COMMERCIAL VEHICLE WORKSHOP

MARCH 2024 The trade magazine for servicing and repair professionals

BUSINESS

14 The DVSA provides an update on the move to digital working for the industry.

What’s going on in the used LCV market? The VRA provides a snapshot.

RTX is the show to go to. Make sure to put it in your diary.

COMPLIANCE

Brigade’s Emily Hardy on the DVS dilemma facing operators.

FUELS, LUBRICANTS & ADDITIVES

22 Duckhams is a name synonymous with British motoring. CEO Mike Bewsey looks at the past and present.

25 The VLS is on the case with spurious claims about lubricant performance.

30 Tom Hyde, TotalEnergies, considers the role of oils in an ever-developing vehicle parc.

EMISSIONS

33 Replacement DPFs offer the best performance in the long run, says Eminox.

36 Get rid of AdBlue crystals once and for all. Additive specialist Forté provides some pointers.

38 Paul Dobbyn, Powerflow, argues that enhanced maintenance is the way forward.

40 Optimising onboard power systems makes vehicles more efficient, claims Fischer Panda.

DIAGNOSTICS

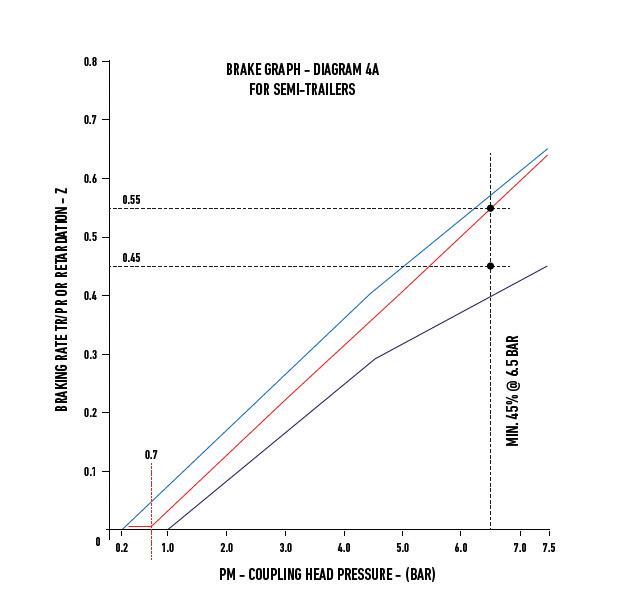

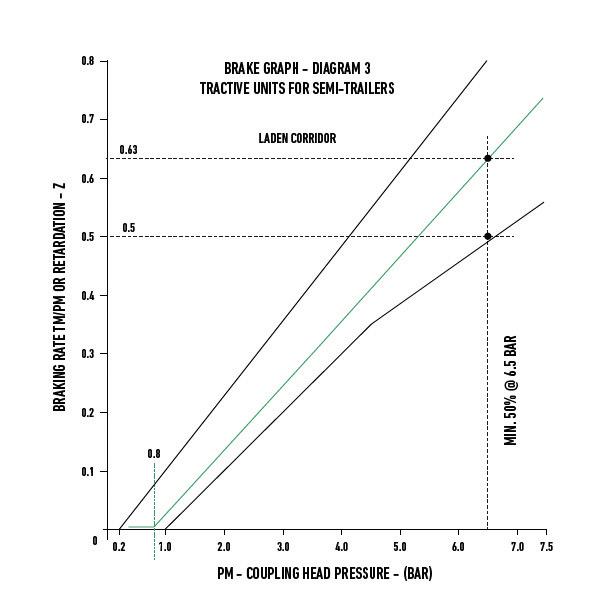

42 BPW examines typical truck and trailer braking issues and how they can be resolved.

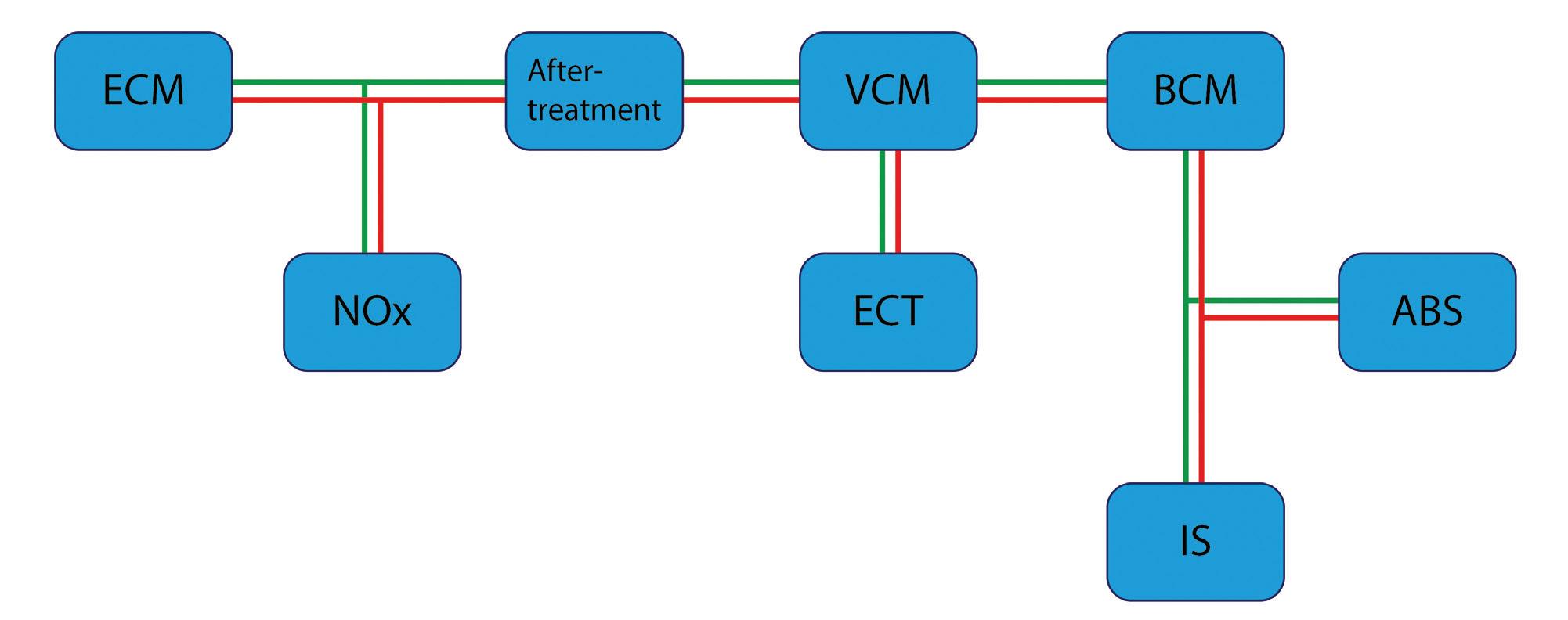

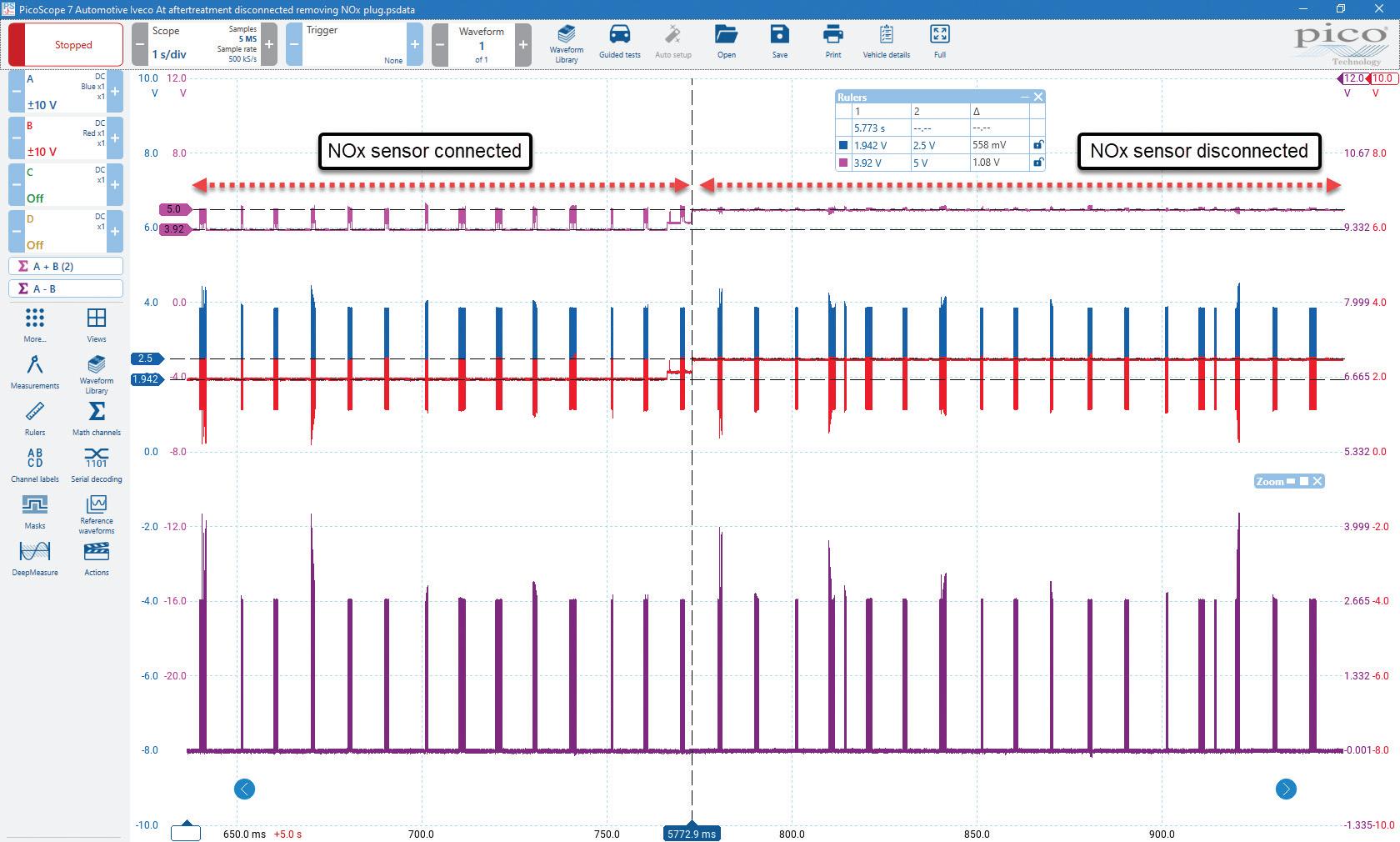

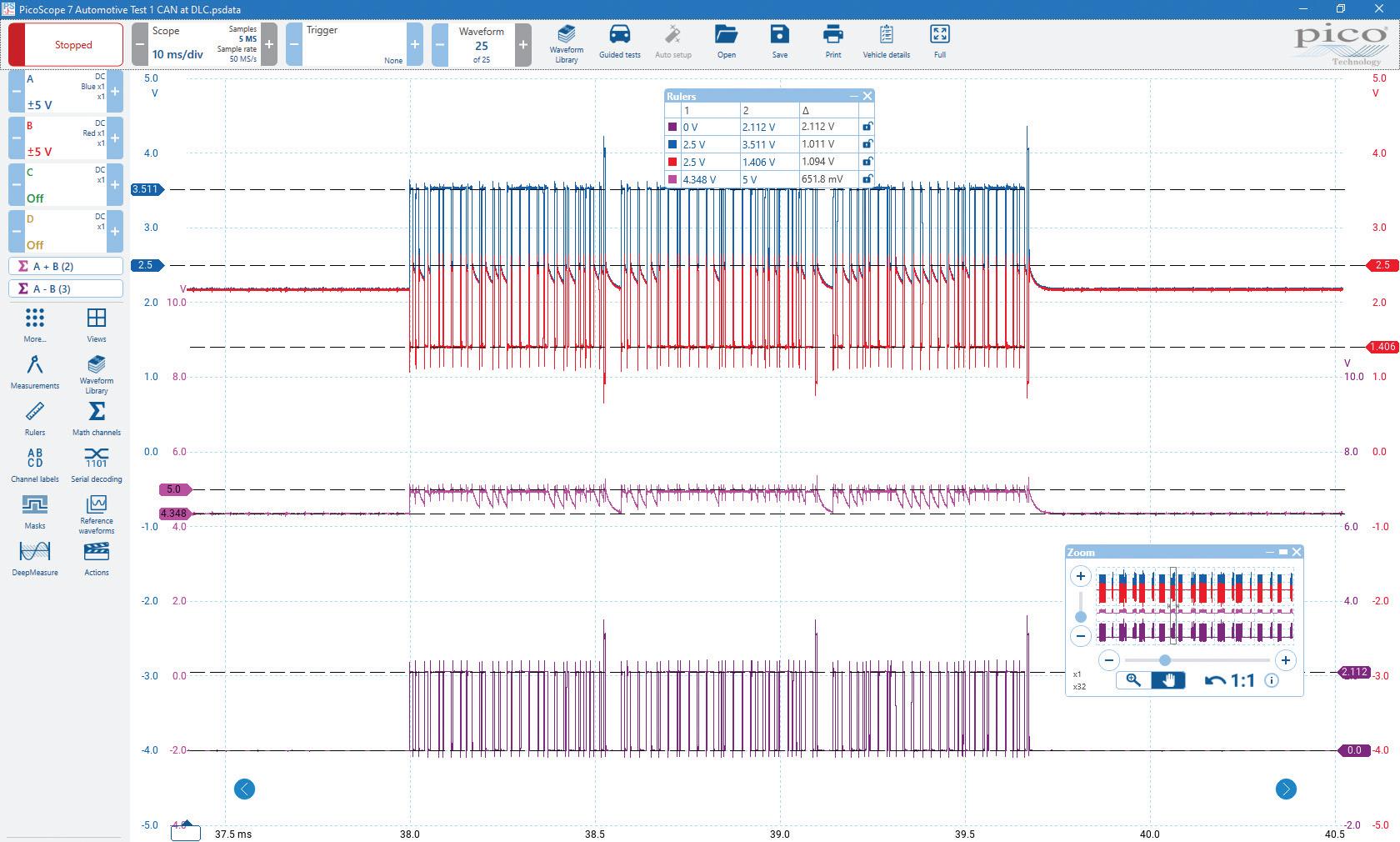

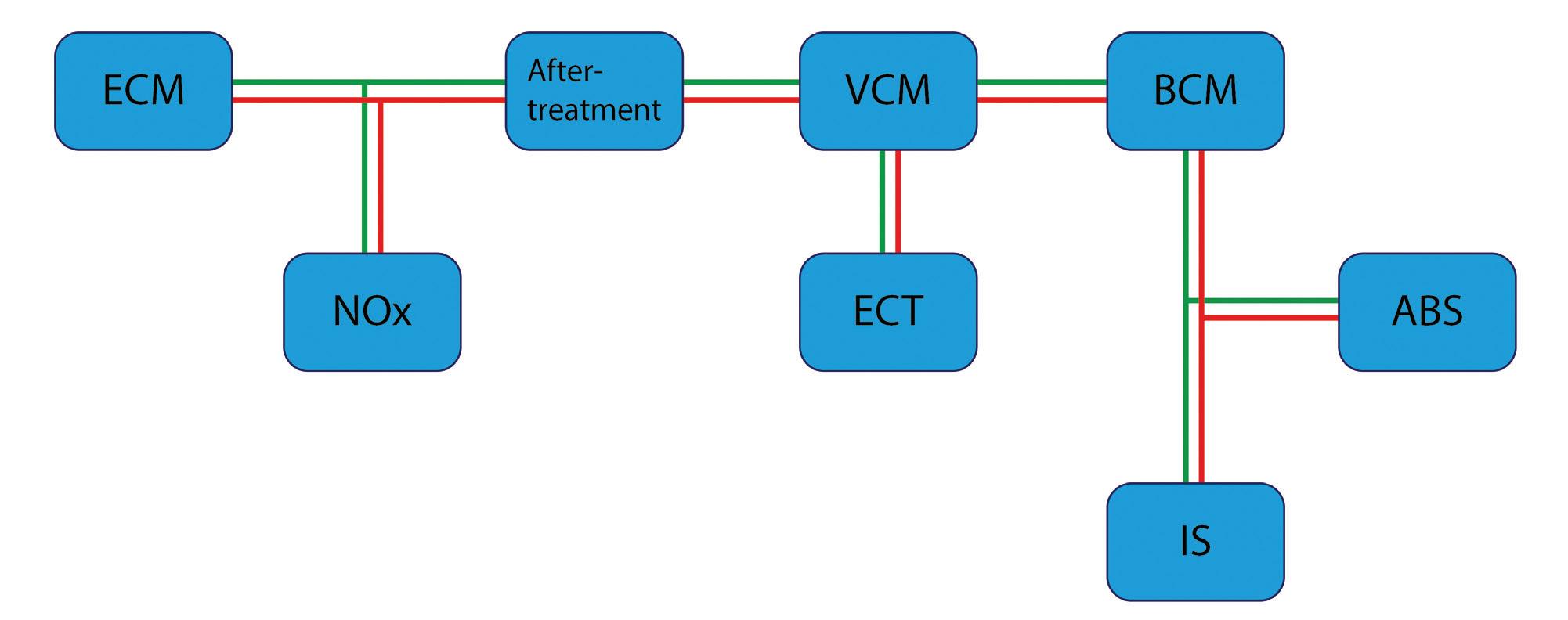

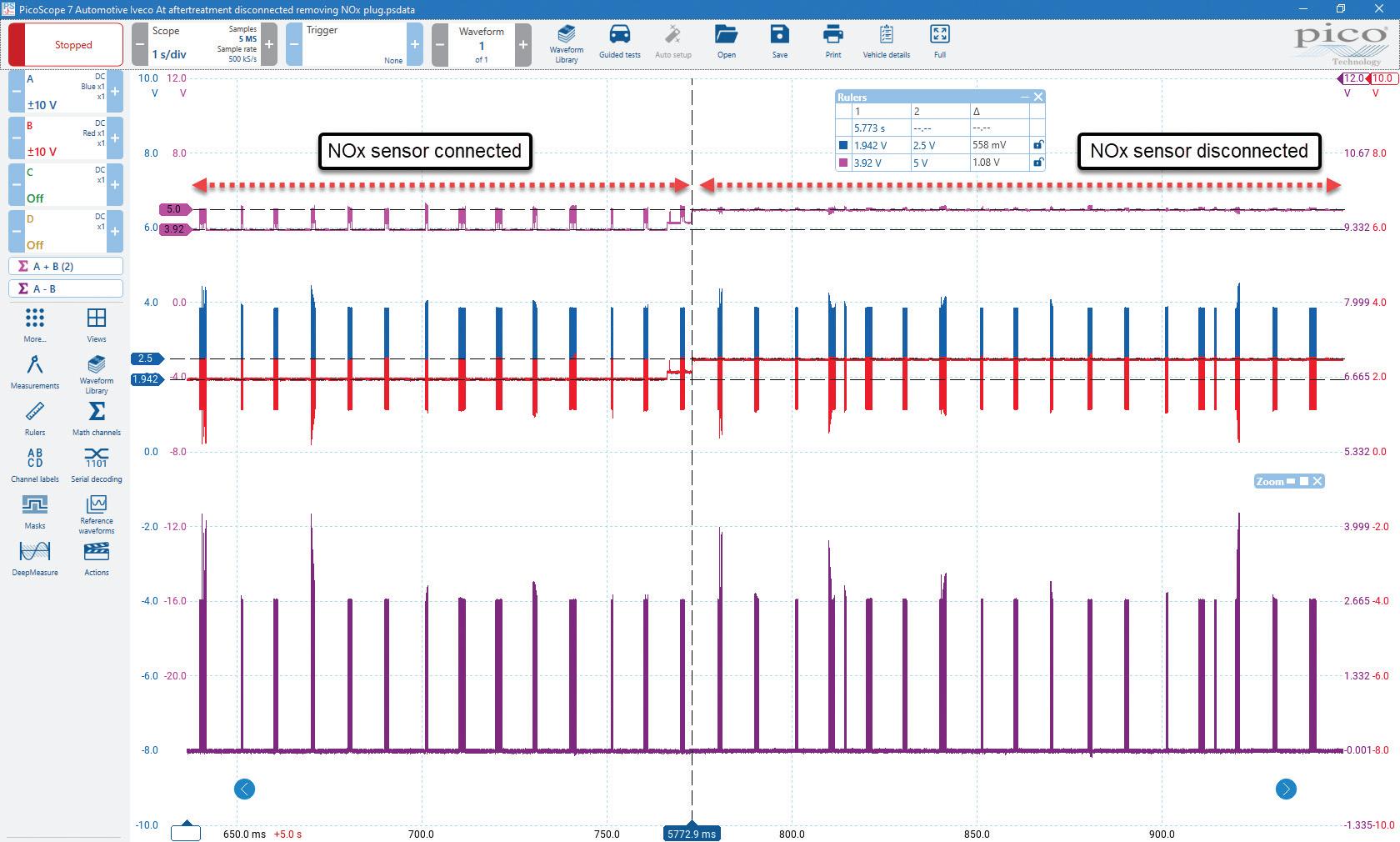

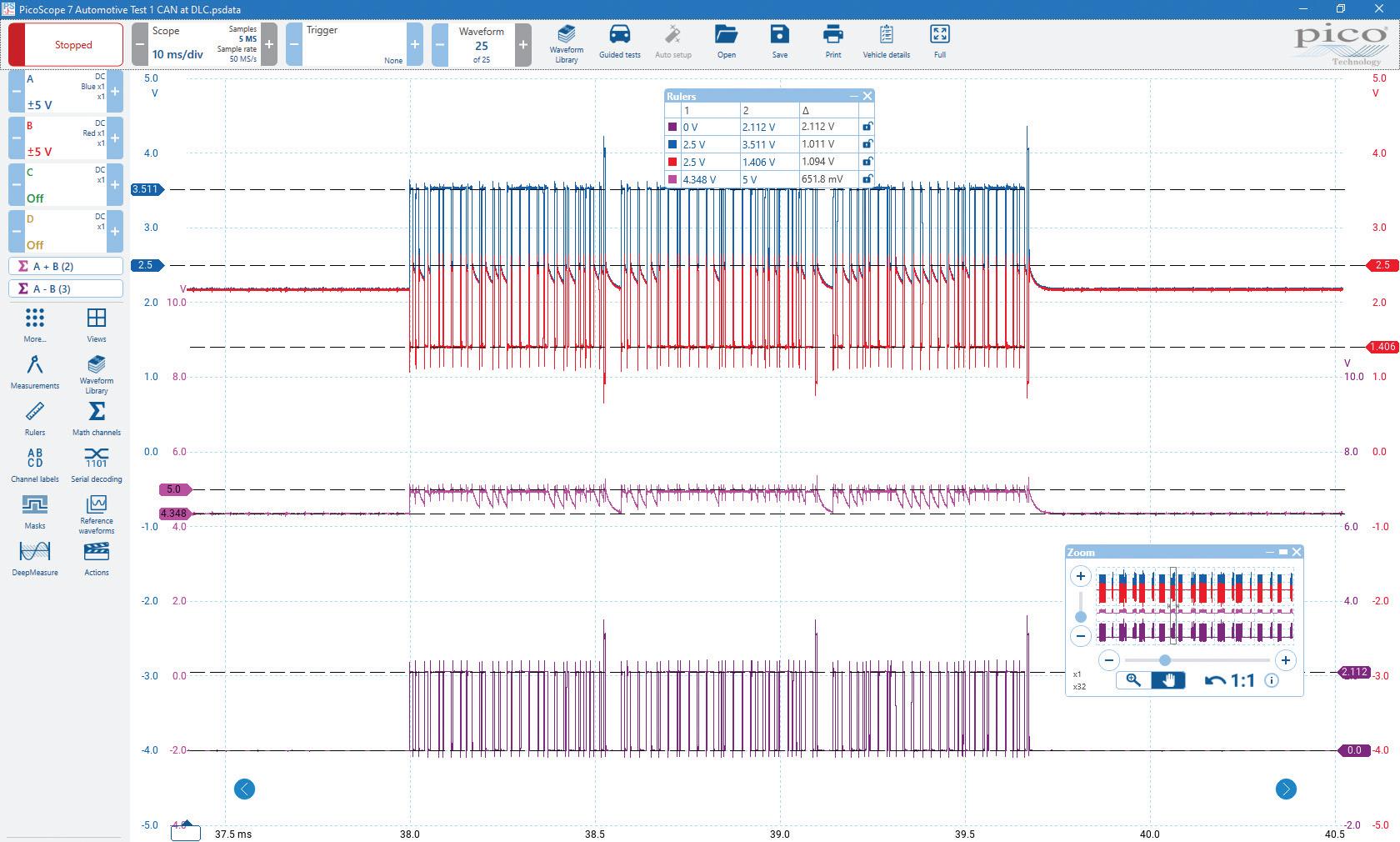

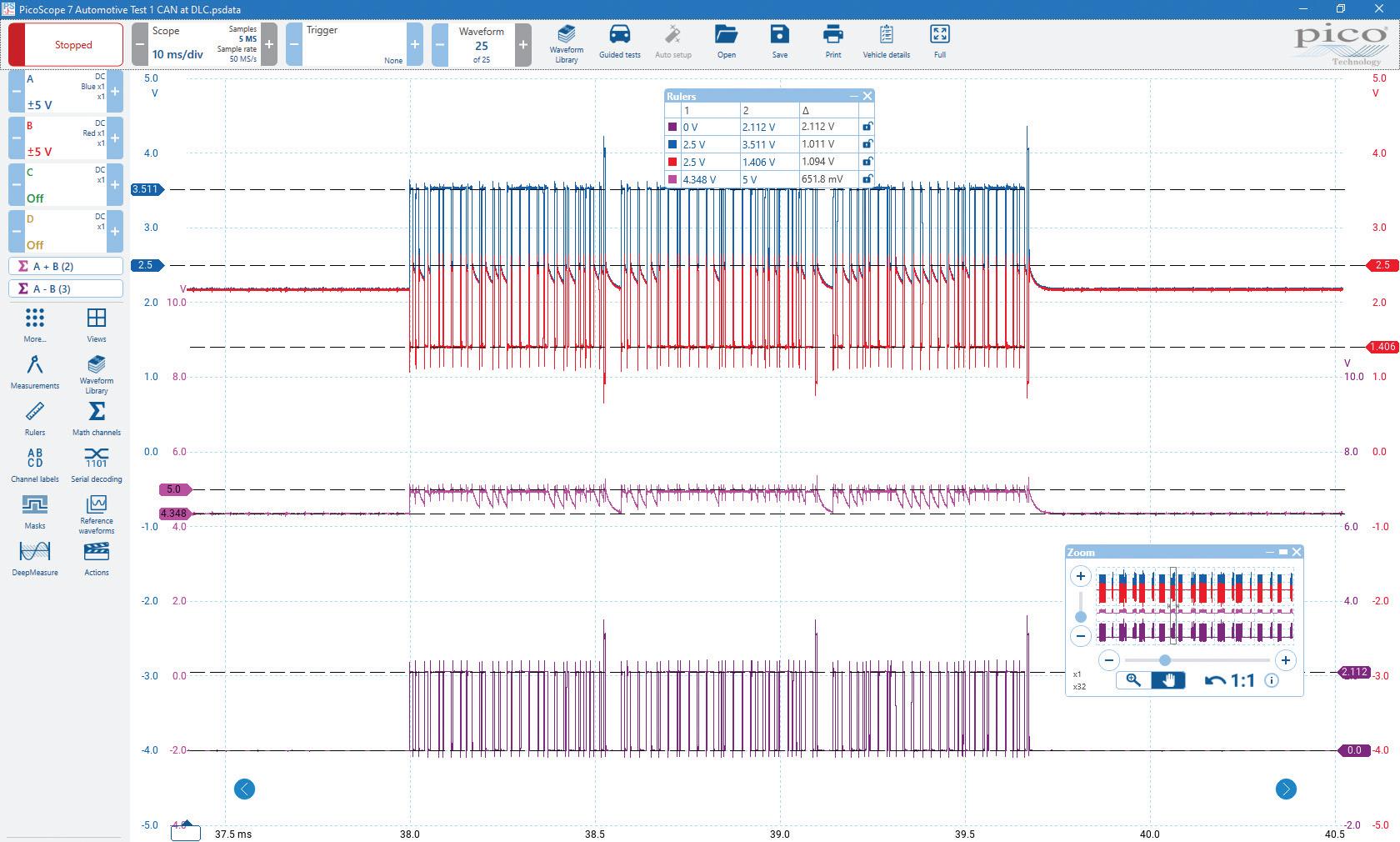

46 What was at fault? Ben Martins, Pico Technology, resolves an intermittent problem with an Iveco Eurocargo.

Repairify provides some answers to the shortage of ADAS qualified technicians.

No fuss, no problem trailer diagnostics with Dr Air Brake.

CONTENTS Issue 3 Volume 21

Viewpoint

News

Traffic news

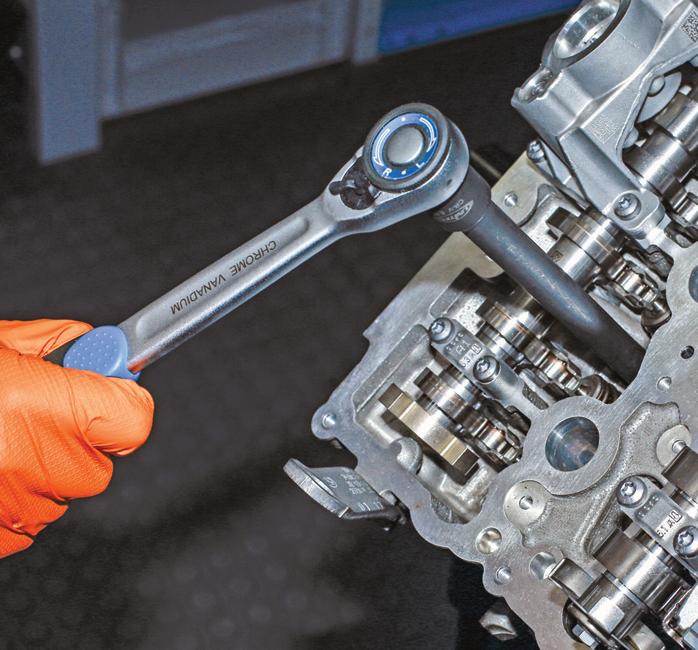

In the workshop

What’s new?

Digital digest REGULARS

5

6

10

54

56

58

MARCH 2024 CVW 3 20 25 42

VIEWPOINT

Editors

JOHNNY DOBBYN

JOHN LEVICK

workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Advertising Sales Manager

MATTHEW BOASE

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates:

UK £30 post paid

Airmail £80 post paid Europe £50 post paid

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by

Stephens and George

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2024

TESTING TIMES

The government’s decision to retain the current 3-1-1 format for MOTs can only be a good thing. Vehicle safety is a non-negotiable and as industry bodies have pointed out, going with the proposed extended format between tests would have had only marginal savings for motorists. In fact, analysis from the AA suggests that an annual MOT can potentially save drivers between £200 and £400 as picking up developing faults each year means drivers aren't hit with higher repair bills further down the road.

When the proposals were first mooted the industry piled in with compelling arguments against its adoption. Short of saying the proposals were madness, leading voices chimed in with fully-leaded arguments against their adoption, citing vehicle safety as the critical factor.

As Mike Hawes, SMMT chief executive pointed out at the time, “stretching MOT intervals will undermine the safety net at a time when vehicle miles driven are increasing.”

Sue Robinson, chief executive of the National Franchised Dealers Association (NFDA, was equally adamant on the matter: “An MOT is the best way to identify minor issues before they become serious problems, which are often more expensive to fix. The change would significantly increase the risk of defects in vehicles and have a detrimental impact on road safety as well as on motorists’ finances in the long term.”

And it’s not just the finances of the motorists that are at stake. Although the proposals were aimed at Class 3 and 4 MOTs, for you, our readers, that still represents thousands upon thousands of smaller vans and larger passenger vehicles that might not be turning up annually to your workshop for an MOT and the servicing opportunity that goes with it. While we agree that the safety of vehicles is of the utmost importance – it is – the prospect of seeing revenues diminished by only seeing a vehicle every two years is hardly cause for celebration.

