PMM

PUT A SPRING IN YOUR STEP: ALL THINGS A /C COVERED INSIDE

INSIDE AN NHS WORKSHOP

YOUR LETTERS ANSWERED

RECRUITING THE NEXT GENERATION

OILS UPDATE

Let’s get technical

INSTALLATION TIPS ON CLUTCHES, SUSPENSION, BELTS & THE TESLA CONTROL ARM

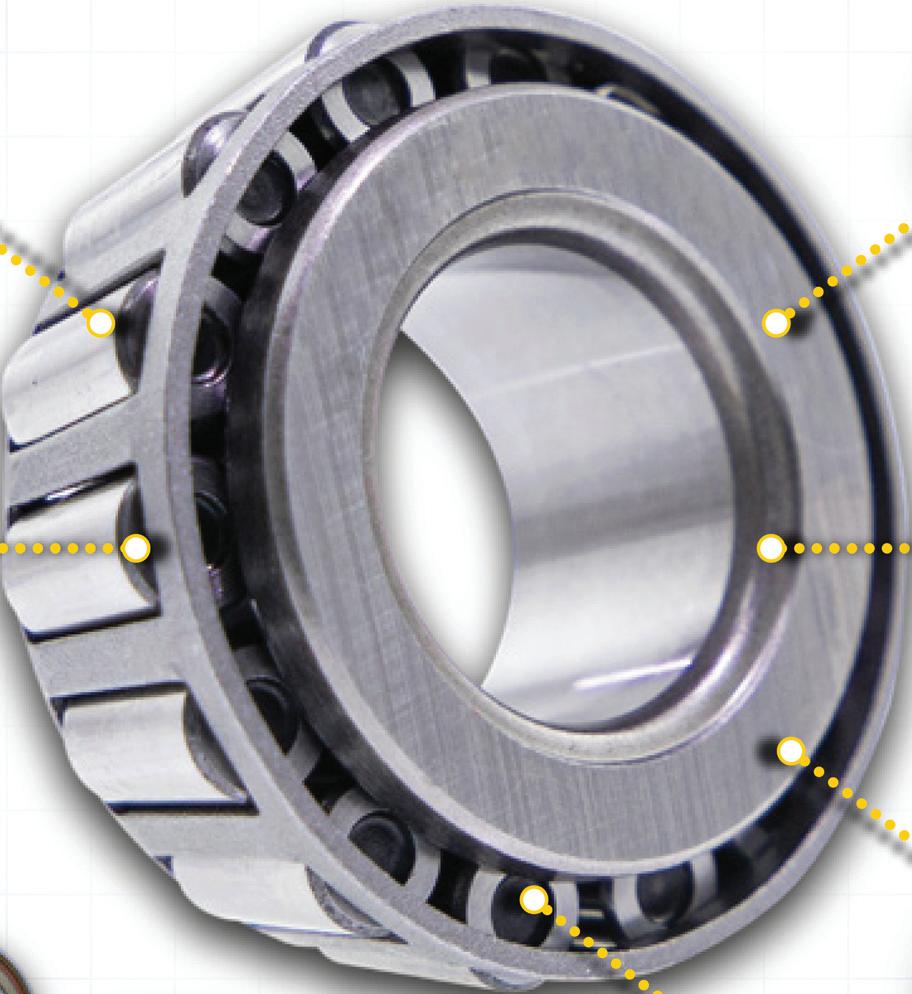

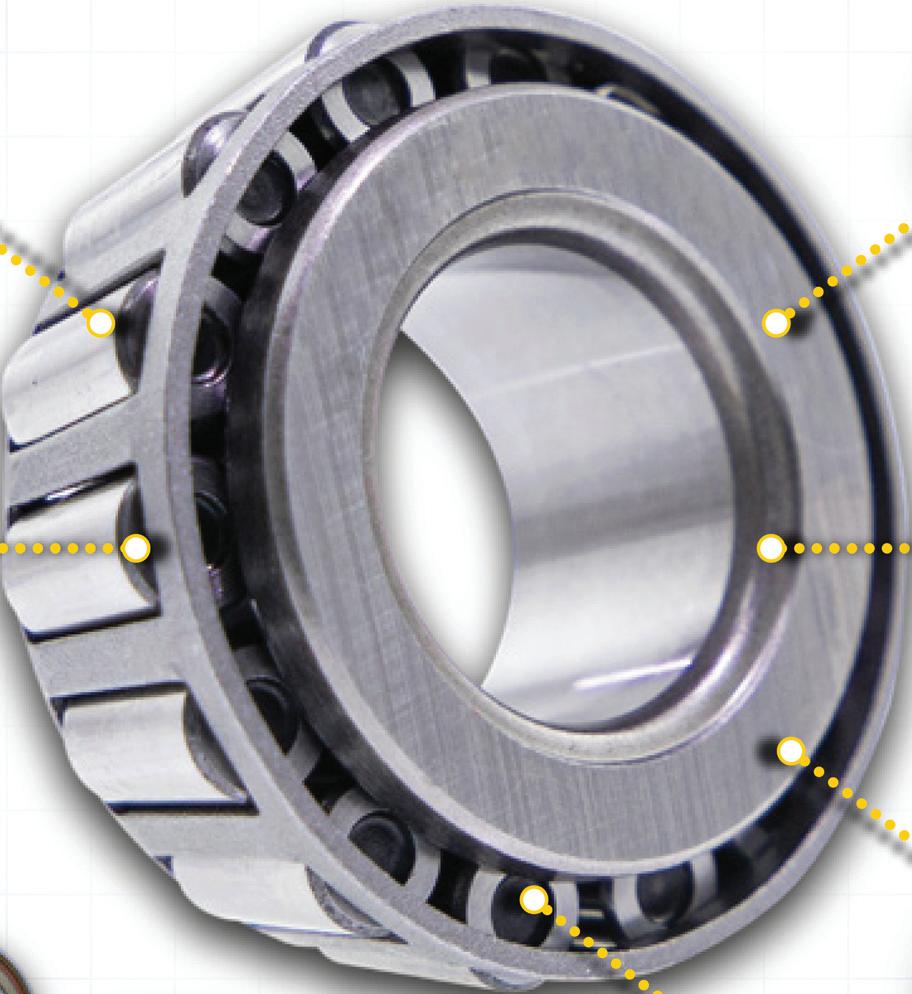

COMMON FAULTS WITH WATER PUMPS & WHEEL BEARINGS

TRAINING FROM DELPHI, LUCAS OIL,VARTA & SCHAEFFLER

SERVICING AND MAINTENANCE TIPS ON THERMALMANAGEMENT, BATTERIES & WHEEL ALIGNMENT

EV FLUIDS & FILTERS

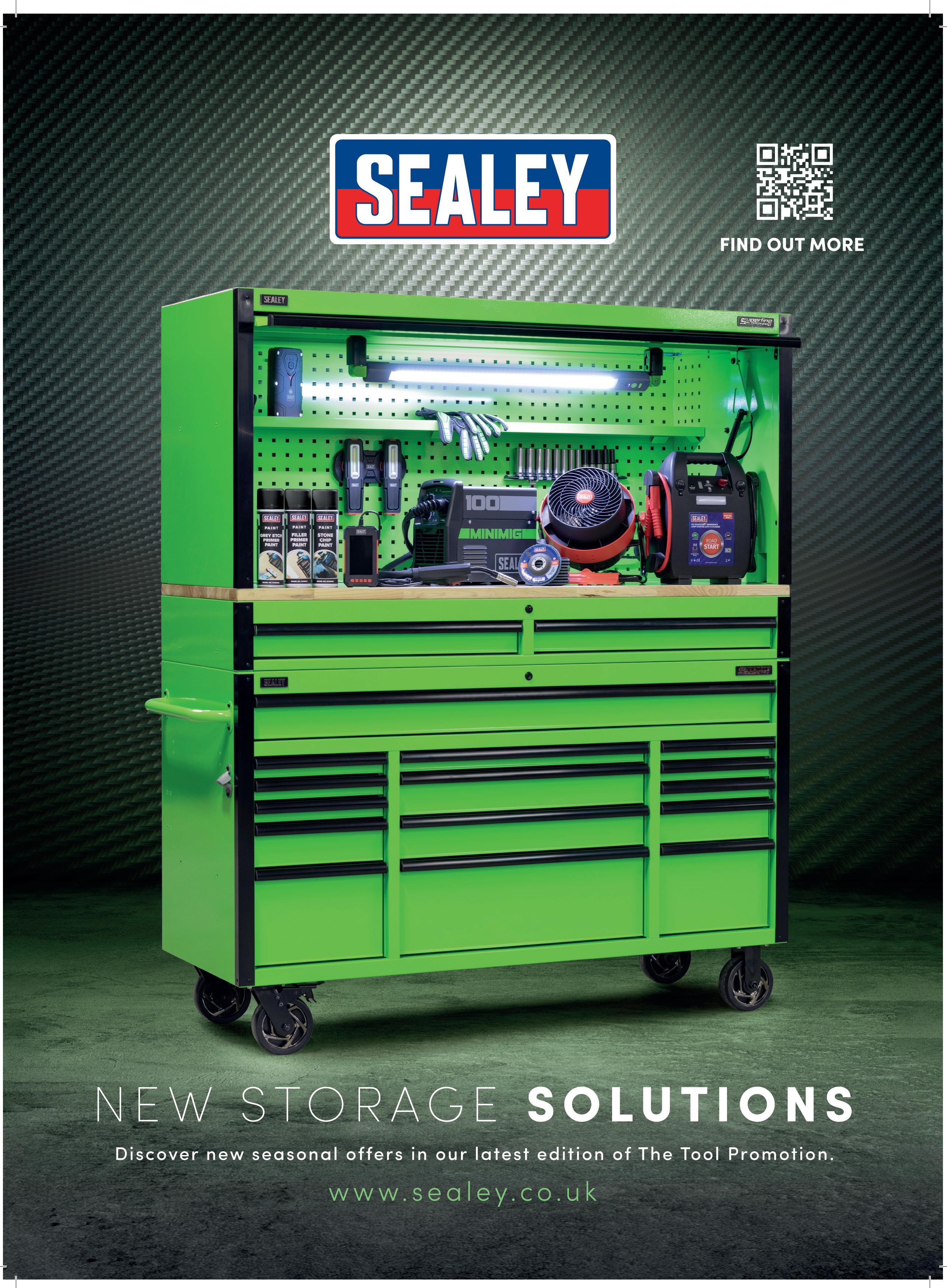

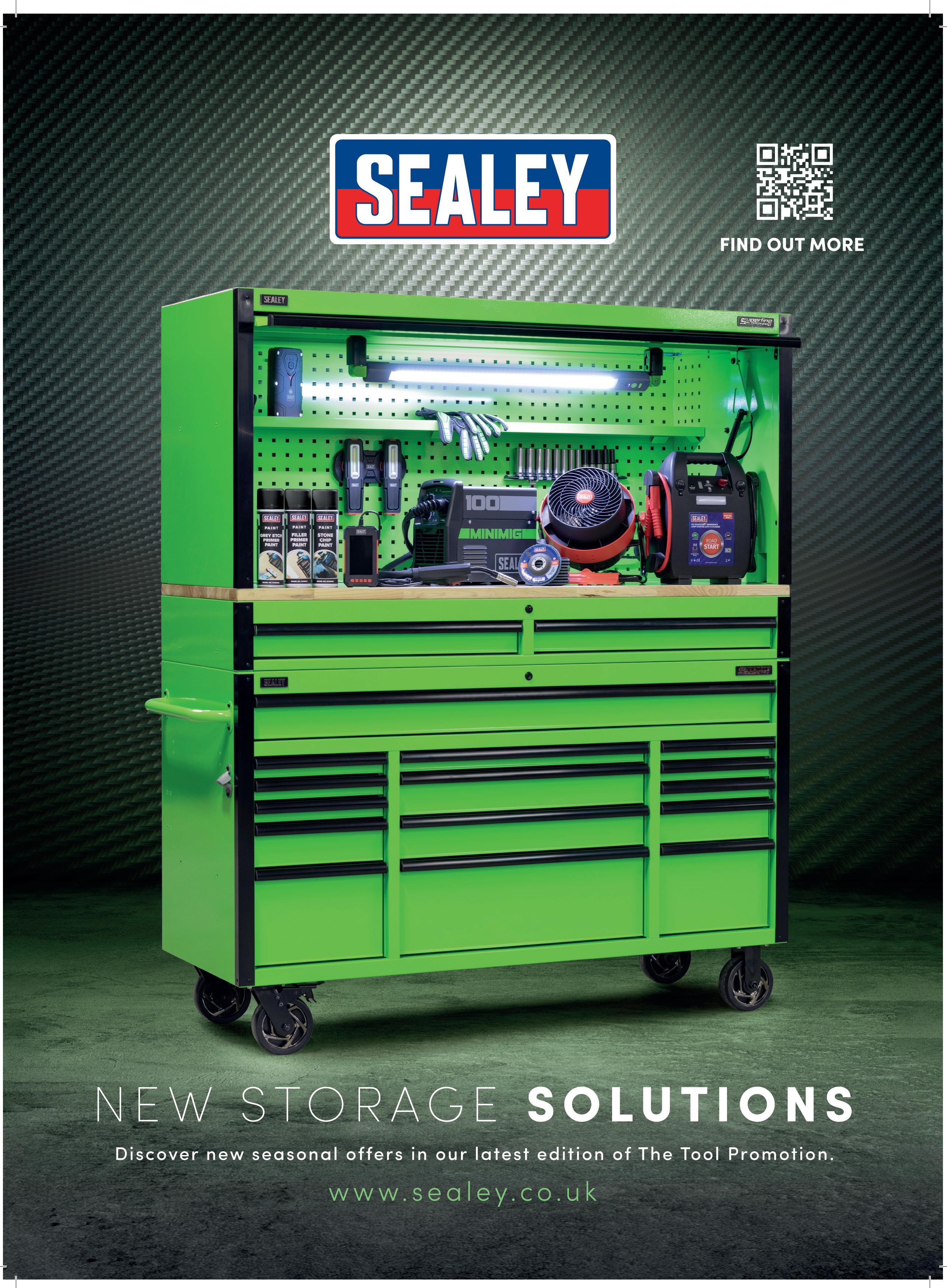

NEW PRODUCTS FROM SEALEY, BARTEC,LASER TOOLS & AUTOGEM

FREE TOTHE TRADE

APRIL 2023

PROFESSIONAL M OTOR M

ECHANIC

Editor’s Picks

12 A MESSAGE TO ELON

Head over to page 12 for a step-by-step guide on how to install Meyle’s replacement control arm intended for Tesla models 3 and Y, brought to you by the aftermarket parts supplier itself.

