Construction PLANT NEWS

JUST THE TICKET

The exhibition season is upon us. Intermat has been and gone and now our thoughts turn to Hillhead. It promises to be an interesting and lively event as Richard Bradbury, managing director of event organizers The QMJ Group, outlines in his preview on page 17. It is encouraging to hear him talk of the unprecedented demand from exhibitors, which hopefully will be reciprocated with unprecedented visitor attendance figures. They will have plenty to see and do.

Exhibits will include a full range of combined equipment displays with excavators, wheel loaders, ADTs, crushers, screeners and much more. Big display highlights will be a 100tonne excavator from Hyundai and the ‘all-electric’ stand of Volvo CE with dealer SMT GB, whilst Hitachi will be showcasing both machines and its fully connected site solutions.

Interestingly Bradbury is keen to point out the show’s tech factor when it comes to the digitalization of the sector. From telemetry solutions to machine control, drones, AIdriven safety, and the latest advanced 3D site management and modelling, the connected site will really come alive this year. And thanks to the continued investment in the WiFi connectivity onsite, the event will have live data feeds even from the demonstrations on site.

Visitors will also notice a big change in the show’s layout, as the organisers have increased the size of the indoor pavilion by more than 30%. In addition to this they have recognized the importance of Hillhead as a meeting place, which was highlighted in feedback from the last show in 2022. As a result, they have created the Big Hillhead Cafe and food court as an outdoor hub for visitors and exhibitors alike. Let’s just hope the weather plays ball.

And it’s worth bearing in mind that the exhibitors really appreciate your attendance. For them it is a significant investment, but the payback can be even more significant, not just in monetary terms, but in starting new relationships and cementing existing ones. E-commerce, websites and doing business digitally might be the way things are done these days, but nothing beats face to face meetings, discussions and a bit of banter.

Many commentators have, over the years, harped on about the decline of trade shows, and when Covid was at its height, you could be forgiven for thinking that their demise was sealed and that nobody would ever venture forth again, whether to exhibit or to visit. Happily, the naysayers have been proved wrong; people actually enjoy going to these industry events, especially after the bunker-like existence we all endured during the pandemic. Just look at last year’s Plantworx. It’s good to get out, good to meet new and old, good to talk!

We’ll see you there.

Happy reading

The CPN Team

Editor JOHNNY DOBBYN JOHN LEVICK

cpn@hamerville.co.uk

Advertising Manager

MATTHEW BOASE mboase@hamerville.co.uk

Group Manager

ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer DONNA BOOTH

Group Production Manager CAROL PADGETT

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2024

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

POCKET MONEY

POCKET BOX’S LATEST ENHANCED SOFTWARE SOLUTION IS CLAIMED TO MEET GROWING DEMAND FROM SME CONTRACTORS FOR AN ALL-IN-ONE SYSTEM TO MANAGE VEHICLES, PLANT, TOOLS AND DRIVERS. THE NEW ASSET MODULE IS DESIGNED TO SAVE TIME, MAINTAIN COMPLIANCE AND REDUCE COSTS, WHILE TACKLING EQUIPMENT THEFT, LOSS AND UNDERUTILISATION.

and inventory management features.

WWW.RDR.LINK/CAT001 i

GORDON’S JUST THE TONIC FOR DEVELON

CASTLE DOUGLAS-BASED JAMES GORDON LTD (GORDONS) HAS BEEN APPOINTED DEVELON’S AUTHORISED DEALER FOR THE WHOLE OF SCOTLAND. Based in Dumfries and Galloway, Gordons was already the authorised dealer for the the Southwest and Borders regions, Glasgow, Edinburgh, Inverclyde, Renfrewshire, the Lothian Counties, Argyle and Bute, Isle of Mull, Stirling, Falkirk, Lanarkshire and Ayrshire in Scotland and for the county of Cumbria in Northern England. Now with the new appointment, the territory has been expanded to include Aberdeenshire, Angus, Fife, Highlands and Inverness-shire, Moray, Orkney, Perth & Kinross, Shetland & the Outer Hebrides and Skye.

GREAT START

DEVELON SAYS IT CAN LOOK BACK ON A VERY SUCCESSFUL DEBUT YEAR IN EUROPE AND WORLDWIDE. DERIVED FROM THE WORDS ‘DEVELOP’ AND ‘ONWARDS’, THE NEW DEVELON BRAND CAME INTO BEING IN EARLY 2023, THROUGH THE RENAMING OF THE ORANGE DOOSAN CONSTRUCTION EQUIPMENT BRAND.

It was officially launched at the Conexpo trade fair in Las Vegas in the USA in March 2023. Subsequently, local trade fairs across the globe have all been used to further debut the brand at a more regional level.

Jayden Lim, Develon Europe CEO, said: “I would like to thank all of our staff, dealers, suppliers and customers for their support in the transition period, all of whom have embraced the new Develon brand. They are also happy with the fact that there is virtually no change in our core values, sales network, products and technologies - all remain the same.”

Kevin Fraser, group sales director at Gordons, said: “We are delighted to be representing the Develon brand throughout Scotland. We have received a good response from existing customers - as well as new prospects, there is a high existing population of Develon/Doosan machines in the areas we have added, which we have taken under our wing.”

For more information WWW.RDR.LINK/CAT002 i

The development of electric machines remains one of Develon’s key priorities with a new 2-tonne electric miniexcavator recently released, and further compact models due this year. The company has also developed electric battery packs as a part of its strategy to expand its business, to one that is more embracing, and inclusive of electrification solutions. Through such efforts, the company plans to make headway in the market where the expectation for ecofriendly equipment is high.

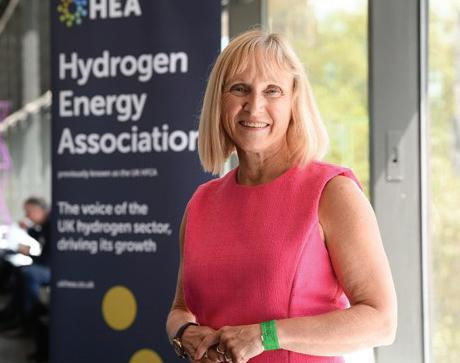

EXPAND HYDROGEN’S ROLE SAYS ASSOCIATION

THE COUNTRY’S LEADING HYDROGEN TRADE ASSOCIATION HAS CALLED FOR HYDROGEN TO PLAY A GREATER ROLE IN THE DECARBONISATION OF CONSTRUCTION MACHINERY.

In a response to the DESNZ and DfT consultation on non-road mobile machinery (NRMM), released by the Hydrogen Energy Association (HEA), the organisation, which represents 120 leading hydrogen businesses across the full value chain, said the Government’s vision understates the opportunity for hydrogen in comparison to electrification.

It called for a more “holistic approach” and said the “government must give more foresight to a pragmatic, long-term roadmap that details specifically how NRMM will be supported in achieving the endpoint of Net Zero by 2050.”

In the response, which addresses a series of questions raised by Government, CEO of the HEA Celia Greaves said hydrogen is well suited to the high energy output and flexibility demands of NRMM.

WWW.RDR.LINK/CAT004 i

GOLD AWARD AT THE 2024 ROSPA (ROYAL SOCIETY FOR THE PREVENTION OF ACCIDENTS) AWARDS, LEADING TO THE COMPANY WINNING THE PRESIDENT’S AWARD FOR THE THIRD YEAR IN A ROW. Heath McHugh, head of SHEQ at Mabey Hire, said:

“We’re delighted to have won the President’s award for our twelfth consecutive RoSPA gold. This achievement is something we’re extremely proud of and reflects the commitment and hard work of everyone across the business, to ensure the health and safety of anyone handling and using our equipment, whether that’s our own employees or our customers.

“As a specialist temporary works provider, we provide our customers with the equipment they need to deliver their construction and engineering projects in a safe and efficient manner. We’re committed to continually improving how we work and ensuring that we keep people safe, whether that is at their desks, at one of our 16 depots, out on site or on the road. Our motto is: everyone home safe and well, every day.”

WWW.RDR.LINK/CAT005 i

BEACON OF HELP

LIGHTHOUSE, THE CONSTRUCTION INDUSTRY CHARITY, HAS PUBLISHED ITS 2023 IMPACT REPORT WHICH DETAILS THE VITAL SUPPORT AND IMPACT IT HAS DELIVERED TO THE CONSTRUCTION COMMUNITY IN THE UK AND IRELAND. With a focus on emotional, physical, and financial wellbeing support, the charity says it has delivered £3,927,992 of charitable support and been a beacon of hope to 4435 families in need, a 30% increase on the previous year.

Against a challenging backdrop of continued cost of living increases, material price rises, unpredictable workloads and labour shortages, the report reflects a year of resilience, growth, and

ONLINE PLATFORM FOR USED MACHINES

LIEBHERR HAS ANNOUNCED THE LAUNCH OF ITS OWN HOSTED DIGITAL PLATFORM: THE USED EQUIPMENT MARKETPLACE. THE INITIATIVE IS CLAIMED TO BE A FIRST FOR A MAJOR GLOBAL OEM AND MARKS A SIGNIFICANT ADVANCE IN THE DISPOSAL OF USED EQUIPMENT, FOCUSING ON CONSTRUCTION AND MATERIAL HANDLING MACHINES.

