THE VULTURE 25 SCRAPS

ANY CAR BAR NONE

AN EYE IN THE SKY, A FOOT ON THE GROUND

The Dig climbs aboard Hidromek’s HMK102B Supra K4 backhoe and rather likes it.

Cast your mind back to Christmas 1971, if you’re old enough that is, and you are watching the Morecambe and Wise Christmas special. Eric is playing Grieg’s piano concerto in front of pianist, composer and conductor Andre Previn, or Mr Preview as the duo called him. When Previn commented on Eric’s playing, saying that he was playing all the wrong notes, Eric famously countered with ‘I’m playing all the right notes –but not necessarily in the right order.’

What’s this got to do with the construction and plant machinery business, you may ask? Well, it would seem, according to a new bit of research from Aggreko, that while there appears to be plenty of machinery to go round, it’s not necessarily in the right place, doing the right job.

Why’s this a concern? Well, one of the report’s key findings is that the difficulty in securing appropriately sized equipment is severely affecting site efficiency. According to the research, over a third of UK construction managers reported experiencing operational inefficiencies due to incorrectly sized equipment within the past year. While this is lower than the European average of 50%, it remains a significant issue that directly impacts both sustainability and costs.

Incorrectly specified equipment not only wastes energy and fuel but also leads to greater carbon emissions and a higher likelihood of equipment failure—both of which undermine sustainability targets. For a sector increasingly under pressure to reduce embodied carbon, this is a critical area of concern.

Within the pages of the report Aggreko’s Tom Adlington urges managers to use ‘the expertise of their solutions provider to choose the correct equipment for the job’ seeing it as ‘a vital step in achieving efficiency. Correctly sized and specified equipment offers savings on energy and is key to sustainability—making it a true win-win situation for the operator.’

Which is all well and good but what if there isn’t sufficient kit to go round? Or rather there isn’t sufficient kit of the right type to go round? You only have to look at recent CEA data (news page 6) on equipment sales to see that less new kit is being purchased, 29% down on last year and across all formats.

It’s an interesting conundrum which begs as many questions as it does answers. Aggreko offers some insights into resolving the issues, citing ‘advanced technologies’ as key to improving both efficiency and sustainability. That may be the case for the long term, but it will be some while before we have a large enough pool of electric/hydrogen/FCEV-powered machines to go round.

However, the good news is that we in the UK remain very conscious of working in a more sustainable manner. According to the report, 82% of UK respondents recognized the increased importance of sustainability, a number that reflects the growing regulatory and environmental pressures facing the sector.

Now we just need the right machines, in the right place!

Happy reading

Editor JOHNNY DOBBYN JOHN LEVICK cpn@hamerville.co.uk

Advertising Manager MATTHEW BOASE mboase@hamerville.co.uk

Group Manager ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer DONNA BOOTH

Production Assistant CLAIRE PICTON

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2024

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

RETAIL SALES OF CONSTRUCTION AND EARTHMOVING EQUIPMENT FELL BACK IN JULY AFTER SHOWING INCREASES IN THE TWO PREVIOUS MONTHS, ACCORDING TO RECENT DATA RELEASED BY THE CEA.

modest recovery so far this year.

In terms of equipment type, telehandlers (for construction) (-18%) remain the best performing product so far this year, ahead of wheeled loaders (-25%). Crawler excavators were one of the

GAP HIRE SOLUTIONS HAS FOUGHT OFF GLOBAL COMPETITION TO WIN A PRESTIGIOUS ROSPA AWARD. IT HAS RETAINED THE GOLD AWARD, FOR THE SEVENTH YEAR, IN THE HEALTH & SAFETY PERFORMANCE CATEGORY AND OBTAINED GOLD FOR FLEET SAFETY.

Malcolm Campbell, performance and Improvement specialist at GAP, commented: “We are thrilled that GAP has once again earned these prestigious RoSPA Gold Awards for 2024. This achievement reflects our unwavering commitment to maintaining the highest standards in Health & Safety and Occupational Road Risk. It’s a testament to the dedication of all our operational teams in ensuring safety is at the heart of everything we do.”

Sponsored by Croner-i, the RoSPA awards scheme is the longest-running of its kind in the UK, and receives entries from organisations across the globe, making it one of the most soughtafter achievement awards for the health and safety industry.

As of this year, the RoSPA award entry process can be used as reflective practise to contribute to continuing professional development (CPD).

of the year have slipped back to a 5.5% shortfall compared with 2023 levels.

For more information WWW.RDR.LINK/CAW001 i

TRIME UK, THE MANUFACTURER AND SUPPLIER OF SUSTAINABLE SITE LIGHTING TOWERS AND ASSOCIATED EQUIPMENT, HAS HAD A SECOND TRAINING COURSE OFFICIALLY ACCREDITED FOR CPD PURPOSES. THIS FOLLOWS ON FROM THE INITIAL CPD-ACCREDITED COURSE FOR ITS X-ECO LED PRODUCT.

The new accreditation covers its sustainable lighting tower, the XECO hybrid lithium and the course comprises a hands-on look at the operation and maintenance of the lighting tower, with particular emphasis on the carbon-reducing and low noise levels that the X-ECO hybrid lithium provides.

The course concludes with an informative and interactive Q&A session, finalising with a final short test paper relating to information given during the training course. Each candidate receives an official certificate, confirming their successful participation.

For more information

WWW.RDR.LINK/CAW002 i

WWW.RDR.LINK/CAW003 i

AFTER YEARS OF CAMPAIGNING JCB HAS FINALLY HELPED SECURE A CHANGE IN REGULATIONS WHICH WILL ALLOW TRAILERS TO BE TOWED ON THE ROAD BY WHEELED CONSTRUCTION MACHINERYPOTENTIALLY SAVING CUSTOMERS THOUSANDS OF POUNDS A YEAR.

The decision affects towing rules in England, Scotland and Wales and has seen the Vehicle Certification Agency (VCA) create a new Vehicle Special Order (VSO). Under the new regulation, it will be possible for customers to use wheeled engineering plant, such as backhoe loaders and wheeled excavators, to tow a trailer on the highway, for the purposes of construction, maintenance, and repair of roads.

Richard Brooks, JCB’s group productiInnovation director said: “Recognition by the VCA of the benefits of safely towing a trailer behind these types of wheeled machines will be welcomed by contractors and equipment owners.”

Operators wanting to take advantage of this change in the law, can apply in writing to the VCA, advising that they wish to use a machine, or a number of machines, to tow on the road. Applications should be submitted to vso@vca.gov.uk and must include the name of the person or organisation making the application.

For more information WWW.RDR.LINK/CAW004 i

HIRE ASSOCIATION EUROPE & EVENT HIRE ASSOCIATION (HAE EHA) HAS ANNOUNCED THAT IT IS DEVELOPING A NEW THEFT AND FRAUD REPORTING PORTAL THAT COULD SUPPORT THE RECOVERY OF ALMOST £3M WORTH OF EQUIPMENT WITHIN THE YEAR.

Working in conjunction with the National Construction & Agricultural Theft Team (NCATT) and The Official Construction and Agricultural Equipment Security & Registration Scheme (CESAR) the new portal will be aimed at HAE EHA members. They will be able to effectively share information on incidents with each other and specialist policing teams, enabling HAE EHA members to better safeguard their businesses against the rising threat of crime.

The collaborative initiative, which HAE is supporting with a significant investment over a three-year commitment, is made up of businesses, police and industry bodies, to tackle the growing crime rates against industry. A report, published by NCATT and CESAR, revealed that the total value of tools and equipment recovered from the sector in just the first quarter of this year was almost £700k.

Mark Bradshaw, public affairs manager at HAE EHA, said: “The rising crime rates against businesses in the hire sector is very worrying but the progress that the CESAR and NCATT teams have made is truly commendable and we are very proud at HAE to be part of this drive to combat crime affecting hire companies.”

INVERNESS-BASED MACGREGOR INDUSTRIAL SUPPLIES IS BOBCAT’S NEW AUTHORISED DEALER FOR THE HIGHLANDS AND ISLANDS, ABERDEENSHIRE AND PERTHSHIRE.

“We are excited to become an authorised Bobcat dealer,” said John MacGregor, managing director at MacGregor. “Under the management of my colleagues, Douglas Fraser and Keith Bremner, I’m sure the Bobcat brand will be even more successful in Scotland. Our team’s extensive experience with Bobcat equipment, combined with our dedication to exceptional customer service, positions us to deliver even greater value to our customers.”

The new appointment follows the recent acquisition of Balgownie, the previous Bobcat dealer by MacGregor, adding staff with vast knowledge and expertise. The acquisition has ensured that MacGregor continues to offer top-tier parts and service support for existing Bobcat owners, maintaining the high standards which customers expect.

The company has also added a range of Bobcat machinery to its hire fleet, supporting industries including construction, renewables, oil and gas and agriculture. This expansion allows the company to better meet the evolving needs of its customers across various sectors.

As well as sales of the entire Bobcat range of machines and attachments, MacGregor offers a full selection of genuine Bobcat accessories and parts to support customers in its area. This is backed up by a substantial stock of brand new, certified used and second-hand Bobcat machines for sale.

For more information

WWW.RDR.LINK/CAW005 i

For more informationabout Bobcat and Bobcat products, WWW.RDR.LINK/CAW006

errors, which can lead to equipment delivery failures. Furthermore, operational teams can find addresses quickly and efficiently, streamlining the contract management process as a result.

“This feature can also be used by operational teams that need precise site addresses for contracts so drivers get to the correct locations. It reduces costs associated with incorrect deliveries while improving address accuracy,” added Thomson.

