13 Electrification of fleets is fizzling out says Paul Hollick, chair of the AFP.

14 Ever wanted to understand diesel pricing? Portland Analytics provides a detailed backdrop to what’s paid at the pump.

MOTs surge as vans stay on the road longer. ATS

Spillard Safety Systems looks forward to the forthcoming

Sapphire Vehicle Services is on the hunt for precious

It’s not simply a job, it’s a career. That’s the view of fleet owner Northgate.

24 Keeping the cabin first class in terms of air quality is important, says UFI Filters.

27 MANN FILTER feels the force with its centrifugal filters.

28 Farécla shows how bodyshops can polish up their act and save time and money.

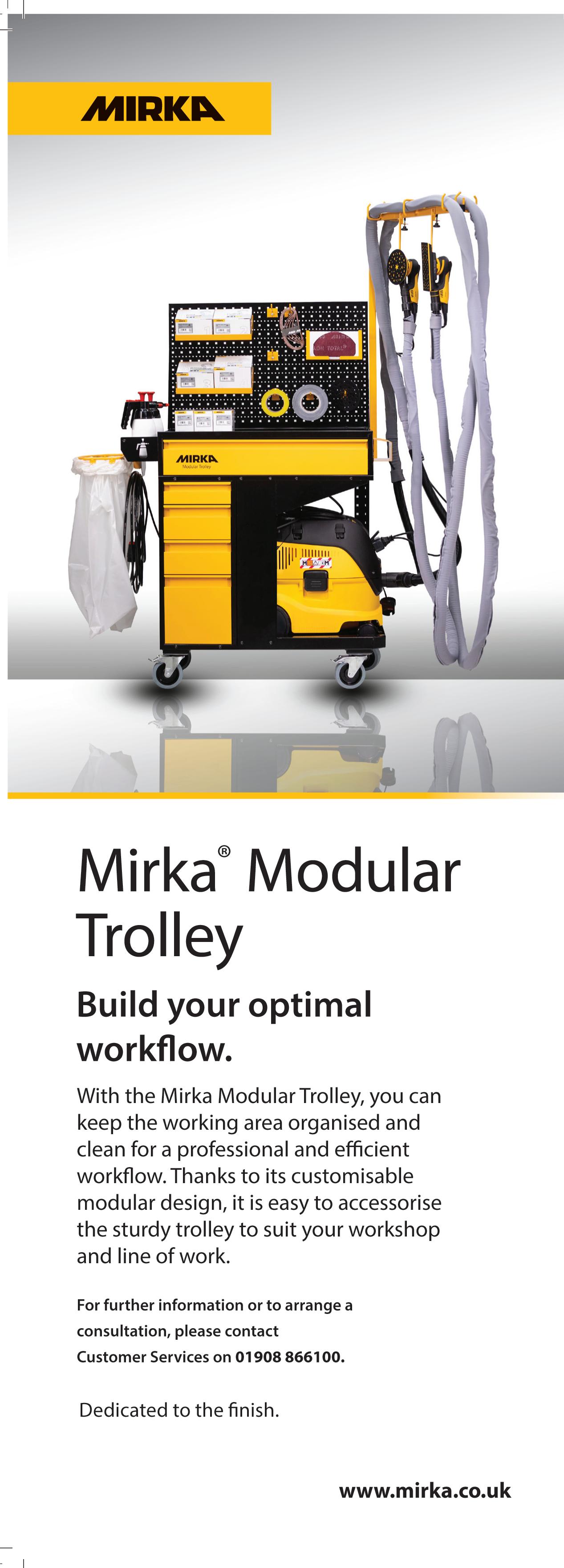

32 HAVS is something not to have. Mirka talks about the dangers of vibration and dust.

34 What’s new in body, repair and maintenance.

37 Knipex is offering readers the chance to win one of its handy tool backpacks. Feeling lucky?

Editors

JOHNNY DOBBYN

JOHN LEVICK

workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Senior Account Manager

ALEX DILLEIGH

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates: UK £30

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens and George

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2023

We pose the question not to scrutinize or criticize the content and delivery of modern apprenticeships, but to ask whether we as an industry, like many others, have learned or understood the best way of engaging would-be talent in the CV repair and aftermarket sector?

The value of an apprenticeship cannot be overstated, and we have fortunately moved on from the dark days of yesteryear when its worth was deemed risible. For example, in 1968 the Royal Commission on Trade Unions and Employers’ Associations concluded that “apprenticeship is a farce and provides less training than a properly constituted course lasting only a few months…The fact that a man has completed an apprenticeship does not therefore of itself guarantee that he has acquired any particular level of skills, or that he has passed any form of test of ability.” Quite the mauling for apprenticeships. Things have moved on and we are lucky that organisations such as the IMI can see the bigger picture, and while promoting apprenticeships as a good thing, have realized that the perception among target groups might be different. This is borne out by figures that suggest apprenticeship starts in the first eight months of this year are 31% down on the same time frame for years 2018/19, yet at the same time more and more roles need to be filled.

So, to address the imbalance, the IMI has embarked upon a campaign to make the sector more appealing, more relevant and more valuable. The organisation says that the campaign will hinge on real voices telling real stories about their positive career experiences and highlighting the opportunities that exist for individuals, whether at the start of their working life or looking for a change in direction. It should not be dismissed as yet another marketing initiative but more a positive step to meet the challenges the sector faces.

The good news is that there are several companies out there who are already committed to what one might call positive recruitment where they are offering a career rather than simply a job. From day one of employment there are goals, benchmarks, aspirations, incentives to do well. And that’s what is important to showcase.

You can read in these pages the direction companies like Sapphire and Northgate have taken to not only recruit and nurture talent but to do it with an eye on the future, offering the younger generation a lifetime career with personal growth very much a part of the programme. It’s a refreshing take on recruitment because both businesses realize that it isn’t a cost, it’s an investment that will help secure future revenues as the SMR market changes in scope and nature.

We have an aging workforce, and we need an injection of youth. Old habits die hard but let them. New habits are where it’s at.

Happy reading!

8,249

The IMI has welcomed the outcome of an exceptional funding band review that will seeanuplift in funding for HeavyandLights Goods Vehicle apprenticeships, calling it “a small step in the right direction”.

However, it went on to say that more needs to be done to address skills issues. Steve Nash, CEO of the IMI said: “First and foremost, it’s great news that the Department for Education has responded to pressure from across the logistics industry to improve funding for apprenticeships. This is critical to the sustainability and growth of the UK economy. However, we have to be realistic about the current skills gap and recognise that the sector not only needs to build a pipeline of talent for the future, the immediate needs must be addressed too. That is why the IMI will continue to argue the case with the Migration Advisory Committee for the inclusion of Heavy Vehicle Technicians on the Shortage Occupation List.”

Van fleet operators expect major cost increases in every area of fleet operations, according to new findings from Arval Mobility Observatory, an automotive research and information company.

During the next 12 months, 79% believe there will be rises in service and maintenance, 71% in insurance premiums, 69% in vehicle lease rates, 67% in EV charging, 63% in tyres, and 61% in petrol and diesel prices.

MAN has announced that it will start production of its electric long-haul truck in 2024, adding that there are already more than 500 order enquiries.

Production of the new MAN eTruck will take place at the main plant in Munich. It will initially come off the production line alongside conventional diesel trucks. The company has set itself a target of around half of all trucks produced annually are to be electric by 2030.

Shaun Sadlier, head of Arval Mobility Observatory in the UK, said: “We’ve seen fleet price increases right across the board over the last couple of years and, as this new question from Arval Mobility Observatory Barometer shows, our respondents very much expect that trend to continue.

“In every category of expenditure, there is an assumption that prices will rise further during the next year, notably when it comes to service and maintenance, insurance, lease rates and tyres.”

The number of LCVs registered in the UK grew for the seventh consecutive month in July, increasing by 44.2% to 26,990 units, according to the latest figures published by the Society of Motor Manufacturers and Traders (SMMT).

In the best July since 2020, registrations were also up 4.4% compared with prepandemic 2019 volumes, a result of rising demand for new vans, pickups and 4x4s and the easing of supply chain issues constraining production. The largest volume growth was recorded for medium-

sized vans which more than trebled, up 227.4% in the month. Registrations of the largest LCVs increased by 29.3% to 19,111 units and accounted for 70.8% of the market registered in the month. Deliveries of 4x4s and pickups also saw growth, up 159.3% and 48.3% respectively, while registrations of vans weighing up to and including 2.0 tonnes were the only segment to decline, falling -40.9% to 427 units. Mike Hawes, SMMT chief executive, said: “Following a solid first half, van sales have enjoyed an extremely positive month, beating even prepandemic levels.”

The Conti Urban bus tyre is becoming smart. Continental is factory fitting the complete tyre family with its latestgeneration sensors.

The Conti Urban HA3, Conti UrbanScandinavia HA3+ and Conti UrbanScandinavia HD3 smart tyres are available to purchase now. This makes Continental the first manufacturer to offer an entire family of tyres with sensors, another step in its commitment to fleet digitalisation.

The tyre sensors transmit live data on tyre temperature, pressure and predicted tread depth via bluetooth. Fleet management accesses this data using a stationary yard reader station or telematics units. If any data anomalies are detected, immediate action can be taken.

The intelligent Conti Urban tyres therefore help to reduce vehicle breakdowns and downtime, lower carbon emissions and cut costs. According to the company this creates the optimum conditions for carrying satisfied passengers through cities aboard well-utilised buses in an environmentally sound manner and continuing to be a successful transport operator in the future.

Used LCV values averaged £9,205 across June, down by £434 (4.5%) compared to May and representing the lowest monthly average value recorded in over two years, according to reseller BCA. The company puts the decrease down to the shift in stock mix heavily influencing the movement compared to earlier in the year.

Sold volumes of light commercials remained positive across BCA’s daily programme of online LCV sales as buyers and vendors remained reasonably aligned on pricing expectations. Buyer numbers continued to rise month-on-month, as they have for most of this year. Performance against price guides fell to 97.5% (from 98.9% in May), underlining the widening disparity between values paid for the very best and worst condition vehicles.

Digraph, the independent aftermarket commercial parts distributor specialising in HGV, coach and bus parts, has been acquired by LKQ Corporation. The deal sees Digraph join an expanded group of LKQ companies in the UK and Ireland alongside LKQ Euro Car Parts, LKQ Bodyshop and Arleigh Group.

Following the transaction, Digraph will be integrated into the enlarged LKQ UK & Ireland group, providing it with significantly enhanced buying power and the support of its combined financial strength, with new investments planned in its people and systems. The business will

Stuart Pearson, BCA COO UK commented: “The two-tier market developing in the LCV sector is typically seen when volumes rise with an influx of poorer quality stock. Vendors are increasingly aware that vehicles in poorer condition have to be valued realistically to generate attention from buyers. This is exacerbated when corporate volumes of similarly-specified, base colour and often poor condition vans are added to the mix.

“In contrast, interest for well presented, better grade vehicles that can purchased and retailed from the forecourt quickly remains as high as it has all year. We continue to see some exceptional values generated for LCVs with a strong retail specification and in a good colour, particularly for vehicles with a relatively low mileage and on a recent registration plate.”

TNS 365, the specialist provider of fast-response pay-as-you-go commercial vehicle and trailer breakdown repair solutions, has opened a new call centre operation in Greater Manchester.

The strategic move was triggered by increased demand for TNS365 services, including in and out-of-hours call handling for CV operators, HGV repairers, tyre fitters, vehicle hire companies and tail lift providers. Founder and director Adam Drake is gearing up for continued growth in the sector.

continue to operate as a separate legal entity under the Digraph brand. There will be no changes to its branch network.

James Rawson, Digraph’s CEO, has announced his intention to stand-down from the business on completion of the deal. Andy Southby, currently managing director of the LKQ Bodyshop division in the UK and Ireland will assume responsibility of Digraph alongside his LKQ Bodyshop responsibilities.

“Our clients rely on our callhandling team to keep response times to a minimum when reacting to any breakdown or equipment failure situation. We have a dedicated UK network of commercial vehicle technicians, usually no more than an hour away from the breakdown, and our new operation will continue to maintain and improve our current high standards of customer support,” explains Drake.

Leading vehicle bodybuilder, TVS Interfleet, is launching its new apprenticeship programme this month.

There are eight places across its Wisbech and Market Deeping sites, with the aim of training the next generation of vehicle bodybuilders. The apprenticeships will be run in conjunction with the College of West Anglia who will provide classroombased learning and skills development.

To ensure the apprentices are able to access the highest level of training and development, the company has developed a buddy system which will be part of a mentoring package.

Ian Walch, operations director, at TVS Interfleet, says: “The company has grown significantly over the last couple of years and we're continually looking at ways to strengthen our workforce to meet our ambitious growth plans. Now is the right time to open a new apprenticeship programme that will provide opportunities for local individuals who are leaving school. On successful completion of the programme, individuals will have the skills and qualifications to secure a job for life. It is hoped that they will continue to work and flourish for TVS Interfleet and be part of our exciting journey.”

Organisers of the CV Show have announced the dates for next year’s event. Held once again at the NEC, Birmingham, the show will take place the 23-25th April.

Following this year’s exhibition, which attracted over 11,000 visitors, next year’s show will feature new technologies, including the latest innovations in the road transport sector such as zero-emission vans and trucks, as well as cutting edge solutions and services designed to help fleet operators run their businesses efficiently and cost effectively.

