3SECONDARY EDUCATION teChNOlOgy aND DigitIzAtiON ANDA lUSIA

1

1 SUSTAINABLE TECHNOLOGY

Take action!

Final Challenge Save water!

SCAN THE CODE TO FIND OUT ABOUT THE CHALLENGE

TECHNOLOGICAL

DEVELOPMENT

over time meant

Evolution of industrial society

Of the following types:

Neolithic revolution

First industrial revolution

Second industrial revolution

Third industrial revolution

Sustainable development goals Industry 4.0

2030 targets

Improve carbon footprint

require

Sustainability initiatives

Effects on nature

Climate change

Atmospheric pollution

Soil degradation

Marine pollution

has

Effects on society

has caused

Inequalities

the consequences of which are

Poverty

Discrimination

Poor quality of life

Circular economy

Circular economy

Reuse and repair

Sustainable design

Emissions trading Sustainable infrastructures

Bioclimatic architecture

Sustainable transport

Global emissions market

FOCUS O N

Technology and sustainability 1

The concept of sustainability applies to the moderated consumption of resources with the aim of preventing them from disappearing.

Sustainable resources are those that meet the needs of the present without compromising the needs of future generations.

Areas of sustainability

Sustainability affects different interrelated areas: social, environmental and economic. These relationships force us to approach it as a complex problem, where we may lose in the short term to gain something for the future.

Sustainability must be:

– Socially and environmentally tolerable: no one should lose their rights to resources.

– Economically and environmentally viable: any economic investment must make use of existing resources.

– Equitable, in the social and economic spheres so that no village loses wealth or is affected in its environment.

For example, for a factory to become more sustainable, it needs to invest in more energy-efficient machines. This will achieve an environmental improvement. On the other hand, people will need to learn how to use the new machines and will need training to do so, linking the environmental and social spheres.

Numerous initiatives have arisen from the awareness of the rationalisation of energy expenditure and the consumption of natural resources:

• Electric, collective and low-emission transport.

• Automatic control of systems through IOT (Internet of Things).

• Development of circular economies for the reduction, reuse and recycling of resources and products.

• Intelligent agriculture for the optimisation of resources.

• Progressive change to energy based on renewable sources.

An example of progress in sustainability to reduce energy consumption is the evolution of lamps:

What factors define and affect sustainability?

Viable Tolerable

Equitable

Destabilised, fossil fuels, greenhouse effect, overexploitation.

1 There are times of the year when water becomes a scarce resource. Reclaiming rainwater, rather than extracting it from aquifers, allows aquifers to recover and saves the energy required to transport it.

Evolution of industrial society 2

Humanity has always sought to improve its living conditions, and has undergone technological revolutions up to the present day.

Foundations of the Industrial Age

Palaeolithic: making tools from stone and wood and the mastery of fire. The latter provided heat, lighting, protection from insects and predators, and made it possible to cook food. It was the trigger for many later technological revolutions, based on the transformation of materials by applying heat.

Neolithic revolution: around 10 000 years ago, human settlements grew and gradually evolved from nomadic hunter-gatherers to permanent settlements, domesticating animals and cultivating the land. Fire continued to be an essential resource in people’s lives.

The production of surpluses, the development of trade, the use of new materials and the increase in population gave rise to the first civilisations: Sumer, Babylonia, Assyria, Phoenicia and Egypt.

Antiquity: examples of technological advances are the centralised heating systems in some buildings in ancient Rome or the first steam systems, designed by Heron of Alexandria (1st century AD).

2 Timeline. Research the earliest human civilisations from 10 000 years ago to the beginning of our era, ordering them chronologically and placing them on a map. Use several parallel timelines in which you identify European and Middle Eastern civilisations, Far Eastern civilisations and those that followed in the Americas.

What inventions triggered the Industrial Revolution?

The First Industrial Revolution

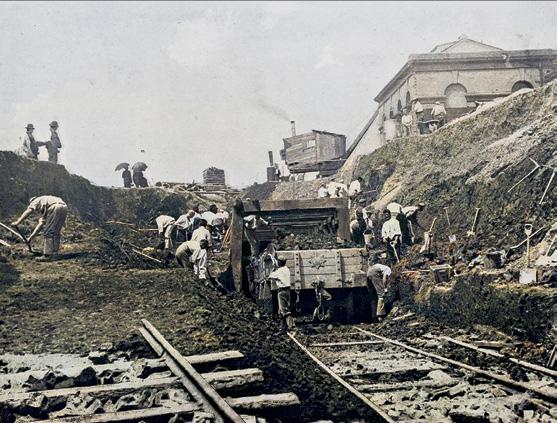

The development of new technologies in the 18th century, especially from the 1760s onwards, led to profound social and economic changes, most notably mass migration from the countryside to the cities and the rise of industry.

The main drivers of this revolution were the use of fuels such as coal and the development of the steam engine.

The origins of the steam engine go back to Denis Papin (1647-1712).

There is a patent from 1606, registered by the Spaniard Jerónimo de Ayanz y Beaumont, in which he explained the design of the first machine that used steam power to move mechanisms.

Between the 18th and 19th centuries, other inventors such as Thomas Newcomen and James Watt perfected the steam engine. It could be used in fixed machines (water pumps, textile industry) and in machines for transport (trains, ships).

3 Find out what is currently known about Tartessia, one of the first civilisations in the south of the Iberian Peninsula and answer the following questions:

a) Around which river did they settle?

b) What metals were they mining?

c) With which civilisations did they interact?

The Second Industrial Revolution

Electrical systems, developed since the mid-18th century, reached maturity at the end of the 19th century. At this time, the main advances were:

• Steel fabrication, which enables the construction of taller and sturdier buildings.

• The development of the petrochemical industry, with the invention of the first plastic materials.

• The introduction of scientific theories into production systems, which allow manufacturing companies to increase productivity.

• The development of telecommunications, with the development of the telegraph and the invention of the telephone and radio.