All MCS Rental Software users can now take advantage of MCS’s new smart address search feature.

purchases, hire purchase, contract hire, and part-exchange deals on machinery that enable users to work safely at height.

Rory Duggan, director, PlatformSupermarket.com, comments: “We’re aiming to provide the easiest and most convenient way to own a platform. We’ll ensure the machines are perfectly matched to customer requirements, and that they are looked after for years to come. Our unique positioning with Horizon Platforms allows us to do this like no one else can.

“Owning a machine can be the most cost-effective option for construction companies, as it means the machine is always available when they need it the most. The feedback we’ve had so far has been outstanding.”

WWW.RDR.LINK/CAW007 i

For more information

JCB DEALER, WATLING JCB, HAS EXPANDED ITS TERRITORY INTO THE WEST MIDLANDS WITH THE ACQUISITION OF MIDLANDS JCB.

Effective from September 2nd 2024, Watling JCB is now the dealer for Staffordshire, Herefordshire, Warwickshire, and Worcestershire, acquiring and operating from the existing Midlands JCB depots at Smethwick, Hereford, and Stoke-on-Trent. All existing Watling JCB depots will remain unaffected by the expansion.

Watling JCB managing director, Richard Telfer said: “It has been my life’s mission to create a business providing world-class customer support while maintaining our core family values. This new development creates an opportunity to bring these industryleading service levels to a whole new customer base and I really look forward to working closely with our new customers.”

WWW.RDR.LINK/CAW008 i

For more information

The family business has been JCB’s dealer in the East Midlands and East Anglia since 1976. It has a wealth of knowledge and experience in the sales and support of JCB construction equipment and generators, winning the JCB Global Best Customer Service Award in 2023.

WWW.RDR.LINK/CAW009 i

Aggreko survey highlights UK construction managers’ concerns over sustainability and operational inefficiencies. CPN looks at the findings.

The construction industry is facing a ‘perfect storm’ of challenges, as detailed in a recent report by global energy solutions provider Aggreko.

The report, titled “A Perfect Storm for European Construction?”, surveyed more than 850 construction managers across the UK and Europe to understand the obstacles they face in an increasingly strained market.

The news for the UK is mixed – very aware of the importance of sustainability yet seemingly unable to do anything about becoming more sustainable in practice. Meanwhile, construction managers struggle to find the right kit for the job.

Aggreko, the Glasgow-based global provider of energy services, conducted the comprehensive survey of 853 construction managers across eight major European regions: the UK, Ireland, France, Germany, Italy, Spain, Benelux, and the Nordics.

Its report sheds light on the mounting pressures faced by the construction sector due

to soaring material costs, labour shortages, and higher interest rates. For UK construction managers, these challenges are compounded by an even greater focus on sustainability, with 82% of respondents stating that sustainability is more important now than it was three years ago— one of the highest scores among all regions surveyed. This push for sustainability, driven by EU targets for carbon neutrality by 2030, is placing additional demands on an already strained industry.

The challenges facing the UK construction industry are, in many cases, reflective of broader European issues. The industry is grappling with sluggish productivity and slow growth, trends that have been exacerbated by global economic factors outside the sector’s control. Despite these overarching “macro” challenges, the construction sector faces a unique set of obstacles. The complex and dynamic nature of

“...82% of respondents stating that sustainability is more important than it was three years ago...”

construction projects creates additional strain on contractors and equipment providers, particularly when markets are stretched thin.

One of the report’s key findings is that the difficulty in securing appropriately sized equipment is severely affecting site efficiency. According to Aggreko’s research, 37% of UK construction managers reported experiencing operational inefficiencies due to incorrectly sized equipment within the past year. While this is lower than the European average of 50%, it remains a significant issue that directly impacts both sustainability and costs.

Incorrectly specified equipment not only wastes energy and fuel but also leads to greater carbon emissions and a higher likelihood of equipment failure—both of which undermine sustainability targets. For a sector increasingly under pressure to reduce embodied carbon, this is a critical area of concern.

“...correctly sized and specified equipment offers savings on energy and is key to sustainability...”

In the UK, sustainability is at the forefront of the construction industry’s agenda. As noted in the report, 82% of UK respondents recognized the increased importance of sustainability, a number that reflects the growing regulatory and environmental pressures facing the sector. However, the report also reveals that almost 16% of UK construction managers admitted they do not currently measure the environmental impact of their projects, highlighting a significant gap between intent and practice.

For UK construction managers, accurately sizing equipment can have a significant positive impact on both efficiency and sustainability. Tom Adlington, sector sales manager for building services and construction at Aggreko, emphasizes the importance of getting this right: “The strain on construction managers is already exceedingly high, so adding the stress of having inefficient and incorrectly sized equipment is something they could do without.”

Adlington continues: “Using the expertise of their solutions provider to choose the correct

equipment for the job is a vital step in achieving efficiency. Correctly sized and specified equipment offers savings on energy and is key to sustainability—making it a true win-win situation for the operator.”

Aggreko’s findings underscore that optimizing performance through correct equipment sizing can significantly reduce wasted power and fuel consumption, contributing to overall sustainability efforts. By ensuring that machinery is tailored to the specific demands of each site, construction managers can improve operational efficiency and meet sustainability targets embedded in many modern contracts.

Alongside equipment sizing, the adoption of advanced technologies is key to improving both efficiency and sustainability. Hybrid technologies, such as the combination of traditional generators with battery energy storage systems, offer a practical solution to many of the challenges identified in the report. These systems deliver enhanced efficiency, reduced emissions, and lower noise levels, making them particularly attractive to construction managers focused on minimizing their environmental impact.

Adlington highlights the benefits of hybrid systems: “New technologies are giving stakeholders a real selection of viable solutions for their energy needs. Combining these solutions in one efficient package can provide savings and give construction managers the peace of mind that comes with knowing everything is taken care of.”

Incorporating hybrid power technologies

allows construction managers to optimize energy use, especially in markets where borrowing costs and material shortages limit flexibility. These systems provide a scalable and efficient alternative to traditional power generation, helping contractors to navigate both operational and environmental demands.

While the findings of Aggreko’s survey highlight the challenges facing the construction sector, UK construction managers may find some solace in the fact that they are faring better than many of their European counterparts. In Europe as a whole, 50% of construction managers reported that incorrectly sized equipment had impacted site efficiency, compared to the 37% of UK managers who experienced similar issues.

Nevertheless, the stakes remain high. With the EU introducing stricter environmental legislation such as the Energy Performance of Buildings Directive and the Construction Products Regulation, which will soon require contractors to measure emissions across the entire construction process, the importance of optimizing both efficiency and sustainability cannot be overstated.

As the UK construction industry continues to navigate economic pressures and growing sustainability demands, there are clear opportunities for improvement the report argues. In particular, it urges construction managers to focus on optimizing equipment sizing and embracing hybrid technologies as a means of improving both operational efficiency and sustainability.

Aggreko’s conclusions are optimistic. Without downplaying the challenges, it argues

that there are solutions within reach such as leveraging advanced technologies and ensuring the correct specification of equipment. It says that UK construction managers using these options can not only meet their environmental obligations but also stay competitive in a rapidly evolving marketplace.

The new K4 series backhoes were among a whole raft of new generation machines exhibited by Hidromek during the last Bauma two years ago. To see what all the fuss was about, we managed to get hands on with a demonstration model, the 9240kg HMK102B Supra K4 to be precise.

When the machine rolled out of the shed into some much welcome sunshine, my first impression was of a stylish thing of beauty. I have to say Hidromek’s talented in-house design team have done a fantastic job with this backhoe, aesthetically the sloping bonnet and front grill design look especially good, while the red grab handles and all black wheels just appear to give the machine a dominating style.

We took a look around the machine before taking it for a spin. Popping the large bonnet, it raises up effortlessly assisted by two hydraulic

After his summer recess he’s back. Some say he likes nothing more than grading and shaping, others that backfilling and compaction are where he’s at. All we know is that we call him The Dig. This month he goes all backhoe.

gas struts, allowing access to the Stage V emissions compliant, 4-cylinder Perkins 904JE36TA water cooled, turbocharged diesel engine, which offers an impressive power output rating of 74.4kW (100hp) at 2200rpm.

Easy to remove side panels allow greater access for regular servicing work. It’s tightly compacted inside but oil, fuel and air filters are all well located and accessible when needed.

The front grill is also easily removed for access to the cooling packs, which in turn can be tilted outwards for ease of cleaning any debris build-up. A hefty looking bumper/counterweight is located below the grill for added protection of the cooling system components.

Having checked the engine out I appreciated the cloth strap attached to the bonnet which allows you to pull down on it for

easy closure, a nice little touch.

At the front business end, the machine is fitted with a 4-in-1 multi-purpose bucket which has a load capacity of 1.1m3, bucket mounted flip over forks come as standard, a handy feature of course, but so often a thorn in the side for any backhoe loader operator on a busy site!

Nice sturdy steps are provided on the 70litre hydraulic oil tank for access up into the cab, with the lower ones painted red being able to fold upwards to prevent any damage from impact with materials. On the nearside just above the step a handy tool box panel opens up to reveal the optional electric refuelling pump and pipework, for filling up the 140-litre fuel tank. The fuel tank itself is situated on the offside as is the 15-litre AdBlue tank with its familiar blue cap. I assume the refuelling pump

features an auto cut off when the maximum fill point is reached if you are stood on the pump side of the machine when fuelling up.

