JULY/AUGUST 2023 The trade magazine for servicing and repair professionals COMMERCIAL VEHICLE WORKSHOP VEHICLE FILTRATION Time toclean up Also in this issue... Fuels forthe future ■ Zero emission trucks ■ Backward compatibility of oils ■ Ford Transit clutch replacement ■

REGULARS

ALTERNATIVE TECHNOLOGIES

13 TotalEnergies’ Tom Hyde offers some interesting insights into future fuels and technologies.

16 CVW talks to Asher Bennett, CEO and the driving force behind Tevva trucks.

19 Electrification of components such as axles and transmissions is the way forward says ZF.

22 HVO is one fuel being touted as a diesel replacement. CPI Euromix is one company that is going down this alternative fuel route.

25 Quattro Plant showcase the advantages of swapping diesel for electric.

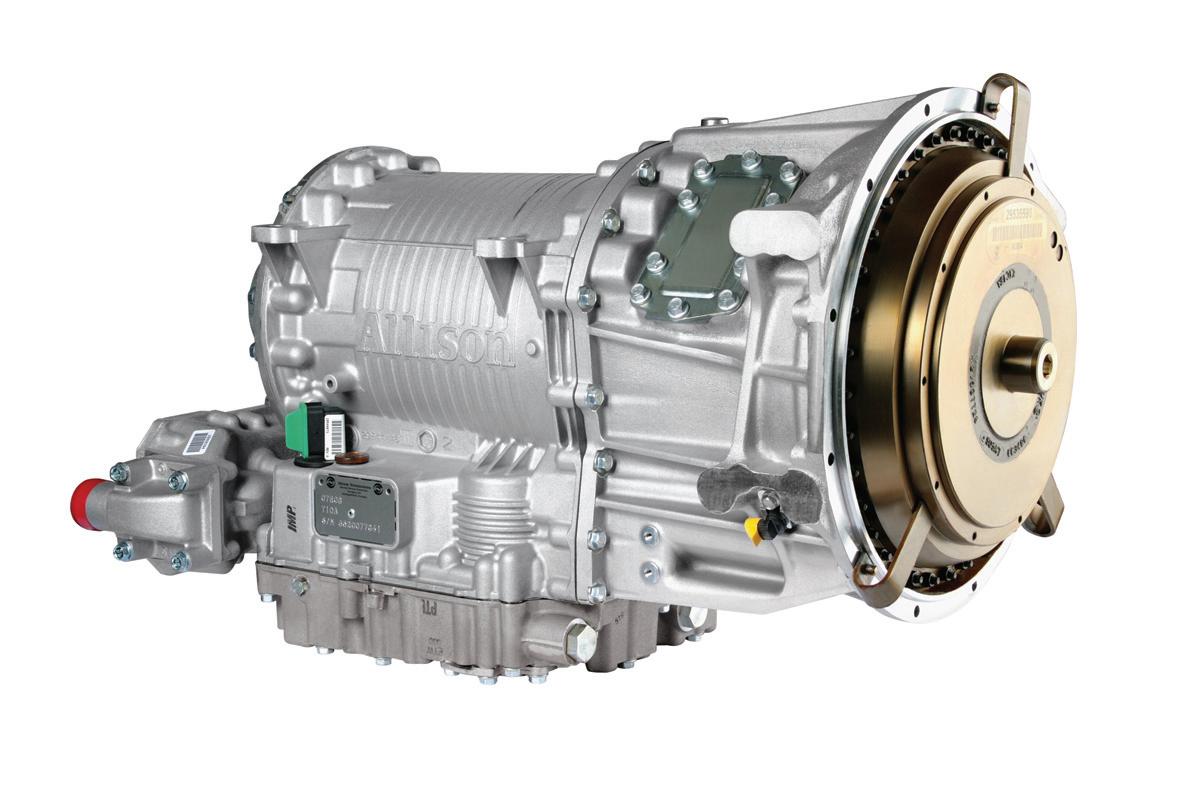

26 Allison Transmission’s xFE units are helping to deliver fuel savings for Biffa.

Filtration just got more important according to

The Ford Transit gets an E-makeover.

FUELS, LUBRICANTS & ADDITIVES

Don’t take backwards compatibility for granted, warns VLS. Motul is 170 years old but its oils are very much looking

