IMESA The official magazine of the Institute of Municipal Engineering of Southern Africa www. infrastructurenews.co.za INFRASTRUCTURE DEVELOPMENT • SERVICE DELIVERY • ROADS • BUILDING • MAINTENANCE • ENERGY ISSN 0257 1978 Volume 47 No. 01 • January 2022 • R55.00 (incl. VAT) IN THE HOT SEAT Steel pipes: the backbone of any water network Kenny van Rooyen, Managing Director, and Callum Storar, Contract Sales Manager, Hall Longmore INDUSTRY INSIGHT Roads & Bridges Upgrading low-volume routes Water Demand Management & Water Security The two recurring extremes –droughts and floods John

ISSN 0257 1978 Volume 48 No. 02 • March 2023 • R55.00 (incl. VAT) The future of smart water and energy Delving into landfill design and development Waste & Recycling Our longstanding reputation as pump innovation leaders is built on a solid foundation of experience, technology and a passion for developing fit-for-purpose solutions.”

Montgomery GM for APE Pumps and Mather+Platt

For any industrial or municipal entity considering a renewable power-driven water or wastewater treatment approach, the cost of implementation is relative. The primary concern is uninterrupted production, coupled with mediumto longer-term energy savings, says NJ Bouwer, executive at NuWater, which is pioneering the integration of solar as well as hybrid systems to run its customdesigned systems. P6

IN THE HOT SEAT

Optimal fluid transfer is central to all process industries – from water and wastewater to the petrochemical and energy sectors – and pumps are the driving force that makes this possible. IMIESA speaks to John Montgomery, GM for APE Pumps and sister company Mather+Platt, about the group’s innovative approach to ensuring sustained delivery. P12

INDUSTRY INSIGHT

An industry pioneer since 1924, Hall Longmore’s commitment to research and development continues to refine its class leadership in the steel pipe sector.

Kenny van Rooyen, managing director, and Callum Storar, contract sales manager, about the key role of steel in service

INSIDE VOLUME 48 NO. 02 MARCH 2023 MESA IMESA The official magazine of the Institute of Municipal Engineering of Southern Africa www. infrastructurenews.co.za IN THE HOT SEAT Steel pipes: the backbone of any water network Kenny van Rooyen, Managing Director, and Callum Storar, INDUSTRY INSIGHT Roads & Bridges Upgrading low-volume routes Water Demand Management & Water Security The two recurring extremes –droughts and floods John Montgomery GM for APE Pumps and Mather+Platt The future of smart water and energy Delving into landfill design and development Waste & Recycling Our longstanding reputation as pump innovation leaders is built on a solid foundation of experience, technology and a passion for developing fit-for-purpose solutions.” ON

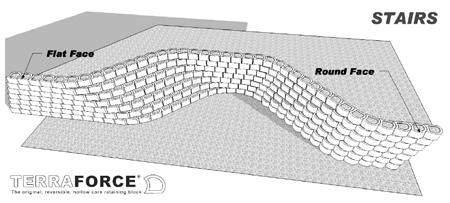

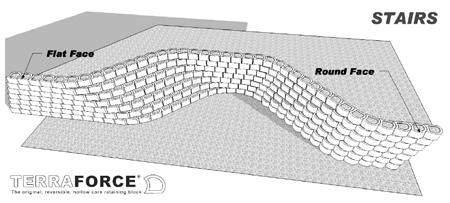

COVER www.infrastructurenews.co.za Regulars Editor’s comment 3 President’s comment 5 Index to advertisers 64 Cover Story The future of smart water and energy 6 Africa Round-up Infrastructure news from around the continent 10 Hot Seat A pump leader for 71 years and counting 12 Industry Insight Steel pipes: the backbone of any water network 14 Economics Infrastructure targets and engagement 19 Water & Wastewater Staying relevant in a changing sector 20 Groundwater Making rural water supply more sustainable 23 Perfecting South Africa’s Water Networks Scientific ways to carry out water master planning and execution 24 Instrumentation All in one, adaptable flow meter 26 World Water Day If the world were 100 people 27 Water Demand Management & Water Security Magnetic water meters save utilities millions 28 How do we fix SA’s critical water challenges? 31 The two recurring extremes –droughts and floods 32 Leading Water Projects Making an impact through water treatment infrastructure 36 57 VEHICLES & EQUIPMENT WASTE & RECYCLING 40 32 Waste & Recycling Kendal’s new ADF design promotes water reuse 39 Growing market for waste challenges 40 So, your municipality needs a new landfill? Delving into development and design 42 Aloes Cell 3B extension incorporates piggyback lining 46 Renewable Energy & Electrification Solar tax rebates a step in the right direction 48 Cape Town’s cash-for-power programme 49 The grid and its digital twin 50 Software designed to facilitate wheeling 51 Concrete Retaining Block Systems The Terraforce Book of Ideas 52 Roads & Bridges Research team develops practice manual for paved low volume roads projects 54 Health & Safety Revised OHS Act requires far stricter compliance 56 Vehicles & Equipment Meeting readymix demand in Bamako 57 A decade of class leadership in trucking 58 Cement & Concrete Concrete technologists vital for preserving SA’s infrastructure 60 Surge in African construction creates niche opportunities 61 The downside to quality shortcuts 63 Waterproofing Sika SA adds Index range to local line-up 64

THE

IMIESA speaks to

delivery. P14

The prosperity of every community depends on high quality water, managed as efficiently as possible. It’s a big responsibility, with some tough challenges. We’ve made it our business to understand the demands.

Sanitaire ICEASTM SBR is a unique solution for biological treatment featuring a continuous flow process from aeration to settling to decanting – all in a single basin. Add to that reliable, high efficiency aeration; robust decanter design; easy single source control and nutrient removal capability. One solution, for clean consistent effluent, with the advantage of reduced capital and running costs as well as simplicity in operation.

xylem.com

MANAGING EDITOR Alastair Currie

SENIOR JOURNALIST Kirsten Kelly

JOURNALIST Nombulelo Manyana

EDITORIAL COORDINATOR Ziyanda Majodina

HEAD OF DESIGN Beren Bauermeister

CHIEF SUB-EDITOR Tristan Snijders

CONTRIBUTORS Chetan Mistry, Sibusiso Mjwara, Dwibin Thomas

PRODUCTION & CLIENT LIAISON MANAGER

Antois-Leigh Nepgen

GROUP SALES MANAGER Chilomia Van Wijk

BOOKKEEPER Tonya Hebenton

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS subs@3smedia.co.za

ADVERTISING SALES

KEY ACCOUNT MANAGER Joanne Lawrie

Tel: +27 (0)11 233 2600 / +27 (0)82 346 5338

Email: joanne.lawrie@3smedia.co.za

Finding the optimum balance to energy and water demand

Water scarcity and adequate supply remain serious concerns, with somewhere between two and three billion citizens globally currently experiencing water shortages, according to the UN World Water Development Report 2023. Unless addressed, the situation will continue to deteriorate, with rising population numbers exacerbating the problem.

PUBLISHER Jacques Breytenbach

3S Media

Production Park, 83 Heidelberg Road, City Deep Johannesburg South, 2136

PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 www.3smedia.co.za

ANNUAL SUBSCRIPTION: R600.00 (INCL VAT)

ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2023. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste Vosloo

Tel: +27 (0)43 705 2433

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Narisha Sogan

Tel: +27 (0)31 266 3263

Email: imesakzn@imesa.org.za

NORTHERN PROVINCES

Secretary: Ollah Mthembu

Tel: +27 (0)82 823 7104

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Olivier

Tel: +27 (0)79 390 7536

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7114

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma Van Der Walt

Tel: +27 (0)83 457 4362

Email: imesafsnc@imesa.org.za

All material herein IMIESA is copyright protected and may not be reproduced without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers.

