PLUMBING & BATHROOMS INSIDE A PRESSURE REDUCING VALVE

TOOLS & EQUIPMENT

PRESS FITTINGS, WORKWEAR AND MORE...

PRESS FITTINGS, WORKWEAR AND MORE...

HEAT PUMP TRAINING

25 TRENDS IN BATHROOM PLUMBING

The trends shaping the future of bathroom design and installation

28INSIDE A PRV

The inner workings of two pressure reducing valves

10

Some of the

20 SUPPORTING CUSTOMERS

13COMMISSIONING – A VITAL TOOL

Ensure heat pumps are operating efficiently

16 HEAT PUMP UPGRADE

Advancements in heat pump technology are making systems greener

18 ONLINE HEAT PUMP TRAINING

Ideal Heating has launched a new online heat pump course

20LOW-CARBON CHOICES

How installers can support homeowners in reducing their carbon footprint

22 OFF-GRID DECARBONISATION

Achieve net zero and tackle social inequality

31 USING TUNDISHES

Examining the use of tundishes for unvented hot water cylinders

38 GIVEAWAYS

35PRESS AHEAD

Rothenberger has unveiled a new ‘compact’ press tool

36 IN THE MIDDLE

A warm and flexible mid-layer can help maintain body temperature

38 GIVEAWAYS

WIN safety shoes and pipe freeze kits

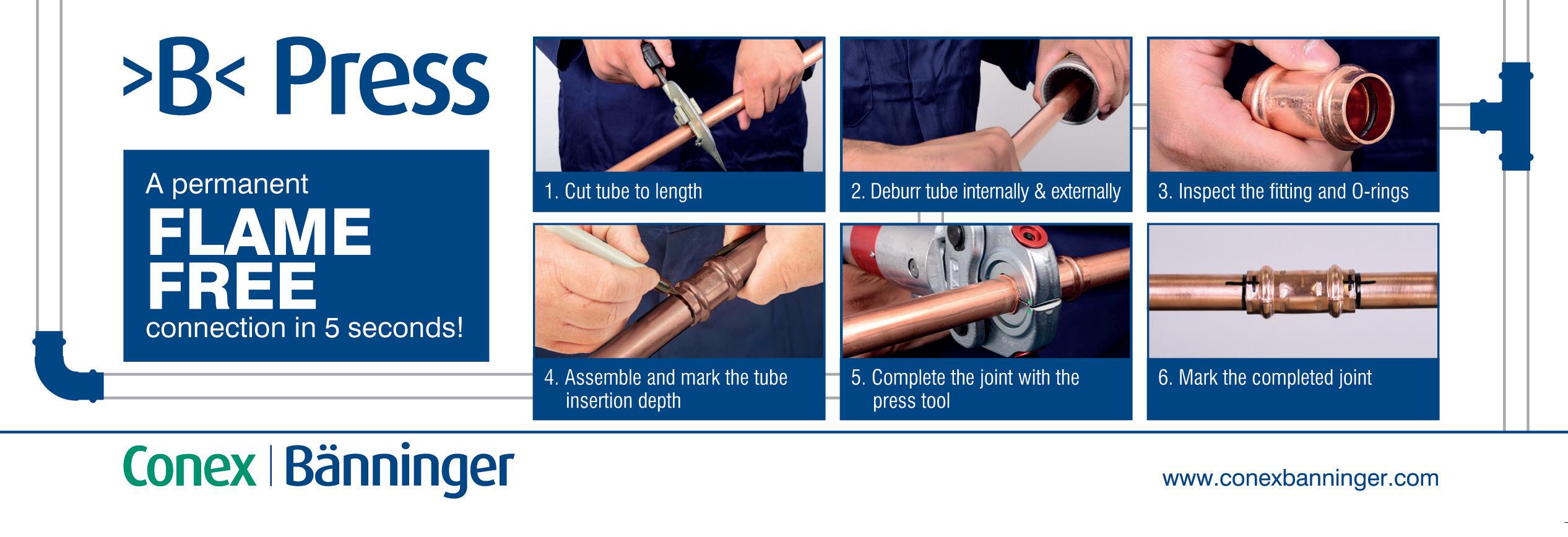

41 HIGH PRESS

A look at >B< Press copper fittings from Conex Bänninger

43 ADEY introduces new ‘super compact’ filter

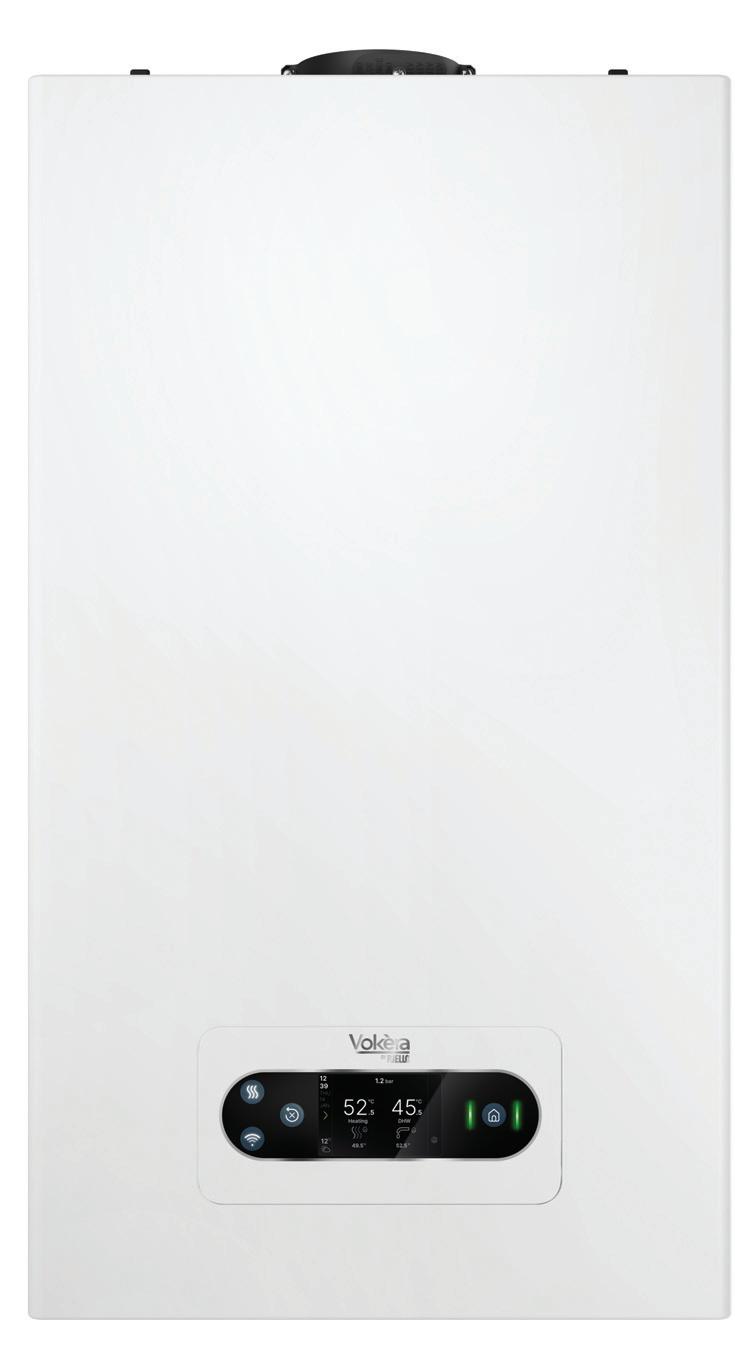

44 Vokèra unveils new Pinnacle boiler range

46 Boilers, multi-tools, hammer drills & more...

@phpi phpionline.co.uk

@professionalplumber

phpi@hamerville.co.uk

EDITOR

JONATHAN COLE

phpi@hamerville.co.uk

ADVERTISEMENT MANAGER

OLIVER SHANNON oshannon@hamerville.co.uk

DIGITAL MANAGER

KELLY NEWSTEAD

DESIGNER

GEMMA WATSON

GROUP PRODUCTION MANAGER

CAROL PADGETT

PRODUCTION ASSISTANT

CLAIRE THWAITES

DISTRIBUTION MANAGER

KARL CLARK

PRINTED BY

PCP TELFORD

PUBLISHED BY

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF.

Tel: (01923) 237799

Fax: (01923) 246901

Copyright © 2024

PROFESSIONAL HEATING & PLUMBING INSTALLER is a business journal for those involved in the installation, maintenance and repair of heating and plumbing systems. It is available to the trade at leading heating and plumbing merchants and specialist outlets throughout the UK.

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

Subscriptions to PHPI are available for 1 year (11 issues) at the following rates:

UK £30 post paid

Airmail £80 post paid

Europe £50 post paid

51,535

(Certificate of Average Distribution for the issues between January and December 2023)

Driven by the need to reduce the UK’s carbon emissions the shift to low carbon heating has been underway for a number of years. On a domestic level, Air Source Heat Pumps have emerged as perhaps the key technology to shift home heating towards electricity and away from gas.

The challenge is a considerable one. Gas has been the main fuel of choice for decades in domestic heating. Installers are familiar with how products work, and how to install, commission and repair them. Understandably, many will be content to continue working with gas appliances for the foreseeable future. Equally, consumers are broadly comfortable with their operation and familiar with the type of heat being delivered.

One key issue to greater heat pump adoption is consumer demand. In a recent survey of consumers by Energy Systems Catapult 69% said they don’t know enough about heat pump technology.

However, it would appear the people best placed to provide more information about Heat Pump technology – heating engineers – are also yet to be convinced. A recent survey, conducted by Baxi and Gemserve in August 2024, reveals that just 9% of installers are currently fitting heat pumps.

And it would appear that this position will only change slowly. The survey also revealed that half of installers say they are “somewhat” or “extremely unlikely” to start fitting heat pumps in the next three years. When it comes to Heat Pumps, it is clear that if the technology is to more widely adopted then Heating Engineers require more information.

One route to achieve this is practical training. A number of manufacturers and others are increasing the amount of Heat Pump training available. We recently visited Baxi’s new training centre in Warwick where the company runs a number of hands-on training courses for installers interested in learning more about Heat Pumps. The company also has other facilities across the country to bring training closer to installers.

Once armed with greater levels of knowledge it is likely engineers will feel more confident in discussing Heat Pumps with potential customers and installing the technology.

However, it is homeowners that will make the final decision on the type of heating system being installed at their property. If more heat pumps are to be installed the consumer barriers around them need to be addressed and stronger demand fostered.

You can read more about the Baxi and Energy Systems Catapult surveys on page 7

Jonathan Cole EDITOR

In a survey of UK consumers, 69% said they don’t know enough about heat pump technology.

The survey of more than 1,000 mortgage homeowners, outright homeowners and aspiring homeowners also revealed less than a third (31%) said they are familiar with heat pumps (know a fair amount or a lot about them). 18% of respondents said they don’t trust the technology. The research, by Energy Systems Catapult in partnership with Heatio and Perenna, indicated that a lack of affordability, finance options and lack of knowledge and trust in heat pump and solar panel technology, the installation process and proposed benefits are the main barriers to installation.

