AND YOU CAN TOO, AS WE CATCH UP WITH SOME OF THE CONSTRUCTION INDUSTRY’S MOST INTERESTING AND KNOWLEDGEABLE CHARACTERS ON THE NEW GROUND BREAKING PROFESSIONAL BUILDER PODCAST WITH SMITH AND JONES.

LEARN A NEW BUSINESS SKILL OR FINE TUNE AN OLD ONE FROM THE GUYS AND GIRLS AT THE SHARP END, WHO HAVE BEEN THERE, DONE IT AND GOT THE PB T SHIRT TO BOOT!

EDITOR

LEE JONES

EMAIL: ljones@hamerville.co.uk

EDITORIAL ASSISTANT

EDWARD KELLY

EMAIL: ekelly@hamerville.co.uk

GROUP ADVERTISEMENT MANAGER

CRAIG JOWSEY

TEL: 07900 248102

EMAIL: craig@hamerville.co.uk

NORTHERN ADVERTISEMENT MANAGER

IAN DUFF

MOBILE: 07810 353525

EMAIL: probuilder@sky.com

GRAPHIC DESIGNER

DONNA BOOTH

GROUP PRODUCTION MANAGER

CAROL PADGETT

DIGITAL MANAGER

JASMINE SMITH

EMAIL: jsmith@hamerville.co.uk

DIGITAL ASSISTANT

LYDIA MCFARLANE

EMAIL: lmcfarlane@hamerville.co.uk

DISTRIBUTION MANAGER

KARL CLARK

PRINTED BY PCP TELFORD

PUBLISHED BY

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Fax: (01923) 246901

Email: pb@hamerville.co.uk

The barriers to more small building firms delivering new homes have long been identified. Our antiquated planning system is over stretched and under-resourced. Applications take far too long and – for time-poor tradespeople with property development aspirations in particular – the process is difficult to navigate. A lack of certainty over the outcome is hardly likely to encourage firms to embark upon what all too often proves to be an epic planning journey. At the same time, SME builders still struggle to access finance on adequate terms, whilst the smaller parcels of land they need are often difficult to find.

The benefits of unleashing the potential of SMEs onto the new build market are, however, equally accepted. Small builders tend to construct on the basis of quality rather than quantity, providing bespoke homes, or the more compact developments that individual clients and local communities actually want. By contrast, the over reliance on a small group of large housebuilding companies has done little for either standards or consumer choice.

In addition, given that smaller plots are their stock in trade, SMEs are ideally placed to regenerate brownfield sites in our towns and cities – an ambition which has been the avowed policy of every politician who approaches the subject of housing from time immemorial.

sidestep as much of it as possible, and the extension of Permitted Development Rights (PDRs) for shops, and other commercial units, is designed to help them do just that. Similarly, projects that repurpose barns, agricultural buildings and warehouses will see a relaxing of red tape.

The government is committed to building one million homes over this parliament, and if we are to meet that albeit unlikely target then SME builders will be required to contribute to a much greater degree. According to the Federation of Master Builders – a trade association which has done much to campaign on the subject – in the 1980s SMEs were delivering 40% of our new homes. Forty years on, that figure is just 12%. PDRs will only go so far in turning the tide which is why a £24m Planning Skills Delivery Fund has been allocated. It is hoped that the money will help local authority departments speed up applications.

Professional Builder is a business magazine for firms and individuals involved in all aspects of the building industry. It is available nationally –free to the trade through leading builders’ merchant outlets. © 2023

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Subscriptions to Professional Builder are available at the following rates:

UK: 1 year (11 issues) –£30.00 post paid Europe & Overseas: 1 year (11 issues) –

£50.00 post paid

Airmail: 1 year (11 issues) –

£65.00 post paid

So just how do we help SMEs deliver on much needed new homes? Proposals to unblock the planning system have come along with the frequency of new Prime Ministers over the last few years, with Housing and Levelling Up Secretary, Michael Gove, the latest to throw a hard hat into the mix with what is described as a renewed government focus on the issue.

On the face of it, many of the policy objectives from the corridors of Whitehall are in perfect step with the muddy boots of SME builders on the ground. Contractors have already learnt from bitter experience that the best way to engage with the current planning regime is to

There are a number of other ways that our legislators can loosen the constraints that currently stifle housing delivering. Whilst the green belt needs to be protected, there are areas of this untouched land that are far from pastural idylls. Some of these may well be already close to local amenities, services and transport links and would be ideal for development. Allowing SME builders access to these sites, with the consent of local communities, would deliver properties in the best possible locations. Moreover, making self and custom builds a more accessible and affordable option can boost numbers, and promises housing that conforms to higher environmental standards.

That we are in the grip of an acute housing shortage is well-documented, with the prospect of home ownership receding more and more into the distance for far too many. One of our nation’s most valuable economic resources – the army of local, jobbing builders who are already improving our existing housing stock – have to be part of the solution, but they will need help with the tools to get the job done.

“Small builders tend to construct on the basis of quality rather than quantity”

The building industry responds to Michael Gove’s housing speech and ten-point plan

Michael Gove, Secretary of State for DLUHC made a speech on July 24th, outlining the Government’s 10-point plan for housing. Some of the main points of the speech included regenerating important towns and cities by building more densely, supercharging Cambridge and green belt protection.

Reaction from industry organisations have been mixed so far. Brian Berry, Chief Executive of the FMB welcomed a plan for more housing but stressed that “too many SME house builders are stuck in planning purgatory.” He added that “the Government’s focus on urban areas needs to be balanced with the need to address housing shortages in our rural communities.”

Richard Beresford, Chief Executive of the NFB, also welcomed back positive housing

Suffolk man set to go home three years after suffering brain aneurysm thanks to Band of Builders

policy but equally thought the plan “felt like another tweak which didn’t address the core reasons we have a housing crisis.”

The report shows that the Lighthouse Construction Industry Charity delivered an unprecedented £3,322,739 of charitable services last year and created a Social

Value of £9.12 for every £1 of charitable spend.

The charity also helped more people than ever before last year, with 3,421 families

The construction charity has finished a ground-floor bedroom and wet room for the family home of 21-year-old Luke Goold-Hannatt, who was a trainee bricklayer at the time of the aneurysm. More than 70 tradespeople from across the UK answered the call to build the extension which also included a bedroom for a specialist live-in carer.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV003

Derby builder to take on role of Project Manager in iconic TV series, DIY SOS

Ian Hodgkinson, founder and managing director of Hodgkinson Builders (the focus of BBC Three’s Brickies), will be the new Project Manager on DIY SOS: The Big Build.

The first episode of the new series will see a dilapidated building transformed into a performing arts school for 500 children and young adults, many of whom have additional learning needs.

You can read all about Ian Hodgkinson and the Brickies BBC Three series on the Professional Builder website by visiting WWW.RDR.LINK/BAV004

JCB has launched the biggest-ever fundraising drive for the NSPCC in its history – with a target of £2 million.

The appeal will culminate in 2025 when JCB celebrates its 80th anniversary – and 40 years of support for the UK’s leading children’s charity. The fundraising is set to take a number of forms with fun runs, football tournaments and much more.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV006

The shortlist for the annual Brick Development Association (BDA) Brick Awards has been unveiled.

A number of stunning projects have been nominated in a range of highly competitive categories and the winners will be announced at a glittering ceremony at the Royal Lancaster Hotel in Lancaster Gate, London on Wednesday November 8. The ceremony will be hosted by popular TV personality and architect George Clarke.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV007

BSIF launches checklist to take the risk

With an increasing volume of substandard products on the market, the British Safety Industry Federation (BSIF) has issued a handy checklist to help specifiers and users check whether PPE is fit for purpose.

BSIF analysis carried out last year showed that just 15% of 127 non-BSIF member products tested were fully compliant with relevant standards.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV008

The Industry Impact Fund, launched alongside CITB’s Business Plan for 2023-24 earlier this year, invites CITB-registered employers to apply for funding for their training and skills solutions for the biggest skills challenges in the industry. Employer’s ideas must be new and innovative, not previously supported by CITB, as well as scalable.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV009

With rapid and continued growth expected in the UK heat pump market up to 2028 and beyond, Eurovent Certita Certification (ECC), has published a new white paper. Detailing the difficulties and opportunities facing the UK heating market as it moves away from fossil fuel boilers, the white paper highlights the importance of installing highly energy efficient heat pumps.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV010

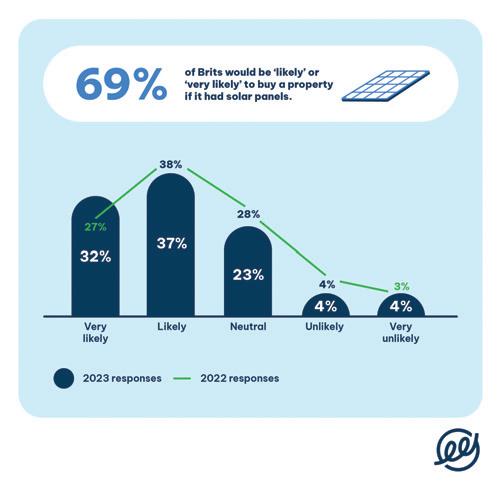

New data from theecoexperts.co.uk has revealed that 69% of the UK would purchase a home with solar panels

This figure is up from 65% the previous year, signifying the rising popularity of domestic solar panels.

