PROFESSIONAL MOTOR

NEWS GSF Car Parts trials electric delivery bikes PEOPLE & INDUSTRY Jepson & Co celebrates 130-year milestone MARCH 2024

FACTOR

VOLUME 24 ISSUE 3 MARCH 2024 8-10 NEWS 28-35 BUSINESS SPECIAL REPORT MOT testing frequency retained, DfT confirms..................................................................................12 Driving change to thrive: Bridging the skills gap and ensuring a positive future....................14 EXHAUSTS & EMISSIONS Keeping up with car emissions standards..........................................................................................40 LIQUI MOLY launches additive for AdBlue........................................................................................42 BM Catalysts supports growth of SCRs with new technical video..............................................44 STEERING & SUSPENSION KYB and VW Group continue partnership with new DCC Pro....................................................45 Polybush champions polyurethane bushes......................................................................................46 PROFESSIONAL MOTOR FACTOR MARCH 2024 I 3 REGULARS Viewpoint...........................7 News....................................8 Product Spotlight...........48 What’s New?...................50 17-27 PEOPLE & INDUSTRY 38 TRENDS CONTENTS

Editor TOM HENMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Group Manager

ROBERT GILHAM

Senior Account Manager ALEX DILLEIGH

Design ADEEL QADRI

Group Production Manager

CAROL PADGETT

Production Assistant

KERRI SMITH

Professional Motor Factor is an essential business magazine for those with decision-making responsibilities within motor factors.

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way; Watford, Herts; WD24 4YF

Tel: (01923) 237799

www.pmfmag.co.uk

tom@pmfmag.co.uk

Twitter: @PMFmag

Facebook: @ProMotorFactor

LinkedIn: Professional Motor Factor

Magazine

Copyright © 2024

Professional Motor Factor:

Certificate of Average Net Circulation for the 11 issues distributed between July 2022 and June 2023

Net total: 4,071

United Kingdom: 4,071

(Pg 10) ©Yingyaipumi/AdobeStock (Pg 12) ©Parvin/AdobeStock (Pg 36) ©Daenin/AdobeStock (Pg 36) ©Deemerwha studio/AdobeStock (Pg 40) ©LALAKA/AdobeStock (Pg 42) ©Ruslan/AdobeStock

Power of working together

So, the MOT frequency is here to stay. Between issues – always convenient for a magazine editor! – a press release from the Department for Transport arrived in my inbox, confirming the news that a vehicle’s first MOT would still take place after three years and every year after that. A win for the automotive sector, judging by the furore in the lead-up to the announcement and relief shared by the sector in the aftermath.

Such has been the reaction to this news, we have dedicated a doublepage feature to it (pg 12). There is a genuine feel of togetherness and the industry working together to help achieve this outcome, and everyone associated with this particular fight deserves a pat on the back.

LKQ UK and Ireland CEO, Kevan Wooden, said: “This is a fantastic outcome for UK road users and the aftermarket. We lobbied hard alongside our industry partners to push back against the proposed changes on the grounds that they would put the UK’s hard-won reputation for road safety at risk, endanger our national net zero ambitions and increase costs to motorists – and this is without mentioning the impact it would have had on work volumes in the aftermarket.”

A word to everyone that participated in our report into mental health and how the industry, again, collaborated to bring the stigma and severity of this topic to the fore: thank you. I was heartened by the interest and reaction to it, and that was only possible by the efforts and initiatives that many organisations and companies within our sector have created. Long may they continue, and I hope they inspired others to create their own.

Of course, there is still work to do – and that is a neat segue to an interview I’ve conducted with the [M]enable founder, Stephen Whitton (pg 18). Stemming from personal struggles, he recognised the urgent need to address mental health; however, as the conversation unfolded, it became evident that the issues addressed by [M]enable transcend gender, leading to a broader focus on promoting mental well-being for all individuals.

He also lamented the resistance that he encounters, at times, by those that view discussions surrounding mental health as “opening a can of worms”.

Moving on, we have two special reports this issue: the first is on the aforementioned MOT news, while the second is on the topic of training and recruitment (pg 14). Ultimately, we want to see the skills gap narrow and inspire the next generation to ensure our sector has a proud longterm future – it’s that straightforward right…?

Like last month, contributors weren’t shy in sharing their views. One of those is David Clarke, the managing director of Autosupplies Group, who gave a forthright and passionate response, calling for a “reframe”:

“Training and recruitment are the two biggest issues facing our trade. Training staff helps to improve customer service, giving customers the correct information and sending the correct parts first time.

“We need a reframe of the parts industry; within Autosupplies there are numerous roles spanning telesales, customer services, sales, warehousing and logistics to name but a few. The motor trade can offer a very varied career for anyone, and it needs to be encouraged.

“All employees have their own training programmes to ensure development, and those employees that need training are focused on and given the support they need.

“With these changing requirements and evolving customer base, our future is all about our people, the team. We have to ensure employees are fully trained and our recruitment process is the best it can be.”

What do you think of this emotive topic? What are we getting right and how can we improve? As always you can contact me at tom@pmfmag.co.uk. In the meantime, have a great March.

PROFESSIONAL MOTOR FACTOR MARCH 2024 I 7

Tom Henman Editor

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

VIEWPOINT

IN ASSOCIATION WITH

GSF trials electric delivery bikes

GSF Car Parts has begun piloting an innovative new green solution to navigate traffic around its London branches by partnering with VOK Bikes.

GSF has 180 branches across the UK and Ireland, 14 of which are located in and around London, supplying OE and aermarket parts, tools and more to independent garages, national chains and the public. GSF’s Tottenham Branch was the first to take delivery of two VOK Bikes, an electric cargo bike designed to make short work of the busy capital and allow GSF drivers to navigate streets to serve their customers in a fraction of their previous times.

e VOK Bikes are able to travel in cycle lanes and areas restricted to motor vehicles. e branch will use the VOK Bikes as part of a trial to determine their efficiency, impact and effectiveness compared to traditional delivery vehicles such as vans and motorbikes.

GSF Car Parts CEO, Steve Horne, said: “We are always looking for the best, most efficient way to serve our customers across the UK. e capital city can pose more challenges than most. London has notoriously bad traffic, low average speeds and lots of stop-start driving, so we’re exploring alternative methods to get from A to B and are delighted to be piloting these VOK Bikes.

“As a business whose bread and butter is distribution, we have a responsibility to test alternative means of fuel that are greener and more sustainable for the environment, which is exactly what this trial gives us the opportunity to do.”

really excited for these bikes to arrive and quickly saw the difference they’re going to make for us. We’ve even had some customers ordering straight aer receiving a delivery to see how quickly we can get back to them.

With delivery times cut down to as short as just 10 minutes to some garages, the bikes are already proving a hit with customers!

GSF Car Parts Tottenham General Manager, Mustafa Ugan, said: “We were

AAG acquires Parts in Motion

Alliance Automotive Group UK (AAG) has expanded its e-commerce business by acquiring Automotion Factors Limited T/A Parts in Motion (PIM).

AAG UK Managing Director, Steve Richardson, said: “PIM is not only a key member of our Trading Group with whom we have a longstanding relationship, but also a major player in the e-commerce segment.

“When making acquisitions, we always prioritise companies that add value to our offering, and PIM allows us to further enhance our digital capability, making it a great fit for us and a logical

step in our development.”

For PIM, it believes joining the AAG family gives it a competitive advantage and access to the resources needed to start the next chapter in its story. Whilst PIM will continue to operate under its existing management team, the business will become part of AAG’s digital team led by Jonathan Eden and Lewis Selby.

Gavin Samwell, CEO of PIM, said: “We’re delighted to have found the natural home for our business in AAG. The digital sector is extremely competitive, so becoming part of a leading global aftermarket organisation makes sense for

“The traffic in Tottenham gets extremely heavy, especially when there’s a football match being played, so the VOK Bikes will allow us to carry on uninterrupted and greener.”

the future of our business. We’re proud and appreciative of our team and the business they’ve helped us develop. It will be exciting to see where we can take the business from here.”

PIM generates annual sales of approximately £20m.

Hartlepool TMD strike ends after staff agree pay deal

Strike action by more than 180 TMD Friction workers has ended aer Unite secured a two-year 11% pay deal.

Around 150 workers began industrial action in early January with that number increasing to over 180 by the end of the month.

Now, however, the workers have voted to accept a deal of 7.5%, backdated to June 2023 and 3.5% from June this year.

Unite General Secretary, Sharon

Graham, said: “Our members at TMD Friction would not be moved and their determination on the picket line secured a vastly improved pay offer. Unite is totally committed to improving our members’ jobs, pay and conditions and the victory at TMD shows it is a commitment that is winning for workers.”

e deal stipulates that if inflation hits 5% in June 2024, then a review of pay would be triggered in January 2025. If any other TMD

employee at the Hartlepool site outside of the Unite bargaining unit receives a higher rise during the length of the deal, then Unite members will be paid the difference.