• Again, there were profound changes in society, demand for products increased and the capitalist economy emerged.

In Andalusia, in the mid-19th century, several industrial initiatives arose, especially in the textile, iron and steel and mining industries. During this period, Andalusia supplied a third of the world’s iron and copper production and 12% of the world’s lead production.

4 The railway, the hallmark of the first industrial revolution, enabled the development of other areas in the second, such as mining and metallurgical production. This enormous influence also reached Andalusia, in the so-called “railway impulses”, which took place from the mid-19th century and the beginning of the 20th century.

Research: Who proposed the theory of the mass production system? What kind of products were the

The Third Industrial Revolution Humanity experienced unprecedented growth throughout the 20th century.

From the 1950s onwards, engineers made major advances in electronic and computer systems, and new computerised equipment enabled the information society. In the last decades of the 20th century, engineers developed and built the Internet as a global information network.

Globalisation is one of the main characteristics of this era, driven by:

• Improved transport efficiency.

• Media development.

• Application of automatic systems in manufacturing. These circumstances have facilitated access to the market for goods and services. Financial transactions are electronic and improved transport allows goods to move faster and more efficiently. One of the consequences is the enormous growth of e-commerce.

first to be mass-produced? What were the social consequences?

5 Tables. Make a list of ten products that you can buy in your country and another list of ten products that you can only buy electronically from other countries.

6 Which companies do you think are leading the way in e-commerce?

Effects of technological development 3

Technological progress has negative consequences both for the natural environment and for a large part of the population.

Effects on nature and living things

The negative effects of technological activity have their main consequence in climate change.

Life on Earth needs oxygen (O2) and carbon dioxide (CO2) and living things convert one into the other every day. But industrial activities and transport have destabilised this cycle.

The extraction of coal and the emission of gases produced by fossil fuels have increased the level of CO2 enormously in the last century.

How does motorcar exhaust affect the climate?

Did you know?

Terrestrial ecosystems, especially forests, absorb about 30 % of man-made CO2 emissions. These “forest sinks”, in addition to fixing soil and nutrients with their roots, play a key role in combating climate change.

Vocabulary

Compromising, interrelated, equitable, rationalisation

Since CO2 is the main factor for the greenhouse effect, the more of it in the atmosphere, the more heat it traps; this accelerates the melting of the icecaps and glaciers, raises sea levels, increases drought cycles and causes severe storms in different parts of the world.

Air pollution

The main pollutants are divided into two types:

• Primary pollutants, which spread from emission sources directly into the atmosphere, such as sulphur oxides.

• Secondary pollutants, which originate from primary pollutant gases or non-polluting gases. An example is ozone (O3), which is formed by the oxidation of oxygen molecules.

Soil degradation

Soil degradation means that the soil loses its capacity to support life. The extreme situation is desertification. This degradation can be caused by changes in the climate, by the deposition of harmful chemical compounds in the soil, or by overexploitation of the soil with massive use of fertilisers.

7 Sequence chain. Draw a diagram showing how the most important components of the carbon cycle (plant mass, animal mass, atmosphere) are related.

Ocean pollution

The main drivers of ocean pollution are toxic spills, oil spills and the accumulation of plastics, which are ingested and incorporated into the food chain.

Effects on human society

The industrial revolutions have caused some countries to move ahead in technological progress, creating a technological gap. These differences also affect the population within each country.

There are three usually interrelated types of inequalities:

• Economic, when there are large differences between the incomes of one part of the population and the other, resulting in an unequal distribution of wealth.

• Social, when people discriminate because of social position, or because of factors such as religion, gender, culture of origin or sexual identity or orientation.

• Political, when people’s limit others’ rights because of their political beliefs. The consequences of inequality are poverty, discrimination, reduced life expectancy and quality of life, or problems of access to work.

In addition, inequality brings with it a lack of access to basic services such as health care, education, housing, water supply and healthy living conditions with adequate sanitation.

This can lead to migration flows of large populations to other countries, with no guarantees of health and education in the host countries.

Among the policies that can be implemented to promote equality are:

• Employment policies that make work more stable and productive.

• Promote public health, education and social protection services.

• Political transparency and transparency of the country’s institutions.

• The reduction of monopolies.

Gini Coefficient

The Italian sociologist Corrado Gini established a way of measuring equality within countries; this coefficient can take a value between 0 and 100. A value of 0 would mean that all the wealth of a country is equally distributed among all individuals in the country, while a value of 100 would mean that only one person in the country owns all the resources and wealth. Based on these values, policies could be established that aim at a more equal redistribution of wealth in each country.

Vocabulary

Ingested, inequalities, reduced life expectancy, quality of life, sanitation.

8 Look for information on the internet and describe the evolution of the Gini coefficient in Spain. Find a country where the coefficient has improved in recent decades and another where it has worsened and investigate the possible causes of these variations.

Sustainable development goals 4

Member states of the United Nations determined at their 2015 meeting that sustainability is linked to the environmental, social, political and economic spheres, and they adopted the 2030 Agenda, declaring the Sustainable Development Goals (SDGs). The SDGs are seventeen goals for 2030.

How does the technology gap affect social inequalities?

9 Write down in your notebook one action you can take in your daily life to support the achievement of each of the Sustainable Development Goals.

10 Round Table. Discuss which Goal is the most easily achievable and which is the most difficult to achieve. What did you base your choice on?

11 Go to the Cooperanda website, https://cooperanda.org. It shows numerous Andaluisan projects in support of the SDGs. In teams, choose one of their projects and prepare and give a short presentation about it to your class. Goal

Vocabulary

Environmental, achievable, affordable, well-being.

Sustainability initiatives 5

Encouraged by the Sustainable Development Goals, companies and public institutions have promoted sustainability projects.

Industry 4.0

The fourth industrial revolution, also known as Industry 4.0, is often defined as an extension of the third, since the trigger is the automation of production processes, with the incorporation of robotics and interconnectivity between companies and between people. Some of the most important advances are:

• Robotics and automation, with the creation of autonomous control devices focused on the manufacture of goods.