28 RECRUITMENT ISSUES

In your workshop and in the industry, you might have noticed a problem with recruitment. Simon King from Autotech Recruit discusses issues with retention and job security.

30 EMERGENCY SERVICING

Ever wondered what an NHS workshop is like?

PMM’s Kieran Nee visits one to find out the similarities and differences between the issues they face compared to an independent garage.

48 ‘OIL’ ABOUT EVS

52-55

THE MODERN WORKSHOP

Contents VOLUME 24 ISSUE 4 APRIL 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM APRIL 2023 3 34-41 A/C & THERMAL MANAGEMENT 42-46 TYRES, WHEELS & ALIGNMENT Regulars 7-10 AFTERMARKET NEWS 12-21 TECH TIPS 22-28 BUSINESS & TRAINING 30-33 SPECIAL REPORTS 57 PIT STOP 58 OUT & ABOUT 61 ONLINE REPORT 62 PRODUCT SPOTLIGHT 63 MYTHBUSTERS 64-65 WHAT’S NEW?

With EVs becoming ever popular, their fluid counterparts will soon become mainstream, and Castrol is expanding its range to cover them. Read inside to find out more. HYBRID&ELECTRIC VEHICLES

48-50

Editor KIERAN NEE

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

1 year (11 issues) £50

Airmail 1 year (11 issues) £65

Printed by Walstead Peterborough

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts, WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk

Website: www.pmmonline.co.uk

Facebook: /ProfessionalMotorMechanic

Twitter: @pmmmagazine

Copyright © 2023

Will anything happen?

Aweek is a long time in politics, they say, and there are a lot of weeks between now and 2030. But if seven years are an eternity in political matters, they can pass in the blink of an eye when it comes to changing both the infrastructure and habits of a country whose mindset is increasingly wedded to a rosier past. Yet, it is this circle which needs to be squared in order for there to be any hope of transitioning away from the internal combustion engine in the allotted timeframe (no new ICE-only vehicles sold by 2030, no hybrids by 2035).

Outside of the trade press, not much thought seems to be given to the logistics and practicality of moving wholesale to electric powertrains. EVs are portrayed mostly as the logical next vehicle for the aspirational middle-class whose environmental consciousness is simply a given. EVs, now that they offer every comfort available, are the perfect display token ensuring everyone else knows that driver has “done their bit” (see also: reusable coffee cups, ‘upcycling’). After all, what is the point of saving the planet if no-one even knows about it? Given this semi-unasked for social status, is it any wonder that half of the media praises EVs to the high heavens, whilst the other half demonise them and their owners as all that is wrong with the modern world (the American ‘woke’ usually worms its way in around here, giving the lie to the journalist’s supposed man-on-the-street cred)?

Refreshingly, asking those in the aftermarket usually turns up a more practical, if fairly uniform, view: Can’t happen, won’t happen – battery-powered vehicles don’t make sense and never will for most people. I will lay my cards on the table here: I am not a petrol fanatic and I do think we all need to make practical life changes to protect the planet, but I am not fully convinced that electric vehicles are the solution and I do struggle to see how the nation’s entire car driving population will switch to EVs. I hope I’m wrong and that in 20 years’ time or so we will all be driving them and, more importantly, charging them without too much extra hassle (well, I actually hope that public transport improves and costs come down so that we don’t need to drive as much, but maybe that’s a little too ‘pie in the sky’).

I won’t go into the reasons for and against EVs here, it’s not my place. Far more knowledgeable people than I discuss this topic daily. The only thing I would like to remind anyone reading this, from either side of the debate, is that EVs are only meant to be a means to an end, with the end being a more environmentally-friendly transport solution. If you are radically opposed to EVs, ask yourself is it the concept of an electrically-driven vehicle which is annoying you or the connotations those vehicles have? If you are fanatically supportive of EVs, be honest: they won’t save you money or save the planet, but they will reduce local emissions. Until each side is honest with themselves, I fail to see anything more than a deadlock come 2030.

Kieran Nee Editor

VIEWPOINT

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE PMM PODCAST

NEWSIN BRIEF

■ GARAGES ARE MISSING OUT ON APRRENTICES

The IMI warns that automotive businesses are missing out on valuable apprentices that could help bridge the skills gap, despite funding being available through the government’s levy scheme.

■ AUTOMOTIVE SUPPLIER REBRAND

BorgWarner’s aftermarket and fuel systems divisions are to be renamed ‘Phinia’. This news comes as Brady Ericson has been anounced as president and Chris Gropp as vice president to run the spin-off which is expected to be completed in late 2023. The name is said to loosely translate to ‘beauty’ in Gaelic.

■ MOTORSPORT PARTNERSHIP ANOUNCEMENT

MB Motorsport and British touring car championship (BTCC) frontrunner Jake Hill have announced a new title partnership with Laser Tools, that will see Laser Tools Racing with MB Motorsport take to the BTCC grid in 2023.

■ DOUBLE CLUTCH SYSTEM TRAINING COURSES

Schaeffler has announced a series of IMI-approved double clutch system training courses, kicking off in Southam on the 26th and 27th of April.

with Freya Coleman

Call for clarification to draft MVBEO

The Independent Garage Association (IGA) is calling for clarification to the new UK motor vehicle block exemption order (MVBEO), to ensure that consumers are given clear information on their freedom to choose who repairs their vehicles and are not financially disadvantaged by the new regulation.

Stuart James, IGA chief executive, is concerned for “the lack of requirement for in-vehicle messaging to inform customers that they have an alternative solution for servicing via an independent operator. We would also like to see a requirement for authorised repairers to make it clear to consumers that they can chose who services, maintains and repairs their vehicle without invalidating its warranty”

He continues “In addition, the MVBEO makes no reference to a mechanism for

independent operators to access security related information for repairs. Whilst we understand access to such sensitive information needs an element of control, it is vital that there is a recognised system in place for vetted businesses or individuals to provide these services to consumers to ensure fair competition and timley access to vehicle repairs.”

Dangers of working under vehicles

Figures recorded by HSE in the five years up to March 2022 show that 13 workers in the motor vehicle repair industry were killed when work took place under a vehicle that wasn’t properly supported.

Since then, another four have been recorded including Leslie House (pictured) who was working outside his home when he was crushed to death by the Land Rover Freelander he was underneath, which had rolled off the wooden blocks he used to prop it up. He was pronounced dead at the scene by the emergency services.

Official and anecdotal reports of a wide range of working practices gone wrong are leading to fears mechanics and enthusiasts are putting their lives in danger routinely.

HSE’s advice to the trade:

■ Never work beneath a vehicle that is only supported on jacks.

■ Never work beneath a cab or tipping trailer unless it is propped.

■ Never crawl beneath a vehicle fitted with air suspension unless it is properly supported.

PMM APRIL 2023 7

PMM NEWS

PMM NEWS with Freya

NEWSIN NUMBERS

8.5 %

the amount the UK’s used car market declined in 2022 according to figures from the SMMT.

27.1 %

the chance you have of failing your MOT in Kirkcaldy. A-Plan Insurance analysis has revealed this town, situated on the East coast of Scotland, is the area of the UK most likely to fail an MOT.

17

vehicle warranty providers now adhere to The Motor Ombudsman’s longestablished code, designed to keep industry standards in the provision and administration of extended vehicle warranties.

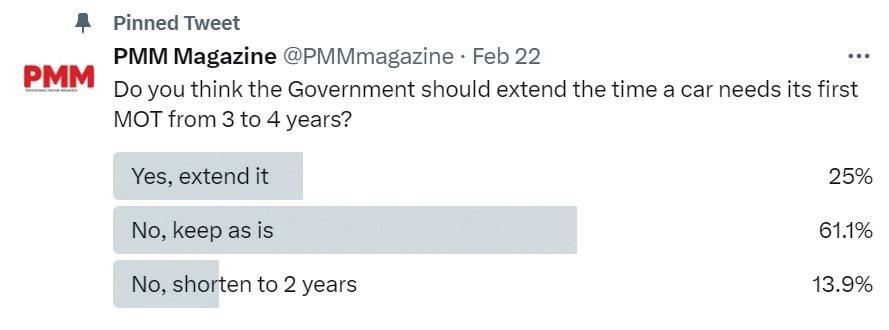

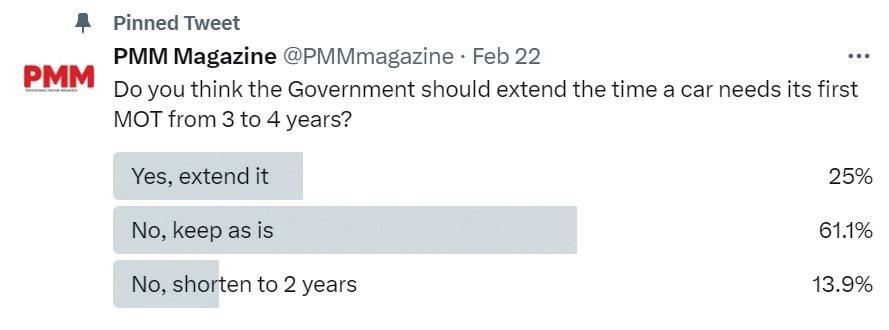

MOT changes

From the 1st of April, the DVSA will change requirements for the calibration of some testing equipment.

This includes decelerometer calibration and the calibration of roller brake testers, plate brake testers and headlamp aim testers.

From April, all decelerometers must be calibrated at intervals not exceeding one year, a change from the previous two year cycle.

Also, calibration of brake testers and headlamp testers will no longer be acceptable if completed by vehicle testing station staff.

Coleman

Level up

Training provider Martec Training plans to boost skillsets for employees within the automotive sector with the launch of a new IMI-accredited apprenticeship route.

This latest level three apprenticeship is targeted towards vehicle damage, mechanical, electrical and trim technicians and will enable those already working in a body shop or garage to further advance their

abilities and knowledge within automotive technology.

As one of the region’s IMI approved centres, this higher-level apprenticeship qualification will be made easily accessible to automotive apprentices throughout the North Staffs area and beyond, delivered from Martec’s Newcastle-based training centre.

8 APRIL 2023 PMM

In pictures: Winners of the CAT Awards including Delphi Technologies for the Delphi Academy for Training Scheme of the Year and Bosch for Supplier of the Year.

FOR UP-TO-DATE NEWS, SIGN UP FOR THE WEEKLY E-NEWSLETTER AT WWW.RDR.UK/AAW040

DATES FORTHE DIARY

■ The BIG Awards are back this year on Friday the 22nd of September at Leicester City Football Club. Categories include the business improvement award, the diversity equality and inclusion award and the training and development award among many others.

EV concerns

The Motor Ombudsman has revealed that issues relating to the purchase process or service received from a business sparked the majority (41 per cent) of consumer complaints about EVs in 2022. This marks an 8 per cent year-on-year increase in the volume of disputes by individuals for these concerns.

For customers who submitted a dispute about the purchase of an EV during 2022, 83 per cent were in conjunction with a new car, with 17 per cent stemming from used

Oil “undervalued”

Nigel Bottom, managing director of Witham Group, gave his verdict on the price of motor oil in the PMM podcast, telling host kieran Nee “I think lubricant has certainly been very undervalued from a raw purchasing point of view”

Bottom explained further, arguing “if you look at climbing a set of stairs, we’ve gone up 10 steps and we’re probably only back down one or maybe one and a half, so by no means are we back to where it was”

He puts the reason for the fluctuating prices down to the war in Ukraine and the

models. In fact, new vehicle delivery delays resulting from supply chain issues and semiconductor chip shortages accounted for over 10 per cent of customer service and purchase-related disputes. Other complaints raised by motorists originated from the use of high-pressure sales techniques, and missing vehicle documentation. Inaccurate information provided to consumers, a lack of communication by sellers, as well as customer orders being cancelled by retailers without notice, equally caused dissatisfaction.

■ PMM has confirmed it will be hosting a stand at this year’s Automechanika Birmingham, which will take place at the NEC in Birmingham on the 6th, 7th and 8th of June. Come and visit our stand for your chance to be featured on the PMM Podcast!

■ Speed of Sight has announced it will be hosting a track dayat Thruxton Circuit in Hampshire to enable disabled people to drive. The event will take place on Monday 4th September 2023 from 10am – 4pm.

■ OPUS IVS is hosting a new trade technical open evening across the19th and 20th of Aprilat the RMI academy in Runcorn. The evenings are free for garages to attend and will run from 6pm to 9pm, with content geared towards training and skills development.

subsequent sanctions of Russian base stock. When asked if he thinks high oil prices are with us for the foreseeable future he responded “Yes. If you gauge the price on where we were 12 months ago.”

To listen, WWW.RDR.LINK/AAW041

PMM APRIL 2023 9

LETTERS Writetotheexperts

A reader got in touch with a query and PMM product tester and diagnostics expert Tony Powell is on the case.

After scratching his head over it, PMM reader Terry Elliot recently got in contact to explain a problem he was facing with his Range Rover P38. The problem was that the remote locking from the key fob wouldn't unlock in the summertime unless he got really close to the rear windows but in the winter, it was working from about six or seven feet away.

We put Terry in contact with diagnostics expert Tony Powell who offered the following response:“From your description of the problem with your Range Rover P38 and primarily the difference between summer and winter, I would suggest if you have done all the basic checks for powers and earth using a test lamp not a meter that you may have a fault on the receiver or transmitter unit. Assuming you keep the transmitter fob in your pocket, the temperature will be mainly constant, so we can rule this out. The temperature could be causing what is termed a ‘dry joint’ to open and close, causing the reception to fail. When you put the fob next to the receiver, it bypasses the requirements for an aerial and works. You would need to find someone who could fix it”

If you have any queries you want to the PMM team to answer, get in touch pmm@hamerville.co.uk

Product finder tool launch

Castrol has launched an online product finder providing directions to workshops that have appropriate products in stock, encouraging workshops to keep themselves well stocked. The new product finder can also be used by technicians prior to carrying out regular service, maintenance and repair work so that they always use the most appropriate fluids.

MOT tester convicted of fraud

An MOT tester has been convicted for carrying out more than 800 fraudulent MOTs. He has been sentenced to eight months in prison on each of 12 counts of fraud, to run concurrently, and suspended for 12 months, 150 hours of unpaid work, 10 rehabilitation days and ordered to pay towards prosecution costs of £2250.

He was also given the maximum ban of five years from MOT testing by the DVSA and will have to re-apply if he wants to test vehicles again.

The offences were committed between the 1st of August 2021 and the 14th of January

2022, during which time he recorded 1300 MOT test, four times more than the usual number carried out in six months. Some of the vehicles being recorded were as far as 279 miles away from the test station and had a decelerometer brake test recorded Marian Kitson, the DVSA’s director of enforcement said “He was both defruading the MOT system and the public who rightly expect the MOT to help keep them and their families safe while using the roads...We will ensure that anyone who compromises safety in persuit of personal gain feels the full force of the law.”