The new online platform is designed to provide a secure and user-friendly method to dispose of the thousands of used machines that Liebherr acquires as part of operations annually.

Daniel Hecker, business development sales at Liebherr-EMtec, said: “With the launch of this marketplace, focused on our specific product segments, we provide a central platform for our global used equipment business. Customers are able to independently search our virtual marketplace for the used equipment they need, while our sales partners register and manage their listings via the platform and its associated apps.

“The marketplace brings together on a single platform the entire supply and demand sides of our used equipment business. It combines Liebherr’s strengths of personal advice and customer relationships with the much greater visibility a global digital marketplace offers.”

WWW.RDR.LINK/CAT006 i

impactful initiatives.

The charity’s caseworkers played a pivotal role, supporting 2435 complex cases and securing £1,675,309 of funding through collaborative working with other charities and ensuring that people were accessing their statutory entitlements.

There was a 20% increase in the number of people accessing vital counselling services, with a huge 42% of the charity’s grant expenditure being invested in fast access to both virtual and face to face counselling offering vital support with a variety of emotional wellbeing issues.

WWW.RDR.LINK/CAT007 i

to both new and existing customers of the brand. With strategically located depots holding large volumes of spare parts and a vast network of fully trained field service engineers, customers, the company says, can be confident they will receive the highest standards of after-sales service.

Henry Moore, Molson Group commercial director commented, “We are thrilled to have been asked by Thwaites to expand our dealer territory yet again. We have a long history with the brand which we will call on to support the existing valued customer base throughout the region.”

and distribution; in administration and customer communications; in in-house machine maintenance and repair; and in mobile field service engineering roles.

“On the personnel side, we have an expanding and committed team, all totally focused on building the business and delivering the best service we can for customers,” O’Driscoll said.

“In the important areas of parts availability and supply, our depots are well stocked and supported by an efficient UK-wide distribution structure. So too in tech-support where our team of mobile service engineers continues to expand,” he added.

For more information

WWW.RDR.LINK/CAT008 i

WWW.RDR.LINK/CAT009 i

For more information

ACCORDING TO EURO AUCTIONS, EUROPE’S BIGGEST LIVE AUCTION FOR CONSTRUCTION AND AGRICULTURAL MACHINERY, COMMERCIAL VEHICLES, TRUCKS AND INDUSTRIAL EQUIPMENT, SURPASSED ALL PREVIOUS RECORDS WITH 7,600 ITEMS GOING UNDER THE HAMMER.

Between 24th and 27th April, a world audience focused on the sale site in Leeds, where 690 vendors and 5,200 registered bidders participated and where 7,600 lots were sold to the highest bidder.

With a hammer total of £53.42 million, of which £37.66 million sold online, and a floor total of £15.81 million, vendors from around the world sold equipment and machinery through the sale. Vendor numbers continued to increase with 690 vendors sending equipment and machinery

to Leeds from 24 countries worldwide.

Chris Osborne, territory manager Euro Auctions, commented: “In terms of pricing we have seen the market level since the end of 2023. Following the COVID hype across markets we’ve seen a normalisation in pricing in the last 12-18 months but since December 2023 to date, we have had five months of consolidation where prices have remained stable, firm and good for buyer

and seller alike. When prices are stable, buyers and sellers can have more confidence in trading. In a rising or falling market people who don’t urgently need to sell or buy can sit on their hands and wait not knowing if trading now will produce the best deal.”

WWW.RDR.LINK/CAT010 i

A lower carbon approach is no longer a ‘nice to do’, it should be central to every organisation’s strategy in the current climate, explains Andy Williams, SHEQ manager at UK road planing contractor Jet Plant.

TAKING THE SUSTAINABLE PATH

When Jet Plant set out our target to reduce fossil fuel usage by 50% by 2025, it was an ambitious yet necessary objective. Around 40% of UK carbon emissions are linked to the built environment, according to the government, and while this includes emissions linked to heating buildings, construction activity alone accounts for around 50 million tonnes of CO2 emissions each year.

With the UK obligated to achieve net zero (a 100% reduction of greenhouse gas emissions compared to 1990 levels) by 2050, it’s clear we all need to do our bit.

Carbon neutrality is vitally important for us, but it is also of increasing importance for our customers, and we are seeing more of them coming to us asking how they can reach net zero faster.

Around three quarters of our business comes from small to medium sized privately owned surfacing contractors who know what they need to achieve, but might not have the understanding, budgets or in-house expertise to

“With

make significant changes in the short-term. Often they rely on suppliers to help contribute to their sustainability efforts.

We have put a lot of time and investment into developing a comprehensive sustainability plan. We are part of a supply chain and everyone in that chain knows it is something they will have to deliver. However we have taken the lead, giving others an example to follow. Whilst doing so we continue to invest and innovate as we set the standard for sustainable road planing in the UK.

the UK obligated to achieve net zero (a 100% reduction of greenhouse gas emissions compared to 1990 levels) by 2050, it’s clear we all need to do our bit.”

“Our vehicles are specified with the environment and reduction of CO2 emissions as a priority, Euro 6 engines are also the latest level currently available and provide the best fuel savings possible. “

Sustainable practices

Our sustainability strategy includes a number of measures to help reduce carbon emissions and improve sustainable performance across the business. Last year we announced the decision to fuel all planers with hydrotreated vegetable oil (HVO).

As a direct which is produced from waste materials. As a direct result we have comfortably achieved the 50% reduction in fossil fuel usage target from the planer fleet in comparison to the corresponding months the previous year.

We’re sourcing utilities from only renewable carbon neutral providers. We’re switching all company cars to electric vehicles. And we’ve taken steps to ensure responsible disposal and recycling of planings.

In February, we also announced a new £3 million investment in state-of-the-art machinery, including lorries and planing machines, to further boost our sustainability credentials.

The Volvo trucks we purchase are manufactured in carbon neutral factories with low environmental impact. Our fleet now run with eight wheel Tridem tippers so when transporting the planer to site they have the same manoeuvrability as the six wheeler tippers.

This increased payload means that for every 90 tons of planings to be removed from site the tridem makes five trips as opposed to six trips with a six wheeler. The means reduced CO2

emissions but also less HGV movements and less congestion.

Our vehicles are specified with the environment and reduction of CO2 emissions as a priority, Euro 6 engines are also the latest level currently available and provide the best fuel savings possible. We review fuel suppliers to ensure all are ethical and traceable on a regular basis ensuring only pure HVO is provided and not blended or mixed. All are ISCC certified or ZEMO accredited.

We also recognise that the key to a more sustainable operation will be better utilisation of our equipment –for example, we’ve enhanced our fleet management systems to reduce total fuel consumption. This latest investment will help meet the growing demands of our customers, but it will also support us to continue to operate in a more sustainable way.

We are utilising external training resources to improve the performance of our HGV drivers. This has already seen a number of drivers massively improve both their mpg and idling time performance.

Jet Plant is also on the pathway of reducing paperwork that the operators and drivers complete every day. All daily defect checks for HGVs, vans and planers are now digital and we are currently working on switching to digital duty of care notes and hazardous waste consignment notes. This will further reduce the

Looking forwards

Looking to the future, it is evident that the importance of environmental performance and carbon emissions will only keep growing. National and international targets are edging closer, and consumer awareness is rising which adds value to the commercial and reputational benefits of responsible operations.

Those who measure and disclose their performance will stand out from the competition. Large companies in the EU that meet specific criteria are already obligated to measure and report their performance under new regulations.

Jet Plant has set out five commitments towards a more sustainable business: to reduce well to wheel CO2 emissions by an average of 50% per shift; to reduce fossil fuel usage by an average of 50% per shift; to improve mpg performance by 5% across all fleet; for company cars to be EVs (already in place); and for all utilities to be sourced from renewable carbon neutral providers (also in place).

Despite the good progress that has been made, we recognise that just being the sustainability leader in the industry is not enough.

POSITIVE CONTRIBUTION

Battery energy storage systems (BESS) have a vital role to play in helping construction address the challenge of noise and emissions restrictions on site. Tom Adlington, sector sales manager, Building Services & Construction at Aggreko, shares his thoughts on why the effective use of BESS as part of a hybrid power package will be increasingly important.

Increased pressure on emission regulations, decarbonisation goals, decreasing fuel consumption on site, variable load concerns, capex spending – the challenges construction managers need to overcome can seem endless. Yet, these challenges can be addressed effectively through the use of new technologies, with one key example being BESS incorporated within a hybrid temporary power package.

Using BESS can, for example, reduce noise and emissions, and address capacity limitations from constrained power connections or limited generator capacity. However, to realise the full benefits of BESS, it is vital that it is used optimally.

So, how can this be achieved?

1. Correctly understanding load profiles

Understanding load profiles may seem simple but recognising what exactly needs to be powered when considering BESS for a hybrid power solution is critical, the load profile of a site needs to be understood. Whether power requirements will change over time will also have significant impact on a site’s overall power needs.

