Sorry to bang on about it but if you attended Hillhead 2024, you’ll know where we’re coming from! Once you’re there, fantastic. Plenty to see and do, machines galore, innovations by the bucket load. But, and it’s a big but, getting there was an absolute nightmare. Hours in traffic, single track roads and then a twenty-minute walk to the display area itself if you didn’t fancy waiting for the bus. Even then, if you were the 17th person in the line, you’d be disappointed and have to wait for the next one.

If it was challenging for visitors, then spare a thought for the poor exhibitors. Tales of having to leave digs at 6am to ensure prompt arrival at their stands were commonplace. No surprise then that everyone looked jealously at the blue skies above every time another helicopter circled and landed. Mind you those arriving by air were blowing some big cash by all accounts, £12m allegedly by one punter alone.

Having said all that Hillhead was deemed to be a big success. A just-received press release from the organisers froths with excitement, claiming the event ‘was the most visited show ever in terms of the volume of visits over the three days, with visitors spending more time at the show than ever before and a record number attending for more than one day. In total there were 26,626 visits over the three days, which was 8% higher than 2022.’

It continues ‘in terms of unique visitors, with 19,577 attendees (+6.2% compared with 2022) this year’s show had the second highest ever number of unique attendees (only 2018 was higher at 19,753, although that show had less volume over the three days).’

And finally, it says that ‘the last Wednesday was easily Hillhead’s busiest day ever with almost 10,800 people on site throughout the day!’ These are indeed impressive stats, and we should indeed thank and congratulate the organisers on a job well done, travel aside.

However, the biggest plaudits should probably be reserved for all the visitors, all 20,000 of them, who displayed enormous patience and staying power to actually get to the venue.

Access to Hillhead has always been a hoary old chestnut and one wonders whether the time between shows induces a kind of memory loss with attendees forgetting how painful the experience was.

We are not saying that we have the solution, and there are probably traffic constraints that we don’t know about, but when you look around as you sit in your stationary car at the land available that could be utilised for better access, then you do wonder.

Anyway, moan over, it was great to attend Hillhead and we are already looking forward to the next one. If you want to see some highlights from the show, then be sure to turn to page 16 for the first of our reviews.

Happy reading

Editors JOHNNY DOBBYN JOHN LEVICK cpn@hamerville.co.uk

Advertising Manager MATTHEW BOASE mboase@hamerville.co.uk

Group Manager

ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer GEMMA WATSON

Group Production Manager CAROL PADGETT

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2024

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

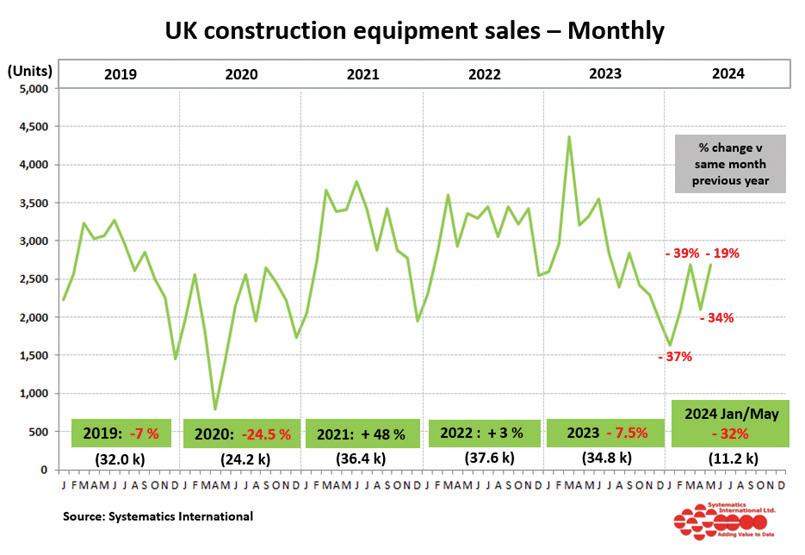

RETAIL SALES OF CONSTRUCTION AND EARTHMOVING EQUIPMENT INCREASED IN MAY AFTER FALLING BACK IN APRIL, ACCORDING TO THE LATEST FIGURES RELEASED BY THE CEA.

were the two best-performing higher-volume products, while road rollers continue to be the

information

RYGOR PLANT, PART OF THE RYGOR GROUP, HAS CONFIRMED THAT IT HAS BECOME AN OFFICIAL DISTRIBUTOR FOR HPC MOBILAIR PORTABLE COMPRESSORS.

Tony Reeves, head of sales, said: “I am delighted that Rygor Plant is now offering customers the full range of HPC KAESER Mobilair compressors as part of our wider product line-up. We know that the needs of our customers are diverse and continually adapting, which is why Rygor Plant has enhanced its offering further, to provide even more customer choice. The Rygor Group has been supporting customers across the earthmoving sector for decades and our team across the group and specifically at Rygor Plant, has extensive knowledge of the requirements of our customers, so I cannot wait for myself and team to bring this product to them and their businesses.”

For further information WWW.RDR.LINK/CAU002 i

MILLER UK DISPLAYED FOUR OF ITS MOST POPULAR HEAVY-DUTY BUCKETS AT HILLHEAD, WHICH HAD BEEN SPECIALLY BRANDED WITH THE LIGHTHOUSE CONSTRUCTION CHARITY’S #MAKEITVISIBLE INITIATIVE.

The buckets were sited around Hillhead - on Miller’s stand itself, as well as on customers’ stands including Case Construction, SMT GB and Hitachi Construction Machinery UK.

For further information

WWW.RDR.LINK/CAU003 i

FOLLOWING ITS RECENT 75TH ANNIVERSARY IN APRIL, CHIPPINDALE HIRE & SALES HAS GOT MORE BIG NEWS AS IT ANNOUNCES THE LAUNCH OF ITS ONLINE SALES PLATFORM.

Following a two-year research period with customers, the firm has developed a clear, straightforward website with intuitive navigation, one-click processing and account hubs which make it easy for customers to find and pay for exactly what they want. The new e-commerce store offers an extensive selection of tools and equipment, with all products hand-selected by experts, ranging from Stihl’s market-leading gardening tools to robust construction equipment like mixers and breakers from top brands including Atlas Copco, Belle and BOMAG. For further information

JET PLANT HIRE SAYS IT IS CONTINUING TO HELP DRIVE INDUSTRY STANDARDS IN SUSTAINABILITY AND COMPLIANCE, WITH REGARDS TO USED PLANINGS AND SWEEPINGS REMOVED FROM ROAD SURFACES.

During the last year Jet Plant has delivered hundreds of thousands of planings from its work sites. The majority of those planings have gone to local businesses, with others delivered to asphalt plants to be recycled into new materials. On average Jet Plant generates nearly one million tonnes of road planings per annum.

By repurposing 100% of road planings, the firm says it is actively reducing waste and helping conserve natural resources, aligning with its strong environmental responsibility goals.

Charlotte Chetland, planing sales team leader, commented: “Jet Plant is committed to setting the industry standard in sustainable planing solutions. Our focus on sustainability, compliance, cost efficiency, versatility, and traceability shows our dedication to delivering value to our customers while minimising our environmental impact.”

For further information

WWW.RDR.LINK/CAU005

IN WHAT IT CLAIMS IS AN UNPRECEDENTED NEW INITIATIVE FINNING UK & IRELAND IS SUPPORTING THE FUEL ECONOMY ON THE LATEST MODELS OF CAT MACHINES.

The fuel promise is available to customers who take one of the company’s service contracts (customer value agreements) when they purchase any of the latest models of excavators, wheel loaders, dozers and trucks.