• Process analytics, such as data intelligence or Big Data, and data mining, which collect and analyse huge amounts of information to find patterns or generate services.

• Artificial Intelligence, which enables computers to generate software.

• Nanotechnology, or the manufacture of ever smaller systems and devices, with applications in medicine or materials design.

• Internet of Things: Internet-connected devices and sensors that collect information from the environment and coordinate and optimise their operation.

The footprint or contribution of Industry 4.0 can be seen in different areas:

• Individual: personalisation of the products and services that can be accessed, as well as a high level of connectivity with other people or access to services on the internet.

• Companies or organisations can predict demand to adjust production. They also automate processes, lowering production costs.

• Natural systems or ecosystems can benefit from the ability to monitor pests and protect animal species.

The circular economy

People have proposed a circular economy as a response to the “throwaway” philosophy. It promotes extending the useful life of resources and products, reducing the use of natural resources and limiting the use of materials that are difficult to reuse. It therefore involves:

What initiatives does the circular economy model promote?

• Repairs: Attempting to repair any product before throwing it away and purchasing a new one.

• Re-use: it’s better to share and let other people use things we are not going to use.

• Renovation: in the case of obsolete products, incorporate changes necessary to put them to new use.

• Recycling: disused materials will be managed for recycling.

Andalusia’s Circular Economy Law: implementation of the European Union’s action plan for the circular economy. Its aim is to abandon the current economic model, because if we continue to produce and consume at the current rate:

• We will exhaust all the planet’s resources in a short time.

• The unsustainable amount of carbon emissions will multiply the effect of climate change and irreversibly affect biodiversity.

• Water, food and natural resources will be insufficient for everyone.

12 What do you think “agriculture 4.0” means and what measures can agriculture and livestock farming implement?

13 Make a list of situations where people use Big Data.

14 Thinking heads. Investigate how services such as Google Maps are able to identify when there is a traffic jam on a stretch of road.

Emissions trading

People have proposed many initiatives to reduce carbon dioxide (CO2) emissions into the atmosphere. But other people are reluctant to implement those initiatives, lest their economies suffer in the short term.

Countries with little CO2-emitting industry, for example, have low emissions and consider it unfair to limit their growth because of the excess emissions of other countries.

One of the most successful solutions is to establish a global emissions market. The first step is to allocate a maximum amount of emissions to each country. If a country emits less than its allocation, it can sell the excess rights to other, more polluting countries, so that between them they can offset their total emissions, favouring the economic development of less industrialised countries.

This is a short-term solution that forces the most polluting countries to monitor their emissions while they implement the changes necessary to reduce emissions definitively.

The 2015 Paris Agreement and the 2030 Agenda for Sustainable Development established that certain companies must publish their carbon footprint and develop a plan for reducing their emissions.

Investment in technological innovation is one of the options available to them to achieve this. For those whose economic activity is affected by this measure, emissions trading may be a solution while they adapt.

Sustainable infrastructures

Sustainable infrastructures minimise carbon footprints can minimise carbon footprint or not worsen the climate change. The most common ones are:

Bioclimatic architecture

Bioclimatic architecture tries to make the most of natural resources with the least environmental impact. In these constructions there is a symbiosis between the construction and the environment.

Bioclimatic buildings are based on:

• Natural heating systems, with solar collection, geothermal and thermal insulation systems.

• Collection of rainwater and humidity from the environment for use in sanitation systems instead of using potable water.

• Natural ventilation, through the arrangement of walls and partitions that direct air currents to cool rooms.

• Renewable energy systems, such as solar water heaters or photovoltaic panels.

• Water recycling through separation of grey water and black water.

• Native vegetation in gardens, which are less dependent on irrigation and special care.

Sustainable transport

• One of the main problems in cities is traffic. For this reason, many cities are limiting the use of private and petrol-powered vehicles in favour of collective mobility systems. Some strategies for sustainability in transport are:

• Replace fossil fuel vehicles with hybrid or electric vehicles.

• Promote the use of hydrogen as a fuel for public transport systems.

• Combining multi-modal street systems (cars, buses, trams, bicycles)

• Implementation of integrated traffic control systems to optimise traffic flow.

15 Identify on the map which countries are the largest emitters and which countries can benefit from emissions trading because of their low greenhouse gas emission levels.

16 The classification of an organisation’s carbon footprint defines three levels of scope. Research on the Internet what they are and prepare a presentation explaining what each type of emissions consists of.

The final challenge

Save water!

If you have a vegetable garden in your school or are planning one, water is essential. The most sustainable solution is to collect rainwater. In this way, you will reduce your school’s consumption of drinking water and its costs.

STEP 1

Decide on the location

• In teams, decide on the location of your system. It is common to use the gutters that collect water from the roofs, but if the situation of the garden does not allow it, you can design an independent system.

STEP2

Conduct research

• Research the usual amount of rainfall in your area and how it is distributed throughout the year. Use this data to decide on the volume of the reservoir and the type of plants you want to grow.

STEP3

Gather the materials

SCAN THIS CODE TO CONSULT THE GLOSSARY FOR THIS UNIT.

STEP 4

With your final design in mind, gather the necessary materials, trying to reuse those already available in the school:

• PVC gutters and down pipes.

• Plastic sheeting to make the collector.

• Supporting strips.

• Water storage tank.

• Anchors and flanges.

• Hose or watering can.

• Tap.

Choose your design

• Choose how you want to transport the water to the garden: with a watering can, with a hose or with a pump. Draw up a table with the advantages and disadvantages of each option and adapt your design to this decision.

Maintenance

• Once installed, incorporate any necessary maintenance systems, such as a filter to prevent leaves or insects from getting in, or a water overflow valve if the tank fills up.

STEP

STEP 5 6

Periodic reviews

• Plan periodic inspections to check that the structure and water pipes are working properly.

2 3D PRINTING

Take action!

Would you venture to design a Mozarabic lattice?