Rebecca Sweeney, Business Leader, Homes at Energy Systems Catapult said: “To transform the UK energy system and meet our Net Zero carbon reduction targets, it is essential we engage consumers by offering them innovative energy products and services that they want to take up.”

Share your thoughts with us on the industry via Twitter (@PHPI), Facebook (@ProfessionalPlumber), or by emailing phpi@hamerville.co.uk

Baxi has published its 2024 Installer Skills Survey, revealing that attitudes of heating engineers towards low carbon heating are hard to shift.

Over 300 installers took part in the survey, conducted in August 2024 in partnership with green supply chain consultancy Gemserv. It reveals that just 9% of installers are fitting heat pumps. This is up from 3% in 2022 and 7% in 2023.

Sentiment towards heat pump installation in the future looks weak, with half of installers saying they are “somewhat” or “extremely unlikely” to start fitting heat pumps in the next three years. This compares to 46% in 2022 and even less confidence, 53%, in 2023. There is more enthusiasm for hybrid systems – where a heat pump is combined with a gas boiler – with 30% of installers showing interest.

Government schemes, such as the Boiler Upgrade Scheme (BUS), are met with frustration in the survey. Only 9% of installers rate government schemes as ‘’good’’ or ‘’excellent’’ and 42% say customers never mention the BUS.

A lack of confidence to promote and install low-carbon heating technologies has been a feature of the Installer Skills Survey since it began in 2022. This year, there is a slight improvement, with 11% of installers saying they are ‘extremely confident’ in discussing low-carbon technologies (up from 7% in 2023) and 35% ‘moderately confident’. This appears to indicate that while training opportunities and industry communication are having a positive effect, many installers still lack the expertise to fully promote and install low-carbon heating technologies.

Ian Trott, Baxi’s Head of UK Training said, “While the 2024 survey shows some positive developments, particularly regarding hybrid systems, many of the challenges highlighted by previous surveys, such as insufficient training, poor government support, low consumer demand, haven’t moved on. The transition to low-carbon heating will require more targeted interventions to support installers in overcoming these barriers.”

Installers are being invited to take part in a nationwide, prize-winning celebration as Ideal Heating marks a major milestone in the history of its Logic boiler.

Since its launch in 2009, five million Logic boilers have been manufactured and installed in homes across the UK. To celebrate reaching the manufacturing landmark, Ideal Heating is embarking on a five million celebration Heat & Greet tour, with a host of top prizes and themed merchandise on offer to mark a decade-and-a-half of Logic boilers. The tour will visit trade counters across the UK while the company will also reward the lucky installer who finds the golden five millionth Logic boiler.

The five millionth Logic to roll off the production line at Ideal Heating’s factory in Hull will feature a special commemorative gold label and the installer who finds the boiler will receive it free.

For more details please www.rdr.link/pbi001

To prevent non-compliant heating circulation pumps from being installed unwittingly, Wilo has launched a new service to help installers check the pumps they are fitting are safe for use and compliant with the Energy-related Products (ErP) regulation.

Since 1 January 2022, heating circulation pumps, also known as heating circulators, sold in the UK market must meet the ErP regulations. To meet these regulations, they must have an energy efficiency index (EEI) of ≤ 0.23, as well as conform to other design standards.

To help installers understand if the pumps are compliant before they fit them, installers can take a picture of the label and send supporting documentation of the pump to Wilo, whose team will then perform a visual check of the information to confirm if the pump labelling meets the requirements within one working day. Andy Thompson, National Sales Manager – Plumbing and Heating at Wilo UK, said: “By simply sending us a picture of the label and relevant supporting documentation, we’ll be able to check if the pump labelling conforms to the ErP legislation, what the EEI of the pump is, and if the pump runs on outdated technology, which again is a mark of non-compliance.”

For more about Wilo’s new non-compliant pump checking service please www.rdr.link/pbi002

Triton Showers has been presented with a King’s Award for Enterprise, recognising the brand’s commitment to sustainable development and integrating sustainability into its long-term business strategy and Net Zero goals.

The Nuneaton-based shower manufacturer was presented with the achievement by the Warwickshire Lord Lieutenant, Tim Cox, on Wednesday 4th September, at its Shepperton Business Park head office. David Tutton, Managing Director at Triton Showers, said, “We are incredibly honoured to receive the King’s Award for Enterprise, being one of only 29 select businesses across the UK to be recognised by His Majesty this year in the Sustainable Development category.”

The HIP Learner of the Year competition is gearing up once again, announcing that applications are now open for the competition – now in its sixteenth year.

The competition is designed to provide a platform for apprentice and student plumbers to showcase their skills, gain confidence and win fantastic prizes to support them at the start of their careers. Level 2 and 3 plumbing students will compete in six regional heats across England and Wales, in January and February. Competitors will be judged on various practical tasks by the competition Head Judge, Jerry Whiteley, Technical Manager from the CIPHE. Each regional winner will then compete at the Grand Final, which will take place in March 2025.

Reflecting on her experience, last year’s winner Daisy Turner from Barking and Dagenham College, said, “The whole experience of the competition has been amazing – it just means a lot. I'd encourage anyone considering entering next year to absolutely go for it.”

HIP Female Skills 2025

Applications are now also open for the HIP Female Skills 2025. In February and March next year, HIP will travel to three regions across the country, in search of the top rising stars in the plumbing and heating industries. Zoë Tanner, Managing Director at HIP, said: “We’re thrilled to bring back the HIP Female Skills Competition for its third year. Supporting the next generation of skilled professionals has never been more crucial, and we’re excited to see what 2025 will bring.”

The deadline for entries is 29th November 2024. For more information or to enter the competition please www.rdr.link/pbi003

Baxi is welcoming the return of heating season by announcing its first ever Air Source Heat Pump (ASHP) cashback promotion.

Running until 6th January, Baxi Heat Pump installers can receive £600 cashback for their first three Baxi ASHP installations –up to £1,800 in total. The scheme is part of Baxi’s ongoing drive to support the UK’s switch to low carbon heat. The company hopes to incentivise more installers to develop the skills and knowledge that will ensure homeowners benefit from quality heat pump installations.

Katie Hall, Marketing Manager for Fergus, looks at the case for and against investing in a website for your company.

In today's digital era, having an online presence seems almost obligatory for trade businesses. However, is it essential for every tradesperson to have a website?

A website serves as a digital storefront that’s open 24/7, giving potential clients the ability to discover your services anytime, anywhere. For many, this extended reach is invaluable, especially when combined with the credibility that a well-maintained site can bring. Displaying completed projects and testimonials offers a strong first impression, showcasing the quality and scope of your work. Online booking systems and contact forms enhance customer convenience.

However, the journey to creating and maintaining a website is not without its challenges. The initial costs, ongoing maintenance, and the time commitment required to keep it updated can be significant –especially for busy tradies.

For those who decide to take the plunge, ensuring that your website is user-friendly is paramount. A clear, straightforward design with easy-to-find contact details, a portfolio of your work, and client testimonials can make a world of difference. It’s also worth considering the addition of SEO (Search Engine Optimisation) tools to improve your site’s visibility on search engines, driving more traffic your way.

Not ready to commit to a full-fledged website? Social media platforms like Facebook and Instagram can serve as effective alternatives. These platforms allow you to showcase your work, interact with clients, and gather reviews without the need for a website. Setting up a Google My Business listing can significantly boost your local visibility, making it easier for potential clients to find you in local searches. And, of course, the power of word-of-mouth and strong client relationships cannot be underestimated —referrals remain one of the most effective ways to generate new business.

Whatever path you choose, the key is to stay visible, credible, and connected with your clients.

For more free information and advice on running a successful trade business, as well as a free trial please www.rdr.link/pbi004

Worcester Bosch has announced the launch of PowerUp – two new promotions that offer rewards and a place on an exclusive trip for loyal installers.

From 1st September to 31st December 2024, participating installers will have the chance to qualify for a luxury trip to Porto, Portugal, or win prizes by hitting their personalised gas boiler targets.

The highlight of the promotion is the ‘PowerUp to Porto!’ trip, happening in May 2025, where lucky installers will be treated to a long weekend in the vibrant city of Porto.

To participate, installers need to activate the promotion at www.worcester-rewards.co.uk/powerup to receive their personalised gas boiler target, and then register their installations through their online loyalty account. The first installers to reach their targets will secure their place.

Worcester Bosch is also offering a secondary PowerUp promotion to further reward installers between 1st September and 31st December 2024. All loyalty members can participate by activating the offer via PowerUp and fitting up to 10 extra gas boilers, based on the same period in 2023. The rewards include:

Fit 1 more = Worcester Bosch Flue

Fit 3 more = £75 Amazon.co.uk Gift Card (Restrictions apply, see www.amazon.co.uk/gc-legal)

Fit 6 more = JBL Flip 6 Speaker

Fit 8 more = £150 Tesco Digital Gift Card

Fit 10 more = Bosch Professional Power Tools Kit

With heating season upon us, PHPI looks at some of the recent promotions available to installers this autumn.

To help installers stay on track, Worcester Bosch will be sending out regular email updates tailored to their performance and promotion activation.

Speaking about the launch of PowerUp, Sales and Marketing Director at Worcester Bosch, Jo Shepherd said: “We’re excited to announce the launch of PowerUp and look forward to rewarding our dedicated installers throughout the rest of the year. These standout promotions have been introduced to show our appreciation for their continued support.”

Terms and conditions apply.