10 APRIL 2023 PMM

MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: Engine remanufacturer Ivor Searle’s 10 apprentices, recognising the need to recruit more young people into technical and engineering roles to future-proof the automotive sector.

HOW TO

Install a control arm for Tesla Model 3 and ModelY

Aftermarket parts supplier Meyle provides a useful step-by-step guide to installing its replacement control arm intended for Tesla models 3 and Y.

After Tesla drivers all over the world reported annoying squeaking sounds in Model 3 and Model Y series vehicles, Meyle engineers analysed the problem and in January launched the Meyle HD control arm for Tesla models 3 and Y. Meyle claims its aftermarket offering is a technically superior alternative to the original part.

A reminder to all readers of PMM is that a prerequisite to all work on electric vehicles is for the relevant technician to be qualified to work on EVs and have done the appropriate training beforehand.

TECH TIPS

12 APRIL 2023 PMM

“Meyle claims its aftermarket offering is a technically superior alternative to the original part.”

It is advised to change both control arms, with a job time of one hour each side.

STEP

Remove wheel

STEP

Remove inner wheel arch

STEP

Check all the other suspension parts for damages

STEP Release ABS wire

STEP

Remove the frunk

STEP Remove top mount fixings

STEP Remove ball joint and control arm fixings

STEP Pull the control arm out of the top mount

STEP

Push the new MEYLE HD control arm in the top mount

STEP

The adjustment between the control arm and the top mount amounts to 60mm

STEP

Push the ball joint in the swivel bearing

STEP

Tighten all fixings to manufacturer recommended settings:

■ Ball joint screw – 56Nm

■ Bearing control arm – 50Nm

■ Top mount 13mm screw – 35Nm

■ Top mount 15mm screw – 62Nm

STEP

Axle alignment is recommended.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAW001

HOW TO

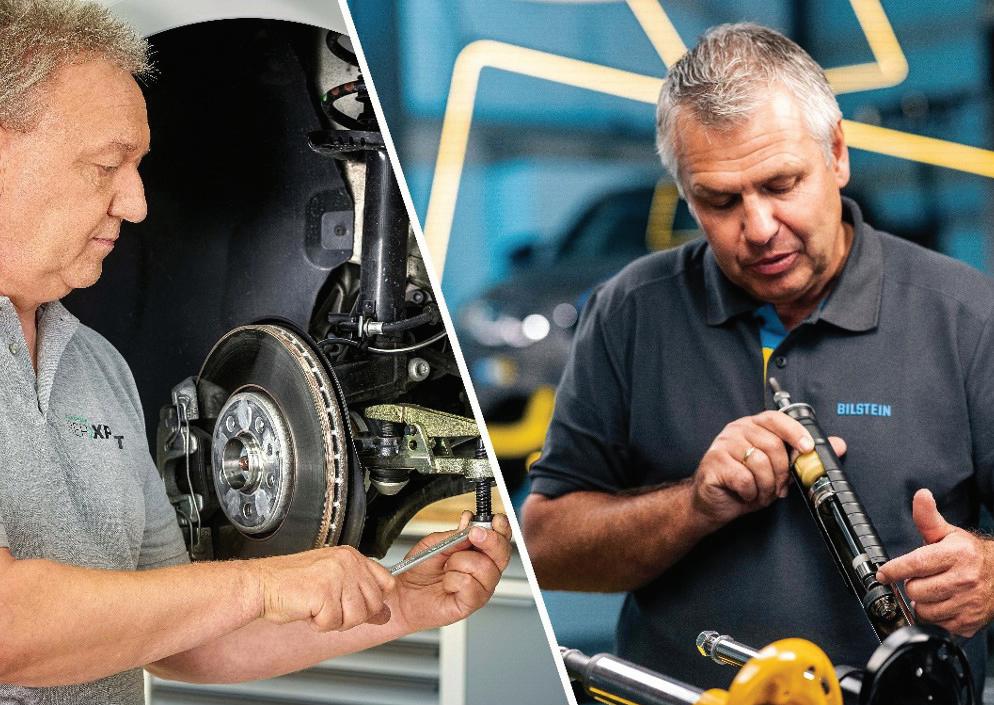

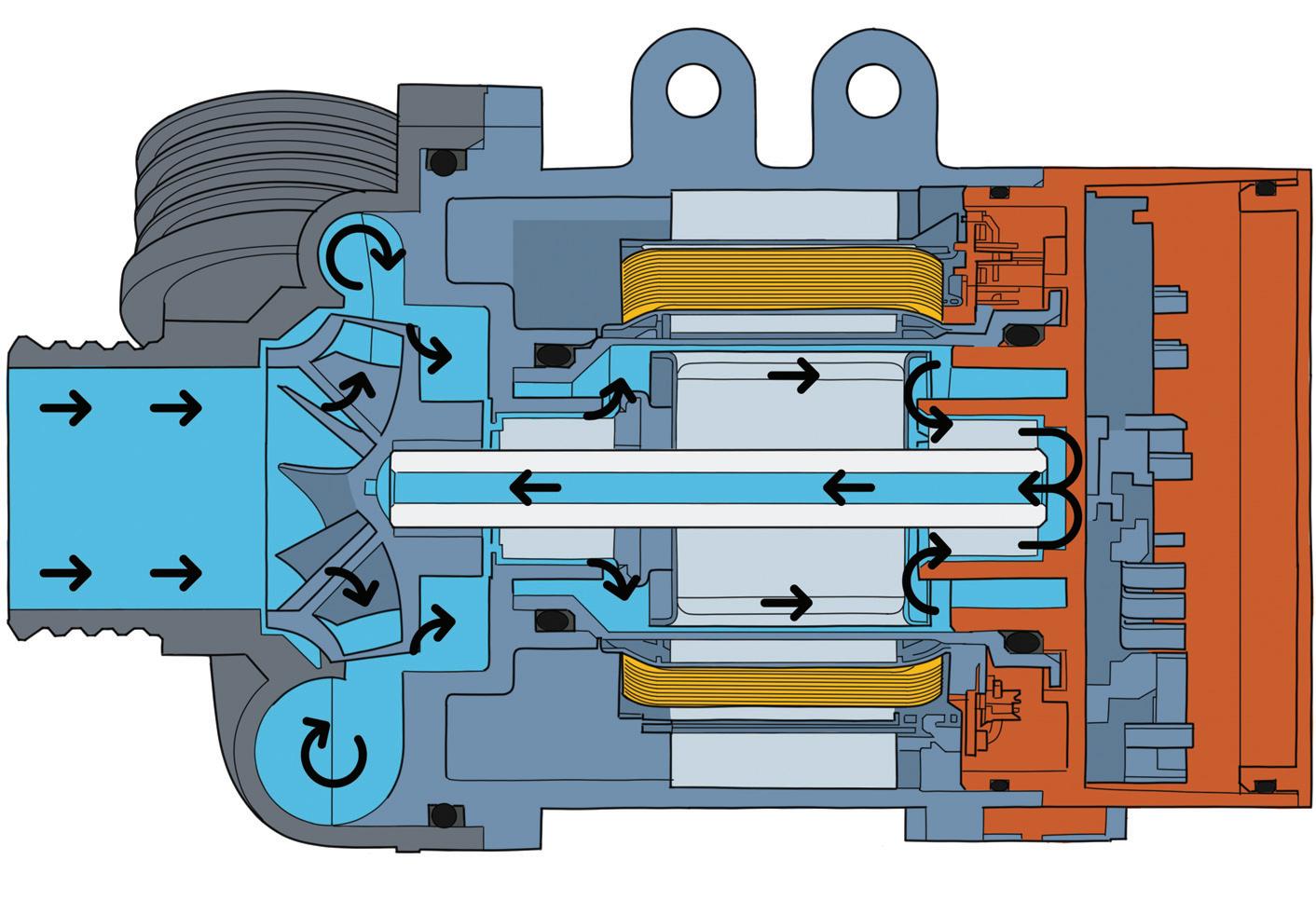

Replace the clutch on 2014 Iveco Daily

Schaeffler LuK’s Alistair Mason guides PMM readers through a clutch replacement on a 2014 Iveco Daily 35C17 that has covered 56,000 miles and had been recovered with no drive. Diagnosis pinpointed the fault to be the clutch and authorisation was given to replace it.

Vehicle Information

Manufacturer: Iveco

Model: Daily 35C17

Year: 2014

Mileage: 56,000

Time: 4.2 Hours

Pull type clutch overview

The advantage of a pull type clutch is that it gives a greater clamp load on the clutch, without an unnecessarily heavy clutch pedal, due to the pivot point/lever ratio of the diaphragm spring being at the outer edge, rather than two thirds or three quarters of the way down the diaphragm spring, and therefore the diaphragm spring must be ‘pulled’ to disengage the clutch. Pull type clutches are generally found in commercial vehicle applications that require the additional clamp load, but can also be found in some of today’s cars. The important thing to know and remember when replacing a pull type clutch, is how the gearbox is removed whilst the release bearing stays attached to the clutch. So, 10 minutes of wisely spent research can save hours of struggling to remove the gearbox!

Gearbox removal

With the vehicle safely positioned on the lift, open the bonnet, disconnect the battery earth lead and stow it safely. This is the only part of the repair that is carried out at ground level, so raise the lift to gain access to the underside, support the gearbox with a transmission jack and then remove the gearbox crossmember by detaching the gearbox mounting nut and crossmember to chassis bolts (Fig.1). With the crossmember

removed, disconnect the prop shaft from the gearbox and unbolt the centre mounting from the chassis (note – it is advised to mark the prop shaft flange and gearbox flange position to eliminate any potential balance issues).

This step gives good access to the electrical multiplugs on the side of the gearbox, so disconnect them, unbolt the bracket and stow away from the gearbox. The gear cables can now be removed (Fig.2) by levering the cable off the ball joints and then easing the outer cables out of their retaining brackets.

Remove the hydraulic slave cylinder by unbolting the metal mounting bracket and stow the cylinder and bracket away from the gearbox. Detach the rubber boot from the release arm (Fig.3), which allows the release arm to pivot far enough around to disengage from the release bearing when the gearbox is being removed.

Ensure the transmission jack is positioned correctly onto the gearbox and, working

CLUTCH

CLINIC

14 APRIL 2023 PMM

around the gearbox, remove the bell housing and starter motor bolts and store them in order of their removal. The gearbox can now be moved away from the engine and at the same time ease the release arm back, so it disengages from the clutch release bearing. Once the gearbox input shaft is clear of the engine and the release arm disengaged, the gearbox can be removed from the vehicle.

Clutch replacement

Remove the six clutch bolts and then the clutch assembly from the flywheel.

In this example, the clutch fault then became evident as, due to ‘slipping’ and overheating, the clutch lining had become detached from the clutch plate and broken up, which had also caused the dual mass flywheel to be exposed to excess heat, this was evident by the blue colour on its surface, affecting the internal springs and grease (Fig.4), (note – it is good practice to clear and vacuum up the broken clutch lining). At this point the customer was contacted and authorisation to also replace the DMF was given.

Turning to the release system in the gearbox, ensure the bell housing is clean and inspect the release bearing guide tube for any wear, and replace it if there is. Check that the pivot point on the release arm is free and also does not have any signs of wear (note –the pivot points are prone to seizing). Apply a light smear of high melting point grease to the guide tube and onto the gearbox input shaft splines and mount the clutch plate, this will confirm it is the correct plate and will also evenly distribute the grease.

Remove the clutch plate and any excess grease,applya light smear of high melting point grease to the pivot points of the release arm/release bearing, fit the new release bearing, engaging it into the release arm as it passes up the guide tube and,when in

position,ensure the releasearmoperates correctly and freely (Fig.5).

Replace the DMF and torque the bolts to the manufacturer’s specification, then clean the DMF clutch face and new clutch pressure plate face using some brake and clutch dust cleaner. Using a clutch alignment tool, mount the new clutch plate onto the flywheel with ‘gearbox side’ facing away from the engine, locate the clutch cover onto the flywheel dowels, insert the six clutch bolts, tighten them in an even and sequential process and finally, torque to the manufacturer’s specification (Fig.6).

A crucial part of this repair is the alignment between the engine and gearbox so that the release bearing locks into the clutch cover on installation. To ensure this alignment is correct, it is critical that the engine to gearbox alignment dowels are installed (Fig.7&8). So, prior to fitting the gearbox, ensure all the alignment dowels are inserted correctly.

Gearbox installation

Using the transmission jack, ease the gearbox into position, confirm the gearbox is located on the alignment dowels and is tight against the engine, then insert the bell housing bolts and tighten them.

The release bearing then needs to be inserted and locked into the clutch by hand. So, pull the release arm backwards, until the release bearing starts to locate into the clutch. At this point, using a lever, ease the arm further back until it snaps into the centre of the clutch, then pull back and forth on the lever to ensure that the bearing is locked into position, then fit the rubber boot. As soon as possible, fit the slave cylinder assembly and operate the pedal to ensure the clutch operation is correct. Once this has been confirmed, the rest of the installation is in reverse order of removal.

After connecting the battery lead, reset all electrical systems as required and always carry out a full road test to ensure a quality repair has been completed.

