HILLHEAD

12 CPN brings you a second slice of the action from Hillhead. We round up the latest machine introductions, both large and small.

17 LiuGong’s charge into electric machines is in full swing. CPN reports.

21 Returning for a second outing The Dig tries his hand with JCB’s new 370X

cpn@hamerville.co.uk e

Nothing goes to waste as Jet Plant gives planings a second life. CPN reports.

No sooner had Sir Keir deftly pickpocketed the keys to No.10 from the outgoing Rishi Sunak, then he was the object of heartfelt congratulations from two of our industry’s trade bodies, the CEA and CPA.

Both had latched onto Labour’s various election commitments to do with housebuilding, investing in infrastructure and the need for decarbonisation. The first two might help stimulate business, that’s for sure, the latter, well it’s a challenge. As an aside, it will be interesting to see the government’s response to the calls for evidence for NRMM decarbonisation.

That’s if the Department for Energy Security and Net Zero, Department for Transport and last, but by no means least, the Department for Environment, Food & Rural Affairs, can actually get their heads together. Above all, the government needs to move quickly to define the way ahead and determine the extent of its intervention to support NRMM decarbonisation.

Unsurprisingly the CEA is fully aligned with Labour’s direction, with Viki Bell, operations director, saying “decarbonisation remains a critical priority for us. Labour’s substantial investment of £23.7 billion in green measures during the next parliament emphasises the central role of green policies in driving growth and prosperity. We anticipate robust support from the Labour Government in advancing innovative technologies, including electric and hydrogen-powered machinery. Establishing a national alternative fuel infrastructure is essential, and we look forward to contributing to these transformative efforts.”

Interestingly the CPA’s policy manager, Chris Cassley, adopted a more forceful tone, stating that “the new government must work with the construction industry in addressing critical issues such as decarbonisation and reaching net zero, improving productivity and business investment, building the new homes that we desperately need, and renewing our ageing infrastructure.

“All of this requires a long-term vision and consistency from government in how policies are developed and implemented. Providing the stability and economic foundations needed for lasting economic growth comes only from engagement with industry in understanding the challenges companies face - and how they can be overcome.”

While both organisations are clearly lobbying for the interests of their members without being too strident, it’s the CEA which raises the slighty taboo topic of closer ties with Europe, with Viki Bell saying that “we urge the new government to ensure regulatory stability and alignment with European standards, vital for maintaining our international competitiveness. Together, we can adopt a sustainable, innovative, and prosperous future for the UK construction equipment sector.”

These are all fine words and sentiments, and let’s just hope that we see the necessary investment and suitable policies under this government to produce the desired results and satisfactory outcomes. However, the paralysis and intransigence over HS2 is probably not the best omen.

Happy reading

The CPN Team

Editor JOHNNY DOBBYN JOHN LEVICK cpn@hamerville.co.uk

Advertising Manager MATTHEW BOASE mboase@hamerville.co.uk

Group Manager ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer DONNA BOOTH

Production Assistant CLAIRE PICTON

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2024

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

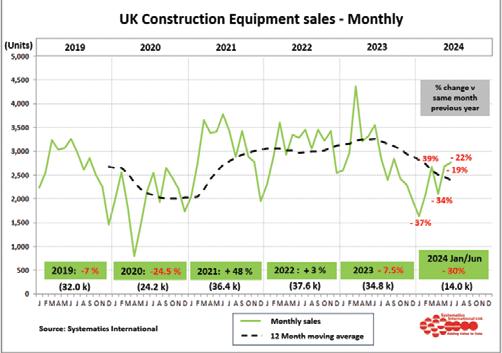

Despite modest improvements in sales, all regions continue to see declining sales compared with last year. Similar to last month, London has been the best-performing region so far this year, with sales at 15% below 2023 levels. The West Midlands has continued to see the weakest sales, which were just under 50% below last year’s levels in the first half of the year, followed by Northern Ireland, where sales were just under 46% below 2023 levels.

WWW.RDR.LINK/CAV001 i

POWERED ACCESS EQUIPMENT MANUFACTURER, SNORKEL, HAS ANNOUNCED ITS MEMBERSHIP WITH MADE IN BRITAIN, A MOVE, IT SAYS, ALIGNS WITH ITS COMMITMENT TO QUALITY BRITISH MANUFACTURING AND SUSTAINABLE GROWTH.

David Graham, general manager, said: “We are delighted that our products can now carry the Made in Britain marque. We have been producing access platforms from this facility for almost two decades, shipping products made here to the UK, Europe and beyond. Many UK and European rental customers still like to buy British as they know the machines come with local product support direct from the factory.”

THIS YEAR’S STARS OF THE FUTURE AWARDS HOSTED BY THE CONSTRUCTION PLANT-HIRE ASSOCIATION (CPA) CULMINATED IN 11 WINNERS AFTER A TOTAL OF 80 NOMINATIONS WERE INITIALLY RECEIVED BY THE CPA. THE AWARDS IDENTIFY SOME OF THE INDUSTRY’S BRIGHTEST UP-AND-COMING TALENT AND ITS FUTURE LEADERS ACROSS VARIOUS OCCUPATIONS.

The winners of each national category were as follows:

■ National plant mechanic of the Year (Level 2) - Bethan Whittaker of KJ Services and Bridgend College

■ National plant technician of the Year (Level 3) - Morgan Wardle of Banks Plant Solutions and Askham Bryan College

■ Hire controller of the year - Millie Scott-Young of Sunbelt Rentals

■ Young plant operative of the year - Josh Jones of L Lynch Plant Hire & Haulage

■ Plant operative of the year - Reece Stray of L Lynch Plant Hire & Haulage

■ Lifting technician of the year - Zac Bradshaw of Commhoist

■ Plant installer of the year - Hayden Chappell of Southern Hoist Services

■ Individual apprentice mentor of the year - Steve Gwynn of Sunbelt Rentals

■ Group apprentice mentor of the year

- Dave Rogers of L Lynch Plant Hire & Haulage

■ Best personal statement award - Shannon Weiss of Finning UK and Finning Academy

■ Judges’ special award - Tom Williams of CBL and Bridgend College

CPA president Brian Jones said: “We’d like to congratulate all the nominees and winners - it’s a tremendous achievement for apprentices to be nominated by their employer or training provider. Testimony to the success of the awards is that many previous award winners have gone on to secure senior positions in the construction plant industry.”

For more information WWW.RDR.LINK/CAV003 i

For more information

WWW.RDR.LINK/CAV002 i

THE HIRE ASSOCIATION EUROPE & EVENT HIRE ASSOCIATION (HAE EHA) HAS CALLED FOR LABOUR TO STAND BEHIND THE PREVIOUS GOVERNMENT’S FULL EXPENSING PLEDGE.

Speaking on behalf of the HAE EHA Mark Bradshaw, public affairs manager said: “The UK hire industry is a vital enabler of construction, facilities management and infrastructure resilience and we are keen to work closely with Keir Starmer’s new government. Specialist hire businesses also help deliver world class sporting, music and business events as well as supply to hospitals and schools and across the public sector.

