the country, as Mark Simm of Rockdoor explained: “To say we were blown away with the response to our first appearance here would be a big understatement. After the initial show being postponed due to COVID, we were delighted to finally get the chance to showcase Rockdoor and it could not have gone any better. We’ve wanted to exhibit for a long time now, but the timing was never quite right, so it’s great to finally tick that box.

“We are so thankful to all the faces, new and old, who took time out of their busy day to come and see why Rockdoor is the most unique composite door of its kind on the market.

“We now look forward to strengthening those existing partnerships and welcoming lots more Rockdoor Trusted Installers across the country.” Rockdoor are thankful for the support received and will be spending the next few weeks actively updating their network of trusted installers as a result of the FIT Show.

A GARDEN ROOM VILLAGE OF INSPIRATION

If homeowners need any convincing about the lifestyle benefits of investing in a premium garden room, then the new village at Carr Gate Garden Centre near junction 41 of the M1 in West Yorkshire is full of inspiration thanks to living space experts, Making Your Space.

With hybrid working increasingly becoming the norm, consumers are looking at ways in which to find a more permanent place to work, separate to the main fabric of the house. But this impressive village takes it a step further with 13 garden rooms on display ranging from a home office, gym, bar, outdoor kitchen, artist’s studio, mini hairdressing salon and children’s playroom. Making Your Space is a dedicated trade only manufacturer of garden rooms with Design Partners in key areas of the UK but are looking to scale this nationally with the promise of a marketing support programme and showroom materials including a unique mini-pod, brochures and flyers. There’s also a unique garden room designer and configurator that can be used to design a bespoke room in real time and to cost it too, with a full office back end with costings and margins that has been developed by Business Micros and The Consultancy. Using the latest off-site construction techniques these premium Garden Rooms can be installed in as little as two days prior to final trades including plastering and electrical works. It’s also a market segment set for strong growth as highlighted in the consumer press and also with the increased traffic on search engines for related terms. Ryan Crossley, director of Making Your Space, commented: ‘This new garden room village shows a wide variety of applications from office to living space, gym or even small business. We’re trade only and actively looking for new Design partners across the UK with the promise of a premium, well thought out product solution and supported by a strong marketing programme and you don’t necessarily even need a showsite to exploit the considerable opportunities that this emerging market sector presents.’ For further information on Making Your Space and their trade only range of premium garden rooms, please call 01422 385613, visit makingyourspace.co.uk, or e-mail hello@makingyourspace.co.uk. You can also follow them on social media channels @MakingYourSpace.

THE ISSUE OF PVC-U RECYCLING IS TAKEN VERY SERIOUSLY BY VEKA RECYCLING – AND VERY EFFICIENTLY!

A tanker is filled with bead

Attending a trade press day at Veka Recycling Chris Champion, Editor of Glass News, had the opportunity to understand the importance of recycling of PVC-U material, the methodology involved and how important recycling has been to the Veka Group, especially during a time of difficulty in sourcing virgin material. Managing Director of Veka Recycling, Simon Scholes clearly explained the company’s role and guided us around the impressive Wellingborough facility.

Simon proudly proclaimed the Veka Recycling Group as being the ‘leader in PVC window recycling’. Emphasising the point by stating that they have built the newest and most advanced PVC window recycling plant in Europe – possibly the world!

For all its size and influence around the world, Veka is still a family owned company, founded back in 1969. Its presence is pretty much worldwide with 25 Veka facilities in 16 countries although that number has now diminished with the announcement that they are withdrawing from Russia and selling the business to the management. Although incorporated in 2006, Veka Recycling Ltd actually became operational in 2007 and based in Kent, with the site in Wellingborough being purchased in 2018 and it is now one of three Veka plants that combined, recycle 100,000 tonnes of PVC-U window material each year. The material consists of post consumer frames and virgin off cuts. So how does it work and whose frames are they? The answer is frames from any system house and it was interesting to see the different brands in the enormous pile awaiting recycling. We watched as contractors brought in material by the wagon load while the white van man was also arriving with frames in the back. They are all weighed in as, yes, you are paid for your old PVC-U and there are people who are making a successful living from collecting frames and off cuts. This all raised a question in my mind as to those on the road representing Veka Recycling….are they salesmen for the recycling solution or buyers looking for product to recycle? And the answer is both although sourcing that constant supply of material is key. As far as Wellingborough is concerned, they alone will recycle 30,000 tonnes in 2022 and that represents around 1.8 million window frames and what is impressive is the full recycling process being on site. The fact that an old frame can be unloaded at one end and reappear as bead, or melt filtrated pellet, at the other end ready to be used in making brand new frames, is impressive. On the face of it the process is relatively simple. Chop it up and keep grinding it down into fine particles to sieve through ever finer filters until all elements of metals, glass and rubber compounds are removed so that pellets can be formed. However, simple it may be, but costly to design and build and over