As part of assessing the load profile, peak demand, low demand, and the base load should be considered. For peak demand, the highest power requirements should be identified, and any high inrush currents caused by powerhungry machinery or motor starts can be noted. Extended periods with minimal power demand or power loads that persist for extended durations should also be considered.

Any patterns or timings can then be identified to establish where power fluctuations occur. Therefore, by understanding the load profile, we can see where BESS can add value, and implement the best possible generator and BESS combination.

This makes it possible to ‘rightsize’ or

“Using

downsize the generator. BESS can provide power assistance during short bursts of high-power demand, enabling the generator to be sized according to the average/base load of the application. In turn the BESS enables the generator to be switched off during prolonged periods of low loads, only to be called upon when the state of charge is low, ensuring the generator always operates at an efficient capacity. Using smart technology, such as Aggreko Remote Monitoring (ARM), enables the use of historical or anticipated load profile information to recommend the right hybrid temporary power package dependent on requirements and give an idea of emissions and fuel reduction from incorporating greener technologies.

BESS can, for example, reduce noise and emissions, and address capacity limitations from constrained power connections or limited generator capacity.”

2. Consider environmental regulations

Noise and emissions are increasingly becoming critical factors for decision makers. BESS can help comply with legal or regulatory restrictions affecting a project and provide a greener intermediate power supply during peak demand.

This was a factor for Sir Robert McAlpine, which had a major construction project where a reduction of 85% in emissions was made across five live tower cranes when paired with a BESS supplied by Aggreko.

The same applies for urban sites where quiet periods during specific hours must be adhered.

BESS can provide a quieter alternative compared to other traditional power sources, such as diesel generators.

3. Determine costs

Cost is one of the first things that comes to mind when considering sourcing additional power supply. After all, balancing the figures is what any project relies on and bringing in new equipment must be carefully accounted for. Temporary BESS solutions allow users to access new technology without the need for upfront CAPEX. Incorporating BESS into a wider hybrid power package leads to reduced fuel costs and emissions.

4. Consider Controls

Controls can help further optimise BESS power distribution and support system reliability by controlling and monitoring parameters. Remote monitoring can also enhance flexibility and responsiveness while driving cost optimisation through reducing fuel consumption.

more information on Aggreko’s

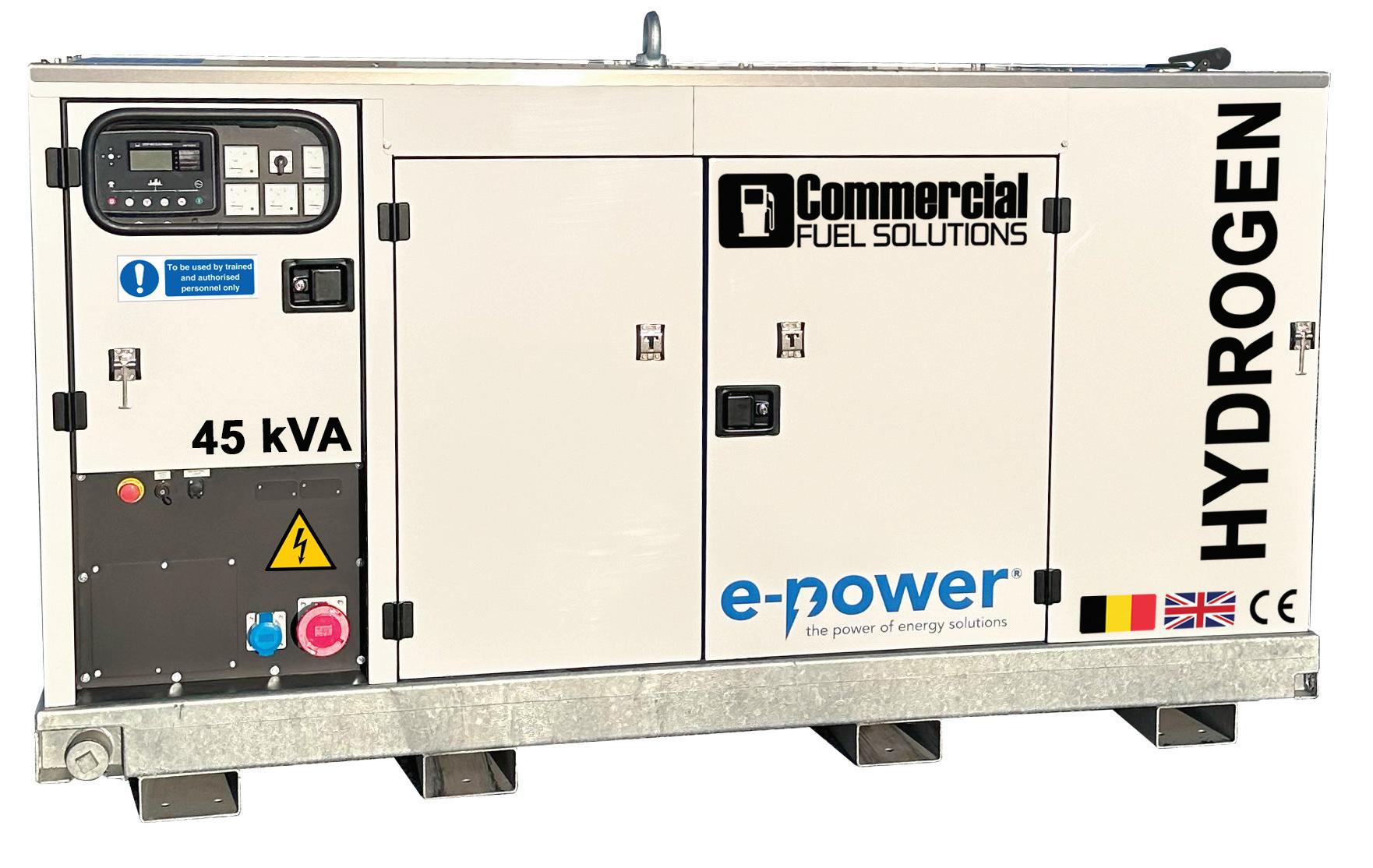

Robin Futcher, founder and CEO of Commercial Fuel Solutions, reveals details about the UK’s first commercially available hydrogen internal combustion power generator.

THE FUTURE

The e-power E45 hydrogen power generator is a ground-breaking product designed to operate on any grade of hydrogen, revolutionising the benchmarks for clean, efficient, and costeffective energy generation. Utilising a hydrogen combustion engine, this generator is a more robust technology than traditional fuel cell technologies, providing a resilient solution for diverse power requirements at a fraction of the usual capital expenditure.

This generator marks a significant advancement in hydrogen power technology, offering a cost-effective, eco-friendly, and highperformance solution for power generation. With its lower capex, ability to withstand fuel impurities, and decreased fuel expenses, it is the clear choice for contractors committed to investing in the future of hydrogen energy and making substantial strides in reducing their carbon footprint.

Commercial Fuel Solutions offers a comprehensive turnkey package. Alongside the H2ICE generator, the company conducts

thorough site safety risk assessments to ensure suitability, integrating DSEAR risk assessments with zoning diagrams and compliance checks. Specially trained technicians manage the installation and commissioning of the generator, while providing necessary training, permits for work, and safe operation oversight. Additionally, we provide all service, maintenance, and emergency call-out coverage within the warranty period.

Moreover, we can supply hydrogen safely and

“Specially trained technicians manage the installation and commissioning of the generator, while providing necessary training, permits for work, and safe operation oversight.”

“The 45 kVA H2ICE generator utilises hydrogen combustion to produce dependable electrical power, offering an emissions-free alternative to traditional fossil fuel-based generators.”

reliably, offer remote fuel consumption monitoring, and seamlessly integrate systems into a customer’s existing infrastructure.

The 45 kVA H2ICE generator utilises hydrogen combustion to produce dependable electrical power, offering an emissions-free alternative to traditional fossil fuel-based generators. This method not only ensures minimal emissions but also capitalises on the cost efficiencies of hydrogen when used as a fuel source. Unlike fuel cell-based systems, the H2ICE generator is less vulnerable to impurities in the hydrogen supply, ensuring sustained reliability and reducing fuel costs over time. This

affordability makes the E45 hydrogen power generator an attractive option for companies and operations aiming to minimise their environmental impact through hydrogen power.

Engineered for durability and easy maintenance, the E45 H2ICE electrical power generator’s sturdy design is suitable for various applications, from site use to emergency backup

power, ensuring uninterrupted critical operations. With reduced fuel expenses and environmental advantages, it presents an ideal solution for forward-thinking enterprises committed to achieving sustainability objectives.

SHOW LIKE NO OTHER

Richard Bradbury, managing director of event organizers The QMJ Group, explains the rationale behind the forthcoming Hillhead show and highlights what visitors can expect to see.

Hillhead is a unique show because its location, a quarry in Buxton, means that it can bring real job site applications to life like no other event. From 25–27 June, visitors will witness an autonomous truck in action for the first time as part of the biggest range of demonstrations in its history.

The immersive nature of the show will blend digitally connected sites and technologies with the sector’s ongoing alternative fuel transformation.