“To continue doing so, we want to see a fairer and modernised approach to incentivising capital investment. Hire companies are currently not eligible for full expensing, something that could unlock much further investment in newer equipment, helping to decarbonise faster, boost productivity and support UK manufacturers and jobs.”

WWW.RDR.LINK/CAV004 i

MARK JARMAN OF BREHENY CIVIL ENGINEERING HAS BEEN CROWNED JCB’S UK EXCAVATOR OPERATOR OF THE YEAR FOR 2024.

Plant operator Mark secured the title –and the top prize of an all-expenses paid trip to Las Vegas –after defeating 20 other finalists and several hundred entrants across the regional heats.

The final took place at JCB’s Kevin Quarry in Staffordshire, where operators battled it out in timed skills tests at the controls of JCB X Series tracked excavators. Sam Cooper from Chasetown Civil Engineering finished second and Tom Balls from JC Balls & Sons came in third.

Post victory, Mark Jarman said: “I can’t believe it. I didn’t think I had any chance of winning until I saw the leaderboard. I have fared well in competitions previously but it is unbelievable to win this one. I am so overwhelmed.

“The event itself was excellent. It was very well organised and I was very impressed with the JCB 370X I drove in the challenge. All in all it was a fantastic day and I can’t wait to celebrate in Las Vegas.”

MELLOR PLANT UK IS THE LATEST MEMBER OF YANMAR COMPACT EQUIPMENT’S OFFICIAL DEALER NETWORK. THE STRATEGIC PARTNERSHIP SIGNIFICANTLY EXPANDS YANMAR’S PRESENCE ACROSS THE NORTHWEST OF ENGLAND, INCLUDING MANCHESTER AND YORKSHIRE.

The family-run industrial equipment supplier has been providing specialist services and engineering expertise in the construction, agricultural, and forestry sectors for over a decade. Under the leadership of founder and director Gordon Hayes, the company has grown from a single van operation into a wellestablished dealership with modern facilities and a dedicated, close-knit team of 11 industry professionals. The new Yanmar tie-up marks a significant milestone in Mellor Plant’s journey, bringing a comprehensive range of Yanmar’s compact equipment to a broader customer base.

“We are thrilled to become an official dealer,” said Gordon Hayes. “Yanmar engines and machines are renowned for their reliability and performance, and we are confident that our customers will appreciate the exceptional quality these products offer. The units truly speak for themselves; now it’s about spreading the word and encouraging our customers to experience them firsthand.”

For more information

WWW.RDR.LINK/CAV005 i

For more information

COOKS MIDLANDS LTD HAS JOINED THE MERLO UK CONSTRUCTION DEALER NETWORK. ESTABLISHED IN 1992, THE COMPANY SUPPLIES AGRICULTURAL AND CONSTRUCTION PLANT EQUIPMENT THROUGHOUT THE MIDLANDS.

It has been selling and servicing Merlo telehandlers to the agricultural sector for many years, and this new arrangement provides opportunities in the construction industry.

WWW.RDR.LINK/CAV006

“We know Merlo well, are impressed with the product, and are keen to expand our reach with the Merlo range of telehandlers and tracked carriers into construction,” said managing director Darren Cook. “Extending our partnership with Merlo into construction allows us to enhance our product offerings and provide even greater value and service to more customers. We look forward to a successful ongoing collaboration.”

For more information

WWW.RDR.LINK/CAV007 i

copy of the tickets via email, including detailed information on individual buckets, total payload, truck, and material type. Key performance indicators include ticket count, average truck rate, pass count per ticket, and total ticket payload.

to see this uplift in takeup of our range of digital solutions. We’ve worked tirelessly to create technology that equips site teams with the solutions they need, without incurring high costs or requiring machines to be idle.”

For more information WWW.RDR.LINK/CAV009 i

For more information

WWW.RDR.LINK/CAV008 i

CADMAN CRANES IS COCK-A-HOOP AFTER TAKING HOME THE CARBON NEUTRALITY AWARD AT THE ANGLIAN WATER SUPPLIER AWARDS. THE COMPANY PICKED UP THE PRIZE FOR ITS COMMITMENT TO SUSTAINABLY TRANSFORMING ITS OPERATIONS AND FORWARD-THINKING APPROACH TO REDUCING ITS CARBON FOOTPRINT.

From embracing sustainable HVO fuel across 100% of its mobile cranes and support vehicles, through to installing solar panels on the roof of its HQ as well as electric car charging and recycled workwear, the company says it’s proud to be leading the change in the crane industry.

Matt Waddingham, MD at Cadman Cranes, commented: “We are incredibly proud to be recognised for our commitment to sustainability. Winning the carbon neutrality award is a testament to our team’s dedication to reducing our environmental impact. For us, sustainability is not just a goal; it is a core value that drives every aspect of our operations.”

KEVIN KEOGH CRANE SERVICES HAS SIGNED UP AS THE AUTHORISED DISTRIBUTOR FOR TRACKED CARRIERS IN IRELAND.

Made in the UK, tracked carriers are compact loadbearing machines designed for a wide range of applications. With high load-bearing capabilities from very compact dimensions, they are a safe and cost-effective alternative to manual handling.

Founder and director Kevin Keogh said: “Our industry has a strong focus on safety when it comes to lifting. We want to advocate and support safety in materials handling too. Tracked carriers are simply a safer and more productive way to move materials.”

For more information WWW.RDR.LINK/CAV011 i

For more information

WWW.RDR.LINK/CAV010 i

Jet Plant Hire, the UK road planing contractor, is doing its bit to deliver a more sustainable way of operating. CPN reports.

Jet Plant is no stranger to doing things that are more environmentally friendly. Last year it announced its decision to fuel all planers with hydrotreated vegetable oil (HVO), which is produced from waste materials. As a direct result the company has comfortably achieved its 50% reduction in fossil fuel usage target from the planer fleet in comparison to the corresponding months the previous year.

Now its latest bid to help drive industry standards in sustainability and compliance, is to give a second life to ‘waste’ products, namely used planings and sweepings removed from road surfaces.

During the last year Jet Plant has delivered huge quantities of planings from its work sites, with the majority of those planings having gone to local businesses, with the remainder delivered to asphalt plants to be recycled into new materials. With around a million tonnes of road planings recovered that’s a lot of deliveries but even that aspect has been tackled to ensure it’s done as sustainably as possible.

The business guarantees complete traceability of all materials, tracking their journey from origin to destination. By carefully recording planing origin and potential destinations on Google maps, as well as minimising travel distances for repurposing, Jet Plant significantly reduces vehicle emissions, contributing to a cleaner environment and ensuring vehicle uptime onsite. Currently the average tip is just 4.7 miles from job site.

Alongside their traditional use in road construction, road planing materials are adaptable and have significant value across a wide range of different sectors. The company also arranges for the finer sweepings to be

“We are committed to setting the industry standard in sustainable planing solutions. Our focus on sustainability, compliance, cost efficiency, versatility, and traceability shows our dedication to delivering value to our customers while minimising our environmental impact.”

delivered into local sites. These are useful for farms and equestrian centres, as it is a softer material for animals to walk on. Recent applications even include an alpaca farm!