SCAN THE CODE TO FIND OUT ABOUT THE CHALLENGE

3D PRINTING

it is necessary to is

3D printers

Design tools

which include

Fused Deposition Modelling (FDM) CAD applications

Prepare the files

Configure the printer

via: choose the format by for example

Stereolithography

Selective Laser Sintering

STL Levelling the print bed

OBJ

3MF AMF

STEP

Calibrating the printer

with everything configured, choose

Types of printing materials

FDM printing

SLS printing

SLA printing

Look at the diagram on this page and draw up, in your notebook, a similar but more complete one, with the information from the flipped cards at the end of this book.

13D printing and design with CAD tools

CAD tools

3D printing, also called additive manufacturing, builds objects by adding material layer by layer in a precise and controlled manner.

The history of 3D printing Engineer and inventor Charles Hull developed stereolithography in the 1980s. This was the starting point of additive manufacturing.

In the 1990s, the first 3D printer became commercially available and since then, 3D printing has experienced tremendous growth.

Tipos de impresoras 3D

• Fused Deposition Modelling (FDM): also known as Fused Filament Fabrication (FFF). This method uses a filament of thermoplastic material that the printer melts and extrudes and deposits layer by layer to form the designed object. It is the most common technique for desktop 3D printers and is suitable for fast homebuilt prototypes.

• Stereolithography (SLA): The SLA technique is based on the polymerisation of liquid resin using an ultraviolet laser, which allows the resin to solidify layer by layer. It is more precise than filament printing, so is suitable for projects requiring higher resolution.

• Selective Laser Sintering (SLS): this type of printing uses a laser to fuse powder particles to produce solid objects. It has a wide range of uses, mostly in industry.

1 Find at least one example of an object that has been printed with each of the types of 3D printer we have seen, indicating what the object is used for.

2 Indicate in the following cases which type of CAD tool should be used:

a) Images of a property for viewing in a real estate agency prior to sale.

What is the application of each of the CAD tools?

Computer Aided Design (CAD) applications are computer programmes that generate models in a digital environment. They make it possible to create any type of object with accuracy and detail.

Types of CAD tools

• 2D CAD software (1): 2D CAD software: used to create two-dimensional drawings. The most widely used is AutoCAD 2D. It is used to draw plans in architecture and civil engineering, as well as to design electronic circuits.

• 3D CAD software (2): allows the creation of threedimensional objects such as industrial machine parts. These are more advanced programs such as SolidWorks and Autodesk Fusion 360.

• Parametric CAD (3): for parametric design, data is entered into the program and converted into a three-dimensional model maintaining its parametric relationships.

• Direct modelling (4): stands out for its usefulness in 3D printing and its involvement in object design projects. This software allows 3D editing in an intuitive and simple way, such as Tinkercad.

b) Plan of a house to be handed over to the workers who are about to start construction.

c) A key ring with your name on it to identify it.

d) 3D printed custom splint to immobilise a broken arm.

e) Typical figurines placed inside ‘roscones de Reyes’.

The most common CAD tools 2

Tinkercad

This is an online CAD software aimed at beginners. Its most important features are:

• Accessibility: it is a web-based tool and can be accessed through any web browser free of charge.

• Ease of use: intuitive and user-friendly drag-anddrop interface. It is a great choice for students and people who want to learn about 3D design.

• Direct modelling: any object can be modelled and edited flexibly and easily.

• Component library: has an extensive library of figures and objects, as well as electronics elements.

• Basic tools: allows the composition of complex objects from geometric shapes.

• Design in the cloud: designs are stored directly in the cloud, so they can be accessed from any computer.

• 3D printing support: 3D projects can be exported in a format compatible with a 3D printer so that they can be printed.

Fusion 360

This is a much more advanced CAD software. It is widely used by design and engineering professionals. Its key features are:

• Parametric modelling and design: This is especially useful for projects that require frequent changes.

• Comprehensive 3D modelling: ideal for generating complex 3D models, from individual parts to assemblies.

• Simulation and analysis: offers the possibility to simulate and analyse the operation of projects under real conditions.

• Rendering and animation: objects can be rendered to create realistic images of each project and animated to see how they move and function.

• Team collaboration: cloud-based, enabling real-time teamwork.

Which CAD tools are the most suitable for an architect?

• 3D printing support: projects can be exported in STL format.

• Free student and business starter licences.

SketchUp

SketchUp is known for its ease of use and versatility for architecture or design. Its key features include:

• Intuitive design: Intuitive design: allows you to easily create figures and objects and turn them into 3D models.

• Creation of 3D structures: ideal for the creation of architectural structures and detailed 3D models of buildings.

• Object library: has an extensive library of free models, known as the 3D Warehouse.

• Extensibility: there are different versions depending on your user profile.

• Community connection: it has an active user community and a 3D component repository.

• Google Earth integration: allows projects to be viewed from the smartphone and geolocated.

3 To better understand the layering of 3D printing, think of an object or animal, imagine building it out of layers of cardboard, draw each layer on the cardboard, cut them out and glue them on top of each other until you get a representation of the object.

Design in Tinkercad for 3D printing 3

Tinkercad can be accessed through any browser by logging on to www.tinkercad.com. Registration is completely free of charge.

Once logged in, click on Create New Project or New Design to start creating a model. After dragging an object to the work area, these are some of the possible actions:

What actions would you use in Tinkercad to create a puzzle piece?

Resize

Once you are in the working area, you can modify its dimensions by simply clicking and dragging the control points.

Rotate

You can use two small curved arrows that appear around the figure to rotate it on the X and Y axes. To rotate the figure on the Z axis, it is necessary to change the viewing angle.

Retain the colour of the figures

If you want to keep different colours in each piece you will have to click on Shape � Solid � Multicolour.

Subtract

Once you have changed the shape, you can join them using the Group option as we have seen before and you will be able to cut out your piece. By modifying the point of view you will be able to appreciate the change that the figure has undergone on all its faces.

Move

To move the figure to another position, just click and hold as you move it to the new location..