For more information please www.rdr.link/pbi005

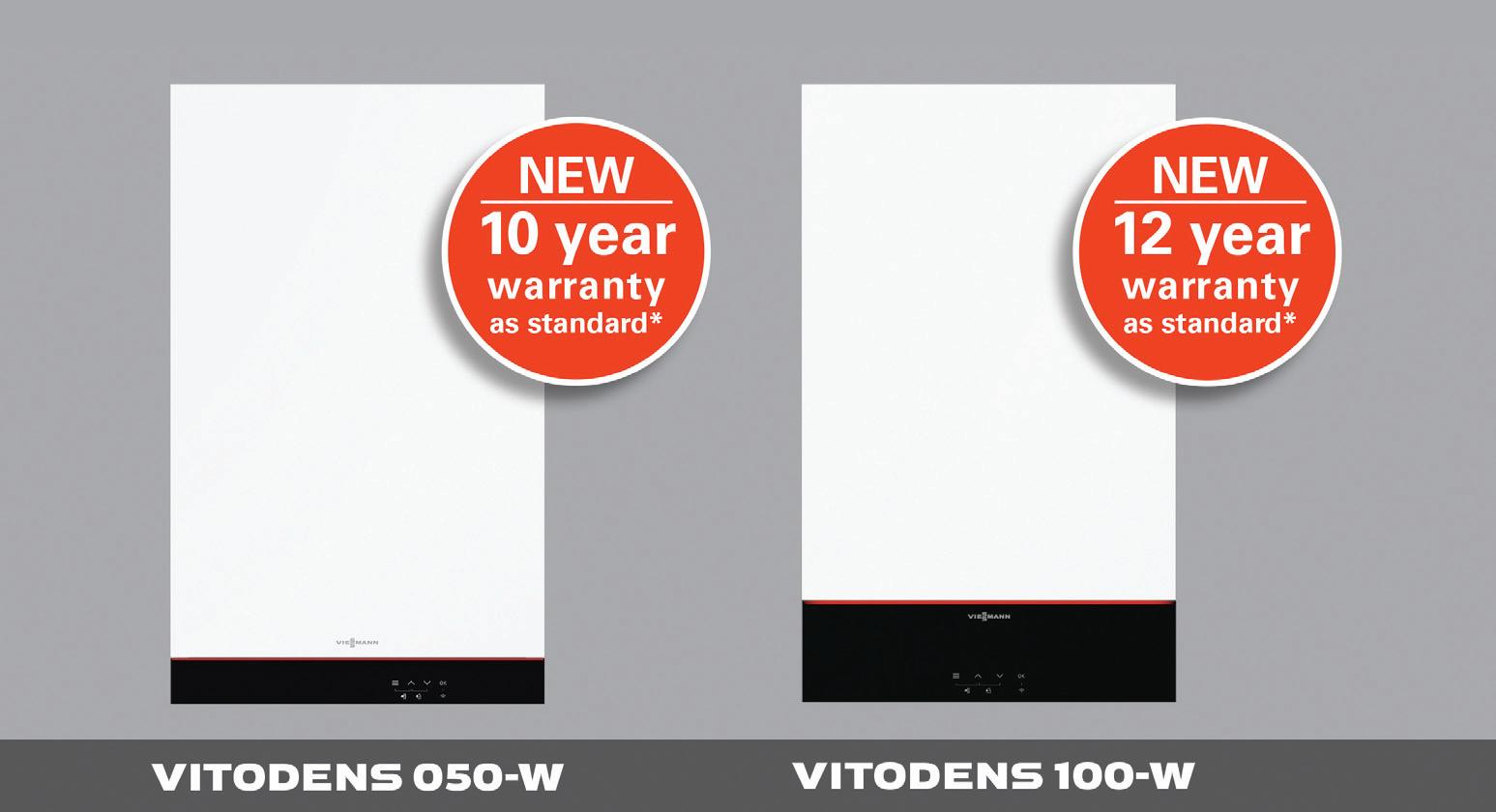

Viessmann is taking a very serious market approach this heating season with this targeted package of sales incentives and warranty extensions.

As the 2024 heating season gets underway, Viessmann has announced a package of incentives for installers of its most popular domestic and light commercial boilers, and heat pumps.

From September 1st to December 31st, the free warranty on the Vitodens 050-W and 100-W domestic boilers is increased to 10 and 12 years respectively, when products are registered on the Viessmann Installer Portal.

Viessmann Vitocal 150-A and 151-A air source heat pumps are now available with an extendable 10-year warranty. This warranty offer does not have an expiration date. Terms apply, which can be accessed via the Viessmann Installer Portal.

The company has also launched five new financial incentive schemes designed to help installers make specifying Viessmann products easier. All promotions are for registrations made on the Viessmann Installer Portal between September 1st and December 31st 2024. Installers should consult the portal for full terms and conditions.

Existing Viessmann installers can enjoy ‘unlimited cashback claims’ of £150 for every five Vitodens 050-W boilers registered and £300 for every five Vitodens 100-W boilers. Claims must be made by January 12th 2025.

For installers new to the Viessmann brand, and subject to the same claim period as above, an incentive payment of up to £500 will be made for their first Viessmann product registered. The payment ranges from £100 for a Vitodens 050-W boiler to £500 for a Vitocal 150-A or 151-A air source heat pump.

“Backed by product and integration technology that the market is hungry for, Viessmann is taking a very serious market approach this heating season with this targeted package of sales incentives and warranty extensions,” said Chris Johnson, Director of Sales at Viessmann Climate Solutions UK.

For more information please www.rdr.link/pbi006

Baxi has launched what it describes as ‘its biggest boiler cashback promotion yet’ to support heating engineers this heating season. From 2nd September, Baxi Works members will receive £300 for every three boilers they install from the brand’s 600 and 800 ranges when they register them on the platform.

Capped at 30 installations, installers could earn £3,000 in cashback this heating season, the highest cashback offer from the company to date. All system, heat only

and combi boilers from the Baxi 600 and 800 ranges are eligible for cashback.

The products have been designed for smooth installation and maintenance. The 600 range includes a 7-year parts and labour warranty, while the 800 models benefit from a 10-year parts and warranty and Adey Magnaclean Micro 2 system filter.

Rob Pearse, Distribution Director at Baxi, said: “Heating season is a busy time for hard working heating engineers carrying out boiler servicing to keep our nation’s homes warm. We wanted to show our appreciation for their hard work, loyalty to Baxi and choosing our latest efficient range of heating solutions to heat their customers’ homes by launching our biggest cashback promotion yet.

“Promotions like this along with the knowledge, expertise and training we offer are all part of our commitment to being installers’ industry partner of choice.”

Baxi’s latest cashback offer will be running until the 6th January 2025 and is open gas safe heating engineers signed up to Baxi Works.

For more information please www.rdr.link/pbi007

This autumn, installers who are new to Navien Choice Plus – the latest evolution of its Navien Choice loyalty programme –will receive additional points on its range of gas- or oil-powered boilers, following their first installation registered with the platform. This means that those installing Navien’s flagship NCB700 ON Combi Crossover boiler, for example, will receive an additional 100 Navien Choice Plus points.

Commenting on the latest promotion, Jason Davies, Sales Director at Navien UK, said: “We’re excited to introduce this fantastic autumn promotion – which is our largest to date. Having recently relaunched our loyalty programme with Navien Choice Plus, we’ve been talking to our loyal installer network to help tailor new incentives like this to ensure new and existing members can truly reap the rewards this heating season.”

Navien will also be rewarding existing members. In addition to the rewards installers already receive through the programme’s tiered system of silver, gold, platinum and diamond, both new and existing members will be able to claim up to 100 more points for every four boilers they install.

The promotion runs until the 30th November 2024. Only selected Navien products will apply.

For more information please www.rdr.link/pbi008

To ensure ASHPs run as efficiently as possible, they need to be correctly installed and commissioned.

Here, Paul Bailey, Heat Pump Engineer at Baxi, shares a commissioner’s insights that can benefit ASHP installers.

Heat pumps are generally very reliable so, when issues do arise, they tend to be as a result of a wider system issue, incorrect installation or the wrong settings being used. Like any heating source, ASHPs work at their most efficient when installed correctly in line with the manufacturer’s instructions. This is why accurate commissioning is essential.

The process ensures settings can be optimised to meet customer heating requirements and makes sure the technology is operating at peak capacity. Since the operating principles of heat pumps are still in their infancy and new to many installers, assisted commissioning is a great way to reassure both yourself and your customers that the installed solution will do the best job it can.

Baxi offers assisted commissioning on the first installation to help identify errors and make any necessary corrections. All factory specifications are checked to ensure the system can operate reliably over an extended period and can therefore provide efficiency and energy savings to homeowners. Correct commissioning which includes proper inspection of setup and operation, is a critical step installers should take to mitigate the risk of any potential underperformance when approaching an ASHP installation.

Commissioning exists to make sure all factory specifications are adhered to. This includes checking the setup and operation of a system. As part of the initial checks, things like condensate drainage, a solid base and minimum clearances around the appliance should all be checked.

So what exactly should those checks be looking out for? It’s important to note that ASHPs should be positioned close to the property, using minimal pipework and kept within easy access for servicing and

maintenance. Sufficient space is also required for the systems to expel cold air out and they should be placed on a solid surface to the manufacturer’s specification. It is at this point that checks can also be made to ensure the heat pump performs to the specification prescribed by room-by-room heat loss calculations. As long as the system including its radiators and emitters have been accurately sized, the home should feel suitably comfortable, even if those radiators are emitting lower temperatures.

Getting these calculations right allows ASHPs to maximise energy efficiency and lower utility bills. Accurate sizing and installation also means installers can schedule domestic hot water times and temperatures that work for customers.

To make heat loss calculations easier, once an installer completes Baxi’s training course they will receive a three-month subscription to Carno with unlimited projects, free of charge. Carno helps installers to pre-qualify their prospective customers quickly with indicative pricing, using available data and images of the customer’s property without the need for a pre-visit.

Users can complete a full room-by-room heat loss calculation and the app will provide a finalised schedule of equipment including ASHPs, water cylinders and heat emitters from Baxi’s catalogue.

Support and training

To put any installer concerns at ease and make sure systems are working correctly for everyone, Baxi’s heat pump engineers can guide them through the commissioning process from start to finish. This ensures any issues are identified and dealt with early on so the system can carry on operating efficiently.

For those installers who wish to become more familiar with the installation process and qualified to install the systems, they can also benefit from Baxi’s full suite of ASHP training courses. From understanding how air source heat pumps work to designing, installing and commissioning them, the programmes assist installers at every level of experience to work comfortably and efficiently with the technology.

Additionally, to support those who qualify as a Baxi Heat Pump Installer with an extra incentive, installers can receive £600 cashback on their first three eligible installations of Baxi HP-40 ASHPs before 6 January 2025. To claim the cashback, heat pumps must be registered through Baxi works and an assisted commissioning with a Baxi Engineer must be completed on the first installation if an installer has not already done so previously.

Many homes are already adopting ASHP technology and there are plenty of success stories where accurate commissioning has played a crucial role in maximising efficiency. When Jonathan and Emma Hayes built their 2,600 sq ft property in Suffolk, they required a heating system capable of improving energy efficiency while also being suitable for the off-grid application.

The new property was well insulated and as energy efficient as possible – the perfect conditions for a heat pump. After carrying out detailed heat loss calculations on the property, the engineer recommended the Baxi HP40 11kW ASHP with a 250-litre hot water cylinder. This solution feeds the underfloor heating, which can emit 11kW of heat even on the coldest of days.

Renew East who recommended Baxi’s HP40 Monobloc Air Source Heat Pump (ASHP) were able to access Baxi’s full heat pump services and expertise both before and during the project in the run-up to its installation.

Once the installation was complete, they were also able to benefit from commissioning supervision offered by Baxi’s expert heat pump engineers, who could ensure the solution was able to deliver its intended design performance prior to handover to the homeowners.

Renew East Director Luke Nicholls said: “The top-notch extra support Baxi has given has also helped the project to run like clockwork. Often with other manufacturers there’s no return of an email, but every single one of my questions has been answered within just a few hours.

“The supervised commissioning support was something I had never experienced before with any other manufacturer, so I didn’t know what to expect, but having the engineer physically with me on site was really helpful. They know the product inside out, so it just made the whole process straightforward.”

To find out more about assisted commissioning please www.rdr.link/pbi009

To find a Baxi ASHP training course please www.rdr.link/pbi010

Innovations in heat pump technology and refrigerants are improving the environmental benefits of systems. For installers ready to adapt, embracing these developments is a chance to capitalise on a growing market while positioning themselves as experts in eco-friendly, sustainable heating solutions.

