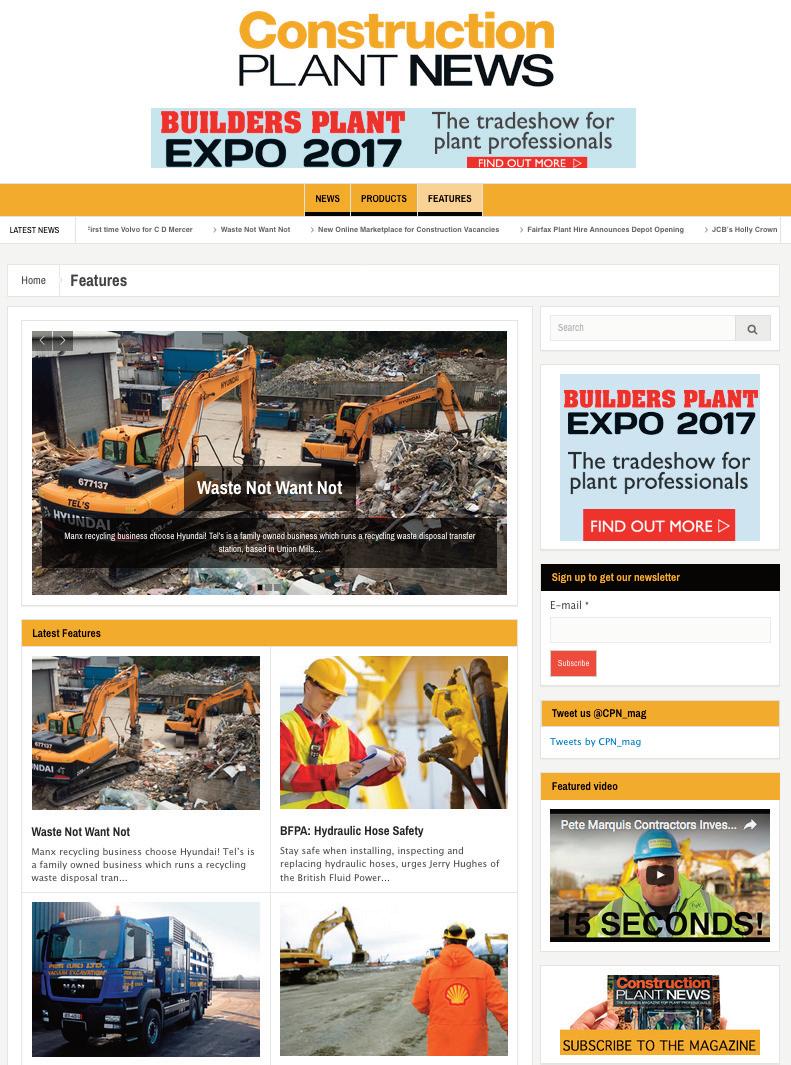

Construction PLANT NEWS

URBAN SPLASH

HYUNDAI BOOSTS STREET CREDIBILITY WITH NEW LAUNCH

CUT THE CHORD

ATLAS COPCO OPENS NEW CHAPTER FOR PORTABLE POWER

MAY / JUNE 2023

HYUNDAI IS BOOSTING ITS KERB APPEAL

SPECIAL REPORTS

10 Industry in Site. Consultants Alan Berger and Carl-Gustaf Goransson consider the race to electrify construction equipment.

16

CPN at Large. CPN reports from Atlas Copco’s ‘Journey to a Sustainable Future’ event and the unveiling of a claimed world first.

C ONTENTS MAY / JUNE 2023 THIS

@CPN_mag cpnonline.co.uk Construction Plant News, Regal House, Regal Way, Watford, Herts, WD24 4YF. cpn@hamerville.co.uk e 13 CPN I MAY / JUNE 3 FEATURES 13 Palntworx Preview ATTACHMENTS 22 CPN looks at CAT’s new roster of products for backhoe loaders and mini excavators. COVER STORY 33 Hyundai’s new 10-tonne townie hits the streets. 22 33 24 16 REGULARS 5 EDITOR’S VIEWPOINT 6 NEWS 19 FLEET ADDITIONS 24 MACHINE FOCUS 30 TECHNOLOGY CORNER 33 NEWPRODUCTS

ISSUE...

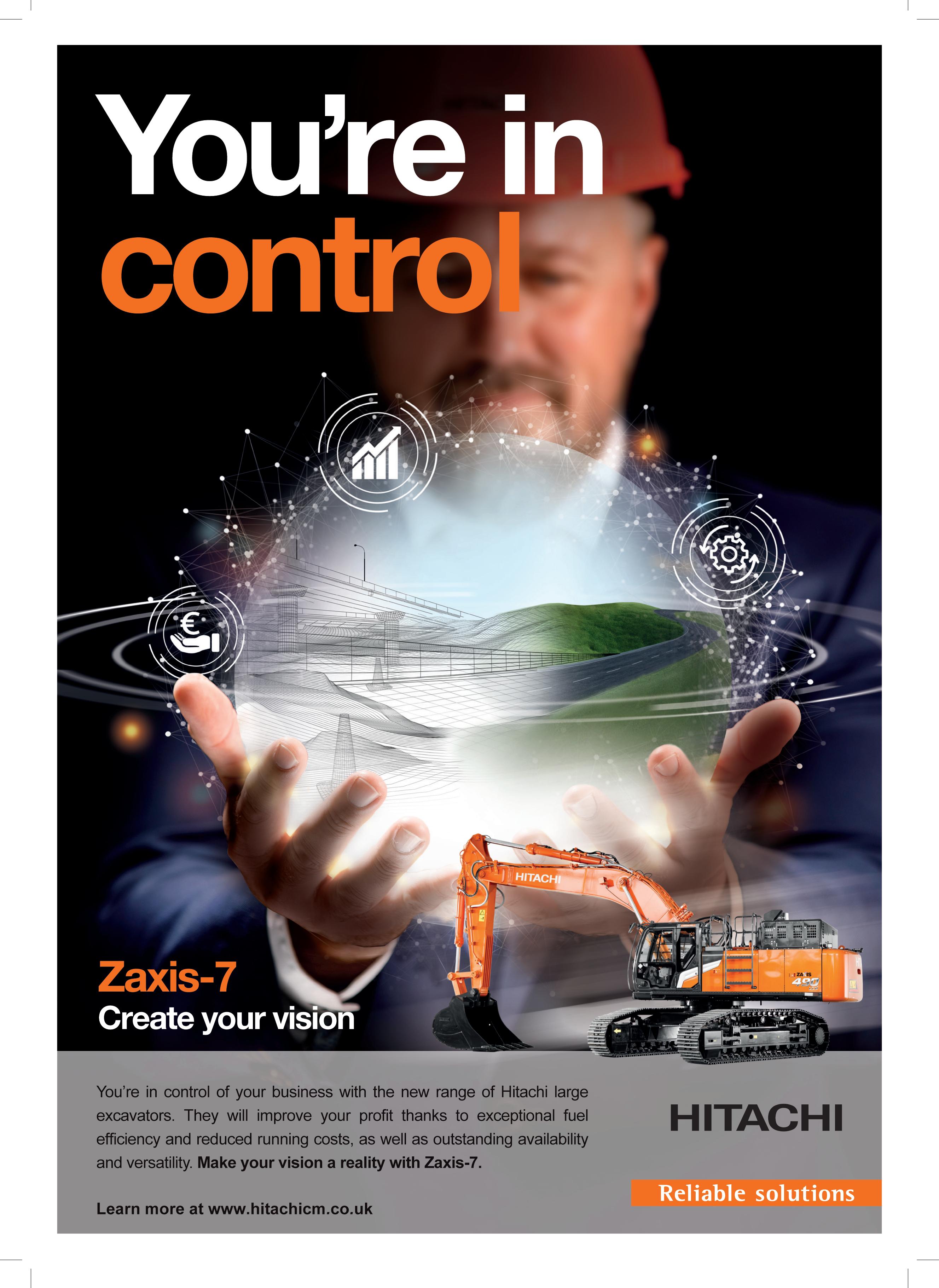

KEEP IT UNDER CONTROL

Topcon’s recently released findings from a survey of construction companies shows that nearly everyone is using some form of machine control – but not all the time. The survey of 1,000 managers, director and business owners working in construction across Europe revealed that 97% of them use machine control in some capacity.

However, few companies are using it all the time – just 1% – while 7% are using it on between 75% and 99% of their projects, 17% on between 51% and 75% of projects, 29% on between 26% and 50% of projects and 46% on fewer than 25% of their projects.

“For many, their experience with machine control is still in its infancy or confined to certain types of projects or applications,” comments Topcon in its analysis. The survey doesn’t break down the answers into different types of machine control or automation and doesn’t split the results by construction company activity.

Looking at the variation in take-up due to size of company, the results show the bigger a company is, the higher the percentage of projects for which it uses machine control: 22% for companies with 10 to 49 employees; 27% for those with 50 to 99 employees, 40% for 100 to 249 employees and 42% for 250 to 500 employee-companies. As Topcon comments, these differences could be due to larger companies having more capital to invest in tech or simply because they are working on larger projects that require machine control.

The survey doesn’t reveal significant differences between the countries surveyed in Europe. Germany and Scandinavia are somewhat more enthusiastic adopters with machine control used on an average of 36% of contractors’ projects. Companies in the UK and Belgium use it on an average of 32% and 31% of projects respectively.

When asked about the benefits of machine control, there was no stand-out answer. Accuracy and improving efficiencies were each pinpointed by 25% of respondents and reducing operator fatigue and improving sustainability by 24%.

