COMMERCIAL VEHICLE WORKSHOP

STANDARD BEARERS

VBRA looks to improve bodyshop recognition

APRIL 2024 The trade magazine for servicing and repair professionals

`Also in this issue… ■ RTX update ■ BPW on EBPMS ■ Levelling up LCVs ■ Solid vs vented discs

BUSINESS

14 Buying reputable lubricant brands has never been more important. CVW investigates.

RTX is the show to go to. Make sure to put it in your diary.

Bridgestone claims to have just the tyre for hard working vans.

Reman turbos can help your bottom line says Ivor Searle.

23 Looking for LCV parts? Then ZF Aftermarket might have the solution.

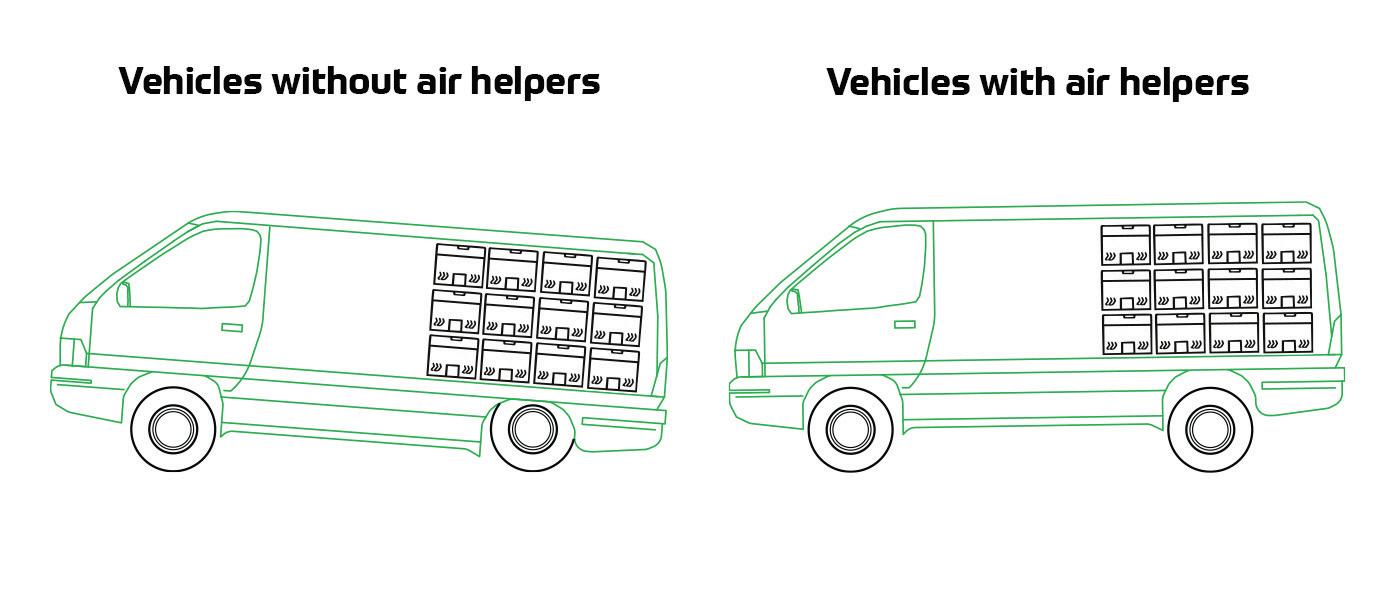

26 Get a little boost for your payload with an air spring helper kit advises Arnott.

BRAKES

28 Vented or solid discs? Fras-Le offers its opinion.

30 BPW looks at the advantages of EBPMS.

33 Fleet owner Farrall’s Group invests in Totalkare to improve operations.

35 Bowmonk-Tapley looks at brake decelerometer testing procedures.

BODY REPAIR & REFINISHING

Carrying out your own windscreen repairs is good for business, says Esprit.

Two years after launch the VBRA provides an update on its Elite Truck & Van Body Repair Standard.

CVW visits a bodyshop that is thriving thanks to its personnel.

CONTENTS Issue 4 Volume 21

Viewpoint 6 News 10 Traffic news

What’s new?

Digital digest REGULARS

5

45

50

APRIL 2024 CVW 3 18 28 37

VIEWPOINT

Editors

JOHNNY DOBBYN

JOHN LEVICK

workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Advertising Sales Manager

MATTHEW BOASE

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates:

UK £30 post paid

Airmail £80 post paid Europe £50 post paid

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by

Stephens and George

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2024

ICE , ICE BABY!

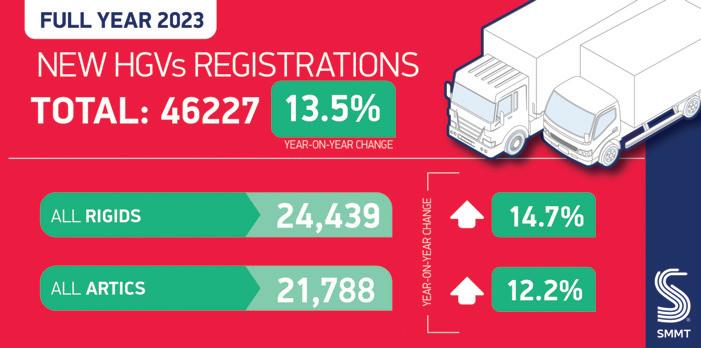

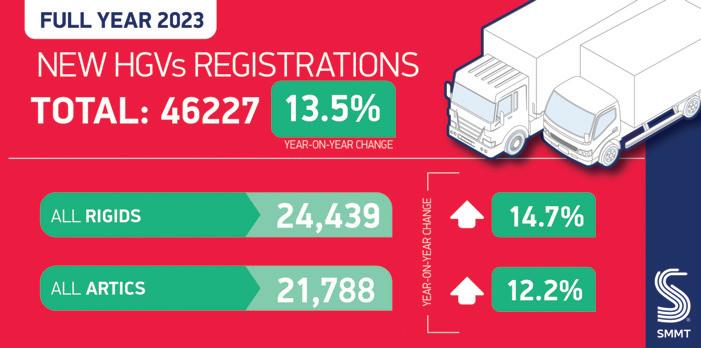

News from the SMMT that the UK truck market grew for the second consecutive year in 2023 (more of that in the news section) can only be taken as an indication that things are on the up. Demand for rigids and articulated vehicles soared, rising 14.7% and 12.2% respectively, according to the society’s figures. Apparently the 46,227 units sold is the best performance since way back in 2019 PC (pre-Covid).

Amongst all the good news was a little reminder that change is in the air. One line in the release read, “meanwhile, with less than one full cycle of truck fleet renewal remaining before 2035, it is imperative that government sends a signal to the market that the shift to zero emission vehicles must accelerate.”

When it’s written like that – ‘one full cycle of truck fleet renewal’ – it’s almost like the beginning of the end of the ICE truck market is upon us. Imagine that –a world in which our roads are eerily quiet as zero emission trucks ply their trade. And workshop technicians sit behind their PCs, making real-time adjustments to a truck’s engine, fuel consumption, suspension et al via onboard telematics. On the walls of their office hang spanners, wrenches and grease guns, a nod to the way things used to be done.

Of course, it’s not going to be like that, well at least not in our lifetime. The boom in truck sales means that there will be plenty of SMR work in the future for workshops, boosted in the longer term by fleet owners and operators keeping vehicles for longer.

Trouble is we are nowhere near the end of the beginning for EV and alternativefuelled trucks. Though there’s a growing choice of models of ‘clean’ trucks, with electric and hydrogen registrations up threefold in 2023, sales of 234 units represent just 0.5% of the market. Let’s face it, that’s not many. Yes, it’s a concern for government and legislators if 2035 is to truly be the environmental watershed so many desire, but the solution does lie in their hands. However, it does mean that there will continue to be plenty of ICE trucks on our roads and in UK workshops for the foreseeable.

The likes of the SMMT are campaigning to help adoption of zero emission vehicles but as it points out operators/owners need to be persuaded that such a move will be commercially viable in an age of tighter and tighter margins.

While the benefits are supposedly clear and obvious – reduced carbon footprint, more efficient operations –scepticism, mistrust, disbelief, call it what you will, exist in people’s minds. While a national charge point infrastructure for HGVs remains unfulfilled, there will always be reticence on behalf of those who’d love to the join the green gang, but also know that old style trucks are going to continue to deliver the revenue and profit their businesses need. Where would you put your money?

Enjoy the read!

TheCVWTeam

8,249 The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication From 1 July 2021to 30 June 2022 Associate member APRIL 2024 CVW 5

@CVWmagazine CVWmagazine

www.cvwmagazine.co.uk

LCV production off to healthy start

UK commercial vehicle (CV) production grew by 26.9% in the first month of 2024, with 11,756 vans, trucks, taxis, buses and coaches leaving factory lines, according to the latest figures from the SMMT.

The strong performance saw January output reach its highest level in 16 years, 28.0% above pre-pandemic 2019 levels, reflecting the sector’s health as it builds on 2023’s positive performance, says the society.

Output was driven by exports, with global demand for British-built CVs up 49.8% to 7,965 units. Nearly seven in 10 (67.8%) CVs were produced for international markets, with the EU remaining the UK’s biggest overseas customer – responsible for 97.4% of exports. Volumes for the UK market, however, recorded a slight decline, falling by -4.0% to 3,791 units, a reduction equal to just 156 units.

Promising outlook

Overall manufacturing growth is expected to continue throughout the year, with LCV volumes set to rise to 173,500 units and hold steady as the sector benefits from new model activity and major investments into zero emission vehicle production.

“A positive start to the year sets the stage for a promising 2024, with the sector delivering the best result in 16 years and recently announced green investment adding to the optimism. Ongoing economic and geopolitical headwinds, however, mean we must enhance the UK’s offer as a competitive manufacturing destination,” said Mike Hawes, SMMT chief executive.

HGV sales hit new benchmark

Demand for new heavy goods vehicles (HGVs) grew for the second year running with UK registrations up 13.5% in 2023, according to the SMMT. Some 46,227 new trucks of all types, sizes and technologies were put on the road last year, representing the biggest annual total since 2019.

The bulk of new HGVs were rigid trucks, up 14.7% to 24,439 units – more than half (52.9%) of the market – while demand for articulated trucks was also strong, rising 12.2% to 21,788 units. More specifically, the most popular truck body type continues to be tractors, typically used for the largest delivery trucks, up 12.4% to represent some 46.4% of the market. Demand for box vans – typically used for chilled and fragile goods distribution in urban areas – rose 19.2%, while uptake of curtain-sided trucks and refuse vehicles increased by 37.4% and 14.4% respectively. Tipper registrations declined, however, down -9.2% compared with a strong 2022.

LCV values on the up

LCV values bounced back in January, reaching their highest point since September of last year and reversing a run of three consecutive monthly falls, according to resellers BCA.

Values improved by £727 over the month to reach £8,764, equivalent to a 9.0% rise. Whilst buyer participation at BCA steadily lifted during January, a much-improved mix of vehicles entering the market helped to support the value lift reported, said the company.

A big deal for RVT

RVT Commercial Vehicles (RVT CV) has been awarded Isuzu Dealer of the Year for 2024, recognizing its strong performance and commitment to the Isuzu brand.

Truck operators in every UK nation made more vehicle investments, with the vast majority (87.5%) in England, rising by 13.3%. Fleet renewal in Scotland and Wales also grew, by 16.9% and 6.5% respectively, while Northern Ireland saw the biggest percentage growth, up 19.7% – albeit with small volumes that are naturally subject to volatility.

Britain’s biggest region for truck demand continues to be South East England, the location of several large ports, accounting for more than one in five (20.8%) of all registrations. North West England and the West Midlands, meanwhile, made up 14.4% and 12.1% of all UK demand respectively.

