4 minute read

Case Study

– WAS THE STATEMENT NO CHILD EVER SAID TO THEIR CAREERS ADVISOR.

Engineering is a broad term and sticking your neck out you could say it’s a career that young people usually get involved in from an early fascination with vehicles. Bikes, cars, planes, trains and the plethora of parts and systems that make them work. Whether right or wrong about the primary drivers one thing is certain Brunel didn’t lie awake at night dreaming of windows and doors.

Despite this it is a very real fact that everything around us in the world has been designed and engineered somewhere along the line. All the products you see in the pages of this magazine are only in existence because someone out there thought of them, then had the opportunity to commit those thoughts to paper and finally someone else financed them to manufacture. The lack of glamour in fenestration products means it is hard to attract real engineering talent into the industry which Made for Trade have learned and certainly know a thing or two about as the business is actually run by qualified Mechanical Engineers as we learn more from MFT’s Chris Wann.

“My background is all Oil & Gas machinery design, which I did for about 8 years. Over that time my employer realised I could also communicate with other human beings (a trait many engineers lack) and so I was moved into concept sales and business development which gave me a real taste for business. Coming into a completely different industry with MFT, which at the time I was worried was career suicide has actually been a massive breath of fresh air. This realisation is something I try and push to all the young engineers I meet as part of our recruitment efforts” Chris continues “most of these sexy industries, like automotive, O&G and aerospace only

offer an opportunity to look at a really small part of the overall system, or they force you to design things that have been seen and importantly proven before, they don’t like risk. Here at MFT we like to throw the rule book out of the window and start projects, where possible, from first principles pushing the industry forward.” The Korniche line of products are exactly what MFT claim to be the new first principal designs that are pushing the envelope and have certainly turned things on their heads with the Lantern roof. It was the fist product on the market that wasn’t just a converted conservatory roof and its only now, some 4 years later that companies are starting to bring out similar sorts of things. For those of you that don’t know about the Korniche lantern it was the first in house designed product from the trade fabricator and it threw the conservatory roof rule book entirely out of the building. It made installation a doddle for even the most inexperienced fitter, delivered to site precision cut with no requirements to do anything other than assemble the simple kit with the provided hex tool. Also, the innovation of the glazing retainer design meant it can be glazed in under a minute which MFT demonstrated to astounded audiences at trade days and trade shows across the UK and Europe. Rumor has it that a couple of industry journalists managed to build one in front of a live audience in under 10 mins. Impressive stuff!

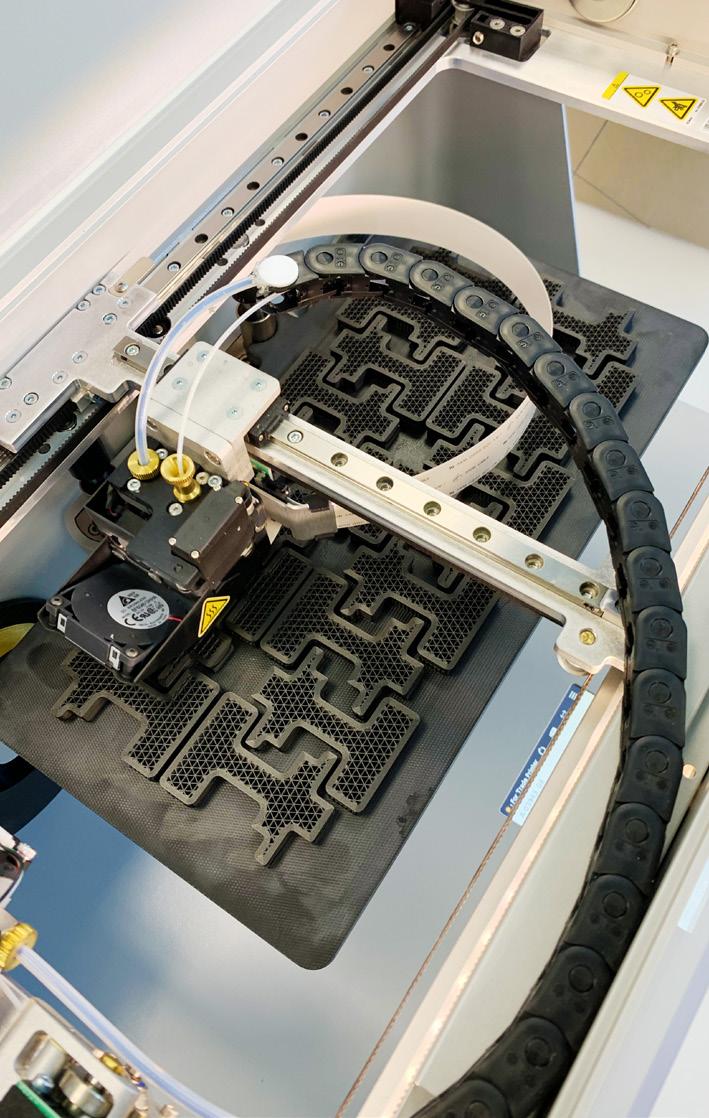

To keep creativity and design at the forefront of MFT’s business they have now built up a team of 8 engineers working from a dedicated research and development office at their Wynyard headquarters. They have some pretty impressive facilities that would be more at home in a full-blown test house. The team works using SolidWorks 3D CAD and analysis software and have 3D printing and workshop facilities to develop prototype designs. 2021’s investment also went into impact, PAS24, and weather testing rigs to pre-test new bi-fold parts way before any official testing took place. Ashley Gaunt, Technical Director commented “Pre-testing all our designs in house cuts out a lot of the to-ing and froing from our chosen accreditation testing partners saving us a considerable amount of time and cost. Its also great for all the engineers to be able to test their designs themselves as it provides insight into what does and doesn’t work and why which is invaluable for trying out innovative new designs.” Its refreshing to see a company in the industry that are taking design and development this seriously and that their products are making a real success story of it. With some interesting patents on proprietary features of their up-coming Korniche bi-folding door which could clearly be applied to other products we can’t wait to see what’s next off the Made for Trade drawing board!