MOTOR FACTOR

Any shift in the 2030 deadline cannot be a free pass to delay EV training, SMMT urges PEOPLE & INDUSTRY

AS-PL excited for future after UK warehouse opening

SEPTEMBER 2023

PROFESSIONAL

NEWS

VOLUME 23 ISSUE 8 SEPTEMBER 2023 6-8 NEWS 26-29 BUSINESS & TRAINING SPECIAL REPORT ............................................................................................................34 ENGINES & TURBOS Belt-in-oil technology is good news for the aftermarket, Dayco encourages........................37 Carwood delivers turbo diagnostic masterclass..............................................................................40 Ivor Searle puts engine remanufacturing under the microscope..............................................42 Quality remains the key for replacement turbochargers, reminds Nissens Automotive....44 BRAKES & CLUTCHES Delphi EV brake pads engineered to offer ‘exceptional’ performance as latest additions unveiled..........................................................................................................................................................45 Comline breaks new ground with caliper offering..........................................................................46 PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 3 REGULARS Viewpoint...........................5 News....................................6 What’s New.....................49 Product Spotlight..........50 10-25 PEOPLE & INDUSTRY 30 MARKET TRENDS & ANALYSIS CONTENTS

Editor

TOM HENMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Group Manager

ROBERT GILHAM

Senior Account Manager

ALEX DILLEIGH

Design

ADEEL QADRI

Group Production Manager

CAROL PADGETT

Production Assistant

KERRI SMITH

Professional Motor Factor is an essential business magazine for those with decision-making responsibilities within motor factors.

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way; Watford, Herts; WD24 4YF

Tel: (01923) 237799

www.pmfmag.co.uk

tom@pmfmag.co.uk

Twitter: @PMFmag

Facebook: @ProMotorFactor

LinkedIn: Professional Motor Factor Magazine

Copyright © 2023

Forging futures through the power of apprenticeships

As I sat down to write this eagerly-awaited viewpoint – I know, it’s been a long couple of months since the previous instalment – I received a ‘breaking news’ notification announcing this year’s A-level results. Naturally, there was a barrage of content immediately available about what potential route to take if results have or haven’t gone students’ way.

This acted as a neat segue into the topic of apprenticeships; I was seduced by a story on the topic and was disappointed at a statistic claimed by the BBC, backed up government figures, that stated that almost half of all apprentices are now dropping out of their course – 70% of those cite problems with the quality of the training.

The automotive industry is characterised by rapid technological advancements and evolving consumer preferences. It is a dynamic sector – perhaps misunderstood by members of the public – that is constantly seeking a skilled workforce to meet its ever-changing demands.

Apprenticeships have emerged as a vital pathway for individuals aspiring to enter this industry and acquire hands-on experience; for example, Jaguar Land Rover announced in February that it had opened a record number of degree apprenticeships to “deepen (its) talent pool for electrification”.

Closer to home in the automotive aftermarket, I am inundated with news about new training courses, modules and topics. There is no shortage of manufacturers, suppliers and organisations that are trying to inspire the next generation, as well as those already integrated into the system.

In an era of electrification, autonomous driving, AI, data analytics, software engineering and machine learning – echoing those aforementioned technological advancements and customer preferences – the automotive industry requires a workforce that is not only adept in traditional mechanical skills but is also well-versed in cutting-edge technologies.

Apprenticeships offer a tailored approach to education and training, enabling aspiring professionals to develop a wide range of competencies while working alongside experienced mentors. This hands-on experience not only imparts practical skills but also fosters a sense of adaptability, crucial for tackling the ever-evolving landscape of the automotive field.

The shortage of qualified professionals has been a long-standing concern, and apprenticeships offer a direct solution by coaching the next generation of automotive experts. As apprentices learn the ropes through on-the-job training, they contribute to narrowing the skills gap and filling the positions that are essential for maintaining and repairing vehicles. By nurturing talent from within, apprenticeships bolster the industry’s sustainability and resilience.

Traditional higher education pathways may not be suitable for everyone, while apprenticeships offer an opportunity for individuals to learn and earn simultaneously. This earns them a wage while mastering skills, making the industry more appealing to a diverse range of candidates, including those who may not have pursued a formal university education. This diversity enriches the talent pool, nurturing innovation and fresh perspectives within the industry.

Professional Motor Factor: Certificate of Average Net Circulation for the 11 issues distributed between July 2021 and June 2022

Net total: 3,260

United Kingdom: 3,260

Apprenticeships also promote a culture of continuous learning and improvement. As apprentices are exposed to real-world challenges and experiences, they develop problemsolving skills and critical thinking abilities that go beyond theoretical knowledge.

The problem, however, is that despite their considerable advantages, the numbers don’t lie: apprentices are dropping out and the quality of their training is the chief factor. I would be fascinated to learn of readers’ stories and experiences of enrolling apprentices – as an industry, what are we doing right? What do we need to improve? How can we narrow the gap? How can we ensure apprentices progress to earn themselves long-term careers? As always, you can get in touch via tom@pmfmag.co.uk.

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

Tom Henman

Editor

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 5

VIEWPOINT

Any shift in 2030 deadline cannot be ‘free pass’ to delay EV training, according to IMI chief

The CEO of the Institute of the Motor Industry (IMI) has urged the automotive sector to keep its “eye on the ball” for EV training, regardless of any move of the 2030 ban on the sale of new ICE vehicles.

In a statement received by PMF on the 26th July, Steve Nash said: “The government has a difficult job to do to balance the UK’s ability to be ready for the 2030 deadline with the hard to ignore environmental threats. The lack of a strong strategy to date for UK-based control of the supply chain is certainly raising questions about the vulnerabilities this could create for our economy and infrastructure.

“However, if the government acknowledges its miscalculation and moves the deadline it is absolutely crucial that this is not seen as a ‘free pass’ to delay investment in infrastructure and training.

“Our latest data already shows that we are already behind the trajectory needed to have an automotive aftermarket workforce EV-ready. The number of newly qualified EV technicians in the first three months of this year is actually 10% lower than the same period in 2022. Even more concerning is our projection that for the second quarter there will be a decline of

31% in technicians obtaining EV qualifications compared to Q2 2022.

“The IMI predicts that by 2030 the UK will require 107,000 IMI TechSafe qualified technicians to meet the evolving demands of the growing parc of EVs. This figure rises to 139,000 by 2032, with our projections indicating a potential shortfall of 25,000 technicians if the current trends persist.

“Any change in government strategy over the 2030 deadline must not, therefore mean investment in EV training can be paused.”

On the 31st July, however, despite speculation, the Prime Minister reaffirmed the government’s position on the ban of new petrol and diesel car sales from 2030.

AAG reveals transport plans for NDC –due to open in

2025

Alliance Automotive Group (AAG) has offered an update in the progress of its brand-new national distribution centre (NDC) in Rotherham, with “advanced transport solutions” designed to enhance delivery and efficiency.

The centrepiece of the new transport fleet will be the NAPA branded wedge double deck trailers, equipped with a lift deck down the middle. AAG reported the design allows for the transportation of materials on two levels, significantly improving capacity and maximising space.

With the new trailers, AAG claimed it will deliver the whole product portfolio next-day, streamlining logistics and reducing delivery times.

AAG UK Group Logistics Director, Neil Warren, said: “The opening of our new NDC in Rotherham marks a significant

Arnold Clark Autoparts launches new trade website

Arnold Clark Autoparts has launched a website for all trade businesses in the UK, including customers at Arnold Clark Autoparts hub sites, to offer 24/7 access to its product range.

After a “successful soft launch” for customers in Glasgow at the start of the year, the trade website was unveiled to all at this year’s Automechanika Birmingham.

Key features include free delivery on orders over £55, a next-day delivery for faster parts service, and the opportunity to shop the company’s range of aftermarket products, including tyres and consumables. The site also allows customers to shop for OE parts from more than 30 manufacturers.

Plus, customers can shop online 24/7, browse parts and compare pricing options, and see which parts are available for any vehicle using the vehicle registration look up tool.

William Marshall from WM Marshall & Sons Ltd, Dumbarton, offered feedback: “The Autoparts website allows me to order my parts when it suits me and lets me see the different product options to choose from. I use it for premium brands and OE suppliers, as well as tyres.

“The great thing is that human touch isn’t lost either; Francine and her team are always on hand through the live chat to source anything I need or answer questions I have about my deliveries. They also go over and above by helping with sourcing parts from other branches, such as Honda.”

milestone for AAG.

"With our state-of-the-art transport fleet and advanced double deck trailers, we are setting new standards in product delivery and optimising our logistics capabilities. This investment underscores our commitment to providing exceptional service to our customers while maintaining the highest standards of safety and efficiency.”

