3 minute read

Machinery

MACHINERY: ‘THE DEVIL IS ALWAYS IN THE DETAIL’

Sean Mackey, Jade Engineering

CY

CMY

K

Adam Jones, Jade Engineering

So says Adam Jones, joint managing director of profile machinery and tooling manufacturer – and now manufacturing process design consultancy - Jade Engineering Ltd.

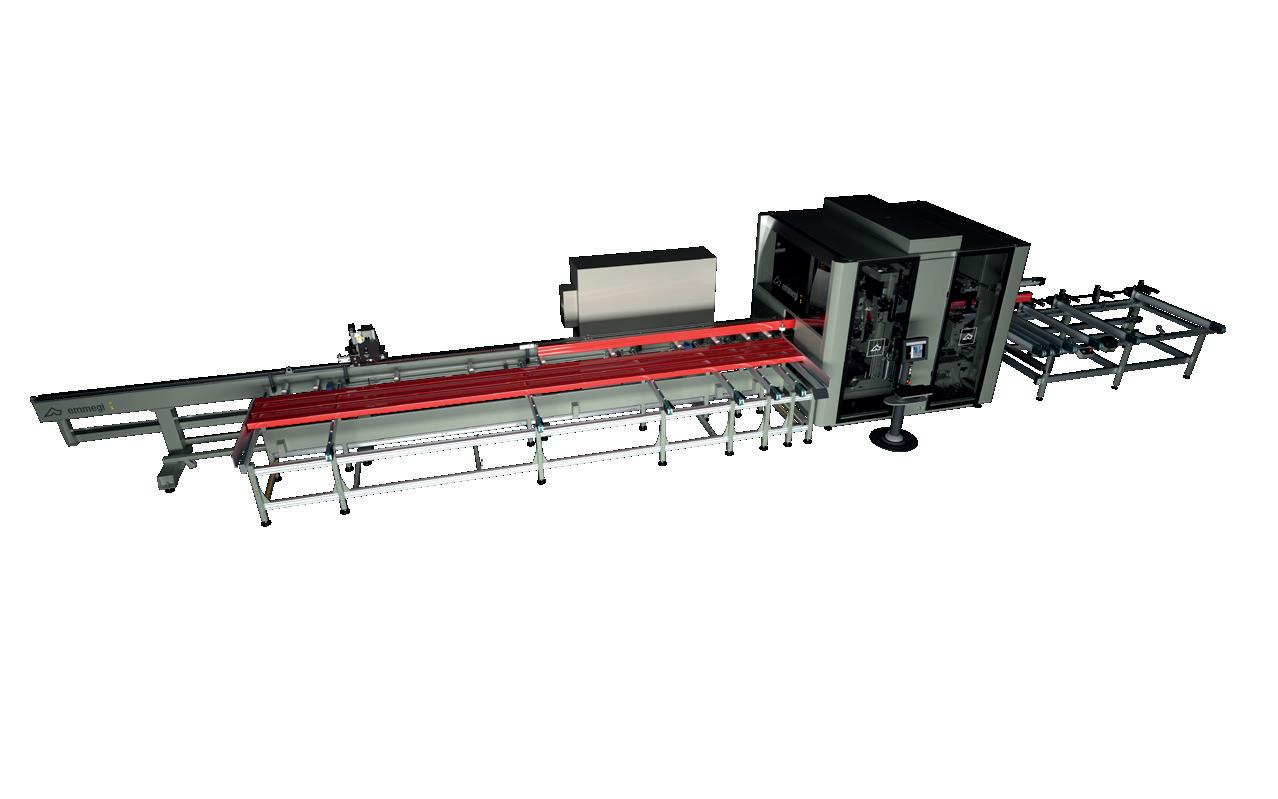

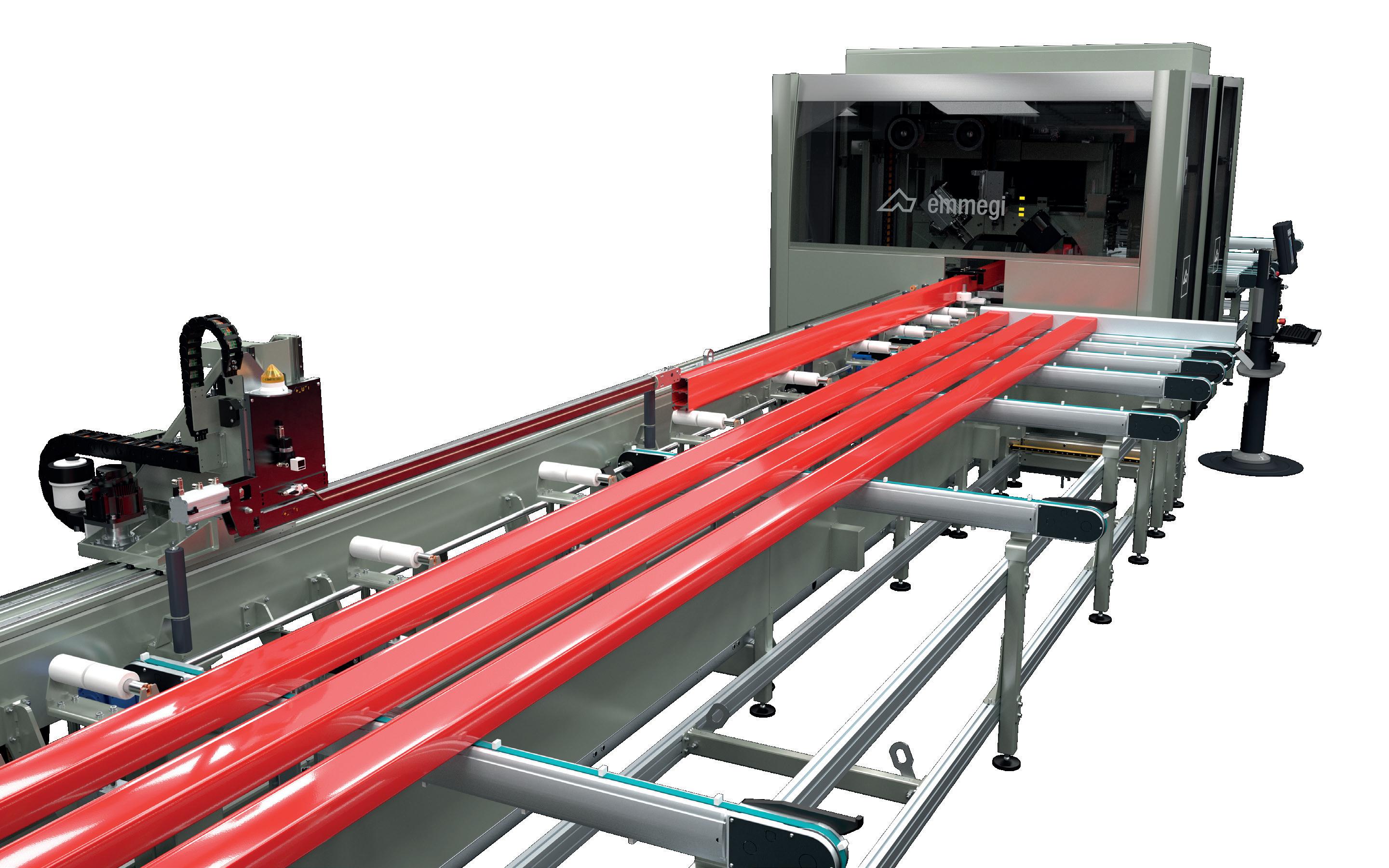

Qualifying his comment Adam says: “You would be surprised how often fabricators decide to invest a large sum of money to step up their output and improve quality - the two main reasons for a company to do so – and then base their decision on parameters that are provided solely by the manufacturer or broad assumptions, rather than independent, expert assessment of their needs. “This is even more surprising when you consider the investment often runs into six figures,” continued Adam. “The point I am making is that whilst CNC machinery has revolutionised frame making over the past twenty years or so, as clever as they are, they are seldom the complete solution.” Which actually works in Jade’s favour, as Adam’s co-director Sean Mackey explains: “CNC machinery works best when producing large volumes of similar specification. And whilst the more sophisticated machines offer greater flexibility, there are many occasions during a shift when specials and one offs are required, but for which it makes no sense to interrupt the flow of the work being processed by the CNC. Which is where our standalone, single function machines come into their own.”

The point made by Adam and Sean is well established by the number of such machines to be found in Britain’s framemaking facilities: hundreds of Jade’s superbly engineered but fundamentally simple machines can be found cheek-by-jowl alongside some of the most sophisticated CNC equipment. But, says Adam, most of these have been supplied over the years following a realisation that the company’s brand new, shiny CNC, does not have all the answers: “We are here to support fabricators – we work with the majority of window and door fabricators through supplying their CNC machines with tooling – and through our experience we would be