COMMERCIAL VEHICLE WORKSHOP

2023 The trade magazine for servicing and repair professionals

JUNE

REGULARS

ROAD TRANSPORT EXPO 2023

10 Check out details of the summer’s biggest CV show –it’s one not to miss!

TOOLS & WORKSHOP EQUIPMENT

16 Bulk haulier Alfred Hymas looks to AES for better, speedier and more accurate tyre maintenance.

18 Check out this beast of a tool. Durofix’s Warthog will have your nuts off in seconds!

20 You can only meet a challenge with the right equipment. K2 Recovery gets a helping hand from Totalkare

23 Stertil Kone gives highways specialist Kelly Bros a lift.

25 Keep safety at the forefront of your workshop procedures, says MAHA’s Nick Austin.

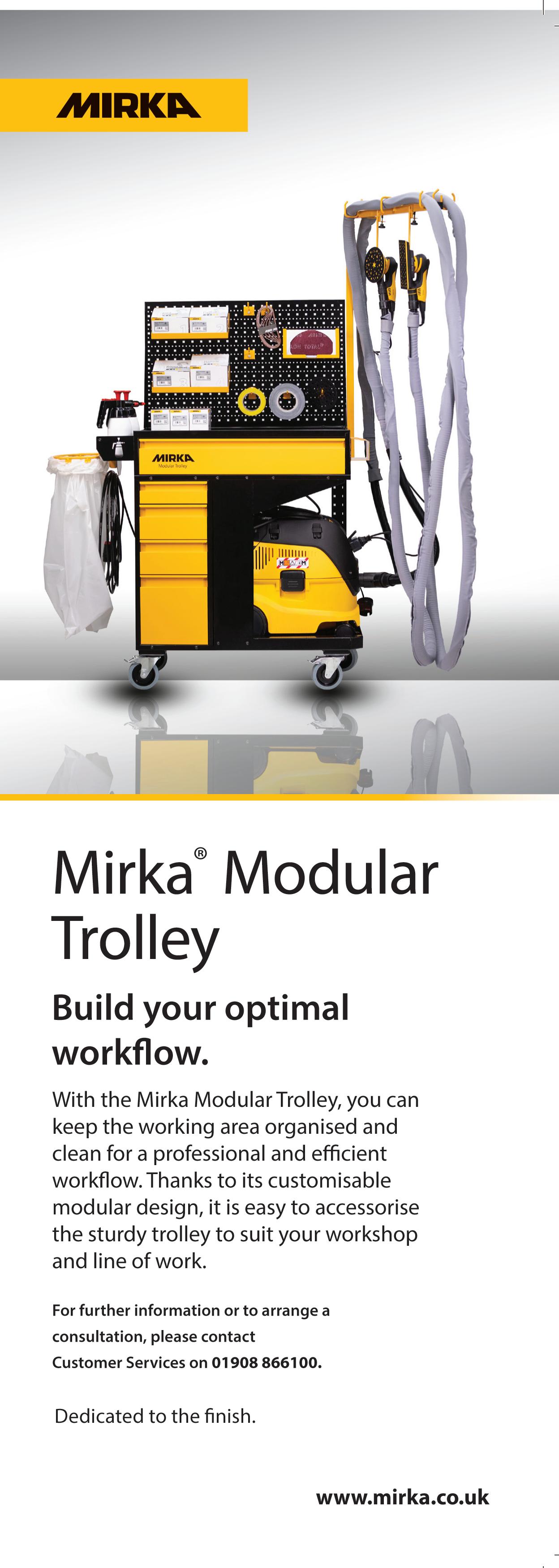

29 Win big! Enter Mirka’s competition and you could walk away with a LEROS sander worth a massive £1500.

TECHNOLOGY & DIAGNOSTICS

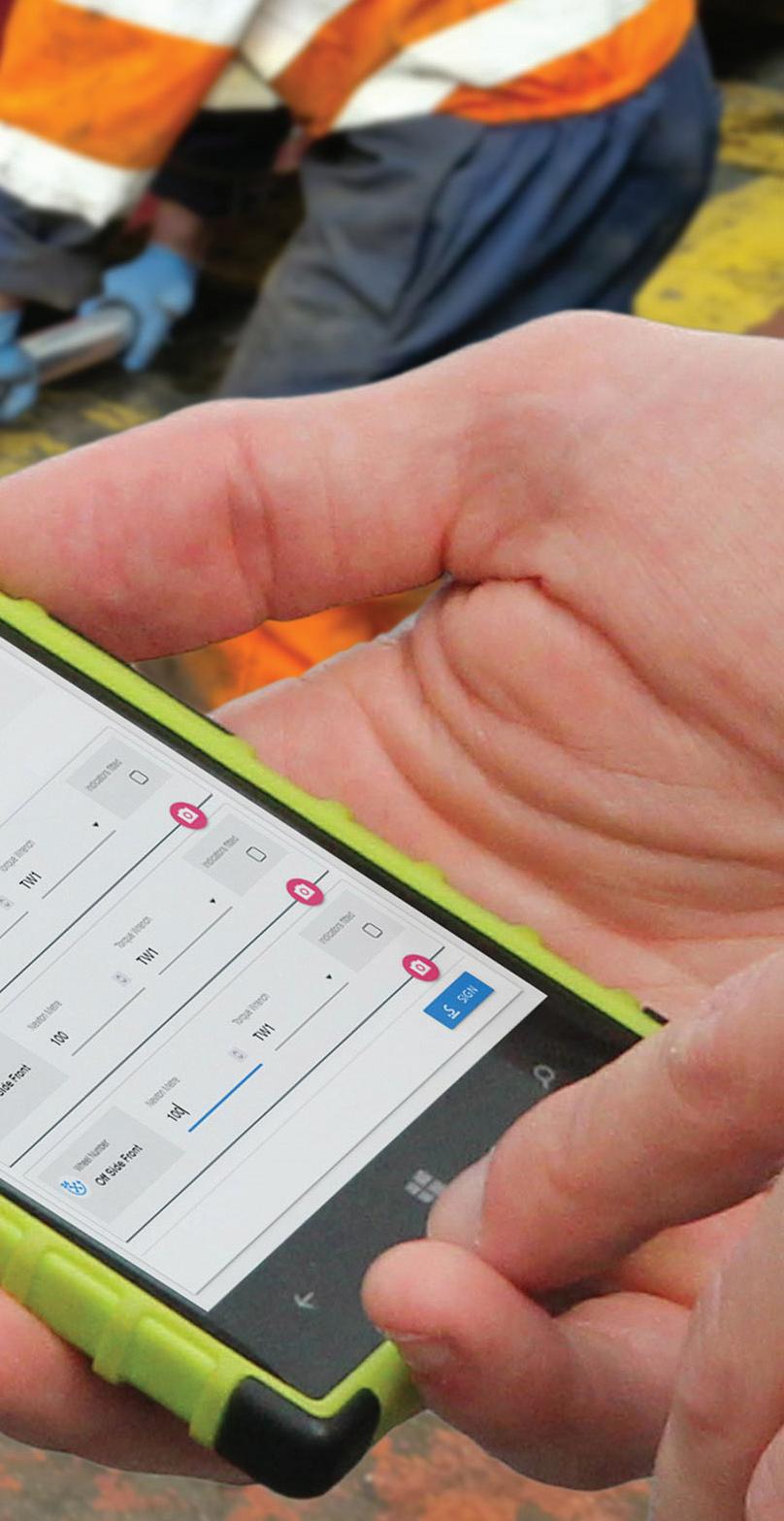

30 A new app from Freeway could prevent wheel loss. Let’s torque about it.

32 Bridgestone’s new road condition monitoring system promises trouble-free travel.

If you are getting bad vibes then Pro-Align’s new diagnostic wheel balancer is for you.

Delphi Technologies’ Luke Garret argues that not all diagnostic tools were created equal. Some are more equal than others.

AXLES & SUSPENSION

38 Shocks have a hard life. Mark Todd at Diesel Technic looks at when, why and how to replace them.

40 Pimp my ride! Bilstein gives the VW Caddy a bit of bling.

Issue 6 Volume 20 Viewpoint Traffic news 42 In the workshop 46 What’s new? 49 Digital digest

CONTENTS

JUNE 2023 CVW 3 18 30 40

VIEWPOINT

Editors

JOHNNY DOBBYN

JOHN LEVICK

workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Senior Account Manager

ALEX DILLEIGH

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates: UK £30

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Walstead Peterborough

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2023

IT’S A GAS, GAS, GAS

‘Gaslighting’ is defined as manipulating someone or a group of people using psychological methods into questioning their own sanity or powers of reasoning. In the modern media environment, it’s associated with major channels ignoring contrary ideas in favour of orthodoxies promulgated by the establishment.

A good example is facemask wearing during the pandemic. There was no evidence to suggest facemasks had any role to play in the prevention of the transmission or acquisition of Covid, yet the wearing of them became more-or-less compulsory regardless of their efficacy. Subsequent research has shown that facemasks – of the type available to ordinary people at least – are next to useless.

Lots of scientists knew this at the time, but were either ignored, pilloried – being called granny killers and the like – or silenced. Now things have eased, these dissenting voices are being heard, albeit a little late in the day. They must have started to question their sanity – thought they were being gaslighted – in the face of such an establishment, for which read government, position that was enthusiastically adopted by the media and many other professionals.

Are we now seeing the same thing with electric vehicles (EVs)?

For some time, EVs have been posited as the answer to decarbonising transport and eliminating fossil fuels from society. The Government is legislating against the production of ICE vehicles in the future and seeking to make life increasingly difficult for current users. Manufacturers, meanwhile, are piling investment into EV production and the future, we are told, will be emission- and fossil-free.

Sceptics and dissenters from this new energy orthodoxy, until recently, have been thin on the ground – despite many commonsensical people having their EV doubts, whether about the viability of the technology, the ability of the grid to be upscaled to charge them all (and the fossil fuel consumption that goes with the extra power generation) or concerns about the materials that go into making them.

Now the contrary voices are being heard and it seems that EVs could be their own environmental disaster – from mining and manufacture, in use and at the end of their lives.

At the most basic level, there’s some powerful pushback from the aftermarket about how EVs – and the bigger the EV, the worse – eat brakes and tyres, shedding harmful PM2.5 particulates into the air at a rate that exceeds that of conventional vehicles. And how EVs with batteries low in the pan are having to be scrapped after trivial bumps, like kerbing, because minorly damaged batteries cannot be repaired.

It goes on from beginning to end. The mining practices, many illegal and unregulated, extracting rare earth elements for batteries are wrecking vulnerable environments and displacing indigenous peoples in a metals Wild West out East. The processing of these minerals is so toxic that currently China is the only country on earth that will take it on.

In use, they require an upscaling of our power grid not seen for a century which, at this point in time, either won’t happen in a timely fashion for most of us or will require loads of new (gas) power stations. Roadside repairs – even tyre changes – are difficult to effect and it’s a disaster if they catch fire. And then when they reach the end of their useful lives, usually a function of battery exhaustion, recycling presents its own challenges.