One of the most notable recent advancements in the heat pump market is the introduction of R290 refrigerant in air source heat pumps. This new refrigerant is transforming the way we think about environmentally friendly heating and promises to make heat pumps even more sustainable.

Advancements in heat pump technology are making systems greener and more energy efficient than ever, says Stuart McWhinnie, Assistant Product Manager at Grant UK.

As with any innovation, however, R290 raises important questions for installers.

‘R290’, also known commercially as propane, is a by-product of the natural gas process that also acts as an excellent heat transfer medium when used in the vapour compression cycle of a heat pump. R290 has been successfully used for several years in air conditioning and refrigeration systems. Its adoption in the UK heat pump market is gaining momentum due to its extremely low Global Warming Potential (GWP) of just 3.

Installers might wonder how it differs from other refrigerants in terms of installation and safety. One key difference is that R290 requires additional safety precautions during installation and servicing. However, R290 operates in a similar manner to other refrigerants within heat pumps. Like R32 and R410a refrigerants, it cycles between liquid and gaseous phases to transfer latent heat from the outside air into useful heat energy for the property’s heating circuit. But thanks to its superior thermodynamic properties, R290 can capture and release heat more effectively, making the systems that use it more energy efficient. This increased efficiency can translate into potential energy benefits for homeowners and a more sustainable heating option overall, compared to units using more commonly available refrigerants.

As R290 rises in popularity, another concern is whether it will be readily available for installers in the UK. Currently, R290 is widely used in air conditioning and refrigeration, so it already has an established supply chain. Its use in heat pumps is growing and availability is expected to increase as demand rises. Suppliers are expanding their stock to meet this growing demand, so installers should not face significant issues in sourcing R290 for installations.

Grant UK launched its latest product line, the Aerona 290 heat pump range, in October 2024. This range marks the fifth generation of our air source heat pumps and takes full advantage of the energy efficiency and low environmental impact of R290 refrigerant without sacrificing performance. These units have earned A+++ energy efficiency ratings (at 35°C flow temperature) and have been tested to perform in extreme temperatures ranging from -25°C to 35°C, making them suitable for homes in a variety of climates.

The Aerona 290 units have ultra-low noise levels, achieving Quiet Mark accreditation thanks to sound-reducing technologies, including acoustic insulation and anti-vibration feet, making them a practical choice for both urban and rural homes, where noise reduction is a priority. Research has highlighted concerns about the appearance of heat pumps, and Grant UK has responded. The Aerona 290 has a sleek black design for a modern aesthetic. Designed to suit a range of property types, from new builds to retrofit projects, they provide a versatile solution for various installations.

To ensure installers are fully prepared to work with R290 refrigerant and the new Aerona 290 units, Grant UK is offering comprehensive training at its Training Academy. The course is designed to equip installers with the skills and knowledge needed to safely and effectively install, commission and service R290-based heat pumps.

The Aerona 290 Air Source Heat Pump installer course covers everything from system installation and electrical wiring to configuring the Aerona Smart heat pump controller and fault finding. Special attention is given to safe handling practices, protective zones and precautions when dealing with R290 refrigerant.

For installers new to heat pump systems or looking to refine their expertise, Grant is also offering a one-day system design course. This course focuses on the basics of heat pump system design, including heat loss calculations, heat pump selection, emitter sizing and sound level calculations. This course is especially valuable for those looking to ensure that each system is correctly sized for optimal performance and customer satisfaction.

Alongside the new Aerona 290 heat pumps, Grant UK is launching a range of ancillary products that will give installers greater flexibility when designing systems. These include new QR Smart Pre-Plumbed cylinders and additional smart heat pump controller kits, which are compatible with both the Aerona 290 and Aerona³ heat pump ranges. These products have been designed to offer installers more flexibility and ease when working with various system configurations, ensuring that the heat pump system is optimised for each installation.

For more information please www.rdr.link/pbi011

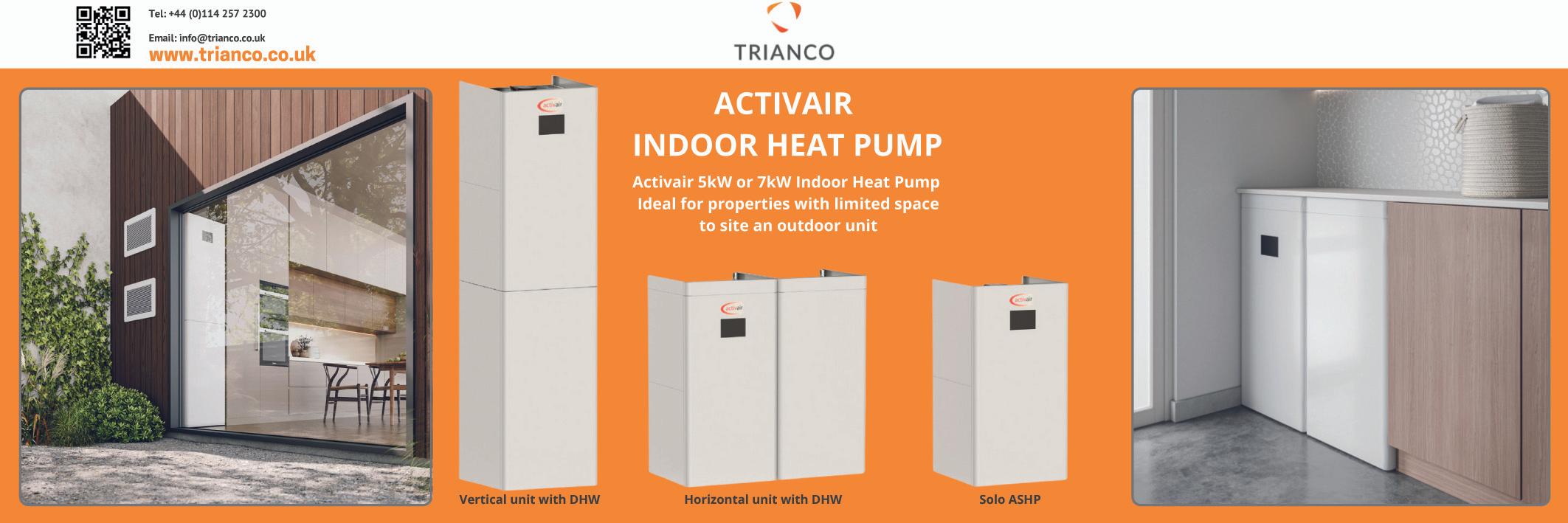

To help more people gain knowledge of heat pumps Ideal Heating’s Expert Academy has launched a free digital course. The new digital On Demand course, ‘Introduction to Air Source Heat Pumps’ covers issues including how heat pumps work, where they can be fitted and how they are controlled.

Ideal Heating says it is suitable for many people across the industry including existing heating engineers, newly-qualified engineers, apprentices, industry partners such as merchants, specifiers and more.

Ideal Heating’s Training Director, Andrew Johnson, said: “It’s so important we equip both installers, and the broader heating industry, with the skills and knowledge they need to play their part in the transition to net zero.

“We’re investing millions of pounds as part of our commitment to re-skilling the industry, the launch of this new on-demand style will allow more people to access free content to continue their lifelong learning.

“It’s really important to me that people can access high quality training that fits around their busy lives and doesn’t burden them with lots of additional costs.”

It’s really important to me that people can access high quality training that fits around their busy lives and doesn’t burden them with lots of additional costs.

Designed to increase the knowledge around Heat Pumps, Ideal Heating has launched a new online heat pump course.

The ‘Introduction to Air Source Heat Pumps’ course is live now. Ideal Heating recommends that it should take between two and three hours to complete.

The course features 11 modules, with subjects including the different types of air source heat pumps, how refrigerants work, electrical considerations, controls, frost protection and funding.

The company says the course can either be completed in one go, or in sections, with participants having the flexibility to jump in and out of modules as needed. Content also remains available after completion and can be referred back to.

The course has been developed in partnership with BPEC, a specialist provider of qualifications, assessments, training courses and learning materials. After completing the course, installers who wish to further their knowledge can register for a range of in-person courses, where they will have the opportunity to work hands-on with heat pumps and gain qualifications and product training on Ideal’s Logic Air and HP290 models.

The Introduction to Air Source to Heat Pumps course is available to enrol now. Please www.rdr.link/pbi012

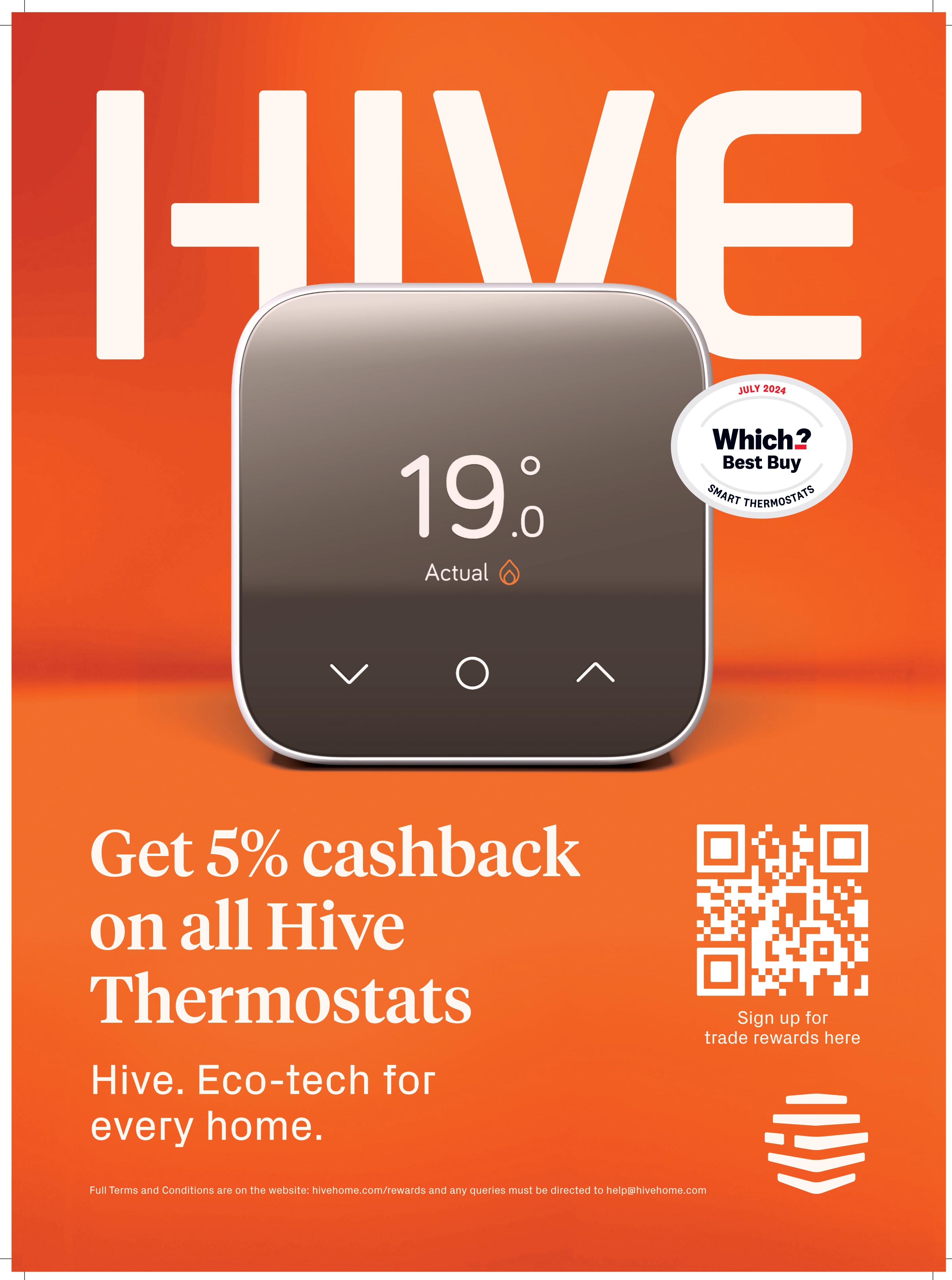

Reducing a home’s impact has to start by selecting an efficient heating and hot water system. These systems ensure comfort and convenience and combined with the right levels of insulation, significantly influence a home's carbon footprint. It’s important to recognise that traditional systems can be energy-intensive, especially those involving separate heating and hot water appliances. Installers can help homeowners achieve energy savings and reduce emissions by advising on high-efficiency systems that combine both functions.

