KITCHENS & BATHROOMS

EDITOR

LEE JONES

EMAIL: ljones@hamerville.co.uk

ASSISTANT EDITOR

EDWARD KELLY

EMAIL: ekelly@hamerville.co.uk

EDITORIAL ASSISTANT

FINLEY CANNON

EMAIL: fcannon@hamerville.co.uk

GROUP ADVERTISEMENT MANAGER

CRAIG JOWSEY

TEL: 07900 248102

EMAIL: craig@hamerville.co.uk

NORTHERN ADVERTISEMENT MANAGER

IAN DUFF

MOBILE: 07810 353525

EMAIL: probuilder@sky.com

GRAPHIC DESIGNER

DONNA BOOTH

GROUP PRODUCTION MANAGER

CAROL PADGETT

DIGITAL MANAGER

JASMINE SMITH

EMAIL: jsmith@hamerville.co.uk

DIGITAL ASSISTANT

LYDIA MCFARLANE

EMAIL: lmcfarlane@hamerville.co.uk

DISTRIBUTION MANAGER

KARL CLARK

PRINTED BY

PCP TELFORD

PUBLISHED BY

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Fax: (01923) 246901

Email: pb@hamerville.co.uk

Professional Builder is a business magazine for firms and individuals involved in all aspects of the building industry. It is available nationally –free to the trade through leading builders’ merchant outlets. © 2024

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Subscriptions to Professional Builder are available at the following rates:

UK: 1 year (11 issues) –£30.00 post paid Europe & Overseas: 1 year (11 issues) –

£50.00 post paid

Airmail: 1 year (11 issues) –

£80.00 post paid

Tool theft is a cruel crime for the trades. The loss of equipment that’s been accumulated over a working lifetime costs its victims thousands, whilst simultaneously depriving self-employed builders with the means to earn a living. Damage to a van adds to the expense and puts the vehicle off the road, with equally debilitating consequences for a business.

Added to that is the inherent frustration. Whilst a determined and undisturbed thief will ultimately gain illicit access to any vehicle there is still a perception that manufacturers could do more to enhance the security of what is the biggest investment the owner of an SME construction company will make.

The makers of LCVs will argue that their new models – on the journey from drawing board to rolling from the production line – are developed on a cycle of years, and criminals have the luxury of time to find weaknesses, but that does still make for a thriving aftermarket in additional locks and alarms. Fitting these is certainly advisable, but it will introduce a further and financial outlay with no guarantee of deterrence. Moreover, when the worst does happen, many won’t even bother to claim on the insurance, assuming that they will either not pay out or that they will only receive the depreciated value of the stolen tools.

exasperation that led Trades United to organise a van rally in Parliament Square. Just a few weeks ago impassioned tradespeople from across the country descended on the capital to drive the issue to its political centre, and the measures that they are proposing are neither costly nor difficult to implement. There are, in fact, laws already on the statute books that could stem the tide and others that could easily be introduced.

Anyone who has fallen victim can tell the familiar tale: They are issued with a crime reference number by the police in the sure and certain knowledge that noone will be brought to justice, and that they well never see their possessions again – but it doesn’t have to be that way.

“Just a few weeks ago impassioned tradespeople from across the country came together on the Trades United Van Rally to drive the issue of tool theft to the Capital’s political heart”

Tool theft is an acquisitive offence and without a market for resale it is deprived of its motive and profitably. Campaigners are consequently calling for a £10,000 fine to be imposed on the organisers of car boot sales and markets that permit the resale of stolen tools. As it stands the Theft Act 1986, which also addresses the handling of stolen goods, is woefully underenforced. Meaningful custodial sentences for both the perpetrators and handlers would reflect the seriousness of the offence and potentially deter others.

Sadly, this class of crime has now reached the proportions of an epidemic with hard working builders representing an all-too easy target for the unscrupulous. Mental health is already a serious concern for the industry and the emotional toll of becoming one of its casualties should not be underestimated.

Perhaps the biggest source of annoyance, however, is the perception that the courts and our legislators are blind to the impact. It is precisely this

Trades United’s founder Shoaib Awan launched a petition urging the Government to act. With the announcement of the dissolution of Parliament prior to the general election this was automatically closed, but it still generated 46,000 signatures. It is, however, imperative that builders support the cause. At the same time, law enforcement agencies and our politicians must recognise that legions of builders are being economically paralysed on a daily basis and they should come together to stop it as a matter of urgency.

Government’s Biodiversity Net Gain scheme needs a rethink, says FMB

The Government needs to rethink its Biodiversity Net Gain scheme if it wants to encourage house building, says the Federation of Master Builders (FMB) The trade association is responding to a

Over 250,000 extra construction workers are required by 2028 to meet demand

National Audit Office (NAO) report which identifies substantial risks to the longterm effectiveness of the scheme. “SME housebuilders were broadly supportive of the aims of a BNG scheme, but they have been warning for some time that excessive regulation and additional costs to firms preparing for the changes,” argues FMB Chief Executive, Brian Berry. He goes on to point to a significant under preparedness of local authorities that “will make it near impossible for smaller firms to manage.”

This is according to the annual industry forecast from the Construction Industry Training Board (CITB). Despite the industry managing to recruit around 200,000 people every year, in 2023, an average of 38,000 vacancies were advertised per month. CITB has invested £267m to help the industry improve diversity, quality and productivity and make construction a more attractive career choice.

New regulations will allow the conversion of unused farm buildings without the need for a planning application

Unused farm buildings will be able to be converted into homes, shops, cafés, sports facilities and a variety of other commercial uses. The proposals form part of the government’s Long-term Plan for Housing, intended to increase both the number of homes and the number of job opportunities.

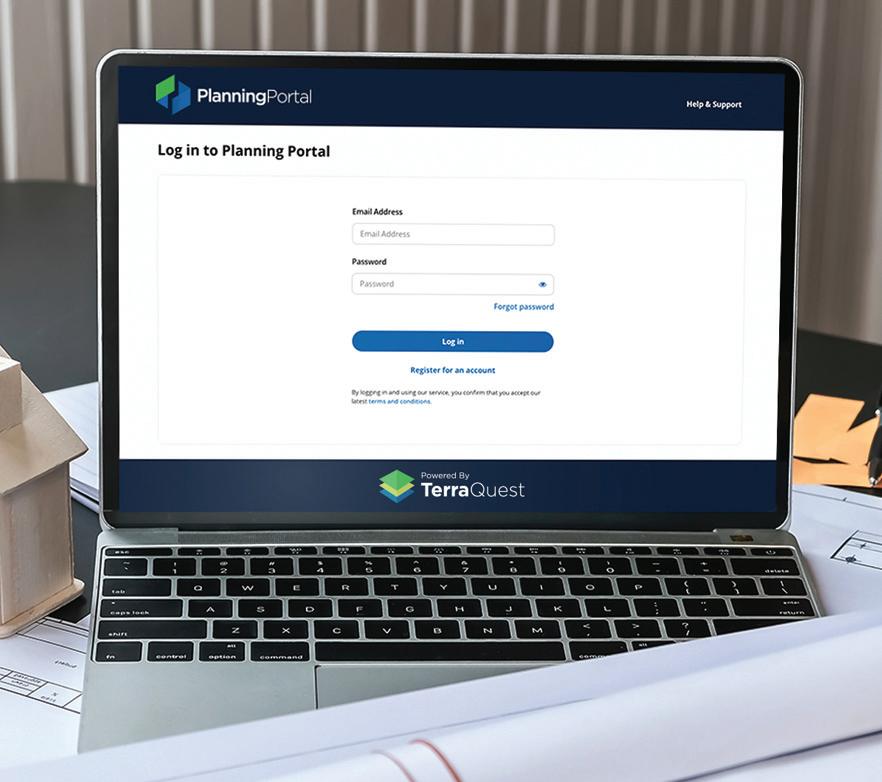

Gain access to planning and Building Control all in one place

TerraQuest, the operator of Planning Portal, has launched its combined portal for Planning and Building Control applications. The service comes with a raft of new features built from the ground up to meet the needs of contractors and developers. The platform offers direct access to planning and building control applications via a single sign-on.

South-east leads on demolitions for new builds

Industry research by APRAO has revealed that the south-east has seen the largest number of demolitions to make way for new builds over the last year. APRAO analysed Government data looking at the number of demolitions to have taken place over the last year across England. Analysis showed that 5,474 demolitions took place over the last year.

Tools worth £98 million were stolen from tradespeople in 2023 according to Direct Line business insurance.

44,514 incidents of tool theft were reported to police forces in 2023 a five per cent increase from 2022. 94 per cent of tradespeople are taking extra precautions to secure their tools, with tradespeople spending on average £626 retrofitting their vans with additional security.

Job management software Fergus has launched Fergus Pay, designed to minimise delays in payments.

The new software provides a seamless way for tradespeople to issue invoices and receive payments swiftly. You can send digital invoices instantly, and customers can pay promptly using their credit cards. The Scan to Pay feature, included at no extra cost, utilises QR code technology to facilitate immediate payments on the job site.

Amid a national bricklaying shortage, business experts have revealed how better inclusion could help to close the skills gap According to ONS figures, women currently make up just 2.36% of skilled trades workers in England and Wales. Despite making up such a small proportion of this workforce currently, 1 in 4 women said they would consider becoming a tradesperson. Historically, women have faced barriers in trade industries, including being discouraged from accessing training due to its traditionally masculine image.

Demand for Boiler Upgrade Scheme applications was 46% higher than the volume received in the same period last year, reports Aira UK

The Boiler Upgrade Scheme has a monthly budget of £12.5 million, roughly 1,666 BUS grants per month. Since the Prime Minister’s relaunch of the Boiler Upgrade Scheme in October 2023, when the funding was increased to £7,500, DESNZ has awarded on average 2,000 grants per month.