While other tyre options are available on request, this machine was sitting on 16/70-20 12 fronts and 16.9-28 14 rear tyres. We felt it could benefit from slightly larger tyres on the rear end. Well-proven axles are supplied by blue chip German manufacturer ZF.

At the rear business end the machine features rubber pads on the jack legs to prevent damage to paved surfaces. This top spec SUPRA model also featured the ‘Powerslide’ side shift function enabling movement of the boom infinitely from left to right and back by the flick of a switch in the cab, such a useful feature on sites where it’s not always possible to push the boom across using the bucket and boom in the traditional way. Another nice feature is the auto boom lock device once

again via a switch in the cab for when roading the machine long distances.

Rexroth safety check valves are fitted as standard on the boom and dipper arm to adhere to health and safety regulations, and for the operator’s peace of mind during lifting operations.

The kingpost, boom and extendable dipper arm looked solid and well built, and the black paintwork really sets it off, also preventing sun glare for the operator during the hot summer months.

The machine features the well proven Bosch Rexroth closed type hydraulic system with a variable displacement piston type pump, renewable flowsharing and valves with regeneration. Hidromek suggests that the K4 series backhoe loaders are 20% faster and up to 3% more efficient, producing more work with less fuel than previous models thanks to improvements in cylinder design.

Climbing into the ROPS and FOPS-approved

provided, covering such things as working lights, windscreen wiper/wash, electronic hand brake, boom lock, and even joystick pattern selection to name a few.

Fans of the morning brew will be delighted to find not one, but two cup holders mounted to the front and rear. The cab also features two full colour information screens, with the smaller front screen mounted on the righthand cab pillar, while the larger rear screen is featured on the console to the operators left when facing the backhoe.

The machine is fitted with Hidromek’s Operator Interface (Opera) and via the rear screen the operator can access a whole host of features, such as oil flows for specific attachments, data on operating hours and machine status, maintenance schedules, language selection and Bluetooth radio control.

The joysticks are integrated into the seat, to enable a comfortable and stress-free operator experience whether working with the front loader or the backhoe. When using the front loader for longer periods the lefthand joystick console can be released and tilted outwards to allow more room in the seat. That left-hand console also features a shifter button allowing the operator to control

the backhoe or loader without changing the direction of the seat.

A very useful feature in the cab is the autotilt feature of the steering wheel. This design, which has been patented by Hidromek, allows the steering wheel to automatically raise forward on release of the seat mechanism allowing the operator to rotate the seat to the rear unhindered by the wheel itself, a nice touch I thought.

In terms of creature comforts this is a nice place to spend your days, fully air-conditioned with plenty of vents in place around the cab, there are numerous cubby holes for those essential personal effects, and even a nice silicone pouch on the right-hand central pillar for storing the mobile phone.

By this time, I was keen to spend a bit of time at the controls, which I did, just in time for the heavens to open on a typically mixed bag day of UK weather.

The visibility all-round from the seat, it has to be said, is excellent, and the sloping design of the bonnet allowed me to see the top of the front bucket easily.

Opting to undertake a bit of front bucket work first, I selected 2nd gear on the Turner 6speed lock up transmission, plenty lively enough for the task in hand. Two- or four-wheel drive can be selected by means of a rocker switch, on the dash, and for on-site conditions, I naturally decided to opt for the latter.

Powering into a heap of old tarmac

planings, I was impressed with the sheer grunt of this machine and its maximum bucket breakout force of 6762kgf, combined with the loader arm breakout force of 7429kgf.

Heaped full buckets were achieved with ease, and the machine which has a rear frame width of 2292mm, felt well balanced even with the bucketful raised to the maximum tipping height during the discharge, I found it to be a nice piece of kit to drive from a front loader perspective, but now it was time to try out the backhoe.

Spinning around in the seat, I was instantly impressed with the aforementioned autotilt

steering wheel feature, a great idea and one less thing to have to worry about when running a backhoe loader, which can only be a good thing. Once turned around, I reached across to my left to deploy the automatic stabilizer function, I have no idea how it works, but they just set themselves up on the level.

With the flick of a switch the backhoe becomes live. Digging and piling the planings up on the heap, I was pleasantly surprised with the smoothness in operation, both in grading and digging applications. All functions worked in harmony with no lag when using 3 or 4 functions at once, most notably when grading in towards the machine whilst bringing in the extending dipper, raising the boom and slewing, it was all so super smooth!

The benefit of the machine being fitted with the powerslide backhoe was very evident, as I was able to slide it across to gain better visibility of the job in hand without the need to be peering around the boom to see, all achieved with the flick of a switch which was great. The machine has a maximum dig depth of 4409mm with standard arm, 5627mm with telescopic dipper extended, reach at ground level is 6845mm standard arm, and 8183mm fully extended.

From my perspective, overall, I was very impressed with this well-built and stylish Turkish contender, the earlier models were good, but with the K4 range they have just got a whole lot better.

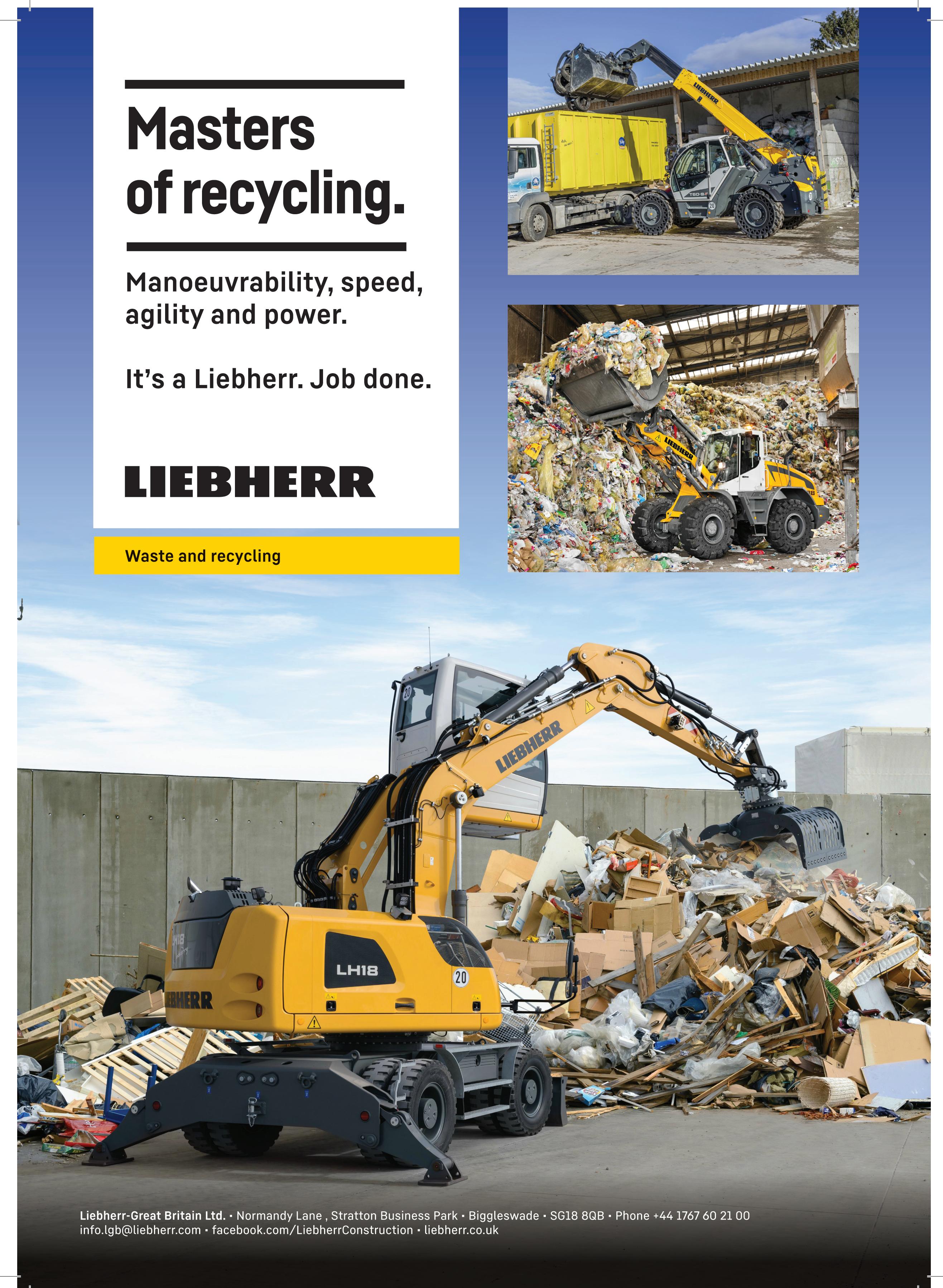

Dumfries-based Vulture Recycling Equipment has chosen Develon’s DX235LCR-7 24.3 tonne reduced radius crawler excavator as one of its machine platforms for use with the company’s new Vulture 25 vehicle recycling kit. The new kit is said to be an exciting development in the field of recycling materials from scrapped vehicles, aimed at maximising the returns from each unit.

Vulture is an expert in this field with many years of experience in the vehicle recycling and metals segregation market. According to the company the Vulture 25 kit is a step change in vehicle recycling, having been conceived and designed to process many thousands of vehicles every year but in a more efficient and cost-effective way.

Comprising specially designed grab and hold down leg components, the Vulture 25 kit is supplied as standard on a modified DX235LCR7 with track pads and a safety screen. The reduced radius configuration of the DX235LCR7 with a rear swing radius of just 1724 mm helps to overcome the lack of space working in crowded scrap and reclamation yards.

