MADE AND BUILT IN EASTERN ONTARIO

We feature five major infrastructure projects, along with the job prospects they bring.

From hot-air balloons to electric race cars: 25 interesting items made in Eastern Ontario. Plus, exciting advances in manufacturing and the EV’s complex supply chain.

Represented by over 100 companies with over 5,000 workers, Kingston’s Manufacturing sector is recognized for its innovative and leading technology.

Clean Technologies / Electric Vehicle Battery Development/ Food Processing/ Material & Process Innovation / Supply Chain

Welcome to the sixth annual edition of STUFF Made and Built in Eastern Ontario. In this magazine, we feature what’s being made and built in the region, what companies are doing the making and what kinds of careers are available now and in the future.

On our opening pages, you’ll find 25 interesting items made in the region — everything from hot-air balloons in the shape of the sunshine and baby formula to electric race cars and jigsaw puzzles. We set out to make this list every year and we're always impressed by the breadth and depth of the list of things our writers find year in and year out. When you’re reading this section, keep in mind that every one of these companies is an employer in Eastern Ontario.

On the construction side of things, we examine five new projects happening in the region. And we could have featured so many more in this current construction boom. We narrowed it down to three hospitals — the new Civic, the Prince Edward County Memorial Hospital and the CHEO expansion — as well as a generating station in Cornwall and the Lansdowne 2.0 project that will include a major new event centre as well as more housing and new north stands for the stadium.

Further, thanks to our friends at the Eastern Ontario Training Board, we have numerous numbers for readers to digest. On these pages, we show a list of the top 20 jobs by job openings and positions in both construction and manufacturing. We also feature the top 20 by projected growth, the top 20 by wage and the top 20 in terms of growth over the past two years. Finally, we have the top 20 jobs by demand in online job postings. It’s a lot to take in and it’s a fascinating read.

In our manufacturing coverage, we feature three companies that are leveraging cutting-edge technologies to get ahead in their ultra-competitive field. Advanced robotics and artificial intelligence are just two of the tools in their kit.

Finally, in a nod to the increasing importance of the electric vehicle to Eastern Ontario’s economy, we examine the supply chain required to build these smarter vehicles that all of us will have to literally get on board with if we choose to buy a car in Canada after 2035.

If you’re looking for a job right now, flip ahead to page 48 and beyond to see which companies are hiring.

STUFF

Published by

Great River Media

President

Michael Curran

Publisher

Terry Tyo

Editor

Jennifer Campbell

Editorial

Phil Gaudreau

James Raiswell

Paula Roy

Advertising

Wendy Baily

CIndy Cutts

Eric Dupuis

Victoria Stewart

Creative Direction/Production

Jeff Eustace

Great River Media, PO Box 91585 Ottawa, ON K1W 1K0

STUFF Made and Built in Eastern Ontario is published by Great River Media. This publication contains information considered accurate at the time of printing. However, the publisher is not responsible for any errors or omissions that may occur. Reproduction in any form is prohibited without the written permission of the publisher.

Have story ideas or feedback for STUFF, contact us at:

Terry Tyo, 613-601-9734 or terry@greatriver.ca

BY PHIL GAUDREAU

From major multinationals to home businesses, there are many companies making surprising stuff in Eastern Ontario. You’ll find everything from giant manufacturing plants creating millions of tires per year to smaller teams turning wood into world-class doors. Whether you dream of self-employment or a predictable, steady career, you can find a great job in Eastern Ontario, creating the things on which we rely and enjoy every day.

belleville

1

Fluid carrier

Ever wonder how fluids, pastes and similar items are transported without spilling? Could you imagine how difficult a cleanup would be if a liquid container burst while in transit? Belleville’s SCHÜTZ manufactures and reconditions what are called intermediate bulk carriers — a sort of large plastic container placed within a metal cage that is easy to ship, protect and reuse.

napanee

Napanee is home to a Goodyear tire manufacturing plant, which recently announced an expansion. Once construction is complete, its more than 1.2 million-square-foot facility will produce tire solutions for electric vehicles in addition to the millions of tires the plant already produces each year.

kingston

Ever look at your cereal bowl and wonder where the different grains, dried fruits or seeds came from? Or enjoy a fruit-flavoured ice cream and think about how the flavour was added? From its Kingston location, Frulact makes “stabilized preparations” that are added to dairy products, baked goods, ice cream, desserts and more.

kingston

4

Earlier this year, Canada Royal Milk received approval to begin producing baby and infant formula from Canadian milk. Expect to see the brand name Niuriss appearing on store shelves soon. Last year, the Chinese-owned company, which has a Canadian arm in Kingston, also launched Capriss, a goat milk powder for milk lovers of all ages.

gananoque

5

While the sights and sounds of hockey may be entertaining, the smells usually aren’t. Hockey mom Emily Prout resolved to do something about it with a line of candles and sprays just for hockey moms. Her Bullseye Hockey company also makes some top-shelf beeswax designed to prolong the life of hockey sticks and your goalie pads. It’s all handmade in Gananoque.

With electric cars becoming more common on the streets, it’s not surprising to see them joining the race track. And the pit crews making it happen are based in Belleville. Scalar Performance has been working on the SCR1, a project to convert a combustion engine car to the first all-electric touring race car, for a couple of years now. Its engineeers are also applying what they’ve learned to other vehicle types, up to and including heavy-duty mining trucks.

7

There’s oil in these parts

Next time your car is in for an oil change, there’s a chance that oil was made in Brockville. Shell’s Brockville plant produces 130 million litres a year of products such as Pennzoil and Quaker State. The oil also ships across the country and to Canada and the U.S.

8

Soup’s on

On a colder fall or winter day, what can beat a bowl of butternut squash soup or chili? If those aren’t to your taste, try one of Perth Soup Company’s other flavours of soup, frozen entrees or dry mixes — all made in Perth using only Ontario-raised chicken, locally raised ground beef and AAA Alberta stewing beef, with seasonal Ontario vegetables for maximum freshness. Its Simply Souperb eats are available at seven locations.

hawkesbury

11

Sensible scents

sharbot lake

9

Conboy maple syrup

For more than 45 years, the Conboy family has been making maple syrup, sugar, jelly and butter in Sharbot Lake. In fact, the farm has been in the family for more than 145 years. The syrup is sold in and around Sharbot Lake, but its reputation goes far beyond Eastern Ontario. Comedian Tom Green declared it “the freshest, best Canadian maple syrup” when he gave a jug to Joe Rogan during a recent podcast taping.

smiths falls

10

Chocolate redux

Here's a sweet treat to look forward to in the future: Hershey is expected to resume production of its chocolate in Smiths Falls. The American confectionery giant operated a plant in Smiths Falls from 1961 until around 2009 and then Hershey reacquired its old plant in 2023. Hopefully we'll soon see Hershey bars, Reese's, and Kit Kats rolling off the production line in the town again.

Green Beaver’s line of personal care products is vegan, biodegradable, GMO-free, certified organic and made in Eastern Ontario in what it calls “the beaver dam.” The Hawkesbury company was founded by former biochemists and microbiologists to help people access a natural and healthier lifestyle. The products are not just sustainable — they’re also available in fun flavours and scents. Green Beaver toothpaste, for example, comes in mint, orange, cinnamon and star anise, while its deodorant options include citrus, lavender and wild rose.

hawkesbury

12

Giving old tires new life

When tires wear out, they’re often converted into products such as rubber mulch, rooftops or flooring. Ecolomondo is developing a better way to reuse old tires. Its Hawkesbury facility can process 14,000 tons of tire waste per year and produce 5,300 tons of recovered carbon black, 42,700 barrels of oil, 1,800 tons of steel, 1,600 tons of process gas and 850 tons of fibre.

Tap technology

There’s a lot of technology that goes into delivering water to your tap at home each day, not to mention keeping it clean and safe to drink. From its plant in Brockville, Newterra makes the equipment that helps treat industrial wastewater in places such as new home developments, golf courses, resorts and mines — places that can’t always connect in to municipal water treatment plants.

As cars are being assembled, the various parts and pieces need to be protected from damage. Cornwall’s Laminacorr makes corrugated plastic sheets, which today are the most commonly used protection for packaging automotive parts, largely due to innovations they pioneered. These same plastic sheets can also be used in signage like you might see during an election or at a real estate listing.