Arnold Clark Autoparts Group Factor Manager, Craig McCracken, added: “The release of the new e-commerce platform for the trade revolutionises the Arnold Clark Autoparts customer experience and is the latest innovation in our digital roadmap that is set to maximise efficiency between Arnold Clark Autoparts and its customers.”

6 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 NEWS

GSF Car Parts volunteers deliver life-changing experiences with Speed of Sight charity

A team of volunteers from GSF Car Parts helped to deliver “life-changing track experiences” with charity partner Speed of Sight in August.

GSF, which supplies independent workshops with parts, tools, garage equipment and specialist training via its network of 180 branches, is a corporate sponsor of Speed of Sight, a charity offering racetrack-based driving experiences to people with sensory impairments, physical or psychological disabilities, or injuries that prevent them from holding a driver’s license.

Speed of Sight hosted a GSF-sponsored track day and family fun fair at Three Sisters Circuit in Wigan, providing track experiences for 20 young people that are supported by the Manchester arm of the Whizz Kidz charity.

GSF Car Parts HR Director, Jo Warren, said: “It was such a privilege for our team to play a part in bringing these amazing experiences to life for the young people supported by Speed of Sight and Whizz Kidz.

“We encourage our team members to make use of GSF’s paid volunteering scheme, and this was the perfect opportunity for it. The feedback we received from our team about the event was brilliant, with everyone bowled over by how heartwarming, eye-opening and moving the experience was for them.

“The work that Speed of Sight does with people of all ages is fantastic and as a national business of passionate people across the UK, the GSF team is proud to be a part of this family.”

Fifteen GSF volunteers from its branches and support teams across the North-West and the Midlands helped Speed of Sight to run the day. The team mucked in on a range of jobs, including track marshalling, greeting, helping participants into vehicles, manning fun fair stands, certificate presentations and more.

The young people, ranging from age eight to 26, had the opportunity to get behind the wheel and drive themselves, with trained professionals with them for an unforgettable experience.

Speed of Sight Co-Founder, John Galloway, added: “We were thrilled to

welcome the staff from GSF to our track day. They were a great help and so positive about us and the charity.

“GSF has become such an important sponsor to us with the money they’ve donated and the staff volunteering when they can, it means that even more people with a disability can have that experience that many of us take for granted – to drive.

“We rely on generous donations from individuals and companies to help us run these incredible experiences for people, so we’re always so grateful when a company, and especially one with an incredible reputation and fantastic staff like GSF, support us.”

@PMFmag ProMotorFactor tom@pmfmag.co.uk www.pmfmag.co.uk

Professional Motor Factor

Ben helps families through cash-strapped summer

Ben, the automotive industry charity, is providing support to individuals and families that are facing money worries, debt or urgent need this summer.

Ben is already providing support for many families that are struggling to make ends meet and unable to afford essentials, such as food and utilities during the costof-living crisis. Over the last 12 months, Ben has supported 128 households that couldn’t afford to put food on the table, 66 households that couldn’t pay their rent or mortgage costs and 52 households that couldn’t afford utility bills.

More people than ever before are contacting Ben’s helpline for support –between April and June 2023, there was a 23% increase in enquiries (year-on-year) and a 20% increase in support cases (yearon-year). Ben stated that people aren’t only said to be struggling to make ends meet, they are also struggling with their mental health.

Ben considers managing money as a key area that impacts on wellbeing. Given the knock-on effect that financial problems can have, increasing levels of stress, anxiety, low mood and depression are made worse when people can’t afford basic living costs.

In addition to supporting basic living costs, Ben also wants to give families, that wouldn’t otherwise be able to afford it, the opportunity to enjoy spending time together and create memories during the holidays. This is as well as taking pressure off families that face impending back to school costs including school uniform, bags and PE kits.

Ben is encouraging people not to struggle alone with their money worries and get in touch.

“I felt at the lowest of low points in my life. I’ve never applied for any sort of benefit or hand-out in my life. I felt ashamed and embarrassed to ask for financial support. Ben made me feel welcome and worthy of this support.”

“The food voucher came through yesterday. My mum cried her eyes out, it’s such a weight off our minds. We can’t thank you enough!”

“I was reluctant to call Ben – typical man, not asking for help… but I did and after the first few minutes, knew I had made the right decision.”

Ben Health and Wellbeing Director, Rachel Clift, said: “Many individuals and families are being pushed to the edge with the current rising cost of living. It’s also impacting other areas of their health and wellbeing so if you work, or have worked, in the automotive industry please get in touch now if you’re struggling or feeling at breaking point. You can contact our free and confidential helpline.”

Ben is there for those who work, or have worked, in the automotive industry and their family dependents. The charity is already supporting many automotive families this summer.

Don’t suffer in silence, contact Ben’s helpline: 08081 311 333 or use the webchat on www.rdr.link/FFX027 You can also access Ben’s out of hours text support line by texting BEN to 85258

For employers who would like to find out more about working in partnership with Ben, or who would be interested in discussing health and wellbeing support for employees, email Rachel Clift at Rachel.Clift@ben.org.uk

NEWS

8 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023

CSF champions customer service as the catalyst for continued business growth

After a successful first visit late last year, our editor, Tom Henman, was invited back to Car Spares Factors – but this time to its HQ in Southgate – to catch a glimpse of the vast warehouse, meet staff and, of course, catch up with co-owner, Sanjiv Shah.

Sanj always exudes a glow, warmth and confidence about him. Each time I’ve met him, I never feel like I’m stealing his time, nor am I keeping him from meeting someone far more important. We exchanged pleasantries, before he escorted me through the telesales arena, which was a hive of activity (they manage thousands of calls a week!), to a quieter spot in his office.

I asked if the phones were usually that busy, to which Sanj, still with a smile on his face, nodded. Sat down, albeit his chair pushed back slightly, he spoke of the importance of, not just the telesales team, but of every member of 60-plus employees within the business, many of whom have racked up years of service:

“Our dedicated call centre team have built a great rapport with our customers. As you can imagine, we’ve been around since

1977, so we’ve got customers that have been with us for more than 40 years, and a lot of that is down to these guys (referring to the telesales team).

“Three of them have been with us for 20 years, a couple more are closing on 10, while we have drivers that have stayed with us for 25!

10 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023

PEOPLE & INDUSTRY

INTERVIEW

“For us, it’s not just about selling, it’s about building relationships. If we are able to gain customers’ trust and confidence, whether that be delivering on time, having the product in stock and understanding it, why would they go anywhere else?”

Collaborating with suppliers

On the point of product confidence, I was curious to learn how CSF, with its abundance of different lines and 60-plus brands in its impressive warehouse facility, goes about sourcing product and securing agreements with individual suppliers:

“If a product is on our shelf, it’s because we have confidence in it. If, for any reason, we find there’s a problem with a product, it comes off our shelf – we won’t supply it. Simple. Because we offer such a range –we don’t just offer one brand of filter, for example – our customers have a choice. Our team know what brands specific customers like, so the conversation is straightforward when taking orders.”

Suppliers come and go – it can sometimes feel like a transfer window! – it’s part and parcel of running a motor factor, especially if it’s part of a buying group, which, incidentally, CSF is. Arguably, it would be understandable if there was a transition period, as the product and sales team get brought up to speed on range, value, quality etc, but Sanj revealed how CSF tries to reduce that period when a new supplier is added to the portfolio:

“A couple of years ago, the Rapid group took on Duckhams as a main line oil supplier. First and foremost, representatives of Duckhams paid us a visit, conducted a training session with our sales team, then joined our business development managers as they toured the local garage network and gave full workouts to our customers. This process allowed everyone in the chain to be brought up-to-speed quickly, gain confidence, and ensured little delay in supply. It was brilliantly handled.”

Quizzed on whether it’s a situation he would rather avoid, though, Sanj admitted that it can be a “headache”, but as product replacing the incumbent is “potentially better” it is a headache worth suffering.

When there is concern among customers, however, CSF takes a cautious approach. When CSF felt like it had to switch brake supplier, Sanj admitted there was some uncertainty because the previous supplier was admired.

Sanj revealed how he appeased any disgruntled customers: “We sent sets of brake pads to customers, free of charge,

and suggested that they fit them and see how they get on. As I mentioned before, we have total confidence in any product we sell, so while we were a little apprehensive about losing business, our reputation and the quality of the new supplier meant that business was maintained – it comes down to trust – and garages now ask for that supplier.”

Controlling everything in-house

As I mentioned before, I was paying a visit to CSF’s headquarters. Here, it has a 12,000sqft warehouse, which Sanj is looking to add a mezzanine too, by the way, as the motor factor looks to eke out every last inch of space available!

Products are then transported to their respective destination – either direct via warehouse or another CSF branch – with the aim of delivering the order to its final destination within the hour if direct or, at the latest, same-day if diverted from the warehouse to branch.