Novus Holdings is a Level 2 BBBEE Contributor: novus.holdings/sustainability/transformation

Within the South African context, the opportunities to address local challenges are reflected in the SAICE 2022 Infrastructure Report Card. Overall, South Africa scored a C+ (‘Satisfactory for Now’) for the supply of potable water to major urban areas, and a C- for sanitation (including wastewater). More concerning is the D- (‘At Risk of Failure’) for bulk water resources. Going forward, it’s clear that the impacts of climate change will require a major mindset shift away from a conventional reliance on surface water to areas like wastewater reuse and desalination. We also need to urgently stem non-revenue water losses that cost utilities millions in lost revenue and further threaten the country’s water security.

From an infrastructure perspective, South Africa’s Minister of Finance, Enoch Godongwana, stated during his Budget Speech in February 2023 that some R132.5 billion has been allocated for water and sanitation in the 2023/24 and 2025/26 financial years. If well invested in futureproof systems, this will certainly help to alleviate maintenance backlogs, as well as fund5 new developments that support residential and commercial expansion.

Combatting water shedding

Another equally important allocation for 2023/24 to 2025/26 is the approximately R157.8 billion for energy, which is vital for sustaining our power and water security.

Current grid outages disrupt every element of our lives when pump stations, water and wastewater treatment plants experience extended stoppages, and reservoir storage levels drop to critical levels. As South Africa enters the winter period – where demand

can peak at around 33 000 MW (when available) –the challenges for municipalities and water utilities will intensify.

Solar incentives

While renewable energy is vital to combat climate change, it’s now rapidly becoming the ‘go-to’ option for South Africa as an immediate solution to our energy crisis, and the implementation of key national development goals.

Historically, there’s been a steady upward trend for wind, solar PV and CSP generation, collectively, as reflected in the CSIR Energy Centre’s recent statistics. This group’s contribution has risen from some 3 134 MW in 2016 to 6 230 MW in 2022. Last year, that equated to some 16 TWh of energy produced compared to 176.6 TWh for coal.

While the gains have been moderate in the past, it’s certain that the pace of renewable implementation is going to accelerate exponentially. This will be spurred on by a surge in rooftop solar following the announcement of tax incentives for households and businesses.

In parallel, progressive metros are providing their own enabling frameworks. A prime example is the City of Cape Town, where – from June 2023 – businesses, and subsequently residents, with approved generation capacity will be paid NERSA-agreed-on tariffs to feed excess energy back into the municipal grid.

Many innovations are born out of necessity, and renewable energy is one of them. It’s also a trend that will shape the future of infrastructure designs in terms of process optimisation. In this respect, water demand management and energy are joined at the hip.

Alastair

Cover opportunity

IMIESA March 2023 3

EDITOR’S COMMENT To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Joanne Lawrie on +27 (0)82 346 5338. Infrastructure News @infrastructure4 S IMESA infrastructurenews.co.za IN THE HOT SEAT of any water network Kenny van Rooyen,Managing INDUSTRY INSIGHT Roads & Bridges Upgrading low-volume routes Water Demand Management & Water Security The two recurring extremes –droughts and floods John Montgomery GM for APE Pumps and Mather+Platt The future of smart water and energy Delving into landfill design and development Waste & Recycling fit-for-purpose solutions.” The ABC logo is a valued stamp of measurement and trust. IMIESA is ABC audited and certified.

t: +27 (031)266 3263 e: conference@imesa.org.za marketing@imesa.org.za www.imesa.org.za IMESA ORGANISER THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA) CONFERENCE ENDORSED BY CONTACT US FOR DETAILS Earn up to 2.5 CPD points by attending 25-27 October 2023 Save the date 86 TH IMESA Conference BOARDWALK HOTEL Gqeberha (Port Elizabeth)

ACCESS TO WATER AND SANITATION IS A HUMAN RIGHT

Municipalities worldwide are essential enablers of infrastructure that supports socioeconomic development. They implement national policies in sync with their own specific programmes to ensure all stakeholders receive equitable services. Foremost among these is the provision of water and sanitation, which is a priority for national government and falls under the UN’s Sustainable Development Goal 6.

Agreat deal has been achieved in this respect since our democratic transition in 1994, but more needs to be done to bridge the gaps, alongside the need to keep pace with population and urbanisation trends. However, it’s equally important to ensure that rural communities are also serviced to the same standard, particularly those currently residing on land outside the municipal distribution network.

Services on privately owned land

A key development in this respect is the Department of Water and Sanitation’s (DWS’s) initiation of the Draft Water and Sanitation Services Policy on Privately Owned Land. As IMESA’s president, I attended the DWS’s launch of the national public consultation process, held at the Birchwood Hotel in Gauteng on 16 March 2023.

By definition, privately owned land is not controlled, leased or owned by the state. Examples are wide-ranging and include church properties, commercial farms, game parks, mine-owned land, tribal land, trust properties and sectional title developments. Consultations within the provinces began in December 2022 and were completed in February this year. Now it’s the public’s turn to provide their input and to understand the crucial importance of this endeavour.

Water services authorities (WSAs)

As IMESA, we view the draft policy as a highly encouraging development and, as municipal engineers, we will play a key role in its implementation going forward – from both a new build, as well as operations and maintenance perspective. More specifically, though, the responsibility for managing the process rests on the shoulders of the WSAs, which are legally responsible for executing water and sanitation services within their municipal jurisdiction. However, there are various routes to implementation.

As stated by the DWS, “The provision of water services to people living on privately owned land can be done by the municipality directly, or through a water services intermediary as captured and introduced within the Water Services Act (No. 108 of 1997).” A water services intermediary could be the landowner.

An enabling regulatory environment

The primary objective of the draft policy is to establish an enabling regulatory environment, supported by suitable funding and grant mechanisms, in addition to municipal infrastructure development budget provision. That will include provision for indigent communities.

Collaboration between the public and private sector is fundamental to the success of the programme, including the willingness of private landowners to allow municipalities access to evaluate existing on-site water and sanitation facilities. Where groundwater is being abstracted, for example, this would include ad hoc water quality testing. In terms of site access authorisation, this may require the amendment of municipal by-laws.

Either way, it’s a two-way partnership. During the public consultation process, for example, some stakeholders, which included farmers, raised the issue of being excluded from certain services. These include scenarios where a pipeline servitude passes through their land, but with no improved service spin-off for the landowner, or where infrastructure development takes place outside the farm boundary with no downstream benefit. The point raised is that everyone must benefit. At this stage, the DWS says that the full extent of the envisaged infrastructure provision still needs to be determined via a census study, but the extent is certain to be significant.

IMIESA March 2023 5 PRESIDENT’S COMMENT IMESA

Sibusiso Mjwara, PrTechEng, MIMESA, MSAICE, MWISA, MIPET

smart water and energy

For any industrial or municipal entity considering a renewable-power-driven water or wastewater treatment approach, the cost of implementation is relative. The primary concern is uninterrupted production, coupled with medium- to longer-term energy savings, says NJ Bouwer, executive at NuWater, which is pioneering the integration of solar as well as hybrid systems to run its customdesigned systems.

THE FUTURE OF A

technology-driven engineering leader that prides itself on innovation, NuWater designs, builds, finances, operates and maintains water and wastewater treatment plants for the South African and international market, both for public and private clients.

“The emphasis is on achieving optimal efficiencies by selecting the best technology fit for our client’s process requirement, with examples including the treatment of contaminated groundwater, seawater desalination and complex industrial effluent utilising various filtration techniques,” explains Bouwer, adding that key technologies

employed by NuWater include ultra-lowpressure reverse osmosis (RO), nanofiltration, ultraviolet water purification treatment and ultrafiltration.

The starting point, however, is the available power source, which is always top of mind, from both a cost and availability perspective. This is especially the case in South Africa, where daily extended power outages – dubbed ‘load-shedding’ – continue to occur, setting off a chain of negative reactions. In the municipal potable water space, for example, load-shedding impacts the entire network from treatment, pumping, and conveyance to reduced reservoir capacities, often resulting in water shortages, or ‘water-shedding.’