Interestingly Topcon argues that machine control will help encourage more younger people to enter the industry and that it can help less experienced operators do a higher quality job. It asked respondents whether "advanced tech such as machine control is a key solution to attracting the best talent”; 77% said yes with only 8% disagreeing.

When it came to barriers to adoption of machine learning, it is perhaps surprising that upfront investment in technology came bottom of the list with 22%. At the top, 27% selected lack of government initiatives or support, followed closely by a lack of buy in from senior decision makers at 26%. Incompatibility with current machinery and time and resources needed for training were next at 25%, with a lack of regulation and standards and resistance to change both scoring 24%.

Like in many other areas of construction people are looking at legislation and regulatory pressure to drive adoption, rather than drive it themselves, an odd state of affairs when the benefits are tangible and at hand. Enjoy this issue.

Editor Johnny Dobbyn

John Levick

cpn@hamerville.co.uk

Group Advertisement Manager

CRAIG JOWSEY

craig@hamerville.co.uk

07900248102

Advertisement Manager

JACOB TATUM

jtatum@hamerville.co.uk

07825773737

Magazine Designer

ADEEL QADRI

Group Production Manager CAROL PADGETT

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Walstead Roche

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2023

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

Total Average Net Distribution 8.329 July 2021 –June 2022

V IEWPOINT

CPN I MAY / JUNE 5

ILLUMIN8 TARGETS GROWTH WITH BOELS

DUTCH FIRM BOELS RENTAL HAS ACQUIRED LEADING UK LIGHTING TOWER RENTAL SPECIALIST ILLUMIN8 LIGHTS LTD.

LATE MODELS IN DEMAND

BUYERS ARE PAYING TOP DOLLAR ACCORDING TO AUCTIONEERS EURO AUCTIONS AFTER IT CONDUCTED FOUR UK SALES RECENTLY.

In all over 17,000 pieces of heavy plant and construction machinery went under the hammer fetching a sale total of £134 million, with an inventory that included over 2,500 excavators.

“General contracting is very buoyant right now and we are seeing a lot of good mini diggers, 8t, 10t and 20t excavators on the market, in addition to lighter site machines which are in abundance. OEMs are delivering new machines and as such, buyers are now rationalising fleets, downsizing and normalising their stock,” reports Chris Osborne, Euro Auctions sales manager.

According to the company OEMs are now supplying, and dealers disposing of used machines in a swop for new, so there are plenty of good late machines available. At the latest sales, the volume of excavators, dozers, crushers and screeners, dump trucks, loaders, telehandlers, back hoes and manlifts were 2018 to 2023 plate machines and represented 24% of all machines sold in those categories.

WWW.RDR.LINK/CAJ002

CLEMENTS IN SALE TO FGS

COVENTRY-BASED CLEMENTS PLANT & ACCESS HIRE HAS BEEN BOUGHT BY KENT OPERATOR FGS PLANT, PART OF HEATHCOTE HOLDINGS GROUP. CURRENT MANAGING DIRECTOR, ADRIAN HUTCHINSON REMAINS ALONG WITH THE REST OF THE TEAM.

Talking about the purchase FGS Plant divisional managing director Stuart Willy said: “We are very impressed with the way the business is run and see huge synergies and shared values which will benefit both teams. We are especially excited by their bespoke created digital Tee-card system, which was a factor in helping them win the 2022 Executive Hire Show Independent Passionate Hirer of the Year award. We intend implementing this throughout our plant division in the coming months, with the whole group plant divisions working closely for the benefit of the teams and its customers.”

WWW.RDR.LINK/CAJ003 i

i

6 MAY / JUNE I CPN

NEWS

For more information WWW.RDR.LINK/CAJ001 i

Neil Fenwick (Illumin8) and Asif Lafief (Boels Rental)

GAP EXPANDS IN NORWICH

NORWICH IS THE LATEST LOCATION FOR GAP HIRE SOLUTIONS’ NEWEST DEPOT.

With extensive growth in the area, GAP made the decision to expand its premises and relocate to a larger site, creating a number of jobs within the local area. Located at Broadland Business Park, the extensive three-acre site can be easily accessed from the A47.

The brand-new depot will provide products and services from four of GAP’s specialist divisions, consisting of Plant, Tools, Lifting and Survey & Safety. These services will be available throughout most of East Anglia, consisting of Norfolk and Suffolk.

WWW.RDR.LINK/CAJ004 i

TREATED LIKE KINGS

THOUSANDS OF JCB EMPLOYEES TOASTED THE CORONATION IN STYLE THANKS TO A COMMEMORATIVE GIFT FROM THE BAMFORD FAMILY.

More than 8,500 special hampers were presented to JCB and agency employees in the UK to mark the historic event thanks to an idea from Carole Bamford, wife of JCB Chairman Anthony Bamford.

The presentation of hampers rounded off a week of Coronation celebrations at JCB when thousands of employees at plants across the UK took part in a company-wide street party. JCB treated employees to a twocourse celebration lunch over four days with classic British cuisine served on traditional street party trestle tables.

LETTERS OF INTENT FROM HYUNDAI

HYUNDAI CONSTRUCTION EQUIPMENT HAS INTRODUCED A NEW GLOBAL BRAND NAME AND CORPORATE IDENTITY, INCLUDING A ‘FORWARD MARK’, AN UPDATED VISION OF THE COMPANY’S TRADITIONAL TRIANGULAR BRAND SYMBOL.

The new name is HD Hyundai CE, which supposedly recognises ‘Human Dreams’ and ‘Human Dynamics’. The new brand is said to demonstrate the company’s move from simply providing customers with machinery, to delivering smart products and services, based on intelligent technology.

WWW.RDR.LINK/CAJ007 i

INTELLIGENT MOVE

VEHICLE TRACKING EXPERT MOVING INTELLIGENCE HAS JOINED FORCES WITH UKBASED SECURITY AND TRACKING SPECIALIST, AMI GROUP LTD. THE ACQUISITION MARKS AN IMPORTANT STEP IN THE DUTCH BRAND’S UK STRATEGY.

For more information

WWW.RDR.LINK/CAJ005 i

MECALAC MOVES

Founded in 2004, AMI Group Ltd. is a leading developer and supplier of advanced location and security solutions. Its technologies secure over £350m of equipment in the UK alone, including excavators, generators, engines, and vehicle fleets.

Patrick Horst, CEO at Moving intelligence commented on the acquisition:” We are delighted to welcome AMI Group into the Moving Intelligence family, enabling us to take the next step into the B2B market. Together we will continue to push the boundaries of our market both nationally and internationally.”

Fitted with the latest production line technologies, the new site will also be responsible for manufacturing the company’s brand new REVOTRUCK product, which was unveiled at BAUMA.

Heath Davies, general manager, commented: “As a global leader in the design and manufacture of compact machinery, we’re committed to investing in our future. In the past few months alone, we’ve revealed an increase to our UK production capability with REVOTRUCK – a pioneering addition to our range –and ED6 - our 6-tonne electric dumper.”

Peter Stockton, operations director at AMI Group added: “Moving Intelligence is the perfect fit for our business and more importantly our customers in the UK. The acquisition gives our team access to a strong and exciting portfolio of products and further strengthens our development and technical expertise. We’re heavily focused on executing a seamless transition for our customers and partners, whilst venturing on an exciting journey within a larger international organization.”

WWW.RDR.LINK/CAJ008 i

For further information

WWW.RDR.LINK/CAJ006 i

CPN I MAY / JUNE 7

IN A MOVE TO BOLSTER OUTPUT MECALAC CONSTRUCTION EQUIPMENT UK HAS RELOCATED ITS MANUFACTURING TO A NEW FACILITY.

MCHALE HEADS TO TAMWORTH

NEWLY APPOINTED UK DISTRIBUTOR FOR METSO OUTOTEC CRUSHERS, MCHALE PLANT SALES, HAS PICKED TAMWORTH AS THE LOCATION FOR ITS FIRST MAINLAND DEPOT. CHOSEN FOR ITS STRATEGIC LOCATION THE NEW BASE IS SITUATED ON THE LICHFIELD ROAD INDUSTRIAL ESTATE WHERE IT WILL ACCOMMODATE OFFICES, MACHINE STORAGE, PARTS WAREHOUSE AND A REPAIR AND MAINTENANCE WORKSHOP.

GLORY FOR SHELLPLANT

EPIROC’S 2022 DEALER OF THE YEAR AWARD WAS RECENTLY AWARDED TO NORTHAMPTONSHIRE-BASED SHELLPLANT IN RECOGNITION OF BOTH SALES’ GROWTH AND SUPPORT FOR CUSTOMERS ACROSS THE SURROUNDING COUNTIES.

Keith Lambourne, Epiroc’s sales manager for the UK & Ireland cited the company’s commitment to holding its hydraulic attachment tools in stock when delivery times have been challenging for everyone in the industry. In the last five years alone, Shellplant has doubled sales of hydraulic breakers, compactors, grabs and spares and consumables.

WWW.RDR.LINK/CAJ010 i

SANY IN THE DRIVING SEAT

FOLLOWING A STRATEGIC REVIEW, SANY HEAVY MACHINERY UK LTD HAS TAKEN OVER THE CONSTRUCTION EQUIPMENT FRANCHISE FROM MC TRUCK & BUS LTD.

Customers who have purchased SANY equipment from MC Plant will continue to receive support from SANY’s dedicated team of experts.