15

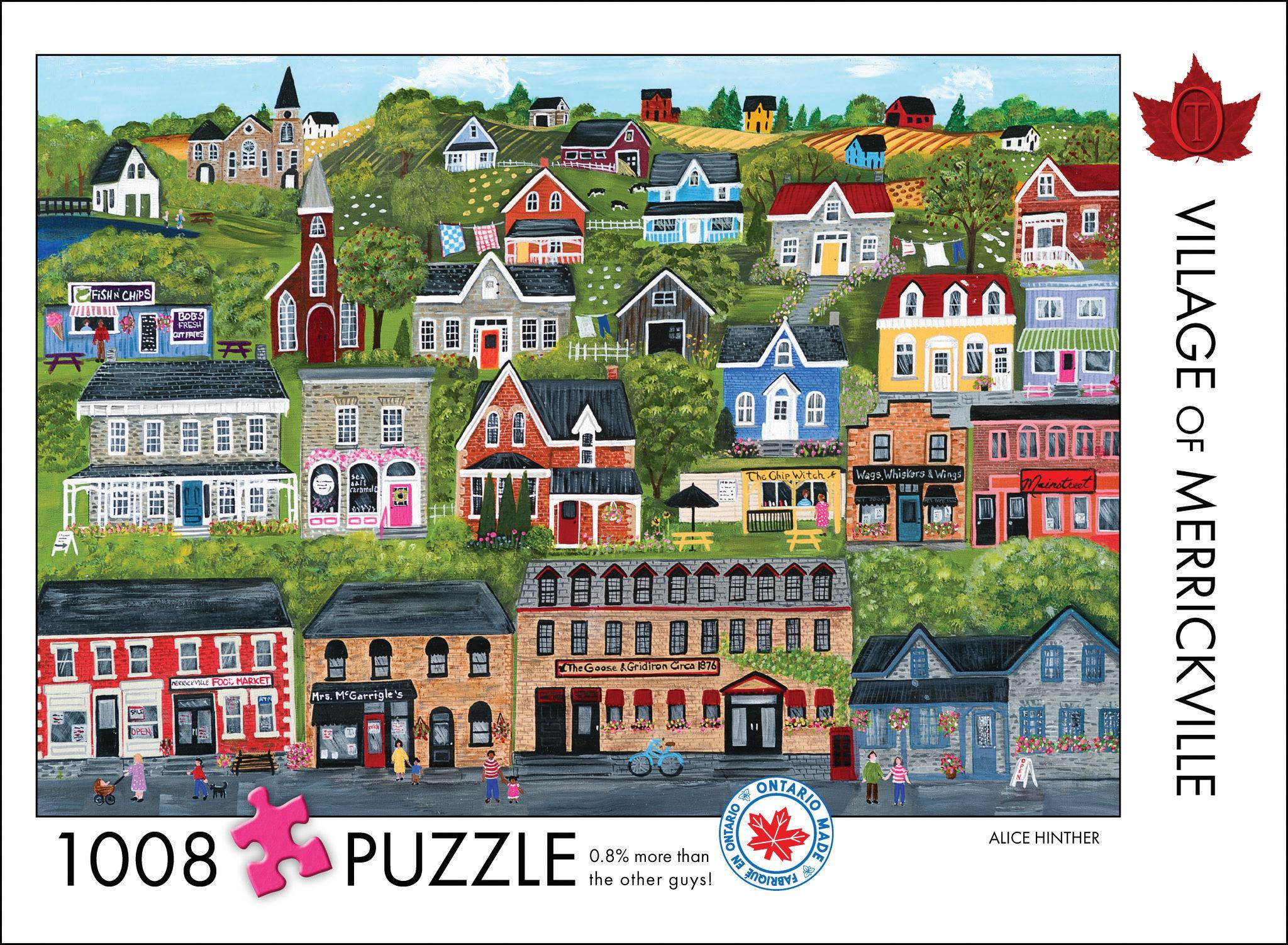

Solving a puzzle

Why was it that Canada didn’t have a puzzle manufacturer?

It’s a puzzling question that Michael J. Bainbridge and Brigitte Gall didn’t answer per se, but they did address it by creating one. Using photos amassed by Bainbridge in his decade-long career as an award-winning mineral photographer, they launched TheOccurrence, a “100 per cent owned, operated and unreasonably proudly Canadian jigsaw puzzle manufacturing company” located in rural Merrickville. Self-professed science nerds and art geeks, they design, print, cut and box their puzzles at their location.

Whether you want to rest well or keep yourself safe on your next outdoor adventure, 1890.ca has you covered — from bath bombs and body lotions to an all-natural bug and tick spray. “Happy Glamper” is made from a unique blend of natural ingredients that the 1890 team says are proven to be effective against common insects. And as you settle into your tent, make sure to apply the “Go To Sleep Babe French Lavender and Chamomile” magnesium body lotion from the Merrickville company.

17

“Crazy” kombucha Canada’s only fair-trade kombucha happens to be made in Balderson, northwest of Perth. While it was originally explosive growth that led Loon Kombucha Inc. founder Gabe Johnston to move from just south of Perth up to Balderson, it turns out the high-quality, alkaline and fully mineralized well water in Balderson were the secret ingredients to set Loon apart. Loon now ships its seven flavours across Canada.

18

Fauxmagerie Zengarry

They call it “the crème de la crème of plant-based cheese” and it’s not at all cheesy to say they have a growing slice of the market. Fauxmagerie manufactures a cashew nut-based cheese that is made right in Alexandria and shipped out to nine Canadian provinces and one territory. Its creamy Swiss vegan cheese even won Best Swiss-Style Cheese in 2022 and 2023 at the Vegan Cheese Awards.

perth

19

Coutts Coffee Roastery and Café

Coutts Coffee Roastery will soon celebrate 25 years serving — what else? — coffee! It ships in fair trade, organic beans directly from small farmers across Africa and South America. The Coutts team roasts the beans in-house in small batches, using a traditional method to achieve the ultimate development of each coffee's unique characteristics. It offers 20 unique blends including Sherriff’s Brew, named for the 180-year-old building it calls home.

pembroke

20 A world of wood Forestry and logging dates back to the founding of Pembroke some 200 years ago, and companies such as Roseburg carry on that tradition today. It produces lumber, hardwood, engineered wood, plywood, wood chips and medium-density fibreboard (MDF) — the latter being what companies such as IKEA use for some cabinets and furniture. Roseburg’s Medex® MDF is even used by companies such as Holt Hill Audio for its custom-built speakers and monitors.

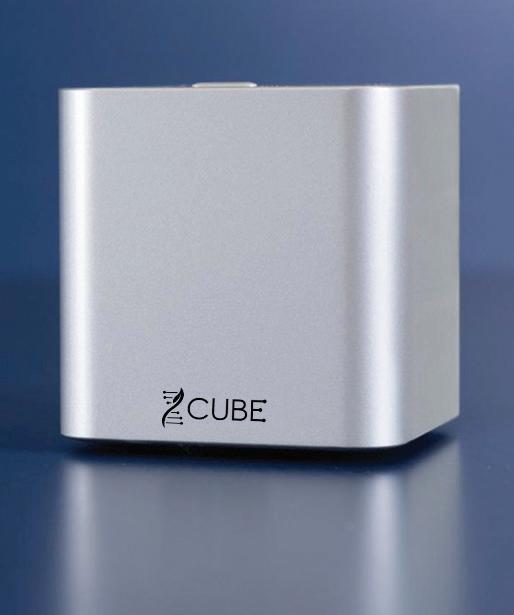

If you have a stroke, you’re at risk for a second one within a week. There are ways to prevent a second stroke, but doctors need quick information to prevent and treat blood clots that could lead to additional strokes. Genomadix’s Cube is a rapid-test device providing 99 per cent accurate results within an hour — far quicker than current methods. The Ottawa company can also test for a gene that can help predict Alzheimer’s Disease and harmful bacteria such as Legionella.

ottawa

A woodworker’s dream plane

Being able to precisely trim your lengths of wood is an important part of any woodworking or craft project. Veritas Tools, a division of Lee Valley, recently introduced a Shooting Plane, a tool that makes the job easy and consistent. It’s one of the many dozen tools offered by Veritas. The tools are processed from raw casting to finished product at the company’s Ottawa headquarters.

Eurocom was the first company to introduce upgradeable graphics processing units (GPUs) and central processing units (CPUs) into laptops more than 30 years ago. Now marking 35 years in business, it continues to offer high-performance and customizable laptops. Just last year, it introduced the Raptor X17, described as the “world's most powerful Mobile Supercomputer.” What’s a mobile supercomputer? Essentially, Ottawa’s Eurocom makes it easier for its customers to upgrade a laptop’s performance without having to buy a whole new system.

arnprior

24

Magnificent millwork

Wood-n’t you love to spend your day crafting beautiful wood pieces for someone’s home? The team at T.L. Stewart has been doing that for 30 years. It makes butcher block counter tops, staircases, cabinets, furniture, wood siding and flooring, doors and custom mouldings in up to 500 styles. For the past 20 years, it has also made specialty cutting boards sold in the Arnprior area.

belleville

Hot air balloons have had the same basic shape since the 1950s. Bard Balloons is part of a new wave of hot air balloon-makers creating more exotic designs and shapes, such as Météo, which features a three-dimensional sun, cloud and rainbow; Alien Rocket, which is shaped like a spacecraft; and My Deerling, a reindeer with ears and antlers. For more daring flyers, it has even made balloons with glass floor baskets.

Eastern Ontario Training Board

We offer a variety of programs to job-seekers and employers to support workforce development

Since 1998, The Eastern Ontario Training Board (EOTB) has been committed to responding to the needs of employers and job seekers in Cornwall, the United Counties of Stormont, Dundas and Glengarry, the United Counties of PrescottRussell and Akwesasne; it has also recently added the Ottawa region to its catchment area.