There are various contributing factors that have resulted in this power crisis – a key one being major maintenance backlogs on South Africa’s ageing coal-fired power stations. While these are scheduled to be decommissioned over time as part of South Africa’s Just Energy Transition away from fossil-fuel-derived energy to greener alternatives – like wind, solar and bioenergy – that doesn’t solve the immediate power gap.

Intelligent plants that are energy efficient

“Clearly, renewable energy is an environmental imperative, plus it makes economic sense; however, in our case, it’s now an immediate

COVER

STORY

A NuWater solar-powered water treatment package plant installed for a remote operation

6 IMIESA March 2023

NJ Bouwer, executive at NuWater

socio-economic imperative as South Africa faces a potential collapse of its conventional coal-fired grid. This is having a catalytic effect, significantly accelerating the desire to adopt renewables as a power risk mitigation measure. This is spurring huge demand for NuWater’s high-efficiency, intelligent-energypowered plant solutions,” Bouwer continues.

Another driving factor is the historically high cost of energy in South Africa with Eskom, the country’s national power utility, recently announcing further major tariff hikes for 2023. This is another pressing motivation to find offgrid alternatives.

Depending on the scale and feedwater qualities, water and wastewater treatment can be somewhat energy intensive if the correct pairing of technologies is not selected. For desalination, for example, the cost of running purely on grid power can be 60-70% of the plant’s overall operational expenditure. “That’s a big incentive for considering a switch to ‘free’ off-grid renewable energy or looking at a hybrid system. The latter might combine conventional power, renewables and backups like diesel or gas turbine gensets. It all depends on the baseload requirements,” says Bouwer.

A question of solar space

If space limitations are not an issue, then huge solar arrays can be established. Classic examples can be found in the Middle East, where extensive solar fields power the world’s largest desalination plants, supporting the development of flourishing metropolises by harnessing two natural resources – sunlight and seawater. Other key ingredients are enabling government policies, and the right geographic location.

To date, NuWater has installed and commissioned solar-powered package plants in South Africa and Africa. These have typically been in the range of 50 000-150 000 ℓ/day, operating at a power consumption of 0.2-1.2 KWh/m3. The amount of energy required depends on the degree of water or wastewater contamination.

Among the cases in point are four standalone solar-powered water purification plants that NuWater has designed, installed and commissioned in Pemba, Mozambique, to serve remote rural villages. The treatment

strategy here is particularly intensive, entailing the removal of silica, organics and high levels of salinity from in-situ groundwater to produce clean, safe potable water.

Filling infrastructure gaps

For communities in need, NuWater’s solarpowered modular plants are certainly a game changer and could help bridge the divide for a wide range of stakeholders affected by loadshedding, inadequate or no existing services.

“Let’s take the example of a rural school accommodating 1 000 learners, with each pupil requiring around 5 ℓ/day. By installing a solar-powered package plant, and dependent on the feedwater source, you’d only need around 0.5 kWh/m3 to treat some 5 000 ℓ/day of potable water. To achieve this, the plant would need up to eight 400 W solar panels,” Bouwer explains.

Industrial scalability

Another parallel development is the growth

IMIESA March 2023 7 COVER STORY

For communities in need, NuWater’s solar-powered modular plants are certainly a game changer and could help bridge the divide for a wide range of stakeholders…”

An internal view of the inverter and battery storage setup housed within a mobile container forming part of a NuWater treatment plant powered by renewable energy

in demand from industrial clients, some of whom are installing their own large-scale rooftop and allied solar power generation systems to run critical processes off the grid.

In a recent example, NuWater has secured a contract to treat some 500 000 ℓ/day of water, sourced from an on-site borehole, for an FMCG manufacturer. In this instance, NuWater also treats the downstream industrial effluent.

“Advancements in battery technology will continue to extend the boundaries of energy storage capabilities, which includes industry research and development on electrolyte batteries. The cost of solar panels, battery storage and inverters also keeps falling, making it more and more attractive to go the selfgeneration route. There are also opportunities to

dovetail systems with other options like wasteto-energy,” says Bouwer.

Tailored process solutions for municipalities

Within its broad portfolio of solutions, NuWater is currently providing specialist services for municipalities across South Africa. Examples include eMalahleni Local Municipality (Witbank) in Mpumalanga, George Municipality in the Western Cape, and Ndlambe Municipality (Port Alfred) in the Eastern Cape.

In the case of eMalahleni, the municipality’s existing water treatment works was not set up to remove mining-related contaminants. In response, NuWater has installed a modular plant on-site to meet this specific process requirement.

Meanwhile in George, the municipality has taken its main system offline in order to maintain and upgrade the existing treatment works. During this period, NuWater’s plants are responsible for augmenting the town’s potable water supply.

Port Alfred

NuWater’s scope of works in Port Alfred is complex and underscores its turnkey capabilities. This seaside tourism destination has been subjected to crippling droughts in recent years. The only viable option was desalination.

“We’ve installed what we believe are the highest efficiency RO systems that are commercially available and affordable to endusers,” says Bouwer.

NuWater’s solution incorporates specialised booster sets incorporating energy recovery systems. Low-energy membranes further reduce power demand. “The plant’s setup has also been purpose-designed so it is ultraefficient on the cleaning cycle, ensuring that energy consumption is as low as possible,” Bouwer continues.

For Port Alfred, solar power was ruled out as an option due to the location of NuWater’s plants in shady ravines where the available sunlight was considered insufficient for the plant’s baseload requirements.

Some renewable possibilities

For mining, industrial and municipal clients, there are ‘out of the box’ water treatment options to consider if South Africa enters Stage 8 in the winter months. Stage 8 or removing 8 000 MW from the grid would result in some 12 hours of load-shedding in a 24-hour period, especially devastating for end-users.

One scenario would be to use solar power (at scale and space permitting) combined with battery storage to process the bulk of the daily potable water requirement within a 10- to 12-hour window and then store it for 24-hour use in reservoirs or tanks. The only power then needed during load-shedding, or at night, would be booster pumps for water distribution, which could be run via gensets or batteries.

“For municipalities, the massive volumes of water that would need to be stored and then pumped at a steady rate could prove to be challenging, but the concept is workable in theory,” adds Bouwer.

“One thing is certain. Climate change threats, spiralling conventional power costs, and loadshedding all make renewable energy very attractive. It’s a win-win for the environment, and vital for our future water security,” Bouwer concludes.

8 IMIESA March 2023

COVER STORY

www.nuwater.com

Assembly in progress on an RO package plant at NuWater’s facility in Cape Town

An artist’s impression of a NuWater solar-powered treatment plant concept

An aerial view of NuWater’s package plant solution for eMalahleni Local Municipality

+ CONSERVE

Micropilot FMR20: Level radar with the process indicator RIA15 simplifies remote commissioning

Promag W 400: Versatile, weight-optimized electromagnetic flowmeter fits perfectly all standard applications.

Memograph M RSG45: Advanced data manager takes compliant, safe and secure operations control to a higher level.

You meet your e�ciency goals and reduce costs without compromising on water quality.

understand the challenge

finding the right

e�ciency and compliance

standards

Contact us to find out more Email: info.za.sc@endress.com Tel: +27 11 262 8000 Web: www.endress.com Improve your processes with our comprehensive portfolio of measuring instruments:

OBSERVE

We

of

balance between plant

with industry

and legal requirements.

and operations.

SENEGAL

Malicounda power project now fully operational

Located in Mbour, 85 km south of Senegal’s capital Dakar, the plant is anticipated to deliver 956 GWh of power per year, which represents a 17% increase in the country’s power generation capacity.

Wärtsilä delivered the 130 MW Flexicycle power generation technology. The Malicounda power plant comprises seven 18V50 engines and a steam turbine, combining the advantages of a simple-cycle operation with the high efficiency of a combined cycle plant. Its fast load-following power capability means that the plant is ideally suited to maintain system reliability, and able to offer the flexibility needed as intermittent renewable energy is progressively added to Senegal’s

power grid. The plant will initially operate on heavy fuel oil; however, there is an option to convert the plant to run on locally supplied gas from the GTA field once it becomes available, further lowering the cost of energy.