PMM APRIL 2023 15

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAW002

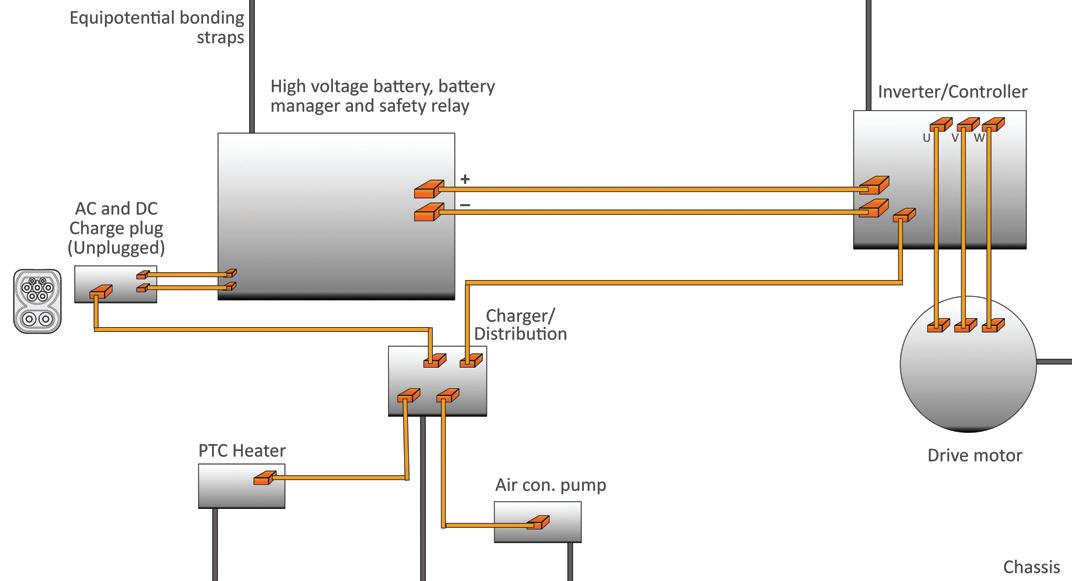

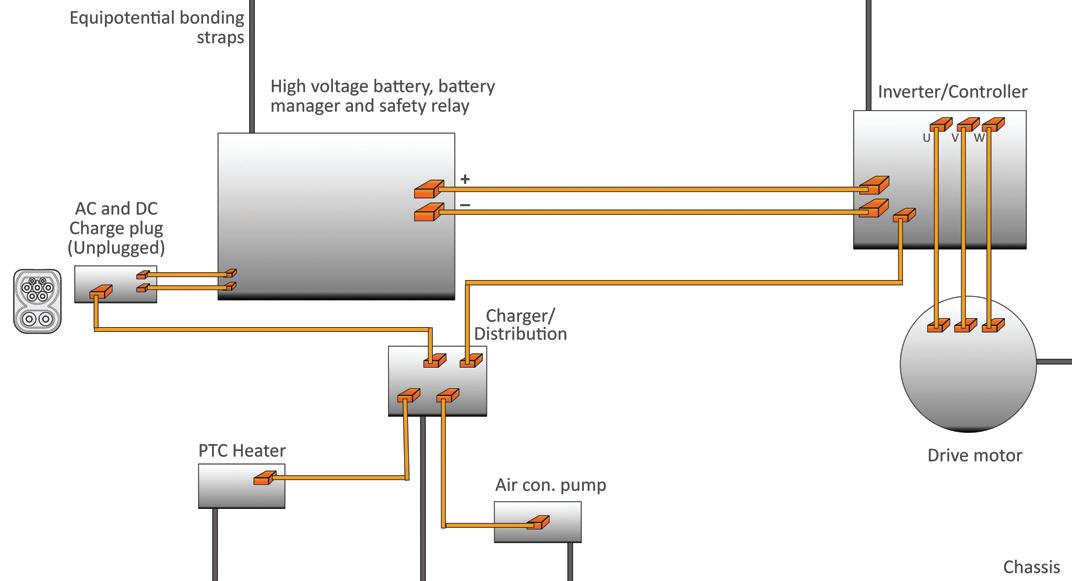

EQUIPOTENTIALEVBONDING

Equipotential bonding (EPB) is the process of electrically connecting metalwork and conductive parts, so that the voltage is the same throughout these various parts (an equal potential). EPB is used to reduce the risk of equipment damage and personal injury. It is sometimes simply referred to as bonding and is commonplace in domestic and industrial electrical installations. Its main purpose is safety.

In the near future, all workshops and garages will have to deal with a significant number of high voltage electric vehicles. Checking the safety and reliability of vehicle high-voltage systems is something we will need to become more familiar with.

EVs use an insulated return system so that there is no connection between the highvoltage circuits and the chassis. As part of the start-up process (when the vehicle is switched into ‘Ready’ mode) the on-board insulation monitor device runs a number of tests.

If a failure of this ‘monitor’ is detected, then the vehicle will not

switch on. However, if an insulation fault occurs on a HV component that is not properly bonded, the insulation monitor will not find and monitor this hazardous issue.

The reason that all the components are bonded to the chassis is so that even if insulation faults occur, the potential (voltage) difference between all the main metal components will always be zero – so no electric shock will occur. In theory, this should never happen so the bonding is like a belt and braces approach –better safe than sorry though because the high voltages used can be fatal.

When repairs are carried out the insulation resistance or isolation strength of high-voltage system components is always tested by the technician. The continuity of cables, including the braided shielding is also checked.A value of 500 V is often used for an insulation test but for some systems it is becoming necessary to use 1,000 V. Isolation strength (insulation resistance) of some components can deteriorate over time.

A key part of UN regulation ECE R100 states the specified equipotential bonding between two HV components shall be less than 100 mΩ (a tenth of an ohm). To measure milliohms (mΩ),

special equipment is needed, a normal multimeter is not suitable.

EPB is used to reduce the risk of equipment damage and personal injury from high voltages. Checking EPD can be more involved than it may first appear. However, with the proper equipment, suitable training and time, it is very easy. To date, here in the UK anyway, the equipotential bonding resistance between the components and chassis has not been carried out as a matter of course – other than as a physical ‘hand and eye’ check.

For some organisations, these sort of measurements and records are becoming more important. For individual technicians it is also becoming important to prove all tests have been carried out and so prevent future litigation.

In the next article I will highlight one method of testing EPB and how in the future it could become an income stream for your workshop.

FIG.2 This bonding strap connects the case of a high voltage component to the chassis on a Golf GTE

FIG.2 This bonding strap connects the case of a high voltage component to the chassis on a Golf GTE

PART ONE Sponsored by WANT TO KNOW MORE? FOR MORE INFORMATION GO TO WWW.RDR.LINK/ AAW003

FIG.1 EV system block diagram showing main components and chassis equipotential bonding

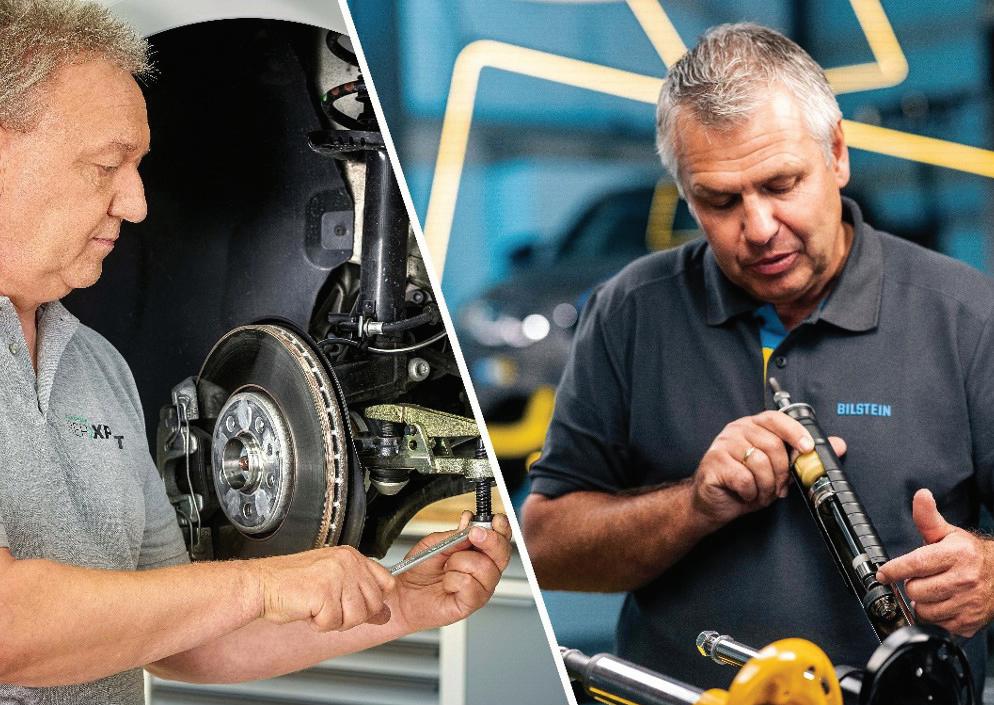

Replacing and installing shock absorbers BEST PRACTICE

KYB offers readers of PMM advice for replacing shock absorbers.

Checking for external failure during an MOT is obviously important, but this fails to consider that shock absorbers naturally wear over time – meaning there aren’t always obvious signs indicating wear or failure. The reason for this lies within the inside of a shock absorber cylinder, which houses a number of carefully calibrated valves. Each valve contains a stack of compression discs (Fig.1), each less than 1mm thick. When a piston rod is compressed, oil is forced through these valves, creating the resistance needed to absorb any bumps in the road. By the time a car reaches 50,000 miles, fluid has passed through these valves over 75 million times. Inevitably, this causes the discs to wear and deteriorate, meaning that fluid passes through more easily, decreasing the damping rate significantly and making the shock absorber much less effective.

To ensure problems don’t slip under the radar, KYB recommends asking your customer if they have noticed any of the following symptoms before checking for external signs:

■ Car pulling to one side.

■ Car unstable when cornering.

■ Vibration in steering wheel.

■ Excessive bouncing over bumps.

■ Nose diving.

■ Veering in side winds.

The importance of priming

Occasionally, a shock absorber will be misdiagnosed as faulty when removed from its packaging for installation. However, the fix is often very simple: priming. Shock absorbers are generally stored and transported horizontally, causing the gas and hydraulic fluid within to mix with one another. Pockets of air begin to form within the oil, affecting the damping force of the shock absorber. Whilst priming is not fundamental to the

operation of shock absorbers, installation without priming can lead to customer complaints about unusual noise or ride harshness as the shock absorbers “break in”. To avoid this, pump the shock absorber 4-5 times in its vertical working position to ensure that the oil and gas move to the correct areas prior to fitting (Fig.2).

Using the right tools

Using incorrect tools risks damaging the shock absorber and can prove costly, with unhappy customers returning for further repairs. There are plenty of tools on the market specifically designed to help – these include:

■ Torque wrenches. It is often considered easier to use an impact wrench to install and remove mounting kits quickly. However, KYB strongly advises against this practice, as using impact wrenches can:

1. Spin the piston rod, causing damage to the valving within the shock absorber. The holes within these valves are lined up in a specific way to allow for fluid movement – if these are misaligned, it can reduce effectiveness of the shock absorber.

2. Cause the bottom nut holding the valving together inside the shock absorber to come loose. Tightened between 7-12Nm in the factory, this nut is prone to loosening when the incorrect tool is used.

3. Sever the thread, leading to complete failure of the shock absorber (Fig.3).

Instead, use a torque wrench and tighten to the manufacturer’s torque recommendation after the full weight of the car has been applied.

■ Strut Nut Kit: When completing the above, don’t place gripping pliers on the piston rod when tightening the upper nut. This can score the highly polished chrome shaft, increasing wear on the upper seal, in turn causing a hydraulic fluid leak. Instead, using a strut nut kit will allow you to hold the piston rod securely without damaging the shock absorber (Fig.4&4a).

If you don’t have a kit, most shock absorbers have an area where it is safe to hold onto the piston rod using a spanner, located near the top of the shaft, just above where the thread starts. Or for some, there’s an indent for a hex key at the top.

WANT TO KNOW MORE? FOR MORE INFORMATION

PMM APRIL 2023 17 TECH TIPS

WWW.RDR.LINK/AAW004

a b

HOW TO

Replace the timing belt on a 2007-16 Renault Kangoo II

This month’s Belt Focus comes from Dayco. The timing belt is being replaced on a 2007-16 Renault Kangoo II, fitted with a 1.6 litre petrol engine (K4m.8.30)

The popular Renault Kangoo, also badged as the Nissan Kubistar, has been in production since 1997, with a second generation introduced in 2007, the petrol version of which, until superseded in 2016, used a 1.6litre engine that featured a timing belt-driven water pump. As replacing the belt also requires the auxiliary drive system to be removed, Dayco recommends that all the systems’ components – primary and auxiliary drive – be replaced at the same time.

This step-by-step technical guide will help technicians through the process, to avoid complications and ensure a first-rate job.

As with all primary drive system jobs, the work should be undertaken when the engine is cold, so ideally the vehicle will not have been run for at least four hours.

After disconnecting the battery earth cable and draining the coolant, remove the windscreen wiper arms, then the bonnet seal on the plastic bulkhead, the two trims either side of the windscreen, the cover set in the bulkhead and finally, the bulkhead itself. This reveals a cross-piece and, underneath, the wiper motor and linkages that both now need to be removed, along with the dividing plate, followed by the airbox.

Vehicle Information

Manufacturer: Renault

Model: Kangoo

Year: 2007-16

Engine: 1.6 petrol (K4m.8.30)

After removing the front offside wheel, detach the inner cowling and its reinforcement mounted in front of the crankshaft pulley. With access to the auxiliary drive system, use a spanner on the tensioner to take the tension off the belt so it, and then the tensioner, can be taken off. Now remove the lower tie rod attached to the powertrain.

Returning to the top of the engine, remove the two plastic plugs covering the camshafts, mounted at the opposite end to the timing drive system. Then remove the plug in the engine block behind the cooling

fan and insert the crankshaft timing pin (Tool 1489) (Fig.1), rotating the crankshaft clockwise with the pulley bolt, until the pin locates. The camshaft timing tool (1496/1750) can now be fitted where the plugs were removed.

Support the engine underneath with a suitable jack and remove the right-hand upper engine mount (Fig.2) followed by the engine mounting flange that also acts as the upper timing belt case. Next, detach the crankshaft pulley. As this holds in place the crankshaft pinion, which has no locking tab, the engine must be timed first. Then remove the lower timing belt case.

Holding the camshaft pulleys in place, loosen their fasteners (Fig.3), but again, as these also have no locking tabs, loosen them only after the engine has been timed. Then remove the belt tensioner, idler and the timing belt, which gives access to the water pump, and can now be removed.

18 APRIL 2022 PMM

BELT FOCUS

“As replacing the belt also requires the auxiliary drive system to be removed, Dayco recommends that all the systems’ components – primary and auxiliary drive – be replaced at the same time.”

Ensuring that the cooling system has been flushed through and no debris is present, fit the belt tensioner stud into the new water pump from Dayco kit KTBWP4601 (Fig.4), tighten it to 5 Nm (-0+2) and then install the pump with its gasket. Although none should be used on the gasket, the threads of the bolts that secure the water pump do need to be spread with sealant. Attach the new belt tensioner ensuring that the locking tab is located in the slot in the water pump body (Fig.5). Remove the crankshaft pinion, clean its inner section and the exposed shaft, but do not lubricate these contact surfaces. Likewise, do not lubricate the surfaces between the camshaft pulleys and their shafts.

Install the timing belt and then the idler, but leave the slack section facing the belt tensioner. Tighten the idler fastener to 50 Nm. Using an hex key, rotate the tensioner so that the index is aligned with the centre of the reference mark (Fig.6) and tighten the fastener to 30 Nm. Then tighten the fasteners on the camshaft pulleys to 30 Nm + 85°. Refit the lower timing belt cover and then after checking that the crankshaft is correctly

resting against the timing pin previously inserted into the engine block, position the crankshaft pulley and tighten the new fastener from the Dayco kit to 40 Nm + 145°. Remove the crankshaft timing pin and camshaft timing tool and, using the crankshaft pulley bolt, rotate the engine clockwise several times and then retime the system properly re-using the special tools. Through the lower window of the lower timing belt cover, check that the index and the reference mark on the belt tensioner are correctly aligned (Fig.7). If necessary, turn the tensioner through the window to

reposition it correctly.