8 I PROFESSIONAL MOTOR FACTOR MARCH 2024 NEWS

Autovaux Car Parts to open fourth branch | Pays tribute to Delphi

Autovaux Car Parts, an independent supplier of parts and accessories, is set to open a fourth branch.

e expansion into West Yorkshire represents a significant milestone for the family-run business, which has evolved since founding in 2000, with existing branches in Dewsbury, Leeds, and Castleford.

Originally focused on Vauxhall parts, a relocation to Dewsbury in 2017 paved the way for the establishment of an all-makes range in 2018. Autovaux reported its components meet OE standards and are available at competitive prices.

Attributing success to consistent reinvestment into the business and strategic collaborations, Autovaux Managing Director, Paul Starling, highlighted the pivotal role played by Delphi.

Paul said: “Delphi’s support was instrumental in the early days. Whether it’s assistance with marketing projects, customer service or technical queries, Delphi's always been there for us.”

Autovaux currently employs more than 70 staff, with some 30 vans providing deliveries within a five-mile radius of branches, guaranteeing a maximum one-

HELLA customer experience centre proving a hit

HELLA has reported its customer experience centre is proving to be beneficial in showcasing the breadth of the product and service solutions it delivers to customers.

e facilities, which went live in the final quarter of 2023, has already hosted an IAAF regional meeting and are proving popular with visiting customers too.

HELLA Marketing Manager, Helen Goldingay, said: “The most frequent feedback we get from visitors is ‘we didn’t realise HELLA did all that’ as often they’ll think of us primarily as an OE lighting manufacturer.

“Besides being able to view the latest OEM LED headlamps, we’ve also got displays for the huge range of retrofit lighting solutions we offer into specialist sectors such as off-highway, leisure, commercial vehicle and agricultural.”

HELLA is also an OEM supplier of electronics; the display area marks out the various systems available to the aermarket. ese

MAM Software adds delivery app to Autopart

MAM Soware has announced the integration of its Electronic Proof of Delivery (ePOD) mobile app into Autopart. e company is confident the move will increase operational efficiency, ensure seamless delivery management and improve customer service.

e app’s electronic proof of delivery signatures synchronises with the Autopart business management system, facilitating quick query resolution. Drivers also benefit from features that enable them to manage unforeseen events on-the-go.

In terms of delivery oversight, ePOD digitally captures and tracks every step of the delivery management cycle in real-time. Integrated notifications from Autopart inform customers of impending deliveries in a timely sequence. Furthermore, it equips drivers to scan delivery notes, record recipient names/signatures and capture images of

include EVspecific, CV and EMS sensor ranges.

Other product lines, such as rotating electrics, bulbs, batteries and wipers, are displayed within a workshop-style background. HELLA Hengst filtration and Hella Gutmann Solutions’ diagnostics platforms are also featured.

e Hella Gutmann diagnostics programme, meanwhile, is augmented by an in-house remote services team, a training academy and a technical support team.

shortages/damaged goods for immediate review by branch staff.

Additionally, ePOD adapts to the driver's skills and experience, allowing them to efficiently manage deliveries. Experienced drivers can inform branch staff of any issues detected in real-time.

e integration of ePOD with Autopart means a reduction in invoice disputes through enhanced tracking and digitally recording of deliveries. Customers will receive automatic notifications regarding upcoming deliveries and access to signed Proof of Deliveries (PODs) will be provided via email or internet.

hour service agreement. It gives garages access to more than 800,000 parts stocked in Autovaux’s 45,000m2 of warehouse space.

PROFESSIONAL MOTOR FACTOR MARCH 2024 I 9 @PMFmag ProMotorFactor Professional Motor Factor tom@pmfmag.co.uk www.pmfmag.co.uk

IN ASSOCIATION WITH

Autowave: Joining the IAAF the ‘right fit’ and ‘mirrors our own direction’

Autowave, a provider of car keys, key cutting, and programming equipment, is pleased to announce its recent membership to the Independent Automotive Aermarket Federation (IAAF). e company said the move emphasises its commitment to aligning itself with the Federation’s short and longterm objectives.

Autowave specialises in the production, development, and distribution of highquality car keys and programming equipment. With headquarters in Nottingham, production facilities in Shenzhen, China, and a distribution centre in Bucharest, Romania, Autowave has established itself as a trusted partner for locksmiths, motor factors, and garages alike.

Autowave CEO, Ravi Kotecha – who

marked the company’s integration into the Federation at its recent conference and awards dinner – has hailed the decision to join the IAAF, citing it as the “right fit and mirrors our own direction”.

He said: “We are excited to join the Independent Automotive Aermarket Federation and collaborate with like-minded industry professionals to drive positive change and innovation in the sector.

“Our mission is to revolutionise the way car keys and programming equipment are perceived and utilised within the aermarket sector, and this partnership further solidifies our commitment to that goal.”

IAAF CEO, Mark Field, said: “Autowave's inclusion in the IAAF underscores our ambition of widening the reach of the Federation and bringing knowledge from

TotalEnergies and Halfords agree supply deal

TotalEnergies Marketing UK has announced a multi-year agreement with Halfords. e deal sees the range of Quartz automotive lubricants made available to customers at Halfords retail stores nationwide and online.

Quartz products, which are tested, approved and recommended by OEMs, have been developed with the “latest technologies to exceed stringent manufacturer requirements” and help deliver enhanced engine cleanliness, protection and fuel efficiency for petrol, diesel and hybrid engines.

is includes the Quartz Xtra range, created with ‘eco-science’

different product areas as we campaign to promote and secure the future of our trade against the backdrop of evolving legislation.”

technology to improve fuel economy and tailored for modern ICEs and hybrid vehicles, and Quartz Ineo, incorporating age-resistance technology which provides protection against extreme engine temperatures, oxidation and build-up of sludge – saving on maintenance costs and keeping engines younger for longer.

DAMS to become DAMS Lucas Oil

Formula 2 outfit DAMS and Lucas Oil will continue their existing partnership by being re-named DAMS Lucas Oil ahead of the upcoming campaign.

e two parties have been working closely with each other since the beginning of the modern FIA Formula 2 era in 2017, with the Le Mans-based squad’s mechanics and engineers using a variety of Lucas Oil’s products, including Brake Cleaner, Slick Mist Speedwax, Slick Mist Interior Detailer, Metal Polish, Slick Mist Tire and Trim Shine.

ese products have played a “crucial role” in the success of DAMS and other teams across several motorsport disciplines, while also benefiting the trade and general public.

DAMS Lucas Oil enters the 2024 campaign looking to build on a solid 2023,

with F2 race winner, Jak Crawford, and two-time podium finisher, Juan Manuel Correa, joining the team.

Lucas Oil Director of Sales and Operations UK and Ireland, Dan Morgan, said: “e partnership between DAMS and Lucas Oil has grown ever stronger since its inception in 2017. Increasing sponsorship with DAMS in F2 will serve as a catalyst for brand elevation, amplifying its presence, credibility, and marketability within a highly competitive automotive industry. e exposure that Formula 2 races and events bring allows us to both test and showcase the best that Lucas Oil has to offer

in front of a vast and passionate demographic.”

Charles Pic, DAMS team owner, said: “I’m delighted to see the continued development of our partnership with Lucas Oil. Since 2017, we’ve had the opportunity to grow our brands together through close collaboration.”

10 I PROFESSIONAL MOTOR FACTOR MARCH 2024 NEWS

MOT testing frequency retained, DfT confirms

Motorists will continue to undergo their first MOT test three years after purchasing a new vehicle, the Department for Transport (DfT) has announced. The decision comes as a response to the government’s consultation on updating MOT testing for cars, motorbikes, and vans.

L83%

Drivers polled by the AA supported the annual MOT

aunched in January 2023, the consultation aimed to strike a “balance” between the cost to motorists, road safety, advancements in vehicle technology, and efforts to tackle vehicle emissions. After consideration, though, the government has opted to retain the current MOT testing regime, with subsequent tests scheduled annually.

Roads Minister, Guy Opperman , said: “We have listened to drivers and industry, and keeping MOTs in their current form shows once again that we are on the side of motorists.

“By offering clarity on MOT tests, alongside our recent street works consultation and unprecedented £8.3 billion to resurface roads, we are helping motorists drive with peace of mind and ensuring Britain’s roads continue to be some of the safest in the world.”

The decision to maintain the existing MOT system was widely

argued by the automotive industry, supported by analysis from the AA, which claimed that annual MOTs potentially save drivers significant sums by identifying developing faults early, thus averting more substantial repair costs in the future.