CLUTCH, TRANSMISSION & STEERING

39 Shaeffler gives a master class in replacing a clutch on a Ford workhorse.

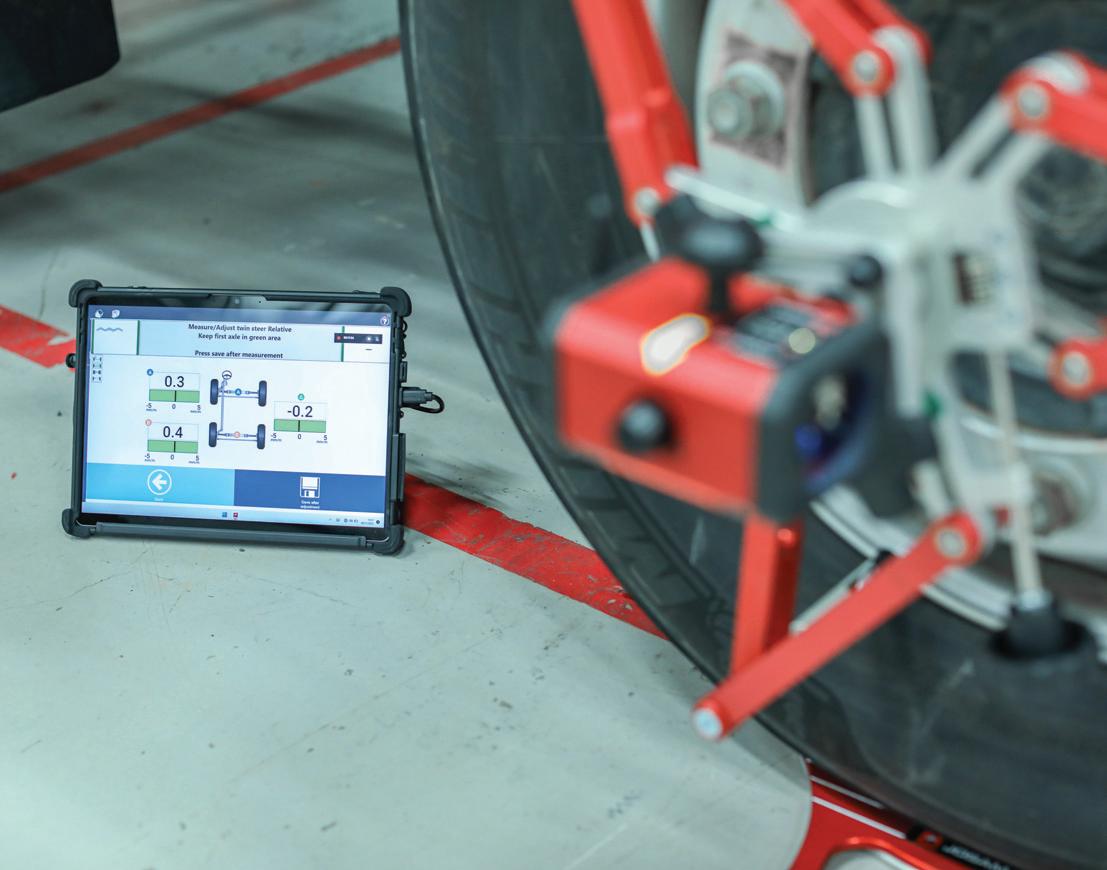

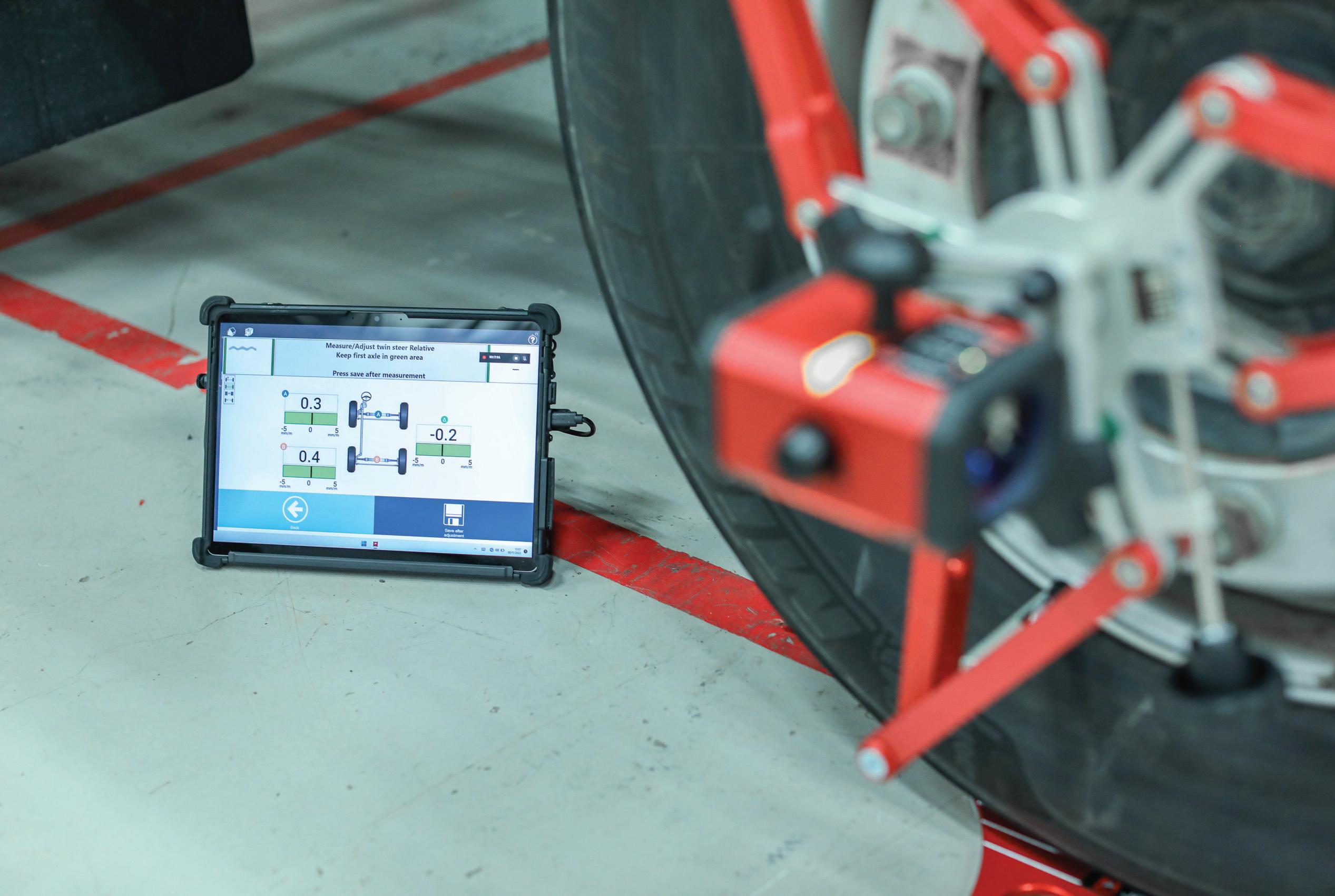

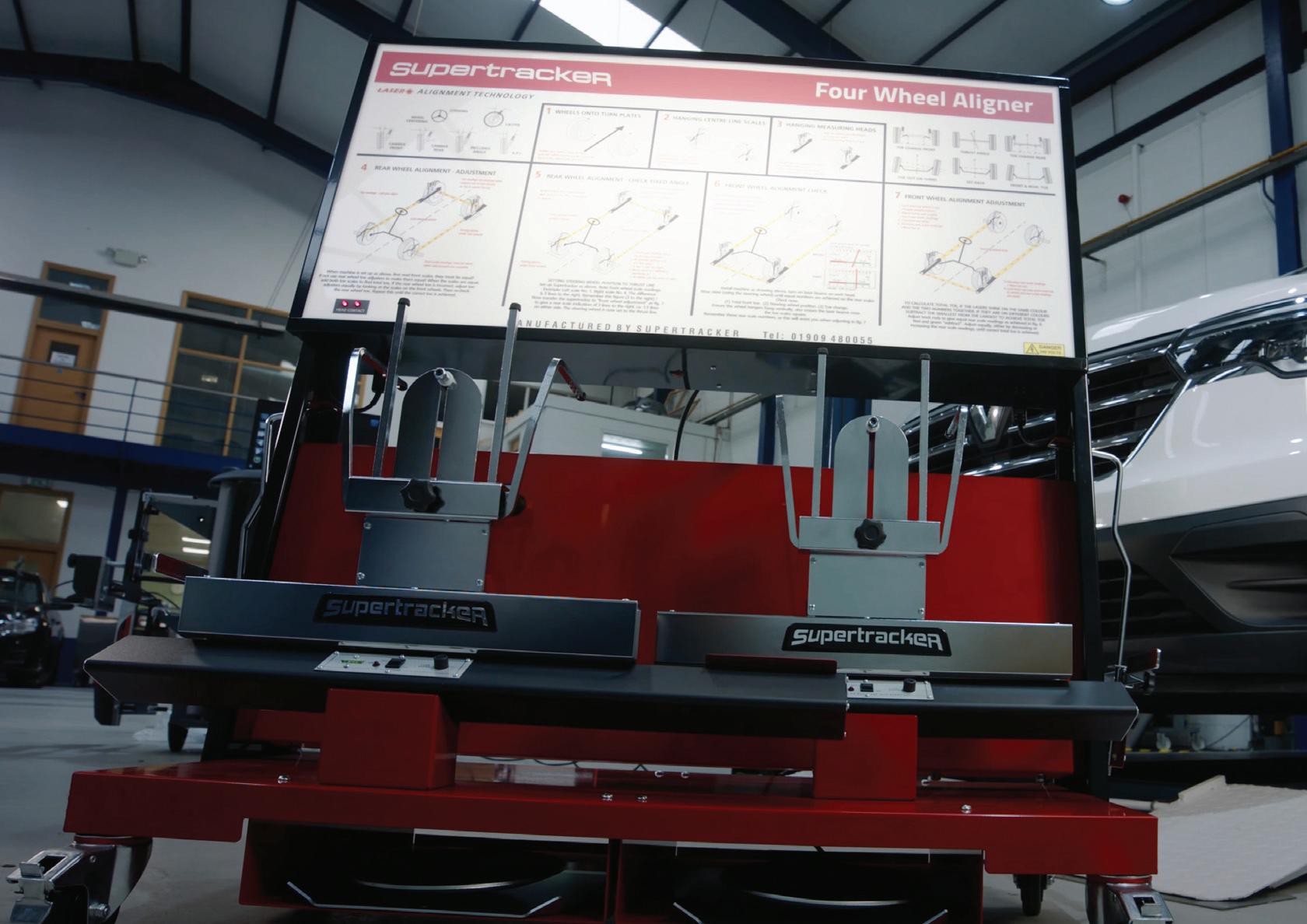

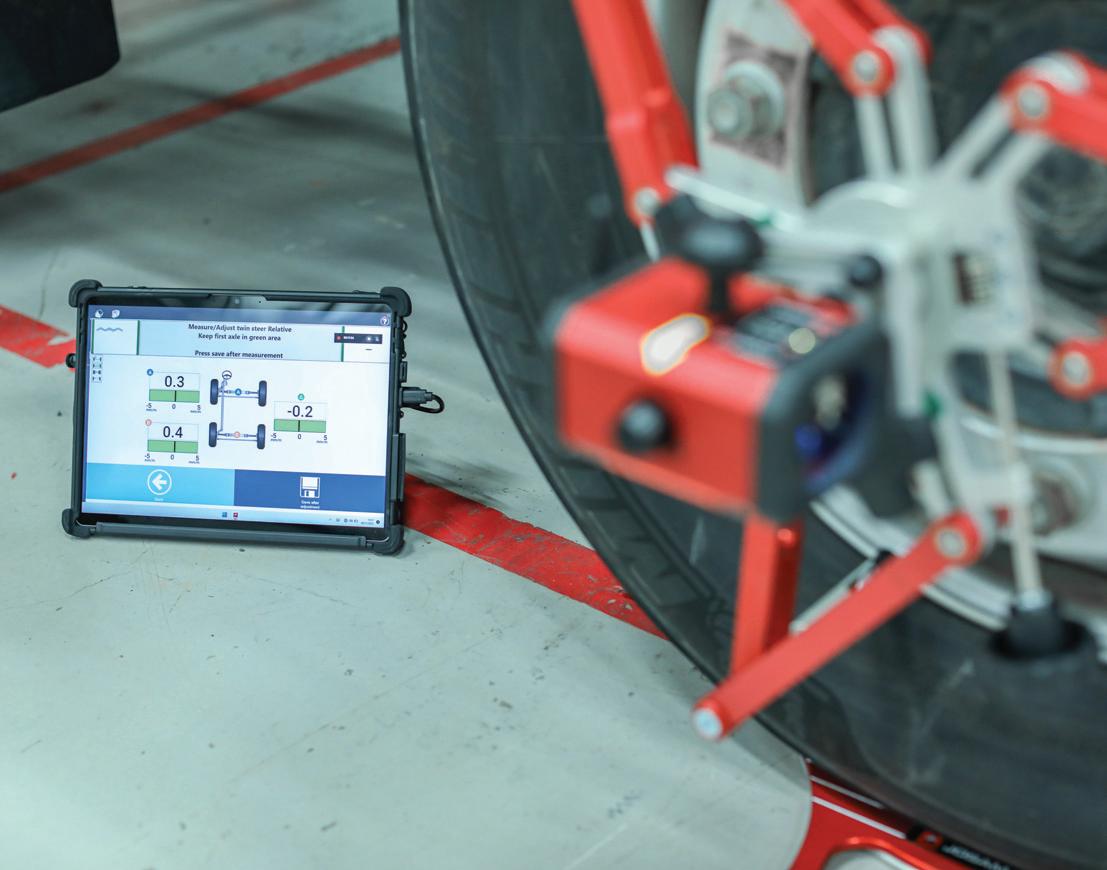

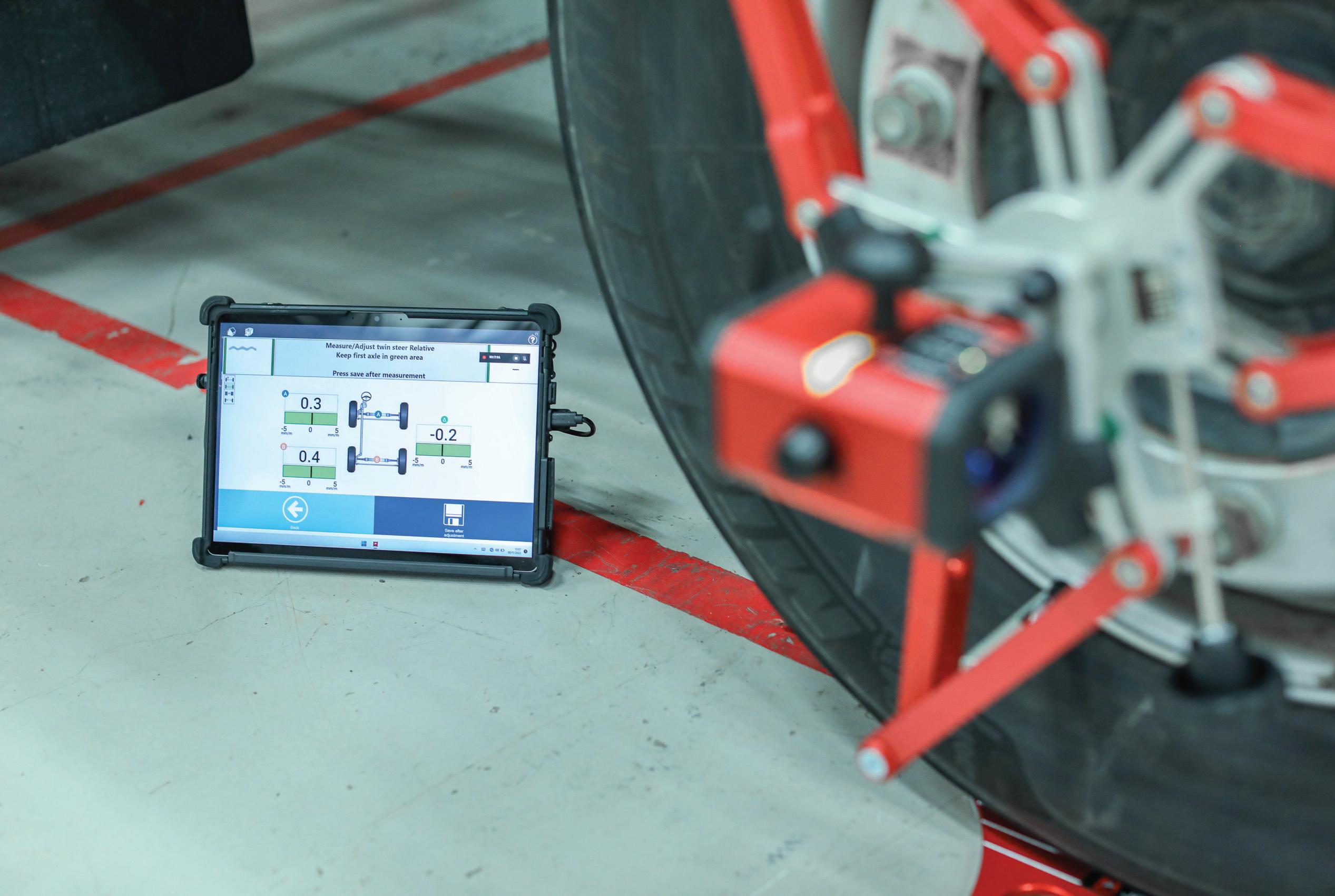

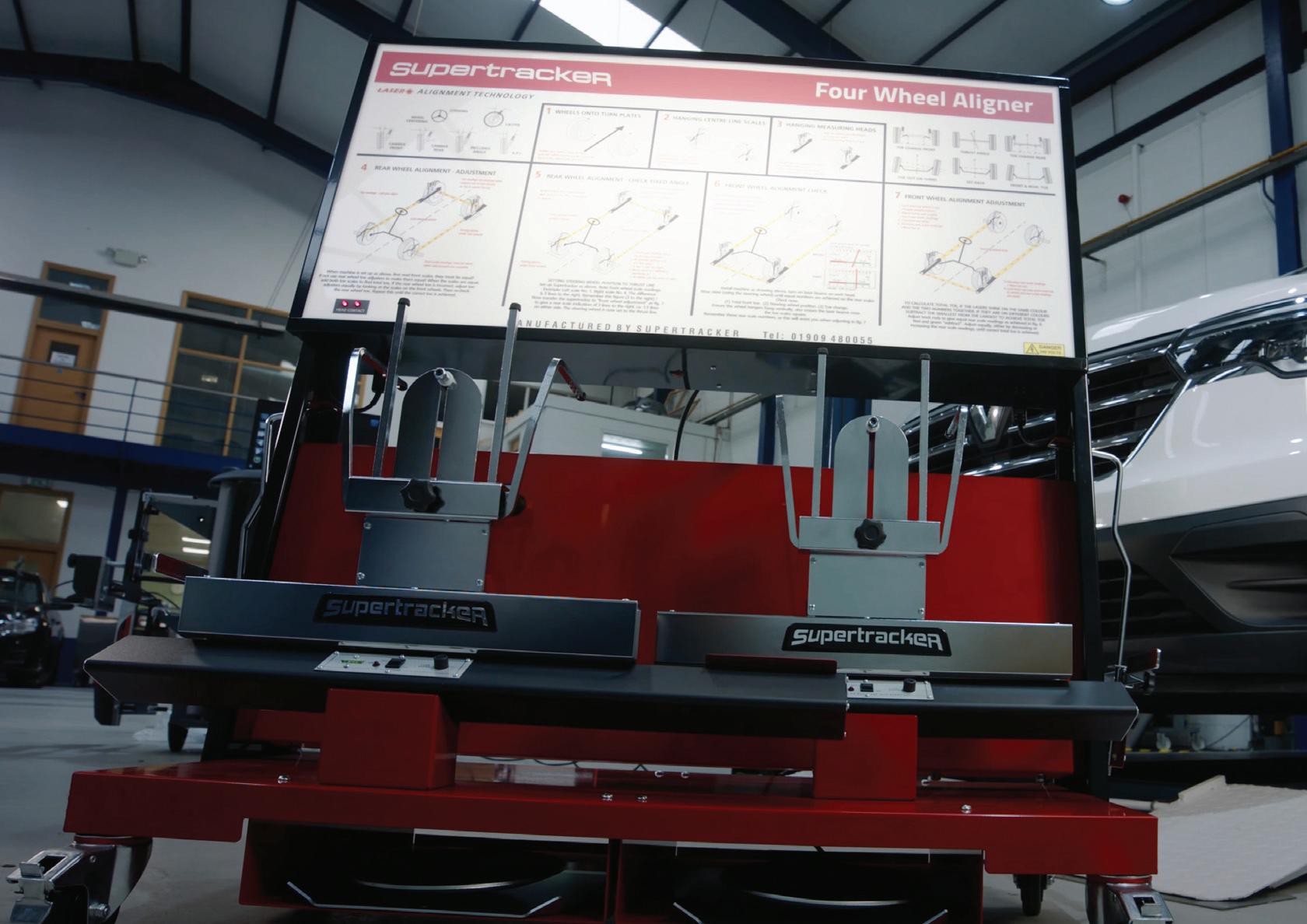

42 Tyre specialist turns the corner after using equipment from AES.

Issue 7 Volume 20 5 Viewpoint 6 News 10 Traffic news 45 What’s new? 49 Digital digest

CONTENTS

JULY/AUGUST 2023 CVW 3 19 36 42

VIEWPOINT

Editors

JOHNNY DOBBYN

JOHN LEVICK

workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Senior Account Manager

ALEX DILLEIGH

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates: UK £30

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens and George

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2023

8,249

GEARING UP FOR THE FUTURE

It’s been a busy month here at Workshop Towers. So busy in fact, that it’s difficult to pin down one subject or topic to write about in this column, given the diverse nature and sheer volume of news, reports and technical features we’ve encountered since the last issue of CVW

So many things are newsworthy, so many issues are topical and relevant that it would be negligent not to give them a mention here. And interestingly all have a bearing on the existence of the commercial vehicle workshop, both now and going forward. Just what will the workshop of the future look like? How quickly are things likely to change? Just what should one do to prepare for this sea change?

The nature of work will always be dictated by the types of vehicles that come into the bays. So, for the foreseeable future it’s still going to be very much ICE-powered vans and trucks that need attention. And that doesn’t look like changing any time soon. As the Association of Fleet Professionals report in the news section, fleet operators are keeping their vans for longer, while take up of BEVs is still woefully slow with electric vans representing just one in 24 of new van sales. But, and it’s a big but, there are government and industry forces at work, that will over time change the nature of that vehicle parc and consequently the demands made of workshops and garages. Yes, we are talking electric but also other viable fuel sources that will have an impact on how vehicles are serviced and maintained. Hydrotreated vegetable oil or HVO is one such fuel, but it probably poses few challenges in terms of having to do anything vastly different from conventional diesel. Hydrogen, whether packaged in a fuel cell or as a primary source in its own right, is an exciting and entirely sustainable option yet would be an entirely new prospect and would demand a whole range of new working protocols. Incidentally working on hydrogen-powered vehicles might come sooner than you think – a recent study indicated that hydrogen-powered cars will take off by 2028. Putting HVO, hydrogen or e-fuels aside for a moment, gearing up for work on electric trucks would seem the sensible option. Even looking in the pages of this magazine will tell you that e-trucks are on the move, with all the OEMs offering a host of variants, which are being avidly snapped up by customers. We asked Tevva CEO, Asher Bennett, what his advice would be for any workshop looking to transition to EV work and he recommended that staff complete the relevant IMI training (up to level 4) and then attend any additional training offered by the manufacturer.

This might be advice worth heeding, if only because the new intake of apprentice mechanics and technicians are likely to be so much more willing to embrace working with new technologies and the rapid developments which are sure to follow.

Happy reading!

TheCVWTeam

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication From 1 July 2021to 30 June 2022 Associate member JULY/AUGUST 2023 CVW 5

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk

Heavy funding needed NEWS

The Institute of the Motor Industry (IMI) has called upon the government to act in relation to inadequate funding for heavy vehicle apprenticeships. Steve Nash, CEO, has written to the Secretary of State for Education to express the professional body’s deep concern regarding the current state of the heavy vehicle maintenance and repair landscape.

Network coverage

Prometeon Tyre Group is working in partnership with its tyre dealers across the UK to launch its new SuperTruck UK network that supplies its branded tyres alongside tailored maintenance and audit services for truck fleet operators.

The SuperTruck service offer is flexible and runs alongside the supply of Pirelli-branded tyres produced by Prometeon under licence. Selected dealers will benefit from tailored training and technical support from Prometeon’s tyre experts.

Win big!

Set to run from 1st July to 30th September, the latest tool promotion from Sealey features a wide range of innovative tools and accessories, including a new range of floodlights.

It also offers an exciting opportunity to win the ultimate 105-piece tool kit worth over £865. Entry is online and participants have a chance to get their hands on a veritable treasure trove of top tools.

To discover all the new products featured in the latest tool promotion and to enter the competition, visit Sealey’s website www.sealey.co.uk.

The IMI believes the current level of financial support falls significantly short of meeting the demands and challenges of the heavy goods industry. The amount of money on offer does not make a viable business case to support effective learning, especially considering the expensive equipment and the effects of inflation.

“Given the recent actions taken by the Migration Advisory Committee in considering the inclusion of Heavy Vehicle Technicians on the Shortage Occupation List, it’s clear that government understands the pressing need for a larger workforce in the Heavy Goods sector”, explained Nash.

“We welcome this initiative but surely focusing on ‘home-grown talent’ would also make sense. It is crucial that the UK creates an environment that attracts and retains

skilled professionals in heavy vehicle maintenance and repair. This can only be achieved by ensuring that adequate support, training, and career development opportunities are available to encourage individuals to enter and remain in this field.”

The IMI has also highlighted the importance of having a fully engaged and skilled heavy goods vehicle maintenance workforce in light of the recently proposed Heavy Vehicle Testing Call for Evidence, which aims to increase the time between tests. The safe and efficient movement of goods is critical to the functioning of the economy. However, without a workforce equipped with the proper skills to maintain and repair heavy vehicles, the proposed changes could compromise road safety and disrupt the logistics industry.

Hot remedy from Bridgestone

Bridgestone’s commitment to its retread tyre offering has been boosted with a multimillion-pound upgrade of its range, leading to more ‘hot’ products being produced than ever before from its Lincolnshire factory.

Under the new ‘Bandag Hotread’ name, the company claims its retread solutions will become some of the most advanced in the UK, featuring 17 new products covering HGV, bus and coach markets. It will see a greater shift in emphasis from cold to hotcure products, in response to demand from commercial customers.

The significant investment will see new state-of-the-art machinery brought into Bridgestone’s Bulldog Factory in Bourne and will transform its retread offering, which is a sector that currently accounts for around 24% of commercial tyres sold in the UK per year.

Retread tyres use less than one-third the amount of raw materials used in new tires and enable the reuse of other components, such as the casing. The retreading solution significantly contributes to the reduction of discarded tyres as well as the reduction of waste in communities.

David Almazán, Bridgestone’s commercial business unit director, said: “There is a move towards the lowest total cost of ownership of product, combined with increasing awareness of the need for a more sustainable and circular economy where recycling is standard. Retread is economically good for the customer and takes a central role in our commitment to develop sustainable tyre technologies and solutions that preserve the environment for future generations.”

6 CVW JULY/AUGUST 2023

New owner at the wheel

Pro-Align, one of the UK’s leading suppliers of wheel servicing equipment begins a new phase with a change of ownership following the retirement of two of its founding directors.

Paul and Kathryn Beaurain leave the business while Philip Wylie will continue as the company’s sole owner, utilising his extensive automotive industry and investment banking experience.

Having originally formed as a wheel alignment centre in Northampton, ProAlign became the exclusive UK distributor

for Hunter branded equipment in the UK in 1996. During this time, the Hunter name became synonymous for high-quality equipment and technological innovation which is coupled with Pro-Align’s reputation for service and support.

Today, Pro-Align has more than 5,000 wheel alignment, tyre changer and wheel balancer installations at more than 4,000 locations around the UK and Ireland.