8,249

Let’s work against climate change, decarbonise and work towards Net Zero by all means; yet it’s about time the establishment stopped gaslighting us about how wonderful EVs are and started a proper debate about, and triggered meaningful investment into, alternative fuels such as renewable diesel and hydrogen.

Happy reading!

TheCVWTeam

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication From 1 July 2021to 30 June 2022 Associate member JUNE 2023 CVW 5

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk

Brigade stands with driving charity

Global vehicle safety systems supplier Brigade Electronics has become the latest company to pledge its support to international development organisation, Transaid.

Managing director, Philip HansonAbbott, said: “We are delighted to be supporting Transaid and working with the charity in its essential efforts to improve road safety across Africa. We hope our knowledge and expertise in this field will be invaluable to Transaid in helping to deliver its vital work. We look forward to being part of the charity's endeavours and, together, saving even more lives.”

Improving standards

Brigade joins some of the largest and most influential organisations in the transport and logistics sector, which contribute time, expertise and resources to help Transaid achieve its primary goals of improving commercial driving standards and ensuring people have access to healthcare in sub-Saharan Africa.

Transaid's Acting Co-Chief Executive Florence Bearman expressed her gratitude for the company's commitment, saying: "We are delighted to welcome Brigade on board, and look forward to working closely with a company whose vision aligns so closely to our own."

Semis get longer

The announcement by the government that longer-semi trailers (LSTs) will be approved for use in the UK from 31st May has been welcomed by Logistics UK, who has hailed it as an opportunity to reduce road emissions and industry costs.

Able to transport a higher volume of goods, resulting in fewer vehicles needed and subsequent reduced running costs, LSTs will provide a much-needed economic boost for the sector that is currently facing escalating costs related to decarbonisation investments and soaring inflation, according to the organisation. It will also bring many environmental benefits due to lower congestion, and with less vehicles on

the road, also has the potential to increase road safety, it adds.

Chris Yarsley, Logistics UK's senior policy manager – Road Freight Regulation comments: "The introduction of LSTs into general service will increase the scope and scale of the goods which our industry is able to transport, increasing efficiencies and reducing the environmental impact of delivering for the UK's economy. Over the past few years of the trial, our members have proved that LSTs provide operators with a cost-efficient, environmentally prudent alternative to conventional vehicles and our members remain committed to rolling them out across the wider industry as soon as possible."

Tyres inflating costs

Rising costs mean that tyre management is becoming the dominant factor in everyday fleet running costs, FleetCheck is reporting.

The fleet software specialist says that tyres now regularly account for more than 50% of fleet service, maintenance and repair (SMR) budgets – a situation that the arrival of electric vehicles (EVs) will only make more acute.

Peter Golding, managing director at the fleet software specialist, said: “A trend appears to be emerging where tyre costs are forming such a large proportion of overall fleet SMR spending that increasing attempts are being made to proactively manage them, in much the same way as currently happens with fuel.

“Factors such as cornering at high speed, clipping kerbs and driving through potholes

can have a very definite effect on tyre life and, to a greater or lesser extent, are the result of driving style. In a similar manner to how some fleets now monitor their drivers to ensure they meet minimum standards in terms of fuel consumption, we're expecting more to track tyre wear and, in cases where it appears to be excessive, to attempt to manage behaviour on the road.

“We’re already working with some of our fleet customers in this area, helping them to produce reporting based on real world data that will enable them to build a picture of their tyre use and take appropriate action. Of course, this kind of information also means they can see which tyre brands are performing the best when it comes to wear performance and to compare this to pricing.”

6 CVW JUNE 2023

NEWS

Core strategy

RS Automotive Core is the latest company to join the Independent Automotive Aftermarket Federation (IAAF).

The company is a UK-based buyer and seller of core automotive aftermarket parts including calipers, steering racks, steering pumps, EGR valves, diesel injectors, driveshafts, diesel pumps, AC compressors, turbos, starter motors and alternators.

Alastair Whatmore, managing director, comments: “Being part of the federation allows us, along with other members, to be represented at government level. Its work to promote the aftermarket in a fair and accurate fashion is ahead of the curve with what is happening with vehicle manufacturers.

“It also gives RS Automotive Core the chance to network with likeminded industry professionals and access to the IAAF’s range of business services.”

Boost your batteryknowledge

VARTA is hosting a one-day conference at the British Motor Museum on the 14th June, for fleet managers, transport managers and commercial vehicle engineers. The event will include:

● Deep-dive the latest market trends in battery technology and why VARTA batteries are future-proof.

● Live Q&A with technical consultants from its HQ in Germany – meet with 'The Battery Guru’.

● Services to help support your business.

● On-the-day promotions! Win merchandise & vouchers.

● PLUS breakfast and lunch provided, and free entry to museum.

It is free to attend. To register go to https://mailchi.mp/5583ef665d44/varta-cvevent-invitation

Changes at the top

West Yorkshire-based Imexpart Ltd (IMEX) has appointed Martin Butterworth as its new managing director. Founder and current managing director, Arthur Pinkney becomes CEO.

In this role, Arthur will continue to lead the company's strategic initiatives and vision, while Martin will be responsible for the day-to-day operations of the business.

Martin brings a wealth of experience to IMEX, having previously held senior management positions at various automotive parts distribution businesses. He has a proven track record of delivering results and driving growth in highly competitive markets.

All about value

“I am honoured to join IMEX at such an exciting time," said Martin and "I am looking forward to working with Arthur, the management team, and the entire IMEX community to deliver exceptional value to our customers and shareholders.”

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk

Used values reach high point

LCV values climbed during the first quarter of 2023 according to the latest insight from reseller BCA, to reach an average of nearly £10,000 during March 2023, their highest point since July of last year.

Average LCV values rose by £126 in March compared to February, to reach £9,977 and sold volumes improved significantly. Performance against price guides averaged 102.6% during March.

BCA’s weekly valuation reports for March show that average values climbed steadily above £10,000 for the first time since January despite sold volumes being significantly higher in March.

Upbeat demand

Stuart Pearson, BCA COO UK commented: “Our data shows improving average values, excellent buyer engagement and rising volumes of LCVs sold during the first quarter of 2023, a more positive sales performance than many might have expected given the difficult economic conditions that continue to impact the small business sectors.”

He added: “Retail demand remains upbeat according to anecdotal reports from professional buyers and this is helping to support stable values in the wholesale used LCV sector. Whilst the market has been particularly positive during the last quarter, there will always be many moving parts relating to value, performance and desirability.”

Top job!

Rygor Commercials has been named on the UK’s Best Workplaces List (large companies) for 2023. This prestigious accolade follows its inclusion on the UK’s Best Workplaces for Wellbeing list in February this year, awarded as a result of feedback from team members about how the business supports their overall health and wellbeing, both inside and outside the workplace.

Van sales accelerate yet again

The UK new light commercial vehicle (LCV) market recorded its fourth straight month of growth with 22,665 new units registered in April, according to the latest figures from the Society of Motor Manufacturers and Traders (SMMT).

Registrations in the month grew by 4.9%, regaining ground on pre-pandemic levels. In the year to date, 109,937 new LCVs have been registered, just -13.7% off 2019, down from -15.1% last month. The largest volume growth was recorded for vans weighing greater than 2.0 to 2.5 tonnes, which more than doubled to reach 4,318 registrations. The 4×4 segment also grew, by 370.5%, to

Tools galore!

The latest edition of Sealey’s The Tool Catalogue is hot off the press! With over 12,000 products waiting to be discovered, the company says this is the go-to resource to find any tool for any job.

But that's not all, the new 1400-page catalogue features over 1,100 brand-new products bringing the latest innovation in tools - developed to make tasks easier, allowing safer and smarter working. From

leapfrog ahead of vans weighing up to and including 2.0 tonnes, which became the smallest sector as registrations fell -48.2% to 428 units. Deliveries of pickups also declined, by -7.6%, while vans weighing greater than 2.5 to 3.5 tonnes fell by -6.2% –although at 15,205 units this remained the largest market segment with a 67.1% market share, reflecting the general trend towards larger vehicles.

Commenting on the figures, Mike Hawes, SMMT chief executive, said: “Four months of growth signals recovery is in sight for the van market, with easing supply chain issues raising confidence and boosting the overall market outlook.”

state-of-the-art power tools in the SV20 Series to specialized equipment in its extensive vehicle service range, this catalogue has it all.

According to Sealey every tool is designed with the customer in mind, with extended guarantees on all products and 120,000 spare parts available.

8 CVW JUNE 2023

NEWS @CVWmagazine CVWmagazine www.cvwmagazine.co.uk

This summer’s bumper trade show, Road Transport Expo (RTX), is shaping up to be an unmissable event for anyone involved with the running or management of an HGV fleet. CVW checks out what’s in store.

In the know

SHOW AND TELL

With its ‘all about the truck’ mantra, RTX combines a vast exhibition of the latest vehicles, equipment and fleet services with a free-toattend drop-in Knowledge Zone conference.

All the major HGV OEMs will be at the show – DAF, Iveco, Isuzu Trucks, MAN, Mercedes-Benz, Renault Trucks, Scania and Volvo – with their latest vehicle ranges to explore on the stands or take for a test drive over at the Ride & Drive zone (or simply a ride in the passenger seat if you prefer).

For those working in the repair and maintenance sector, there will also be plenty to keep you busy during your time at the show, with a range of leading manufacturers showcasing the latest testing and workshop equipment. From

Throughout the show, RTX will be running drop-in sessions on its Knowledge Zone stage. These will be covering a range of topical subjects, from road safety regulations through to fleet decarbonisation and key industry challenges.

WEDNESDAY 28 JUNE

In the morning, you can participate in a series of Transport Compliance Briefings, led by Logistics UK.

THURSDAY 29 JUNE

The morning’s session will focus on the industry’s journey towards a net-zerocarbon future, from the position today, to the government’s ambitious targets to phase out sales of new diesel trucks.

mobile machinery through to lifting gear, emissions-measurement systems and workshop pits, you will be spoilt for choice.

Plus you can check out a wide range of fleet essentials on display, including leading tyre brands, vehicle lighting, oils, lubricants, rubber matting and much more.

You’ll also be able to keep up to speed with the latest fleet safety and compliance regulations by attending one of the drop-in conference sessions across all three days of the show (see box for key themes).

In the afternoon, you can attend an engaging session hosted by safety specialist SMUK, called ‘Gearing up for Change’, which will look at how the latest technology can keep your business compliant with tightening safety legislation.

In the afternoon you will also be able to join in the discussion about future truck technology, from fuels to servicing requirements, during our exciting ‘Big Debate’ session after lunch with a line-up of major HGV manufacturers.

Check out www.roadtransportexpo.co.uk for the full schedule.