Furthermore, 83% of drivers polled by the AA “overwhelmingly” supported

the annual MOT: “With one in 10 cars failing their first MOT, we fully support the government’s pragmatic decision to maintain the first MOT at three years and annually thereafter,” said AA CEO, Jakob Pfaudler

Looking ahead, the government said the DfT was committed to ensuring MOTs remain relevant in the face of evolving vehicle technologies. Measures will include exploring more effective tests for diesel particulate emissions, assessing improvements for EVs, and considering adjustments for larger zero-emissions vans.

The decision to maintain the current MOT system has garnered support from industry stakeholders (right). Included in the DfT statement, Society of Motor Manufacturers and Traders Chief Executive, Mike Hawes , praised the collaboration between government and the automotive industry, asserting that the decision will uphold the UK’s “strong road safety record”.

12 I PROFESSIONAL MOTOR FACTOR MARCH 2024 SPECIAL REPORT MOT

LKQ UK and Ireland CEO, Kevan Wooden

“This is a fantastic outcome for UK road users and the aftermarket. We lobbied hard alongside our industry partners to push back against the proposed changes on the grounds that they would put the UK’s hard-won reputation for road safety at risk, endanger our national net zero ambitions and increase costs to motorists – and this is without mentioning the impact it would have had on work volumes in the aftermarket. As with Block Exemption, we have once again shown the impact the industry can have when it comes together to push for what’s right.”

GSF Car Parts CEO, Steve Horne

“We’re incredibly pleased to see common sense prevail for the good of everyone in the automotive industry and on the roads, because the current MOT cycle is a pivotal part of vehicle safety and maintenance.

“Every year the British public places its trust firstly in the skills, knowledge and experience of the independent aftermarket to carry out its MOTs, and then in suppliers, like GSF, to get their vehicles the OE quality parts they need to remain safe and roadworthy.

“We appreciate that the cost of running and maintaining many vehicles has risen at a time when families are already feeling the pinch on their wallets and, while it’s right that the government should seek new ways to make motoring affordable for consumers, this should not come at the expense of safety when it comes to MOT cycles…”

Alliance Automotive Group UK Managing Director, Steve Richardson

“I’d like to extend my thanks to the automotive industry, in particular the IAAF and UK AFCAR for supporting the campaign. The MOT is a safety critical part of vehicle maintenance and as such, it’s paramount that vehicles on UK roads are regularly maintained.

“We will continue to offer our market-leading service and support to all customers to ensure we are providing the best value proposition possible.”

Autosupplies Group Managing Director, David Clarke

“The decision to keep the MOT frequency as it currently stands (the first test at three years) is good news for everyone in the automotive industry.

“Plans to extend the first test from three to four years have been met with the full power of the entire automotive industry including motorists, who have been united in their view that extending the test frequency risks driver safety.

“Every argument put forward to change the date of the first test has been overcome. An extended test won’t save motorists money and will in fact generate higher bills from worsening, unchecked problems. While it is right to consult on modernising the test process, the debate over the test frequency, the third in over a decade, should never be on the table.”

“We welcome the government's commitment to maintaining the first MOT at three years and annual testing thereafter. This aligns with our findings on the importance of regular checks for road safety and vehicle maintenance.

“The decision to further explore modernising tests for electric and automated vehicles is a positive step towards addressing the unique challenges and advancements in vehicle technology. We also appreciate the focus on diesel emissions, which is crucial for environmental concerns. The conclusion of the consultation also underscores the need for ongoing adaptations in MOT testing to keep pace with rapidly evolving vehicle technologies and environmental considerations.”

“I also think it should be appreciated more just how much independent garages prioritise safety and the importance of roadworthy vehicles on UK roads.

“It’s a real concern when the MOT test frequency comes up for debate because I think the opinion of the motor trade needs to be front and centre of the discussion. That’s because garages see first-hand the vehicles coming in for test and are rightly alarmed if unroadworthy vehicles were to go unchecked for a further 12 months.

“We’ve been feeding back our thoughts and that of our customers to our trade association, the IAAF, and I’m pleased that they have used this to protect the current MOT test frequency.”

SPECIAL REPORT MOT PROFESSIONAL MOTOR FACTOR MARCH 2024 I 13

Independent Automotive Aftermarket Federation (IAAF) Chief Executive, Mark Field

Institute of the Motor Industry Policy Lead, Hayley Pells

Driving change to thrive: Bridging the skills gap and ensuring a positive future

The skills gap and attracting the next generation of automotive talent are intrinsically linked. We address the issues, potential reasons behind them, but also share some of the ideas, solutions and real-world stories to narrow the window, inspire and protect our sector.

In 2022, the Institute of the Motor Industry (IMI) predicted a 160,000 shortfall of workers in the UK automotive sector in the next decade, forecasting a 2% decrease in the number of jobs available in the sector by 2031 – blaming an aging population, decreased immigration and the ‘green agenda’ for creating a major skills challenge.

Commenting on its Automotive Sector Employment report at the time, IMI CEO, Steve Nash, said: “An aging population is a significant contributor to the dilemma. Many of our older workers are set to retire over the coming years and fewer younger workers are joining the labour force. Without doubt, more needs to be done to attract young blood into the UK’s automotive sector.”

Encouragingly, however, ahead of National Apprenticeship Week, the IMI announced that the number of automotive apprenticeship starts in England, in the first three months (August to October) for academic year 2023/24, was 9% higher than the same period last year; in fact, it was the highest first-quarter performance since the academic year 2019/20.

IMI Research Manager, Emma Carrigy, said: “This uplift indicates a renewed interest in both the automotive sector generally and apprenticeships as an entry route, both of which are critical to build the talent pipeline for the future.

“Our new analysis suggests automotive is gaining a broader appeal, potentially fuelled by the advanced technologies that are becoming more commonplace, such as ADAS and electric vehicles.

“And what is particularly interesting is that there has been a pronounced uplift in intermediate-level apprenticeships, which may reflect a growing demand for foundational skills and entry-level qualifications, possibly serving as a gateway to more advanced training or responding to current job market needs.”

Despite the IMI’s encouraging figures, there is work to be done. The industry as a whole is working hard in improving matters: in an era marked by rapid advancements, Alliance Automotive Group Training Manager, Scott Simpson, recognises the pivotal role of education in bridging the skills gap within the industry:

“The rapid advance of vehicle technology has changed the landscape for the modern automotive technician. Showing no sign of slowing, future developments risk the industry skills gap widening still further.

“Each new and emerging technology delivers a fresh challenge for technicians, who have already seen their skills requirement widen. As such, the value and importance of training to narrow the skills gap cannot be understated.

“Working with high voltage vehicle systems can carry personal risk, as well as bringing new technical challenges.

Workshop Pro Training offers EV courses from 25 quality training providers across the UK and Ireland at levels one to four. Their popularity demonstrates both the demand and value technicians receive from this training.

“To remain effective in this changing world, there are training needs in many more areas, ADAS systems, high voltage air conditioning systems, business skills and compliance training, OEM diagnostics and hydrogen vehicle systems to name but a few…”

14 I PROFESSIONAL MOTOR FACTOR MARCH 2024 SPECIAL REPORT INDUSTRY FUTURE

The Lucas Oil Academy continues to gain momentum, with Leicester College and Furness College hosting rounds of technical training. These sessions aim to explain the evolving role of additives and lubricants in modern vehicle maintenance.

At Leicester College, the LOA team met level one, two and three students, while, at Furness, there was a mix of students from both the engineering and automotive faculties. The brief in each case was to provide an overview of the commercial side of the industry, to help students develop a greater understanding of additive technologies, which, according to Lucas Oil, are increasingly seen as advanced engineering solutions.

These sessions always include an overview of potential career opportunities, with the LOA collaborating with Mike Smallbone of Aftermarket Business Solutions. Mike, bringing his wide-ranging CV to the fore, discusses the pathways and potential roles within workshops, motor factors, retailers and other distributors.

Autosupplies Group Managing Director, David Clarke, said: “Training and recruitment are the two biggest issues facing our trade. Training staff helps to improve customer service, giving customers the correct information and sending the correct parts first time.