Group

To create more complex structures, you will need to group objects into basic shapes. Select the objects you want to group by holding down the Shift key and choose the Group option.

Subtract

If you want to subtract one shape from the other, you have to convert the shape to be subtracted into a hollow shape.

Align

This option is only enabled when at least two figures have been selected. Clicking on the Align button will activate three black dots on each axis to align the figures in the desired place (centre, any edge and height on the vertical axis).

Save and export: It is unnecessary to save the designs since Tinkercad is an online programme. Once we finish, we can export them as OJB, STL or GLB files.

File preparation for the 3D printer 4

File formats for 3D printing

The most common are:

• STL (Stereolithography): most 3D printers use this; it represents the geometry of a three-dimensional object but does not contain colour or texture information.

• OBJ (Object): They can contain information about the geometry and colour of the object, making them more versatile for 3D printing and 3D graphics applications.

• 3MF (3D Manufacturing Format): stores complete information about the model such as colour, texture and other properties.

• AMF (Additive Manufacturing File Format): similar to STL, but allows storing additional information such as colours and materials.

• STEP (Standard for the Exchange of Product Model Data): this is not a 3D printing specific type of format; it is used to specify precise product models.

Preparation of files for 3D printing

Parameters whose configuration we must know to obtain a print that adapts to the project:

• Filling density: the amount of printing material that will be inside the object. Values range from 0 %, where the object would be hollow, to 100 %, which results in a solid object. Typical densities are between 20 % and 30 %.

• Layer height: determines the height of each layer that the 3D printer will deposit. Low values will give a high quality print, but it will take a long time. The higher the value, the shorter the printing time, but also the lower the quality.

• Print speed: determines the speed of movement of the 3D printer’s XYZ motors. With a low printing speed, we can achieve a highquality finish, but as we increase the printing speed, the quality of the finish decreases.

• Printing supports: these are additional structures that are printed together with the main part, they are used to support parts of the part that protrude, preventing them from deforming during printing. There are several types of support:

– Tree-type brackets: these are thin, branched brackets that resemble the shape of a tree. They are suitable for models with delicate details and small contact areas.

– Grid-type supports: along with tree-type supports, these are the most commonly used. They have a grid shape that provides a good balance between support and ease of removal. They are suitable for most applications.

– Column type supports: these are supports in the shape of a column. They are used in large areas and in heavy or large models as they are more solid.

What parameters would you use to 3D print a highly detailed and very solid model of a helmet?

4 Of these objects, indicate which ones you think should be printed using supports:

5 What layer height, print speed and fill density settings do you think we should use to print a prototype? What if we were to print the final object?

3D printer configuration 5

Parts of a printer

• Printing bed: surface on which the object is to be printed. It must be perfectly level and at the right temperature to ensure good adhesion of the first layer of print. Certain materials, such as PLA, require the bed to be heated to adhere properly.

• Extruder: also known as the print head, it is the part responsible for melting the printing material and depositing it layer by layer. It consists of a hot nozzle or hot end that melts the printing material and an extrusion motor that pushes or pulls the filament towards the nozzle.

• Axes and motors: 3D printers have at least three axes (X, Y and Z). The motors control the movement of the print head on the printing platform.

• Power supply: responsible for supplying power to all components of the printer.

• Structure: the framework that supports and holds together all the other components.

• Spool holder: a device used to contain and guide the printing material filament from the filament spool to the printer extruder.

Print bed levelling

This step is critical in the process as it ensures that the first layer of print is uniform and adheres correctly to the bed. Depending on the printer model, levelling is either manual, automatic or hybrid. It is normal to adjust the position of the bed by precisely raising or lowering it at different points with the help of the levelling screws. Once you have levelled the bed, carry out a simple print test with a large surface area.

Printer calibration

This process involves adjusting different printer parameters to obtain accurate prints; let’s look at some important ones:

• E-Step Calibration: regulates the amount of filament that is extruded. There are 3D design patterns that once printed help set the right amount.

• Temperature calibration: this involves adjusting the temperature of both the hotend and the print bed depending on the material to be used. The correct temperature calibration is essential for a good finish.

• Retraction: this controls the way in which the extruder stops ejecting the filament while the nozzle moves. The time and speed can be adjusted depending on the materials and this will minimise unwanted filaments in the print.

• Printing speed: together with the layer height, this is a very important parameter if we want to achieve a good print quality. Slower printing speeds allow more precise prints.

What settings do we need for optimal 3D printing?

6 Think about it: Is the configuration of the printer static, i.e. once you do it, do you need to change the configuration parameters again?

7 Indicate whether each of the statements is true or false:

a) The power supply heats the printing material until it melts and passes through the nozzle.

b) The coil holder is where the printer deposits its layers.

c) The motors are responsible for moving the print head in the three axes (X, Y and Z).

d) The quality of a good print depends only on the height of the layer.

e) The print bed is a thin layer that is printed to calibrate the printer.

f) The retraction calibration is related to the filaments in the print.

g) To ensure good adhesion of the part we must adjust the temperature of the printing bed.

Types of 3D printing materials 6

The choice of printing material is one of the most important decisions to make when configuring a 3D printer. Our choice of material depends on the type of printer.

FDM printing

• Polylactic Acid (PLA): a biodegradable material made from corn or sugar cane starch. It is easy to handle and easy to print with, does not emit unpleasant odours and adheres well to most printing beds. It does not withstand high temperatures well. It is used for printing aesthetic prototypes, games and toys, art pieces for decoration and figures that do not have a lot of mechanical stress.

• Acrylonitrile Butadiene Styrene (ABS): a tougher, more durable material with good impact and heat resistance. It emits odours and fumes, so requires ventilation. It also requires a heated bed for proper adhesion and a printer with a closed chamber to prevent warping. It is used in functional prototypes and certain automotive parts and industrial components.