The case for keeping an annual MOT is compelling, and most would say bleeding obvious. It is perhaps ironic that under the auspices of its ‘bonfire of red tape’, whereby we are all supposed to be liberated from rules and regulation in order to help the economy grow, the government would have effectively been dealing a financial blow to our sector should it have carried out its proposal.

As it is vehicles are being kept on the road longer according to SMR platform provider epyx. Its data shows that the average age for the whole of last year of a fleet van at the point of service or repair was 3.58 years old. In 2019 the average age was 3.03. An argument, if ever there was one, not to tinker with MOTs for larger vehicles.

Happy reading!

TheCVWTeam

8,249 The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication From 1 July 2021to 30 June 2022 Associate member MARCH 2024 CVW 5

@CVWmagazine CVWmagazine

www.cvwmagazine.co.uk

Age concern

The average age of fleet vans continued to rise in 2023, according to new data released by epyx. For the whole of last year, the average age of a fleet van at the point of service or repair was 3.58 years old in 2023, 3.39 in 2022, 3.25 in 2021, 3.16 in 2020 and 3.03 in 2019.

The statistics have been compiled from epyx’s 1link service network platform, used by vehicle operators totalling more than four million units to manage and process service, maintenance and repair (SMR).

Tim Meadows, chief commercial officer at epyx, said: “One of the persistent effects of the pandemic for fleets has been an ongoing ageing of the vehicles they operate. While we’re now in a situation where something of a recovery has taken place, van production over the last few years has been much reduced.

“...they especially have an increased propensity for major components to fail...”

“What is perhaps surprising in looking at our statistics, bearing in mind that vehicle supply has improved substantially, is that the rate of ageing does not appear to be slowing and is still increasing. It’s clearly going to take some time for this metric to stabilise and start to fall.

“This has very real repercussions for vehicle operations in practical terms. Older vehicles, especially those with higher mileages, will always tend to need more SMR. They especially have an increased propensity for major components to fail, such as gearboxes. This is not just expensive, but means vans spend more time in workshops, unavailable for use.”

Registrations rise again

UK demand for new light commercial vehicles (LCVs) grew by 8.4% with 23,962 vehicles hitting the roads during January, according to the latest figures published by the SMMT. The increase marks 13 consecutive months of growth and the highest January total since 2021.

Growth was most pronounced for mediumsized vans, up by almost two thirds (60.9%) as 5,040 were registered, representing 21.0% of the whole market. While the largest vans continue to be the most popular, registrations fell by -4.5% to 14,839 vehicles, they still represent more than six in 10 (61.9%) of all new vans. Pickup and 4×4 uptake also increased, up 18.2% and 62.4% to 3,002 and 729 vehicles respectively, while registrations of the smallest vans dropped by a fifth (-19.8%) to just 352 units

New van registrations are also increasingly zero emission, as demand for

new battery electric vehicles (BEVs) grew to 1,186 units in January, up 19.4% on the same month last year. As a result, some 60,517 new BEVs have joined Britain’s roads since 2018, with access to the Plug-in Van Grant helping businesses to reduce their carbon footprint and cut carbon emissions.

Mike Hawes, SMMT chief executive, said:” More than a year of growth shows the importance of vans to Britain’s economy, and surpassing 60,000 electric vans is a crucial step in our net zero journey.”

Lots on show

HELLA’s recently-opened customer experience centre is proving to be a big hit with visitors, says the company.

“The most frequent feedback we get is ‘we didn't realise HELLA did all that’ as often they'll think of us primarily as an OE lighting manufacturer,” says marketing manager, Helen Goldingay. “Besides being able to view the latest OEM LED headlamps, we’ve also got displays for the huge range of retrofit lighting solutions we offer into specialist sectors such as off-highway, leisure, commercial vehicle and agricultural.”

As an OEM supplier of electronics, there