Vehicle recycling expert Vulture teams up with Develon’s crawler excavator to unleash its fearsome Vulture 25 kit. CPN reports.

The process carried out by the DX235LCR-7 equipped with the Vulture 25 kit allows the operator to quickly separate more metals from the vehicles to maximise profits in a faster and more efficient way. This allows users to strip components such as engines, transmissions, suspensions, axles, aluminium radiators and copper looms to maximise profitability. The amount of copper recovered can be a surprise to even a seasoned operator.

Richard Stewart, managing director of Vulture Recycling, said: “We have had good experience with the Develon DX235LCR-7 and several other Doosan excavators before that. The booms on these excavators have always proved very strong for carrying and manipulating the grabs and other components added as part of the Vulture recycling kit.

“The high operator comfort of the cab on the DX235LCR-7 complements the machine’s exceptional operational stability, providing

excellent balance when manipulating vehicles and stripping components from them. The new grab and hold down leg designs, together with the wire recovery option are all different on the Vulture 25 kit, improving productivity with fast removal of engines, 1 and 2, alloy, wire and more.”

Stewart continued: “Operators of the Vulture 25 kit on the Develon excavator much prefer the grab’s two ram design which is much easier to place like pliers on any component they want to remove rather than one fixed leg which is harder to place accurately. This grab is tough, very tough with many components from the brutal crushing industry plus it has been the subject of very significant testing and comes with CE marking, a handbook and a spares list. The rotator is very strong and quick in operation – essential for fast hour after hour throughput in the recycling yard. The wire recovery system offers a new tidy and time saving option, allowing users to recover

even more.”

The DX235LCR-7 is powered by the latest generation DL06V six-cylinder Stage V diesel engine, providing a power output of 141kW (189hp) at 1900rpm. The DL06V engine exceeds Stage V regulations without exhaust gas recirculation (EGR), combining this with superefficient DOC/DPF+SCR after-treatment technology to ensure minimal emissions. Thanks to the new technology, maintenance of the diesel particulate filter (DPF) has been greatly reduced, with no maintenance required until the machine has operated for 8000 hours.

Operators get a state-of-the-art cab on the DX235LCR-7 that offers a spacious and ergonomic environment, taking comfort and ease of use to new levels. As well as a high quality seat, the enhanced cab promises more features as standard than other machines on the market, ensuring super controllability and high precision in all applications.

The Develon DX235LCR-7 excavators for use with the Vulture 25 kit were supplied by Castle Douglas-based James Gordon Ltd (Gordons), the authorised dealer for the Develon range for Scotland and Cumbria.

Gordons was established in 1865 and is a premier distributor of agricultural and construction equipment in Scotland. With six strategically placed depots, the company is committed to providing a fast and efficient local service for machinery, attachments and – most importantly – the best possible aftersales support. Gordons is now solely responsible for sales and servicing of the Develon crawler, wheeled and mini/midi excavator, wheel loader, articulated dump truck and attachment ranges in Scotland and Cumbria.

012

Feltham Demolition harnesses the power of the JCB 131X tracked excavator for its toughest assignments.

When Feltham Demolition specified its latest machine, it equipped it with bucket and dipper ram guards, side impact protection, cab cage and belly plates for the rigours of the job.

Supplied by dealer Greenshields JCB, the 131X has so far demolished two large portable classrooms and a theatre at East London University, five houses in Oxshott, Surrey and is now dismantling a warehouse in Staines, Surrey.

“We’re very happy with the machine, it is running really well and the fuel economy in particular is brilliant,” says managing director Stephen Carr. “We are a small company with just a few machines and like to keep everything in house if we can, so reliability and efficiency are really important to us.”

Carr is happy to see his faith in British

manufacturers rewarded, commenting: “We like to buy British where possible and believe JCB to be a great British brand. The JCB 131X is undoubtedly one of the best machines on the market.”

The company has previously hired JCB machinery and bought its first new machine, an

eight-tonne JCB 86C-2 excavator last year. This performed so well that the company soon ordered the JCB 131X.

Demolition is a firm fan of Hyundai machines, having acquired two HD Hyundai HX330AL crawler excavators at the back end of last year, citing the brand’s reliability, durability and high level of back-up from local dealer HES Enterprises.

The company’s fleet includes an HX520, two HX380As, the two new HX330As, an HX300A and an HX140A. The machines are operated with a wide range of attachments, from buckets and hydraulic breakers, to shears, selector grabs, pulverisers and a magnet.

“We used to have other brands, but Andy Shaw at HES had been working to get a machine into our fleet. We started with an HX380AL during the pandemic. Now, as the machines have come due for replacement within the fleet, we have changed them to Hyundais,” said director Chris Forshaw.

“They are reliable and pretty good on fuel. But it’s the back-up, if we had an issue with this machine now, HES would be here today. If there is any issue, HES always helps us out.”

The dealer also prepares the HD Hyundai machines to Forshaw’s own exacting demolition specification, adding protective side skirts and additional safety handrails to the upper structure. A full cab protection frame is included, while rebar cutters are added to the

track frames to protect the undercarriage and the upper structure of the machine. The company opts for OilQuick and Steelwrist quick couplers, that don’t require the operator to leave the cab when changing between attachments, boosting site safety.

project. Handover of the scheme to client Crown Student Living is scheduled for

“...we're delighted to announce that we will continue to use this gamechanging technology...”

cameras eliminate blind spots and restricted views created by the building and the close proximity of the lifts to the crane’s mast. They also provide up to 40% zoom resolution, allowing the crane operator to see areas that would typically be out of their line of sight. While safety and efficiency are the most obvious benefits, the physical working conditions for the crane operator are much improved; the cabin comprises kitchenette and welfare facilities. It is predicted that such digital machinery will inspire the next generation to consider tower crane operation as a cutting edge, technological profession.

Mark Jones, Winvic’s managing director of Multi-room, said: “Winvic is known for embracing innovative technologies, materials and methods of construction and we’re pleased to be the first contractor in the UK to utilise ground control tower crane technology. It is transformational for the safety and wellbeing of crane operators and an important step for the industry.

“During our 12-week trial period, in collaboration with Skyline Cockpit and Radius Group, we analysed the data and assessed the benefits and we’re delighted to announce that we will continue to use this game-changing technology at the 33-storey Crown Place Birmingham for the remainder of the project’s

Alan Pulver of Crown Student Living said: “Winvic is doing an amazing job for us at our latest PBSA to be known as Crown Place, Birmingham. Winvic is forward thinking, and it is no surprise that it is using Skyline Cockpit which certainly sounds like a winner. The ground control system for operating tower cranes will be a great advance to the construction industry, and we are proud to be associated both with Winvic and Skyline Cockpit in this groundbreaking venture.”

Northamptonshire-based earthworks contractor James King (Plant) has added two HD Hyundai HX220A L and two HX140A L crawler excavators to its growing fleet of equipment. The company operates 53 major pieces of plant, including 10 HD Hyundai excavators.

All of the HD Hyundai machines have been delivered to local dealer Willowbrook Plant’s in-house specification, with standard hydraulic breaker lines, HD Hyundai’s all around vision monitor (AAVM) 360° camera system and a full ‘boxing ring’ of safety handrails on the superstructure.

“We have also added GPS preparation for our Trimble machine control system on the 22-tonne machines,” said director Patrick King.

One of the UK’s leading multi-disciplined contractors was at the front of the queue when it came to purchasing seven new JCB 370X excavators. The machines were among the first of JCB’s latest X Series models to roll off the production line.

South Wales-based Walters Group ordered the brand new machines to work predominantly on a series of highway earthworks projects. Supplied by dealer Holt JCB, the first three of these heavyduty earthmovers have jumped straight into action. They join a further three 220X models in the Walters Group’s significant JCB excavator order.

Walters Group chief operating officer, Huw Richards said: “The JCB 370X looks an extremely impressive excavator, and having gone through extensive testing pre-launch, we look forward to their introduction into our fleet. Options to buy excavators made in the UK are somewhat limited and we are keen to support JCB as it introduces an X Series model in the medium sized excavator category.

Plant manager Gary Follen continued: “The Hyundai reliability is superb. We don’t have to put many spanners on them. Generally, we don’t get any problems once they are up and running.”

The company dedicates one operator to each machine, with many of its staff having been with the firm for multiple years. “We’ve got a very loyal workforce and we treat them well. They really like the Hyundai excavators,” added King

The business has had a positive 2024 and is looking for continued growth going forwards, as it looks to meet the changing needs of its customer base.

WWW.RDR.LINK/CAW016 GOTO

“We know we can rely on our dealer Holt JCB with whom we have a long-established relationship. The team understands how critical uptime and performance is to our business.”

Founded in 1982, Walters Group has workshops and offices in Aberdare and Avonmouth. The company delivers nationwide civil engineering predominantly focused on earthworks, demolition, quarrying services as well as plant hire. Walters Group runs one of the largest independently owned plant fleets in the UK, supported by its own extensive pool of operators and maintenance personnel.

B Jeffrey Construction, the York-based civil engineering contractor, has taken its first HD Hyundai HX48Az midi excavator from local dealer Taylor & Braithwaite. It will operate alongside two HX85A compact machines, two 14-tonne HX140A L excavators, an HX210A L and an HX220A L.

“We purchased our first HX140A L in 2022 and the operator loved it. The machine was just so stable,” said director David Jeffrey.

“The Hyundais are quicker than our previous machines and they seem to be much better on fuel as well.”