Commenting on the move, the company’s sales director, Denis McGrath said: “Of the many locations we examined, Tamworth stood out as one from which we could reach out to machinery owners and operators whose priorities in terms of technical backup and after-sales support we fully understand.

“We will implement an approach to customer service proven in Ireland and Northern Ireland where sales, service and parts operate in lockstep,” McGrath added.

WWW.RDR.LINK/CAJ009 i

“We are extremely grateful to MC Plant for its partnership and support over the past two years. In the short term we expect business as usual and we are delighted that most of the sales and service team from MC Plant have joined the SANY team to ensure a smooth transition. Longer term, this is an exciting step for the SANY UK business,” commented Leigh Harris, SANY business development director.

WWW.RDR.LINK/CAJ011 i

EVEN MORE PARTS FOR MACHINES

CONSTRUCTION AFTERSALES PLATFORM PARTSFORMACHINES IS GROWING ITS SUPPLIER BASE WITH A RAFT OF NEW QUALITY BRANDS, WHILE SUBSTANTIALLY INCREASING THE NUMBER OF REFERENCES OFFERED BY MANY OF ITS EXISTING PARTNERS. It welcomes global filter giants, Mahle to its ranks along with new names including Ashtree blindspot mirrors; WAI Products - who supply alternators, starter motors and EV Cables; OKO tyre sealants; Tohren hydraulic seals and spare parts, and Tigren industrial products and tools.

In line with its increasing audience and sales outside of the UK, PartsforMachines is also now able to offer its products in both Sterling and Euros.

“These are exciting times for all of us at PartsforMachines,” says PFM spokesman Simon Maurice. “Now, with our constantly increasing sales as well as the enhanced functionality and expanding interaction with our audience, PartsforMachines continues to move ever closer towards being the one-stop shop that the platform’s creators envisaged.”

For more information WWW.RDR.LINK/CAJ012 i

8 MAY / JUNE I CPN NEWS

Metso Outotec officials Adam Benn (left) and Anthony Bouvié (second right) pictured with a group of McHale Plant Sales officials during a visit to its Dublin base ahead of the announcement by Metso Outotec to extend its distribution remit to include England, Scotland and Wales in addition to its on-going responsibility for Ireland and Northern Ireland markets. Pictured with them, against the backdrop of a Metso Outotec Lokotrack crusher, are (left to right) Darragh O Driscoll (Head of Business Development), Tim Shanahan (Director), Denis McGrath (Director) and Anthony Ryan (Aftersales Director).

Shellplant Epiroc Award 2022.jpg – Ted George, Area Sales Manager for Epiroc, presents the 2022 Dealer of the Year Award to Julian Payne, Partner of Shellplant, with Tom Haywood (left) and Craig Johnson (right) from the Shellplant sales team.

CONSTRUCTION EQUIPMENT-

the struggle for supremacy

competence has created its own problem –namely how can leading manufacturers retain their premium positions over ‘lesser’ brands and woo buyers?

Construction equipment has been on a path towards commoditization for many years, simultaneously increasing the importance of the dealer-customer relationship and challenging the premium positioned OEMs to find new ways to demonstrate their value to customers. Indeed, we have commented on this topic several times in recent years, noting that the difference in performance and fuel efficiency between different brand and model machines has been declining. With only a few exceptions, increments in these key buying criteria now tend to be small, and price competition has been intense when supply is in balance with demand. For equipment users, this means they can focus more on the level of support from their dealer or rental company and pricing rather than being too concerned over which brand machine they are getting.

counts, there are 20+ different potential energy sources that could make up the global portfolio of solutions across different locations and applications. Electric products in their various forms (battery, fuel cell, etc.) will certainly be part of this change. So, why are we talking about electric products and commoditization at the same time? We believe that electric machines bring the potential to forestall the complete commoditization of the bulk of the construction equipment market for at least a decade. How is this so?

The overall commoditisation effect that we see in the traditional diesel products is the result of 70+ years of refinement of the same basic technologies – diesel engines applying power through mechanical geartrains and hydraulics. After seven decades of refinement of this package, even with the advent of software control, it is increasingly difficult to come up with something that the competition has also not thought of. It’s not just the powertrain, even the fundamental shape of machines is dictated by the physical constraints that these technologies bring.

S PECIAL REPORT: CONSTRUCTION IN SITE 10 MAY / JUNE I CPN

The race to electrify construction equipment is merely the first skirmish in a longer – bigger – campaign to redefine how machines are designed, operate and look, say sector consultants Alan Berger and CarlGustaf Goransson

Consider the loader-backhoe

This machine is a 1950s adaptation of the humble farm tractor, where the loader is by necessity wrapped around the engine that sticks out the front of the machine, leaving the rear as the only logical place to put the backhoe. The tractor part itself is constrained by the need to fit an engine, transmission, and axle to drive the machine, while leaving a comfortable place for the operator to sit. So, what happens when you remove the diesel engine and its need to have a relatively straight line to the axle, which needs a straight line to the wheels? While mechanical energy needs to route through rigid gears and shafts and hydraulics through relatively stiff hoses, electrical energy is transmitted through wires that can bend around corners. Perhaps even more importantly, there are countless ways to control these electric systems through software.

We have only begun to build these electrified machines. All are still in their infancy and most just substituting the diesel engine for a battery and some motors. There has been little work done to rethink the fundamental structure of the machine and to exploit the performance potential that a more software-controlled machine offers. Further, battery electric componentry itself is quite immature, with significant – as yet untapped – opportunities to optimize batteries, fuel cells, motors, and their installation for specific machine types. This creates potential for an entirely new race to develop the best machine for each application –with the winners being those who figure out to get the best performance in the smallest and most energy efficient package.

This also means that really understanding the

capability of the electrified machine is important for end-users. There will be substantial differences between some brands for years to come. Things that can really matter to the user include efficiency that connects to battery operating time in their specific application, weight and cost. It is also important to consider the machine’s ability to handle attachments, ability to operate at high and low temperatures and power needs for charging. These are in addition to potential changes in visibility, machine weight and configuration. Softwarecontrolled machines may be able to be more optimized for certain tasks, but the level and effectiveness of this control will also vary considerably between manufacturers.Finally, some features will eventually require a pay-peruse fee or subscription that must be factored into the total cost of ownership.

Who is best positioned to win this race? As with the automotive sector, electrics’ relative simplicity compared to ICE combined with the consequent lower investment required, means that barriers to entry are falling. That said, the largest OEMs are aiming at gaining first mover advantage and trying to maintain or improve their current position in the new competitive hierarchy. We have previously written that Chinese OEMs have not been able to make real progress penetrating the EU and NA markets. China has a significant head-start in electrification: if geopolitical considerations allow, could this rewriting of the rule book be the opportunity that enables Chinese OEMs to gain a significant market share foothold in the west?˚

■ ABOUT THE AUTHORS: Alan Berger and Carl Gustaf Göransson are managing partners of the commercial vehicle advisory practice, abcg™. The practice offers unrivalled experience, deep industry knowledge and an external 360˚ perspective to clients, qualifying them to deliver accelerated, sustainable transformation that propels business performance from good to exceptional. Equally focused on delivering successful outcomes as well as conceiving strategy, abcg™ help to identity and remove points of friction and provide hands on support to implement the required change.

For further information on abcg, WWW.RDR.LINK/CAJ 013

CPN I MAY / JUNE 11

i

SHOW & go!

According to the organisers Plantworx 2023 is about to hit the ground running. This year’s event will be the ultimate one-stop-shop for the latest and greatest construction equipment and technologies. With a plethora of innovations and new zones, visitors will see cutting-edge market offerings and the latest technology pipeline developments.

Many of Plantworx’s 300 plus exhibitors will be making their show debut.

The event will host many industry-leading machinery original equipment manufacturers (OEMs) presenting their electrification strategies for off-road vehicles and equipment. Many stands will feature live demonstrations from the likes of Hitachi Construction Machinery, and the Chinese heavyweights XCMG (who will be at Plantworx for the very first time). Other big names on the list include Caterpillar, Hidromek, Hydrema, Hyundai, SMT (Volvo), Takeuchi, Sany, Sunward Europe, Liugong, Mecalac, Yanmar Compact Equipment, Kubota, Develon (formerly Doosan), Bobcat, AVANT, BOMAG, Brokk UK, RSP Suction Excavators, Merlo, Manitou and many more.

Plantworx is also set to showcase the latest advancements in engine and battery

technologies. Xerotech with Hibernium and Lifos have been shortlisted for Plantworx Innovation awards and will be exhibiting for the first time. Atlas Copco is a regular exhibitor at Plantworx, this year showing its ZBC battery storage system, which is also shortlisted for an Innovation award.

These new battery technologies are a

promising development in the world of renewable energy and are sure to be a highlight of Plantworx.

The digital revolution is in full swing, and a deluge of technology and connectivity companies are hitting the market. These technology solution providers are working tirelessly to achieve an all-encompassing

CPN

PREVIEW PLANTWORX 2023

Get ready for Plantworx 2023: the biggest showcase of construction equipment and technologies! CPN casts an eye over what’s what.

connected site.

It’s not just about the machine; it’s about the telematics, cameras, and sensors that work together seamlessly to enhance the machine’s functionality. The data collected by these systems provides contractors and fleet owners with real-time insights into their equipment’s performance and health. Through a single platform, contractors and fleet owners can monitor the location, usage, and health of their equipment, all in one place.

Plantworx 2023 has attracted a number of these businesses, including equipment management platform experts MachineMax, ABAX Telematics and Plant Tracking, as well as connectivity solutions company Plinx and Onwave, who is showcasing Onwave Locator (OWL), which is a SaaS application, developed by Onwave to aid customers with the dissemination and communication of hazard and work site information to remote workers.