is also a display area for various systems available to the aftermarket. These include EV-specific, commercial vehicle and EMS sensor ranges.

“There’s a lot to show visitors and we’re really looking forward to hosting more customers this year,” adds Helen. “There’s no substitute for demonstrating practical solutions like ADAS calibration within our training workshop, or chatting directly to the remote diagnostics team about the ways in which they support garages to work effectively on the latest vehicles.”

More developments and events are planned for 2024.

6 CVW MARCH 2024 NEWS

Zero in on emissions

Provisional CO2 targets for heavy-duty vehicles that will phase out almost all sales of new diesel trucks by 2040 have been agreed by the EU.

Manufacturers will have to cut the average emissions of new trucks by 45% in 2030, 65% in 2035 and 90% in 2040.

Meanwhile, trailer manufacturers will also need to improve their emissions performance by 10% in 2030 – a weaker target than proposed by the European Commission. The CO2 target for buses was also reduced to 90% in 2030, reaching 100% by 2035.

Lobby group Transport and Environment (T&E) estimates the EU targets will result in around 30% of trucks sold in 2030 and at least three-quarters in 2040, being zero

emission, either electric or hydrogen.

The European Commission will review the effectiveness and impact of the new targets by 2027. This, it says, will help it assess the expansion of the scope to small lorries, the role of a methodology for registering heavy-duty vehicles (HDVs) exclusively running on CO2 neutral fuels and the role of a carbon correction factor in the transition towards zero-emission HDVs.

Tacho solution earns recognition

Webfleet Tachograph Manager, the all-inone solution for downloading, analysing and archiving tachograph data, has achieved approved IT supplier status from the DVSA as part of its Earned Recognition scheme.

Apprenticeships in demand

Kent-based Sparshatt Truck and Van, the award-winning Mercedes Benz and Fuso dealer, is experiencing a rise in demand for automotive apprenticeships following a 200% increase in applications for its training academy in 2024.

Owing to growing interest and understanding of job opportunities in the automotive sector, and rising needs for highly skilled technicians in the industry, Sparshatt received over 240 applications for spots on this year's intake, compared to 80 the year prior, with the uplift in sector apprenticeships meaning expansion to the programme is being considered.

Beverley Wise, Webfleet regional director for Bridgestone Mobility Solutions, said: “As an integral part of Webfleet, our solution simplifies compliance management, allowing businesses to focus on what they do best while ensuring road safety and regulatory adherence. We are thrilled with this accreditation from DVSA, which is a testament to the solution’s design and functionality, tailored to meet the stringent demands of modern fleet management.

“It not only recognises the reliability and efficiency of Webfleet Tachograph Manager but also solidifies our commitment to enhancing road safety and compliance.”

According to the Institute of the Motor Industry (IMI), the latest three-month period has seen the highest rise in new starters compared to the previous year, with an uplift of 9%, and a particular rise in apprenticeships being undertaken by those aged under 19.

MOT remains 3-1-1

The government has published its response to the consultation on updating MOT testing for cars, motorbikes and vans, which confirms that the first MOT will remain at three years from registration. Every subsequent MOT will also continue to be taken once every year.

Launched in January 2023, the consultation sought views to ensure roadworthiness checks continue to balance the cost to motorists, road safety, advances in vehicle technology, and tackling vehicle emissions.

To ensure MOTs are fit for the future, the government will further investigate how to better monitor diesel vehicle emissions through the DVSA. This will include whether testing should do more to ensure that diesel vehicles comply with emissions regulations.

Sales pitch

AutoCommercial.co.uk is a new online platform that provides a dedicated space for buyers, sellers, and agents to list and discover automotive businesses and properties, according to founder, industry veteran Martin Wilson.