Drivers, safer roads, and minimising environmental impact are just some of the other important topics that the show's exhibitors and live theatre sessions will cover.

A crack driving team from Webfleet, Bridgestone’s fleet management solution, has smashed the Guinness world record title for the greatest distance travelled by an electric van on a single charge – a whopping 311.18 miles (500.8 km).

The record-breaking feat was achieved by Webfleet-sponsored drivers Kevin Booker, Sam Clarke and Fergal McGrath in a FIAT E-Scudo, fitted with energy-efficient Bridgestone Duravis tyres.

Independently verified video footage, odometer, GPS and battery level data revealed that the compact van, with a 75kWh battery and a WLTP of 205 miles, averaged 4.5 miles per kilowatt hour (kWh) on a circular route across Cambridgeshire,

Lincolnshire and Northamptonshire.

The journey took 13 hours and nine minutes during daylight hours. The FIAT EScudo needed no modifications and the route combined urban and rural roads to replicate ‘real world’ conditions.

“This remarkable achievement is testimony to the determination and technological ingenuity of all those involved," said Beverley Wise, Webfleet regional director for Bridgestone Mobility Solutions.

“We’re thrilled to have become a Guinness world record title holder. The previous record of 258.85 miles was set in the US, bringing it to the UK is symbolic of our nationwide commitment to become a global leader in e-mobility.”

Ringway and its longterm strategic fleet partner Econ have successfully trialled the first electric multi-purpose highway maintenance HGV truck in the UK.

Econ has developed a new electric quick-change body (EQCB) system, built on the newly launched 19-tonne Volvo FE

Electric 4×2 chassis. The Econ EQCB can be supplied with three demount bodies, to get yearround utilisation of the electric Volvo chassis. It has a winter 6m3 spreader body, an insulated end tipper body specifically designed for highway maintenance works, or a caged tipper body for street scene activities.

The Econ E-QCB system uses hydraulic rams and locking systems, that enable the bodies to be switched in 15 minutes, controlled by a single trained operator. Volvo’s FE Electric has a recharging time of 2.3 hours with a high powered 150kW DC charger, giving a range of up to 150 miles, and features two electric motors as well as a 2speed gearbox.

Ringway will also be dynamically testing the QCB system and the 19-tonne Volvo FE Electric 4×2 chassis with a view to using it in other aspects of the highway services it delivers.

The development is the product of a collaboration between Econ Engineering’s R&D team and product specialists from Volvo Trucks UK & Ireland, as well as the supplying dealer Crossroads Truck & Bus.

"For Ringway, this trial further demonstrates how we are constantly seeking to innovate and evolve to meet our carbon reduction goals and those of our clients without compromising the service," said Mitesh Solanki, managing director, Ringway.

For more information on Volvo Trucks

Basildon Borough Council has cooked up an energy saving and environmentally-friendly plan for its food waste collection service.

Working with NRG Riverside, the contract hire and fleet solutions provider, the council has taken delivery of seven fully electric food waste trucks as part of an innovative contract hire agreement. The trucks are expected to contribute to a saving of over 900,000kg of CO2 over the contract’s lifetime.

Basildon's first high-spec 12.5t Electra eCargo with Hillend Engineering micro XHD body went into service in April 2023, with the entire fleet operational at the beginning of July.

The vehicles have been provided on contract hire,

benefiting the Council with the latest low-emission vehicle technology without requiring a large cash outlay, no risk and fixed price over the agreement term.

NRG Riverside’s fleet delivery enables Basildon to run the country's first full electric food waste collection service.

The Electra eCargo Micro XHD vehicles are ideally suited to Basildon's decarbonisation targets. They feature a payload of 7,900 kg with 140kWh battery

capacity and a range of up to 250km. The 150kW DC fastcharge capability means the trucks can be double-shifted and exceed their range by over 100 miles in under an hour. Having been designed with a very short wheelbase of 3.3m makes them easy to operate and manoeuvre in busy city centres and narrow streets.

For more on the Electra eCargo WWW.RDR.LINK/VBB002

Bathroom and appliance distributor, PJH Group, is adding 75 new sustainable vehicles to its transport fleet, all of which will be carrying the firm’s new livery.

The vehicles, a mix of DAF and Renault Trucks, ranging in size from 3.5t vans to 44t articulated trucks, are extremely low emission Euro 6 engine

models, bringing a considerable reduction in the company’s carbon footprint, as well as benefits such as greater fuel efficiency and reliability. The new fleet also forms part of PJH’s investment in continuously improving its already high customer service levels, supporting further its growing next-day delivery proposition.

Speaking about the

investment, Shaun Berry, national transport manager, PJH, said: “This is the biggest refresh of PJH vehicles ever carried out in a single year. The new fleet will assist PJH enormously in attaining its sustainability goals as well as lowering its costs, through a reduction in fuel use, and reliability.

“With the number of deliveries we make annually approaching the 340,000 mark, and a next-day delivery offering to 91% of UK post codes, the new vehicles will improve our customer service as their greater reliability means more vehicles on the road able to complete deliveries on time.”

For more information on Renault Trucks

WWW.RDR.LINK/VBB003

Leading insulation, drywall, and ceiling product distributor CCF has upgraded its vehicle fleet to offer a more efficient and reliable service to its customers across the UK.

As part of the company's ongoing commitment to improving sustainability across its business operations, CCF has invested in 70 new fuelefficient Scania P360 32t curtain siders fitted with a Moffett kit. By increasing capacity from 26 to 32 tonnes, the larger vehicles will replace the smaller, older trucks within the existing fleet so that more orders can be delivered in fewer journeys. The new fleet has a Direct Vision Standard (DVS) 3-star rating and is fully compliant with the Euro 6 emission standard. The new vehicles will help reduce both pollution and embodied carbon within the transportation of CCF's extensive product offering, which includes insulation, plasterboard, and ceiling solutions, to construction sites around the country.

For more information on Scania WWW.RDR.LINK/VBB004

CCF puts energy into improving efficiency across its vehicle fleet

Van fleets are returning to established strategies designed to reduce emissions as many choose to slow their electrification process. An increasing number are working to further reduce CO2 in their existing diesel vehicles rather than adopt further electric vehicles (EVs).

There has been a general assumption among van fleets in recent years that the arrival of EVs would mean a decisive move towards meeting corporate environmental, social and governance (ESG) targets in the medium to long term but, for many, it has become clear that electrification is just not going to happen at the expected speed, so they are returning to established strategies.

There is a renewed interest in areas such as utilisation analysis, driver training and idling reduction, all of which can help to cut CO2, NOx and other emissions. Interestingly, this doesn’t appear to be just a case of returning to the ‘old school’, with new products designed to help fleet

managers in this area continuing to make their way to market.

This trend is very much a result of van fleets slowing their adoption of EVs in the face of several difficulties. We know that many of our members who were committed to electric van adoption as soon as supply was available have slowed or even put a temporary halt on the rate of acquisition. They are hitting a range of operational issues –range, payload, charging infrastructure and more – that means replacing existing diesel vehicles directly with electric equivalents is not yet practical. This doesn't mean that they are intending to resist electrification but that more work needs to be done in all kinds of areas including domestic and public charging, changes in operational practices and improvements in the vehicles themselves.

An area of frustration for some AFP members is the lack of action being taken when it came to making hydrogen a practical alternative to electrification for vans.

In other European countries, there is considerable public and private investment underway in creating a hydrogen transport infrastructure but in the UK, it barely exists. This means that the hydrogen vans that are entering production globally are unlikely to make their way here in anything other than very small numbers.

Many fleet operators believe a mix of hydrogen and electric power would be ideal for the van fleets of the future, and it does feel as though this is a potential solution that is being effectively denied for no good reason. There may also be a role for synthetic fuels, and this is something that needs further investigation.

MORE FROM THE AFP HERE, WWW.RDR.LINK/VBB005

“... there is renewed interest in utilisation analysis, driver training and idling reduction...”