Anecdotal reports suggested that momentum steadily grew throughout the month, with retail demand rising as January progressed and the improving economic backdrop undoubtedly helping to generate more confidence in the used LCV sector.

Stuart Pearson, BCA COO UK commented: “There has been a steady lift in confidence in the used LCV sector since the turn of the year, although it still feels like there is room for this to improve further. As we said last month, the LCV wholesale market is likely to see a return to more seasonal trends in the coming weeks.”

Based in Shrewsbury, RVT CV has also secured titles for Contract Hire Dealer of the Year, Accessories Dealer of the Year, and Regional Dealer of the Year, underlining its leadership in the Isuzu UK dealership network. With a record number of sales across the UK in 2023, RVT CV has played a significant role in achieving this milestone for Isuzu, particularly with the D-Max model. Its focus on high standards in operations and customer service has distinguished the company within the network. Scott Thomas, managing director at RVT CV, expressed gratitude for the award, crediting his team's hard work.

6 CVW APRIL 2024 NEWS

Video library rolls out new episodes

Four guides are joining the Continental tyre advice video library, which is intended to improve the knowledge and skills of operators and technicians in industry.

These additions build on the success of Continental's five existing videos, covering crucial topics like tyre fitting, tyre wear, and the construction of commercial vehicle tyres.

Developed in collaboration with the ContiAcademy training centre, the guides advise fleets of all sizes on key issues to maximize vehicle safety and performance. They also serve as a reminder of the essential aspects of tyre service and maintenance.

Student salvation

Workshops throughout the UK can now make use of an under-used, well-educated pool of labour through ‘Student2Skill’, a program that matches international students in the UK with part-time jobs in garages.

Developed by the Easy2Recruit employment agency, it offers students a chance to gain important hands-on experience and possibly even earn vocational qualifications, while businesses get to fill their skill gaps with eager staff. Company founder, Ambi Singh, came up with the idea when he had difficulty in hiring and retaining skilled staff for his own garage business.

Harris DAF plots growth

Home counties DAF dealer group, Harris DAF, has opened the doors to a new, purpose-built five-bay workshop and ATF service at its principal site in Grays, Essex.

The investment will generate employment opportunities for 15 technicians over the next 12 months, including an intake of five DAF apprentices.

The 900m2 workshop is situated on a two-acre plot adjacent to the existing premises. With five full-length bays, planning exists to extend the workshop footprint to accommodate 10 bays. Harris DAF Grays will operate 24/7 during the week, with daytime opening at weekends.

“We’re excited with the potential that our new workshop provides for operators,” said managing director, Gary Carpenter.

The videos address several important areas: roadside tyre fitting; workshop tyre fitting; truck tyre wear; and tyre ingredients.

For more information on ContiAcademy’s training courses or to view the complete set of tyre advice videos, visit Continental's website or contact them directly.

Bottleneckthreatens DVS compliance

CCTV and telematics specialist

Centrad is raising the alarm for UK fleet operators about upcoming TfL Direct Vision Standard (DVS) regulations.

It warns of potential supply bottlenecks for the necessary Progressive Safe Systems and urges operators to act swiftly to avoid lastminute rushes. With an estimated 170,000 to 180,000 vehicles needing upgrades to meet the new standards by October 28, 2024, the demand for both the hardware and installation services is expected to outpace supply.

“We’re aiming to pair mature international students with UK garages for part-time work within the UK automotive sector, focusing on roles like tyre fitting,” he said. “Many will already have work experience and advanced academic qualifications but are eager to learn trades too and can offer a wealth of skills and capability to the UK workforce.”

With the number of international students in the UK on the rise, from 442,000 in the 2014/15 academic year to 680,000 in 2022/23, this initiative taps into a growing talent pool, according to Singh.

”Demand from customers for a high level of service is only increasing and we expect to be very busy going forward. The new workshop means job opportunities for DAF apprentices and for technicians more widely. With electric vehicles beginning to enter the market in growing numbers, now is an exciting time to embark on a workshop career and here at Grays we utilise state-of-the-art equipment and deliver first-class training to provide a wide-ranging skillset.”

“With the deadline looming and installation slots filling up, it's crucial for operators to partner with reputable suppliers early on. This proactive approach can streamline the transition, minimize costs, and ensure that fleets meet the new requirements without facing penalties,” advises managing director Geoff Cross.

100 up for VLS

Verification of Lubricant Specifications

(VLS), the independent body dedicated to ensuring lubricant standards, is celebrating the start of its 100th case, marking a significant milestone.

The case, numbered VLS010201, is investigating claims about a 10W-40 HDDO lubricant purported to meet specific OEM specifications that were initially only endorsed for first-time use by the OEM.

VLS says that this investigation highlights its commitment to maintaining quality and trust within the lubricant industry, especially notable during its tenth anniversary year –a year that saw the highest number of cases since 2015.

VLS has examined a broad spectrum of lubricant products, ranging from engine oils for passenger cars and commercial vehicles to specialized fluids like hydraulic oils and gear oils, even including a synthetic cutting fluid for aluminium.

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk APRIL 2024 CVW 7

NEWS

Johnsons keeps a clean sheet

Axle weighing specialist Axtec is helping Southallbased Johnsons Hotel, Restaurant & Catering Linen, stick to the letter of the law with a delivery of 45 Axtec OnBoard load indicators.

The weight of laundry is unpredictable, as the linen may be wet, and may vary considerably day-to-day, increasing the risk of axle over-loading. To eliminate this risk whilst maximising productivity, the new load indicators accurately monitor vehicle loading and unloading, and ensure Johnsons’ vehicle fleet, a mix of 3.5-tonne panel vans from MAN, Mercedes and Renault, plus DAF 7.5 tonners, runs legally and, above all, safely.

DVSA gives thumbs uptoV8

The DVSA has approved MAHA UK’s Eurosystem V8 software, so it is now in line with the latest Authorised Testing Facility (ATF) requirements.

The approval ensures MAHA’s testing lanes, equipped with tools like the MBT 7250 brake tester and MLT 3000 headlight alignment tester, comply with current standards and are prepared for modern testing protocols.

“The DVSA approval of our Eurosystem V8 software reaffirms our commitment to compliance and modernity in testing equipment,” commented managing director Neil Ebbs.

The software update streamlines the testing process, enabling inspectors to personalise tests with their names, provide

detailed printouts categorising deficiencies, advisories, and notes, and implement significant procedural changes, such as hydraulic fall-off calculation for rear axles and automatic PDF export for efficient documentation.

Brakes off quarterly reporting

Webfleet’s brake performance report, designed to remotely monitor trailer brake behaviour, is now recognised by the DVSA as meeting its requirements for electronic brake performance monitoring systems (EBPMS).

Gathering data continuously from the trailer's electronic braking system (EBS) not only improves road safety but also reduces fleet downtime costs by lessening the need for the standard quarterly brake tests. It simplifies the process of identifying trailers with EBS issues through a report that visually presents performance values and trends over time.

Beverley Wise, Webfleet regional director for Bridgestone Mobility Solutions, said: “This achievement showcases our dedication to leading the industry in safety and efficiency for UK fleets.”

Following the DVSA’s recent emphasis on the importance of brake testing in its Guide to Maintaining Roadworthiness, from April 2025, brake tests will need to be conducted using laden roller tests or EBPMS, with limited exceptions. Wise also noted: “We’re ahead in preparing for these upcoming regulations, providing fleet operators with the tools they need to comply.”

Campaign for speedier sales

Developed to accelerate the sales of surplus vehicles, Campaign Manager is a marketing tool from epyx that enables fleets to target individual vans and trucks with ‘special offers’ as they are being sold off.

This tool is integrated into the 1 link disposal network platform, a service used by fleets since 2005 to sell over 500,000 vehicles, and enables vendor to offer various incentives such as lowinterest stocking loans and free delivery on remarketed vehicles.

“Campaign Manager equips remarketing managers with a suite of special offers, similar to those in retail, to encourage buyers to make a purchase,” Tim Meadows, epyx’s chief commercial officer, said.

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk

TRAFFICNEWS Lifestyle drives

Ford Pro has launched a new series of range-topping commercial vehicles under the MS-RT brand with the reveal of all-new Transit Custom MS-RT and Ranger MS-RT.

The two exclusive new models have been designed andengineered in a close collaboration between Ford’s global team and the specialists at MS-RT – an offshoot of Ford’s rally partner M-Sport –to deliver a combination of dramatic motorsport-inspired looks, enhanced driving experience and outstanding load carrying capability.

“We’re delighted to add MSRT models to our Ford Pro portfolio, offering an exciting, halo option for customers who need a commercial vehicle but also want to make a statement about their business,” said Hans Schep, general manager, Ford Pro Europe. “More customers are wanting a work vehicle for the week but something that supports their lifestyle at the weekend. These new MS-RT vehicles are the perfect answer.”

Derived from the latestgeneration Transit Custom and Ranger platforms, the two MS-RT models combine bold visual appeal with engineering upgrades. The E-Transit Custom MS-RT derivative is available with a 210kW (285PS) electric powertrain making it the highest power output production Transit Custom ever. Alongside the “ultimate van”, the 3.0-litre V6 diesel-powered Ranger MS-RT uses a unique suspension and wheel set-up to enhance its onroad capability and make it the “ultimate street truck”.

Want to know more about these models?

WWW.RDR.LINK/VBI001

10 CVW APRIL 2024

FMs reel in new business

VOLVO

DS Smith Logistics has taken delivery of 61 new Volvo FM 460 Globetrotter 6×2 tractor units as part of a major fleet renewal programme.

Volvo Trucks secured the order from the paper, packaging and recycling business on the back of the strong performance of a demonstrator that highlighted the reliability, fuel economy and payload potential of the FM.

The new FMs, paired with curtainsider trailers, will be used to take paper reels from DS Smith’s Kemsley Paper Mill to customers across the UK. The trucks then bring bailed fibre into the mill, which is recycled back into paper reels. It’s a 24/7 operation which will see the FMs double-shifted and clock-up in the region of 130,000 miles annually.

Each tractor unit is powered by a D13k Step E engine, producing 460hp and a maximum torque figure of 2,300Nm. These are paired with Volvo’s 12-speed I-Shift automated gearbox technology and I-See predictive cruise control, which ensures further sustainability and operational efficiency gains through perfectly timed gearshifts and active speed management. To maximise that fuel economy potential all the

new trucks are fitted with A-rated Michelin X Line Energy tyres. To boost safety, the trucks are supplied with multiple cameras which can be viewed through the driver’s nine-inch side display, plus an added lower window in the passenger door to help meet the 3-star Direct Vision Standard (DVS) rating for working in central London.

For more info on Volvo, WWW.RDR.LINK/VBI002

Charge ofthe e-brigade

MERCEDES-BENZ

Mercedes-Benz is promising more range, more technology and safety with the launch of a new electric Sprinter.

A complete portfolio with several upgrades to standard specification will be on offer, including van and chassis body styles in N1 or N2 vehicle class. There will be two lengths on offer, L2 (long) or L3 (extra-long),

two trim levels, pro and select, a choice of 81 or 113 kWh battery capacities and a towing capacity of up to 1.5 tonnes. For the first time, there is also a choice of two motors, with either 100 or 150kW peak output.

Equipped with the largest battery, (113 kWh 414 Van L3 PRO model), the electric range for the eSprinter, based on the WLTP combined cycle, is up to 271 miles (436 km) – more than

FCEV shows its utility

FIRST HYDROGEN

Initial findings from First Hydrogen's month-long vehicle trials with gas distribution network, Wales & West Utilities (WWU) show remarkable performance from the hydrogen-powered-fuel-cell vehicle (FCEV), claims the company.

Data collected halfway through the trials shows the advantages of the van's fuel cell powertrain in real world operation, with no decrease in performance or range when operating in colder temperatures.

double the previous model.