Automotive properties for sale can be listed on an open market basis as is customary but it is equally possible to advertise on a confidential basis adding a new dimension to automotive property sales. The site allows users to upload anonymous summaries of businesses or properties, ensuring confidentiality and privacy.

“AutoCommercial.co.uk aims to connect buyers, sellers, and agents in a transparent, efficient and confidential manner, streamlining the process for all parties involved,” claims Wilson.

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk MARCH 2024 CVW 7

TyreSafe pumped with MOT decision

Potential safety risks and ‘limited’ savings for UK motorists have been cited as the reason for the government’s decision to retain the current intervals between mandatory MOT test for cars, vans and motorcycles.

TyreSafe and 4,500 organisations responded to the MOT consultation, which has now concluded, detailing the significant risks extending the first MOT for vehicles from three years to four or even five. DVSA figures show the most likely reason for a vehicle, up to six years of age, to fail its MOT is tyre defects.Department for Transport (DfT) concluded:“The Government intends to maintain our exceptional record on road safety–with it being one of the best in Europe.

“We agree with a number of respondents who identified that any savings made by motorists would at best be extremely marginal and limited by additional costs from defects not identified at MOT deteriorating and thereby requiring more expensive repairs (e.g. increased call outs for tyre defects), as well as increased insurance premiums.”

Stuart Lovatt, TyreSafe chair, said: “This is a very welcome announcement from the Department for Transport and we applaud them for listening to the views of road safety organisations such as TyreSafe for factoring in the risks posed to road safety in extending the first test to four years. While TyreSafe supports any initiatives which help reduce cost to road users and minimise their impact on the environment, the DfT has rightly pointed out the ‘saving’ of an MoT test fee is marginal when compared to the potential costs driving with defects can have on people's budgets.”

Must do better

The IMI has issued its response to the Department for Transport’s report in relation to the HGV testing consultation and in particular the implications for those operations that are part of the DVSA Earned Recognition (ER) scheme.

In a statement Hayley Pells, policy lead at the IMI said: “It seems that the statement published by the Department for Transport on 26th January was more of a presentation of findings rather than a full conclusion, with more work clearly needed to reach a satisfactory approach for the HGV sector.

“The IMI made a full and informed submission to the original consultation and we will continue to work hard onbehalf of those in the heavy duty vehicle sector to

Web feat

Imexpart, the truck and engine parts supplier, has unveiled a new website, which it says, provides enhanced usability and navigation, enabling customers to easily explore the extensive range of products in the truck and engine categories. It also incorporates an online chat facility for immediate assistance.

ensure that the experience of professionals is properly accounted for.

“Investment in skills development is critical to maintain the integrity of this vital component of the automotive sector; without properly maintained heavy goods on UK roads our economic infrastructure is under serious threat. The DfT’s proposals seem to suggest that reduced testing for those part of the ER scheme is likely.”

Other functions include an online credit account form and a dedicated portal for

Foreign talent

Easy2Recruit, an agency that specialises in helping UK garages access overseas talent, is heading into 2024 in optimistic fashion after a hectic first six months in business.

The company recruits skilled staff by accessing technicians working abroad, thanks to partnerships with overseas recruitment specialists. It says it is currently working with a number of garages to help obtain their sponsor licences and place technicians in the first quarter of this year. The government announced changes to the Skilled Worker visa programme in December which will see the minimum salary sponsors need to pay workers rise by 48%, from £26,200 to £38,700 from April.

The change came after the government came under renewed political pressure to

wholesale customers for convenient account management. It also offers a range of resources such as downloadable bulletins, brochures, and new product line information. With an up-to-date news section, it ensures customers stay informed about the latest developments and insights. A ‘requesta call back’ form is available for straightforward and direct communication with the team.

reduce net migration, despite many areas of the economy being negatively affected by a lack of workers. “We can help business access exceptionally talented and committed overseas technicians and there’s a huge need for this in the automotive sector,” said Ambi Singh, CEO. “The changes announced to minimum salaries in December mean our focus will move towards recruiting specialist master technicians and working more with larger businesses with locations in parts of the UK where cost-of-living and salaries tend to be higher.”

8 CVW MARCH 2024 NEWS @CVWmagazine CVWmagazine www.cvwmagazine.co.uk

TRAFFICNEWS

Tiger rises to the challenge

Warburtons, Britain’s largest bakery brand, has chosen Tiger Trailers to provide 38 rigid box vans to join its nationwide fleet of vehicles delivering fresh bread to 18,500 stores across the country every day.

Built on 14-tonne DAF chassis from local firm Lancashire DAF, each rigid is fitted with Warburtonsspecification racking along its sides, along with adjustable centre aisle load bars to suit the customer’s loading requirements. The rigids also boast crew doors on each side of the body’s rear to expedite the loading process, access to which is covered with a hinged alloy floor section, maximising

load capacity. The Dhollandia tail lift aids drivers with large loads, and the two Labcraft B3 Banksman reversing lights help in low-light conditions. They are finished in Warburtons’ trademark orange, painted in house at Tiger.

Steve Gray, head of transport at Warburtons, commented: “It has been reassuring to have been involved throughout the design and manufacturing

process. We have taken delivery of 10 of the vans already and are very impressed with the final product. We are looking forward to a further 28 due joining our fleet in spring this year.”

Tom Stott, technical sales manager at Tiger Trailers, added: “It’s been a pleasure to work closely with Steve and his team at Warburtons. At Tiger we are proud to offer competitive lead times and

guarantee a premium product without compromising on quality. To have done so for one of Britain’s most-recognisable brands is something to be celebrated, and we are hopeful to build on the relationship we have established with Steve and Warburtons in the future.”

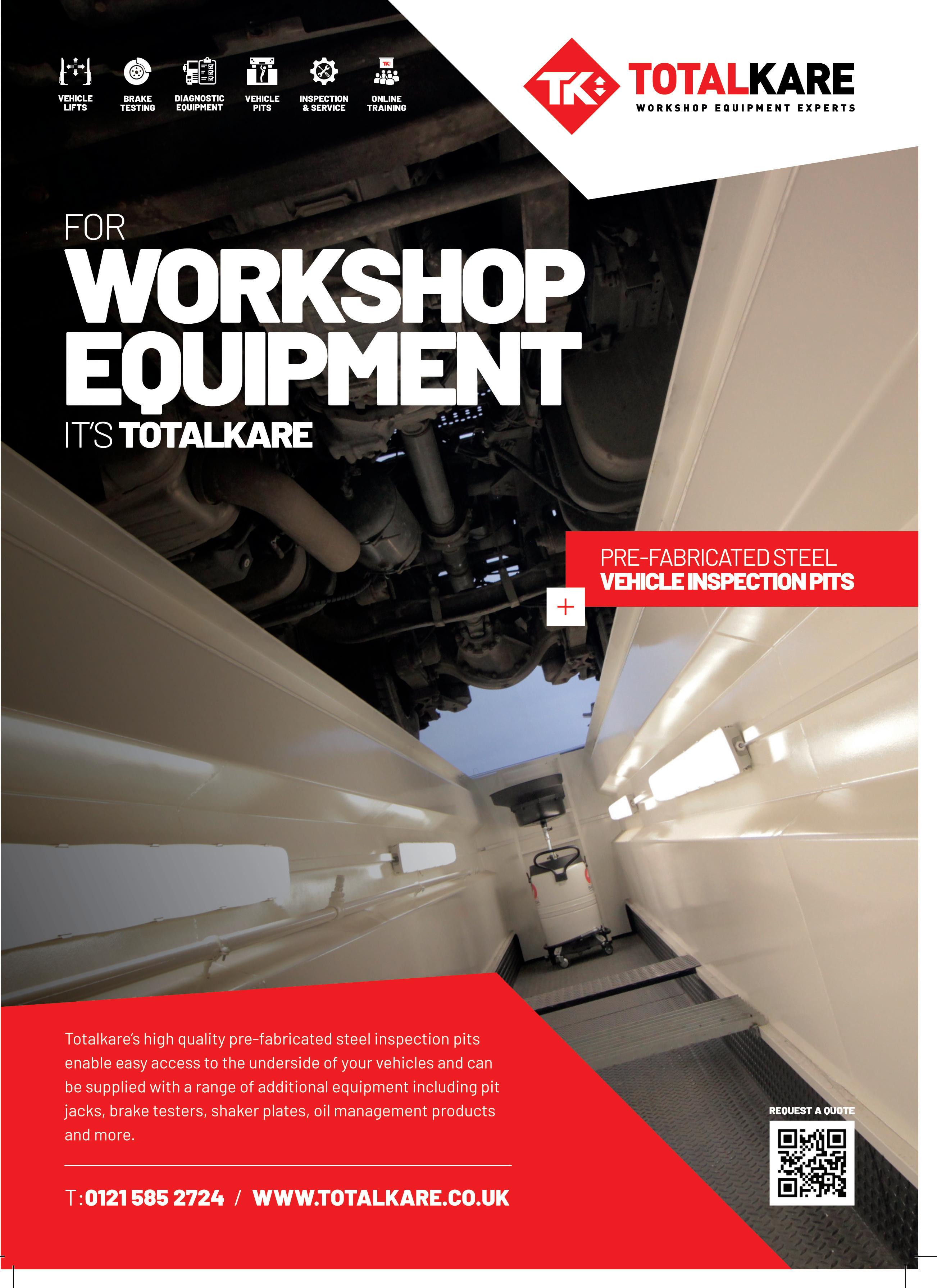

For

10 CVW MARCH 2024

more info on For more info on Tiger Trailers, WWW.RDR.LINK/VBH001

ISUZU

British Airways is adding nine new Isuzu D-Max Utility double cab pickups to its fleet to help airside operations at Heathrow and Gatwick Airports.

Sourced from dealer Weybridge Isuzu, the initial three vehicles will go to Heathrow Airport, with the other six destined for Gatwick. With a towing capacity of 3.5 tonnes

Isuzu just the ticket for BA

and the ability to carry a payload of over a tonne, alongside a reputable track record of reliability, the D-Max is a tried and tested workhorse that is set to play a vital role in supporting BA’s ground operations.

The vehicles are finished in Splash White and have been branded with the iconic British Airways logo and upgraded with accessories, including an underrail liner and MountainTop roll cover on the load bed, as well as a revolving amber hazard

warning light on the roof.

James Biggs, managing director at Weybridge Isuzu, said: “It is incredibly exciting to have been chosen by British Airways as its preferred supplier of these critical vehicles. We always aim at delivering firstclass service and we look forward to ensuring the Isuzu D-Max meets and exceeds expectations.”

For more info on Isuzu, WWW.RDR.LINK/VBH002

VOLVO

Following the recent purchase of a Volvo FE Electric truck, Knowles Logistics’ new wheels are already proving to be a hot choice for its driver, Ben Fox.

Having driven it for a threeweek period to establish its suitability within Knowles’ operation, Fox has been enthusiastic about the vehicle highlighting its responsiveness, nimble handling and low noise output as the standout benefits when behind the wheel.

Primarily used for urban deliveries within the Cambridgeshire area where

Great FEedback

Knowles Logistics is based, driver Ben believes the Volvo FE to be well suited for shortdrop routes.

“Overall, the driving experience of the FE has been positive. Reduced noise pollution comparative to a combustion engine HGV means that the truck is ideally suited for urban areas, especially for night-time operations and driving within quieter neighbourhoods.

“With instant torque and a vibration-free operation the truck provides a comfortable experience, which ultimately contributes to a smoother overall driving environment.

This can be particularly handy when navigating during rush hour or handling especially heavy loads.

“While range still remains an ongoing concern, they can still be a valuable asset as long as its limitations are well understood. Having recently operated it on trial within the Cambridgeshire area, the vehicle presented no range issues as we were only travelling around 150km per day – which is well within its 200km capabilities.”

For more info on Volvo, WWW.RDR.LINK/VBH003

Urban fulfiller

RENAULT TRUCKS

Renault Trucks is unveiling the latest version of its Renault Trucks Master Red EDITION: a commercial vehicle that, it claims, is versatile, connected and optimised for urban use.

In its electric version, it stands out for its silent running, with no CO2 emissions when in use and enabling unrestricted access to all urban areas.

Largely on account of its completelynewaerodynamic design, the Renault Trucks E-Tech Master Red EDITION boasts a significant reduction in energy consumption, of up to 21% compared with the previous generation. The electric versions, with a 40 kWh or 87 kWh battery, offer a WLTP range of over 410 km.

The internal combustion versions, with a new, more efficient engine platform, offer much lower CO2 emissions, while offering power ratings from 105hp to 170hp and a new ninespeed automatic gearbox.

The range is available in five body styles: chassis cab (L2, L3), platform cab (L2, L3), panel van (L2H2, L3H2, with L2H3 and L3H3 available to order from Q4 2024), crew cab panel van (L2H2, L3H2) and people carrier.

The manufacturer has also designed four option packs: “Delivery” to simplify delivery operations; “Parking Assist” to make manoeuvring easier in city centres; “Storage” to optimise load space; “Driver Assist” to maximise the safety of both drivers and road users.

For more info on Renault Trucks, WWW.RDR.LINK/VBH004

MARCH 2024 CVW 11

TRAFFICNEWS

Low carbon recipe for kitchen manufacturer MERCEDES

British kitchen manufacturer, Moores, haas added a further six Mercedes Actros fuel-saving vehicles to its fleet.