The Malicounda power plant is a central part of the government’s Plan Sénégal Emergent to strengthen the country’s emerging economy and provide electricity access to everyone by 2025. It was one of the first public-private partnership (PPP) projects in West Africa, involving the African Development Bank, Africa50, the Infrastructure Development Fund for Africa and Senelec (Senegal’s state power utility), setting a model of cooperation to meet the continent’s growing energy needs.

Matelec (the plant EPC contractor) will operate the plant and Wärtsilä has a 10-year maintenance agreement.

MOZAMBIQUE

Mega dam may displace thousands

An estimated 1 400 families could be displaced by the Mphanda Nkuwa hydropower project due to be built across the Zambezi River in what would be Southern Africa’s largest dam. Another 200 000 people could be affected downstream.

The government of Mozambique has touted the 1.5 GW Mphanda Nkuwa Dam, in the district of Marara, Tete province, as key for the Southern African nation to address energy poverty and reach its goal of universal energy access by 2030.

Both the World Bank, through its private investment arm – the

International Finance Corporation – and the African Development Bank are supporting the project and pushing for the dam’s construction.

At the end of 2022, Mozambique became Africa’s newest gas exporter despite 72% of its population having no electricity access. The Mphanda Nkuwa Dam is the country’s largest venture into renewable energy and is designed to supply power domestically.

The dam will be built in the lower part of the Zambezi River basin, around 60 km downstream from the existent giant hydropower plant at Cahora Bassa. Under current plans, the project is expected to reach financial close in 2024, with commissioning to start in 2031.

INFRASTRUCTURE NEWS FROM AROUND

THE CONTINENT

10 IMIESA March 2023

NAMIBIA Rural water development programme a

success

Under the programme, 20 short pipelines with maximum length of 20 km were constructed in several regions across the country. Programme highlights included:

• 141 boreholes were drilled.

• 2 877 private off-takers were connected to pipeline water supply.

• 53 boreholes/water points were installed.

• 3 575 existing water-supply infrastructures were repaired and maintained.

• 91 water-point associations were established.

Furthermore, 625 communities were supported with emergency water tanker services, while 114 existing water-point infrastructure sites were rehabilitated, and 57 boreholes were cleaned and tested. Additionally, the Ondangwa-Omuntele water supply pipeline scheme in the Oshikoto Region was recently completed.

The Ministry of Agriculture, Water and Forestry, with funding from Disaster Risk Management, is currently extending the scheme due to the complexity of water-supply needs in rural areas. The contractor is currently connecting additional manifolds and water meters on the pipeline to provide water to newly identified beneficiaries. A pipeline network will be constructed to provide water to the communities in the Onamatanga area. An engineering consultant has been appointed and is currently developing the preliminary designs.

ZAMBIA Solar to combat power outages

The Riverside Solar Plant in Kitwe is a project of the Copperbelt Energy Corporation. The solar plant covers over 30 hectares, is split into two and comprises 61 300 solar panels, 150 inverters, six transformer stations and 4 km of transmission lines. With an annual yield averaging 54.9 GWh, the plant will save 51 kt of carbon. At this capacity, the Riverside Solar Plant can supply 10 000 houses.

GHANA

Plans for US$700 million gas processing plant

The Ghana National Gas Company (GNGC) and its joint venture partners have signed a project implementation agreement for a second gas processing plant (GPP).

The plant will be referred to as Train Two of the GPP (or GPP Train 2) and will have an initial capacity of 150 million standard cubic feet per day (MMscfd), expandable to 300 MMscfd.

Located at Atuabo in the Ellembele District of the Western Region, the plant will provide optimal capacity for Ghana Gas to process natural gas volumes in increments from the Greater Jubilee and Tweneboa, Enyera, and Ntomme fields. It will be capable of processing natural gas liquids (NGLs) into their pure propane, butane and pentane components, which will then be stabilised into condensate components. The lean methane- and ethane-containing gas will be tied into the lean gas exported from the existing GPP Train 1 and sent to an onshore export pipeline. The purified butane and propane will then be stored in their respective storage tanks.

The plant will also have a storage facility, an additional compressor package at the Atuabo Mainline Compressor station, utilities and a liquid waste treatment system. It will contribute considerably to Ghana’s gas production, help its industrialisation and meet its energy needs by preventing power outages. Its construction will help create 1 000 jobs. About 90% of the gas will be used in fertiliser production and the iron and steel processing industries. The plant will also help to improve the liquid output processed from natural gas to 80%, compared to the existing 40-50%.

IMIESA March 2023 11 COVER STORY TRENCHLESS TECHNOLOGY | SEWER REHABILITATION

A pump leader for 71 YEARS and counting

Foremost, we’re an OEM. In addition to this, we are a Grade 8 contractor in terms of the Construction Industry Development Board rating system, providing turnkey civil, electrical and mechanical engineering services for clients in South Africa and Africa. A prime example in terms of the latter are the systems upgrades we’ve completed for Malawi’s Blantyre Water Board over the years.

Why is operations and maintenance (O&M)

becoming a growing trend?

There are various factors, but a key one is the cost optimisation benefits of outsourcing specialist skills to technology leaders that have decades of applied experience. OEMs are best equipped to enter into service level agreements (SLAs) – essentially O&M contracts – on their own systems.

What defines the group’s excellence as an OEM in pump design, fabrication and execution?

JM The starting point is our rich history. Mather+Platt traces its roots back to the late 19th century as a pump manufacturer that evolved with the First Industrial Revolution in England. Since then, Mather+Platt has been a forerunner in pump system product development. The same is true for APE Pumps, founded in 1952. Both companies have led the market in terms of ongoing research and development for niche single- and multistage pump applications. Subsequently, we now also form part of multinational leader WPIL Limited.

Seven decades in business is an exceptional track record. How has this been maintained and achieved?

Institutional knowledge is key. Every design drawing we’ve ever produced is on file so, irrespective of the date of manufacture, the group can either recondition or replace an APE or Mather+Platt pump from scratch. Plus, we have the in-house skills to execute this on a turnkey basis, with all materials sourced in South Africa.

We invest in our people, with a major emphasis on keeping them up to date with the latest technologies, and our personnel are proud to work for APE Pumps and Mather+Platt. A high percentage have long service with the group, which reinforces our commitment to long-term customer relationships.

Succession planning is another key focus, and we continue to recruit young qualified technical personnel at all levels to meet current and future requirements. This includes mechanical engineers, artisans and apprentices for specific trades that include fitters and turners, and patternmaking.

How would you define the group’s business model?

For industrial clients, as well as municipalities and water utilities, the advantage is that these O&M contracts are entered into on a fixed-cost basis, plus it’s an off-balance-sheet solution for the client. Our pumps are maintained optimally during the warranty period for new installations, and for their indefinite life thereafter. We conduct regular performance tests to ensure that all our pumps run 100% to specification. Currently, we have SLAs in place with leading public and private sector clients. As part of our commitment to excellence, we also provide training for our clients’ in-house technical teams.

How are O&M and asset management interlinked?

Every asset must be designed with a clear indication of its projected life-cycle costing and lifespan. That’s a primary concern for any asset owner because they need to budget for predictive and preventative maintenance. Asset investments should never be allowed to run to destruction due to a lack of maintenance planning.

Like any mechanically functioning system, best-in-class products need world-class service. They also require expert installation and optimisation.

Physical inspections are part of our SLA but –thanks to the latest developments in telemetry,

12 IMIESA March 2023 HOT SEAT

Optimal fluid transfer is central to all process industries –from water and wastewater to the petrochemical and energy sectors – and pumps are the driving force that makes this possible. IMIESA speaks to John Montgomery, GM for APE Pumps and sister company Mather+Platt, about the group’s innovative approach to ensuring sustained delivery.