Comprehensive paperwork ensures meticulous tracking of every step in the planing process. From removal by the onsite team, to driver responsibility and sign off by the end user, Jet Plant maintains strict compliance. This goes beyond required industry standards and regulations, ensuring transparency and accountability throughout the process.

The business has more than 20 years of data with detailed information on local tips and is constantly looking to grow and adapt that database, thanks to the knowledge and experience in the team.

By repurposing 100% of road planings, Jet Plant is actively reducing waste and aiming to

help conserve natural resources, aligning with its strong environmental responsibility goals.

Charlotte Chetland, planing sales team leader at Jet Plant, commented: “We are committed to setting the industry standard in sustainable planing solutions. Our focus on sustainability, compliance, cost efficiency, versatility, and traceability shows our dedication to delivering value to our customers while minimising our environmental impact.”

Jet Plant believes its unwavering commitment to sustainable practices and excellence in planing solutions reinforces its position as an industry leader, setting the benchmark for others to follow.

As promised in our last issue, CPN’s Nick Johnson brings you a second instalment on what was new and eye-catching at Hillhead.

Hillhead 2024 is over for another year, but there is no denying that the biennial quarrying industry extravaganza once again delivered its trademark combination of exciting new product/service launches, countless technological innovations, and more live plant/equipment demonstrations than ever, say the organisers.

Simply put Hillhead 2024 was the most visited edition ever in terms of the volume of visits over the three days, with visitors spending more time at the show than ever before and a record number attending for more than one day. In total there were a staggering 26,626 visits over the three days – marking an 8% increase over the 2022 edition.

In terms of unique visitors, with 19,577 attendees from 67 countries (+6.2% compared with 2022) this year’s edition had the second highest ever number of trade visitors (only 2018 was higher at 19,753, although that show had less volume over the three days). Hillhead 2024 also recorded the event’s busiest ever show day in its 42-year history, with almost 10,800 visitors attending on day two.

HERE’S OUR TAKE ON WHAT WAS ON OFFER.

Making a welcome return to the Hillhead show this year, JCB displayed an interesting array of new and updated products. Particularly prominent was one of the company’s two newly improved rotary telehandlers.

Complete with increased capacity, new styling, a better display screen and a standard Vision Pack (with side and rear cameras), the new 558-260R PRO on show provides a maximum lift heigh of 26.0m and a maximum lift capacity of 5,800g (an increase of 300kg on the previous 555 series machine). There is also a new 21.0m lift 558-210R PRO rotary telehandler.

On the excavator front, JCB was highlighting its recently introduced 37 tonne class 370X tracked excavator and, at Hillhead 2024, the company launched a brand new 145XR. This reduced tailswing X Series model weighs in at

15-18 tonnes and is powered by an 81kW JCB Stage V compliant Dieselmax engine.

Hillhead visitors could also see how JCB’s hydrogen powered machine programme is developing. On show was the latest preproduction hydrogen backhoe loader and a G60RS H genset powered by a JCB hydrogen combustion engine

GOTO

WWW.RDR.LINK/CAV013

Particular emphasis was being given by this prominent Chinese construction equipment maker on its green coloured electric machines at Hillhead. Brand new for the show was the 820TE 100% electric wheel loader which has an operating weight of 6,600kg and a standard bucket capacity of 1.2m3. This compact machine has an LFP battery with a rated storage capacity of 70.5kWh.

LiuGong’s larger 870HE electric wheel loader weighs 24,200kg and has a standard 4.7m3 bucket. Its LFP battery has a 423kWh rated storage capacity.

The new 24.1 tonne 922FE electric tracked excavator has an electric motor which delivers 140kW of power. Equipped with 430kW battery, it is claimed that this machine can work a full 810 hour shift before needing to be recharged.

Another most interesting LiuGong exhibit was the diesel engined 9017F RC – a concept remote controlled small tracked mini without an operator’s compartment. Fitted with a LGB45 hydraulic breaker for the show, this machine is based on the company’s conventional 1.7 tonne mini excavator.

GOTO

WWW.RDR.LINK/CAV014

A particular highlight on the Develon stand was the new DD130-7 bulldozer which has been designed to provide very good visibility. This machine weighs 15,300 kg and is fitted with a 117 kW Perkins 1204J engine.

The DD130-7 can be fitted with 560mm, 710mm or 760mm wide track shoes. There are three angling blade options and a three-tooth parallel ripper can be fitted at the rear. A telematics system is a standard feature.

GOTO

WWW.RDR.LINK/CAV015

Develon has entered the European dozer market with this new 15,300kg DD130-7.

Whilst Sany was highlighting its larger SY500H and SY390H tracked excavators at Hillhead, visitors could also see how this very large Chinese construction equipment maker is intent on scoring here with other machine types. Prominent with its fully extended boom was the largest of the company’s recently introduced European style, low boom telehandlers – the 4,000kg maximum capacity STH1840 with a maximum lift height of 18.0m.

Sany is also adding vibrating rollers to its UK product offering and there was a STR50C8K lightweight tandem on its own stand and a self-propelled SSR130C-10H roller (weighing 13

tonnes) on the Clee Hill stand.

The STR50C-8K weighs 4,500kg, has a drum width of 1,380mm and is powered by a 36kW Kubota D2607 diesel engine. Smaller tandem rollers with drum widths of 1,000mm and 1,200mm are scheduled to be launched here next year.

Sany also showed what it claims to be the world’s first small battery powered planer. The prototype SCM500E-10 planer weighs 6,300kg, has a milling width of 500mm and a maximum milling speed of 33m/min. The unit will shortly be trialled in the UK.

GOTO

WWW.RDR.LINK/CAV016

Following last year’s rebranding of Doosan Portable Power machines to carry the Bobcat name, a new Bobcat liveried PA12.7V portable compressor appeared at Hillhead. This is a 250cfm class compressor, fitted with an HDI D24 engine rated at 54.7kW.

The single axle PA12.7V towed compressor is equipped with FlexAir technology which allows it to operate in the pressure range of 5.5 to 12.1 bar and offer free air deliveries from 185 to 250cfm. There is the option of either an optional integral high-performance 6 or 8.5 kVA integral generator which can supply electrical power without reducing air output. Other options include an aftercooler, lubricator and spark arrestor.

WWW.RDR.LINK/CAV017 GOTO

New machines from Case at Hillhead included the 651G Evolution wheel loader and the second version of the 21 tonne class CX210E-S crawler excavator. With a standard bucket capacity of 2.3m3, the 651G Evolution is powered by a 6.7litre FPT Industrial diesel engine. The CX210E-S is around 500kg heavier than the standard CX210E, due to the heavy-duty build of its front-end equipment, lower structure and undercarriage.

On the compact plant front, new Case models on show included the 12ev electric compact wheel loader and the TL100 mini tracked loader. Powered by a 23 kWh cobaltfree lithium-ion battery, the 12ev has a standard bucket capacity of 0.5m3

The ‘stand on the back’ TL100 weighs 1,640kg and is powered by an 18.5kW Kubota D1305-E4B diesel engine. Operating capacity is 500kg on wide tracks.