The contractor had been operating equipment from a competitor for some years but rising purchase costs and unreliable backup pushed it to seek an alternative supplier. With a growing fleet of machinery and job sites across the North of England and beyond,

having reliable parts and service were critical.

The machine has been equipped with a Strickland S-Lock quickhitch by Taylor & Braithwaite and it has been supplied with an optional four-way adjustable dozer blade, making it far more versatile than a stabiliser for heavy lifting.

While B Jeffrey Construction does have its own service team, the company relies on the dealer while the machines are under warranty.

“They are under warranty for two years, so we will use Taylor & Braithwaite’s fitters initially,” said Mr Jeffrey. “We get a really personal service from them if we need any back-up.”

The company tends to keep its machinery for up to five years and it continues to replace older models with new HD Hyundai machines.

WWW.RDR.LINK/CAW018 GOTO

Sunbelt Rentals has invested in an additional eleven Trime X-solar security towers. This latest acquisition strengthens its existing stock of CCTV and security equipment.

Commenting on this latest investment, Ross Gibbons, business unit director – safety and communications –commented: “With these X-solar security CCTV towers, we selected systems at the higher end of the market to ensure they meet our high standards and reflect the quality and longevity of products associated with Sunbelt Rentals. We also took into account that these products have to withstand transportation to the site and harsh weather conditions.”

“Trime was already one of our trusted partners, who we have worked with over many years regularly utilising their high-quality tower lights, so we know the company meets our expectations when it comes to quality and service. As part of our purchase process, all products must undergo stringent examination in the form of a structured product review to ensure they meet our high standards. Trime ticked all the boxes regarding quality, quantity, cost and guaranteed delivery window,” added Ross.

The X-solar security is powered by four solar panels that recharge an internal battery pack which ensures zero emissions and zero noise. The tower features a 6m vertical galvanized manual mast, hydraulically operated for simple rise and fall. The mast is also fitted with a T-Bar head ready to support a choice of security or monitoring equipment. Up to four X-solar security towers can be fitted onto a single truck. It also has forklift pockets and a central lifting eye to simplify transport and storage.

WWW.RDR.LINK/CAW019 GOTO

ECL Civil Engineering has agreed a 90-machine deal with distributor Marubeni-Komatsu comprising a range of crawler excavators, including 40 Komatsu PC55, three Komatsu PW148, 24 Komatsu PC138, 10 Komatsu PC210 excavators and two 19-ton D61 dozers.

“Our primary goal with this latest investment is to extend and replenish our fleet with the best equipment available in the market to ensure the safety and efficiency of our fleet operatives. Additionally, we aim to minimise CO2 emissions and continue to commit to greener construction practices,” said managing director, Steve Tysoe. “We have a longstanding relationship with the Marubeni-Komatsu team, built on their unwavering reliability and the quality of their products, making them the right supplier for our business.”

ECL says it continues to experience increased demand for its groundworks and civil services, particularly in sustainable, low-carbon construction projects.

“We are extremely excited to partner with ECL with this latest purchase in Komatsu cutting-edge technology. We will support ECL in maximising the return on its investment through proactive machine and fleet support while delivering solutions to enhance the productivity of these machines. We see this as the next stage of a positive long-term relationship, and we look forward to hearing the many success stories of the projects these machines will help deliver,” commented Brian Graham, managing director at Marubeni-Komatsu. WWW.RDR.LINK/CAW020

Rother Valley Tree Services Ltd has purchased a new top-of-the-range Bobcat T86 compact track loader and several Bobcat attachments including the new Bobcat FRC200XT high flow forestry mulcher from AMS Bobcat, the local authorised Bobcat dealer. The Doncaster-based business promises high quality work in every aspect of arboriculture, from small private clients to large commercial and local authority contracts.

Customers also include prison services, waterways, railways, utility companies, private estates/woodlands and many private home and land owners. Utility arboriculture alone represents an estimated £150 million of arboricultural work in the UK each year, adjacent to electricity supplies, plus work close to rail, waterways and telecommunications networks.

AMS Bobcat has equipped the T86 with a forestry application kit, which is required when using the machine with a forestry mulcher. As

In a move that is said to have delighted its operators, Tru7 Group has invested in a fleet of 20 new JCB 140X tracked excavators.

The Ipswich-based construction group purchased the JCB X Series models to operate on general construction and housebuilding sites as well as working on high-profile energy contracts across the UK.

Supplied by dealer Watling JCB, they join existing JCB Loadall telescopic handlers and backhoe loaders.

Tru7 Group CEO and owner, Guy Nicholls said: “We kept hearing how good the JCB 140X model was and felt it was time we tried some. So we ordered 20 models to test out within our operations. The machines have proved to be very good, and the drivers love them. The modern styling, excellent driver environment, and tough build quality make them ideal for our work.

“For many years we have been fortunate to have Watling JCB as our dealer. It is without doubt an outstanding company from the top down - and the team really are a pleasure to deal with.”

part of the order, the company also purchased Bobcat 82in root grapple and pallet fork attachments.

Steve Smith, managing director of Rother Valley Tree Services, commented: “I was intending to purchase the T770 model from Bobcat, but AMS Bobcat introduced us to the idea of the new T86 and its Super Flow output and the more powerful attachments it can power, such as the new FRC200XT forestry cutter. Now part of our fleet, the T86 has more than matched what we were promised!”

Carl Chadburn, plant manager, added: “The many jobs we are able to do are specialist, with only a few companies being able to offer these services in the UK. The T86, the new forestry cutter and the other Bobcat attachments we’ve purchased from AMS complement the rest of the vehicles and machinery in our fleet, giving us access to an even larger array of solutions to help complete even the most difficult of jobs.”

WWW.RDR.LINK/CAW021

Transporting soil and turf with the Hinowa HS701 high-tip machine has accelerated operations to the point that turf laying projects for customers that include golf courses, sports pitch owners, and local authorities can be completed up to 20% faster.

Wimborne Turf, based in the town of the same name in Dorset, once hired in a minidumper about every two months or so to help with material moving for larger projects.

But since buying its own Hinowa machine, the company’s turf laying teams are finding they are using it multiple times a week because it delivers such significant advantages.

Wimborne Turf general manager Dean Flower explained: “Our Hinowa minidumper moves over four times as much soil in one go as our wheelbarrows do, so can do the work of four people.

“It hasn’t replaced muscle-power but it very much speeds things up, especially on the larger turf laying projects we often tackle. I’d say it can reduce project times by up to 20%.

“It’s also excellent for working on hilly ground, where wheelbarrow work can, quite

Teams at one of the UK’s biggest turf suppliers have experienced a step change in productivity since the company invested in a Hinowa tracked minidumper.

naturally, slow down. We’re very impressed.”

The turf-laying teams appreciate how the minidumper copes well with wet ground, and can turn easily in these conditions, even with full loads: it is a result of Hinowa fitting more powerful engines than its competitors.

Soil, turf, waste material and equipment can all be transported, tipped, or loaded into a flat bed truck with the Hinowa HS701’s hi-tip function.

In a recent project, it helped Wimborne

Turf’s team to lay and grade 40 tonnes of soil in just one day.

The minidumper was supplied by Access Platform Sales, the UK and Ireland authorised distributor for all Hinowa products, which also includes tracked spider lifts and tracked forklifts.

APS regional sales manager Jonathan Wiseman said: “We’re delighted the team at Wimborne Turf are so happy with their Hinowa minidumper. It’s having precisely the impact it’s designed to make in terms of operational effectiveness.

“...it hasn't replaced muscle-power but it very much speeds things up...”

“Many clients tell us that their machines pay for themselves through higher productivity and lower manual handling costs.

“Health and safety benefits through reduced manual handling injury risks are also significant, as is the positive impact on a company’s reputation when clients see work being carried out so quickly and efficiently.”

The simplicity of the diesel-engine powered Hinowa HS701 minidumper

Wimborne Turf operates is appreciated by work teams, added Flower.

“The machine is easy to use and is so compact it can be tracked through a standard 2ft 6ins garden gate, which is impressive,” he added. “It’s also proving to be very reliable.”

Wimborne Turf selected the fixed tracks version of the minidumper. It has a maximum working load of 550kg and can tip a load at a height of 1365mm (the distance from the

ground to the bottom of the tipped bucket).

The minidumper can be supplied with tracks that can be widened from 758mm to 1058mm, which provides extra stability over sloping or uneven ground.

The Hinowa HS701 is 758mm wide and 1925mm high, so it can be tracked through standard doorways or along narrow paths.

The minidumper can be supplied with a diesel or petrol engine and in other formats, including a standard dumper bed; an extra hightip dumper bed; a self-loading shovel; and a flat skip bed with foldable sides.

The Hinowa HS701 is just one of a family of minidumpers. It includes: the Hinowa HS1102, a standard dumper with a maximum capacity of 700kg; the Hinowa HS1103, with a maximum capacity of 1000kg and a bucket that slews through 180o for fast tipping either side of the machine; and the Hinowa TX3005, which has a full cab and a maximum capacity of 2875kg.