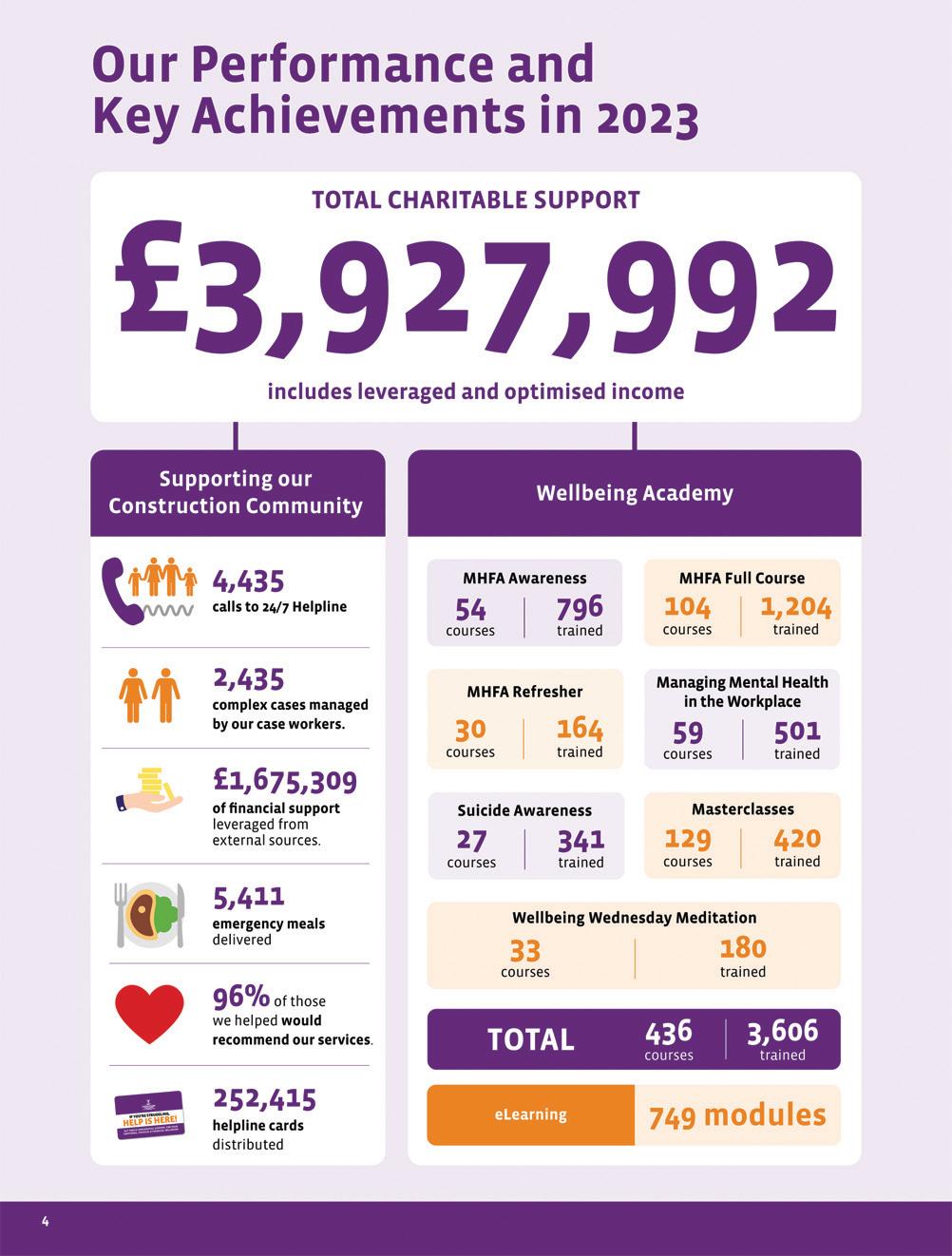

The Lighthouse Charity saw a 30% increase in demand for support

The charity has published its 2023 Impact Report which details the vital support and impact that its services provide. £3,927,992 worth of charitable support was delivered, and 4,435 families supported. The report also outlines some of the strategic collaborations that have facilitated sustainable futures for the people in our industry and to support a new generation of workers.

Tradespeople could soon park on double yellow lines

Experts at Lease Van are calling for tradespeople to legally be able to park on double yellow lines throughout the day when on site or attending a maintenance job. The campaign comes after the news that 3.5 million parking fines were issued to tradespeople last year – costing them a massive £177 million.

Band of Builders project for Newport stroke victim

The family of a stroke victim from Newport have thanked volunteers from national construction charity Band of Builders (BoB), who have built Keith Parry a ground-floor extension so he can sleep in his own bedroom for the first time in more than two years.

Nearly 50 tradespeople – including plant workers, bricklayers, builders, roofers, plumbers, electricians and decorators – and other BoB supporters volunteered on the three-week project, which was sponsored by Tarmac Blue Circle.

No Falls Foundation launches first of its kind research into falls from height

In order to gather more comprehensive data on the underlying causes and circumstances of falls from height, the No Falls Foundation is embarking on the largest study of its kind in the UK to date. Year on year, falls from height statistics show little improvement. Up to 992,000 working days were lost and the total cost is estimated to be over £847 million.

Whether it’s working at height or falling objects we all know that there are inherent hazards on a building site. There are, however, invisible and cumulative threats than can be just damaging. The effects will build up unseen and unnoticed over many years and – before you’ve even noticed it –the damage has already been done.

The majority of skin cancers are caused by exposure to harmful UV rays and working on site beneath a relentless sun makes tradespeople particularly vulnerable. There is a common misconception that our overcast climate reduces the risk, but damaging ultraviolent radiation can being doing its creeping and malign work even on cloudy days.

Chris Burdett is the owner of

Working in the construction industry has many benefits and being in the great outdoors in the summer months would be a shining example – but builders should beware. Chris Burdett tells an all-too common tale of the dangers of UV exposure.

Harpenden-based Urban Spaces, a company which utilises innovative construction techniques to create modular home extensions, garden rooms, and annexes. Just over a year ago he noticed something unusual below his eye and he would go on to discover that it was a problem that far too many tradespeople have experienced.

“It started out as a lump that I could feel underneath the surface of my skin,”

“We’ve made huge strides in health and safety since I started out as a 16-year-old, but putting sun cream on before you start your working day is still not something that’s even considered by enough tradespeople – and that should be the message. Not only that, if you do notice any unusual changes to you skin get it checked out as soon as you can.”

recalls the 48-year-old. “I didn’t really think anything of it for quite a while, but it then developed into a scab. When I picked at it, it started bleeding and that didn’t really stop for months. The waiting list to be seen on the NHS was so long that I went to see a private skin specialist. Unfortunately, they misdiagnosed the condition, and I was told it was nothing to worry about. I still had the NHS appointment booked so I went to it anyway and was told it was a Basal Cell Carcinoma (BCC) and the testing later confirmed it. As soon as the Doctor found out what I did for a living

he told me what would have caused it.”

There are two main categories of skin cancer – melanoma and non-melanoma with Basal Cell Carcinoma (BCC) falling into the latter category. It is the most prevalent type of skin cancer worldwide and is invariably caused by exposure to the sun. It can be found anywhere on the body but is most common in areas that are regularly exposed to UV rays.

“I started out as a bricklayer straight from school and have been in the trades for 32-years now,” continues Chris. “I would have been working outdoors for the majority of that time and also spent a couple of years on site in Australia. To be honest, when I started on the tools the risk of developing skin cancer really wasn’t something that was ever brought up or discussed. We’re more aware of the dangers now, of course, but you still see younger builders wearing no top, with shorts on and not bothering with sun protection. As I’ve discovered to my cost, they are storing up problems for the future.”

It is estimated that up to 90% of skin cancers are actually preventable. For most builders staying safely indoors is clearly not an option but there are straightforward measures that can be adopted. Applying suncream with an SPF (Sun Protection Factor) of at least 30 should be part of your daily routine. It should be reapplied regularly, whilst covering up wherever possible will equally mitigate the risk.

Chris wants to highlight his diagnose to other builders: “Although my

✔ Use suncream first thing in the morning with a minimum SPF (Sun Protection Factor) of 30 and re-apply regularly during the day

✔ Stay out of the sun wherever possible – during breaks, for example

✔ Make sure you’re covered up, including wearing a hat and keeping your top on

✔ Check your skin regularly and if you’re concerned about any changes seek medical advice

condition is unlikely to be life threatening it is complicated by the fact that it’s close to the eye which means, when it’s removed, I’ll then need a skin graft, and the procedure will be under general anaesthetic. All of that will not be pleasant, and it could easily be avoided. Not only that, once you’ve had BCC it does make it more likely it will recur, and you are at greater risk of other types of skin cancer. As much as anything, it’s been a warning for shot for me, and I now apply sun cream every day without fail.”

“We’ve made huge strides in health and safety since I started out as a 16year-old, but putting sun cream on before you start your working day is still not something that’s even considered by enough tradespeople – and that should be the message. Not only that, if you do notice any unusual changes to you skin get it checked out as soon as you can.”

IF YOU WOULD LIKE MORE INFORMATION ON SKIN CANCER THEN TAKE A LOOK AT THE HEALTH COLUMN ON PAGE 67 OF THIS ISSUE, WHERE GP, ALICE FITZGIBBON PROVIDES HER EXPERT INSIGHT AND ADVICE.

FOR MORE INFORMATION ON URBAN SPACES VISIT WWW.RDR.LINK/BBF015

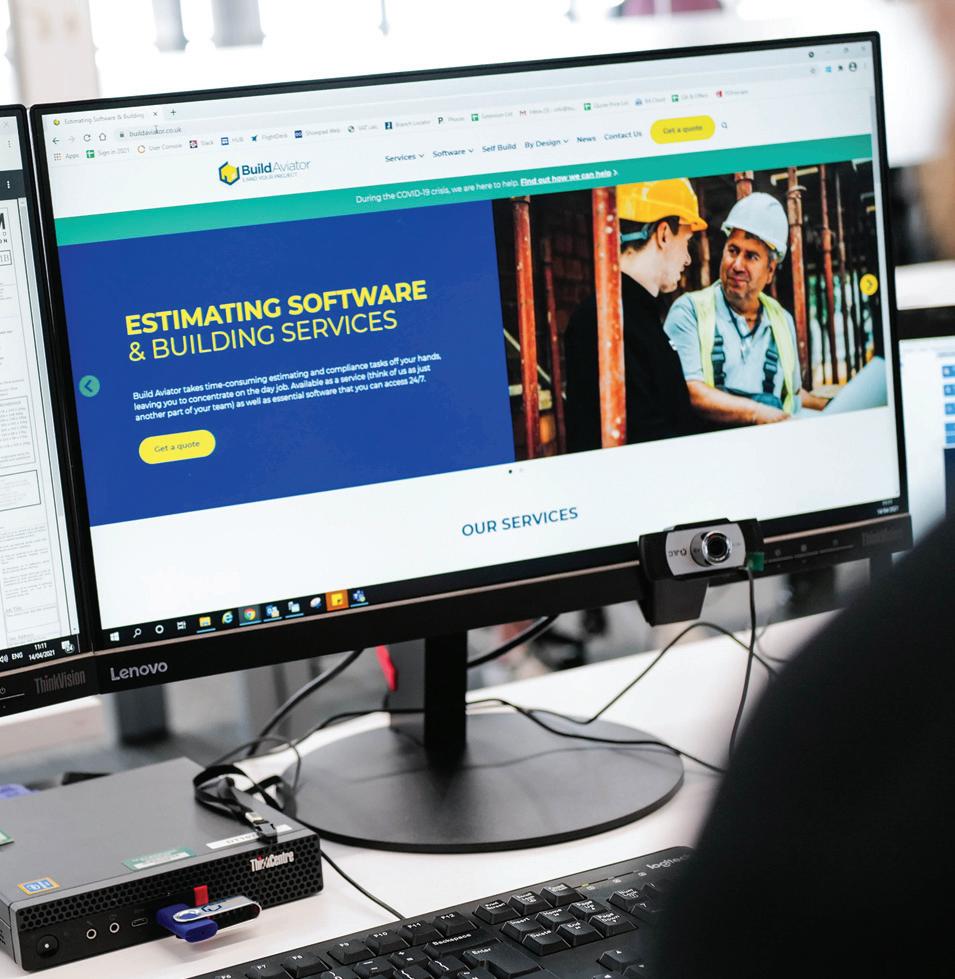

Jatinder Singh Hunjan of JS Legacy describes how Build Aviator has helped protect his profit while impressing clients

Jatinder has never been one for numbers. When transitioning from a plumbing & heating engineer to running his own construction company, finance was a major concern.