• Polyethylene Terephthalate with Ethylene Glycol (PETG): combines the printability of PLA with the strength of ABS. It is a durable, water and UV resistant material. It also has good chemical resistance. It has high transparency and is suitable for contact with food. Its main use is in mechanical parts, packaging, bottles, machine parts and outdoor applications.

• Polyvinyl Alcohol (PVA): soluble in water so it is mainly used as a support material in combination with other materials that will create the piece. Once the printing is finished it is easy to remove leaving only the principal material.

SLS printing

• Powdered nylon: is a strong and flexible material with high impact and abrasion resistance. It is also resistant to UV radiation, heat, moisture and most solvents. Its good properties make it one of the most practical materials in the medical world, for the construction of machine parts, gears and functional prototypes.

Printing SLA

• TPU (Thermoplastic Polyethylene): a flexible and elastic material that resists impacts very well. It is perfect for damping vibrations. It is similar to rubber and is present in flexible parts such as phone cases, sports shoes, stamps and customised rubber products.

• Resins: they offer high precision, finely detailed impressions and a smooth, matt surface finish. Their properties make them ideal for use in jewellery, dental prosthetics and high-quality parts.

What does the choice of material for 3D printing depend on?

8 Which material would you select for printing in the following cases?

a) A mould for cutting out biscuits.

b) The handle of a frying pan.

c) A children’s toy.

d) The wheels for a remotecontrolled car.

9 In which cases do you think it is inadvisable to use PLA printing material, and PVA material? Research what kind of 3D printing material can be recycled.

3D printing 7

Layered 3D printing process

The print configuration information is stored in the print file. The nozzle moves to the first point and starts to deposit melted filament onto the print bed. This first layer will adhere firmly to the bed and serve as a base for the following layers.

Once the first layer is complete, the printer lowers the bed along the Z-axis, or raises the nozzle. The printer proceeds to deposit a second layer of material on top of the first layer. This process is repeated until the entire part is built.

Most of the materials used melt with heat and solidify quickly on contact with the previous layer. An exception to this would be SLA printing where it is necessary to expose the part to ultraviolet light to achieve the desired melting.

Once the printing process is finished, wait for some time for the part to solidify completely before carefully removing the part from the printing bed.

What problems can arise if you don’t keep the nozzle clean?

Common problems in 3D printing

• Media clogging: occurs when the media cools down in the nozzle and solidifies, or when there is dust or particles clogging the nozzle outlet. To avoid this, make sure the media is clean and dry before loading it into the printer. In more drastic cases, the solution is to disassemble the nozzle and clean it.

• Poor layer adhesion: this occurs when the bed is incorrectly levelled, the printing or bed temperature is incorrect or we chose the wrong printing material. We must clean the surface of the bed before each print.

• Deformation of the part: this occurs if the first layer does not adhere correctly, due to sudden changes in temperature, when the object is poorly designed or if we have not used appropriate supports. To avoid this problem, it is necessary to level the bed well, avoid draughts or temperature changes during printing and use the appropriate supports.

• Separation between layers: this is mainly due to a poor choice of printing speed or temperature. Adjusting the printing speed and temperature can avoid this.

• Excess material or threads: this happens when the nozzle continues to extrude material as it moves from one location to another. In the printer settings you can adjust the retraction speed to momentarily stop the extrusion while the nozzle moves to the next location.

• Stopping the print prematurely: we will need to ensure that the filament is in a holder that allows it to unwind smoothly, check the electrical connections and process our designs in a stable file format.

• Rough or uneven finish: the main cause lies in the printing parameters, such as the distance between layers or the printing speed. A lower layer height and a slower printing speed will give a smoother finish.

We advise you to pay attention to the piece while printing on your first print jobs.

10 Identify the source of the problem and explain which parameters you would modify in each case:

a) The part splits.

b) The part has many filaments between the detailed structures and the surface is rough.

Responsible use and practical applications of 3D printing 8

Basic safety standards

• Adequate ventilation: Some materials used in 3D printing can emit fumes or expel harmful particles. When working with these materials it is essential to locate the 3D printer in a well-ventilated area.

• Continuous monitoring: it is necessary to keep an eye on the printing process. This way we can detect problems and pause printing until they are solved.

• Proper maintenance: The 3D printer requires regular maintenance to ensure its safe operation. This maintenance should consist of cleaning the components that have the most contact with the filament, such as the nozzle and the print bed, and checking the electrical connections and cables.

• Electrical safety: make sure it is connected to a grounded socket and that cables and plugs are in good condition.

• Materials storage: some printing materials may absorb humidity affecting the print quality or causing problems in the process. Store such materials in a cool and dry place and use desiccant bags.

Ethics in 3D printing

Regulating 3D printing is tricky because it enables people to make things at home instead of buying it. Governments must establish rules to deal with the legal and moral issues of 3D printing, especially in areas such as medicine, industry and retail.

We may not copy or reproduce objects that are protected by copyright without proper permission from the copyright holder. Designing or printing dangerous or illegal objects is prohibited. This includes any firearms, bladed weapons, dangerous devices or any other objects that may break the law or put people at risk.

The development of 3D printing has impacted our everyday lives by offering numerous new applications, greater customisation to individual needs, productivity improvements and opportunities for innovation.

3D printing in everyday life

Here are some examples:

Is it safe to touch the hot parts of a 3D printer while it’s in operation?

• Personalised prostheses: 3D printing has made it possible to develop individualised prostheses for people who have lost a limb.

• Fashion design: it is used to create exclusive costume jewellery accessories and in the design of haute couture dresses, eyewear and other accessories.

• Interior design: customisation of lamps and decorative elements adapted to the needs of each home.

• Architectural models: printing of models of architectural projects.

• Personalised toys: it is possible to print educational toys adapted to different needs.

3D printing in industry

• Aerospace: 3D printing makes it possible to manufacture lightweight and strong aerospace components, such as engine parts and aircraft structures.

• Automotive: used to build some parts for vehicles and to customise components, but mainly to print prototypes.

• Dentistry: this is one of the fields that takes most advantage of 3D printing. Dental prostheses, orthodontic aligners, crowns and bridges are printed in a personalised way.