Once the engine has been timed correctly, refit the timing tool plug in the engine block and insert the plastic plugs covering the camshafts on the cylinder head by applying sealant to their edges.

Refit all the components in their reverse order, but check, and if necessary, replace the crankshaft pulley with Dayco DPV1260 and the auxiliary belt tensioner with Dayco APV3180. However, Dayco recommends the auxiliary belt 6PK1200 is always replaced. For vehicles manufactured after 2013, check the auxiliary belt requirement, as some versions use 6PK1130.

Finally, refill the cooling system, start the engine and carefully check for leaks and ensure the radiator fan operates at the correct temperature, replace the thermostat Dayco DT1091H if necessary. Then, once the engine is cold, check the level of the fluid again.

PMM APRIL 2022 19

WWW.RDR.LINK/AAW005

WANT TO KNOW MORE? FOR MORE INFORMATION

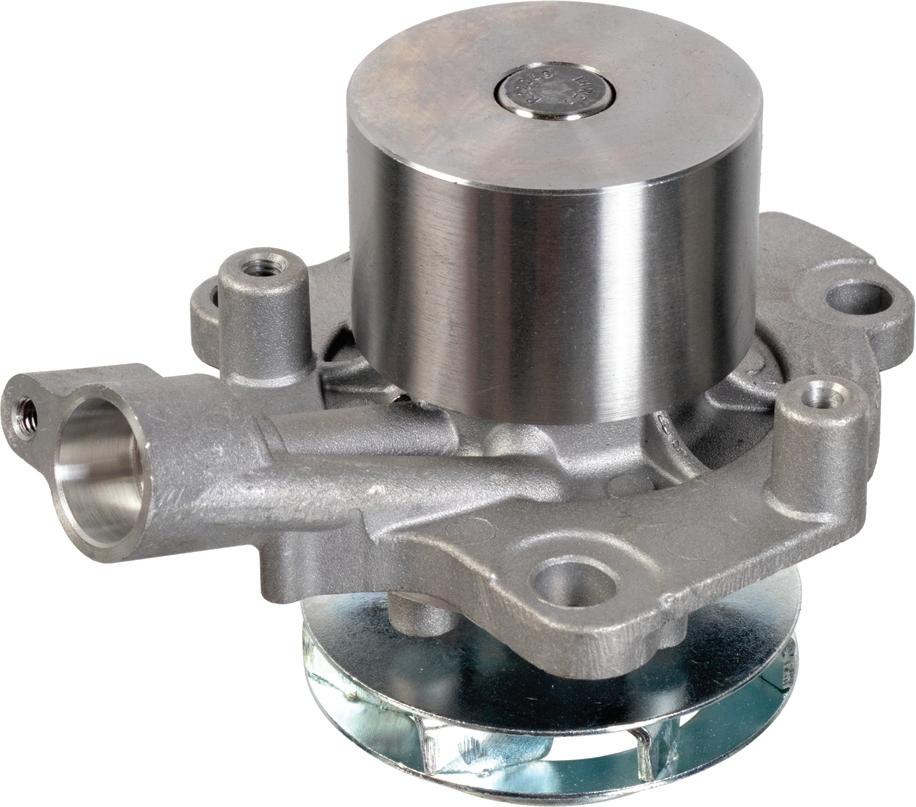

COMMON FAULTS

Water pump issues

Febi explores some common water pump faults across a range of makes and models.

MODELS

Various Audi, SEAT, Škoda and Volkswagen models with 1.6 & 2.0 TDi engines.

FAULT

The engine is overheating, the coolant temperature gauge reads over 110°C and the interior heater is performing poorly. Additionally, cooling system fault codes may be logged in the engine control unit (ECU)

CAUSE

The water pump fitted to these vehicles has an ECU-controlled collar, which interrupts the coolant flow to make the engine more thermally-efficient. However, the control collar can seize, or the plastic impeller can break-up or come away from the shaft.

SOLUTION

Ensure the engine is cool, then remove the coolant-filler cap. Remove the small pipe to the coolant header tank and hold this over the filler neck of the header tank. There should be a small trickle of coolant flowing with the engine at idle, and this should increase in flow upon increasing the engine speed. If the flow rate does not increase, this would suggest a faulty water pump.

Replace the defective water pump with febi 180948, which features an improved control-collar design; this has been thoroughly tested to eliminate the potential failure of the original water pump. The solenoid valve must be removed from the old original pump and fitted to the new pump, including new seals, which are provided in the kit.

Fill the cooling system with the correct coolant, then vacuumbleed the cooling system. Finally, carry out the cooling system bleeding procedure using a suitable serial-diagnostic tool to expel all the air from the cooling system.

MODELS

FAULT

The water pump leaks.

CAUSE

The water pump fitted by the vehicle manufacturer can leak, because the material used is perforated steel sheet. In the worst case, this can lead to significant engine damage.

SOLUTION

febi recommends using water pump no. 32682. This modified version of the water pump is manufactured from aluminium die casting. This makes the pump significantly stronger and prevents leakage. Additionally, febi supplies water pump 32682 including the required gasket and suitable bolt set.

Fitting Tip: When fitting the new version (32682), use the bolts supplied with water pump. Torque setting for bolts is 28nM. The vehicle manufacturer’s specifications should always be followed. Both old and new versions are still available in the aftermarket; however the new version does not contain the required bolts.

TECH TIPS 20 APRIL 2023 PMM

Citroen C1 1.0, Daihatsu Cuore VII 1.0/Sirion 1.0, Peugeot 107 1.0, Subaru Justy 1.0, Toyota Aygo 1.0/Yaris 1.0

MODELS

Various Volkswagen, Audi, Seat and Skoda models fitted with the 1.4 litre TDi engine.

FAULT

Engine overheating, coolant temperature gauge reading over 110° C and poor interior heater performance. Also cooling system fault codes maybe logged in the engine control unit.

CAUSE

The water pump fitted to these vehicles has an ECU controlled collar, which interrupts the coolant flow to make the engine more thermally efficient. However, the control collar can become seized, or the plastic impeller can break up or come away from the shaft.

SOLUTION

Ensure the engine is cool, then remove the coolant filler cap. Remove the small pipe to the coolant header tank and hold this over the filler neck of the header tank, there should be a small trickle of coolant flowing with the engine at idle. This should increase in flow when the engine speed is increased. If the flow rate does not increase, this would suggest a faulty water pump.

Replace the defective water pump with febi 108778, this is a conventional water pump, which eliminates the potential failure caused by the control collar. The solenoid valve must be removed from the old pump and fitted to the new pump. This is so the engine management system can recognise it. Failure to replace the solenoid valve will log an engine management fault.

Fill the cooling system with the correct coolant, then vacuum bleed the cooling system. Finally carry out the cooling system bleeding procedure, using a suitable serial diagnostic tool, to expel all the air from the cooling system.

MODELS

Audi, Seat, Skoda, Volkswagen - Various models 1.6 & 2.0 TDi engines

FAULT

Engine overheating, coolant temperature gauge reading over 110° C and poor interior heater performance. Also cooling system fault codes maybe logged in the engine control unit

CAUSE

The water pump fitted to these vehicles has an ECU controlled collar, which interrupts the coolant flow to make the engine more thermally efficient. However, the control collar can become seized, or the plastic impeller can break up or come away from the shaft.

SOLUTION

Ensure the engine is cool, then remove the coolant filler cap. Remove the small pipe to the coolant header tank and hold this over the filler neck of the header tank, there should be a small trickle of coolant flowing with the engine at idle. This should increase in flow when the engine speed is increased. If the flow rate does not increase, this would suggest a faulty water pump.

Replace the defective water pump with febi 103078, this is a conventional water pump, which eliminates the potential failure caused by the control collar. The solenoid valve must be removed from the old pump and fitted to the new pump. This is so the engine management system can recognise it. Failure to replace the solenoid valve will log an engine management fault.

Fill the cooling system with the correct coolant, then vacuum bleed the cooling system. Finally carry out the cooling system bleeding procedure, using a suitable serial diagnostic tool, to expel all the air from the cooling system.

WANT TO KNOW MORE? FOR

MORE INFORMATION

PMM APRIL 2023 21

WWW.RDR.LINK/AAW006

TRAINED UP

battery e-learning course.

The Varta team has announced a new suite of battery e-learning courses which are now live on its partner portal which will complement the company’s more traditional face-to-face-training. The various courses will complete the digital knowledge portfolio, following the company’s YouTubechannel’s educational playlists, technical articles in the Battery World, Battery Finder and other social media platforms.

User experience

The company’s goal is to provide the best user experience during its training – both online and offline. “Our E-Learning offerings are aimed at everyone who deals with batteries in their daily business”, says Ulrich Germann, training and technical support manager at the training academy.

“We want technicians and sales advisors, wholesalers and retailers to be able to understand the new technologies and today’s

complex vehicles. We want to share our profound knowledge in a user-centric approach so that our customers can be successful in their daily business.” They continue.

Keeping up with modern technology

The first technological advancements around the battery came with the introduction of start-stop systems. Since then, fuel-saving functions go far beyond simply switching off the engine at traffic lights; many standard features are not even noticeable by the driver. For workshops to be able to repair these complex systems in the future, the training modules will continually update to ensure technicians are prepared. In addition to general topics such as “warehousing and storage” or the “Varta brand and USPs”, there is also more indepth technical material such as “vibration resistance” or “deep cycling capabilities”. The next technological leap is already underway, as the role of the traditional 12 V battery is more important than ever for hybrid and even pure electric vehicles.

BUSINESS & TRAINING

22 APRIL 2023 PMM

Expanding the range

After the launch, a new series on the topic of drivetrain electrification and the role of the 12 V battery in electric vehicles is already in development. Varta e-learning courses are currently available within its partner portal. Registered users get access to a complete offering of digital training on:

■ basic battery knowledge

■ advanced passenger cars

■ heavy commercial vehicles

Simply login and click the ‘menu’ in the top left of the screen, then you have free and unlimited access to the Varta portal.

“We are very pleased to be able to support the UK and Irish aftermarkets with these free-toaccess e-learning courses and hope that technicians and factor staff find them useful and informative.” says John Rawlins, marketing manager. “Our intention is to provide bitesize online training to complement the face-to-face training we already provide; we don’t intend to stop that”.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAW007

“Our intention is to provide bitesize online training to complement the face-to-face training we already provide.”

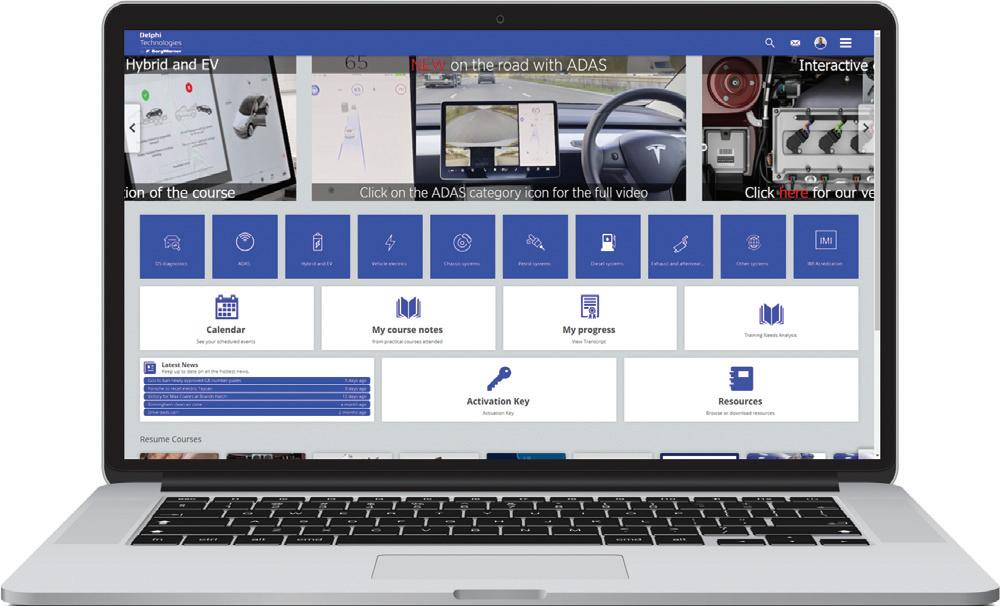

Reasonsto TRAIN yourteam

We saw an uptick of interest in our training services during the Covid lockdowns. The disruption left lots of garage owners and technicians with extra time, leading to exploration of our diagnostics solutions, training and skills development. Since then, garages have maintained interest – within an industry changing very fast. Autonomous driving technologies, electrification of the vehicle parc and different diagnostic processes are amongst the key step-changes independents face. Cars are changing, the drivetrains, the onboard technology and the methods of interacting with the vehicle are all transforming.

Yet with new car sales stalled and motorists holding on to vehicles longer, many independents are seeing brisk business.

More and more garages are looking to adopt structured training and development programmes to maximise these opportunities. Even doing some of the simplest service jobs now require access to the vehicle’s ECU and coding capability so new skills, new equipment and a commitment to continual learning are absolutely essential.

Training centre

We’ve focused on future technology within our Warwick training centre, with vehicles, service equipment and test rigs for technicians to work on – there’s still no substitute for ‘hands on’ learning.

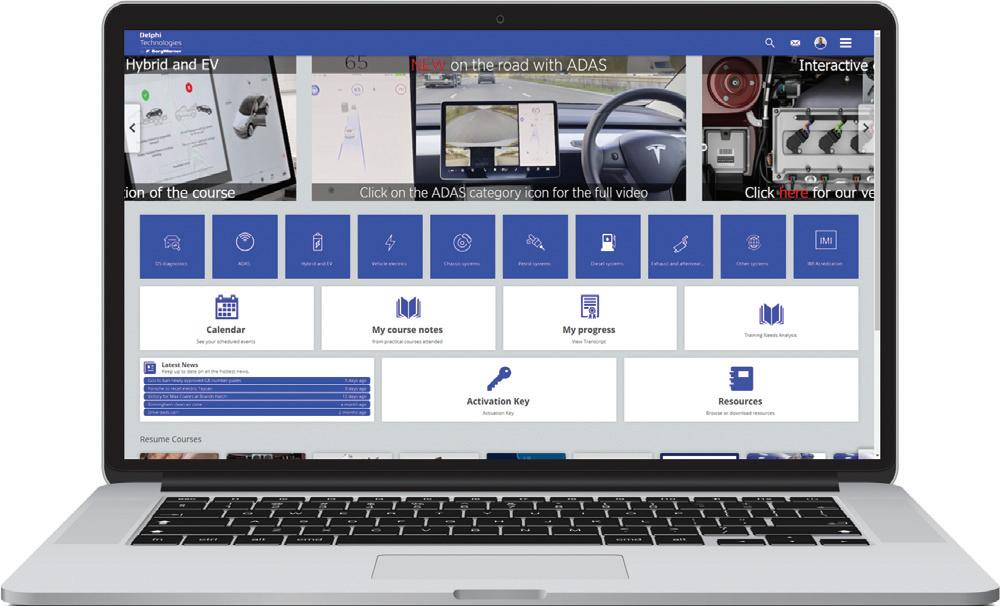

The growth of the Delphi Technologies Academy, launched in 2021, has been rapid with around 1,200 users gaining flexible access to over 300 courses and modules, all of which have been compiled by in-house trainers.