Once the right system is in place, managing energy usage daily becomes equally as important. Intelligent control systems make such a difference in enabling homeowners to optimise their heating for maximum comfort. Installers can introduce customers to smart control technologies that adapt to their heating habits, ensuring the boiler only runs when necessary and at the most efficient capacity.

Likewise, smart thermostats and AI-powered management systems can analyse usage patterns, adjust to external factors such as the weather and continuously tweak the system's output. By reducing unnecessary energy consumption, homeowners can lower their carbon emissions. This level of intelligent control gives the homeowner more confidence that their system is running at peak efficiency, contributing to a more energy-efficient home.

In addition to smart controls, another key tool in the installer's arsenal is Home Energy Management Systems (HEMS), providing detailed reports on a home's energy usage, allowing homeowners to make data-driven decisions. When homeowners can see exactly how much energy they're using – and when – they can take active steps to reduce consumption. By using the data, installers can demonstrate the value of this insight by showing how even small behavioural

With growing pressure to adopt low-carbon heating solutions, homeowners are increasingly seeking advice from installers to help them make informed, sustainable choices. Sean Keleher, Technical Director at Navien UK, discusses how installers can support homeowners in reducing their carbon footprint by making low-carbon choices, and looks at the systems and controls they can recommend.

smart thermostats and AI-powered management systems can analyse usage patterns, adjust to external factors such as the weather and continuously tweak the system's output.

changes can lead to measurable reductions in energy use and, by extension, lower carbon emissions (as well as bills). By offering systems that include HEMS functionality, installers enable homeowners to improve efficiency and gain a deeper understanding of their energy habits, reinforcing their commitment to low-carbon living.

The Navien NCB500 ON and NCB700 ON Combi Crossover boilers, when combined with the Navien Smart Plus ON AI Controller, provide an excellent solution for homeowners who want to reduce their carbon footprint and manage their energy-usage.

Our boilers integrate heating and hot water functions into one highly efficient system. Unlike traditional setups where separate systems can lead to inefficiencies and higher energy consumption, integrating

these functions streamlines energy use.

The efficiency of our NCB ON boilers is further enhanced by our Smart Plus ON AI Controller. Our advanced technology analyses and learns from a home's specific heating patterns and considers external factors, such as local weather conditions, using OpenWeatherMap.

In addition, our ON AI app allows homeowners to manage their heating system remotely. Through this app,

homeowners can adjust settings, monitor real-time energy usage and control their heating from anywhere. This remote access allows the homeowner to adjust based on their immediate needs and preferences, ensuring that energy is used efficiently and only when necessary.

Additionally, HEMS software is included with our Smart Plus ON AI Controller and offers detailed reports on energy usage. These reports provide valuable insights into energy consumption patterns and highlight areas for potential improvement.

For more information on the Navien NCB500 ON and NCB700 ON Combi Crossover boilers and ON AI technology please www.rdr.link/pbi013

To learn more about supporting homeowners in reducing their carbon footprint, please www.rdr.link/pbi014

Malcolm Farrow, Head of Public Affairs at OFTEC argues that achieving net zero and tackling social inequality can go hand in hand.

Summer 2024 saw huge change in Westminster.

We have a new party in government, a new prime minister, a new secretary of state for energy and hundreds of new MPs. However, in rural communities up and down the country, homes and businesses still face the same decarbonisation challenges and the same barriers to transitioning to low carbon heating. Labour now has unique opportunity to forge a new path which delivers on net zero whilst tackling social inequality.

Currently, plans for off-grid decarbonisation are somewhat in a state of limbo. The previous Conservative government proposed to phase out the installation of fossil fuel boilers and transition these properties onto heat pumps. However, after pressure from consumers and backbench MPs, plans were repeatedly put on hold and no firm policies were put in place.

This was driven by several factors. Firstly, the nature of rural off-grid housing stock makes it very difficult to switch these buildings to a heat pump. Properties typically have poor energy efficiency and require significant renovation as part of a heat pump installation. Even with the available government grants, the cost and disruption were a real barrier.

The cost-of-living crisis squeezed household finances - and government budgets - even further which meant that there hasn’t been the money to enable households to make these big investments. Weak consumer demand has also affected industry confidence and meant there weren’t enough installers to deliver on the government’s targets even if they could be met.

The existing Boiler Upgrade Scheme provides up to £7,500 for a heat pump installation, increasing deployment but disproportionally benefiting higher income households as they have the disposable income to meet the remaining cost. Some argue that as long as heat pumps are installed, that’s all that matters. However, low-income households, who typically live in poorer quality housing, are unlikely to apply, and such policies risk a growing social divide on the journey to net zero. But could that emphasis change? Social justice is hard-wired into Labour’s DNA and could inform their approach to decarbonisation. With the right blend of policies, achieving net zero, tackling the economic inequality blighting so many rural communities and creating opportunities by fixing the skills shortage

could go hand in hand. This would require policies rooted in a more holistic approach and driven by an overarching commitment to fairness, rather than one just focussing on heat pump installations.

The skills shortage is an underlying challenge that has held back the rollout of heat pumps in the heating sector. It affects not just heat pump installers but all areas of the retrofit supply chain. Labour needs to deliver a skills revolution, starting from schools all the way through to college and apprenticeships. Our education system needs to give equal value to the skilled technical trades and promote the opportunities of a career in the industry. Alongside having the workforce, increasing the pace of low carbon deployment is critical too, and can be achieved by focussing on policies to prioritise heat pumps initially where economies of scale are easiest to achieve. This means targeting urban and suburban

areas which will help to bring down costs and ultimately make them more accessible for harder to treat off-grid homes.

This is key because heat pumps have a key role to play in the decarbonisation of the whole domestic heating sector. OFTEC is actively supporting the rollout through our heat pump training courses to help more installers diversify. In fact, over a third of all OFTEC training undertaken so far this year was heat pump training.

However, for some properties, heat pumps still won’t be viable. That’s not because their owners aren’t concerned about carbon emissions. Far from it, these households are often some of the most vocal and determined to be greener. For many rural off gas grid homes the existing challenges outlined above will not be easily overcome, even with more socially targeted retrofit funding. What’s overlooked here is the need for consumer choice and availability of the type of low carbon heating system which meets these individual’s needs.

Our education system needs to give equal value to the skilled technical trades and promote the opportunities of a career in the industry.

Such pragmatism is important, given the political tightrope the new government has to walk. Whilst Labour is fully committed to net zero, the Party will be aware of the backlash the last government faced trying to force homes to change their heating system. As a result, during the election, Labour said this is not a route they would go down. Recent changes to the Winter Fuel Payment has also created difficulties for the government and will have a big impact on older people who live in rural areas. Labour will be cautious about the policies they push forward to this voter group.

It’s increasingly clear that other alternatives will be needed. We’ve demonstrated the viability of renewable liquid fuels such as Hydrotreated Vegetable Oil (HVO) as a replacement to kerosene. With minimal disruption, a simple conversion to the boiler of less than £500 and a potential to reduce emissions by 88%, it’s an ideal solution to the problems we’ve outlined. Our survey of several thousand rural households also shows over 80% support.

We will continue to work proactively and positively with the new government to secure the policy support needed to rollout renewable liquid fuels more widely. The industry already has an extensive workforce, supply chain, training, experience and high safety standards so it is well placed to scale up the transition to renewable liquid fuels very quickly. All we need, is the green light from government.

For more information please www.rdr.link/pbi015

The bathroom industry has undergone significant evolution in recent years, driven by technological advancements, changing consumer preferences, and an increasing emphasis on sustainability. Andrew Shankster, Product Training Manager at Geberit UK explores key trends shaping the future of bathroom design and installation, and how industry professionals can leverage them to their advantage.

One of the most notable shifts in the industry is the move towards multi-layer piping systems. These solutions offer an alternative to traditional materials, addressing common issues such as corrosion, scaling, and heat loss. Multi-layer pipes typically consist of three layers, with a central aluminium layer sandwiched between two plastic layers. This construction offers a combination of flexibility and stability, making installation more efficient.

The benefits of multi-layer piping systems for installers are substantial. The installation process is streamlined, with no need for hot works or additional consumables on site. These systems are versatile, suitable for various applications from potable water to heating systems. Their durability, including resistance to

corrosion, cracking, and scale build-up, ensures a longer service life. Furthermore, the excellent thermal insulation properties of multi-layer pipes contribute to energy efficiency, aligning with the requirements of Part L of the Building Regulations for the conservation of fuel and power.

Products such as Geberit FlowFit exemplify these advantages, offering press-fit technology that further optimises the installation process. With only two pressing jaws required for the entire range, it presents an efficient solution that can enhance productivity, particularly in confined spaces. Embracing multi-layer piping systems can differentiate installers in a competitive market, offering clients a modern, efficient solution that aligns with the growing demand for sustainable and cost-effective installations.

The rise of shower toilets

Another trend gaining significant traction is the increasing popularity of shower toilets. These advanced fixtures, which combine the functions of a toilet and a bidet, are increasingly perceived as a luxury item in residential bathrooms and are becoming more prevalent in commercial settings.

Shower toilets, such as the Geberit AquaClean Alba, offer several benefits that resonate with modern consumers: enhanced hygiene through integrated washing functions, improved comfort features like heated seats and adjustable water temperature, increased accessibility for users with mobility issues, and sustainability benefits through reduced toilet paper usage and efficient water consumption.