When we open the show this year, visitors will be met by 600 exhibitors in a sell-out event. Demand from exhibitors has been unprecedented and we have already blasted a huge amount of material, creating a demonstration experience that will be our biggest yet. It will incorporate a squared off quarry face area with two large elevated levels, making more demonstrations possible throughout the day.

These will include a full range of combined equipment displays with excavators, wheel loaders, ADTs, crushers, screeners and much more. Big display highlights will be a 100-tonne

excavator from Hyundai and the ‘all-electric’ stand of Volvo Equipment with dealer SMT GB, while Hitachi will be showcasing both machines and their fully connected site solutions.

For this show, we have also recognized the continued importance of showing visitors how our industry is progressing. For example, our autonomous truck demo with Bell Equipment will be a real eye-opener this year. We are also a showcase for a lot of electric-powered machines, some of which will feature in our live demonstrations for the first time.

Personally, I think the real impact of Hillhead is in our ability to educate the industry. Yes, we have the wow factor with the big machines, but we also have the tech factor when it comes to the digitalization of our sector.

From telemetry solutions to machine control, drones, AI-driven safety, and the latest advanced 3D site management and modelling, the connected site will really come alive this year. And thanks to our continued investment in the WiFi connectivity onsite, we will have live data feeds even from our demonstrations on site.

Visitors will also notice a big change in our

layout, as we have extended the indoor pavilion by more than 30%. In addition to this we have recognized the importance of Hillhead as a meeting place, which was highlighted in feedback from our last show in 2022.

With this in mind, this year we are creating the Big Hillhead Cafe and food court as an outdoor hub for visitors and exhibitors alike. This will be supported with more permanent welfare facilities, and we will also have new water hydration stations around the site with cold, filtered water available for free. Encouraging visitors to bring their own water bottles will be a great addition, especially if the weather is kind to us.

And for those big-picture social media moments, our enlarged viewing platform will definitely give visitors that selfie opportunity.

So, this year, Hillhead will continue to be the place where visitors can keep up to date with what is going on and, in particular, use their time to understand the transition the industry is undergoing as we embrace digitalization and alternative fuels in our drive to be a low-carbon, sustainable sector.

H ILLHEAD PREVIEW

BOBCAT

Bobcat is showing new products for the first time at the Hillhead 2024. They include the super compact TL25.60 telehandler, the T86 compact track loader and the S650 skid-steer loader. The stand display will also include the top-of-the-range T40.180SLP 18m telehandler, the L85 compact wheel loader, the E10z, E27z and E60 mini-excavators, T590 and S76 compact loaders and models from the Bobcat portable power, compaction and material handling ranges.

John Christofides, regional sales director for Bobcat EMEA, says: “We are very much looking forward to the Hillhead exhibition, where visitors will be able to the see the very latest from Bobcat. As our stand at Hillhead will show, Bobcat offers solutions for all types of job sites both big and small, for customers in construction, rental, quarrying and many other industries.”

WWW.RDR.LINK/CAT014

CASE

There will be a host of new and improved machinery on display, both static on the stand and working at the quarry face, including the recently unveiled 651G premium wheel loader and the new ‘Essential’ CX210E-S crawler excavator. There will also be a glimpse of the future on show, with its latest full electric compact wheel loader 12EV.

Keen operators will be welcome to take a turn at the controls, in the popular Operator Challenge, with a range of prizes available throughout the exhibition. There will also be live demonstrations of equipment in the quarry’s waste and recycling area, in the secondary rock handling area and in ‘Crusher Alley’ where

blasted rock is initially processed.

Equipment on the working displays will include the CX250E and CX210E-S crawler excavators, along with the 651G, 821GXR and 1021G wheel loaders. Static machinery on the stand will include the latest CX15EV and CX25EV electric mini excavators, plus the electric compact wheel loader 12EV. Additionally, models from the latest mini and midi excavator line-up, the larger crawler range, wheeled excavators, loaders and compact wheel loaders will also be represented.

WWW.RDR.LINK/CAT015

CON MECH ENGINEERS

Con Mech Engineers is returning to Hillhead with an expanded product range this year, thanks to several strategic distribution agreements with global manufacturers. At this year’s stand, the company is promoting its Blademaster range, as well as announcing that it has secured distribution agreements with BS Track Undercarriage and Dozco Rock Breakers.

The new partnerships mark a significant enhancement in the company’s offerings.

Bernard Nestler, general manager at BS Track, said: “The UK market should have access to undercarriage components made of UK steel. Our partnership will allow UK customers to buy high-quality track groups that perform well. Con Mech Engineers is the ideal distributor due to its reputation for supplying high-quality wear parts manufactured in the UK.”

NG Bangur, director of Dozco, added:“The strategic partnership with Con Mech Engineers aims to expand Dozco’s presence in the UK market and provide customers access to its high-quality rock breaker range, which focuses on customer satisfaction and cutting-edge technology. Dozco is confident that its

international-standard high-quality rock breaker range at a most competitive price and joining hands with Con Mech Engineers, whose commitment to delivering top-notch customer service and vast network perfectly aligns with Dozco’s core value, will redefine the rock breaker segment.”

WWW.RDR.LINK/CAT016

DEVELON

The static display on Develon‘s stand will include the DX530LC-7 53 tonne crawler excavator, the DL420-7 wheel loader and the DA45-7 articulated dump truck (ADT). In the demonstration area, further products for the quarry face that will be going through their paces include the DX420LC-7 43.5 tonne crawler excavator, the DL550-7 wheel loader and the DA30-7 ADT.

Among new products being shown for the first time are the new DX140RDM-7 22.5 tonne demolition excavator and the new DD130-7 dozer. Compact equipment is another strong aspect, with the DX27Z-7 and DX55R-7 miniexcavators and DL85-7 compact wheel loader on show. The stand display will be completed by Develon‘s DX235LCR-7 24.3 tonne crawler excavator.

WWW.RDR.LINK/CAT017

HILL ENGINEERING

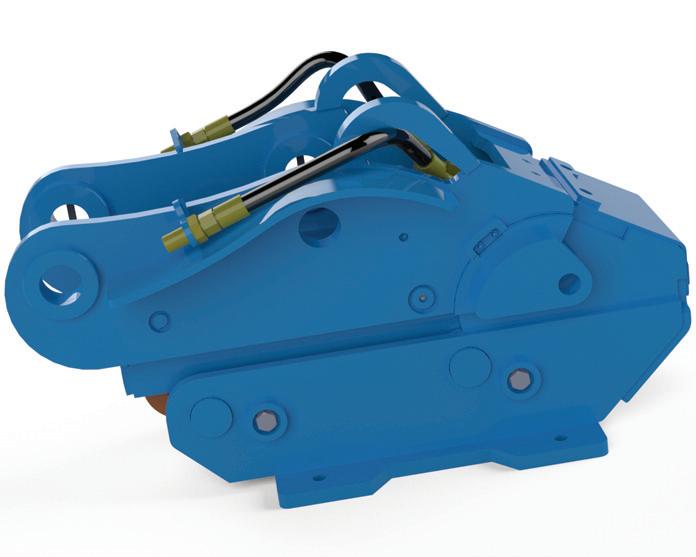

Specialist plant machinery attachments manufacturer Hill Engineering is introducing two new products. The new version 20-tonne Tefra Connect coupler and Tefra Connect display unit

will be on display for the first time as well as a Tefra quick hitch for a JCB 3CX, a 20-tonne Tefra Tilt coupler, a 35-tonne Tefra, and a 13tonne bucket and thumb combination.

The Tefra Connect is said to be a revolutionary coupler that can connect any hydraulic work tool safely and automatically from the operator’s seat. Combining the versatility and functionality of the Tefra pin grabber coupler, and manufactured in SSAB Strenx steel, the next-generation Tefra Connect sets new standards in on-site efficiency.

With a Tefra Connect-equipped excavator, operators can maximise machine use and reduce or eliminate the need for other machines onsite, reducing machine costs, fuel consumption and transport movements –particularly beneficial on inner city or congested sites.

The secret to the Tefra Connect is that it uses a patented “power coupling plate” bolted to the hydraulic tool which enables a rapid, leakfree and safe connection between the coupler and hydraulic tool.

While similar systems for automatic hydraulic oil connections are already available, Tefra Connect has added an innovative twistwhen the hydraulic powered tool is finished with, it can be released and placed to one side, revealing a regular variable pin centre Tefra coupler which can be used to pick up other pinned attachments in the usual way.

WWW.RDR.LINK/CAT018

HD HYUNDAI

HD Hyundai will launch its biggest Stage V crawler excavators yet in the 80-tonne HX800A

L and the 100-tonne HX1000A L at this year’s Hillhead quarry show. Both of these heavy-duty machines have been designed for quarry and bulk earthmoving duties. The HX800A L is powered by a 403kW (548hp) Stage V diesel engine, driving two 504lpm hydraulic pumps, while the HX1000A L uses a 469kW (629hp) diesel engine, powering three 523lpm pumps.