The warehouse facility has allowed CSF to keep all of its stock in-house, rather than relying on a third-party, which one could argue is tying up its cash in stock. Sanj, however, believes it’s a worthwhile investment, increases margin and enables the factor to have greater control over its outgoings.

The biggest benefit, though, Sanj claimed, is that garage customers are not having to wait for a prolonged period of time for a delivery: “When a customer rings for a heat resistor on a Nissan, we’ve got it on a shelf; if they require an air con condenser on a Hyundai, we’ve got it on the shelf. These can be packaged up and delivered within the hour – that’s one of our key service deliverables.

“If can we get a part delivered within the hour, generally, the customer doesn’t mind paying that little bit extra for the convenience.”

This change in strategy also meant an alteration in terms of how CSF route its

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 11 PEOPLE & INDUSTRY INTERVIEW

deliveries; while CSF can service orders with fewer drivers than it has on its books, Sanj reported that the customer service would drop as a result.

He explained: “At every depot, we have one or two extra drivers. One or two drivers are always kept local, so garages within a mile or two-radius of each depot are receiving their orders within 10-15 minutes, while the rest are tasked with deliveries further out. The advantage of that is our local customers have become very loyal – they know what they’re getting and when they’re going to receive it.

“It also quickens our deliveries further away because our drivers finish their local deliveries, then tag the others at the end. The drivers are in-and-out of the warehouse quickly. Start times are staggered too, so there is a constant stream of drivers entering and exiting a depot every 15-20 minutes.”

Fully-immersed – but structural change enables rest!

With every conversation I have with Sanj –whether it be at CSF HQ, a branch or even Automechanika Birmingham – his drive and determination to see the business succeed is abundantly clear. I’m confident that desire, as well as the responsibility he and his business partner, Avnish, have could be overwhelming – and indeed that has been the case, as Sanj revealed – but the pair are now in a position where they can “switch off on a Sunday” before the cycle starts again on Monday morning:

“Even I’m able to switch off!”, he said with a chuckle. “I’m able to switch off a lot easier than I used to, let’s put it like that. There were times I would be in the office at 6am and not get home until 8pm, but that was in the earlier days when we were trying to get to grips with systems, processes and products.

“As the years have progressed, though, we’ve gained experience and employed the right people to help shoulder some of that responsibility. In recent years, especially, we’ve gone a step further by employing a management team and defining departments, such as operations, dispatch, deliveries, sales, procurement, accounts, admin and marketing.

“This has allowed us to step away from the ‘nitty-gritty’ and fully focus on what our jobs should entail: oversee and evaluate the business, identify new opportunities and carry out plans for the future to ensure we all enjoy long-term success.”

Impact of COVID-19 still being felt

It may or may not feel like a distant memory, but the impact of COVID-19 is still being felt for some businesses. At CSF, while there were some historic reminders, such as hand sanitiser and the occasional ‘social distancing’ sign, dotted around the warehouse, it was ‘business as usual’.

Whether to shut or stay open, particularly during the opening phase of

the pandemic, was a dilemma, but Sanj claimed it was an easy call:

“OK, we shut for 10 days, but we then reopened with 25% of staff. Within a week of that, we were up to 50%, and within a month, we had our entire team return to work. We put the protocols in place – did what we needed to do – and believe it or not, we were busier than ever!

“Some of our competitors shut down while we were open, so a lot of customers that weren’t using us quickly did, and a lot of those have been retained. Because of that, the business has carried on growing, to the point where July 2023 was our best-ever turnover month in the history of our business.”

One garage, for example, was spending an average of £400-a-month but is now spending £12,000-a-month! Sanj added: “We’ve got another dozen garages that have followed in the same vein: we weren’t their go-to but now we’re their main supplier.”

Another branch to open?

CSF’s figures are only going in one direction at present, to the point where 2023 is projected to show a 15% increase on 2022’s turnover. Sanj paid tribute to the staff for their “monumental” efforts in helping CSF grow exponentially: “Without them, none of this would be possible! I hope we return the compliment.”

With the figures and Waltham Abbey branch, the baby of the bunch, already the third highest in terms of sales rankings and enjoying a “phenomenal time”, it must be time to dust down the map and search for the next site as Sanj and Avnish grow the CSF empire?

With a wry grin, he simply responded: “We’ll see.”

For more information about CSF, www.rdr.link/FFX028

12 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 PEOPLE & INDUSTRY INTERVIEW

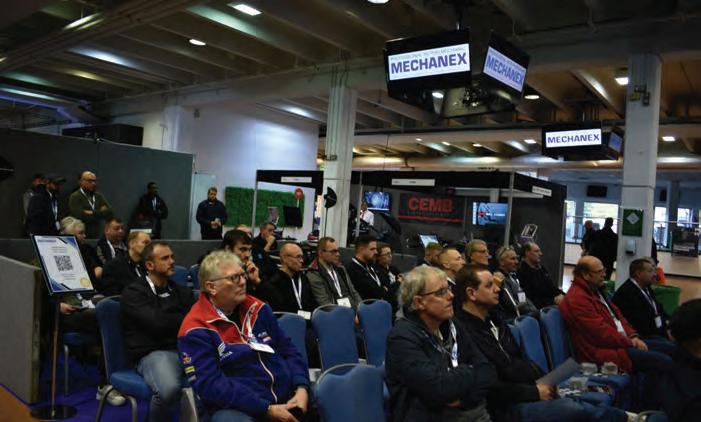

REGISTER FOR FREE AT WWW.MECHANEX.INFO THE HANDS-ON TRADESHOW FOR INDEPENDENT WORKSHOPS TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS ● FREE CPD TECHNICAL SEMINARS ● FUTUREDRIVE ZONE ● FREE ENTRY ● FREE PARKING ● FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL SANDOWN PARK, SURREY 7TH & 8TH NOVEMBER 2023 The regional Tradeshow for aUTo rePair Professionals PROFESSIONAL MOTOR MECHANIC MECHANEX FEATURING LIVE SPONSORED BY

Movers & Shakers

PCL

Gearing up to take the lead on business development in the South of England is Michelle Foord, PCL’s new area sales manager.

With a background in manufacturing, PCL reported Michelle has a proven track record of building customer relationships within the railway and automotive industries. Her appointment came just in time for her to join PCL’s team at Automechanika Birmingham 2023. Since then, she has since spent time familiarising herself with PCL’s portfolio and operations at its production facility in Sheffield.

Michelle said: “It’s been fantastic to spend time on the shopfloor, getting into the detail of the products, how they’re put together, and the time, effort and skill involved in the process.

Simply Brands

Simply Brands has strengthened its team with the appointment of Sam Robinson to the role of business development manager.

Sam brings considerable product, marketing and sales knowledge to his new role having spent the past 10 years at TRICO.

He said: “My role at Simply Brands is primarily to help build new and existing customer relationships, as well as helping the team drive forward new and innovative product lines, so the knowledge and experience gained over my career in the aftermarket to date will certainly help.

“The production facility is incredibly impressive and immensely clean – I couldn’t believe it was a working factory from how clean it actually is. The whole operation runs so smoothly – the picking, fulfilling of the shelves, the traffic light systems – all the departments work seamlessly together.”

The next step, Michelle said, is getting out on the road: “In the short-term, my focus is meeting my customers and understanding their business needs. My long-term focus is growth and identifying further potential in the South.

“I’m really looking forward to meeting existing customers and looking at where the gaps are to build new business and get a plan in place.”

“For me, the love of the automotive aftermarket and the contacts I’ve made has always been the main driver in my ongoing enthusiasm for the industry, but hopefully my ability to analyse and understand trends to help customers identify opportunities allows me to put it to practical use.”

Welcoming Sam to the Simply Brands team, its CEO, Ollie Page, said: “I am delighted that we have secured the services of an aftermarket person of Sam’s calibre. His management style is complementary to that within our business and his existing customer relationships, as well as the respect and reputation he brings from his years working in various roles for TRICO.”

PEOPLE & INDUSTRY APPOINTMENTS

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 15

PMF introduces this month’s movers and shakers as they begin a new stage of their career in the UK aftermarket.

To connect with Sam on LinkedIn, www.rdr.link/FFX002 To connect with Michelle on LinkedIn, www.rdr.link/FFX001

Granville has grown from the most modest of beginnings, from occupying the space above a residential garage, through sub-letting office space from British Benzol and finally moving into its own premises in the mid-nineties; the journey has been one of continued evolution and improvement. Managing Director, James Holland, takes you on that journey:

Granville divulges journey – culminating in a rebrand

In the early 2000s, Granville began manufacturing engine oil on-site and filling became a larger and more sophisticated part of the business as the years progressed.