The ongoing energy crisis over the last 12 months has led to a shortened break-even point for solar panels, now on average taking just 12.9 years to pay for themselves, and greater electricity bills savings with an average of £608 a year.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV011

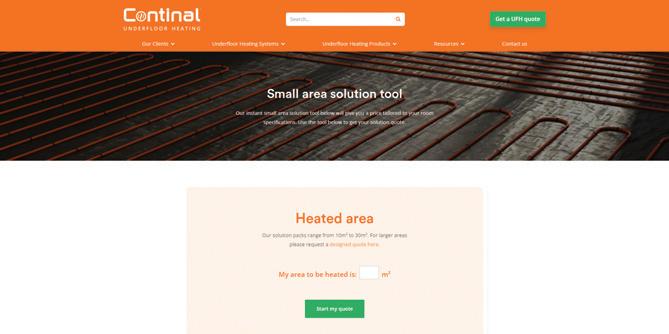

48% of heating installers are not aware of updates to Part L

This figure comes from research from Polypipe Building Products. The survey of 150 heating installers also revealed that 27% don’t understand the Building Regulations at all and 30% of installers feel that while they have tried to gain an understanding of the updates, the regulations are not clear.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV012

The latest workforce census from the Homebuilder Federation revealed just one in four students gained employment after completing a full-time construction course. The trade body said this showed the UK education system was failing to deliver ‘practical and employable’ skills and warned this could lead to a housebuilding slump.

Brokers Hank Zarihs Associates reported on this and said development finance lenders had noticed that challenges in hiring the right staff often contributed to projects finishing behind schedule.

FOR MORE DETAILS VISIT:

Keystone Group will be the main sponsor of the competition this year. Owen Coyle, Divisional CEO, Keystone Group said: “SkillBuild provides an excellent platform to showcase new construction talent, as well as acting as a catalyst to inspire others to take up tools and join the industry.”

This comes at the same time as the launch of Keyskills, the Keystone Group’s education initiative providing support to skillup a new generation of bricklayers in the UK and Ireland.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV014

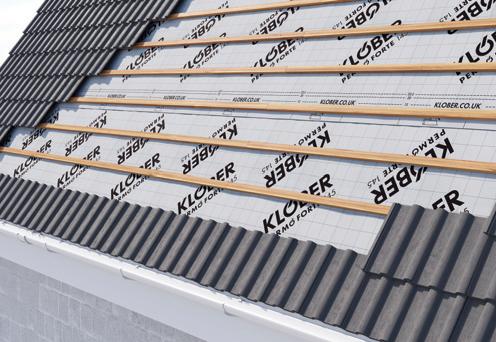

Klober is urging specifiers to consider futureproofing against changing weather. As climate change doesn’t just influence temperature and can cause more intense wind events too, the company is highlighting the growing importance of multi-layer roof membranes that can better withstand movements and shifts during high winds and stop tiles from dislodging.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BAV015

This month will see the return of the FMB Master Builder Awards and amongst the hopefuls will be Brighton and Hove-based Build My Home. The Sussex firm entered the race for the national prize having triumphed in the House Builder category at the FMB’s Southern Counties Master Builder Awards. Already no stranger to winning industry accolades, Build My Home previously garnered the prestigious Heavenly Builder prize at the trade association’s 2019 event.

Company Director, Michael Ford and Senior Site Manager, Dennis Kroese are equally well versed in completing premium projects and we caught up with the pair at what, on completion, will be a palatial six-bedroom property with commanding views across the South Downs and the sea.

Experienced carpenter and project manager, Michael Ford set up Build My Home back in 2013 with the help of his father, and fellow Director, John. “Our target market is high-end residential and that can be new build or renovation”, explains the 41-year-old. “One-off bespoke properties are a good size for us, and we typically have three or four projects on the go at any one time, most of which is sourced through architects we’ve worked with regularly over many years and who value our attention to detail.”

The plot on which the winning build would ultimately occupy started life as an unprepossessing row of eight garages,

contractor that’s delivering dream homes for its clients.

situated behind a Georgian townhouse in Brighton City Centre. There was planning permission for a single-storey dwelling on the same footprint, but the client bought the property with the intention of excavating underground and adding a second level. What was a major exercise in digging was complicated by two protected elm trees flanking the site, and a wall of historic interest to the rear –which had to be underpinned.

The Build My Home team made use of a self-healing Sika membrane for the exterior of the basement with 300mm of reinforced and waterproof concrete that would then accommodate three bedrooms, three bathrooms and a central

staircase to the floor above. The property’s energy needs are primarily serviced by an air source heat pump.

Above the basement sits a block and beam floor, whilst floor to ceiling windows and glass partitions add a contemporary feel. The maintenance-free longevity of Millboard Composite Cladding provides a timber effect, complemented by a living roof that blends with the surrounding gardens.

“We started in April of 2021 and had to contend with Covid issues throughout the build schedule,” Michael recalls. “Huge fluctuations in materials prices and an unpredictable supply of labour were definitely challenging. We had to wait an

age for the glass, for example, whilst timber and plaster were problematic. The city centre location meant that all of the surrounding homes were occupied by people working from home, so we had to make sure we were respectful and considerate to the local community, whilst at the same time operating a 20-tonne digger for the excavation.”

“Being a carpenter by trade I try to build in timber frame where we can because the speed and sustainability credentials can’t be beaten,” continues Michael. “The award-winning project in Brighton and our current job both make use of that building method.” The latter, South Downs build is also a testament to the skill and experience of the Build My

palm room at the rear. The substantialimprovement works have also had to be undertaken whilst protecting expensive parquet floor finishes and decorative features that the homeowner had installed during the pandemic: “Our clients will invariably command substantial budgets and they demand high-quality. This house

will include features such as a suspended log burner in the main bedroom, for instance, and decorative cork cladding on the exterior, so you can often be dealing with materials that are new to you.”

We asked Michael what FMB membership means for him and his company? “We’ve been members since we started trading as Build My Home and I do value the professionalism that comes with being associated with a leading industry body. My dad [John Ford] is on the board for the southern region and, whether it’s in that context, or at the award ceremonies, meeting other builders does make you feel part of a community, because we’re all faced with the same issues. It feels like someone’s got your back and is representing your interests. We’re fully in favour of the campaigns they run on encouraging more SME housebuilding, for example, as well as on training and mental health.”

“The Master Builder Awards are also a great opportunity to recognise the quality work that’s out there, and it’s a great story for us to tell on social media and through our website.”

Tradespeople rely

their

to be able to do their jobs. Having these tools stolen can have a devastating impact professionally, financially and even mentally.

In the current climate, where the cost of living is soaring and world events such as the conflict in Ukraine have put strain on supply chains, the demand for stolen goods has rocketed. In research conducted by NFU Mutual, almost 9 in 10 tradespeople and contractors have been victims of theft.

If you must leave tools in your vehicle, store them in a robust, lockable toolbox or van vault that is fixed in place

Pay close attention to where you park, ensuring it’s a safe, well-lit area, ideally somewhere busy or with CCTV

Where possible, park with the doors close against a wall, garage or fence to limit access

Install slam locks or deadlocks on all doors

Consider a bulkhead or grille to create a barrier between the cab and load area

Always double check the vehicle is locked before leaving, as some criminals use jamming devices to gain access

Prevention is always better than a claim, but sometimes the worst is unavoidable. Always ensure you’re protected with appropriate insurance, and that you understand what is and isn’t covered with your policy.

NFU Mutual provides cover for a

To combat this, the new Equipment Theft (Prevention) Bill has passed through the House of Commons and is expected to be signed into law later this summer. This bill aims to ensure high value tools and machinery are marked, registered and traceable if stolen, making it harder for thieves to sell stolen tools, and

Mark, register and record your tools

Take photos of all your tools, serial numbers, and proof of purchase so that you have a comprehensive record of your equipment

Register your tools online with a free database service

To make your equipment less desirable to thieves, clearly mark all tools with something unique, such as your name and postcode

details can’t be removed and to assist

helping to re-unite them with their owners.

But it’s still important to implement precautionary measures, and tradespeople are being urged to step up their security to both protect their livelihoods and help deter criminals from stealing goods in the first place.

Whether your equipment is kept inside a van or a building, don’t leave tools on display

Don’t stockpile high value items such as lead and copper, or leave them lying around for longer than necessary

Secure any free-standing equipment to a fixed point, even within a building

Restrict and control vehicular access to the work site

Double check all locks and security measures before leaving any site

When working offsite, ensure you plan ahead, thinking about your destination, route, and any extra security measures you need to take

Always remain vigilant of your surroundings

variety of trade businesses –from builders and plumbers, to carpenters and electricians. It’s also flexible so you can choose optional covers to meet your needs now and in the future.

building, but that should not be contentious – the change of use is the important one, and with PDRs, the council’s hands are effectively tied.

Anyone can develop property by buying a property or some land and then hiring various professionals to get to work. But it can be a risky business, even if you have years of experience in the building sector. So, if you are thinking of turning developer, here are a few thoughts on the five biggest risks.

Our current planning infrastructure originated in the 1950s, and today we are faced with local planning authorities that are under-resourced, over-stretched and demotivated. Planning applications that supposedly should be assessed within eight weeks (thirteen weeks for larger projects), nearly always take much longer.

The smart move is to avoid as much of the planning system as possible, and the

Government has given us a tool for the job called Permitted Development Rights (PDRs). These rights allow us to change a wide variety of commercial buildings into residential use without having to apply for full planning permission. In most cases, we’ll still need council approval. However, with PDR’s there is a short and prescriptive list of things they can object to.