Three driving programmesmaximum range, economic and comfort - control engine power, torque and climate control, while regenerative braking also helps to maximise range.

Like all electric vans from Mercedes-Benz, the new eSprinter is capable of both AC and DC charging. The on-board charger can be charged with direct current at up to 115 kW (standard for the UK) at a fastcharging station, meaning the battery with a usable capacity of 113 kWh can be charged from 10-80% in around 42 minutes at a maximum of 115 kW.

For more information on Mercedes-Benz WWW.RDR.LINK/VBI003

Information from onboard telematics, over a combined distance of 1,029 km, reveals the vehicle has been operating for between six and seven hours per day in temperatures of between 2°C and 17°C, without impacting range.

First Hydrogen has also demonstrated how its fuel cell's powertrain delivers power, when needed, achieving outputs of 60kW in transient accelerations and in previous trials the vehicle has achieved a peak range of 630km (400 miles). This indicates the vehicle can manage more demanding duties for WWU, such as carrying heavier payloads, driving over hilly terrain or powering auxiliary equipment.

For more info on First Hydrogen, WWW.RDR.LINK/VBI004

APRIL 2024 CVW 11

TRAFFICNEWS

DNP looks to the Isuzu D-Max to fulfill a wide range of jobs on challenging terrain.

PROGREEN

Recipe for success Park life

Prohire’s sustainable vehicle hire and alternative fuels division, ProGreen, has delivered Bettys & Taylors of Harrogate’s first refrigerated electric vehicles.

Commissioned by the owners to support the transition from diesel to electric vehicles, as part of a decarbonisation strategy, ProGreen delivered two bespoke, all-electric temperature-controlled vans, purposely designed for Bettys craft bakery.

Whereas previously each individual tray needed to be

Dartmoor National Park (DNP) is acquiring three new Isuzu D-Max pick-ups to add to its growing Isuzu fleet. Having amassed a now six-strong fleet, all finished in mercury silver colour, DNP has elected to accessorise its D-Max vehicles with canopies, towbars, roof bars, work lights, and heavy-duty seat covers to prepare the vehicles for their pivotal role in maintaining the park's outdoor spaces.

The Isuzu D-Max was originally selected by DNP based on a variety of practical

removed one at a time by the bakers, the new vans feature a tail lift to safely and efficiently lower the trolleys containing all

of the trays of delicious cakes, pastries and treats, in one go.

Paul Farr, Bettys product director, said: “From the outset,

and financial factors, demonstrating a highly respectable 3.5-tonne towing capacity and a payload of over a tonne. The impressive build quality and reliability make the D-Max a rugged contender, whilst the frugal running costs and comprehensive warranty make it a suitable choice for DNP as a cornerstone of its ranger operations.

Want to know more about the Isuzu D-Max?

WWW.RDR.LINK/VBI005

Prohire took time to understand our specific needs, particularly the importance of maintaining our product quality during transit, and we are pleased to now see these bespoke vehicles out and about in Yorkshire. Our family business has a long commitment to protecting our planet, and these new vehicles are a positive next step in our approach to reducing our impact on the environment.”

For more information on Prohire, WWW.RDR.LINK/VBI006

12 CVW APRIL 2024

BUYER BEWARE

While the complexity of the UK lubricant market grows, so do the activities of less scrupulous blenders and resellers. CVW investigates.

Manufacturers of engine oils and other lubricants work closely with trusted technology providers, formulating the very highest quality and robust formulations to meet the growing needs of ever-changing vehicle and machinery. There are continual updates to oil specifications from the OEMs and government agencies. As more specific engine, gear, hydraulic and transmission designs evolve, so too must the lubricants used within them. According to Nigel Bottom from Witham Group, an independent lubricant manufacturer: “We are seeing a continued lean towards lighter viscosity grades and brand and engine specific specifications rather than generic qualities. As the pool of different applications continues to grow, the service dealerships and end users will have to

“...as one cleans up their act, others step in their place...”

carry more and more grades in stock, to cover off the increasing range of specifications they have to choose from to ensure the correct lubricants are used for the correct applications.

Illegal practices

“As qualities rise, so ultimately do the prices, and with pressure of costs increasing, the return on investment is harder to chase. In the lubricant market, we are unfortunately seeing less scrupulous lubricant resellers and blenders suspectedly using and sourcing illegal sanctioned products, sourced ultimately from Russia, at heavily discounted prices. In some cases, they are being offered at lower prices than our cost raw material and the illegal practice of ‘product dumping’ is taking place. We are advising our customers to not get caught out by this practice and to support the global sanctions in place for good reasons.

“The great work of the United Kingdom Lubricants Association (UKLA) and the VLS (Verification of Lubricant Specifications) continues, with more than 20 different oil companies and grades being reported as being non-compliant in one way or another. The pleasing result being, after a six-month review, the offending companies have changed their operation and stopped claiming their products reach certain standards and specifications. Sadly of course, as one cleans up their act, others step in their place! Witham Group is committed to offering only the approved correct lubricants at all times, and through our team ensure our customers receive only what they require.”

BUSINESS APRIL 2024 CVW 15

FOR MORE INFORMATION WWW.RDR.LINK/VBI007

RTX GETS MOTORING

What did you think in 2023?

“It’s been really good this year – it is well laid out and it’s easy to find things. In particular, I like the Ride & Drive as this enables me to trial different vehicles and see what performance you get out of each model that’s here. It’s been well represented, and I’ve really enjoyed it.”

Mark Brook, Southern

“Road Transport Expo has very much become THE SHOW for the road transport industry and Volvo Trucks is very much looking forward to exhibiting in 2024.”

Martin Tomlinson, head of media and truck demonstrations, Volvo Trucks UK & Ireland

“Considering this is the second time this event’s been held, it has been absolutely incredible. The number of visitors we’ve had on our stand has been truly staggering. We anticipated after last year that the event would be good, but it completely surpassed our expectations.”

Pete Murphy, MD, Isuzu Truck UK

If last year’s RTX was a roaring success, then this year’s event promises to be even better, offering a one-stop shop for the road transport sector.

Visitors heading to the Road Transport Expo (RTX) this summer had best be wearing their comfy shoes, with more than 200 exhibitors already confirmed for the bumper tradeshow and the list growing daily.

Taking place from 4-6 June at NAEC Stoneleigh, Warwickshire, RTX is back for its third year with its ‘All about the truck’ focus. The show is already confirmed to feature all eight major truck OEMs – DAF, Iveco, Isuzu, MAN, Mercedes-Benz, Renault Trucks, Scania and Volvo –alongside new entrants to the UK HGV market, Sany E-Trucks and HVS, as well as van manufacturers Maxus and Ford.

All under one roof

You’ll also be able to find everything else you need for your business, from the smallest consumables through to tyres, specialist bodies, workshop equipment, tankers and trailers, all in one vast venue.

To make the most of your day at RTX, why not take a browse on roadtransportexpo.co.uk to help you decide which stands to put on your ‘must visit’ list? You can filter using a simple A-Z search of company names, or by the product type that you are interested in.

There will also be a range of exhibitors showcasing their expertise in non-product-

BUSINESS 16 CVW APRIL 2024

related areas such as training, compliance, finance/leasing, recruitment, insurance and law.Visitors in 2023 were delighted with the varied choice of exhibitors taking part in RTX, with 98% rating the quality and quantity of stands to explore as ‘excellent/good’ and a whopping 96%

saying they would most likely visit the show again this year.

If you have attended before, then we would love to see you back at NAEC Stoneleigh this June, and if you are new to RTX, then please do come and along and join the buzz. It’s completely free to attend.

OR WWW.RDR.LINK/VBI008

What else can I do at RTX?

Ride & Drive

If you hold a valid HGV licence and fancy getting behind the wheel of one of the latest diesel or alternativelyfuelled trucks, then RTX is the show for you. We will, once again, be creating a dedicated route for visitors to try out vehicles on the day of their visit. If you prefer not to drive yourself that’s no problem, as there will be a team of professional drivers on hand to take visitors out for a spin to feel the driving experience from the comfort of the passenger seat.

Knowledge Zone

A free-to-attend seminar programme will be available for visitors to drop into during the show. You’ll be able to choose from a number of topical presentations, debates and interviews with industry experts, policy makers and leading fleet operators. Sessions will be taking place in one of the exhibition halls at the venue and you can join in the discussion on your mobile phone using Slido technology.

REGISTER FOR YOUR FREE PLACE AT THIS YEAR’S EVENT AT ROADTRANSPORTEXPO.CO.UK

A TYRE FOR ALL REASONS

As van fleets explore more ways to balance the books against a challenging economic backdrop, Bridgestone has revealed a way to help save thousands of pounds per year. CVW reports.

The Bridgestone Duravis Van tyre is claimed to be one of the company’s most advanced products across its entire consumer and commercial ranges, offering huge savings whilst simultaneously minimising downtime and contributing to a lower cost of ownership.

Tests carried out by independent body, the TÜV SÜD, revealed that the Bridgestone Duravis Van tyre offers best-inclass mileage for extended tyre life as well as best-in-class dry and wet braking performances. It also achieves the highest EU label rating for wet grip, helping to keep drivers safe on the road, even in challenging wet-weather conditions.

According to Bridgestone’s consumer sales director Brett Emerson “the Duravis Van tyre provides many tangible benefits to van fleets and van drivers, including cost, convenience, and incredible longevity. The tyre is the result of many pioneering technologies including

the innovative and sustainable ENLITEN technology. This set of technologies provide best-in-class tyre performance, while delivering sustainability benefits thanks to the tyre’s best-in-class mileage and increased fuel/energy efficiency.”

Independent study

The tyre is perfectly suited to both ICE and EVs, helping to optimise performance. Specifically for EV drivers, the tyre’s higher wear tolerance counters the increased weight and higher torque of EVs, while its low rolling resistance saves battery life.

Not content with fleets having to take Bridgestone’s word, last year, the company commissioned an independent study with Warwick Business School, where the benefits of operating on Duravis Van were underlined, both economically and sustainably, with lower CO2 emissions also proven to be generated as a result.

LCVS

18 CVW APRIL 2024

The rubber, which boasts an EU label grade B for rolling resistance, was benchmarked against grade D alternatives, with all comparison data sourced from UK Government figures. The study factored in fuel prices and forecasted future fuel price rises, with DfT and DVLA data referenced to calculate the number of vans currently on UK roads. It concluded that 95.85 litres of petrol could be saved per year when operating on a Duravis Van tyre compared to a D rated alternative, equating to savings of 80.79 litres in diesel and 373.12 kWh per year for EV vans.

Savings galore

The research showed that because the tyre also offers greater longevity than grade D alternatives, costs are also reduced through fewer annual replacements. For van fleets of five vehicles, overall savings amounted to around £895 per year and for a fleet of 100 vehicles, the figure extrapolates to £17,900.

The tyre also comes equipped with a revolutionary Sidewall Protector Rib, which ensures that the product can withstand curbside damage, which represents an occupational hazard for van drivers.

It complements the Duravis All Season tyre, Bridgestone’s first-ever all-season tyre for the light truck segment. Engineered to last with a robust and durable construction, the tyre delivers an excellent wear performance and reduced downtime periods. Plus, with a best-in-class EU label A grade for wet grip and 3PMSF certification, the Bridgestone

DURAVIS All Season provides safety, peace of mind and convenience in all weather conditions year-round.