The academy gives a convenient way to enhance skills and knowledge without the challenges of attending physical training. There’s a Training Needs Assessment which includes a series of questionnaires and online ‘practicals’ before suggesting modules to complete tailored to that user. Hybrid and electric vehicle training is the perfect example of the benefits of a true blended learning experience.

For the more advanced EV course we provide six hours of online pre-learning on electrical systems to try and get the foundation knowledge of electrical principle to then build upon in the training centre.

Online can also be great for reinforcement or showing specific things that can’t easily be staged in the training centre; for the technicians there’s also the benefit of being able to learn at their own pace.

CPD pathways

We at Delphi are at the forefront of delivering structured training with “more than 70 per cent” of delegates following a defined training pathway, mapped to industry-recognised IMI qualifications. Available paths include IMI Fast Fit, Service/Diagnostic and Master Technician assessments. The first two are Level 2 qualifications, with Diagnostic Technician being a Level 3 and Master Tech a Level 4.

Each of the pathways provides between four and seven modules which are one or two days in duration. IMI Accreditation is then dependent upon completing an additional assessment day afterwards. Each online

BUSINESS & TRAINING

24 APRIL 2023 PMM

Delphi Technologies’ technical services manager Luke Garratt, discusses how UK technicians could be gaining CPD points for their training.

module is also IMI Continuing Professional Development (CPD) accredited. Videos typically include an easily digested overview, concluding with a quiz to test learning.

An Advanced Lighting Technologies course, for example, takes just 25 minutes to complete, introducing the various types of lighting used on current vehicles including LED and laser lights.

New technologies

We’ve focused our training around emerging new technologies. This means autonomous Advanced Driver Assist Systems – or ADAS – systems such as adaptive cruise control, emergency braking and adaptive headlights as well as, of course, vehicle electrification. Training on this technology is absolutely vital for safety first and foremost, after that, garages need confidence and technical competence to start working profitably.

Four of the five most popular training courses relate to EVs and hybrids. The latest figures from the SMMT show why. 2022 saw registration of electric vehicles surge at the expense of petrol and especially diesel.

Diesel registration fell 38.9 per cent compared to the previous year. On the flip side of the coin, battery EV registrations rose over 40 per cent to 267,000. In fact, total hybrid and EV sales exceeded petrol and diesel engine vehicles combined, with a 52.6 per cent share.

Our Hybrid and Electric Vehicle Level 3 course enables a technician to disable and power up high voltage system safely to change components. Beyond this, there’s a two day Level 4 course which covers diagnostics. With the power off, fault finding can be difficult so this course goes much more deeply into diagnosing live high voltage systems including high voltage battery repairs from different manufacturers.

The UK aftermarket has been talking about hybrid and EVs as a future opportunity for years but over the last 18 months we’ve seen a shift with many more garages looking to get involved now. This urgency is due to the looming 2030 deadline, dire warnings from policymakers over unpreparedness for our EV future and the baseline business case rising numbers of EV vehicles presents.

Value for money

Garages have to make tough calls on how to allocate their resources. We’re finding staff retention is a key driver for training these days. Recruiting skilled technicians is difficult and expensive so a modest ongoing investment in training over several years can pay for itself in making it easier to attract new technicians. Staff retention is boosted too because technicians who feel they are developing their abilities won’t be as easily tempted to move for a few pounds more in their pay packet.

It’s a big ambition but we want to offer the complete training solution. That means covering lots of scenarios and technologies within a flexible blended framework that provides a clear progression route for the technicians and business owners involved. WANT

PMM APRIL 2023 25

TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAW008

“Four of the five most popular training courses relate to EVs and hybrids. The latest figures from the SMMT show why.”

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

New mechanic TRAINING

In a new series of technical seminars, the UK’s next generation of professional motor mechanics is learning how additive technology is being used to reduce vehicle emissions and to support garage service and maintenance routines. They are also learning the value of informing customers about the continuous maintenance dividends that automotive additives can deliver.

The Lucas Oil Academy, which is the training arm of US brand Lucas Oil Products, works closely with technical colleges. It’s been using shows such as Mechanex, Race Retro and local trade events to demonstrate and promote additive benefits for student mechanics.

“For example, we explain that because

our Heavy Duty Oil Stabiliser provides a coating to all internal engine components, it is perfect for cars with oil-fed timing chain tensioners,” says Lucas Oil Academy technician Nathan Owen. “Good examples of the kind of models that particularly benefit are found among certain cars in the Vauxhall range, often associated with engine noise and rattling. Our LOA students learn why this kind of product is ideal for tired or worn engines. It’s because it raises oil pressure. It adds lubricity. It lowers oil temperature. It helps to extend the operational life of the oil. That’s a quality that’s especially useful for car owners who are often tardy about bringing their vehicles in for a service.”

Students of the LOA learn how to apply additive technology more appropriately. They

return to their local garages more able to offer a range of alternative solutions that can benefit both garages and their customers.

“For customers struggling with the cost of living crisis, additives that can reduce emissions or extend component life offer solutions that are more affordable. For garages, additive sales provide not just solutions but add preventive maintenance options that will increase garage efficiency and put numbers on to the bottom line,” adds Nathan Owen.

PMM APRIL 2023 27

BUSINESS & TRAINING

TO KNOW MORE? FOR MORE INFORMATION

WANT

WWW.RDR.LINK/AAW009

Lucas Oil discusses its new training academy and what it can offer aspiring technicians.

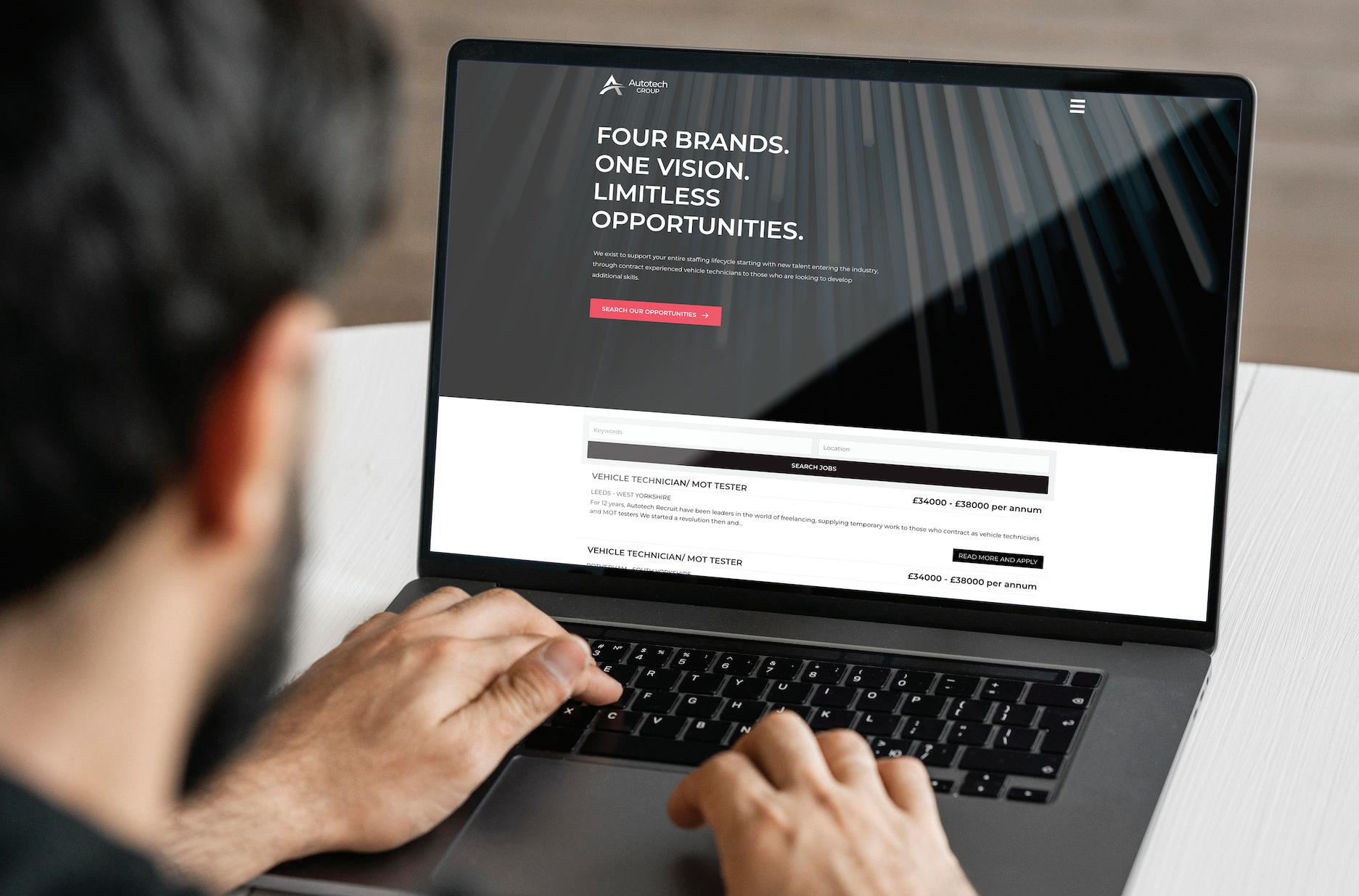

Want secure FLEXIBILITY?

For the automotive industry, retention has been a problem for some time and attracting the right talent is an ongoing issue. We are starting to see salaries rise, particularly for vehicle technicians, and, whilst this does put additional pressure on employers, it is incredibly positive and long overdue. As the saying goes, money talks, but people, especially those with sought after skills, recognise their worth and the industry needs to keep up with new technology, while exploring all potential avenues, to ensure they attract and keep hold of the right people.

Last year was a candidate’s market and 2023 is likely to follow suit. People are seeking a greater level of flexibility and employment on their own terms. If they don’t get it in their current job, they are very likely to look elsewhere, and retention rates have become a real problem for most organisations.

The structure of the UK workforce is changing profoundly. Flexibility is the key driver of this change, and 65 per cent of businesses surveyed revealed they understood the need to play the ‘flexibility game’ to attract the right people as it opens them up to a much wider pool of talent. But flexibility isn’t a one size fits all solution, and of course, for the automotive industry, working from home really isn’t an option. It may be choosing the hours they work and when they work to strike a better work life balance. We have contractors working for us who prefer seasonal work so they can spend time indulging their hobbies or working on their other side businesses.

People want greater choice today. It’s why there are now over 4.2 million self-employed workers in the UK.

The freelance revolution

Sparked by the financial crisis and the unemployment that followed, freelancing became one of the biggest trends of the 2010s. At the time, it was a necessity for many but, when the pandemic hit, it became a choice. People had a taste of hybrid working

and they wanted more of it. For employers, 64 per cent say that using contractors helps them to address the skills gap, while enabling them to turn the tap on and off as needed when it comes to specialist support.

This sentiment fits the automotive industry exactly, and it’s one we have been beating the drum about for over a decade. Using temporary vehicle technicians and MOT testers to cover resource gaps, whether brought on by sick leave, holiday or a lack of available talent, is a solution automotive bosses are tapping into time and again. These contractors are in charge of their own destiny, they know that training and being skilled in the latest automotive technology will help them remain agile and employable.

It’s widely known that the automotive industry is fishing for talent in a rapidly depleting pool. While there are initiatives in place to upskill existing workers and harness a new generation, we also need to look at those who left the sector and lure them back in.

Technicians who, faced with the evolution of vehicles, opted to retire early rather than upskill, are now starting to return to working and flexibility is key.

Job security

While contracting is undeniably on the rise, for many, job security can be a real deal breaker. With mortgages to pay and mouths to feed, particularly during the cost of living crisis, taking the plunge to become a contractor can be daunting and bring a host of concerns. When we started the business back in 2010, it was a contractor revolution. Freelancing within the automotive industry was relatively unheard of, today while our network continues to grow, demand is outstripping supply and the contracts are becoming more long term. Any fears of not having enough work are unfounded. But to appeal to more people and reach out to those who left the sector in a bid to entice them back, we are offering full-time permanent employment, with all the benefits that entails, and the variety of work that comes with being a freelancer.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAW010 BUSINESS & TRAINING

Here, Simon King, managing director of Autotech Recruit discusses the challenges the automotive industry is facing when recruiting.

28 APRIL 2023 PMM

Technicianson the FRONT LINE

PMM’s editor Kieran Nee went to Banstead to visit Ross Crook, an area workshop manager for the Southeast Coast Ambulance Service to find out what particular challenges an NHS workshop faces and discovers that there is more in common with an independent garage than he had first thought.

It was at our annual Mechanex trade show, last year, that Ross Crook and John Giles, area workshop managers for the NHS’ Southeast Coast Ambulance Service first approached the PMM team to ask if there was any way we could help. Not being the handiest of people (editors rarely are), we asked how we could possibly be of any use to someone in charge not just of repairing vehicles but repairing actual life-saving ambulances. I like to think my editorial viewpoints are somewhat interesting and maybe raise the odd smile, but they’re hardly emergency services-level useful.

And then came the familiar lament, one we’ve grown so used to hearing in recent years it’s almost becoming a cliché: “We

can’t get any staff, it’s becoming a real problem”. So I went to the service’s Make Ready Centre in Banstead, one of the 12 workshops that Ross and John oversee, covering over 600 vehicles, 398 of which are ambulances, to find out more about what is involved in repairing vehicles for the NHS.

Each workshop has between four and six technicians on site, working seven days a week, 52 weeks a year, including early and late shifts. Besides the routine maintenance, there is a lot of un-planned repairs to do, so the workshops needs to be able to react quickly and ensure the fleet is back on the road as quickly as possible.