“We need a reframe of the parts industry; within Autosupplies there

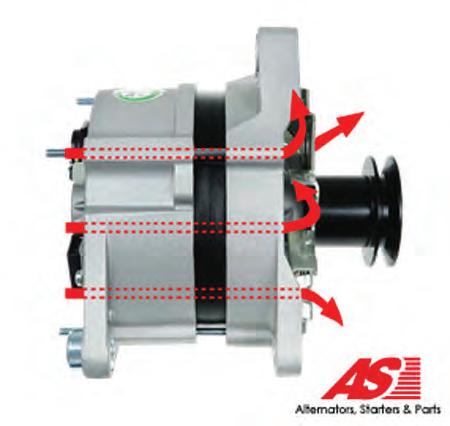

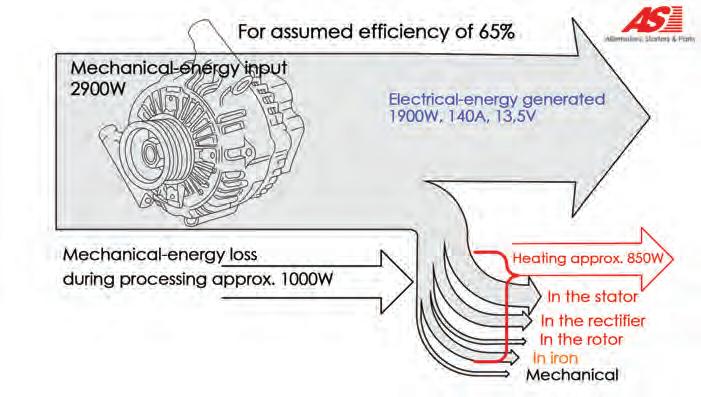

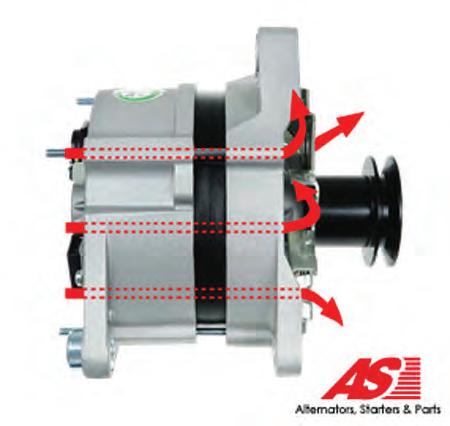

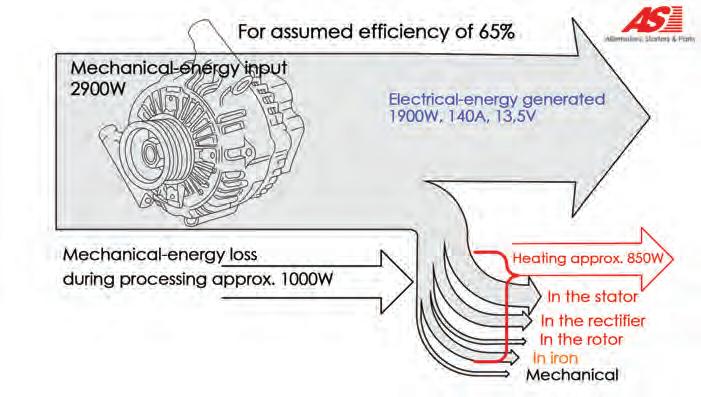

The importance of skills and training within our industry cannot be overstated, according to Autoelectro’s Harnek Bhogal: “At the heart of our success lies in the expertise of our engineers, many of whom boast decades of experience in remanufacturing starter motors and alternators.

“Their wealth of knowledge isn’t merely confined to replicating existing products; it’s fuelled by a relentless pursuit of improvement and innovation. This technical acumen isn’t exclusive to the production floor; it permeates throughout our entire organisation, including our sales team.

“Situated on-site alongside our production facility, our sales team undergoes comprehensive training to ensure they possess an in-depth understanding of our products and their components. This knowledge is invaluable, particularly when addressing customer enquiries pertaining to specific vehicle applications or nuanced alternator configurations, as it means we offer our customers the best service possible.”

are numerous roles spanning telesales, customer services, sales, warehousing and logistics to name but a few. The motor trade can offer a very varied career for anyone, and it needs to be encouraged.

“All employees have their own training programmes to ensure development, and those employees that need training are focused on and

Last year saw a “back to basics” approach from many businesses, as the industry “wrestles” with both upskilling for emerging technologies and immediate technician shortages, according to Delphi.

UK and Nordics Technical Services Manager, Luke Garratt, said: “We had a rise in EV training demand, as we had anticipated; however, we saw a much more dramatic increase in people going back to ‘grassroots’ training.”

Demand for training on topics like wheels and tyres, braking systems, steering and suspension and four-wheel alignment surged. Delphi believes this is caused by difficulties experienced by many businesses in recruiting skilled technicians.

Luke continued: “For many garages now, that really experienced member of the team in the workshop, that would help everyone and offer their advice or opinion, just isn't there anymore. This means the only option is to get people on board and then train them on the basics.”

given the support they need.

“With these changing requirements and evolving customer base, our future is all about our people, the team. We have to ensure employees are fully trained and our recruitment process is the best it can be.

“We conduct regular staff training sessions with suppliers, internally onsite and externally with suppliers.”

SPECIAL REPORT INDUSTRY FUTURE PROFESSIONAL MOTOR FACTOR MARCH 2024 I 15

REGISTER FOR FREE AT WWW.MECHANEX.INFO THE HANDS-ON TRADESHOW FOR INDEPENDENT WORKSHOPS

AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS ● FREE CPD TECHNICAL SEMINARS ● FREE ENTRY

FREE PARKING ● FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL

TOP

●

MOTOR MECHANIC MECHANEX FEATURING LIVE YORKSHIRE EVENT CENTRE HARROGATE YORKSHIRE EVENT CENTRE HARROGATE 16TH & 17TH MAY 2024 SANDOWN PARK SURREY SANDOWN PARK SURREY 12TH & 13TH NOVEMBER 2024

The regional Tradeshow for aUTo rePair Professionals

PROFESSIONAL

PMF introduces this month’s movers and shakers as they begin a new stage of their career in the UK aftermarket.

Movers & Shakers

JRP Distribution

JRP Distribution has strengthened its sales team with the appointment of Andy Taylor, who brings with him more than 30 years of aftermarket experience.

Having previously held positions with the likes of TRICO and Juratek, Andy has taken up the role of key account manager at JRP.

In his new position, Andy will update customers across the UK and Ireland with JRP’s latest product offerings and support them in growing their sales through range development, customer promotions, and co-ordinating with the distribution company’s marketing team to increase brand awareness.

JRP, which has a 60,000sqft warehouse and office in Chichester, supplies more than 5,000 products to various sectors, with automotive its core business. Its brands include Autobar, Ecomotive, Simply Brands, J-B Weld, Tecniks, FRSH Scents and Invisible Glass, amongst others.

Andy said: “I’ve seen all levels of the trade, from retail to wholesale, and worked for OE suppliers and manufacturers, as well as distributors in my tenure, so I’m very excited to face a new challenge and help to grow JRP’s business. It’s a fantastic company with a long history that is not afraid to venture into new areas where there’s a need and it can supply a quality solution.

“I know that I’ll be kept extremely busy at JRP and look forward to speaking to current and future customers in my new role. It’s a sustained period of growth for JRP, so I’m enthusiastic to see the business continue to expand in 2024. We have high ambitions for growth, all of which we believe are achievable. I’m looking forward to the challenge and joining at such a busy time for the company.”

Simply Brands

Simply Brands has appointed Tom Kay as digital manager.

Tom, who has more than a decade’s worth of experience specialising in website management, will be responsible for all things digital – including social media, as well as redeveloping the website to make it “faster, more efficient and more user friendly” for both the trade and public in the UK and Europe.

The new recruit will also be helping to develop ways to deliver application and product data to customers, including mobile responsive application finders.

Tom said: “I’m very excited to be a part of the Simply Brands team; the company has grown so much, so quickly that I can really get stuck in and make my mark on the company. We’re going to be looking closely at the customer experience across all our platforms, and a new website will be at the centre of that work and will be a big transformation and the flagship around which we will improve our digital presence.

“I’ve not worked in the aftermarket before, but I’m in good hands with the Simply Brands team and I’m looking forward to learning more and bringing my experience to the table.”

Pro-Align

Pro-Align, the garage equipment supplier, has appointed Kasia Rzepka to the newly created role of head of operations.

Kasia will oversee the company’s aftersales and engineering teams of around 25 people, with an aim of delivering 100% customer satisfaction.

Kasia said: “Pro-Align is a great company but also one with massive opportunities. Under its new ownership, the company has some incredibly exciting and ambitious growth plans, but these are totally reliant on delivering the very best levels of customer service and care within the industry.

“I’m ambitious and like a challenge, so this feels like the ideal fit for both me and for Pro-Align, and I look forward to making a real difference to customers across the whole of the UK.”

Kasia is no stranger to the automotive industry, having previously held positions of operations and assistant general manager for Manheim Auctions, as well as a logistics operations role with DHL. While in these roles, she won an internal employee of the year award and was also a shortlisted finalist in two other national automotive awards.

PEOPLE & INDUSTRY APPOINTMENTS

PROFESSIONAL MOTOR FACTOR MARCH 2024 I 17

To connect with Tom on LinkedIn, www.rdr.link/FAD002 To connect with Kasia on LinkedIn, www.rdr.link/FAD003 To connect with Andy on LinkedIn, www.rdr.link/FAD001

(L-R): Pro-Align CEO, Clive Seabrook, and Kasia Rzepka

Where did the idea for [M]enable emanate from?