The council must determine the application within eight weeks –otherwise it is automatically approved. You will still need full planning permission if you are changing the elevations of the

There are a lot of variables that determine whether a deal works financially, and you need to make a lot of assumptions, especially at the outset. If you dial every cost assumption to the minimum, your numbers will project a hefty profit. Dial costs to the maximum, and you will show a loss. The trick, then, is to be as pragmatic as possible.

A good tip is when you are putting together your spread sheets, ensure you can’t see your overall profit percentage figure when you input your assumptions. If you can, then as you see your profit percentage figure reduce, there is a high risk that your subconscious will make your assumptions less prudent – it’s human nature. The solution is to input every assumption reasonably and only enter your target sale values (GDVs) afterwards. That way, you’ll only see your profit percentage AFTER inputting your cost assumptions.

An important piece of de-risking advice is

always to target a 20% profit margin based on GDV (gross development value, i.e., your selling prices). So, if your units are expected to sell for a total of £500k, you want to target a £100k profit at the outset. You should also include a contingency budget of 10-15% of the construction costs. You won’t be able to predict the additional costs that will crop up as your project progresses, so you need to build in enough fat to ride out a few storms. And there will be bumps in the road; the trick is to ensure you are still left with a decent profit once you have crossed the finish line.

Also, don’t be tempted to target a fixed profit figure rather than a percentage. For example, you might think that targeting a £200k profit sounds pretty good. But if the GDV were £5million, you’d only make a 4% profit margin. It doesn’t take too many unexpected costs to wipe out 4%, so

Risk can also crop up while your team is on-site. The most common problem occurs when developers fail to specify precisely what they want. A developer may have specified ‘a dozen internal

blamed for installing cheaper doors, and while the doors can be changed, that involves extra expense. The lesson? If you don’t indicate what you want exactly, your contractor will likely install the cheapest available, so be very specific.

Always have more than one exit for your project at the outset. You may want to sell your finished units, but what if the market has tanked when you come to sell? The logical thing to do could be to refinance the project onto a buy-to-let mortgage and then let the units out until the market rebounds. On the other hand, if you were planning to rent out the units but the rental market bombed, then your plan b could be to sell. Either way, ensure you have worked out a plan b at the start and that you know the numbers involved.

The average time to settle a civil claim through the small claims system stands at 360.5 days, but alternative dispute resolution (ADR) offers potentially huge cost and time-saving benefits as a resolution can often be turned around in days, not weeks.

Alternative dispute resolution (ADR) applies to a range of methods that settle disputes between a builder and a customer which they can’t settle at the complaint stage.

So-called ‘softer’ methods of ADR include mediation and conciliation, where a professional and impartial mediator facilitates a conversation between the builder and customer, with both methods not usually legally binding.

There is also adjudication, which can involve an ombudsman, but the outcome is usually only binding on the business. There is also arbitration, where a dispute is referred to an independent arbitrator to produce a ruling based on evidence from both parties.

ADR also offers a more formal process called expert determination, where a complaint is reviewed by an industry expert to provide a legally-binding ruling. As an industry expert reviews the case, expert determination is often a quicker process than arbitration.

The expert is well-acquainted with the nature of the dispute and won’t have to spend time providing both parties with notes on the reasoning behind their decision. Expert determination helps both parties reach a fair resolution, and such services can pre-emptively be included in service contracts so home improvement professionals and their customers are safe in the knowledge that if a dispute emerges, it can be addressed effectively.

The ADR process is a lot quicker and more efficient than the court process. For

Settling customer disputes in court are a thing of the past with ADR, reveals Tracy Dilworth, senior dispute resolution officer at Dispute Assist

example, trained and impartial dispute resolution officers at Dispute Assist, an ADR provider under the Chartered Trading Standards Institute, boast an average and industry-leading resolution time of just 5.2 days.

The entire process has a maximum resolution period of 90 days – much less than the average of 51.2 weeks for a civil claim to proceed through the UK small claims system in the courts – although extensions can be agreed if required and agreed by both parties.

While the cost of legal advice and court appearances can spiral and add financial pressure on a building business, using ADR avoids this altogether for both parties in dispute.

The use of ADR – and in particular expert determination as a swift and effective way to settle a dispute – can increase trust in builders who promote that they use it, because potential customers know that any future dispute will be handled professionally.

By using ADR, parties can choose to keep all relevant information confidential, unlike details being disclosed in a

courtroom, to allow a business to maintain its brand reputation and minimise any impact on future sales.

And further peace of mind is obtained, as businesses who use an ADR provider are compliant with the Consumer Rights Act of 2015. Under this Act, businesses selling to consumers are legally required to point customers to an ADR provider if a dispute can’t be handled in-house.

While the courts once seemed like the only option available to builders in dispute with customers, an array of ADR methods now await them. There are varying levels of ADR to suit every dispute, so builders can carry on with their work assured that any issue will be handled quickly and smoothly, and for a reasonable fee.

We give our verdict on new products in our unique site tests, but now we want to give you the chance to try them – AND KEEP THEM – for yourself! All you have to do to enter the free draws is simply just type in www.rdr.link followed by the unique code.

10

SAMAC

PERFORMANCE DECKING SCREWS

Samac Fixing’s professional grade

Performance Decking Screws feature self-countersinking ribs, ensuring a flush, professional finish. The screws also benefit from a reduced head size, specifically designed to fit in the narrow space between decking boards. Coupled with a locking thread at the top, they reduce movement of the decking boards, maintaining the overall longevity. It’s all hands on deck with Samac!We have 10 high performance screw tubs to give away.

FOR YOUR CHANCE TO WIN VISIT: WWW.RDR.LINK/BAV021

10

THOMPSON’S ONE COAT WATER SEAL

Thompson’s is giving 10 lucky winners a tin of One Coat Water Seal, as well as some Thompson’s goodies. The product uses a micro silicone emulsion to stop water penetration and freeze-thaw damage. Recommended for use on buildings and other structures, like low garden walls – and especially on surfaces exposed to hard driving rain – it provides long lasting waterproof protection within hours. It’s a performing seal on site and we have 10 to give away. Simply use the rdr.link to go to the entry details.

FOR YOUR CHANCE TO WIN VISIT: WWW.RDR.LINK/BAV022

SHOWER TRITON AMORE DUELEC ELECTRIC SHOWER

The Amore DuElec

9.5kW electric shower is Triton Showers’ latest answer to consumer demand for spa-style bathrooms. Adding the manufacturer’s DuElec diverter accessory kit offers users the choice to divert water between a fixed overhanging rainfall shower head and a five-spray handheld option. It has an Energy Efficient A Rating and is available in gloss black, white and chrome finishes. The forecast is most definitely for showers! One of these Triton units must be won.

FOR YOUR CHANCE TO WIN VISIT: WWW.RDR.LINK/BAV023

BUILD AVIATOR ESTIMATES

Get a free estimating report from Build Aviator. With product summaries, a bill of quantities, a schedule of works, and pricing sheets, all prepared by an experienced estimator with live material prices, not only does it you give you greater accuracy and profitability, but the weekend and evening off too. Estimate to accumulate with Build Aviator and 10 free estimating reports.

FOR YOUR CHANCE TO WIN VISIT: WWW.RDR.LINK/BAV024

10

STONELUX BRICK FILLER

Discover a solution for flawless brick repairs with Stonelux Brick Repair Filler. Specially formulated for interior and exterior applications, this pre-mixed filler combines convenience with quality for professional results. The textured formulation and brick shades blend seamlessly with existing brickwork ensuring repairs that are virtually invisible. It’s perfect for addressing chips, cracks, drill holes and spalling. Get your fill with this month’s great round of giveaways. One of 20 tubs of Stonelux brick filler could be yours.

FOR YOUR CHANCE TO WIN VISIT: WWW.RDR.LINK/BAV025

Easy to Enter! It’s now easier than ever before to enter the competitions on our website. We’ve collected all the competitions on one handy page, meaning you only have to enter your details once! www.rdr.link/BAV026

Professional Builder has teamed up with Carhartt to offer one lucky reader the chance to get kitted out for winter, while 10 runners-up get a cool Carhartt Beanie.This is your chance to get kitted out for winter with the ultimate professional workwear package, courtesy of Carhartt. The prize up for grabs includes:

● Ripstop Cargo Work Trousers

● Classic relaxed fit K87 Pocket T-Shirt

● Carhartt Hoodie

Super Dux Active Jacket

Mesh-back Logo Graphic Cap

10 runners up will receive a cool Beanie – perfect for those cooler days on site.

Carhartt is the authentic workwear brand founded in 1889 in Detroit, Michigan, USA. For more than 130 years, the company has been known for its rugged construction, innovative designs, exceptional quality standards, durability and comfort.

Carhartt’s first products were overalls made of duck and denim fabrics. From this overwhelming success, more and more workwear was designed with premium fabrics, comfortable fits and details such as triple-stitched main

working men and women.

For your chance to win, answer the following questions on the Professional Builder website by following the link: www.rdr.link/BAV027

In what year was Carhartt founded?

a) 1889b) 1999c) 2009

In which US city was the company founded?

a) New Yorkb) Detroitc) Los Angeles

Today Carhartt prides itself on helping and protecting hardworking who?

a) Menb) Womenc) Men and women

For more information on the Carhartt range visit www.rdr.link/BAV028

Terms and conditions apply.