Under the new ownership, the business will continue to be managed operationally by experienced CEO Clive Seabrook, who has been at the helm of the business since 2019.

Used prices pass the £10k mark

After a strong start to 2023, average monthly used LCV values continued to climb in April, reaching their highest point since early 2022, according to reseller BCA.

Average values rose by £348 (3.5%) in April compared to March, to reach £10,325, the first time average values have passed the £10K mark this year and the highest figure recorded since February 2022. The mix of vehicles on

offer was responsible for the increase in value with performance against price guides largely stable at 102.4% during April.

Stuart Pearson, BCA COO UK commented: “LCV sales at BCA continue to return strong results during 2023, with rising average values and excellent engagement from the large number of professional buyers that support our specialist commercial vehicle sales programme.”

Sparkling deal for Setanta

MAN Truck & Bus Ltd.'s franchised partner for Northern Ireland, RK Trucks Centre, has changed ownership and become part of Diamond Trucks Ltd who in turn is owned by the Setanta Vehicle Group in Dublin.

Harry Nash, Setanta Group managing director, said: “We are delighted to announce our purchase of the long established and well run Northern Ireland-based MAN parts and service dealership which has sites at Carryduff and Dungannon.

“The MAN brand of vehicles, vans, trucks and coaches, are well received in Ireland and we very much look forward to working with the teams at RK Trucks, meeting with customers and investing in and growing the business.”

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk

Fifth month of growth for van sales

The number of UK light commercial vehicles (LCVs) registered in the UK grew by 15.3% in May compared with last year, reaching 25,359 units, according to the latest figures from the Society of Motor Manufacturers and Traders (SMMT). It represents the fifth consecutive month of rising deliveries as the market rebounds from a tough 2022.

Registrations of the largest LCVs, weighing greater than 2.5 to 3.5 tonnes, rose by 8.3% to 17,173 units, representing nearly seven in 10 (67.7%) new vans, while deliveries of mediumsized vans weighing more than 2.0 to 2.5 tonnes reached 4,143 units, up 57.2%. As fleet operators continue to opt for models with larger payloads, demand for small vans at or below 2.0 tonnes fell by -42.3%, while the number of newly registered pickup vans increased by 13.3%.

Rising demand

More businesses switched to zero emission workhorses, too, with the battery electric vehicle (BEV) market up 19.7% to 1,041 units, representing around one in 24 new vans. Rising demand means that 7,028 all-electric vans have been registered so far in 2023, an increase of 15.5% on the same period last year.

Electric switch

Commenting on the figures Mike Hawes, SMMT chief executive, said:” A van market rebound is an opportunity to deliver an increasingly environmentally sustainable recovery and a boost to the economy. But every lever must be pulled to support the electric switch. With the forthcoming ZEV Mandate, we also need a national plan to deliver public charging infrastructure that encourages plug-in van uptake, to give the UK confidence over what can – and must – be a stable, successful transition for businesses up and down the country.”

Operators opting for longer stretch

Van fleet operators are discovering that replacement cycles can be stretched to up to eight years without encountering major problems, according to the Association of Fleet Professionals.

Paul Hollick, chair at the industry body, cited a range of new skills from fleet managers were making these longer cycles operationally viable and economically attractive.

“Businesses have, of course, been forced into this situation by the huge difficulty of getting hold of new vans in recent years but in the process, have found that

Web feat from Webfleet

Webfleet, has launched Webfleet Trailer, a dedicated high-end trailer management solution designed to support transport and logistics companies with trailer fleets operating long haul.

The company describes it as a proactive monitoring and reporting tool fully integrated into its telematics platform, giving fleet operators a one-platform-solution for both fleet vehicles and trailers. It connects to all leading Electronic Braking Systems (EBS). By monitoring the trailer’s health via EBS connectivity to trailer fault systems, such as braking and stability, the solution helps to improve safety and security. With real-time visibility of load data, it also helps fleet managers with compliance for permissible cargo weight and reduces the

Low carbon fuels debate

A leading energy expert at Aston University has advised government to invest in low carbon fuels - as well as electric - if it wants to reach its 2050 net zero ambition.

Professor Patricia Thornley led a Department for Transport (DfT) advisory paper on low carbon transport fuels. The paper advised that decarbonisation of the UK's transport systems will need the government to support the use of lowcarbon fuels alongside widespread battery electrification where possible.

Professor Thornley examined the

replacement cycles can be extended to lengths that would previously have been considered unimaginable.

“Some fleets that typically operated vans for 5-6 years at a maximum are now, in some cases, hitting 7-8 years without encountering any real difficulties. The overall message is that more management attention is needed to keep these vehicles safe and reliable but that the economic benefits outweigh the issues.”

A key part of the strategy was simply to become “really good” at service, maintenance and repair (SMR) management, Paul added.

rollover risk from overloading.

Thanks to actionable insights, such as load status, fleet operators can improve trailer utilisation and limit empty runs. Webfleet Trailer is also said to reduce the risk of breakdowns and disruption to schedules by detecting tyre issues early. Tyre Pressure Monitoring System (TPMS)equipped trailers have access to live and historical data with notifications of abnormal tyre pressure or temperature.

challenges and opportunities of developing and using different fuels and their potential impact on the wider energy system.

The authors highlight that low carbon fuels such as those made from agricultural waste can deliver reductions in carbon emissions, helping to meet the government’s 2050 net zero ambition. As a result, they state that continued investment in this area is crucial.

The paper also states that at this point it's not yet clear if low carbon fuels will support just the transition to full electrification of the UK’s transport systems or will be a long-term solution.

8 CVW JULY/AUGUST 2023 NEWS @CVWmagazine CVWmagazine www.cvwmagazine.co.uk

MERCEDES-BENZ

South Wales builders’ merchant Undy Building & Timber Supplies looked no further than another MercedesBenz Atego from Euro Commercials, when it needed a new delivery truck – thanks to the proven performance of its long-running predecessor.

The new truck replaced a previous Atego supplied by the same dealer a full 20 years ago. Still going strong with a little over 250,000 km on the clock, it was snapped up by a buyer in Cardiff.

TRAFFICNEWS Plant company grabs another Merc

A 1321 model, the latest addition to the fleet is powered by a 155kW (210hp) 5.1-litre engine and has a ClassicSpace S day cab. The chassis is equipped with an alloy tipper by Neath Bodybuilders, who also fitted a Hiab X-Duo 078 loader crane with Kinshofer grab, rated at 7.4 tonne/metres and with a maximum outreach of 11.6 m.

For more information on Mercedes Benz WWW.RDR.LINK/VBA001

Mercedes-Benz vehicles already make up the bulk of the York-based company’s eightstrong line-up, and director

Stuart Handley was adamant he wanted another – especially as he would be driving it himself.

Supplied by dealer BLS Truck & Van, the new Arocs 3246 has a ClassicSpace S-Cab, decked out with a colour-coded bumper and mudguards, protective headlamp grilles, air horns and a light bar. The 320mm engine tunnel allows the driver’s seat to be set lower than higher-riding variants, and means fewer steps are required for entry and exit. Power comes from the top-rated 355 kW (455 hp) version of Mercedes-Benz Trucks’ 10.7-litre in-line six-cylinder engine.

The chassis is fitted with a robust Governor all-steel tipping

body by L Townend, of Holmfirth, with Harsh underfloor tipping gear, and had a Palfinger Epsilon M125 crane arm with Kinshofer clamshell grab installed behind the cab by TH White, of Devizes.

“We’ve been very well served by the Arocs tippers we already run,” revealed Mr Handley. “They don’t give us any problems and have been noticeably more reliable than vehicles we’ve tried from rival brands. They’re popular with our drivers too, and I can see why. The cabs are extremely well designed and comfortable.”

To find out more WWW.RDR.LINK/VBA002

10 CVW JULY/AUGUST 2023

Merchant copy

and superior

another Mercedes-Benz Arocs

at the top of the

a new

Proven reliability

handling meant

was

list when A1 Plant & Haulage needed

truck.

VOLVO

Nationwide tunes into FMs

Powered access specialist Nationwide Platforms has taken delivery of two new Volvo FM Electric 4x2 tractor units.

Supplied by Rory Kelly at Volvo Truck and Bus Centre South & East’s Coventry depot, the FM Electrics will be used to pull step frame trailers transporting hire equipment to and from sites around Birmingham and the northwest.

The FM Electrics both feature three electrical motors, generating an output of 666hp and 2,400Nm of continuous

torque, paired with a standard IShift gearbox to deliver a smooth and ultra-quiet in-cab driving experience.

For more on Volvo, WWW.RDR.LINK/VBA003

Local hero

VOLVO

In a first for the company haulier Knowles Transport has purchased a new Volvo FE Electric truck to run a local collection and delivery schedule. Having subjected the vehicle to an initial threeweek trial to establish its viability and to garner views from its drivers, Knowles acquired the 19tonne vehicle as well as a 150kWh supercharger that can deliver full charge within two hours.

Sargeant tips FUSO the wink

FUSO

Essex building contractor BK Sargeant & Son is strengthening its ranks by calling up a proven tough performer, in the shape of a 3.5-tonne FUSO Canter tipper.

Based in rural Great Yeldham, Essex, the familyowned firm specialises in conversions and refurbishments of historic buildings – a role for which the Canter has demonstrated its fitness for purpose time and again.

“This is our eighth,” said director James Sargeant. “We’ve tried other vehicles in the past but for our particular set of requirements the Canter really is the ideal package.”

As a 3C15 model the new Canter is powered by a 3.0litre common-rail turbo-diesel engine producing 110 kW (150 hp) and an impressive 370 Nm of torque which, thanks to variable turbine technology, is available from low engine speeds.

This engine drives through a smooth-shifting and fuelefficient DUONIC automated dual-clutch transmission with eco mode, parking and creep functions. The chassis has a 2,500 mm wheelbase – the shortest of eight sizes available – and was fitted with an alloy tipping body by KMR Engineering, of Ipswich.

To find out more on the FUSO Canter WWW.RDR.LINK/VBA004

The Volvo FE Electric is powered by twin electric motors producing 225kWh and 850Nm torque with a Volvo 2-speed gearbox. The total energy storage of the vehicle is 265kWh which helps the truck to maintain a 200Km range. The truck is a 4x2 wheeled 23ft curtain side fitted with a tail lift. Featuring lane keeping assist and adaptive cruise control, the FE Electric provides a smooth ride for both occupants and cargo thanks to its front and rear air suspension setup. The truck will be run on a local collection and delivery schedule due to its size and capabilities. Its short wheelbase (only 5500mm) and nimble handling make it ideal for urban environments.

For more info on the Volvo FE Electric WWW.RDR.LINK/VBA005

JULY/AUGUST 2023 CVW 11

FUELLING THEFUTURE

With the 2050 net zero deadline looming, the future of commercial vehicles in the UK is still unclear. The UK government is looking to new technology and materials to transform the sector. Tom Hyde, technical support manager for TotalEnergies UK, looks at developments in technology and materials.

Helping the UK meet its 2050 net zero deadline will be a significant priority for all sectors in the future, but especially for those working in transport. According to research released in 2022, HGVs accounted for 19% of road transport emissions in the UK, making reform to this sector a significant piece of the UK’s sustainability puzzle. The phased transition from fossil fuels for all vehicles, including HGVs, will require new infrastructure, a great deal of investment and the right political structure to make zero-emission transport ubiquitous.

Creating viable alternatives

Essentially, to meet climate requirements, the UK needs to provide readily available substitutes to traditional fuel sources. Renewable biomethane or hydrogen, for example, are practical alternatives, and there are projects ongoing to develop a hydrogen ‘ecosystem’ for transportation in Europe, such as TotalEnergies’ partnerships with Daimler Truck AG and Air Liquide. A significant benefit to these fuel sources is

that vehicles operate and are refuelled in a similar way to the fossil fuel powered HGVs and vehicles – meaning minimal alterations to drivers’ schedules and working patterns.

The obstacle to overcome will be ensuring both supply chain resilience and affordability to encourage adoption. While the UK government has invested in several initiatives, the role of hydrogen itself on the path to net zero is still being debated. As ‘green’ hydrogen (produced using renewable energy) is not yet at the scale necessary for widespread use, so-called ‘blue’ hydrogen is seen by many as a stop gap solution, despite its fuel intensive production process.

Electric potential

The debate over electrification also charges on. In April this year, the Society of Motor Manufacturers and Traders urged UK ministers to devise a plan to assist the UK road haulage sector to decarbonise ahead of the phase-out of new diesel-engine vehicles in the coming decade. The trade body called on the government to publish a suitable strategy by early 2024, after finding that there is not a single dedicated electric charging or hydrogen refuelling site for HGVs on Britain’s major roads.

Charging infrastructure (or lack thereof, in this case) is often cited as an obstacle to electric truck adoption. It is worth noting that there have been significant developments in this sector, and trucks designed for base-to-base use are on the market. However, the weight and size of most heavy-duty batteries is another issue, as it could limit the number of goods that HGVs can carry.

ALTERNATIVE TECHNOLOGIES JULY/AUGUST 2023 CVW 13

“...charging infrastructure is often cited as an obstacle to electric truck adoption...”

The lack of viable infrastructure has also led to a lack of market confidence in electric HGVs. In fact, a recent GiPA survey found that only 3% of HGV operators would consider moving to electric when planning fleet renewal options.

A successful transition to electric will require a long-term plan to drive the rollout of a dedicated UK-wide HGV charging and fuelling network, combined with worldleading incentives to encourage uptake and attract model allocation. The sector may also need to think creatively in terms of infrastructure. For example, the Centre for Road Freight Sustainability has suggested that the best method for charging HGVs consistently would be an Electric Road System (ERS), which would charge HGVs via overhead cables, reducing both battery size and the scale of charging infrastructure required.

Self-driving vehicles?

Automation technology also has the capacity to be transformational to the haulage sector.

The UK government recently pledged £81 million in joint UK government and industry support for selfdriving technology. One of the companies to benefit from this is hydrogenpowered commercial vehicle innovator, HVS, which was awarded £6.6m of this government funding to develop a zero-emission, autonomous HGV for the UK market. Whilst the company is still operating with prototypes now, the combining of hydrogen fuel cell technology with self-driving efficiency is a sign of the progress that could

revolutionise the industry. The idea could also help address the shortage of HGV drivers currently faced by the UK, while creating jobs in the manufacture and operation of these vehicles. It is likely to be years until self-driving vehicles are integrated into everyday life due to the current lack of suitable infrastructure and legal and insurance frameworks to keep vehicles and people safe. However, in the interim, there is sure to be an increase in new autonomous and partially autonomous solutions.

What to do now?

With renewable-powered transport and electrification all on the horizon, ensuring best servicing practice and using the best products available, such as high-quality, fuel-efficient lubricants, is a step that HGV operators and fleet managers can take now to ensure they’re maximising both

ALTERNATIVE TECHNOLOGIES

14 CVW JULY/AUGUST 2023

“..it is likely to be years until self-driving vehicles are integrated into everyday life...”

productivity and sustainability.

Major strides have been made over the past few years in terms of innovating engine oils and lubricants. The result is increased uptime and lower maintenance costs – particularly through products such TotalEnergies’ RUBIA TIR 9900 FE 5W-30 –as a result of reduced friction and viscosity of lubricants. These efficiency gains provide both emissions reductions and cost control benefits which equate to between 2% and 3% increases in fuel efficiency for commercial vehicles.

The future together

Our priority as a sector needs to be investing in new energy sources and technology for the long term, while ensuring vehicles are maintained and operated as sustainably as they can be right now. Achieving net zero emissions by 2050 will require collaboration between public and private sectors, and is something that government, industry, and regulators will have to work together to achieve.

TO LEARN MORE ABOUT TOTALENERGIES WWW.RDR.LINK/VBA006

CLEANING UP INTHE TRUCK MARKET

CVW talks to Asher Bennett, CEO of Tevva, the technology company and truck manufacturer, about the company’s aspirations and why the future is within range.

QWhere is Tevva with its respective truck platforms?

AB: Tevva is scaling up customer sales of its 7.5-tonne battery-electric truck in 2023 –across the UK first, then Europe. The 7.5tonne battery-electric truck will be followed by a 7.5-tonne hydrogen-electric truck, which benefits from a hydrogen rangeextender that enhances range from 180km to over 400km. Since much of the mediumduty truck segment requires longer range capabilities, our customers are excited about the prospect of our hydrogen truck and hydrogen as a back-up fuel to lithium-ion batteries. We will also produce a 19-tonne hydrogen-electric truck from 2024.