Andrew Bradbury, product manager at Finning, explains: “For most industrial operations using heavy plant machinery, fuel can account for up to 30% of costs. Although fuel prices have stabilised in the UK & Ireland, we have still seen a significant increase over the last few years and the long-term picture is uncertain at best. Anyone buying a new Cat machine with one of our customer value agreements means we can guarantee the average fuel consumption will be below a certain level specified for that machine.”

The fuel promise states that Finning will reimburse the customer in the form of credits if consumption levels rise above the agreed level.

For further information

WWW.RDR.LINK/CAU006

THE CONSTRUCTION EQUIPMENT ASSOCIATION (CEA)HAS RELEASED ITS 2024 MANIFESTO, OUTLINING A COMPREHENSIVE STRATEGY TO ADVANCE THE UK CONSTRUCTION EQUIPMENT INDUSTRY.

Focusing on decarbonisation, digital transformation, skills development, and regulatory consistency, the manifesto highlights critical areas for growth and alignment with global standards.

Viki Bell, CEA director of operations, said: “In the Spring of 2024, the CEA policy group was established to prepare this manifesto, which sets out our position for a clear and transparent approach to tackle the challenges facing the construction equipment sector and the wider construction, engineering, manufacturing, and education sectors.”

The manifesto underlines the CEA's commitment to being the industry voice and advocating for policies that support sustainable growth and innovation.

WWW.RDR.LINK/CAU007 i

For further information

WORK HAS STARTED ON A NEW $500 MILLION JCB FACTORY IN NORTH AMERICA – THE BIGGEST-EVER INVESTMENT IN THE COMPANY’S HISTORY.

At an official ground-breaking ceremony at the site in San Antonio, Texas, Alice Bamford, daughter of company chairman Anthony Bamford, cut the first sod of earth. The factory will make Loadall telescopic handlers and aerial access equipment, with production scheduled to start in 2026. The factory will also have the capacity to expand into the manufacture of other products in the future.

Chairman Lord Bamford said: “Construction equipment manufacturers sell more than 300,000 machines every year in North America, making it the single largest market in the world. JCB has been growing its share steadily over the past few years and the time is now right to invest in our manufacturing capacity in North America, where we already have one factory. Today really is a milestone day in the history of our family company.”

RAIL PLANT GIANT QUATTRO PLANT HAS ACQUIRED 130 RRVS IN A MULTI-MILLION POUND DEAL FROM THE FORMER TXM PLANT, WHICH FELL INTO ADMINISTRATION IN JANUARY 2024.

Quattro engineers inspected each of the 130 road-railers and the company is currently busy with a re-branding overhaul of the fleet.

“We had a mammoth logistical operation on our hands moving all this kit whilst carrying on our normal operations. We put an excellent field team out there to assess every single piece”, says John Murphy, Quattro managing director. “Our team did an absolutely sterling job in a very short space of time. These additional machines will help us fulfil some of the years of work Quattro has ahead of us. Once prepped, the RRVs will go out on site immediately, guaranteeing work for the future.”

For further information

WWW.RDR.LINK/CAU010 i

For further information

WWW.RDR.LINK/CAU008 i

GERMAN FORMWORK AND SCAFFOLDING BUSINESS PERI SE HAS TAKEN OVER MABEY HIRE.

Under the terms of the deal, which was signed in May, Mabey Hire will continue under its current management, brand and name and will operate as an independent company under the umbrella of Peri UK.

“Becoming part of the Peri Group is an excellent opportunity to better serve the needs of our customers and offer them the best service possible. Therefore, we already look forward to working together to expand the business by serving more customers in both the UK and internationally” said David Adams, CEO of Mabey Hire. “Together, we will work to achieve cross-selling opportunities to offer our customers an even broader range of infrastructure and renovation products and continue the drive to always provide the best possible service to our customers,” added Ian Hayes, managing director Peri UK.

For further information WWW.RDR.LINK/CAU009 i

The Euro Auctions sale in Leeds claims to be the largest auction in Europe, extending to over 100 acres and selling 7,500+ items of heavy construction plant and machinery at each sale. But who is Euro Auctions and why should it be selling your equipment or why should you be buying from it? CPN finds out.

Plant auctions were once seen as the place where worn out kit was sent at the end of its life. But times have changed and auctions are now viewed as the place to buy good, fresh, lateplate and often unused equipment.

For rental companies rationalising their stockholding, for contractors refreshing their fleets, for businesses needing a cash injection or operators retiring from the industry, auctions, such as Euro Auctions, can and will turn your iron into cash.

Whilst many may see Euro Auctions as a UK business, the company is a global player, and the largest privately-owned auction house in the world. The company was founded in Northern Ireland over 20 years ago and the Leeds auction site is the largest in Europe. Many still believe the business was the subject of a takeover by its largest

competitor Ritchie Brothers in late 2021. However, in April 2022, the UK competition watchdog, the Competition and Market Authority (CMA), contested the takeover and the deal did not go ahead. Now, today Euro Auctions remains a privately-owned family business, run by the five Keys brothers. It is number one in EMEA (Europe, Middle East and Africa) with a global reputation, and permanent auction sites in Europe, the Middle East, Australia, the USA and Canada. The failure of the 2021 takeover bid galvanised the business to continue its global expansion. In 2023, three sites in Canada were acquired under the Michener Allen banner, giving the business greater global reach. Whilst in the Middle East, in Abu Dhabi, a new site was acquired with the appetite to be the biggest operator in the Gulf.

The flagship sale site in Leeds has gone from strength to strength, and now regularly sells 7,500 plus machines in a three-day auction, where over 700 vendors from 30+ countries consign lots to this single sale. Hammer totals of upward of £50 million are commonplace. To understand the sheer scale of this auction, for each event, more than 1,500 excavators, over 1,000 commercial vehicles and approaching 1,000 MEWPS and telehandlers go under the hammer. However, quite amazingly, once the sale is over, and the yard is cleared, it’s full to bursting just six weeks later, ready to go again.

Following depressed production throughout Covid, OEMs are now supplying volumes of new machines. With main dealers now disposing of used machines in a swop for new, Euro Auctions is attracting good solid inventory of fresh, late machines at all auctions. Trusted by main dealers and OEMs as part of their used machinery disposal strategy, the auction house achieves true market value for consignments. As a result, at all sales, the volume of excavators, dozers, crushers, screeners, dump trucks, loaders, telehandlers, and backhoes, that are 2018 to 2023 plate, represent 24% of all machines going over the ramp. That is the calibre of the equipment for sale and why consignors sell here.

The events attract a truly international audience where bidders from over 100 countries register to buy at each sale. The top buying countries are consistently the UK, Republic of Ireland, Belgium, The Netherlands, Poland, Spain, and Romania. Buyers from North and South America are still evident at all sales as buying in the UK represents good value with buyers taking multiple machines off the ramp with a single bid.

Global buyers bidding at the Leeds sale are now able to request ‘live inspections’ for all on-site lots. Unable to make the live sale? Needing that extra assurance before you bid? An inspector can carry out a live comprehensive inspection on the prospective bidders' behalf, through voice and video linkup, thus enabling them to bid with confidence.

So, what makes Euro Auctions unique? One of the defining strengths and selling points when compared with the rest of the market, is the live, parade-style sale. The machines line up in their thousands. The chant of the auctioneer and the buzz created by the live crowds at the Leeds auction site is truly palpable.

The gathering of buyers and sellers, of dealers and representatives of most OEMs create a market buzz that helps the sale gain momentum, creating that competitive edge, which encourages good prices as bidders compete to win lots. Tyres are kicked, friends unite, buyers and sellers chat and exchange anecdotes, and this in turn creates the magic of the sale which is Euro Auctions.

lifting sector, Cadman Cranes has come a long way on its green journey over the past few years. CPN talks to MD Matt Waddingham about the transformation of its operations and what the future looks like for the business.