As angle grinders and rotating saws are some of the most dangerous tools in construction, having a simple jig to avoid having to hold a brick in place with a foot and running a rotating blade right next to it seems like a nobrainer. We had a chat with Grindermate’s creators, Mark Thompson and Jim Wigan, about the product’s background.

Both have 20 years of industry experience, Mark as a quantity surveyor and director, and Jim from running his own building company. Jim describes

he did, so it was more to do with keeping him safe – he had an accident and nearly severed his toes! So, I wanted to keep my anxiety levels down as a boss. We were doing thousands of cuts, so I made a prototype wooden jig for him to use, just something so I could go to work and not worry about the labourers in the background – Grindermate sort of created itself from there on!”

The initial Grindermate was a simple wooden platform which Jim built himself for his labourers to use, with a single straight slot in the middle – but he soon needed to upgrade the jig: “We ran into a

problem doing angled cuts as the brick wouldn’t stop moving around, so I developed it a bit more so we could cut angles on it.”

To make Grindermate into a viable product which could be manufactured cost-effectively as one piece, Mark and Jim decided to see if the concept would work in plastic instead of wood. Mark and Jim had a plastic prototype made which they started rolling out on building sites for Jim’s staff to try out – and tweaked the design according to their feedback. “The concept hasn’t really changed that much from when we started, just little finishing touches. We made the platform wider to make it more stable and

embossed the measuring pieces on the plastic rather than having them inserted separately, as the workers found they could see them better on the plastic that way,” Mark describes.

An issue they encountered during field testing was Grindermate moving around on the ground during cutting. As the goal was to make cutting bricks and blocks safer, workers stepping on the jig to hold it still would have defeated the purpose, so Mark & Jim added the “teeth” to Grindermate’s underside.

Mark’s connections in the building industry turned out to be helpful in getting Grindermate out in front of big names, but they needed to find a middleman to sell to the large companies – which led them to Metex, as Mark describes: “We got Metex’s name from my accountant. We gave them a call and it was one of those random conversations that actually led into something tangible! We met them (Metex directors Daniel Bamford & Daniel Hopkins), presented the product to them, and they were really keen. The business was small enough for the product to be important to them, but at the same time big enough to make it happen, so that’s why we chose them to come along on this journey with us!”

Jim and Metex then combined their

skillsets to finalise the design. Metex director Daniel Bamford, with a background in product design and engineering, found Jim’s on-site experience important in the process: “In the final development of Grindermate, we benefited from Jim’s extensive site experience. He has led the final detail design of the product, which has been finetuned as a result of feedback from site. The reaction from contractors and builders’ merchants has been very positive and we are pleased to be promoting a product that has genuine site safety benefits.”

The two introduced add-ons such as a trough at the back of the platform to collect brick dust generated during cutting. Meanwhile, Mark pursued patents for the design and registered relevant trademarks.

Seasoned tradespeople are sometimes set in their ways and getting them to adopt new tools can be a challenge, but Jim isn’t daunted: “One thing they can’t avoid is the fact that it’s safer. I’m having work done at my house now and my labourers have been using Grindermate daily – you couldn’t take it off them now! Once you get it into their hands and they try it out, I think they can be won over.”

The safety aspect is the most important reason they believe Grindermate will take

off on construction sites, as Jim can tell from his own experience: “As a boss, you’ve got an obligation to provide PPE to your staff, like steel toecap boots, for example. The legal responsibility comes back to the owner if a staff member has an accident, so a lot of bosses on construction sites will hopefully encourage their staff to use Grindermate.”

Mark adds: “It’s all well and good if people say they don’t want to use it, but as a boss you’ve got a responsibility for people, to make sure that you’ve done everything you can for that person to be safe. And there’s no two ways about the fact that using Grindermate is a safer method of working.”

The two aren’t planning on stopping with Grindermate and there are plenty more ideas Jim would like to work on: “We’ve come up with concepts for additional features. An example is dust suppression, as on site the dust often becomes an issue. Grindermate is for blocks and bricks, so we’d like to have a version for using up on a roof to cut tiles. I’m looking forward to adapting it and going through the design process again!”

FOR FURTHER INFORMATION ON GRINDERMATE FROM METEX VISIT WWW.RDR.LINK/BAV029

The Cavity Tray Cleaner could well be a brickie’s best friend. Professional Builder’s Lee Jones finds out more

Like so many inventions that have subsequently proven to be invaluable, the Cavity Tray Cleaner is the product of lived experience. Exeter-based bricklayer, Ashley Williams, has been running Smart Brick Services for five years now – and has served 11 years behind a trowel – and it’s that insight that has produced a tailormade solution for the trades.

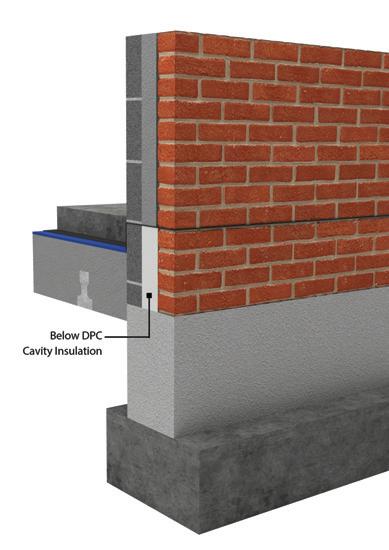

“Building Inspectors want the cavity trays between the two walls to be spotless and clean,” explains the 31-yearold. “The problem is that removing the mortar is a time-consuming and awkward job. The current practice is to take out every fourth brick all the way along the run when you’re working at the cavity tray level in order to scrape out the muck from above and between the wall ties.

“You’d invariably use a piece of roofing batten or any old scrap timber for the purpose. It’s actually a job which is pretty hard on your back. Not only that, when you put the bricks you’ve removed back in they tend to stick out against the rest of the run, which is not ideal if you want to produce a high-quality finish. In addition, the trays – and even the wall ties – can be damaged by the action of scraping the muck out.”

The Cavity Tray Cleaner is, by contrast, a straightforward and time-saving solution. It can be inserted or taken out in seconds and thoroughly cleaned in

minutes, with the added advantage that you only have to remove two bricks or one block.

The product itself connects in series to produce a custom length for each specific job. At the ends of the tray are male and female profiles that snap together via the help of a bump fit to provide a secure

lifting eye bolt on the end allows it to be easily pulled out. Moveover, the Cavity Tray Cleaner is made in Britain from recycled plastic and is a patented design.

In common with many budding inventors, the journey from lightbulb moment to finished product has been a long and winding road for Ashley, and he admits to being surprised at how difficult bringing a solution to market has been. It was, however, a determination that his solution would work that would spur him on. “I had the idea five years ago and it’s fair to say that I over-engineered some of the early versions because the key is simplicity, not just for the end user but also in the manufacturing. From the initial design, however, there’s only been three versions in total. The tooling required to produce the Cavity Tray Cleaner was a significant investment, and I’m very proud that it will be made in this country.”

“Every bricklayer I’ve shown it to has said straight away that they want one,” concludes Ashley. “It’s a simple answer to a job that nobody enjoys, saving time and producing a better job at the end of it.”