John Montgomery, GM, APE Pumps and Mather+Platt

coupled with the group’s purpose-designed apps – all our pumps can be condition-monitored remotely 24 hours a day. Process elements monitored include flow rate at a given head, bearing temperatures and pump vibration. In the unlikely event of an unscheduled incident, the pump can be set up to shut down automatically or via remote intervention, with a maintenance team sent to site.

We now also employ digital twinning during installation, where we can verify the virtual model of the final design against the physical system recorded via lidar scans. This allows us to cross-check, match and verify all elements during commissioning.

What’s the criteria for an SLA?

SLAs can be concluded for brand-new group installations, as well as on our older systems installed years ago. In terms of the latter, we guarantee to restore these pumps – irrespective of their current condition – to OEM specification at a saving of around 60% of the value of a new pump. We then maintain them from there on. Upgrades, like variable-speed drives, also significantly improve energy efficiency.

A relatively small investment in an SLA definitely pays for itself by ensuring uninterrupted production, which is especially critical for water or wastewater utilities, or a power station. It’s all about having right the team onboard.

How does your pump service exchange work?

We have an extensive inventory of new and reconditioned pumps on hand. This enables us to swop out a client’s pump when it needs an overhaul and replace it with a new one during a

scheduled changeout operation. That provides major peace of mind for the client. We have also extended our facility in Germiston to house a full range of pump spares as backup for our extensive pump population and SLA clients in South Africa and Africa.

Is the group investing in new fabrication machinery?

Absolutely. New capex investments include an 8 m lathe with a 1.4 m swing. We now also have what we believe is the second largest key cutter in South Africa, as well as a new CNC horizontal boring machine, plus we’re investigating the acquisition of 3D scanners to further enhance our existing quality control systems.

We’re set up to do everything in-house. This extends from the design phase to the patterns, fabrication, machining, assembly, installation, alignment and commissioning.

What are some of the group’s recent and current projects?

We supply solutions for most of South Africa’s water and wastewater utilities on an ongoing basis, in addition to energy sector clients, plus industrial end-users.

A recent project example is a solution we provided for Transnet at Robinson Dry Dock in the Port of Cape Town. The dry dock has undergone an extensive refurbishment.

Our scope as an OEM was to supply replacement pumps, which have now been installed and commissioned. These successfully met the specification, as well as passing all the client’s tests on this critical facility, which is employed to refurbish local and international vessels.

Significantly, the new pumps were replacements for existing APE and Mather+Platt pumps that have been running at the dry dock for the past 60 years. As an interesting aside, most of the other dry docks in South Africa also run on our pump sets.

A current project is for Umgeni Water’s Hazelmere pump station, which supplies water to reservoirs in La Mercy and Verulam in eThekwini. Umgeni is currently upgrading the pipeline network capacity to meet future demand. To ensure optimum performance, our scope entails the installation of six APE pumps in total, all made in South Africa, which replace those installed previously by a French OEM.

And in closing?

Our longstanding reputation as pump innovation leaders is built on a solid foundation of experience, technology and a passion for developing fit-for-purpose solutions. Irrespective of the age of the thousands of APE Pumps and Mather+Platt pumps out there since 1952, we can restore them to pristine condition and keep them working optimally.

IMIESA March 2023 13 HOT SEAT

www.matherandplatt.com

www.apepumps.co.za

Steel pipes: THE BACKBONE OF ANY WATER NETWORK

An industry pioneer since 1924, Hall Longmore’s commitment to research and development continues to refine its class leadership in the steel pipe sector. IMIESA speaks to Kenny van Rooyen, managing director, and Callum Storar, contract sales manager, about the key role of steel in service delivery.

Worldwide, steel remains the mainstream choice for bulk water conveyance, just as it did some 150 years ago, which underscores the performance benefits of this material to handle sustained high pressure rating requirements and variables like hydraulic shocks.

The introduction of advanced welding techniques in the 1920s presented a major breakthrough for steel pipeline integrity, further entrenching their place as the standard for water boards globally. Over time, the coating systems employed to combat corrosion and extend their lifespan have also improved significantly.

The general benchmark in the modern-day steel pipe manufacturing sector is to provide a 40- to 50-year design life once installed and subject to the fluids being transferred, such as water, wastewater, oil or gas. However, in Hall Longmore’s case, a number of their systems in the bulk water and mining sector have lasted for close to 100 years. Examples can still be seen in operation on some West Rand mines in Johannesburg.

Vital catalysts

“Pipelines are often the unsung heroes in the infrastructure supply chain. However, they are essential catalysts for socio-economic growth, and the foundation for all current and future town and city master plans in terms of projected water demand – and we’re proud of our role as a manufacturer in engineering enduring infrastructure solutions,” says Van Rooyen.

“Steel pipes are futureproof, locally sourced and cost competitive. Plus, they also help to minimise non-revenue technical water losses

14 IMIESA March 2023 INDUSTRY INSIGHT

Kenny van Rooyen, managing director, Hall Longmore

Callum Storar, contract sales manager, Hall Longmore

due to their robust composition. They are also climate-change resilient in the sense that steel pipes tend to withstand extreme weather, as was the case during the severe floods that hit Durban and surrounds in 2022. Once commissioned, it’s virtually impossible to pull steel pipe sections that have been welded together apart,” Van Rooyen continues.

“From our perspective, steel is the answer. However, to make a sound business case, it’s important for municipal and water engineers to clearly understand the place and the designed performance characteristics for all alternative pipe materials available on the market, whether it’s GRP, plastic or concrete. Asset owners need to factor in the life-cycle cost and obtain the best possible return on investment for any product, technology or system employed. New contractors entering the market also need to be well informed.”

Examples of areas where steel pipe tends to outperform other materials include their ability to cope well with live and dead loads when installed under roads, in dolomitic conditions where subsidence is a risk factor, and in hilly terrain where there’s a greater risk of water hammer.

Widest possible choice

Meeting the requirements of the bulk supply reticulation market, Hall Longmore manufactures medium-pressure pipes designed to operate within the 16 to 40 bar range, which makes them highly scalable in terms of current and future water demand coupled with network upgrades.

“What makes Hall Longmore unique in South Africa is that we produce pipe sections in the broadest possible spectrum in terms of diameters and wall thickness options,” explains Storar.

Manufacturing falls into two key categories, namely electric resistance welded (ERW) steel pipe and helical (commonly, but incorrectly, referred to as spiral) welded steel pipe, using the submerged arc-welding process (SAW). Hall Longmore’s standard OD range for ERW is from 219 mm (8”) to 610 mm (24”) and for SAW from 508 mm (20”) to 2 540 mm (100”). However, the nature of the helical process allows for bespoke diameters compatible to clients’ existing infrastructure.

“This manufacturing flexibility enables us to supply a complete town or city network, from

the initial bulk infrastructure to the progressive phasing in of the distribution infrastructure to meet ongoing residential and industrial expansion,” says Storar.

Outside the water market, Hall Longmore manufactures what are referred to as ‘oil country tubular goods’ (OCTG) pipes for the local and global petroleum and gas market. OCTG pipes must meet, and in some cases exceed, the requirements of the American Petroleum Institute (API) standards, considered among the strictest in the world for any sector. For these installations, there’s zero margin tolerated for ruptures, leakages or environmental disasters. “Clearly, this means that Hall Longmore’s quality control (QC) has to be world-class,” says Storar.

To further refine its QC processes, Hall Longmore recently invested in the latest automated radiographic testing (RT) technology. As per international standards, steel pipe manufacturers are mandated to employ RT technology for non-destructive testing on submerged arc welds.

The key difference now is that Hall Longmore has switched from analogue to digital X-ray techniques, which are far more precise.