MW. Covid was certainly a turning point for us. It was strange and uncertain time for business. But it did allow us a moment of reflection and we were able to ask ourselves some tough questions. Before Covid we were mindlessly chasing profit. However, once we returned there was a desire, a need, for it to be about more than that. From this point, our purpose and values crystallised and a big part of that was sustainability – in all its forms.

Plus it helped having my son come home from school telling me that my generation has ruined the world and asking what I’m doing about it!

QWhat was the first step you took to becoming more sustainable and when did you start implementing processes to become more sustainable?

MW. It’s important to be clear that sustainability for us is not just about the environment, it’s also about people and communities and the resilience of our business.

Our environmental sustainability journey started in early 2021. We looked at our business and asked ourselves where we were doing the most harm. It wasn’t a hard question – moving hundreds of tonnes of metal around the country every day is thirsty work. The cranes run at under three miles to the gallon, and we get through a lot of fuel. We have been tracking our CO2 since 2016 but that’s all it was – and the more we grew, the more CO2 we produced. Which is why we started looking at alternatives to diesel.

Batteries are not powerful enough for a mobile crane on the road and hydrogen,

though exciting, is some way off yet. We started looking at biofuel alternatives without any real understanding of what they were. We stumbled upon some articles about hydro-treated vegetable oil (HVO) and after a bit more digging, we were staggered by the properties and benefits that this fuel demonstrated.

QDid you find that there were barriers to becoming more sustainable to start with? What did you do to overcome this and measure your success?

MW. Because we were the first to ask the question about sustainable fuel we didn’t have approval from the manufacturers. Thankfully our main supplier – Liebherr –were already looking at it and I like to think our enthusiasm influenced them to sign off on HVO for all their newer machines. Once we had that we haven’t really looked back.

Since we’ve switched to HVO fuel, we’ve reduced our CO 2 by 95% in four years. We also measure our waste recycling, energy recycling, water consumption, road miles, community and charitable engagement, staff retention as well as CO2 in our supply chain. We put targets on these things and call that success.

We’re only a small company and our real success, which is more difficult to measure, comes from how we can influence others. If we can bring about, or at least accelerate change, then that’s where we can have the real impact.

QHow have you engaged with the wider team / suppliers / partners to ensure everyone is onboard and shares your principles?

MW. I want everyone on board, but I am not going to tell anyone what to think. Saying that, the engagement has been positive, and our people are challenging things, asking questions and promoting it to our customers. We just need to provide the information, tell our people why we are doing things, give opportunities to engage and be consistent.

With regards to the wider supply chain, this is the current challenge – but we’re working on it!

QDo you have any tips for other businesses looking to follow suit?

MW. Just go for it. It’s not that difficult once you commit to it. You don’t have to change the world; you just have to make an impact where you can.

There is an investment of time and money, however it allows you to target clients and projects where sustainability is prioritised – this is often where the real money is being spent.

QWhat are your core sustainability goals over the next five years?

And where do you see the sector in 10 year’s time?

MW. We want to be net zero for our own operations by the end of 2025. This may mean offsetting the last few tonnes which is something we want to understand better.

We need to ask ourselves: is it better to pay an amount of money to get some carbon credits for a project somewhere in the world and be able to say you are net zero? Or is better to forget net zero and donate that money to a local school to put up solar panels or a bio-diversity garden? I don’t have the answer yet.

Being sustainable is quite easy in some industries but plant operators are changing the landscape of the country so we’re going to be making an impact. The key is to make our impact in the least harmful way possible. After that I think incentivisation is the keyfrom end user to investor through main contractors to plant operators right down to manufacturer, we need to link sustainability to success.

Ultimately, this is not going away. I think it will be the challenge of ours and our children’s lifetime and whether it’s by choice or by regulation, companies are going to have to adapt. But we’ve been doing that for decades, I have every confidence in the will and ingenuity of this industry.

And that was just the traffic. CPN’s Nick Johnson reports on Hillhead 2024, where great weather, great visitor numbers and great displays were let down by poor logistics and awful access.

The sun shone on the Hillhead quarry this year and there was much new kit on show to lift visitors’ spirits. Unfortunately, the show was let down by poor access, resulting in diabolical traffic jams and epic queues to get in.

The CPN team took just over two hours to cover 10 miles on the opening day, with the last four miles accounting for 90 minutes of that. We spoke to someone on day two who took three hours to get in, setting out from central Buxton – a mere two-and-a-half miles away.

Long-standing visitors of many years related how getting to and into Hillhead has never been great, yet this year was the

worst yet. And having braved the traffic, the queues at registration weren’t much shorter. One wag quipped that if the plant industry had a secret service, Hillhead would be charge of Q Branch.

But once in, it was an impressive spectacle. This year’s show was bigger than ever and noticeable trends were the number of new electric machines, more site dumpers with reversible seats and controls and the increased presence of Chinese equipment makers with large stands.

Here are some of the highlights we encountered, with another hefty dose of new machines to follow in the September issue.

The long-established British site dumper maker Thwaites used Hillhead 2024 to finally reveal its prototype design for a cabbed machine with a rotating seat and controls. Called the Rotator R9, this articulated dumper was shown with a 9.0 tonne capacity non-rotating skip.

The Rotator R9 utilises a 3.6L Deutz TCD engine rated at 55kW and a Bosch Rexroth hydrostatic transmission. The machine will come with a United suspension seat, air conditioning and front and rear cameras as standard. A rotating skip option will follow.

Thwaites was also highlighting how its dumpers will be equipped next year to meet the new manufacturing standard EN474 2022: part 6. From Spring 2025 Thwaites conventional 9-tonne capacity forward tipping dumpers will be supplied exclusively with cabs. The smaller 6-tonne capacity dumpers will become compliant by either being supplied with a cab or the new Thwaites ROPS+ system which includes an additional latch bar which is pulled down over the operator and locked into position.

For more on Thwaites,

WWW.RDR.LINK/CAU013

A big talking point was the appearance of Bell’s new autonomous ADT on the demonstration haul road at the show. This 40-tonne capacity truck has been used by Chepstow Plant International at Sibelco’s china-clay Cornwood quarry in Devon since March, when it was launched as the first autonomous ADT in the UK. Hardware for this drive-by-wire ADT has been supplied by technology platform specialists, xtonomy, and this includes radar sensors, high-precision GPS, multi-channel communication systems and on-board processing hardware.

An interesting machine on the Bell stand in the main showground was an EU-marked Bell B30E 6x6 articulated water truck with a water capacity of 27,000l. Sign-written as the Collins Dust Suppression Unit, this unit has auto spread (to ensure a uniform spread of water regardless of vehicle speed), on board water weighing and five pneumatically operated spray valves at the rear.

Another notable exhibit was a CEmarked TC11A tracked carrier. Powered by a 186kW Cummins B6.7 engine, this machine has an unladen weight of 14,000kg and its skip capacity is 11,000kg.

For more on Bell,

WWW.RDR.LINK/CAU014

Having done very well in the UK with its Dual View site dumpers, Wacker Neuson made a surprise reveal with a bigger capacity model at Hillhead. Shown in prototype form, the forthcoming DV125 has a 12.5-tonne capacity skip.

Wacker Neuson reports that orders for 20 DV125s have already been received from UK customers. The new flagship

DV125 with its rotating seat and controls has a rear tipping skip with a heaped capacity of 7.0m3. The company also displayed its recently introduced DDV45 Dual View dumper which has a rotating cab and a swivel skip with a payload of 4,200kg.