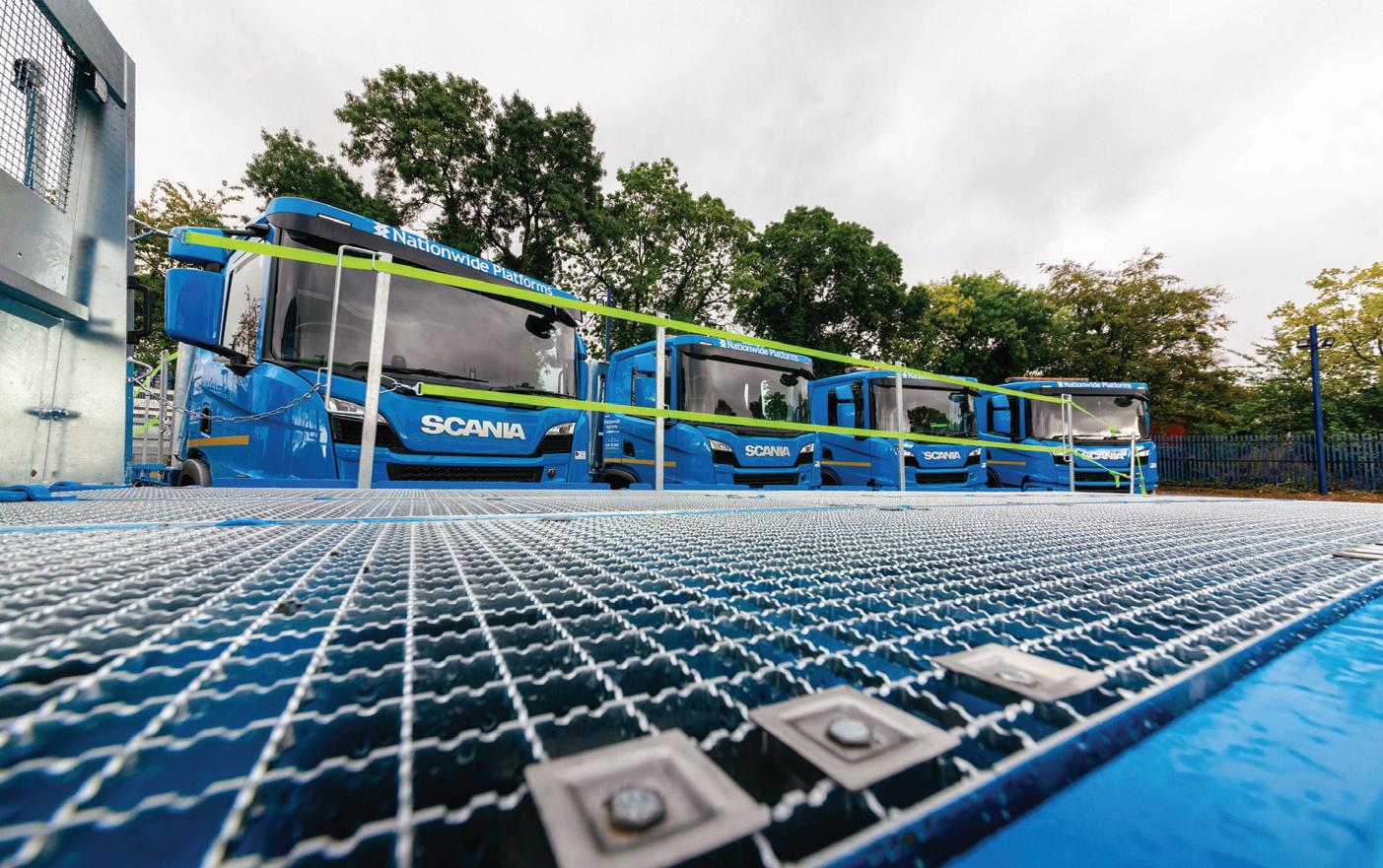

Need to move a bit of kit about but not sure what type of truck deck will be right for the job? Plant body builder Sterling is on hand to advise.

Okay, you already know that you want your mode of transport to be safe and durable enough to handle some tough situations but what materials should you choose?

Having designed and manufactured beavertail truck bodies for various sectors in the industry, we know that each has its own unique decking requirements. So, what factors should be taken into account to make the right decision?

The point-loading of the load is one of the most important considerations when choosing decking. While some trucks will transport a full load of small lighter kit per run, other trucks will transport less items which may be very heavy. Some machines, whilst they may be small have extremely high point loading, e.g., a road planer or 3-wheel forklift. Other machines such as large 14 tonne excavators haven’t necessarily got the highest point loading but tend to have the greatest mass.

Then there’s also the matter of the type of traffic to be accommodated. A truck body, its decking, and loading ramps will have to tolerate anything from steel tracks to rubber wheels and tracks to metal drum rollers.

Rubber tracks and tyres would cause less stress on surfaces as the rubber is a softer material whereas steel tracks can even cause damage to some deck surfaces. Rollers with their smooth steel drums have little grip so again have their own unique decking requirements.

There are basically four different types of decking for truck bodies, which can be configured in different combinations to meet the individual requirements of each operation. Each type of decking has certain characteristics which makes it suitable for each individual application.

“... a Sterling build exceeds this specification by fitting crossmembers closer together at 300mm...”

Timber decking is the most popular choice for truck decks; and the most popular type of wood used is Keruing, a Malaysian hardwood. It is long lasting and has an excellent strength to weight ratio. This tough wood has the same density as Red Oak, and twice the hardness rating of White Oak. The secret to its strength lies in the interlocking wood grain. This has a good point-loading strength, meaning it is great for most applications, particularly steel tracked vehicles and equipment with a high point loading.

To improve grip, some clients prefer to use a heavy-duty steel grating instead of timber. This is material has its own inherent strength so isn’t required to be combined with other materials. The grip provided by this surface is particularly good for rubber tyres, but is not as suitable for steel tracks, and drum rollers. The grating is zinc galvanised prior to fitment, making it resistant to rust. This is a very popular option for access machinery hire firms as it is particularly handy when carrying scissor lifts, cherry pickers and spider-lifts.

Steel expanded mesh is a great complementary product to the timber deck and is fitted atop of the timber to give fantastic grip. The mesh is galvanised and is usually used for trucks that have a variety of equipment transported on them, from rubber tracked diggers to road planers to scissor lifts. A good half-way house between the two surfaces outlined above.

Steel durbar has extremely high impact strength and is used on decks that carry very heavy weights. As it can be very slippery, particularly when wet, it is typically confined to small areas of the deck that will be subjected to extreme point loading such as the area in the centre of the deck where the knuckle of 14-tonne excavators tend to sit. A deck option other than steel durbar plate in this application is at risk of damage.

Whilst deck type selection is important, it is just as crucial that the supporting frame beneath the deck is appropriately built. For example, the industry standard spacing between supporting crossmembers is 400mm, but a Sterling build exceeds this specification by fitting the crossmembers closer together at 300mm giving far greater point loading leading to vastly reduced deck wear.

In addition, commonly used box section crossmembers are prone to rust meaning that over time, the deck support becomes compromised. The Sterling product is built using I-beam or C-section crossmembers as all the ‘black’ steel on these can be fully paint protected meaning your deck will have sufficient underlying strength for a far greater period (often years) than alternative builds.

Sterling manufactures beavertail truck bodies and is based in North Yorkshire. It builds plant bodies for 14-32 tonne trucks, manufacturing over 230 beavertails in 2023.It has an extensive after sales service team throughout the UK. For more information

WWW.RDR.LINK/CAW024

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

from their customers. For a company like Flannery Plant Hire (FPH), which gets 80% of its business through tender, the issue of health and safety will be up there alongside price as one of the major qualifications.

Its answer has been to invest in sophisticated technology, complemented by a comprehensive training scheme for every level of the business — apprentices, qualified operators, and managers – through skills hubs operated in partnership with Balfour Beatty.

So, not only was FPH one of the first major plant hire companies to buy products from Xwatch Safety Solutions when it started back in 2019 but many of its customers specify the company’s products too. Kier Group, Balfour Beatty and Morgan Sindall, for instance, specify Xwatch XW4s and XW5s. Other customers

Technology and training go hand in hand for one of the UK’s major plant hire firms, when it comes to improving site safety. CPN reports.

specify the Xwatch 3D collision avoidance system, which integrates with the Leica MC1 3D machine control software and so enables users to create or import 3D avoidance zones above and below ground directly into the MC1 tablet without additional screens.

Upwards of 45% of Flannery’s fleet is equipped with Xwatch systems, including almost 300 XW4 height and slew control systems along with XW5 total protection RCIs (rated capacity indicators) – and there are more to come. “We have just purchased 75 Cat machines, all equipped with Xwatch,” says Ben Seabright, Flannery’s buying manager. “The user-friendly interface of Xwatch makes it easy for operators to adapt quickly and work more effectively.”

Flannery’s attitude toward safety in construction revolves around utilising all available tools to keep the operator, site personnel and the public safe. For example, on a road project, this would include height, slew, and full 3D avoidance to prevent machines from entering the carriageway, vastly improving site safety. Another example would be MoD facilities, which can be particularly complex, with diverse surroundings demanding various ‘tools’ for operators to focus on their tasks safely and effectively.

One challenge in modern construction machinery is in-cab clutter, where too many screens obscure the operator’s view. Lights and constant alarm tones can overwhelm operators, running the risk of becoming just background or white noise. Tasks in busy worksite environments demand intense concentration and strict personal safety rules— in-cab clutter risks distracting the operator, and the constant alarms may go unheard.

“Xwatch systems are designed to manage and control safety parameters actively,” says managing director Patrick Flannery. “This enables our operators to focus on the job at hand without being overwhelmed by excessive in-cab notifications.”

Flannery’s business model gives it a great deal of clout because everything can be planned in the medium term. Right now the company is working on projects that include the A3, M5 and M25 National Highways widening works at Wisley and HS2 which, as is usual practice, it tendered for between six and nine months ahead. This means that it can plan its purchases 12 months ahead.

“...this setup distinguishes us from other plant hire companies and allows us to quality assess and train operatives to a high standard...”