“The idea for [M]enable stemmed from my personal experiences during the pandemic. Both of my successful businesses were heavily impacted by the lockdowns, and I also went through a significant personal crisis, which exacerbated underlying mental health issues.

Stephen, the founder of [M]enable, shares the genesis, evolution, and mission of his platform focused on mental health within the industry. Stemming from personal struggles, Stephen recognised the urgent need to address mental health in a traditionally masculine-dominated sector. However, as the conversation unfolded, it became evident that the issues addressed by [M]enable transcend gender, leading to a broader focus on promoting mental well-being for all individuals. A Q A

“The idea to create a platform addressing men’s mental health in the automotive industry came from a desire to provide a voice to this important topic and challenge the stigma surrounding it.”

Can you tell me about these “successful businesses”?

that, I had a background in automotive consultancy and finance. Ultimately, I have been in the industry for 35 years, 16 of which was working for OEMs.”

Q A Q

“Before founding [M]enable, I was running two training businesses concurrently, specialising in coaching, facilitation, and conference hosting. Prior to

How do you navigate the stigma surrounding mental health and change cultural norms within the automotive sector?

Q A

You mentioned that [M]enable initially focused on men’s mental health but has since evolved – can you elaborate on that evolution?

“While [M]enable initially focused on men’s mental health due to the male-dominated nature of the automotive industry, we soon realised that the issues we were addressing transcended gender. Masculine culture, characterised by traits like competitiveness and goal-oriented behaviour, affects everyone in the industry, regardless of gender.

“As a result, we expanded our focus to promote mental well-being for all individuals in the automotive sector.”

“We challenge traditional notions of masculinity by promoting open dialogue and emphasising that seeking help is a sign of strength, not weakness. By fostering a culture of empathy, understanding, and inclusivity, we aim to create a supportive environment where individuals feel comfortable discussing their mental health without fear of judgment.

“One prevalent issue is the resultsoriented nature of our industry. This stems from the mass manufacturing and consumption framework we operate within, necessitating a distribution network and franchise models. Consequently, targets are imposed, leading to pressure for

18 I PROFESSIONAL MOTOR FACTOR MARCH 2024 PEOPLE & INDUSTRY Q&A

achievement, as financial and personal commitments are at stake.

“Additionally, many entrepreneurs in our field, like independent repairers and garage owners, are driven by passion but face unique challenges, having invested their own resources into their businesses.

“Another aspect is our diagnostic and fix-it approach, mirroring how we manage people. However, this mindset doesn’t align with addressing individual challenges and personal stories effectively.

“We recognise that we’re not ‘fixers’ or ‘rescuers’ but rather aim to listen, understand, and empathise. While I’m not a mental health expert, my background in Neurolinguistic Programming (NLP) and continuous self-development equips me with insights and tools to support my team.

“Importantly, we have a referral network, including organisations like Ben, to provide professional intervention if needed.”

Have you faced resistance or scepticism within the sector regarding your efforts?

“Unfortunately, yes, there has been some resistance, particularly from those who view discussions about mental health as opening a ‘can of worms’ or perceive it as a distraction from work.

“Additionally, I would argue some companies have paid lip service to the issue without making meaningful cultural changes.

“That said, we’ve also encountered significant support, particularly from women in the industry who recognise the importance of addressing mental health issues.”

Can you explain the concept of ‘mental wealth’ and its significance in promoting well-being?

“Mental wealth reframes the conversation around mental health from one of illness and pathology to one of growth, success, and self-care. By focusing on mental wealth, we emphasise the importance of nurturing mental well-being proactively, rather than solely reacting to mental health crises.

“This shift in perspective encourages individuals to prioritise self-care and resilience, leading to a more positive and supportive work environment.”

Have you observed positive outcomes since adopting the concept of mental wealth?

A Q A Q A Q

“Yes, we’ve seen increased interest and receptiveness from businesses within the sector since adopting the concept of mental wealth. By reframing the

conversation and offering proactive solutions through initiatives, like ‘well-being winners’, we’ve empowered businesses to prioritise mental well-being as a key component of their culture.”

How can businesses or individuals within the sector become wellbeing winners?

A

“Becoming a well-being winner involves making a commitment to prioritise mental well-being within an organisation. Companies undertake an initial assessment and then commit to a year-long programme to achieve a gold, silver or bronze standard. This may be participating in more assessment programmes, implementing recommended strategies for improvement, or creating a culture of support and openness regarding mental health.”

A Q Q

Finally, Stephen, would you mind telling our audience if you are still addressing the challenges that led to the founding of [M]enable?

“This is important to address because some of your readers may be encountering their own journey… While I continue to face personal challenges, I’ve learned to live with the outcomes and focus on maintaining mental wealth. While there’s still work to be done, I’m in a much healthier place mentally and remain committed to supporting others on their mental health journeys.

“The purpose of this article is to provides insights into the origins of [M]enable, its evolution, challenges faced, but, most importantly, promoting mental wealth within the automotive sector, our sector.”

PEOPLE & INDUSTRY Q&A For more information about Ben, www.rdr.link/FAD005 For more information about [M]enable, www.rdr.link/FAD004 PROFESSIONAL MOTOR FACTOR MARCH 2024 I 19

Get to know

Mr JLM Lubricants!

Today, JLM Lubricants is available in 40 countries, servicing motor factors and technicians with technical sprays, lubricants, coatings, leak-stop sealants, cleaners and rinsing agents.

The inception of JLM Lubricants, though, made in The Netherlands, can be traced back to Gilbert taking over his father’s business, which specialised in distributing parts across Europe. Gilbert encountered a pivotal moment when he was approached by a non-European manufacturer with a unique additive. Seeing an opportunity, Gilbert decided to take a chance on this product, and it turned out to be a significant success.

However, as the market evolved, demands shifted. Concerns about the product’s effectiveness and the changing landscape of the industry led him to reevaluate his approach. This moment prompted Gilbert to consider launching his own brand, one that could address the needs of the market more effectively while allowing him greater control over the products he offered.

JLM Lubricants is born

Gilbert said: “The decision to create my own brand was not one I made lightly. I understood the importance of positioning a brand carefully in a competitive market. I knew that simply having a product was not enough; it needed to be superior to existing offerings and backed by evidence of its effectiveness.”

One of the earliest challenges Gilbert faced was in proving the quality of JLM Lubricants’ products – he said: “In an industry where trust and credibility are paramount, I knew we needed more than just marketing claims to win over customers.”

In business, success often hinges on a delicate balance between personal passion, industry knowledge, and strategic decision-making. For Gilbert Groot, the founder of JLM Lubricants, this journey began with frustration but evolved into a story of innovation and perseverance. Our editor, Tom Henman, made the journey to Amsterdam to meet the man himself:

This led him to seek validation through rigorous testing, including road tests conducted by a German university specialising in automotive technology. These tests provided the scientific evidence needed to substantiate JLM Lubricants’ claims of premium performance.

Armed with this evidence, JLM Lubricants entered the market with confidence, focusing initially on the LPG sector where Gilbert had established networks and expertise. However, it wasn’t long before the brand expanded to address emerging needs in the industry, particularly in response to the growing issue of DPF blockages.

Gilbert continued: “Recognising an opportunity to provide a solution to this widespread problem, we developed a DPF additive that quickly gained widespread attention and enhanced the brand’s reputation.”

As JLM Lubricants continued to grow, Gilbert faced the challenge of managing expansion while maintaining the integrity of the brand. With enquiries pouring in from around the world, Gilbert had to make tough decisions about where to focus the brand’s efforts.

He said: “Recognising the importance of partnerships and sustainable growth, I prioritised markets where JLM Lubricants could establish strong relationships and provide ongoing support to our customers.”

Personal journey

Gilbert’s reflections on the challenges of building JLM Lubricants, one of which being the strain of travel and the impact on him and his family were palpable. Asked if he still travels, he responded: “Of course I travel – there is no escaping from it in international business – but I am more

selective than in the past. One of the beauties in life is cultures, meeting people. And I’m very much a people’s person, so that part I enjoy… But the wear travelling has on a person is often underestimated. And I have young children, and I learned an important lesson given by my dad…”

He paused, a thoughtful expression crossed his face, before continuing: “My dad said: ‘Gilbert, don't make the same mistake I did.’ What mistake did you make? I'm perfectly happy. I have no complaints about my dad. He said: ‘I was never there; I was always working.’ That stuck with me.”

This poignant exchange underlined the delicate balance entrepreneurs often strive to maintain between their professional ambitions and their personal lives. It revealed a different side of Gilbert, shedding light on the human experiences that shape a business journey.

Look out for part two of our interview with Gilbert in the April issue, where Tom explores JLM Lubricants’ journey in the UK.