WWW.RDR.LINK/CAV018 GOTO

The Italian machinery specialist displayed its 12 tonne, 10m reach P120.10, which comes with CVT transmission, its advanced stability control system (ASCS), attachment recognition safety system, large in cab LCD display screen and flow-sharing hydraulics fitted as standard. The ASCS ensures a high level of safety, checking the operating parameters of the handler in real time to improve its stability. This heavy-duty panoramic handler is equipped with 160 l/min

hydraulic flow.

Probably best known, in the world of construction, is the Merlo Roto for positioning loads in a radius of up to 360˚. At Hillhead, Merlo showed the ROTO50.30PLUS, with stage V 170 hp engine, five tonne capacity and reach of up to 30m. S PLUS models have dual hydraulic pumps, a tilting cab and automatic management of the multi position stabilisers as standard.

WWW.RDR.LINK/CAV019

Hillhead was used by HD Hyundai for the UK launch of two heavy crawler excavator models –the 100 tonne H1000A and the 80 tonne HA800A - and its largest wheel loader – the HL985A. Weighing 35 tonnes, the Cumminsengined HL985A loader is designed to work with a 7m3 capacity bucket.

Both the big excavators have Perkins engines. The HX800A L uses the six-cylinder Perkins 2506J providing 400kW and the larger HX1000A L is powered by the 460kW Perkins 2806J.

WWW.RDR.LINK/CAV020

With a unmissable NEW sign in front of it, the latest Bomag BMP8500 trench roller was at Hillhead 2024. Now powered by a 14.5kW Kubota D1005 engine under a restyled bonnet, this articulated padfoot roller has an operating weight of 1,595kg and its drum width is 610mm or 850mm (with extensions).

New features include an integral amber warning beacon, a strengthened centre joint with a bigger diameter pin and a new radio remote control unit. This control unit works all rollers of the same type and has two batteries. It is possible to recharge one using the roller’s integral charger whilst operating the machine with the other. Total run time of both batteries is said to be 35 to 40 hours.

WWW.RDR.LINK/CAV021 GOTO

ILINK, spare parts availability and advanced service and maintenance techniques. This comprehensive approach demonstrated our commitment to providing robust support and solutions for all our customers.”

Four BEV machines were on show. The 9027FE mini excavator offers a compact and powerful solution, suitable for work in confined space, while the 922FE excavator combines muscle and high efficiency with the latest in electric

“This event was a great opportunity to engage with our valued customers and dealers, discussing LiuGong’s BEV machines and our expertise in electric technology.”

“At the ‘BEV Experience’, guests saw first-hand not just our impressive range of BEV machines, but also the comprehensive strategies and solutions we offer. This event highlighted our commitment to sustainable technology, reinforcing our leadership in the transition to electric construction equipment in Europe.

9057F, are designed to deliver efficiency and reliability. The excavator segment included the 915 FCR, 922F, 936F, and 952F, models that enhance productivity with their advanced features. Additionally, its wheel loaders, such as the 856T Series, 877H, and 890H, are engineered to boost operational efficiency and

The DRESSTA series includes highperformance dozers, celebrated for their durability and strength. The TD-16N sets the benchmark for visibility and safety, while the TD-40, with its impressive 67 tons of pure performance, is engineered to handle the most demanding tasks with precision and power.

LiuGong’s aerial work platforms, showcased at the event, include scissor lifts and boom lifts tailored to meet diverse height requirements and applications. The scissor lifts, ranging from 8m to 14m in working height, comprise the LSC 0607DE, LSC 0808DE, LSC 1012DE, and LSC 1212DE. These lifts are designed for optimal safety and efficiency at multiple

Complementing this line-up are boom lifts with working heights from 22m to 28m, featuring the LD 20JE and LT 26JE. These platforms are engineered to handle a wide range of elevation tasks with precision and

As a leader in China’s booming BEV technology sector, LiuGong, it says, is at the forefront of driving a revolutionary wave in BEV R&D. Its plans include launching over 40 BEV models by 2027, including new electric excavators, wheel loaders, telehandlers and access equipment. It adds that its pioneering efforts in electric machines are part of the company’s strategy to become the number one leader in BEV technology in Europe by 2027.

European product director, Harry Mellor, commented: “At the ‘BEV Experience’, guests saw first-hand not just our impressive range of BEV machines, but also the comprehensive strategies and solutions we offer. This event highlighted our commitment to sustainable technology, reinforcing our leadership in the transition to electric construction equipment in Europe. As a company, we are on a mission to create a more sustainable future in the construction equipment industry and our continued investments in R&D, customer insights, and new facilities like the one here in Stalowa Wola exemplify that commitment.”

Attendees also had the opportunity to interact with LiuGong’s dedicated BEV team, comprising experts from product management, service, parts, and sales departments. This was complemented by an exclusive tour of LiuGong’s new regional hub in Stalowa Wola, demonstrating its commitment to market readiness and

investment in Europe. This integrated facility includes a dealer training centre where professionals gain hands-on experience with the latest machinery and technology.

Additionally, the hub features a sophisticated parts distribution centre equipped with advanced smart logistics and ordering systems, ensuring efficient and timely

delivery of components. The product proving grounds offer a practical environment for testing and showcasing the capabilities of LiuGong’s equipment range. Furthermore, the service repair centre underscores the dedication to exceptional maintenance and support services.

LiuGong Europe chairman, Howard Dale, concluded: “We wanted to give our customers and dealers an unforgettable and informative journey through LiuGong’s electric capabilities, and we did just that with the ‘BEV Experience’. Our guests left with a deeper understanding of our impressive line-up of BEV machines and an appreciation of the hard work that the LiuGong team put in behind the scenes at facilities like this new regional hub in Stalowa Wola. Through the ‘BEV Experience’, we have once again showcased our substantial market readiness and significant investments in our facilities and the European market. As a result, LiuGong continues to establish itself as a highly credible alternative to the old mainstream brands.”

CPN’s newest team member is back. Some say he loves his off-set booms, others that he’s a fan of back actors. All we know is that we call him The Dig. This month he is going heavy metal.

The new and long awaited 370X replaces what was previously the largest model in JCB’s range of hydraulic excavators, the JS370LC, and is the biggest and most powerful X-Series model to date, competing in the 35-40 tonne sector.

With over 4-years in the making, the new model builds on the DNA and proven success of the original X-Series models that were first launched back in 2018 with the roll out of the 220X, and subsequent models including, 131X, 140X, 150X and 245XR

I’m guided up to the engine bay by allaround guardrails and grab handles, and anti-slip

tread plates kept me sure footed on my way up. In a move away from previous engine makes fitted, the 370X is powered by the latest EU Stage V and EPA Tier 4 Final emissions compliant Cummins L9 diesel engine, a well proven power pack in the heavy equipment sector.

The 8.9-litre, six-cylinder, engine is said to boast a 14% power increase over the outgoing JS370, with 240kW (322hp) available at just 1,700rpm. The engine delivers this maximum power within a reduced operating rev range, to increase fuel economy and reduce overall noise levels.

Service intervals have also been extended, hydraulic oil intervals are now doubled to 2,000 hours, with engine coolant service now required at 3,000 hours, while having to change the air filter has now been extended to 2,000 hours, although I’m sure the purists amongst us would still like to give it a blow-out periodically especially on dusty job sites.