• Medical industry: 3D printing makes it possible to print models of organs and tissues that are used for practice before performing surgery on real patients. Some implants are also printed to provide structural support.

• Food industry: 3D food printing is still in the process of development. Some firms use it to create edible decorations.

• Construction: taking advantage of the physical properties of concrete, some firms are experimenting with 3D printing to construct small buildings.

As this is a relatively new technology, there are still many lines of research to be explored.

11 True or False: It’s okay to leave a 3D printer running unattended for long periods of time.

12 Why is it important to ensure proper ventilation in the area where a 3D printer is operating?

The final challenge

Making a Mozarabic lattice with SketchUp

Based on the Mozarabic-style lattices that can be found in the autonomous community of Andalusia, make a personalised one. To do this, establish a module that is superimposed on another to form a complex structure.

STEP 1

Draw a star

• Start by drawing an eight-pointed star.

• Then find its centre by joining opposite vertices as shown in the figure.

STEP2

Copy the star

• Select the star with the cursor icon and copy and paste it nearby. Make sure they do not overlap.

• Scale the star you have duplicated so that it is slightly larger than the original. You can do this by pressing the S key on your keyboard and dragging the pointers in the corner of the image.

STEP3

Form a double star

SCAN THIS CODE TO CONSULT THE GLOSSARY FOR THIS UNIT.

STEP 4

Form lines of stars

• Then select the star. Copy the original star next to it and move it until they overlap.

• Repeat the previous step until you have three stars joined in the same row. This will create a second row of stars, all overlapping each other.

• Be sure to delete ancillary lines that will only interfere with the work.

STEP 5

Colour it

• To give it some colour, go to the materials tab and choose the ones you like best. To paint the design, place the end of the paint can on the surface you have created.

• Now move the large star to the centre of that star, until it is positioned in the centre of the original small star.

• Delete all unnecessary surfaces. You can use the eraser or select what you want to delete and press the Delete key on your keyboard. At this point you should have a double star as shown in the image.

SUSTAINABLE TECHNOLOGY 1

1 Technology and Sustainability

Sustainable resources

Satisfy the present without harming the future

• Transportation

• Automation

• Circular economies

• Precision agriculture

• Renewable energies

First technological revolution

Development of tools and mastery of fire

Society

Areas of sustainability

The economy

The environment

1 Explain how the environment and economy are related by sustainability.

Foundations of the Industrial Age

The Neolithic revolution

Population growth, animal domestication and land cultivation.

First civilizations:

Trade development, the use of new materials and population growth.

2 Explain the main characteristics of the first technological revolutions.

The First Industrial Revolution

Main triggers

Use of fuels the first fuel was coal

Steam engine

stationary machines

means of transport

The Second Industrial Revolution

Petroleum and related fuels

Main triggers

Electricity

Impact

Social changes

mass migration from the countryside to cities.

3 Describe the changes in society brought about by the arrival of the steam engine.

Thomas A. Edison and Nikola Tesla the drivers of electrical systems

Main developments changes in construction

Steelmaking

Development of the petrochemical industry invention of plastic

Scientific theories in manufacturing productivity increase

Communications boom invention of the telegraph and radio

4 Describe the advances of the Second Industrial Revolution..

Main triggers

Globalisation

Advances in electronic and computer systems

The Third Industrial Revolution

Information society

The Internet

Improved transport efficiency

Communications development

Automatic systems in manufacturing

Impact

Access to commodities markets

Economic exchange between countries

Fast and efficient movement of goods

E-commerce growth

5 Explain what changes rapid transit has brought to commerce.

Negative effects of technological development

Climate change

CO2 emissions

Due to industries and transportation

Melting glaciers, sea level rise, droughts, storms.

Primary pollutants

Spread from emission sources

Atmospheric pollution

Soil degradation

Marine pollution

Secondary pollutants

Originate in the atmosphere

Desertification

Due to changes in climate, deposition of harmful chemical compounds and overexploitation

Caused by toxic spills and accumulation of plastics

6 Explain what effect plastic has on the environment.

Negative effects of technological development on society

Generates inequalities

Economic Unequal distribution of wealth

Social

Discrimination of all kinds

Political Persecution for political ideas

Promote Equality

Employment policies

Promotion of public servides

Political and institutional transparency

Reduction of monopolies

Sustainable Development Goals

Consequences of inequality

Poverty Lack of access to basic services

7 Explain how the consequences of technological development can be avoided.

8 Say which goals you think are most important and explain why.

Emissions trading

Initiatives to reduce emissions

Global emissions market.

Assign maximum emissions amount by country

Proposed remedies

Agenda 2030

Publish the carbon footprint. Develop emission reduction plans

Issues arising

Injustice between countries limits the growth of the least wealthy countries

Reducing production affects the economy

11 Look at the map of the countries with the lowest average emissions and net removals of carbon dioxide and analyse the relationship between the pollution produced and the level of economic development of the country.

Natural heating systems

Solar collection, geothermal energy

Rainwater harvesting

Use in health systems

Ecological design

Natural ventilation

Walls to direct and refresh air

Use of hybrid or electric vehicles

12 Say how you could get around to contribute to more sustainable transportation.

Renewable energy systems

Solar collectors, photovoltaics

Sustainable infrastructure

Water recycling

Separation of grey and black water

Sustainable transport

Hydrogen as bus fuel

Multimodal street systems

Native plants

Need less watering

Traffic control systems

3D PRINTING 2

Introduction to 3D printing

Design and production of plastic parts

Uses filament spools With ABS and PLA plastics

Fused Deposition Modelling (FDM)

uses a filament composed of thermoplastic material that is gradually melted and extruded.

TYPES OF 3D PRINTERS

Stereolithography (SLA)

is based on the polymerisation of liquid resin using an ultraviolet laser.

Selective Laser Sintering (SLS)

uses a laser to fuse powdered particles.