For installers, the growing demand for shower toilets presents an opportunity to expand their service offerings and develop expertise in high-value installations. While the installation process may require additional skills, particularly regarding electrical connections and specialised water supply requirements, mastering these systems can position installers as specialists in a growing market segment.

The trend towards minimalist, spa-like bathrooms has driven demand for concealed installation systems. These behind-the-wall solutions create a sleek, uncluttered aesthetic while maximising space – a crucial consideration in modern bathroom design. Concealed cisterns for wall-hung toilets are at the forefront of this trend. While they may present initial challenges, such as accommodating uneven wall surfaces or working in compact spaces, the end result is a stylish and space-efficient solution that increasingly appeals to clients.

To successfully navigate concealed system installations, installers should familiarise themselves with adjustable mounting frames to compensate for wall irregularities, utilise manufacturer-provided templates and measuring guides for precise positioning, and consider systems designed for efficient installation, such as Geberit Sigma and Omega concealed cisterns. These products offer features like tool-free installation options and easily accessible service openings, facilitating both installation and future maintenance.

Perhaps one of the most significant shifts in the industry is the growing demand for personalised, bespoke bathroom designs. Clients increasingly view their bathrooms as personal retreats and seek spaces that reflect individual styles and needs. This trend towards customisation is evident in the popularity of modular bathroom furniture and mix-and-match concepts. For example, Geberit's Mix & Match concept allows customers to combine basins and furniture across different ranges, creating personalised wash places.

For installers, this trend towards bespoke designs necessitates an expanded

product knowledge base, increased flexibility in working with diverse materials and installation requirements, and enhanced collaboration with designers and clients to understand and implement unique visions. It also requires problem-solving skills to overcome installation challenges that may arise from custom designs.

The importance of training

To maximise opportunities in this evolving market, installers should prioritise continuous professional development. This includes staying updated on the latest products and installation techniques through manufacturer training programmes and industry events. Investing in specialised tools for working with new materials and systems, such as press-fit tools for multi-layer piping, can enhance efficiency and capability.

Marketing strategies should be adapted to showcase expertise in trending installations, such as shower toilets or concealed systems, through digital platforms and client testimonials. Building strong relationships with suppliers who offer products aligned with these trends

can provide a competitive edge and potential business referrals.

Additionally, the ability to educate clients on the benefits of new technologies and designs can be a valuable differentiator. Installers who can effectively communicate the advantages of bathroom solutions –whether it's the improved hygiene of a shower toilet or the space-saving benefits of a concealed cistern – are better positioned to secure high-value projects.

The bathroom industry is undergoing a significant transformation, and installers have the opportunity to be at the forefront of this evolution. By embracing these trends and continually expanding their skills and knowledge, plumbing and heating professionals can offer clients bathrooms that are not only functional but also sustainable, personalised, and innovative. Adapting to these changes and positioning oneself as an expert in modern bathroom solutions can lead to business growth and success in this dynamic market.

For more information please www.rdr.link/pbi016

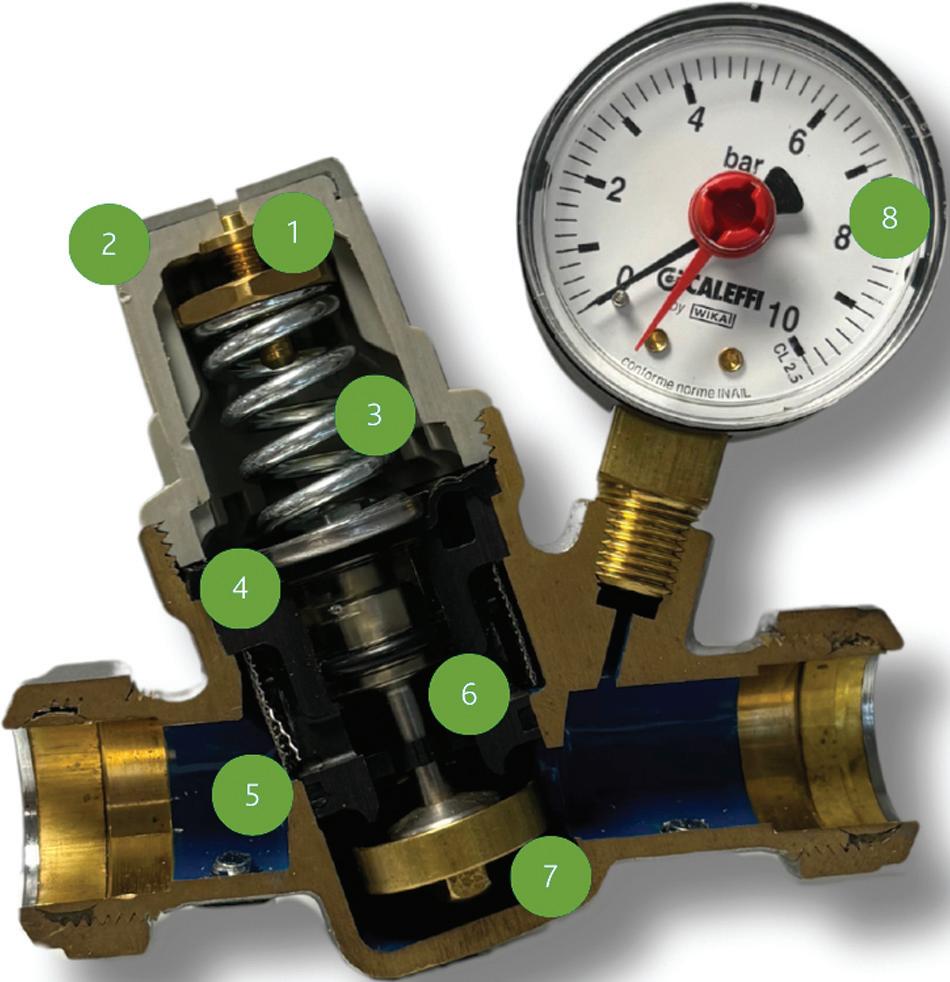

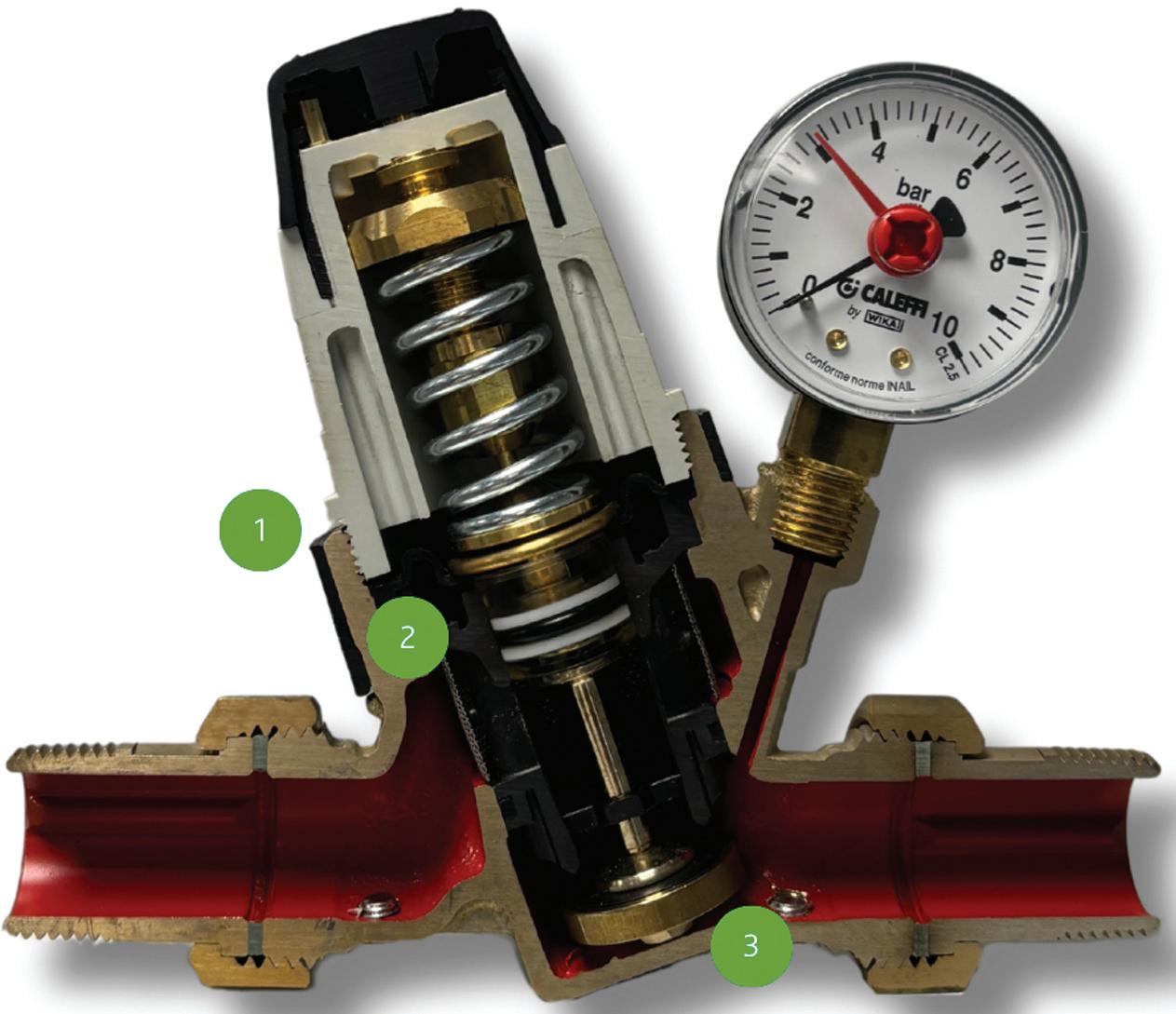

Ed Morris, Technical Manager at Altecnic, delves into the inner workings of two pressure reducing valves: the Caleffi Series 533 PRV and the Caleffi Series 535 High Temperature PRV.

Apressure reducing valve (PRV) is an essential device in plumbing applications, designed to regulate and maintain a constant downstream pressure, regardless of fluctuations in the incoming pressure. By controlling the pressure, PRVs protect appliances and systems from damage, conserve energy, and optimise performance.

The Caleffi Series 533 is a widely used PRV in residential and light commercial applications. The core components of this valve include:

The adjusting screw is located at the top of the valve and plays a critical role in setting the desired downstream pressure. By tightening or loosening the screw, the tension on the internal spring changes, which alters the force applied to the diaphragm. This controls the outlet pressure. The adjusting screw allows for the valve’s performance to meet specific system requirements.

The cover of the pressure reducing valve encloses the upper part of the valve, protecting critical components such as the adjusting screw and spring from external elements like dust, moisture, and debris.

The adjustable spring is one of the most crucial parts of the PRV. The spring is located above the diaphragm and is compressed or relaxed to adjust the set

pressure. The amount of tension in the spring determines the force exerted on the diaphragm, thus controlling the pressure on the downstream side.

The diaphragm is a flexible membrane that responds to the pressure differential between the inlet and the outlet. When the downstream pressure exceeds the set value, the diaphragm pushes against the spring, reducing the flow. When the downstream pressure drops, the diaphragm relaxes, allowing more water to pass through.