Last year, for example, Flannery invested heavily in new machinery for upcoming key infrastructure projects. While the company has tapered its CAPEX this year, more than £105 million has already been committed for new machinery and equipment.

The result is that it can strike up partnerships with particular OEMs such as Cat, Komatsu, JCB, Volvo, Bomag and Wacker Neuson.

And it is the same when it comes to site safety systems, says Patrick Flannery. ”We choose our partners carefully, looking for those who share our ethos of delivering first-class service efficiently. This is why we collaborate with a select few OEMs and partners who can react quickly and ‘get it done’.”

So now it is partnering with Xwatch to simplify operations and improve productivity and safety by creating a streamlined, integrated system in which a single set of machinery controls incorporates all technological partnerships.

This initiative dovetails with Flannery’s

three skills hubs. These are supported by companies such as SITECH/Trimble, Leica, and Xwatch and train its staff on the latest semiautonomous machinery.

The skills hub has also launched its compliance plus program, focusing on operator competence, machine control familiarisation and eco-operation.

“All technology is contained within a ringfenced site at the skills hub,” says Patrick Flannery. “This setup distinguishes us from other plant hire companies and allows us to quality assess and train operatives to a high standard required for the diverse nature of the work they will be required to undertake.”

Flannery’s far-sighted approach means that it has leveraged its purchasing power so that it has a strong input into the technology being developed and then recruited its suppliers – or partners – to develop the training required.

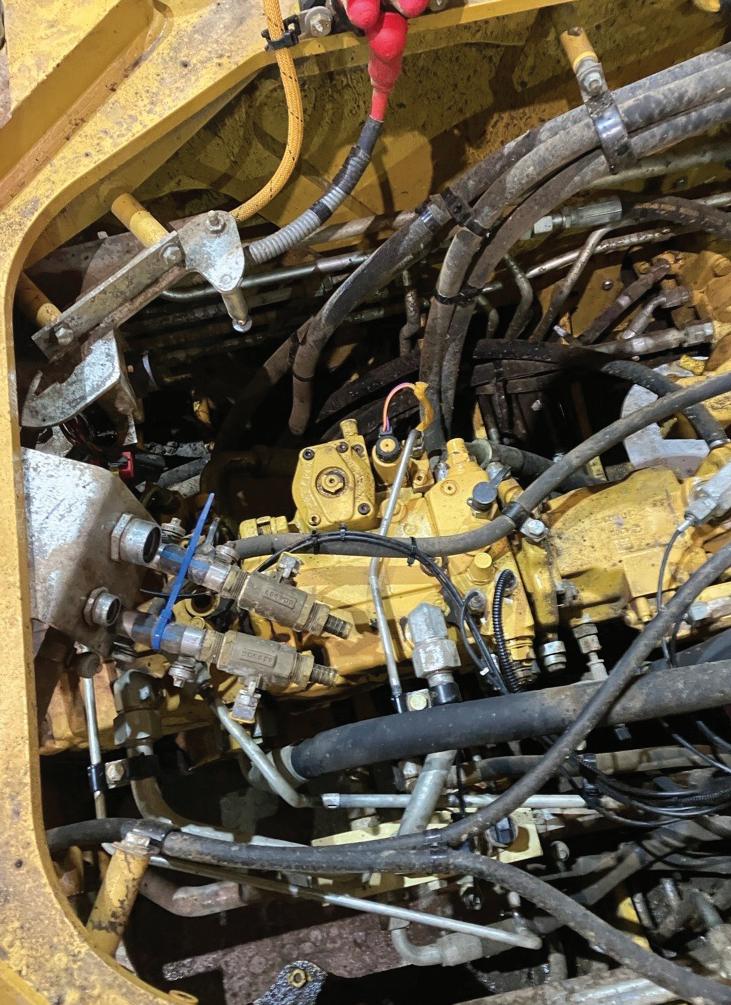

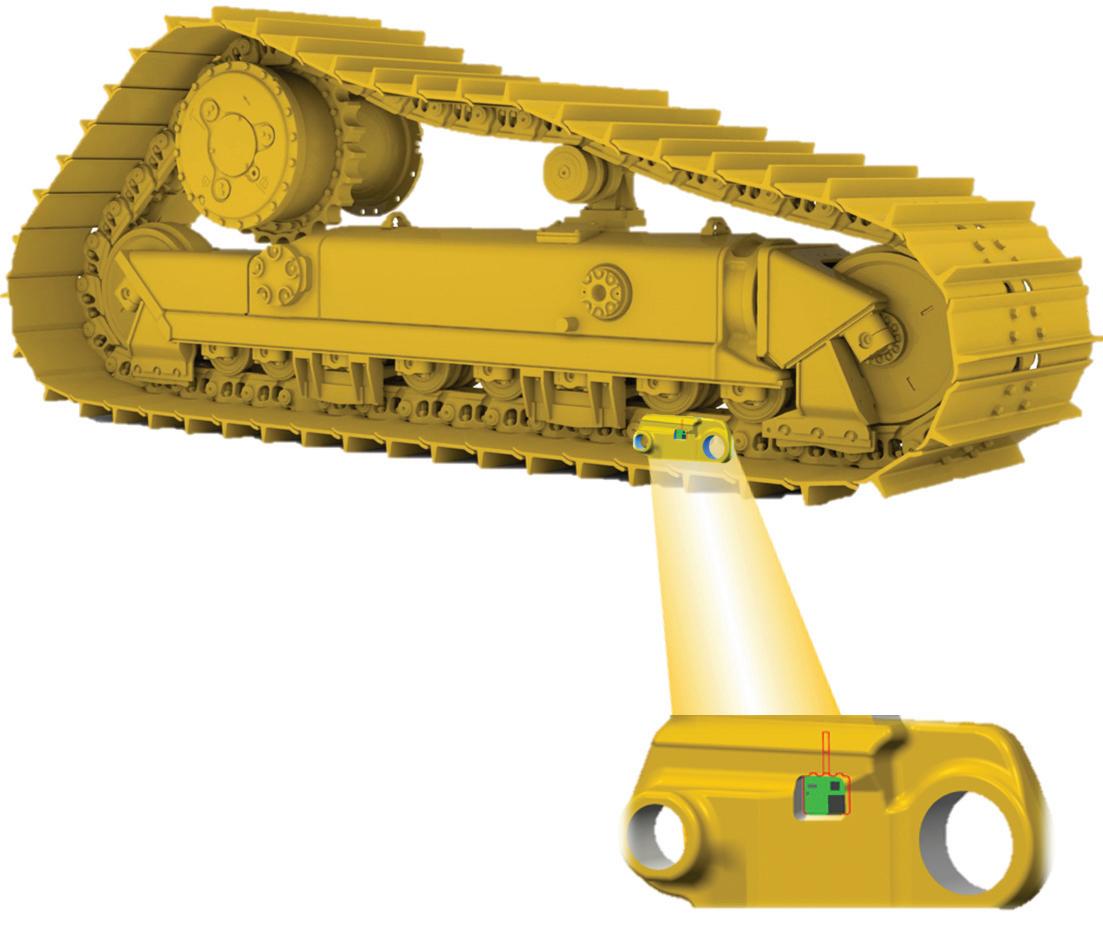

Paul Reddish, workshop customer service controller at Finning UK & Ireland, reveals how its engineers breathed new life into a beloved Cat D6 dozer owned by Smiths Construction.

was booked into the Chesterfield workshop to carry out the work.

We treat every machine rebuild as unique. Which means we put the machine under the microscope and carry out a thorough prerebuild inspection. During this we were able to identify wider issues with some of the machine’s systems and components. For example, we spotted excessive play in the pins for the blade lift and twist mechanisms. The inspection we carry out is very thorough and highlighted smaller problems from missing bolts on the under guards to an inoperative back rest adjustment on the operator seat.

A powertrain rebuild involves reconditioning the final drives and brakes, cleaning and testing the existing radiator pack and replacing the drive pump coupling with a

As part of the certified rebuild specification on this machine, around 3,000 individual parts like hoses, gaskets, belts, seals and wiring were

“...the hydraulics on the machine were beginning to show signs of wear and tear...”

replaced with new ones. The remaining components, forming the main bulk of the engine, were individually inspected to assess their condition which was measured against strict reusability guidelines. Many of the parts needed replacing, in some cases brand new parts were ordered, but most were either reconditioned on site, or sent off to be remanufactured.

Part of the rebuild included addressing the severe wear on the engine’s crankshaft. Years of operation had resulted in significant scoring and out-of-round conditions on the main and rod journal surfaces. A Cat reman engine was used to replace the existing engine having already been completely reconditioned. In turn, the existing engine from the D6 was sent to Caterpillar to be remanufactured.

For the hydraulic rebuild, the motors,

“...rebuilds cost around 50-70% of the price of a new machine...”

pumps and oil cooler were treated in the same way as the engine, with part-by-part reconditioning, replacement or remanufacture. Hoses, couplings and cylinder seals were replaced with new components. The main control valve and hydraulic tank were reconditioned.

The control valve required significant attention. Years of exposure to contaminated hydraulic fluid had resulted in erosion of the spool lands and bores. To address this, new valves, seals and solenoids were fitted.

As well as applying its engineering skills to meticulously follow Caterpillar specifications, the Finning rebuild team was mindful of the need to keep the customer updated on the progress of the project throughout. This involved filming walk-around videos with commentary detailing the work completed, which were sent to Smiths on a weekly basis.