FRIDAY 30 JUNE

The Knowledge Zone reveals brand-new industry research, which will drill down into the key challenges facing operators for the year ahead. Drop in and listen to the lively on-stage debate with panellists drawn from the Road Haulage Association, Motor Transport and Asset Alliance.

To round off the day’s Knowledge Zone sessions, advancements in diesel technology will be the talking point for Will Shiers, editor of Commercial Motor and his team of experts.

ROAD TRANSPORT EXPO 2023 Preview

10 CVW JUNE 2023

Networking

RTX is a perfect opportunity to catch up with your industry colleagues and make those all-important new business connections.

The organisers have pulled out all the stops to make sure you get the most from your time at the event, with plenty to entertain you. There will be tasty food outlets, including an on-site farm shop; plenty of seating areas to relax with colleagues or meet with new customers; easy signage and navigational tools; and a free shuttle bus to transport you from the venue to key local train stations.

“We can’t wait to welcome visitors to RTX this summer,” says Vic Bunby, divisional director at show organiser DVV Media International.

“With more exhibitors and an enhanced visitor experience, we believe the event provides an ideal platform for fleet operators to explore the latest technology, while networking with industry peers. We do hope to see you all there this June!”

Easy to navigate

To make the most of your day at RTX, why not take a browse on roadtransportexpo.co.uk to help you decide which of the 200-plus exhibitors you’d like to put on your ‘must visit’ list. You can filter by a simple A-Z search of company names, or by product type that you are interested in.

The interactive floorplan, found on the RTX website, will help you locate your preferred stands and see where everyone is placed around the venue.

To help visitors navigate on the day, there will be plenty of clear signage, large maps, a dedicated team of show-makers around the venue, and even a set of electric

Show & Tell!

More than 200 exhibitors will be heading to RTX this summer and suppliers will be showcasing and demonstrating a wide range of HGV fleet technology, with products including:

● The latest diesel, biogas, electric, hydrogen and hybrid technology –ready to ‘Ride and Drive’ on the day;

● Trailers, bodies and refrigeration systems;

● Vehicle safety gear and fleet compliance platforms;

● Training and recruitment services;

● Legal, insurance and compliance teams;

● Wheels and tyres;

● Refuelling and charging infrastructure;

● Workshop and maintenance equipment;

● Trade associations;

● And much, much more

● Make sure you check out www.roadtransportexpo.co.uk as new exhibitors are being added all the time!

buggies to whizz you from one outside area to another should you want a ride.

And for those preferring to use their phones to find their way around, an RTX app will be available for visitors to download. This will also keep you in the loop for any exhibitor announcements or product demonstrations taking place on stands.

Last year’s show visitors were delighted with the wide range of exhibitors taking part in RTX, with 92% rating the number of stands to explore as ‘excellent/good’ and a whopping 95% rating the calibre of those companies as ‘excellent/good’.

JUNE 2023 CVW 11

TO REGISTER FOR YOUR PLACE AT THE ‘SHOW OF THE SUMMER’, SIMPLY HEAD OVER TO WWW.ROADTRANSPORTEXPO.CO.UK

RTX takes place from 28-30 June at NAEC WarwickshireStoneleigh, and is completely free to attend and to park.

AFTERCARE RESPONSE

Aftercare Response, which provides mobile maintenance and breakdown services in the UK, is preparing to discuss fleet requirements and the need to keep existing vehicles on the road rather than investing in new ones. The company’s services include on-site vehicle body repairs, tail-lift installation and repair, fleet maintenance contracts, and emergency roadside assistance. Its Aftercare Response video enables engineers to share videos providing recommendations to customers for a fully-informed decision on the suggested work. The platform offers transparency, improved knowledge, and supports warranty claims. Staff are also trained to work safely with new vehicle technology, including tail-lift fitments for all types of manufacturer panel vans.

Stand G37

CONTINENTAL TYRES

Continental Tyres is promoting its ContiPressureCheck tyre pressure monitoring system, the ContiConnect 2.0 virtual tyre management platform and its Conti360° Solutions fleet tyre management programme. All three –individually or used together – maximise efficiency and minimise business costs for fleet owners and operators. The company is also displaying its range of retread tyres, including the award-winning Hybrid HS5 and HD5 tyres, which are designed for mixed regional use.

Stand B9

ASPÖCK UK

Aspöck UK is showing its wide range of lighting, radar detection, solar panels, and electrical systems. Among the new products are the EcoLED III rear lamp and the RADC 1.0 rear monitoring system for truck trailers. The lens of the lamp is chemical- and scratch-resistant and welded, ensuring durability while the lamp itself is IP6K9K certified. The RADC 1.0 is equipped with a sturdy radar sensor that monitors a large area of up to 3 by 10 metres. The system is quick to assemble and easy to retrofit, automatically activating when the reverse gear is engaged to monitor the return area for rigid and moving objects.

Stand R47

MALAYSIAN RUBBER COUNCIL (MRC)

The agency is actively seeking buyers for precured treads, retreading materials, and related rubber automotive components for both OEMs or for aftermarket use for repair and maintenance. It also aims to raise awareness of the different companies and product expertise in the sector to world markets. Malaysian rubber companies offer a wide range of products, including tyres, truck bumpers, hoses, gaskets, seals, tubing, and belts.

Stand R35

ROAD TRANSPORT EXPO 2023 Exhibitors 12 CVW JUNE 2023

TRUCKFILE

Truckfile is showcasing its fleet and workshop management technology that enables fleets to reduce downtime by flagging up issues in advance. Its system combines data on vehicle health and offers an overview of advisories, defects, and faults. Truckfile Voice uses Honeywell voice-directed technology, which allows anyone carrying out a service, repair or inspection to use entirely verbal commands spoken into a microphone on a headset to record the job, potentially boosting efficiency by up to 20%. The company’s fleet management technology can also be linked to Truckfile's driver walk-around app, Driver Check, which uploads daily inspections and saves the vehicle's geographical location and reports for its lifetime.

Stand G60

TRAFFICNEWS

Exol tops up its fleet

Independent lubricants supplier Exol Lubricants has renewed its delivery fleet with new Scania trucks to optimise service levels and to meet ongoing customer demand.

The new trucks will work out of its Rotherham blending plant site and Wednesbury headquarters.

Steve Dunn, sales and marketing director at Exol Lubricants, said: “We regularly renew the fleet, decommissioning older vehicles in favour of new ones, which helps us to meet increased delivery demands, be more efficient with fuel, and reduce overall emissions per delivery.

“Newer trucks also mean we lose less time to service, maintenance and repair, and with fleet uptime maximised we can ensure quick delivery turnarounds for our customers.”

For more information, WWW.RDR.LINK/VAZ001

New trailers for MBBA

KRONE

Container logistics specialist MBBA is expanding its trailer fleet after winning new business.

It has invested in 13 new skeletal trailers from Krone, partly replacing older units but also to cater for the additional contracts from clients. Based in West Thurrock, the company transports goods to and from ports including Tilbury, London Gateway, Purfleet, and Felixstowe. Some of the trailers will go into its own fleet and others are destined for

subcontractors. The new fleet includes some goosenecks to provide additional stability for certain loads.

The Krone Box Liner trailers have a flat chassis configuration for carrying 20ft, 30ft, 40ft and 45ft containers. Krone container chassis are designed to be durable and versatile, with a sliding axle bogie and folding locks at rear. They come with a 10-year guarantee against corrosion perforation.

For more information, WWW.RDR.LINK/VAZ002

JUNE 2023 CVW 15

HAULIER TRIESTO CUTBULK OF COSTS

largest and best-known bulk hauliers, Alfred Hymas, is using a wheel alignment system to reduce tyre wear and cut workshop time. CVW reports.

Taround North Yorkshire. Whether they are ferrying limestone from the quarries in the Yorkshire Dales to concrete producers or delivering agricultural produce and feeds to grain merchants and feed companies, the company’s blue and red livery is easily recognised.

But operating in a predominantly rural region and travelling on the poorly maintained B-roads takes its toll, as workshop manager David Porritt explains.

“Our vehicles carry heavy loads and often on uneven road surfaces so it's important to keep close tabs on every axle, chassis and wheel to make sure everything remains perfectly aligned,” he says. “Otherwise, tyre wear and other problems quickly take their toll, causing expense, potential hazards, and vehicle downtime.”

To guard against this, Hymas switched from its previous system to the Josam Camaligner from AES UK. David and his technical team say the main reason for this was because they need a system that is less complicated to operate and that was faster and more accurate.

Disruption and downtime

David and his team have recently moved to a six-bay workshop with DVSA spec brake rollers and a 5ft overhead crane at Sinderby, near the A1, where they also maintain and service other fleets. He says that damage caused by misaligned wheels is common.

“In addition to our own vehicles, we also provide maintenance services for external fleets and often see cases where lack of regular wheel alignment has causeddamage which has gone unnoticed,” he says.

“Early detection and corrective action are essential to head off safety and cost issues, to say nothing about potential disruption and downtime.”

TOOLS & WORKSHOP EQUIPMENT

16 CVW JUNE 2023

Incorrect wheel alignment increases rolling resistance and adds to fuel consumption with even a slight misalignment resulting in premature and rapid tyre wear. If left undetected, the problem can cause blowouts and increase the chances of high level particulate (PM) dispersal.

To prevent this happening, Hymas technicians routinely check wheel angles such as camber, toe, axle offset and steering box middle during every MOT or when they fit a new tyre. The operation is swift, simple and accurate, as readings are automatically measured by the Cam-aligner. It uses the chassis centre line as a point of reference and, when it has completed the task, the computer produces a concise report.

“All quick and easy," says David. “The cost benefits were apparent from the start and in the first year, the system is well on the way to paying for itself. We are making big savings in-house and also providing a more cost-efficient and improved service to our customers.”

The portability of the tool is an asset because it can be taken directly to the vehicle rather than customers having to bring their vehicles into the workshop for servicing. This is not only far more convenient for the customer but it also reduces the vehicle’s downtime and keeps it on the road.

Training and support are also key factors for David, ensuring that his whole team were able to operate the tool from the get-go.

“We started with an onsite group training session and then the AES team stayed close, returning the next month to make sure things were going smoothly. The Cam-aligner is not difficult to use, but it was reassuring to have the initial support and good to know AES is always at the end of a phone if needed.”

The Alfred Hymas fleet is predominantly Volvo and Renault and works out of operating centres in Great North Road, Sinderby, Thirsk (Head Office), Ripon, Keighley and Masham. Servicing both long- and short-term contracts, the company transports more than 6,500 tonnes per day.

TO FIND OUT MORE WWW.RDR.LINK/VAZ003

“...the cost benefits were apparent from the start...”

GO NUTS!

The Warthog from Durofix is an unusual beast. Like its subSaharan counterpart, it’s a tough and sturdy animal and because it’s cordless you can use it anywhere.