Perseverance and ambition following Brexit

Granville was acquired by Tide Water Oil Company in 2016, an Indian lubricant blender looking for a manufacturing base inside the EU. It selected Granville in the UK as an established and successful business with clear potential for growth and development and a shared desire to offer quality products at affordable prices. Little did it realise that just two months following the completion of the transaction, the UK public would vote to leave the EU.

Despite the challenges presented by Brexit, Granville embarked on an ambitious campaign of expansion. In 2017, following negotiations with the current owners, Granville acquired Unit 28 – immediately next door to our existing manufacturing facility – adding 8,000sqft to the existing 37,000 enjoyed by the business. This smaller building provided a significant opportunity through the land surrounding the two buildings.

Outwardly, the business appeared to be plateauing in terms of sales volume; internally, work was continuing in earnest on an end-to-end programme of improvement. First the bund, a concrete area of containment within which our tanks are sited, was doubled in size. This made way for six new base oil tanks and five additive tanks to be installed in 2018 –adding 520,000L to our raw material storage and reducing the need for handling of barrels to the blending platform by 90%.

From there two new high speed filling lines were installed along with in-feed tables and the foil sealing of the product to ensure product quality at the consumer.

By 2019 Granville embarked on our biggest project yet, the design and install of a solubilisation plant. Base oil thickness at different temperatures is modified using specially formulated packages named viscosity modifiers. These provide the low and high temperature pumpability that engines require – 0W/20 or 5W/30, for example – and are made by dissolving different polymers in base oil. These polymers must be shredded and dissolved at high temperatures to ensure that they form a fully homogenous fluid.

To achieve this, Granville acquired new mixing vessels and an ultra-modern thermal fluid heating system – a more environmentally friendly alternative to steam heating. To ensure that the polymer is able to dissolve efficiently, Granville’s maintenance team designed and built our own shredding platform that reduced the polymer to the exact size that we require whilst minimising stress to the product.

Following the acquisition of the ‘red building’, as it is now affectionately known, in 2017, plans were drawn up and the process of planning approval had been progressing in the background. When this was finally granted in 2019, the project was tendered, and Hobson Porter was appointed as main contractor to execute the £2.2m expansion to the rear of the building.

16 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 PEOPLE & INDUSTRY COMPANY PROFILE

“Raw material shortages quickly put the business under significant pressure. With that in mind, two 125,000L tanks were hurriedly procured, installed and commissioned during a six-week period in the summer of 2021 – adding an additional 250,000L of base oil storage to the site in an effort to ensure continuity of supply to our customer base. With expanded storage, additional blending and filling capacity and newly completed storage space, demand for Granville lubricants reached an all-time high.”

Incorporating warehouse space, dedicated loading docks and charging stations for our expanding fleet of ride on pallet trucks, the site is now efficiently segregated between the ‘blue building’ housing raw material/component storage, bulk oil blending, quality control (QC) and production/filling functions. Meanwhile, the ‘red building’ now serves as Granville’s dedicated distribution facility with everything being produced transferred across the shared yard. Finally, a dedicated goods-out yard on the west of the site ensures that incoming materials do not affect finished goods being shipped to customers.

Combatting raw material shortages triggers “all-time high” in demand

If constructing a new building whilst dealing with the COVID-19 pandemic and social distancing requirements – whilst being a key part of keeping UK haulage moving –weren’t challenging enough, raw material shortages quickly put the business under significant pressure. With that in mind, two 125,000L tanks were hurriedly procured, installed and commissioned during a sixweek period in the summer of 2021 –adding an additional 250,000L of base oil storage to the site in an effort to ensure continuity of supply to our customer base.

With expanded storage, additional blending and filling capacity and newly completed storage space, demand for Granville lubricants reached an all-time high. With limited space and social distancing constraints, the only option for the business was to introduce shift working. Such a drastic change to working patterns is usually a protracted affair with challenging negotiations, but as Granville has always been – and continue to operate as a ‘family’ style business – staff were happy to adjust. Following brief consultations, they voluntarily moved to shift working almost immediately – a testament to the team spirit for which we stand!

Now operating 16 hours, five days-perweek, with the additional capacity from investment finally paying dividends to the performance of the business, the time was right to overhaul the laboratory on site.

Much more than a QC lab, Granville operates an end-to-end development environment, tuned to ensure that our products excel at providing maximum engine protection and the highest levels of fuel efficiency. To that end, the lab was relocated near to production and doubled in size with over £100,000 of additional equipment capacity to vital tests, such as NOACK volatility and high temperature high shear testing. This ensures that our lubricants are fully and comprehensively tested for even the latest generation of hybrid vehicles.

As 2022 progressed, even with all the additional expansion and investment, the plant continued to struggle – mainly due to bottles!

The sourcing of bottles, especially when using bespoke bottle designs as Granville does, is always a challenge, as bottles are often ordered 14 weeks in advance –production delays add a further headache to production planning! Consequently, at the end of 2022, Granville made the decision to invest in blow moulding equipment, so that we could manufacture our own bottles on-site.

With two modern and environmentally friendly ‘all electric’ blow moulding machines on-site, Granville embraced the challenge of blowing bottles, but with one final challenge: moulds are made to suit a machine, and whilst our ‘performance’ mould used for the gold range could be modified to fit the new machines, our Hypalube bottle would not fit and would require a new mould to be manufactured.

As that design was already six-or-seven years old, the decision was made to modernise and redesign the bottle from scratch. With the opportunity too good to miss, we chose to completely re-brand.

New beginnings

As the journey to refine a new bottle progressed, we turned to nature and embraced the hexagon – the strongest shape in nature for the foundation of our new logo, with a three part ‘G’ emblem symbolising our three pillars: service, distribution and availability.

Following the new flexible logo design and premium gold look, the ‘hex’ bottle sought to pair sleek modern lines with the hexagonal pattern for an added flourish. The new logo, bottle and labels work together to project a modern and consistent look and feel to the new branding.

For more information about Granville, www.rdr.link/FFX003

PEOPLE & INDUSTRY COMPANY PROFILE

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 17

Six years of UFI Filters UK success – what’s the secret?

UFI Filters has OE pedigree; UFI claimed it is trusted by 95% of VMs and eight out of the 10 most popular vehicles in the UK are originally equipped with its filtration systems. It is a company that is also growing its presence in the aftermarket, particularly at factor level, with a range that now offers more than 3,000 references that cover passenger and heavy-duty.

UFI Filters UK, led by Sales Director and General Manager UK and Ireland – Aftermarket, Karl Ridings, has quadrupled its results in six years following the opening its depot for the British and Irish markets. The company, moreover, expects another double-digit growth in the business this year. This result has been possible, thanks to partnerships with what it described as key distributors and trading groups in the UK.

UFI Filters UK has marked these achievements by moving into bigger offices in Alcester and strengthening its customer service team to maintain the high levels of service. The company reported that local growth has been possible thanks to many winning factors:

A dedicated warehouse in UK, which benefits from the services of supply chain partner DB Schenker

A dedicated sales team counting four sales managers for different areas and a commitment to developing the business into different market segments, for light vehicles and heavy-duty

Its new partnership in 2023 with Parcelforce, which offers a next-day delivery with high level traceability and tracking

The launch of the heavy-duty range for the British and Irish aftermarket, which is allowing UFI Filters to open new channels of distributors – the target is to reach a solid market share in the heavyduty segment over the coming years

What is UFI Filters’ main focus right now?

Karl reported that the company has several focuses right now: “One being the recently introduced range of heavy-duty filters to the UK and Ireland. For passenger cars and light vehicles, we have enjoyed tremendous growth in the last five years, even during the pandemic. For UFI, it’s very important to maintain the service level our customers expect, in terms of availability, sales support and customer service, but also the continued growth with existing and new customers.”

He continued: “Being a company with a strong OE pedigree, a characteristic widely recognised by the market, does not simply mean that we are OE suppliers: it also

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 19 PEOPLE & INDUSTRY INTERVIEW

demonstrates that we have specific technologies and expertise, such as our inhouse production of the filter materials that make up the media of our filters.”

To this end, the company has developed six different recipes called ‘FormulaUFI’, which cover the entire range of filtration: fuel, air, oil, passenger compartment and hydraulics. These can be customised according to the needs of individual applications, to meet the requirements of the VMs.

Karl added: “Indeed, innovation is in the DNA of our company. This has allowed us to develop new technologies, underlined by, to date, more than 280 patents, which ensure a superior product quality on the aftermarket.”

Mythbusting

“UFI only supply OE to Italian brands!”