“In 2000, I began my career in the plumbing and heating trade as an apprentice. I focused on plumbing and heating until 2012 when I shifted to residential construction and launched JS Legacy. Today, we are a core team of four, working with a trusted network of subcontractors. We deliver high-quality residential projects across London and the Southeast.

When I transitioned from a plumbing and heating engineer to construction, my biggest challenge wasn’t the different trades; I was confident in my skills. The hardest part was managing the numbers and presenting them to clients in a professional manner.

Initially, I used a cost-per-square-metre approach and sent basic estimates via email. This method fell short when clients had questions or wanted to adjust the scope of work. Although I understood the costs, I struggled to articulate them clearly, leading to embarrassing and

unprofessional moments. Furthermore, this approach didn’t allow me to separate labour costs from material costs, nor account for in-house or subcontractor expenses. I’d pay everything out and hope for a profit, which was not sustainable.

In 2020, I realised a drastic change was necessary to continue building properties for my clients. I explored various estimating options and quickly settled on Build Aviator. Unlike most alternatives, Build Aviator integrates fully with our builders’ merchant, using actual material costs. When I looked at other estimating services, I found that most were using a generic material cost which, in reality, wasn’t what you’d pay or they expected the builder to say what they pay for each item.

This seamless integration means I only need to provide in-house and

unknowingly cutting into my profit.

I’ve used Build Aviator for over four years now and have a dedicated estimator, Simon Piela. Simon is more than just a number cruncher; he understands construction and has taken the time to understand how JS Legacy operates, making him a valuable part of our team. He reviews specs, examines drawings, and often points out things I might have missed. His knowledge and the overall service also mean that once we’ve won the job, he can support us for the duration. If I need to talk through the detail when we get to a specific part of the build or if changes are needed, he’s a video call away. Having this support gives me confidence and clarity on my costs and protects my business and profit.

Today, my estimates are far more detailed than a simple email. I personally present a comprehensive estimate to clients, including a summary of costs and a work schedule branded with JS Legacy’s logos

and colours. I also share the complete bill of quantities that’s provided in the ‘Builder’ version of the Build Aviator report. While not everyone does this, I find sharing this level of detail reassures clients by showing them exactly how we arrived at the final figure. Therefore, if a client initially baulks at the total cost, breaking down each element allows us to adjust the spec to fit their budget. This detailed approach also minimises the

chance of unforeseen costs.

While unexpected issues can arise, thorough upfront planning reduces their frequency. When they do occur, this level of detail facilitates informed and transparent conversations with the client, allowing us to make necessary adjustments. This was impossible with the cost-per-square-metre method. Using Build Aviator has transformed my business, increased profitability, and freed up time for me to focus on what I love –delivering top-quality builds on-site.

It has also improved my work-life balance by reducing financial stress. I now have dedicated admin days with minimal time spent on estimating and reclaiming my evenings and weekends for myself and my family. Build Aviator has made JS Legacy more profitable and professional, giving me more time to enjoy life.

PB’s Edward Kelly interviews

Gary Ross, Founder and CEO of blip –the insurance company that’s making sure you get your money’s worth.

Insurance is always a tricky subject. It’s an expense tradespeople have to pay for but may never see the benefit from, becoming a necessary part of the job and one that you just have to live with. That being said, you’d rather have it when you need it than be left in a sticky situation without the right cover!

blip insurance is looking to change this perception of insurance as just a boring necessity. It is the brainchild of Gary Ross, who, growing up with family members in the trades, recognised the complex nature of small business insurance and saw ample room for something new and different. He explains: “Insurers are a great asset to society. They’re strong and robust but all that brings in a high degree of bureaucracy and means they’re slow to move. That’s where the journey of blip

began, I just felt that we need to take insurance back to basics.”

So, blip came along and was officially launched at the beginning of the year with Wakam as partner, helping to provide the premiums. Distinctly though, the insurance provider is a profit share business, meaning that all policy holders get a share of the profits of the premiums annually. Getting your money’s worth indeed!

Gary describes the thought process behind this: “The premiums of the many pay for the losses of the few. It was the idea to make insurance a bit interesting. If the loss ratio is good, why would you not distribute

that profit back to your policy holders?

“It’s very simple, if the premiums are more than the claims, after making an allowance for expenses, then whatever’s left will be distributed to our policy holders, proportionate to what they paid in in the first place.

“We should hopefully be able to return 10% of our total premium back to our policy holders. Whilst I’d love to say it’s rocket science, it’s not. It’s a very simple equation that hopefully shows that degree of transparency and that we’re all in it together.”

Gary goes on to highlight that getting a good rate upfront was key too. Because of the digital nature of the business, expenses are lower which, in the long run, should mean more money back in policy holders’ pockets.

Keeping things simple was important for Gary too: “I’ve been in the insurance world for a long time and I know that small businesses are actually the best risks but they get treated just the same as if they’re McAlpine. They’ll get sent a 70-page policy which they’ll never read and even the underwriter probably can’t explain half of it.

“It’s something that you buy and you want it to be cheap and with a bit of luck, you’ll put it in the drawer and won’t look at it again.”

Added value is a key differentiator here with blip too, with small business toolkits

available to help those in the trades trying to grow their business. There’s a digital community hub too, that Gary describes like “LinkedIn for tradesmen”. Anyone who buys a blip policy gets a community account, where they can talk to other policy holders and publish posts. This could be used for anything from business advice to selling extra bags of cement.

The four key covers blip offers are designed for businesses with less than five employees. As well as public liability, blip offers employee liability, business equipment cover, and a 24/7 no fault personal accident cover that pays in two weeks.

The business equipment cover is something Gary and the team at blip are highlighting in particular and a specific tool theft cover is available now that aims to pay out within 24 hours. Gary explains: “The rise in tool theft is an epidemic. Tool theft isn’t just a loss of equipment; it’s a threat to livelihoods and the integrity of skilled trades. Each stolen tool represents hours of hard work and investment, hurting the foundation of small businesses and hitting the pockets of tradespeople during a cost-of-living crisis.

“Growing up with family working in the trades I know first-hand the toll it can take mentally and physically. Add the stress of having your tools stolen when you have deadlines to meet and it can be truly ruinous. It’s time we address this epidemic as an industry, providing quick solutions to get tradespeople back on the tools and support those who build our communities.”

On the subject of mental health and

“Insurance can be a difficult environment to navigate, particularly as a time-poor tradesperson trying to make the most where you can. Having a provider like blip come onto the scene keeps things simple”

tough times in the trades, blip has also partnered up with Band of Builders (BoB), the national construction charity. The partnership will see the insurance provider support the charity through charitable sponsorship and by providing blip

members the opportunity to donate the value of up to 10% of their premium to BoB through its pioneering profit-share model.

Speaking on the partnership, Gavin Crane, CEO of BoB says, “Teaming up with blip, who share our passion for giving back, marks a significant step forward in enhancing the well-being of our community. In the construction industry when life poses challenges, decisionmaking can be difficult for small business owners. blip’s business toolkits provide practical templates and guidance, easing stress and enabling businesses to grow. This collaboration is a positive step in tackling the challenges faced by tradespeople, offering actionable support for our community members.”

It goes without saying that insurance can be a difficult environment to navigate, particularly as a time-poor tradesperson trying to make the most where you can. Having a provider like blip come onto the scene keep things simple while giving back to its policy holders certainly feels like a breath of fresh air. Who knew insurance could be fun? “It’s just a blip with blip insurance”

We

UVEX

UVEX PHEOS NXT

SAFETY GLASSES

HULTAFORS

ERGONOMIC TOOL CARRIERS

Take comfort and performance to new heights with one of 20 uvex pheos NXT safety glasses. Featuring non-slip 3D side arms and twist technology to adapt ergonomically to any head shape for a secure fit, they are comfortable all day long. Wearers can also enjoy distortion-free vision thanks to a large rimless panoramic lens and uvex supravision coating. Meanwhile, UV400 technology offers 100% protection against harmful UV radiation up to 400nms.

We’re always keeping an eye on the latest health and safety products, including this uvex protection.

SAMAC FIXINGS

ROOFTEC FLEX PLUS

Samac Fixings is giving away five rolls of 300mm x 5m Rooftec Flex Plus, the self-adhesive versatile roofing solution designed for the toughest conditions. Perfect for sealing, waterproofing, and protecting roofs, Rooftec Flex Plus offers superior adhesion and flexibility.

Enter now for the chance to enhance your roofing projects with this high-quality product.

The new tool carrying range from Hultafors has been designed for the real world and with professionals in mind. Made from highly durable 1680D fabric, the Ergonomic Tool Carrier features 25 pockets and tool holders, packable rain and dust cover, protective molded base, padded shoulder strap, fold-away handle with an extra-long rubberclad grip and has been tested to carry a 60kg load. Carry away another prize courtesy of Hultafors. One of three of these versatile units could be yours.

MASCOT

CUSTOMIZED

Win the perfect duo this summer from Mascot Customized. The 22149-605 shorts are water and dirt-repellent and durable with ultra-light stretch material for a unique freedom of movement. Add the 22050-012 holster pockets using the Click Pocket System to work as your toolbox on the go. The material is made with CORDURA to keep your holster pocket stronger for longer against sharp objects. With another great round of giveaways, Professional Builder is always your lucky Mascot. There’s three sets of shorts and holsters on offer.