The Series 533 includes an integrated filter mesh, which filters out impurities and debris from the incoming water before it reaches the sensitive internal components. This helps to prevent clogging and prolongs the valve's lifespan.

The control stem acts as an intermediary between the spring and the valve disk. When the adjusting screw changes the spring's compression, the control stem transmits this force down to the valve disk. As the control stem moves up or down, it either allows more water to flow or restricts it, which helps fine-tune the pressure output.

At the heart of the PRV's control mechanism is the seat and valve disk. The seat is a surface that the valve disk presses against to stop or allow water flow. As the diaphragm moves, it either lifts the valve disk off the seat to allow flow or presses it down to reduce flow, thus modulating the pressure.

For easy monitoring, the Series 533 includes ports where pressure gauges can be attached to measure both upstream and downstream pressures. This allows for easy calibration and troubleshooting of thevalve.

While the Series 533 is designed for standard water systems, the Caleffi Series 535H PRV is specifically engineered for high-temperature applications, such as hot water systems where temperatures do not exceed 80°C. The basic operation remains similar, but the materials and design are modified to handle more extreme conditions.

The valve body of the Series 535H is built with materials capable of withstanding higher temperatures. This ensures that the valve performs consistently in environments where traditional valves would fail.

The diaphragm in the Series 535H is made from heat-resistant materials like EPDM (ethylene propylene diene monomer) or PTFE (polytetrafluoroethylene). These materials can endure high temperatures without losing flexibility or structural integrity, ensuring consistent pressure regulation even under thermal stress.

The seat and valve disk in the Series 535 are also upgraded to withstand the intense heat of steam or high-temperature water.

The choice between the two different types of PRV depends largely on the system requirements. For everyday water pressure management, the Series 533 offers a balance of precision and durability. For high-temperature systems, the Series 535H steps up, providing performance where other valves might fail. Understanding the components of these valves allows engineers to select the best valve for their needs, ensuring long-term efficiency, safety, and reliability.

For more information on Altecnic’s range of pressure reducing valves, please www.rdr.link/pbi017

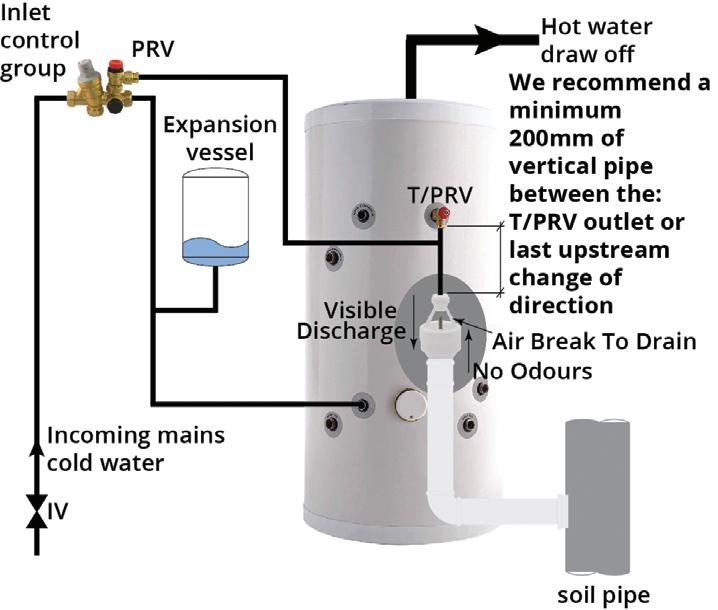

Russell Armstrong, the inventor of the hotun dry trap tundish, investigates the regulations and the use of tundishes for unvented hot water cylinders

Understanding G3, H1 and the Water Regulations is crucial for ensuring safety and compliance.They provide important and useful guidance for installers.

The G3 Regulation outlines the standards for the installation of unvented hot water systems. Document H gives the requirements for preventing foul air from entering the building. The Water Regulations are there to ensure that potable water is protected from contamination.

Larger unvented water heaters are popular due to their ability to deliver a good quantity of hot water. These systems are pressurised, which if not correctly installed can lead to dangerous situations.

Relevant general requirements for installations

Safety Features G3 Regulations stipulate that unvented systems must include specific safety features to prevent risks i.e. over pressure (PRV) and/or over temperature (T/PRV). Cylinders are therefore factory fitted with such devices.

Expansion Vessels Are essential in managing system pressure and preventing undue stress on the water heater and associated plumbing.

Regular Maintenance Maintenance is essential for safety. It is recommended to carry out regular servicing, including testing safety devices. This is an often overlooked part of the homeowners regime and various industry associations (e.g. Hot Water Association (HWA)) are keen to help promote regular maintenance as part of good practice.

Installation for impaired users The installer should give consideration for people with extra needs in accordance with this clause on page 23, G3:

3.55 Any discharge should be visible at the tundish. In addition, where discharges from safety devices may not be apparent, eg. in dwellings occupied by people with impaired vision or mobility, consideration should be given to the installation of a suitable safety device to warn when discharge takes place, eg. electronically operated

Safety devices found on an unvented water heater and the use of tundishes

Inlet control group (PRV) provides protection from excess pressure coming from the cold main and should be discharged visibly, local to the cylinder.

Combined cylinder Temperature and Pressure Relief Valve (T/PRV) this does the same as above, but also protects the system from excess temperatures.

What must a tundish do?

High temperature (90-95°C), high volume (>16LPM) discharge pipework must be designed carefully. Discharging water at these temperatures and volumes can be very

dangerous. A tundish must be able to cope with the full flow on that particular installation. Good practice would be to carry out a full flow test at time of installation, per the tundish manufacturers recommendations.

The tundish must also provide visibility of any discharging water, both when the water is running and more importantly after the PRV has stopped discharging.

Traditionally the subsequent D2 discharge pipework is routed through the building terminates, in a protected way, outside the building. However, this run of pipework is expensive in materials and extensive in time.

Introducing the Water Regulations and Building Regulation H to the installation

It has now become normal practice to run this discharging water to a local soil pipe. But that introduces the need to comply with the Water Regulations (to prevent contamination) and Document H1 to prevent foul air from entering the building.

This is why you will need to install a dry trap tundish that has a designated “air break to drain”. This type of product provides protection from backflow or back siphonage contamination, and the dry trap prevents odours and noxious gasses from entering the building.

How to ensure your chosen dry trap tundish prevents odours

Approved Document H does not specifically mention the testing of dry trap tundishes but states the following:

In the Secretary of State’s view the requirement of H1 will be met if a foul water drainage system:

a)Conveys the flow of foul water to a foul water outfall (a foul or combined sewer, a cesspool, sceptic tank or holding tank);

b)Minimises the risk of blockage or leakage;

c)Prevents foul air from the drainage system from entering the building under working conditions;

1.38 The pipes, fittings and joints should be capable of withstanding an air test of

The hotun range of products are designed for hot water applications with the installer in mind.

positive pressure of at least 38mm water gauge for at least 3 minutes. Every trap should maintain a water seal of at least 25mm. Smoke testing may be used to identify defects where a water test has failed. Smoke testing is not recommended for PVC-U pipes.

Our recommendation is to adopt the test found in clause 1.38 to ensure that your dry trap tundish is compliant.

All hotun dry trap tundishes are manufactured to this standard and are batch tested to confirm compliance.

Doing a simple compliance test on site is a good idea. The “blow” test (pressurising the D2 outlet connection

side) gives a good indication of air tightness. If you can blow through the tundish then foul air would also be able to escape and it would therefore not be deemed compliant with Document H1, 1.38.

The hotun range of products are designed for hot water applications with the installer in mind to ensure their clients get a compliant installation using just one simple product. Another product in the hotun range is the tundish alarm unit, hotun detect. It ensures that the building user has an early alert to any unwanted T/PRV activity. This alert prevents excess wasted energy and water. A repair can then be made at the earliest signs of problems and at a convenient time to suit all.

For

www.rdr.link/pbi018

Joining pipe is a daily task for most plumbers and in recent years many have been considering press fittings. Using this method, installers do not have to consider ‘hot works’ and pipes can be connected quickly and with minimal effort. To press the fittings a plumber will require a press tool.

These tools need to be substantial enough to power through the press quickly and light enough for one handed operation. Rothenberger’s ROMAX Compact III is 2.5kg (without press jaw) and at just over 34cm in length has been designed for use in constricted locations. It can press from 15mm to 35mm in copper and up to 40mm in plastic/MLP.

The company says the press cycle is achieved in around three seconds with a pressing force or 19kN. The tool features Constant Force Technology (CFT), to deliver constant pressing force over the complete pressing cycle. There is also a new Jaw Locking System designed to secure the jaws in place and enable users to attach and detach the press jaws with ease. The company suggests around 130 presses are possible with a 2.0Ah battery.

Rothenberger has unveiled a new ‘compact’ press tool.

Data acquisition is increasingly important across many areas of life and users of the ROMAX Compact III can also benefit from real-time data acquisition of relevant machine parameters and the creation of press protocols directly on site. Both can be achieved via the ROTHENBERGER App. In fact, the ROMAX Compact III is ROTHENBERGER’s first smart press machine with Bluetooth connectivity. Via the ROTHENBERGER app, tool and smartphone can be connected, providing the user both machine and press data. Through the App the tool can also be locked.

For more details please www.rdr.link/pbi019

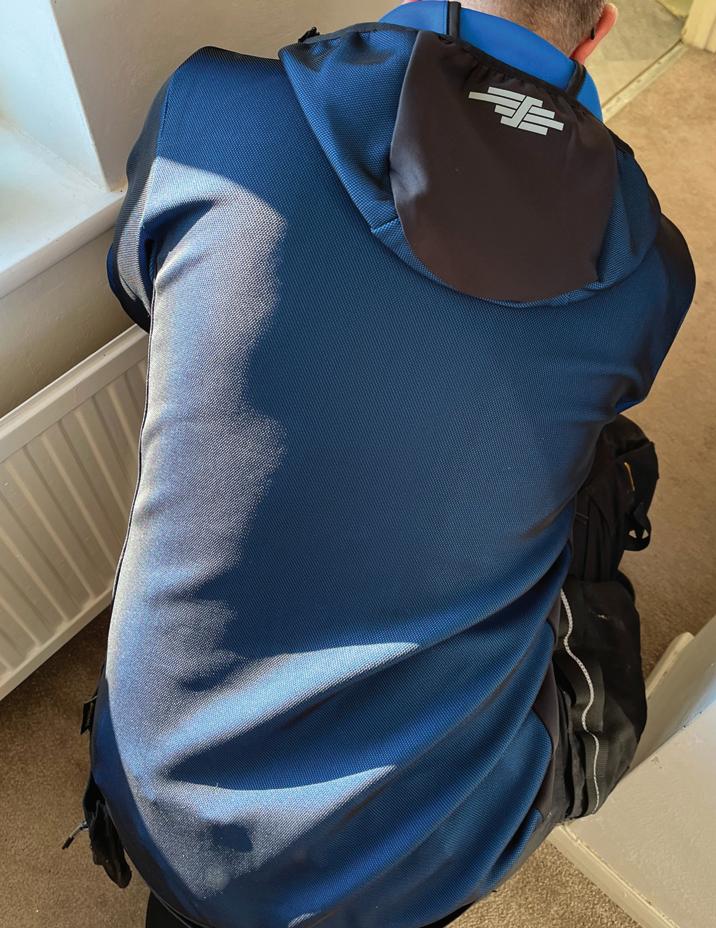

Founded in Sweden in 1975 by electrician Matti Viio, Snickers Workwear is well known for its trade clothing with a catalogue including everything from sweatshirts to socks. Whether it is hot and sunny or cold and rainy – or anything in between – the company has solutions to help tradespeople stay efficient throughout the working day.