EOTB ensures access to labour market information, supports stronger linkages among employment service providers, engages employers to help identify skill gaps, employment opportunities and training needs and helps workers secure and maintain jobs and careers.

Through its Newcomer Employment Welcome Services (NEWS) initiative and Eastern Ontario Local Immigration Partnership (EOLIP), the EOTB has branched out to address the needs of newcomers who have moved to Cornwall, StormontDundas-Glengarry and Prescott + Russell, from other countries.

Local Labour Market Plan

Yearly publication that examines labour market demand and supplying Cornwall, Stormont, Dundas and Glengarry, PrescottRussell and Ottawa

Newcomer Initiatives

NEWS and EOLIP

Provides employment and settlement assistance for Newcomers, Permanent Residents, Convention Refugees

Newcomer Employment Welcome Services (NEWS) provides employment & settlement assistance to newcomers.

Its goal is to attract, integrate, employ, help settle and retain immigrants in Cornwall and the United Counties of Stormont, Dundas and Glengarry as well as the United Counties of Prescott & Russell.

The Eastern Ontario Local Immigration Partnership (EOLIP) consists of various multi-sectoral community partners that collaborates to ensure newcomers receive the assistance they need through a referral process.

The EOLIP’s area covers Cornwall and the United Counties of Stormont, Dundas and Glengarry as well as the United Counties of Prescott & Russell.

When I first arrived with my family on May 3rd 2024 in Cornwall, Ontario, I was filled with a mix of emotions—hope, uncertainty, and a bit of fear about what lay ahead. I had left everything familiar behind and was stepping into the unknown. But from the moment I set foot in this community, I was met with a warmth and kindness that I never expected.

We were eagerly expecting the arrival of our newborn! The community hospital welcomed us with open arms, and the kindness and care we received from all the nurses and doctors was truly heartwarming. We are deeply grateful for their support during this special time. I'm thrilled to announce that my daughter was born safely on July 5, 2024, at the Cornwall Community Hospital; we are overjoyed and grateful for this precious blessing.

Mir Hussain Razawi and his family, originally from Afghanistan, moved to Cornwall for a better life.

“Cornwall didn’t just offer me a place to live — it gave me a home.”

who greeted me on the street, everyone seemed genuinely happy to have me here. It wasn’t just about offering assistance or providing resources—it was the small gestures, like a smile, a handshake, or a simple "Welcome to our community," that made all the difference.

Cornwall didn’t just offer me a place to live—it gave me a home. The support from the community made me believe in the possibility of a new beginning.

The Eastern Ontario Local Immigration Partnership (EOLIP) played a crucial role in this, connecting me with others who had walked a similar path and showing me that I wasn’t alone.

Today, I feel like I belong. I’m proud to call Cornwall my home, and I’m grateful for the warm welcome that made it all possible. This city has shown me that no matter where you come from, you can always find a place to belong. And for that, I will always be thankful.

I want to express my deepest gratitude to the Government of Canada and the immigration services for bringing us to safety from a difficult situation. Your compassion and support have given us a second chance at life, and we are forever thankful for the opportunity to build a brighter future here.

Thank you for your kindness and for opening the doors of this beautiful country to us.

The people of Cornwall welcomed me with open arms. From the volunteers at the Newcomer Employment Welcome Services (NEWS), to the friendly neighbours who

As I’ve settled into my new life here, I’ve come to appreciate not just the physical beauty of Cornwall, with its rivers and parks, but the beauty of its people—their generosity, their openness, and their unwavering belief in the power of community.

I am committed to doing my best to contribute to the growth and prosperity of Canada. I will work hard to build a better future, and I will raise my children to do the same. Together, we will strive to make this country even greater, ensuring that our efforts today help create a brighter tomorrow for all Canadians.

Mir Hussain Razawi

If you’re someone who is looking to start your career, or who is considering a career change, you owe it to yourself to look at the construction sector. No matter where you look across the country — and especially across Eastern Ontario — construction is booming. Governments at all levels are investing heavily in the sector to meet the needs of a growing population. That’s why you see so many schools, hospitals, roads, highways and bridges springing up almost everywhere you look. The private sector is just as busy, with almost as many office towers, condo buildings and warehouses under construction.

Importantly, construction is also playing a major role in shaping Canada’s future. Construction, for example, is leading the effort to build more homes to address Canada’s housing affordability crisis, and it’s helping to reduce Canada’s greenhouse gas emissions by greening buildings.

We’ve compiled a list of five major projects that are either planned or currently underway across our region. These are major works that will take years to complete, will make meaningful differences to the communities they serve for generations to come and will generate hundreds of skilled jobs.

CHEO’s New Integrated Treatment Centre, Ottawa

CHEO started construction on its new Integrated Treatment Centre — known as 1Door4Care — in November 2023. The goal of the project is to merge seven care locations that the hospital currently leases across Ottawa into a single, state-ofthe-art, purpose-built site on CHEO’s main Smyth Road campus.

The six-storey, 200,000-square-foot building is expected to be completed in 2028. It will include a host of features and functions such as a multi-use clinic space, a physiotherapy rehab gym and spaces for care for patients with complex needs.

And with sustainability foremost in mind, the building has been designed to achieve Leadership in Energy and Environmental Design (LEED) Silver certification.

Building the $370-million facility is a team led by one of Canada’s largest contractors, EllisDon. During the construction period, the project will draw on the expertise of countless construction trades workers, with trades such as concrete finishers in demand early on, and electricians, sheet-metal workers and steamfitters in demand in its middle and later stages.

Staying with the health-care sector, work is about to start on another long-term hospital project, this one in Picton.

A new, two-storey, 92,000-square-foot Prince Edward County Memorial Hospital building has been designed to respond to the needs of this growing community. It will feature an expanded, 24-hour emergency department with as many as 13 rooms, a helipad, a surgical suite, a dialysis unit and other specializations.

Like the CHEO build in Ottawa, the new Prince Edward County Hospital will call on the expertise of a wide variety of construction trades. Those building the outer shell of the building will include heavy equipment operators, concrete finishers and crane operators; those called on in later stages of the work will include electricians, mechanical trades and floor covering installers.

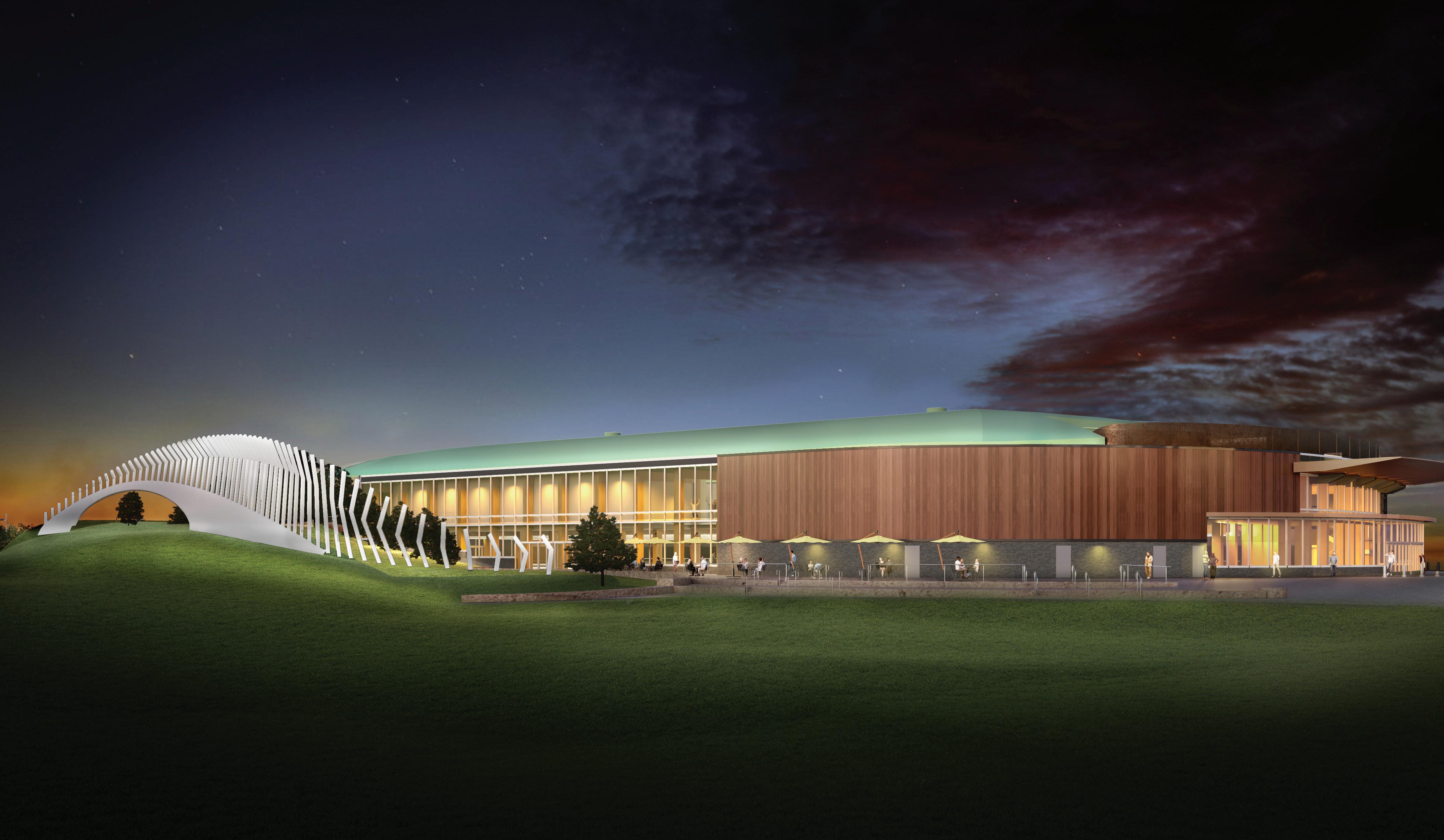

The City of Ottawa is currently in the early stages of planning its second major expansion and reconfiguration of the Glebe’s Lansdowne Park.