Safety is also an essential consideration in the construction industry. With the inherent risks that come with building and infrastructure projects, safety measures must be put in place to protect workers, the public, and the environment. Companies including Spillard Safety Systems, Xwatch Safety Solutions, GKD,

“All of these companies will be showcasing their latest safety solutions. Leica and Xwatch will be announcing a world-wide first with a recent collaboration that first debuted in Las Vegas.”

14 MAY / JUNE I CPN

PREVIEW PLANTWORX 2023

SiteZone, Leica, and Prolec are at the forefront of providing innovative safety solutions to the construction industry.

All of these companies will be showcasing their latest safety solutions. Leica and Xwatch will be announcing a world-wide first with a recent collaboration that first debuted in Las Vegas.

Spillard will be showcasing its AI Human Detection System (HDS), which has been shortlisted for a Plantworx Innovation Award. GKD, SiteZone are other companies that are dedicated to improving safety in the construction sector. Their range of products includes proximity detection systems and access control solutions that help to prevent accidents and unauthorized access to construction sites.

The award-winning Official CESAR Scheme is set to emphasize the criticality of security and demonstrate how its multi-layered security marking technologies can thwart criminals who seek to target plant and machinery once again. Additionally, Datatag ID (who operate CESAR for the CEA) will be unveiling KIST, a web-based administration portal.

Sustainable welfare cabins are an innovative solution for providing comfortable and environmentally-friendly temporary accommodation in remote or challenging locations. These cabins are designed to meet the needs of workers who require on-site accommodation and facilities, while also minimizing the environmental impact of their operations. Two award-shortlisted companies in this space are Boss Cabins and Genquip Groundhog who will be showing their latest green innovations at the show.

The versatility of a machine is often determined by its attachments and the show sees a record number of attachment manufacturers exhibiting. Leading brands such as Auger Torque, Digga Attachments, Digbits, Arden Equipment, Worsley Plant and BPH Attachments will showcase their latest products, alongside the top tiltrotator companies like Engcon and Steelwrist.

Machine control and guidance systems have become the norm on most site machinery, whether factory or retrofitted. Nasco Digtec’s iDig 2D and 3D will demonstrate the very latest in dig technology.

Technology zone

The construction industry has come a long way in the past few decades, and technology has played a significant role in that progress. From machine control to telematics, GPS systems, and safety systems, technology has transformed the way construction sites operate. To showcase the latest advancements in construction equipment

technology, Plantworx is launching the Get Connected Technology Zone, a dedicated space for technology providers in the construction equipment sector.

It bring together companies that have new and innovative ways of delivering solutions. The focus will be on the people-plant interface, telematics, the connected site, and safety systems. Indoor companies such as Ongrage Machine Control, Unicontrol, Sitech, Sodex, Plinx, MachineMax, GKD, and FTC are amongst exhibitors.

Outside exhibitors include Conquip, Hyundai Construction Equipment Europe, and Thomas Plant. These exhibitors will demonstrate their products in action on “working machinery,” which will have the technology previously installed. Exhibitors will arrive ready “to plug and play,” demonstrating the ease of integrating new technology into existing construction equipment.

Simulation zone

The Simulation Zone is an innovative and interactive area that offers an opportunity for novices and experienced operators alike to

upskill and learn machine control systems, advanced technologies, and gain insights into the world of construction.

Plantforce Rentals, a pioneer in simulation training, is once again spearheading the Simulation Zone. It has partnered with leading industry players like Trimble and Leica Geosystems to provide visitors with a comprehensive and immersive experience.

In addition to showcasing the future of the construction site, Plantworx 2023 will also highlight the key challenges facing small and medium-sized construction sector companies in the areas of immersive technologies and data. The event will provide an excellent opportunity for attendees to learn about new technologies and the ways they can benefit their operations.

Rob Oliver, executive director of the show organisers has recently shared his insights on Plantworx 2023. He stated: “Plantworx is back and bustling, following the successful Conexpo event and the UK’s Executive Hire Show. We are promising a wide range of new to the market products from an array of leading OEMs. As the industry witnesses a surge in companies embracing electric-powered solutions and making strides in hydrogen technology, Plantworx 2023 is set to be the most impressive edition yet. It is the showcase for groundbreaking machines and cutting-edge innovations that will propel the construction sector into the future.”

CPN Pre-register for Plantworx and avoid the queues WWW.RDR.LINK/CAI 014 i

ELECTRIC

dreams

CPN was invited to Atlas Copco’s ‘Journey to a Sustainable Future’ event in Antwerp, Belgium where a world’s first was unveiled amidst discussion about how best to tackle the transformation to a climate friendly, low-carbon future.

In the latest sign of its progressive shift to more sustainable equipment, Atlas Copco has expanded its portable electric product portfolio to include an all-new batterydriven portable screw air compressor. The BAir 185-12 is, according to the company, the first of its kind within the global industrial marketplace and represents a major milestone in Atlas Copco’s roadmap towards a sustainable future.

“We are committed to accelerating the transition away from carbon dependency and towards renewable energy sources,” explained Maarten Vermeiren, product marketing manager of sustainability and digitalization at Atlas Copco, Portable Air Division. “By introducing the first battery portable screw compressor, we want to play our part in enabling a sustainable transformation and help build a better tomorrow – for society and the planet alike.”

The B-Air 185-12 features 5-12 bar of pressure, a stable flow rate of 5.4-3.7 m3/min and 55kWh battery storage capacity. With power delivered from its onboard power pack, in operation a fully charged unit is independent of the need for fuel or a local power source to plug into and has the capability to perform for up to a full typical work shift. In turn, it provides both portability and productivity for those working on sites where regular access to electricity is not practical.

Making the switch from an internal combustion engine (ICE) to electric motor brings with it a host of benefits, including less downtime and maintenance requirements. With far fewer moving (and therefore wearing) parts compared to a diesel-powered unit, the electric B-Air 185-12 only needs to be serviced every 2,000 hours, as opposed to 500 hours for a

C PN AT LARGE 16 MAY / JUNE I CPN

typical ICE powered unit. The machine’s state-ofthe-art variable speed drive (VSD) and permanent magnet motor reduce the total cost of ownership, by automatically adjusting the motor speed to match air demand in real-time and increasing energy efficiency by up to 70%. The machine has an expected lifetime of 40,000 hours, powered by the battery pack which, it is claimed, is good for 1,800 days use.

Through Atlas Copco’s rigorous proving process, which includes rapid ageing testing under harsh conditions and climactic chamber testing, the B-Air 185-12 has been proven to perform optimally even in the most extreme of climatic conditions – ranging from +45°C (+113°F) to a glacial -25°C (-13°F); and 4,500 metres (14,764 ft) above sea level. The unit is also designed to excel in densely populated urban areas where emission and noise pollution are tightly restricted, thanks to it producing no local emissions and having low noise levels. The quiet nature of the compressor enables

operators to work without noise distraction, enhancing both productivity and safety.

The future is electric

The new battery-powered unit marks a vital step, says the company, in the electrification of its product offering, and is just one of many developments the company currently has in store to deliver sustainable solutions to its customers. The unit came to life thanks to the

long-term partnership with Perslucht Wilda, Atlas Copco’s distributor in The Netherlands for more than 40 years.

Bert Derom, president of Atlas Copco Portable Air Division, believes the B-Air 185-12 is a tangible symbol of the business’ commitment to delivering real-world solutions to help customers and their customers adopt a more sustainable way of working, and to turning the tide on climate change. “ We ultimately want to offer a sustainable alternative to every user and every application, and this new battery powered unit is a leap closer to that goal.”

The B-Air 185-12 is scheduled to go into production in September, using a compact and modular concept with multiple autonomy variants.

For more information on B-Air 185-12 WWW.RDR.LINK/CAJ014

CPN

i THE B-AIR 185-12

TECHNICAL DATAVALUE ATLAS COPCO B-AIR 185-12 Working pressure bar (g) 5-7-10,3-12 Free Air Deliverym³/min 5,3-4,8-4,6-3,7 Free Air Deliverycfm185-173-161-130 Operating ambient temperature range (standard)ºC-25ºC / +45ºC Motor Installed motor powerkW (Hp)26(35) Electricity requirements Input voltageV380-480 Rated frequencyHz50/60 Dimensions Undercarriage (L x W x H)mm3762 x 1593 x 2100 Undercarriage weight kg 1500

BY NUMBERS

"...The B-Air 185-12 is a tangible symbol of the business' commitment to delivering real-world solutions..."

FOR ALL THE VERY LATEST INDUSTRY NEWS AND NEW PRODUCT INFORMATION VISIT

WWW.CPNONLINE.CO.UK

FOR ALL THE VERY LATEST INDUSTRY NEWS AND NEW PRODUCT INFORMATION VISIT WWW.CPNONLINE.CO.UK

Packed with articles on a wide range of industry topics, www.cpnonline.co.uk is the first place to visit for all the latest news in plant and machinery – from the smallest skid steers and micro excavators to the giants of the tower crane market, or the heavyweights in crawler excavators, weʼve got it covered.

Get the latest information on the industryʼs biggest deals, as contractors and plant hirers renew their fleets in our Fleet Additions section, as well as all of the newest products to hit the market. Our website is updated daily, bringing you the most important industry news quicker than ever before.