In fact, the company bills it as the world’s most powerful cordless 1” jumbo impact wrench that removes HGV wheels for fun. The Warthog, or to give it its proper reference the RI60176, which doesn’t sound quite so menacing, is a nut buster par excellence. Capable of delivering over 3,000Nm of max tightening torque and over 4,000Nm of max reverse torque, it can crack the toughest of hard-to-remove nuts.

It's powered by Durofix’s exclusive 60V battery platform, that is reckoned to be 35% more efficient than equivalent 20V batteries, so that’s a bigger operating window and more wheels per charge. The Warthog also comes with two battery bays with the batteries working in series so doubling runtime. It will run on a single battery on either side so if one pack is getting in the way, simply remove it. It comes complete with a charger, so with a bit of judicious replenishing, you could have it operating for hours.

And it’s a clever beast to boot. Its 5stage electronic torque control (ETC) and auto shut-off at pre-programmed torque

TOOLS & WORKSHOP EQUIPMENT

18 CVW JUNE 2023

levels means you can’t overtighten nuts or leave them too loose. It sports a 1” drive with either the choice of a 2” or 6” anvil so plenty of flexibility there.

Despite its muscular performance the Warthog weighs a very portable 11kg without battery or 12kg with. Its low HAV rating, thanks to its rubberised handle and internal vibration dampening system, also means you won’t lose your fillings operating it.

So here we have a serious alternative to compressor-based equipment, that gives you the freedom to roam and change wheels in any location, safe in the knowledge that you’ll get the job done quickly, safely and accurately.

Not in the market for a tool that size but maybe need something for car-derived vans? Then have a look at the RI60166A1 –sadly no beastly aka for this one – a compact electronic clutch wrench which is

both light and powerful. Featuring a ½” drive and capable of 800Nm torque, it has a 3-stage ETC pre-programmed to 100/300/500Nm cut-offs. Its 60V Li-ion battery delivers both power and long running time through its all-in-one brushless motor. It comes with a single battery and a charger.

TO TRACK DOWN THE WARTHOG WWW.RDR.LINK/VAZ004

SUMMIT HAPPENING

When K2 Recovery decided to upgrade and expand its Kettering workshop it turned to Totalkare to provide the right kit.

“Our business has been expanding over the years and with an increased vehicle throughput, we felt it was the right time to upgrade our workshop equipment,” explains Dave Bown, managing director and co-founder.

Established in 2012 by Peter Harvey and Dave, the company operates around the clock serving the Midlands and beyond, as it also provides a comprehensive national breakdown and recovery service. The company has grown rapidly, thanks in part to its loyal staff, many of whom have been with it from the start.

Dave’s shopping list was extensive – an electro-hydraulic two post lift, heavy duty four post lift, diesel smoke meter, and a headlamp tester – all from Totalkare. He says

that the investment is already paying off.

“The equipment saves us time and money, without compromising the high quality of service we provide to our customers. It’s also increasing our workshop flexibility.”

The 5,500kg capacity two post lift from Totalkare has a base-free design and is an ideal when a fixed post lift is needed and the flexibility of a mobile vehicle lift is not required. The two post lift is suitable for vans, minibuses and pickup trucks through to small heavy vehicles and so is the perfect complement to the four post model.

Totalkare’s heavy duty four post lift is suitable for vehicles up to 33,000kg, yet K2 Recovery has opted for the 25,000kg, ninemetre model as this is ideal for most passing through their workshop for repair and maintenance. For ease of use the four post lift is supplied as surface or recessed mounted and with the choice of drive

TOOLS & WORKSHOP EQUIPMENT

CVW reports on how one workshop equipment provider helped its customer with a mountainous task.

20 CVW JUNE 2023

on/drive through options.

“The two-post lift is perfect for any vans that come into our workshop requiring maintenance work, and the four post is ideal for the heavier vehicles,” Dave comments.

The diesel smoke meter is a diagnostic tool that detects and measures the amount of light blocked in a sample of smoke emitted from diesel engines in cars, vans, buses, coaches and trucks. It is one way to gauge whether the engine is running efficiently so it can help with fuel economy. More importantly, given the increasing number of clean air zones in the UK, it will show whether not the engine is meeting the emissions standards for these zones. So now the company’s customers can be sure that their vehicles are running efficiently and will not fall foul of the law.

The top reason that HGVs and PSVs fail their annual test is lamps – 3.5% –followed by headlamp aim at 3.4%. K2

Recovery’s Totalkare headlamp tester checks both the orientation and intensity of a vehicle headlamp to ensure that it meets the minimum required standards, so this is one issue that will not bother its customers as this tool will ensure that all vehicle headlamps are in working order and comply with DVSA standards.

So what is in the name, K2 Recovery? A postcode perhaps. No, it is the Himalayan mountain known as the Savage Mountain after George Bell –a climber on the 1953 American expedition –told reporters, “It’s a savage mountain that tries to kill you.”

Dave has a safer and more down-toearth reason for naming the company after this peak. “We chose K2 because it might not be the highest mountain in the world, but it’s the the hardest to summit and we relish a challenge and appreciate you rarely get something without effort in life.”

FOR MORE INFORMATION ON TOTALKARE

WWW.RDR.LINK/VAZ005

About K2 Recovery

K2 works with a strong network of agents providing services covering the length and breadth of the UK and Europe, with operations managed through a 24 hours, 7 days a week call centre. All vehicles and control room are equipped with the latest GPS tracking and mobile data terminal technology so the quickest resource can be dispatched to cut down ETA times.

It covers Northamptonshire, Cambridgeshire, Leicestershire and Bedfordshire with depots in Kettering and a control centre and main storage facility with large secure undercover and open-air storage located on Telford Way industrial estate; its Robinson Close depot houses its workshop facilities and is an integral part of the company’s intervention policy to save on long-distance recoveries and to get the customers back on the road again.

JUNE 2023 CVW 21

PROFESSIONAL MOTOR MECHANIC MECHANEX

TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS

● FREE CPD TECHNICAL SEMINARS ● FUTUREDRIVE ZONE ● FREE ENTRY ● FREE PARKING ●

FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL

R E G I S T E R F O R F R E E AT W W W. M E C H A N E X . I N F O THE HANDS-ON

WORKSHOPS

TRADESHOW FOR INDEPENDENT

S A N D O W N PA R K , S U R R E Y 7T H & 8T H N O V E M B E R 2 0 2 3

The regional Tradeshow for aUTo rePair Professionals

FEATURING LIVE

LINESOF DUTY

Emarkings? Well meet Kelly Brothers whose claim to fame is that it provides a complete approach to road safety. With over 50 years’ experience it has, over that time, refined a unique process to manufacture and apply road marking and anti-skid products. Its sustainable manufacturing plant produces in excess of 300 tonnes of material per day, which is complemented by a fully trained and experienced contracting and surveying team working across Ireland and the UK. Not surprisingly the company is committed to making roads safer for everyone.

That commitment is backed up by a varied fleet of light and heavy-duty vehicles that need to be maintained on a regular basis. The ease of use, technological

made them the ideal choice for Kelly Brothers in this scenario.

Battery benefits

Each set of lifts, type ST1075FWA, comprises four wireless mobile columns, each offering a lifting capacity of 7.5 tonnes thereby providing an overall safe lifting capacity of 30 tonnes. Each column incorporates Stertil Koni’s revolutionary ebright smart control system which allows workshop engineers to operate the columns individually, in pairs or in any other combination from any column in the set.

The Stertil Koni ST1075FWA heavy-duty lift is powered by long-life deep cycle batteries which provide optimum performance for at least a week on average

before recharging is necessary. Also, battery life is prolonged because, unlike a screwlift, power is only used to raise a vehicle therefore less time is spent recharging the lift - charging is carried out via a 230v single phase supply. Importantly, with no cables on the workshop floor, the risk of tripping is removed, providing valuable health and safety benefits.

Featuring full-colour touch screen consoles, the ebright smart control system has been designed and developed to simplify operation by providing maximum visual information about every lifting operation - all at the fingertips of the workshop engineers.

TOOLS & WORKSHOP EQUIPMENT JUNE 2023 CVW 23

MORE INFORMATION ON STERTIL KONE WWW.RDR.LINK/VAZ006

“...less time is spent recharging the lift...”

Stertil Kone is helping to keep one company very much on the road. CVW reports.

GIVE SAFETY A LIFT

Safety in the workshop should be the number one priority says Nick Austin, sales manager, MAHA UK. Here he offers a few pointers on what to do and not to do when working with lifts.

Lifting equipment needs to be assessed by a professional every 12 months, in accordance with Lifting Operations and Lifting Equipment Regulations 1998 legislation. That same equipment also needs to be maintained regularly, the frequency of which is set out by the manufacturers’ recommendations in keeping with Provision and Use of Work Equipment Regulations 1998.Not doing so can lead to investigation by the Health and Safety Executive, then, if culpable, fines and even imprisonment, depending on the severity of the respective issue.

Irresponsible users are not only putting the vehicles they’re working on in danger, but also their employer’s reputation. More importantly, they’re endangering themselves and their colleagues.

TOOLS & WORKSHOP EQUIPMENT JUNE 2023 CVW 25

Two-post lift guidance

Sadly, we are still seeing scenarios where correct maintenance procedures for lift pads and arm locks, as well as the use of appropriate adaptors, are not taking place.

Despite the risks, you still notice deteriorated rubber pads on the ends of lifts where steel is then exposed. The whole point of the pads is to provide suitable contact with the vehicle to avoid it slipping off.

The solution to that is checking the pads regularly and replacing when necessary.

Replacement rubber pads are readily available and not expensive to replace, so why take the risk?

Over time arm locks can weaken, due to wear and tear and considerable use, but misuse is also a common problem. The arm lock mechanism on any two-post lift is one of the most important safety features and should be checked for correct function before and during every use. Correct positioning and locking of the arms are very important.

It’s also not unheard of to see technicians use a two-post lift without the correct adaptors; instead, they use blocks of wood!

Rather than have a 200mm sleeve to reach the chassis or use a U-shaped adaptor that goes each side of the chassis, like an anti-slip sleeve – the rubber pad comes off and the anti-slip goes on – we continue to see an ordinary two-post lift with a great big oily block of wood between the vehicle and the lift pad, which is completely unsafe!

Once again, this issue can be easily avoided - there are so many adaptors available – but as workshop managers are under pressure to get a vehicle up in the air, a block of wood is a solution!

It’s important that operators are provided with the right adaptors, as it is vital to ensure the safe and effective use of a two-post lift. Once again, it’s a safety issue and could lead to serious consequences if an incident occurs. Like the rubber pads, they’re not expensive and certainly not as expensive as a new two-post lift!

There are many types of adaptors on the market, for a variety of vehicles including EVs. By locking onto the chassis via a locating hole or dedicated position along the sill, they offer increased stability to prevent slip, so why buy a lift but not the adaptors?