The company will also unveil its biggest wheeled loader, with the launch of the HL985A. This 35-tonne shovel will be capable of working with 7.0m3 buckets, making it an ideal digging and rehandling machine for the mining, quarrying and heavy civils sectors. Powered by a 321kW (430hp) diesel engine, the HL985A boasts a bucket breakout force of up to 28,400kg and a full turn tipping load of 22,950kg in standard configuration.

Also on display will be a full range of equipment, including wheeled and crawler excavators, along with additional models from the A-Series wheel loader line-up. HD Hyundai will also demonstrate three of its popular quarry models, including a large crawler excavator, a large wheel loader and an articulated dump truck, on the working demonstration area that surrounds the showground.

WWW.RDR.LINK/CAT019

SANY

With a new, larger and more prominent stand location in front of the quarry face demonstration zone, visitors will be able to see a range of products that includes excavators, telehandlers and tandem rollers as well as enjoy watching all the action in a real-life quarry environment from either an indoor or outdoor viewing area.

SANY’s static excavator line-up will include mini, compact and larger machines, ranging from the new lighter weight, 1.8 tonne SY18C to the larger 40-tonne SY390H, many of which will feature a new generation operators cab to aid more comfortable, intuitive and productive working.

Joining the excavators will be the brand new STH1840 telehandler, one of the first machines to feature in its telehandler series along with the smaller 14m (STH1440) and 7m (STH742) models, all powered by Stage V Deutz engines and designed to offer the ultimate in safety, comfort and performance.

For those visitors looking to see machines in action, then the 50-tonne SY500H and 40-tonne SY390H crawler excavators will be working in the quarry face demonstration area. Powered by a Stage V Cummins 298 kW (SY500H) / 252 kW (SY390H) engine and Kawasaki pumps, these heavy-duty tracked excavators provide plenty of power and maximise on fuel economy. Visitors will also be able to see the 30-tonne SY305C working in crusher alley during the event.

VOLVO

At Hillhead 2024, SMT will champion sustainability with the UK public debut of the 23 tonne Volvo EC230 Electric excavator, alongside solutions to optimise and decarbonise sites with existing machines, as well as machine rebuilds, used parts, and used equipment to promote a circular economy.

Visitors will be able to see the Volvo EC230 Electric in action and experience its advantages first hand in the exhibition’s demonstration zone. Working alongside the Volvo L120H Electric Conversion wheeled loader and a fully electric truck from Volvo Trucks, this trio showcases Volvo Group’s commitment to cleaner and more sustainable ways of working.

“At SMT, we are committed to helping our customers work towards and achieve net zero –and we believe that journey starts today, by optimising your current site and fleet,” says John Lawrence, product manager for Site Solutions at SMT. “With our range of customisable solutions for your site and operators, SMT can assist in continuous improvement across your operations. By targeting key areas that affect cost and emission output, we can help you reduce your carbon footprint and help you achieve your sustainability targets.” WWW.RDR.LINK/CAT021

Leaps forward

CPN travels to Bobcat’s HQ and discovers the OEM has been pretty busy these past 12 months with an array of new machines and new technologies.

There were two major events going on in Czechia recently. One was the International Ice Hockey World Championship, the other was the annual Bobcat demo days event.

Amazingly the Czech team won the trophy on home soil, while Bobcat was winning over more than 700 distributors and customers who were invited to the event.

This year’s edition featured more than 90 demo models, including Bobcat’s brand-new lineup of material handling units, skid-steer loaders, compact track loaders, compact wheel loaders, mini-excavators, telehandlers, ground maintenance equipment, light compaction models and more, all available to ride and drive.

There were also glimpses of the future, such as the TL25.60e electric telehandler concept. The model, which is still in development and not yet commercially available, has a rated capacity of 2.5 tonne and a lifting height of almost 6m, matching the performance offered by its diesel-powered equivalent. With three separated electric motors designed to maximize efficiency, a hydrostatic transmission to boost performance, a maximum speed of 25km/h and the same super-compact dimensions as the conventional Bobcat TL25.60, the cutting-edge electric concept delivers low noise levels, minimal operating costs and impressive versatility.

From the selection of recently introduced machines on offer, CPN got into the seat of the M-Series S630 and S650 Stage V skid-steer loaders, which have been developed for use in European markets. The models’ D24 engines, which feature Bosch fuel-injection systems, deliver superior performance while adhering to strict emission regulations, enabling attendees to see Bobcat’s long-standing commitment to sustainable operations in action. Product manager, Jiri Karmazin, revealed that the S model “was back by popular demand” and that customers wanted a workhorse that was cheaper and less featured than the R model, adding that customers “can option it upwards” should they wish for more bells and whistles.

This year’s event also featured the new

lineup of Bobcat rotary telehandlers, which deliver great visibility thanks to the patented panoramic cab. The latest range comprises nine Stage V models with lifting heights of between 18 and 39m that have been designed for European markets, and four Stage IIIA machines with lifting heights of 18 to 26m that have been developed for use in the Middle East and Africa.

Technology update

Attendees had the opportunity to experience Bobcat’s transparent OLED (T-OLED) screen technology, which has been developed in collaboration with LG and BSI Research. TOLED enables operators to access an array of functionality without taking their eyes off the worksite, offering clarity, responsiveness and visibility. It also has the capacity to facilitate a range of more advanced applications, such as real-time virtual reality (VR) simulations for utility line mapping.

Bobcat also showcased its operator presence technology, a concept that is currently being developed for excavator models. Operator presence employs a 3D time-of-flight (ToF) camera – advanced technology more commonly utilized in emerging sectors such as autonomous vehicles, robotics, gesture recognition and virtual reality (VR) – to enhance safety by monitoring users’ movements and the wider cabin environment. By actively tracking the operator’s presence and interactions within the cabin, the system can prevent unintended machine actions, ensuring a safer work environment – especially in close quarters. It can also detect multiple occupants, instantly disable workgroups to avoid accidents and recognize when a joystick is released, deactivating the associated workgroup while maintaining drive. These proactive safety measures are designed to minimize the risk of accidents, improve operator control and, ultimately, enhance overall worksite efficiency.

The pedestrian detection camera was in action too. The device’s software is able to differentiate between humans and their

surroundings thanks to its AI-enabled processing capabilities, helping to eliminate unnecessary operator alerts. The innovation’s database is also able to identify humans in different postures and positions, including standing, kneeling, crouching, sitting, with their backs turned, and even when they are only partially visible.

Also on show was Bobcat’s digital access software, an advanced system that allows operators to use smartphones as ‘keys’ to specific machines, providing an alternative to existing passcode entry functionality while ensuring units understand the preferences of their users before they begin work. In addition, this innovation enables fleet owners to lock out certain functionality or attachments in line with the respective skillsets of their employees.

In addition, Bobcat demonstrated how its construction lineup is delivering even greater levels of sustainability to users. The manufacturer’s mini-excavators, skid-steer loaders, compact track loaders, compact wheel loaders, telehandlers, rotary telehandlers, mini track loaders and forklifts have been approved for use with HVO biofuel and other EN 15940 standard paraffinic fuels.

Summing up the demo days event Jan Moravec, Vice President of Product, Bobcat EMEA, said: “Our team has introduced a diverse selection of models over the past 12 months, and we have been looking forward to giving our customers and partners the chance to try out Bobcat’s latest advancements in person.”

FRENCH CONNECTION

It wasn’t romantic but it was good to see the crowds back at Intermat in Paris. CPN offers a few insights into what was going on.

For the many millions of visitors to Paris in the springtime, it is the lure of its many sites and attractions that appeal. For 127,500 visitors in late April, it was the lure of Intermat 2024, the construction equipment trade show. Last held in 2018 and cancelled in 2021, they were possibly curious as to what they might see after such a long hiatus. However, they came in their droves to see the 1,065 exhibitors, including 68% from outside France, and witnessed the industry’s drive for environmental and technological progress. Despite the absence of some big names, the event felt vibrant, lively and well attended.

Electrification

“It’s not new, it’s now,” said one exhibitor we spoke to. He was referring to the ongoing electrification of machines that featured heavily across the many stands of OEMs in the industry’s bid to drive decarbonisation and sustainability.

Many OEMs were trailing their electric machines with lots of claims being bandied about. For example, Chinese OEM LiuGong said

its plan is to be the number one in battery electric vehicles (BEV) technology in Europe by 2027. To that end its line-up included four new BEV machines for the European market, two excavators, the 9027FE and 922FE, and two wheeled loaders, the 820TE and 856HE.

Elsewhere, there were plenty of examples of electric machines of every hue and colour, from the most mini to some sizeable beasts. The multiple machinery demo zones both outdoors and on stands gave visitors a chance to discover the the latest developments in safety,

productivity and energy efficiency.

Of course, no show is complete without a glimpse of the future and Develon surely made an impact with its Concept-X 2.0 autonomous construction equipment in the guise of its DD100-CX dozer and DX225-CX crawler excavator. Both machines feature a new cabinless design and a linear core design language. And they certainly drew the crowds as attendees witnessed the equipment performing everyday jobsite tasks.