YOU CAN ALSO FOLLOW US ON TWITTER @CPN_mag

SUPPORT SWINGS THE DEAL

Reliability and support are key to JC Plant Hire & Groundworks, which keeps Pembrokeshire’s roads in good condition for the local authority. Owner-operator Juan Cruz has a longstanding relationship with CAT dealer Finning UK & Ireland, so when he needed to replace the company’s current CAT 432 backhoe loader he approached Iwan Jenkins, territory account manager, Wales Region for Finning.

This time Juan wanted a reliable option similar to his existing machine but preferred a used model. While Finning could have facilitated a trade-in or sold the existing machine on Juan’s behalf, Juan chose to sell it privately. Iwan searched for a used but updated model and managed to locate a 2018 machine with only 1,000 hours of usage. Juan sat in the machine, loved it, and decided to purchase it.

“We chose a CAT 432 F2 which I like because it has things like a larger cab size, there is an auto shut off on the revs and the new machine is a lot quieter than the old one,” said Juan. “Reliability is the biggest factor when we choose our machines and we’ve found that is guaranteed with Cat equipment – even when buying used.”

In addition to low usage, the used CAT 432 backhoe loader came with a 12-month hydraulic and power track warranty, as well as two new buckets.

“With the 12-month warranty it also means if there are any issues with it, I can get those ironed out in that time as we’re working five days a week and the machine can be in use more than five hours a day,” comments Juan.

The machine was also equipped with telematics, enabling JC Plant to access important data such as location, fuel usage, and proactive maintenance alerts. This information facilitates quick fixes and minimizes downtime with the support of Finning’s engineering team.

WWW.RDR.LINK/CAJ015 GOTO

CITY HIRE’S AFFAIR WITH KUBOTA CONTINUES

City Hire, a leading London-based equipment hire business, has significantly expanded its Kubota micro and mini excavator fleet, adding 12 machines to its existing inventory.

The latest purchase is in addition to the 22 Kubotas the company bought last year, so it now has a fleet of 40 Kubota excavators, all in the 0.8 to 3.0 tonne range.

The company’s loyalty to Kubota machines began in 2017, says company director Lionel Burgess, and has continued because of their popularity and reliability.

“Our excavator fleet is 100% Kubota and it’ll stay that way. Our customers ask for Kubota excavators by model and the machines are always well received,” he explains.

“From an operational point of view, Kubota’s are extremely reliable with low operating costs and, after three or four years, the residual values are exceptional,” Burgess said.

City Hire has a wide and varied customer base that includes house builders, civil engineers, commercial builders, and interiors contractors, all of whom rate Kubota equipment for its performance, economy, and intuitive controls.

The newly added machines, supplied by Boss Plant Sales, Kubota’s authorised dealer for London and the southeast, include six K008-5, four U17-3, and two U27-4GL models.

These high-performing units are all equipped with an auxiliary hydraulic circuit, hydraulic quick hitches, and a comprehensive range of digging and ditching buckets. City Hire also offers Socomec hydraulic breakers, supplied by Boss Plant, which are regularly leased with a Kubota.

City Hire is headquartered in Southall, near Heathrow, and has distribution centres in Dagenham and Liverpool.

GOTO

WWW.RDR.LINK/CAJ016

SOS OPTS FOR MECALAC DUMPERS

Wrexham-based rental firm SOS Plant Hire has further expanded its growing fleet with five units from Mecalac. Alongside two TA9 models and a TA3SH swivel-skip, the company has also placed an order for two one-tonne TA1 units.

A favourite with hire operators, Mecalac’s site dumper range is renowned for its durability, reliability and class-leading build quality. With payloads from one to nine tonnes, each model features ergonomic controls and state-of-the-art safety technologies.

Sean O’Sullivan, founder of SOS Plant Hire, commented: “Mecalac site dumpers offer adaptability and innovation as standard. Consistently a favourite among our customers, their flexibility and versatility are revered by operators.

“When it came to further expanding our fleet, we reached out to the team at Norwest Plant. Having worked closely with the team over a number of years, we knew they’d help to pick out the best machinery to suit our needs.

“With three of the five units ordered already on-site and available to our customers, we’re delighted with our decision. The Mecalac units are the perfect addition to our fleet and we look forward to seeing them operational across the region over the coming months.”

SOS Plant Hire provides an extensive range of equipment on short- or long-term hire to customers across Wrexham, Chester, Flintshire, Denbighshire, Shropshire, the Wirral and Merseyside.

GOTO

GOTO

WWW.RDR.LINK/CAJ017

CPN I MAY / JUNE 19 F LEET

ADDITIONS

F LEET ADDITIONS

MEP HIRE BUYS 150 MICRO SCISSOR LIFTS

MEP Hire has taken delivery of 150 Genie GS-1432m micro scissor lifts to equip its network of 11 branches.

“Thanks to their lightweight construction of just 900 kg and compact footprint, Genie GS1432m micro scissors are a good offering for mechanical and electrical customers working on suspended flooring,” explains Andy Menham, product and sector development manager for MEP Hire.

“MEP Hire partners with Genie due to the impressive build quality of its machines,” he says. “They’re not only robust, reliable and efficient but they’re also incredibly easy to operate, allowing users to complete tasks safely and efficiently.”

Genie GS-1432m micro scissor lifts, as well as Genie’s other micro scissor model, the GS1932m, offer versatile access at low-level heights — a specialty of MEP Hire. Micro scissor lifts are a safe and more productive alternative to ladders and vertical lifts. Both the GS-1432m and GS-1932m micro scissors are compact enough to drive through doorways with standard fixed guardrails and are lightweight enough to be transported in standard elevators.

GS-1432m micro scissors feature Genie’s fully-sealed and maintenance-free AC electric drive, which helps reduce the total cost of ownership while boosting productivity. E-Drive is four times more efficient than traditional hydraulic drive, which benefits runtime.

WWW.RDR.LINK/CAJ018

DRIVER CHOOSES VOLVO FH 540 SLEEPER CAB

Inverness-based Campbell Plant Hire has expanded its delivery fleet with the addition of a new Volvo FH 540 sleeper cab 6x2 tractor unit.

Supplied by Volvo Truck and Bus Centre North & Scotland, the eye-catching truck will be paired with a Nooteboom trailer to transport heavy plant equipment across the Scottish Highlands.

“Driver preference played a major part in this latest order. He’s a big Volvo fan, and we were only too happy to provide him with the tools he likes when it came to upgrading his truck,” says John Maclachlan, director at Campbell Plant Hire.

Equipped with Volvo’s D13K Euro-6 engine, the FH delivers 540 hp and a maximum torque of 2,600 Nm. The 12speed I-Shift gearbox, combined with Volvo’s I-See predictive cruise control system, enhances sustainability and operational efficiency through active speed management and precise gearshifts.

Backed by a four-year Volvo Gold Contract for maximum uptime, the FH is expected to cover approximately 50,000 to 60,000 miles per year.

GOTO

WWW.RDR.LINK/CAJ019

MURPHY PLANT PLUMPS FOR XWATCH FOR SAFETY

Murphy Plant has chosen the Xwatch XW5, Height, Slew and RCI (rated capacity indicator) for its 300-strong fleet on the basis of its reliability and simplicity.

“A lot of innovation has gone into producing the XW5,” says Brendan Sugrue, managing director of Murphy Plant. “It is simple to use and there are far more safety features than other products in the market.”

Sugrue says that the company will now specify Xwatch systems, including XW5, Height, Slew, and RCI, on all new machinery added to their fleet.

“I was also impressed that the Xwatch team provides onsite familiarisation training for our operators, who are now also qualified to train other operators on using Xwatch,” Sugrue added.

The XW5 system supports a “lifting” beacon that indicates when the rated capacity indicator (RCI) is enabled. This simple yet effective feature allows operators to easily identify if they are following the correct protocol. Murphy Plant has recently invested more than £4 million in brand new Komatsu machines, all of which will come installed with the XW5 system.

Another point in favour of Xwatch systems is that they are compatible with MachineMax, the company’s telematics equipment management platform.

“Consolidating and using data to its full potential allows our business to be more efficient.” Sugrue explains. “By combining the data together you are able to streamline, improving fuel efficiency, safety of operation and vehicle maintenance in real-time.”

The MachineMax system does exactly that: consolidates data from equipment telematics and sensors to generate insights into how operations can be improved. It is compatible with any make, any model, anywhere and this includes the Xwatch systems, which is fitted with a Can bus mounted event recorder.

Murphy Plant is one of the largest providers of plant, transport and equipment in the UK, managing and maintaining more than £100 million worth of plant, transport and specialist equipment. It is a part of J. Murphy and Sons Limited, a leading global, specialist engineering and construction company.

GOTO

WWW.RDR.LINK/CAJ020

20 MAY / JUNE I CPN

GOTO

Left to right: Andy Menham, UK Product and Sector Development Manager, MEP Hire, and Mark Timmons, General Manager, MEP Rainham Depot, MEP Hire

BATTERY-POWERED BOOM LIFT AIDS MOVE TO CARBON-NEUTRALITY

Contract Plant Rental is incorporating lithium electric LGMG boom lifts into its fleet to support its clients in transitioning to a carbonneutral future. The Wellingborough-based company’s head of access, Stuart Lambert, believes that the rise of lithium technology is inevitable as customers seek more environmentfriendly kit.

Lambert argues that, by offering the LGMG platforms, the company provides its customers with a zero-risk option to incorporate lithium MEWPs (mobile elevating work platforms) into their fleets, allowing them and their own clients to experience the clear advantages over diesel firsthand.