The Lansdowne 2.0 project proposal includes a new event centre and northside stands for the TD Place stadium, more retail spaces and the addition of two residential towers of up to 40 storeys each that would provide an influx of housing in the downtown core.

The city’s goal is to start work on at least the event centre and north-side stand components of the project in the first half of 2025.

If Lansdowne 2.0 gets the green light to proceed as planned, it will draw on construction workers from almost every trade imaginable. Early stages of the work will require skilled heavy equipment operators, general trades workers and demolition contractors. Later works will call on electricians, air-handling and plumbing trades, as well as finishing trades such glaziers and roofers.

And don’t discount the significant need for construction managers and supervisors, whose expertise will be needed to co-ordinate work on a busy site that will likely still be open to the public during construction.

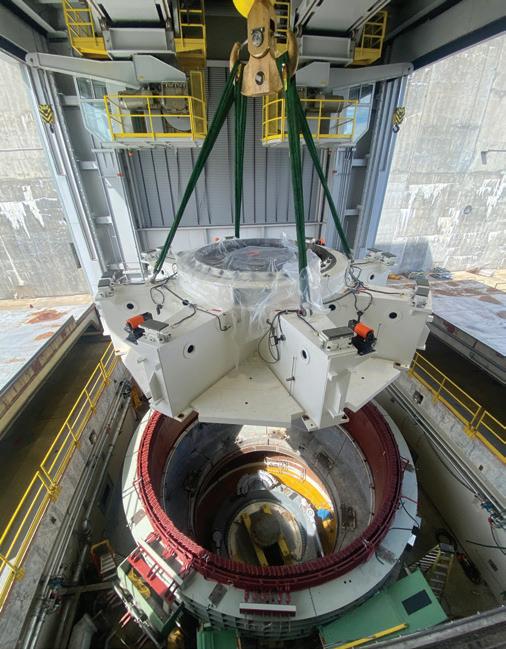

In Cornwall, Ontario Power Generation (OPG) has announced the start of work on the refurbishment of the R.H. Saunders Generating Station.

The facility is the second-largest generating station in the province, with an output of a whopping 1,045 megawatts, or enough energy to power more than 800,000 homes annually.

OPG’s plan to refurbish the station calls for work to unfold in 16 stages across as many years. Estimated for completion in the early 2040s, the project will add up to 160 gigawatt-hours of additional clean electricity to the station’s output. That’s the equivalent to powering more than 19,000 additional homes.

Along the way, the project will create hundreds of highly skilled jobs across various civil, electrical and mechanical trades, as well as trades helpers and seasoned construction supervisors and managers.

The largest project on our list by dollar value, the redevelopment of the Ottawa Hospital’s Civic Campus, also promises to be one of the most impactful.

The project is in the early stages of planning and building a massive, integrated campus on a 50-acre site adjacent to Dow’s Lake in Ottawa. The project plan calls for the construction of a 2.5-million square-foot, state-of-the-art health-care facility and academic research centre that aims to deliver world-class health care, while also training the next generation of health-care workers and enabling the discovery of life-changing research.

Valued at more than $2 billion, the project will be the largest of its kind ever

built in our region. The Ottawa Hospital is currently working with a construction joint venture led by PCL Constructors Canada and EllisDon Corporation in the project’s development phase to define project requirements and build out its schedule and budget.

There’s not a construction trade that won’t be touched by this transformative project.

Construction is already underway on the building’s parking garage, with trades such as labourers, concrete finishers, crane operators and truck drivers in high demand.

Work on the hospital building itself is expected to start later this year or early next and continue through to late 2028 or early 2029. Initially, that construction will draw on many of the same trades as the parking garage. As the building comes out of the ground, demands will shift to require

electricians, elevator mechanics, plumbers, refrigeration and air conditioning mechanics, sheet metal workers, floor covering installers — and more.

Opportunities everywhere you look

When it comes to construction employment, the potential impact of just these five projects alone is massive. Together, they will create hundreds of jobs across the trades and other occupations within the sector. And this says nothing for the countless other projects that are planned or underway across our region and that aren’t listed here.

If you’re considering your career options, add construction to your list. There’s arguably never been a better time to join the ranks of this vibrant and dynamic industry.

Where the jobs will be

CHEO, OTTAWA

• Concrete finishers

• Electricians

• Sheet metal workers

• Steamfitters

PRINCE EDWARD COUNTY

MEMORIAL HOSPITAL, PICTON

• Heavy equipment operators

• Concrete finishers

• Crane operators

• Electricians

• Mechanical trades

• Floor covering installers

LANSDOWNE 2.0, OTTAWA

• Heavy equipment operators

• General trades workers

• Demolition contractors

• Electricians

• Air-handling trades

• Plumbers

• Finishing trades (such as glaziers and roofers)

• Construction managers

• Construction supervisors

R.H. SAUNDERS GENERATING STATION, CORNWALL

• Civil trades

• Electrical trades

• Mechanical trades

• Trades helpers

• Construction supervisors

• Construction managers

THE OTTAWA HOSPITAL

CIVIC CAMPUS REDEVELOPMENT, OTTAWA NOW:

• Labourers

• Concrete finishers

• Crane operators

• Truck drivers

SOON:

• Electricians

• Elevator mechanics

• Plumbers

• Refrigeration mechanics

• Air conditioning mechanics

• Sheet metal workers

• Floor covering installers

A shared first-year curriculum in these programs allows you to build a foundation of electrical skills and techniques while learning about wind turbines, automation, and renewable energy.

• Energy Systems Engineering Technician

• Electrical Engineering Technician

• Instrumentation and Control Engineering Technician/Technology

• Wind Turbine Technician

After first year, you may choose the program that best suits your career goals and interests.

STUFF takes an in-depth look at what jobs are available in these fields and what kind of pay you can expect if you pursue them.

In Eastern Ontario, construction and manufacturing — whether traditional or cutting-edge — are big business and if you have the aptitude and the inclination, there are all kinds of jobs that await you. Thanks to the Eastern Ontario Training Board, the charts that follow answer questions such as, "Which ones will pay the best?" and "Which ones are most in demand at the moment?” and “Which ones are likely to be in demand in the next couple of years?” Among the highest-paying jobs we list in the construction and manufacturing sectors are engineering managers, who make $139,568 a year. There are high-skilled jobs and low-skilled ones that are in demand in both sectors. Read on to see where you might like to start your career.

20

20

Electricians (except industrial and power system)

Construction managers

Residential and commercial installers and servicers

Other professional engineers

Heavy equipment operators

Contractors and supervisors, carpentry trades

Landscaping and grounds maintenance labourers

Painters and decorators (except interior decorators)

Electrical and electronics engineers

Civil engineers

Carpenters

Contractors and supervisors, mechanic trades

Contractors and supervisors, heavy equipment operator crews

Construction trades helpers and labourers

Heating, refrigeration and air conditioning mechanics

Interior designers and interior decorators

Architects

Telecommunications equipment installation and cable television service technicians

Concrete finishers

Industrial electricians

Projected

Supervisors, other mechanical and metal products manufacturing

Electrical and electronics engineering technologists and technicians

Other products assemblers, finishers and inspectors

Occupational health and safety specialists

Supervisors, other products manufacturing and assembly

Mechanical engineers

Labourers in food and beverage processing

Furniture and fixture assemblers, finishers, refinishers and inspectors

Aircraft assemblers and aircraft assembly inspectors

Industrial designers

Supervisors, motor vehicle assembling

technologists and technicians

20

jobs in the

(between

20 fastest-growing jobs in the manufacturing industry (between 2022 and 2024)

20 most in-demand jobs in the construction industry by online job postings

Administrative officers

Administrative assistants

Plumbers

Material handlers

Occupational health and safety specialists

Construction trades helpers and labourers

Accounting and related clerks

Purchasing and inventory control workers

Transport truck drivers

Human resources professionals Carpenters

Roofers and shinglers

Delivery service drivers and door-to-door distributors

Shippers and receivers

Janitors, caretakers and heavy-duty cleaners

Financial and investment analysts Receptionists

Retail and wholesale buyers

Sales and account representatives — wholesale trade (non-technical)

Construction managers

20 most in-demand jobs in the manufacturing industry by online job postings

Sales and account representatives — wholesale trade (non-technical)

Material handlers

Other products assemblers, finishers and inspectors

Retail and wholesale buyers

Administrative assistants

Corporate sales managers

Delivery service drivers and door-to-door distributors

Retail salespersons and visual merchandisers

Supervisors, supply chain, tracking and scheduling co-ordination occupations

Aircraft mechanics and aircraft inspectors

Financial and investment analysts

Administrative officers

Welders and related machine operators

Human resources professionals

Accounting and related clerks

Manufacturing managers

Other labourers in processing, manufacturing and utilities

Other customer and information services representatives

Central control and process operators, petroleum, gas and chemical processing

Other business services managers

Ontario’s Specialist High School Major program connects students with industry partners opening up different pathways to success

These are what students today are looking for when they are choosing their career path. It isn’t a linear path but one that crisscrosses and constantly evolves. Students, and their parents and guardians, are keen to understand and explore the options before zeroing in on what suits them best.