Coatings

Selecting the right pipe diameter and wall thickness is essential for optimum network

performance, as is the selection of the right corrosion protection method. Cathodic protection (CP) is common and it’s recommended that any proposed new installation be reviewed by a CP specialist

As Storar points out, the internal and/or external coating system specified should always be determined following a detailed investigation by the client of the in-situ conditions. Factors to consider include the resistivity of the soil, as well as overhead powerlines and railway lines that emit AC or DC currents that may need to be countered cathodically.

“Hall Longmore is an industry leader in the technology and application of protective coatings and linings to steel pipes,” Storar explains, adding that the applications are tailored to suit the needs of specialist corrosion engineers.

Hall Longmore has the widest range of accepted pipeline coating and lining systems in the South African context. These include polymer-modified bitumen (PMB), fusion-bonded medium-density polyethylene (MDPE), three-layer polyethylene (3LPE) and rigid polyethylene (RPu) for exterior protection to underground pipelines subjected to highly corrosive conditions, and various liquid epoxy as well as cement mortar/concrete internally linings. The latter is a preferred

IMIESA March 2023 15 INDUSTRY INSIGHT

Traditionally, welded joints have dominated, but there’s a definite shift in the market to rubber ring joint applications.”

A section of Hall Longmore’s production facility in Wadeville, Gauteng

Hall Longmore supplies a range of external and internal coating systems to match each site installation requirement

Hall Longmore’s RRJ system has been well accepted by the market, as there’s far less, if any, site welding required

lining medium for smaller-diameter (less than 610 mm) potable water services due to its ability to be reinstated at the joints without man access.

Couplings

The Achilles heel for every pipeline – irrespective of the material composition, whether it be GRP, HDPE, steel or one of the other recognised pipe materials – is its joints, since they determine overall system integrity.

Within the steel pipe sector, there are numerous options available. Examples include welded, flanged, flexible couplings, bell and spigot (a secondary welded option) and rubber ring joint (RRJ) joints.

Hall Longmore’s RRJ system has been well accepted by the market as there’s far less, if any, site welding required. As a further plus, Hall Longmore provides training for contractors in the correct RRJ installation methodology.

“Traditionally, welded joints have dominated, but there’s a definite shift in the market to RRJ applications. One of the reasons for this is the steady decline of specialist welding skills in the construction sector. Time and cost are other key

factors, since RRJ couplings promote faster connection speeds without compromising the performance of the pipeline in any way on quality,” Storar continues.

The RRJ, in combination with a fit-for-purpose UV-resistant coating, is designed to perform for some 100 years underground and 50 years above ground. The RRJ system is suitable for steel pipes ranging from 300 mm up to 1 500 mm internal diameter.

Sewer systems

While steel pipes dominate in the water sector, they are not the main option for wastewater. One of the chief reasons is that sewer lines are predominantly gravity fed, negating the need for a pressure requirement to facilitate fluid transfer.

However, Hall Longmore does fabricate and supply niche solutions in wastewater, with

examples including rising mains and pipe bridges. Since sewers are among the most corrosive environments, these pipe systems need to be internally lined with calcium aluminate cement (CAC), which tends to be costly but highly effective. Other alternatives for general industrial effluence include bitumastic polyphenolic epoxies.

Meeting SA’s development goals

“It’s never a ‘one size fits all’ approach, since there are many variables to consider for each pipeline project. However, there’s a good reason why steel pipes are the benchmark for water utilities globally. And when it comes to service delivery, many South African communities trust steel because of its legendary durability to sustain infrastructure, with the demand for new pipe networks growing every year,” adds Van Rooyen.

“We’re standing by to deliver and are highly encouraged by the news that the South African government has allocated some R132.5 billion for water and sanitation in the 2023/24 and 2025/26 financial years. That’s a substantial investment, which will go a long way towards meeting the country’s commitment to providing safe drinking water and dignified sanitation for all,” Van Rooyen concludes.

www.hall-longmore.co.za

INDUSTRY INSIGHT

16 IMIESA March 2023

Fabrication of a helical welded steel pipe, using the submerged arc-welding process

THE ULTIMATE Borehole Pump Controller

An all-in-one solution that caters for all aspects of legislation, operation, control and monitoring.

Can be retro tted to existing boreholes or easily installed as an on going concern o ering full scope of package to new installations.

CONTROL ASPECTS

Using variable speed drive technology, we are able to start the pump to the minimum speed as required, modulate the speed of the pump around a number of control conditions such as level in a tank or reservoir, pressure control and/ or ow control or constant level control of the ground water level.

MONITORING ASPECTS

By monitoring borehole water level, pump discharge pressure, ow and anti-tamper -all available for remote viewing, this solution provides advanced monitoring tools for management, control and condition monitoring.

LOGGING ASPECTS

All data is collected and stored securely in JOAT’s Hydralytix monitoring platform, to be used for condition monitoring and trend analysis, along with compliance and audit reporting.

For more information, contact: Tel: +27 (31) 700 1177 www.joat.co.za

Proudly EOH

BIENNIAL PROJECT EXCELLENCE AWARDS CALL FOR ENTRIES

To recognise outstanding achievements in municipal infrastructure, we are calling for entries that showcase projects that demonstrate the best of civil engineering as a science and how engineering enhances the lives of the local communities, through excellence in:

Planning and design

Construction methods

Innovation and originality

Meeting social and technical challenges

Contributing to the well-being of communities

CATEGORIES

1 2

ENGINEERING EXCELLENCE IN STRUCTURES & CIVILS

E.g. Projects demonstrating engineering science, use of alternate materials, innovative construction processes, etc.

COMMUNITY UPLIFTMENT & JOB CREATION

E.g. Projects demonstrating labour-intensive construction, skills development, community awareness/participation, etc.

3

ENVIRONMENT & CLIMATE CHANGE

E.g. Environmental rehabilitation, renewable energy, drought solutions, coastal initiatives for rising sea levels, pollution control, educational/ technical initiatives, etc.

CLOSING DATE FOR SUBMISSIONS

03 July 2023

Only projects that have reached practical or substantive completion by 30 June 2023 will be accepted for the Excellence Awards. Adjudicators reserve the right to reallocate entries in the 3 categories.

ENTRY FORMS AND AWARD CRITERIA

Available for download on the website: www.imesa.org.za

THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA)

QUESTIONS

Contact Debbie Anderson on +27 (0)31 266 3263 or email conference@imesa.org.za

IMESA

INFRASTRUCTURE targets and engagement

At this year’s AfriSam Budget Breakdown event, Dr Azar Jammine, economist at Econometrix, highlighted key trends, stating that the R903 billion in public sector infrastructure expenditure earmarked for the 2023/24 to 2025/26 financial years is encouraging.

These numbers are so big that if we were to see their full implementation, it would be a game changer not only for the construction sector, but for the entire economy,” said Jammine. “Where the real hope lies is in government getting its act together and starting to implement its capital projects.”

He noted the importance of how Minister of Finance Enoch Godongwana dealt with plans to restructure Eskom’s capital debt, as any worsening of the energy crisis could undermine the economic predictions in the 2023 Budget Speech. If load-shedding is exacerbated, Jammine said the country may not even reach its meagre 0.9% growth target for the year. In such a scenario, government’s own spending plans would be further dampened by lower tax revenues.

The question Jammine posed is whether there is the political will within the governing party to allow Eskom’s debt restructuring to take place. Such a move is inevitable, however, as he foresees a complete realignment of politics in the general elections of 2024.

Stimulating employment

Focusing on the construction industry, Jammine once again painted a sobering picture, but highlighted the sector’s potential to deliver economic

benefits. Currently, construction provides some 7.8% of the country’s employment, even though it makes up just 2.6% of GDP.

“Implementing government’s infrastructure projects would spark massive job creation, and the economy could grow by 5-6% a year,” Jammine explained.

Commenting on Jammine’s presentation, Richard Tomes, sales and marketing executive at AfriSam, said “Although the operating environment remains challenging, one of the positive elements AfriSam has noted is the increase in the infrastructure spend budget allocation, and we remain hopeful that the implementation of the infrastructure projects will gain momentum and start delivering true value for the construction industry.”