Full bathroom refurbishments can be a large-scale expense, so customers want the confidence that they are investing wisely. When faced with so many brands, product designs and finishes, it is all too easy to become overwhelmed. And this is where builders can add real value; taking the lead to suggest products that not only look great together for the wow factor, but also take into consideration the customer’s functionality objectives.

Clients need an individual approach to suit their requirements. For example, the bathroom design and functionality needs of a family home will differ sharply from those desired by a couple living in a modern apartment. Whilst elderly or vulnerable clients will have ease, reliability, and safety-first expectations as key priorities for their bathroom solutions.

The bathroom market offers an extensive choice of mixers, basins and other common bathroom components. But, for clients, when it comes to making their final choice, they could remain

concerned about products manufactured by different companies working well together. An effective way to create client confidence is for builders to emphasise the way manufacturers present both complementary function and longevity objectives when it comes to bathroom product combinations.

The ExcellentFit service from Hansgrohe, for instance, helps to provide the answers to such reservations, enabling building contractors to assure

clients that combinations of mixers and wash basins have been investigated and assessed against a number of points. The service is based on ComfortZone tests undertaken by Hansgrohe’s experts at the company’s Technical Service Centre. The team tests multiple potential mixer and ceramic combinations to assess their functionality and projected whole life performance and publish recommendations.

This avoids those fitting the products

having to undertake the time-consuming work of drawing up their own comparisons and allows them to suggest combinations of wash basin and mixer to clients within just a few minutes and with the full knowledge that they will work together, the mixer spout will reach the chosen basin properly and won’t splash the user due to the water being dispensed from the incorrect angle.

To ensure the service is as helpful as possible to builders, the testing process also includes ceramic solutions created by other manufacturers alongside Hansgrohe’s own ranges. This provides a comprehensive and holistic overview and a supporting tool for builders to inform client conversations and decision making.

Alongside the confidence of knowing that potential bathroom product combinations have been carefully scrutinised, builders need to marry this knowledge with informed guidance for their clients when it comes to delivering a solution that meets individual needs.

Across bathroom refurbishment projects, builders can be faced with different scenarios for which their expertise, guidance and recommendations must pivot accordingly.

For example, a bathroom used by multi generations, including youngsters must strike the balance between functionality, safety, and style. Here, practical considerations such as installing a thermostatic shower control is essential to

avoid unwanted temperature changes to the water. Also, thinking about solutions that offer varied shower spray patterns can also enhance the experience for all ages. While consideration given to the specification of energy saving products can help busy home environments optimise water and energy use.

Equally, where multiple generations need to be factored in, builders can advocate products that provide comprehensive water flow control. A forceful water jet may not be suitable for the elderly so products should be proposed to deliver a more relaxing shower jet as opposed to a more invigorating experience. Specified products should allow the user to alter the intensity of the water and even the droplet formation can be an extra selling point that not only looks great but does not add any additional hassle to the project install.

Compact bathroom footprints also

present unique challenges when it comes to creating a style-led vision and functionality success. The key is not to overpower the limited space but work smartly with the available area, so the balance of style, function and practicality is maintained. Keeping the overall design sleek and opting for all rounded edges on units will deliver an appropriate aesthetic but also provide practical benefits when space to move around is tight.

Contracting builders should always be mindful of regulatory compliance when suggested solutions and ensure that all their recommendations meet the prevailing industry standards to deliver peace of mind for clients. Specifying product solutions that comply with industry standards such as WRAS, KIWA and NSF are important when looking at creating bathroom visions that guarantee long-term performance, assured function, and safety.

Finally, builders should ensure they are up-to-speed and have access to the product information, design suggestions and price points they need to commence informed and inspirational conversations with clients. Such resources are key to transforming a vision into a high performing reality to create bathrooms with a wow factor.

The Bathroom Concepts brochure, Bathroom Concepts 2024 from Hansgrohe helps bring to life how the overall finished project will look, and, provide several alternatives when it comes to combinations of showers, mixers and accessories that work together across the room. Saving time when recommending products for projects, it also provides quick access to pricing information so accurate quotations can be compiled quickly and easily.

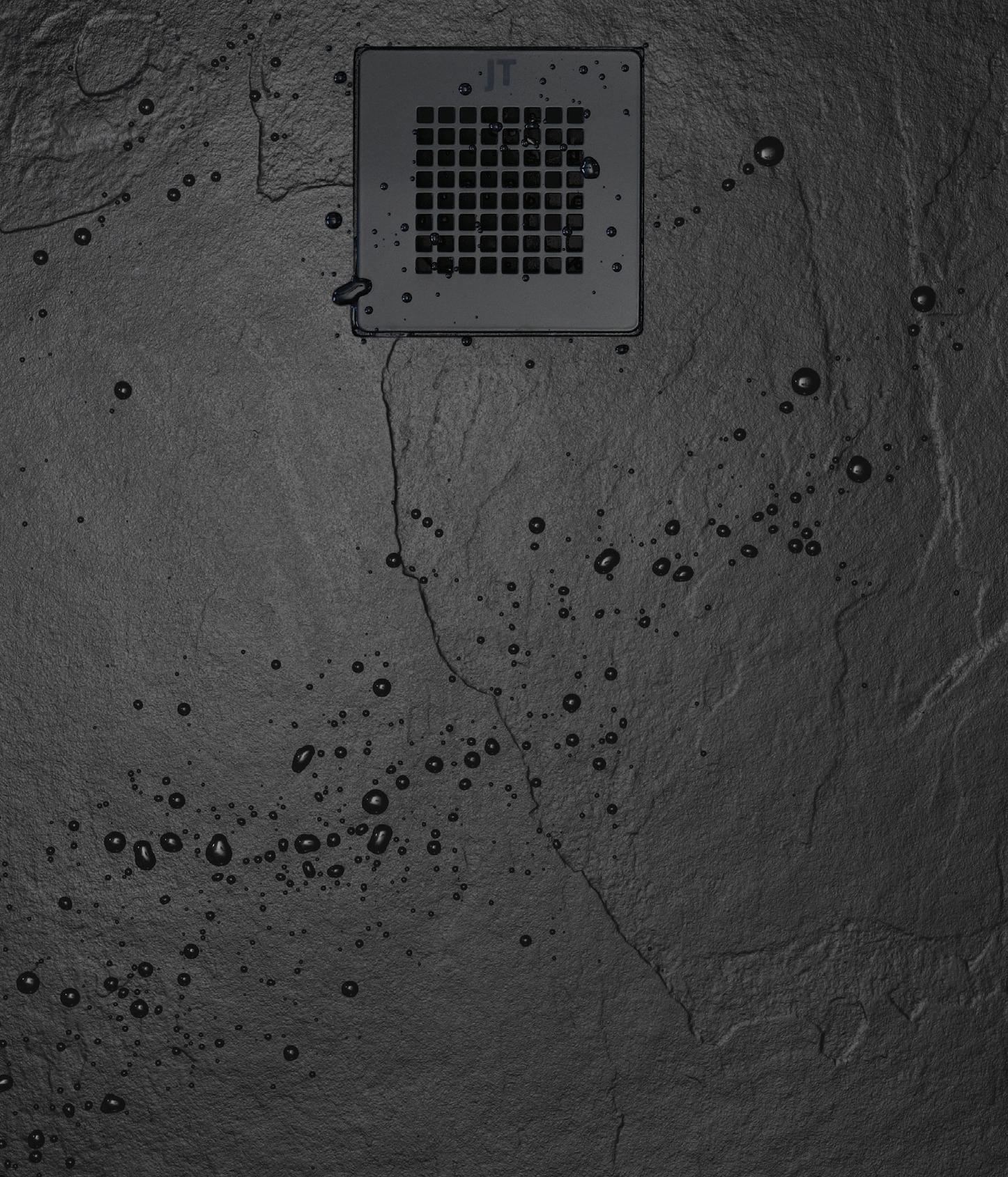

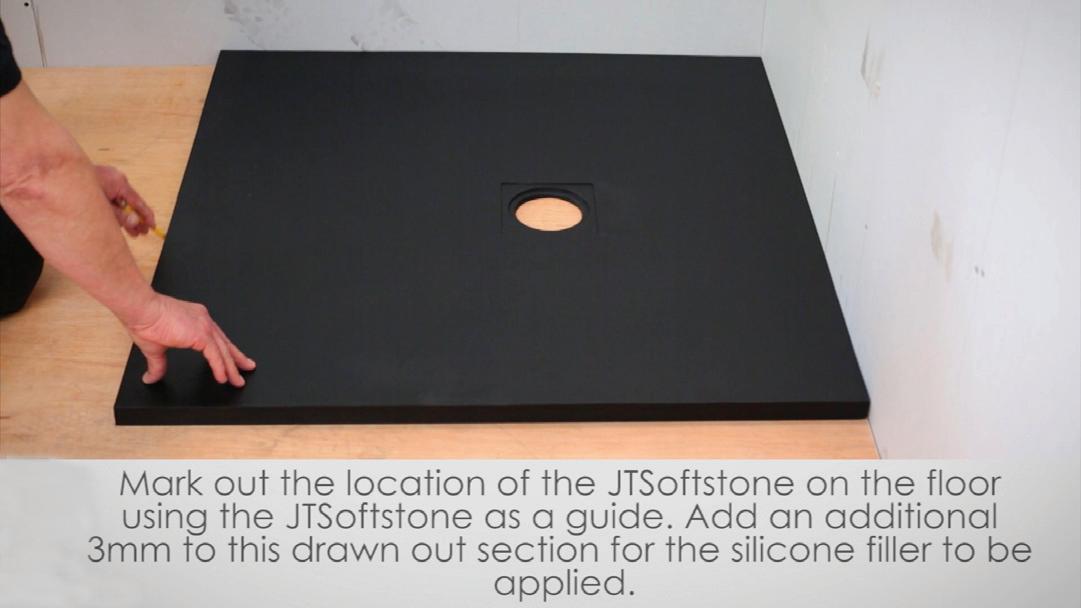

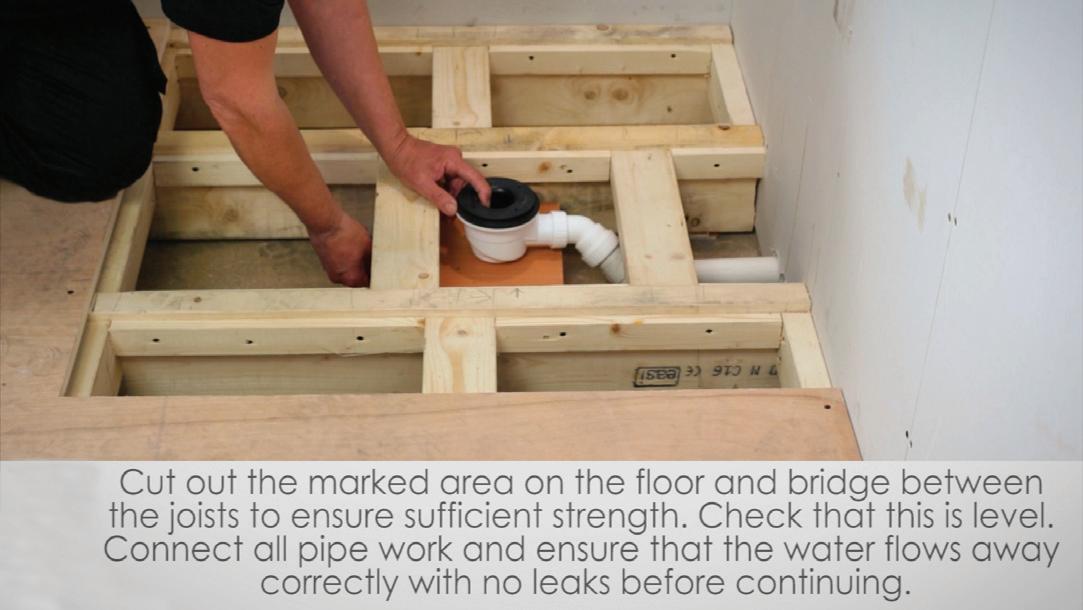

Lee Hudson, at Just Trays (JT) outlines the steps you need to take for a successful shower tray installation