For more information about JLM Lubricants, www.rdr.link/FAD026 PROFESSIONAL MOTOR FACTOR MARCH 2024 I 21 PEOPLE & INDUSTRY INTERVIEW

From sustainability and availability to education and support, Castrol National Key Account Manager, Courtney Forman, reveals the supplier’s motor factor approach.

Considering growing environmental concerns, how is Castrol addressing sustainability in its products and operations?

A

“Castrol refreshed its top-up lubricant bottles in Europe with a new bottle design, which uses up to 20% less plastic in some bottles. The newly designed bottles come in half-litre, onelitre, four-litre, and five-litre sizes and have been available to all workshops and retailers from September 2023. They come with the additional benefit of being more compact on the shelf and easier to transport compared to the previous bottles.

“At the start of 2024, Castrol unveiled a bold new ‘Onward, Upward, Forward’ strategy to meet the changing needs of customers:

l Onward: advancing mobility solutions that help people and goods move with greater efficiency through innovative technologies and a commitment to the principles of circularity.

l Upward: helping Castrol’s industrial customers, and the machines they rely on, to perform better, improving the efficiency of their operations.

A Q A

“The introduction of the newly designed bottles is part of Castrol’s delivery of its PATH360 sustainability strategy that sets out aims to help save waste, reduce carbon, and improve lives. The company’s new five-litre bottle in Europe uses 20% less plastic compared to the previous fivelitre bottle, one of the best-selling products in the Castrol range.”

QCan you provide an overview of Castrol's latest developments in the automotive aftermarket, particularly concerning product innovations and market positioning?

l Forward: exploring exciting opportunities and a path of progressive diversification. Castrol’s initiatives include end-to-end digital and service solutions, data centre immersion cooling, and battery thermal management. This forward-thinking approach underscores Castrol’s commitment to staying at the forefront of innovation.

“To remain at the cutting edge of innovation and be future-ready, Castrol is investing further in its global technology hubs and

has a planned $60 million investment in a new, state-of-the-art EV battery testing centre and analytical laboratory in the UK.”

Q

What trends are Castrol closely monitoring, and how is the company adapting to these to stay ahead of the curve?

“The EV market is predominately becoming more prevalent in the automotive industry, and Castrol launched a range of advanced Castrol ON EV fluids

22 I PROFESSIONAL MOTOR FACTOR MARCH 2024

in 2022, including EV transmission fluids, EV thermal fluids and EV greases.

“The market for EVs will most likely coexist with continued demand for ICEs and hybrids for many years. Castrol aims to keep helping ICE and hybrid vehicles be more efficient, while aiming to lead the way in EV fluids.

“Castrol will also focus on launching more ‘circular’ products and offers by reusing base oils, which are the main constituent ingredient in lubricants. More circular transmission fluid has already been tested in an extreme environment, with Jaguar TCS Racing successfully utilising Castrol’s transmission fluid in its Formula E race cars at the 2023 Monaco E-Prix.”

Could you share insights into Castrol’s newest products and technologies, emphasising how these innovations cater to the evolving needs of motor factors and their customers?

A

“Castrol MAGNATEC 0W-30 GS1/DS1 features a unique, patented DUALOCK technology that provides car engines with 50% better protection from warm-up wear and restart wear. Castrol MAGNATEC 0W30 GS1/DS1 is designed for use across all Fiat petrol and diesel vehicles where Fiat recommends an ACEA C2 or earlier specification 0W-30 lubricant. The new product is the first Castrol engine oil to meet Fiat 9.55535-GS1 and Fiat 9.55535DS1 specifications.”

Are there any collaborations or partnerships that Castrol is currently engaged in that benefit motor factors?

A

“In 2023, Castrol announced a three-year strategic partnership with Tetrosyl. It enables more motor factors and workshops to get enhanced access to the complete range of Castrol products.

Q Q

“A significant 15.7 million cars manufactured by mainstream OEMs across the UK, equivalent to 39.9% of the country’s car parc, can be serviced using just five MAGNATEC products. Castrol has ensured its MAGNATEC product line is a reliable and robust choice for motor factors and their customers to choose MAGNATEC as a primary lubricant for a high proportion of vehicles, including Citroën, Fiat, Ford, Honda, Kia, Peugeot, Toyota and Vauxhall cars.

“The most recent edition to the MAGNATEC product line is the new formulation that has been designed to meet the specific needs of Fiat GS1 and DS1-compatible engines, found in models, such as the Fiat Panda and 500, Jeep Compass and Jeep Renegade, and Alfa Romeo Mito.

Q

How is Castrol planning to support motor factors through incentives? Are you able to elaborate on any specific initiatives aimed at boosting sales and encouraging upselling?

A

“Ensuring Castrol is visible to consumers is key to driving sales for motor factors. The company provides a range of support measures, from digital assets that can be used on websites, to a range of in-store point-of-sale and marketing material.

“Throughout the year, Castrol runs different promotional activities, including the opportunity for Castrol customers, who make a complying purchase, to win tickets to sporting events, including major football tournaments, F1 and MotoGP. Not only does Castrol provide exciting marketing activities aimed at driving purchases, but it also runs bespoke promotions to motivate purchases and the replenishment of stock.”

Q A

“Motor factors are now able to order Castrol lubricants, along with products from other brands, such as QH, TJ Filters, Carlube, Bluecol, CarPlan and many more, through Tetrosyl and receive support via the Tetrosyl customer service team.”

What are the key marketing campaigns and initiatives that Castrol is currently undertaking to engage with motor factors?

“To grow within motor factors, Castrol has structured a recommended stock pack based on in depth analysis. This analysis has looked at the UK car parc, the age of vehicles on UK roads, and the most popular oils that are needed or requested by customers. This analysis enables motor factors to purchase the fewest number of lubricant products which can cover the largest number of vehicles.

Q A

In terms of supporting motor factors, what training programmes and resources does Castrol offer to ensure that staff are well-equipped?

“As engine requirements continue to develop, with constant advances in the market, Castrol aims to educate its customers to enable them to make educated decisions on which engine oils to purchase.

“Castrol takes on this responsibility in several ways: firstly, the company ensures motor factors have the recommended Castrol range to help reduce complexity for customers, which can often be overwhelming.

“It recognises the importance such matters have when it comes to motor factors managing their costs. Castrol continues to market stock packs, along with relevant merchandise and marketing materials, to promote and communicate products suitable for motor factors.”

“Secondly, Castrol provides motor factors with point-of-sale and marketing materials which utilise QR codes to direct customers to Castrol’s online ‘product finder’ website. This enables consumers to input their registration and instantly receive an approved list of Castrol oils that are suitable for specific vehicles.

“Lastly, Castrol provides motor factors and consumers with easy-to-understand Castrol reference guides. These short booklets explain the different Castrol products and the makes and models that they can be used in. Castrol’s key objective is to ensure consumers are educated when selecting, checking and refilling engine oil, and that all motor factors can be confident about selling and recommending the Castrol product range.”

PEOPLE & INDUSTRY Q&A For more information about Castrol, www.rdr.link/FAD006 PROFESSIONAL MOTOR FACTOR MARCH 2024 I 23

Jepson & Co hits 130-year milestone: ‘It’s been quite a journey!’

This significant milestone is a fantastic opportunity to thank our valued partners, loyal customers, and our amazing team, all while anticipating the exciting developments that lie ahead.

Long-standing commitment to you

Jepson & Co has always been about building strong partnerships and delivering top-notch service, especially to you, our motor factor colleagues, many of whom have been with us for over a decade – over to our chairman, Peter Jepson, who is also the great-grandson of our founder, George Henry Jepson:

“When I think about how we’ve grown from hand-painting numbers on colliery wagons to a £20 million business supplying over 20% of the market, it’s been quite a journey. And we’ve remained a family company right here in Sheffield.”

These lasting partnerships and the awards we’ve received over the years reflect our dedication to excellence and innovation. Our customers’ satisfaction means the world to us, and we rank among the top-five for B2B satisfaction scores by the Institute of Customer Service, with a Net Promoter Score about four times higher than the UK average. Our passionate team, who absolutely love number plate components and kits –because someone has to, right!? – have been the driving force behind our success.

Empowering customers with easy artwork, full support and cost savings

Over the years, we’ve created many innovations that make number plates easy for you – some of these include:

l Customer support: Our friendly customer support team is always here to help. Got a question or a challenge? Reach out to us anytime, and we’ll be there to assist. We take pride in our responsive and knowledgeable team.

l Cost-saving wastage reports: We know that every penny counts. Jepson & Co

As Jepson & Co celebrates its 130-year anniversary, Jo Hackett, marketing and administration manager, takes a moment to reflect on the company’s history while eagerly looking forward to a future “filled with even more innovation and growth”:

“When I think about how we’ve grown from handpainting numbers on colliery wagons to a £20 million business supplying over 20% of the market, it’s been quite a journey. And we’ve remained a family company right here in Sheffield.”

provides detailed wastage reports to help you identify where you can cut costs. By minimising waste, you can optimise your operations and boost your bottom line.

l Simplified artwork creation and editing: We understand the challenges you face. That’s why we’ve made artwork creation and changes a breeze, so you can effortlessly design and update your number plates. Our user-friendly tools and straightforward processes put you in control.