QTrials of the technologies seem to have gone well - did they meet expectations?

AB: Indeed. Tevva trucks have been on UK roads since 2016, including 15 rangeextended electric vans operated by UPS in Southampton and Birmingham since 2019. These vehicles have covered more than 500,000km in full-service, creating a rich data lake that has been used to inform the engineering process for the 7.5-tonne battery-electric truck. We have a number of trials with other companies ongoing and in the pipeline, including Kinaxia Logistics, TG Lynes and Royal Mail. We look forward to reporting the results soon.

ALTERNATIVE TECHNOLOGIES

16 CVW JULY/AUGUST 2023

QWhen can we expect first production models on the streets? Any customers on board?

AB: Tevva trucks are already on the streets and you can expect to see more very soon. We’re producing several hundred trucks this year, all of them with customers already or waiting.

QWhat kind of applications are the trucks best suited for?

AB: For the right use case, like last mile delivery, the 180km range on our 7.5t battery-electric truck is enough. For longer haul, the 7.5-tonne hydrogen-electric truck enhances range from 180km to over 400km.

Clearly public infrastructure has a long way to go, though there are positive signs and considerable investments being made by governments around the world to accelerate the roll out of charging infrastructure. For our hydrogen-electric trucks, we are also working with energy partners to deliver low-carbon hydrogen to our customers’ depots.

QWhat will drive the takeup/adoption of these vehicles?

AB: We appreciate the British government’s support which enables us to make our 7.5t battery-electric truck even more appealing to fleets. But for this country to meet its net zero goals, more action is needed to stimulate electric vehicle manufacturing in the UK, which is the only bright spot in an industry that has reached its lowest ebb for over 60 years.

Brexit put us in a position where we

were free from EU state aid rules as a nation, limiting the amount of support governments could give specific industries. Yet, the UK needs to catch up to its European neighbours regarding incentives for electric truck adoption. More action is required to accelerate the decarbonisation of commercial vehicles, and we’re asking the UK government to urgently adopt truck incentives in line with those found in Europe.

QFor the ICE-oriented workshop, what would be your advice if they want to transition to servicing/maintaining alternative fuel based trucks?

AB: Our advice for those workshops wishing to transition to alternative fuel based trucks is - most importantly - to ensure their staff are trained correctly, and they have the right workshop tools to

operate on this technology. In terms of training, we would recommend that staff complete the relevant IMI training (up to level 4) and then attend any additional training offered by the manufacturer.

As for tools, the manufacturer will recommend some basic safety guidelines on insulated tools and barriers around the vehicle, alongside simple best practice, such as only allowing correctly trained technicians to work on the electric vehicles.

There will also be processes that need to be adopted and followed within the workshop to allow for safe EV servicing and maintenance. The general servicing costs of commercial EVs are far less than ICE vehicles, as there are fewer moving parts. FOR

JULY/AUGUST 2023 CVW 17

MORE INFORMATION ON TEVVA

WWW.RDR.LINK/VBA007

TECHNOLOGY FOR THETIMES

ZF says its mission is to allow vehicles to see, think and act. what the technology company has in store for the commercial vehicle segment.

As the push towards zero-emissions transportation accelerates, the CV sector has a critical role to play in hitting the brakes on climate change. With transportation accounting for more than one-fifth of global carbon emissions - and trucks and buses representing the largest contributor - the CV sector must take the lead in making zero-emissions vehicles a viable reality.

According to the International Energy Agency (IEA), the international governmental body overseeing global energy use, emissions from the trucks and buses sector will need to reach a peak within the next few years and then make a rapid decline if we are to hit net-zero scenario milestones.

segments is proving a tougher prospect. Developing viable alternatives to diesel for heavy-duty trucks with regional and longhaul range capabilities, which by IEA estimates account for three-quarters of heavy-duty vehicle fuel consumption, is proving particularly challenging.

Electrify everything

ZF says it is leading the charge to bring new, greener and more sustainable technologies to the CV industry. It foresees a mix of new technologies, specifically a blend of batteries and hydrogen fuel cell systems, emerging as the dominant solution to address the pressing challenge of achieving zero emissions.

cells can be used for long-range journeys. This hybrid approach takes advantage of the respective strengths of each technology, paving a way towards viable and sustainable zero-emission transportation. New systems that are suitable for light, medium, and heavy-duty vehicles, and trailers such as all-electric central drives, axle drives, and eComponents are reshaping the thinking around powertrain systems.

CV operators can quickly reap the benefits by integrating electrification technologies into their fleets to generate efficiency savings that electrified power systems can bring.

ALTERNATIVE TECHNOLOGIES JULY/AUGUST 2023 CVW 19

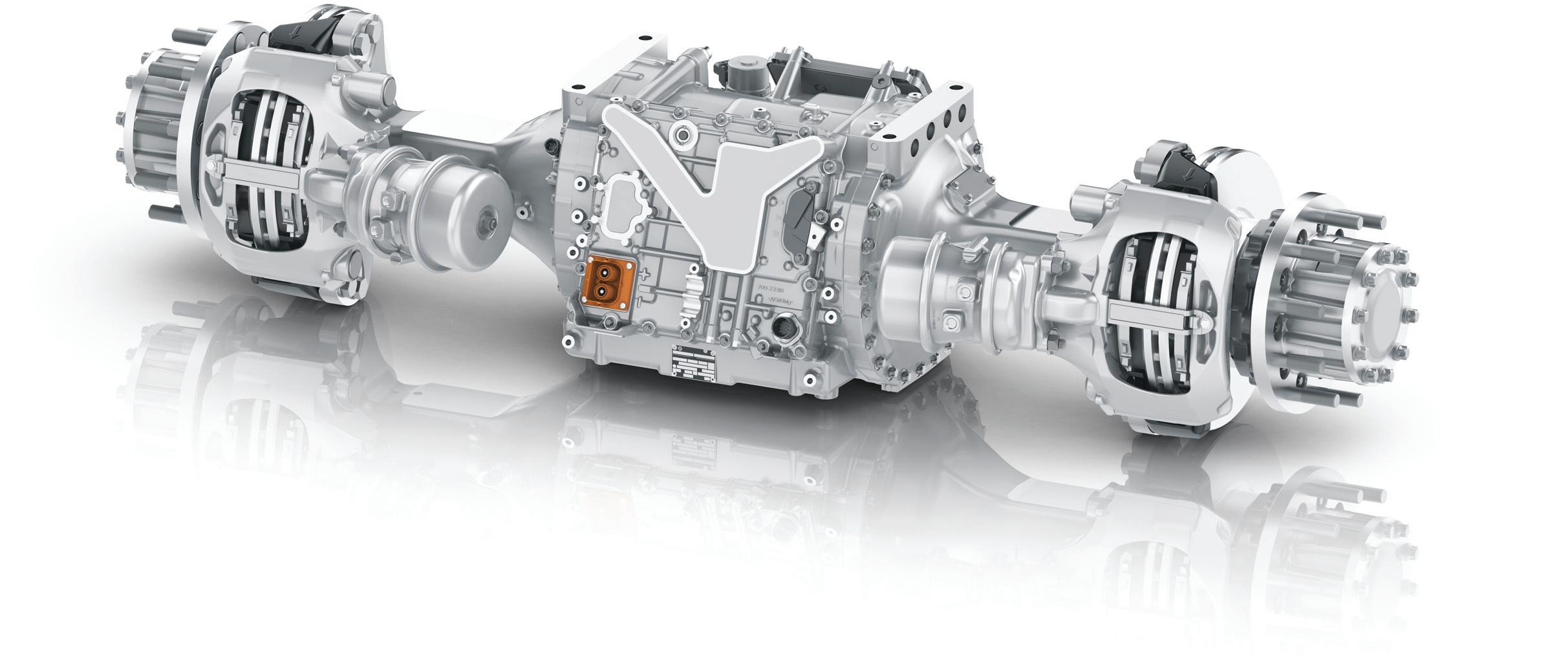

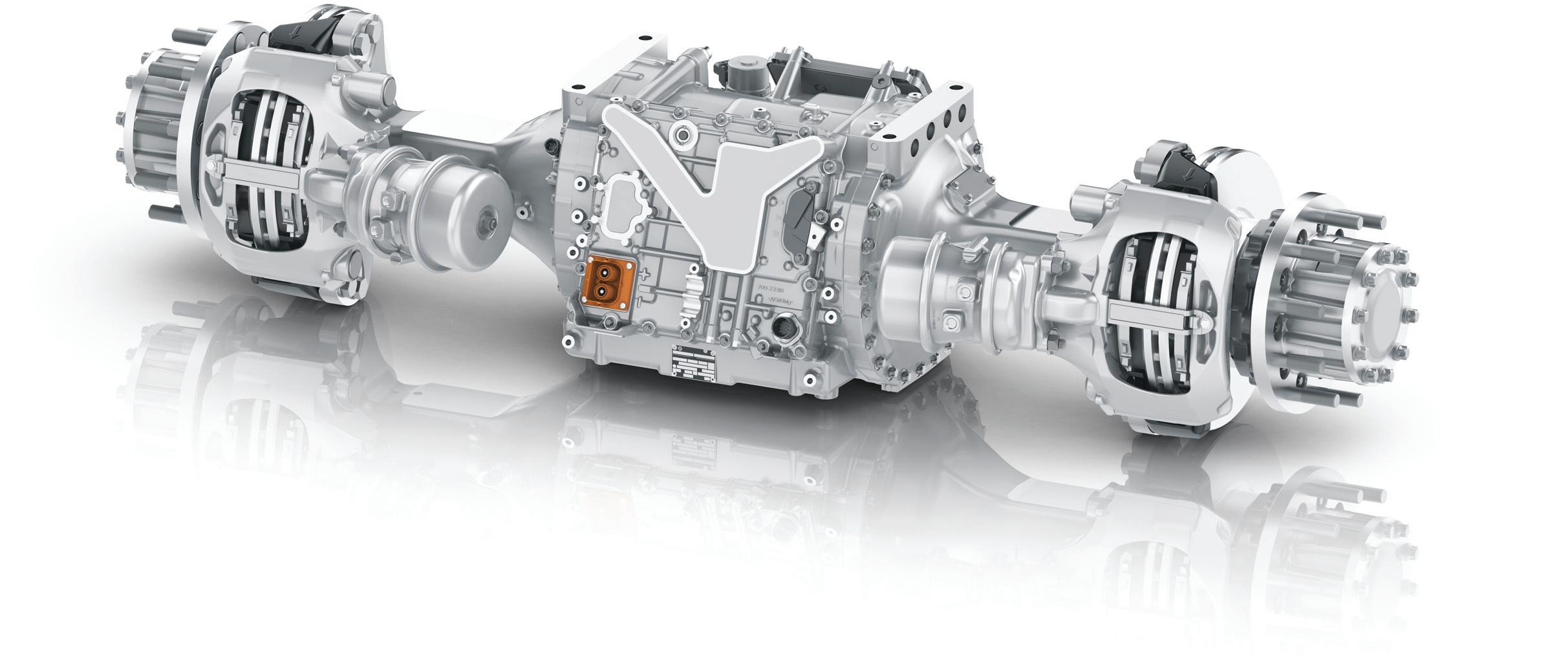

One such innovation that has been developed is the new AxTrax 2. A modular, axle-based e-powertrain system, AxTrax 2 can help manufacturers and fleet operators ease the implementation of electrification for almost types of CVs up to 44 tons.

First unveiled at the recent Advanced Clean Transportation Expo in Las Vegas, it features a compact design that maximises the available space for batteries while giving manufacturers design flexibility for future vehicle concepts.

Increased integration

It can also be fully synchronised with key vehicle functions, including braking, ADAS, and automated driving systems, to help enhance vehicle safety and efficiency, while enabling advanced digital and telematics systems via CAN bus to communicate and share e-axle system information. Production in Europe is set to begin in 2024, with the U.S. following in 2025.

“With our modular electric drive kit, ZF can provide customers with everything they need to electrify their commercial vehicles from last-mile delivery vehicles up to 44-ton trucks,” explains Winfried Gründler, senior vice president of Driveline Systems with ZF’s Commercial Vehicle Solutions division.

“Consisting of complete axle and central drive systems that, like other ZF electric systems, uses open technology, AxTrax 2 can be easily combined with a battery or a fuel cell system, for example. The kit is complemented

by a wide range of eComponents.”

Embracing modular principles, AxTrax 2 can either be integrated into ZF’s full epowertrain systems or it can provide a ‘mix-and-match’ option for manufacturers to use alongside their own components, taking advantage of synergies and common interfaces.

Concepts and innovation

ZF is also keen to harness a dynamic commercial vehicles sector by enabling new entrants to employ its systems and components as well as its advanced engineering expertise to bring their new concepts and innovations to market.

For example, ZF’s recently announced collaboration with British truck maker, Tevva, has helped the company integrate ZF’s regenerative electronic braking system (EBS) for its new zero-emission 7.5-ton truck. The EBS system enables the truck to capture up to four times more energy than a traditional air brake system, further optimizing the range and performance of the truck.

“Our broad product portfolio, including ZF's standardised EBS, enables faster timeto-market for new, innovative market players such as Tevva,” says ZF's Heiko Eggers, head of commercial vehicle EMEA application engineering for braking and ADAS. “Tevva’s commitment and agile engineering expertise allowed us to meet our stringent safety requirements and complete our project. We look forward to seeing the first trucks on the road.”

Collaborations such as these help accelerate the development of the technical solutions that will drive the industry toward the new future.

TO FIND OUT MORE ABOUT ZF

ALTERNATIVE TECHNOLOGIES 20 CVW JULY/AUGUST 2023

WWW.RDR.LINK/VBA008

HVO POWERS SUSTAINABILITYSTRATEGY

As one of the UK’s major suppliers of dry silo mortar, CPI Euromix has a nationwide network of nine factories supplying building sites all over the country. The material itself is like readymixed concrete without the need for just-in-time deliveries as it can be stored on site until it is needed yet it has all the benefits of factory production, such as consistent quality and colour.

The company plans to cut its carbon footprint by switching its whole fleet of wagons to the diesel alternative, hydrotreated vegetable oil (HVO), starting with a pilot scheme at its plant in Northfleet, Kent, where it has six trucks.

"We decided to switch to HVO because it's proven to be a cleaner fuel option for both on and off-road commercial fleets,” explains Stuart Russell, commercial manager at CPI.

“HVO is compliant with EN15940 standards, which govern cleaner transport fuel for use in road vehicles, and it offers an immediate reduction in CO2 emissions without requiring changes to engine infrastructure or machinery.

“What we really appreciate about HVO is that unlike conventional biodiesel, it uses hydrogen as a catalyst instead of methanol, which makes it cleaner burning and ensures a longer shelf life.”

HVO is a renewable and sustainable alternative to fossil-based fuels such as petrol or diesel. HVO is produced by refining and hydrogenating vegetable oils like rapeseed, palm, or soybean oil, resulting in a clear and odourless liquid that can be used as a drop-in replacement for diesel or petrol.

Higher cetane rating

There are several benefits to using HVO over traditional fossil-based fuels. It produces fewer greenhouse gas emissions, including CO2 , than fossil fuels. This is because the carbon in HVO comes from plants that have absorbed CO2 from the atmosphere during their growth, resulting in a lower net emissions output. It also has a higher cetane rating than diesel (more than 70 compared to 51), which means it burns more cleanly and efficiently in diesel engines, leading to improved performance and reduced engine wear. HVO is sustainable because it is manufactured using renewable vegetable oils and can even be produced from waste materials such as used cooking oil, which reduces

ALTERNATIVE TECHNOLOGIES

22 CVW JULY/AUGUST 2023

CPI Euromix is determined to be sustainable in every element of its business, including fuel, so it is switching to HVO. CVW takes a look at what is involved.

“...it offers an immediate reduction in CO2 emissions...”

reliance on fossil fuels and promotes a circular economy.

“Our vehicle drivers are delighted to be trialling this excellent scheme,” says Stuart. “Employee buy-in is essential to us establishing our reputation as an environmentally responsible manufacturer, so we’re very glad that they’re cooperating with such enthusiasm.”

Environmentally conscious

Stuart points out that the company’s move towards running its fleet on HVO rather than diesel is part of its overall sustainability strategy.

