2 minute read

BOOST EFFICIENCY WITH VIRTUAL SHOPFLOOR FROM PST

Efficiency is at the core of any successful fabrication business, which is why many in the industry are already seeing the benefits of Virtual Shopfloor, a unique and powerful manufacturing software from Production Software Technology (PST) that can help achieve a flat pack rate of 97%.

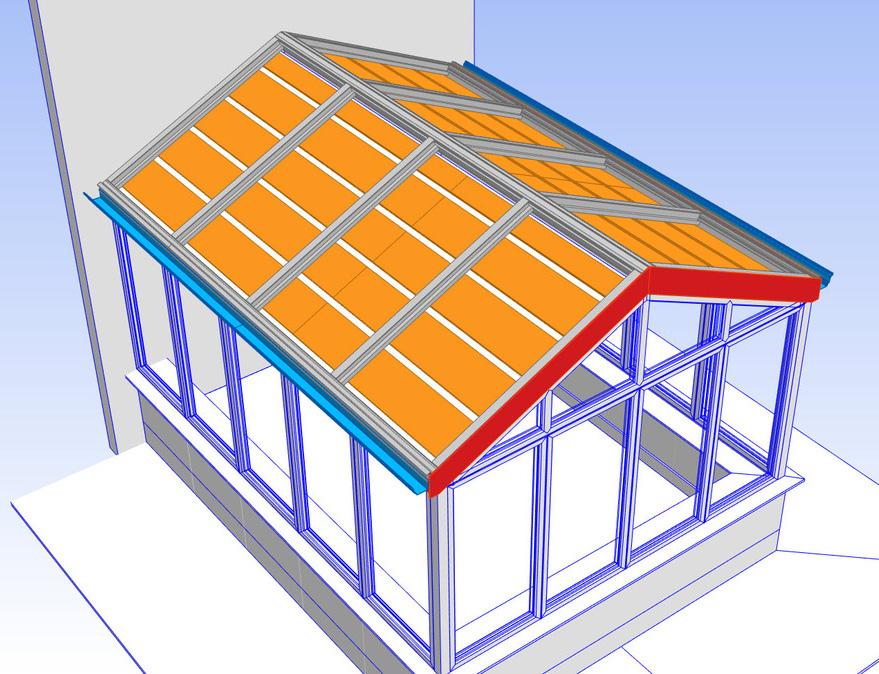

Compatible with a wide range of glazing products, Virtual Shopfloor is a manufacturing-based software that allows fabricators to choose from a library of 3D model templates or create custom designs from scratch using the free form tool. All designs are bespoke to the products they manufacture, and can be built on using easy to use drag and drop tools. Manufacturing and installation reports can then be generated with the option to send instructions directly to CNC machinery.

PST Managing Director Neil Travers explains: “Virtual Shopfloor has been designed with many benefits for modern fabricators – these include the transfer of cutting instructions directly from the platform to the saw interface by creating various saw driver output files, as well as an instant costing feature that allows for the customisation of pricing using a simple matrix and the inclusion of extra costs such as labour and site costs.

“The software also comes with an integrated reporting suite, allowing fabricators to create branded sales and survey reports, as well as numerous manufacturing reports such as full-spec small parts drawings, top cap cutting templates, and customisable hardware printouts.

“Essentially, Virtual Shopfloor eliminates the need for fabricators to use various software programs at once, giving them everything they need in one place, creating a seamless workflow from sales and survey right through to manufacturing.

“With industry-leading flat pack rates, a dramatic drop in trial build rates and substantial annual savings, Virtual Shopfloor is widely recognised as the de-facto solution for the glazing industry, and in today’s competitive market, is the ultimate tool to help fabricators get ahead.” For more information or to sign up to a 14day free trial, visit www.pstonline.co.uk.

I am delighted DE, that you are on board with Part L (and the rest), which has now been with us for a year this month, at least for RMI (Repair, Maintenance, Improvement), or home improvements to you and me; New Build has had a year to catch up, with its own regs now statutory from 15th June 2023, if my memory serves me correctly.

However, an awful lot of your oppos out there hadn’t a clue that the Regs had changed despite their lives depending on it, with FENSA failures apparently going through the roof in the months immediately following the imposition of the new Regs last year. At the risk of being a tad controversial DE, many (most?) installers would be knackered without advice and guidance from us trade fabricators. I have indeed noticed the increasing references to Future Homes. I may have made such a reference myself DE, when I have been promoting Gerda residential doors that you will have seen at the recent FIT Show, where I have exhibited them for the second year. In doing so, I am also guilty as charged of jumping on to that particular bandwagon, one that is gathering pace despite it currently having no steering, only a wheel at each corner and no brakes whatsoever. But let me try to add some clarity, even if there is not a great deal to give at this precise point in time…