Wacker Neuson

WWW.RDR.LINK/CAU015

This Finnish company was using Hillhead 2024 to promote its innovative electric breaker attachment. Designated the Leka Toras 35, this groundbreaking product is said to be 70% more energy efficient than comparable hydraulic breakers. Seen for the first time in the UK, the Leka Tora 35 weighs 540kg (with a 90mm diameter tool and mounting bracket). Input power is 18kW and its adjustable impact rate is 60 to 900 bpm. Impact energy is 300 to 1,500 joules. The attachment can be used on carriers weighing seven to 16 tonnes.

For more on Lekatech,

WWW.RDR.LINK/CAU016

A highlight on the Hydrema stand was the recently introduced electric version of the company’s unique small size ADT. The DT6 electric compact dump truck has a front mounted cab and a rear mounted 3.5m3 capacity swivel skip that carries a payload of 5.5 tonnes. The DT6 electric truck has two electric motors, one 24V motor for the control systems, cab controls and hydraulic valves and one 96V motor to power the ZF eTrac transmission, hydraulic pump and cab heater. There are eight 63kWh lithium-ion batteries - four located on each side of the cab. Charging is via an integrated 18kW fast charger in the machine.

For more on Hydrema, WWW.RDR.LINK/CAU033

This dealer provided the UK public debut of the new 23-tonne class Volvo EC230 Electric excavator.This environmentally friendly machine is powered by a 600V lithium-ion battery with a capacity of 264kWh. Running time (depending on application) is said to be around five hours with a recharge in as little as 80 minutes.

The stand also featured a Dynapac roller and paver as this dealer has been appointed the exclusive distributor for all Dynapac product lines in Great Britain. The new partnership will be effective from 1st October this year. The deal follows the sale by Volvo CE of its paving equipment business to Ammann in June.

For more on SMT GB, WWW.RDR.LINK/CAU034

Hillhead 2024 enabled Dynapac to provide the first UK showing of what is claimed to be the first electric paver in the world. Designated the SD1800We, this wheeled paver weighs in at 10.3 tonnes (with standard screed). The SD1800We can lay material at up to 350 tonnes/h and, with its telescopic screed fully extended, maximum mat width is 4.1m. Maximum paving speed is 25 m/min.

Power for the 55kW 3-phase permanent magnet synchronous motor (PMSM) in the SD1800We is provided by a 98kWh lithiumion battery. Recharging from 5% to 80% is said to take less than one hour with DC charging.

For more on Dynapac UK, WWW.RDR.LINK/CAU035

Creating a lot of interest on this company’s stand was the new Komatsu PC210LCE electric excavator. This 21-tonne class machine features lithium-ion battery technology developed by Proterra. The excavator has 451kWh of battery capacity and is designed to operate for up to eight hours before recharging is necessary.

The PC210LCE and the diesel-engined PC210LC-11 both now have the new Komatsu excavator cab. This features a new

premium seat, a new sunblind design, new coming home lights, new high visibility handrails, a new LED central internal light and an additional door handle. There is also a new control levers option.

For more on Komatsu, WWW.RDR.LINK/CAU036

Amongst all the different types of dieselengined machines on the Liebherr stand was the new L507E electric compact loader. This Generation 8 machine weighs 5,815 – 6.415kg and can be fitted with 0.8 to 1.6m3 capacity buckets. The L507E incorporates a 322V lithium-ion battery with a capacity of 32.2 or 64.4 kWh. This allows running times before recharge of up to eight or 16 hours. The loader has maximum travel speeds of 20km/h as standard or 30km/h in Speeder configuration.

For more on Liebherr, WWW.RDR.LINK/CAU037

Whilst Sany was highlighting its larger SY500H and SY390H tracked excavators at Hillhead, visitors could also see how this very large Chinese construction equipment maker is intent on scoring here with other machine types. Prominent with its fully extended boom was the largest of the company’s recently introduced European style, low boom telehandlers – the 4,000kg

maximum capacity STH1840 with a maximum lift height of 18.0m.

Sany is also adding vibrating rollers to its UK product offering and there was a STR50C-8K lightweight tandem on its own stand and a self-propelled SSR130C-10H roller (weighing 13 tonnes) on the Clee Hill stand. The STR50C-8K weighs 4,500kg, has a drum width of 1,380mm and is powered by a 36kW Kubota D2607 diesel engine. Smaller tandem rollers with drum widths of 1,000mm and 1,200mm are scheduled to be launched here next year.

Sany also showed what it claims to be the world’s first small battery powered planer. The prototype SCM500E-10 planer weighs 6,300kg, has a milling width of 500mm and a maximum milling speed of 33m/min. The unit will shortly be trialled in the UK.

For more on Sany, WWW.RDR.LINK/CAU038

The latest Smartpower+ generation of Brokk remote controlled demolition robots were on display at Hillhead. Three new rubber tracked models were lined up for the attention of visitors – the 70+, 170+ and 200+ with respective weights of 560kg, 1,600kg and 2,100kg. These new Brokks each feature an improved interface, augmented sensors, less wiring, more data processing power and over-the-air upgrades. They come with a new lightweight, more durable remote controller that has a bigger display screen. The first 70+ machine in the UK has been sold to EPS Drilling.

For more on Brokk, WWW.RDR.LINK/CAU039

A new machine receiving its first UK showing at Hillhead was Sunward’s prototype SWE50UF mini excavator. Weighing in at 5,350kg, this mini is 2,000mm wide and it is powered by a 29.7kW Kubota D1803-7 diesel engine. Production versions of the SWE50UF are expected to become available for sale at the end of this year. The Hillhead prototype was shown fitted with a 250mm diameter attachment.

For more on Sunward, WWW.RDR.LINK/CAU040

This Alton, Hampshire-based company used Hillhead for the UK exhibition introduction of the PowerBully 9D tracked dumper. Made in Germany by Kassbohrer Gelandefahrzeug AG, this machine weighs 12,450kg unladen and its rear tipping skip has a capacity of 7,500kg. The PowerBully 9D is 2,590mm wide and it is powered by a 173kW Cummins B6.7 diesel engine. Top speed is 14.5km/h. There is also a bigger capacity (11,500kg) PowerBully 12D tracked carrier. Swivel skip versions are likely to be introduced in the future.

For more on Waterbrook, WWW.RDR.LINK/CAU041

This Japanese company was putting the spotlight on its new 2-tonne class TB320 3 series tracked mini excavator. Designed for use as a tool carrier this machine provides a good array of auxiliary hydraulic service lines. It features a longer than average track frame to provide better operational stability when using attachments. Also attracting the attention of Hillhead visitors was the new 7-tonne class TB370W compact wheeled excavator. Features include a tilt-up cab for easier servicing, 270˚ cameras and cruise control. Equipped with a two-piece boom, the Hillhead show machine carried an Engcon EC206B5 tilt rotator and a GB03-150 grading bucket.

For more on Takeuchi, WWW.RDR.LINK/CAU042

This Suffolk-based compact plant maker used Hillhead 2024 to unveil its new CR450 diesel-engined tracked jaw crusher. This machine is powered by an electric start 14.9kW Kubota engine and its crusher mouth has a 460 by 205mm opening.

The fixed width (970mm) CR450 rides on rubber tracks and it can be operated by an optional remote control unit. Feed height is 1,396mm and the minimum discharge height is 1,035mm. The machine weighs 1,450kg

For more on Dragon, WWW.RDR.LINK/CAU043

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

Introducing CPN’s newest team member. Some say he brags about his bucket skills, others that he’s sharp with a blade. All we know is that we call him the Dig. This month he goes big with minis.

In 2021 a new era for Case began as parent company CNH Industrial acquired the privately-owned Italian manufacturer, Sampierana SpA, which has a long history of producing its own Eurocomach range of mini and midi excavators. The move effectively gave Case access to an in-house designed and manufactured range of compact excavators.