“As a company, we are committed to sustainable business practices, and each initiative we undertake is guided by principles aligned to CPI's ISO 14001 environmental management accreditation.”

ISO 14001 is an international standard that prescribes a structured approach to environmental protection, enabling organizations of all sizes to develop and implement policies for environmentally responsible and sustainable practices. So Stuart has other examples in which the company has switched to energy sources with less emissions.

“Last year we introduced an electricpowered forklift to our Rotherham bagging plant, coupled with CPI's zerocarbon electricity source,” he says. “The shift to a battery-powered vehicle resulted in a healthy reduction in CO2 and diesel particulate emissions.

“We’ve also invested in a solar arrays initiative that presents an opportunity for partial power self-sufficiency in the months and years to come. The solar arrays plan is currently being implemented at various locations across CPI's production sites, and we've already taken action at our Harlow, Manchester, Bilston, and Bristol factories. We anticipate that each installation will produce up to 80 mW of energy each year, equating to a saving of more than 6% on the company's annual power consumption.”

Swift wins

HVO looks likely to become more popular as companies seek lower emissions. Euromix CPI is not the only UK company seeking to reduce its carbon footprint and, on the face of it, running a fleet on HVO looks like a swifter win with less investment required than installing solar power.

FOR MORE INFORMATION ON CPI EUROMIX

WWW.RDR.LINK/VBA009

JULY/AUGUST 2023 CVW 23

PROFESSIONAL MOTOR MECHANIC MECHANEX

TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS

● FREE CPD TECHNICAL SEMINARS ● FUTUREDRIVE ZONE ● FREE ENTRY ● FREE PARKING ●

FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL

R E G I S T E R F O R F R E E AT W W W. M E C H A N E X . I N F O THE HANDS-ON TRADESHOW FOR INDEPENDENT WORKSHOPS

S A N D O W N PA R K , S U R R E Y 7T H & 8T H N O V E M B E R 2 0 2 3

The regional Tradeshow for aUTo rePair Professionals

FEATURING LIVE

CLEAN SWEEP

Quattro Plant Ltd is one of the UK’s leading cross-sector plant hire companies and, like many organisations operating a fleet, is committed to reducing carbon emissions in line with the Paris Agreement. One of the ways it is looking to achieve this reduction is the retrofitting of existing vehicles to be cleaner and greener.

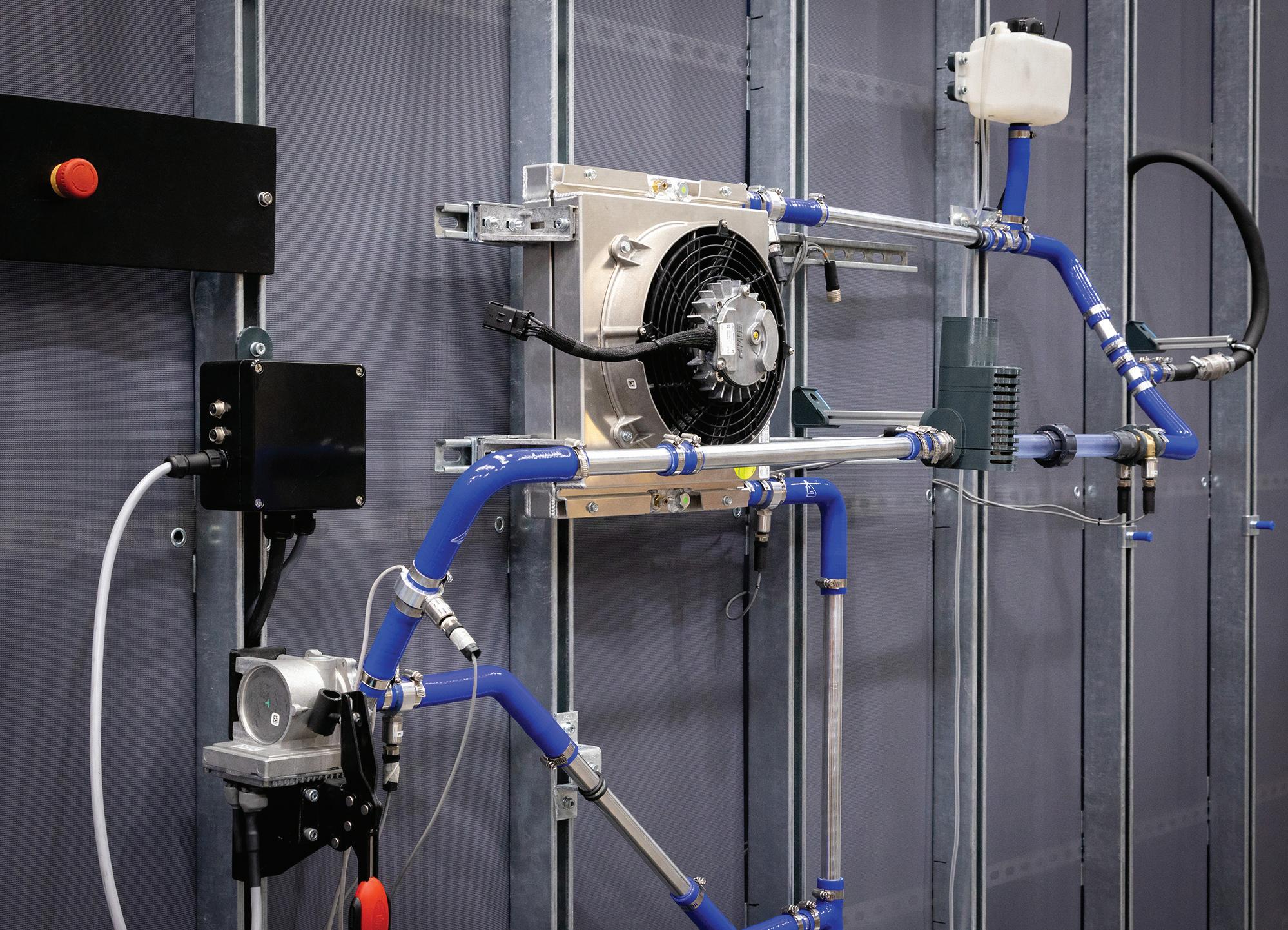

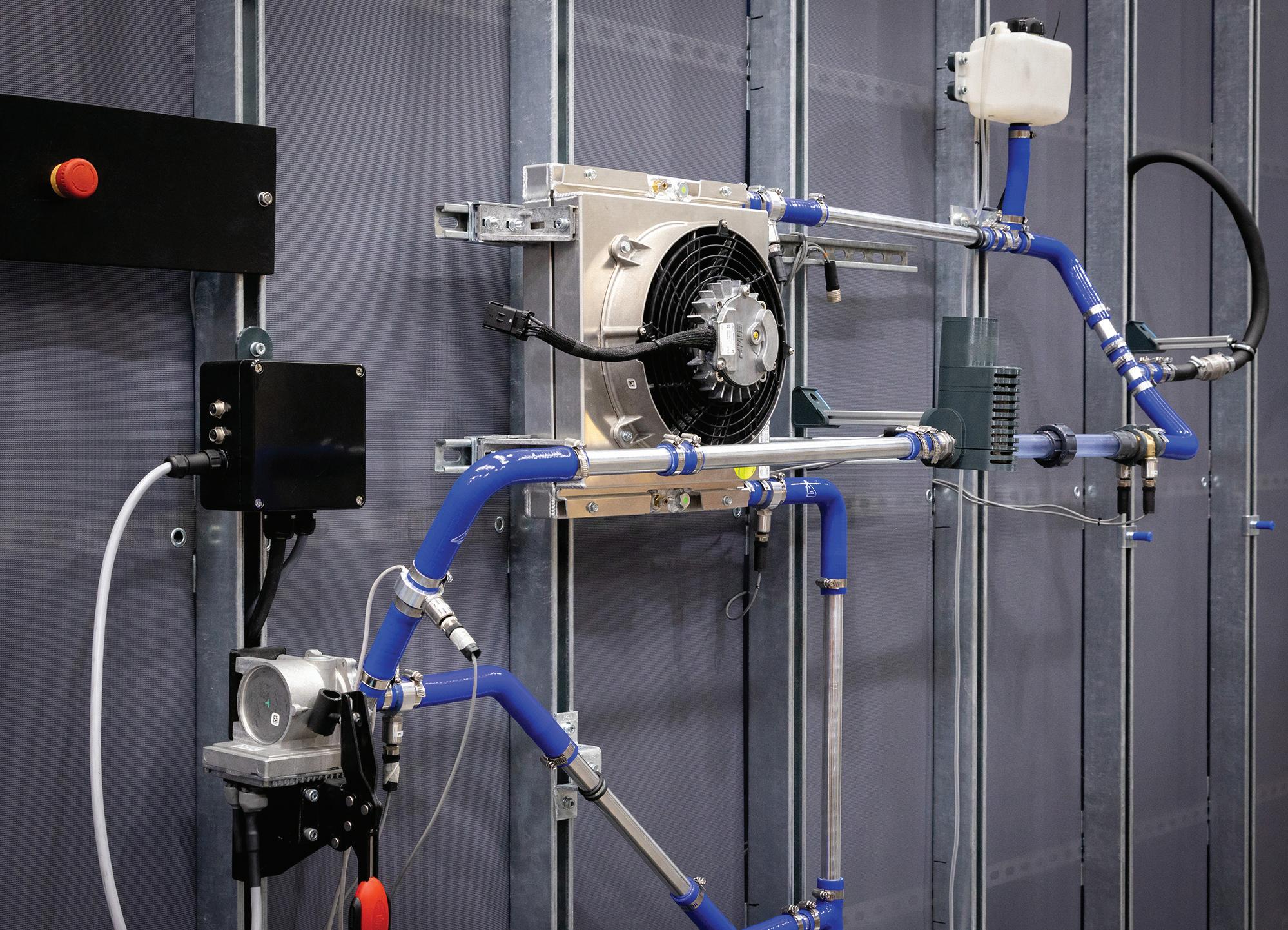

One such vehicle was a road sweeper where the diesel engine was being swapped out to be replaced with an EV powertrain consisting of high voltage (HV) motors and inverters and the associated power electronics. As part of the conversion a complete EV cooling loop was required.

Quattro Plant’s in-house R&D department initially contacted Technical Services as a component provider for the cooling loop. This opened the opportunity for Technical Services to share its expertise in the design of complete cooling systems and to work in collaboration with Quattro on the wider cooling loop.

By working at a system level, with collaboration from both engineering teams, Technical Services was able to understand more about the application. One of the main drivers was the cooling loop needed to work with non-conductive dielectric coolant. This was achieved by integrating a range of premium components including the pumpa keystone to the cooling loop - that had been subjected to enhanced durability testing, specifically with dielectric coolants.

Cool running

Dielectric coolant is a non-conductive heat transfer fluid. It is specifically used to flood the high voltage high current internal areas of components that need to be thermally managed to take the heat away without causing a short. Therefore, careful application engineering was needed due to the wide changes in coolant viscosity when using a dielectric oil versus a glycol-based coolant.

The cooling system schematics and CAD drawings, defining the architecture and component selection for the cooling loop was approved. For ease of installation the complete cooling loop was supplied to

Quattro Plant with semi-constructed sections and components to speed up installation.

Technical Services collaborated closely with the engineers throughout the project and helped supervise the installation process.

The cooling loop was successfully installed and provided the required solution enabling the engineers to seamlessly convert the road sweeper vehicle from diesel to battery electric. Retrofitting the vehicle proved to be a cost-effective and efficient way of upgrading the road sweeper to be compliant with Clean Air Zones and Ultra Low Emission Zones where charges apply for diesel vehicles. Testing and validation of the vehicle has been carried out with excellent results and positive feedback from drivers.

Working at a system level gave Technical Services insight into the performance range of individual components and the combinations of components in different configurations. This included everything from looking at the architecture and layout to the power and control strategies. By successfully balancing the cooling system Technical Services achieved the desired outcome for the application ticking all the boxes for efficiency, durability, and performance.

JULY/AUGUST 2023 CVW 25

Retrofitting of current ICEpowered vehicles with cleaner sources of power is one of the ways companies are meeting their commitment to sustainability. CVW reports on one business which is doing just that.

FOR MORE INFORMATION ON TECHNICAL SERVICES WWW.RDR.LINK/VBA010

ALTERNATIVE TECHNOLOGIES

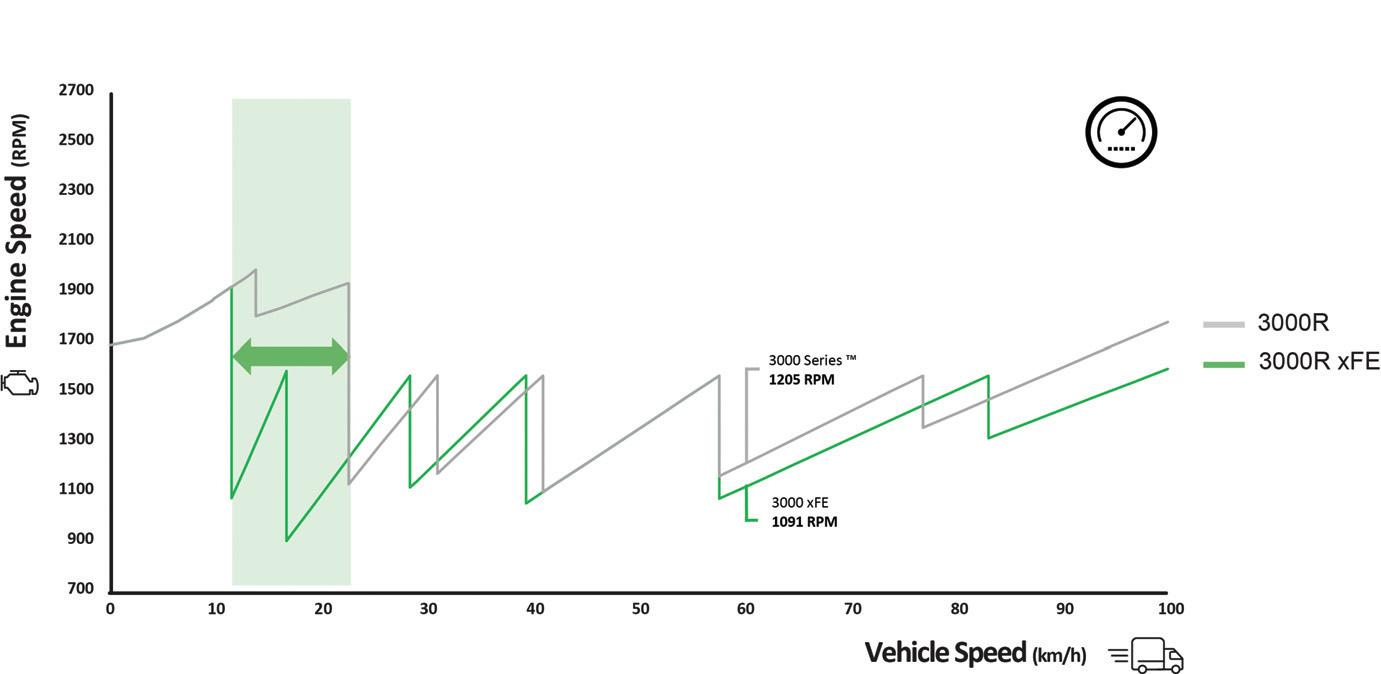

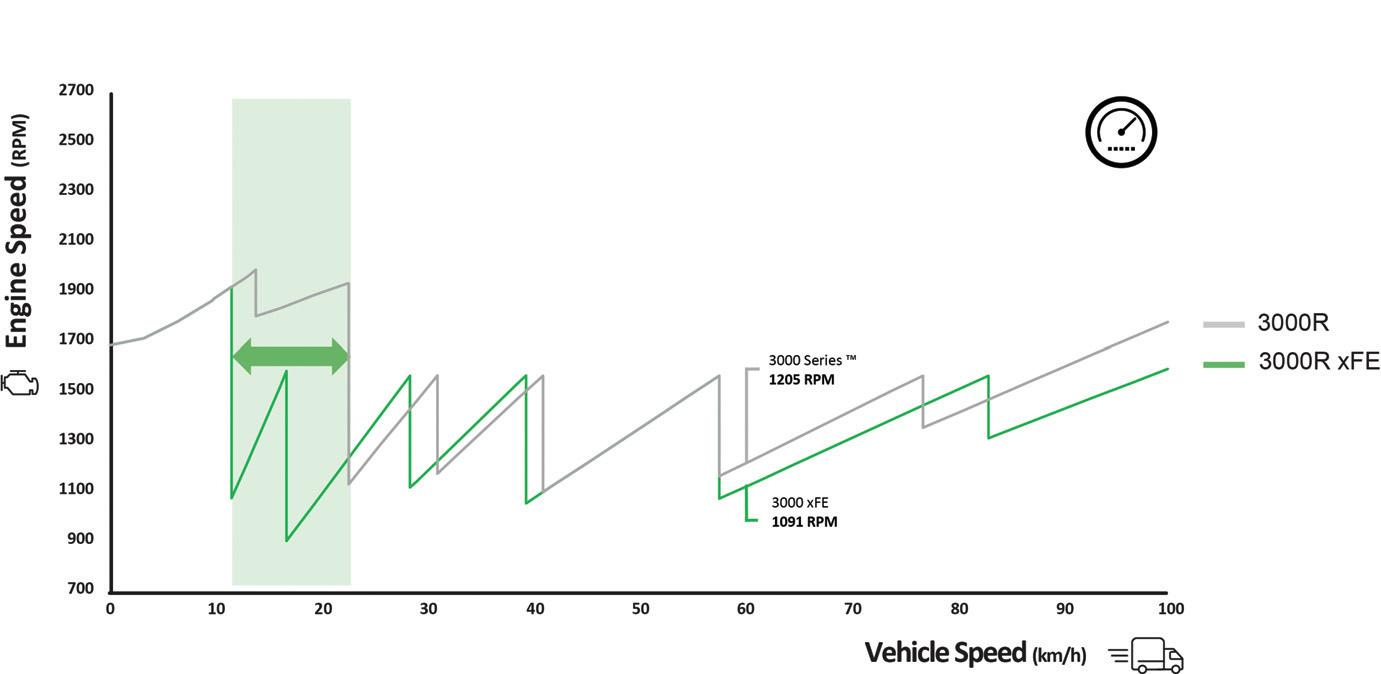

Allison Transmission has delivered on a promise of fuel saving from its xFEfully automatic transmissions after trials on a pair of refuse collection vehicles showed diesel consumption reduced by almost five percent.