Yet another demonstration of the company’s roadmap to carbon neutrality, the fleet is now 100% compliant to Euro 6 standards for fuel emissions, with consumption reduced by 20% versus older models.

This fleet upgrade has helped to reduce the company’s carbon footprint by 195 tonnes across the entire fleet, which further supplements the 200-tonne saving Moores has already made.

Overall, Moores has reduced its carbon footprint by 395 tonnes of CO2 per year, equivalent to the amount of CO2 that 15,200 trees would remove from the atmosphere, and this is only the start. The company continues to position sustainability as a core fundamental part of its long-term business strategy.

For more info on Mercedes, WWW.RDR.LINK/VBH005

FCEV goes on trial

FIRST HYDROGEN

Automotive and green energy developer, First Hydrogen, has started one month of vehicle trials with gas distribution network, Wales & West Utilities (WWU).

First Hydrogen's hydrogen fuel cell powered vehicle (FCEV) has been designed to meet the needs of fleet operators, such as WWU, who are seeking a zero emissions vehicle that can manage long distances, carry heavy payloads and tow, with fast refuelling. First Hydrogen's FCEV achieves more than 630km or 400 miles on a single refuelling.

WWU is the gas emergency and pipeline service for Wales and the south west of England and operates 24 hours a day, year-round to deliver vital gas network services for more than 7.5 million customers. The First Hydrogen trials are taking place during winter, WWU’s busiest

FORD

period for emergency gas call outs. Typically, cold temperatures can reduce the range for battery electric vehicles (BEVs), affecting reliability for fleet operators. Depending on the weather over the next month, the trials could also generate data to indicate the FCEV's advantage over BEVs in lower temperatures.

The trials commenced with training for WWU's drivers, enabling them to safely operate the vehicle and understand its technical differences. While completing First Hydrogen's driver training accreditation scheme, WWU's technicians performed manoeuvres with the vehicle and completed a call out to a customer's residence. Importantly, they also practised refuelling the vehicle with green hydrogen, supplied by Protium Green Solutions, at Hyppo Hydrogen Solutions' refuelling unit. Both organisations have

helped to develop a hydrogen ecosystem to support First Hydrogen's trial with WWU.

Steve Gill, executive director automotive at First Hydrogen, said: "It is great to see Wales & West Utilities' enthusiasm to start trials and we are eager for them to test the vehicle within routine fleet operations. Our FCEV has clear benefits for utility businesses, such as WWU, and we're keen to generate performance data during the trial that will further demonstrate how our vehicles can help decarbonise similar fleets.”

For more information on First Hydrogen WWW.RDR.LINK/VBH006

New Transits come fully loaded

Ford’s all-new Transit Connect compact van is ready to roll and completes the brand’s new generation line-up of highproductivity electrified Transit commercial vehicles.

Advanced, efficient powertrains include the first Transit Connect plug-in hybrid, which offers businesses a generous targeted 68-mile electric range, as well as both AC and DC fast charging capability.

Customers also benefit from enhanced carrying capacity and capability with load volumes up to 3.7m3, and a transformative

new seating concept for Kombi models. Additional premium features include a connected digital cockpit and Transit Connect’s broadest ever suite of advanced driver assistance systems.

As the third generation of Ford’s popular Transit Connect

compact van, the all-new model forms part of the strongest-ever compact van line-up, along with the all-new Transit Courier, and the forthcoming electric ETransit Courier.

Transit Connect enters production in spring 2024, with initial deliveries of the diesel van scheduled for summer this year as part of a phased launch plan. Transit Connect PHEV will join the range before the end of the year, with Kombi models completing the line-up in early 2025.

For more information on Ford

WWW.RDR.LINK/VBH007

12 CVW MARCH 2024

Gordon Thomson, head of vehicle testing policy at DVSA, brings us up to speed with the latest developments on the agency and its ongoing work with the industry to modernise vehicle testing and recording.

DIGITAL FUTURE

It’s been a while since we updated you on how our digital transformation project for heavy vehicle testing (Commercial Vehicle Service) has progressed. Since that update, we successfully rolled out the new Manage Your Vehicle Testing (MyVT) digital service. ATFs and pre-funded account holders now have a digital account to manage their transactions with us.

I want to share how we delivered this new service – by working in partnership with industry – and explain what’s next for heavy vehicle testing in the digital space.

You can also have a look at my last blog post* on implementing DVSA’s strategy and vision for heavy vehicle testing.

The purpose of the digital transformation project was to provide a better platform for our vehicle testing services. By doing this, we were able to enhance the user experience and provide clearer, real-time data.

During last year, we successfully supported all pre-funded account customers to migrate over from their old account onto the MyVT service. Whilst there were a few issues as we migrated

everyone over, we’re pleased that the new service is now running smoothly and you should be seeing the benefit of this.

Customers have been telling us that they like the real-time view of their transactions, and we are now starting to see the benefit of the testing data from our new service, particularly in our ability to analyse why vehicles fail test in finer detail. In time, we want to share that richer information with industry.

Real-time benefits

One of the big improvements brought about by our new service is the ability to capture data quickly and make test results available in real-time. You can now see your MOT result on the MOT history service as soon as the annual test is completed. You can then view and/or download a copy of your pass certificate as needed.

Currently only certificates from 2021 are available to download on the MOT history service – but you can see the whole test history of vehicles and trailers from 2018.

Now that we’re able to offer certificates digitally via the MOT history service, we want to move away from issuing a paper copy of pass certificates at the time of test.

The MOT history service contains the digital test record for every vehicle. It provides the most up to date and secure way to check the MOT history. Using this service also reduces the need for paper and is more environmentally friendly.

BUSINESS

14 CVW MARCH 2024

Credit: UK Truck & Plant

Credit: MAHA UK

Now that digital certificates are available, from 29 April this year we are going to stop printing MOT pass certificates, by default, at the time of the test. In most cases, you won’t need the physical piece of paper and I’d encourage you to view the vehicle’s record on MOT history instead ensuring the details on the certificate are correct and check for any advisory items. But, by exception, the VSA will still print a copy if you really need one – for example, if you have any difficulties accessing the internet.

No paper needed

We will continue to print failure certificates for the time being. We are considering whether to take the same approach with failures in the future and it would be useful to receive any thoughts or comments you may have. We will of course let you know if we intend to change or approach moving forward.

I’d encourage you to start thinking about how your business can adopt these changes, if you’re not already accessing MOT certificates digitally. We recognise there are responsibilities under the operator’s licence but in nearly all cases, you don’t need the piece of paper if the

“...I’d encourage you to start thinking about how your business can adopt these changes...”

information is recorded and available digitally - should we or the traffic commissioners need to view it.

We’ll work with the industry, our testing colleagues who work at ATFs and testing sites, and our enforcement colleagues to make sure everyone is aware of the changes. Until then, you’ll still receive a copy of your MOT certificate as normal at the point of test.

Publications such as the Inspection Manual and Guide to Maintaining Roadworthiness will be revised to reflect

these changes in due course. We’ve also worked with the Traffic Commissioners, so they are aware of these changes and ability to view vehicle records digitally.

We recognise there may be some circumstances where you will find it useful to print the certificate from the MOT history service, for example, if the vehicle is being used on an international journey.

Moving forward, we are looking at digitally aligning the whole process across Vehicle Testing including making “Ministry Plates” more easily accessible online and removing the need to display these on vehicles. We are working on this now and will provide further details on this soon.

I understand this might be quite a big change for some of you, but it’s important we best use the digital services we have available to provide a modern and efficient vehicle testing service, which meets your needs. It also aligns with DVSA’s vision to 2030 and plans to move towards a digital first approach in the light vehicle MOT scheme too.

MARCH 2024 CVW 15

FOR MORE INFORMATION ON THE DVSA, WWW.RDR.LINK/VBH008

TAKING STOCK

Adealers are increasingly ignoring "scruffy" van stock, especially larger models, that need a high degree of work for sale, with all those present agreeing that there were too many big vans in poor condition on the market.

According to Julian Pullen, senior editor, commercial vehicles and motorcycles, cap hpi: “It used to be said that if a van needed £1,000 of work, it sold for £1,500 less. Now that latter figure is more like £2,000 to £3,000. People just don't want scruffy stock.”

Stuart Peak, national LCV manager,

“...businesses that bring (vehicles) up to scratch quickly and efficiently could fill a gap...”

Manheim, agreed: “Dealers know that if they buy a vehicle that needs work, it could take between six to 12 weeks to get it done at the moment plus, given the present market, its value might fall £500600 in the meantime.”

Diminishing returns

It was easy to understand the logic of dealers, added Graham Howes, head of digital sales, Motor Auction Group: “They don't want to tie their money up for that kind of period. There's a lot of untidy large vans around and, in the time it takes to get them up to standard, they could turn around two or three vehicles in better condition.”

Louis Maxwell, senior insight manager, Auto Trader, added: “We're seeing interest

from buyers concentrated in newer vans and the oldest stock. It’s the middle group – anywhere from two to five years –especially where condition is poor that is under the most pressure.”

The situation could lead to a growth in companies that help to recondition these vehicles before sale, Julian suggested.

“We think there could be new developments in this area. Certainly, there's a lot of poor-quality stock around at the moment and businesses that bring it up to scratch quickly and efficiently could fill a gap in the market.”

BUSINESS MARCH 2024 CVW 17

FOR MORE INFORMATION ON THE VRA, WWW.RDR.LINK/VBH009

Association (VRA) was too good

turn down.

Remarketing

to

SHOW ‘N’GO!

It’s promising to be the transport event of the year.

Whether you’re an owner, driver, technician or enthusiast, then RTX is a must. CVW hears the latest from the organisers.

Award-winning Road Transport Expo (RTX) is a diary must-attend this summer for anybody involved in the road haulage sector, taking place from 4-6 June at NAEC Stoneleigh in Warwickshire. The bumper tradeshow, with its ‘all about the truck’ motto, will provide visitors with the perfect meeting place to connect with industry colleagues and make essential new business connections.

Now in its third year, RTX has expanded to now comprise three large indoor exhibition halls and a vast outside space to host larger vehicles and equipment. More than 200 exhibitors have already confirmed they will attend this year’s event, including every major truck manufacturer.

There is also a host of exhibitors providing equipment and technology aimed at vehicle repair and maintenance providers, which can be easily searched for on roadtransportexpo.co.uk

Tick key categories –such as ‘Repair & Maintenance’, ‘Workshop equipment/vehicle weighing equipment’ and ‘Vehicle washing/cleaning products’ –to help you plan your visit.

You may also like to take one of the latest vehicles out for a test drive if you have an HGV licence, or simply experience the ride in one and ask questions about the technology as a passenger if you prefer, over in our Ride & Drive area.

“...there is also a host of exhibitors providing equipment and technology aimed at vehicle repair and maintenance...”

BUSINESS 18 CVW MARCH 2024

“If you haven’t yet visited the show, we are sure you’ll be impressed by the sheer scale of this year’s event as there is so much to see and do,” says Vic Bunby, divisional director at show organiser Road Transport Media.

“But what’s also fantastic about RTX is the lively, sociable atmosphere throughout, with exhibitors pulling out all the stops to engage with visitors and plenty of great places to relax, grab a bite to eat and catch up with colleagues.”

RTX is completely free to attend for visitors and you can book a place at roadtransportexpo.co.uk

Remember you can keep up-to-date with our exhibitor list at roadtransportexpo.co.uk.

REMEMBER YOU CAN KEEP UP-TO-DATE WITH OUR EXHIBITOR LIST AT ROADTRANSPORTEXPO.CO.UK OR WWW.RDR.LINK/VBH010

In the know

Whilst visiting RTX, you may also want to attend one of the free Knowledge Zone sessions taking place throughout the show on a purpose-built conference stage. Visitors can drop in and listen to industry experts on a number of key themes, such as:

■ Vehicle safety and compliance

■ Fleet decarbonisation

■ Government policy

■ Innovation and technology

■ Recruitment/apprenticeships

■ The future of HGVs

CLOUDY VISION

Goods vehicles over 12 tonnes now require a permit to drive into Greater London under Transport for London’s Direct Vision Standard (DVS).

DVS is based on a ‘star rating’ indicating how much a driver can see from the cab and was developed to protect vulnerable road users (VRUs) such as cyclists and pedestrians.

But from October 2024 the minimum star rating requirement is increasing from one to three stars. Operators that fall short of the required star rating will need to apply for a Progressive Safe System (PSS).

technology now required. Emily Hardy, marketing manager, outlines the issue.

What is PSS?

The PSS requires a significant shift in technology. Unlike the previous safe permit, which required obstacle detection systems on the nearside, PSS demands technology that can predict collisions based on the trajectories of the vehicle and the vulnerable road user (VRU). This prediction is crucial in determining if a collision is imminent.

Furthermore, the system includes a specified alarm strategy designed to alert the driver to the severity of the situation. Moreover, some technologies fitted to meet the current DVS requirements will not be applicable from the October deadline.

However, the unprecedented demand for safety systems in the last few months means many operators will struggle to meet TfL’s deadline. In addition, component shortages have hit hard – a problem that extends beyond the HGV sector – and all safety technology installations must be signed off by a competent installer.

Feedback and grace

TfL has sent out a survey to assess the market readiness of DVS phase 2 and to decide whether an extension is required for the current three-month grace period. Brigade is urging operators to complete the survey so that TfL has a greater understanding of the situation.