Critical issues

Switching the focus to mobile column lifts, but maintaining the emphasis on safety, following the correct maintenance procedures for the wheels, hydraulic dolly and fork locks, as well as the use of correct adaptors, are all vital in preserving safety and longevity of this type of equipment.

Regular visual inspection, the testing of safety components and replacing when necessary is the obvious solution – but not always followed! It’s critical this approach is adhered to.

The fork lock mechanism fitted to mobile column lifts is a critical safety feature. It should be checked for correct function before and during every use. Correct positioning and locking of the forks are of paramount importance.

Furthermore, though robust, moving the lifts carelessly or on rough surfaces can cause wear/damage to the wheels. Also, lifting a vehicle before fully lowering the dolly can cause premature wear and damage to components.

FOR MORE INFORMATION ABOUT MAHA UK, WWW.RDR.LINK/VAZ007

TOOLS & WORKSHOP EQUIPMENT 26 CVW JUNE 2023

“...we continue to see an ordinary two-post lift with a great big oily block of wood...”

T

It has been designed for the user and its lightweight ergonomic design ensures it is balanced, no matter the angle at which it is used. The tool’s random orbital movement ensures it responds precisely to the operator's movements, which makes the sanding process more efficient, while the brushless motor technology ensures a constant speed with no loss in efficiency under heavy pressure and load. In addition, it weighs in at 3.5kg, so it is easy to handle and allows the operator to sand surfaces for extended periods without fatigue.

HOW TO ENTER

SANDING TALL

Win

he Mirka LEROS is the perfect tool for the light commercial and CV market because of the combination of the LEROS’ length and its 225mm sanding head that ensures the large surface areas of these vehicles can be sanded in fewer passes.Do more with the LEROS

Commercial vehicles have a large surface area that needs sanding, and this will lead to considerable dust being produced, which can affect the health and wellbeing of the workforce as well as the end-product. So, when the LEROS is combined with Mirka’s net abrasives such as Abranet and a mobile dust extraction system this trio of Mirka products provide dust-free sanding. This benefits workers because it will protect their long-term health and creates a cleaner and more pleasant workspace. In addition, having a dust-free workshop allows for multiple sanding operations to take place at the same time as well as optimising finishing processes and increasing efficiency that, in turn, reduces the key-to-key times of jobs.

To be in with a chance of winning the Mirka LEROS, WWW.RDR.LINK/VAZ008 and answer the following question:

Q

A. Mansfield

B. Milton Keynes

C. Maidenhead

Where is Mirka (UK) Ltd headquartered?Deadline for entries is: July 31st 2023. Terms & conditions apply. See website for details.

TO FIND OUT MORE ABOUT THE MIRKA LEROS, WWW.RDR.LINK/VAZ009

JUNE 2023 CVW 29 COMPETITION

TO BOOK A DEMONSTRATION OF THE MIRKA LEROS, WWW.RDR.LINK/VAZ010TO REQUEST ONE. a LEROS from Mirka worth over £1500 in our easy to enter competition.

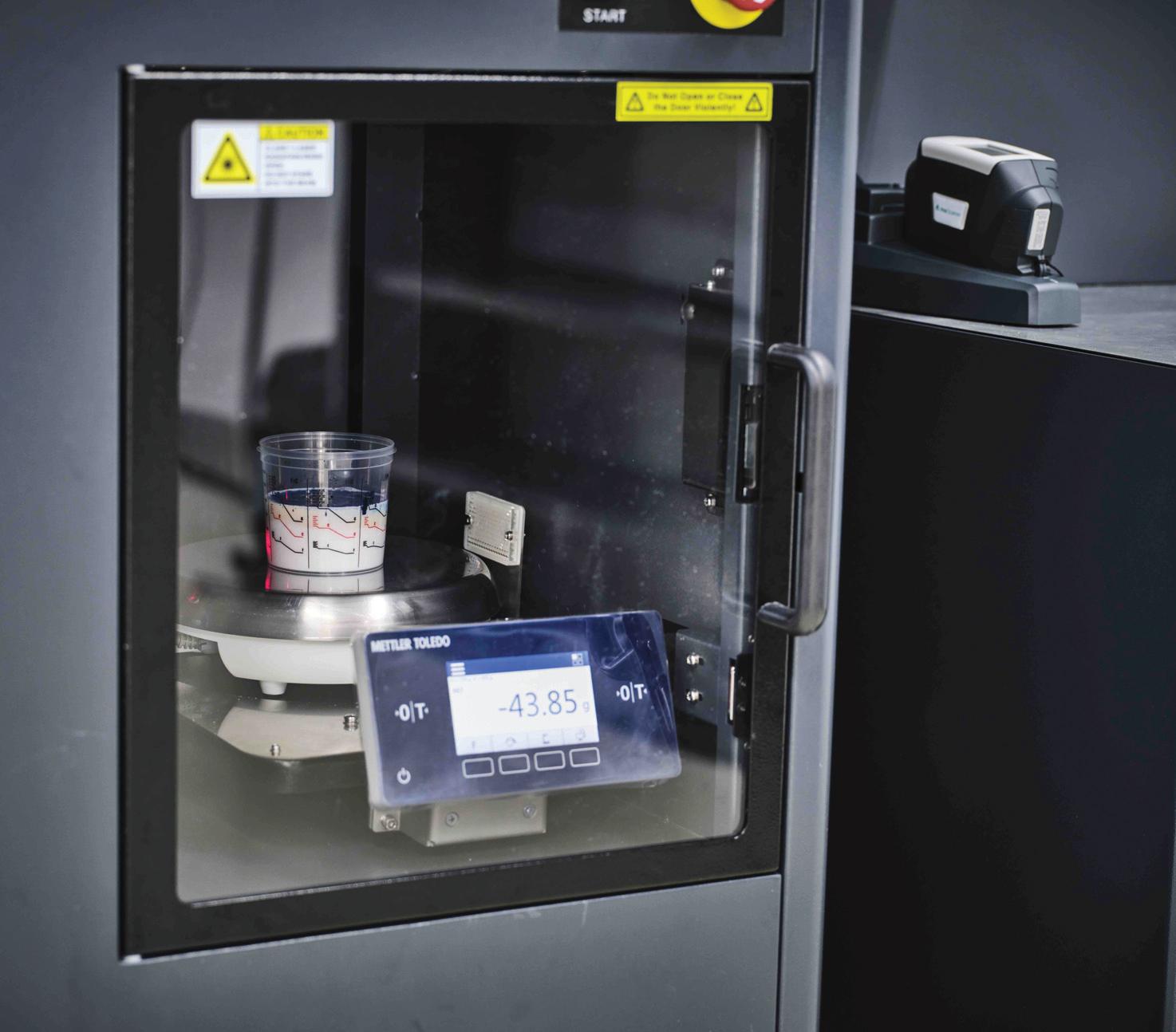

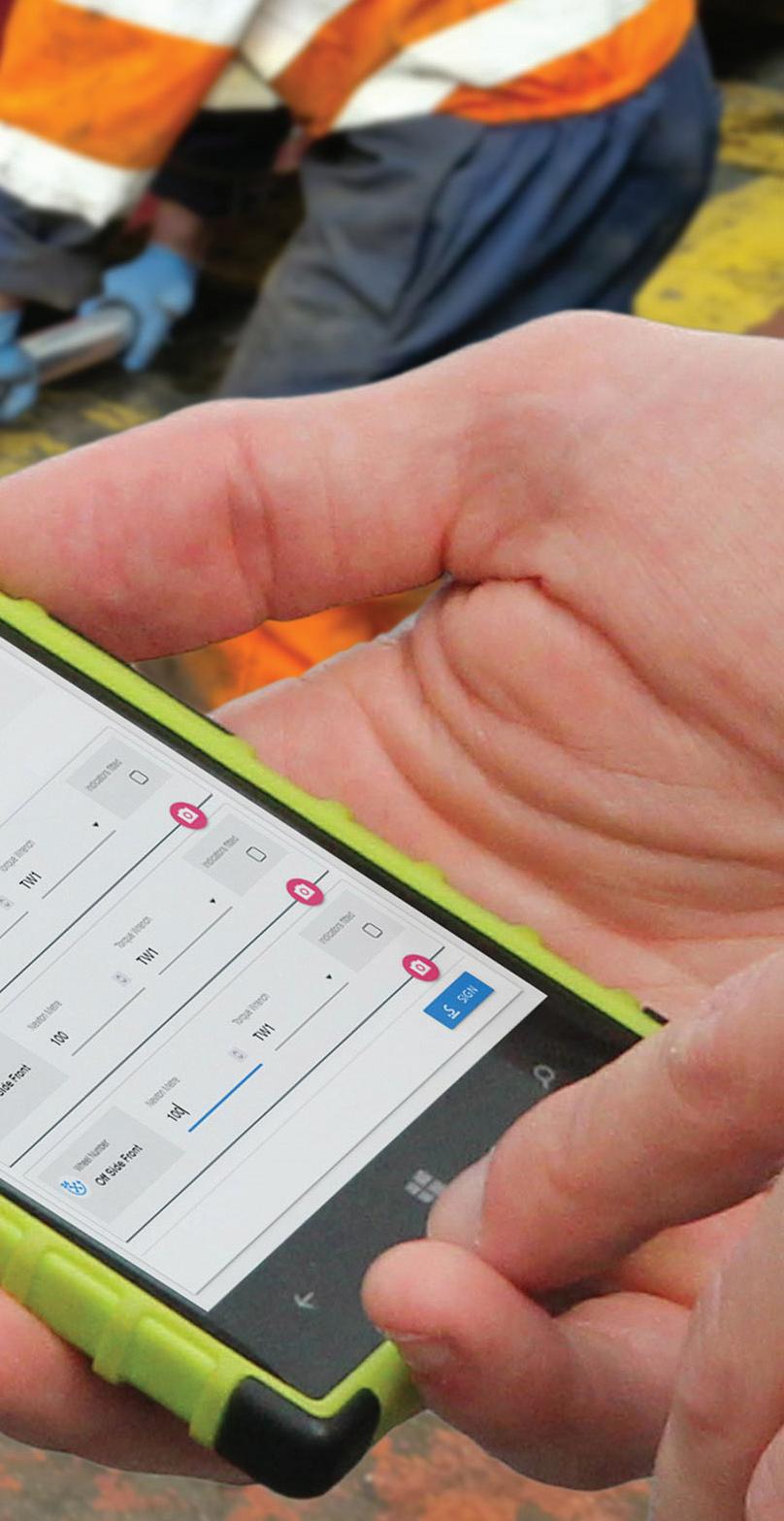

TORQUING SAFETY

accelerate and bounce several metres into the air so that anything it hits will be smashed by a force of several tonnes. Understandably, a “wheel loss incident” will trigger a DVSA investigation that could cost the operator their licence.

torque and re-torque process. The fullydigital solution, which is accessible on a smartphone, provides a simple way to manage the re-torque process following any wheel disturbance, wherever vehicles happen to be.