One advantage, Ross explains, over an independent workshop is that they know what vehicles are coming up for servicing and

when – it’s all planned well in advance. But it’s not just the ability to pre-plan which will be whetting the appetite of the put upon independent technician: “As much as possible, a lot of the work we do is not just planned, but also preventative maintenance. So a lot of the guidelines that we work to are above and beyond what the manufacturer or the general road user might use. For example, we might have our brakes all replaced at 50 per cent. Our tyres are all replaced at 3-4mm, depending on the vehicle model.” In short, the NHS vehicles are treated similarly to any other piece of equipment it uses to care for people and everything practicable is done to eliminate the risk of nasty surprises.

SPECIAL REPORT

30 APRIL 2023 PMM

There is a flipside to this prudence. As the more fiscally concerned of our readers might already be getting their letter stationary ready, it’s worth pointing out that Ross’ crew are subject to the same cost restrictions as the rest of the civil service: “Ae also have to get the balance right financially, because we need to consider that we are an outfit that's spending money and that we need to make sure that we're getting value for money for our users and for our trust and for the wider public.”

As might be imagined, sourcing parts at a moment’s notice isn’t quite as simple as going down to the local factor and certain “online marketplaces” are certainly out of the question: “We have a lot of frameworks that we need to work within. Some of our suppliers are set up through certain frameworks, so that makes it slightly challenging in getting parts at times because of the framework. The sheer complexity of our vehicles as well. We've got the equipment to look at.”

Let’s take a look at some of that extra equipment: “Some have got ramps and winches in order to bring stretchers onto the vehicle. We’ve got a tower lift assembly. Then you’ve got your systems which are integrated into the vehicle itself – the blue lights, of course, extra ECUs that control things in the back. We've got additional heating and cooling, we've got additional braking. So, for example, this vehicle we've got here today has got an electromagnetic brake underneath to improve the braking system.” And that’s not even going into the medical and patient care equipment on board.

The nature of the driving – quick, across terrains, high mileage (“upwards of 1,000 miles a week”) – and the extra weight means parts such as brakes and suspension wear out rather more quickly than normal. But such an accelerated service schedule has unexpected consequences, as Ross explains: “Because we are doing so many miles and because we have such a number of vehicles, we probably see faults even before the manufacturer sees them. Data’s a massive thing for us, and I think actually it’s quite underutilised in an independent environment. If you can look at some of your metrics, even in its most basic form, you can try and understand your business a little bit better to discover which

areas you can improve on and what challenges you face – it may allow you to step out of the situation and have a conversation with your parts supplier or something.”

Skills shortage

Beyond the advanced technological solutions put to use by the service to ensure a steady balance of jobs throughout the year, it is a distinctly human problem which Ross is struggling to solve: getting people through the door in the first place. “I’ve kept an eye across the board and it seems we’re just facing the same problems as the rest of the industry –there really is a national skill shortage and it is something that’s really hitting us hard. I think it’s definitely getting worse. When I’m driving around visiting site to site, I notice there are a lot more vacancy bulletins out there.”

When I ask Ross what he thinks may be the reason for the shortage, he turns to the increasing complexity of modern vehicles: “We’ve got to remember there are lots of things on vehicles which are continually updating. For us in particular, a lot of people don’t know that ambulance and blue light service maintenance for vehicles in some areas is done in-house.”

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAW011

PMM APRIL 2023 31

OILS under the spotlight

Amidst an ongoing war in Ukraine and disruptions to global supply chains, prices of oil remain uncertain. Couple this backdrop with a cost-of-living crisis at home and, the VLS is warning workshops, we could be seeing a wave a counterfeit oil on these shores.

Rising costs are putting immense pressure on workshops and motorists alike to save money where they can. As a result, the industry trade body, the Verification of Lubricant Specifications (VLS), is expecting a rise in counterfeit lubricants as criminals look to cash in and sell cheaper alternatives to genuine products.

“Counterfeiting affects many vehicle parts and accessories, and lubricants are no exception,” according to chairman Mike Bewsey. “Modern vehicle engines are highly complex. They require sophisticated lubricants using advanced chemistry, backed by the investment of millions of pounds, dollars or euros by major additive companies. These additive companies use extensive bench, laboratory or real-life engine testing to guarantee performance standards and safety.

Although the vast majority of lubricants on the market are genuine, types of counterfeit oils might include:

■ Virgin base oil with a sub-standard additive pack or lower spec base oil being used

■ Virgin base oil with no additive pack at all

■ Used oil that has been repackaged and presented as new oil

■ Re-refined product that is unsuitable for its stated application

■ A lesser-spec oil presented as a premium specification

Compared to standard formulations, counterfeit products might have fewer or even no additives at all. This can significantly affect the lubricant, resulting in poor or possibly even dangerous performance compared to genuine products. Just like using the wrong oil, using counterfeit oil could lead to accelerated wear in gears and bearings, the formation of lacquers on surfaces such as pistons and the development of sludge that could restrict oil flow. All of which could lead to increased maintenance costs and, if left unchecked, eventual engine failure.”

Cash-strapped motorists may also try to buy oil themselves to save money. With limited knowledge in such a technical area, they risk buying counterfeit oil online or from other unscrupulous sources, which isn’t what it purports to be.

Too good to be true?

VLS is urging workshop owners, mechanics, technicians and end users alike to take a series of common-sense steps to reduce the risk of buying and using a counterfeit product:

Purchase lubricants from reputable sources such as official distributors or wellregarded motor factors. Avoid purchasing finished lubricants from unofficial sources or less reputable internet sites where the source of the product is unclear. Avoid products that appear to be heavily discounted or are being sold in a hurry, such as ‘fire sales’ or ‘stock must go’ end-of-line promotions.

Check for authentic marks on packaging, such as batch codes. Most reputable

lubricant blenders use batch codes as part of their ISO quality assurance processes. If a product does not have a batch code or authentic serial number, there is a greater risk that it might not be genuine.

If a lubricant manufacturer is claiming ACEA specifications, check to ensure that they are a signatory to the European Engine Lubricants Quality Management System Letter of conformance for lubricant manufacturers

(https://www.sail-europe.eu/ registrations/lubricant-marketers)

Check any packaging and product labels carefully. Fraudsters will aim to maximise revenue at minimum cost, so they may use lower-quality packaging or labelling. Does the packaging look and feel of appropriate quality and as you would normally expect? Looking at the product label, is the spelling and use of grammar correct? Is the colour on the label an exact match against previously purchased authentic products or are the colours slightly washed out? Are the text and images clearly printed or a bit blurred and not as sharp and well-defined as they could be?

Is the pack integrity supported by a tamper-evident seal that is evident?

Ask for Technical and Safety Data Sheets. Reputable suppliers should have no problem producing these or advising you where to access them. Suppliers trying to pass off counterfeit lubricants may be evasive about providing this important information.

Taking these simple steps can ensure counterfeit products don’t cause unnecessary breakdowns or damage your reputation.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAW012 SPECIAL REPORT

32 APRIL 2023 PMM

LIGHTS, camera, ACTION!

PMM is looking for the next star for its YouTube channel.

Do you work in an independent workshop? Are you an experienced technician with plenty of knowledge to share? Do you want to raise the profile of your workshop and be at the forefront of new industry developments? If you have answered yes to all of the above, then we have the perfect opportunity for you and your workshop. We are looking for the best technicians in the country to join the PMM team at the forefront of the independent aftermarket. We care about educating and informing our sector and we know you do too! We want your help to make our media output the best it can be.

IF YOU’RE INTERESTED, EMAIL KIERAN NEE AT PMM@HAMERVILLE.CO.UK WE CAN’T WAIT TO HEAR FROM YOU!

This is an opportunity for technicians and MOT testers of all ages and from anywhere in the UK to get their hands on the latest tools and products, get in front of the camera and provide cutting edge product reviews for the PMM YouTube channel.

This is an opportunity for technicians and MOT testers of all ages and from anywhere in the UK to get their hands on the latest tools and products, get in front of the camera and provide cutting edge product reviews for the PMM YouTube channel.

KNOW YOUR PARTS

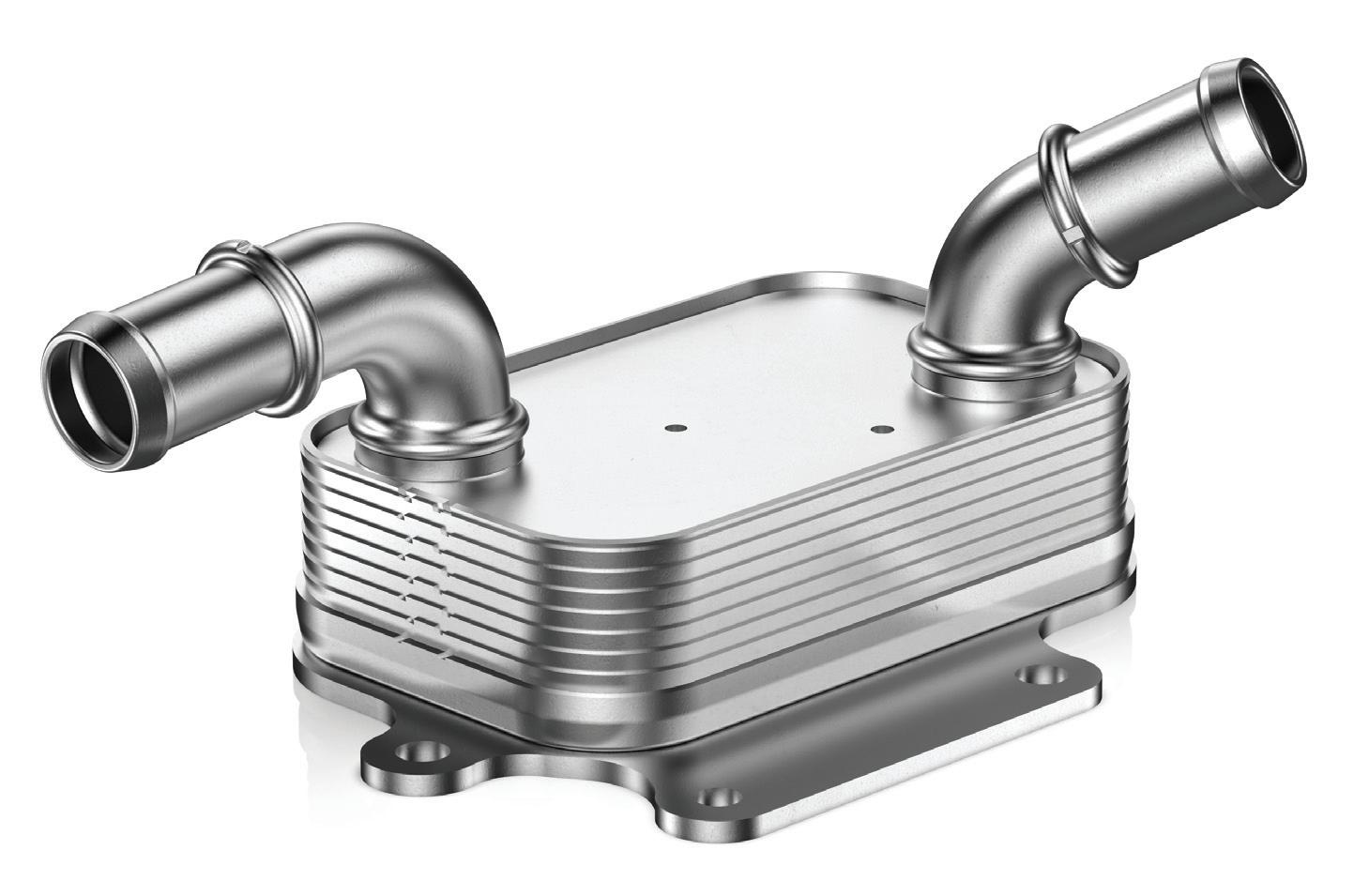

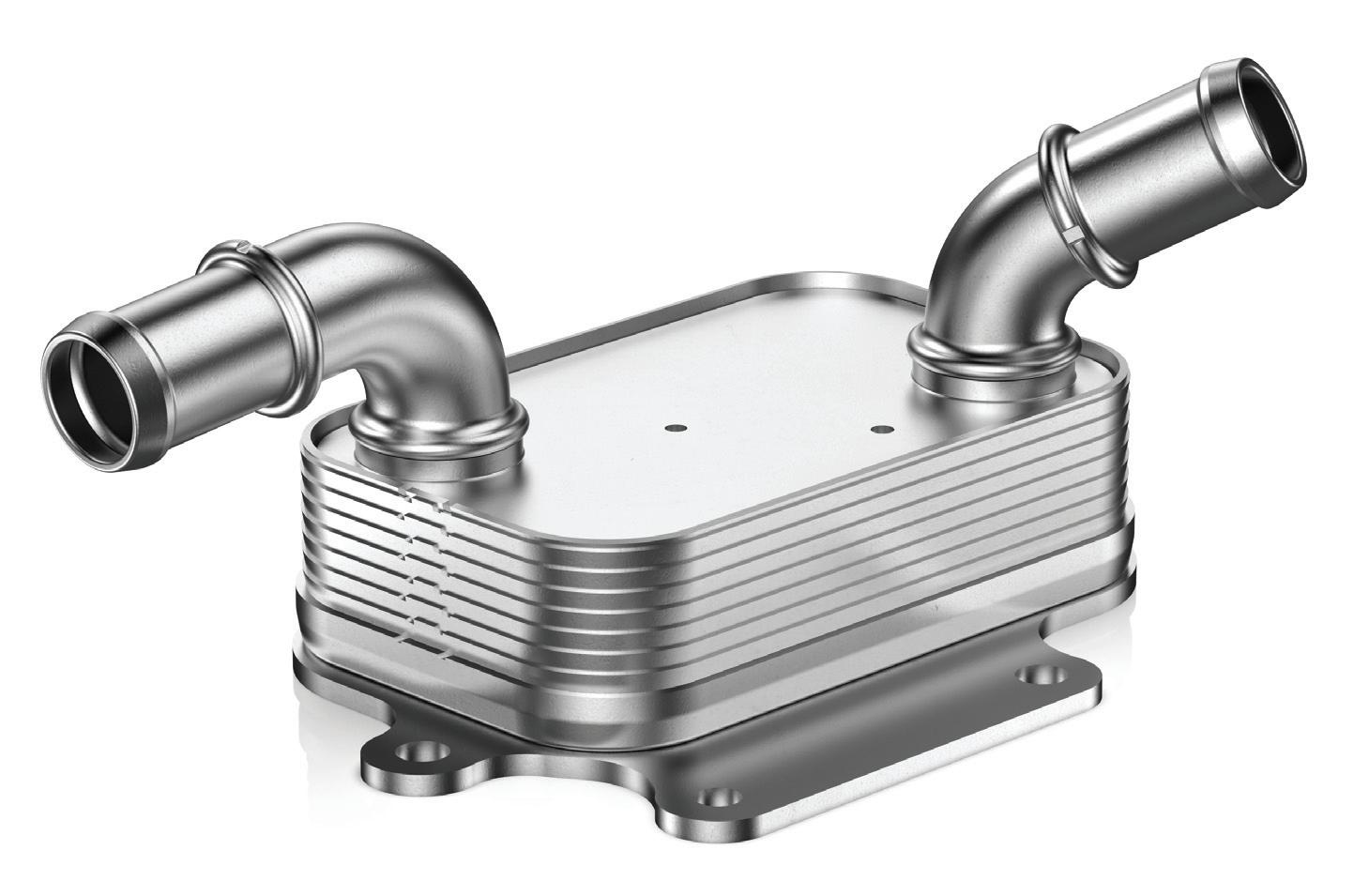

Thermal management system

Febi explores what technological changes are occurring within the thermal management system and gives advice to workshops on maintaining these systems.