It is our opinion that an extension is required because of the sheer volume of vehicles that will need to be fitted –

COMPLIANCE 20 CVW MARCH 2024

currently estimated to be in the region of 210,000 vehicles, – as well as the late release of the final technical specification and the shortage of fitters in the industry.

For example, the PSS requires a sensor system at the front. The front system requires two alarms: one when the driver detects a VRU when preparing to move off and one when the vehicle detects a VRU as it has begun its forward manoeuvre. A front detection system was previously recommended but not mandatory and so few operators fitted it.

Another issue is confusion throughout the industry. Although Brigade has had its products independently tested the DVS spec does not require this and manufacturers are being allowed to test their products in-house, which is inadequate and, in effect, marking your own homework.

Phasing in

We are advocating for a phasing-in period because even a sixmonth grace period would not be enough. It is our opinion that vehicles that have only had products fitted for a year should have their permits extended, so newer vehicles with no equipment can be prioritised.

It’s worth noting that operators will only be eligible for the grace period if they can demonstrate fitting works are booked or attempts have been made in good faith to fit the PSS to relevant specified vehicles. TfL and London Councils have committed to the grace period and further details about how to apply will be released nearer the time.

FOR MORE ON BRIGADE, WWW.RDR.LINK/VBH011

Mike Bewsey, global CEO of the original British motor oil, Duckhams, reports on how engine oil technology has changed since the company was first founded in 1899.

SMOOTH OPERATOR

The past few decades have seen immense change in lubricants, driven by increasingly sophisticated engine technology. But cast your mind even further back to 1899, when the international combustion engine and motorised transport, whether by land, sea or air, was only just beginning. Entrepreneurial chemist Alexander Duckham began a legacy of innovation that has transformed oils and lubricants, alongside the accelerated development of transport, to where we are today.

Our roads look different to how they did back then. However, the importance of engine oil, particularly in commercial vehicles, has remained largely unchanged.

An article in June 1933, found in the Duckhams archives, states: “The man in the street and, it may be said, some operators of commercial fleets, cherish the misguided opinion that commercial vehicles do not require the best in motor fuel or the best in oil because – well, they are only commercial vehicles. The older they become, the more confirmed the opinion,

hence they reach the scrap heap years before they need do... quality lubrication is certainly vital to long life. Nothing but the best lubricant is good enough.”

Today’s advanced, sophisticated lubricants deliver increasing benefits, helping OEMs deliver lower emissions and higher fuel economy, vital metrics for fleet operators. Workshops are getting increasingly used to dealing with fully synthetic oils with lower viscosities. EV fluids are also being developed to cater to the specific needs of fully electric buses, waste collection vehicles, vans and HGVs.

But for workshops, the age of the internal combustion engine isn’t over. ICE vehicles are likely to be around for many years to come.

Diesel dominates

According to the latest ACEA Vehicles in Use 2023 report, vans are now, on average, 12 years old, trucks 14.2 years and buses 12.7 years, a marked rise since 2018, when vans were, on average, 10.5 years old, and trucks and buses 11.7 years old.

Whilst alternatively powered vehicles are increasing their share of new vehicles, diesel still dominates new commercial vehicle registrations. In January 2024, ACEA data reported that 89% of new van

22 CVW MARCH 2024

FUELS, LUBRICANTS & ADDITIVES

registrations in the UK were diesel, 95% of new truck registrations were diesel, and 76% of new bus registrations were diesel. These vehicles will still be on the roads and in workshops by 2035 and beyond.

Hydrogen-fuelled vehicles may also be gaining traction as a viable alternative. JCB has already retrofitted a Mercedes-Benz Sprinter van and a 7.5-tonne Mercedes-Benz truck with its hydrogen-powered internal combustion engine, the same as those already powering prototype JCB construction and agricultural machines. The tests demonstrated how simple converting commercial vehicles to hydrogen could be.

Oils for our time

Catering to the diverse and ageing vehicles on our roads, Duckhams offers highperformance engine oils formulated to keep engines of all ages moving.

For commercial vehicles, Duckhams Diesel Gard is a range of top-tier, multigrade diesel engine oils for heavy-duty using modern additive technology and high-quality virgin base oils, providing advanced protection for all vehicles operating under severe conditions. Diesel Gard Pro uses cutting-edge additive technology and high-quality synthetic base oils to provide outstanding protection for all heavy-duty vehicles operating under severe conditions. Duckhams Fleetmaster multigrade diesel engine oils for heavy-duty diesel engines meet current specifications and provide complete protection for all new and old generation vehicles.

The essence of engine oil throughout the 20th century

Over 100 years ago, Duckhams developed revolutionary new process oils that controlled the build-up of carbon deposits. In 1933, Duckhams introduced the industry's first Synchromesh Gearbox oil, and in 1951, Duckhams launched the first multi-grade oil—the iconic green Q - 20W-50, which transformed lubrication technology.

In 1909, pioneer Alexander Duckham achieved the first powered cross-Channel flight alongside Louis Blériot and in 1949, Duckhams powered Goldie Gardner's MG to break the world land speed record, a track record of winning on land and in the sky. From conquering the British Motorcycle Championship in 1955 to recent triumphs at the OR BRIC Superbikes Championship in

Thailand and the Porsche Carrera Cup GB in 2023, Duckhams continues to back winners in motorsport.

In 2024, we’re celebrating our illustrious history, and our commitment to advancing this legacy of innovation remains unwavering. Since the brand’s successful relaunch in 2018, Duckhams has received strong support from distributors and partners across the UK and developed its global network, with products now available in twenty-seven countries across Europe, the Middle East and Asia.

Innovation

We have always blended innovation with quality to create products that make movement frictionless. We will continue to innovate and support mechanics and motorists, whatever the future vehicle parc requirement, be that petrol, diesel, hybrid, electric or hydrogen-powered vehicles, for the next 125 years.

Any workshop unsure of what engine oil to use can always use our convenient online look-up tool at

https://www.duckhams.com/uk/find-myoil/?country=GBR. Simply type in the registration and find the perfect blend for each vehicle.

MARCH 2024 CVW 23

FOR MORE INFORMATION ON DUCKHAMS, WWW.RDR.LINK/VBH012

SLIPPERY CUSTOMERS

As guardians of lubricant authenticity the VLS is always on the look out for misleading claims about performance. Now it’s on its 100th investigation. Chair Jacquie Berryman gives an insight on recent cases relating to HGV and LCV engines.

Formed in 2013, the Verification of Lubricant Specifications (VLS) exists to provide a credible and trusted means to verify lubricant specifications. Workshop technicians must have confidence that, in an increasingly complex market, the lubricant they select for a particular vehicle really can deliver what it claims.

In 2023, VLS celebrated its 10th anniversary while dealing with the highest number of cases since 2015. The recent rise reflects both the work VLS has done to raise awareness of the importance of lubricant standards and the increasing complexity of the market. Over the past twelve months, the diversity of cases received has been greater than ever before as awareness of VLS extends across all aspects of the UK lubricants industry.

The 100th case concerns a 10W-40 heavy duty diesel oil (HDDO), which is now under investigation. A complaint has been received regarding the product's claims to meet an OEM specification, which is not known to be generally available in the automotive aftermarket.

Several heavy-duty and light-duty products have recently been investigated, as well as a universal tractor transmission oil, several passenger car and light commercial vehicle engine oils, central hydraulic fluids, hydraulic oils, gear oils, and transmission fluids.

Specious claims

Case VLS010196 concerned a complaint concerning a heavy-duty 5W 30 LS-FE engine oil claiming to meet Volvo VDS-5 / Renault RLD-5 and Mack EOS-5 specifications. The complainant alleged that additive technology complying with these specifications had not been made widely available in the automotive aftermarket, and therefore, such claims should be removed as

“...the named party did not provide any technical evidence in support of the performance claims...”

they are misleading if they could not be supported. Following an investigation by the technical review panel, VLS upheld the complaint on the basis that VLS agreed there was no widely available market general additive technology that had been released to be able to meet these performance claims. The named party did not provide any technical evidence in support of the performance claims, and therefore, the claims are unable to be verified.

Case VLS010193 concerned a C2, C3 5W30 LS-PRO engine oil suitable for light-duty vehicles. The complaint alleged that the product claimed performance against VW 502.00/505.00 specifications together with API SN and ACEA C2, C3. Although the ACEA claims are possible, the VW 502.00/505.00 is not compatible with API SN on the 5W-30 viscosity grade due to the phosphorous limits. VLS reviewed and upheld the complaint as by claiming conflicting specifications and not meeting key performance requirements, the product's claims were misleading. The named party took action to remove some of

FUELS, LUBRICANTS & ADDITIVES MARCH 2024 CVW 25

the claims from product labelling, bringing the product back into compliance.

Case VLS010188, an investigation into a Multi UTTO (Universal Tractor Transmission Oil) WB 101, is due for a sixmonth review in April 2024. VLS will be looking for evidence from product testing that the product supports the specifications it is claiming in relation to low-temperature properties. If the product is found to be non-compliant at this stage, then it will be notified under VLS's primary authority scheme to Buckinghamshire & Surrey Trading Standards.

Three cases are currently under active investigation, whilst many of the cases have been brought to a successful conclusion, resulting in affirmative action from the companies involved. Marketing claims have been amended, technical data sheets revised, products relabelled, and, in some cases, stock uplifted and removed from sale.

The lubricants sector is transforming in response to OEM design changes and the need to meet increasing emissions

legislation. The strive towards electrification, alternate fuels, Euro 7 proposals, trends towards lower viscosity products and increasing use of biofuels are all having an impact. It's more important than ever that we have a robust, anonymous process that holds producers to account and protects end users.

Film stars

VLS has an excellent track record in managing non-compliance. The technical review panel, made up of expert technical professionals from across the lubricants industry, has worked incredibly hard over the last twelve months to deal with a significant volume of varied and challenging cases. Our objective is always to bring products into compliance, and we thank many of the companies involved in these investigations for taking swift corrective action to protect end users.

We are confident that 10 years later, the message around compliance is being heard. Lubricant blenders, manufacturers, and

distributors alike know that they will be held accountable by VLS to ensure that lubricants are correctly described and really can deliver what they claim. But as the industry evolves, we know there is still work to be done to ensure an open and fair marketplace in which end users can have confidence.

FUELS, LUBRICANTS & ADDITIVES 26 CVW MARCH 2024

FOR MORE INFORMATION ABOUT VLS, WWW.RDR.LINK/VBH013

DRIVE TO SURVIVE

Tom Hyde, technical and product quality manager at TotalEnergies UK dispenses some practical advice with regards to HGVs, lubricants and sustainability.

Set to be valued at over $4 billion globally by 2025, road haulage is a critically important global industry. But the sector faces a major challenge. HGVs and freight transportation remain reliant on carbon-heavy resources. To achieve net zero by 2050, road transport emissions will need to drop approximately 80% by 2035, requiring dramatic cuts in fossil fuel usage, combined with the adoption of sustainable low-carbon emission technologies.

Whilst there is no single solution for curtailing HGV emissions, the urgency of this challenge is creating a paradigm shift in the industry, with manufacturers, researchers and policymakers collaborating to facilitate decarbonisation and adaptation.

“...using the right lubricants to maintain engines is essential to the operation of fleets looking to become more sustainable...”

While much of this remains a work in progress, fleet managers and workshops can take steps immediately to contribute to the green transition:

STEP ONE:

invest in fuel-efficient vehicles and products

Ultimately, the most effective way to reduce carbon emissions is upgrading fleets to modern, fuel-efficient, or even renewably powered vehicles that comply with the latest emission standards. Most operators, though, will still be choosing diesel engines when they next renew their fleets – so optimisation and efficiency are key.

Advanced technologies such as aerodynamic enhancements, low rolling resistance tyres, andidle reduction systems can also increase vehicle efficiency and be more sustainable in the long run. Alongside this, regular maintenance of vehicles is crucial to ensuring peak operation – this means properly inflated tyres, clean air filters –and well-maintained engines.

Using the right lubricants to maintain engines is essential to the operation of fleets looking to become more sustainable. Lubricants have historically been seen as a something of an afterthought or technical detail, but according to TotalEnergies’

30 CVW MARCH 2024

FUELS, LUBRICANTS & ADDITIVES

findings, the right lubricants can deliver 5% fuel or energy savings across heavy duty machinery and vehicles. Even modest savings in fuel efficiency can add up across a fleet, and, in turn, across the industry, saving fleet managers both time and money.

Lower maintenance costs and increased efficiency is possible through the right lubricant choice – by choosing products with reduced friction and viscosity (such as our own RUBIA Optima 3500 FE 5W-30), engines can be kept in good working order, for longer. These efficiency gains provide both emissions reductions and cost control benefits equating to between 2% and 3% increases in fuel efficiency for commercial vehicles.

Where fleet managers spend time and money choosing the right vehicle, the same time and care should be spent choosing the right products to maintain these essential pieces of equipment. To this end, TotalEnergies’ LubAnac oil diagnosis can also allow fleet managers to diagnose worn lubricants, providing preventative maintenance and extending the life of equipment – which may also improve resale value.

STEP TWO:

eco-friendly driving practices

Encouraging and training drivers to adopt fuel-efficient and eco-friendly driving habits. This includes practices such as smooth acceleration and deceleration, maintaining a consistent speed, and avoiding unnecessary idling.