As with the previous X-Series models, under the skin the machine is brimming with top-quality blue-chip Japanese components, including the very latest generation Kawasaki tandem hydraulic pump and Kayaba (KYB) valve block. Hydraulic pump pressure has been

increased to 350 bar, but this rises to an impressive 380 bar when deploying the power boost function.

Increased diameter hydraulic service pipework, and the raised hydraulic pressures ultimately result in more power at the business end of the machine, combining to make a more powerful and smooth digging experience.

A number of field-follow machines have, in the words of JCB, been ‘tested to extreme’ racking up thousands of hours in the process,

provided, immediately behind the cab, we discover the large air filter housing, cavernous storage space, and there was even a convenient storage area for a track spade. The rear panel reveals the cooling packs, coincidentally, on the other side of the radiator a hydraulicallyoperated cooling fan with reversing function is fitted. This bay is also home to a very small windscreen washer bottle.

Climbing up into the seat, I was instantly reminded just how good the JCB Command Plus ROPS cab is, without a doubt one of the most spacious and luxurious places to spend a shift. According to JCB the cabin has 2.86m3 of volume inside and in cab noise levels of just 69dB.

not just here in the UK but one 370XNLC example that was being demoed in the quarry, with the new JCB HM330T hydraulic breaker on, designed specifically for the 370X, had previously been working in a quarrying application in Croatia breaking up hard heavy rock. The team using that machine there, was so impressed that it has asked for its return to the quarry after the launch event.

A redesigned 6.45m monoboom with cast boom foot is fitted as standard, and end users can specify either 2.63m, 3.23m or 4.03m dipper sticks, to suit the application the machine is working on. The heavy-duty options are fitted with crush bars to protect the lower front of the dipper arm from any potential damage from rock or demolition debris.

Bucket pins have been ‘beefed up’ with an increase in diameter size, while a new JCB dual pin quick-hitch can be specified to enable pick up of 90mm or 100mm pinned attachments.

Walking around the new machine, it’s all very similar to the rest of the X-Series range, doubleskinned steel panel doors are fitted, offering strength and durability, on the offside a single panel reveals access to the hydraulic pump. On the nearside twin panel doors are

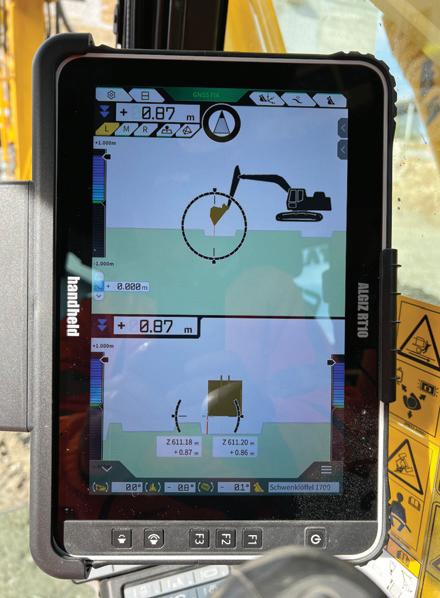

The Command Plus cab has now also been further improved with the introduction of a brand new 10in touchscreen monitor which features a new user interface called JCB UX.

The tablet style monitor looks top drawer, and is easy to navigate around. It appears that the focus has been on making it more user friendly with customisable hot keys, to allow operators to personalize settings to suit individual preferences.

The JCB UX interface has up to 25 user profiles available, so different operators can have the machine set up how they like it, at the click of a button; this includes setting up different joystick configurations if they prefer an alternative layout.

Another nice touch is the adoption of ‘how

function as well in that mode, so I opted for the power mode, which I found to be lot more responsive, in addition to being more powerful.

I spent my last 20 minutes on the machine shaping up the heap, and sealing it from the weather, I was so impressed with the smoothness while grading and the overall performance of this big machine, which is clearly carrying on the legacy of the original XSeries machines and taking it to new heights.

This machine ticked all the boxes and left a lasting impression on me personally. Its already gaining many fans out in the field with a significant number of big-name blue-chip companies ordering and taking delivery of 370X models, a testament to the big excavator’s quality, strength and durability.

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

PSR Turnkey Solutions Ltd, based in Rotherham in South Yorkshire, has tasked new Bobcat mini excavators and a new Bobcat compact track loader for use on its renewable energy and drainage projects across the UK. The new equipment was supplied by AMS Bobcat Limited, based in Scunthorpe, the authorised Bobcat dealer for Lincolnshire and South and East Yorkshire. The machines comprise a Bobcat E19 1.9 tonne and two E27z 2.7 tonne mini excavators and a T450 compact track loader.

PSR Turnkey Solutions specialises in civil engineering and construction projects with a focus on building a better future for local communities in the UK, specifically infrastructure for the rapidly expanding renewable energy industry as well as for drainage projects.

As Paul Strutt, managing director, says: “We specialise in building the infrastructure for the growing renewables market, from preparing the foundations for concrete plinths for rechargers for electric vehicles to building battery energy storage systems (BESS) to support the National Grid.”

The new purchases have already been employed in contracts as far apart as Scotland and west London. In fact, one of the two new E27z mini excavators is currently working on

Yorkshire contractor PSR Turnkey Solutions has eyes for only one machine brand as it gears up for growing markets. CPN reports.

the installation of an environmentally friendly air source heating system to replace gas boilers at a leisure centre in Ruislip to the west of London.

Paul Strutt adds: “We moved from another brand when we bought the Bobcat machines. We were impressed by the design and the performance of the excavators and the new loader. The presentation by AMS Bobcat and the support it provides were also crucial in the

purchase decision and we look forward to working closely with AMS and Bobcat in the future.”

One of the most attractive features of the new M-Series T450 compact track loader for the contractor is its attachment capability. There is a wide choice of different types of attachment that can be combined quickly and safely with

the T450, via the quick-change Bob-Tach attachment mounting system, delivering versatility and time-saving efficiency across a huge range of different applications.

Strutt continues: “The T450 is a very handy addition to our fleet. One of the first attachments we have bought is a sweeper, to provide clean up on site. I also see the T450 as a replacement for dumpers as it does not have to be filled up by other machines on site as it can do all that work itself.”

The E19 mini excavator delivers impressive performance in confined spaces with the need for only minimal repositioning. The operator can hydraulically retract the undercarriage to a width of only 98cm to travel through gates or between walls and houses, then expand it to 136cm for a wider footprint and greater performance.

The E27z is part of Bobcat’s R-Series mini excavators from 2-4 tonne, comprising four more models – the E26, E27, E34 and E35z. All five machines offer a mix of high digging forces, stability and smooth controllability of working functions complemented by low weights for easy transportation. The new E27z with its cab and bucket has an operating weight of 2700kg, a maximum digging depth of 2847mm and maximum reach at ground level of 4814 mm.

Battery storage, or battery energy storage systems (BESS), are devices that enable energy from renewables, like solar and wind, to be stored and then released when the power is needed most. Battery storage technologies are therefore seen as essential in speeding up the replacement of fossil fuels with renewable

“We moved from another brand when we bought the Bobcat machines. We were impressed by the design and the performance of the excavators and the new loader.”

energy, playing an increasingly pivotal role between green energy supplies and responding to electricity demands.