Creating a future together

Looking ahead, Jepson & Co is ready to embrace the opportunities brought by the ‘Fourth Industrial Revolution’. We’re committed to providing

you with practical, convenient solutions for on-site number plate making.

Our 30-strong customer support team are actively exploring technological advancements, like AI, to enhance our services and make your life easier. Features, like connected software, automatically keep DVLA records up-todate, and we’ve even integrated TeamViewer remote desktop into our software for lightning-fast technical support.

As we mark our momentous 130-year milestone, we invite our partners, clients, and the community to join us in celebrating this journey. We can’t wait to see what the future holds, as we continue to innovate and provide unwavering service.

PEOPLE & INDUSTRY MILESTONE

For more information about Jepson & Co, www.rdr.link/FAD007

24 I PROFESSIONAL MOTOR FACTOR MARCH 2024

CSF: ‘We concentrateon what we’re doing’

In the second part of his visit to Car Spares Factors’ newest branch in Harrow, formerly Saxons Motor Factors, our editor, Tom Henman, hears about CSF’s latest plans, digitisation and whether competition keeps co-owner, Sanjiv Shah, awake at night:

To recap, the acquisition of Harrowbased Saxons brought CSF’s familyrun portfolio to seven. The stable now includes branches in North London, Hertfordshire, Essex and Middlesex.

Sanjiv Shah, the co-owner of CSF, explained the logic behind the takeover –why now? – and how he wants to progress a business that is already profitable, with a 40-year track record, and has a fiercely loyal customer base.

Comfortable with the existing site, Sanj confessed that a move in the future, copying the existing CSF model and site layout was on the radar – but not quite yet – so the next obvious question is what is on the radar?

Sanj replied: “We’ve got a lot in the pipeline: our consumables catalogue has just been released. We have just launched a range of bodyshop consumables that are in stock at our Waltham Abbey and Park Royal depots and are accessible to all depots within a matter of hours through our inter-branch delivery service. We are in the process of starting a strong marketing campaign to push the message out and make our customers aware of this additional service we now provide.

“The reason we’ve done it is because there are very few bodyshop consumable suppliers in-and-around London. If we bolt that to our ‘within one-hour service’, where there are bodyshops that have

garages attached to them, we’re confident we can service both trades.”

Diversification or spotting a gap in the market?

There’s always an idea, always a plan with Sanj, but timing is critical with every decision he makes. Having interviewed him three times, I know he doesn’t rush into any decision. While his business development managers have been pushing for a line of bodyshop consumables for quite some time, Sanj admitted that “we’ve held off, held off, held off” but “we’ve now got to the point where the investment isn’t huge, yet the return is good”.

On the garage side, CSF already carries plenty of consumables in stock but garages “didn’t realise” the vast range available from stock.

Sanj said: “Garages know about our parts, but airline couplings, air conditioning valves, etc, they didn’t know we actually stock these items on our shelves, and we can deliver them quickly.

“Once we understood this, we got to work on our 92-page catalogue, just to open garage owners’ eyes. Now the printed versions have arrived, we’ll give our branches batches, and they’ll flood the area.”

Website and app

Sanj also mentioned that the CSF website will be given a major facelift, to bring it in-line with the CSF image refreshed just over a

year ago. Furthermore, upon reading a copy of the winter newsletter – CSF publish four per year – I encountered the CSF app too.

Since its launch in 2023, plenty of software updates and enhancements have been made, with the aim of making it as easy as possible for customers to search and order products.

The key app features: customers can send an order or enquiry at the touch of a button and receive a response within minutes, upload images if needed, receive live mobile push notifications and driver

26 I PROFESSIONAL MOTOR FACTOR MARCH 2024 PEOPLE & INDUSTRY FACTOR FOCUS

notifications, such as when one is on their way, confirm or decline a quote, and select specific parts from a list and quickly view all active or historic enquiries on a phone.

Sanj said: “The CSF app enables our customers to order quickly from us. They can view our products and at the click of a button, place an order. It doesn’t replace our call centre team, but provides a supplementary ordering channel.”

A typical Sanj response followed: “I block it (competition) out – and the reason I block it out is because this industry is about relationships, it’s about trust, it’s about loyalty, and a garage will only give a motor factor one chance. We’re thrilled with our relationships, our business.

“We’re concentrating on what we’re doing, focusing on what we do well. As long as we do that, we don’t have to worry about nationals or other independents – could I sit here and worry about it? Yes, but do I? No. There is too much business out there.

Competition? No problem!

I interviewed Sanj shortly after news broke about the ownership changes at GSF, compelling me to ask about whether that development bothered or worried him –does competition bother him at all, or does it force him to raise his and CSF’s game?

“You can have the ambition to be the biggest, the best, or you can have the ambition to run a steady business that generates enough income to support you and your family, your staff and their families, pay suppliers, bills etc. As long as you’re doing that, I think most people would be happy – we’re happy.”

For more information about CSF www.rdr.link/FAD008

Meet Jo Loughman: Behind the scenes with Schaeffler

First-up in the new ‘INside Schaeffler’ series is Jo Loughman, a long-time member of staff and the current customer service and deputy operations manager. The idea behind the concept is for both customers and workshops to get to know the people behind the scenes.

Jo, who has been part of the Schaeffler family since 2001, is a self-confessed fitness fanatic – crossfit, spinning, running, canicross, swimming, jet skiing, cycling, swimming among her sporting hobbies – and aspires to see Mount Everest.

A music lover and sun-worshiper, Jo believes integrity and honesty are two of her best qualities, which don’t just come in handy in her personal life but with her Schaeffler hat on too.

A Q

What does your role at work mean to you?

“Having started in the warehouse 22 years ago, I’m now one step away from running the site operationally. So, my job, apart from my family, is my biggest achievement – like my friendships, I am all in and fully invested.”

What does your job consist of?

“My role has significantly changed over the years. Apart from the key account work and supporting my customer service team, a lot of my time now is dedicated to finding and improving efficiencies to keep Schaeffler current with the customer base.”

Tell us something that you think your customers could benefit from knowing?

A Q A Q A Q

“The customer service team is not a big call centre; we are six ladies servicing over 1,200 accounts and taking an average of 4,500 calls a month – and we are awesome at what we do!

“I also run my own business outside of Schaeffler called Fullcycle Studio. We are a

spin studio and we have been running for 10 years. We currently have 29 bikes, and my husband and I are the instructors.”

What technical or product advice may help customers that they may not yet be aware of?

“Schaeffler are not the OEM on all clutch applications; therefore, we have to complete our range with other OE suppliers so don’t be alarmed when opening the box if it does not say LuK! You can be assured they are all OE quality.”

For more information about Schaeffler, www.rdr.link/FAD009

PEOPLE & INDUSTRY FACTOR FOCUS

PROFESSIONAL MOTOR FACTOR MARCH 2024 I 27

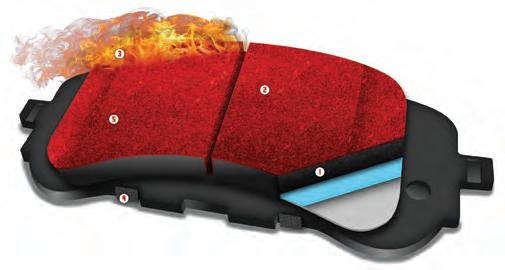

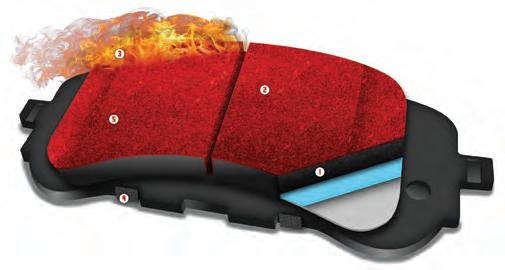

Allied Nippon EV+ a ‘valued-added proposition’ as EV registrations top one million

Following the launch of EV+ brake pads and the Society of Motor Manufacturers and Traders’ (SMMT) announcement that one million EVs are now registered in the UK, Allied Nippon underlines how it hopes its new range will benefit customers.

Allied Nippon has made a bold leap into the future with the introduction of its EV+ range. Specifically engineered for EVs, the brake pad manufacturer believes this new range is set to impact the way you approach braking for the evergrowing fleet of EVs on the roads.

With the latest SMMT figures confirming over one million EVs are now in operation across the country, and the EV share of vehicle parc steadily increasing, Allied Nippon’s move to launch a dedicated EV+ range could hardly have come at a better time, according to EV+ Project Lead and Allied Nippon Development Manager, Matt Ellis.