The pre-use installation checks are crucial when it comes to shower trays. It cannot be underestimated just how important it is that all trays are correctly installed to ensure any problems or issues in the future are prevented. The installation process requires a sound understanding to guarantee sustainable,

long-lasting results for clients and this is a fundamental reason why we’ve continued to expand our shower trays offering at JT – people want a fit and forget solution.

“The first step that is required prior to starting the installation process is to perform a detailed and thorough assessment to ensure that it will not only be a successful installation of the shower

tray, but an efficient one. The shower tray enclosure dimensions must be compatible with the shower tray that you have picked out beforehand. It’s important to scan for any kind of transit damage, and to carry out a water test to see if there are potentially any outstanding problems before starting the installation process.

“The connections for the water supply will also be crucial. As such, it is essential to plan the necessary connections for this, alongside any additional features. You want the overall design to compliment the chosen shower tray and so – to make sure this happens – it has to be compatible with the plumbing fixtures. This will all contribute to making the installation as smooth and effortless as can be.

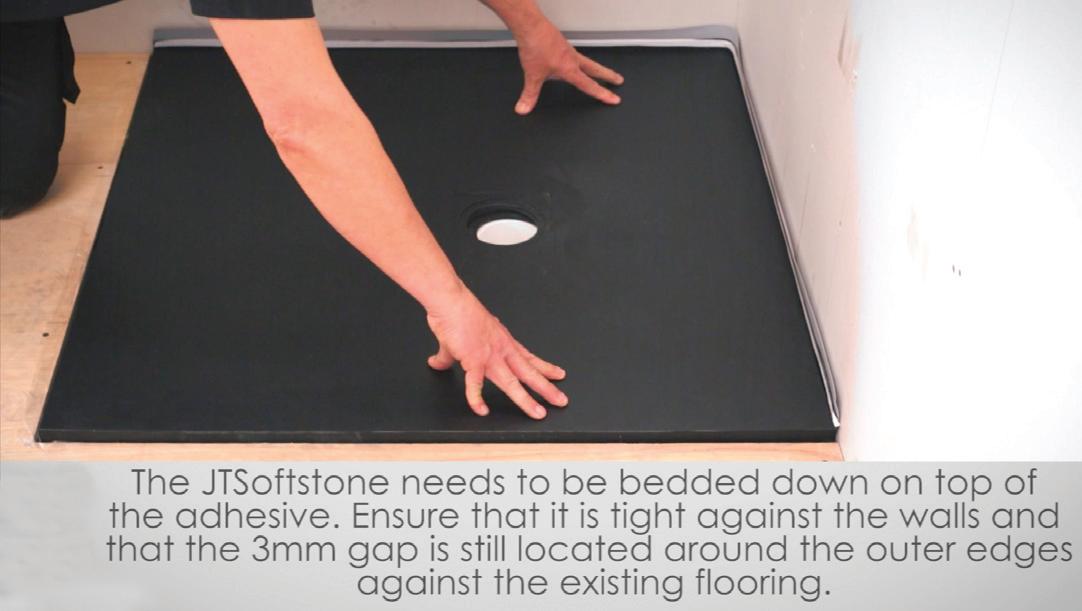

“Nobody wants to experience drainage problems or a potential water overflow, so to ensure that this doesn’t happen, the shower tray must be level across all areas to avoid any issues. A good quality silicone sealant is really important when it comes to finalising the installation of the shower tray. You must allow it to fully set for a full 24 hours to keep your client’s bathroom safe from leaks and in peak condition.

“Of course, at times there will be some shower areas that aren’t the most conveniently shaped. At JT, we pride ourselves on offering great variety when it comes to shower trays that provide customers with the confidence they need when it comes to installation in an awkward space. This is all with the aim of avoiding having to compromise on the design.

“A great example of this is our fantastic bespoke service for our Softstone by JT trays – our team are able to create the perfect showering CAD diagram service to bring every possibility to life and make it achievable for any kind of bathroom

“We are committed to guiding and helping our clients as much as possible, and so as part of this we have created a range of step-by-step video guides on the installation process which can be found on our website.”

space. This is done with all the necessary advice that is required to guarantee a successful installation.

“Evolving the way in which we work with and help our customers is always at the forefront of our mind here at JT. We are committed to guiding and helping our clients as much as possible, and so as part of this we have created a range of step-by-step video guides on the

installation process which can be found on our website.

“We stock a variety of sizes that range in colour and fit, to ensure they will be suitable for any client’s needs. Our antislip solution is also available across all the JT ranges, featuring anti-slip properties that are built into the acrylic skin of each tray, which is to the best-in-class standard at Class C. Anti-slip creates an enhanced

life cycle with added piece of mind for consumers, that certainly doesn’t compromise on delivering the same colourless high-level slip resistance.”

TO FIND OUT MORE ABOUT THE JUST TRAYS (JT) PRODUCT RANGE GO TO: WWW.RDR.LINK/BBF026

YOU CAN ALSO DOWNLOAD THE LATEST PRODUCT BROCHURE HERE: WWW.RDR.LINK/BBF027

IF YOU WOULD LIKE TO VIEW THE JUST TRAYS (JT) VIDEO INSTALLATION GUIDE LIBRARY VISIT WWW.RDR.LINK/BBF028

In the rapidly developing world of professional construction and installation, efficiency is crucial. The tools and products used can significantly impact the success of any project, and as many experienced installers and builders will attest, when it comes to product, ease of installation is equally as important as quality, durability, and the final aesthetic.

Installer-friendly products play an increasingly crucial role in both the current and future landscape. They streamline the installation process by being easy to handle, requiring minimal tools, and coming with clear to follow instructions. This reduces installation time, cuts labour costs, and allows installers to complete more projects, enhancing overall profitability. Thankfully, many installers are no longer having to accept complex and poorly designed products that can result in extended timelines or costly errors.

High-quality installations also lead to greater customer satisfaction and can enhance the reputation of both installers and manufacturers. In addition to these

benefits, such products also accommodate and facilitate universal learning opportunities for installers at all stages of their careers, especially important as we look to attract more young people into the trade industries.

In recent years, our bathrooms have evolved into integrated living spaces within homes and hospitality settings. This shift has increased the demand for concealed fittings, as customers and designers alike seek sleek, aesthetic finishes that maintain premium functionality. Manufactures can meet this demand by providing solutions that cater to modern design needs while ensuring ease of installation for professionals. Sustainable design is another emerging trend, with products that are easy to install and environmentally friendly gaining traction to meet the growing demand for green building practices.

We see it as our job as a manufacturer to respond to current challenges in the industry and thus support our professional partners in their daily work as effectively as possible by responding to demand and catering to their needs. For example, our concealed portfolio has been specifically designed and created to support with ease of installation, while also providing

retailers with a desirable product portfolio that caters to consumer demands and keeps up with trends.

For WCs, products such as the GROHE Rapid SL and SLX flush frame installation systems for wall-hung toilets exemplifies ease of installation with pre-assembled components and intuitive design, while offering a state-of-the-art plumbing solution with whisper-quiet functionality and sleek design, as well EcoJoy technology, which reduces water consumption by up to 50% without compromising on performance. This allows installers to complete jobs quickly and efficiently, reducing labour costs and minimising client disruption.

Our latest innovations also meet the demand for concealed products. The Rapido Shower Frame comes with preassembled components like mixed water pipes and concealed elements, allowing installation in just a few steps. Its 80mm installation depth fits almost any plasterboard wall, streamlining both the installation and planning processes. Such considerations enable quicker and more precise installations, seamlessly reducing the likelihood of mistakes, improving work quality, and minimising the need for costly rework.

Our commitment to installer-friendly product design not only seeks to improve working conditions for installers but also contributes to the overall success of construction projects. Embracing this approach leads to better outcomes for everyone involved, from manufacturers to installers to end-users. Meaning everyone is considered.

For manufactures to successfully cater to this growing category, a deeper understanding of the daily challenges installers face is needed to make a tangible impact. This involves collaboration between product designers and professional installers throughout the development process. Key principles include simplicity, ergonomics, and innovation. Digital tools offering real-time installation guides are becoming increasingly valuable, aiding in installation accuracy and efficiency.

Recognising the importance of installer-friendly products, GROHE designs its offerings to enhance efficiency, improve safety, and boost job

Professional portfolio addresses the need of today’s sanitary professionals by offering a bespoke product portfolio with the highest standards of quality, technology, sustainability, and design. A commitment to responding to industry challenges, and catering to professional needs, ensures that products

As the trend for wet wall laminated panels continues to grow, Stephen Murray, Sales Director at Perform Panel, explains why demand for the product has never been higher

While wet wall laminated panels are in no way a new product – we’ve been supplying them for over 35 years – there has been a significant uplift in interest in recent years.

For a long time, tiles were seen as the only option for bathroom walls, with wet wall panels used more commonly in commercial applications. These days, however, laminated panels have come into the spotlight as a stylish and cost-effective alternative to tiles, offering a number of hygiene and maintenance benefits, as well as versatility and ease of installation.

At Perform Panel, we’ve seen substantial growth in the last five years. While Scotland remains a firm focus, we’ve expanded into England over the past few years and, last year, we’ve moved into Europe for the first time. We’re partnering with a distributor to supply Perform Panel to the Netherlands and Belgium, with further opportunities being explored.

