17 minute read

Welsh Railway History

The Black Bridge and its Place in Welsh Railway History

This is the story of how a small timber deck underline bridge which has been in service for 108 years has required innovative technology, human strength and £3.6 million to eliminate line closures due to flooding.

Advertisement

The Cambrian Line - A Chequered History of Ownership!

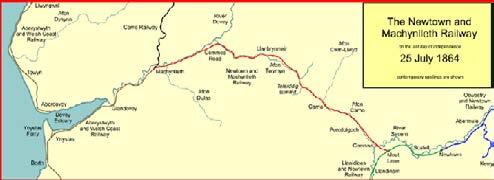

What we now know as the Cambrian Line was built in the mid-19th century, not by a single company but, by no less than five companies over a period of 14 years between 1855 and 1869. These were: • The Shrewsbury and Welshpool Railway (between Shrewsbury and Buttington), • The Oswestry and Newtown Railway (between

Buttington Junction and Newtown), • The Llanidloes and Newtown Railway (between

Newtown and Moat Lane Junction) • The Newtown and Machynlleth Railway (between

Moat Lane Junction and Machynlleth), and • The Aberystwyth and Welsh Coast Railway (between Machynlleth and Aberystwyth/

Pwllheli).

The section west of Buttington Junction became part of the Cambrian Railways in 1864, which in turn became part of the Great Western Railway under the Grouping Act of 1921. The chequered ownership continued as, on nationalisation these lines were operated first by the Western Region of British Railways and later by the London Midland Region. In a later reorganisation, passenger services were operated by the Regional Railways Central sector. Following privatisation in the mid-1990s, passenger services were first operated by Central Trains, then by Wales & Borders from 2001, Arriva Trains Wales from 2003 and, finally, Transport for Wales from 2018! Although the line escaped the Beeching Act, nevertheless 26 stations have been closed, although one, Bow Street, was reopened just this year and the reopening of Carno station

Black Bridge

has been proposed and an application is at the final stages of approval.

Today, in addition to its normal duties of providing services for people to get to work and for children to get to school, the line plays a key role as a scenic route, as well as linking many coastal resorts and connecting to seven narrow-gauge tourist lines (the Talyllyn Railway, Welshpool and Llanfair Railway, Ffestiniog Railway, Welsh Highland Railway and the Vale of Rheidol Railway).

With long sections of single line and limited passing points, minor disruptions on the Cambrian Line quickly lead to compound delays and partial cancellations. This, combined with short turnaround times at each end of the route, led to severe unpunctuality during much of the first decade of the 21st century. The extension of the

service to Birmingham International in late 2008 has helped address this by eliminating the tight turnarounds at the heavily congested Birmingham New Street station. Maintenance changes and additional padding in public timetables has also helped improve performance figures overall.

The Black Bridge

As mentioned above, because most of the line is single track, any disruption to the flow of traffic can rapidly bring the route to a halt, causing great distress to children, business travellers and the tourist trade. During the present century there has been a major problem with a small bridge located just east of Machynlleth, known as The Black Bridge – coincidentally apposite for its recent reputation! This bridge is in a narrow valley and is home to the Afon Dulas or North Dulas river which forms the border between Merionethshire/Gwynedd and Montgomeryshire/Powys in Wales. Another river called Afon Dulas joins the Dyfi from the south, upstream of its confluence with the North Dulas: locally this is referred to as the South Dulas.

The Afon Dulas rises from a source in the hills above Aberllefenni and passes through Corris, Esgairgeiliog and Pantperthog before joining the Afon Dyfi at Ffridd Gate near Machynlleth. The Dulas is recorded as an important land boundary in 1200 and, in a document written in 1428, the land owned by Einion ap Seisyllt, in the time of Llywelyn the Great, is described as "tota terra inter aquas de Dyfi et Delwas" (Latin, meaning: all the land between the rivers Dyfi and Dulas). It ultimately flows into the River Dyfi and hence to the Irish Sea.

The South Dulas rises in Glaslyn, below the slopes of Foel Fadian, and passes the hamlet of Forge and Plas Dolguog before joining the Dyfi. Close to its confluence with the Dyfi, it is crossed by the Cambrian Line on a bridge known as the Black Bridge and this is where our story begins!

The Black Bridge is just to the east of Machynlleth, on the stretch of the Cambrian originally built by the The Newtown and Machynlleth Railway, which

An Aberystwyth to Carmarthen train at Talerddig Summit (Ben Brooksbank)

built the line from a junction with the Llanidloes and Newtown Railway near Caersws to the market town of Machynlleth. The topography of the district was challenging, and a practicable line had to be routed north of the most mountainous region and climb steeply. Newtown and Llanidloes were centres of flannel manufacture at the time and, in frustration, promoted their own railway joining the towns as there were no railway lines in Central Wales at that time. The Llanidloes and Newtown Railway was authorised in 1853 and opened in 1859. The L&NR was not connected to any other line, but encouraged by the development, another railway was locally promoted: the Oswestry and Newtown Railway. This was authorised in 1855 and opened in stages from 1860, eventually connecting to the Shrewsbury and Chester Railway, and thence the developing English network, at Oswestry in Shropshire.