Getting attached

Away from manufacturers, there were the inevitable attachment brigade. Working exhibits

such as engcon’s were popular as Martin Engström, product manager at engcon revealed. This year, the interest in our products was greater than ever before in terms of the number of visitors to our stand. There was particular interest in our third generation tiltrotator. Showing off our products live in front of an audience helps create an understanding of how the tiltrotator works and contributes to better profitability for our customers. The interest in test driving the machines on site was enormous.”

With the presence of the big beasts, it’s all too easy to forget that Intermat is a show for everyone, even the smallest of manufacturers. So, it was good to chat with Danish OEM, HG Machines, whose electric dumpers are very popular domestically but who was looking for UK distributors to expand its network. They are nice bits of kit with the HG E2000 dumper offering 12 hours work on a full charge.

Inevitably many find Intermat to be the appetizer before the main event, Bauma next year. If it is, then this year it was quite tasty and certainly it put itself back on the menu for the industry.

Charge of the light brigade

Unveiled at Intermat, Yanmar’s latest batch of compact machines includes a fully electric wheel loader, mini excavator, and tracked carrier. The manufacturer says the zero emission and cordless-in-use V8e, SV17e and C08e are tailored to meet the diverse demands of modern and sustainable construction projects and indoor work environments – without compromising on power and performance.

The SV17e mini excavator (1,955kg operating weight ), is powered by a robust 18.3 kWh battery, it features two operating modes to optimise battery life and adapt to varying project demands. Performance-wise , it is capable of digging forces of 9.9 kN and 8.9 kN from its short and long arms, respectively, and is further bolstered by a 16 kN bucket force.

Ideal for compact spaces, the SV17e measures 2.33m in height and has a variable width of 0.98 to 1.32m. Its nearly silent operation minimises noise, enhancing the comfort for machine operators and making it particularly suitable for working indoors, as well as in environmentally sensitive or noiserestricted areas. Additionally, zero emissions guarantee a more operator and eco-friendly

CPN looks at Yanmar’s recently launched trio of new small electric machines that are claimed to be every bit as good as their ICE counterparts.

workspace. The SV17e’s capabilities are enhanced by a maximum digging depth of 2.62m, a reach of up to 4m, and a maximum dumping height of 2.675m. Other features include an LCD interface, and an optional fast charger for quick replenishment with a slow charging time (20-80% SOC) of approximately four hours and a fast-charging time (20-80% SOC) of about two hours.

The new V8e wheel loader (4,500 kg operating weight) offers a fusion of power and sustainability according to Yanmar and is designed to meet the demanding requirements of modern construction environments. The unit boasts four working modes (bucket, fork, eco, power) to fit the operator’s needs, combined with a bucket volume between 0.8

and 1.2m3 and with a payload on forks of 1,890kg to maximise performance. It is further coupled with a high-capacity battery (available in standard 39.9 kWh with an option to upgrade to 53.2kWh), provides up to 4.2 hours of continuous operation in bucket mode. The loader is further equipped with a synchronous motor offering 22kW rated and 30kW peak power, enhancing its efficiency in various operations.

Prioritising operator safety and comfort, the V8e features a newly designed cabin with increased visibility and comfort: an adjustable armrest and steering column, heated seat, and both LED headlights and LED work lights for optimal visibility. For charging convenience, the unit also comes with an on-board fast charger (11kW standard, upgradeable to 22kW) and includes the most common adapters, allowing for easy integration into existing power infrastructures.

Yanmar’s C08e tracked carrier (730 –880kg operating weight) is designed to work across even the toughest terrains. It combines a highperformance electric motor that provides 5.5kW rated and 6.5kW peak power, with a hydrostatic transmission to ensure smooth handling and operation on inclinations up to 20°. Its haul body can carry between 0.34 to 0.42m3, tailored for high-demand tasks. The

“Yanmar is keen to let you know that its electric product launch is a testament to the wider group’s commitment to the Yanmar Green Challenge 2050 –an initiative that outlines the company’s pledge to achieving net-zero greenhouse gas emissions by the mid-21st century.”

vehicle operates on a 10.4kWh battery, featuring three selectable working modes –eco, performance, and high performance –to optimise energy use and extend battery life up to three hours in the most demanding mode.

The carrier offers a half working day autonomy, depending on the application. For charging, the C08e uses a standard 3.3kW offboard charger, compatible with a P17 blue plug for grid connection and a REMA socket for direct machine linkage, which fully recharges the battery from 20% to 80% capacity in just 3.5 hours. With additional features like automatic electric motor shutdown and optional vessel configurations, the C08e sets a

new standard for electric utility vehicles, combining robust functionality with environmental consciousness.

Yanmar is keen to let you know that its electric product launch is a testament to the wider group’s commitment to the Yanmar Green Challenge 2050 – an initiative that outlines the company’s pledge to achieving net-zero greenhouse gas emissions by the mid-21st century.

For more information about the Unplugged range, please visit WWW.RDR.LINK/CAT 031 i

Dynamic duo

evolving needs of the construction sector. CPN runs the rule over the new machines.

Operator comfort

SANY says that the telehandlers are well equipped to allow operators to work in optimum conditions whatever the requirements of the job. The ROPS/FOPS cab of the telehandler series has been designed in Germany and provides maximum comfort due to numerous standard features such as the 10in

“The first two machines to launch in the series are the STH1440 (14m) and STH1840 (18m) models with a 7m variant planned for release later this year.”

expansion strategy. With our unwavering commitment to innovation, quality, and customer satisfaction, we are confident that SANY telehandlers will set new benchmarks for performance, safety and operator comfort, empowering our customers to achieve greater success in their operations.”

The telehandlers are now available to purchase through its network of dealer partners across the UK and Ireland, providing customers with access to sales, service and support.

All SANY telehandlers are registered and protected with the CESAR Datatag Scheme and CESAR ECV for quick and easy verification of emissions category and they also come with a three-year/ 3000-hour warranty for complete peace of mind.

For more informartion about SANY’s range of telehandlersand other construction machinery solutions, please visit, WWW.RDR.LINK/CAT 032

“The telehandlers are now available to purchase through its network of dealer partners across the UK and Ireland, providing customers with access to sales, service and support.”

Construction PLANT NEWS INTRODUCING RDR.LINK/

A digital service for our readers...

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

So, in articles you may now see things like:

Simply enter rdr.link/ followed by the unique six digit code into your browser and it will take you to the required resource

F LEET ADDITIONS

HYUNDAI CE PD DEVELOPMENTS

Manchester-based groundworks and civil engineering specialist contractor PD Developments has enhanced its operational capabilities with the addition of a Hyundai HW150A CR wheeled excavator to its growing fleet of equipment. The machine is the company’s first wheeled excavator, joining a line-up of crawler machines from three to 23 tonnes operating weight.

“We’ve hired in ducks before and found them to be a very versatile piece of kit,” says director Damian O’Grady. “The ability to move about quickly on site, to lift and carry and to be able to dig as well, it does a bit of everything.”

PD Developments was established three years ago by Damian and fellow director Paul Lackey. The groundworks subcontractor initially hired in its equipment as required, for a variety of civils projects across the North-West. It purchased its first machine, a 9-tonne HD Hyundai, from local dealer HES Enterprises and has since built the fleet to 10 excavators and a growing number of site dumpers.

“Dealing with Andrew at HES is easy,” says Damian. “If you want a new machine, you rarely have to wait, as HES usually has the equipment in stock. They also provide a good level of service, looking after all of our Hyundais.”

HD Hyundai’s HW150A CR is one of a growing range of A-Series wheeled models, with operating weights of 6-21 tonnes. Tipping the scales at just over 17 tonnes, the HW150A CR has a compact radius counterweight design, making it ideal for urban use or for confined job sites. The machine is powered by a Stage V compliant Cummins diesel engine with an all-in-one exhaust after treatment system.

WWW.RDR.LINK/CAT0033 GOTO

HYUNDAI CE JJ SUGRUE

Suffolk-based plant hire and contracting company JJ Sugrue has added its first HD Hyundai HX85A compact excavator to the fleet, with a second machine already on order. Supplied by local dealer Ernest Doe & Sons, the 8.5-tonne excavator is the 38th HD Hyundai machine to be purchased by the company.

Started by Jerry Sugrue in 2006, as an owner operator business, the company has grown steadily to a fleet of almost 200 machines, with more than 80 staff on the payroll. Sugrue offers its fleet of equipment with a team of experienced operators, or on a self-drive basis across the East Anglian region.

The fleet includes almost 30 HD Hyundai machines, ranging from the compact R17 mini excavator, through to HX145A midweight excavators. Indeed, the company has run every model of HD Hyundai excavator up to the 14-tonner, other than the R55, over the last decade.

The HX85A is a big step forward from the previous generation 8-tonne model. Boasting a powerful Stage V Yanmar diesel engine and a load sensing hydraulic system, the HX85A is available with monoboom or two-piece articulated boom and a four-way angle dozer blade.

“We do run the latest HX130A excavators as well. We bought the HX85A to trial it on site and now we’ve already ordered our second one. They are really good machines,” says Jerry. “They are good value for money, reliable and the longevity is excellent. We usually change our equipment at four or five years, but we have had some of the HD Hyundais for longer than five years.”