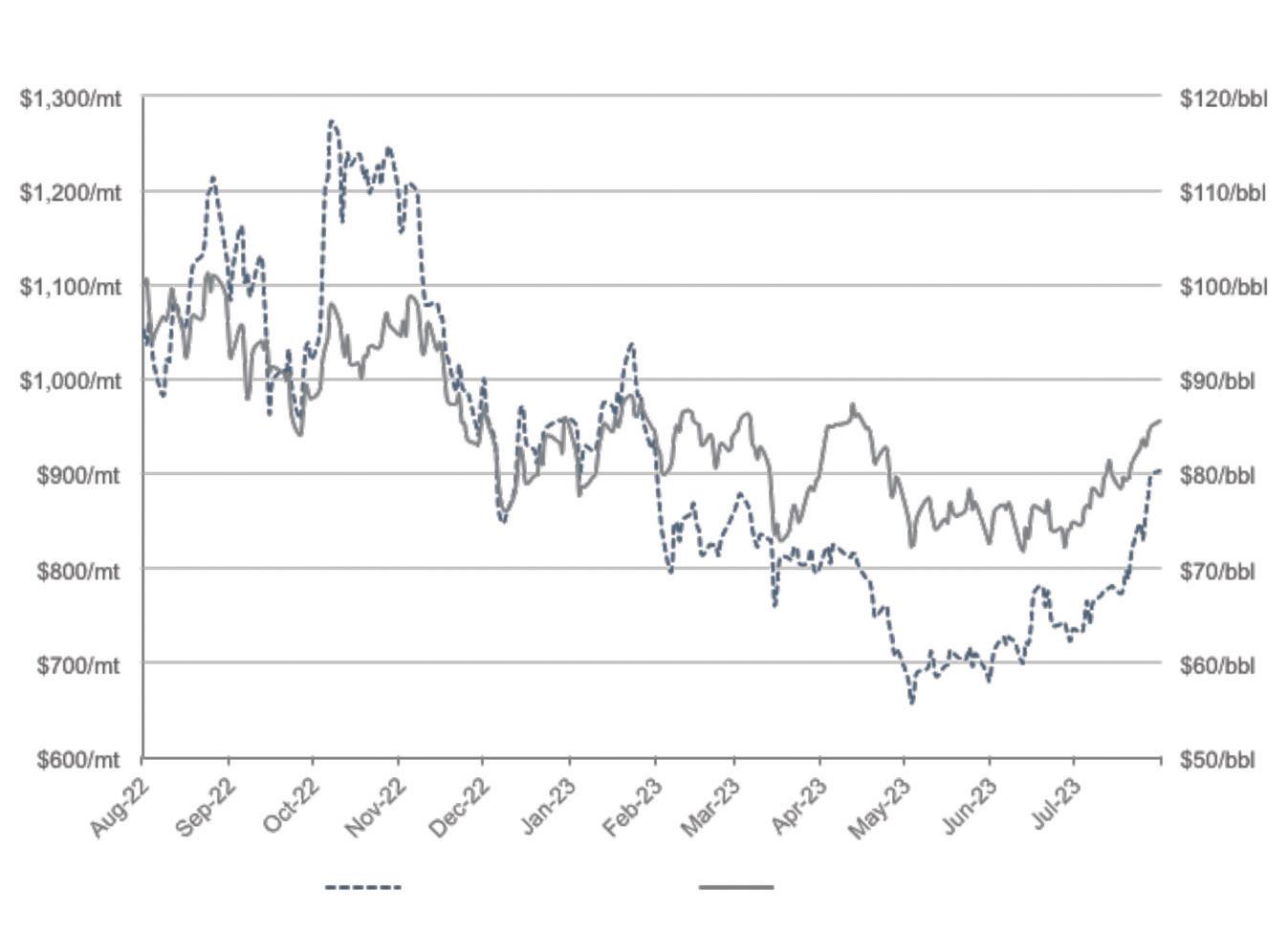

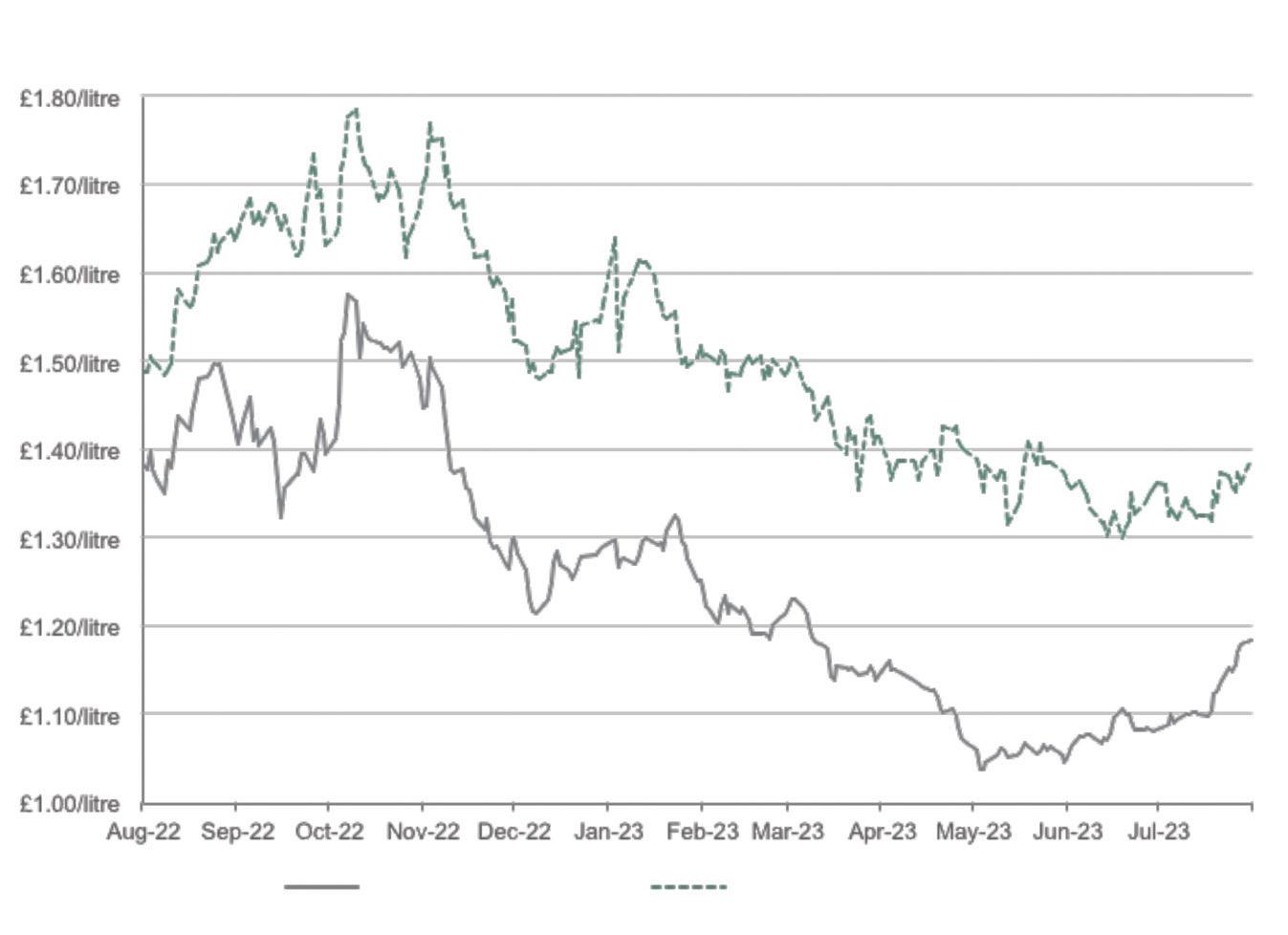

Oliver Nightingale-Smith of Portland Analytics explores the relationship between the price of traditional fossil-based diesel and renewable diesel over the last year, highlighting the various market dynamics affecting the price of each grade.

Prices of traditional and alternative fuels alike have been subject to considerable price volatility over the past 12 months, with shifting supply and demand economics combined with a turbulent geopolitical landscape leading to increased price sensitivity.

Traditional wholesale diesel pricing generally follows a similar trend to its underlying oil benchmark, Brent crude, which is used to set the price of oil in European markets. In August 2022, Brent crude was trading around the $100 per barrel (bbl) mark, falling to a low of $70/bbl in June and recovering to the mid-$80/bbl range at the time of writing. Wholesale diesel prices followed suit, declining from $1,050 per metric tonne (mt) to $650/mt on 3rd May, before rising back to around $900/mt at the end of July.

The decline in prices during the latter part of 2022 was dictated by a worsening global economic outlook, with record levels of inflation and a looming recession met with rising interest rates across several major central banks. Faltering economic recovery in top oil importing nation China caused significant demand concerns,

alongside US consumer confidence dropping to an over one-year low. Despite OPEC+, the group of oil producing nations, announcing further production cuts of two million barrels per day in October causing a brief spike in prices, persistent Chinese demand woes and declining manufacturing activity in European and US economies caused prices to fall by year-end.

2023 began with increased demand optimism, largely due to signs of China’s promising economic recovery, alongside additional OPEC+ output cuts leading to an increase in oil prices in January. However, persistent monetary policy tightening led to weakened energy demand across Q1 and 2, seeing prices fall to an 18-month low in June. That said, in recent weeks, the market has been supported by supply constraints, with Saudi Arabia and Russia announcing output cuts for August, alongside heightened demand, particularly in the US which recently saw the largest week-onweek draw on oil stocks since records began.

These trends have been reflected in the price of UK commercial diesel, declining by £0.21 per litre over the last year from £1.37 to a low of £1.03 in May, rising back to £1.20 at the time of writing. Alongside declining wholesale prices, pound sterling has strengthened against the US dollar, peaking at $1.31 in July, contributing to the fall in UK pricing.

Whilst the price of renewable diesel broadly follows similar trends to its fossilbased counterpart, there are additional factors affecting price, such as the availability of feedstock and the cost of compliance with carbon reduction obligations across Europe.

Renewable diesel in Europe is primarily produced through the hydrotreatment of fats and acid feedstocks, such as used cooking oil (UCO), hence it is often referred to as hydrotreated vegetable oil (HVO). The cost of UCO has fallen by around $400/mt over the past 12 months due to a combination of weak biofuels demand and stronger exports from Asia. UCO is also used as a feedstock within traditional ‘first generation’ biodiesel, e.g. UK-standard B7 (7% biodiesel blend) –weakness in the traditional diesel market therefore causes a negative impact on feedstock prices due to lower demand.

As there is currently little to no indigenous production in the UK, the wholesale price of renewable diesel is set by the European market, which is heavily impacted by the cost of meeting various carbon reduction targets within the EU. Renewable diesel can be used as a tool for fuel suppliers to meet these obligations, therefore the cost of compliance through alternative methods e.g. blending other biofuels products such as methyl ester, also affects the price.

Several countries temporarily reduced or paused biodiesel blending mandates in 2022 in response to rising prices as a result of the Russian invasion of Ukraine (e.g. Sweden has cut its obligation from 7.8% to 6% from 2024 to 2026). This has further reduced the demand for biofuels, causing prices to fall, which has seen the price of renewable diesel follow suit – over the past 12 months, Portland’s wholesale HVO index has fallen from $2,800/mt to $2,200/mt at the time of writing.

Carbon reduction legislation also impacts the price of renewable diesel for end users in the UK. The Renewable Transport Fuels Obligation (RTFO) mandates that a certain percentage of fuel suppled in the UK must be made up of renewable sources. This is traditionally met by blending fossil product with methyl ester, which generates a Renewable Transport Fuels Certificate (RTFC), used to meet the obligation.

Renewable diesel produced from waste feedstock, such as UCO, generates two RTFCs when imported to or produced in the UK. Producers/importers can use these certificates to either meet their own biofuels obligations under the RTFO, or sell them on to other obligated businesses. As a result, RTFCs have a trade value, which ultimately affects the sale price of HVO in the UK. The higher the RTFC value, the greater financial benefit HVO producers/importers receive, therefore leading to a lower differential against traditional diesel – an increase in RTFC prices has seen this narrow in recent weeks.

The combination of these factors has seen the price of renewable diesel for road use in the UK fall significantly in the last 12 months, currently around £1.45 per litre, a difference of c. £0.25 per litre vs B7 biodiesel, down from a high of c. £1.78 per litre in November.

Portland Analytics is a fuel consultancy providing a range of specialist advisory services across both the traditional and alternative fuel markets. It’s online fuel price information service, Portland Pricing, is the home of UK market fuel price data for commercial fuel users, including a dedicated renewables pricing service. For more information,

“...the RTFO mandates that a certain percentage of fuel supplied in the UK must be made up of renewable sources...”

As a company ATS Euromaster has seen a significant 216% uplift in the requirement for Class 7 MOTs compared with 2020 as fleet managers adapt to longer commercial vehicle lifecycles. With the squeeze on new commercial vehicle availability because of the war in Ukraine combined with the shortage of semiconductors since 2020, fleet managers have been adapting fleet lifecycles by making their vans work longer before

replacement. The Association of Fleet Professionals recently reported that its members were seeing extensions that ranged five to eight years before replacement. As a result, managers are needing to adapt their management of service, maintenance and repair (SMR) spend and manage MOT requirements.

Mark Holland, operations director, ATS Euromaster, reports on the huge increase in Class 7 MOTs seen by the company and examines the implications.

CLASS 7 MOT CHECKLISTthings to be aware of:

Tyres, wheels

Brakes

Horn

Exhaust system

Mirrors

Doors

Exhaust emissions

Towbar

Boot and tailgate

Seats

Vehicle structure

Fuel system

Seat belt SRS

Steering and suspension

Wipers, washers

Windscreen

Electrical component Lights

Registration plate

Bonnet

We've been watching the MOT demand for Class 7 vehicles increase year on year. In 2021 we saw a 70% uplift in MOT class 7 volumes compared with 2020 volumes. Then 2022 delivered an 86% uplift on 2021 volumes. So, demand has been growing at a staggering rate as the commercial vehicle fleet ages, but what we are also witnessing is changing attitudes to fleet management. For example, if a van comes in for new tyres, we may also be asked to do a vehicle health check at the same time to identify any areas of concern that might keep the vehicle off-road. It's a typical example of fleet managers becoming more adept at running older and higher mileage vehicles.

Latest Government figures show that nearly 40% of Class 7 vehicles fail their MOT. Lamps, reflectors and electrical equipment lead the way as the most likely cause of failure (20.35%), followed by brakes (15.41%), then suspension (10.24%).

In terms of the greatest percentage of dangerous defects, brakes at 44.58% and tyres (35.79%) were a long way ahead of any other defects.

These figures correlate very closely with what we are seeing in our MOT bays. Vans are being worked extremely hard and with much of it final mile delivery work; this involves plenty of component sapping kerb bouncing and heavy braking in built up areas.

With brakes and tyres comprising the greatest percentage of dangerous defects, it suggests that regular maintenance is at risk of dropping off the agenda for some van operators. At an MOT test, examiners will be looking for brake condition and operation, along with service brakes, secondary brakes and parking brakes as part of the inspection.

When inspecting tyres, examiners will be looking to make sure the tyre load rating is suitable for the axle weight, as well as tyre condition, such as cuts, nips or gorges that may expose the steel belts of the carcass, as well as sidewall bulges.

Many of the vans that come to ATS centres are from self-employed drivers. A

majority are final mile delivery drivers who are driving up and down kerbs all day and every day. In turn this means greater costs with wheel alignment, shock absorber, and suspension work, and damaged tyres on a more regular cycle.

With the cost of parts increasing - last year ATS Euromaster saw the spend on SMR maintenance increase by 17% when comparing Q1 2022 to Q1 2021 - and the cost-of-living crisis really beginning to bite, we believe the issue of MOT failures will continue to increase as the van fleet ages.

We would urge fleet managers, if they are not doing it already, to consider planned maintenance as vehicle replacement cycles lengthen to prevent the costliest item of alla vehicle off road. A service such as our free digital vehicle health check can give you that valuable insight to help avoid that.

FOR MORE INFORMATION FROM ATS, WWW.RDR.LINK/VBB007

Transporting goods in and around London is set to get even more complicated for commercial vehicle operators, with the Direct Vision Standard (DVS) set to be adapted next year.

A bone of contention for companies, the DVS currently requires companies operating vehicles over 12 tonnes to obtain a safety permit before they enter the capital – another potential financial implication for firms already struggling with rising energy and fuel costs.

Whilst the full guidelines are yet to be finalised, we are led to believe that come October 2024, stricter rules will be introduced to improve the safety of all road users.

This means that HGVs will need to have a three-star rating or fit a Progressive Safe System in order to operate.

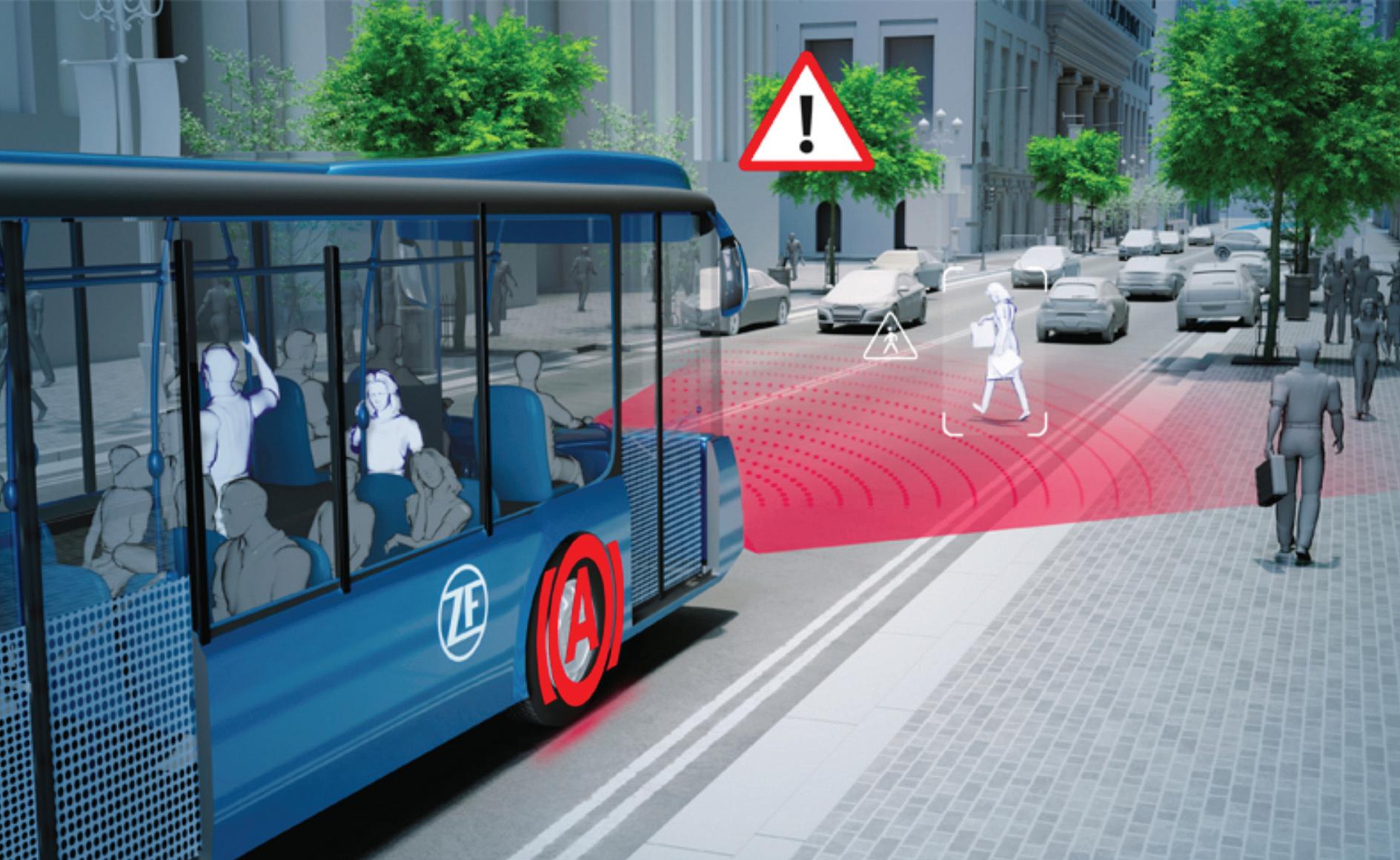

The requirements get even more complex when management teams realise that the new DVS guidelines could mean any camera/alert technology must only recognise human shapes and not the vast array of inanimate objects on roads in and around one of the busiest city centres in the world.