1 Indicate the differences between each type of printer.

Types of CAD tools

2D CAD software

Used to create two-dimensional drawings

AutoCAD 2D is one of the most widespread design software programs.

3D CAD software

Enables the creation of three-dimensional objects

These are more advanced programmes such as SolidWorks and Autodesk Fusion 360.

Parametric CAD

Creates a threedimensional model while maintaining its parametric relationships

The most widespread parametric CAD is Siemens NX because of its application in mechanical engineering and automotive engineering.

Direct modelling

Allows you to edit any 3D model in an intuitive and simple way

An example of such programmes is Tinkercad.

2 Explain which programme you would use if you wanted to draw a map of your school playground.

Most widespread CAD tools

Tinkercad

Accessibility Web tool

Ease of use

Intuitive interface

Direct modelling

Any object is editable

Component library

Large library of figures

Basic tools

Shaped compositions

Design in the cloud

Cloud storage

Compatible with 3D printing 3D compatible format

Fusion 360

Parametric design

Parametric modelling

Comprehensive 3D modelling

Generate complex 3D models

Simulation and analysis

Simulates real conditions

Rendering and animation

Render objects in 3D

Team collaboration

Working in the cloud

Compatible with 3D printing 3D compatible format

Licences

Free and paid

3 What are the advantages and disadvantages of the three CAD tools mentioned above?

SketchUp 2D Software

Intuitive design

Convert figures into 3D

Creation of 3D structures

Ideal for architecture

Object library

Extensive library of objects

Extensibility

Free and paid licences

Connecting with the community

Shared resources

Google Earth integration

Geolocation of objects

Design in Tinkercad for 3D printing

4 Say what process you would follow to build a puzzle piece.

STL

Stereolithography

The most widely used format in 3D printing.

Represents geometry but does not contain colour or texture information.

OBJ Object Another common way of representing 3D models.

They can contain information about the geometry and colour of the object.

3MF

3D Manufacturing Format

A new format.

Stores complete information about the model

File formats for 3D printing

AMF Additive Manufacturing File Format

STL-like format, but more complex.

Allows the storage of additional information, such as colours and materials.

STEP Standard for the Exchange of Product Model Data

Additive

Manufacturing File Format

Stores complete information about the model.

It is a specific type of 3D printing format.

5 Explain which file format you would choose to save your design of a 3D object if you wanted to have information about the geometry and colour of the object.

Preparation of files for 3D printing

Print media

Determines

Amount of the object to fill with the printing material.

Suitable for models with delicate details and small contact areas. Tree

6

3D printer configuration

Parts of a printer

Coil holder

Guide the material filament

Axles and engines

Controls spindle movement

Extruder or head

Deposits material in layers

Structure

Printer frame

Print bed

Printing surface

Power supply

Supplies energy

Print bed levelling

Print settings

Ensures that the first layer of print is uniform and adheres properly to the bed.

Coil holder

Z-axis

Extruder

Structure

Power supply

Types of 3D printing materials

FDM printing

PLA

Printing of aesthetic prototypes

ABS

Printing of functional prototypes

PETG Used in mechanical parts

PVA Used as support material

Nylon

Used in medicine and machinery

TPU Used in flexible parts

Compatible with 3D printing 3D compatible format

8 Say what material you would choose for a 3D print if you wanted to build an orthopaedic prosthesis.

Printer calibration

E-Step Calibration

Regulates the amount of filament

Temperature calibration

Adjust the temperatures

Retraction

Controls the extruder

X-axis

Warm bed

Y-axis

Electronics and display

Print speed

Printing accuracy

7 Say which parameter should be adjusted to achieve better print quality.

Printing SLA

Resins

Offer high precision

3D printing process

Consists of the creation of three-dimensional objects by adding material in a precise and controlled manner, layer by layer.

Rollers pushing the filament into the nozzle

Close-up of the nozzle depositing the molten plastic

Plastic filament spool

Bed

Heating and melting of the filament

Depending on the model, the bed and/or the nozzle move in the direction of the three axes, X, Y, Z.

9 Explain how a 3D printed object is formed.

Common problems in 3D printing

CAUSE

Material backlog

Poor adhesion of coatings

Deformation of the part

Separation between layers

Excess material or threads

Printing stop

Rough or uneven finish

The printing material cools in the nozzle and solidifies.

The bed is incorrectly levelled or the temperatures are incorrect.

The first layer does not adhere properly causing an imbalance between layers.

Incorrect selection of printing speed or printing temperature.

The nozzle continues to extrude material as it moves.

Related to a power supply problem or a file error.

Compatible with 3D printing 3D compatible format

SOLUTION

The media must be clean and dry before loading it into the printer.

Level and clean the bed before each print.

Avoid draughts and temperature changes.

Adjust the print speed and temperature.

Adjust the retraction speed.

Check electrical connections and process our designs correctly.

Set the layer spacing or print speed appropriately.

10 Analyse what problem has arisen if a part appears to be melted.

Basic safety standards

Responsible use of technology in 3D printing

Adequate ventilation To avoid breathing toxic particles

Continuous monitoring

Monitoring the printing process

Adequate maintenance

Clean and check components

Electrical safety

Connected to grounded socket

Storage of materials

Store in a cool, dry place

Ethics in 3d printing

Capacity to enable decentralised production of consumer goods

We must respect copyright and intellectual property rights

We must not design or print dangerous or illegal objects

11 What are the ethical issues associated with 3D printing?

Practical applications of 3D printing

Everyday life

Customised prostheses

Accessible prostheses

Fashion design

Create unique accessories

Interior design

Personalised decorative elements

Architectural models

Personalised toys

12 Explain

Industry

Aerospace

Lightweight aerospace components

Automotive

Part for vehicles

Dentistry

Produces dental prostheses

Medical industry

Print model organs

Food industry

3D food printing

Construction

Small buildings

© This edition: GRUPO ANAYA, S.A., 2024 - Valentín Beato, 21 - 28037 Madrid - Printed in Spain.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior permission of the publishers.