The LGMG T20E, launched in 2022 as part of a range of four lithium electric stick booms, operates with near zero emissions and low noise for 2-3 days on a single charge, offering multiple standard and fast-charging modes. Supplied by Access Platform Sales (APS), it features a spacious basket with a capacity of up to 300kg (restricted capacity of 450kg). Additionally, the LGMG T22E offers a maximum working height of 23.8m and a maximum outreach of 17m.

Contract Plant Rental firmly believes that lithium platforms surpass traditional diesel

power in terms of benefits, particularly in light of the increasing number of low and ultra-low emissions zones being implemented across the UK. Many contractors and end-use clients now require low and zero emissions working at height options on their sites to meet their carbon reduction targets.

The LGMG T20JE, equipped with four-wheel drive and steering, including three steering modes, offers enhanced manoeuvrability and safety with features like one-touch wheel

alignment. Its oscillating, full floating axles provide excellent grip and traction on uneven and soft terrains, and the platform’s maximum tilt angle of five degrees and 45% gradeability further contribute to its versatility.

In addition to the environmental advantages, the adoption of electric platforms eliminates the high costs associated with diesel fuel and the need to store it on worksites, ensuring a more cost-effective and efficient solution. WWW.RDR.LINK/CAJ021

GOTO

Many tools make light work

Let’s start with the rubbish. CAT’s demolition and sorting grapple line, the new G306 and G308 models are specifically designed for 5- to 6-ton and 7- to 10-ton mini hydraulic excavators respectively. These new models excel in waste, recycling and heavy-duty material handling applications where precise material placement is required, the company claims. With open and close functions controlled by the machine’s first auxiliary function and rotation head handled by the second, these grapples deliver fast and productive material handling with 360˚ of bidirectional rotation.

The slim design makes it easier to get into tight spaces, and material capacities range from 160 l (0.21 yd3) with the G306 to 240 l (0.31 yd3) for the G308. Vertical perforated shelves offer high wear resistance, positive penetration, good load visibility and easy positioning, while the oversized heavy-duty cylinder with load holding valve delivers

constant clamping force, even when manoeuvring the grapple or machine. Providing reliable operation with low maintenance intervals, the swing bearing features a singleball heavy-duty, internally driven design. For longer life, the weld-on base edge design is made of HB500 Brinell equivalent material and bolt-on cutting edge (BOCE) from highstrength, abrasion-resistant steel.

Take a tilt at that

Caterpillar has also upped its game in the tiltrotator (TRS) segment with the new G206 and G208 multi-purpose grapples, expanding its grapple technology in combination with the TRS6 and TRS8 models for 5- to 10-ton mini hydraulic excavators. These grapples give maximum manoeuvrability with TRS attachments, and an integrated bracket

A TTACHMENTS 22 MAY / JUNE I CPN

Loads of jobs, one machine – that’s the beauty of attachments. CPN looks at CAT’s new roster of products for backhoe loaders and mini excavators.

provides minimal offset to optimize performance and functionality.

With the G206 sized for 5- to 6-ton excavators and the G208 for 7- to 10-ton models, these multi-purpose grapples deliver 14.5-kN (3,260-lbf) and 18.4-kN (4,136-lbf) maximum closing force respectively. An integrated cylinder load holding valve maintains grapple closing pressure with no leakage, while the hard-mounted piston accumulator maintains grapple arm closing forces with shifting loads. Optimal routing of the integrated jumper lines and hoses safeguards against damage and dirt infiltration for long-term reliability.

The grapple design is optimally matched to the tiltrotate system, and the rotation of the TRS allows for quick and easy material engagement. To avoid any bending torques in radial direction, these grapples feature a welded box structure. With grapple arms and arm edges built with AR450 steel, the arm offers high abrasion resistance for longer wear in extreme conditions.

For the flat earthers out there, the CAT vibratory plate compactor line has been augmented and refreshed with the new CVP28 and CVP55 models coming on stream and the relaunch of its CVP16 and CVP40 compactors with new design enhancements.

The CVP range is performance-matched to CAT machines, covering all backhoe loaders and excavators ranging from the CAT 302.7 to

the 313. They offer compaction widths from 304.8mm (12in) to 660.4mm (26in) and compact areas ranging from 0.19 m2 (2 ft2) to 0.53 m2 (5.7 ft2) at vibration frequencies from 33.3 to 40 Hz (2,000 to 2,400 vpm).

Their heavy-duty steel frame delivers maximum power to the ground. Rubber mounts isolate vibrations from the compactor attachment, minimizing vibration feedback to the rest of the machine. The high efficiency gear-type hydro motor is vibration driven for consistent, reliable power. The design’s access cut-outs are laser cut for easy access to hardware when mounting the top bracket. The compactor is simplified with standard auxiliary hydraulics.

To provide greater the flexibility to the CVP range, post and plate driver attachments bolt to the bottom of the CVP28 for specialized applications. All models can be equipped with a backfill blade to help spread out material in the ditch prior to compaction, and a swivel mount rotates 90˚ in each direction to minimize machine movements.

Designed for small paving jobs in residential and commercial applications, the new CAT cold planers deliver economical restoration of asphalt and concrete surfaces. They efficiently mill imperfections prior to resurfacing and remove deteriorated pavement and traffic lane stripes.

Offering a working width of 350mm (13.8in) and 120mm (5in) maximum milling depth, the new PC35 is designed for operation with side-shift backhoe loaders and 5- to 6-ton mini hydraulic excavators. The new PC45 replaces the PC404 with its 450mm (17.7in) cutting width and 150mm (6in) cutting depth and is ideal for use with backhoe loaders and extends the planer’s compatibility to 7- to 10ton mini hydraulic excavators.

The cold planers come as standard with a cut depth indicator, giving the operator a quick view of set depth. Delivering consistent depth control, milling depth is manually adjusted and locked in. The heavy-duty gear motor provides high torque and efficiency across the speed range, while a hydraulic relief valve limits pressure to the motor for increased longevity. Helping to maximize productivity, a standard pressure gauge provides feedback to the operator to allow for ground speed adjustments. Simplifying operation, the PC35 and PC45 reuse existing hammer lines and are equipped with drum centre and width indicators.

CPN I MAY / JUNE 23 For more information WWW.RDR.LINK/CAJ022 i

TO ANSWER CASE

In round two of our discussion with CASE, CPN asks about its E-Series wheel excavator range.

CPN:WHAT’S

THE WEIGHT RANGE OF THE E-SERIES AND CAN YOU TELL US ABOUT ANY NEW FEATURES THAT STAND OUT?

The new CASE wheel excavators range comprises four models ranging from 14 to 18 tons, plus a fifth 21-ton model which will be launched in Europe later in the year. The new models are comprehensive in terms of covering the most important market expectations, with two conventional tail swing machines (WX140E / WX160E) and two short radius models (WX155E SR / WX175E SR) for when space is tight on job sites. All models are available in 2-piece boom configurations to maximize flexibility, while also being capable of fitting a mono boom up to the WX160E.

The entire wheel excavator range is a new departure, or maybe that should be a revisit, for CASE, returning to this market segment after several years away. Every feature of these models stands out as being totally new, all of them contributing to our customers’ business profitability and providing operators with a most comfortable, controllable and efficient excavator.

M ACHINE FOCUS 24 MAY / JUNE I CPN

CPN:WHAT ABOUT ONSITE SAFETY, VISIBILITY AND COMFORT? WHAT’S NEW IN THE CAB AND FOR THE OPERATOR?

Outstanding visibility and safety are guaranteed with the standard secondary monitor that allows the rear camera view to be always on screen. This uses the 360° CASE maximum view monitor camera system, which not only enables a real all-around view both in 2D and 3D of the machine’s surroundings, but is even capable of detecting pedestrians approaching the machine and warns the operator about the risk. A rear radar device can be also fitted on conventional tail swing models to further enhance safety.

In addition there are a number of features that promote safer working: cab FOPS level 2; safety valves on boom, arm, blade, front axle; alarms for safety belt, travelling and overload warning; functions like the swing lock for deactivating any unwanted turret rotation; and the auto safety lock to inhibit impromptu activation of the hydraulic functions by mistake.

Visibility from the cab is also a high priority. The cab windows provide optimized surfaces and the parallel windshield wiper makes sure that neither rain or snow can impair the operator’s view, while the standard LED working lights can brightly illuminate the area in front and behind the excavator.

Operator comfort is a must-have and to that end the cab interiors and controls are designed to create a positive and stress-free environment: pneumatic heated Grammer seat, telescopic steering wheel, main touchscreen display with integrated A/C, jog dial to navigate menus, adjust speed when using cruise control on road or select engine throttle independently from the power mode, auto braking to relieve strain when the machine has to move, stop and move again often, smart key for making even the engine ignition easier than ever.

CPN:HOW HAVE YOU IMPROVED THE OPERATOR EXPERIENCE AT THE CONTROLS?

The operator really has full control over every function and movement of the machine, not only thanks to the advanced flow sharing system at the heart of the CASE wheel excavators’ hydraulics, but also because the proportional joystick controls allows finetuning all of the operations by locking the front

oscillating axle when needed, finger-touch steering, or using hydraulic tools in the preferred way by choosing among push, detent and proportional activation.

Other features that also contribute to the overall machine performance include: fine swing which makes turret rotation smoother and

more accurate if activated; creep speed which is ideal for travelling and also working on challenging ground conditions; ride control ensures that the excavator can travel on bumpy terrain still keeping its fully loaded bucket intact; and boom flotation is a great help for scraping ground easily and with less effort.

M ACHINE FOCUS

CPN:WHAT HAVE YOU DONE TO IMPROVE FUEL EFFICIENCY, REDUCE EMISSIONS AND MAINTAIN OR INCREASE TORQUE?