This is where the Specialist High Skills Major (SHSM) diploma opportunity comes in. This provincial program supported by the Ministry of Education and delivered through the local school boards in partnership with industry partners, helps students explore a career path that matches their skills, interests and

Choosing a career for a high school student is not a straight path but more of an exploration expedition. Parents and guardians are essential companions in this journey. SHSM students going home and sharing their experiences help both generations understand the multitude of opportunities available beyond the traditional roles like a doctor or a lawyer. SHSM introduces and reinforces the belief among students, parents and guardians that there are many career paths that can be just as beneficial and lucrative.”

- CURTIS VAN DE LIGT, OCDSB SHSM LEAD, CURTIS.VAN.DE.LIGT@OCDSB.CA

• Build Relevant Industry skills;

• Industry Recognized Certifications at no cost;

• Authentic Experiential Learning with Industry partners;

talents while earning a Specialist Ontario Secondary School Diploma.

This program helps students engage with industry partners, focus on learning in a specific sector, and gain relevant experience while getting the credits they need to graduate. It helps students gain employment, apprenticeship, college or university after graduation. For the employer, it provides them with a qualified workforce that is ready to hit the ground running.

The Ottawa-Carleton District School Board currently offers 38 programs across 14 SHSM sectors including manufacturing, construction, business, arts, horticulture and more. SHSM facilitates the ‘what next’ decision-making process by providing students, and more importantly, also their families with a window into the multitude of career opportunities available.

• Reach Ahead Opportunities (Dual Credit, OYAP); and

• Innovation, Creativity, Entrepreneurship Opportunities.

• Fresh set of eyes and ideas;

• Instant access to prospective employees;

• Workforce with sectorspecific certifications and training;

• Access to bright minds coming out of high school; and

• High-school graduates who can hit the ground running.

How high school programs connect students and industry partners:

71,000 Ontario students enrolled in SHSM programs

2,600 SHSM programs being offered across Ontario Over 700 Ontario High Schools offering SHSM programs

19 SHSM sectors covered in the programs offered

SHSM provides flexibility to students with their post-graduation transition to apprenticeship training, college, university or the workplace, with the option to shift between pathways, should their goals and plans change.

Even if students choose not to pursue their choice, it’s an easier, quicker and less expensive way to explore their options than enrolling in a postsecondary program, for example. Those who do continue are more likely to complete college or university because they know it’s what they want to do.

The SHSM program focuses on experiential learning combined with developing a mindset suitable for 21stcentury careers. The program fosters design thinking, showing students how to go from an idea to a complete product and beyond. Students can bring fresh eyes and ideas, offering creative ways to approach a problem or a challenge offered by their industry partners.

It also helps teachers deliver the curriculum in an authentic way, without it being just about the textbooks. Students get to see how school translates to the real world and they discover there can be a purpose to their lessons.

Industry partners gain from this partnership just as much as a student does. SHSM enables students to obtain sector-recognized certifications, complete training courses and gain valuable onthe-job experience. Not only does the industry get access to the bright minds coming out of high school but they are also gaining a workforce that is already skilled, certified, and well immersed in the industry culture. Employers don’t need the additional time or training to get their new hires up to speed.

Through our partnerships with these NGOs and others, I have learned a great deal about the real issues affecting our local and international communities, as well as about myself. As youth and students, it can be easy to feel helpless when confronted with the real issues going on in our world. Being a part of SHSM has taught me that I am so much more capable than I think and no matter where you are in your life, you can make a difference.

- ANNA MONETTE, NON PROFIT SHSM STUDENT

For more information, please visit ocdsb.ca/shsm

It’s so fun! you get the opportunity to go on field trips, see things, learn things, talk to people who are actually in the field that you’re interested in, and meet new people. I think this is the class that’s helped me make the most friends since high school

- 911 SPECIALIST SHSM STUDENT

As an aspiring business owner, I can confidently say that the SHSM business program gave me a head start in understanding how the real world works. It helped me see what the business world is truly like and narrowed down the type of business I’d like to open in the future. On top of that, the connections and certifications are very valuable!”