Trading trends

Industry data shows that considerable overcapacity is still evident in the nonresidential building sector, especially commercial office and retail space. This is subduing demand for new developments, with the

total value of non-residential building plans passed in 2022 hovering around the R1 billion mark, compared to R3 billion in 2016. The brief recovery in the residential building sector – as homeowners renovated for home offices – has also tailed off. Additionally, cement demand suffered negative growth in 2022 and is expected to improve only marginally over the next few years.

Rallying the sector

“With many of us operating in the same industry, material matters such as the external environment we operate within not only relates to AfriSam, but also to our stakeholders’ businesses,” added Tomes, explaining the rationale for the annual AfriSam Budget Breakdown event.

“We hope that the information being shared will not only provide them with insight about some of the decisions that AfriSam takes, but will also provide them with valuable insights to enable decision-making in their own businesses or organisations to ensure their future success and sustainability,” Tomes concluded.

IMIESA March 2023 19 ECONOMICS

Dr Azar Jammine of Econometrix presenting at AfriSam's Budget Breakdown event in February 2023

Jammine’s full presentation can be downloaded at www.afrisam.co.za/ budget-breakdown-2023.

Richard Tomes, sales and marketing executive at AfriSam

Naidu Consulting has grown exponentially – with water and sanitation projects having played a fundamental role. The consulting engineering firm has a vision of becoming a leading service provider of quality, economic and innovative engineering solutions.

Diversification in an evolving sector

The chairman of Naidu Consulting – Selvan Naidu – spearheaded the formation of the Water & Sanitation Division through the designs and implementation of various projects within eThekwini Municipality, which included multiple reservoirs, reticulation systems and bulk water supply systems. Among the largest projects undertaken by the Division were the Western and Northern

Aqueducts in eThekwini Municipality. These projects sparked the growth of Naidu Consulting’s Water & Sanitation Division, which boasts a diverse range of skills,” explains Terence Thumbaya, Head of Division, Water and Sanitation,

Diversification of skill sets

Thumbaya adds that the Division’s focus is to ensure it provides innovative and

sustainable solutions throughout the project life cycle. This is done with highly skilled and experienced professionals who provide a consistent level of the highest-quality service and unique personal attention to its clients. The combined expertise and knowledge in the Water & Sanitation Division allows Naidu Consulting to cover a spectrum of services within the various disciplines.

Ashveer Goorun, Sector Manager: Water & Sanitation Division, notes that, in South Africa, there has been an emerging emphasis on water-loss management and water conservation. “Our skill set around pressure management and non-revenue water has evolved through the implementation of successful non-revenue water contracts.”

Goorun adds that Naidu Consulting also has an in-house, registered, Approved Professional Person who specialises in hydrological studies and dam designs up to Category II dams. He explains that water security is a key priority among many of Naidu Consulting’s clients and ageing infrastructure poses a threat to the sustainability of water supply systems. “As a result, Naidu Consulting has reinforced itself as a company that can provide value-added services in asset management, non-revenue water and water conservation.”

Due to climate change and global warming, stormwater management must be

WATER & WASTEWATER

20 IMIESA March 2023

When increasing the storage at the Shongweni Reservoir, Naidu Consulting together with the contractor, sponsored the local soccer team with new soccer gear, which included complete kits, a soccer ball, bag and whistle

Digitalisation was used in the design workflow and in the Mhlabatshane BWSS project for Umgeni Water

considered in the design or construction of any infrastructure, especially in light of recent flooding. “Our team has played a significant role in the assessments, repairs and replacement of infrastructure that was damaged during last year’s floods in KwaZulu-Natal. One of the most notable projects was the repair of the Tongaat Water Treatment Works within 105 days. In addition to that, we have been assessing culverts, bridges, stormwater systems, as well as flood lines for high-value assets,” states Goorun.

Digital transformation is another skill set that Naidu Consulting continues to embrace and develop. “The Water & Sanitation Division has, over the last few years, successfully introduced digital design into our project workflow. This was illustrated in the proposed Mhlabatshane Abstraction Works where a digital twin was created for Umgeni Water. The next digital initiative in the Water & Sanitation Division is exploring the practicality of augmented reality. Global trends show the use of this technology to take the projects team from the office environment to site locations with the use of readily available smart devices,” explains Thumbaya.

ESG

He adds that the Division strives to apply the environmental, social, governance (ESG) principles throughout a project’s life cycle,

WATER AND SANITATION PROJECTS

Western & Northern Aqueducts

The Western Aqueduct is the single largest water infrastructure project undertaken by eThekwini Municipality. It brings water into Durban from the Midmar Dam and Spring Grove Dam, providing additional ultimate capacity of 272 Mℓ/day of water.

For Phase 2 of the Western Aqueduct project, Naidu Consulting was responsible for the design of 18.4 km of pipe (DN 1 400 and DN 700) and contract administration and construction supervision for 34.1 km of (DN 1 600 and DN 700) continuously welded steel pipeline. This included the transient analysis for the entire Western Aqueduct Phase 2 bulk water system.

Owing to the rapid expansion of residential, commercial and industrial developments in the northern regions of Durban, eThekwini Municipality initiated the Northern Aqueduct Augmentation project. Naidu Consulting was responsible for the design, contract administration and construction supervision of 20.5 km of DN 1 200 and DN 600 steel pipe.

Mhlabatshane Bulk Water Supply Scheme (BWSS)

Digitalisation was used in the design workflow and in the Mhlabatshane BWSS project for Umgeni Water, where a digital twin of the river abstraction works was developed – allowing for enhanced design efficiency and, ultimately, reduced environmental impact.

which enables the project team to ensure quality, risk management, community outreach and social facilitation.

eThekwini Municipality’s Water and Sanitation (EWS) Unit identified within its bulk reservoir supply network the need to increase storage at the Shongweni Reservoir site, which is supplied from the existing Georgedale Reservoir. The works under this contract consisted of the construction of a 6 Mℓ reinforced concrete reservoir with ancillary pipework.

In accordance with Naidu Consulting’s ESG initiatives, the community within the corridor of the infrastructure upgrade was assisted with the following:

• The construction of a creche had halted due to not having building material. Naidu Consulting, together with Robin Hood Foundation, donated M140 concrete blocks.

• The local soccer team was sponsored with new soccer gear, which included complete kits, a soccer ball, bag and whistle.

• Victims that were affected by the 2022 KwaZulu-Natal floods were housed in Shongweni community hall. They were supplied with gas, food, blankets and mattresses.

Growth

With Naidu Consulting’s head office located in KwaZulu-Natal, the company has grown in size and expanded its local footprint to the Western Cape, Eastern Cape and Gauteng regions. Naidu Consulting has also

diversified outside of South African borders by providing professional design services to entities within Lesotho and Mauritius. With a diverse client base in both the public and private sector, the Water & Sanitation Division continues to strive for diversification.

Thumbaya states that Naidu Consulting’s growth has come from a dynamic team comprising a broadened skill set and the ability to adapt and meet clients’ expectations. “The water and sanitation sector requires a broad range of expertise to work on an assortment of projects – from bulk water supply, treatment and distribution to dams, stormwater and sewer infrastructure.” Rather than dwelling on the problems that constrain infrastructure delivery, Goorun believes in creating value-engineered solutions that work. He also believes that future engineers will have to respond quickly to challenges. “The emphasis is on getting the job done, on time and on budget, and bringing the community on board at all stages. It is an exciting time for young engineers to join the water and sanitation sector, and increase their expertise on a variety of projects.”

www.naiduconsulting.com

IMIESA March 2023 21 WATER & WASTEWATER

Among the largest projects undertaken by Naidu Consulting’s Water & Sanitation Division were the Western and Northern Aqueducts in eThekwini Municipality

Improving South Africa’s Water Quality Since 2016

Environmentally Friendly and Sustainably Manufactured South African Activated Carbons

mproving

Let ’s Purify Water Together

Making rural water supply more sustainable

Standalone water supply points in rural areas are vital to the schools, clinics and communities they serve, but the systems are often not functional, says Gert Nel, principal hydrogeologist and partner, SRK Consulting. He suggests some ways to make progress.