There are several reasons for this increase in demand. With recent challenges with tiles – such as material and skills shortages – panels have really

come into their own. Unlike tiles, wall panels are easy to install. Some plumbers will now only take on jobs where panels are specified, as it makes the job much more straight-forward and cost-effective, without reliance on the involvement of a skilled tiler.

Improvement in quality and range of the product have also supported growth. In the last 5 years alone, we’ve invested in our manufacturing plant as well as our product range, increasing from 16 decors to 74 decors, including a new range of 26 tile effect panels that we recently launched into the market. There really is something for everyone, with the result comparable to the finish of tiled walls, but

with all the additional benefits.

The interest in panels is not just for bathrooms – we’re seeing panels being specified for a wide range of applications. Panels are being used in kitchens as splashbacks and living rooms as feature walls. They’re also ideal for gyms, hospitals, shops, schools, airports... the list is endless. Basically, anywhere that needs a wall covering solution, perform panel can be the solution.

Along with ease of installation, wet wall laminate panels offer a multitude of builtin benefits. They are five times quicker to install than tiles and can even be fitted

straight on top of existing tiles, so no need for tricky removal. There is also no requirement for grouting – or grouting maintenance – which means no curing time and no messy clean-up. A full wall, using made to measure panels or standard sizes, can be fitted in just a few hours – and can be used straight away without needing to wait for drying time.

This speed of installation alone makes panels much more cost-effective, saving a huge amount of money on labour. However, the panels themselves are also much more economical to buy than tiles. There are also designs and finishes to match all tastes, with a range of textures, including stone, hi-gloss, and matt.

There are other laminated panel brands available on the market to suit a variety of requirements. One of Perform Panel’s additional benefits is a unique high-performance NuLock tongue-and-groove click system. This gives an accurate, seamless, practically invisible finish, which is a major improvement on the traditional straight joint profile. We also offer a range of wall panel trims to seal and finish edges and joints, and our own brand adhesive and silicone sealant, which has been developed specifically to ensure optimum performance with our panels and trims.

All our boards are manufactured using either a 5-ply plywood or 7-ply Birch plywood core, which we find to be the preferred option for installers, as it is stronger with a higher density. The boards are bonded to HPL (High-Pressure Laminate) to the front face and a backing HPL to reverse.

To complement our plywood core and our Nu-Lock “click” system, Perform Panel offers a market leading 35-year warranty.

While paper forms the basis of High-Pressure Laminates, the paper is impregnated with phenolic and melamine resins, dried and compressed to form a hard-wearing, stable coating. The laminate can be bonded to various substances and is resistant to most chemicals. The result is a hygienic, low maintenance product, with a luxurious finish.

Laminated panels are a revolutionary product, offering a perfect blend of aesthetics, durability, and convenience to meet a full range of budgets, needs, and tastes. With their easy installation, low maintenance, and exceptional resistance to moisture and stains, panels are a gamechanger for domestic and commercial environments – not just in bathrooms.

As we move into Europe, it’s exciting to see where the product will go next.

product round-up

Following the popularity of its Metalla 310 hinges, Häfele UK has launched a new colour option. The black nickel finish, Metalla 310 is suitable for standard 110° opening, wide-angle openings, post hinge, and 30 or 45-degree openings. It is also available in a soft-close or a non-soft-close variant.

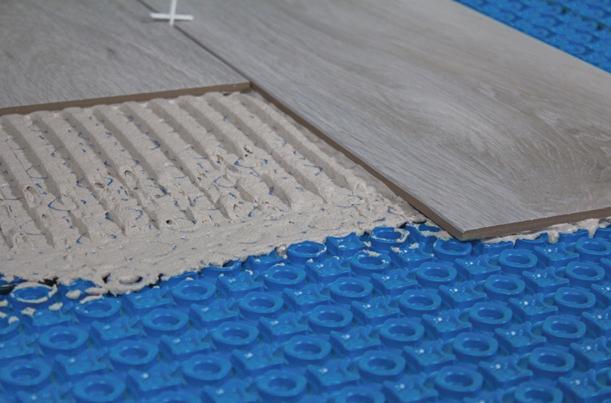

Whether it’s ceramic, porcelain or moisturestable stone and mosaic tiles, Mapei’s Keraquick Easy S1 rapid-setting flexible cementitious flooring adhesive will do the job. It can be used to install tiles onto most floor substrates, and underfloor or undertile heating systems.

The Lumi+ is a new series of electric showers from Aqualisa. Available in three power options (8.5kW, 9.5kW or 10.5kW), the unit has two easy-turn brushedchrome dials to control power and temperature, minimising consumption of both electricity and water. The shower is equipped with eight water and electric entry points, allowing straightforward installation.

GET MORE DETAILS AT: WWW.RDR.LINK/BBF032

The Zenith range of compact laminate kitchen worksurfaces from Bushboard replicates the texture of real stone and marble whilst also providing anti-bacterial protection. The waterproof and non-porous material allows for installation of undermount sinks to create curved edges and bespoke areas.

MORE DETAILS AT: WWW.RDR.LINK/BBF033

GET MORE DETAILS AT: WWW.RDR.LINK/BBF034

The selection of flooring options from Parador includes its eco-friendly flooring alternative, Modular ONE Hydron. What is described as a unique PVCand plasticiser-free plastic surface looks and feels like real wood but is 100% waterproof and, therefore, ideal for use in damp rooms, whilst also representing a sustainable choice.

Bathroom manufacturer, VitrA has added two new frame and concealed cistern models to its portfolio. The frames are supplied with a wall connection fixing kit and feature three water inlet options. The products include further features that aid installation, are all subject to performance testing and have a 10-year warranty.

Should you be building with 150mm cavities? Knauf Insulation explores the issue.

One of the most significant shifts in housebuilding is the increasing adoption of 150mm cavity width in masonry construction.

In a recent survey of housebuilders, conducted by this publication and Knauf Insulation, 41% of participants said they are already building with 150mm cavities, and just over a quarter are considering it. This might seem unnecessary, but the construction industry is changing rapidly due to increasingly tight regulations and a move towards more sustainable building practices.

This is fast becoming the new normal, which is why in this article we will explore how we got here and the benefits of building with 150mm cavities.

Closing the performance gap

‘Real performance’ isn’t just an aspiration anymore. It’s an important plank of the Future Homes Standard which, although still under consultation, has a clear

direction of travel. Closing the gap between designed and actual performance means being realistic about the unforced errors that can happen under real site conditions.

For example, rigid board insulation is often chosen due to its theoretically lower lambda values and installed in traditional 100mm cavities, with the expectation that it will achieve a low U-value. In reality rigid boards are challenging to install correctly. They first need to be cut to exact sizes and taped with precision to ensure a continuous insulation layer, but the real challenge comes from making them sit flush against the substrate, which is close to impossible if the surface has even minor imperfections.

One way to tackle this issue is to use insulation that’s easier to install correctly. Mineral wool insulation, for example, is flexible, allowing it to adapt to minor imperfections in the substrate and fully fill the cavity. The slabs also ‘knit’ together, further minimising gaps and maximising thermal performance. Using 150mm of mineral wool insulation allows housebuilders to meet energy efficiency requirements both on paper and in the real world.

“Stricter regulations and a greater awareness of thermal, fire safety, and environmental credentials, mean housebuilders have a lot of boxes to tick. Creating homes with 150mm cavities will help you meet the necessary requirements today and futureproof buildings for the tighter standards of tomorrow.”

Beyond thermal performance, current compliance and future regulations are pushing many builders towards 150mm cavities.

The impact of the 2017 Grenfell Tower tragedy on the industry and its regulations is hard to overstate. Many insurers, local authorities and customers now ask for non-combustible insulation as standard, regardless of the height or use of the building, going beyond even the updated guidance in Approved Document B (Fire Safety).

Environmental regulations are also going through a period of change. While Approved Document L addresses operational carbon reduction, by requiring lower U-values and increased thermal performance, it is likely that embodied carbon will be factored into future regulations. Embodied carbon is the total greenhouse gas emissions released over a product’s lifecycle, including raw material extraction, manufacturing, transportation, and the construction process. Some industry groups are supporting a proposed ‘Part Z’ Building Regulation which would require embodied carbon to be

assessed on all projects.

As standards continue to rise, building with narrow cavities will become a constraint. Switching to 150mm allows housebuilders to choose insulation that is non-combustible and has lower embodied carbon. Glass mineral wool, for example, has the lowest levels of embodied carbon of any mainstream insulation material and Knauf Insulation’s glass mineral wool has the best possible Euroclass A1 reaction to fire classification.

While the benefits to thermal performance, safety, and sustainability are clear, using 150mm cavities with mineral wool insulation also has economic benefits. Mineral wool is cost-efficient compared with many types of insulation, and its price doesn’t depend on the volatile petrochemical and oil markets, unlike materials such as PIR. As countries look to decarbonise, the supply of petrochemicals will likely be reduced, putting further pressure on the price and availability of many insulation products.

Mineral wool slabs or blown-in

insulation are also easier to install correctly than rigid boards and require no additional taping or fixings, minimising waste and saving on people-hours needed on a project.

Finally, building with wider cavities gives you flexibility to adapt your specification, without delay to your project, should your usual insulation choice become unavailable.

Stricter regulations and a greater awareness of thermal, fire safety, and environmental credentials, mean housebuilders have a lot of boxes to tick. We’ve also seen a clear movement in the industry towards regulating embodied carbon and non-combustible materials in all buildings. Creating homes with 150mm cavities will help you meet the necessary requirements today and futureproof buildings for the tighter standards of tomorrow.