Strutt explains: “Lithium-ion batteries, which are used in mobile phones and electric cars, are currently the dominant storage technology for large scale plants to help electricity grids ensure a reliable supply of renewable energy. We’ve begun deploying this technology with heavier equipment, working with a company that makes battery storage systems for industrial, commercial and residential buildings.”

Established in 1992, Scunthorpe-based AMS Bobcat is one of the longest standing Bobcat dealers in Europe and has been in partnership with the manufacturer in the UK for over 30 years. In that time, AMS has notched up sales of over 4000 new machines into a wide range of industries, including construction, agriculture, shipping, plant hire, mining, landscaping and demolition.

With this level of experience, it is not surprising that AMS offers an excellent level of expertise and knowledge of the Bobcat range and the other products it offers, whether it be new and used equipment sales, parts supply, service repairs or long and short-term rental.

AMS also offers a full selection of genuine Bobcat accessories and parts to support both new and existing Bobcat customers in its area. Customers benefit from AMS’s well-established on-site service network, covering everything from emergency repairs to routine maintenance. The company offers flexible service agreements including 24 hours a day coverage, depending on the requirements of the customer.

For more information about Bobcat machines, please visit WWW.RDR.LINK/CAV 024

Waste management company, Viridor, has put its money where its mouth is by deploying the first fleet of Cat eMH24 electric-drive material handlers at its Bargeddie and Polmadie plants in Scotland.

The four Cat eMH24 machines will handle large quantities of black bag waste, enhancing Viridor’s recycling capabilities. Any residual waste that cannot be recycled will be converted into electricity to power these electric-drive material handlers. The result: a significantly smaller CO2 footprint compared to traditional diesel-powered machines, reduced operating costs and greater productivity.

Paul Cairney, operations manager for Viridor (Bargeddie), says the move is part of the company’s commitment to reducing its carbon footprint as part of its Environmental, Social, and Governance (ESG) strategy.

“By operating these new Cat eMH24 electric-drive material handlers, we are expecting at least a 50% reduction in CO2 and operating costs,” he says. Cairney highlighted the straightforward electric-drive motor and hydraulic pump of the Cat machines, which enhance uptime and productivity while lowering operating costs.

The decision to transition to electrically driven machines required a comprehensive solution from Cat dealer, Finning, which collaborated

with Murray Cable, part of the Finning group, to install the necessary high-voltage cabling to power the Cat machines at the remote recycling facilities. The installation was completed in just two weeks, working nights and weekends to avoid disrupting the day-to-day operations.

The machines have also won the approval of operators such as Chris Egan, who has more than 20 years of experience, and says the Cat eMH24 is one of the best machines he has operated. He particularly likes the quieter operating environment, smooth hydraulic controls, and the elimination of refueling and exhaust gases.

With these new machines, Viridor says it will continues to lead the way in sustainable waste management, showcasing a practical and innovative approach to reducing environmental impact and enhancing operational efficiency.

HE Services is boosting its 3,500 plus fleet with Bobcat tracked loaders, including the latest model – the Bobcat T76 tracked loader.

“Adding the Bobcat T76 tracked loaders to our fleet underscores our commitment to providing our customers with the best equipment available,” said Malcolm Gough, national hire manager at HE Services.

“Bobcat’s track record of innovation and quality aligns perfectly with our mission to

offer machinery that enhances productivity and meets the rigorous demands of our clients’ projects.”

The Bobcat T76 tracked loader is claimed to be a game-changer in the construction and landscaping sectors, boasting a powerful 73hp (54.5kW) engine to deliver impressive power and efficiency. Its vertical lift path ensures greater lift capacity and height, making it ideal for loading, grading, and material handling tasks.

The loaders have an operating weight of

5,051kg and a rated operating capacity of 1,426kg, so are suitable for a variety of heavyduty tasks.

In addition to its technical specifications, the T76 tracked loader features a state-ofthe-art cab with enhanced visibility, ergonomic controls, and superior comfort, ensuring operators can work efficiently and safely for extended periods.

Available to hire from any of HE Services’ 11 depots across the UK, this acquisition of the latest plant machinery marks the beginning of a sizable expansion and enhancement of HE Services’ already extensive machine inventory

WWW.RDR.LINK/CAV026 GOTO

Shannonside Civil Engineering is a big fan of Hitachi excavators. Over the past ten years it has used more than 200 and it has just bought a ZX225US-7 and ZX350-7 to add to its fleet of more than 100 Zaxis models ranging from three to 30 tonnes.

“Since I moved here in the 1980s from Ireland, I have operated and supervised Hitachi machines, from the UH063 and EX150,” says managing director Brendan Carty, who founded Shannonside in 2004.

“They were all reliable and user-friendly. When I set up my own company, there was no doubt what colour the machines would be. I like the fact that the machines go to work site-ready. We’re not waiting a week for other suppliers to come and calibrate the bucket, for example.”

Brendan is not the only advocate of Hitachi construction

AG Wilson Civil Engineering, a family-owned civil engineering contractor based in Co Armagh, Ireland, has invested in three 24tonne SANY excavators, supplied through Irish dealer Sleator Plant, with another three machines on order.

General manager for Sleator Plant, Aaron McCaul, reckons the decision was a combination of familiarity and trust in both the supplier and the machines.

“The specification of the machines, along with the five-year warranty, makes the SANY option a positive one for the business,” he notes. “Their trust in the team at Sleator Plant also helped in their decision to place a large multi-unit order.”

The additions join an already robust fleet of SANY equipment that includes five 8-tonne SY80U excavators, a 16-tonne compact wheeled excavator, and two 16-tonne SY155U machines.

AG Wilson’s relationship with Sleator Plant began with its first SANY excavator purchase in December 2021. Since then, the company has been consistently impressed with the performance of the SANY machines and the exceptional support provided by

equipment within the company – the operators are also enthusiastic about the brand. Tim Philpotts has worked for Shannonside for eight years and was the first to work with the company’s Zaxis-7 models.

“I’ve been working with the ZX225USLC-7 since July 2023. It’s versatile enough to fit into any space, but also big enough to make an impact,” he says.

“The layout of the cab is good, with controls in easy reach –everything is where you need it to be. And the Engcon tiltrotator makes life easier, as less movement of the machine is required, and it makes it quicker to do the work.”

Like all the latest Zaxis-7 machines, the two recent additions to its Hitachi fleet are are equipped with Leica Geosystems machine control and Engcon tiltrotators, supplied by HCMUK’s Hitachi connected technology team. They are currently working alongside two other medium excavators, a ZX130-6 and ZX225USLC-6, on a housing development for Persimmon Homes in Cheltenham. Shannonside is responsible for preparing the infrastructure, roads and drainage system for 260 houses, and the project is expected to last four years.

Carty’s Midlands-based company specialises in housing, infrastructure, and commercial projects, and operates on multiple sites within an 80-mile radius of its Redditch headquarters.

WWW.RDR.LINK/CAV027 GOTO

Sleator Plant.

AG Wilson, established in 1979, has built a reputation for delivering comprehensive civil engineering services across the UK and Ireland. With more than 40 years of experience, the company prides itself on technical expertise, a dedicated workforce, and a commitment to integrity in every project it undertakes.