JCB COBALT PLANT HIRE

Kent-based Cobalt Plant Hire has invested in a fleet of new JCB machines worth £4 million – including 19 X Series excavators. Its JCB fleet has been joined by new 140X and 220X models supplied by dealer Greenshields JCB. The X Series models are also joined by 85Z-2 and 86C-2 midi excavators and six and nine-tonne site dumpers.

Cobalt Plant Hire was established in 2022 by

SUNWARD LOUDONHILL

Scottish civil engineering company and quarry operators Loudounhill Contracts has added Sunward to its portfolio of plant machinery.

The Ayrshire-based business, which specialises in groundworks and hard landscaping for housebuilders in the region, has acquired two Sunward SWE 155F medium excavators and a Sunward SWE 25F mini-excavator from local dealer Kattrak.

Established in 1986, Loudounhill has more than 35 years of experience in the industry, working on housebuilding and commercial construction projects of all sizes across central Scotland. It played a part in Mactaggart and Mickel’s award-winning Greenan Views development in Doonfoot.

The company also opened its own quarry – Thirstone Quarry in Crawfordjohn, Biggar, in 2008 – to supply aggregates to customers in Ayrshire, Glasgow, Edinburgh and Lanarkshire.

Sunward’s SWE 155F 15.6-tonne excavators are a versatile fit for large construction, be it buildings, roads, quarrying, demolition or forestry, while the 2.6-tonne SWE 25F mini can be transported on a small trailer with up to three buckets and a

Barry Verrent and Mick Lippard with support from JCB Finance. Offering self-drive plant hire, it employs ten people at its Rochester base and operates a total fleet of 190 machines including tracked excavators, dumpers, telescopic handlers and compaction rollers.

Cobalt’s joint managing director Barry Verrent says the X Series excavators are proving a big hit with hire customers, with former users of competitor machines now becoming big fans of the X Series models.

He said: “We choose JCB as we have an

excellent relationship with the team at Greenshields JCB. The service has been really good and we really like the X Series.

It’s a powerful excavator. Operator comfort is a big thing for us and so the comfort levels in the cab stand out. As long as the operator is happy, we’re happy. The customer feedback has been very good. Even those customers who previously used competitor machines are now converts to the X Series.”

WWW.RDR.LINK/CAT035 GOTO

hydraulic breaker.

Loudounhill quarry manager Robert Craig had contacted Kattrak looking for new machines for its fleet, and the dealer suggested they try Sunward. It has not looked back. Robert says: “We select our fleet based on price and warranty and Sunward was the best deal around. Our operators are delighted with the machines. They find them easy to operate and are very happy with the build quality.”

WWW.RDR.LINK/CAT036

PRECISION GRADING FOR FAMILY BUSINESS

National groundworks company Connop & Son has invested in the most advanced Cat compact track loader from Finning UK & Ireland to tackle their commercial and agricultural concrete flooring projects.

Connop & Son, a family run business which begun in the 1970s, is a longstanding customer of Finning and already operates several Cat machines within its fleet to complete large scale agricultural and commercial flooring to a high standard.

This latest Cat 299D3 XE compact tack loader (CTL) model represents the highest performance and most advanced technology available in the CTL line. As early adopters of machine control Connop has also combined it with a Trimble 3D laser grade system for even greater cutting accuracy, together with a Cat GB124 smart grader blade attachment which transforms this compact equipment into a powerful precision grading solution.

While conducting significant grading work for applications like concrete a highly precise grading system ensures there is no wasted fill material. Using smart technology like this means operator productivity is enhanced and more efficient, while being able to complete their work in fewer passes also decreases the wear and tear on the equipment.

The GB124 blade attachment Connop has fitted to its machine means the hydraulic wings give it the capability of a mini grader, and with the Trimble laser system fitted as well means it is

easily possible to achieve accuracy up to 5mm.

The fleet already includes two Cat telehandlers, a 320 excavator, a D6T dozer and a D6 Next Generation dozer which is currently on hire. The 299D3 XE CTL is a replacement for an existing machine and was chosen by company director, Chris Connop, after he enjoyed a demo of the smaller Cat 279D3.

He says: “I was looking for something reliable and after the demo of a 279 two years ago I was impressed overall by the machine. After that we got a call from Finning asking for feedback and I

explained that I thought the attachment needed some changes and now that’s exactly what they’ve built. I think we may be the first in the country to have this machine and it’s excellent. It’s in use five days a week and our driver absolutely loves it.

“We use it in projects such as industrial builds with 2D and 3D prepping as it’s fitted out with Trimble GPS and it adjusts everything to suit, and with a warranty up to 6,000 hours we’ve got everything covered.

“I can’t fault Finning as we’ve found them good with supplying parts and service and I’m talking with them now because we’re looking for a new bulldozer. Although Cat machines command a premium product price, we know we can trust the reliability and they retain their value.”

FOR MORE INFORMATION

WWW.RDR.LINK/CAT037 i

machinesinaction

TOP FLIGHT

Four JCB electric machines have landed at Manchester Airport as part of fleet engaged in the £1.3 billion transformation of Terminal 2.

Preston-based Bradley Group is determined to use electric equipment for the majority of its internal demolition projects, all part of its commitment to environmentally conscious practices.

When the company got the contract to work on the Manchester Airport project it needed new kit to carry out all the internal dismantling and strip out work that is part of a programme set for completion in 2025.

It chose the machines – two 19C-1E electric mini excavators and two 1TE electric site dumpers – after seeing them in action against the opposition,

“In the process of selecting our equipment provider, we conducted demonstrations of various brands,” director Andrew Hill said.

“JCB was the undisputed choice, showcasing the most effective electric machines. We are also pleased with the back-up service JCB provides.”

He said that the initial order had been for one electric mini excavator, but a second order soon followed due to the impressive performance of their first purchase. Supplied by dealer Gunn JCB, their roles include the demolition of walls, breakout out of screeds, loading dump trucks and moving hard-core.

According to Andrew, there had been some excellent feedback from operators, who were impressed by the machines’ even smoother tracking, which set them apart from their diesel counterparts.

Operators also appreciated the

convenience of simply plugging in a machine rather than refuelling with diesel and being able to carry out a full shift on a single charge.

The four machines are part of the JCB ETech range of electric equipment which is zero emissions at the point of use and enables contractors to work in emissions and noise sensitive environments – including indoors, underground and in urban areas. The 19C-1E was the world’s first fully electric excavator when JCB launched the innovative model.

MORE INFORMATION

ON SITE AND ON ROAD

Machine performance, productivity, operator acceptance, fuel consumption and dealer back-up are all factors in Welsh groundworks contractor Hywel Griffiths Plant Hire & Groundworks choosing Case Construction Equipment.

The company, established 28 years ago in Clunderwen near Carmarthen, first turned to Case when looking for a mid-weight dozer. “We had been thinking about it for a while and had a Case 1650M on demo,” says Hywel Griffiths. “In the end though, we went for an 1150M, as it better suits our work.”

Fuel economy was a major factor in the move to Case, as was the level of service and machine back-up provided by local dealer Riverlea Industrial. “Riverlea are brilliant. The back-up is great,” says Hywel. “I used to service everything in-house, but now we get a service package with Case and all of our kit is looked after by Riverlea. It’s half the price of some competitors.”

The Case fleet includes a 1.2-tonne mini, an 8-tonne CX85D SR, three 13-tonne CX130E crawler excavators, a CX145D SR, a CX225 MSR and a CX245D SR. A second CX245D SR is currently on order to replace an older machine.

All of the excavators, bar the CX130Es, are short radius models,

allowing easier access to confined job sites and reducing the risk of potential damage from impact in congested working areas. The CX130Es have also proven extremely economical to run, saving money when compared to the company’s last excavators. “The CX130E is doing around £7.50-9.00 an hour on fuel, compared to our previous machines at £13-15 an hour. That’s a huge saving,” he added.

With strong order books and a relatively new fleet of machinery, Hywel Griffiths Plant Hire & Groundworks is looking to the future. It has certainly come a long way from the early days with a single 8-tonne excavator. The company’s Case machinery looks set to become a familiar sight on construction projects across the region.

W W W. CPNONLINE . CO.UK

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

Sustainable

argument

In response to the pressing global issue of climate change, the United Kingdom and the European Union have set a challenging yet necessary objective – to attain ‘net zero’ CO2 emissions by 2050. The construction industry, traditionally known for its substantial environmental footprint, is now in the spotlight to significantly contribute towards achieving this goal.

Under the increasing demands from government bodies, local authorities, and broader communities for more sustainable practices, there’s a clear onus on project developers and owners. The paradigm for new projects is shifting. More efficient buildings, more community and green spaces, and lower carbon emissions are just some of the criteria popping up around new projects.