We believe this subtle but important change could be very costly to distribution and logistics specialists throughout the UK. Most of the traditional technology currently in place does not deliver that human detection only capability that Transport for London (TfL) will demand in just over twelve months.

This means companies - who need to operate in Greater London - will have to invest in new equipment that will need to be

With further changes to the Direct Vision Standard (DVS) due in 2024, will this herald more potential headaches for operators working in Greater London? Craig Spillard of Spillard Safety Systems looks at the implications and the type of technology that could make a real difference.

retrospectively fitted or, if buying vehicles from new, be specified at the point of sale.

There is a feeling at a higher level that constant audible/visual alerts, when identifying anything from a bin and an advertising sign to a human being and bike, can lead to the driver switching them off or totally ignoring the technology. This could potentially lead to an increase in accidents and, in the worst-case scenarios, severe injuries or fatalities. Nobody wants that.

As a business we are already seeing clear evidence that companies are acting now to try to get ahead of the Direct Vision Standard changes.

Interest in our Human Detection System (HDS) from commercial vehicle operators has risen 50% in the last six months and this has seen some big-name adopters, including AF Blakemore, Lomas Distribution and Carlsberg Marston’s.

Over £250,000 has been channelled into the development of the HDS, which can be installed on the side, front and back of vehicles to intelligently detect only the shape of a pedestrian/cyclist/motorcyclist within two metres in real time.

Once detected, this then delivers an audio alert to the driver, as well as clearly visualising the distance by measurement and colour codes displayed on the cab monitor.

The system will help transport operators protect other road users and, importantly, ensures they are compliant with the future

version of the Direct Vision Standard.

A lot of focus will now be on workshops and how they can accommodate the retrospective fitting of this type of technology. There are hundreds of thousands of vehicles that will need to be upgraded so it will be a fairly big challenge, especially with the timescale being so short.

We’ve stepped back and looked at what this means, increasing our engineers to help meet demand for our HDS, but also working with clients and their workshops to train their staff to potentially fit the systems.

When we move into our new facility shortly, we’ll also be unveiling a new training school that will train industry professionals in fitting Spillard technology. We’re all in this together so a more collaborative approach must be taken.

Sapphire Vehicle Services is on the hunt for car mechanics or other keen candidates who have the drive and ambition to ‘think big’, to join its drive torecruit and retain more truck technicians. CVW reports.

The skills shortage in the truck repair market is well documented and widely voiced. Rather than continuing that refrain some companies are putting their best feet forward in a bid to secure more technicians. Sapphire Vehicle Services is one such enterprising business. One of Britain’s most successful independent commercial vehicle aftersales providers, Sapphire looks after upwards of 28,000 trucks and vans at its 16 workshops nationwide. Its plan is simple - train up

people who already have a foundation of relevant experience, by giving them the skills needed to work on heavy vehicles.

Sapphire bosses hatched the scheme to help bolster its ranks, after identifying a scarcity of qualified, experienced technicians in the market.

“We’re an ambitious business with plans for growth,” explains managing director Perry Reeves. “But to be able to expand, while continuing to offer our customers the very high levels of service they expect, we need to recruit.

“HGV technicians of the high calibre we demand are in short supply, so we decided to tackle the problem head-on. We already have an apprenticeship programme, which takes young people, typically fresh from college – but that is a longer-term project.

“Alongside it, the technician upskilling course we’ve devised will take people who already have much of the knowledge and experience they need and fast-track them straight into our workshop teams.”

The fast-growing independent commercial repair specialist is now inviting a new crop of applicants for places on its training programme.

“As Perry says, this course is targeted at people with a strong foundation of relevant experience,” says Sapphire training manager Tony Hewins. “Most will already be

working as car or van mechanics, although we’ll also consider people who might be in related fields – possibly working on marine engines or agricultural vehicles.

“We’re looking for a group of up to 12 candidates. We’ll take them on as full-time employees and provide them with a 12month programme consisting of six blocks of classroom training, each a weeklong, interspersed with time back in the workshop where they can put their new skills to use in a real-life setting.

“At the end of the year we expect all to pass their IRTEC accreditations and become fully-fledged heavy vehicle technicians, with a recognised professional qualification which typically comes with a higher rate of pay than car mechanics can earn.

“They’ll also be working for a successful, expanding business that values ongoing career development, so there’s a great deal of potential for further improvement. All they need is the determination to learn and succeed.”

Classroom training will take place at Sapphire’s Northampton depot and be delivered by partner Blyth Automotive. Sapphire operates workshops across country, though, so applications are invited from candidates based anywhere in the UK.

Each weeklong block will focus on a different topic, starting with an inspection and maintenance module and continuing through chassis, electronics, diagnostics and transmission before a final review of the entire course content.

Sapphire’s successful apprenticeship programme, meanwhile, continues to take an input of eight or more candidates per year, for a two-year course culminating in a nationally recognised NVQ Level 3 qualification in Heavy Vehicle Maintenance and Repair.

“Both of these projects have another benefit,” adds Perry. “As well as training in technical skills, those on the courses have a chance to learn about Sapphire and gain an appreciation of our very strong customer service ethos. The idea is that when they graduate, they are fully equipped, in every sense, to slot successfully into our teams

“We’re always on the lookout for competent and experienced truck technicians

but there’s a shortage of qualified people across the country. That’s why we are being proactive and training our own. This twopronged approach has required a major spending commitment, but we’re convinced it’s money well spent, and that we’ll benefit from a significant return on our investment, in the shape of a crop of highly effective and dedicated workshop team members who will help to drive our business forwards.”

Trainee Ryan Jones spent three years as a car mechanic, working for an independent factor, before joining the Sapphire upskilling programme. He’s now based at the company’s depot at Ham’s Hall, near Birmingham, less than 10 miles from his home in Tamworth.

“The scheme was attractive to me because I’ve always wanted to work on trucks, ever since I was a kid,” he said. “That aside, though, it’s a great opportunity. I’m already earning more than I did

previously and have lots of potential to progress my career. There’s no shortage of encouragement for staff here to continue to train and increase their expertise and qualification level. I also find trucks much easier to work on – there’s a lot more room to manoeuvre than in the crowded engine bay of a typical modern car!”

ANYONE EAGER TO JOIN THE PROGRAMME SHOULD CONTACT SAPPHIRE’S HEAD OF TALENT ACQUISITION GARY ROGERS, ON 07590 984994 OR GARY.ROGERS@BALLYVESEY.COM, OR GROUP COMMERCIAL MANAGER GRANT TADMAN ON 07880 264909 OR GRANT.TADMAN@SAPPHIREVS.COM.

WWW.RDR.LINK/VBB009

Fleet owner and operator Northgate is looking after its own. The company is aiming to create a career path for its commercial vehicle workshop technicians with ongoing training development where they are incentivised on how many training courses they attend each year, both online and physically.

The company wants to keep people learning and developing with 50 technicians currently being recruited as it reinforces its service and maintenance capabilities across its nationwide network of 54 workshops.

It is also considering doubling from 40, the number of apprentices it takes on as it bolsters its workforce that manages its Northgate fleet of 50,000 LCVs and HGVs, plus the 15,000 cars on its Auxillis fleet, which is also part of Northgate Redde plc, along with a large number of fleet managed vehicles for its customers.

“We have been very proactive over the past 18 months in recruiting technicians and putting together a career path for each one. Our fleet is very diverse and so technicians can work on a number of different cars and commercials, as well as being part of the growing electric vehicle revolution,” explains Tim.

“Working for us is not like working for a dealership where you are just working on one brand of vehicle. We can offer variety and being incentivised on the number of training courses means that salary can increase by expanding the learning and growing the experience.

“We have built a strong career path for technicians and workshop staff that can also end up in general management across the business. They are well paid roles, and we aim to keep our technicians employed for longer simply by investing more in their careers,” he adds.

As the skills shortage bites one business is actively looking at the future and addressing its needs. CVW talks to Tim Bailey, fleet director at Northgate.

Northgate is also working closely with vehicle manufacturers to give apprentice technicians formal training on specific light commercial vehicles. This extends to visiting vehicle production lines and being part of manufacturer training courses, which further adds value to a technician’s role and lifetime CV. They can become vehicle specialists that can then support other technicians within their individual workshops.

With a growing fleet of electric vans Northgate is increasing the number of technicians and workshops that can service and maintain EVs in addition to its ICE vehicles. This coincides with its IMI Electric Vehicle Accreditation, which enables it to manage its own EV training internally.

Thirteen per cent of Northgate’s new job vacancies are for mobile vehicle technicians which are branch-based, and deployed where they’re needed on customer sites,

avoiding the need to visit a workshop.

With EVs having fewer moving parts, the future trend could be to carry out more basic servicing remotely, providing operators with speed and convenience.

“We’re getting more of our technicians ‘EV Ready’ as our fleet gradually transitions from internal combustion engines to electric,” says Bailey.

“Diesel and petrol vehicles will be on our roads for many years beyond 2030 but we are playing a major part in helping fleets with their electrification journey. This includes supplying vehicles and services related to EVs and obviously looking after the servicing and maintenance from our workshops.

“We want to make this transition as simple as possible, but the whole process will take time, and many will be running diesel vehicles alongside EVs for years to come. We are expanding our workforce to transition alongside our customers’ needs,” he concludes.

Northgate’s strategy of running its own workshops has continued with the acquisition of traffic management specialists Blakedale in 2022 and FridgeXpress the chilled and freezer van rental business in 2023 who both operate their own customer support and maintenance facilities. They run nearly 1,000 specialist traffic management and chilled and freezer rental commercial vehicles between them.