After weighing in, material is added to the pile Scrap PVCu starts its journey by going in the hopper

Weighing in Any profile is welcome for recycling Bead is bagged up ready for delivery

£15m has been ploughed into this new UK facility. Veka is committed to educating the trade and, indeed, the consumer to the fact that recycled PVC-U is ideal in many ways and the recent pandemic proved the point when polymer was in short supply. Not surprising therefore that Veka PLC, the Burnley-based systems division, has become Veka Recycling’s biggest client and by supplying recycled pellet in volume Veka was able to offset much of the widely reported disruption to PVC-U resin that occurred in recent months.

Managing Director, Simon Scholes, said: “The Wellingorough plant was built from scratch to take advantage of the latest recycling technologies and we now produce the highest quality polymer for use in a range of products, including brand new window and doorframe profiles. We have the ability to promote and deliver PVC-U windows as truly sustainable at a time when plastic generally is under close scrutiny and to make the most of what is a tremendous resource. And of course, greater emphasis than ever in now placed on recycled PVC-U material following the supply chain issues that have hit the industry in recent times.” Homeowners are becoming increasingly aware of ways to reduce their environmental impact, with retail installers also reporting an interest shown by homeowners in the future of the windows being removed from their homes: “The recent FIT Show provided considerable anecdotal evidence that homeowners now want to know that the PVC-U windows being removed from their homes will be dealt with sustainably. This is gathering momentum, with more retailers now proactively advising homeowners that their old windows will be recycled,” explained Simon. The leadership shown by Veka in pioneering recycling of PVC-U extends to educating everyone in the supply chain and cleaning up the image of reprocessing, says Simon: “We are determined to make sure people understand the logistics and realities of recycling windows, especially the potential consequences for installers and their homeowner customers for committing waste fraud, which is a serious issue.”

The visit to Veka Recycling was not only eye opening but also very interesting, made more so by Simon’s explanations and guidance through the whole process. It was like being taken round by your favourite High School teacher! Simon is obviously a huge fan when it comes to recycling and his knowledge allied to his sense of humour made it easy to see the benefits afforded by this Veka Recycling facility. Old frames for new is definitely the way to go!

Simon Scholes explains the principles of recycling The start of the filtering process sorts the larger pollutants

SIKAPLAN SINGLE PLY MEMBRANE INSTALLED FOR PORCH ROOF REFURBISHMENT

A failing porch roof at a residential block of flats in Birmingham was repaired and replaced by Solihull based R & R Services.

R & R installed a mechanically fixed Sikaplan RoofPro single ply membrane, with fully adhered flashings around the upstands and porch roof perimeter. A recyclable, injection moulded, roof drain and leaf guard are fastened securely to the roof deck. The new, efficient flat roof now improves the look of the entrance and gives a much nicer front-facing aspect to the block. It also gives the block owners the reassurance they wouldn’t suffer the same problems they had with the previous, underperforming roof. Rob Dodd, Managing Director, R & R Services said: “We have a long standing relationship with the block owner and this is just one of many projects we have completed for them. The Sikaplan RoofPro single ply membrane is a brilliant product. We have used many other membranes in the past, but this is our team’s favourite to work with. It’s a perfect combination of versatility, high performance and good looks.”

The Sikaplan membrane provides an all-weather seal and is compatible with virtually all commonly used substrates in new build and refurbishment projects. Sikaplan RoofPro has a life expectancy of more than 35 years (BBA Certificate Adhered 21/5926 and Mechanically Fixed 21/5916)), is ETA accredited and comes with 10/15 and 20-year materials guarantee. If you are interested in becoming a Roof Assured by Sika installer visit http://www.roofassured.co.uk/installers/become_an_installer/

EUCHNER CTA

HEAVY DUTY TRANSPONDER-CODED SAFETY SWITCH WITH GUARD LOCKING

Featuring a robust, IP69K rated construction and class-leading guard locking force up to 8,000 N, the CTA range of safety switches from industrial safety engineering specialist Euchner can, when combined with an Euchner IO-Link Gateway, communicate and send process and device data – including comprehensive diagnostic messages and information on preventive maintenance – to higher-level control systems to enable rapid and targeted troubleshooting.