CVW takes a look.

FUEL SAVINGS GOTO WASTE

Introduced to the European mediumduty truck market in June 2021, the 3000 xFE and 3200 xFE transmissions differ from their standard counterparts allowing early lock up in first gear versus second gear. The double overdrive ratios in the fifth and sixth gears are also optimised, resulting in an improved ratio spread of 11%.

These new features target improvements in fuel economy and exhaust particulates. Earlier lock up reduces transmission power losses from the torque convertor, reducing heat from the powerpack and allowing the truck’s engine to operate at lower rpm for a given road speed. The optimised overdrive

gears reduce the engines cruise rpm for further fuel consumption and exhaust emissions improvements.

Many refuse trucks operate in low-speed urban areas where air quality is at its most critical. The xFE series is designed to help address these ongoing concerns and improve operators’ return on investment. Further fuel savings come from Allison's FuelSense 2.0 software and electronic control system, which is installed as standard on the xFE transmissions.

Carbon and fuel reduction

The advantage has most recently been demonstrated via a 12-month UK trial incorporating 24 months of data, involving removing the standard Allison transmissions from two Dennis Eagle Elite 26-tonne trucks operated by Biffa on commercial waste collection duties and replacing them with the xFE equivalents.

Operating on identical routes throughout the West Midlands and the Wirral, and on a variety of duty cycles, the trucks with the Allison xFE transmissions returned an average fuel saving of 4.8% compared with their previous performance.

The results support the theoretical CO2 emissions saving calculated using the European standard VECTO fuel

ALTERNATIVE TECHNOLOGIES

26 CVW JULY/AUGUST 2023

Allison 3000 xFE transmission v 3000 Series. 100% full throttle profile.

consumption tool of up to 3.7% on the municipal utility cycle when compared to the Allison 3000 Series closeratio transmission. This provides an essential carbon reduction option for vehicles within fleets that may be unsuitable for EV alternatives at the current time.

“These compelling results are supported by telematics data from DE Connect, providing CANbus information instantaneously for componentry functionality, vehicle fuel usage, and realtime vehicle tracking information, Allison iSCAAN data gathering and analysis tool, and finally our own in-house telemetry engineering system, “explains Nathan Wilson, account and area sales manager UK

& Republic of Ireland, Allison Transmission.

“All systems aligned, showing fuel savings from the earlier lock-up in first gear. Achieving this reduces the time the transmission spends in lower gears, rather than torque-converter mode and allows engine speeds to be reduced by 400 rpm at the lock-up point. The xFE’s gear ratios in fifth and sixth are faster than those in the standard Allison transmissions, allowing greater efficiency at higher speeds and

lower rpm, again reducing fuel consumption.”

“Biffa is committed to driving sustainable innovation across all its operations and we are proud to be involved in another successful partnership with Allison Transmission,” adds Steve Cole, Biffa’s group fleet and procurement director. “We provided historical data from our telematics system, operated the vehicles on identical routes over a 12-month period and installed additional telematics to validate the findings, which showed material fuel and carbon savings.”

WWW.RDR.LINK/VBA011

FOR MORE INFORMATION

To start it’s worth reminding ourselves that filtration is an important process that separates what is useful from what is harmful. As is the case with conventional drives, the components of electric vehicles must be protected from contamination and wear in order to ensure optimal performance. We can do this in two ways: with established products – and with future-proof innovations. High-quality filtration solutions will extend and optimize the service life and performance of fuel cells, electric axles, and batteries. While electric vehicles do have fewer powertrain components, these parts also need to be checked and replaced over time. This creates opportunities for the aftermarket. The following filtration solutions are used for the different drive types.

Filtration requirements of fuel cells

Fuel cells are extremely sensitive to particles, corrosive gases, and water in the intake air as well as to impurities in the cooling circuit. These impurities include, for example, dust particles that obstruct the flow of gas and can form deposits on cell membranes.

FILTER TIPS

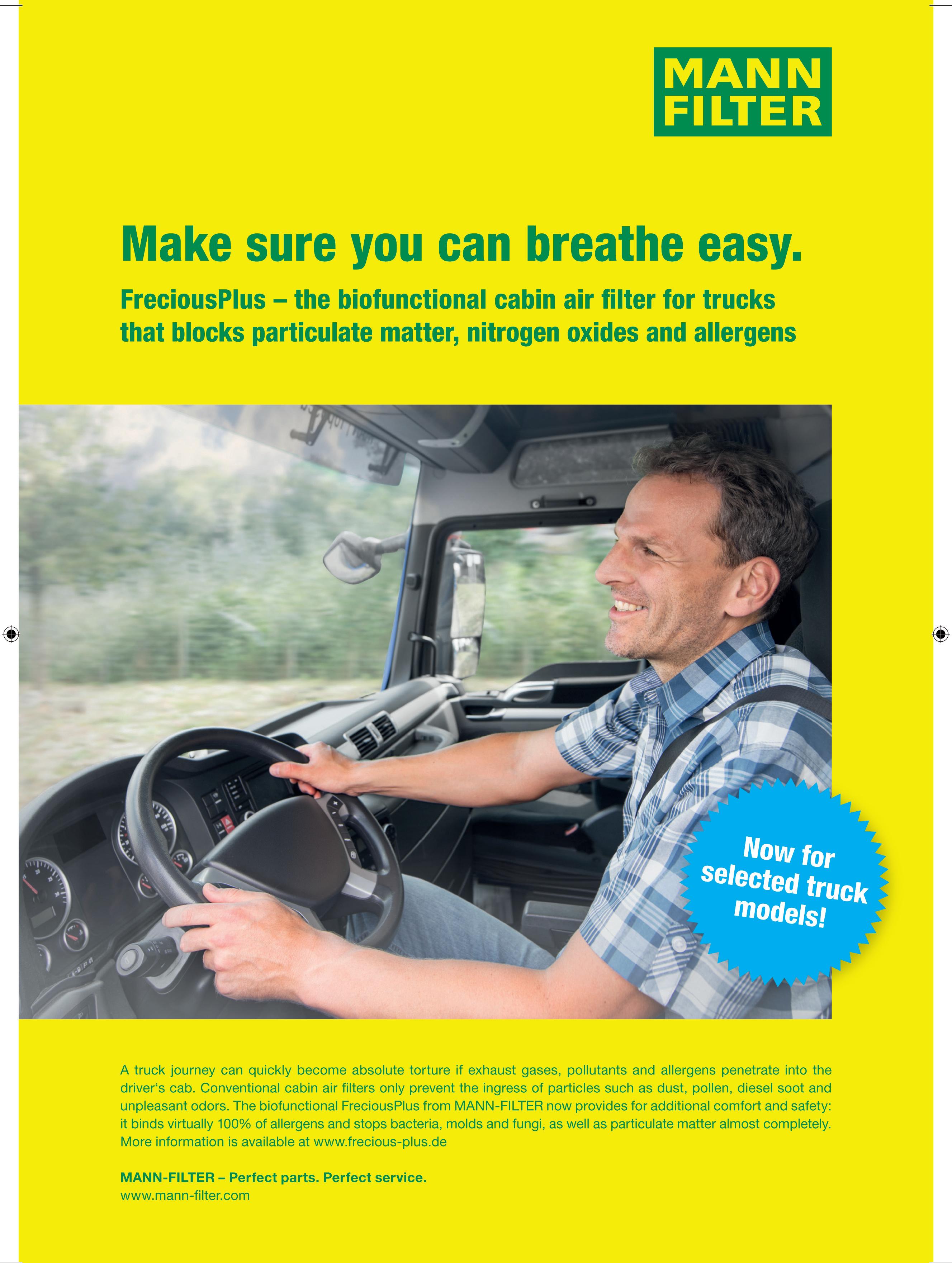

Electric vans and trucks don’t need filters, do they? Absolutely, they do, says Dr. Michael Harenbrock, principal expert E-Mobility at MANN+HUMMEL

Corrosive gases can severely damage the catalyzer, thus causing a significant decrease in performance within the fuel cell system. Effective filtration is therefore essential for protecting sensitive components. A cathode air cleaner ensures that intake air is clean. This cleaner has a particulate filter layer that separates solid particles from the intake air, while its tailor-made activated charcoal layers adsorb harmful gases, like sulphur dioxide (SO2), nitrogen oxide (NOX), and ammonia (NH3). This protects the fuel cell's catalyzer from being irreversibly damaged, which shortens the system's service life. An ion exchange filter removes positively and negatively charged

ions from the cooling fluid, keeping the cooling fluid's conductivity as low as possible to prevent short circuits in the fuel cell stack. The coolant particulate filter is designed to protect the coolant pump from wear and prevent blockages in narrow cooling ducts within the fuel cell stack. This filter removes harmful particles from the cooling circuit.

E-axle filtration

When the electric motor, power electronics, and transmission are integrated into one compact unit, these components are referred to as e-axles or electric drive units. This compact design enables the use of one joint fluid circuit for all three components, which cools the electric motor and power electronics and also lubricates the transmission. Passenger cars usually have a basic reduction gear, while commercial vehicles normally have a multi-speed transmission that often requires better filtration to protect the hydraulics. Tailormade filtration solutions for this , such as the MANN-FILTER W 7071 transmission oil filter for the Mercedes-Benz eActros 300 and eActros 400 are available.

ALTERNATIVE TECHNOLOGIES

28 CVW JULY/AUGUST 2023

Filtration for battery systems

In battery-electric vehicles, the battery system is the most valuable component. This system must be protected from water and dust, and it must be operated within its optimal temperature range to maintain its maximum charging capacity. Higher temperatures will decrease the battery's performance, and severe overheating will even destroy the battery cell. There are two approaches for cooling battery systems: air cooling or liquid cooling.

With air-cooled systems, MANN+HUMMEL uses cooling air particulate filters to protect the fans and battery system from dirt particles in the

cooling air. For these filters, developers use materials and knowledge from cabin air filters. The coolant in liquid-cooled batteries – often a mixture of water and glycol – may contain harmful particles that originate, for example, from the surfaces of components in the cooling circuit or from the assembly process. These particles may cause the

cooling ducts to become blocked, thus causing a loss in pressure and overheating of the battery. The coolant particulate filter developed by MANN+HUMMEL efficiently separates dirt particles from the coolant to protect the system from pressure loss, wear, and overheating.

An opportunity for workshop business is a given with electric vehicles through an annual change of cabin air filters. The reason for this being that this component is used both in combustion engines as well as electric vehicles to protect drivers and passengers alike from harmful particles and pollutant gases in the intake air. For example, the MANN-FILTER FreciousPlus has a biofunctional coating that binds to harmful substances, allergens, and mold spores, improving the air quality of the vehicle cabin. To maintain the filter's performance, however, it must be replaced every 15,000 kilometers or once per year.

With a wide range of filters necessary for alternative drives, there will continue to be a need for filtration in the future, which represents great maintenance potential and revenue for workshops.

JULY/AUGUST 2023 CVW 29

MORE ON MANN+HUMMEL WWW.RDR.LINK/VBA012

FOR

“...severe overheating will even destroy the battery cell....”

FORD GAUGES FUEL CELLTECHNOLOGY

range in energy-intensive use cases.

energy source for its ETransit all-electric vans. CVW reports.

Part-funded by the Advanced Propulsion Centre (APC), Ford’s consortium of six automotive technology leader and fleet operator partners will also help to determine the supporting hydrogen refuelling infrastructure required.

Hydrogen fuel cells produce electricity by combining hydrogen from an onboard tank and oxygen, with the only resulting emissions being water. The system essentially uses the hydrogen tank as a “gas battery” to improve range and deliver faster charging than the solid batteries and mainsconnected chargers typically used by EVs.

working shift.

Matching conventional fuels

A test fleet of eight hydrogen fuel cell Ford ETransits will run for six-month periods over the three-year project to 2025. The test fleet data will provide insights into the total cost of owning and operating a large van with enhanced zero-emission range and uptime that matches a diesel-powered equivalent.

Ford Pro, the company’s commercial vehicle (CV) and services division, will use the pilot to expand its conversion expertise, supported by the company’s Dagenham site and Dunton Technical Centre, in Essex.

ALTERNATIVE TECHNOLOGIES

30 CVW JULY/AUGUST 2023

Tim Slatter, chair of Ford in Britain, said: “Ford believes that the primary application of fuel cells could be in its largest, heaviest commercial vehicles to ensure they are emission-free, while satisfying the high daily energy requirements our customers demand.

“Ford has an unmatched history in the commercial vehicle sector with the Transit, and we are excited to be exploring new ways to make clean deliveries an option for even our hardest-working vans on the road.”

Project validation

Ford’s hydrogen fuel cell E-Transit project with the APC will validate the vehicle’s business case through input from fuel cell powertrain experts and fleet operators including Ocado Retail. Other partners on

the project are BP, capturing hydrogen usage and infrastructure requirements; Cambustion, testing the fuel cell system; Viritech, designing hydrogen storage systems; and Cygnet Texkimp, providing the pressure vessels’ carbon fibre tooling.

Ford has researched fuel cell technology since the 1990s, developing many prototypes, refining test fleet vehicles in partnership with customers, and in 2021 demonstrated an E-Transit fuel cell vehicle at the CENEX Low Carbon Vehicle Show. At a European level, Ford is still involved in a number of publicly-funded projects that are also exploring the use of hydrogen technologies, both for use with internal combustion engine-powered vehicles and fuel cells.

WWW.RDR.LINK/VBA013

TO FIND OUT MORE ON THE E-TRANSIT

“...Ford believes that the primary application of fuel cells could be in its largest, heaviest commercial vehicles...”

AGE CONCERN

Beware the risks of using the latest engine oils on ageing customer vehicles, advises Mike Bewsey, chairman of industry trade body the Verification of Lubricant Specifications (VLS).

The number of vehicles on UK roads is growing, but it’s also ageing.

According to the latest European Automobile Manufacturers Association (ACEA) 2023 ‘Vehicles in Use’ report, there are 42.9 million vehicles on UK roads, including 6.1 million commercial vehicles and buses. The average age of light commercial vehicles is 9.3 years, up from 7.8 in 2019. For medium and heavy commercial vehicles, the average age now stands at eleven years, an even more substantial increase as in 2019, it was 7.4. The economic impact of COVID-19, automotive supply chain challenges, issues around the move to electrification and the cost-of-living crisis mean that business owners and fleet operators are holding onto their vehicles for longer than ever.