The newly acquired SY215C excavators will be deployed immediately on a pipeline

project in Scotland. In addition to these, AG Wilson has placed further orders, including a 40-tonne SY390H excavator and two SY75C machines, which will bring the total number of SANY machines in its fleet to 16.

The extra capacity that these machines will bring will enable the company to maintain its programme of increasing operational efficiency and capacity.

WWW.RDR.LINK/CAV028 GOTO

We are used to seeing countless jobs carried out by mini excavators, but a novel application involving a new Develon DX20Z-7 model demonstrates just how flexible the machines are and how imaginative operatives can be. And needless to say, for those of you thinking of building a home in Spain, it’s food for thought.

Ismael Cabrera, manager of Ciment i Estructures Costa Brava, explains: “On the latest job where we used the Develon DX20Z-7 mini excavator on a house renovation project, there have been so many advantages thanks to the machine’s versatility. The excavator was able to move freely inside the house, even going down the narrow stairs of this family home. This has translated into operator comfort, savings in time and costs, and provided a solution where other larger machines were unsuitable.”

In the home in question, a number of jobs were carried out with the mini excavator, but the most unusual one without a doubt was the installation of 26 panes of glass of various sizes, and weighing between 320 and 400kg.To do this, a special suction cup attachment had to be used for installing the panes, allowing the excavator to access certain windows directly from inside the home, instead of using a truck-mounted crane externally. This made the installation easier, quicker and safer.

Ismael Cabrera added: “We find projects are increasingly more difficult and refurbishments are even more so. In our area, specialist jobs are very costly and we have to try to do the work with our own workers and our machines, so

that it is profitable. Previously we carried out this type of work with rented machinery. Now we can save on hire costs, paperwork and by doing it ourselves we bring it together better and in a more agile way.”

He continued: “In the company, there are four of us who operate the machines and we all agree that the Develon DX20Z-7 is very easy to handle, in addition to being very comfortable for the operator, providing unbeatable visibility, high safety and robustness. In terms of fuel consumption, we have found it is very low. Our overall rating of the DX20Z-7 would definitely be 10.”

JCB’s venerable backhoe loader never ceases to find new applications, the latest replacing static waste compactors across a group of recycling centres –saving the operator time and money.

Bryson Recycling operates five household waste recycling centres across Conwy and Denbighshire in North Wales where it traditionally used static waste compactors.

Now the company has invested in two versatile JCB 5CX PRO Wastemaster models which are able to complete the waste compacting requirements as well as a series of additional roles.

Using a jaw bucket attachment on the back actor, the backhoes can pick, sort and compress the waste within a container – fitting more waste in each and reducing the number of container collections needed to process the recyclable material. They also move containers using an integrated skip hook at the front end and with their roading capabilities, they can operate across all five sites in Wales.

Bryson Recycling site manager, Dan McCabe, said: “We chose JCB due to its longstanding reputation for quality craftmanship. We read in the trade press that the 5CX PRO Wastemaster was specifically designed for

household waste recycling sites and that certainly spiked our initial interest.

“After seeing it in action at a demonstration event we were confident that the machine would have a positive impact on our operations and that has definitely proved to be the case. We refer to the 5CX PRO Wastemaster as a ‘Swiss Army knife’ as it has so many capabilities which benefit the waste management industry.

“Prior to this purchase we used static waste compactors which were expensive to maintain and run in comparison to the productivity they could achieve. By using the JCB models we have surpassed the capacity we could previously process with the static waste compactor and are reducing costs in the process. Furthermore, the 5CX models stand out for their ability to raise on four jacklegs for greater visibility, move waste containers

with the front hook, while also having the added flexibility of driving the machine quickly from one site to another.”

With a 4-speed transmission (complete with Torquelock), the JCB 5CX Wastemaster can travel at up to 25mph (40km/h). JCB’s Smoothride System minimises bounce loadings; this means increased operator comfort, increased travel speed, reduced material spillage and reduces wear on the loader arms.

Bryson Recycling is the largest social enterprise recycler in the UK. It collects and processes recycling materials from over 50% of homes in Northern Ireland, operating 11 recycling centres in Donegal and Wales as well as providing collection services for gardens and residual waste.

FOR MORE INFORMATION

WWW.RDR.LINK/CAV030

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

So, in articles you may now see things like:

Simply enter rdr.link/ followed by the unique six digit code into your browser and it will take you to the required resource

Case’s new D-series graders – the 836D and 856D – feature many of the operator comfort and productivity benefits launched with the previous C-Series machines.

Both models come with electro-hydraulic joystick controls or mechanical levers, which means the operator has the ability to choose depending on preference. The electro-hydraulic system uses three-axis joysticks, which are built into multi-adjustable armrests for maximum operating comfort. The joysticks are equipped with multiple roller switches and buttons, to control various machine functions.

Powered by a Stage V six-cylinder FPT diesel engine, with Hi-eSCR2 emissions technology, the D-Series graders deliver a dual power curve, with automatic switching as higher transmission ratios are reached. This ensures maximum power is available as travel speed increase, boosting productivity.

Compliant with HVO and other XTL synthetic fuels, the 6.7-litre diesel engine features a maintenance-free diesel oxidation catalyst (DOC) with selective catalytic reduction (SCR) exhaust after-treatment system. An Ergopower transmission automatically delivers smooth shifting between gears, with all-wheel drive models having a creep mode for compaction work, reducing the need for additional machines on site. Both the two- and four-wheel drive models are available with optional 24» tyres, ideal for uneven ground conditions.

The D-Series graders feature a low-profile ROPS/FOPS cab, delivering good visibility. A reduced overall height makes for easier

transportation between job sites. Full width tinted glazing and a commanding view to the front and at the moldboard, ensure optimum control, whatever the task.

D-Series graders can be tailored to the application with a choice of different moldboard widths, moldboard extensions, an overload clutch, a five-tooth ripper, additional counterweights and LED working lights. An A-shaped frame and central saddle provide maximum stability and versatility for the cutting edge.

The moldboard design, on a roller-mounted encapsulated slewing ring, avoids any backlash and reduces wear, while supporting high mechanical torque for maximum control. With fewer greasing points, maintenance is reduced, boosting uptime and ensuring increased profitability for the customer. The D-Series graders are compatible with most popular plug-and-play machine control systems to further boost productivity.

Develon now offers a range of four different Stage V super long reach excavators from 24.6 to 52.2 tonne, comprising the DX225LC-7 SLR, DX300LC-7 SLR and DX530LC-7 Semi-SLR and SLR models. These machines are ideally suited for jobs such as excavating lakes, cleaning settling banks, drainage work, digging in sand and gravel pits, slope forming and other long reach applications.

To carry out this work, the DX225LC-7 SLR features 8.5m boom and 6.2m arm components, with a maximum digging reach of 15.37m, a maximum digging depth of 11.66m and a maximum digging height of 13.05m. The bucket digging force is 10.0 tonne and the arm digging force is 6.0 tonne.