Wheel loss is a serious issue that poses a significant risk to road safety but checking that every nut on every wheel is an easily overlooked task. CVW looks at a new app that that simplifies this.

Challenging task

Following correct wheel nut re-torque procedures is an important part of any vehicle safety management system but managing and reporting re-torque events remains a tedious manual process.

“Wheel nut re-torquing is a real headache for operators as it is often required after the vehicle has left the workshop and maybe at a completely different location,” says Patrick Tandy, managing director of Freeway.

“We’ve already digitised every conceivable aspect of the workshop – job cards, driver safety inspections, stores and purchasing to name a few – but re-torquing has been the most challenging. In fact, we see this development as the final frontier in the automation of fleet maintenance management.”

30 CVW JUNE 2023 TECHNOLOGY & DIAGNOSTICS

Re-torquing is typically required after 30 minutes and again a day later or after a specified distance travelled, for example, 30 minutes after the wheel is replaced and again between 40 and 80 kilometres travel. In the workshop the Freeway Re-Torque app is used to record the initial wheel disturbance. The technician is guided through the torquing procedure with the recording of torque settings and the torque wrench used, backed up with photographs to record the work. Re-torque events are then assigned to a job card and engineer with the software automatically scheduling the re-torquing at the specified intervals. The app shows the current status; overdue, done or scheduled.

Any authorised person can access the app from their smartphone so vehicles that have arrived at another depot can be dealt with by those onsite. Instructional documentation can be linked to the re-torque work events and accessed directly from a mobile device. This ensures that engineers are provided with the right knowledge to do the job correctly every time and to be fully compliant with any specific standard operating procedures. Depending on the set up, users may be blocked or warned if, for example, the torque wrench was the same as the one used for the previous torquing.

Wheel loss is a serious issue that can have catastrophic consequences so apps such as this might well be a vital tool in cutting the risk of them happening, enabling fleet operators to protect their drivers and make our roads safer for all.

TO FIND OUT MORE ABOUT RE-TORQUING

TO FIND OUT MORE ABOUT RE-TORQUING

WWW.RDR.LINK/VAZ011

“...wheel loss is a serious issue that can have catastrophic consequences...”

DAMAGE LIMITATION

Bridgestone believes that advanced data solutions such as BRC can play a significant role in increasing road and driver safety and meeting the EU and UN targets of halving the number of road deaths by 2030. The severity of this issue is borne out by recent figures. Around 20,600 people were killed in road crashes in the EU last year, a 3% increase on 2021 as traffic levels recovered after the pandemic. In the UK the equivalent figure is 1,760 deaths.

The company argues that monitoring the roads and providing accurate feedback on their condition will make a substantial

contribution to tackling the issue. Its first offering is BRC, a suite of solutions powered by artificial intelligence (AI). This employs data from connected vehicles to provide up-to-date insights on the state of roads and signage.

The suite, currently consisting of Road Damage Detection (RDD) and Road Asset Visualization (RAV), uses anonymised and aggregated data provided by connected vehicles managed by Webfleet. Together these products can identify the location and severity of road damage, as well as visualise various road assets.

Bridgestone believes that this will enable traffic authorities to manage roads while also providing commercial fleets with upto-date information on road conditions.

“Bridgestone Road Conditions can help increase road safety and comfort by providing real-time data insights on road damage that allow preventive road maintenance, infrastructure planning and optimised traffic flow,” explains Raghunath Banerjee, vice president of data solutions at Bridgestone Mobility Solutions.

“These advanced data solutions will play a fundamental role in the digital transformation of future mobility, enabling development of smart cities, mobility-as-aservice providers as well as connected and autonomous vehicles.”

Damage prevention

The Road Damage Detection product identifies road anomalies by analysing anonymised and aggregated data leveraged from connected vehicles that are equipped with fleet management software provided by Webfleet, Bridgestone’s telematics arm. Using sensors and vehicle data, this tool accurately determines the locations of road damage, such as potholes, cracks and patches.

The Artificial Intelligence (AI) algorithm enables the severity of road damage to be defined, helping drivers and fleet owners reduce the risk of accidents, as well as prevent damage to tyres and vehicles. Cities and road authorities can utilise these insights for preventive maintenance and infrastructure planning.

32 CVW JUNE 2023 TECHNOLOGY & DIAGNOSTICS

There is a growing move towards harnessing the power of connected vehicle data and combining it with artificial intelligence to provide insights that aid fleet management. CVW looks at Bridgestone Road Conditions (BRC), the latest product from Bridgestone Mobility Solutions which it claims could cut road deaths.

“...BRC can help increase road safety and comfort...”

Edge of learning

The Road Asset Visualisation (RVA) product then refines this information by supplying intelligence on roads and infrastructure. It does this by analysing multiple connected vehicle sensors as well as camera data. It is able to do this thanks to what is called Edge AI – the type of artificial intelligence to be found on any device that uses video analytics. These range from smart speakers, smart phones, laptops, and robots to self-driven cars, drones, and surveillance cameras.

In the case of RVA, Edge AI is applied to vehicle-mounted cameras so they can process data directly on the device in real time, ensuring data privacy by uploading only anonymised data to the cloud for further analysis. This way, road assets and characteristics such as road signs, traffic lights and lane markings can be visualised and flagged if they are damaged, vandalized or blocked by vegetation.

Bridgestone Road Conditions is currently available in UK, Ireland, France, Spain, Portugal, Italy, Poland, Netherlands, Belgium, Germany, Switzerland and Austria.

FOR MORE INFORMATION ON BRIDGESTONE'S ADVANCED DATA SOLUTIONS PLEASE VISIT: WWW.RDR.LINK/VAZ012

BALANCING ACT

Wheel servicing specialist, Pro-Align, has launched a new automated wheel balancer for heavy duty commercial vehicles. CVW has a sneak preview.

It’s a big claim but the HD Elite from workshop equipment specialist, Hunter, has been designed to solve even the toughest of wheel related vibration issues, while helping to increase tyre life and reduce driver fatigue. Compared to traditional wheel balancers, the HD Elite’s automated process reduces operator error and, importantly, speeds up the balancing service, making it suitable for commercial vehicle workshops working on larger vehicles, such as HGVs, buses and coaches.

However, the balancer works with tyre sizes up to 52 inches and can lift up to an impressive 227kg, making it a great choice for those workshops servicing both light and heavier commercial vehicles as well.

Designed with technicians in mind, the HD Elite has an intuitive touchscreen interface, including features to help workshops use their time and money in the most efficient way, such as ‘SmartWeight’, which optimises and reduces the weights needed to accurately balance commercial vehicle wheels.

According to Clive Seabrook, CEO, ProAlign the new HD Elite is an exceptional diagnostic system and he’s excited to be bringing it to workshops in the UK and Ireland. “The system is quick, easy to use and more accurate than less sophisticated options. It’s highly beneficial for workshop efficiency and reducing vehicle maintenance times, but more importantly, minimising troublesome wheel vibration issues.”

The balancer uses laser technology and a diagnostic load roller to solve vibrations by measuring the entire wheel contact patch for accurate results.

Seabrook explains: “Excessive wheel vibration is often considered nothing more than an inconvenience for fleet operators but if left untreated can actually cause serious health issues for drivers, such as repetitive strain and back injuries.

“With the HD Elite, tyre rollout issues can be minimised to help significantly reduce wheel vibration, safeguarding drivers and increasing overall tyre life in the process.”

Sounds like a good result all round.

JUNE 2023 CVW 35

TO MINIMISE VIBRATION WWW.RDR.LINK/VAZ013 TECHNOLOGY & DIAGNOSTICS

CONSCIENTIOUS TOA FAULT

While many diagnostic tools may claim extensive coverage, you should really look at the breadth and depth of application coverage to ensure they’re able to cater for today’s rapidly advancing commercial vehicle parc.

Certain tools will claim extensive vehicle coverage, but in fact will only diagnose limited systems within them. Make sure that you look closely at the level of coverage provided.

For example, Delphi’s BlueTech vehicle communication interface (VCI), together with Delphi’s DS software for trucks, trailers and buses, gives workshops access to more than 70 brands, 675 models and 16,000 unique system selections.

Research, review, repair

It offers a number of built-in features for quick, easy and accurate diagnostics and repair, including Intelligent System Scan, Intelligent System Identification, help files with step-by-step instructions, a report

function and its latest addition, a diagnostic fault code search function.

With growing pressure to boost workshop efficiency and minimise vehicle downtime, choosing a tool that’s intuitive to use is an important factor too. Being able to search for fault code supporting information without being connected to the vehicle, and determine whether it’s a critical issue, or if the vehicle can go on the road, is hugely useful.

In addition to reading and erasing fault codes, Delphi’s VCI also allows technicians to reset adaptations for key systems such as exhaust gas recirculation (EGR), air mass meter and electronic brake system (EBS), perform dosing tests, regenerate the selective catalytic reduction (SCR) system

and calibrate suspension levels.

Just as important as having the right kit is knowing how to use it. We’re all aware of the exponential pace of change but it can be challenging to keep up with the new systems and procedures that are filtering into the market. It’s why we’re offering a complete diagnostic solution, going much further than simply providing the tool.

Guided diagnostics

Delphi provides free e-learning diagnostic courses for software licence holders, arming technicians with a complete understanding of the very latest diagnostic procedures including Security Gateway and Pass Thru.

Workshops using the BlueTech VCI benefit from an automated security gateway process, enabling technicians to seamlessly service security-protected vehicles whilst DTC-assist functionality offers guided diagnostic assistance. It also delivers extremely fast scan times for an extensive range of diagnostic interrogations

36 CVW JUNE 2023 TECHNOLOGY & DIAGNOSTICS

Get properly equipped if you want to profit from diagnosis and repair, advises Delphi Technologies’ Luke Garret, UK & Nordics technical services manager.

“...choosing a tool that’s intuitive to use is an important factor...”

with multiple CAN channels, integrated Diagnostics over Internet Protocol (DoIP) and CAN FD protocol, which is expected to become much more relevant in the coming years.

Profitable route

As vans and trucks continue to become more technically advanced, workshops should opt for a diagnostic provider with proven capability in state-of-the-art commercial vehicle engine management and powertrain control technologies. Thanks to its OE pedigree, Delphi knows how these vehicles work and what it takes to get them back on the road when they don’t.

With the right tools and know-how to diagnose and repair them, the opportunity to tap into the growing commercial market looks particularly lucrative.