Karl responded: “UFI Filters is an Italian based company, but we are chosen by 95% of VMs worldwide. UFI supplies a wide portfolio of OE brands. Apart from the Italian brands, there are European brands from German carmakers BMW, Volkswagen, Mercedes and Porsche, the French PSA and Renault, the Swedish

Volvo, as well as from the Asian Nissan, Hyundai and KIA.” “UFI doesn’t have a complete filter range”

Karl answered: “We have over 2,300 references for light vehicles in our catalogue, covering more than 98% of the European car parc with each family of filters.”

“UFI is only OE on fuel filters”

Karl: “For us, continuous technological innovation, the search for solutions with extreme performances and investments in technologically advanced products are the three key success factors that have made UFI an OE leader. Throughout the years, we have convinced our OE customers to develop filtration technologies that combine UFI’s capability to develop its media tailored to customers’ needs with the knowledge of how to integrate multiple functions into a state-of-the-art modules and systems.

“Fuel filters are just one of the product families that reflect our strengths in filtration products for OE. Also, oil and air filters are supplied to the world renowned

carmakers, as well as blow-by filters for light commercial vehicles.

“The group continues to build its OE range, thus laying the foundations for the further implementation and enrichment of our aftermarket offer. Our distributors can always count on the OE pedigree of our products. The aftermarket filter programme incorporates our OE filters and our philosophy of already meeting tomorrow’s demands, today.”

Onus on delivery times

If you stock the fastest-moving parts and rely on rapid availability of what is new to the market, the recently added UFI captive parts might be on your radar.

UFI is aware, however, that space can be at a premium and workshops aren’t always sure of what vehicles will arrive at their doors on any given day; therefore, a stock refill needs to be “extremely rapid and reliable”. UFI Filters’ UK distribution centre enable factors to rely on a ‘last order’ time for a next-day delivery service.

Karl added: “Our recently established partnership with Parcelforce has helped us to increase this already high service level with a great level traceability and tracking; in fact, if you place an order, you will be able to see the availability of the UFI distribution centre on your computer system and can immediately order the parts.”

Digital ordering already accounts for 95% of all orders. Also, more rarer vehicles, you can still utilise the service for next-day delivery.

Initiatives of UFI Filters to support distributors

UFI’s business development team is committed to demonstrating the company’s

20 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 PEOPLE & INDUSTRY INTERVIEW

“Being a company with a strong OE pedigree, a characteristic widely recognised by the market, does not simply mean that we are OE suppliers: it also demonstrates that we have specific technologies and expertise, such as our in-house production of the filter materials that make up the media of our filters.”

“The group continues to build its OE range, thus laying the foundations for the further implementation and enrichment of our aftermarket offer. Our distributors can always count on the OE pedigree of our products. The aftermarket filter programme incorporates our OE filters and our philosophy of already meeting tomorrow’s demands, today.”

Karl Ridings

unique selling points, while the sales team are actively supporting customers, utilising marketing leaflets, brochures and using OE product samples to demonstrate quality and OE technology.

Karl said: “For our new range of ARGENTIUM cabin filters, we are offering initiatives to our distributors for an initial stock pack.”

UFI Filters ARGENTIUM is an antibacterial filtering media, with the exclusive ‘FormulaUFI.Stratiflex’. It consists of three layers of synthetic polymer fibres: antimicrobial, adsorbing and structural. The antimicrobial layer incorporates silver particles with an antimicrobial action, thanks to Biomaster silver biocide (tested to ISO 22196:2011 standards) which inhibits bacterial growth by up to 99%.

When combined, these layers block pollen, dirt and tyre dust, stopping the growth of fungi, mould and bacteria while adsorbing sulphur dioxide and nitrogen oxides.

Thanks to the presence of activated carbon, UFI Filters claimed ARGENTIUM ensures a filtration efficiency of over 98.5% for particles with a diameter of 2.5 microns and also eliminates harmful gases and unpleasant odours, as indicated by laboratory tests carried out in accordance with ISO 11155-1.

The main plus is its retention of characteristics and its effectiveness against microbial growth throughout its entire life cycle – up to 12 months. ARGENTIUM is a product developed using UFI’s OE background.

Customer testimonial

New partnerships are being forged regularly. UFI Filters believes this represents a “mutual advantage” for both players, with the OEM providing the strength of a brand, with a quality product, sales and marketing team.

E&M Motor Factors’ Edryd Evans said: “We strongly believe in this collaboration with UFI Filters, and we trust that this is just the beginning of a long-term partnership.

“It was essential for us to introduce UFI products into our stock, along with the support of UFI’s account manager supporting with stock management and essential newto-range. The UFI customer service team are always on-hand to support our business, and I am very happy with their service.

“With UFI being OE on the bestselling car models, (this) provides our customers with the quality of an original product. E&M Motor Factors business is expanding one of our branches and with the imminent opening of a new branch in Lampeter. Filtration is such an important product group for E&M Motor Factors, along with UFI Filters being a major OE supplier, we are both looking forward to working together to grow both businesses.”

For more information about UFI Filters, www.rdr.link/FFX004

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 21 PEOPLE & INDUSTRY INTERVIEW

“It was essential for us to introduce UFI products into our stock, along with the support of UFI’s account manager supporting with stock management and essential new-to-range. The UFI customer service team are always on-hand to support our business, and I am very happy with their service.”

The Verification of Lubricant Specifications (VLS) is an independent organisation that wants to bring “transparency to the lubricant marketplace and protect and educate the end-user”. To mark a decade in trying to achieve its goals, we are pleased to present an interview with VLS Chairman, Mike Bewsey.

Mike, thanks for taking to PMF for this 10-year anniversary special – how would you describe VLS' work in the sector over the last decade?

“Over the past 10 years, VLS has become an integral part of the automotive aftermarket. Our goal has always been to uphold the highest standards in the UK lubricants industry and to protect and educate end-users. Since 2013, we have investigated 89 lubricant complaints, from low temperature properties through to compliance with

industry standards and OEM specifications concerning a variety of applications, including engine oils, gear oils and industrial lubricants. We believe that lubricants manufacturers and marketers are now paying more attention to what they blend and claim and that companies realise that if they think a product is making false or inaccurate claims, they can report it to VLS, where it will be robustly investigated.

“Additive companies have also commented that more companies are contacting them about Candidate Data Packs and the technology test results required to support marketing claims. That behaviour change demonstrates that VLS is successfully raising awareness and education so that suppliers know just how important it is to check and evidence the claims they are making.”

What has surprised you the most during the last 10 years?

“Mistakes or oversights are easily made, even by large organisations. Many of the businesses subject to investigations have been grateful to VLS for highlighting errors that they have been able to address before significant issues arose. Our role is to encourage compliance

amongst members and the wider sector rather than penalise non-compliance. The lack of understanding in some companies has been of concern; however, the appetite of members and the board to work together for the greater good of everyone in the industry has been very welcome.”

What challenges have VLS had to overcome to appease any doubters?

“In the beginning, there were many challenges. There was no blueprint from across the world that we could replicate in the UK. VLS was a first for the sector. To

22 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 PEOPLE & INDUSTRY Q&A

“Mistakes or oversights are easily made, even by large organisations. Many of the businesses subject to investigations have been grateful to VLS for highlighting errors that they have been able to address before significant issues arose.”

VLS: Motor factors can play their part in upholding the highest standards in Europe for lubricant manufacture

A Q A Q A Q

succeed, the organisation had to have teeth and be able to enforce change – but on what legal basis? We had to ensure the investigation process was anonymous and rigorous enough to be respected. We had to persuade member companies to donate their experts' time, so that we could access the skills we needed to confidentially and anonymously analyse product test reports and make valid, reliable case determinations. Companies were understandably concerned about the robustness of the process in which we would ask them to become involved.

“After months of discussion and advice, with the correct process and professional indemnity insurance in place, VLS was ready to accept its first case. Since then, publishing the outcome of the cases on the website –including where member companies have been investigated – has helped to improve the industry's understanding of how compliance could be achieved and allowed VLS to operate with total transparency.”

Has VLS adapted its approach?

“The VLS process remains broadly the same as it was 10 years ago, but we have adapted to changes in the market. After an influx of cases regarding misleading marketing claims, VLS produced guidance on marketing claims in 2019 to bring greater clarity to members on

what VLS considered to be valid performance claims.

“VLS also published guidance on presubmission test protocols where it would accept the test results of parties making product complaints ahead of the case being accepted under a strict set of guidelines.

“In 2022, VLS began a proactive approach to product testing. The number of cases reported to VLS dropped postCOVID 19, so the board decided to supplement the cases it received with test reports published by an independent laboratory based in North America, which undertook routine product compliance testing on a regular basis on products available in a variety of markets, including the UK. Several cases were opened and investigated as a result.