FOR FURTHER INFORMATION ON THE CAVITY TRAY CLEANER VISIT

WWW.RDR.LINK/BAV030

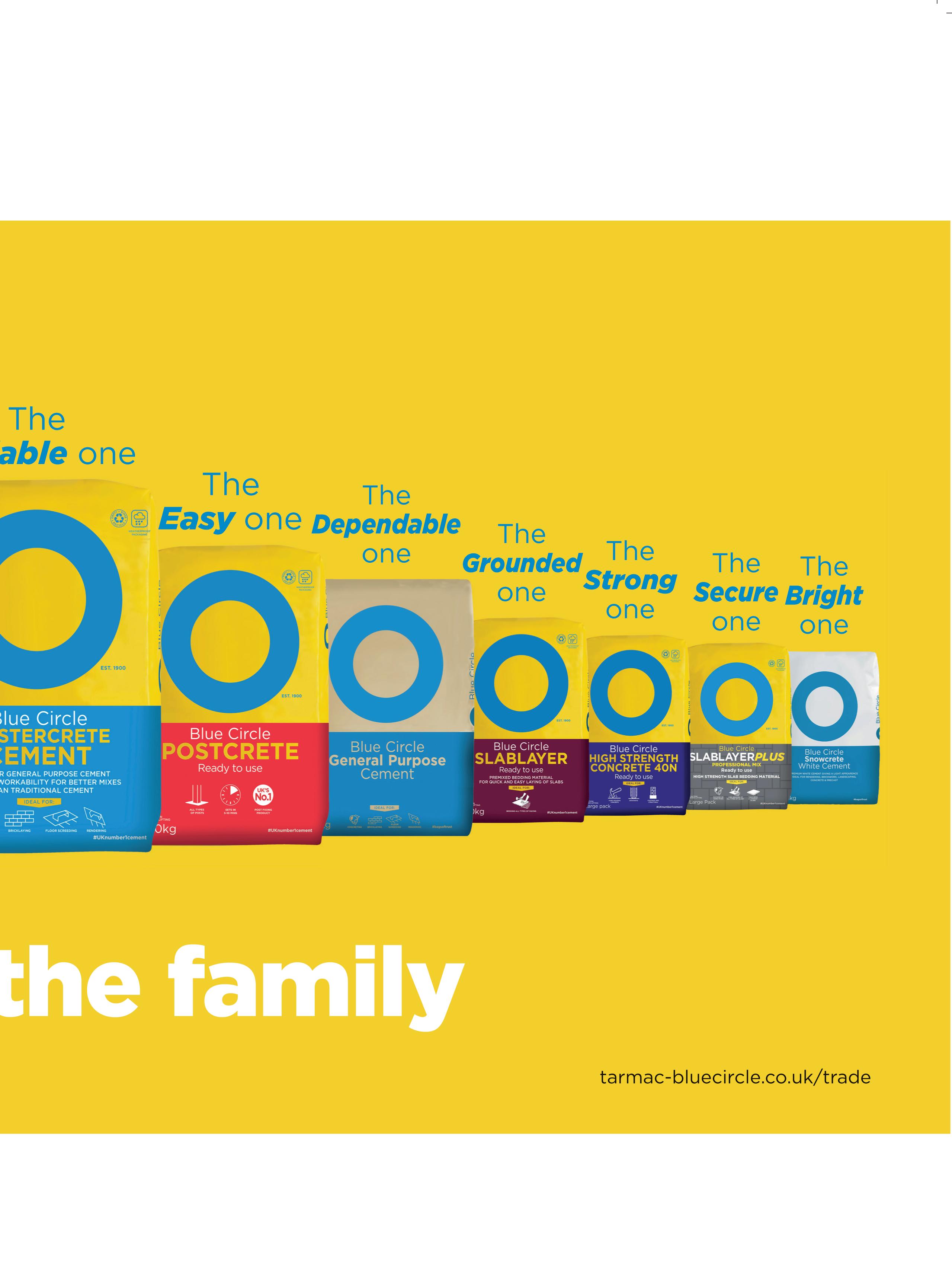

Modern and visually appealing, concrete is increasingly being used in exterior garden design, with its durability, resistance and functionality making it a popular material for many UK builders. In this article Ryan Moss, senior commercial manager at Tarmac, looks at how builders can use concrete to make a bold statement in outdoor spaces.

In 2021, Brits spent an astounding £18.6 billion on their garden, making the average money paid by a single adult, £690 (Statista). This is due to the growing trend to use the garden for leisure and outdoor living. Builders have now been presented with the opportunity to be even more creative and add more value to their customers’ outdoor spaces.

Here’s our top four recommendations on how builders can use concrete to make a bold statement in the garden.

An increasingly popular trend, living walls

perhaps more aware of the wellbeing benefits too.

In smaller gardens – where there is not enough space to allocate hard landscaped areas for sitting and entertaining alongside spaces for growing – vertical living walls provide a fantastic opportunity to combine the two.

In its simplest form, a vertical wall can be trailing or climbing plants which are planted in wall-mounted containers or pockets, sometimes with a sheet of polythene behind. Lower maintenance solutions, such as tiered wood shelving planters or vertical frames with hanging plant pots can also be used, providing a cost-effective vertical growing option.

For a real visual impact, however, suggest turning a new or existing wall into

a vertical garden to provide additional space to grow flowers. By using complex moulding forms and pouring concrete, you can create incredibly stylish costeffective designs.

Walls can be much more than just a practical boundary solution. A wall can create a standout feature, define a space or frame a view to add real ‘wow’ factor to the garden. Tall walls can also be used to seclude a space, providing privacy and security.

Of course, tradespeople have a choice of materials for walls including timber, bricks and blockwork, but concrete offers a practical, stylish and easy solution with a host of design opportunities too. By

simply building forms and pouring a highstrength product such as Tarmac Blue Circle High Strength Concrete (40N), it is easy to create eye catching dividers as part of a garden project.

When using moulds or forms – and adding alternative materials for texture and contrast – the possibilities are endless. For example, if customers are looking to add height to an existing wall, suggest using a no-mix concrete product, such as Tarmac Blue Circle Postcrete, to secure upright posts to the wall. These can provide a frame for horizontal slats of hardwood, such as cedar, which will add texture and interest to the space.

Another simple but effective way to create zones in the garden is through decorative aggregates. From chippings and cobbles, to slate and bark, there are a wide range of materials available through merchants to help create zones and borders.

solutions that can complement existing planting or landscaping too.

Homeowners are also looking for ideas to improve their kerb appeal and make maintenance an easier task. A practical trend which we expect to see more of in 2023 is hardscaping. This involves large concrete slabs which are a more permanent feature and could even

Concrete castings can be produced in a wide variety of shapes and sizes, enabling homeowners to get creative with designs that are not only functional but also hard-wearing.

Of course, not all landscaping projects are determined by the bigger jobs. Something as simple as checking for unstable fence posts or empty joints between paving slabs can keep a garden in shape during summer.

For unbalanced fence posts, use a quick setting, no mix concrete product, such as Tarmac Blue Circle Postcrete. Bury the post below the ground, then simply fill the hole one third with clean water and pour in the Postcrete evenly around the post until dry powder is visible on the surface. The Postcrete will set in as little as 10 minutes.

Bond It is no stranger to innovation. Over the last two decades, the company has pioneered numerous advances in sealants, adhesives and building chemicals that have led to a quantum leap forward in terms of capability or performance.

“Our track record includes developing some of the very first hybrid sealants and adhesives,” comments Kirstie Cooper, marketing manager at the business. “These innovative products utilise advanced polymer technology to offer the combined benefits of silicone and polyurethane sealants but with none of either material’s drawbacks.

“The recent addition of Geo-Fix to our range makes absolute sense because it’s of a similar ilk. We may not have

Geo-Fix was developed by paving expert, John Andrews and draws on his twenty plus years of experience spent working in this landscaping area. Available in an Original and All-Weather formulation, the product provides users with a superior means of pointing pavers, cobbles, flags, slabs, and stone setts.

Unlike other products which require the addition of water or the mixing of separate components, such as sand, cement and water, Geo-Fix is supplied pre-mixed and ready to use. This saves time, effort, and mess both in terms of preparation and cleaning up afterwards. Quick and easy to install, it is applied by simply brushing it into the joints and can be finished by compacting with a pointing tool.

Trials conducted with professional contractors highlighted just how effective

Geo-Fix is at saving time and labour. They revealed that paved areas could be pointed twenty times faster than they could with traditional wet mortar.

“Geo-Fix’s speed and ease of installation delivers major commercial advantages” explains Kirstie. “It saves on the labour costs of a project and the bigger the job, the bigger the savings. In addition, by making projects quicker to complete, Geo-Fix allows users to increase the amount of work they take on and the revenue they can make.”

Other impressive benefits include the fact that its technical performance surpasses that of both wet mortars and of other dry mortars that use polymeric sand.

As an example, Geo-Fix cures more quickly and can reach full loadbearing

If you’re looking for a quicker, easier way of pointing paved, flagged and other areas, Bond It has the perfect solution. Professional Builder catches up with the business as the new and exclusive UK and Ireland distributor of Geo-Fix.

capacity in hours rather than days. It also offers greater flexural and compressive strength and is non-staining if any excess is swept off surfaces after use.

Plus, as it is supplied vacuum packed in sealed foils, which are then placed into an outer tub, it offers an increased shelf life. The outer tub is also made using post-consumer recycled (PCR) plastic, diverting waste from landfill.

The range even provides greater flexibility as to when work can be carried out. Geo-Fix Original can be used at temperatures down to - 5°C whilst Geo-Fix All Weather can be used in all conditions – including the wet. The latter is also ideal for porcelain paving, which is becoming increasingly popular due to its durability and ease of maintenance.

As porcelain paving is just 20mm thick, it’s essential that any jointing compound can still perform effectively in a joint with a dramatically reduced depth. Geo-Fix All Weather provides that capability and can be used in joints as shallow as 15mm.

To help the trade maximise the opportunities being created by the growing trend towards porcelain paving, Bond It will be introducing further specialist products over the coming months.

Summing up, Kirstie adds: “Geo-Fix is one of those mouldbreaking developments that redefines expectations. Since adding it to the Bond It range, we’ve found that customers who try it wish they had discovered it sooner and are adamant that they won’t go back to using anything else.”

Restore masonry with the Stonelux Brick Repair range. Professional Builder puts the questions to the manufacturer.

QHow about if I want a different colour?

A That’s no problem either – simply blend colours together or enhance shade precision with compatible Stonelux Pigments.

painted. This brick effect paint transforms the appearance of brickwork and seamlessly conceals imperfections.

QTell us about Stonelux Brick Filler?

A pre-mixed solution that’s specially formulated for both interior and exterior applications, Stonelux Brick Repair Filler features a textured formulation that mimics the appearance of natural brick. It will seamlessly blend with existing brickwork, ensuring a repair that is

QWhat about Stonelux Brick Tint?

A This premium-grade brick tint is designed to enhance and restore the natural beauty of porous masonry. With it you can say goodbye to unsightly patches and mismatched bricks, and effectively conceal repairs, and colour corrections by blending flawlessly with existing brickwork.

QHow durable is the solution and is there any on-going maintenance?

There’s no more frustration with visible repair work, unsightly stains or mismatched bricks. Instead, you can quickly and easily mask imperfections and tie in mismatched bricks with existing masonry. You can also deal with unsightly graffiti and bothersome stains and spills.

QWhat kind of repairs can it tackle and what colours are available?

A From minor chips and cracks to drill holes and other damage, the filler will tackle a wide range of needs, enabling you to restore the integrity and beauty of brick surfaces effortlessly. In order to blend repairs into the existing brickwork there’s a selection of 11 popular brick shades.