Certified by the 3 Peak Mountain Snow Flake (3PMSF) and Mud + Snow (M + S) markings, Bridgestone’s DURAVIS All Season is fully winter-ready. The tyre achieves this thanks to a combination of compound design, a V-shaped layout to improve snow mobility and an optimised carcass construction. The DURAVIS All Season’s notable performance in the wet and snow is also down to Bridgestone’s new nano-selective compound mixing technology which allows better silica dispersion in Bridgestone’s Nano Pro-tech compound. FOR

PROVISION

AND

WWW.RDR.LINK/VBI009

MORE INFORMATION ABOUT BRIDGESTONE’S

OF VAN PRODUCTS

MOBILITY SOLUTIONS,

David Eszenyi, commercial director of remanufacturer Ivor Searle, examines the common causes of turbocharger failure and offers a solution.

WHYDO VANTURBOS FAIL?

With around 4.9 million primarily diesel vans in the UK’s motorparc and an average vehicle age of nine years, according to SMMT data, it’s clear that demand for replacement turbos continues to present a strong business opportunity for workshops.

Although designed to last the lifetime of the vehicle, turbochargers are engineered to high tolerances, so a number of external factors can cause damage, leading to premature failure. Symptoms include a loud whining noise, power loss and slow acceleration, as well as difficulty maintaining high speeds, a smoking exhaust and illumination of the ‘check engine’ warning light in the instrument cluster. Based on our remanufacturing experience, we’ve identified some of common causes of turbo failure:

Oil and exhaust system contamination

Effective engine lubrication is critical for turbo operation, so a lack of oil, or use of the incorrect specification, can produce contaminants in the engine, that can contribute to turbo failure. Oil contamination, as well as carbon deposits from incomplete combustion, build up in the turbo over time, resulting in faults such as the vanes sticking in variable geometry turbos causing power loss.

Contamination can also be sent ‘upstream’ into the turbo due to problems in the exhaust system, such as a blocked or restricted DPF. Turbos are designed to handle high exhaust gas temperatures of around 800°C, so excess exhaust gas temperature beyond this point can also harm turbos, causing the turbine shaft to melt and, in some instances, detachment of the turbine wheels away from the shaft.

With this in mind, we always recommend that workshops replacing a customer’s turbo always check the van’s DPF at the same time and, if needed, get it professionally cleaned.

Foreign objects

Foreign object debris, or FOD, can destroy a turbo in seconds. Occasionally, foreign objects, such as fragments of metal from broken engine components, dust particles, small stones and other debris can be ingested into the compressor or turbine inlet, resulting in it colliding with the compressor wheel that runs at over 100,000 rpm. Even the smallest particle hitting the compressor wheel can unbalance the turbo, causing catastrophic failure.

LCVS

20 CVW APRIL 2024

Over speeding

Based on the principle of forced induction, turbos are designed to increase the air supply that feeds the engine. Over speeding occurs when the turbo rotates at a greater speed than its operational limits and beyond its safe parameters, eventually causing it to fail by damaging the turbine or compressor wheels and bearings. Leaks, cracks or damaged seals between the compressor and the engine can harm the turbo, making it operate beyond intended limits. Further causes of turbo failure include moisture ingress and wear and tear on high mileage vans and vehicles that have been subjected to harsh duty cycles.

Cost control

In many cases a replacement with a remanufactured turbo is the answer. For instance, at Ivor Searle, demand for our all makes programme of remanufactured LCV turbos continues to grow, not least because

it is far more cost effective to buy a reman turbo than sourcing a brand-new OE unit. The saving can be as much as 40%. The turbo remanufacturing process involves a complete strip down of the unit and thorough cleansing using pyrolytic technology, after which all internal components are replaced. All external housings are meticulously examined and checked against OE specification and any non-conforming components are also replaced.

All our turbochargers undergo stringent quality checks and test procedures throughout the remanufacturing process to ensure maximum durability and service life. Prior to final assembly, the turbocharger’s rotating assembly is balanced on state-of-the-art VSR equipment to OE specification and oil flow rates are checked at the same time. Every turbo receives a detailed final inspection and is flow tested to ensure optimum performance.

TO FIND OUT MORE ABOUT IVOR SEARLE’S REMANUFACTURED LCV TURBOS, WWW.RDR.LINK/VBI010

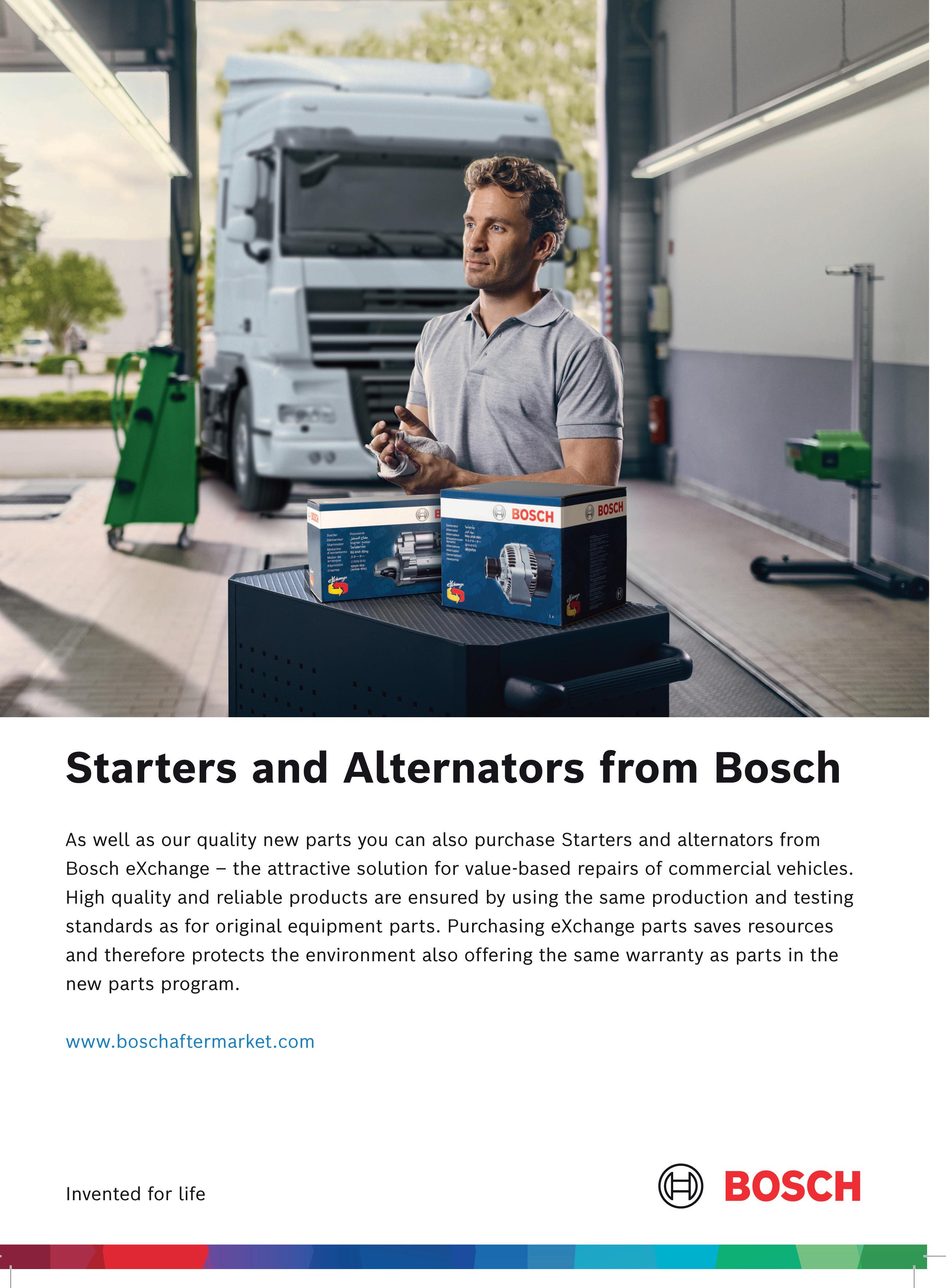

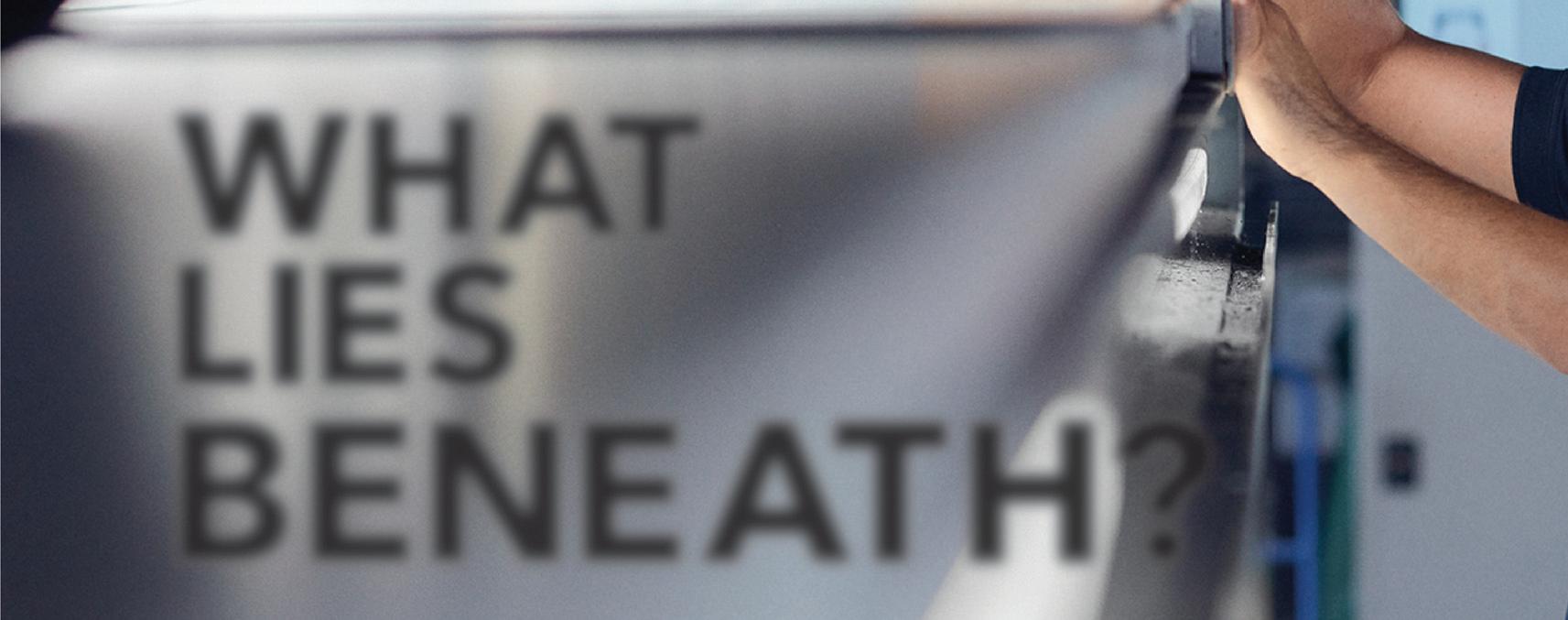

WHAT LIES BENEATH?

LCVs are the bread and butter for many workshops. Worked hard and often neglected it’s no wonder parts and components suffer. ZF Aftermarket offers some advice on what to look for.

High mileage, heavy loads, constant use – the light commercial vehicle is a workhorse. With this class of vehicle subjected to considerable pressure and stress, together with the average age of LCVs in the EU being 11.9 years, this segment of the vehicle parc offers significant service and repair opportunities for workshops.

According to the European Automobile Manufacturers’ Association (ACEA), 34.8 million LCVs (up to 3.5 tons gross vehicle weight) are in circulation throughout the European Union and the UK. Counting more than 6.3 million vehicles, France has by far the largest van fleet, followed by the UK (5.3 million), Italy (4.3 million) and Spain (3.9 million vans).