“Also, in 2022, VLS amended its verification process so that if, during an investigation, VLS finds issues of noncompliance which fall outside the original case complaint, then these will be brought to the attention of the named party, who will be asked to address these areas. At the six-month review stage, if these ‘advisories’ have not been addressed, then the fact that there were advisories which were brought to the attention of the named party had not been addressed, these will be published along with the case outcome. This enables us to ensure that all areas of concern are addressed, not just those raised in the initial complaint.

“VLS has also developed a Primary Authority relationship with Buckinghamshire and Surrey Trading Standards. Working in partnership, Buckinghamshire and Surrey Trading Standards now assist VLS in ensuring that VLS can work collectively with statutory authorities on improving compliance amongst members and the wider sector. It also provides VLS with an escalation route to local Trading Standards Authorities. It has also reviewed all of VLS' advice and guidance issued so that it is endorsed, supported and approved by Trading Standards.”

Motor factors reading this and discovering VLS for the first time –what is your message to them?

“VLS is here to help. The engine oil market is an incredibly complex market, which is constantly changing. Motor factors have a vested interest in the quality and standards of the products they sell to their customers. We are here to support motor factors in helping them understand the lubricants market and the types of questions they must ask suppliers to ensure they are protecting their endusers. We welcome motor factors becoming members of VLS, so they can gain insight into the common issues affecting the industry and play their part in upholding the highest standards in Europe for lubricant manufacture, blending and marketing, so protecting the interests of their customers and end-users.”

What do factors need to be wary of when it comes to incorrect claims/labels?

“If a product sounds too good to be true, check it out. Understandably, with margins under pressure and space at a premium, lubricant marketers are keen to service the maximum number of applications with the minimum number of products. But they must be able to prove their marketing claims, so that motor factors can have continued confidence in the products they are selling. VLS has clear guidance on our website about the different marketing claims being used, such as ‘suitable for’ or ‘approved’, and the evidence manufacturers must be able to provide to support those claims.

“VLS plays a vital role in ensuring that lubricants are labelled accurately and meet the specifications they claim, and are genuinely suitable for today's increasingly sophisticated engines, where engine oil choice really does matter. If required, this includes working with Trading Standards to ensure that robust action is taken, and incorrectly labelled products are brought into line.”

For more information about VLS, www.rdr.link/FFX005

PEOPLE & INDUSTRY Q&A

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 23 A Q A Q A Q

“Motor factors have a vested interest in the quality and standards of the products they sell to their customers. We are here to support motor factors in helping them understand the lubricants market and the types of questions they must ask suppliers to ensure they are protecting their end-users.”

WIX Filters continues to review market so factors receive ‘very best level of service’

We caught up with Gary Winslow, product and marketing manager, to ascertain what developments are taking place at WIX Filters, trends its observing and how it is supporting you.

Please tell our readers what’s new in the world of WIX Filters!

“Due to an ever-changing aftermarket, WIX Filters is focused on the evolution of the filtration sector, always looking to provide range optimisation and world-class aftermarket service and product to our customer base.”

What impactful trends are WIX seeing in the aftermarket and how is it adapting?

“As the point above, the product mix is evolving from just air, oil and fuel filters. Cabin filtration continues to grow and be a hot topic, with protection of the vehicle inhabitants now a key area of development, with more and more VMs now looking at vehicle systems that monitor the internal air quality and cabin environment – making the cabin filter pivotal to the A/C system. With lifestyle

choices and more focus on health and wellbeing, this trend looks set to continue.”

What do factors expect from WIX Filters?

“Factors require a consistent, quality product for their aftermarket range, with no doubts as to what product is in the box. WIX Filters offer this consistent quality with our own production facilities and quality systems.”

How does WIX support its factor customers?

A Q A Q A Q A Q A Q A Q

“WIX offers an extensive range, trusted manufacturing processes and confidence in providing a quality aftermarket product that meets existing BER legislation. Motor factors are also supported by our market-leading national sales team, providing the highest level of customer service.”

Anything new in the pipeline?

“WIX continues to deliver a quality brand and product to a continuously evolving and fastpaced aftermarket – all at a value for money price-point.”

Does motorsport continue to play an important part in WIX’s strategy?

“As part of the MANN+HUMMEL range of brands, WIX Filters in the UK is committed to the support of our customers with the points discussed above: quality, service and value for money.

“Due to the cost-of-living crisis and everincreasing pressure on price points across all markets, MANN+HUMMEL (UK) made the decision to invest finance once allocated for motorsport into our product lines and customer support for the time being. WIX Filters has delivered multiple price reductions on parts over the past few months and continue to review the market to assist our customers and motor factors with the very best level of service.”

For more information about WIX Filters, www.rdr.link/FFX006

PEOPLE & INDUSTRY Q&A

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 25

“Due to the cost-of-living crisis and ever-increasing pressure on price points across all markets, MANN+HUMMEL (UK) made the decision to invest finance once allocated for motorsport into our product lines and customer support for the time being. WIX Filters has delivered multiple price reductions on parts over the past few months and continue to review the market to assist our customers and motor factors with the very best level of service.”

Morelli Technical Training and Assessor, Ian

Gilbert, joined us for a chat about how Morelli’s relationship with Esprit Windscreen Repair Equipment, as a distributor of its products, has benefited both businesses.

Esprit Windscreen Repair Equipment and Morelli partnership blossoming

Morelli is a nationwide distributor of products for the automotive business, and windscreen repair is one of the services that it sells to its thousands of customers nationwide. Morelli, like Esprit, is a family business –albeit Morelli has a few years on Esprit, as it was established in 1957 to Esprit’s 1981. Ian works at Morelli’s training centre in Coventry and trains across the board in its huge variety of products.

Ian (right) explained that he had first used Esprit when he came to work for Morelli 13 years ago: “Esprit products are really easy to use, and I find training customers in using Esprit to be very straightforward. They always get the hang of it pretty quickly”.

Ian agreed that Esprit is a great company to deal with: “All the staff are very friendly and pleasant.”

Ian also opened up about how being a distributor of windscreen repair worked for the Morelli business, setting out how customers would buy through Morelli and then they would assist with training and follow on sales.

For distributors, he advised building of relationships was key and that the close relationships between distributor and customer meant that Morelli built and maintained these relationships that would then last for years.

Having a close relationship with suppliers, including Esprit, was also vital to ensure that customer demand could be

met, new products could be discussed, and customers were kept up-to-date with the products that they could provide. Ian explained that many of Morelli’s customers for Esprit products were repeat business, showing the strength of the Esprit brand, product and also the service that they received from Morelli.

Ian went on to talk about the Morelli training centre, which has recently expanded in its Coventry base to take over the whole building: “We carry out all sorts of training here, as well as having exhibitions of the products that we sell, and this expansion gives great opportunities to the companies that we distribute for to exhibit and show their products to potential and existing customers.”

Morelli ‘extremely valued’ Esprit Director, Victoria Evans, said: “Morelli are an extremely valued and long-term customer of Esprit, and we hugely value the experience that Morelli, and all our distributors bring to our business”.

Victoria went on to explain that the distributor model was vital to the Esprit business model: “Distributors know our product so well; they can pass on that expertise to their customers and build on those relationships. We have distributors

worldwide, and in turn, we’re distributors for products, such as BTB windscreen removal products from Australia.

“Esprit have also just acquired Rejel, a distributor of automotive products including windscreen removal tools, Dinitrol, clips, trims and various other products.”

Victoria concluded by revealing that the expansion of the training centre in Coventry was fantastic news for suppliers of Morelli: “The more opportunity Morelli have to train and showcase products, the better. We’ll be working with Morelli to show our products and provide marketing and literature to their customers who attend their facility.”

For more information about Esprit, www.rdr.link/FFX007

26 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 BUSINESS & TRAINING CASE STUDY

‘Highly competitive’ Hella Gutmann finance initiative extended

Over several decades, Hella Gutmann has consistently developed tools that have allowed independent workshops to tackle the various service and repair requirements that have become necessary with modern vehicle design.

From a diagnostic perspective, Hella Gutmann believes the mega macs range has been at the forefront of the technology and with products such as the mega macs X and the macsRemote, that trend continues. During this process, it also provides valuable workshop solutions, not just in the here and now, but for the future, thus ensuring that they can compete effectively over the long-term.

However, Hella Gutmann’s experience of Automechanika Birmingham illustrated that its vision extends beyond the equipment – but also the means to access it cost-effectively, which is why the company has unveiled a “highlycompetitive” finance option.

Initially introduced as a show offer to allow both workshops and technicians at the event to quickly turn interest into ownership, the response was so positive that the initiative has been extended to become another Hella Gutmann option,

offered alongside its unique modular licenced data package formula.