On the one hand, this is good news for workshops. With older vehicles on the roads, there is more demand for servicing, repairs and MOTs. However, as vehicles age, some aspects of servicing, such as choosing the right engine oil, can become more complex.

Engine technology has evolved significantly over recent years. To meet government requirements for reduced emissions and business owners’ needs for vehicle durability, economy and performance, smaller engines are running at higher temperatures to maximise efficiency, power output and fuel economy. Longer oil drain intervals, taken together with smaller sumps, and the need to minimise emissions have created the need for less viscous, synthetic and semi-

synthetic oils to provide the lubrication required in these challenging conditions.

But are these highly efficient, low viscosity lubricants suitable for the ageing vehicles being serviced in workshops? The latest formulation is no guarantee of success. Traditionally, when newer oils were developed, they were designed to be ‘backwardly compatible’. However, this is becoming increasingly difficult as modern engines develop so quickly.

Don’t look back

For example, Volvo VDS-5 is a new heavy duty fuel-efficient diesel engine oil specification with an SAE viscosity of 5W30. Designed for use in the latest 13L engines (Euro VI Step D), it is not backward compatible with previous Volvo long drain specification fluids such as a Volvo VDS 4.5 SAE 10W-30 grade. The lower viscosity results in lower oil pressure, which could lead to multiple dashboard warning triggers. It is, however, expected to deliver over 0.5% fuel economy improvements versus 10W-30 oils.

Using the wrong oil risks accelerated wear, the formation of deposits and damage to emission control devices. Left unchecked, it could lead to eventual engine failure, meaning higher maintenance costs for your customers and potential damage to your

FUELS, LUBRICANTS & ADDITIVES JULY/AUGUST 2023 CVW 33

“...there is more demand for servicing, repairs and MOTs...”

business’ reputation. Putting an oil with a low level of sulphated ash, phosphorous and sulphur (SAPS) into a vehicle requiring a high level may not offer the wear protection required. The additives for a lower SAPS oil will differ as well. Additives help to provide the performance characteristics of an engine oil, but modern lubricants are designed to deliver performance through a thinner, less viscous oil that might not be suitable for older vehicles.

Cheap and nasty

It could be tempting to use cheaper oils to offset rising costs. However, the cheapest possible oil could be a full SAPS oil. This could damage the emission control system, poison the catalyst or block the diesel or gasoline particulate filter, reduce the overall efficiency and result in failure of the particulate filter or catalyst, both expensive to replace. Too much phosphorous from a high SAPS oil can also poison the selective

catalytic reduction units designed to reduce nitrogen oxide emissions. Short term gain may lead to long term pain for you and your customers.

VLS strongly recommends referring to the vehicle handbook or using an online database to identify the correct oil for each and every vehicle. Looking beyond the viscosity to specific ACEA and OEM standards is essential. This ensures that the lubricant is fit for purpose in that specific vehicle. If you are in any way unsure of which oil to use, get in touch with the OEM.

The Verification of Lubricant

Specifications (VLS) is an independent trade body that helps technicians and motorists understand the lubricants industry and ensures that lubricant products can deliver what they claim.

FUELS, LUBRICANTS & ADDITIVES 34 CVW JULY/AUGUST 2023

TO FIND OUT MORE WWW.RDR.LINK/VBA014

“...modern lubricants are designed to deliver performance through a thinner, less viscous oil...”

GUY MARTIN EXPLORESTHE FUTURE OF OIL IN COMMERCIAL VEHICLES with Morris Lubricants

Using the best quality oil, with the correct specification has always been a priority for commercial vehicle technicians, but with constant engine hardware adaptions, making the right choice can feel daunting. Now, a brand-new video series with truck mechanic, heavy goods vehicles (HGVs) expert and TV presenter, Guy Martin alongside Morris Lubricants, shows how the right oil can improve fuel efficiency and avoid breakdowns, whilst also providing an insight into the design of future, alternative commercial vehicle power options.

Guy, who has worked on HGVs for more than 25 years discusses how oils and lubricants are evolving to meet the foreverchanging requirements of new engine designs, with Morris Lubricants’ Technology Manager, Adrian Hill.

In the first episode, Morris Lubricants reviews how oil formulations and engine designs have evolved to ensure current emissions’ compliance, including the function of aftertreatment devices such as diesel particulate filters (DPFs) and AdBlue Catalysts.

The second episode focuses on how the move toward Euro VII will see a further reduction in exhaust emissions with aftertreatment devices becoming even more efficient.

Fleet managers, commercial vehicle mechanics and workshop technicians will start to see an increase in demand for a new generation of thinner engine oils. In many instances, oil film thickness has been reduced to passenger car engine oil levels, but for use in commercial vehicles with payloads that clearly far exceed an average road vehicle.

Of key interest to the sector is episode three, which considers future alternatives for commercial vehicle power options. In this episode, Guy and Adrian discuss the possibilities - from electrification to hybrid vehicles to hydrogen internal combustion engines or fuel cells.

Adrian Hill, Technology Manager at Morris Lubricants adds: ”There is a lot of interest from the commercial vehicle sector in what the future holds for diesel internal combustion engines. The drive towards cleaner and more fuelefficient technologies is set to continue at pace, so episode three looks at the key factors required for the successful implementation of any potential innovation; the available technology, usable infrastructure

and affordable price parity.”

The final episode reviews the vehicle driveline, dedicated to taking power from the engine to the wheels, and how choice of design can contribute to the reduction of emissions.

Adrian Hill concludes: “In creating these series of videos with Guy, we wanted to provide viewers with insight into how the correct choice of oils and lubricants is of vital importance. Moreover, we wanted to offer some insight into the potential future landscape for commercial vehicle power technologies.

“The modern heavy duty diesel engine is complex and is still evolving. These new engine architectures, power technologies and fuelling strategies produce real world emission reductions, but they will only achieve this if they are used with new generation engine oils, which are as critical as any other component.

“Having Guy's input as a skilled mechanic, who is witnessing these rapidly evolving engine technologies firsthand has helped provide practical insight into the challenges that commercial vehicle technicians are facing.”

The video series has been launched on Morris Lubricants website, YouTube channel and other social media channels.

ADVERTORIAL

Guy Martin, knows the importance of using quality oils and lubricants.

TO WATCH THE FULL SERIES OF VIDEOS WITH GUY MARTIN WWW.RDR.LINK/VBA015

Adrian Hill (left) and Guy Martin (right) discuss the future of HGVs.

FRENCH CONNECTION

Motul might be a French company but it has its eyes firmly on the UK CV market with an expanded offer that comprises more than simply oil. CVW is on the case.

One of the oldest names in the lubricants market, Motul is proud to be celebrating its 170th birthday this year. This, of course, means that it has been lubricating machines since long before the invention of the motor vehicle. Motul has focussed on innovation and excellence and, when the motor vehicle was invented, it saw it as the chance not only to create the right lubricant for a job, but also to find new solutions and new opportunitiessomething that has continued throughout its history, and today the brand and product offer are stronger than ever.

Motul continues to make inroads into the UK CV market with an offer of quality lubricants together with an ever-increasing resource to enhance value for its customers and end-users. To meet the constant demand for improved mechanical performance, Motul has developed a high quality, high-performance range of heavy-duty products which meet and exceed the standards demanded by industry OEMs

and CV customers everywhere. It fully recognises the specific requirements of trucks and the range covers different generations of diesel engine, with products aimed directly at helping optimise running for

those who operate them. So, whether the requirement is for fully synthetic, mineralbased or for Motul’s Technosynthese technology (which combines synthetic and best mineral base oil stocks) the company offers a tailored product to meet operator’s specific needs.

The Motul Tekma label is to be found on the brand’s premium engine oils. These are specially designed to reduce engine wear, improve fuel economy and prevent mechanical failure, even under the most severe operating conditions. Naturally, Motul products meet the varying compliance needs for engines - ranging from CATII through to CATVI. The range carries OE approvals from the leading

LUBRICANTS

FUELS,

& ADDITIVES

36 CVW JULY/AUGUST 2023

manufacturers - from Renault to Mercedes, MAN to DAF, Volvo to Scania and beyond.

Though renowned for its high quality, cost effective engine oils, Motul actually offers the industry much more. It has a complete range of fluids to cover just about every potential application - covering transmission oils, hydraulic fluids, coolants, additives and greases.

Motul now has a dedicated technical resource in the UK, which is available to all factor, workshop and end-users who sell or use the products.

For workshops, Motul also produces a comprehensive range of metalworking fluids and is even likely to have provided the fluids that were involved in the original casting of many of the metal parts used in trucks and trailers. This “Casted, Drilled, Filled” philosophy is further proof of

Motul’s complete involvement in every stage of the automotive process. Therefore, from manufacture through to running the finished product, Motul lubricates each phase. Few - if any - other lubricant brands can make the same claim - and it brings a completely new depth of meaning to the concept of “one-stop-shop.”

Those who know the Motul name will probably be aware of its stellar reputation both as an innovator and as a lubricant force in motorsport. Motorsport and competition continue to provide the proving ground for new products. Motul uses motorsport as a development hub and this technologytested on race tracks around the world or, in the case of trucks, also in the deserts of the Dakar Rally - filters down to Motul’s everyday motoring product ranges.

TO FIND OUT MORE ABOUT MOTUL, ITS HISTORY, ITS TECHNICAL STORY, ITS PARTNERSHIPS AND ITS PRODUCTS CHECK OUT: WWW.RDR.LINK/VBA016

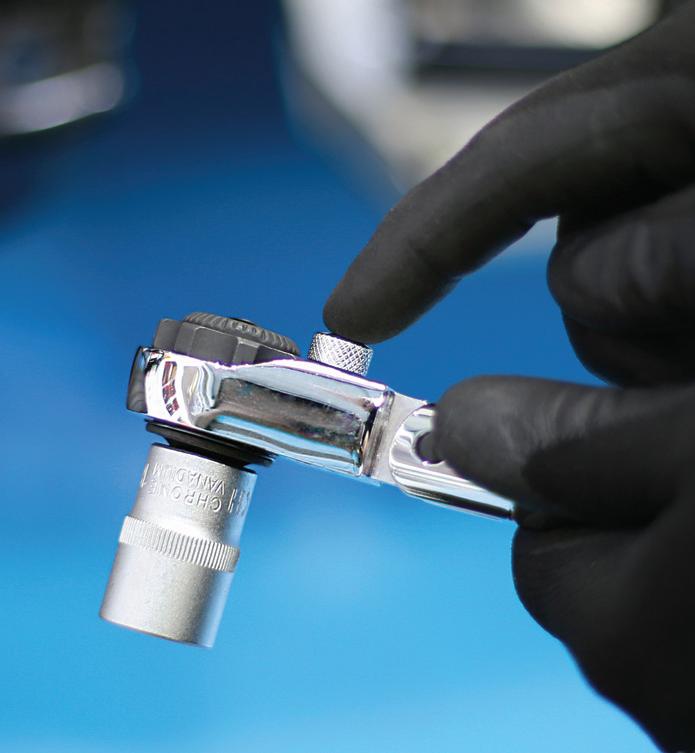

CLUTCH CONTROL

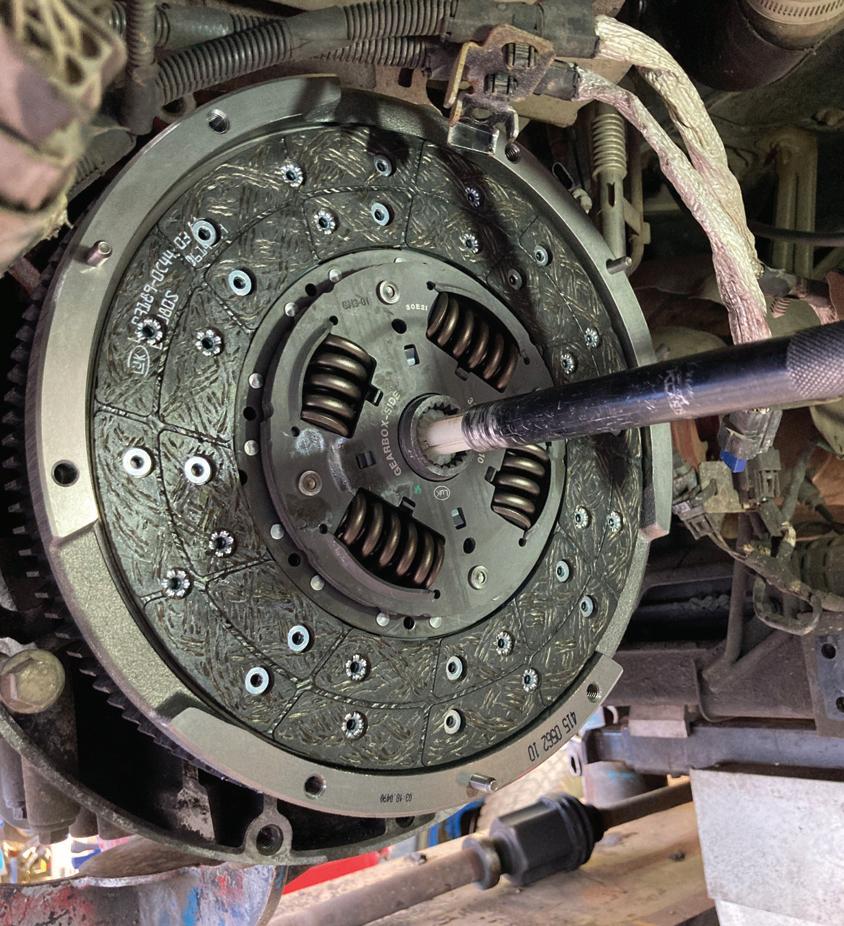

Schaeffler’s Alistair Mason puts best practice at the heart of this clutch replacement on a front wheel drive 2012 Ford Transit fitted with a 2.2 TDCi engine that has covered more than 113,000 miles.

Noticeably, there are more vans on the roads these days as delivery businesses are booming, mainly down to online purchasing increasing customer demands, as well as tradesman that rely on their vans to transport essential equipment. So, the key to these repairs is to carry out a fast and efficient repair, whilst eliminating any defects that will cause more downtime of the vehicle.

The vehicle in question was diagnosed with a worn clutch due to slight ‘clutch slip’ and the customer was also advised that it would be good practice to replace the dual mass flywheel (DMF), as the vehicle had covered more than 113,000 miles and usually transported heavy loads.

A Schaeffler LuK RepSet DMF kit was ordered for the vehicle, as this contains all components required to replace the clutch and DMF, and both are designed and manufactured to work perfectly together. It is therefore strongly recommended not to mix and match different brands in one system.

Prior to starting the repair, the QR code was scanned on the side of the box (Fig.1) using Schaeffler’s REPXPERT app, and the technical documents were checked to find any service information or bulletins that were critical to the repair. 30-second scan for information could easily save hours should a service instruction be overlooked, for example. So, with all the parts and information available, repair instructions and torque values printed off, it’s time to carry out the repair.

The advised workshop equipment:

■ Vehicle lift, two post or wheel free is ideal

■ Transmission jack

■ Engine support

■ Self-adjusting clutch tool

■ Waste oil drain system

■ Clutch bleeding tool, a vacuum bleeder is recommended

With the vehicle positioned on the lift, it’s best practice to connect a ‘back up’ battery to retain the radio code, then disconnect the negative battery lead located under the driver’s seat. Open the bonnet, remove the engine cover, air filter/box assembly (which will allow good access to remove the gear cables), upper section of the gearbox mounting, electrical multiplugs and upper bell housing bolts, then clamp

CLUTCH, TRANSMISSION & STEERING JULY/AUGUST 2023 CVW 39

Vehicle Information Make Ford Model Transit Year 2012 Engine 2.2 TDCi Mileage 113,000

the flexible section of the hydraulic clutch pipe and disconnect the pipe from the concentric slave cylinder (CSC).

With the vehicle still placed on the ground, slacken both front hub nuts, raise the lift to access the underside, drain the gearbox oil and, whilst the oil is draining, remove both front wheels. Release both bottom ball joints, remove the hub nuts, release the O/S driveshaft support bearing, remove the outer CV joints from the hubs and then both front driveshafts.