Acknowledging this shift, construction original equipment manufacturers are focusing their efforts on electrification, seeking to replace fossil fuels with greener, less polluting alternatives. Concurrently, companies are exploring technologies that promote operational efficiency, limit rework, and

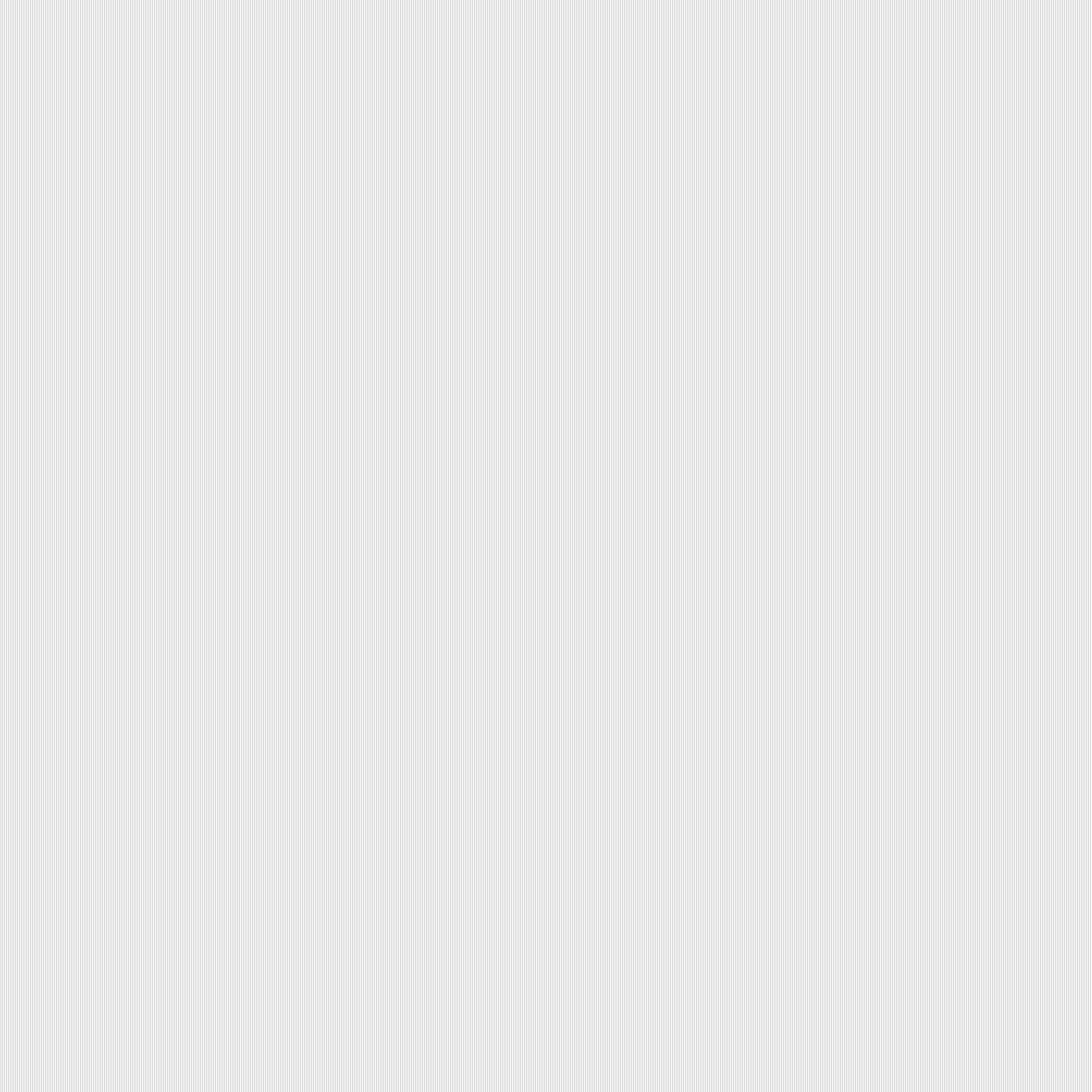

Richard Clement, deputy general manager at Smart Construction shares his take on how civil construction can evolve through technology to meet the growing demand for sustainable construction.

support informed decision-making, all with the aim of reducing their overall carbon footprint.

Boosting efficiency

The wave of construction technology that has popped up in the last decade or so gives contractors a way to save time and money while being more competitive in the eyes of sustainability-minded GCs and owners. Smart Construction’s portfolio of solutions features these different technologies and applies them to each individual project to make planning and process more efficient.

Some of the ways contractors can use construction tech to boost efficiency include: ● GPS-enabled machinery: 3D Machine guidance and control help even inexperienced

operators get their work done right in one go.

● Equipment tracking and optimization: GPS tracking, and other telematics data can help contractors monitor their equipment in real-time. This can reduce fuel consumption and unnecessary wear on vehicles and fleet, while helping them identify ways to do the same work in a faster, more efficient manner.

● Drones can be used for site surveying and project monitoring. The use of drones can minimize human error in design or estimation and dramatically decrease the time needed to measure quantities and make critical decisions about projects. Drones are especially valuable for large sites. Once a time consuming and inefficient task, surveying has become a quicker job for site managers to review progress and

“The use of drones can minimize human error in design or estimation and dramatically decrease the time needed to measure quantities and make critical decisions about projects.”

make decisions, relaying data to remote teams where required.

● Digital twins: 3D modeling can make planning easier and more accurate, reducing the risk of rework and wasted materials.

Digital twins also streamline communication between everyone involved in a project. In earthwork, efficiency is sustainability. As

owners and developers start focusing more and more on the sustainability of their projects, earthwork contractors can position themselves as “sustainable” partners by becoming more efficient. It doesn’t require huge investment in new electric fleets and machinery, or spending an inordinate amount of time tracking your carbon emissions.

TRACK AND TRACE

To meet increased demand, Develon has introduced the latest iteration of its fleet management system - MY DEVELON: a new digital platform for managing construction equipment.

Using the MY DEVELON app or on a web browser, customers and dealers can access and manage maintenance and operation data for their Develon construction equipment,” says Kevin Lynch, marketing communications manager at Develon Europe. “Customers can remotely check the status of their equipment and communicate with their machines by sending certain messages.”

Some of the newest features now available on the platform offer the ability to download service tools and get personalized quotes for parts for Develon equipment.

“We provide a menu for customers to request a quote for genuine parts from their

local dealer,” adds Lynch. “It is a very useful resource for customers. They can select the parts they want to receive a quote on and send it to their dealer. Additionally, customers can subscribe to our exclusive digital services.”

More dealers and customers are utilising telematics systems, according to data tracked by the manufacturer. Although some customers can be intimidated by the amount of data, Develon and its dealers are working hard to develop training programs that help educate customers on how to navigate the system. This starts with dealers using brief, streamlined training materials, which are very effective with sales specialists.

Sustainability milestones can be achieved as a by-product of becoming more efficient in daily operations.

“When a customer purchases a new machine, our dealership sales specialists provide some basic training about telematics with the customer,” says Lynch. “When the customer leaves with the new machine, the customer has a telematics profile. The customer can log in and start tracking the new machine immediately.”

REBUILD IS ELECTRIC

Commissioning machine rebuilds is already an integral part of Heidelberg Materials UK’s fleet management plan. Recently the company welcomed a rebuilt Cat 988K XE with electric drive back to its Whatley asphalt plant. CPN reports.

988K XE means there are fewer moving parts than on a manual transmission. This means there are less components – around 20% fewer - and therefore less moving parts to recondition and replace as part of the rebuild process.

“Although there are more electrical inspections needed once the rebuild is done, a large proportion of the electrical components, such as the power inverter and drive motors, can be removed from the original machine and reused making it a more circular, sustainable option for customers. Caterpillar reuse and salvage guidelines ensure we can offer a second life to components if they pass this process.

“A further advantage is that the rebuilt machine benefits from having the latest engineering updates, which may include parts or electronic software. So despite being built originally in 2017, the rebuilt machine has the same functionality and performance of the later 2022 model, ensuring maximum longevity

“Rebuilding the latest technologically

advanced machines shows a rebuild is not purely for older machines, the rebuild offering is aligned with newer technologies and is moving with the times to ensure the latest new machines sold have a rebuild solution in place when needed”.

Gary Huxley, product support sales manager at Finning, said: “Managing machines throughout their operational life is a key part of Heidelberg Materials UK’s fleet management approach. We’ve worked with the company for more than 20 years with Cat machines making up a large proportion of its total fleet.

“They typically take advantage of the engineering support and warranty packages we

offer to ensure their machines are maintained and serviced and kept operating effectively, while minimising unexpected downtime.

“Rebuilt machines are becoming a mainstay in the company’s fleet. Between 2021 and 2023 they have had 14 machines rebuilt, including a Cat 988K that had a Cat certified powertrain rebuild at 17,000 hours and is still going strong at 28,600, and a Cat 988H which has been rebuilt several times and is still operating with 47,000 hours on the clock. The company has also previously commissioned rebuilds of a Cat 972, five Cat 980s and seven Cat 775s.

“The success of previous rebuilds was certainly a factor in their decision to choose

“Sustainability is at the heart of our operations. We have set ourselves ambitious targets and we are already making significant gains, having reduced our operational CO2 emissions by more than 50% since 1990,”

to have this latest machine rebuilt and they have already commissioned the rebuild of their second Cat 988K XE machine operating at the asphalt plant in Whatley.”