As a result, as well as selecting the level of capability that the tool is required to provide, in terms of the work that it typically undertakes, the workshop can now also purchase the equipment at a competitive rate, over a longer

“The initial scheme is a three-year option offering that can be applied to our X3 and X5 licences. Starting at £49 per week, workshops will receive a mega macs X with an X3 software package, as well as an Android tablet. Increase to £59 per week and the mega macs X will come with X5 enhanced data, a Flex 10b rugged tablet plus a macsRemote. However, the ultimate option, at only £75 per week, also includes a MT-HV Pro high and low voltage measure module, which allows workshops to safely discharge high voltage systems and work on hybrid and EVs! And each offer also includes the licence renewal for the full three-year period.

turn, Hella Gutmann is confident this strategic decision, allowing technicians to get their hands on their chosen diagnostic tools, will boost workshops’ efficiency and profitability.

Hella Gutmann UK Sales Manager, Julian Goulding, said: “We have long been able to provide workshops with worldclass diagnostic solutions, but with this move, we can now make ownership even more achievable.

“It is vital for the aftermarket – motor factors and ourselves included – that independent garages invest in diagnostics and training now. This will give them the ability to take on jobs involving the latest technologies, such as ADAS and EV. These technologies are no longer restricted to new vehicles and the service opportunity on them exists today. We are committed to working with the factors to upskill the independent garages and this offer is just one aspect of our support.”

For more information about Hella Gutmann, www.rdr.link/FFX008

BUSINESS & TRAINING FINANCE

HELLA has extended its mega macs X finance offer to workshops – available through distributors and the manufacturer itself – with monthly payment plans available. The company has lauded the decision as an “affordable way” for workshops to futureproof their business.

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 27

New AS-PL warehouse triggers ‘significant sales increase’

Customers expect a quality product, professional service, and rapid delivery –

AS-PL strives to meet all of these expectations. Four months after its new warehouse in Liverpool opened, we learn of its impact:

AS-PL offers a full range of alternators, starter motors, and components, with over 24,000 products corresponding to nearly 610,000 reference numbers. This offer includes a mix of new and ‘surcharge free’ remanufactured units, parts, and components for passenger cars, lorries, agricultural machines, boats, motorcycles, and the industrial market.

Irrespective of the product category or application, AS-PL reports that each product undergoes strict testing procedures, meets the highest standards, and is tested using specialist test equipment. In addition, every product is covered by a two-year warranty, and all units come complete with a test certificate.

Impact in the UK

Since it began trading in the UK and Ireland in 2017, AS-PL has gradually made its presence felt with a “high demand” for its diverse range – justifying its decision to establish itself in a new market away from its homeland in Poland.

Such has been the success of AS-PL in the UK, it recently opened a 1,000sqm warehouse in Liverpool, which it believes will be able to supply demand now and in

the future. Relocating from London, with 1,500 pallet spaces, a three-level mezzanine with a total area of 500sqm and offering a next-day delivery throughout the UK, this move suggests a significant moment in the company’s history.

Sales boost after warehouse opening

Early indications have shown the move is paying off; the first three months generated “significant sales increases” and the number of UK customers purchasing AS-PL

This is a point emphasised by AS-PL UK

Regional Sales Director, Kevin Sharp: “I'm really proud of how our company has grown over the years. The UK warehouse opening is an amazing opportunity for us to further establish ourselves on the UK market as a professional distributor of high-quality alternators and starters.”

AS-PL Sp. z o. o. Regional Sales Director, Kamil Olejniczak, added: “The competitiveness of our offer has enhanced as well as the recognition of the AS brand in this part of Europe and allowed us to exploit our potential even better, using our more than 30-year experience, knowledge, and high quality that we have developed and want to continue for the next decade.”

components has “doubled” in the three months after the new warehouse’s unveiling.

Furthermore, the number of alternators, starters, and ancillary parts stocked in Liverpool has already been increased to keep pace with demand. All AS-PL products are listed on MAM Software Autocat v8 and TecDoc.