The company, thanks to its involvement with the Italians, now offers a range of 20 different mini excavator models from the one tonne CX12D up to the CX65D which competes in the 6-tonne class.

It is in the unique position of being able to offer no less than four mini excavator models featuring a two-piece-boom, including the smallest in-class TAB boom equipped CX20D 2-tonne model, up to the previously mentioned 6.5-tonne CX65D.

I’ve been keen to get my hands on one of these new models since they first started arriving in the UK, and fortunately I was invited down to my local dealers M&M Plant (Devon & Cornwall) Ltd, to spend some time in the seat of the 2.5-tonne offering, the CX25D.

It’s probably fair comment to say that the old Hyundai inspired Case mini excavators were looking rather dated, so it’s great to see these eye-catching Italian-designed

machines replacing them in the line-up. If we were talking cars then it would be like upgrading from a Kia Soul to a Ferrari Roma, such is the gulf in design aesthetics.

Of course, the CX25D is not the newest machine, we have been seeing it for a while now in its more traditional red Eurocomach plumage as the 25ZT model, but in the familiar Case tan livery and branding it takes on a whole new identity of its own and very smart it looks too!

With an operating weight of 2580kgs in its canopy variant, or 2710kgs with fully enclosed cab, these zero tail-swing machines are ideal for small groundworks contractors or jobbing builders and are easily transportable in-line with local towing regulations.

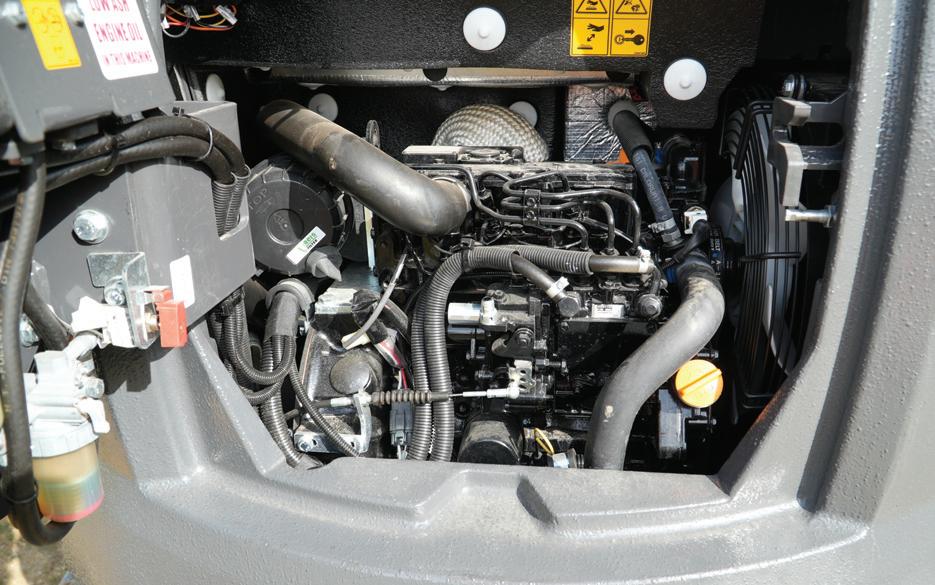

I took a walkaround this stylish 2.5tonner. The machine has a number of unique features, the most notable being that when you open the rear engine bay panel, you notice that the tough plastic door also integrates the 26-litre fuel tank, which is very clever use of a space that would otherwise be wasted. It’s such a simple but

effective idea, you wonder why nobody else has done it before. Additionally, just below the tank you find the fuel filter and water separator, which with the panel open, are super easy to work on when changing the filter or draining off water.

For those wishing to use heavy work attachments or fitting a tiltrotator, an additional counterweight can be specified, but will obviously negate the machines zerotailswing capabilities slightly.

Nicely packed inside the bay is the almost industry standard, Stage V emissions compliant, 3-cylinder Yanmar 3TNV76 diesel engine, which produces a power output rating of 13.7kw (18.6hp) @2200 rpm. Access for daily checks and oil filter change is good as one would expect these days.

Wandering around to the offside of the machine, and a large top bonnet raises upwards, while a side panel is easily removed to gain access to the radiator, cooling pack,

and expansion bottle. The plastic hydraulic oil tank which has a capacity of 26-litres, is also located under the bonnet but also forms the off-side front body work.

Below the hydraulic tank area, a lockable metal panel can be removed to gain access to the 12v battery, and the battery isolation switch. The battery looks like it could be a little tricky to remove, but I’m sure there is a practical method for doing so.

A similar lockable plate cover on the rear nearside allows access to hydraulic pipework and the Casappa hydraulic pump, hydraulic pressure testing ports are also located in this area.

The whole cab can be tilted by removing two large bolts and it has a support spring to assist with the weight, especially useful if you need to gain access to major components like the Eaton slew motor and the main hydraulic valve block, as well as the rear side of the engine.

With a long history of manufacturing them, it’s safe to say Sampierana know a thing or two about undercarriages and the one on the CX25D looks well-built coming as standard with 280mm wide rubber tracks and has a track length of 1997mm. Four bottom rollers are fitted and one top roller, overall track width is 1500mm, which is the same width as the blade and makes for a steady working platform. Track motors are supplied by Transmital.

At the business end, this machine featured the more UK favoured longer 1550mm dipper arm, which combined with the standard boom offers a maximum dig depth of 2900mm and a maximum dumping height of 3310mm and bucket breakout force of 2200daN. This unit was fitted with a Strickland fully automatic quick coupler.

The machine comes as standard with a boom ram guard, but I note that none of the other two rams feature rod protection guards. One single or double effect 45 – 210 bar auxiliary line comes as standard but a second and third can be added as an option.

And so, to the cab, popping the door, I was delighted to discover that when fully opened and retained, the door frame sits nicely in a recessed area, well out of the way to avoid any potential damage from accidental impacts. The rear rotation radius on this extremely compact machine is just 750mm. Climbing into the cab, the door entrance is nice and wide to facilitate access and egress, this cabbed version features a cloth manual suspension seat, which features nice body hugging contours and makes for a nice comfortable driving position.

hand side console, facing the operator a multi-function dial offers feedback on the machine’s fluid levels, temperature and other vital information.

heap of shillet material, to enable me to dig with a toothed digging bucket to get a feel for this machine.

Just for the record, track speed in tortoise is 2.6km/h while switching to the hare position offers you a top speed of 4.3km/h.

I was impressed with the machine's digging power, as it certainly packed a punch, almost effortlessly in the dig and the feedback through the Rexroth servo-assisted joysticks was extremely positive, far superior to the feel on the levers on the old C-Series models. These new models definitely seem to be on another level.

The cab on these D-Series models certainly has a more spacious feel to them compared to the outgoing C-Series models. The legroom on the floor is okay but a taller operator might struggle a bit. Folding travel pedals are provided which can give extra foot space when folded away.

I really liked the simplicity in this cab, with just a handful of rocker switches for the working lights, flashing beacon, windscreen wiper/wash and quick-coupler. On the right-

To the rear of the console, I discover a good old fashioned style throttle lever, no electronic rotary dial in this machine, so less to go wrong. Talking of levers, I noticed one problem with the dozer lever, it is mounted so close to the side windows, that you cannot physically get your hand around it. Apparently, this issue had already been identified and a solution/modification is already being implemented on new machines.

I put the machine to work on some land adjacent to M&M’s depot at Kennards House near Launceston. Initially pressing the button, a little awkwardly on top of the dozer lever, I selected the tortoise track speed, offering me more torque on the climb up onto a

I decided to swap buckets to do some grading and shaping work. The machine excelled itself in the grading department, silky smooth and precise with the movements. The machine is quite fast in operation and a slew speed of 11rpm is pretty much the standard for this size of mini excavator; I also like the off-set boom function being on an electro-proportional roller thumb control on the left-hand joystick, making it super easy to slew the upper-structure and slew the off-set at the same time.