Visual inspection

These vehicles are often used daily to carry high payloads meaning they are also subject to high wear. Failure rates for LCV vehicle safety inspections are higher in all age categories than for passenger cars, reflecting this increased wear. For example, the failure rate for LCVs over ten years old is 30%.

Many businesses use their vehicles' full permissible payload in daily usage. While the chassis itself may be designed for this kind of usage, compression ball and tie rod

joints, stabilizer links and other steering and chassis parts suffer considerably under permanent load. At ZF Aftermarket we recommend workshops visually inspect the chassis, test it for height clearance each time an LCV comes in for repair, replacing damaged and worn components as applicable. This is the only way of guaranteeing safe vehicle handling and ensuring the vehicle passes the next vehicle safety inspection as test centres have

hydraulic joint play detectors that ruthlessly pinpoint faults within the chassis system.

Let’s take the Volkswagen T5 LCV model range as an example. It is one of the most popular vehicles in the segment under 3.5 tons. Under our Lemförder brand, we supply a comprehensive range of chassis parts, including control arms, stabilizer links and rubber-bonded metal mounts.

Wear damage on the suspension-strut mount often occurs on this vehicle due to

LCVS APRIL 2024 CVW 23

the undersized ball bearing in the initial design. Volkswagen subsequently replaced the component with a version with a larger bearing, although both versions can still be found in the market. ZF Aftermarket offers both variants but we advise customers to upgrade to the new version where the initial version is still fitted. When removing the affected parts, the technician must always note which of the two variants is fitted to the vehicle. A damaged spring plate on the earlier bearing variant means having to replace the entire assembly as new spring plates are no longer available. The workshop should therefore install a new suspension-strut mount, the spring plate and the ball bearing. We also recommend always replacing these parts per axle to ensure consistent vehicle handling on both sides.

Follow procedure

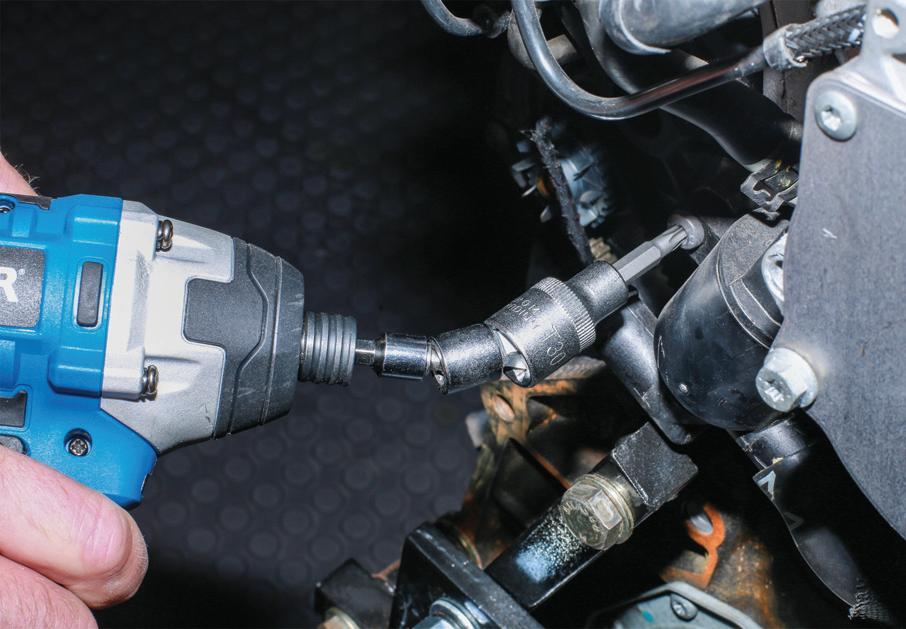

Certain points need to be considered when replacing the T5 control arm. After removing the old part, the technician should clean the supporting surface of the ball stud on the steering knuckle using sandpaper, followed by a suitable cleaning agent. Otherwise, rust and dirt particles may penetrate the joint of the new control arm via the ball stud, resulting in rapid wear.

The mechanic must not tighten the mounting bolts and nuts with the suspension still in the fully unloaded state, otherwise the rubber bearings would be deformed when lowering the vehicle onto

the wheels. This preloading of the bearings may lead to premature wear. The next work step is to lower the vehicle until the chassis is fully compressed. There may, however, be instructions governing the position in which the bolts and nuts are tightened depending on the vehicle model – so follow VM’s installation procedure. All chassis data specified by the vehicle manufacturer relates to the design position. A four-post lift can be useful here. It allows the nuts and bolts to be tightened to the specified torque. Finally, the workshop must check and set the wheel alignment according to the manufacturer's specifications.

LCVS

24 CVW APRIL 2024 FOR MORE INFORMATION ON ZF AFTERMARKET, WWW.RDR.LINK/VBI011

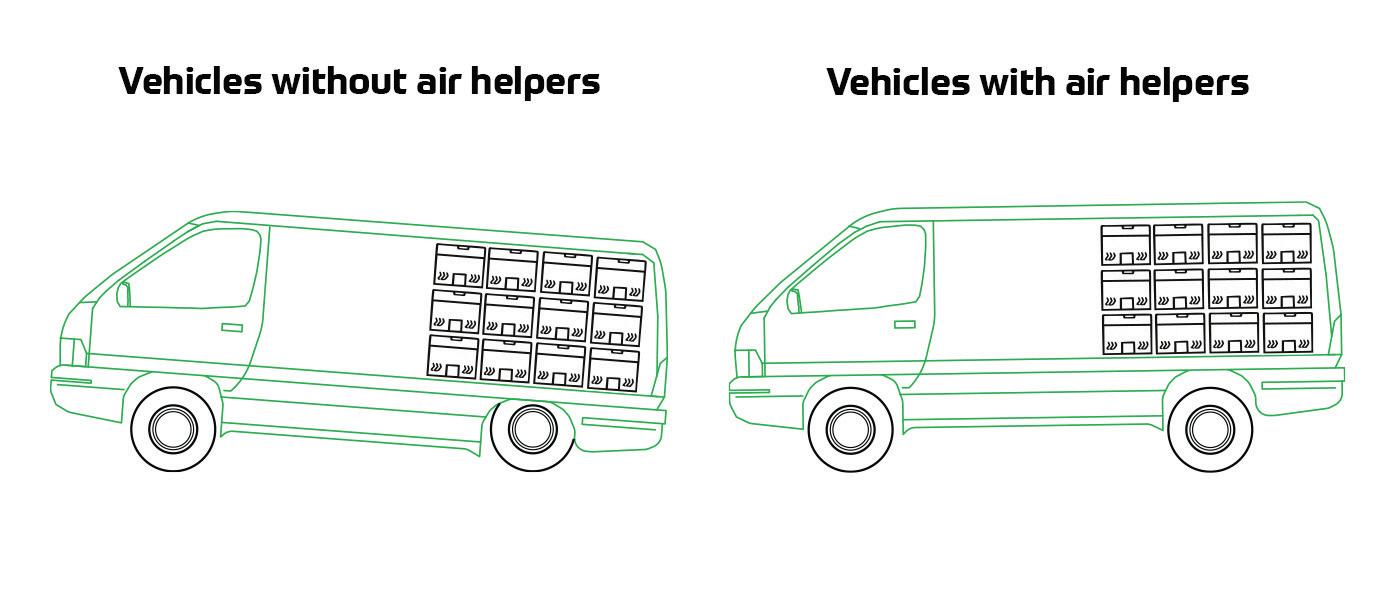

AIR FIX KIT

Arnott explains the compromise LCV vehicle manufacturers need to make concerning suspension and why an air spring helper kit can provide the perfect solution.

Light commercial vehicles are designed for a wide variety of uses but are mainly used for transporting people, cargo, or a combination of both. This means that LCV manufacturers need to offer multiple configuration options so all customers can tailor the vehicle to their specific needs giving rise to different configurations including people carriers, vans, chassis cabs. Additionally, the different chassis options are selectable with different interior configurations, in multiple lengths, heights and maximum permissible weights.

The LCV suspension system needs to provide a safe, durable, and heavy-duty construction to cope with the occupants and/or goods that are transported, all while providing the highest possible level of ride comfort. The challenge here lies in the extensive configuration choices, meaning that the vehicle's suspension needs to be constructed to manage a wide range of load conditions.

Almost all manufacturers use either a conventional coil set-up or a leaf spring configuration in their suspension systems. The advantage of using coil springs is that it provides more overall comfort, whereas a leaf sprung suspension, due to its progressive nature, can handle heavier loads.

Compromise

The compromise LCV manufacturers need to make is inevitable because the suspension solution needs to be suitable for both an empty as well as a fully loaded vehicle. Therefore, suspension solutions are developed for average loads, providing the maximum possible comfort when empty

and at the same time providing necessary safety and stability for a fully loaded vehicle. Consequently, the suspension can be too strong, making the ride harsh and uncomfortable for an unloaded vehicle.

On the other hand, the suspension is too weak for permanently loaded vehicles, overstressing the suspension in the long-term, causing premature wear of the suspension and an uncomfortable driving experience.

Driving on the limit

Given that a chassis and suspension are designed for an average load, the higher the load capacity the bigger the “challenge” for the original suspension’s ride and handling capabilities. Even if a buyer knows he will often or always exceed this average load, they still need to rely on the “standard range of suspension” offered by the vehicle manufacturer and select the correct base vehicle as a start.

The solution

What the vehicle needs if the average load is (almost) always exceeded is an increase in load meaning additional permissible total weight to generate more payload. A reinforced conventional spring could be a cost-efficient solution, but it remains a compromise since it has a fixed value of strength. Consequently, this set-up will hardly ever be ideal, making the suspension still too or not harsh enough depending on load conditions.

Air helpers offer an adjustable solution to manage cases of more permissible gross weight or an increase in the maximum permissible axle load. First, the spring reinforcement optimizes the suspension, increasing the safety and usability of the vehicle. Air helper springs are the most convenient and flexible solution because no matter if the vehicle is empty, permanently

LCVS

26 CVW APRIL 2024

“...air helper springs eliminate premature wear and tear and improve drivability...”

partly loaded or always fully loaded, it always has the capacity of providing the best possible drive comfort and maximum safety and stability! Second, since the suspension is not overstressed, air helper springs eliminate premature wear and tear and improve drivability, increasing the vehicle's lifespan. Other advantages are the adjustability for uneven load and manual leveling when parked.

Increased load

Arnott air helper springs are designed and engineered to complement the suspension, preventing it from sagging with increased payload and providing extra stability and increased ride comfort. For example, our latest release is an air helper spring kit for the 2006-current Fiat Ducato/Citroen Jumper/Peugeot Boxer (AH-4471), that makes it possible to achieve a gross weight of 4090kg while rear axle load can be increased to 2240kg for the 15in (stock wheel size) light chassis.