Moreover, leveraging technology in driving not only streamlines operations but

also can help ensure compliance with regulatory requirements. For example, implementing telematics systems can provide real-time feedback to drivers, optimising fuel efficiency. Modern telematics systems provide real-time data on vehicle location, fuel consumption, and driver behaviour – information vital for making informed decisions and preventing unnecessary fuel expenditure.

Another crucial aspect of managing an HGV fleet is training. Well-trained and engaged drivers are less likely to be involved in accidents and more likely to operate vehicles efficiently. Regular driver training programs can reinforce good practices, contributing significantly to reducing fuel consumption and emissions.

STEP THREE:

optimising load management

On a practical level, efficient route planning can help minimise fuel consumption and reduce emissions. Route optimisation software to plan the most fuel-efficient paths and combining shipments to maximise the payload of each journey, reducing the overall number of trips. Implementing balanced load management practices can contribute to overall fuel savings and improve the overall efficiency of your fleet.

STEP FOUR: getting to grips with disclosures

Organisations throughout the UK are establishing goals to meet net-zero greenhouse emissions by the UK’s target date of 2050. Mandatory disclosure of

emissions is becoming a standard requirement for both UK and international businesses. The Companies Act 2006 also mandates that publicly listed companies in the UK measure and report their emissions, and a growing number of entities are incorporating emissions measurement and disclosure into their Corporate Sustainability Reporting. Numerous UK enterprises are also actively participating in the Science Based Target Initiative, setting ambitious emissions reductions by 2030 and 2050.

Getting to grips with reporting requirements and adapting to this change will become essential as the UK moves closer to its net zero deadline, and some 'first mover’ logistics and freight operators, such as Stobart, have already taken steps to introduce SBTi commitments. More in the industry will undoubtedly follow, and looking ahead, there will likely be financial penalties for companies that do not reduce their environmental impact and adapt – and potentially commercial implications if customers choose to partner with supply chain providers who align with their own emissions reduction goals.

By increasingly integrating these practices and considerations into operations, HGV fleet managers can make significant strides toward creating a more sustainable and environmentally-friendly transportation system.

MARCH 2024 CVW 31

FOR MORE INFORMATION ON TOTALENERGIES, WWW.RDR.LINK/VBH014

PARTICULATES MATTER

Dr David Phillips, engineering director, Eminox explains what operators, fleet managers and workshop professionals can do to maximise efficiencies and achieve compliance with DPFs.

Whether operating or maintaining a singular commercial vehicle or an entire fleet, it’s important to understand the purpose of a diesel particulate filter (DPF) in keeping a vehicle running and compliant with the latest emissions legislation.

A DPF that is in full working order can remove 99% of particulate matter (PM), or soot. Therefore, when a DPF is not working as effectively as it could, tangible detrimental effects will be had on emissions compliance, air quality and public health.

Regular servicing and maintenance will go some way to alleviating the challenges faced when DPFs fail. However, dashboard lights can appear at other times, primarily when a DPF becomes blocked. This is most typically evident through compromised vehicle performance, black exhaust fumes and unusual engine smells, and all can have a negative impact on maintaining essential emissions compliance.

Compliance is a priority

It is important for commercial vehicle owners and operators to ensure that current legislation and emissions regulations are met and they act responsibly to achieve this. Whilst some downtime may be necessary to ensure DPFs are working effectively, it is essential this is done to maintain legal compliance for the vehicle. This is particularly important when driving in the everincreasing amount of UK based Ultra-Low Emission or Clean Air Zones (ULEZ or CAZ)

“...low quality cleaning processes are not as effective as a replacement DPF...”

as significant fines can be applied for noncompliance. For those who operate vehicles on the continent, even higher standards of DPF testing have been introduced in Belgium, Netherlands, Switzerland and Germany and it is expected that future adherence is likely in more countries.

Periodic Testing Instrument – Particle Number, referred to as PTI-PN essentially replaces smoke testing and gives a particle

number measurement, rather than an opacity measurement. It is carried out whilst the vehicle is idle and stationary using a portable PN tester.

By setting a new testing standard for in service DPF monitoring, it is important to appreciate that whilst it is possible to get DPFs cleaned, low quality cleaning processes are not as effective as a replacement DPF and may therefore not meet the new required standards of PTI-PN testing.

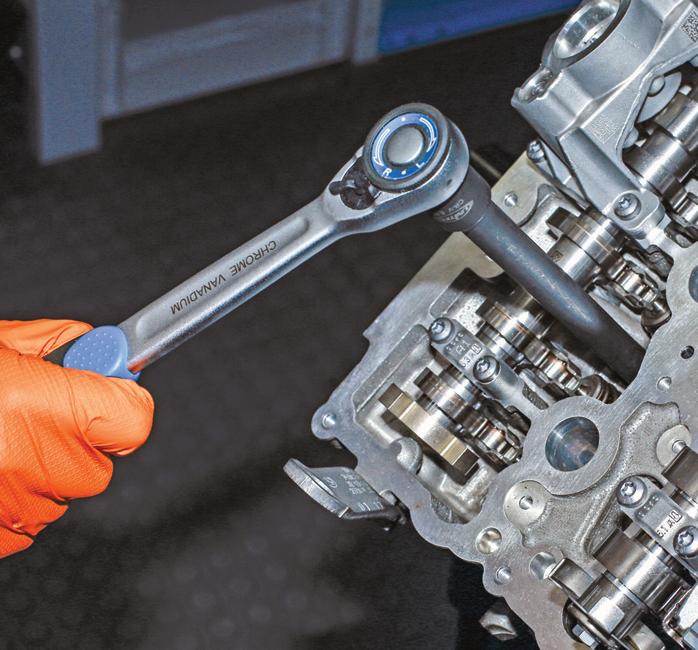

Replacing a DPF

Replacing a DPF is not a difficult process, and the benefits far outweigh the minimal downtime necessary to do so. Knowing that vehicle DPFs are in optimum working order

EMISSIONS MARCH 2024 CVW 33

brings reassurance regarding vehicle compliance, continued performance, and minimal downtime for fleet operators.

By choosing high quality replacements, operators benefit from greater flexibility surrounding vehicle deployment, safe in the knowledge that vehicles, whether in the UK or on the continent, will meet the latest standards of DPF testing.

For workshop professionals, knowing that a replacement DPF is manufactured by one of the leading developers and manufacturers of EATS technologies only serves to add further reassurance.

The expertise that Eminox has regarding vehicle emissions legislation and compliance, and its range of real world tested, market leading type

approved products, makes them the ideal partner for emissions reduction technologies, including replacement DPFs.

These have brought, and will continue to bring, reliability and cost efficiencies for operators striving to ensure their vehicles are environmentally sustainable and achieve emissions compliance, whilst prolonging the life of fleets.

By choosing approved, proven technologies from pioneering designers and manufacturers such as Eminox, compliance and cost can be managed whilst the transition from diesel powered fleets to electric and other alternative fuel sources takes place.

EMISSIONS 34 CVW MARCH 2024

TO DISCOVER MORE ABOUT EMINOX AND ITS ESTABLISHED RANGE OF EURO 6 REPLACEMENT DPFS WWW.RDR.LINK/VBH015

CRYSTAL CLEAR

Additive and clean engine specialist, Forté, talks Adblue crystals - what crystallisation is, the causes, the signs to look out for and how to get rid of them.

What is crystallisation in selective catalytic reduction (SCR)?

Simply put, crystallisation in SCR refers to the formation of crystal deposits on the surfaces of the catalyst within the SCR system.

So, what causes it, you might ask? AdBlue crystals are primarily caused by the reaction of ammonia-based reductants, such as urea or ammonia, under certain conditions. While crystallisation is more likely to occur in colder temperatures, it can also affect vehicles that mainly operate in cities and towns at low speeds.

Does crystallisation impact the AdBlue tank? In short, yes. When crystals form in the AdBlue tank, lines and pump it can cause damage and prevent the level sensor in the tank performing properly. As a result, when the vehicle is filled with AdBlue, it will not register the fill and report that the tank is empty, stopping the system and vehicle working.

Understandably this prompts many technicians to wanting to understand how best remove AdBlue crystals to ensure vehicles run smoothly and replacement tanks do not need to be ordered.

What are the tell-tale signs of crystallisation build-up in an SCR system? There are a number which you might encounter individually or in conjunction with each other. They include:

● reduced NOx reduction efficiency

● increased NOx emissions

● unusual odours like ammonia

● altered engine performance

● warning lights or fault codes

● visible smoke or fumes

● system error messages

Regular monitoring and maintenance are crucial for early detection and resolution of these issues. Here at Forté, we believe it’s all about prevention...

Is crystallisation preventable? Yes, crystallisation in SCR systems is preventable through proactive maintenance measures. Cleaning the oil and fuel system at regular intervals will maintain oil system cleanliness and efficiency, fuel injector spray patterns and operation. This in turn will maintain exhaust gas temperatures to aid the operation of the SCR catalyst and reduce system faults.

EMISSIONS

36 CVW MARCH 2024

“...this will help to maintain exhaust gas temperatures to aid the operation of the SCR...”

When trying to better understand how to remove AdBlue crystals, adding proprietary treatments, such as our exhaust crystal preventer in the Adblue system at every refill, will prevent crystallisation build-up and reduce component failure.

Are there any other treatments to consider to help remove AdBlue crystals? We recommend using our advanced formula diesel treatment to clean the fuel system at regular intervals and maintain fuel system cleanliness, efficiency and restore fuel injector spray patterns and operation. This will help to maintain exhaust gas temperatures to aid the operation of the SCR catalyst and reduce system faults.

In addition, using the Forté exhaust crystal preventer in the AdBlue system will prevent crystallisation and reduce component failure. We recommend using these products alongside each other for the best performance, and in between services, when refilling the AdBlue tank, add Forté exhaust crystal preventer directly to the AdBlue tank. When it comes to

understanding how to remove AdBlue crystals, our products and expert advice can help prevent, reduce and fix the effects crystallisation can have on vehicles.

WANT TO KNOW MORE ABOUT FORTE, WWW.RDR.LINK/VBH016

KEEP ON RUNNING

In an era where fleet managers grapple with the choice between electric and internal combustion vehicles, enhanced maintenance emerges as a strategic third path, argues Paul Dobbyn, director, Powerflow Ltd.

Fleet managers are currently navigating a challenging decisionmaking landscape, pondering whether to adopt electric vehicles (EVs) or buy new internal combustion engine (ICE) vehicles. The consensus advice seems to lean towards patience.

The introduction of EVs poses logistical hurdles, including concerns about range and recharge times, while acquiring new ICE vehicles is hindered by long lead times and the dual concerns of initial expense and potentially poor residual values.

There is a third way, though. Enhanced maintenance, a regime that goes beyond the recommendations of the manufacturer, can deliver a vehicle that lasts longer and operates more efficiently and that also promotes the overall aim of sustainability by doing so.

ICE challenges

If you can keep your current ICE vehicle then you lower your capital costs because you do not need to raise a massive deposit and pay the purchase costs. You also have a far lower carbon footprint. Whether it is an EV or and ICE any new vehicle will involve emitting tonnes of CO2 during manufacture, while an EV requires tonnes of CO2 just to mine the precious metals needed for its battery. According to the International Energy Agency, electric cars use 173kg more minerals such as lithium, nickel and copper than petrol cars. Now, extrapolate that to a commercial vehicle.

Nevertheless, the decision to keep ICE vehicles operational is not without its challenges, notably the potential for increased maintenance expenses and the risk of more frequent operational downtime. But these concerns can be effectively managed and mitigated through a robust enhanced maintenance programme. Enhanced

maintenance is not merely an upgrade to standard practices but a necessary evolution for those seeking to extend the operational lifespan of their vehicles beyond the typical three-year tenure.

Large fleet operators have already recognized that clean engines perform more efficiently and have a direct impact on the longevity of the vehicle. This maintenance strategy focuses on the deep cleaning of engine components to remove soot and other by-products of combustion, which if left unchecked, contribute to the wear and tear of engine parts.