Talking of the off-set with the CX25D you get 65˚ to the left and 62˚ to the right. Personally, I still long for a return to the days when manufacturers used to offer a full 90˚ to the left, like on the old Komatsus towards the end of the 1980’s and early 90’s, that combination was great for doing ditch cleaning work and the like offering great visibility to the job in hand, but for some reason, manufacturers don’t seem to offer it anymore.

This machine didn’t have any air-con fitted and on what was a very hot day, I decided to have both the door and front window open. There are three air vents located around the cab, but I opted for the natural fresh air approach on this occasion.

Overall, I walked away from this test drive feeling very impressed with these new Case machines, and I feel they will do very well in the marketplace. In addition, with the knowledge that even newer models like the CX75E coming down the line, I see a bright future for Case’s new and extended mini/midi excavator range.

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

So, in articles you may now see things like:

Simply enter rdr.link/ followed by the unique six digit code into your browser and it will take you to the required resource

’s recent trips we got to see the latest iteration of Bobcat’s TL25.60 – an electric version of the compact telehandler that is coming down the tracks.

operator to move around the job site with ease and to minimise accidents or mistakes.

The TL25.60e has an extra tough design with a robust frame and boom for working in every possible environment. The shielded design provides protection for all components and a steel plate protects the base of the machine. Like all Bobcat telehandlers, the TL25.60e has a box section layout and significant ground clearance for peace of mind.

Serge Boyer, product manager for telehandlers, sees a bright future for the electric version: “Just like its diesel-powered counterpart, the Bobcat TL25.60e has been built with versatility at its core. Thanks to its compact footprint, low noise levels and zero-emission operations, this concept telehandler is suitable for a diverse range of applications, including work on confined job sites and in city centres.”

In preparation for the Irish government’s proposed €450million upgrade of the N5 carriageway that links Dublin to the popular tourist regions dotted along the north-west coast, lead contractor, Mayo-based civil works firm, Wills Bros of Foxford, has increased its equipment portfolio with investment in a number of Komatsu machines.

Komatsu distributor, McHale Plant Sales’ chairman, Michael McHale described it as one of the “most significant investments” in plant and equipment made in Ireland in recent times.

Equipment included in the deal are three D85PX-18 dozers, a HB365LC hybrid excavator, two wide-track, low ground pressure PC170 LGP excavators, and a double-digit mix of HM300-5 and HM400-5 ADTs, all of which will work alongside existing Komatsu units within the Wills Bros fleet.

The N5 carriageway upgrade is scheduled to take up to four years to complete, and upon completion should remove the tag of it being ‘one of the most treacherous sections of primary road in Ireland’.

“When completed, it will improve road user safety, enhance regional accessibility, and better the connectivity between Dublin and the northern and western regions of the country,” said Ireland’s Minister for Transport, Eamonn Ryan TD.

Welcomed by politicians, local tourist organisations and commercial interests, the project involves the construction of approximately 34kms of new single carriageway that will extend from the existing N5 Ballaghaderreen bypass to the townland of Scramoge in Co. Roscommon. WWW.RDR.LINK/CAU019 GOTO

A machine built to celebrate the 70th birthday of the JCB backhoe loader is set to play a major role in training the operators of the future. Sheffield-based K-Plant Hire has taken delivery of one of the first platinum edition JCB backhoe loaders.

The firm, a plant hirer and groundworks contractor for local authorities and private sector companies across South Yorkshire and North Derbyshire, also runs an operator training business. It is for this division that the new platinum edition backhoe loader, supplied by dealer TC Harrison JCB, will be deployed - as the perfect high specification machine to develop the skills of young plant operators in training.

K-Plant Hire owner, Mark Kay said: “The beauty of the backhoe loader is that it is so versatile. There is nothing on a site that you can’t do with them. They do everything our customers want and all the operators love them. They have plenty of power, they’re comfortable, the durability is excellent. It’s simply a great all-round machine so we feel it is really important that operators entering the industry develop the skills to operate them, including the servo controls, and can truly maximise their potential.

“We were delighted to secure one of these limited-edition models as it stands out from the crowd and gives us something rare and different in the fleet. The machine definitely looks the part when training and gives us a high specification machine that is perfect to get the youngsters trained up on.”

GOTO

WWW.RDR.LINK/CAU020

Equipment rental specialist,ACE Plant, has expanded its fleet of Trime lighting towers, with the addition of 40 Trime X-Eco hybrid lithium units. Commenting on this latest investment, ACE Plant’s George Wheeler said:“We have dealt with the Trime brand for some time and we feel that its products are the best in the market. We appreciate the connectivity and telemetry systems built into these units. Being able to control the lights via an iPad has also proven to have been very beneficial for some of our customers.”

The Trime X-Eco hybrid lithium is an LED lighting tower that is powered by a combination of a lithium battery backed up by a small, fuel efficientYanmar1500rpm 2cylinder diesel engine. There is a 50-litre fuel tank which is fully bunded, guarding against spillage and leakage. It can be fully recharged in less than two hours. This means that for 80% of the operation, the unit is powered exclusively by its batteries and therefore emits zero noise and zero carbon emissions.

WWW.RDR.LINK/CAU021 GOTO

Mason Bros, the authorised Develon dealer for South and Mid Wales, has supplied an order for eight new Develon wheel loaders placed by the UK operation of HeavyMovement. The order comprises six DL420CVT7 and two DL280-7 models. Most of the wheel loaders are equipped with Develon’s transparent bucket safety system, that allows a wheel loader operator to see the bucket blind spots on the machine through the in-cab monitor. The DL420CVT-7 wheel loaders have been supplied for use at the melt shop project for one of the largest steel recycling companies in the UK. The DL280-7 wheel loaders are in use at two other locations as part of the contract. The melt shop has the capacity to produce 1.2 million tonnes of low emission circular steel annually, from UK-sourced scrap metal.

Richard Smart, UK project manager for HeavyMovement UK, said: “The high performance and fuel efficiency of the wheel loaders were very important and the added safety provided by the transparent bucket system was also key in selecting Develon.”

GOTO

WWW.RDR.LINK/CAU022

The UK’s largest privately-owned landfill operator, Valencia, is acquiring a record number of large plant attachments from Ulrich, including the manufacturer’s largest-ever high tip high-discharge bucket.

So far this year it has purchased five high tip buckets, bringing the total to 16 since its parent company, Frank Solutions, acquired Viridor two years ago. The most recent high tips range from 10m3 to Ulrich’s largest-ever - a 14m3 capacity bucket, big enough to hold 20 of Ulrich’s factory workers - that was required to complement the larger dumper trucks the operator has also been acquiring due to an expansion in recycling facilities, with six new waste transfer sheds currently under construction.

“This creates extra shovel work and larger operations mean larger dumpers which equates to larger shovels to move the waste quicker,” said Valencia’s national fleet and plant manager, Mark Smalley.

“We probably will purchase more Ulrich attachments this year as we have some older non-Ulrich buckets in the fleet that we inherited from the Viridor takeover that will be replaced along with any more Volvo shovel acquisitions. Again, these will be used for waste handling,” added Mark.

“Plant quality is paramount to us and Ulrich products are quality with service. With them, everything is done correctly and in a timely manner. They are our goto supplier.”

WWW.RDR.LINK/CAU023 GOTO

The work, carried out by a joint venture between Volker Rail and Story Contracting, is taking place in a restricted space, with all equipment expected to perform multiple tasks in a confined area. Faced with the challenging setting the contractors called upon Penrith-based plant hire business Waitings to supply its latest HD Hyundai HX235A LCR compact radius excavator.