A solicitor based in Machynlleth, named David Howell, made energetic moves to form a railway, beginning with a public meeting on 20 December 1856 at Machynlleth. There was support for a railway, and the engineer Benjamin Piercy prepared plans for a route. A 23-mile line from the Llanidloes

Machynlleth Station about 1885

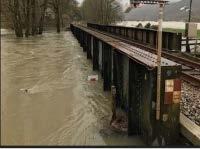

The Black Bridge with the South Dulas in flood in March 2021!

and Newtown Railway near Caersws to Machynlleth was shown to be feasible. It involved a climb from 412 feet to a summit of 693 feet at Talerddig with a maximum gradient of 1 in 71, and an even steeper descent to near sea level at Machynlleth with four miles at 1 in 52 to 1 in 60.

The Newtown and Machynlleth Railway was incorporated by Act of 27 July 1857, with authorised capital of £150,000. The Bill was unopposed in Parliament. The first sod was cut in November 1858, the delay suggesting land acquisition and money-raising difficulties. There was to be a tunnel at the Talerddig summit, but this was changed to a cutting in the rock. Briwnant-Jones suggests that the rock material was found to be suitable for the construction of bridges on the line, and that the change had a beneficial effect on the contractors' costs. When made, the cutting was 120 feet in depth: for some years this was the world's deepest railway cutting. Flat-bottom rails were specified for the permanent way, but this was changed to bullhead rail between Caersws and Talerddig.

The N&MR now set about getting Board of Trade approval to open the line for passenger operation, and Captain Henry Tyler made two visits; on the second occasion, 30 December 1862, he approved the opening subject to some conditions. Trains started operating the following day, 31 December 1862. However, it appears that the construction contractor (Davies) conveyed some goods wagons and possibly passengers unofficially before that. A grand opening ceremony was held on 3 January 1863. The line appeared to run smoothly until the start of the present century but then problems started to occur with flooding around the Black Bridge. From just a couple of incidents a year at the start of the century, this had risen to eight in 2018 and a total of around 30 by the present time. Sadly, these incidents last several days with the bridge deck under water, making the passage of the diesel trains impossible.

It was at this point that Transport for Wales and Network Rail decided that this could not continue as the likelihood of more incidents occurring each year was going to be exacerbated by climate change bringing more rain on the surrounding Welsh hills, and hence flooding of the South Dulas river at the Black Bridge.

So, what is the problem? The problem is that when there is a heavy rainfall in the surrounding mountain area, the water collects in the North and South Dulas rivers and passes on downstream, close to its confluence with the Dyfi, and it is here that the restriction caused by the bridge causes the water level to rise, ofttimes above track level in just an hour or two, making it impassable to trains.

The bridge itself is at a slight angle and skews over the South Dulas. Because the bridge abutments are aligned with the river, when the water level rises, the eastern pier tends to collect the debris, creating two impacts – hydrodynamic and hydrostatic – against the bridge.

It is for this reason that it was decided that something had to be done to get the bridge at track level out of the flood zone. Each time the bridge was typically closed for several days and if was once or twice a year, it probably wouldn’t have had much impact but now it obviously it is becoming continual.

Because of the nature of the land that the train goes through, there would be a certain tolerance level among the passengers – once or twice you can live with but when it is eight times in a year, especially during the Summer months, it doesn’t really bode well and it’s not just the tourists. If you go right down among the passenger lists, the TOC is there to run a railway – Transport for Wales wants to run trains to move passengers around and people want to go to work and school – if they can’t do that then, essentially, TfW is not providing a service. This is the whole reason for doing this. People want to be able to go to work and children want to go to school. It also leaves large sections of the Cambrian Line in central Wales isolated.

Work on the Bridge and Ecology

The initial surveys and designs, carried out in the Autumn of 2020, showed that it was necessary to lift the bridge by 1m from its present position to clear the flood zone for a once in a 150-year period. Once the flood zone is reached then it would have to be an extreme amount of water, even with the

(Top) An aerial view of the site (Above) May 2021 (Right) Thursday May 13 2021, Workbegins!

bottleneck of the bridge to cause another problem. Another problem was that the South Dulas is a fish spawning river and so there was only going to be a narrow window when the work could be carried out. As a result, negotiations and discussions were carried out with Natural Resources Wales and ecological specialists to do everything possible to protect this sensitive local environment. It was necessary to work out how people, materials, plant, and equipment could be moved to site, where and how to set up the site compounds and obtaining the necessary licenses from Natural Resources Wales.

It is here that Chris Howchin, Capital Delivery, Works Delivery, Wales Route, Network Rail, takes over the story, “The initial design was done 12 months ago but the designs themselves were constantly being revised as the timescales were incredibly tight – getting from design concept to completion in just 12 months. We couldn’t go into the water course during the winter months for environmental reasons, so various assumptions were made, for example on the pre-existing abutments, they would be good for when the bridge was built, but when you start adding more concrete weight on top, were they robust enough to take the added tonnage on top. We assumed that there was going to be a lot of work that we needed to do, more reinforcements, more steelwork going in, the amount of material that we needed to pull in. We looked at putting some innovation into the track so you don’t have to have such a wide area, so you could thin it down as you go up. That saved on a lot of cost.”