- AZZURA AGOSTINI, BUSINESS SHSM STUDENT

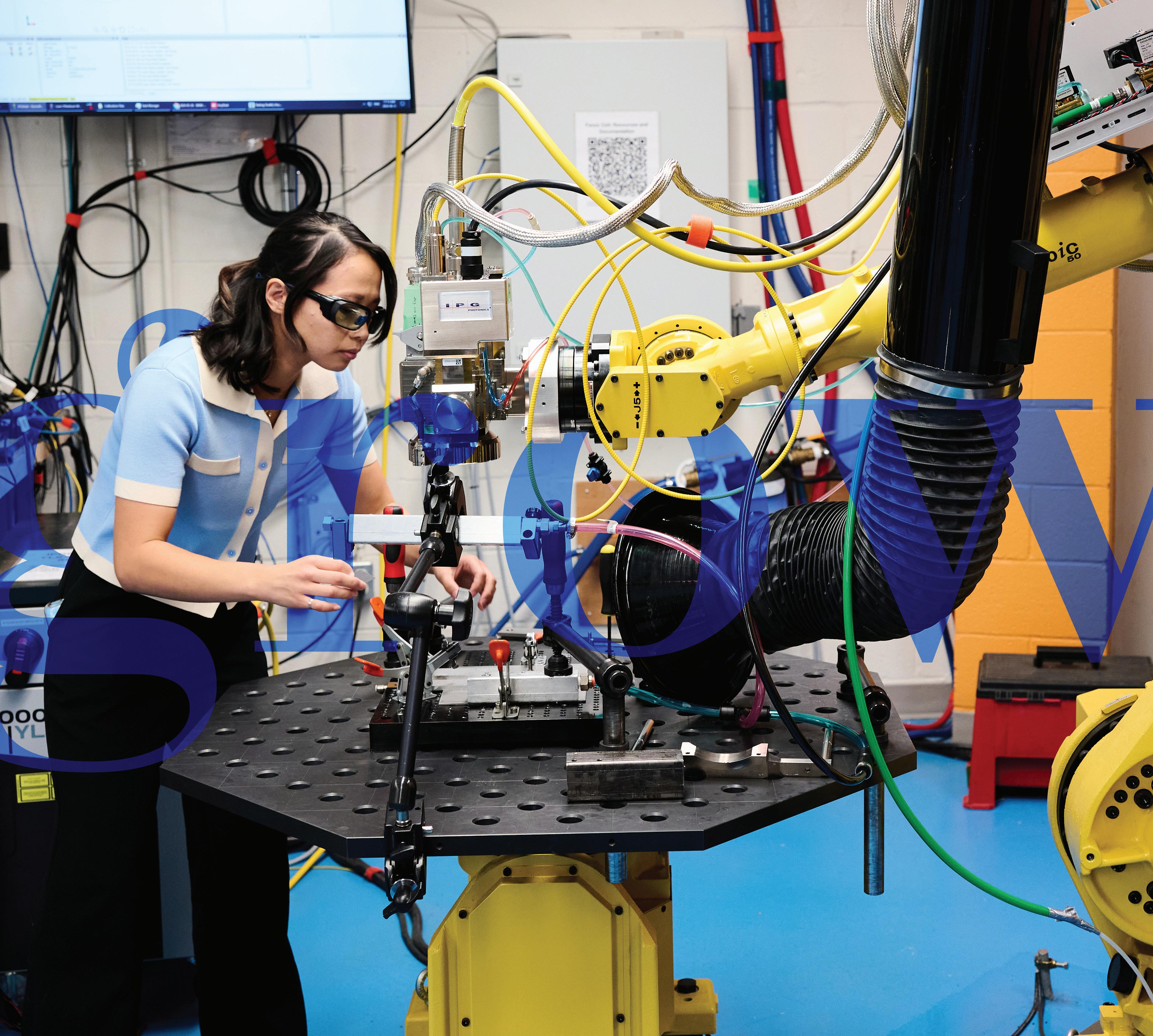

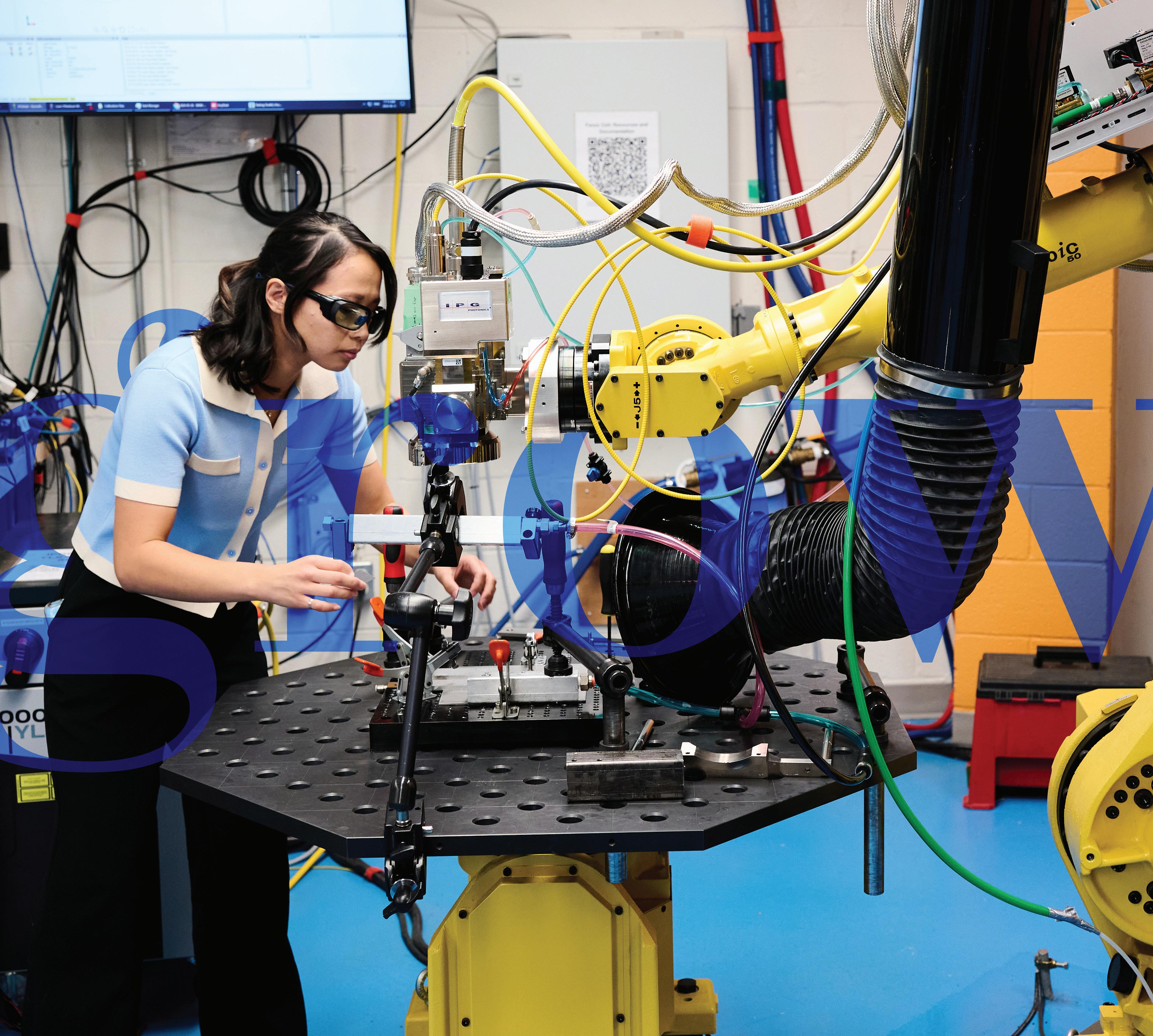

Enhancing precision and optimizing innovation are just two of the ways smart manufacturing companies are using technology to get ahead of their competition. And they’re creating jobs as they go.

BY

PAULA ROY

In today’s ultra-competitive manufacturing landscape, savvy companies are leveraging cuttingedge technologies to drive innovation, optimize processes, reduce waste and enhance precision. From advanced robotics and artificial intelligence to additive manufacturing such as 3D printing, new tools are empowering manufacturers to operate more efficiently and even create previously unimaginable products, reshaping the future of manufacturing at the same time. The transformative intersection of technology and industry — dubbed the fourth Industrial Revolution or Industry 4.0 — is happening right here in Eastern Ontario.

Arnprior-based MetaLigna Modular Inc. was recently able to implement advanced technology into its operations thanks to a grant from the Canadian Manufacturers and Exporters’ (CME) Technology Investment Program. MetaLigna is a leading provider of innovative solutions for the housing and construction industry throughout North America and beyond. Its expertise lies in Design for Manufacture Assembly (DfMA) of modular and kit-of-parts light-gauge steel buildings. With an emphasis on sustainability, its products are engineered for rapid assembly, using state-of-the-art technology and precision manufacturing processes to ensure optimal performance and durability.

light gauge steel modules are crafted for sustainability, using recyclable materials and energy-efficient designs to ensure quick, eco-friendly assembly with lasting quality. Right: MetaLigna's custom-designed rollforming machine boosts efficiency in cold-formed steel production with advanced controls and automated tooling.

/ PACIFIC SAFETY PRODUCTS

• Cutting operator

• Sewing assembler

• Production manager

• Final inspector

METALIGNA

• Machine operators

• Assembly line workers

• Quality control inspectors

• Production supervisors

• Logistics co-ordinators

• Shipping and receiving clerks

• Quality assurance managers

• Compliance officers

• CNC operators

• CAD/BIM technicians

• Draftspeople

MECHATRONIC DESIGN SOLUTIONS

• Mechanical engineers

• Electrical engineers

• Software engineers

• Automation technicians

• Automation engineers

• Millwrights

• Industrial electricians

CME’s funding allowed MetaLigna to successfully integrate the Light Gauge Steel X6 Roll Forming System into its operations. Following extensive software customization, this advanced machinery has doubled the number of light gauge steel stud and track profiles the company can produce, allowing MetaLigna to manufacture kit-of-parts buildings up to 12 stories instead of the previous six.

“As practitioners of high-tech manufacturing methodology, all of our designs are created and reviewed digitally before going to production,” explains Tapanga Koe, Metaligna’s continuous improvement manager. “Our repeatable solutions use proven methods to reduce costs and waste, improve quality, create jobs and rapidly manufacture structures of any occupancy that are also energyefficient, pest-resistant and can be assembled at the client site with less manual labour.”

MetaLigna’s investment in advanced technology is paying off in numerous ways. “We now have good scalability, both in terms of increasing product range and our ability to purchase a greater quantity of steel,” Koe says. She notes that the company only buys Canadian steel and it’s 90 per cent recycled. “Because our manufacturing is really precise, we also have very little waste in our process,” she adds.

In terms of benefits to customers, Koe confirms there are cost savings and improved scheduling. “We are able to meet or exceed our deadlines and can close building envelopes as much as 50 per cent faster than planned, as happened on a recent Ottawa project. We can also

work with the client’s blueprints to value-engineer the framing using our proprietary design techniques so it will cost them less.

“We are planning on moving more towards automated assembly with robotics, which will open up further opportunities for our employees to enjoy more comfortable technical positions, with lots of training provided in house,” says Koe.

Another group offering support to local companies is the Excellence in Manufacturing Consortium (EMC), an inclusive and diverse not-for-profit organization connecting more than 2,000 businesses in Eastern Ontario, many of which have already implemented some form of advanced applications into their operations.

One such manufacturer is Med-Eng/ Pacific Safety Products, also located in Arnprior. It makes body armour for Canadian military and law enforcement. Sean Cale is the company’s director of sales operations and he notes that its biggest challenge is human resources. “Our volume of work has increased exponentially, but workers are decreasing exponentially at the same time. As a result, we are looking at ways we can continue to automate to meet demand.”

He explains the company has already implemented automated fabriccutting machines as well as automated sewing machines, and notes it is seeing improvements in production speed and quality from these technologies.

“Now we are looking at what we like to

call ‘cobots’ which can transfer projects in process across the shop floor, so the humans currently performing this task can be freed up for more significant, value-add work. It’s our hope that this technology could help with improved focus for team leads and line leads and that the smoother transition of materials will improve delivery times for clients. As for our employees, ideally, becoming a more advanced technology company could help make us more appealing for workers.”

Customized engineered robots

Ottawa-based Mechatronic Design

Solutions is helping manufacturers in the region and across North America harness the power of advanced technologies by applying its expertise in developing customized engineered robots and automation machinery. CEO Etienne Poisson explains that his team’s specialty is designing equipment for difficultto-handle materials, often in the food processing industry.