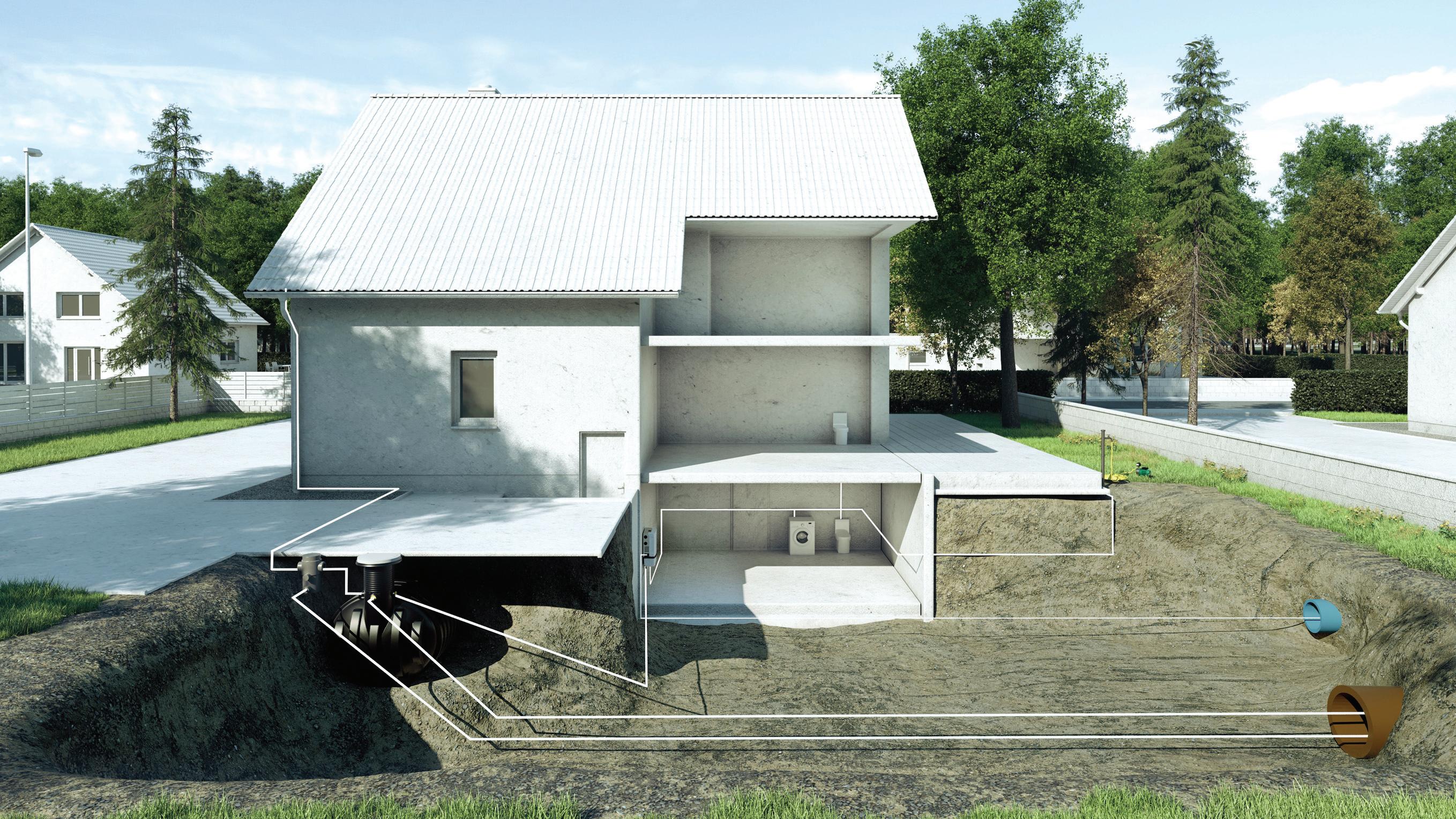

Climate change and the increase in urban flooding have put significant pressure on the UK’s ageing sewage infrastructure. The need for effective, innovative drainage solutions has never been greater.

Sustainable drainage systems have been designed to tackle these challenges. Unlike conventional drainage solutions that typically direct stormwater into sewers and watercourses, SuDS mimic natural processes to manage rainfall by storing water, allowing it to infiltrate into the ground, or slowly release it. This approach not only lessens the impact of urban development on the natural water cycle but reduces the strain on our sewer systems.

Yet, despite sustainable drainage systems (SuDS) being available for some time, the adoption of these systems has been slow. To increase uptake across the industry, we must understand the barriers preventing the adoption of SuDs, and the legislative changes set to make these systems a mandatory part of new residential projects.

There are many benefits to SuDS, the most significant being that they mitigate urban flooding by reducing the runoff entering sewer systems during heavy rainfall, which improves water quality by naturally filtering out pollutants. On top of this, SuDS can also enhance biodiversity and urban green spaces by being incorporated into the landscape through green roofs, rain gardens and permeable pavements, all of which contribute to the cooling of urban environments by counteracting the urban heat island effect.

Therefore, by integrating SuDS as standard, housebuilders will be able to align with broader environmental goals and legislative requirements while meeting the needs and expectations of future residents. However, despite their benefits, SuDS adoption in new developments faces several barriers. The UK’s fragmented regulatory landscape, with varying local standards, causes confusion and deters developers with complex approval processes. Ambiguous SuDS definitions and guidelines complicate project integration, making regulatory compliance and achieving environmental benefits difficult.

The lack of technical expertise in hydrology and site-specific conditions requires bespoke approaches, raising concerns about high upfront costs,

particularly for retrofitting sites. Historically, this has deterred developers despite potential long-term savings. If we are to overcome these obstacles, we need cohesive policies, clear guidance and more support for developers via technical resources, specialist support, training and even financial incentives. Promoting sustainable drainage practices and addressing climate change challenges requires cross-party collaboration.

SuDS adoption in the UK is heavily influenced by the legislative framework for water management and urban development, notably the Flood and Water Management Act 2010. This legislation promotes SuDS use by mandating sustainable surface water management in new and redeveloped sites.

Schedule 3 of the Act, yet to be fully implemented in England, mandates SuDS for all new residential developments over 100m. Its introduction in England, following Wales’ 2019 implementation, standardises SuDS use and integrates them into broader planning processes.

Developers must integrate SuDS considerations from the earliest planning stages to comply with these regulations. This involves navigating complex approval processes, adapting designs to sitespecific conditions, and maintaining SuDS long-term.

Effective SuDS implementation depends on understanding a site’s unique characteristics, such as environmental conditions, soil types, topography and hydrology. These factors determine how water behaves, impacting the suitability and effectiveness of various SuDS components. Customising SuDS solutions to fit the unique conditions of a site ensures that they will complement the natural water cycle. This approach not only maximises the performance of the

drainage system but also can lead to cost savings over time. By aligning the drainage strategy closely with the site’s natural characteristics, it’s possible to reduce the need for extensive engineered solutions, which can be more expensive to install and maintain.

A site-specific approach to SuDS encourages a more thoughtful and integrated planning process, requiring collaboration to create solutions that respect and enhance the natural environment. It’s clear that widespread SuDS adoption in the UK is crucial for mitigating flood risks, enhancing urban resilience, and promoting environmental sustainability.

This will only be possible through effective collaboration between the drainage sector, policymakers, housebuilders, and developers to promote SuDS and address misconceptions about costs, maintenance, and feasibility. Highlighting successful case studies, providing cost-benefit analyses, and offering technical support can build

industry confidence in SuDS benefits and implementation.

As climate change intensifies, the need for a sustainable, resilient future becomes increasingly critical. Prioritising SuDS in housing development projects invests in the future of communities, ensuring they can handle environmental challenges.

You might think that soil and the grass that grows through it are basic commodities but we’ve always pushed the boundaries of performance and innovation,” enthuses Terry Smithson, Head of Nature Based Solutions at BioScapes – part of the Rolawn Group.

SME housing developers who are struggling to navigate the complexities of Biodiversity Net Gain (BNG) and Sustainable Urban Drainage (SuDS) legislation need look no further than BioScapes

“At the same time we want to deliver easily adoptable and very practical solutions for our housebuilder clients.” It’s an attitude which positions the ecology and horticultural specialists as the perfect partner in a new and often unfamiliar legislative landscape.

Biodiversity Net Gain (BNG) as a concept has been a long time coming but that doesn’t mean that the confusion around compliance has abated, especially amongst smaller developers. In January of 2024, legislation was introduced to compel housebuilders who were constructing 10 or more units to make a 10 per cent improvement in BNG, with some local authorities asking for as much as 20 per cent. In April 2024, that requirement was extended to smaller new build schemes of one house and upwards. In effect, there are now very few exemptions.

So, how does that translate on the ground? Essentially, planning permission will be dependent on an assessment of the level of biodiversity on the land, both prior and post development. This can be achieved on the actual site of the new property, or it can be achieved off-site, whilst there’s a third option of purchasing statutory biodiversity credits.

For a smaller developer, who is invariably focused on a quality build rather than quantity, there are obvious benefits to the on-site approach, not least providing the homeowner with an aesthetically appealing installation through which they can enjoy the acknowledged well-being benefits that engaging with nature brings. Attractive and creative biodiversity installations will equally offer the added selling point of diversifying a property from the competition.

Sustainable Urban Drainage (SuDS)

It’s not just BNG that needs to be taken into account either, because developments with more than one dwelling must now demonstrate that they are implementing Sustainable Drainage Systems (SuDS). The rationale for their implementation –including climate change, more frequent extreme weather events, with consequent water run-off and flooding – is well known, but it again begs the question what does it mean in practice?

“As a starting point, the four SuDS pillars are water attenuation, as well as the cleaning of water run-off from impermeable surfaces,” continues Terry. “It also needs to include amenity benefits, and promote biodiversity, with that final point feeding directly back into the BNG legislation.

“Whilst volume housebuilders are prepared for the new BNG and SuDS regimes it’s fair to say that there’s a distinct lack of awareness amongst SME developers,” Terry adds. “Even if they are mindful of what’s required, there’s still a knowledge gap of what solutions they need and where to source them.” Indeed, there has already been criticism from the National Audit Office and the FMB (See PB’s News on Page 9) which has cited additional costs and a lack of preparedness on the part of some local authorities.

The message from BioScapes, however, is that it doesn’t have to be a complex or onerous process – and the company has the product range, and expertise, to prove it. “Our units are all-inone solutions that come together to address SuDS management and biodiversity requirements. They look good, promote wellbeing, can be comfortably introduced into relatively small spaces, and are easy to maintain.”

There’s a whole range of BioScapes products that will help housebuilders conform to BNG regulations and the same principles remain consistent throughout.

The most compact on offer is the WildPod Mini®, which brings together ten interconnected habitats in a 35 x 56 x 60cm wooden unit, with the addition of a unique rainwater catcher. Delivered in flat pack form, it’s easy to assemble and position, only requiring the addition of up

to 80litres of topsoil and compost, 10litres of clay for the reservoir habitat, and 6litres of deadwood habitat materials. Once in place, you can watch the wildlife colonise a protected ecosystem where species will interact as they would naturally.

At the other end of the scale, the patented BioCube® can be as large as 4m2, is made from recycled steel and plastic, with a modular assembly that again makes for an easy build. This solution has a much longer lifespan and flexibility in terms of what can be added. Habitats come together in a layered construction which will include a main

planting area, zones to attract bee and butterflies, wet habitats and much more. Between these two is the mid-sized NatureArk®, which is supplied with the habitat materials required, which means only plants need to be added.