able to advise on the potential issues that the fabricator will run into ahead of the installation, thus anticipating any issues and preventing interruptions. “Typically, volume manufacturing might be interrupted by remakes, one-off frames and perhaps tidying up a job by hand, which it doesn’t pay to interrupt the flow of the CNC for,” said Adam. “Our specialist machines require minimal set-up and prep, run at the flick of a switch and will mill, cut, weld or clean extremely accurately and quickly. They prevent bottlenecks, carry out repeat tasks quickly and accurately and allow the bigger kit to do what it does best. And they are reliable – we probably shot ourselves in the foot with that,” he joked, “as we have machines out there that are 25 years old or more.” Jade’s engineers have developed and demonstrated such a deep understanding of frame manufacturing that the firm has crystalised its expertise into a third division of the firm, adding to Jade Tools, and Jade Machines. Logically tagged Jade Consult, its projects include the design and implementation of machining processes and equipment for the fabricators of solid roofs for Guardian Warm Roof; similar ‘Swiss-Army knife’ tools for aluminium profiles on behalf of Garnalex; and a full production line for Roseview’s latest iteration of the company’s award-winning Ultimate Rose vertical sliding window. As if to emphasise the point made by Adam and Sean regarding the essential role for standalone machinery even in sophisticated frame making facilities, Roseview’s Olney and Wollaston, Northamptonshire facilities are peppered with Jade end millers and punch tools, located between the CNCs. Jade Consult includes design, development, machinery specification and supply, commissioning and even training: “It’s tremendously satisfying,” said Sean,” because it’s at the heart of what we do as engineers. And why my favourite section on the new Jade website is the ‘Problem? Solved.’ section…because it’s a gallery of what we do best, why so many fabricators who had our machine tools installed by their system supplier when they switched, then become our customers directly. We are proud of that.”

www.jade-eng.co.uk