Nel highlights that these rural supply points – located in areas that cannot be reached by bulk water supply – number in their thousands. The schemes usually include one or more boreholes as a water source, with a pipe network for water distribution and a water treatment system typically comprising a filter and chlorinator.

“Where these systems are installed for a school, for example, there is often a few months’ supply of chlorine that is provided at the outset – to be manually applied by the

users,” he says. “In my experience, however, there is seldom any backup support or funding to ensure that these water supply initiatives are sustainable in the medium to long term.”

Funding and training

The key issue is usually that the school is not equipped or funded to adequately manage their groundwater source. There is no proper training by suitably qualified people on basic groundwater management, for instance.

“If the water stops flowing, there is seldom anyone available with the necessary experience to establish what the possible causes could be, and to know how to resolve them,” he says. “It could be that the water has dried up due to overpumping and lack of water-level monitoring – or there may be an electrical fault.”

Chlorine availability, load-shedding

He notes that there may also be quality issues to monitor and address. Many remote rural areas struggle to secure new supplies of chlorine once the initial stock is depleted. Local hardware stores in these areas may not always have stock, and delays can create water quality risks for the users.

“Lack of reliability of the electricity network – and regular load-shedding – exacerbates these challenges,” says Nel. “Water storage tanks are generally designed to work with a permanent water flow so, when energy outages stop the pumps

from working, there is often insufficient water available. The operation of water treatment systems may also be disrupted by load-shedding.”

Compounding the issue is the high rate of crime in many of these areas, which affects communication, among other things. Battery backup systems for cellular phone masts –and the solar panels that recharge them – are often stolen. With the cellular connection being disrupted, it takes longer to report and resolve issues with the water supply points.

Recommendations

In terms of the steps that could be taken to make rural water supply points more sustainable, he suggests that the tenders for these contracts should include aspects relating to training, awareness raising, mentoring and ongoing support for the water users. In a school environment, there could be a valuable ‘teaching moment’ for explaining the basics of groundwater management – for both teachers and learners. By understanding their groundwater source and potential challenges, they can plan ahead and mitigate most of these challenges.

“It is also vital that the water authorities understand more about the challenges that users experience on the ground, so more research and investigation is certainly necessary. Such a process will help inform sustainable solutions, including social, educational and technical support elements,” Nel concludes.

IMIESA March 2023 23 GROUNDWATER

Gert Nel, principal hydrogeologist and partner, SRK Consulting

water master planning and execution Scientific ways to carry out

sophisticated formats such as CAD or GIS – the gold standard being hydraulic model formats.

So, known network performance must be determined up front, because that heavily influences what needs to be achieved to execute each municipality’s Spatial Development Framework (SDF) plan in terms of residential and commercial expansion.

Engineers utilise this town planning information to virtually extend existing water infrastructure into all these proposed development zones. They then determine the best locations for new water and wastewater treatment plants, pipelines and reservoirs. That groundwork further determines how much the network will cost to build and maintain.

Tables of unit costs are established for pipelines (diameter, per metre, material), treatment works (per Mℓ/day) and pump stations (flow rate and head). These tables also factor in provincial cost differences.

Using our hydraulic modelling software, the total budget required per suburb to be developed, with a corresponding drawing, is available at the click of a button. These reports generated from the software are used to guide investment by the municipality and developers.

Infrastructure planning for large towns, district municipalities and metros seems an overwhelming and daunting task. Is it really possible to see the future and plan for it?

AV Yes, it is. Thanks to today’s advanced engineering software programs, water network designers have high-tech tools at their fingertips to simulate and model captured data for future planning scenarios. Of course, the accuracy of the information is fundamental to the process, which is why engineers must always first know what exists in the physical domain. That starts on the ground with cadastral survey verification. All proclaimed stands in South Africa are maintained by the Surveyor General. And these

stands can be verified with aerial images superimposed on their cadastral survey maps and cross-checked by linking this information to municipal billing data.

Then there’s the existing municipal water and sewer network, which must be supported by an up-to-date asset management register, coupled with a predictive and preventive maintenance programme.

That’s the ideal, and the legislated requirement. However, the format in which these water networks are monitored and recorded by municipalities at present can vary from something basic like a screen shot to more

Is sufficient information available and from

where is this sourced?

With historical meter reading data, the average unit water demand per land use category – such as housing, industrial, commercial, educational, and recreational – can be determined and used to inform future planning. Some of the most crucial information comes from the as-built drawings.

ECSA’s Guideline of Professional Fees outlines ‘Normal Services’ and breaks this down into six clear stages. Stage 6 is the Close-Out stage, at which completion certificates, manuals,

24 IMIESA March 2023 PERFECTING SOUTH AFRICA’S WATER NETWORKS

Harnessing the power of its proprietary software suite, GLS Consulting leads the municipal engineering market as a water, sewer and electricity modelling and master planning consultancy. IMIESA speaks to Adie Vienings, head: Business Development, about the company’s unique approach to planning and how to get it right the first time when it comes to water networks.

guarantees, final accounts and as-built drawings must be submitted.

As-built drawings record all infrastructure sizes, location, material details and heights above mean sea level. This information is vital for producing real-world hydraulic models that calculate actual and theoretical network performance. With additional engineering tools, the adequacy of existing reservoir sizes and pump sizes can be determined. Areas with ageing infrastructure can also be displayed visually in the software using the captured information of pipe age, material and remaining useful life.

For the modelling process to work optimally, municipal as-built drawing registers should go back as far as possible – ideally to the original plans, some of which might be well over 100 years old in the case of older towns and cities.

How accurate generally is the as-built data?

The key challenge for network planners is that it’s not uncommon to receive less than correct as-built drawings. And for older networks, there are times when the plans have been lost, and situations where ageing infrastructure installed decades ago has been ‘forgotten’, with no modern-day record of their existence.

Accurate as-built data is essential in establishing holistically complete asset registers and lends itself to the development of the evolving hydraulic model. This is because the hydraulic model contains databases of all infrastructure. For example, there is a shapefile and database of all reservoirs with their attribute data, such as year commissioned, replacement value and broad condition assessment (index from 1 to 5).

Likewise, the database of pipelines can be exported from the hydraulic model and summarised using any field in the database. As such, the data summary report types are almost endless – e.g. total pipe length and cost by diameter, total infrastructure replacement value per ward, comparative graph of infrastructure older than 40 years per suburb, etc.

What makes GLS’s software a game changer?

CAD drawings and GIS capabilities to form a complete selfcontained toolkit for water network planners. This enables seamless integration of data from all sources, including imported jpegs and aerial photos, all while working on a single platform.

In terms of recent developments, the software has been extended to include features that allow for rapid population of large models with unit water demands, linking of unit costs to all future infrastructure, generation of plan book pages, and generation of master plan reports in a relativity short space of time. GLS has also collaborated with other technology partners to display the water network of a town in a view-only format and online, similar to seeing features in Google Earth.

Where has GLS’s model/approach worked best in practice?

The municipalities that have got the best value out of perfecting their networks are those that have used their models as a basis to other services. From the asset register and models, some municipalities have gone further to:

• determine the cost of supplying the water service over time, including operations and maintenance (O&M)

• determine water losses in the municipal system and revenue being lost through unbilled consumers

Master Plan Drawing with Project Numbers

As-built drawings record all infrastructure sizes, location, material details and heights above mean sea level

the water network over an extended period of balancing the models

• train O&M staff to access the plan book pages of a specific area of the water network on the internet, so they know the location of pipes, values and all attribute data when in the field

• use all the base data obtained for water planning to then do sewer, electrical and stormwater planning

• train municipal officials to utilise the GLS software.

And in closing?