“We have a proven track record of solving the most difficult automation problems,” Poisson says. “We do this through turnkey development of automated equipment, both bespoke machinery as well as robotics. We also offer industrial automation contracting in multiple forms, such as modifying code on clients’ machines, doing

safety improvements or improving machinery to increase throughput and/or reliability. Finally, we provide research and development services relating to automating and mechanizing processes. In essence, we are involved in everything from the high-level design of manufacturing plants through to solving very specific packaging requirements. Our success is all in the details and how we put the building blocks together in unique ways.”

Cornwall-based Fieldless Farms, which uses automated systems to create an ideal year-round climate to grow greens indoors, is one of Mechatronics’ customers. Poisson says the company was processing and packaging lettuce by hand before taking delivery of a new custom solution, which automates the sorting, mixing and packaging. “Indoor agriculture is a relatively new industry so commercially available machinery doesn’t really exist for this application, but we could build it for them,” he explains. “One of the reasons we are focusing so much of our attention on the food space is that we feel anything that can increase the capacity to produce more food locally is very important.”

Almost every Mechatronic client becomes a repeat customer, Poisson says. “We are helping manufacturers increase capacity while maintaining their workforce at the same level. We help solve

labour dependency or labour uncertainty issues. Manufacturers today that use robotics have an opportunity to attract workforce because people want to work in environments with cool technologies and appreciate that the robots can take over mundane repetitive tasks so some workers can be redeployed to areas where they can add more value.”

As these local companies are proving, there is transformative potential in applying advanced technologies in manufacturing. Companies eager to participate in the fourth industrial revolution are going to continue to find ways to harness the power of strategic investments and workforce development to achieve their goals.

Above: Mechatronic’s high-accuracy hygienic dispenser permits on-the-fly control of dosing quantity. Below: This equipment is used to build steam humidifiers and handles tubes from 0.75 inches to four inches with minimal changes to parts.

Not only are Stormont, Dundas and Glengarry Counties (SDG Counties) home to some of Canada’s earliest settlements; they’ve also been a remarkable innovation hub for almost two centuries, ever since the Loyalists arrived in the area. In sectors such as agriculture, agri-food, manufacturing and more, discoveries, inventions and products made here are known around the world.

The Lactalis plant in Winchester, North Dundas, is Canada’s largest cheese making facility, employing over 400 people to manufacture products under the Cracker Barrel, Black Diamond, Balderson brands, to name just a few.

Muir’s Bakery in North Glengarry is Ontario and Western Quebec’s source of quality haggis and Scottish meat pies. The almost 100 year old business is located in Maxville, home of the largest annual Highland Games gathering in North America.

Some of the best cheese in the world is made in Lancaster, South Glengarry at Margaret Peters-Morris’ Glengarry Fine Cheese. This small operation regularly wins top global cheese awards, recently garnering 5 gold medals for its exceptional products. It also serves as a stellar ambassador for SDG Counties’ thriving dairy sector.

From its tiny roots in Canada’s North, South Stormont’s Igloo Building Supplies has evolved into a major supplier of prefabricated housing components delivered worldwide. They’re a one-stop-shop – creating, packaging, and shipping worldwide over highways, ice roads, and oceans.

North Dundas’ Fortier Stark Industrial fabricates stainless steel manufacturing facilities for the food, beverage and pharmaceutical industries. There are only a handful of such businesses in North America so Fortier Stark is filling a niche market at home and around the world.

Dr. Mahlon W. Locke (1880-1942) Credited as the father of Chiropractic medicine, this South Dundas native was a foot specialist who diversified his Williamsburg, ON practice. With a world-wide reputation for results, he treated hundreds of patients daily, helping bring significant prosperity to the region.

At Newbrabant Farms in South Glengarry, dairy farmers Peter Sommers and Melanie Trottier completed an extensive $7-million expansion that includes two new barns, an innovative sand-manure separator and the largest rotary parlour in Ontario with capacity to milk up to 1,400 cows.

Sometimes called the national fruit of Canada, the McIntosh apple was discovered in South Dundas in 1811 by farmer John McIntosh, who found seedlings while clearing his land. Since the 1880s, the McIntosh has consistently remained one of the top 10 apples sold in North America.

In North Stormont, Moose Creek Precast is a family-owned and operated precast concrete company. Founded in 1950, it’s one of Eastern Ontario’s oldest precast companies, offering a wide range of top quality concrete products and precast concrete supplies across the region.

warehouse in a prime location on Highway 401 is already set for expansion. It’s another success story for a firm that’s been a leader in logistics since 1945.

For more information visit www.madeinsdg.ca and youtube.com/@MadeInSDG and facebook.com/SDGCounties

The Canadian government has mandated all vehicles sold after 2035 must be electric. This shift means new job opportunities.

BY PHIL GAUDREAU

At UCore's Kingston plant, it separates rare earth elements from each other. These elements are used to make permanent magnets for EVs.

Nearly 11 per cent of vehicles sold in Canada in 2023 were electric, according to Statistics Canada. It’s still a small slice of the overall market, but one that is growing rapidly.

Part of the reason for the growth is that several countries, including Canada, have proposed electric vehicle (EV) mandates intended to increase the number of zero-emissions vehicles on the road, which means you’ll likely see more Teslas, Chevrolet Bolts, Hyundai Ioniqs, Ford Mustang Mach-Es and electric versions of existing gas cars, SUVs and trucks.

However, there are significant differences between manufacturing electric vehicles and traditional gas guzzlers. And while Eastern Ontario isn’t home to any car manufacturing plants, there are jobs in the region that will be a part of the North American electric vehicle supply chain.

Nine Kingston-area businesses are a part of Project Arrow, Canada's first zero-emissions concept vehicle.

Did you know electric vehicles are 30 to 40 per cent heavier than gas-powered vehicles? The main driver of their weight is the electric battery. Keeping that extra weight suspended above the road and ensuring the heavier vehicle can still come to a full stop in a hurry means EVs need specialized tires.

Goodyear is one of North America’s largest tire companies and it operates a plant in Napanee, producing millions of tires each year. The company is expanding this facility to produce tires specifically for electric vehicles, and adding 200 jobs as well as more co-op placements.

“These new jobs include production technicians, skilled trade production support staff technicians, mechanical and/or chemical engineers and quality and production specialists,” Goodyear spokesperson Kylie Ulanski says.

Keeping those tires moving are those aforementioned heavy electric batteries at the heart of these new-age vehicles. In the coming years, Belgian-based Umicore is expected to open a plant in Loyalist

Township, creating as many as 700 jobs and supporting the production of up to 800,000 electric vehicles each year.

While the plant’s construction was recently delayed, the company indicated in July that it’s making changes to its plans to ensure the plant is sustainable for the longer term.

Novelis is another company working on electric car batteries. The company’s Kingston plant is part of a global operation that makes Novelis the world's largest recycler of aluminum, and one of the uses for that metal is building EV battery enclosures.

Creating these electric vehicle components, particularly the batteries and motors, requires raw materials including what are called “critical minerals.” You may have only ever heard of this group of 31 elements in chemistry class, but many of them are essential to the manufacture of electric vehicles, wind turbines and the electrification of many industries.

Three of the more commonly known critical minerals are nickel, cobalt

and lithium — all central minerals in rechargeable lithium-ion batteries. This list also includes a group of minerals called rare earth elements, 17 distinct elements which are often turned into powerful magnets. Despite their name, rare earth elements are not rare, and are found in everything from computer hard drives and speakers to wind turbines, MRI machines, electric motors and more. But they are challenging to mine and refine.

To reduce the mining and the shipping of rare earth elements from China, some manufacturers are turning to North American suppliers of recycled critical minerals, and this increased demand means substantial growth for recyclers.

One major hub of critical metal recycling is in Kingston. Cyclic Materials was founded in Kingston and, in 2022, opened a pilot plant to recycle rare earth magnets. The company intends to recycle 8,000 tonnes of rare earth magnets annually at the plant. Its process involves breaking down old electronics to keep the magnets and recycling, or disposing of the remainder.

A snapshot of kinds of skills these companies are seeking

Goodyear Tires in Napanee

• Skilled trade production support staff technicians

• Mechanical and/or chemical engineers

• Quality and production specialists

Cyclic Materials

• Operators

• Plant managers

• Health and safety officers

• People with chemical and mechanical skills

• Logistics associates

Ucore

• People with chemical and mechanical skills

• Post-secondary graduates with training in chemistry or engineering

Cathode active materials are the ingredients that determine the performance of a battery, including how long a car can drive without charging. Umicore's contain nickel, manganese and cobalt.

Ucore is a Nova Scotia-based recycler of rare earth elements, which also set up a demonstration plant in Kingston with a target of processing 2,000 tonnes of total rare earth oxides by the end of 2024. Ucore takes those mixed rare earth oxides from companies such as Cyclic Materials and further separates the elements into a purer oxide, meaning instead of a blend of any number of the 17 rare earth elements, its clients receive the specific element they need.