TO

WWW.RDR.LINK/VBB010

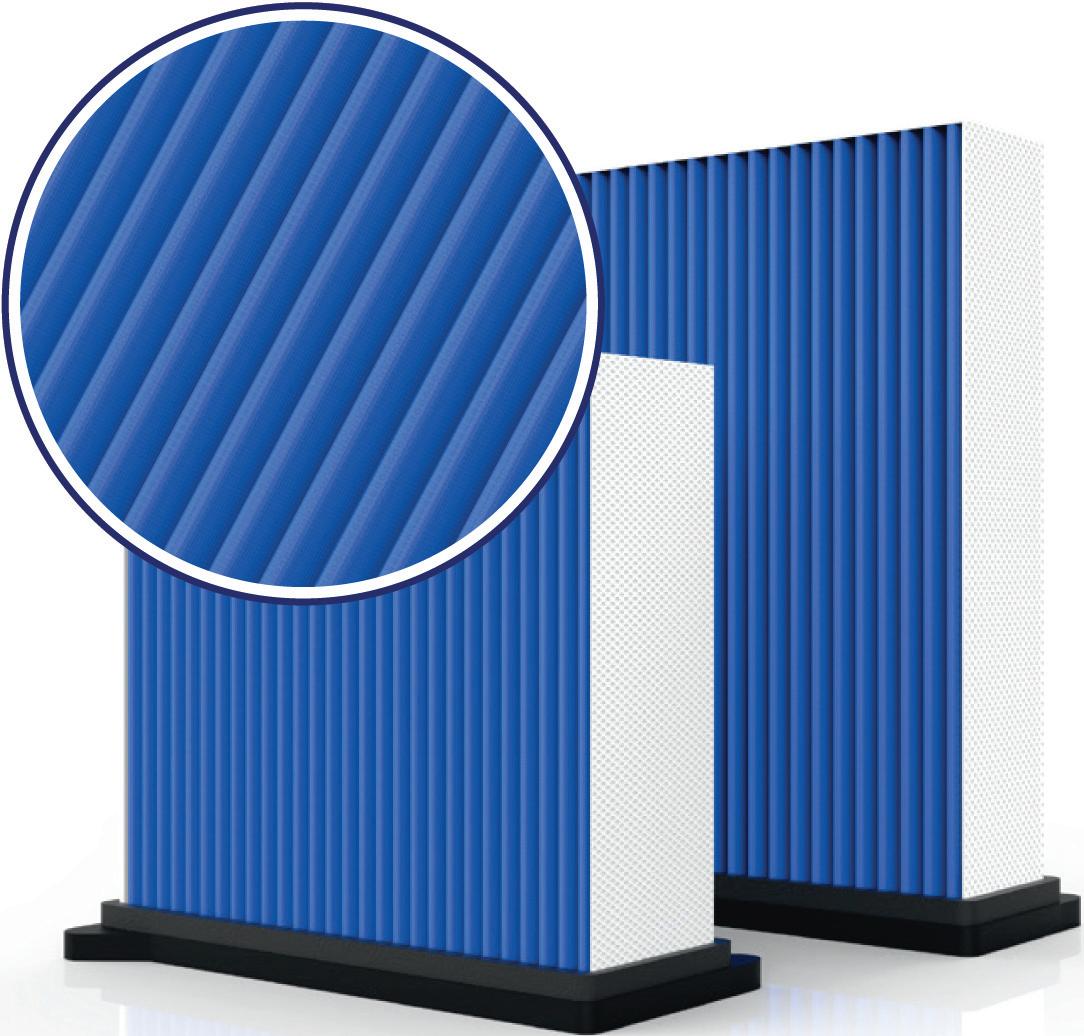

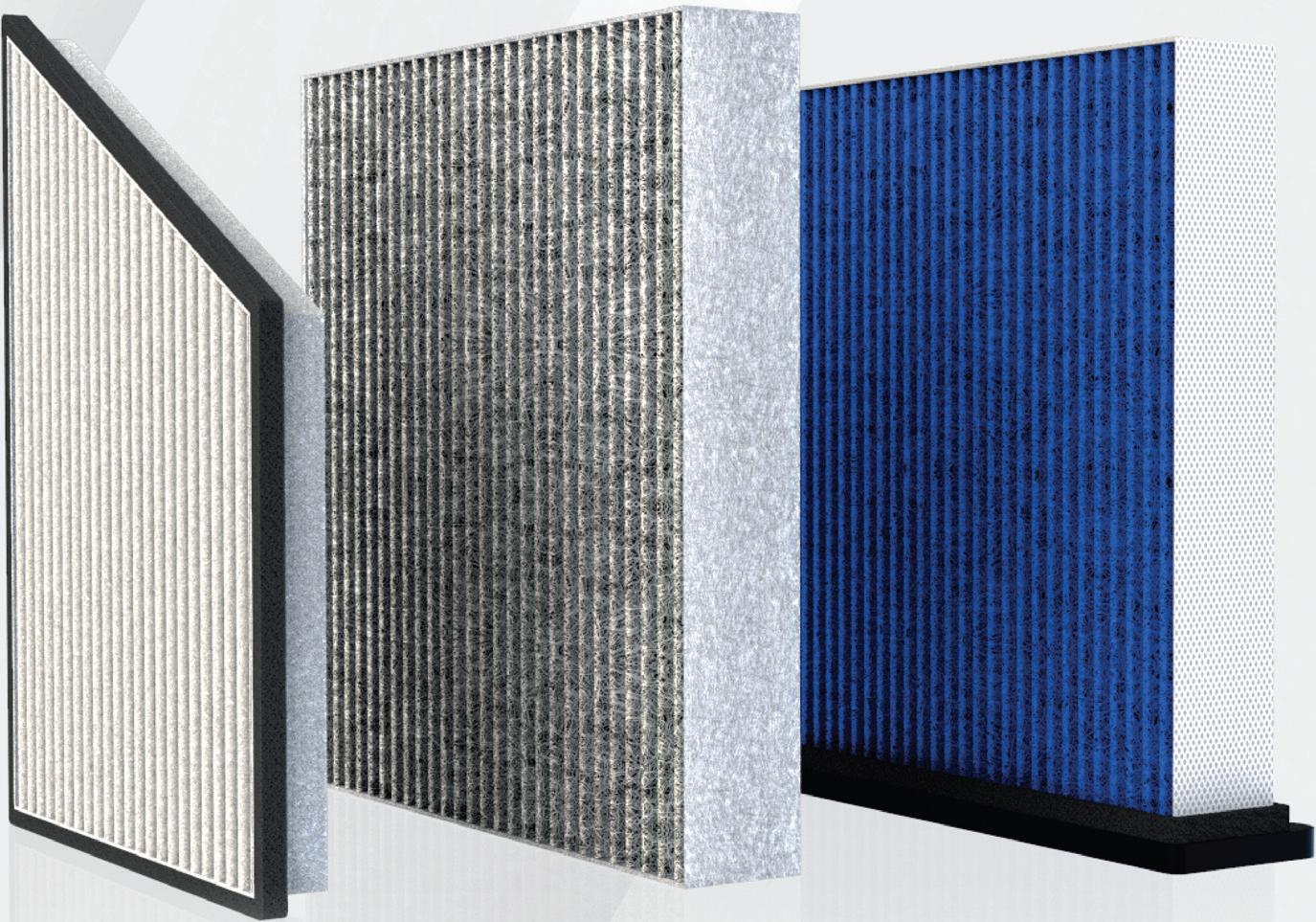

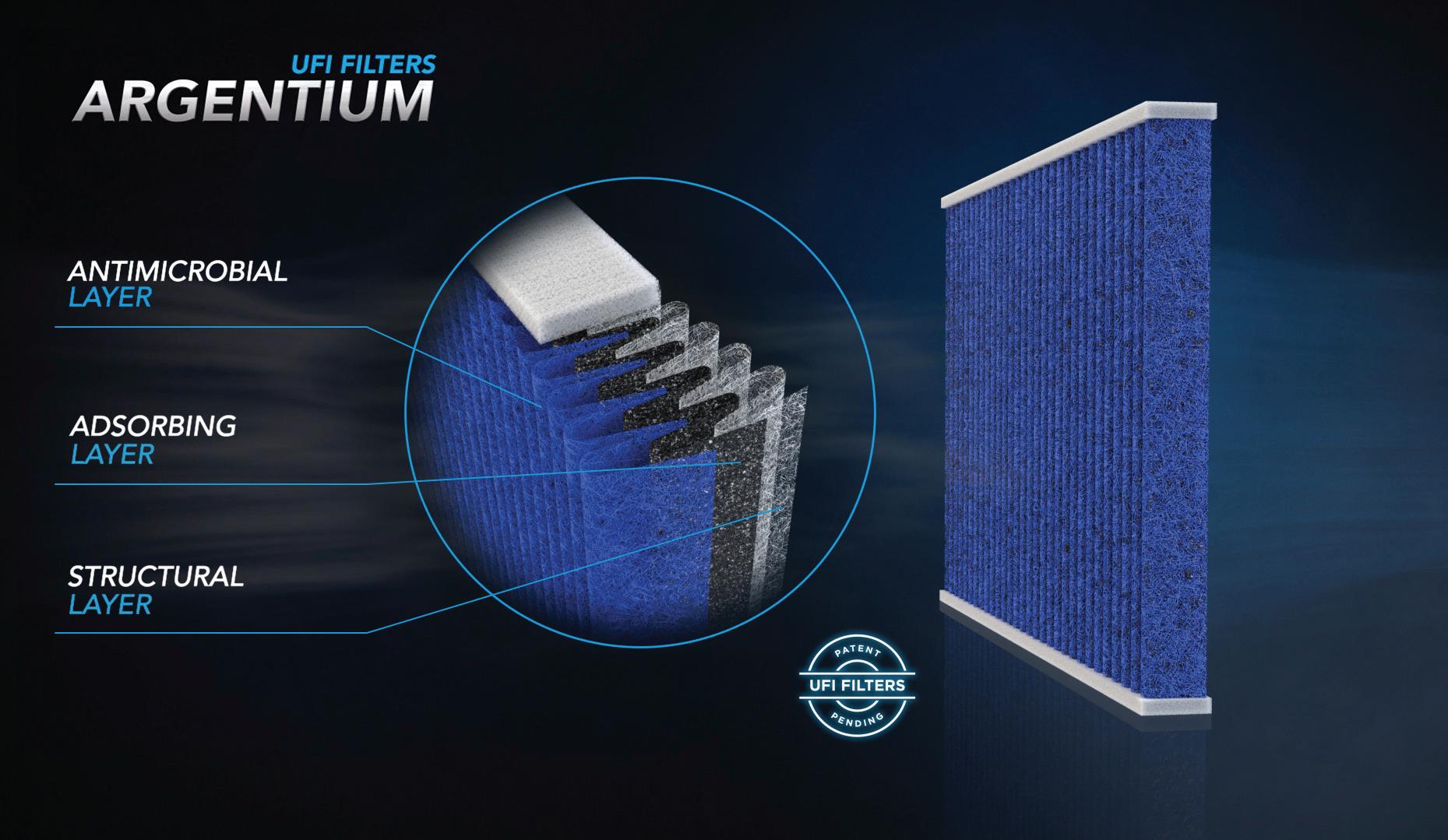

With the introduction of its UFI Argentium filter range for trucks and buses, UFI Filters has made the next level of cabin air filtration available to the commercial vehicle sector. Karl Ridings, sales director and general manager UK & Ireland - Aftermarket at UFI Filters, explains how Argentium helps to make the air inhaled by professional drivers and bus passengers even purer, while also improving driving comfort.

Everyone agrees that a properly functioning cabin air filter is of utmost importance to everyone inside a vehicle. Although the concentration of dust in the atmosphere and the presence of various harmful particles such as PM10 and PM2.5 varies with weather conditions and geographic location, levels inside the vehicle can be as high as six times the outdoor level. This surprising fact is due to the tunnel effect created by the ventilation circuit. The direct effects of any poor air quality on both

drivers and passengers can include allergies, sore throat, sneezing, reduced alertness and even poor visibility due to condensation on the windscreen and windows.