The new CASE excavators up to WX175E SR are all fitted with a four-cylinder, 4.5 litre Cummins engine, that offers efficient combustion and PM reduction without any exhaust gas recirculation (EGR). The engine has a compact aftertreatment design and automatic DPF cleaning, and is also compatible with HVO and other synthetic fuels, all more eco-friendly alternatives to diesel and even better than traditional bio-diesel, which these machines are capable of using up to 20%.

Of course, the overall fuel consumption efficiency of the new E-Series is a result of the combined performance from both the engine and the machine’s hydraulics.The Eco power mode is able to optimize fuel saving while still supplying competitive performance and, usefully, the machine can even provide information and guidance to the operator to improve fuel consumption, through the real-time fuel gauge, as

well as an array of reports (last 7 days, last 12 hours, by power mode, ECO report showing idle percentage), plus letting the operator switch on and customize the duration of the auto idle and auto engine shutdown, to make sure that the machine is not burning fuel needlessly.

CPN:CAN YOU TELL US ABOUT YOUR SITEWATCH AND SITECONNECT SYSTEMS?

To further boost the flexibility, up-time, productivity and profitability of its new Eseries wheel excavator range, CASE has created a range of connected and nonconnected after-sales services, CASE Service Solutions, which supports customers’ experiences of CASE equipment.

Plant fleet managers benefit from

geolocation, fleet security using geo-fences and unauthorised use alerts, and flexible reporting from the complete fleet management tool CASE SiteWatch. This powerful tool includes the ability to track key performance indicators (KPIs) such as fuel consumption, utilisation rate, machine hours and idle time, enabling productivity and profitability to be monitored and optimised. The data is easily accessible via an online portal.

CASE SiteConnect enhances telemetry data used by CASE’s uptime team to provide dealers with alerts based on machine performance. Fast corrective action to minimise downtime is possible, as dealers remotely access machine data and take corrective action faster. This enables dealers to be proactive in managing customers’ machines and boosting uptime.

For more information WWW.RDR.LINK/CAJ 044 i

"...fleet managers can benefit from geolocation, fleet security using geo-fences and flexible reporting..."

Abbey days!

Temporary works specialist Mabey Hire was called in by Derby City Council when it needed to reconnect a local community. The historic villages of Darley Abbey and Darley Abbey Mills are bisected by the river Derwent but the bridge was condemned due to safety concerns back in May 2022, preventing travel between the two communities.

As such, Derby City Council knew that a temporary bridging solution would be required and Mabey Hire was appointed to design, supply and install a temporary bridge.

The temporary bridge design, which spanned 45m in length, was made from Mabey Hire’s Compact 200 (C200) modular footbridge system, designed specifically for pedestrian applications, with the addition of steel mesh in-fill panels for added safety.

The main challenge on the project came from the installation, with a severely tight site space and limited access. Due to the location, the 45-metre-long temporary bridge was delivered to site in modular panels, before being assembled in skeleton form on a residential road and then lifted into position by a 500-tonne capacity crane.

Speaking about the project, Lee Matthews, major projects manager at Mabey Hire said: “This was a huge and incredibly complex installation, requiring all our engineering team and in-house installation team’s expertise to plan and safely execute logistically. Due to the location, it was decided that a crane-lift would be the safest approach but even that presented challenges. As well as the residential street being the location for the bridge assembly – a very

tight space – the site also included a row of protected trees, which made the site constraints even harsher when considering the crane lift.

“We were working with exceptionally tight tolerances – at one point, part of the crane was just a couple of metres away from a resident’s front door! It’s testament to our experience and expertise that we were able to achieve the lift and installation with a 500tonne crane – rather than the larger crane that was originally discussed. Credit goes to our experienced installation team and site manager,

Paul Ogden, who worked tirelessly to ensure that this installation was a success, as well as always being on hand to answer any questions that the local community had.”

Rich Giles-Grant, senior technician –Structures Design & Bridges at Derby City Council added: “The main challenge on the project was definitely the limited space available, with an extremely tight area to work in. It was for this reason that we chose to work with Mabey Hire, as they really are specialists in what they do. The support we had from the team was fantastic, both on site during the installation and in all the preparation and planning that went beforehand. With these challenging logistics, effective collaboration really was key.

“It’s great to have now reconnected the community, with the village relying on the footbridge to access the local businesses and amenities on the opposite side of the river.”

M ACHINE FOCUS 28 MAY / JUNE I CPN

more information WWW.RDR.LINK/CAJ 023 i

For

O’Keefe scripts winning episode for film complex

O’Keefe is using lime stabilisation techniques to improve ground conditions on the site of a new film and TV studio complex near Reading.

Working for main contractor Curo Construction, O’Keefe’s enabling works package includes cut-and-fill stabilisation and the construction of pile mats, roads, deep drainage and retaining walls.

During the tender design period, O’Keefe proposed a costsaving solution entailing soil stabilisation and the use of a proprietary Tubosider storm water system as part of the site drainage element.

The cost and environmental impact of excavating the site and replacing poor soil with imported fill was prohibitive whereas using stabilisation to bring site-won material up to the standards of an engineering fill for reuse was better both economically and environmentally.

There was also a technical obstacle to overcome. Testing had revealed a high

sulphate content which can react with the lime used for the soil stabilisation, causing the ground to heave. O’Keefe visited the site and collected samples of the materials from the cut. These samples were then analysed at O’Keefe’s own in-house geotechnical laboratory and tested alongside trial mixes using lime and ground-granulated blast-furnace slag (GGBS),

a well-proven cement substitute, in varying proportions.

After successful testing, O’Keefe offered Curo a mix design to meet the earthworks specification using lime and GGBS.

Sarens refines big operation in northwest

Sarens, the heavy lifting, engineered transport and crane rental specialist, has been directly involved in the turnaround, upgrade and improvement works that have taken place at the Essar Stanlow refinery. The works –carrying out major maintenance and repair operations throughout the facility –have affected critical plant infrastructure such as the cracking unit and have been spread over more than nine weeks.

For the project, Sarens deployed 39 cranes of various sizes, with load capacities ranging from 12 to 750 tonnes, as well as 55 members of its engineering team and technical staff to the Essar site, 16 of whom have been permanent staff at the Sarens depot at the refinery since November 2020. In addition, during the operation, the team also used different units of SPMTs (self-propelled modular trailers) and other jacking and skidding systems to transport materials inside the plant.

To facilitate manoeuvering and optimise transport processes, its technical team used, among other resources, a programmable electronic steering system for its SPMTs, with the aim of providing accurate alignment of plant during the installation. In addition, new structural steel supports designed and

provided by Sarens for the LR1750 crane –the one with the highest load capacity used on this occasion –were also used as a pedestal to pick-up a set of existing ring piles, to avoid the need for site civil works.

Essar’s Stanlow plant is one of the largest in terms of production volume in the UK. It is currently responsible for the production of up to 16% of the fuels used by British transport, especially in the North West region. The plant produces 4.4bn litres of diesel, 3bn litres of petrol per year –enough for a vehicle to drive around the world 20 million times –and up to 2bn litres of jet fuel per year.

This project, the first of this magnitude since spring 2018, has required the shutdown of virtually all the refinery’s units to comply with the inspections required by regulators, as

well as to carry out various overhauls and upgrades to essential equipment and the installation of new equipment, necessary to maintain the plant’s operation continuously and without downtimes.

CPN I MAY / JUNE 29

more information WWW.RDR.LINK/CAJ 024 i

For

WWW.RDR.LINK/CAJ 025 i

For more information

IMPROVE YOUR IQ WITH NEW BOBCAT APP

BOBCAT HAS LAUNCHED ITS NEW MACHINE IQ TELEMATICS SYSTEM, CONNECTING CUSTOMERS TO THEIR MACHINES’ INFORMATION AT ANYTIME, ANYWHERE AND FROM ANY DEVICE.

The telematics system allows customers to check the health of their machines and remotely track information that enhances maintenance, security and performance, all from smart devices or laptops. This simple and powerful tool lets customers get the most out of their Bobcat equipment, achieving more while protecting their investment at the same time.

There are various ways for Bobcat customers to connect with Machine IQ. They can join up by going on the web at my.bobcat.com, creating an account and logging in. Alternatively, the mobile app for Machine IQ can be downloaded from Google Play/Apple store, where

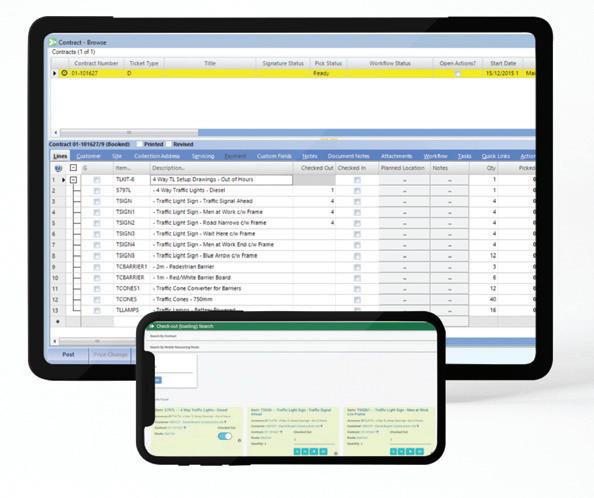

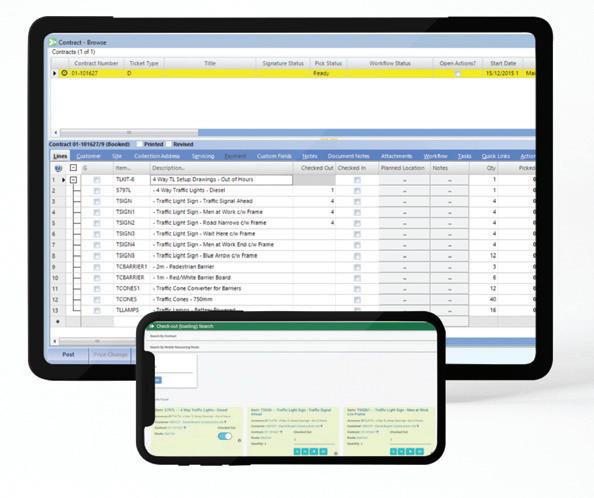

TRACK ‘N’ TRACE

Without the check-out process, rental companies would typically have picked the rental equipment to be shipped from the depot but wouldn’t necessarily know what exactly was loaded onto a delivery vehicle. This is then made even more challenging to keep track of when using thirdparty haulage companies, says MCS.