A Not only is it hard wearing but it will equally avoid the need for expensive brick replacements. An advanced formula ensures deep penetration into the pours of the brick or stone surface. As a result, a permanent stain is achieved that does not alter the natural make-up of the substrate. This tough yet breathable solution will not require any touch ups or maintenance.

QCan I use Stonelux Brick Coating on non-porous masonry and brickwork that’s been painted?

A Absolutely. Unlike traditional brick tints, Stonelux Brick Coating can be used on non-porous masonry and will restore brickwork that has been previously

QWhat’s the colour range?

A As with the Brick Repair Filler, there’s 11 popular brick colours, all colours are intermixable, with compatible Stonelux Pigments available for further colour customisation. From traditional warm red tones to contemporary greys, Brick Coating offers endless possibilities for personalisation.

AG has launched three paving flag and block products, Tavira, Tri Stone and Plaza Quattro. All of the products are produced sustainably in the UK and are 100% recyclable. The range boasts a long-life cycle, fast and safe installation and an attractive finish. The new additions have a variety of possible applications too, including patios, pathways, balconies and driveways.

GET MORE DETAILS AT: WWW.RDR.LINK/BAV034

Proven to eliminate black spot, algae, lichen and more on most external hard surfaces such as stone, wood, plastic, concrete and coated metals, Monty Miracle Patio Cleaner is an ideal option for keeping exterior surfaces looking as good as new. The chemical liquid solution can be rinsed off with a garden hose, completely neutralises following the process and is 100% biodegradable.

GET MORE DETAILS AT: WWW.RDR.LINK/BAV035

Following extensive customer feedback and internal product development, CCP Building Products, has expanded on its Cement Free Ultra-low Carbon Concrete Building Block. Now utilising its Greenbloc technology across its complete product portfolio, its range of concrete blocks and bricks provide the specifier maximum choice dependent on the desired carbon saving of any given project with Standard, Premium and Ultra variants.

The aircrete range from H+H includes Foundation Blocks Standard Grade which are suitable for low-rise housing. There are already highly thermally efficient, but the manufacturer also offers Celcon Solar Grade blocks that prioritise heat loss even more. With a compressive strength of 2.9 N/mm² the block has a thermal conductivity of just 0.11 W/mK. It is sufficiently loadbearing for two storey dwellings and can be used below DPC.

WWW.RDR.LINK/BAV037

Produced at three of the company’s UK-based factories, using locally sourced clay, Forterra’s Repair, Maintenance, and Improvement (RMI) range of bricks has aesthetics tailored to local areas and a minimised transportation environmental impact. This range is curated from the company’s Butterley bricks, known for their use in landmarks like Kings Cross St. Pancras station.

Made in Britain and not fired like clay, Keyblok Linear from Marshalls PLC offers a sustainable alternative to traditional clay pavers. Quick installation is helped by interlocking grooves and nib detailing too, while impressive tolerances reduced the risks of chipping. This ensures a pristine finish that will withstand heavy pedestrian and vehicle

The first tranche of builders and specifiers to use a new style of insulation created by the manufacturers of the popular Actis Hybrid range have been as delighted with its ease of use and functionality as its creators predicted when they launched it in the spring.

The first major new product to hit the merchants’ shelves from the manufacturer in a decade, Eolis HC ensures installation is not only twice as quick as traditional alternatives but has also been heralded as a way to transform insulating lofts and barn conversions. The two-in-one reflective insulation with an integrated vapour barrier enables builders and roofers to reduce the number of steps required to achieve an impressive U-value as well as airtightness in roofs.

Triplex technology means it is especially useful for those dealing with shallow rafters where headroom is at a premium. Part of the reason for this, in addition to the thinness of the product, the bulk of whose insulating property lies

in its air gaps, is because it doesn’t require the usual 25mm air gap to avoid condensation – at least for most locations throughout the UK.

For the boring but necessary regulatory details about why this is, use the rdr.link below. Otherwise, just take our word for it and read on!

WWW.RDR.LINK/BAV040

and dusty cutting that entails. Instead, installers can just lay the product, like a blanket, across the rafters on the inside (warm side) of the building, sealing each section to the next with an integrated selfadhesive lap.

Time trials show that when insulating a roof, installation time using BBAcertificated Eolis HC is at least twice as quick as insulating between rafters with PIR board for that very reason. And while speed and ease of use is perhaps its headline plus point, it has others – such as not producing irritating dust or fibres, making for a healthier and more pleasant working environment – and meaning no respiratory protection is required. It’s also better for the environment and the health of the occupants of the home it’s used to insulate.

Rated A+ for its environmental impact, Eolis HC has a BREEAM exemplary level of VOC release for indoor air quality and contains no harmful chemicals. It’s made with 100% recyclable components and the unique structure of the Triplex technology

4 Align a timber batten where the product is fixed onto the rafters and cut along with an Actis cutter or a sharp knife, pressing the timber batten firmly onto the product.

1Remove the packaging. OR – if you need to cut it lengthwise do this before removing the wrapping using an

5

Butt-join and overlap Eolis HC with the next layer of the product and seal using the built-in self-adhesive tape. Vertical joints should be butt-jointed and sealed with Actis tape

7Fix horizontal or vertical battens (size in accordance with specification eg 25mm, 38mm, 50mm battens), nailing or screwing through the Eolis HC to the timber structure in preparation for the plasterboard stage. Where joints between plasterboard sheets are unsupported, timber noggins should be installed.

...and in a timber wall, follow the roof instructions above, with one additional, final step:

3

Install the product across the face of the timbers, taking care that the insulation thickness is maintained between fixing points. Staple to the timbers every 250mm, using min 14mm galvanised staples.

from which it is made allows less material to be used to achieve a U-value which would otherwise require a thicker product.

And with climate change leading to hotter summers and the new Part O (for overheating) of the Building Regulations now in force, it’s handy to know that the reflective films from which it is created reflect 95 per cent of infrared radiation, helping homes stay cooler in hot weather as well as warmer in the winter.

The easiest way to learn how to install new Eolis HC is to watch one of the

8

Around windows and doors, seal Eolis HC with Actis tape and secure with a batten knock-out panel and the foresight to use attic trusses, an integrated garage can easily become a room in the roof.

helpful Actis how to step-by-step videos. As well as an overview showing the start to finish process from unpacking to plasterboard, there are also mini, bitesize

snippets showing how to cut the product, how to insert electrical wires and pipes through the Eolis and how to cut round doors and windows.

YOU CAN ACCESS ALL OF THESE BY USING THE RDR.LINK: WWW.RDR.LINK/BAV041

YOU CAN ALSO WATCH A TIMED INSTALLATION VIDEO DEMONSTRATING HOW QUICK AND EASY IT IS TO INSTALL EOLIS HC HERE: WWW.RDR.LINK/BAV042

will provide a maximum return for the trades

With the pressure on to cut costs and reduce your prices, or go for the cheapest option to protect your profit margin, there’s huge temptation to trade down to lower cost products when visiting your local builders’ merchants. Peter Wilson, brand manager of floor levelling compounds manufacturer Setcrete, shows how going in the opposite direction and opting for premium or specialist products can actually pay dividends in terms of huge time savings on a job or deliver ‘professional shortcuts’ that enable builders to circumvent normally required aspects of the subfloor preparation process.

With the economy the way it is –increasing materials prices on one side and pressure to keep job quotes as low as possible – it’s natural to look at lower cost materials to keep your costs down for customers. OK, you’ll probably have to compromise a bit on quality and the products you use might not be as user friendly as your usual brand, but at least

you’ll cut costs.

However, when it comes to subfloor preparation and levelling compounds, there are some situations where it actually pays to trade up from your ‘go to’ preference and use specialist or premium products that will save you time and money and boost your profitability.

Rapid setting, rapid drying levelling compounds, for example, make it possible to level a subfloor so that it’s ready to receive a floorcovering after only two hours. Furthermore, as these superfast products are ‘walk on hard’ after just 30 minutes, they minimise the time that an area is out of commission.

This compares with conventional compounds which need 2-3 hours to become walk on hard and 24 hours before a floor covering can be applied.

The timesaving allows a complete flooring installation to be undertaken in a single day, rather than having to return the following day to finish the work. If

you’ve got a full work diary, the efficiency savings mean you can get through jobs more quickly, as well as using a levelling compound that’s a pleasure to work with.

Also, on the time-saving front are deep base levelling compounds that enable floor areas to be built up by up to 50mm and be ready for the next stage of the floor installation just six hours later. Conventional, general purpose levelling compounds can be applied up to a maximum thickness of around 10mm.

These deep base products can be used to level up adjacent floors, for example, where an extension has been built next to a kitchen/dining area, or to fill in a trench where an internal wall has been removed.

Superfast drying delivers a walk on hard time of 90 minutes and the subfloor is ready to receive a floorcovering after just six hours.

Achieving the same result using a sand/cement screed would require a day

or two before the floor could be walked on and weeks before the subfloor was dry enough to install a floorcovering.

In situations where an old floorcovering has been taken up, as part of a refurbishment, old adhesive resides will often be left behind, firmly bonded to the subfloor. Before applying most levelling compounds to re-level the subfloor for the new floorcovering, it is essential that this old residue is removed, which normally requires hiring a grinding machine or scabbler.