Whether it’s recycling, manufacturing or helping to keep the supply chain moving, there are many opportunities for work in this new green economy. “Green jobs” are expected to rise by as many as 300,000 positions in Canada between 2023 and 2030, according to a report from the Smart Prosperity Institute and Future Skills Centre. And that’s on top of a significant shortage of workers in manufacturing in Ontario, which includes open positions and expected retirements, according to Canadian Manufacturers & Exporters.

Where

So, if you want to work for companies hiring in green jobs, how should you prepare yourself?

If being hands-on with the parts and pieces of a car interests you most, you might want to try a job in manufacturing. Goodyear hires people with high school diplomas into positions such as production worker, which involves operating machinery and moving materials around the plant. Those with three years of post-secondary education in engineering can qualify for Goodyear’s Manufacturing Leadership Development Program, becoming shift operations managers the following year.

“Production technicians require a high school diploma or equivalent,” Ulanski says. “Skilled trade production support staff technicians need previous training, education and experience in skilled trades. Mechanical and chemical engineers must have a degree, with experience requirements varying by role. Quality and production specialists are preferably degree-holders.”

Perhaps you are organized and gifted with details. You might consider a job in supply chain and logistics — keeping the raw materials flowing in, and the product flowing out. Companies such as Cyclic Materials hire logistics associates to keep track of inventory and ensure shipments have the right documentation for their final destinations.

Maybe involving yourself directly in the recycling aspect of the business interests you. At Ucore and Cyclic Materials, they are looking for people with chemical and mechanical skills who help ensure the integrity of what they’re recycling, improve their processes and ensure the equipment is working as it should.

“As we continue to expand our core engineering team in Kingston, if we find the right engineering talent we will continue to add to the team,” said Kunal Phalper, senior vice-president with Cyclic Materials. “We also anticipate opening further commercial facilities in Kingston that will require more engineers as well as other manufacturing roles, such as operators, plant managers, and health and safety officers. This is a high-growth area in an emerging field.”

Often these hires have completed relevant science or engineering programs from an accredited college or university and may have prior experience working in metal recycling or mining environments.

“We like to hire local post-secondary graduates with training in chemistry or engineering,” said Michael Schrider, vicepresident and chief operating officer with Ucore. “Along with our partner, Kingston Process Metallurgy, we work hand in hand with Queen’s University as a conveyor belt of talent that is helping our company reach commercialization.”

If you have an interest in science, an eye for details and a passion for sustainability, there is a wide range of career options waiting for you in the electric vehicle industry.

Goodyear Tire and Rubber Company’s Napanee plant expansion brings cutting-edge technology, 200 new jobs, and support for electric vehicle and all-terrain markets in Eastern Ontario

The Eastern Ontario region continues to rack up big wins in terms of economic development, with the recent announcement by Goodyear Tire and Rubber Company that it will expand its plant in Napanee.

The $575-million project will bring 200 highly skilled jobs to the region, and will expand and modernize the plant with cutting-edge technology. Expected to be completed by mid-2027, the expansion will be able to accommodate the evolving needs of the electric vehicle (EV) and all-terrain vehicle markets. The plant will also incorporate environmental solutions that will continue its net-zero footprint.

“This announcement speaks really highly of Eastern Ontario as a region,” says Stephen Paul, director of community and development services with the County of Lennox and Addington. “When you’re looking at an investment of this scale, that could happen anywhere globally, to have that take place and have that trust and faith in an Eastern Ontario company. This is so important for us, but also just speaks to all the great things that are happening regionally here.”

The company will be recruiting for maintenance and production technicians, engineers, project specialists and management positions, Paul adds. Goodyear already employs 800 at the plant.

The project is a multi-level government partnership, with the federal government providing $44.3 million, the Government of Ontario contributing $20 million, and the Town of Greater Napanee, the Township of Stone Mills and the County of Lennox and Addington providing approximately $2 million in incentives over four years through an Industrial Community Improvement Plan.

Paul says Goodyear’s expansion signifies the strength of the community in terms of supporting business. “This is just another example of all that we have to offer. It speaks highly to the labour force that we have here,” he says, adding that the spinoff from this will be substantial. “What you see within our community is indicating that Ontario is absolutely open for business and we’re open for large-scale investment and that’s happening and it’s going to continue to happen here in the future. I think it’s an exciting time for us.”

The Eastern Ontario region also offers an availability of industrial land, support services, and of course, a strong labour force that’s available. Partnerships with nearby educational institutions also increase the attractiveness of the region, Paul adds.

“The investment by Goodyear in Napanee is a testament to the confidence that manufacturers have in Eastern Ontario’s workforce, supply chain and ready access to domestic and global markets,” says Jay Amer, executive director of Ontario East Economic Development. Ontario East members work collaboratively to attract new investment and support growth from existing companies with important support from our provincial and federal economic development partners, he adds.

“What you see within our community is indicating that Ontario is absolutely open for business and we’re open for large-scale investment and that’s happening and it’s going to continue to happen here in the future.”

The region also offers an all-inclusive package for an employer or a large-scale manufacturer, says Paul. “We have a really strong team approach that involves all those partners and that allows the companies to be successful and to be able to be well-integrated within the community and to take advantage of the services and labour force that we have here. And I think that’s really key,” he says.

Goodyear is one of the world’s largest tire companies. It employs about 71,000 people and manufactures its products in 54 facilities in 21 countries around the world. Its two Innovation Centers in Akron, Ohio, and Colmar-Berg, Luxembourg, strive to develop state-of-the-art products and services that set the technology and performance standard for the industry.

Celebrating our 35th anniversary, MCON is a local and family-owned, industrial manufacturing facility that was founded in 1989 with roots dating back to 1956. Established in Ottawa, we serve Eastern, Northern, and Central Ontario.

Our precast concrete products include reinforced circular and elliptical concrete pipe, circular and box maintenance holes, catch basins, box culverts, oil grit separators and gravity-retaining wall systems.

We serve clients of all sizes. We believe that building a solid relationship with a small contractor just starting out will help them grow their business, just as many large customers today have helped us do after all these years.

Some of our larger customers are Cavanagh Construction, Taggart Construction, Tomlinson, Robert Excavating and Gordan Barr.

We have implemented 7S lean manufacturing and an everybody matters approach to manufacturing. We believe that putting your people first will contribute to a more satisfied workforce, improve quality, and expand our customer base.

As we continue to grow our manufacturing facility and operations, we strive to invest in highly skilled professionals who approach each request with a fresh perspective. By implementing a progressive mentorship program, milestone recognition, and conducting scheduled reviews with a development plan, we foster a culture that values continuous growth and improvement.

2150 Richardson Side Rd. Ottawa, ON K0A 1L0 Canada www.mconproducts.com hr@mconproducts.com

opportunities and

At Central Precast, we are constantly exploring innovative ways to leverage precast concrete solutions to address our customers' most demanding needs. This is why we place such a strong emphasis on investing in our team—our ability to deliver exceptional solutions is directly linked to the expertise of our workforce. We have cultivated a close-knit, familial atmosphere within a forward-thinking work environment, empowering our employees to challenge conventional approaches and strive for the utmost quality in our products.

When you choose to join Central Precast, you can expect to receive top-notch training, ongoing support for your personal development, and a clearly defined pathway for professional advancement. We are continuously seeking out individuals who embody the qualities of teamwork, positivity, motivation, and a genuine enthusiasm for learning.

Whatever your role is, you get to be part of a winning team creating the highestquality precast concrete products.

For over 65 years, Central Precast has been a leading manufacturer of precast concrete products, from concrete infrastructure to unique esthetic solutions. Central Precast is also the largest and most diversified dealer of landscaping and masonry products in Eastern Ontario.

We build teams and trust through honest relationships, responsible actions and hard work.

• Company events and food truck days

Modular buildings, architectural, insulated and structural precast panels, bleachers, site furnishings (planters, benches, bollards, parking curbs, pillars and columns, tree grates, waste and fence systems), custom signs and custom products. We are a dealer of landscape and masonry products.

We work directly with public and private sectors in the general construction industry such as the City of Ottawa, National Capital Commission (NCC), Enbridge Gas, EllisDon, PCL, Broccolini, Bird, HEIN, Minto Group, Mattamy Homes and Uniform Urban Developments.

Fast-paced work environment, which focuses on ensuring our people have the proper training and support to have a fulfilling career and go home safe each

evening. We are committed to inclusion, maximizing differences and giving back both locally and globally.

We strive to empower the future generation of leaders, building a long, rewarding career for our employees. We value our employees — this has been proven with many employees who have been with us for 20, 25, and 50-plus years.

25 Bongard Ave. Ottawa, ON 613-225-9510 centralprecast.com

• Financial bonuses and milestone awards

• Dental benefits

• Drug benefits

• Eye-care benefits

• Retirement plan/ RRSP contributions

• Casual dress code

• Free parking

• Life insurance

• Three or more weeks of vacation time

We’re growing Cornwall.

Businesses are investing in Cornwall, and together with the public sector are helping to transform the city by creating new housing, new employment opportunities and stronger community organizations.

Come join us as we create a sustainable community, where the only limit is your imagination.