With the new powerful combination of MCS Third-Party Transport and Check-Out, this process is now easily trackable with a clear record of what equipment is where at all stages of the rental journey.

Further to its new check-out feature, MCS Third–Party Transport feature enables hirers to manage third-party transport deliveries and collections via a mobile app. Third-party haulage drivers can now capture delivery signatures and take site photos that will instantly be available in MCS-rm so that hirers can improve cash flow and invoice customers much more efficiently.

Additional enhancements within the MCS Transport Mobile app include the latest what3words integration, making it even easier to navigate to a precise 3x3m location, especially useful for finding specific locations on large construction or event sites.

Nick Thomson, MCS sales director, comments: “MCS Check-Out is a great feature for transport managers to see exactly what has been loaded onto a vehicle for shipping, especially for rental companies where a different team member has picked the equipment to who is loading it for delivery. It can slot into each business’ processes differently, but we have also introduced specific extensions to fit specific practices. For instance, making the CheckOut feature mandatory meaning personnel cannot move onto their next job without completing the process first.”

WWW.RDR.LINK/CAJ027 i

there are also QR codes that can be scanned using the camera on a mobile device to sign up to Machine IQ.

Machine IQ can easily be installed on compatible Bobcat machines already in the field. Customers should contact their local dealer to check compatibility. Bobcat dealers can also explain what Machine IQ can do to help customers’ businesses and how to link their Bobcat machines to their account.

WWW.RDR.LINK/CAJ026

TWO WAY STREET

UTILISING CUTTING-EDGE MOBILE DATA TECHNOLOGY, SMT GB’S CONNECTED SUPPORT ENSURES THAT MACHINES, FLEETS AND THEIR MANAGERS ARE KEPT IN CONSTANT CONTACT.

By employing IoT roaming, machines equipped with Connected Support are kept in constant two-way contact with the cloud via the strongest available network to their current position. Not only does this remove the risk of poor signal causing the loss of real-time data insight, but also improves the reliability of Volvo Co-Pilot apps and ensures the machine’s software is kept constantly up to date, so that the customer is able to get the most out of their machine at all times.

Available with a choice of 12- or 36-month contracts, and with data allowances of 1GB or 5GB, Connected Support can be tailored to the specific requirements of a customer. Connect Support subscriptions include dedicated remote support from SMT specialists to help customers ensure assets and sites are connected and actionable insight is being communicated.

To learn more about Connected Support, please visit the SMT GB website.

WWW.RDR.LINK/CAJ028 i

T ECHNOLOGY CORNER 30 MAY / JUNE I CPN

i

TWO NEW FEATURES TO HELP RENTAL COMPANIES EFFICIENTLY GET EQUIPMENT OUT TO THEIR CUSTOMERS HAVE BEEN RELEASED BY MCS RENTAL SOFTWARE.

THEFT DETERRENT

SUNSTONE’S IO SYSTEM IS A TECH SOLUTION DESIGNED TO SPECIFICALLY TACKLE SITE CRIME, ESTIMATED TO COST THE INDUSTRY £800M A YEAR.

This is a rapidly deployable security and communication hub that is designed to support multiple CCTV cameras of any type, but with options to scale as required. The security version of the IO provides around the clock surveillance with intrusion detection, perimeter security alerts and other AI video analytics options that can be streamed, via a mobile network, to any location or device. It also comes with a PA horn for instant, live or pre-recorded audio deterrents and out-of-hours alarm monitoring with pre-agreed escalation process.

The IO System is said to be highly versatile. It is capable of connecting to multiple IO devices on one site to expand its range of services and can be moved and set up in hard-to-reach areas. Along with connecting to various sensors like environmental monitors, IOT devices, and PIR sensors, it can accommodate different types of cameras from multiple manufacturers, including thermal imaging. The camera setup can be quickly installed and operated in a cost-effective manner, providing live streaming with minimal effort.

The base of the product is in a secure, lockable and vandal-resistant cabinet. It is also fitted with tamper alerts and battery back-up in the event of power failure, while all data stored is encrypted and cyber secure. To provide additional protection, Sunstone offers optional battery backup to guarantee uninterrupted service throughout the night and on weekends.

WWW.RDR.LINK/CAJ029

COLLABORATION WORKS

WORKING HAND-IN-HAND WITH THE MYSMT DEVELOPMENT TEAM, TIMBER EXPERT AW JENKINSON AND SMT GB HAVE DEVELOPED A CUTTING-EDGE INFORMATION AND SERVICE PORTAL FOR THE BUSINESS.

To ensure that all of the information stored on MySMT is made easily accessible, the platform is divided into the three distinct areas of: Company, Fleet and Parts.

Company provides the customer with visibility of all financial transactions with SMT GB, all active CSA and warranty contracts, oil sampling reports, ProCare recommendations and service inspection reports.

Fleet provides customers with access to current fleet details, including location, operating hours, information of fuel consumption, productivity data, CO2 emissions and visibility of repair and maintenance data on all machines within a customer’s fleet.

Parts provides access to the newly launched SMT online parts store, allowing customers to look up and order parts 24/7 on the basis of technical drawings.

Louise Butterworth, AW Jenkinson wood purchasing department administrator commented: “It was really straightforward. The team from SMT showed me how the system works, and all the information I needed was there, ready to go as soon as I’d created my user account.

“Because all of the information is there on one screen, you’re no longer having to search through lots of different websites and pages for the information you need. It’s all now right there in the system.”

Explaining the relationship between AW Jenkinson and SMT GB, customer support representative Jamie Stevenson adds: “We are thrilled to work as closely as we do with AW Jenkinson. We not only have the privilege of providing them with the industry-leading equipment they need to maximise their operational efficiency but are also pleased to have had the opportunity to boost their productivity through the development of MySMT.”

WWW.RDR.LINK/CAJ030

POSITION FOR PROFIT

TOPCON POSITIONING SYSTEMS HAS ANNOUNCED THE AVAILABILITY OF A NEW GLOBAL NAVIGATION SATELLITE SYSTEM (GNSS) OPTION FOR ITS MC-MOBILE COMPACT MACHINE CONTROL SOLUTION.

Rounding out the company’s compact solutions portfolio, this GNSS option allows contractors to easily integrate their compact machines into fleets already powered by GNSS technology. This expansion gives owners of skid steers, compact track loaders (CTL) and mini excavators the broadest offering of machine control options to date.

The MC-X architecture combines multiple communication technologies, such as the Sitelink3D connectivity platform, support for numerous elevation sensors, IMUs and GNSS receivers, to tailor solutions directly to a contractor’s workflow — maximizing return on investment (ROI) at every phase of an operation.

The entire MC-X powered portfolio is designed to make machine control easy to use and affordable for a variety of contractors. It ties together mixed fleets of earthmoving (both full-size and compact), asphalt and concrete paving equipment, and is designed to be as flexible as it is powerful, adapting across applications and machine types, improving performance and speed for operators of all skill levels.

WWW.RDR.LINK/CAJ031 i

CPN

i

i

Construction PLANT NEWS INTRODUCING

A digital service for our readers...

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

So, in articles you may now see things like:

For further information on Volvo Construction Equipment

WWW.RDR.LINK/CAE 017

Simply enter rdr.link/ followed by the unique six digit code into your browser and it will take you to the required resource

Designed to help busy professionals rapidly locate more information – look out for & use RDR.LINK/

i

RDR.LINK/

10-tonne

townie hits the streets

HD Hyundai Construction Equipment Europe expanding its wheeled excavator range with the launch of the HW100A, designed with urban environments especially in mind. The compact, versatile machine delivers a best-in-class operator environment, a powerful driveline, multiple steering modes and a range of chassis layouts to suit all job sites.

With a slim counterweight and a tailswing radius of just 1,600mm, the HW100A can work within a single carriageway. The machine is equipped with three steering modes, increasing manoeuvrability in confined site conditions. Twowheel steering uses the front wheels only to turn and is designed for maximum stability when travelling at speed.

Four-wheel steering brings the rear wheels into play, reducing the turning circle from 5.7m to just 3.7m. The third option is crab steering, which turns front and rear wheels in the same direction. This can be used to manoeuvre the machine diagonally into a tight space, or to drive away from a wall or excavation area safely.

Power is provided by a Hyundai D34 diesel engine with two-car exhaust aftertreatment, that includes a Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR). This Stage V compliant engine has no requirement for Exhaust Gas Recirculation (EGR) contributing to reduced fuel consumption and lower maintenance costs.