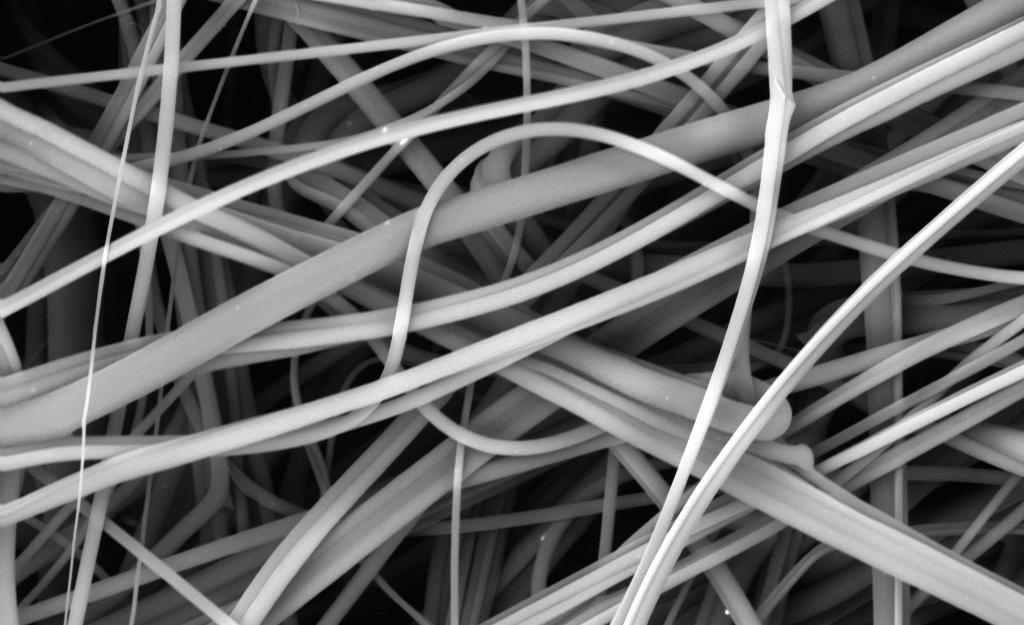

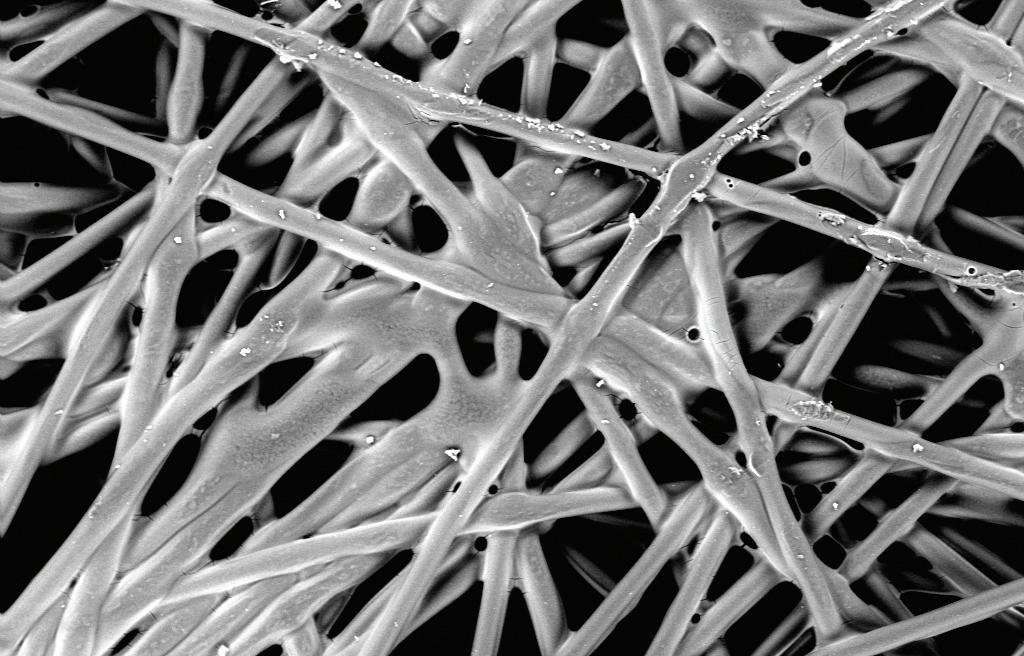

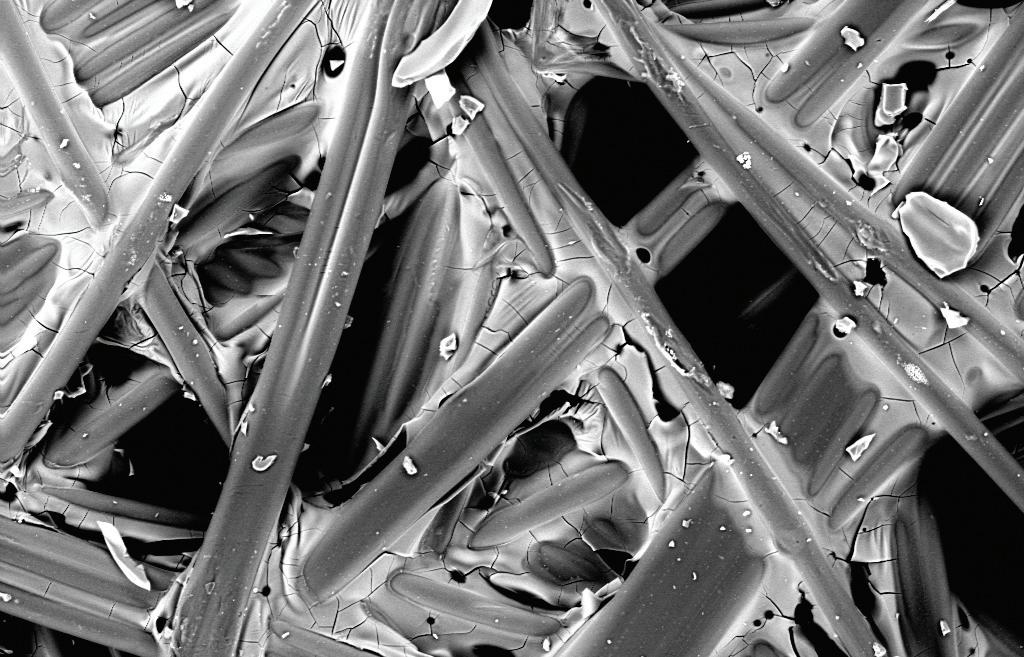

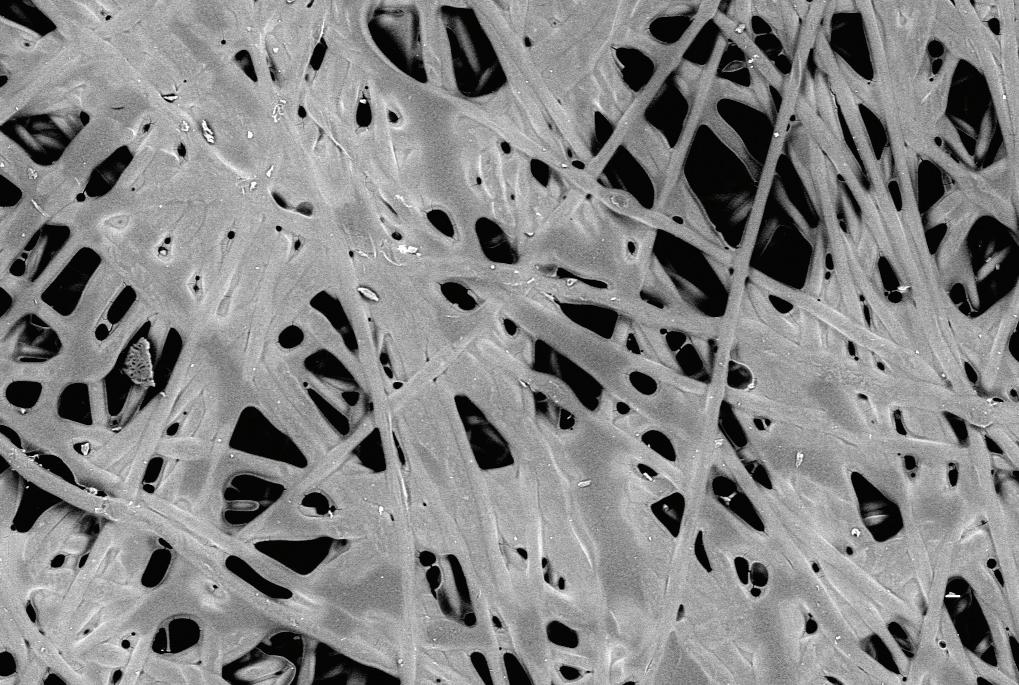

In the past, there were mainly two kinds of cabin air filters – anti-pollen filters with a synthetic non-woven fabric, and filters made of a filtering non-woven fabric combined with active carbon. The former can hold back over 90% of particles with a diameter greater than 2.5 µm, such as dirt and pollen. The latter on the other hand, can prevent particles of between 0.01 and 2 µm, such as gases, bacteria, fungi and odours from penetrating the cabin. Both solutions can be installed to the vehicle owner’s preferences, location and sensitivities, although this may depend on the particular vehicle model in question.

Recently, some cabin air filter manufacturers have extended these traditional options with new product groups that are designed to block and destroy bacteria even more efficiently. These types, however, tend to deteriorate within only a few working cycles after installation. To find an optimum solution, UFI Filters has used its renowned commitment to innovation to develop a different concept called Argentium, which can maintain its full filtering properties throughout the filter’s entire lifetime. The new technology has now been introduced to complement the company’s pollen and activate carbon cabin air filter ranges in the aftermarket. Argentium features distinctive, blue-

coloured fibres and a special fabric structure which incorporates silver particles that deliver powerful antimicrobial characteristics. Furthermore, tests carried out at the UFI innovation centre have shown that this innovative product maintains its ability to inhibit bacterial growth, fungi and mould up to 99%, thanks to the incorporation of Biomaster silver biocide, tested to ISO 22196:2011.

In terms of design, UFI Filters’ new Argentium filtering media is composed of three layers: antimicrobial, adsorbent and structural. Combined, these layers stop pollen, dirt, tyre-wear dust, fungi, mould and inhibit bacterial growth, while absorbing sulphur dioxide (SO2) and nitrogen oxide (NOx). Thanks to the presence of active carbon, the material guarantees a filtration efficiency that exceeds 98.5% for particles with a diameter of 2.5 microns, as well as eliminating harmful gases and unpleasant odours. The filter is fully compliant with the ISO 11155-1 standard.

The UFI Filters aftermarket catalogue currently incorporates 111 cabin air filter references for trucks and buses, now encompassing all three key filtration technologies. This range has grown significantly in recent years, ensuring that more than 98.5% of the vehicle parc on Europe’s roads are covered by UFI Filters.

Options include 84 pollen filters made with synthetic non-woven filter media, capable of retaining over 90% of particles with a diameter greater than 2.5 µm, such as PM10 fine dust, dirt and pollen. UFI pollen filters can be identified in the catalogue by the initial code 53. The company also offers 14 carbon filter references consisting of non-woven filter material combined with activated carbon –which, in addition to removing fine particles,absorb gases and odours, and block industrial and agricultural pollutants such as hazardous NOX, SO2, NH3 and VOC. UFI carbon filters ensure greater protection inside the vehicle and can be identified in the catalogue by the initial code 54.

CV professionals seeking even more filtration benefits can also now select from 13, advanced UFI Argentium filters. Each reference offers the technology’s unique antibacterial properties, including the revolutionary, three-layered filter media featuring Biomaster biocide silver that can reduce bacterial growth by up to 99%. These Argentium UFI filters carry the initial code 34 in the catalogue.

Apart from blocking allergens and fine dust and removing bad smells, cabin filters are becoming increasingly essential to protect drivers and passengers from microorganisms. We are seeing particular demand for Argentium filters for both long-distance

and city-based buses, which carry a lot of passengers. That’s exactly why UFI has concentrated on the heavy vehicle segment. Our first references were launched back in 2022, initially for buses and later for heavy duty vehicles, and now the range covers around 1,000 applications across Europe.

For buses, these applications include the MAN Lyons Intercity and NG series, the Mercedes-Benz Citaro, the Scania OmniExpress, the Iveco Crossway and Urbanway model-series and the Viseon Bus. The expansion to include heavy duty vehicles already offers coverage for a comprehensive range of models from MAN, Iveco, Renault Trucks, Scania, Volvo, DAF and Astra.

Although the standard rule of thumb for replacing a cabin air filter is once a year, in fact it should be done at even shorter intervals for high mileage vehicles or

especially dusty areas – both of which accelerate the rate of wear.

One of the most common reasons for filter malfunction is also one of the simplest to solve. Always select the recommended cabin filter part number for the specific application and follow the vehicle maker and filter manufacturer’s service procedures. Getting these wrong is the surest route to filter malfunction or even collapse!

FOR MORE ON UFI FILTERS, WWW.RDR.LINK/VBB011

Additional oil filtration for heavy-duty CV applications helps preserve hard working engines. Gary Winslow, product and marketing manager, MANN+HUMMEL, looks at the role centrifugal filtration can play.

Oil filters carry out the important task of filtering contaminant from the oil, thus protecting the engine from premature wear and tear. With some heavy-duty engines, i.e. on commercial and light-commercial vehicles where service intervals can be higher than on a car, additional filtration can be utilised to help filter these contaminants whilst also prolonging the life of the primary flow oil filter. One such filter is a centrifugal oil filter.

During the combustion process of diesel fuels, soot particles are formed and pass into the lubricating oil. Modern oils

containing additives trap soot particles in suspension to prevent these deposits clogging the engine. The downside of this is more wear-inducing particles causing the engine oil to thicken, sometimes prematurely. This can put additional strain on the primary oil filter and cause reduced service intervals or early clogging. The solution lies in a process in which part of the lubricating oil is diverted and finely filtered separately by a secondary flow centrifuge. MANN-FILTER centrifuge filters (such as ZR 9007 for applicable DAF applications) filter even the smallest particles, typically down to 1 µm (microns).

For context, one micron is 1,000th of a millimetre (a human hair strand is in the region of 75 micron). This additional centrifugal filtration thus supports the main flow filter.

The centrifuge rotor is rotated by the pressure of the diverted oil flow. Depending on temperature and oil viscosity, more than 10,000 rotations per minute can be achieved, which results in the impurities in the oil being pressed against the outer wall of the centrifuge, compressed and adsorbed. Due to this spinning action, centrifuge filters (also called rotors) reliably free oils of even the smallest solid particles such as dust, abraded metal and soot particles.

As such, when servicing a commercial or light-commercial vehicle, always check if it is fitted with an additional centrifuge filter. This filter is usually disposable and serviced in conjunction with the main filter and should not be ignored.

The MANN-FILTER online catalogue can assist with identifying the correct filter part number for your vehicle, and as with all MANN-FILTER parts, is original equipment quality. FOR MORE ON MANN-FILTER

“...centrifuge filters reliably free oils of even the smallest solid particles...”

CVW gets an update from polishing and compounds pioneer, Farécla, and discovers how a scientific breakthrough in polishing and a process change have combined to save bodyshops time, energy and product.