With the autumn now upon us, and the British weather turning wet and windy, the right clothing can be the difference between a satisfying and productive working day and a miserable one. A key component to any autumn workwear is the mid-layer.

Providing some protection from the elements – though not as waterproof as outer layers – the mid-layer is key for maintaining a stable temperature. Another key factor is flexibility: with plumbers and heating engineers often stretching, twisting and bending, this layer needs to adapt to different body positions without restricting mobility.

The hood also includes a reflective detail on the front.

With autumn bringing cooler days, a warm and flexible mid-layer can help maintain body temperature and keep the wearer productive whether working outdoors or inside. PHPI takes a look at a recently introduced hoodie from Snickers Workwear.

Snickers Workwear has a large range of options in this area, with some new technical mid-layers launched earlier in the year. We recently got hold of one of the company’s Full Zip FlexiWork Midlayer Hoodies in Blue/Black – although this item is also available in two other colour combinations, Black/Black and Khaki/Black.

The company describes it as stretchy and versatile, allowing freedom of movement during work, and the top does allow a good range of movement. There are two large side pockets which can swallow up a host of items, while creating

two inside ‘pocket bags’ as well. A third pocket on the left chest easily stores a smart phone. All pockets are zipped to keep the contents secure.

The pre-bent sleeves feature thumb loops to keep the sleeves pulled down and wrists covered, while the edge of the hood is elasticated so when it is up, the hood does not restrict visibility. The hood also includes a reflective detail on the front to help others see you in dark conditions. The zippers are also reflective, further aiding visibility.

The hoodie is made of a 2-layer mesh/interlock fabric which on cooler days offers a good level of insulation, keeping the wearer warm even during periods of limited movement.

The main fastening is a two-way zipper at the front, which allows the wearer the ability to open the jacket from both the top and the bottom. This detail can help when accessing trouser pockets or to cool down – a handy feature on warmer autumn days or when working inside.

For more information please www.rdr.link/pbi020

Arctic Hayes has teamed up with PHPI to offer five lucky readers the chance to win the Aero Pipe Freeze Kit. Pipe Freeze kits let plumbers isolate a section of pipework, eliminating the need to drain the whole system. Suited to small, single-use domestic jobs, the 8-15mm Aero Disposable Freeze Kit is designed for tricky repairs where a fast fix is needed. Each kit contains a 150ml Arctic Spray Aerosol Pipe Freezer and an Arctic Spray Freezing Jacket, capable of creating a temporary ice plug on 8-15mm horizontal or vertical pipes.

PHPI HAS FIVE KITS TO GIVEAWAY. FOR YOUR CHANCE TO WIN PLEASE www.rdr.link/pbi021 5

The Venture 2 safety shoe from Solid Gear features a NANO toecap and an integrated ETPU footbed designed to provide cushioning and comfort for people spending hours on their feet. A lightweight microfiber upper wraps the foot for comfort and flexible movement, while the new MATRYX® weave and PerformFit™ Wrap technology powered by the BOA® Fit System ensures a 'locked in' fit, designed to provide maximum heel hold, support. and flexible movement.

PHPI HAS ONE PAIR TO GIVEAWAY. FOR YOUR CHANCE TO WIN PLEASE www.rdr.link/pbi022

phpionline.co.uk features the latest industry news, video reviews, technical updates and exclusive competitions, giving you instant access to all things heating and plumbing on your desktop, laptop, tablet or phone. www.phpionline.co.uk Professionalplumber@PHPI

The Gas App UK Horror Show showcases some of the ‘finest’ work spotted by installers across the country. If you spot any masterpieces to rival these, please submit them to the good people at Gas App UK or email us: phpi@hamerville.co.uk

In the latest video on the PHPI YouTube Channel Chirag from CP Utility Solutions takes a closer look at the >B< Press copper fittings from Conex Bänninger.

Plumbers are showing increasing interest in using press fittings, and over the past few issues, PHPI has looked at some of the equipment available, notably some of the press tools. But what about the fittings? A new video on the PHPI YouTube Channel should help, with Chirag, from CP Utility Solutions, taking a closer look at the >B< Press copper fittings from Conex Bänninger.

In the video he talks through some of the advantages of using press fittings – for example, no hot works permit is required –before looking at the various features and benefits of the Conex Bänninger fittings, which include products that are suitable for gas, and options that are WRAS approved.

Chirag notes: “It is very easy to distinguish between the water and gas fittings. So the gas fittings, obviously, in a yellow packet and it also has gas imprinted all across the back as well. Water fittings come in another clear packaging.”

From a health and safety perspective, you’ve got no risk of flame or explosion – it is flame free. Also, from an engineer’s perspective, you are not having to breathe in the fumes from when you are soldering.

Chirag explains that as long as the fittings are used as per manufacturer’s instructions, installers will get a 25 year guarantee. There is also a training programme available to installers.

To demonstrate how the fittings can be used, Chirag uses the gas fittings to replace a gas pipe where a leak has been reported – making quick work of the job before doing the required gas safety checks.

Heading inside, he replaces a small section of pipework near a boiler where a customer has reported a leak. During the installation Chirag demonstrates how to spot when a fitting has not been pressed noting: “You can see, with the O ring, it is not completely flooding out. It does give you an indication that there is a leak there.”

It is very easy to distinguish between the water and gas fittings

He then demonstrates how straightforward it is to rectify the issue using a press tool, even while the pipe is full of hot water. Highlighting some of the benefits, Chirag explains: “You’ can press with water in the pipes, with soldering you can’t do that. From a health and safety perspective, you’ve got no risk of flame or explosion – it is flame free. Also, from an engineer’s perspective, you are not having to breathe in the fumes from when you are soldering.”

To watch the full video please www.rdr.link/pbi023

The MagnaClean AtomSC is the latest addition to ADEY’s MagnaClean filter range.

The company’s smallest filter to date, it has been developed with the needs of the specification boiler sector in mind. Described as ‘super compact’, the AtomSC has a pipe cut-out of only 60mm. It has been designed for installation in the tightest of spaces; either under, or around the boiler.

Melissa Chamberlayne Product Manager at ADEY explained: “By working alongside key contractors in this sector we’ve been able to understand that one of the key challenges of retrofitting boilers and heating systems is installing them in increasingly restrictive locations. The AtomSC aims to address this.”

which is why the new MagnaClean AtomSC comes in a unique Compliance Pack.”

The company says the AtomSC has also been designed with the needs for the life of the system – not just for the installation. With 22mm compression fitment, AtomSC also features filter-to-boiler isolation. By isolating the built-in isolation valve on the filter and at the boiler return, the filter can be drained down and serviced.

A fully removeable filter canister allows the AtomSC to be cleaned, removing all traces of magnetite and preventing any debris re-entering the system.

Available as an optional accessory, the AtomSC also has a flushing adapter making it easy to connect to the system to flush. Compatible with the ADEY MagnaCleanse this allows contractors to save additional time and resources by using less water to re-fill and flush compared to traditional flushing techniques.

The AtomSC is also compatible with the ADEY Rapide® range of fast dose chemicals.

For compliance with BS7593 the AtomSC is supplied as a package including; ADEY MC3+ system cleaner and ADEY MC1+ system protector. Part L compliance can also be achieved by selecting from two further packages containing either ADEY MagnaScale2 or the ADEY ElectroScale2 in-line mains cold water scale reducers.

All packages also include two test strips for the ADEY ProCheck Universal Digital Water Test Kit – results are stored on the ADEY Sense portal so contractors and specifiers can rest assured that BS7593 has been adhered to and evidenced.

For more information please www.rdr.link/pbi024

Vokèra by Riello (part of Carrier Global Corporation) has introduced the top-tier Vokèra Pinnacle boiler range, which it calls ‘an embodiment of a commitment to cutting-edge technology, sustainability, and customer-centric design’.

Available in combi and system variants, the Pinnacle has an A-rated, 94% seasonal energy efficiency in space heating. The company says it can adjust its output to match the heating demand, reducing energy wastage and lowering running costs, while a wide 1:13 modulation ratio minimises short cycling, fuel consumption, and component wear.

The boiler features a stainless-steel heat exchanger and a new digital modulation pump. The company says that the Pinnacle's newly designed, DHW plate heat exchanger guarantees excellent domestic hot water (DHW) performance with no temperature fluctuations.

Smart functionality

The new range also has Smart Functionality for DHW operation and Weather Compensation. In addition, the Pinnacle is LPG 'out-of-the-box,' meaning it’s reconfigurable to work with LPG through a parameter adjustment, eliminating the need for conversion kits thus saving time on the installation. There is also a new digital colour touchpad interface with a guided tour of all its features to make operation intuitive and user-friendly.

With its combination of high-tier components and serviceability, it offers superb reliability and performance gains.

“The Pinnacle is a triumph of technological innovation and efficiency,” said Neil Saunders, Head of Sales UK and Ireland, Residential Heating, Carrier RLC EMEA. “With its combination of high-tier components and serviceability, it offers superb reliability and performance gains. We’re so confident in what we’ve built, we offer a 10-year warranty as standard.”

For further information please www.rdr.link/pbi025

REMS range of tools includes 22kN tools for pipe sizes up to 35mm in copper/carbon/stainless or 40mm in multi-layer, and 32kN and 45kN machines for pipe sizes up to 108mm (4”).

The Mini-Press 22V with its rotatable drive housing and ergonomically designed non-slip pistol grip is suited for smaller pipe dimensions. The company says the 22V, 2.5Ah battery supplied with the tool achieves approx. 390 presses of 15mm fittings with one battery charge at an ambient temperature of approx. 20°C.

With its in-house manufactured and specially hardened range of pressing tongs, the user has flexibility to choose between a multitude of different press-fit systems.

Described as “super light”, the Mini-Press 22V drive unit with battery inserted weighs 2.5kg. It is also compact: the Mini-Press 22V drive unit with M15 pressing tongs inserted is 31cm long. Pressing in hard-to-reach areas has also been considered, the REMS range of multi-angle pressing rings (pressing rings S (PR-2B)) are available as an accessory along with the Z8 mini adaptor.

REMS currently offers an extension to the manufacturer’s warranty for all REMS radial press tools to five years by registering the drive unit within 30 days.

For more information please www.rdr.link/pbi026