Moving up the range, the DX300LC-7 SLR provides a maximum digging reach of 17.51m, a maximum digging depth of 13.78m and a maximum digging height of 14.20m. This excavator has 10.0m boom and 7.0m arm components. The bucket digging force is 10.0 tonne and the arm digging force is 7.1 tonne.

Completing the range, the DX530LC-7 Semi-SLR/SLR feature 9.0/11.0m boom and 6.0/8.0m arm components, respectively. The DX530LC-7 Semi-SLR excavator provides a maximum digging reach of 16.06m, a maximum digging depth of 11.80m and a maximum digging height of 12.80m. The bucket digging force is 19.2 tonne and the arm digging force is 13.8 tonne. The DX530LC-7 SLR excavator provides a maximum digging reach of 19.62m, a maximum digging depth of 15.13m and a maximum digging height of 14.44m. The bucket digging force is 14.3 tonne and the arm digging force is 11.9 tonne.

The DX225LC-7 SLR and DX300LC-7 SLR are powered by the well-proven 6-cylinder, turbocharged DL06V and DL08V water-cooled Stage V diesel engines, providing high power outputs of 129kW (174hp) and 202kW (271hp) at 1800rpm, respectively. The DX530LC7 Semi-SLR and SLR models are powered by the Scania DC13 engine, with an output of 294kW (394hp) at 1800rpm. FOR MORE INFORMATION WWW.RDR.LINK/CAV032 GOTO

The X-Air+1200-40 is the newest member of Atlas Copco’s DrillAir portfolio. This brand-new portable air compressor is designed to “revolutionize” deep drilling applications by offering faster drilling and a notably reduced carbon footprint.

Engineered with precision, the X-Air+1200-40 achieves at least a 10% uplift in performance metrics over prior models. This improvement helps users achieve significant savings in fuel and operational costs, while simultaneously reducing the environmental footprint of their activities, says the company.

The X-Air+ 1200-40 surpasses Atlas Copco’s previous flagship drilling compressor, the Y35. The model boasts 15% more pressure and a 20% increase in drilling speed compared

to the Y35. It features a new high-pressure element – to withstand even tougher operational conditions – and is protected by innovative patented software that ensures longer lifetime and durability. The new unit also introduces a patent-pending hammer

protection functionality, allowing users to limit the flow to ideal hammer settings or unleash the full power of DrillAir as needed.

FOR MORE INFORMATION

WWW.RDR.LINK/CAV033 GOTO

Komatsu has introduced significant upgrades to its crawler excavator operator cab, driven, the company says, by extensive customer feedback and a commitment to operator wellbeing and productivity

High-visibility Komatsu yellow handrails on both the exterior and interior enhance safe access even in low-light conditions, while inside, the operator is greeted by a refined and ergonomic workspace. Inspired by high-end automotive design, the interior features a premium dark colour scheme with a plush floor mat, adding a luxurious touch that is also easy to clean.

The new cab prioritises clear visibility during operation. The front roller blind’s relocated position increases visibility by blocking the sun without obstructing the operator’s view. Upgraded LED lighting, both above the seat and in the rear of the cab, ensures illumination regardless of the time of day.

For operator comfort and reduced fatigue, the new cab also features a UV-protective rear window tint that minimises sun exposure and helps maintain a cool working environment.

Besides the standard upgrades, Komatsu also offers optional features to further enhance the operator environment.

A premium seat option automatically adjusts its position based on the weight of the operator, providing the highest level of personalised

comfort throughout the workday.

New wide armrests with multi-positional locations allow for an optimal working posture. New operation control levers are designed to comfortably mould to any hand size or shape, reducing strain and fatigue over long shifts.

The new cab is available on all crawler excavator models from 17 tonnes to 49 tonnes.

FOR MORE INFORMATION WWW.RDR.LINK/CAV034 GOTO

UNIC Cranes Europe has launched two new mini spider cranes which feature a new telescoping luffing jib / searcher hook. These new models build on the features of the existing URW-546-2 and URW295-2 cranes but feature four new attachments.

Following the recent introduction of two battery-powered RT compact wheeled loaders, Kubota is adding an additional 10 models, powered by Kubota diesel engines.

The new telescoping luffing jib / searcher hook of the URW-546-2, offers a maximum capacity of 850kg, a jib extension range of 2.4m to 5.6m. It features a luffing range of -10° to 60° offsets and a max lifting height of the crane to 22.8m with a maximum working radius of 17m. This new jib provides extra height or reach.

The new telescoping luffing stub jib attachment can be installed with either a positive or negative offset to suit the lifting project, offering a maximum capacity of 850kg and a hydraulic extension range of 2.4m to 4.0m, a luffing range of -10° to 60° offsets and a maximum lifting height to 21.5m and a working radius of 15.3m. The new heavy duty rhino hook attachment fits directly to the main boom head, has a maximum lifting capacity of 1500kg and a offset range of 0°, 20°, 40° and 60°.

The new UNIC URW-295-2, builds upon the proven features of the URW-295 and introduces four attachments, enhancing its versatility for diverse lifting applications.

The new telescoping luffing jib / searcher hook offers a maximum capacity of 750kg, jib extension range of 1.2m to 2.8m, a luffing range of -10° to 60° offsets and a maximum lifting height of 12.5m and a working radius of 8.7m. The new jib offers extra height or reach but retains the benefits of the small chassis and outrigger options of the standard URW-295 model. The new heavy duty rhino hook attachment fits directly to the main boom head, has a maximum lifting capacity of 995kg and a offset range of 0°, 20°, 40° and 60°.

Bobcat..................................(page 36, Outside back cover)

www.rdr.link/VBM100

Develon......................................................................(page 4)

www.rdr.link/VBM101

Eminox....................................................................(page 33)

www.rdr.link/VBM102

Machine Mart............................................................page 16)

www.rdr.link/VBM103

The extended portfolio includes high-lift and heavy lift specifications, with a range of tipping loads that extends from 550kg up to 1,600kg. Lift heights extend from 2.17m up to 2.96m, while operating weights are from 1,100kg up to 2,900kg. Depending on the model, cab or canopy options are available, with ROPS and FOPS protection.

The diesel-powered RT models have power outputs from 15-36kW from their EU Stage V compliant engines. The two most powerful models feature a DPF/DOC emissions control module, along with a 6,000-hour service interval.

Compact dimensions are a feature of the RT range, with the narrowest model, the entry-level RT100-2, measuring 920mm wide. The RT105T-2 features a telescopic boom, increasing its working envelope. The widest model is the range-topping RT280-2, at 1.4m with 31x15.5-15 tyres. Overall height is up to 2.34m, reducing to below 2m when using the folding canopy.

Drive is hydrostatic throughout the range, with the smallest four models using heavy duty Poclain wheel motors. From the RT210-2 upwards, Bosch Rexroth hydrostatic transmission are used to drive mechanical axles, and this enables limited slip or 100% mechanical diff locks to be used to boost traction. Travel speed is up to 30kph, depending on model. FOR MORE INFORMATION WWW.RDR.LINK/CAV036 GOTO

Manitou......................................................................(page 9) www.rdr.link/VBM104

Moving Intelligence......................(page 2, Inside front cover) www.rdr.link/VBM105

Witham Group..........................................................(page 11) www.rdr.link/VBM106