For more information about AS-PL, www.rdr.link/FFX009

BUSINESS & TRAINING SALES BOOST

PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 I 29

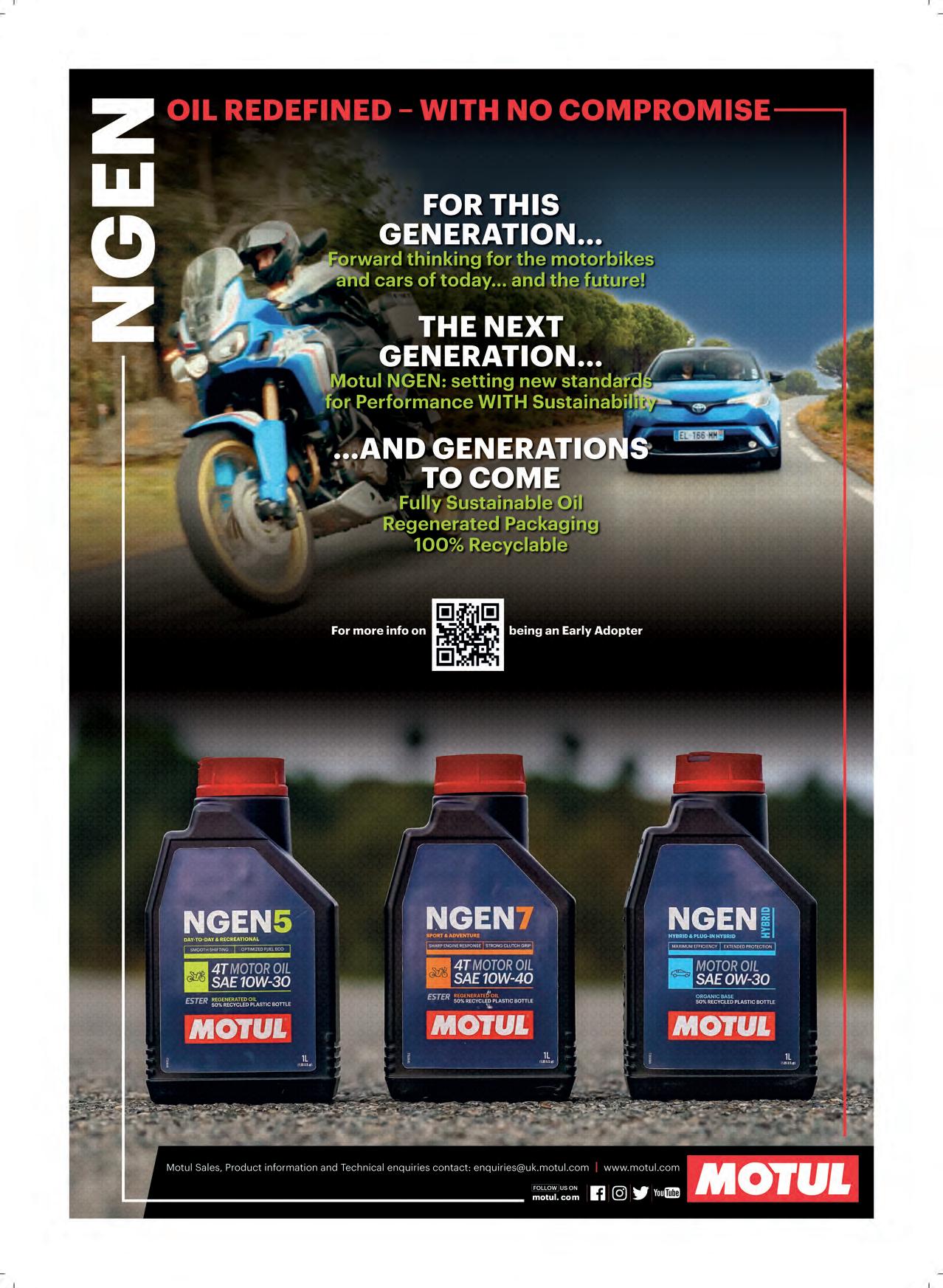

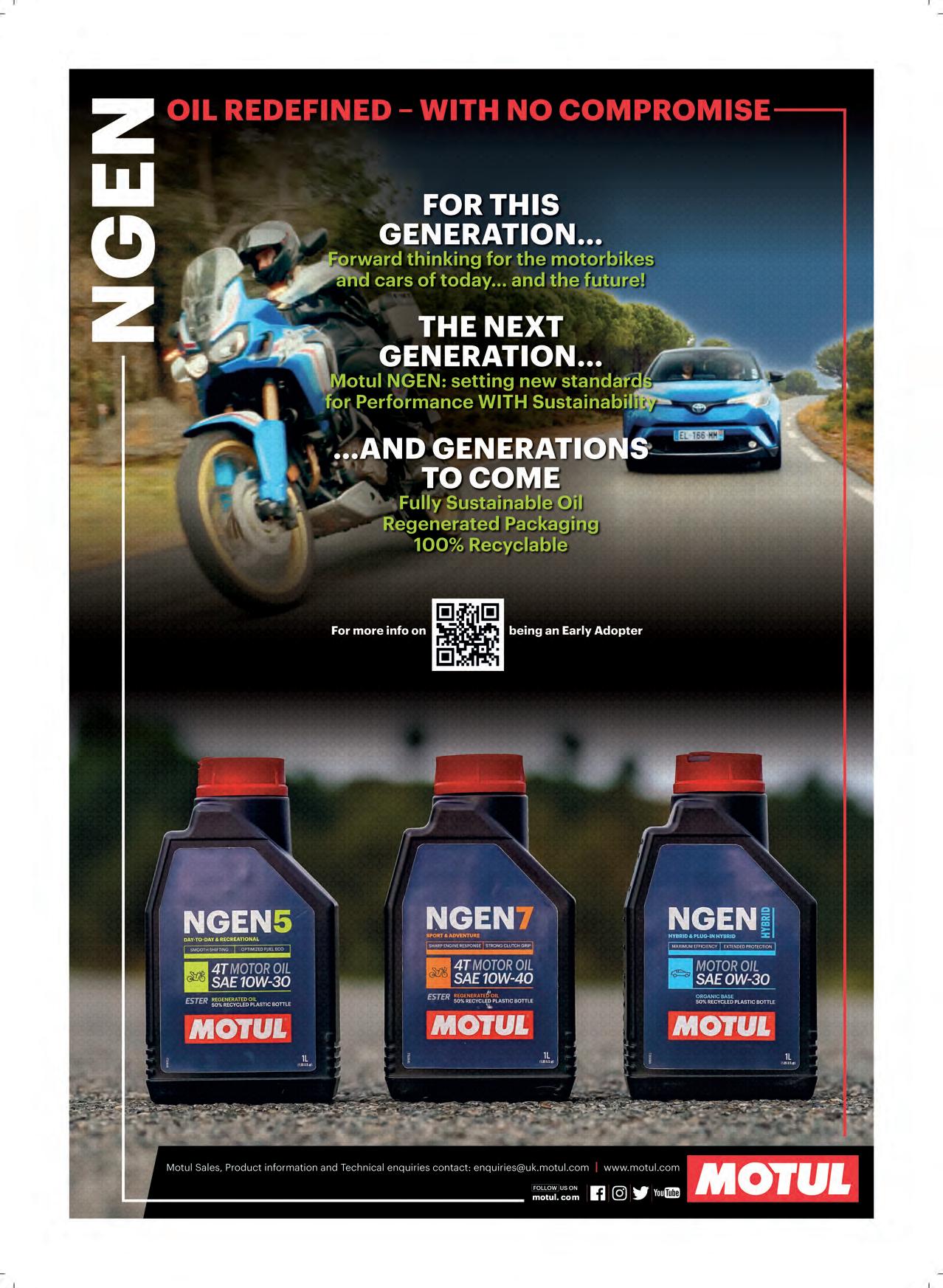

Motul NGEN a game-changer?

Motul UK Sales and Marketing Manager, Andy Wait, explains how the company has embraced motoring, manufacturing and social trends to develop, what it believes, to be a lubricant for future generations:

Motul has an enviable record when it comes to innovation in lubricants. This is, after all, the brand that introduced to the automotive world, arguably, the three biggest advances in lubricants in the second half of the 20th Century.

Today, most people run their cars on lubricants that have completely dispensed with mineral oil, because our motors and gearboxes now use fully synthetic lubricants. Perhaps surprisingly, fullysynthetic motor oils have actually been around for more than half a century, because Motul 300V ushered in the age of the fully synthetic engine lubricant as far back as 1971, using Ester technology derived from the aircraft industry.

This year marks the 70th anniversary of Motul, where it introduced the first multigrade oil for the motor industry –Motul Century – something that truly ushered in the modern era in vehicle lubricants. Before then, lubricants had to be changed in the summer and winter –depending on location – but this new wonder product could be used all-year round, in a broad range of temperatures, thereby reducing lubricant consumption and maintenance.

In between these two events came the next major step in lubricant evolution: the introduction of semi-synthetic motor oil which, for the first time blended-in synthetic lubricants with mineral oil. This revolutionary type of motor oil was launched into the automotive market in 1966, offering all of the advantages of castor oil but without the disadvantages of oxidation, varnish deposit and, not unimportantly, cost. The result was a product that withstood constraints and mechanical loads 10 times higher than the previous-generation mineral oil lubricants.

Unveiling NGEN…

So, when Motul announces NGEN, which is hailed as the “next generation of engine oils” it would hope that the industry thinks it is probably worth looking at in more detail.

Motul looked at the market holistically and at the issues and trends in the industry. It observed that OEMs across the board have prioritised preservation of the environment and Community Social Responsibility, and they are heavily communicating their

desire and determination to improve their environmental impact.

In line with this and, given the large numbers of ICE cars that will be on our roads for many years to come, Motul decided to pioneer a sustainable oil in every key aspect, but, vitally, one that does not sacrifice performance in any respect to achieve this sustainability.

Motul NGEN offers the opportunity for the individual to make a difference when it comes to lubricating their vehicle.

At the heart of NGEN is regenerated oil. This is waste oil that has been recycled, but not through the conventional methods. Motul subjects the waste oil to a highly selective treatment process to achieve the level of performance it expects from its

30 I PROFESSIONAL MOTOR FACTOR SEPTEMBER 2023 MARKET TRENDS & ANALYSIS NEXT GENERATION

products. Let’s be clear, while Motul is reusing waste oil, this is by no means what most people have in mind when the term ‘recycled oil’ is considered, and this differentiation is vital.

With regeneration the waste oil is subjected to more than 10 different processes – several different stages of distillation and various filtration processes – in order to produce a new base oil of outstanding quality.

In launching NGEN products, Motul is using various levels of regenerated oil. NGEN 7, which basically mirrors Motul’s 7100 range, for instance, contains 50% regenerated product in its formulation, while NGEN 5, which equates to Motul’s 5100 series, consists of 75% regenerated product.

Extended to hybrids

Motul is also extending the NGEN concept to produce a Hybrid lubricant with 25% biosourced oil from renewable resources.

By regenerating base oil with the treatment it uses, Motul’s experience at the forefront of Ester technology has also meant that it is actually able, during the regeneration process, to engineer improvements into the lubricant and actually improve on the original oil’s properties, bringing gains such as greater economy, easier start-up and greater durability.

NGEN oils: 100% recyclable

With NGEN reflecting not simply technological shifts and progress, but also a lifestyle choice, Motul has naturally

made sure that it extends the regeneration concept to its packaging as well. Motul NGEN packaging also employs 50% recycled plastic, and the NGEN product containers are, themselves, completely recyclable.

This production of regenerated base oils from renewable raw materials also consumes less energy than the production of virgin base oils, resulting in a 25% improvement in CO2 balance through using the process.

NGEN may not, on the surface have produced the same technological leap forward that, for instance, mutligrade and synthetic oils brought in their day, but Motul firmly believes that this is the future for lubricants.

Unsurprisingly, therefore, NGEN 5, NGEN 7 and NGEN Hybrid will soon be joined by further NGEN products, as the range expands to cover more and more of the vehicle parc.

For more information about Motul, www.rdr.link/FFX010

MARKET TRENDS & ANALYSIS NEXT GENERATION

FACTOR SALES INVESTIGATES…

Analyst Ben Thomson reveals what are the fastest growing and declining products in the aftermarket.

Government regulation, seasonality and even international conflict are all affecting revenues, volumes, and prices. To maximise revenues, you should monitor sales trends to identify areas of product growth or decline. Focus on stocking the correct product groups, with the right suppliers and support customers through the constant change in the aftermarket.

The bestselling 5% of products account for 90% of a typical factor’s sales revenue. We have ranked the fastest growing and declining product groups by year-on-year sales revenue, from reporting factors. We have analysed the percentage change in sales revenue and percentage change in quantity/units sold – and there are clear winners and losers.

Our top takeaways:

Battery revenue growth. Enhanced Flooded Batteries (EFBs) experienced a 52% revenue growth in the last 12 months, while Absorbent Glass Mat Batteries had 44% revenue growth, two of the highest growth rates in the market (Fig 1)! Both were driven mainly by huge volume growth, with prices increasing marginally in comparison. Reasons behind increasing demand are not fully understood, though, some argue that extreme temperatures in summer 2022 caused batteries to deteriorate faster. Regardless, the demand means there is an opportunity for you to increase prices to capture even more value from the unseasonal demand.

Higher energy input costs continue to impact the aftermarket.

What do brake cleaner, AdBlue and synthetic engine oils have in common?