FOR MORE INFORMATION ON DELPHI TECHNOLOGIES VISIT: WWW.RDR.LINK/VAZ014

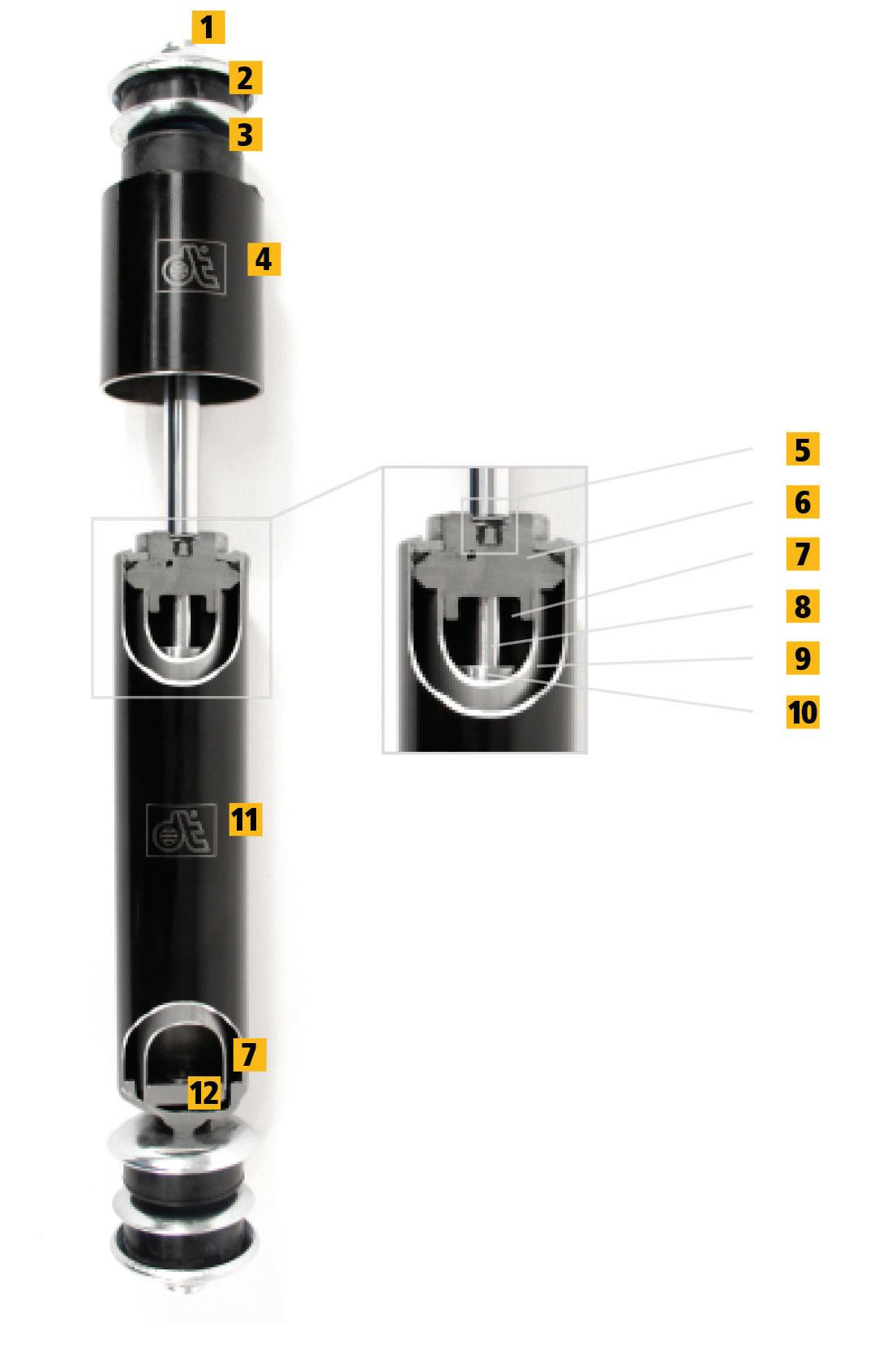

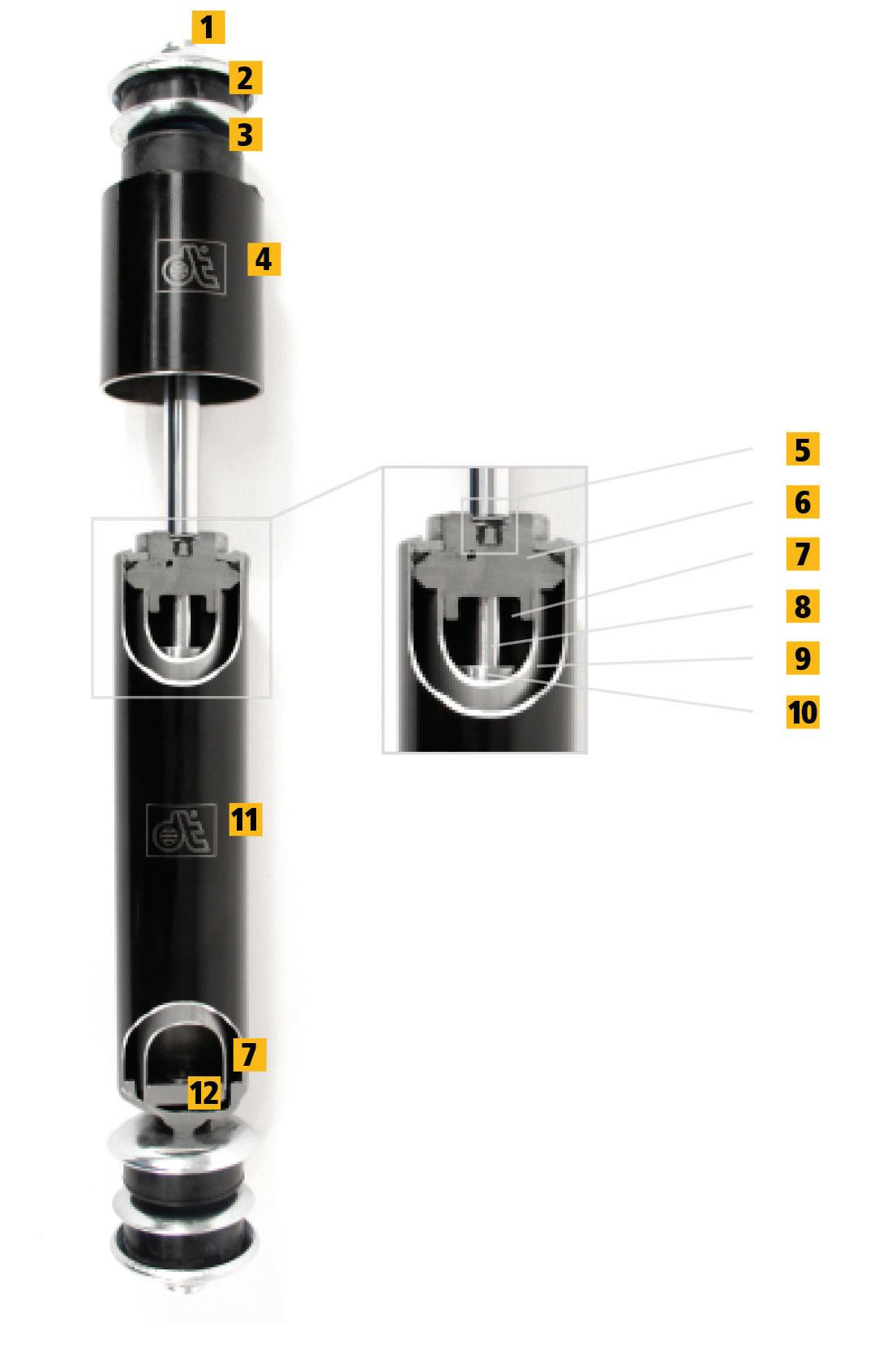

SHOCK TACTICS

Vibrations and shocks can cause loss of control, reduce braking efficiency and increase wear and tear on the vehicle. Mark Todd, general manager at Diesel Technic UK & Ireland, takes a closer look at shock absorbers and why they are crucial for driving safety in trucks, trailers, buses and vans.

Shock absorbers play a crucial role in ensuring driving safety by reducing the vibration of the vehicle's unsprung mass, which includes the wheels, tyres and axle components. They also mitigate the impact of shocks caused by uneven road surfaces by absorbing and dissipating the energy from them.

This improves vehicle stability, handling and ride comfort, while also reducing the risk of accidents and improving the lifespan of the vehicle’s components. Without properly functioning axle shock absorbers, vehicles can become unstable and difficult

guaranteed even at extreme temperatures of between -40 °C and + 70 °C.

The reinforced sheet metal casing tubes have a thickness of 2.5 mm. This prevents premature corrosion. The piston rod has a thickness of 22 mm and is furnished with a chrome plating

The high-quality, multi-lip piston rod seal adjusts itself to normal wear and

Replacement

When it comes to replacing shock absorbers, here are some of the Parts Specialists’ top tips. The first thing is to ensure you are only using shock absorbers suitable for the vehicle, and in accordance with the manufacturer’s specifications.

speed of the piston motion and, consequently, the damping effect.

Most good quality shock absorbers, such as those from DT-Spare Parts, are designed for a service life of 10 million cycles. Corrosion resistance is tested in a salt spray test for 500 hours. In addition:

● The function of the shock absorber is

In their workshop video on replacing shock youtu.be/0JubeamqMYc Diesel Technic’s Parts Specialists Kevin and Lars show how a defective shock absorber can be identified by the oil leaking from the damper tube. Other indicators include uneven tyre wear. The two experts also note that worn suspension can lead to a premature wear or failure of the shock absorbers.

● Always replace shock absorbers in pairs, i.e. at both ends of the respective axle. Make sure that axles, shock absorber mounts, anti-roll bars and the associated chassis components are undamaged. If necessary, perform repair work and axle alignment (for example, after accidents) before exchanging the shock absorbers.

● Check that the shock absorbers are intact. Do not make any modifications to the shock absorbers. Do not open or heat the shock absorbers under any circumstances.

● During the assembly, always observe the part’s correct arrangement for pin joint/supporting joint.

AXLES & SUSPENSION

38 CVW JUNE 2023

Anatomy of a shock absorber

● The shock absorber‘s piston rod must not be damaged during assembly. Only use the designated tool to counter the piston rod.

● In the case of a pin joint, protect the rubber parts from grease during assembly. Slightly lubricate the clamping bolts for a supporting joint during assembly.

● Make sure that the shock absorbers are not assembled whilst under tension. It is imperative to check that the fastening points are aligned. Please note: a defective or missing end stop for the vehicle spring travel could result in an overload and thus lead to damaged shock absorbers.

● Do not tighten the screws of the shock absorbers until the vehicle stands on its wheels. Observe the recommended tightening torques for shock absorbers with pin joint or supporting joint. Do not use an impact screwdriver for the assembly.

● If your truck is equipped with a selflevelling suspension system, you have to make sure that it is properly adjusted after the assembly of the new shock absorbers.

● Avoid excessive or uneven, one-sided loading of the vehicle and observe the correct tyre pressure. Avoid excessive stress due to extreme road conditions.

● Prevent the contact of primer, paint, supplies (e.g. oil, fuel etc.) or preservation wax with the shock absorbers.