FOR MORE INFORMATION ABOUT ARNOTT, WWW.RDR.LINK/VBI012

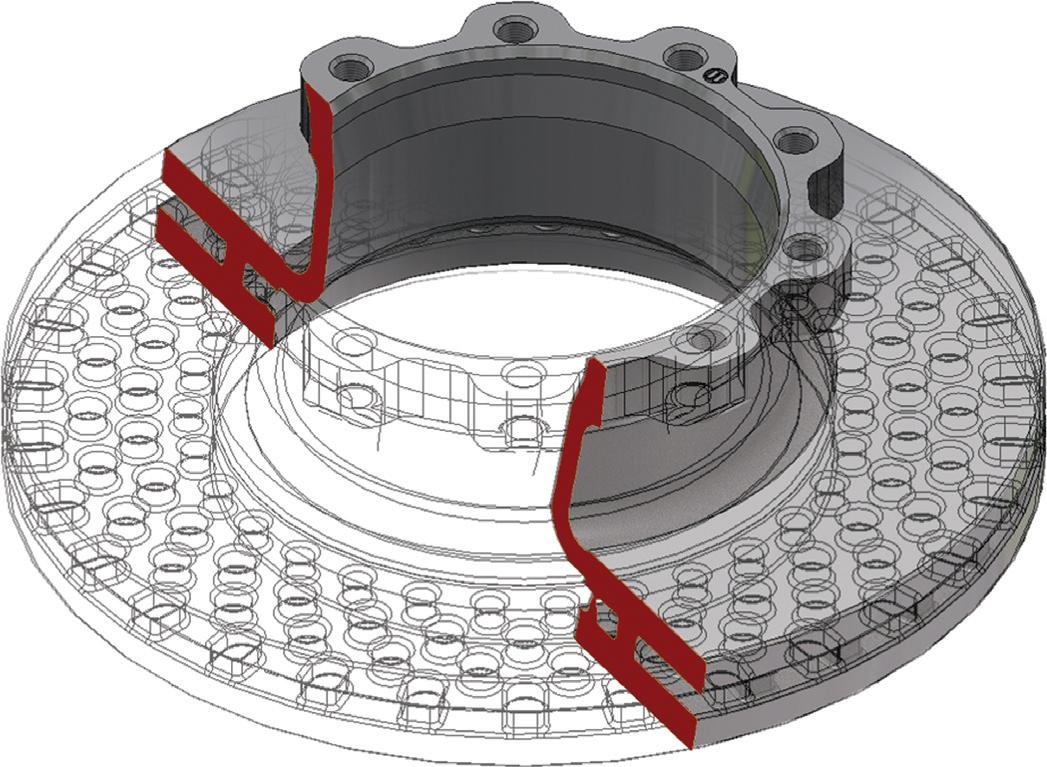

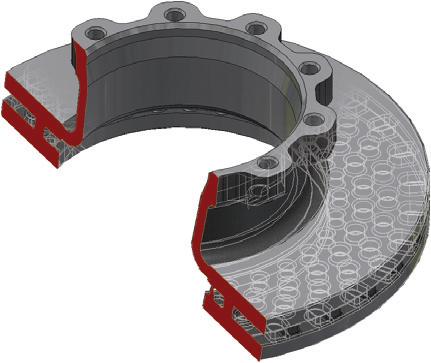

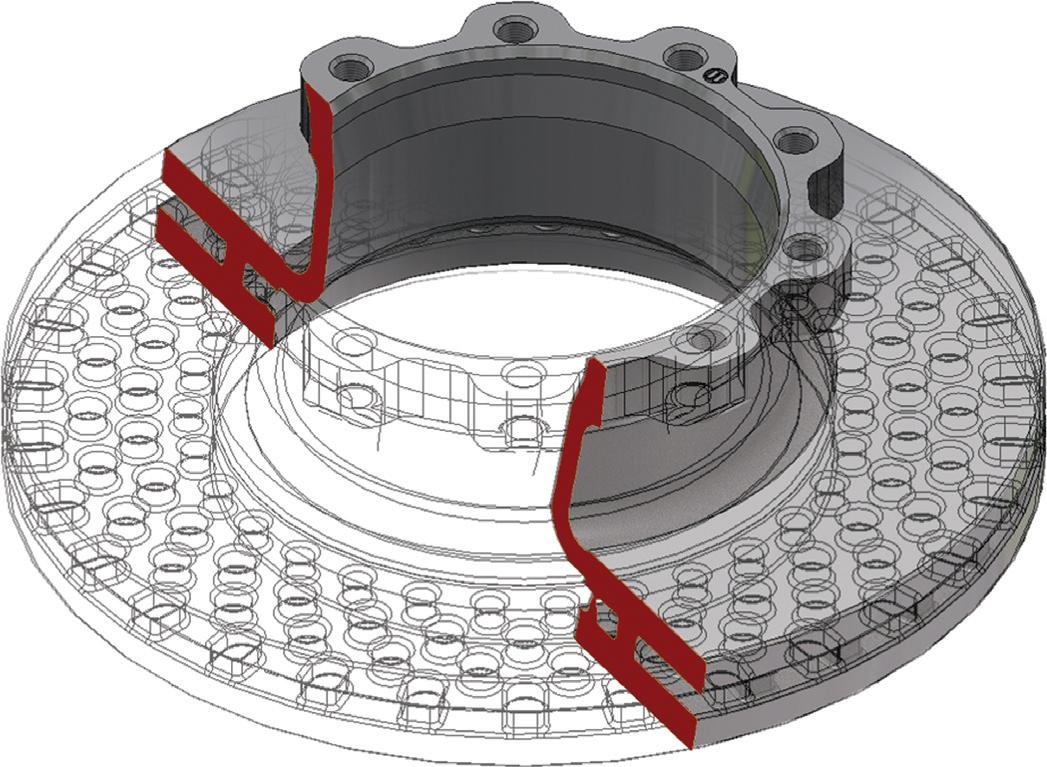

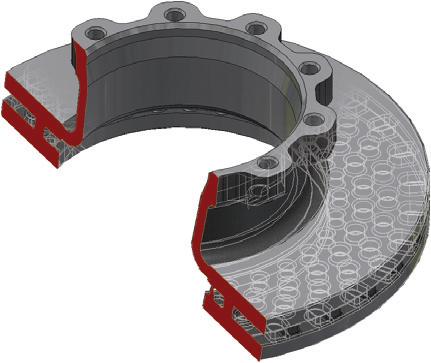

SOLID ARGUMENTS

CV brake specialist Fras-Le discusses the merits of solid and vented discs, how both perform and where they are best suited.

Solid discs have their place, on offroad and quarry applications, for example where mud, sludge etc can fill the vents. This can lead to reduced effectiveness, but for on-road applications vented discs are generally a superior choice –if they weren’t vehicle manufacturers wouldn't fit them as OE.

Vented discs cool up to 40% faster than solid discs, so other components such as rubber seals, tyres and bearings around the brake set up are exposed to high temperatures for less time, providing longer life and better safety.

Don't fade away

Vented discs weigh less than an equivalent solid disc by seven kilograms which amounts to 14kg per axle. Extra weight reduces payload carrying capacityand increases fuel consumption, and because of the extra mass, solid discs are also much more expensive than the equivalent vented rotor by at least 30%. As it has a much bigger mass, a solid disc acts as a much bigger heat sink, so on a single stop the temperature rise during braking will be less with a solid disc than a vented disc.

Some suppliers claim that solid discs do not increase brake fade; this cannot be true when repeated brake stops are carried out. As previously explained, vented discs are designed to cool significantly quicker than solid discs, therefore over a series of repeated stops, a vented brake will be less prone to brake fade.

28 CVW APRIL 2024

For example if the temperature after braking has reached 300˚C then 10 seconds later the temperature of a ventilated disc will drop to say 250˚C. Whereas a solid disc will have only dropped to say 290˚C. Therefore, when the brakes are applied again the temperature of solid discs is higher and therefore more likely to suffer brake fade on subsequent stops.

Due to their mass solid discs may also be less prone to distortion when hot but generally this is not an issue with properly designed vented rotors and thermal “hot spotting”. Plus, crazing and cracking is as much to do with the composition of the cast iron, the choice of friction material and how well it conforms with the disc to ensure uniform pad/disc contact.

the vented disc fails, only completing seven of the 15 cycles required. It is important to note that whilst the UNECER90:02 thermal fatigue test calls for 15 cycles to be completed, it actually requires, as a minimum, a result no worse than the OE part in terms of the number of cycles achieved before failure.

Fras-Le vented brake discs are R90 compliant. Some competitors have used the UNECE R90:02 thermal fatigue test to compare Scania vented and solid disc; the solid disc comfortably passes the test, but

The tests also draw conclusions from the wear figures claiming longer pad and disc life with the solid disc. However, if you look at the actual figures and not the percentage values, then you see there is 0.046mm difference in pad wear and 0.004mm difference in disc wear. These differences

BRAKES

are not significant. A solid disc has its place for particular types of application but for the above reasons, Fras-Le will only supply a UN ECE R90:02 approved product that is safe and cost effective.

Fras-Le has recently introduced its CV braking solutions to the UK market. This marks a significant milestone in the company's global expansion strategy. With a reputation for excellence, technological innovation, and sustainability, Fras-Le is well positioned to become a trusted partner for workshops in the UK’s commercial vehicle sector.

As the transportation landscape evolves, Fras-Le's commitment to delivering cutting-edge CV braking solutions promises to play a pivotal role in shaping the future of brake systems in the UK. FOR MORE INFORMATION ON

FRAS-LE, WWW.RDR.LINK/VBI013

REPORTING FOR DUTY

compliance, efficiency, and safety. BPW idem Telematics offers a solution that could reap huge benefits. CVW delves further.

vehicles. Notably, section 5.3 highlights the critical importance of brake performance assessments during a safety inspection. According to the DVSA, a high percentage of MOT test braking defects are only found during a brake performance test. Due to this, every safety inspection must include a brake performance assessment.

The DVSA stated that as of 1 January 2023, a commercial vehicle trailer must be presented for a roller brake test fully laden. A trailer loaded to at least 65% of its maximum weight will produce more accurate results during a roller brake test, as the grip between the tyre and the roller is more effective.

However, some triaxle and semi-trailers are exempt and can be tested unladen. Exemptions apply when a trailer has design limitations or the type of load the trailer normally carries prevents it from being laden. For further guidance, you should refer to the DVSA Understanding your HGV or trailer’s brake test report

In-service monitoring

Traditionally, trailer brakes are tested on a roller brake rest during an annual MOT. However, times have changed, and now trailer brakes must be tested at least four times per year, one of which must be carried out at the MOT test.

An alternative to a roller brake test is an electronic brake performance monitoring system (EBPMS). Supported by the DVSA, EBPMS can monitor in-service braking performance and provide a report. If there is sufficient data for a viable EBPMS report, this can be presented during a safety inspection and used instead of a roller brake test.

Using EBPMS allows operators to substitute a roller brake test in between an MOT test by continuously comparing the

BRAKES

30 CVW APRIL 2024

performance of the tractor/trailer braking events against the braking demand of the driver. Sharing EBPMS data demonstrates compliance with the DVSA Earned Recognition scheme and can help reduce roller brake tests from at least four to one per year.

It’s important to remember that EBPMS cannot entirely replace a roller brake test. An EBPMS and a roller brake test are two different methods of determining brake performance, and a roller brake test must still be performed during an annual MOT test.

Viable alternatives

BPW idem Telematics has an EBPMS solution that complies with the DVSA industry-standard guide. The system was developed by experienced BPW engineers, alongside the BPW mechatronics department in Germany, and in partnership with BPW idem Telematics, Europe’s leading telematics provider.

This technology continuously monitors the brakes. Data collected from the electronic braking system (EBS), together with the telematics system, generates realtime data reports. These reports can be generated on a daily, weekly, monthly, or annual basis, and the longer the system is used, the more accurate the data becomes. Reports can be accessed via a smartphone app or a telematics portal.

Other advantages of continuous monitoring are:

● brake efficiency is calculated each time the brakes are applied, and therefore, the trailer is tested with varying loads.

● the trailer brake performance is given at normal highway speeds and not just at slow speeds on the RBT.

“...the longer the system is used, the more accurate the data becomes...”

● the foundation braking system is being tested whilst running at its correct working temperature.

● any faults that affect the performance of the brakes will become evident before the next scheduled RBT.

This means that operators can identify potential braking issues well before scheduled maintenance checks, preventing problems from escalating, and causing prolonged downtime. It thus allows fleet managers to make more informed decisions regarding their trailers, leading to increased efficiency, improved safety, and reduced operating costs. BPW plays a crucial role in aiding customers not only in understanding asset reports but also in providing

comprehensive support throughout the installation process. Dedication goes beyond mere assistance; BPW is committed to offering invaluable expertise and guidance through every step of the process. By providing expert advice, BPW ensures that customers experience a seamless transition, thus reaping the optimal benefits of the BPW idem Telematics EBPMS.