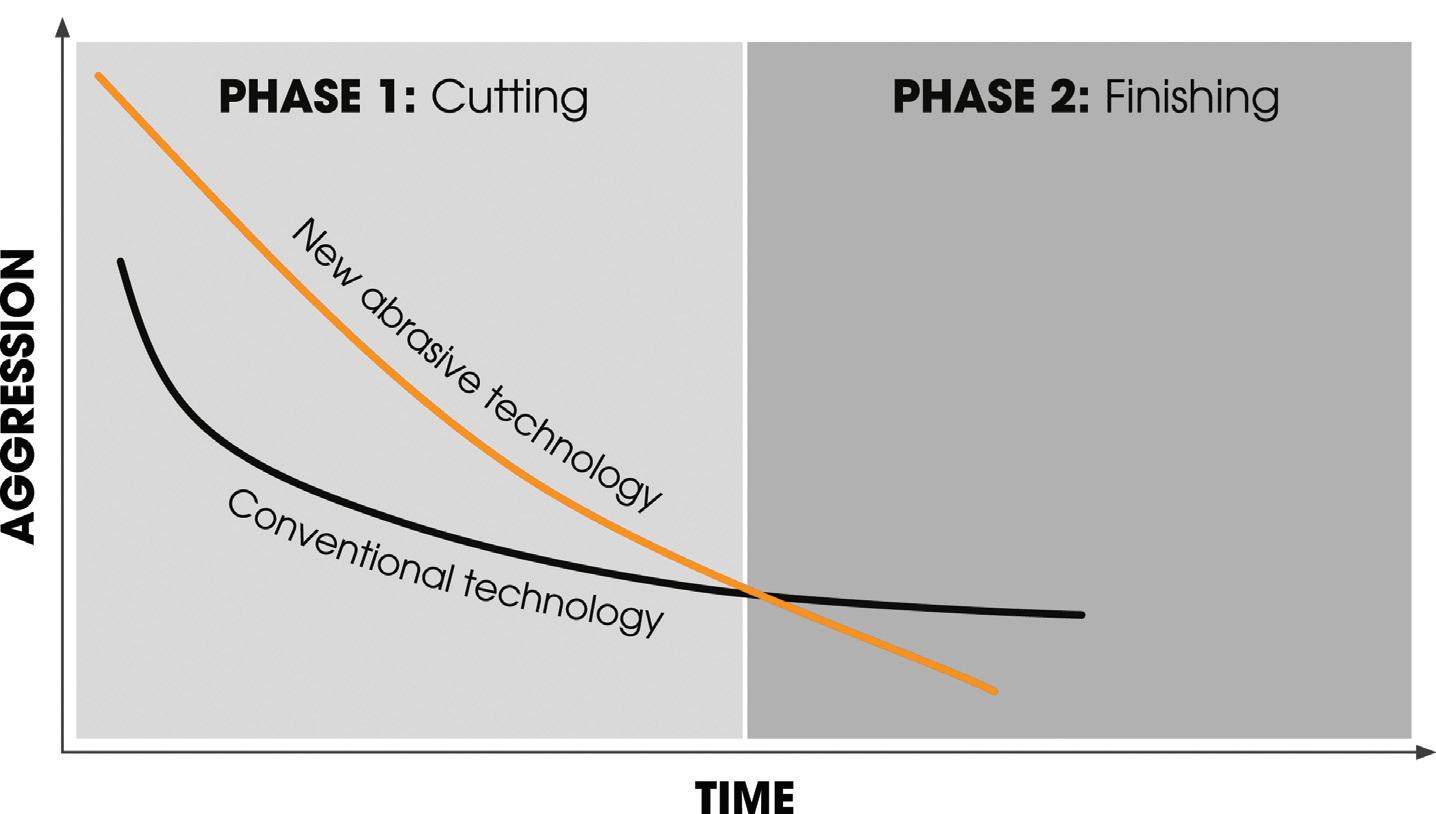

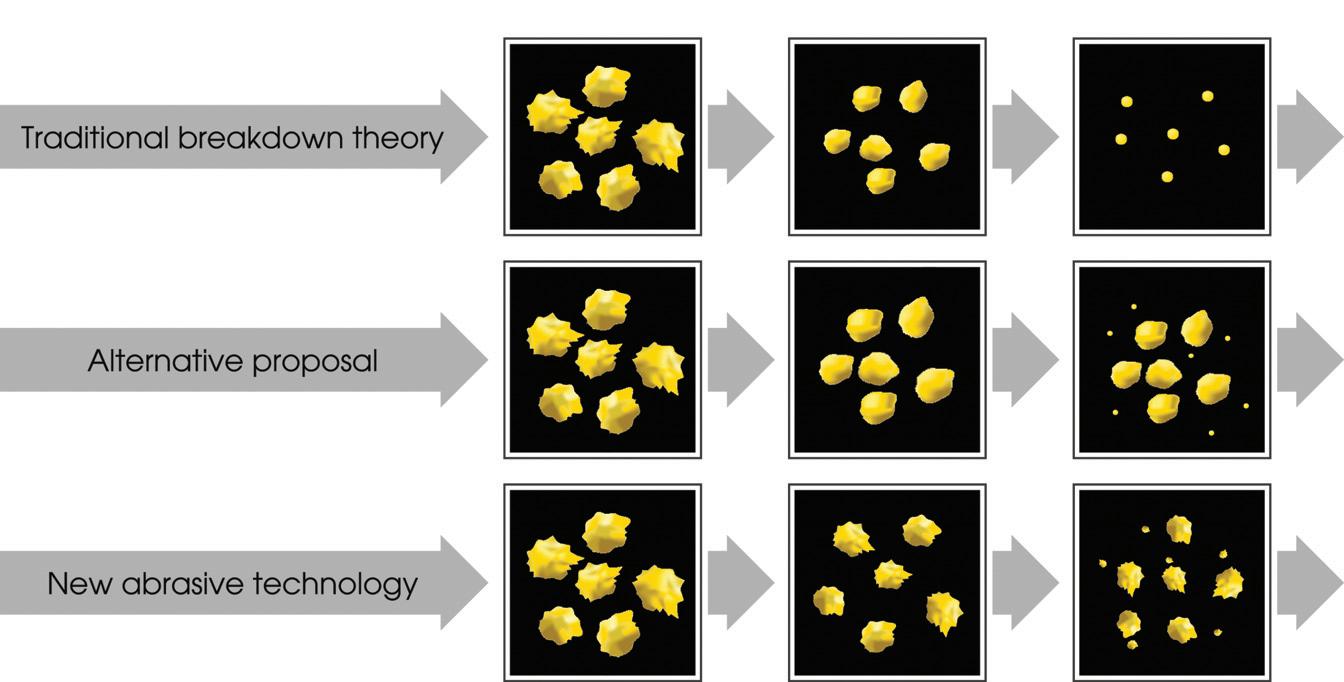

With bodyshops under ever more pressure to cut costs, any process improvement that can help the bottom line is of course welcome. But at first glance many, us included, would not think of post-paint defect rectification as an area offering much scope for significant savings, as polishing is a relatively small part of the overall repair cost. Not so, according to Farécla, on account of a scientific breakthrough in abrasive technology that lies at the heart of the company’s flagship polishing system.

According to the company revolutionary tailor-made abrasive particles in its G360 super fast compound (combined with its dedicated super high cut pad) have brought the unique benefit of enabling the system to polish out P1500 scratch marks to a permanent finish faster than competitors can sand to P3000 and then polish. This seemingly impossible feat is a development which is turning the previous tide of sanding to ever finer grades – despite the expense – in order to maintain key to key times in the face of ever harder paint systems coming on to the market.

Thanks to the new technology the system has been tested to be 35-48% faster than its main rival on standard clearcoats, varying with paint surface and operative. So that also means energy savings per job and the opportunity for increased throughput.

The latest trend, driven by the energy cost crisis – towards low energy (air dry) clears has not changed the central precept of the process improvement. Extensive trials and research confirm that DA sanding with P3000 or finer grade discs is not necessary, as it can be replaced with a rotary polishing step using G360 on its super high cut pad albeit the recommendation for cured low energy clears is sanding to P2000 rather than P1500.

Still more cost savings come, says Farécla, from reduced product expenditure. Live data from a six-month bodyshop trial found that the new system required 56% less product per job compared to its main rival, and that’s before considering the cost savings from eliminating or severely reducing the use of expensive P3000 discs.

“…the number of jobs done by a bottle of G360 would previously have required 1-1½ boxes of P3000 discs. That’s a huge saving. At today’s prices for a shop that changes process and switches away from P3000 that’s equivalent to each bottle having around £100 in cash for your bottom line strapped to the bottle”

Marketing manager, David Stokes explains: “Data from the extended trial conducted at an A-grade bodyshop group concluded that the number of jobs done by a bottle of G360 would previously have required 1-1½ boxes of P3000 discs. That’s a huge saving. At today’s prices for a shop that changes process and switches away from P3000 that’s equivalent to each bottle having around £100 in cash for your bottom line strapped to the bottle, just for the savings on P3000. Then add to that the energy savings from getting each job done so much faster and the attendant opportunity for more throughput, plus the fact that you could now be using less than half as much polish per job, and the financial advantages start to look irresistible.”

Perhaps, a less easily measurable financial benefit of the system is the reduction in reworks reported by very many of the users who make the process switch. One concrete example, however, is a high-volume de-fleet centre for which the number of reworks was a major headache. Plagued by scratch marks reappearing, the site bodyshop manager really appreciated the absence of fillers in G360 which enabled “right first time” permanent finishes. Comparative data shared from pre- and post-switch financial periods showed a reduction in post-paint sanding and polishing materials expenditure of 64%, and even better, an increase in throughput of 30%.

To help bodyshops Farécla has created a savings calculator viewable at www.farecla.com/G360/#G360Calculator. This allows the bodyshop to input its own specific circumstances and see the potential savings that the process change could add to their bottom line, often a five-figure sum for a shop that is moving away from P3000.

When asked about the practicalities of the system we learned from applications and training manager, Mark Taylor that the bodyshop owner and manager are not the only ones to benefit from the new technology. “When you sand with P3000 you make the area to polish four, even five times

greater than the actual denibs, whereas with G360 you are laser focused on those small P1500 denib scratch marks. It’s like keyhole surgery versus open heart. And not only that, the new system gives the operative a whole lot more control as well. When you flat an area with P3000 the P1500 scratches are obscured beneath the matted area so you can’t be certain whether you have sanded for long enough to remove them all, and if there are P1500 scratches remaining you will spend a lot longer polishing. By contrast the G360 system develops a transparent film in use that lets you see the scratch marks disappearing, so you always know where you are in the process.”

“When you sand with P3000 you make the area to polish four, even five times greater than the actual denibs, whereas with G360 you are laser focused on those small P1500 denib scratch marks. It’s like keyhole surgery versus open heart.”Data from electrical testing showed that faster polishing resulted in a 42% net saving in energy

The workshop should be a safe place to work but even for the most well run, dangers are lurking. Sanding and power tool expert Mirka provides a word of caution.

Tools are used by technicians for thousands of hours a year across multiple applications. To handle this amount of work there has been a significant evolution in the way these products are made. Increased investment by manufacturers in R&D ensures suitable tools are developed so users have access to the right product for the job at hand as well as a tool that protects them against the potential health issues caused by hand arm vibration syndrome (HAVS) and dust particles.

User-focused design

HAVS, which affects the blood vessels, nerves, muscles, and joints of the hand, wrist and arm, is becoming a bigger issue for workers as it is a condition they cannot see or are maybe unaware of that is affecting them until it is too late. The reason for this is basically that each worker may have different tolerances for the amount of vibrations they can handle, or they may not realise there’s a problem until they try a

different tool or do not use theirs for a while. This is why tools must have a user-focused design that makes the tools easy to handle. For dust particles, they may seem very small, but they can cause major health issues for employees and could lead to respiratory problems. To combat this issue, extraction systems come into their own. For some people, they may seem like they take up a

lot of space on the workshop floor but, in truth, they don’t and when combined with the right tool, they ensure a dust-free work environment. This is why more and more businesses or single users are investing in systems appropriate for their shops.

Laboratory tests have shown that without dust extraction, dust in the air per kilogram of sanded material is over 200g per kilogram, and dust on surrounding surfaces is almost 800g per kilogram. These may not seem like large quantities but when they accumulate over a long period, they could potentially turn into both a fire and health hazard for the business.

“...each worker may have different tolerances for the amount of vibrations...”

Investment in a suitable mobile extraction system is not a short-term injection of the business’ cash. It should be viewed as a long-term commitment, so that it can provide an effective solution for a cleaner workspace, a reduction in prepping and tidying up at the end of the day, and the potential dust contamination of other tools and surfaces. The smaller systems are more often used in workspaces because they are equipped with a local air supply and extraction and are easy to move and store.

A dust-free environment ensures control of the sanding process and allows for multiple work phases to be undertaken in the same room, delivering efficiency both for the business and in terms of tool usage. It also reduces the risk of ‘dust pills’ and clogging as the dust can no longer collect in lumps on the sanding discs to the same extent and there is no longer a danger that

sanded dust will build up and create grooves on the sanding surface and fill up the disc reducing its sanding capacity. This means that an abrasive such as Abranet maintains its aggressive properties over the entire surface much longer than traditional paper materials that have long wilted and faded, making sanding more even and efficient. Here are some top tips from Mirka for achieving a dust-free work environment and protecting users from HAVS:

■ Ensure that tools and dust extractors are regularly serviced for optimum performance.

■ Make sure the fleece bag in the mobile extraction unit is not full and does not have any rips or holes. If it does, replace it.

■ Periodically remove and clean the motor filter on the extractor. This can be done by placing it in a bag and gently knocking the dust out of the filter. Or better still, use another vacuum or extractor to clean the filter. Once it is clean, replace the filter in the machine.

■ Make sure the seal between the tank and upper section of the extractor is clean and not damaged.

FOR MORE ON MIRKA, WWW.RDR.LINK/VBB014

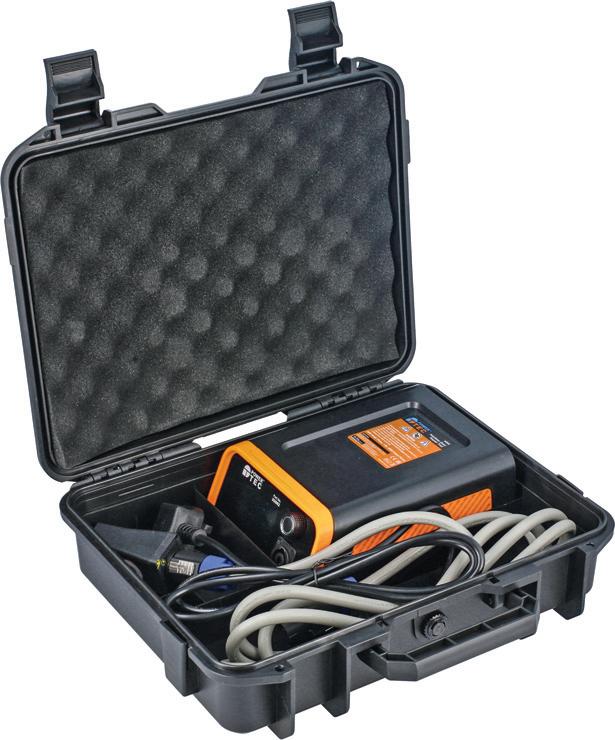

Utilising magnetic-induction heating technology, Power-TEC's latest paintless dent repair tool can remove dents in just 30 seconds without causing any damage to the paintwork.