Equipped with a two-piece main boom and rubber tracks, the HX235A LCR is capable of completing a range of duties, from digging and loading through to heavy lifting and placing concrete. The machine also comes with HD Hyundai’s advanced around view monitoring (AAVM) system, where a combination of four camera feeds provides a panoramic view all around the machine and intelligent moving object detection, which warns the operator if workers or objects intrude within a preset radius of the excavator.

An HD Hyundai HX235A LCR crawler excavator has become something of an internet sensation, while working on improvements to the Dore and Totley train station near Sheffield. Part of the Hope Valley Railway network, the station is having its second platform rebuilt after more than 30 years of service, with the installation of a new overbridge, tracks, signals and other infrastructure.

The HX235A LCR is being operated by Danny Davis, who covers his daytime job with videos on Instagram, under the name of @goldenlevers. From manoeuvring in the snow to laying aggregate in confined spaces, the HD Hyundai has impressed him and his viewers.

“The particular feature that makes the machine ideal for this job is the new A-series frame design, purely for its lifting capabilities,” said Davis. “The platform units are precast concrete and they weigh around 5-6 tonnes each. The HD Hyundai lifts them with ease. It also lands them with amazing precision, as the controls are very precise when you need them to be.”

The HX235A LCR tips the scales at around 18 tonnes, depending on specification. Powered by a 127kW (170hp) Stage V Cummins B6.7 engine, the machine boasts HD Hyundai’s EPFC (electronic pump flow control) system, that improves fine machine control while reducing fuel consumption.

“The machine is a beast. It’s zero slew means it can get into very tight places smoothly. The compound is cramped, with cars and vans and

“... the particular feature that makes the machine ideal for this job is the new A-series frame design...”

I can navigate around with no worries. The AAVM lets me know when people are moving around me on the touchscreen, so I can see if someone is coming into my crush zone.”

Story Contracting has been equally impressed with the HX235A LCR and its skilled social media operator.

“We have a good working relationship with Waitings,” said Rosie Harmison, Volker Rail Story project agent. “We’ve used them for a long time. Machines are always delivered on time, to the required specification and the operators are fully competent in the work they do.”

For more information WWW.RDR.LINK/CAU024 i

MANAGEMENT SOFTWARE MIGHT SEEM A MILLION MILES AWAY FROM MUCK SHIFTING BUT ONE GROUNDWORKS SPECIALIST IS REAPING THE REWARDS FROM ITS USE. CPN HEARS HOW IT’S DOING IT.

Groundwork and drainage specialist CP Dynes has implemented Podfather fleet logistics software to help manage the movement of hundreds of cubic tonnes of excavated waste a month. Working for Morgan Sindall on a £65 million upgrade of the A12, the contractor has increased productivity, improved visibility and streamlined its reporting using Podfather’s logistics planning, route optimisation and ePOD solution. The Essex-based firm has also improved safety, with automated vehicle checks, and reduced its environmental impact with a virtually paperless transport operation.

practices

“The adoption of Podfather was part of a general upgrade of our management and reporting systems,” explains Rhys Dynes, a second generation member of the family run business. “We have been operating for more than thirty years during which time we have grown significantly from our first contract which was valued at £1.5k to drainage projects worth in excess of £10m.

“To support this growth, we are transitioning from old school working practices to more streamlined, digital processes that allow us to capture, record, store and access detailed operational

information,” he continues. “This move to ‘e’ systems, of which Podfather is a fundamental part, also includes an upgrade of various back-office and accounting applications.”

The firm originally introduced Podfather to replace paper tickets used to record and report on the movement of muck from concrete replacement projects on the A12 in Essex. With on average 1,200 loads a month, totalling around 10,000m3, the contractor previously relied on drivers manually recording the type of material, number of loads, drop off points and hours worked. Completed tickets needed to be returned to the office where the information was collated for customer reporting, invoicing and payroll.

“... we are transitioning from old school working practices to more streamlined, digital processes...”

Using Podfather, it can now reactively plan its mobile operation. With real-time visibility of all vehicles, management can react to changes on-site or on the roads, and adjust the resource allocated accordingly. “For example, yesterday we did 30 loads to landfill and, due to light traffic and good running times, we were able to move a vehicle off that job and onto another project. Today is looking similar but tomorrow who knows?” adds contract manager Jack Hutchison. “Using Podfather we can react and adjust accordingly which means each vehicle is optimised in its use and we are overall more productive and efficient.”

Podfather’s automated ticketing features are also improving the utilisation of the company’s specialist fleet as drivers no longer have to fill in duplicate copies of paperwork to show what loads have been transported and where. Once the days’ schedule has been planned in Podfather, instructions are shared with the drivers’ mobile device using the app. This gives

CP Dynes is one of the leading deep drainage and large bore specialists in the UK and Ireland. It has developed a reputation for excellent standards of work, combined with a highquality service, on a diverse range of projects, including road improvement, housing developments and even the Olympic Village in London, all by the safest means possible. Its comprehensive fleet and equipment are self-owned and changed every three years, and all operatives are CSCS and Health and Safety trained and undergo testing in all relevant work practices.

the driver the point of pick and drop off, and the route in between, it also allows them to record details of the load, using customised drop-down boxes, together with date, time, location stamped photos and signatures.

“Using Podfather we have the information we need, when we need it,” concludes Dynes. “We can answer customer or management queries at the click of a button, rather than taking hours sifting through paperwork, and we can even empower our clients giving them access to the system to self-serve information.

“This has had a positive impact for our drivers who spend less time filling in paperwork and more time driving, our back-office team who don’t have to spend hours transcribing paper tickets and for our customers who have a fully documented, evidentially supported audit trail. It’s also good for the environment and good for us as a business both in terms of growth and reputation.”

To find out more, WWW.RDR.LINK/CAU025

Compact and easy to transport, the DX10Z-7 miniexcavator from Develon is only 730mm wide when the tracks and front blade are retracted, so it can easily pass through doors.

The hydraulically expandable undercarriage provides a stable footprint of 1100mm when extended, ensuring stability on the job site. The foldable TOPS (tip over protective structure) canopy meets ISO 12117 requirements and makes access to job sites even easier.

Powered by the Kubota D722 engine, the DX10Z-7 delivers 7.6kW (10.35hp) with low vibration and noise levels, ideal for working in confined spaces in construction, rental, demolition, and landscaping.

The DX10Z-7 has a 1.45m boom and an arm length of 890mm, resulting in a dump height of 2205mm and a digging reach at ground level of 3355mm. The bucket breakout force is 10.8kN and the arm breakout force is 6.3kN. The track length is longer than previous models at 1025mm, improving stability and boosting traction force by 31%.

The mini excavator's cylinder-overboom design protects the cylinder and increases lifting capacity. The front assembly is safeguarded by a bucket cylinder guard, and the optimal hydraulic hose layout runs hoses inside the boom structure, reducing the risk of damage and downtime.

For operator comfort and safety, the DX10Z-7 features a swivel and tilting system for the consoles, allowing a 10° swivel and 35° tilt of both the right and left consoles, a retractable seat belt and an LED boom lamp.

cooling efficiency while keeping noise and vibration low.

The DX10Z-7 has a bucket capacity of 0.024 m³ and an operating weight of 1165kg. The boom swing angles are 68° left and 55° right, with a rear swing radius of 550mm.

The track shoe width is 180mm, and the travel speed ranges from 1.9 km/h in low range to 3.5 km/h in high range. The hydraulic maximum flow rate is 20.8 l/min.