“The basis of this innovative system, known as The BaFix system, is that if you think of an L-beam that you would normally use for a retaining wall and the bottom part of that “L” is where the material would be stacked on while the upright part of the ‘L’ is used for retention – it’s the same system that is used for ballast stone. What it does is to retain it and to provide a fixing for a handrail as you don’t want track workers falling down a 2-foot high step, it also provides room for a walkway – the structure is wide enough to provide this. You have now got the retention so that rather than having a lot of material outside on the angle of repose, trying to make the embankment stable, we now use this system. As a result, we saved about 3,000 tons of stone that needed to go in. It gave us a massive decrease in costs but also time, labour, the plant that was needed just to move all that material. We

(Top left) and (Left) The Bafix System in place

(Above) Clearing the decks)

(Below) Manual lifting in action

needed the railway to move in 7,000 tons of stone and ballast which came in by train ahead of the blockade – if we had had to bring in another 50%, we would have needed more possessions, more plant to get it off so it was a cost saving all the way round. It was the first time that we had used this technology – we had been planning to use it at some time on another site but that never materialised. It has been used elsewhere in the UK in a couple of places and Irish Rail are just starting to use it, but it was the first time in Wales.”

“We had just six weeks for the work, beginning on the 15th May and finishing on the 26th June, with the railway scheduled to resume services on the 28th. During this time, the railway was obviously closed to public train services. Transport for Wales supplied rail replacement services between Machynlleth and Shrewsbury during this time.

The first stage was to clear as much as possible ready to do the bridge lift itself. We removed some of the track but obviously we needed the track to move materials on to the site, it was like peeling it back on either side and then we removed the old ballast and stone which was sent for recycling – it was washed and graded ready to be used again elsewhere so there was no wastage nor any environmental pollution. The stone and ballast that we used had been washed and graded before being brought to site.”

“We then had a problem on site with Knotweed. It had to be contained as hazardous waste and we noticed that one of the lineside neighbours also had a problem with it, so we encompassed that within the management plan – we did not know where it had come from so the easiest thing was to build it into our plan. You could say that the landowner would be pleased – it was actually the owner of the adjacent hotel where we stayed – it was an advantage having hotel accommodation so close by and we were both on a win-win situation – we had somewhere close by to accommodate our employees and they had a full hotel!”

“Just as we started our blockade, the river levels came up due to a weather system that went through, so we had to evacuate the site just two days in until the water levels had receded. Because of the known volatility of the area, we already had an evacuation plan in place, just in case but we then had a mad scurry to remove people plant and equipment as quickly as we could. Fortunately, we had a good 24 hours’ notice.”

Manual Lifting!

“We peeled back the track from the bridge and while that was happening, we started to install temporary works which involved cradling underneath the bridge with I-beams and installing “trees” on to the abutments – these were to be used for lifting the bridge – and were connected to the cradles underneath. We then manually lifted the bridge 1.2m up off the abutments. An engineering safety risk assessment had been done – this was because we needed the precision, which we could not get from hydraulic jacking. It is unusual in the 22nd century but the problem arose from the fact that the deck was in two halves and we fitted four jacking points on each half – they could not be separated; the bridge itself is over 100 years old but it is in fairly good condition, the steelwork is in good

(Top and Centre) Reinforcing the foundations with the bridges lifted

(Lower) The reinforced bridge mounts

(Top) The raised bridge nearing completion

(Above left) An aerial view showing the new trackbed and work in progress on the bridge

(Top right) A train bound for Birmingham Interntional passes over the bridge

condition and what we did not want to do was to create any buckling or twisting in the bridge itself and then have to come back to carry out steelwork repairs.

From an engineering perspective, the methodology was to get that millimetre precision without any twist plus we had an additional problem in that the track was on a curve, in addition to the skew of the bridge, so the lifting points were not always equal to maintain the balance of the bridge deck. As a result, manually lifting a millimetre at a time was the preferred option.

The safety risk assessment suggested that just under 13 km of chain needed to be pulled and we needed to swop shifts so there was a rotation of people going in to pull the chains. Each deck is about 40tonnes, there were 8 lifting points and each winch was 20tonnes capacity so we could have lifted 160tonnes if needed and hence the block and tackle was well over engineered – it was more about the precision and preventing any damage. Eight, 20 tonne chains were used in total and for every 10 meters of chain pulled, the bridge was raised just 10mm! This resulted in more than 12,800 metres of chain being pulled through the lifting blocks for this challenging lift, which took a lot of strength from the teams on the ground.”

“Once the bridge decks had been lifted to 1.6m above the starting position, there was a lot of work to be done around the existing abutments and we used these as a form and extended the formwork off them. These abutments obviously date back to when the bridge was originally built in 1913 and were adequate for the load, they were designed to carry at that time but, with the added concrete which we were putting on top, there needed to be some added steelwork and concrete work around