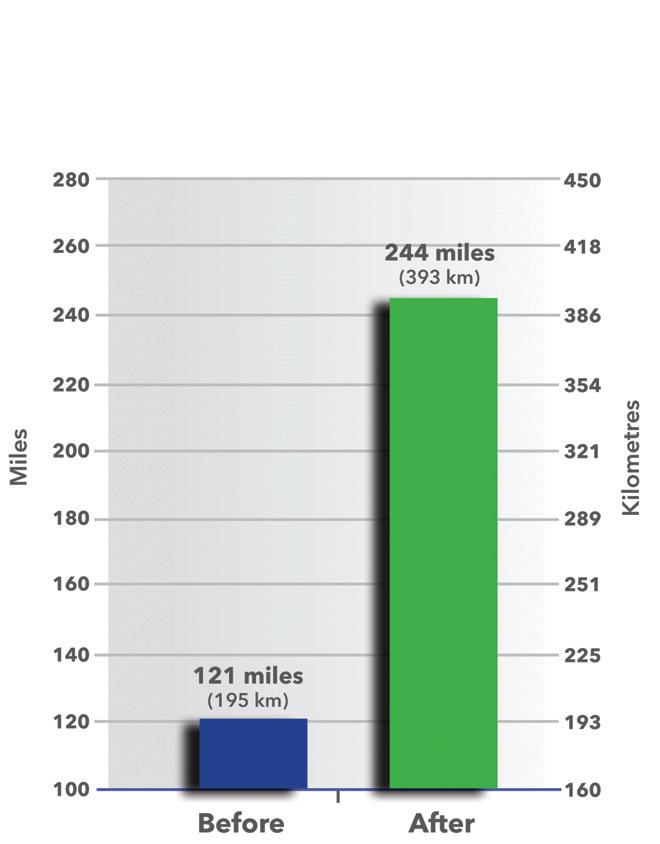

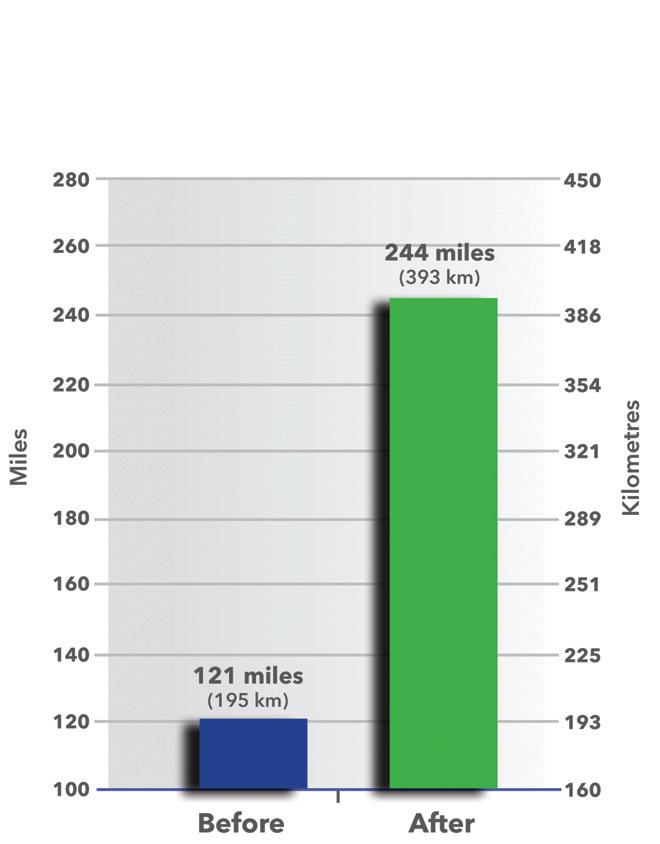

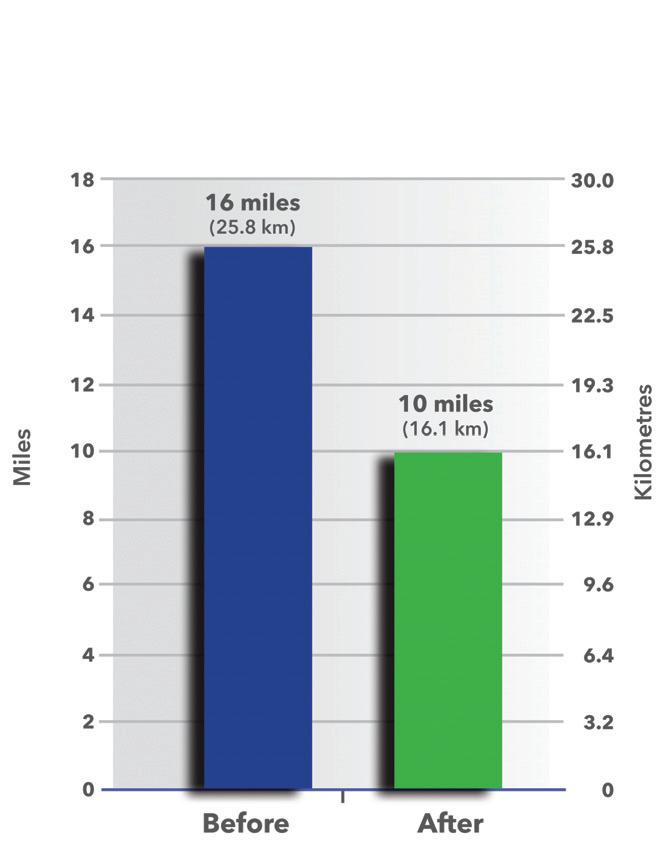

CASE STUDY

Service:

Soot reduction

Soot is both a side effect and a cause of wear in engine components. Soot is carbon, one of the hardest known substances. When soot meets oil it has a has a tendency to connect to other soot particles to make bigger soot particles. The result is like having a liquid emery paper flowing around the engine.

The soot is the inevitable by-product of combustion so you cannot stop it occurring. Yet it can be reduced dramatically – and this is vital to keeping an engine working and working efficiently.

BG 109 Compression Performance Restoration

Products: BG 109, PN 10932, one quart (946 ml), BG SAE 15W-40

Synthetic Blend Engine Oil, PN 714

Vehicle: ................................2008 Ford F-250, Power Stroke® 6.4L

Mileage: ..............................4,859 miles (72,194 km)

Maintenance history: ..........Regular oil changes performed

Driving conditions: ............Avg. 35 miles (56 km) per day city

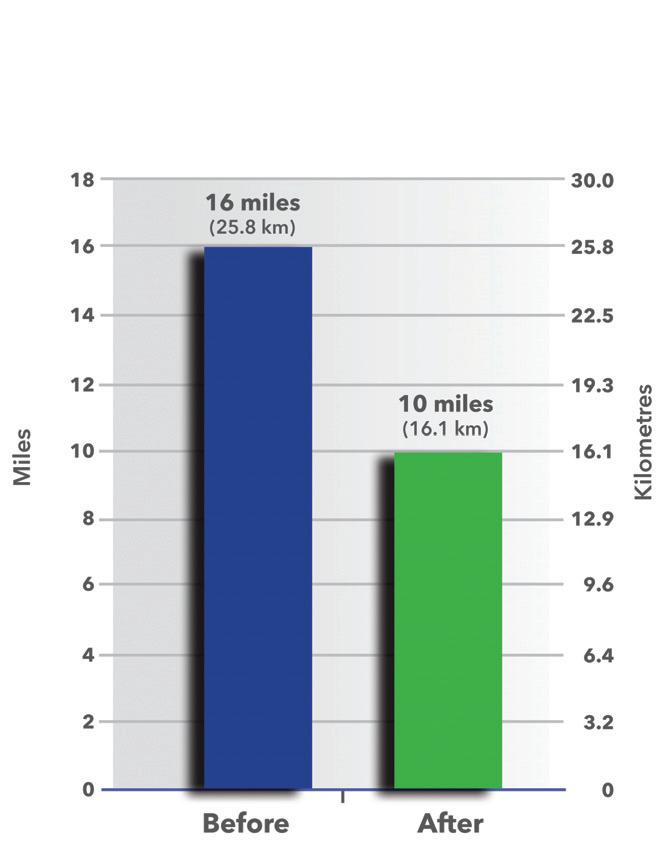

DPF Regeneration Frequency (miles/km driven between regeneration cycles)

DPF Regeneration Cycle Duration (miles/km driven between regeneration cycles)

EMISSIONS

38 CVW MARCH 2024

Soot will deposit itself very quickly on several key components, most damagingly the fuel injectors and the piston rings. When soot attaches to or inside an injector this interferes with the atomisation of the injector causing inefficient combustion and, as a result, yet more soot.

When soot and degraded oil get behind the piston rings it restricts the rings ability to flex and centre. This means that the seal is compromised and leads, very quickly, to two other effects: lost compression and more oil combustion.

Three elements of success

Lost compression also means compromised combustion and consequently more soot –and so the vicious circle carries on. An under-appreciated but actually a major cause of diesel particulate filter (DPF) decline is the impact of oil seeping past the rings, combusting and then depositing metals such as zinc, calcium, magnesium and others onto the DPF – even with low SAPS (sulphated ash, phosphorus, and sulphur) oils. These metal elements effect the efficiency, and shorten the life, of the DPF. DPF life is extended when combustion is optimised. Restoring compression means less soot is produced and the DPF is required to do less regenerations.

Deposits on injectors form relatively quickly in a modern engine and the effect is compounded by the much tighter specifications of an injector, with its ever decreasing aperture size. Deposits in, or on, the injector interfere with the spray atomisation making it harder for optimum combustion. This leaves even more deposits, poor fuel consumption and fuel dilution of the oil – which has its own knock-on effects on the oil's ability to lubricate effectively.

All this is both known and accepted as a real and present problem by fleet managers,

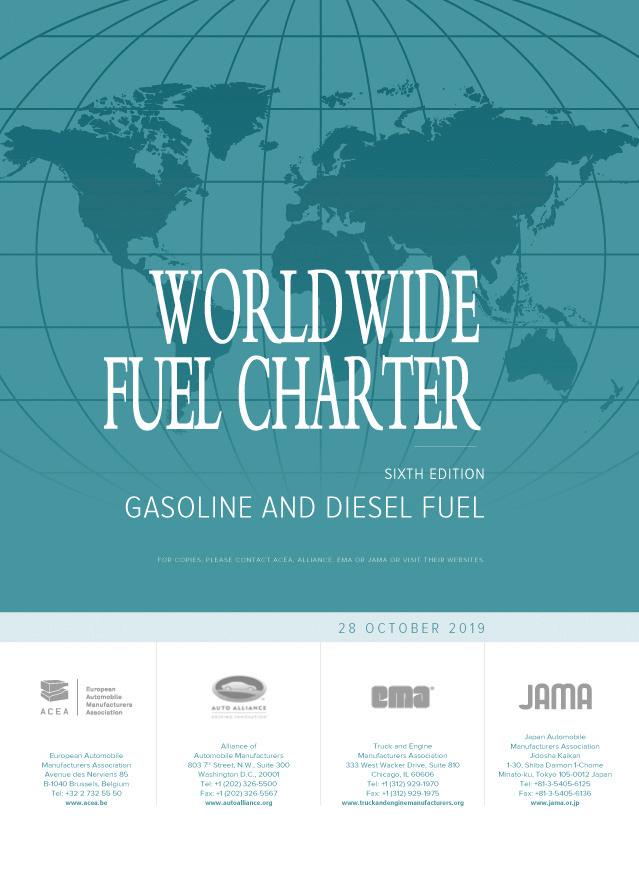

EXTRACT: WORLDWIDE FUEL CHARTER

Influence of Detergent Additives

Cleanliness of the injectors has become a higher priority because of high-pressure injection systems. Modern engines, with their specified performance in terms of power, fuel consumption and emissions over time will depend largely on the cleanliness of their injectors.

yet so many fleet managers stick to the OEM schedule, which does not mention injector and other engine cleaning measures. This is despite their own fuel charter stating that keeping injectors clean is a priority if they want to maintain the specified performance, fuel consumption and emissions.

The whole notion of enhanced maintenance boils down to just three elements:

● service interval injector and fuel system cleaning to restore accurate fuel delivery

● engine cleaning (pre-oil change) to free piston rings, restore compression, reduce blow-by

● oil supplementation to help control soot agglomeration, control acid formation and to maintain viscosity for longer.

By adhering to a regimen that exceeds standard maintenance protocols, fleet

managers can significantly reduce the accumulation of soot and other contaminants within the engine. This approach involves a comprehensive cleaning of fuel injectors and piston rings, areas particularly susceptible to soot accumulation.

Proactive approach

The benefits of such maintenance include restored engine compression, optimized fuel combustion, and extended diesel particulate filter (DPF) life by minimizing the need for regeneration cycles.

Furthermore, enhanced maintenance includes the use of fuel system cleaners and engine performance restoration products, as well as oil enhancers that work to maintain oil viscosity and prevent the negative effects of soot aggregation.

This proactive maintenance does not require additional labour time, as it integrates seamlessly with scheduled service intervals, making it a cost-effective solution for extending vehicle life, enhancing performance, and maintaining fuel efficiency.

In summary, enhanced maintenance represents a strategic pivot from the conventional wisdom of fleet renewal through the acquisition of new vehicles, be they EV or ICE. By focusing on the meticulous care and upkeep of existing fleets, fleet managers can achieve operational efficiency, environmental responsibility, and financial prudence, all while preparing for the future of transportation.

MARCH 2024 CVW 39

FOR MORE INFORMATION FROM POWERFLOW, WWW.RDR.LINK/VBH017

ALL SYSTEMS GO

There are other ways of reducing vehicle emissions, says David Payne, vehicle specialist for Fischer Panda. Here he provides some insights.

Reducing emissions in the commercial vehicle sector isn’t limited to converting to electric or hybrid vehicles or the use of alternative fuels. There are many ways a vehicle can reduce its overall emissions through efforts to ensure onboard equipment also operates efficiently.

These days commercial vehicles come with an array of onboard equipment from air conditioning and refrigeration units to generators and power systems driving specialist tools and kit. By analysing the power and energy needs of these , hybrid systems that seamlessly integrate with the vehicle can be designed, ensuring optimal efficiency, and reducing overall emissions.

These hybrid systems might intelligently manage power distribution by utilising green, efficient lithium batteries from leading brands such as Mastervolt or with the use of highly efficient Fischer Panda generators; or they may handle onboard energy management with renewable energy sources such as solar panels.

The potential to reduce emissions with a vehicle’s onboard systems also helps to achieve a cut down in fuel consumption. We know that a traditional air conditioning unit can demand a lot from your engine; by working with partners such as leading HVAC specialist, Autoclima, Fischer Panda UK is able to install some of the most

“...hybrid systems that seamlessly integrate with the vehicle can be designed...”