● Shock absorber mounts, steering and chassis components should also be checked in the course of the regular maintenance routines. Please note: leaking shock absorbers must be replaced, since it is a safety-relevant component. After an accident the shock absorbers should be replaced as a matter of principle.

● Never assess shock absorbers after driving in wet conditions. If in doubt, wipe the shock absorber down and examine it again after a few days. Road dirt clinging to the shock absorber can easily be mistaken for a leak. Deposits of oil mist can be visible on dry shock absorbers. With an increasing operating time it might become apparent on approximately a third of the reservoir tube. This is not to be regarded as leakage.

● Always dispose of old/defective shock absorbers properly – ideally at a specialist workshop.

JUNE 2023 CVW 39 TO FIND OUT MORE WWW.RDR.LINK/VAZ015

Nut Rubber bushing Washer Protection tube Multi-lip piston rod seal Guide plate Hydraulic fluid Cylinder tube Piston rod Piston Casing tube Cylinder valve

GOOD VIBRATIONS!

The VW Caddy is known for being an all-rounder if slightly dull looking. But not any longer as Bilstein adds a bit of sparkle and muscle to this popular workhorse. CVW casts an eye over the finished article.

The Caddy is known as a particularly versatile vehicle in Volkswagen’s product range. In its fifth incarnation (type SB), the all-rounder is regarded as a reliable if dull van, the size of a passenger car. It is very popular with trade professionals. Now with BILSTEIN EVO S suspension, the new VW Caddy 5 SB looks a whole lot more dynamic and sportier and the new setup is more than just cosmetic.

The new BILSTEIN EVO S coilover suspension allows for significant lowering of 30 to 50mm. Along with the facelift, the stepless and individual lowering ensures that tyres and wheel arch are matching –

no dragging, no problems. This complements the modern design of the panel van, making it look fresher, muscular and more aggressive.

The handling is also more dynamic. The previous leaf springs from earlier generations have been replaced by a modern coil spring design. This resulted in better ride comfort and noticeably better vehicle dynamics. In addition, the rear axle was adjusted to offer the familiar Caddy safety feeling bringing increased agility in all load conditions and best-possible ride comfort.

However, the Caddy’s full potential is only reached with the BILSTEIN EVO S

AXLES & SUSPENSION 40 CVW JUNE 2023

coilover suspension. In addition to the attractive lowering, the VW Caddy with EVO S suspension offers excellent cornering performance. Thanks to the lower stance, the suspension not only reduces weight transfer in bends, but also allows faster speeds in the corner and reduced load-cycle reactions. Moreover, the sport suspension improves directional stability and provides much better feedback through the steering wheel.

When the BILSTEIN EVO S was developed for the VW Caddy, the focus was, as always, on maximum comfort. The coilover suspension does not only perform better, but also offers a firmer ride than the original equipment. The EVO S impresses with its comfort even on longer trips, a consequence of being tested, evaluated and refined in road tests on different road surfaces and on the test bench.

The performance suspension also scores in terms of quality. The special zinc-nickel coating ensures high-quality corrosion protection on all BILSTEIN EVO performance coilovers.

Whatever you think of the mainstream Caddy, the VW Caddy with BILSTEIN EVO S delivers a brilliant performance with a sporty look and outstanding driving dynamics, while remaining reliable, comfortable and suitable for everyday use.

FOR MORE INFORMATION ON BILSTEIN WWW.RDR.LINK/VAZ016

“..the EVO S impresses with its comfort even on longer trips...”

DON’T CLUTCH AT STRAWS

Help is at hand as Schaeffler LuK’s Alistair Mason provides a step-by-step guide to replacing the clutch on a 56,000 mile, 2014 Iveco Daily 35C17.

The advantage of a pull type clutch is that it gives a greater clamp load on the clutch, without an unnecessarily heavy clutch pedal, due to the pivot point/lever ratio of the diaphragm spring being at the outer edge, rather than two thirds or three quarters of the way down the diaphragm spring, and therefore the diaphragm spring must be ‘pulled’ to disengage the clutch. Pull type clutches are generally found in commercial vehicle applications that require the additional clamp load but can also be found in some of today’s cars. The important thing to know and remember when replacing a pull type clutch, is how the gearbox is removed whilst the release bearing stays attached to the clutch. So, ten minutes of wisely spent research can save hours of struggling to remove the gearbox!

Gearbox removal

With the vehicle safely positioned on the lift, open the bonnet, disconnect the battery earth lead and stow it safely. This is the only part of the repair that is carried out at ground level, so raise the lift to gain access to the underside, support the gearbox with a transmission jack and then remove the gearbox crossmember by detaching the gearbox mounting nut and crossmember to chassis bolts (Fig.1). With the crossmember removed, disconnect the prop shaft from the gearbox and unbolt the centre mounting from the chassis (note – it is advised to mark the prop shaft flange and gearbox flange position to eliminate any potential balance issues).

This step gives good access to the electrical multiplugs on the side of the gearbox, so disconnect them, unbolt the bracket and stow away from the gearbox.

IN THE WORKSHOP

42 CVW JUNE 2023

“...ten minutes of wisely spent research can save hours of struggling...”

Vehicle Information Make Iveco Model Daily 35C17 Year 2014 Mileage 56,000 Time 4.2 Hours

The gear cables can now be removed (Fig.2) by levering the cable off the ball joints and then easing the outer cables out of their retaining brackets.

Remove the hydraulic slave cylinder by unbolting the metal mounting bracket and stow the cylinder and bracket away from the gearbox. Detach the rubber boot from the release arm (Fig.3), which allows the release arm to pivot far enough around to disengage from the release bearing when the gearbox is being removed.

Ensure the transmission jack is positioned correctly onto the gearbox and, working around the gearbox, remove the bell housing and starter motor bolts and store them in order of their removal. The gearbox can now be moved away from the engine and at the same time ease the release arm back, so it disengages from the clutch release bearing. Once the gearbox input shaft is clear of the engine and the release arm disengaged, the gearbox can be removed from the vehicle.

Clutch replacement

Remove the six clutch bolts and then the clutch assembly from the flywheel.

In this example, the clutch fault then became evident as, due to ‘slipping’ and overheating, the clutch lining had become detached from the clutch plate and broken up, which had also caused the dual mass flywheel to be exposed to excess heat, this was evident

by the blue colour on its surface, affecting the internal springs and grease (Fig.4), (note – it is good practice to clear and vacuum up the broken clutch lining). At this point the customer was contacted and authorisation to also replace the DMF was given.

Turning to the release system in the gearbox, ensure the bell housing is clean and inspect the release bearing guide tube for any wear, and replace it if there is. Check that the pivot point on the release arm is free and also does not have any signs of wear (note – the pivot points are prone to seizing). Apply a light smear of high melting point grease to the guide tube and onto the gearbox input shaft splines and mount the clutch plate, this will confirm it is the correct plate and will also evenly distribute the grease.

Remove the clutch plate and any excess grease, apply a light smear of high melting point grease to the pivot points of the release arm/release bearing, fit the new release bearing, engaging it into the release

JUNE 2023 CVW 43

arm as it passes up the guide tube and, when in position, ensure the release arm operates correctly and freely (Fig.5). Replace the DMF and torque the bolts to the manufacturer’s specification, then clean the DMF clutch face and new clutch pressure plate face using some brake and clutch dust cleaner. Using a clutch alignment tool, mount the new clutch plate onto the flywheel with ‘gearbox side’ facing away from the engine, locate the clutch cover onto the flywheel dowels, insert the six clutch bolts, tighten them in an even and sequential process and finally, torque to the manufacturer’s specification (Fig.6).

A crucial part of this repair is the alignment between the engine and gearbox so that the release bearing locks into the clutch cover on installation. To ensure this alignment is correct, it is critical that the engine to gearbox alignment dowels are installed (Fig.7&8). So, prior to fitting the gearbox, ensure all the alignment dowels are inserted correctly.

Gearbox installation

Using the transmission jack, ease the gearbox into position, confirm the gearbox is located on the alignment dowels and is tight against the engine, then insert the bell housing bolts and tighten them.

The release bearing then needs to be inserted and locked into the clutch by hand. So, pull the release arm backwards, until the release bearing starts to locate into the

clutch. At this point, using a lever, ease the arm further back until it snaps into the centre of the clutch, then pull back and forth on the lever to ensure that the bearing is locked into position, then fit the rubber boot. As soon as possible, fit the slave cylinder assembly and operate the pedal to ensure the clutch operation is correct. Once this has been confirmed, the rest of the installation is in reverse order of removal.

After connecting the battery lead, reset all electrical systems as required and always carry out a full road test to ensure a quality repair has been completed.

FOR MORE INFORMATION

WWW.RDR.LINK/VAZ017

IN THE WORKSHOP 44 CVW JUNE 2023

“...it is critical that the engine to gearbox alignment dowels are installed...”

VIDEO GAINS SUPERTRACKER

Supertracker’s new explainer video provides a step-by-step guide to using its cordless STR1 range of laser aligners. The fourminute piece offers straightforward, instructional content on how to quickly set up the laser aligner on any four-post platform lift, platform scissor lift, on a level surface, over a pit or on two-post lifts using Supertracker alignment tables. The STR1 laser aligner is a convenient, durable cordless system with hangers to fit wheels up to 24”. It features rechargeable batteries that allow the measuring heads to be conveniently charged from the unit when not in use and is available either as a trolley or a wall-hung half cab as a space-saving option.

WANT TO KNOW MORE?

GOTO

WWW.RDR.LINK/VAZ018

ONLY FANS MACHINE MART

With summer approaching, Machine Mart is thinking about your comfort in the workshop. Its two new Clarke orbital drum fans are great for keeping you cool should the mercury rise. The CAM20R 20” and CAM24R 24" versions both offer 360° tilting and rotating to allow you to alter the airflow to suit your needs, keeping the environment cool. Both fans are designed to create the maximum airflow output whilst also being extremely efficient and sturdy. Both models benefit from robust and durable construction, and feature three balanced high efficiency aluminium blades which are protected by painted steel casing, guard and frame.

WANT TO KNOW MORE?

GOTO

WWW.RDR.LINK/VAZ019

PUT A SPANNER IN YOUR WORKS LASER TOOLS

New from Laser tools is a very handy combination ratchetring/open-end spanner set (part number 8511), that includes 12 spanners in sizes 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, and 19mm. These spanners offer the convenience of a ring spanner but combined with the bi-hex (12-point) ratchet ring and a 72-tooth ratchet mechanism, just 5° of movement is required, allowing fasteners to be turned quicker and making them ideal for use in confined areas. Manufactured from tough durable chrome vanadium with a fully-polished chrome plated finish, they are supplied in a storage case that can be hung on the workshop wall or laid flat in a toolbox drawer.

WANT TO KNOW MORE?

GOTO

WWW.RDR.LINK/VAZ020

CAMERA UPGRADE DURITE