An electronic brake performance monitoring system from BPW idem Telematics can provide significant insights into a trailer’s braking behaviour and flag up problems before they become real concerns.

FOR MORE INFORMATION FROM BPW, WWW.RDR.LINK/VBI014

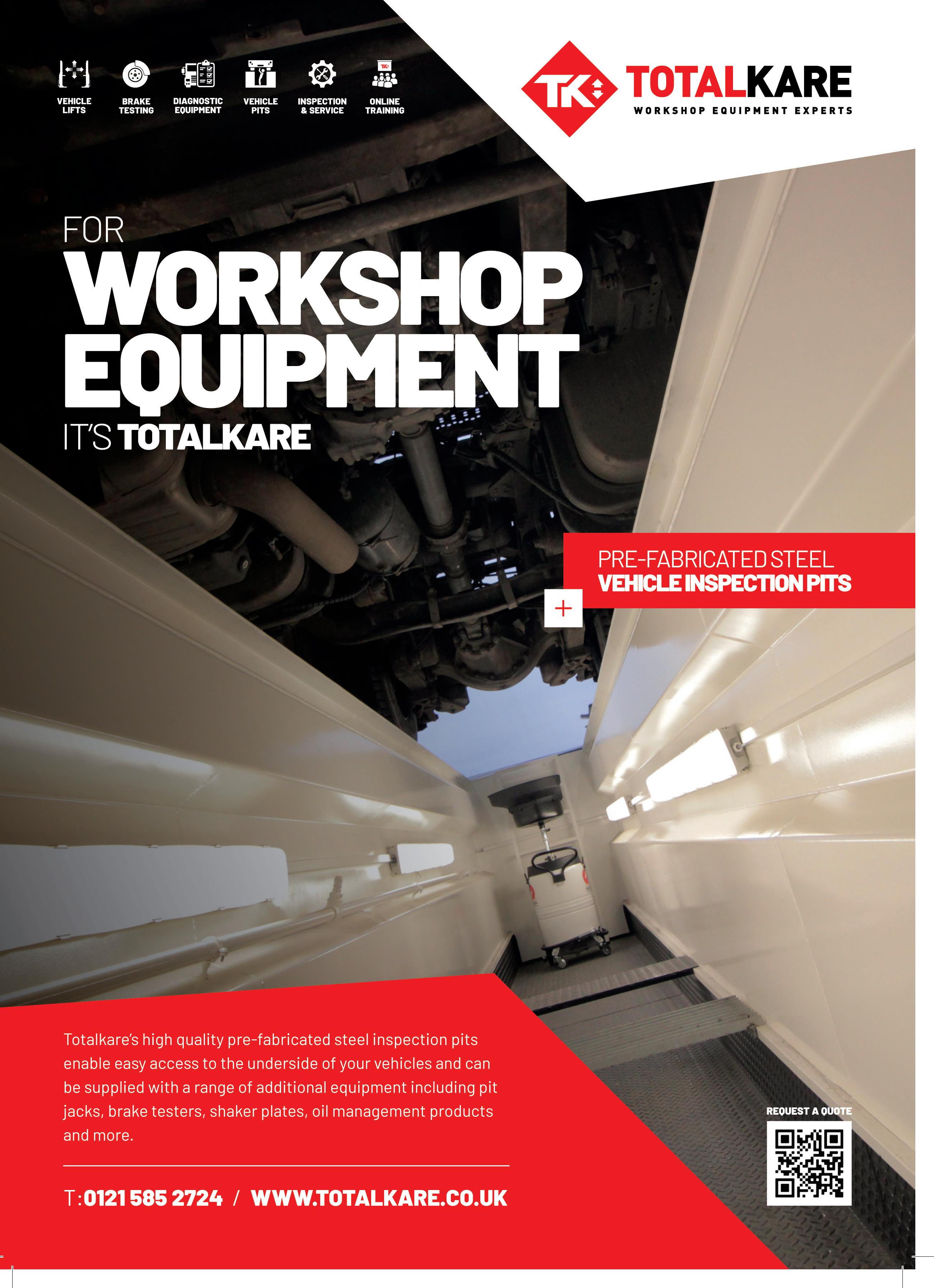

To ensure its fleet of vehicles were stopping safely and correctly, Farrall’s Group turned to equipment specialist Totalkare for its in-ground brake tester. CVW gets the lowdown.

BRAKING NEW GROUND

Leading logistics and transportation company, Farrall’s Group, has invested in its fleet maintenance capabilities by acquiring the state-of-theart Totalkare TK70 in-ground brake tester and T8DC mobile column lifts. The move is expected to transform the company's maintenance processes, ensuring optimal safety and efficiency across its entire fleet.

Established in 1956, Farrall's Group offers an extensive range of services tailored to meet the diverse needs of its clientele. Its comprehensive services encompass road transport, freight forwarding, warehousing and distribution.

Data-driven maintenance

Totalkare’s in-ground brake tester will allow Farrall's Group to assess the braking efficiency of its vehicles. The system utilises advanced technology to simulate real-world braking conditions, providing mechanics with precise data on braking performance. By identifying any potential issues early on, the company can proactively address maintenance needs, reducing downtime and preventing costly breakdowns. The enhanced brake testing capabilities will enable the company to meet and surpass industry safety standards, guaranteeing the wellbeing of its drivers and other road users. Alongside the in-ground brake tester, Farrall’s Group also invested in Totalkare’s groundworks service, enabling it to deal with a single point of contact for the full installation.

APRIL 2024 CVW 33 BRAKES

The in-ground brake tester is also covered by a Totalkare service contract, which includes two routine service and calibration visits from a field service engineer each year.

Getting a lift

The addition of Totalkare’s T8DC mobile column lifts will streamline its in-house maintenance processes, allowing mechanics to efficiently carry out inspections and repairs. The lifts' portability means they can be easily transported to different locations, optimising operational efficiency and minimising downtime. This will translate to cost savings for the company and an increase in overall fleet productivity.

Capable of lifting up to 7,500kg per column, the T8DC column lifts can be used in configurations of four, six or eight columns, and feature adjustable forks to accommodate a range of wheel diameters.

Talking about the recent upgrade, Matthew Farrall, managing director, said: “At Farrall's Group, we’ve always placed an emphasis on safety and efficiency. With

the addition of this workshop equipment from Totalkare, we are taking our commitment to the next level. Our priority is to ensure that our fleet is operating at peak performance, and this investment aligns perfectly with that vision.”

Furthermore, the investment showcases Farrall's Group's commitment to environmental responsibility. Wellmaintained vehicles contribute to lower emissions and improved fuel efficiency, aligning with the company’s sustainability goals and broader industry trends.

George Georgiou, area sales manager for Totalkare, added: “We are pleased to be Farrall’s Groups trusted choice for lifting and testing solutions. This equipment will elevate its standards of vehicle maintenance and safety, ensuring Farrall’s Group maintain its fleet’s peak performance.”

WWW.RDR.LINK/VBI015

BRAKES FOR MORE ON TOTALKARE,

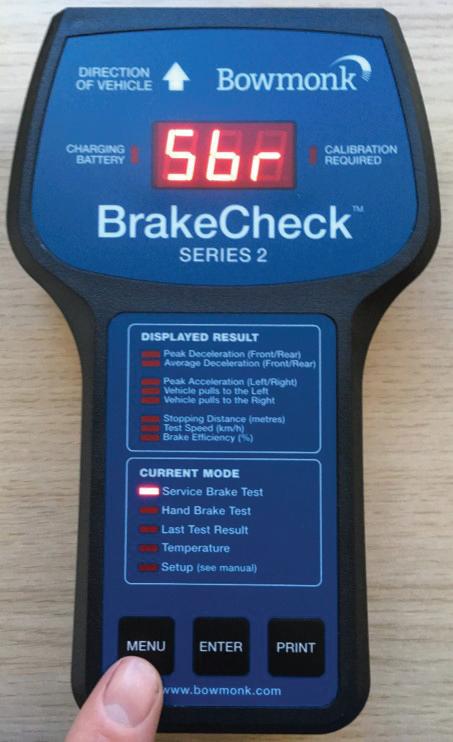

PULLING OUTALLTHE STOPS

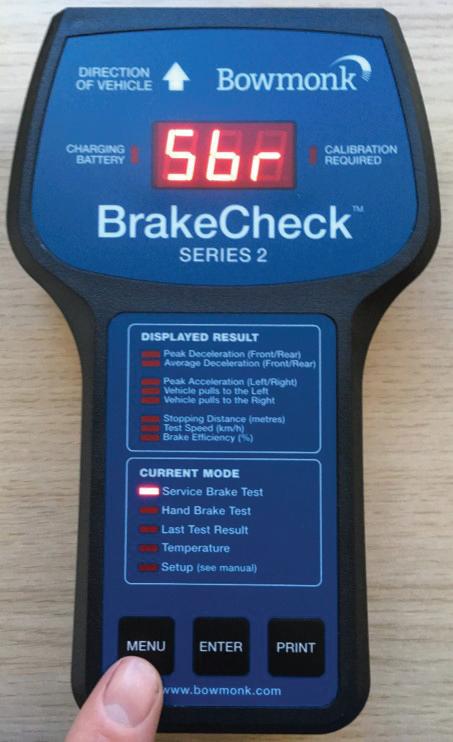

Chris Bailey, Bowmonk-Tapley, walks through the important stages of conducting a brake decelerometer test.

When checking mechanical and operational procedures there is often the risk of performing them in what is perceived to be the correct manner, when actually this is not the case, thus potentially resulting in a failure or malfunction. The same can be said when using complex testing equipment. If a value is generated when using any kind of testing equipment, are we absolutely sure it is the correct value? Are we sure we are correctly applying the appropriate method?

The same can be said for using a brake decelerometer for checking a vehicle’s braking efficiency, which is why we at Bowmonk-Tapley, the manufacturer of BrakeCheck, have produced a step-by-step operational guide.

A decelerometer test can be used on all classes of vehicle where a roller brake tester is either inappropriate or is inaccessible. A decelerometer test requires the vehicle to accelerate to around 20kph, at which point the service (foot) brake is applied as a controlled emergency stop. The same procedure applies to the parking (hand) brake.

HOW TO CONDUCT THE TEST:

1

Position the BrakeCheck unit on a level surface, such as the passenger side foot well.

2 Switch the unit on by pressing and holding the menu button until Sbr appears in the display.

5 When the test area is clear, accelerate the vehicle to a test speed of 20kph.

3 Confirm service brake choice by pressing Enter

6 Once the vehicle is travelling at this speed, check for traffic approaching from behind.

7 If safe to do so, apply the footbrake as a controlled emergency stop, without skidding.

4 When the unit is positioned level enough to start the test the levelling symbol will be shown on the display: Once the symbol is displayed press Enter. The unit is now ready for the test.

8

Once the vehicle has been brought to a complete stop, the unit will generate and display a braking efficiency value.