He continued: “The EV market demands specialised solutions, considering the unique challenges posed by the increased weight and speed of these vehicles. EVs are known for their rapid acceleration and substantial weight due to large battery

packs, necessitating a need for a dedicated brake pad specification.

“Allied Nippon was early to develop the EV+ range; prototypes were initially shown at Automechanika Frankfurt back in September 2022, but our strategy was to wait for the market to be ready for the product range. With the UK EV parc now topping seven figures, the time has come for EV+.”

The advantages of EV+

The EV+ range is not a rebrand of an existing product, a confident Matt said, but

The EV+ range boasts a host of features designed to optimise performance and increase profitability for you and garages:

1) Friction material: Specially selected for low noise and stable stopping power.

2) BRAKEBOOST Instant Friction: A resin-based compound for instant friction during bedding-in.

3) Scorching: A heat treatment process for improved friction stability, especially at high temperatures.

4) Multi-material backing shims: Reduce vibration and eliminate unwanted noise.

5) OE matching chamfers: Ensures effective contact between pad and disc, reducing noise during operation.

6) Identification and branding: Clearly marked with part numbers, batch codes, and ECE R90 reference for

a “ground-up development” tailored to meet the distinctive needs of EVs. The primary objectives were clear: enhanced stopping power and ultra-low noise. Matt believes Allied Nippon has achieved this through its development processes, by combining a new friction compound with a scorching treatment and its BRAKEBOOST Instant Friction layer.

The weight and speed of EVs require a capable braking system. Consequently, Allied Nippon’s development team has introduced a new friction compound in EV+

certification.

7) Environmentally sensitive: Certified copper-free and ‘N’ rated by AASA, safeguarding against marine habitat contamination.

28 I PROFESSIONAL MOTOR FACTOR MARCH 2024 BUSINESS UPSELLING

(L-R): Matt Ellis, EV+ project lead, alongside Dr. Keith Ellis, director in braking product development –affectionately known as Dr. Friction!

brake pads, heat-treated through scorching for enhanced stability. This, coupled with the BRAKEBOOST Instant Friction layer, ensures “superior stopping power”, addressing the challenges posed by heavy EVs.

Furthermore, recognising the smooth driving characteristics of EVs, Allied Nippon has placed a strong emphasis on noise reduction. With EVs being quieter than their ICE counterparts, EV+ brake pads achieved an AA-rating during testing, with a peak output of just 88dB.

Considering a sound below 70dB is essentially inaudible to those inside the vehicle, this peak output shows the success of Allied Nippon creating a hushed braking solution.

Upselling opportunities

Matt underlined the upselling opportunity that EV+ provides: “EV+ presents a chance to not only meet the evolving needs of EVs

but also to elevate the customer experience and drive

additional revenue. By effectively communicating the benefits of enhanced stopping power and ultra-low noise, EV+ premium brake pads offer a genuine opportunity for aftermarket businesses to increase their EV revenues.

“As a specialised EV product, EV+ is competitively priced whilst remaining aligned with Allied Nippon’s ethos of offering world class quality. The unique selling points of EV+ position it as more than just a braking solution; it becomes a value-added proposition for customers seeking the right service parts for their EVs.”

Elevating profits through premium performance

As EVs continue to make their indelible mark on the automotive aftermarket, Allied Nippon's EV+ brake pads are primed to play their part.

Matt concluded: “The upselling potential embedded in EV+ goes beyond offering a product; it’s about providing a greater experience for EV owners and, in turn, maximising revenue in the era of electric mobility. Don't just meet the demand; exceed expectations and drive revenue growth with Allied Nippon’s EV+.”

Range focus

EV+ will be available to stock at the end of March, with the initial range catering 37 popular part numbers, including the Nissan Leaf, Renault Zoe, Tesla Model 3, and Jaguar I-PACE. Additionally, where the model is an exclusive EV application with no ICE variant, EV+ will be the only Allied Nippon reference available moving forward.

For more information about Allied Nippon www.rdr.link/FAD010

BUSINESS UPSELLING

Most companies are considering their environmental impact, both in terms of their operations and also the products that they sell. ESG (environmental, social and governance) policies are now commonplace, and the motor industry is at the forefront of promoting a more sustainable outlook.

Esprit Windscreen Repair Equipment Director, Victoria Evans, reveals how ESG policies underpin the entire company, and, just as important, how you can promote the sustainability of windscreen repair to customers.

So, how did Esprit first turn its minds to ESG and sustainability?

Victoria said: “At its heart, windscreen repair is all about sustainability; its entire existence means that windscreens, which would have to be replaced at high cost, can instead be repaired –significantly extending the life of the windscreen.

“We calculated that in 2023, Esprit sold enough resin to repair 1.3 million windscreens, which is a huge saving in carbon emissions from creating new screens, as well as a significant saving for the companies using our products.

“Underpinning sustainability is the need for deep confidence that the repair will be effective and safe for the end-user every time. This is why we believe in performance testing to ECE R43, which means that Esprit repairs have undergone

Esprit Windscreen Repair Equipment: ‘Green benefits

can also benefit you!’

the same tests that new windscreens go through. Repair isn’t second best; we believe there should be no trade off in repairing a screen over replacing one.

she added: “Since the early days of Esprit, we have always championed a component sourcing strategy of buying as local as possible – and as much as possible from the UK.

“We moved away from that for a while in the early 2000s, when products from overseas were so much cheaper, but in the past 10 years we’ve moved back to our strategy of buying as much as possible from Britain. Ninety percent of our suppliers are now based in the UK, with a sizeable number being within 10km from our manufacturing site. This ensures we are minimising the carbon footprint of our goods, as well as supporting other local and family owned businesses, which has always been important to us.

“It also works well for the business and our customers, enabling us to build strong relationships with our suppliers, allowing us to be agile in response to our customer needs.”

Esprit believes it isn’t just ‘talking the talk’ when it comes to these issues – and the company isn’t satisfied with its progress.

Victoria said: “There are a few components of the kit that we’re currently looking at – going for fully recycled and recyclable packaging for our resin is one that we’ve been investigating for a while, as well as carrying out some injector innovation, which looks like it will reduce the need for drilling and heating, and reduce the amount of resin needed, so we’re excited about that.

“We never stop innovating, but we keep costs as low as possible, ensuring that new or upgraded products can be integrated with people’s existing kits and not replacing items for the sake of it.”

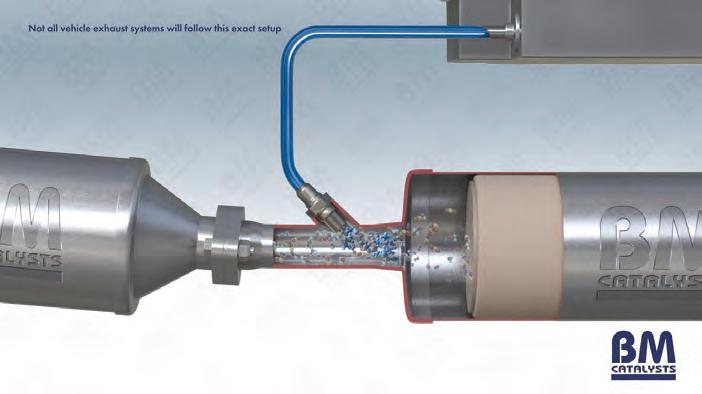

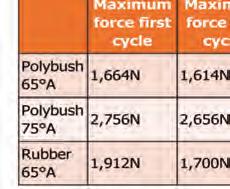

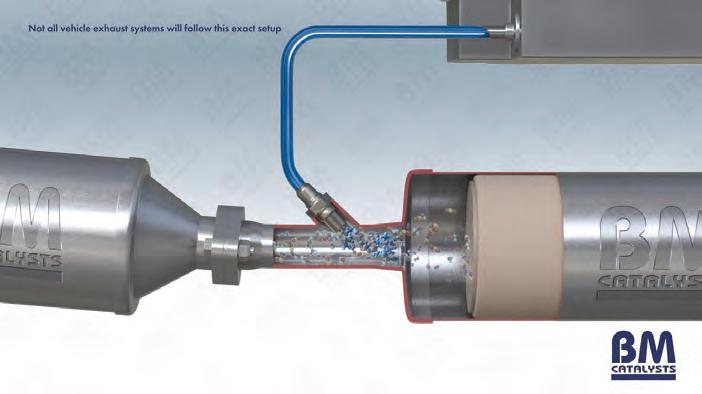

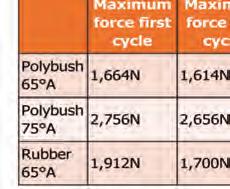

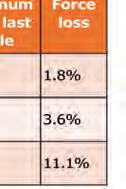

30 I PROFESSIONAL MOTOR FACTOR MARCH 2024 BUSINESS SUSTAINABILITY