This was a good example of how the Caterpillar rebuild philosophy permeates through the Finning team to the customer. It is important to remember that people really care about their machines, and the decision to rebuild is not just a financial one. The business benefits in this case however, are unequivocal. Rebuilds cost around 50-75% of the price of a new machine and include a 5-year powertrain and hydraulics warranty.

With all the recommended maintenance work carried out, and a visit to the paint shop, this 17-year-old D6 dozer looks and works like new. Giving this machine a second life makes sense, and also feels good, for everyone involved.

Develon has launched the DX235RTF-7 tunnelling excavator, an extension to the company’s line-up of special application machines. The DX235RTF-7 is based on the company’s DX235LCR-7 reduced radius crawler excavator and is powered by a DL06V Stage V engine, providing 141kW (189hp) of power.

It utilises the successful compact design and minimum swing radius of the DX235LCR-7, but the key part of the machine is the heavy duty tunnelling front, offering a new arm and boom design with special kinematics and a tilting function.

The excavator has a total operating weight of 25,689kg and offers a maximum reach of 9260mm. The kinematics of the tunnelling front are designed to prioritize horizontal reach and precision over vertical movement. The special kinematics are based around a boom tilting function, providing a 45°/45° tilt in two directions, the movement of which can be operated via a pedal in the operator’s cab.

movement in narrow areas. This allows the excavator to work efficiently in narrow tunnels with the ability to reach the tunnel face and walls, while maintaining a low profile to navigate tight spaces.

The boom and arm configuration is specifically designed for operation in narrow areas, with ranges of movement slightly limited compared a the standard front. It is specifically suited to work in restricted environments, without using the swing

For work in confined spaces, the DX235RTF-7 features a wide range of protective equipment to safeguard against falling debris or contact of the arm with the tunnel ceiling and walls.

Compared to the standard model, the excavator has six LED work lights, four on the front and two on the back, as well as AVM cameras as standard. Other features include PERO rotating piping, centralized greasing points and a dozer blade as an option. The specifications also include a 6.4 tonne counterweight and 600mm wide triple grouser track shoes.

The latest addition to the 3Series range from Takeuchi is a 2-tonne TB320 mini excavator designed for multiattachment use and that is adaptable for a variety of hydraulic attachments including: mulchers, flails, augers, post knockers and tiltrotators.

It comes with proportional control on auxiliary 1 & 2, 3rd auxiliary pre-piped for quick hitch and an optional 4th aux as a factory fitted option. With increased engine power and excellent breakout force (17.0kN/ 9.1kN), the mini delivers power performance when required. The long arm, heavy counterweight and longer track frame add to stability when digging deep (2370mm).

The TB320 has new 3-series styling both inside and out, including LED lighting, Bluetooth, DAB, and spacious operator station with excellent footwell visibility for trench work.

With a compact design and dimensions, it’s safe to trailer tow and easy to transport to and from site. The expanding track frame from 980-1370mm gets access in the most confined spaces. With matching pin and link dimensions to the TB216, the new TB320 is a compatible addition to the fleet.

FOR MORE INFORMATION

Caterpillar has introduced eight ‘next generation’ skid steer loader (SSL) and compact track loader (CTL) models. The four SSLs – the 250, 260, 270, and 270 XE –mark the introduction of the next generation design to the SSL, while the CTLs join the 255 and 265 announced in late 2023. The largest CTLs ever from the company, the 285 and 285 XE compete in a new class size with greater lift height and lift and tilt breakout forces.

All models feature a redesigned engine compartment that places the engine and cooling package lower into the frame for improved stability, giving the operator confidence in handling heavy loads throughout all aspects of the work cycles.

Meeting U.S. EPA Tier 4 Final/EU Stage V emissions standards, the CTLs are powered by the C3.6TA engine, while the 250 and 260 SSLs are powered by the C2.8T and the 270 and 270 XE by the 3.6TA. These new engines maintain horsepower across a wider RPM range compared to the previous engines powering the D3 series and boast significant torque increases – 13% for the 250 and 260, 35% for the 270, and 50% for the 275 and 285 – for improved working performance.

With a vertical lift design, the next generation machines feature significant increases in lift height, breakout forces and ROC to elevate loader flexibility and performance.

The 250 features a lift height of 3150mm, 76.2mm more than the 242D3, a 36% increase in tilt and 26% increase in lift breakout forces, and 21% increase in rated operating capacity (ROC). Offering a maximum lift height of 3353mm, the 260 has

Powered by Stage V D24 engines and Stamford alternators, the new PG40 and PG50 portable generators from Bobcat replace the previous generation Stage IIIA G40 and G60 units, delivering a combination of increased power output and lower fuel consumption compared to their predecessors.

193mm more lift height than the 262D3 and 27% increase in tilt and 24% increase in lift breakout forces, and a 17% increase in ROC.

With 162mm more lift height than the 272D3, the 270 and 270 XE deliver a maximum lift height of 3391mm plus 11% and 5% increases in tilt and lift breakout forces, respectively.

The 275 and 275 XE CTLs have a lift height of 3415mm, 203.2mm higher than the 299D3, plus a 37% increase in tilt breakout force and 19% increase in ROC.

Expanding the SSL and CTL line into the biggest size class, the 285 and the 285 XE deliver a lift height of 3708mm and tilt breakout force of 6314kg.The 285 has an ROC of 2141kg with counterweight while the 285 XE has an ROC of 2185 kg with counterweight.

The new machines feature a larger cab design with 22% more overall volume and 26% additional foot space. With a 2.75-in (70-mm) increase in interior width, the new cab expands footwell-to-ceiling height by 1.8in (46mm) and allows for an additional 1.5in (40mm) of hip room and 1.1in (28mm) more width between the joysticks to improve operator comfort.

FOR MORE INFORMATION

WWW.RDR.LINK/CAW030 GOTO

The engine in the new generators allows Bobcat to offer a true 50 kVA prime unit the new PG50 model and still be below the diesel exhaust fluid system requirement. Alongside the PG50, the PG40 delivers a prime power output of 40 kVA.

In addition, both generators have a new sleek, compact design, with a selection of novel features including optional factory-mounted running gear, with either fixed or variable height, for easy transportation such as

towing behind a car. This upgrade provides unmatched convenience, ensuring mobility on and off the job site.

The Comap MRS16 controller is again at the heart of the PG40 and PG50, with telematics options that allow units to be easily located and for their status to be read remotely. The successful connection system from the PG100 is incorporated in the new models and are claimed to guarantee optimal efficiency, facilitating hassle-free set-up and smooth performance.

Operation is quiet, with the models offering a low noise level – the LWA 88 sound power level on the PG40 and LWA 89 on the PG50, make them among the quietest units on the market. As well as being quiet, the PG40 and PG50 are also clean running, featuring a bunded base designed for 110% fluid containment, where spills are virtually eliminated, ensuring environmental protection and reducing maintenance needs.

FOR MORE INFORMATION

WWW.RDR.LINK/CAW031 GOTO

showcased three aerial work platforms (AWPs), two scissor lifts and one boom lift in the company’s new green livery. The range of scissor lifts and boom lifts covers working heights from 6m to 30m.

The LA16JE is an articulating boom lift with a maximum working height of 17.8m and a platform load capacity of 260kg. It features pure electric power with a 51.2V battery for zero emissions and low noise, advanced safety with dual-channel sensors, automatic braking, and a 360° rotating turret. Its compact design, with a turning radius of just 2.06m (inside), ensures efficient performance even in tight spaces.

An electric scissor lift with a maximum working height of 7.8m, the LSC0608E has platform load capacity of 230kg. Powered by a 24V battery, it delivers zero emissions and operates quietly. Its compact design boasts a tight turning radius of just 0.3m (inside) and 1.78m (outside), ensuring superior manoeuvrability in confined spaces.

With a maximum working height of 14m and a platform load capacity of 320kg, the LS1216HC crawler scissor lift operates on a 48V battery, delivering zero emissions and quiet performance. With a 30% gradeability, 0.4m ground clearance, and low ground pressure, this machine excels in off-road terrains. The steel crawler, equipped with rubber pads, ensures superior traction and longer durability, while its four automatic outriggers, which can be independently operated, provide enhanced stability, making it ideal for demanding environments.

Conidia Bioscience has launched Fuelstat One, a test kit to join the Fuelstat range designed to rapidly detect microbial contamination in diesel fuel to prevent operational downtime and safety issues.

Fuelstat One can be used throughout the fuel supply chain, from storage terminal to fuel tank, offering a comprehensive overview of the fuel’s quality.

The test – a simple, rapid lateral flow test conducted on either free water or fuel phase samples – detects a broad range of bacterial and fungal microorganisms. It provides a fully quantitative contamination value in just 20-30 minutes.

Microorganisms such as bacteria, fungi, and yeast can proliferate in fuel tanks, leading to biofilms and sludge formation, which can clog fuel filters and obstruct fuel lines, causing engine malfunctions or failures. Additionally, microbial activity can produce corrosive byproducts that degrade fuel tanks and components. Contaminated fuel can also reduce engine efficiency and increase emissions. Regular monitoring, maintenance, and proper fuel storage practices are essential to ensure fuel cleanliness and maintain reliability, safety, and efficiency.

These tests are conducted on-site, so complying with ASTM D6469 guidance for testing for contamination within 24 hours. No laboratory is required, avoiding time delays and associated expenses.

The test kits are supported by a Fuelstat Result app that provides instant test results and a PDF report that can be shared worldwide. Registered users can manage results from all tests conducted by their team globally, in real-time, at the touch of a button.

FOR MORE INFORMATION

WWW.RDR.LINK/CAW033 GOTO