APRIL 2024 CVW 35

BRAKES

BRAKES

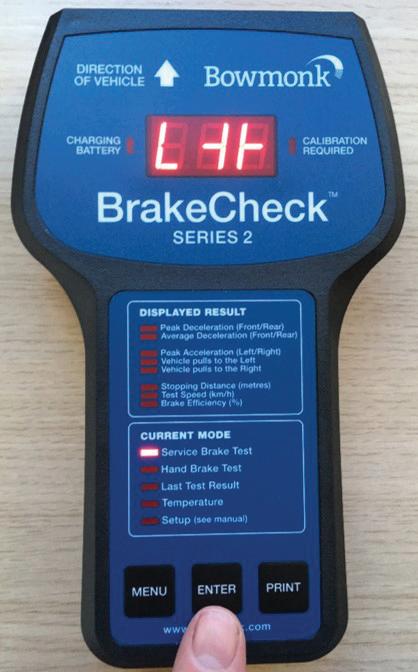

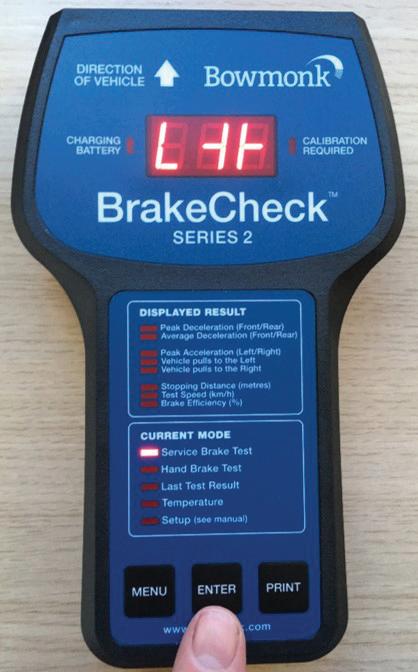

9

Once the service brake test is complete, change to hand brake mode by pressing the menu button (so that the hand brake test LED is illuminated). As before, confirm this choice by pressing Enter, which will take you to the levelling display.

12 Once the vehicle has come to a complete stop the display will show the braking efficiency of the hand brake.

10 Press Enter when the level indicator is displayed.

13 To view the service brake test report, press the menu button until the Last Test Result and Service Brake LEDs are illuminated. Then press Enter to display the result, which can now be printed using the optional wireless printer.

15

To view or print the hand brake test, carry out the same procedure, but use the menu button to illuminate the Hand Brake Test and Last Test Result LEDs together.

11 As before, accelerate the vehicle to the test speed, this time applying the hand brake to stop the vehicle. Note: please check with your vehicle manufacturer if this type of procedure is appropriate.

14 With the BrakeCheck unit positioned approximately 2-3 cm in front of the infra-red printer, switch on the printer and press the print button on the BrakeCheck to print the test result. In addition to the braking efficiency generated will be the percentage of braking imbalance.

16 For PC download option, connect the BrakeCheck to a PC that has the BC print software uploaded and follow the on-screen prompts to download the brake test results.

17 AllBrakeChecks nowhave the MTS connected facility, enabling direct communicationwiththeDVSAinreal time.

FOR MORE INFORMATION, WWW.RDR.LINK/VBI016

CASH IN WITH CHIPS

Victoria Evans, director of Esprit Windscreen Repair Equipment, looks at how the company’s windscreen repair process works and the benefits it can bring.

Are you keen to save money on your external services and bring more of your repair work in house? If so, windscreen repair can be a great way to both save money and save the time off the road while your vehicles undergo repair. And the bonus is it’s straightforward as well.

When Esprit started over 40 years ago, the repair kits were initially sold to bus and coach companies and fleet companies. Their vehicles, with their large expensive windscreens were perfect for repair and so the kit was initially designed with those customers in mind.

When a vehicle suffers a chip or a crack, it should be repaired as soon as possible, to prevent dirt and debris from contaminating the break, which is another advantage to being able to carry out the repair on site. Once your repairer has examined the break and applied the drill gently to the area of damage, the bridge is set up on the screen. The bridge is designed to work on the vertical screens of many fleet vehicles, with the large sucker and the handle used to firmly adhere the device to the screen. The moveable repair arm can be adjusted to ensure it’s exactly over the break.

Once this is done, the injector is screwed into the bridge and then 0.4ml of resin is measured out using the syringe. This is applied into the injector and the plunger gently screwed in, pushing the resin through the break. The plunger is then unscrewed, drawing air out of the break, and allowing the resin to fully penetrate even the tiny cracks at the edges of a break.

This on-off cycle is repeated until no damage is visible. Following this, a small amount of pit fill resin is applied to the small hole left by the damage and this is cured in 75 seconds with the LED lamp. Excess resin is removed, the area is given a little polish and the repair is complete. The whole process takes around 20 minutes and the vehicle is good to drive away immediately.

Cracking job

The Esprit system is even designed to be able to repair cracks, one of the only systems available that has passed performance testing standards on both chips and cracks. There are a number of repair kits on the market, so why choose Esprit? Esprit has received TUV

BODY REPAIR AND REFINISHING APRIL 2024 CVW 37

certification which means that repairs undertaken with our kit are tested to the same standards as a new screen (ECE R43), meaning that if your vehicle is in an accident, the screen will behave in the same way as a new screen – there’s no weak point where the repair has been carried out.

Secondly, you know that the glass isn’t just superficially repaired on the surface, repairs with the Esprit system bond the glass deep into the screen as well as providing an excellent cosmetic result – the screen is as clear and strong as a new screen.

Esprit manufactures kits in the UK, which means that they can normally be delivered the next day, and in the unusual event that something goes wrong, we are at the end of the phone, and can also carry out repairs to your equipment if necessary.

If you haven’t used the Esprit system before, or are new to repair, we also offer training, either onsite in Staffordshire, or at your premises.

BODY REPAIR AND REFINISHING

FOR MORE ON ESPRIT, WWW.RDR.LINK/VBI017

REPAIRING REPUTATIONS

Tom Hudd, national technical manager, VBRA gives CVW an update on the Elite Truck & Van Body Repair Standard.

Back in September 2022, the Vehicle Builders and Repair Association (VBRA) launched its Elite Truck & Van Body Repair Standard. The rationale was clear. We wanted to reduce risk, improve the quality of the repair network and ultimately lower costs by avoiding costly rectification of poor workmanship. Only the framing of a nationally recognised repair standard for commercial vehicles could achieve that. Hence, we launched the Elite Truck & Van Body Repair Standard.

Since then things have moved quickly! The VBRA executive committee has seen a change of chairperson and Jason Mole from

CarComm Coachworks has formally been appointed as chair. Now then, you may be thinking how does that impact the Elite Truck Standard? CarComm Coachworks was the second repairer to achieve the Elite Truck Standard and as such Jason is well placed to discuss the issues in the commercial repair sector and promote the standard and assist the group in further development.

To quote Jason: “Since achieving the Elite Truck Standard (structural) we have had nothing but praise from both insurance engineers and businesses we work with as it is a transparent means of showing existing and potential customers that CarComm Coachworks is compliant and competent to repair all their types of commercial vehicles. I actively promote this within the commercial repair industry, as it is a long

“...since achieving the Elite Truck Standard we have had nothing but praise...”

BODY REPAIR AND REFINISHING

40 CVW APRIL 2024

overdue standard, and the good repairers will support this by achieving all its necessary requirements.”

Numbers grow

The VBRA Commercial has seen an influx of members because of the standard and we now have seventeen repairers on the Elite Truck platform either with the standard or working towards the standard.

The VBRA has been approached by several insurers in relation to the standard and how they may adopt it for their network of commercial repairers and discussions are in hand. As a result of the standard Bret Maycock from Bremco has developed training and is due to receive IMI certification on commercial chassis straightening and awareness training which will include ladder chassis and cab chassis which is the first in the UK.

STANDARD RECAP

The standard consists of several grades of membership:

Elite Truck & Van Body Repair (structural with cab and chassis repair)

Elite Truck Repair (structural with cab and chassis repair)

Elite Van Repair (structural with chassis repair)

Elite Truck & Van (non-structural no cab or chassis repairs)

Each potential Elite Truck & Van Body Repair member must undergo a full audit and inspection before being granted membership. Full details of each member will be held on a VBRA platform specially developed with ITAS which is already used by many manufacturers and insurers. It enables virtual online audit of all qualifications, service and calibration of all equipment with all assets.

This leaves a physical visit to cover any other areas of the standard to be inspected with ongoing inspections being mostly managed online.

The standard will utilise the certifications from the IMI and other bodies to identify competency of technicians in this complex repair sector.

As part of the standard the Elite member will be expected to ensure an independent inspection of completed work over a cost threshold with the inspection available to view online. This is intended to give ongoing quality control to the member and customer.

Talking to Brett he said: “ We have always delivered commercial chassis training and the Elite Truck Standard has prompted Bremco to make the next step and have the training certified by the IMI. It has also created an opportunity to create awareness among repairers that would like to progress onto structural repairs. This is also available to insurance engineers and vehicle damage assessors to upskill the sector.”

Next generation

One of the aims of the VBRA is also to address the issue of apprentices and the skills shortage. At present there is no dedicated commercial panel apprentice standard and as such this is causing a

vacuum in this sector. The new commercial chassis training/certification will help pull together a specific standard that can entice apprentices into the sector and, more importantly, the likelihood of local colleges being able to offer the training will be significant if we can work with government to fund the apprentice standard correctly. There is a lot going on and the landscape of commercial accident repair is changing for the better. This should persuade fleet managers and insurers to act in a diligent manner and use commercial repairers that hold the Elite Truck Standard.

APPLY NOW

WWW.RDR.LINK/VBI018

AS GOOD AS NEW

A commercial truck and van dealership is celebrating its high-quality, Mercedes-Benz approved bodyshop, which helps to breathe new life into trucks and vans. CVW took a trip down to Kent to find out more.

The Sparshatt Truck and Van bodyshop team delivers all levels of collision and body repairs on light commercial vehicles and HGVs, attending to dents, scratches, damaged panels and frames and plenty more from its base in Sittingbourne.

Revitalising vehicles by using only Mercedes-Benz genuine parts, the team ensures vehicles regain their optimal condition after accidents, while its comprehensive painting service allows customers’ vehicles to match company colours, extending to the chassis.

Last year alone, the bodyshop helped to rejuvenate over 500 vehicles to an as-new state, with the average turnaround for a repair just seven days, with many completed in a much shorter time.

Loyal customers

Managing the Sparshatt bodyshop is Declan Gogerly, who has worked his way up through the ranks and gained vast experience in the business: “I have worked in the bodyshop now for 15 years, from being an apprentice right up to becoming a manager.

“I help in all areas from doing estimates, raising jobs, ordering parts, invoicing, ordering of stock, and working on the shop floor when needed. I also manage all the health and safety in the shop, ensuring all colleagues work in a safe manner.

“My day-to-day role is a mixture of things. I check on all the team and get updates on their jobs, as well as checking with the bodyshop estimating manager to see what we have ongoing or completed.”

Since its inception in 1984, the bodyshop has amassed an impressive customer base due to its continued high-standard repairs.

One of the longest-standing relationships is with JBS Haulage, a general haulage

BODY REPAIR AND REFINISHING

42 CVW APRIL 2024

contractor operating in Kent and Yorkshire, with Sparshatt dealing with all its accident repair as well as full refurbishments on selected classic vehicles. More recently, the bodyshop team painted Lenham Storage’s 75th-anniversary vehicles.

Managing a team of seven highly trained bodyshop technicians, Declan puts pride in speed and efficiency, while maximising quality and safety in repairs, with an understanding of the cost to local businesses of their vehicles being out of action.

On the growth of the bodyshop at Sparshatt Truck and Van, Declan said: “My biggest goal for the team is to continue to expand and grow both our customer base and personnel.

“...we would not be so successful without our great team...”

“We are currently in the process of hiring an apprentice, as I believe training young adults is key to the success of any business.The people around you are key to how you succeed and it's no different in the bodyshop. We would not be so successful without our great team. I am entirely grateful for having a fantastic calibre of people around me.”

With operations in Dartford, Sittingbourne, Ashford and Tonbridge, Sparshatt has held a long-standing presence in the South East for nearly 50 years.

With eyes on the future, the dealership boasts a thriving apprenticeship scheme through its standalone training academy, which will take on 2024’s recruits in January next year after receiving over 240 applications.

FOR MORE INFORMATION ON SPARSHATT, WWW.RDR.LINK/VBI019