Otherwise, the stresses imposed on the adhesive residues as the levelling compound is curing can detach the adhesive from the subfloor, creating weak spots that will compromise the integrity of the finished flooring.

However, specialist levelling floor failure. In addition, in such

Again, with a walk-on hard time of just 90 minutes and ready to receive floorcoverings from just four hours, these levelling compounds offer huge time savings on a job as well as cutting out two usual preparation steps and their associated costs.

When times are tough and money’s tight, the natural instinct is to look at where you can make cost savings. There might also be a temptation to cut corners and, maybe, compromise on the quality of the job. But that can be a risky venture.

Taking a look at the alternatives on offer and trading up instead of down is often a more cost-effective way to go. You’ll also get to use products that are purpose-designed for the job and have the reassurance of the product delivering a high-quality finish.

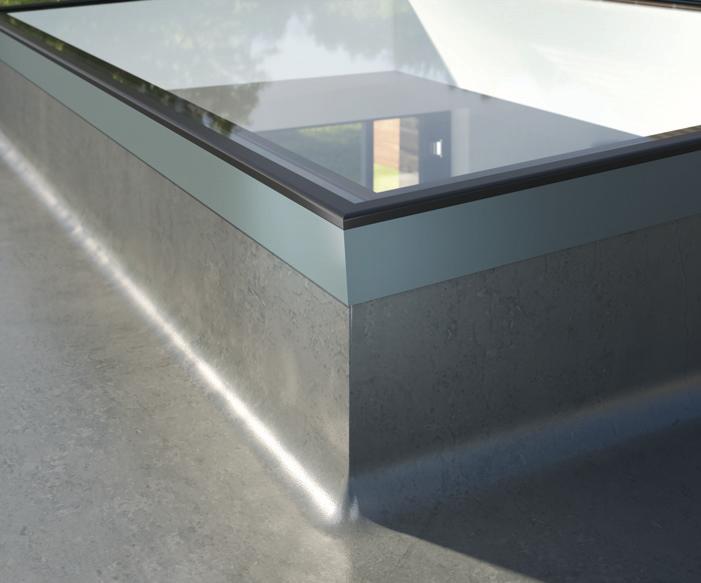

Oak Ridge is a highspecification development of four, energy-efficient family homes located in the heart of Tattenhall village, Cheshire. The substantial, modern 5 and 6-bed detached properties feature large open plan living areas, double bedrooms and home office options, combined with a high-quality specification and distinctive, contemporary design.

Situated in a peaceful, private enclave just a stone’s throw from the bustling village centre of Tattenhall, the luxurious homes offer from 2,211ft2 to 3,487ft2 of internal floorspace, with living and dining areas designed to maximise space and light.

Built by independent property developer, Bligh Developments, all the properties at Oak Ridge have all also been designed to provide A-rated energy performance, to minimise heating and energy costs and provide sustainable, low carbon living, thanks to air source heat pumps, underfloor heating and integrated, modern solar panels.

Premium glazing solutions were also a priority at Oak Ridge, and that included the specification of high-performance, energy efficient Infinity rooflights from TuffX, that were installed on the ground floor kitchen extension.

Maximum light, minimum heat transfer Infinity rooflights from TuffX are manufactured with a clear, toughened safety glass with a high quality, polished edge finish and a distinctive, decorative black border as standard.

The argon gas filled glass units in Infinity rooflights, which also feature Super Spacer warm edge spacer technology, are highly energy efficient, and can be specified with a choice of either double glazing, delivering a U value of 1.2w/m of 0.7w/m

compatible with the forthcoming Future Homes Standard.

Available in a wide range of standard sizes – up to a maximum size of 3,200mm x 1,500mm – Infinity can be optioned with clear or blue tinted glass, as well as unique, high performance solar control coating, which was specified for the Oak Ridge development.

Paul Higgins, TuffX Commercial Director, commented: “Rooflights and lanterns are an increasingly popular way to introduce natural light into a property, but in certain cases there can often be a trade off between light and heat transmission.

“We developed a solution for this with the launch of our Infinity Solar rooflight, which has a unique solar control coating that reflects twice as much heat as standard glass without compromising on the amount of light flooding through.

“It means that building occupants can enjoy all the benefits of a light filled space, with minimal solar gain, to help ensure comfortable indoor temperatures all year round, especially when combined with a glass unit that’s designed to offer exceptionally low U values.

“This is ideal for south facing installations but also helps conform to the new Document O legislation, introduced in June 2022, that’s designed to reduce

excessive thermal heat build-up in dwellings,” he continued.

“Our range includes framed and frameless versions, double and triple glazed options, walk on glass with antislip coatings and more developments currently in the prototype stages to be launched later this year.”

While Infinity rooflights offer a host of benefits to homeowners, they have also been designed to present a number of important advantages to trade customers as well.

All Infinity rooflights come with a 10year guarantee and are manufactured at TuffX’s state of the art, 70,000ft2 factory, with a lead time of four to five days on standard sizes and seven to 10 days on bespoke orders.

TuffX offers an efficient, nationwide delivery with a fleet of 52 vehicles, but one of the main attractions for customers – apart from the inherent quality and performance of the product – is the speed at which an Infinity rooflight can be installed.

Paul explained: “Our rooflights can weigh anywhere between 50kgs and 300kgs depending on the size and specification, and that’s not uncommon for any rooflight product, but a key difference with an Infinity rooflight, is that it can easily be installed in less than 10-minutes. That’s

Bligh Developments has been a customer of TuffX for around 10 years and has specified the company’s rooflights and walk on glass products for numerous prestigious developments in that time.

Kevin Bligh, Managing Director of Bligh Developments, commented: “We love the quality and especially the ease of install of Infinity rooflights, but we also love the product has. In the current climate, energy

Paul Higgins said: “Three years ago we realised there was a gap in the market to manufacture a rooflight which was extremely easy to install to help builders maximise their time in a current climate of labour shortages and extremely busy workloads.

“Typically, our rooflights have been manufactured to be installed in around 10mins when some competitors rooflights arrive in separate components which can take two to three hours to erect and can also have issues with leaks if this process isn’t done correctly. As TuffX has always been at the forefront of R&D initiatives, we also wanted to produce a range of rooflights containing different, unique properties within the glass,” he continued.

“Consumers purchase rooflights to have a frameless appearance with only the glass being on show when viewed internally. We felt that again there wasn’t any differential from a glass perspective on the market and, therefore, introduced a range of Infinity rooflights to give consumers a variety of unique properties depending on their individual requirements.

“In the case of the exclusive Oak Ridge development in Cheshire, the homeowners will be able to enjoy these stunning, contemporary properties, that will be filled with natural light from our stylish, energy efficient products.”

“Occupants can enjoy all the benefits of a light filled space, with minimal solar gain to ensure comfortable indoor temperatures.”

–Paul Higgins, TuffX Commercial Director

SIXTH IN THE SERIES: NO.6

With over 40 years’ experience in the roofing industry, Kevin Taylor, Marley’s Technical and Training Manager shares his knowledge

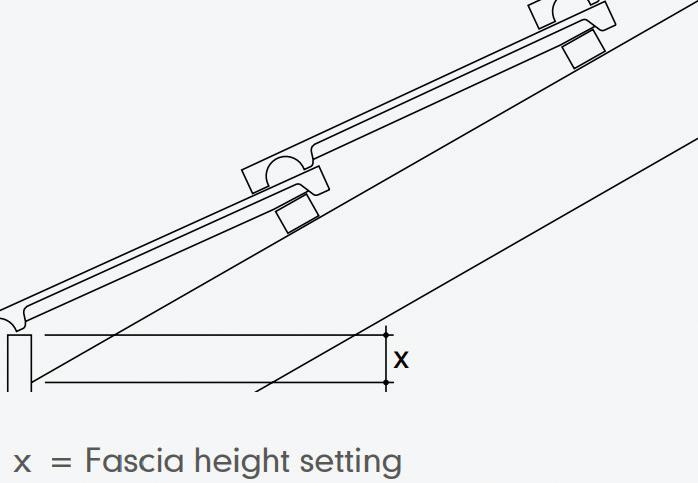

Kevin said: ‘Many people may be surprised to learn that, to comply with BS5534 (Slating and tiling for pitched roofs and vertical cladding – Code of Practice) all roof slates and tiles at the eaves should be supported in substantially the same plane as the main roof.

‘This means setting the fascia board to the correct height so the tiles neither noticeably drop nor kick up. Tiles and slates which are not sufficiently supported

can drop with the result being an unsightly gap below the second course of tiles. This gap, if large enough, can also be vulnerable to driving rain ingress if not addressed before the tiles are laid.

‘If the fascia board is set too high, the bottom row of tiles will kick up and there is a risk that they could be sitting below their recommended pitch. Too much kick at the eaves can also cause flat spots or even negative fall on the underlay/support trays which could lead to ponding and eventually water ingress,

this is especially a problem where the roof pitch is equal to, or close to, the minimum pitch of the roof tile.