Contractors can now tackle dynamic and efficient grading and compaction work using excavators if they are fitted with Cat grading beams for Cat tiltrotators. With 360˚ bidirectional and 40˚ leftand-right rotation, the grading beams feature a mechanically adjustable roller allowing for flexible compaction levels based on material type. An adjustable roller scraper prevents material from sticking to the roller, making it suitable for use with clay, silt, and other sticky materials. The roller’s adjustment is from 10mm (0.40in) below the frame to 20mm (0.79in) above. Available in five widths from 1250 to 3000mm (49 to 118ins), the beams handle a variety of applications from grading pavements to larger site preparation tasks.

The design includes a large top opening with solid extended sides and side plates, enabling the beam to spread, compact, and grade materials efficiently. Hardox 500 wear protection at the bottom of the beam ensures long-lasting operation, and the welded frame increases structural rigidity. Additional support plates on the heavy-duty frame enhance beam strength and extend its service life.

Compatible with Cat grade technology through the Cat tiltrotator attachment, these grading beams improve accuracy and save time by allowing contractors to grade according to plan. Available tool recognition automatically confirms the attachment’s identity, ensuring correct settings for pressure, flow, and dimensions, enabling operators to start work quickly.

FOR MORE INFORMATION PLEASE WWW.RDR.LINK/CAU027 GOTO

Develon now offers a range of four different Stage V super long reach excavators suited for jobs such as excavating lakes, cleaning settling banks, drainage work, digging in sand and gravel pits, slope forming and other long reach applications. The excavators range from 24.6 to 52.2 tonnes and comprise the DX225LC-7 SLR, DX300LC-7 SLR and DX530LC-7 Semi-SLR and SLR models. The DX225LC-7 SLR features 8.5m boom and 6.2m arm components, with a maximum digging reach of 15.37m, a maximum digging depth of 11.66m and a maximum digging height of 13.05m. The bucket digging force is 10.0 tonnes and the arm digging force is six tonnes.

Moving up the range, the DX300LC-7 SLR provides a maximum digging reach of 17.51m, a maximum digging depth of 13.78m and a maximum digging height of 14.20m. This excavator has 10m boom and 7m arm components. The bucket digging force is 10.0 tonnes and the arm digging force is 7.1 tonnes.

Completing the range, the DX530LC-7 Semi-SLR/SLR feature 9.0/11.0m boom and 6.0/8.0m arm components, respectively. The DX530LC-7 Semi-SLR excavator provides a maximum digging reach of 16.06m, a maximum digging depth of 11.80m and a maximum digging height of 12.80m. The bucket digging force is 19.2 tonne and the arm digging force is 13.8 tonne. The DX530LC-7 SLR excavator provides a maximum digging reach of 19.62m, a maximum digging depth of 15.13m and a maximum digging height of 14.44m. The bucket digging force is 14.3 tonne and the arm digging force is 11.9 tonne.

All models are factory-fitted with the Develon's wireless fleet and asset management system.

FOR MORE INFORMATION

WWW.RDR.LINK/CAU028 GOTO

Developed to protect operators of mobile elevating work platforms (MEWPs), the latest equipment from Xwatch Safety Solutions features advanced height and slew limitation controls that continuously monitor the machine’s highest points.

The operator can then set the controls to stop the MEWP from going beyond safe boundaries, a common cause of accidents in restricted or crowded spaces when the machine crushes operators against ceilings or comes into contact with overhead hazards such as live cables.

Compatible with scissor lifts, boom lifts, and truck mounts, the system’s key feature is its fail-safe, fully automatic operation. If a control system fails, the MEWP defaults to a secure state, mitigating accident risks. This feature simplifies the operational process and reduces the need for extensive control system training.

The system also provides full power for moving away from a limit, ensuring quick and safe responses in potentially hazardous situations. The controlled motion technology guarantees stability and precision when the MEWP is extended to high elevations.

An optional chassis sensor further enhances safety by adjusting for terrain slope, ensuring stable and level operation even on uneven ground when outdoors.

Each model in Metso’s Lokotrack EC range of mobile screens and crushers is powered by electricity but able to run on diesel if required. The company says that this reduces the amount hydraulic oil needed for crushing operations.

The first two products in the EC range are the Lokotrack LT400J and the Lokotrack LT350C. The LT400J is a 68-ton mobile jaw crusher designed for primary crushing of hard rock and recycled materials. The LT350C is a 50-ton mobile cone crusher for secondary and tertiary crushing. The LT350C uses the Nordberg HP350e cone crusher for high capacity, while the LT400J features the proven Nordberg C120 jaw crusher. Both units can be combined with each other and with Lokotrack mobile screens to produce high-quality aggregates.

When external electricity is available, the electric power transmission provides high capacity with lower operational costs and reduced CO2 emissions. If external electricity is not available, onboard diesel generators allow for continuous operation. Auxiliary units, such as mobile screens and stackers, can also be powered by these generators, reducing the total power needed for the entire plant.

The Lokotrack EC range uses a modular design, which reduces the number of components and offers scalable solutions for different applications and capacities. All components in the EC range are built and tested to perform in tough conditions, ensuring maximum uptime.

Safety and ease of use are key features. The LT400J and LT350C meet the latest safety standards and are easier to use than ever. With digital tools, the units can be safely operated from the excavator and quickly set up from transport to operation.

Each of the 10 grapples in Komatsu’s sort and demolition range features oversized pins and bushings, a robust double-walled main frame, and perforated Hardox shells so they are tough and cost-effective to maintain.

Fitted with a load control valve as standard, the grapples are compatible with a wide range of crawler and wheeled excavators, from 2.5 to 70 tonne machine class. Their heavy-duty design ensures durability in even the toughest conditions, making them suitable for primary and secondary demolition as well as recycling tasks.

Each grapple includes integrated mechanical end stops to protect the cylinder. The perforated Hardox shells come as standard, and the grapples feature reversible Hardox 500 cutting edges with recessed bolts and nuts. The double-walled, closed high-strength frame, oversized pins and bushings, and oversized slewing ring with internally mounted hydraulic motors enhance durability and performance. From the JRSG290-1 model up, all grapples are equipped with dual rotation motors.

Faster to use than previous models, the three new Cat hydraulic connecting CW (HCCW) coupler models connect seamlessly to the machine’s hydraulics, allowing operators to switch between hydraulic attachments with full functionality in seconds from the safety of the cab.

Compatible with any Cat hydraulic attachment, the HCCW20, HCCW30, and HCCW40 quick couplers are designed for tool carrier capacities ranging from 7.5 to 27 tons. Each model offers a standard 10-ton lift capacity.

The exclusive locking control system feature and sensor technology measure locking wedge position and indicate coupling status to the operator. Complying with the European EN474 standard, multiple electronic and mechanical measures secure the attachment, even in the event of pressure loss. Visual and audible confirmations inside the cab tell the operator when the attachment is connected.

The design features enhanced hydraulic flow to reduce restriction, minimizing heat build-up and reducing engine power requirements. Machined for high-flow performance, the couplings ensure hydromechanical attachments operate at full capability with limited back pressure. Reliable hydraulic fluid connections help prevent spills during attachment changes, and the quick-disconnect design improves lifespan and facilitates easy servicing.

Customers with existing Cat excavator fleets using CW hinges do not need to retrofit their machines to use the HCCW quick couplers. Fabricated tools, such as buckets, can seamlessly switch between existing CW and HCCW couplers. Hydraulic coupling (HC) brackets allow the use of existing hydromechanical tools like shears, hammers, and grapples with the HCCW.

Internally routed hoses in the coupler and bracket protect against damage and reduce overall hose and repair costs. The quickcoupler platform includes durable male and female quick disconnects located in the coupler and attachment bracket. The cover lid and sealing provide added protection for couplings, preventing hydraulic system contamination.