Being Industry 4.0 ready and ideally suited to applications requiring a high Performance Level (PL) and increased locking force, CTA switches combine the convenient form-factor of Euchner electromechanical safety switches but with guard locking and modern transponder-coded safety engineering. Thanks to the transponder technology, a single CTA meets the requirements of BS EN ISO 14119 and achieves category 4/PL e according to BS EN ISO 13849-1 without additional fault exclusion. Special versions are also available for connection directly to decentralised peripheral systems, e.g. Siemens ET200pro. The robust metal housing and head of the CTA ensures a high degree of protection to IP65/IP67/IP69/ IP69K, making it suitable for harsh, dirty environments and an ideal allrounder for almost every industrial use. Its 8,000 N guard locking force is over 4x that of competitor solutions which, coupled with four actuator approach directions and an integrated, funnel-equipped head for improved actuation, makes the CTA reliable and effective for securing safety doors and flaps on machines and systems. This makes it suitable for both process protection and the protection of personnel thanks to integrated guard locking and guard lock monitoring. The design of the head is also particularly advantageous on unstable guard door designs or where the guard isn’t adjusted. Consisting of two components – a safety switch and separate actuator – and with a range of mounting bracket solutions available, the 40mm-wide compact design of the CTA can be mounted either vertically or horizontally and fits perfectly on standard aluminium extrusion profile systems, including those of Bosch Rexroth and Kanya, with the switch mounted on the fixed part of the guard and the actuator on the movable part. When the guard is closed, the actuator engages into the safety switch head. The safety outputs are switched on if the integrated transponder chip in the actuator is detected and the guard locking activated. Thanks to the integrated prevention of inadvertent locking position (faulty closure protection), unintentional activation of the safety outputs is prevented if the actuator is not completely inserted into the head.

The CTA enables comprehensive diagnostic information to be forwarded to the control system, with the safety switches measuring and supplying process-relevant parameters and information on preventive maintenance measures in real time to ensure potential issues are indicated before a machine failure can occur. Diagnostic information includes the number of switches/units in the chain, number of switching cycles (for preventative maintenance and Industry 4.0), the code of actuator presented and code of taught actuator, voltage and temperature. When IO-Link Gateways and ESM-CB safety modules are coupled to the CTA, process and device data can be read from each switch and provided to the control system via IO-Link. The IO-Link Gateway can be used to read process and device data relevant to control from a standalone safety switch or safety switch chain, with the data transmitted in real time to the IO-Link master, representing clear added value in terms of preventive maintenance. Offering triple functionality, the ESM-CB safety module combines an evaluation unit, safety relay and IO-Link slave in a single, compact device measuring just 18 mm wide. For this module, two safety circuits can be connected to the input side, with equipment including an emergency stop chain and mechanical safety switches being connected to one safety circuit. The second safety circuit enables the connection of Euchner safety switches from the BR/BP ranges. For applications requiring multiple switches, the BR version of the CTA allows up to 20 safety switches to be connected. For series connections, all information regarding the status of individual CTA switches is forwarded directly to the control system. Alternatively, for series connection in the field, wiring via M12 and Y-distributors or a passive distribution module allows all safety and status signals to be collected and forwarded to the control system using one cable. A BP version is also available for standalone operation. The CTA can be fitted with an extensive range of optional accessories – mechanical releases, pre-assembled cables or different bolt assemblies, actuators or mounting bracket solutions – including a flush fitting rear escape release, which is retrofittable and ideal for walk-in applications. It can also be coupled with other Euchner safety solutions, including non-contact interlocks and its Multifunctional Gate Box (MGB2), all in the same safety chain and maintaining a Performance Level of PLe.

For further information on the CTA safety switch visit www.euchner.co.uk, email services@euchner.co.uk or call the Safety Technology Centre on +44 (0)114 256 0123.

POLYFRAME SET FOR INTRODUCTION OF PART L AND PART F REGULATIONS

PVCu windows and doors fabricator, Polyframe, is prepared and ready to meet the new Building Regulations following the step-change in requirements which came into force on Wednesday 15thJune.

Polyframe, which is part of the Customade Group, has worked with its profile manufacturers Rehau and Duraflex to ensure that completed windows will achieve an ‘A’ Rating for energy efficiency and a ‘U’ value that meet the standard requirements of Part L, while new Yale trickle vents are fitted to all profiles to satisfy the Part F requirements on ventilation, when the new Building Regulations come into effect. Polyframe has developed an easy-to-read guide on how its products meets the new regulations, including compliance declarations for Rehau and Duraflex profiles for refurb and new build projects, available to customers and installers through https://www.polyframetrade.co.uk/ Phil Walker, Managing Director at Polyframe, says: “As a responsible manufacturer we take the changes in regulations seriously, and have been working to make sure each product we supply to customers is compliant. “Our Rehau and Duraflex profile systems come with a Part L and Part F compliance declaration for the refurb and new build market, offering installers the confidence that they are using products and systems that meet and exceed the new regulations.” For help and advice in negotiating the new Building Regulations and installation expectations, you are advised to contact your windows and doors manufacturer.