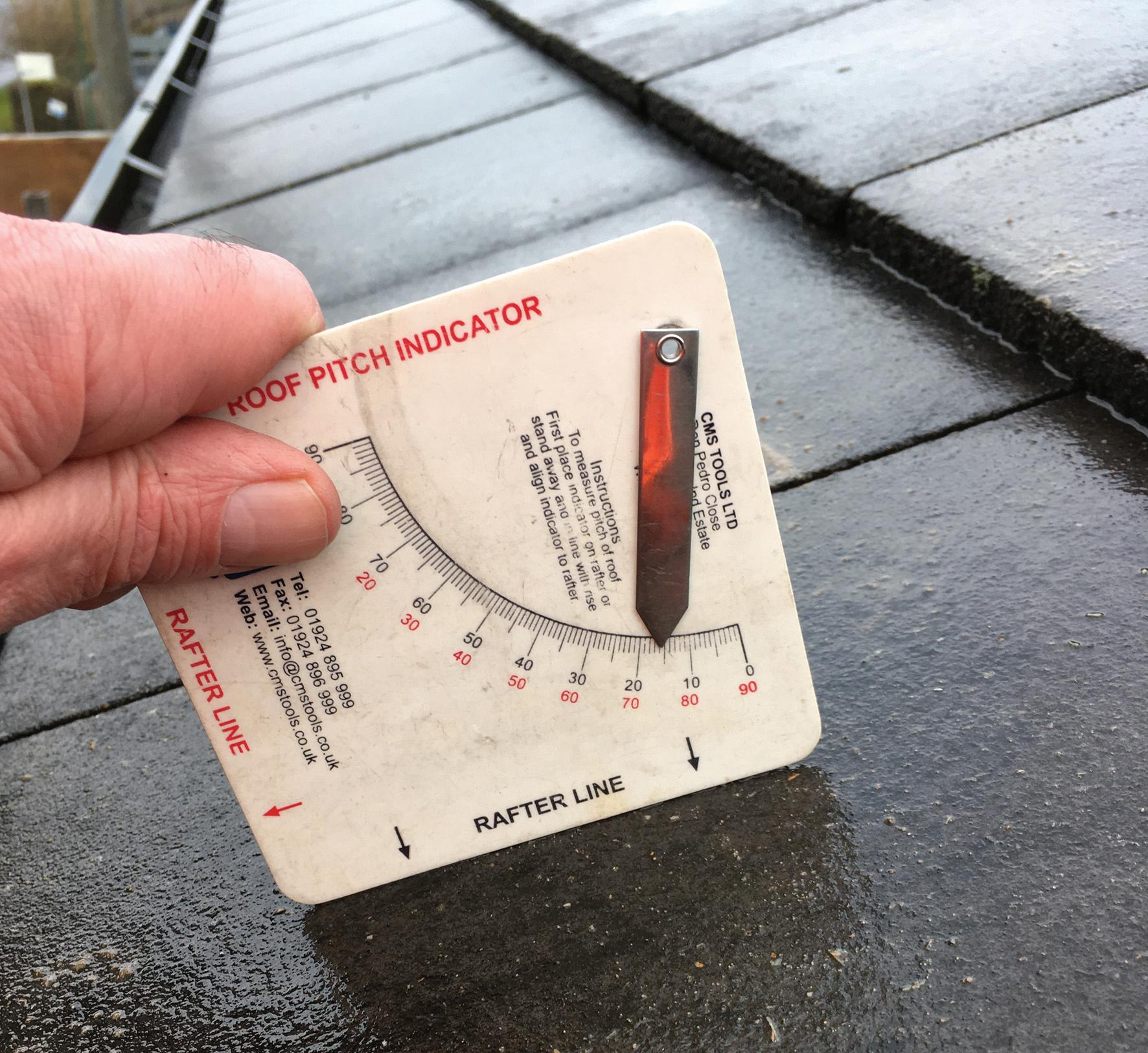

‘There are three factors involved in setting the correct upstand of a fascia board – the type of roof tile or slate, whether to include additional over-fascia vents, and finally the roof pitch. Marley provides tables on the minimum fascia board heights, both with and without over-fascia ventilation strips. It is best to follow such guidance before the fascia board is fixed as lowering or raising the fascia board can be very disruptive and time consuming later, especially if the guttering has also been fixed.

‘It is always best to perform a simple check on site using two short pieces of batten and a couple of roof tiles before work commences. The first batten should

be fixed to allow the tail of the tile to finish 50mm over the fascia board on the rake to provide effective drainage into the gutter (although this can be extended for larger gutters or gutters which are off set from the fascia board). The second batten should be fixed at the maximum batten gauge for the roof tile. The two tiles can now be laid loosely to check whether the tiles noticeably drop down or kick up.

‘If the tiles drop down, then the fascia board will need to be raised, or a timber batten of suitable thickness fixed to the top edge, to make up for the shortfall. This should be installed before any of the roofing materials and before any setting out of the battens is carried out.

‘If the tiles kick up, then two checks need to be made. Lay the support tray loosely (or 5U felt or other UV stable carrier) at the eaves and check there is still sufficient fall to guide any rainwater into the gutters. Using a pitch finder, check the laying angle of the first roof tile, if it is more than 5 degrees below the minimum recommended roof pitch (known as the laying angle of the tile), then the fascia board may need to be lowered or cut down.

‘For most common roof pitches, I find that upstands totalling between 35mm and 50mm work for most interlocking tiles depending on their thickness, and around 55-65mm for plain tiles. For slates, the upstand should be approximately the batten depth + two thicknesses of slate (e.g., 25mm + 2 x 5mm).

‘Traditionally, steep roofs, often with long rafters (such as church roofs, spires, and turrets) were designed with bell-cast or sprocket eaves. This is where additional short sections of rafter are fitted to the eaves at a significantly shallower angle to slow the flow of water down before it hits the gutter. Such details are not suitable for interlocking tiles and should only be used for smaller format materials such as plain tiles and small slates and cedar shingles.’ FOR

Tthe most popular being a rooflight conversion. This is because it’s the simplest and most affordable option. A rooflight conversion involves installing a raised skylight or roof window to create a light and airy space. This is a great option for a customer if they want to add extra light, and potentially some extra space, without making any major changes to the home.

If a customer is looking to gain more space than a rooflight conversion can offer, a dormer conversion may be the right option. This involves adding a small box shaped structure onto a pitched roof,

Alternatively, a full loft conversion can be undertaken, with several options including hip-to-gable conversions, mansard conversions, and L-shaped, all of which would be dependent on the type of property a customer owns and planning regulations within the area. These full conversions will generally involve the removal, addition, or modification of parts of the roof structure to gain additional living space.

Undertaking a loft conversion project in most cases means creating a new roof structure, and, the lower the roof pitch, the larger the living area there will be available underneath the roof.

insulation and creating a warm roof, especially with an older property that more than likely has a cold roof loft. However, constructing a new roof structure as part of a loft conversion usually involves creating various roof pitches, some of which may be very low. With low pitched roofs there are fewer tiling options and sometimes, depending on pitch, there might be no tiling options at all. This is where a ‘sub-roof’ can come into play.

Sub-roof systems have seen a rise in

Onduline has recently launched its new and unique sub-roof system, ISOLINE LOW LINE – the only system in the UK to be BRE tested and BBA Accredited to as low as 10º.

Designed to be used with all roof tiles, new or existing; ISOLINE LOW LINE, lightweight bituminous sub-roof is fixed below the primary tile or slate roof covering, acting as the primary waterproofing layer of a roof, making roof tiles a secondary aesthetical line of defence.

protective layer within the roof structure which acts as the primary waterproofing layer under the tiles when the minimum tile pitch cannot be met.

Tighter restrictions when it comes to roofing came into force with the launch of BS 5534, with amendments in 2015 and 2018 in relation to extreme weather changes and a need to align with European Standards. However, BS 5534 recognises that there are situations where it would be difficult to avoid using a roofing product at less than the recommended roof pitch. It highlights that a roof that is designed below the recommended minimum roof pitches should have a functional weatherproof sub-roof system to remove any rainwater ingress safely to the eaves gutter.

With a suitable sub-roof, all tiles can be used at a low pitch, allowing greater scope when it comes to making modifications to a home. This includes loft conversions, allowing lower pitches and the ability to use either existing tiles, which can save a homeowner money, or new tiles that they would like to fit in due to aesthetics.

All concrete, slate and clay roof tiles can be installed on a roof pitch as low as 10º by integrating a suitable sub-roof, making a huge difference to contractors when it comes to designing and completing roofing projects.

TO FIND OUT MORE ABOUT ISOLINE LOW LINE AND ONDULINE’S OTHER LIGHTWEIGHT, AND DURABLE WATERPROOFING SOLUTIONS, CLICK ON THE RDR LINK WWW.RDR.LINK/BAV046

For any professional taking on roofing, loft and insulation upgrades, an auto-feed screwdriver is a valuable addition to their kit. Utilising collated, beltfed screws, an auto-feed screwdriver is ideal for repetitive fixing and rapid screw driving tasks. This includes fixing down a timber deck for a flat roof or installing the plywood or OSB base for sheet roofing material. It is also a useful tool to have to hand when boarding-out lofts, or for a range of tasks involved in loft conversion projects, including studwork, drywall and flooring installation.

An auto-feed screwdriver has benefits beyond the obvious speed and precision it offers. With the screw held and driven directly from the tool, it leaves one of the user’s hands free to hold the material in place, making for easy work whilst ensuring that every screw can be driven to the exact required depth every time. This ease of operation is increased further by selecting a cordless tool, as this eliminates the restrictions, inconvenience and safety risks of power cables in the work area – especially relevant when working at height.

In addition to choosing a cordless machine, there are also other important factors that must be considered to ensure the right product is selected.

Next up in our series of buyers’ guides for tools, Makita offers some tips on choosing the right auto-feed screwdriver.roofing, flooring & insulation