Fitting the new DMF

Remove the lower gearbox mounting, starter motor, electrical multiplugs and bell housing bolts, but leave two easily accessible to support the gearbox until the gearbox is ready to be removed.

Lower the lift and support the engine with an engine brace and remove the gearbox mounting, then lower the engine slightly on the engine brace as this will aid gearbox removal. Raise the vehicle lift to access the underside, support the gearbox with a transmission jack, remove the final two bell housing bolts and ease the gearbox away from the engine. When the gearbox input shaft is clear of the clutch, lower the transmission jack and remove the gearbox from the vehicle.

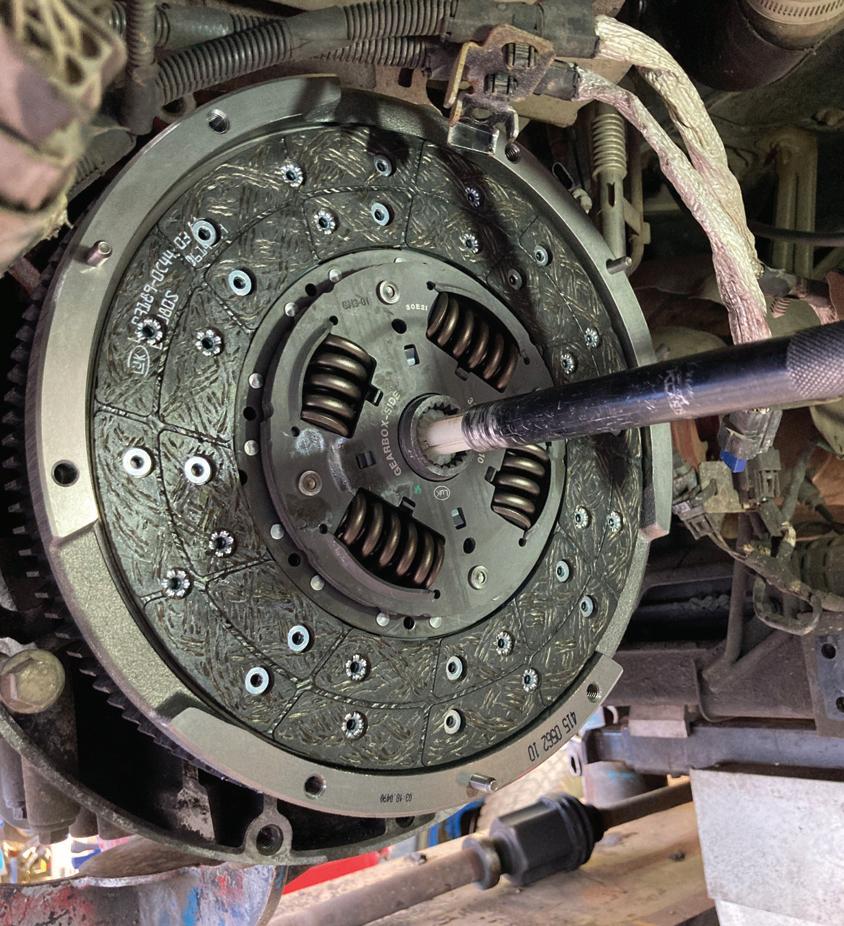

With the gearbox removed, a good indication of whether the clutch is at the end of its service life is if the three small, yellow adjusting springs have extended (Fig.2).

Remove the six clutch assembly bolts, ease the clutch cover off the dowels and then remove the clutch assembly, noting which way round the clutch plate is asit is useful to refer back to.

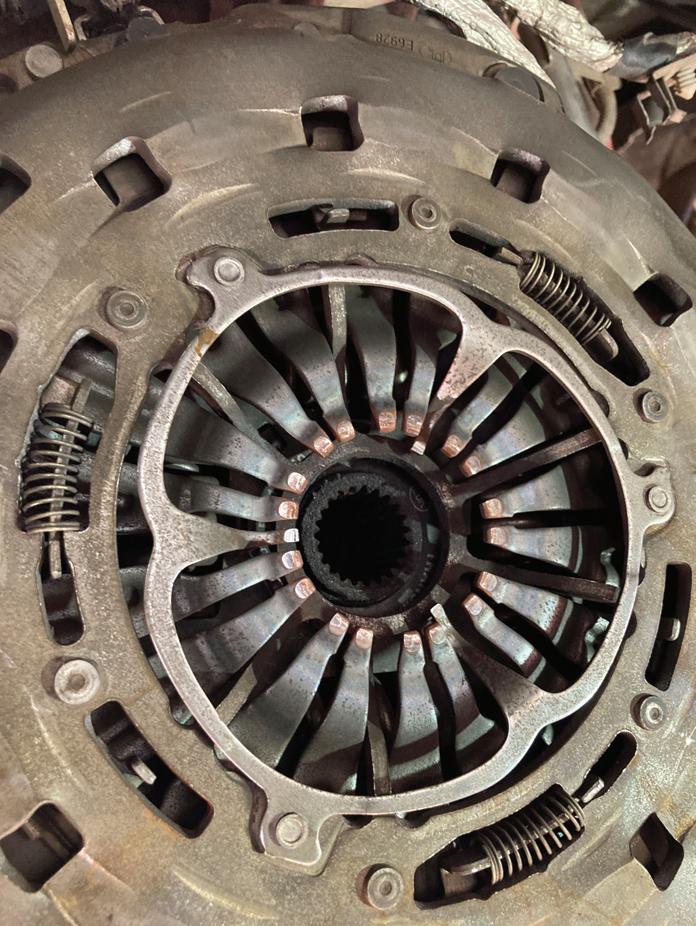

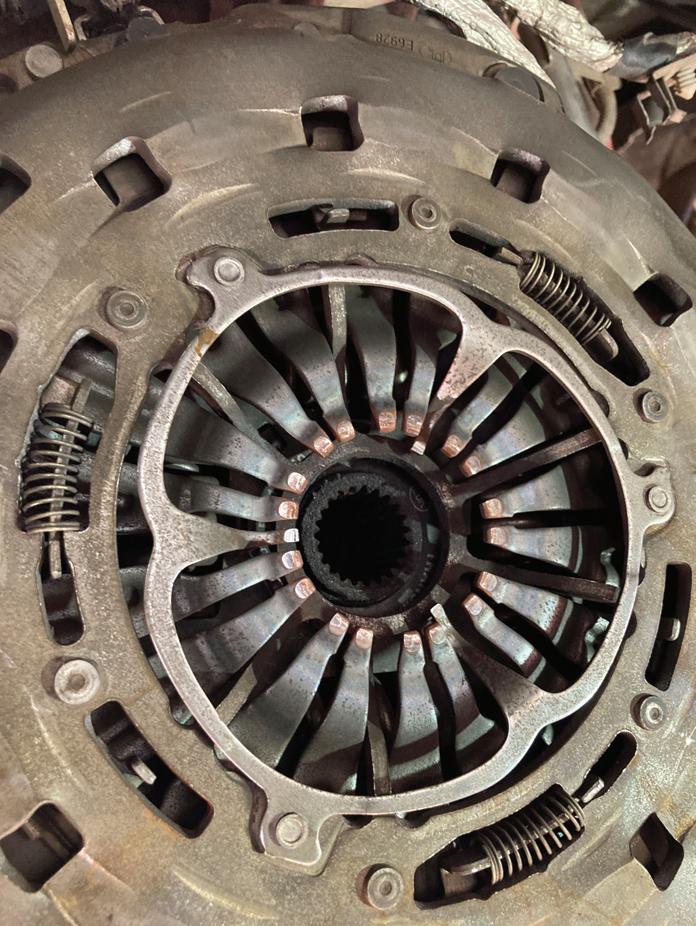

Remove the DMF by detaching the eight flywheel bolts. In this case, slight ‘blueing’ was noticed on the flywheel surface, which would indicate the heat generated with clutch slip and was another good reason to replace the DMF, as this heat will affect the internal grease and arc springs and compromise the DMF’s performance. If required, the DMF can be tested for rotational free play and rock, full instructions and specifications for which are available on REPXPERT. With the flywheel removed, check the back of the engine for any oil or coolant leaks, rectify as required and then clean the back of the engine with clutch and brake dust cleaner.

Turning attention to the gearbox and the release system, remove the CSC, check the gearbox for any leaks and rectify if required. Clean the bell housing and input shaft area to prevent the old clutch dust from contaminating the new clutch and DMF.

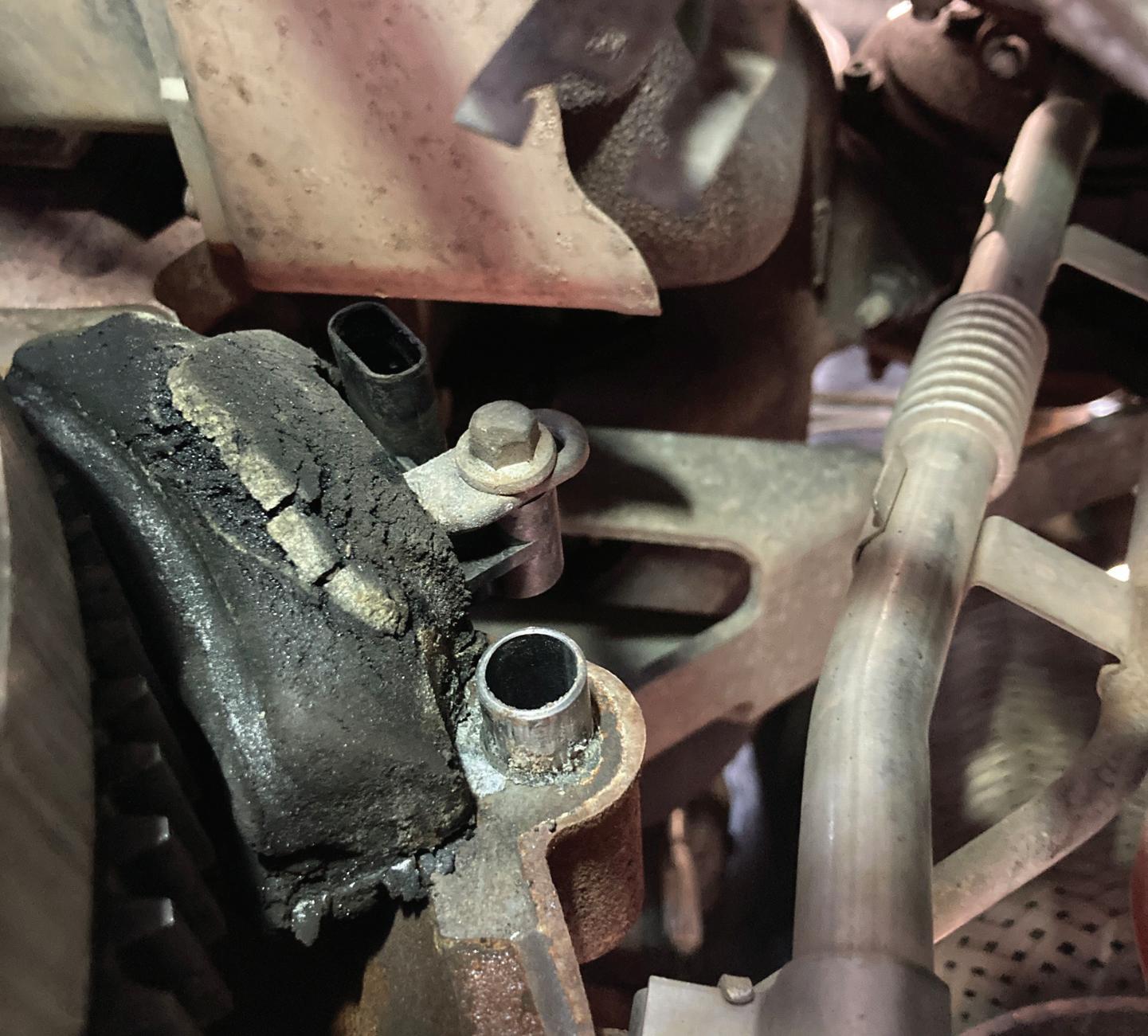

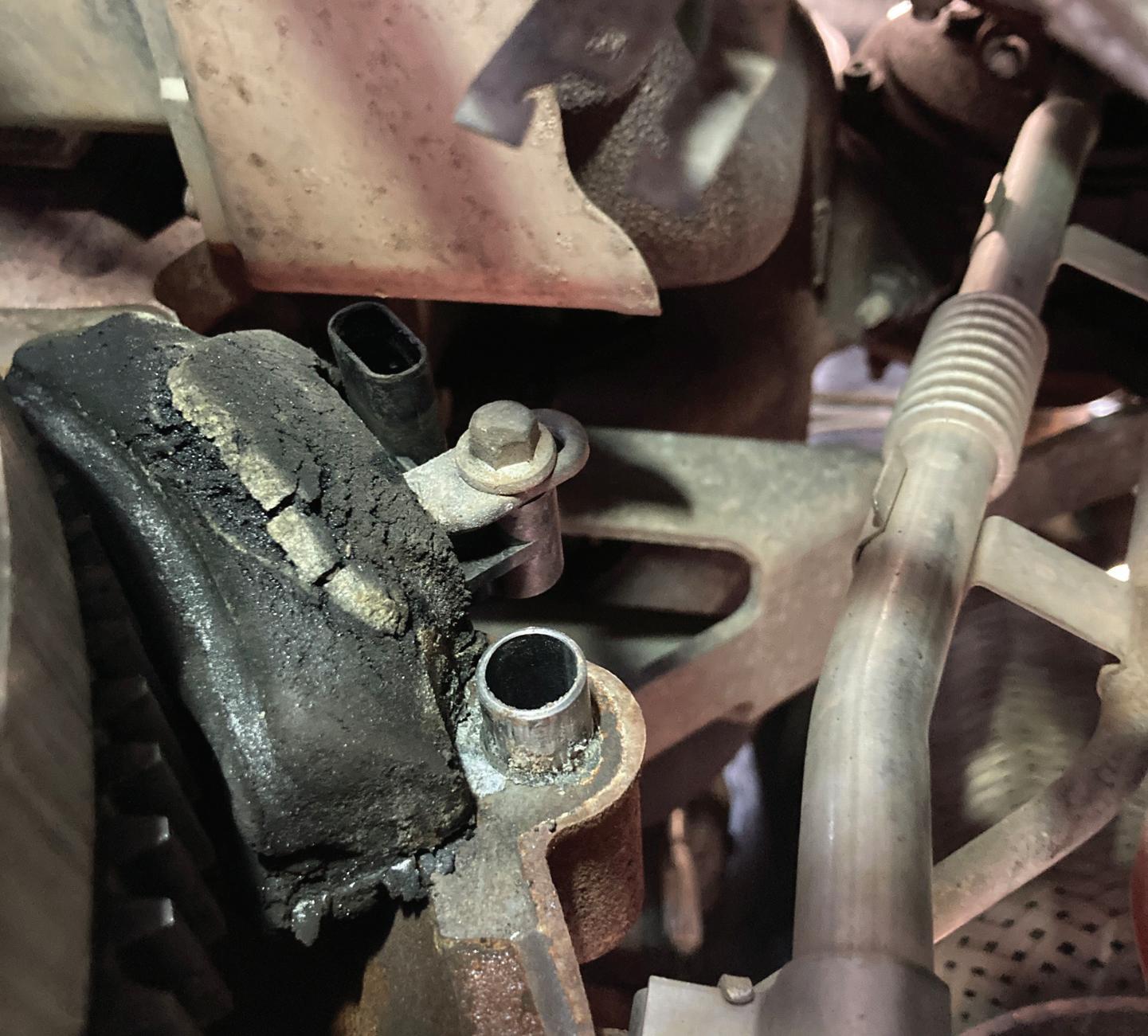

The CSC must always be replaced when replacing a clutch as the guide tube can become dirty, corroded and pitted and therefore damage the hydraulic seal when removing the gearbox.

Remembering to never squeeze the new CSC, as this can cause damage to the new unit, fit the new CSC supplied with the RepSet DMF kit, but ensure the seating area for the CSC is clean. Then mount the CSC squarely and ensure that all the bolts are tightened correctly.

Now apply a light smear of high melting point grease to the gearbox input shaft and mount the new clutch plate onto the input shaft (Fig.3). This will ensure that the clutch plate is the correct fitment and also evenly distribute the grease, then remove the clutch plate and wipe off any excess grease.