“We want our BNG focused products to be plug and play,” continues Terry, “where it’s simply a matter of assembling the box and adding soil and plants. The same ethos is evident with our SuDS and BNG Unit, which is simply attached to the property’s downpipe and is sufficiently compact to be added to any individual home. Moreover, in addition to the products themselves, we can provide support and guidance to smaller developers in particular on exactly what they’ll need.”

“Aside from the regulatory requirements, there’s a real benefit here for the housebuilder,” concludes Terry. “Not only are you making a statement about your green credentials, you’re also welcoming them to their new home with outdoor features that will enhance the build quality.”

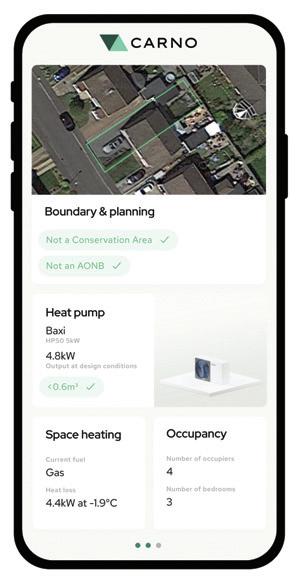

The Mixergy iHP X is an integrated heat pump cylinder that leverages Mixergy’s patented adaptive water heating technology. This product offers a cost-effective and convenient solution for housebuilders and developers aiming to meet the Future Homes Standard. It enhances the appeal of new homes, providing a smart hot water solution to buyers who are increasingly concerned about rising energy bills and their carbon footprint.

According to the manufacturer, it is three times more efficient and can save upwards of five tonnes of carbon per unit, compared to a conventional cylinder. It is also described as ‘best in class’ for energy performance because the plate heat exchanger inside the heat pump unit achieves exceptional heat transfer. Unlike traditional integrated heat pump cylinders that heat water from the bottom up, the iHP X heats from the top down, delivering usable hot water in under 30 minutes. This allows the unit to be up to a third smaller, making it easier to position and install in homes.

One of the significant advantages of the unit is its modular design. The heat pump and cylinder components can be separated to make the system lighter and easier to transport, install, and maintain. Each part is accessible, supporting the ‘right to repair’ ethos by allowing for individual servicing and replacement. This design extends the product’s lifecycle and

allow for substantial warranties – 25 years for the cylinder and five years for the heat pump unit.

Control and optimisation is simplified through the Mixergy app, which allows users to programme the unit to take advantage of smart electricity tariffs and to integrate with solar PV systems for using free electricity. The system’s flexibility and compatibility with various energy sources make it an ideal solution for sustainable living.

A practical example of the technology in action is the renovation undertaken by Laurence Haslop, managing director of

Cambridge housebuilder and developer Develory. Haslop has transformed a 1970s bungalow, which originally had oil central heating, into a modern, efficient home. He chose the Mixergy iHP X for its efficiency and ease of integration with other sustainable technologies, such as infrared electric heating, solar PV, and planned battery storage.

Haslop, who has a strong background of utilising innovative technologies, found the Mixergy cylinder efficient and easy to install. Even without prior experience of the product, the installation was straightforward: “We installed the integrated heat pump cylinder in a cupboard downstairs, but because it’s

modular, it could have easily been located upstairs. The installation only took a day –with more experience, I’m sure we could install it even quicker.”

Heating engineers only need their G3 Unvented certificate. As the refrigerant is pre-gassed and completely sealed within the heat pump module, F-gas certification is not required, opening up the skill base for who can install this product.

Haslop continues: “Develory is focused on providing the latest sustainable technologies that do not compromise the durability of a building. What differentiates us is innovation and how we can add technology to a home or commercial building while making it good value and robust. Every scenario is different and needs to be considered individually. There is never a one size fits all solution. We use the materials and the technologies available to us as a tool to build the best solutions for the clients’ needs.

“The performance aligns well with the needs of small flats and larger houses alike, especially those aiming for the most

sustainable solutions. The ability to heat water quickly and efficiently, combined with compatibility with smart tariffs and solar panels, makes it a really versatile choice. The householder can control how much water to heat based on their needs, optimising energy use and costs.”

Another important consideration was noise. The iHP X was installed in a cupboard that didn’t require soundproofing and has a standard single layered door. Haslop says: “It’s very quiet – which works for us!”.

The system’s ducting was designed to ensure optimal performance, with air in and air out ducts terminating on different sides of the building while ensuring the runs are

not unnecessarily long or complicated, to achieve the highest Coefficient of Performance (CoP) of up to 3.4.

“We have used technologies in this house that our company wants to test and learn from before installing in our clients’ developments. The Mixergy iHP X is a promising solution and we are happy that it will fit in various scenarios, depending on what we want to do with it, and I would recommend it to other housebuilders. I am excited to see how the product develops!” he concludes.

TO LEARN MORE ABOUT HOW MIXERGY TECHNOLOGY CAN IMPROVE THE ENERGY PERFORMANCE OF NEW BUILDS, VISIT WWW.RDR.LINK/BBF040

Andy

Thompson, National Sales Manager – Plumbing & Heating at Wilo UK,discusses the key advantages of rainwater harvesting systems in new build housing developments

It’s understandable to think that water shortages equal a lack of rainfall. Yet, with the UK having experienced the wettest 18 months on record, this can’t be further from the truth. With flooding on the rise, alongside a growing demand for water supply, this leaves a predicted deficit of almost five billion litres of water a day by 2050, more than a third of water currently put into public supply.

As a result, regional new build housing developers face the unenviable task of reducing reliance on potable water supply, all while incorporating services that help to differentiate them from competitors. Rainwater harvesting systems might just be the solution to both.

What are the key benefits to developers?

When it comes to new build developments, it’s becoming more common to see planning permission only given to those that have considered ways

of reducing stress upon local water supplies, storm surges and overflows. Rainwater harvesting systems do just that, preventing flooding downstream while capturing rainwater for reuse in toilet flushing, washing machines and garden irrigation, for instance.

Hose pipe bans are already in place during hot and dry periods, with people prohibited from using them to wash their cars and water their gardens. Enter rainwater harvesting systems to help keep plants looking at their finest for as long as possible. An average house can capture around 70,000 litres of rainwater per year, depending on its geographical location, so why not use softer water, that is ideal for plant growth and nutrient absorption, to keep the hydrangeas alive?

Rainwater harvesting systems also create the potential for new builds to make significant savings for eventual tenants, especially the growing number that are being fitted with water meters. With the average person using around

150 litres of water per day, rainwater can be collected to reduce the proportion that is supplied by the mains to flush toilets, wash clothes, watering the garden – the list is goes on. What’s more, ‘soft’ rainwater helps to reduce limescale, meaning that fewer cleaning products and less detergent is required, presenting the chance for further savings.

The National Building Regulations and Water Supply Regulations 1999 state that rainwater harvesting systems must use an airgap to stop backflow and avoid the risk of contaminating the water supply. Most European systems, however, do not feature an airgap and are therefore not approved for UK use. Developers are encouraged to check that their chosen system is approved prior to the point of purchase.

Another key consideration is the size of the accompanying storage tank. Be it underground or above ground, a general rule of thumb is that tanks should be able to hold a maximum of 18 days’ worth of water. Storage tends to range from 3,000 to 9,000 litres for a domestic property, so developers should consider what the rainwater harvesting system in question will be used for and, as a result, how much water storage is actually needed. Storage tanks should contain a leaf and debris filter, or a filter installed upstream of the tank in a position with easy access for periodic cleaning. It’s generally accepted that filters must be cleaned at least once a month to avoid overflow or a build-up of moss and other debris.

Part G of the Building Regulations 2010 also stipulates a maximum allowance of 125 litres of wholesome water per person per day in dwellings, despite the average usage still sitting at 150 litres. To add more of a challenge, a potential condition of planning permission in new builds that can be implemented is that water consumption should not exceed 110 litres per person per day, meaning that around 25% of water must be sourced from elsewhere; this stipulation can be made where water supply could be under stress in the local area. When deciding between rainwater harvesting systems for new build properties, developers should

“With the average person using around 150 litres of water per day, rainwater can be collected to reduce the proportion that is supplied by the mains to flush toilets, wash clothes, watering the garden – the list is goes on.”

consider a storage tank sizeable enough to help account for this.

While rainfall patterns are used to calculate the yield from a roof area, most areas within the UK will provide sufficient rainfall to effectively utilise a system. Consideration, however, must be given to the collection surface, as this will determine the level of water that can be accumulated, alongside intended uses for the rainwater, number of occupants within the property and the material of the building’s roof.

The latest systems make rainwater reuse a simple task. The Wilo-RAIN1, for instance, offers easy installation thanks to its ready-to-plug system and compact design with various hydraulic connection options. Ease of use goes the extra mile with a unique combination of an intuitive LCD touch screen and a variety of control functions that help to facilitate a convenient operation.

The appliance’s reliability and quiet operation are both features that will undoubtedly be welcomed by residents. Hygiene safety is also guaranteed thanks to a non-return valve, air-gap, and a

break tank, all of which fall in accordance with relevant regulations (DIN 1989 and EN 1717).

Are rainwater harvesting systems soon to become a necessity?

New build developers have a crucial role to play when it comes to increasing both the awareness and uptake of rainwater harvesting systems. With water companies planning to increase household bills to pay for structure upgrades, alongside the prediction that several regions in England will run out of water by 2030, it’s imperative that any method of saving water is explored and acted on.

Within the coming years rainwater harvesting systems are going to become a necessity rather than option, and Wilo is on hand to guide developers throughout the process of specifying a solution for new build housing.

A new range of concrete facing bricks manufactured using carbon sequestration technology to lock in waste CO2 has been unveiled by Marshalls. The Glenwall bricks are aesthetically appealing, environmentally beneficial and resistant to weathering, maintaining their structural integrity and visual appeal over time.

It’s the built-in monitoring device that makes the Domus Ventilation

Decentralised Mechanical Extract Ventilation fan, dMEV-NICO an automatic solution. Providing continuous background extract ventilation for new builds, it is virtually silent in operation, is suitable for wall, ceiling and window mounting and has a modern, unobtrusive aesthetic.

The latest Scandia-Hus show home is being fitted with Actis H Control Hybrid, 105mm Hybris and insulating breather membrane Boost R Hybrid in the walls, achieving a U-value of 0.14W/m2K. It is also using H Control Hybrid in the flat roof. The garage will be used to house a display giving key information to highlight the energy efficiency of the buildings.

Tested to meet BS EN

1364-1:2015, Rockwool’s 50mm Fire Barrier EN is available with a black foil facing on one or both sides, for single- and double-layer systems respectively. Common applications include below concrete soffits, timber joists, steel, copper and plastic pipes, as well as timber beams and cable trays.