The tool is a mains-powered induction heater designed specifically to get rid of soft-edged dents, such as hail damage and carpark dings, from steel automotive body panels. It operates on 230V single-phase power, draws 1.8A, and delivers an output power of 400W.

Adjustable time control, ranging from one to five seconds, allows for precise heat application so dent removal is optimized. Adjustable power control, ranging from 10% to 100%, provides additional flexibility in controlling the induction heating's intensity. The digital display ensures easy viewing and adjustment of all settings, offering accuracy and convenience during repairs.

The paintless dent repair tool complies with CE and RoHS, meeting international quality and safety standards and comes with a 1.5m power cable and a 3m repair head cable.

GOTO

WWW.RDR.LINK/VBB015

Designed to boost customer efficiency, the Priomat 1K universal primer surfacer aerosol 4095 from Spies Hecker shortens repair time significantly and reduces the number of products needed for each repair. The primer surfacer offers high filling power and easy sandability. You can apply it directly on bare metal and most common plastic substrates. It also stands out with shorter drying times compared to other aerosol primers. This enhances fast work processes and improves bodyshop throughput.

The aerosol ensures good sprayability and flow, so application is simple and swift. The primer is re-coatable with waterborne basecoats, solvent-based basecoats, and topcoats and provides excellent corrosion protection.

GOTO

WWW.RDR.LINK/VBB016

HMG PAINTS

HMG Paints is relaunching Ferrozinc, a water-based rust converter, that offers both high performance and ease of use, says the company, claiming also that Ferrozinc is the goto solution for rust conversion in areas where shot blasting, or complete rust removal is impractical or impossible.

Traditionally, rust removal has been a laborious and time-consuming process, involving hours of wire brushing or the use of strong acidic chemicals that pose significant safety hazards. Now users only need to remove loose debris and poorly adhered surface rust, followed by a degreasing step to eliminate any contamination that may interfere with the chemical reaction. Afterward, a thin coat of Ferrozinc is applied to the rusted area, and within 30 minutes, the surface transforms into a black/navy colour, indicating the successful rust conversion. Any excess product can be easily wiped off, and after just three hours, the treated surface is ready to be overcoated with the user's preferred coating system.

Ferrozinc's water-based formulation not only provides excellent rust conversion properties but is also low odour, making it a more pleasant and user-friendly option compared to solvent-based alternatives. The product is now available in a handy new 250ml can as well as its current one and five litre quantities.

GOTO

WWW.RDR.LINK/VBB017

POWER-TEC

Boosting paintless dent removal (PDR) repairs, Power-TEC offers a rechargeable cordless hot glue gun. It removes dents from vehicle bodies without damaging paintwork. Along with glue pads and a dent puller, it assures efficient, flexible operations.

Armed with a powerful 100W heating element, the glue gun heats up in three minutes. This quick start reduces waiting time and promotes swift repairs. It uses a rechargeable 2000mAh Li-ion battery, eliminating the need for a mains power supply. On a full charge, it runs for about 60 minutes, allowing uninterrupted work.

This makes it a handy tool for mobile PDR specialists. It's compatible with Power-TEC's dent puller, the 92308 Hot Glue Dent Removal Kit, the 92376 Slide Hammer with 12 Glue Pads and the 92407 Dent Puller Kit with 10 Pads. Spare glue sticks are available.

GOTO

WWW.RDR.LINK/VBB018

POWER-TEC

Mobile and versatile, the pulling tower from Power-TEC uses a pneumatic vacuum system that eliminates the need for fixings as it firmly anchors to the workshop floor.It enables repairs in confined spaces, offers pulling from any angle, and – according to Power-TEC –reduces repair times significantly.

The tool is straightforward to operate. Simply place the pulling tower conveniently next to the damaged bodywork in need of repair –the mechanical hoist can be easily adjusted to the desired height. The pulling tower’s stability is ensured by the anchoring plate, which securely adheres to the workshop floor using the vulcanized rubber suction pad. By connecting it to the workshop air supply, the tower remains firmly anchored, making it an ideal for glue-pulling on both steel and aluminium panels. It can deliver a pulling traction force of up to 550kg.

A range of accessories such as pole extensions and vertical pull kits increase the tower’s versatility. Repairs on high areas such as truck or van roofs can be tackled using the 700mm pole extension that can extend the tower’s height from 1650mm to 2350mm. For pulling down on damaged floor pans or sills, the vertical pull kit comes into play, featuring a second suction anchoring plate.

The pulling tower is equipped with a claw-hook for use with various tools like weldon squiggly wire, Miracle System bits, glue pads, weld-on tack and pull plates.

WWW.RDR.LINK/VBB019 GOTO

Cromax has introduced the Chroma matt clear system, comprising two newly developed matt clears - CC6020 Chroma matt system clear and CC6010 Chroma semi matt system clear. These inter-mixable clears have been designed to create a best-in-class system, offering refinishers six matt levels to match the wide range of OEM production finishes, from matt (5GU) and semi matt (65GU). New ultra-low gloss level finishes, which are now also in production, can also be repaired with a simple change in product combination. The two clears have been formulated to work as part of the Cromax System, Cromax Pro System, Centari 6000 System or original paintwork.

CC6020 Chroma Matt System Clear and CC6010 Chroma Semi Matt System Clear are based around new matt pigment technology, boasting significantly smaller pigment size, which ensures perfect gloss-level matches. The clears are easy to apply, for any type of repair, and have been designed to be simple to reproduce productive results amongst refinishers.

GOTO

WWW.RDR.LINK/VBB020

SPONSORED BY

TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS

● FREE CPD TECHNICAL SEMINARS ● FUTUREDRIVE ZONE ● FREE ENTRY ● FREE PARKING ● FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL

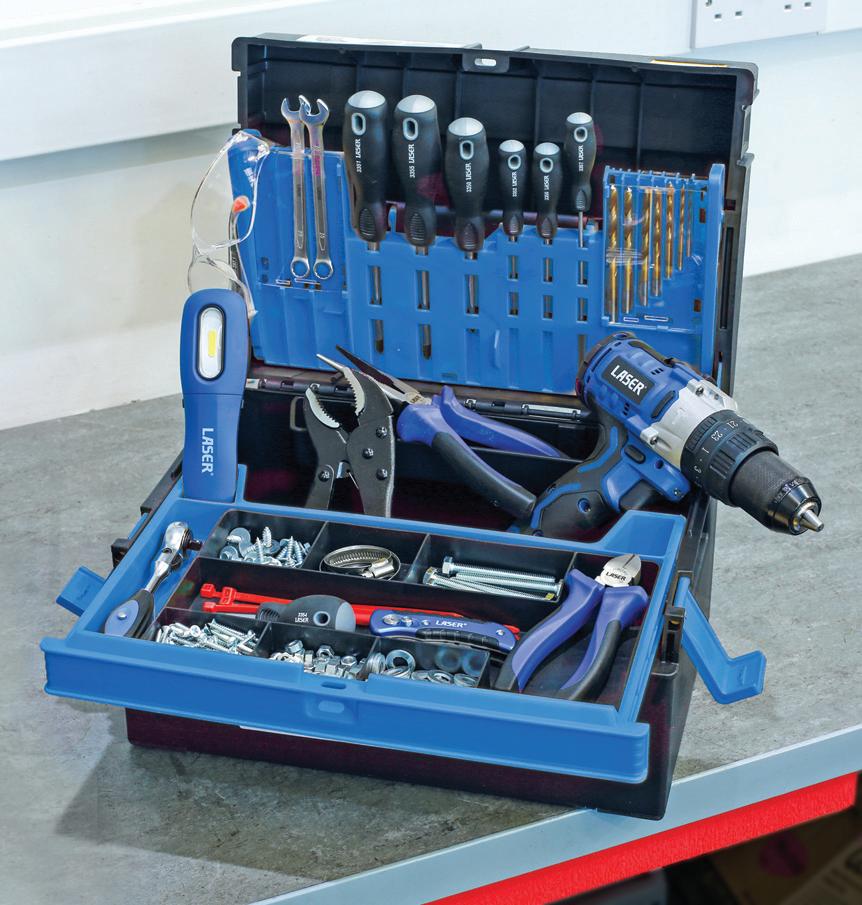

CVW has teamed up with pliers’ specialist KNIPEX to offer one lucky reader the chance to win a KNIPEX Modular X18 (00 21 50 LE) tool backpack.

Carry all your tools, laptop or accessories comfortably with the new KNIPEX Modular X18 (00 21 50 LE) tool backpack, all conveniently stowed away on your back. The KNIPEX Modular X18 is made for those who don’t want to compromise on which tools they take where. The backpack can hold up to 15kg and adapts perfectly to its wearer thanks to the fully foldable front and back, a laptop compartment, a removable tool board and ergonomic back padding.

The durable fabric made from sustainable recycled synthetic fibre is splash-proof and easy to clean. The waterproof, 6 cm high base shell made of impact-resistant plastic ensures that the backpack stands firmly on the ground when open and closed. Innovative FIDLOCK® connectors and adapters with fabric loops and MOLLE straps provide many options for individual tool storage and access to the tools. There are also two separate inner compartments on the front and back for tools, measuring devices and a 15in notebook or tablet.

Award winner

With a total of 21 straps, 37 pockets and a luggage strap, everything that needs to be close at hand can be stowed awaywhether it's tools or a laptop. A luggage strap also allows it to be attached to the telescopic handles of tool cases. The Modular X18 recently won the prestigious Plus X Award in the categories ease of use, functionality, high quality and ergonomics.

For your chance to win WWW.RDR.LINK/VBB021 and answer the following question:

QThe KNIPEX Modular X18 (00 21 50 LE) tool backpack can hold up to how much weight?

A. 5kg

B. 10kg

C. 15kg

Michael Boe, vice president and general manager Global Aftermarket, BorgWarner Emissions, Thermal & Turbo Systems discusses how to maximize the life of a turbocharger, and identifies some checks to carry out before assuming turbo failure.

Although it is feasible for a turbocharger to last the life of the engine on which it’s installed, fleets and independent operators are now keeping their vehicles so much longer that the need for turbo replacement will inevitably become more commonplace as the vehicle population ages. However, it is possible to maximize the life of this component with diligent attention to routine vehicle maintenance.

The first prerequisite is that the vehicle/engine manufacturer’s service schedule is followed, with particular attention to the engine’s lubrication system; more than 40% of turbo failures are oil related, two of the major causes being dirty oil or oil starvation. The rotating parts of the turbocharger are precisely balanced and float on a thin film of engine oil; considering

the tight clearances between them and the high speeds experienced at the bearing surfaces, any oil contamination or starvation can soon cause failure. Therefore, oil and filter change intervals must not be exceeded, the quality and specifications of the oil need to be adhered to, and the correct functioning of the oil circulation system must be ensured.

A further cause of early turbo demise is damage to the compressor wheel caused by a foreign body entering the intake; this can be avoided by ensuring that the air filter system is working effectively and is serviced in clean working conditions. Correct calibration and functioning of the fuel injection system is also vital, as a fault here can lead to elevated exhaust temperatures, which in turn can damage the turbine wheel or crack the turbocharger housing.

Excessive smoke at the exhaust pipe is often assumed to be an indication that the turbocharger has failed, resulting in many being replaced when in fact there is another cause within the engine or one of its ancillary systems that should be investigated first. In particular, the air filter, exhaust system, breather system and fuel system should be confirmed as working properly, as problems in any of these can cause similar symptoms to turbo failure.

Either black or blue smoke may be observed. Certain faults are common to both: on the intake side a clogged air filter, or a dirty compressor or intercooler; on the exhaust side a blockage in the exhaust system or leakage upstream of the turbine; or in the engine itself, valve guides, piston rings, or cylinder bores/liners may be worn, giving rise to increased blow by of combustion gases. If no issues are found

here, it could indicate damage to the turbocharger bearings.

Additionally, black smoke may point to a combustion problem; fuel delivery or defective or poorly adjusted fuel injection leading to over- or under-fuelling, or an air leak at the inlet manifold or plenum chamber due to it being cracked or poorly sealed – so check gasket condition and torque settings of the fasteners. Joints in the intake system suction and pressure pipework should also be checked for air leaks. Another possibility is that the wastegate is not closing properly, in which case a lack of engine power will most likely also be evident. If all of these items prove satisfactory, it’s time to check for damage to the turbocharger’s compressor or turbine wheels, or to the turbine housing.

Finally, blue smoke can also be caused by a blocked or leaking crankcase ventilation system, or by a problem with the oil drain tube, which could be kinked, clogged or leaking. If this is not the case, look for coke and sludge deposits in the centre housing of the turbocharger.