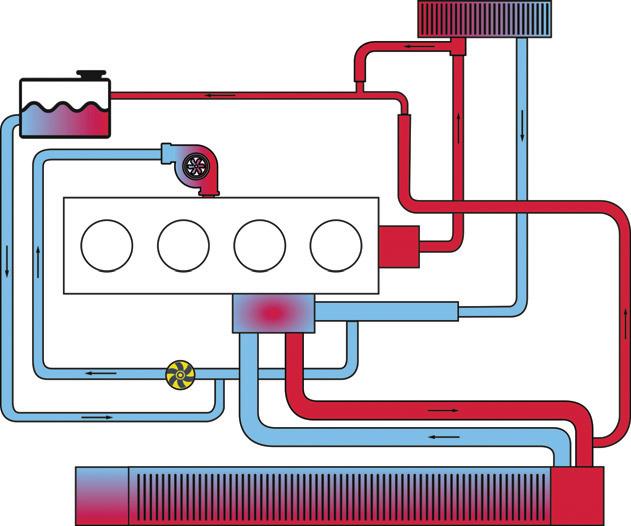

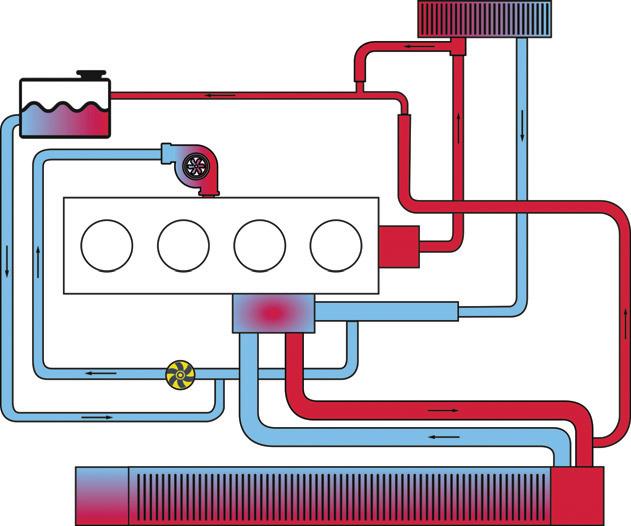

For many decades, 99.9 per cent of internal combustion engines have relied upon water (coolant) being pumped around the engine block and cylinder head to prevent overheating and thermal distortion, caused by heat of the combustion process. As the coolant is pumped through the engine casing it absorbs heat. It then circulates through a radiator to be cooled, before returning to the casing again for the cycle to be repeated. The heating/cooling process is controlled by a thermostat to maintain a constant temperature.

The water pump, like many other auxiliary components (e.g. PAS pump, alternator and A/C compressor), has traditionally been driven mechanically off of the engine crankshaft (or camshaft) via a belt. The trouble with this method is power is continually sapped from the engine which negatively affects vehicle performance and fuel economy/emissions.

Vehicle manufacturers have been developing alternative ways to drive and control these components to improve efficiency and economy, with many vehicles now fitted with electric power steering, and more beginning to use electric air conditioning compressors.

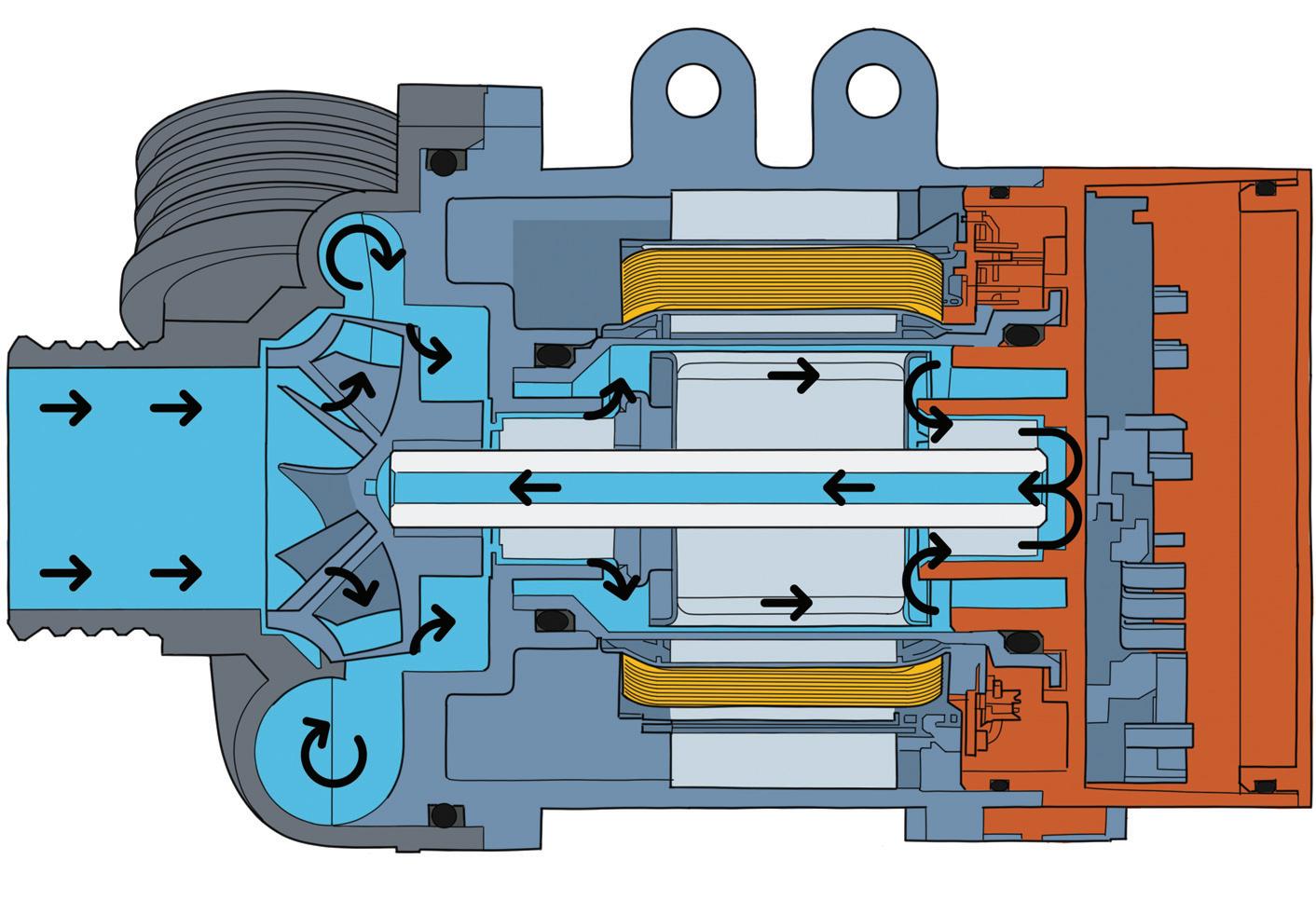

Electronically controlled and powered water pumps were introduced by BMW back in 2004. These have several advantages over the engine-driven pumps being used previously, as the electric water pump is totally controllable under all conditions. The advantages include:

Completely variable speed – the pump can run at any speed depending on what the ECU requests.

■ It can provide a low flow rate when the engine is cold to allow a faster warm-up.

■ It can provide a faster flow rate to cool a hot engine quickly.

The pump can run without the engine.

■ This allows the engine to cool evenly, reducing ‘hot spots’ in the engine

■ Especially useful for vehicles equipped with stop-start or on hybrid vehicles.

These advantages mean greater efficiency and help to reduce a vehicle’s emissions.

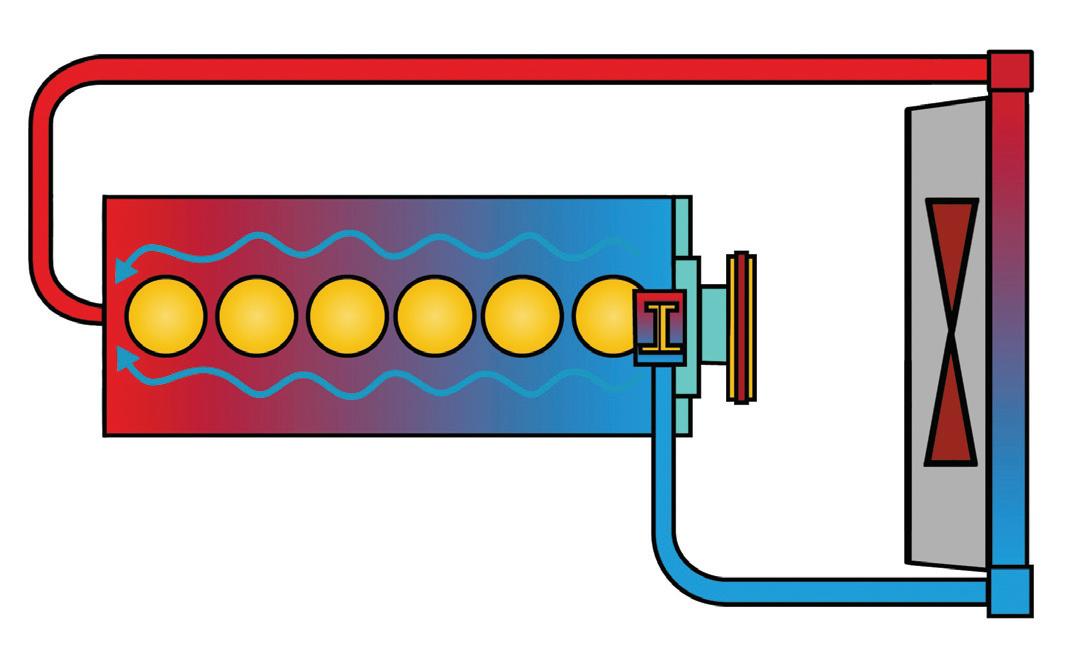

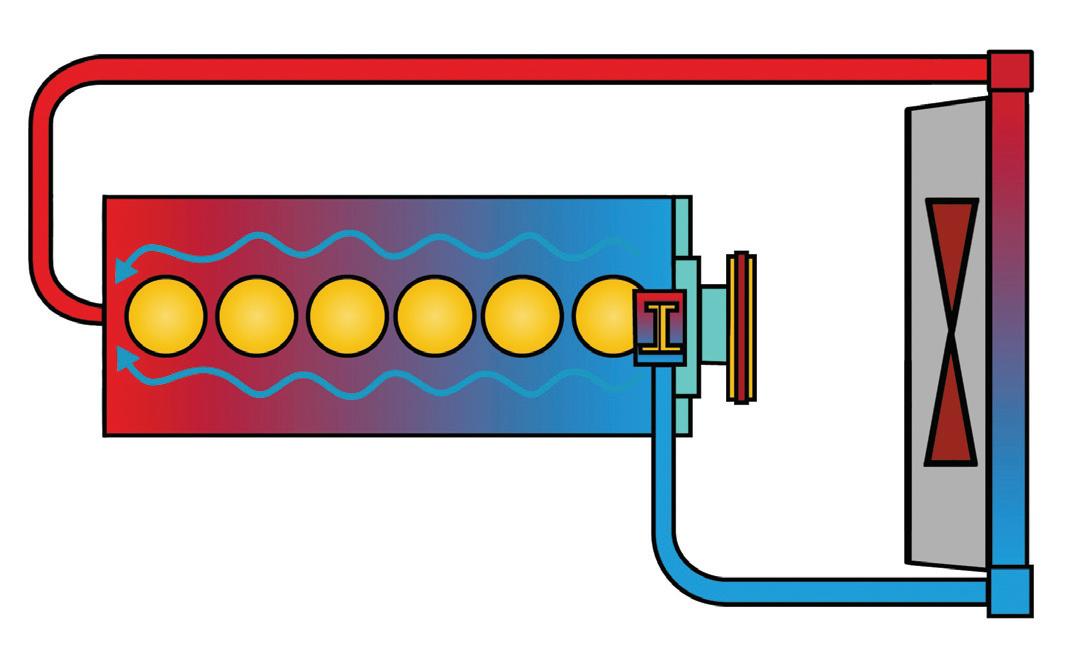

Another major advantage is that an electric pump can be positioned almost anywhere within the engine bay, allowing much greater flexibility and better use of space. The water inlet can be positioned on the side of the engine for cross-flow cooling which helps avoid ‘hot spots’ and provides more efficient cooling across all cylinders (Fig.1).

This is not possible with a belt driven water pump as it has to be positioned at one end of the engine, meaning the coolant is always circulated from one end to the other, resulting in some cylinders running hotter than others (Fig.2).

Intelligent water pump

The electric water pump is controlled by the engine management. It can determine the necessary cooling requirements by watching engine load, operating mode and the data

A/C & THERMAL MANAGEMENT 34 APRIL 2023 PMM

FIGURE

Basic function of an electronic water pump: The cylinder being evenly cooled.

FIGURE

Basic function of a belt-driven water pump: The cylinders are not uniformly cooled, some can run hot.

Cooling diagram

from the temperature sensors. With this information it can determine the correct coolant pump operation and speed, and send the corresponding instruction to the pump’s control unit.

The electric pump also has selfdiagnosing capabilities to aid with fault finding, with fault codes and live data available to read via the vehicle’s serial diagnostic port using a suitable tool. Data for speed, current and temperature can be found in the serial data to assist with diagnosis, as well as a function to actuate the pump to check whether it’s operating correctly.

Codes for incorrect pump speed, excessive temperature, over and under voltage, system blockage, coolant loss and air in the system are examples of the codes that can be generated.

The pump has a four wire connector: power, earth, Local Area Network (LAN) communication, and control from the engine management using pulse width modulation (PWM). The output of the wet-rotor brushless electric motor is controlled electronically by the electronic module, which is located under a cover in the water pump unit.

Maintenance tip

Care must be taken when carrying out maintenance (such as a coolant change) to ensure that the pump does not run dry. If the pump is removed and it is intended to be reused, it should be stored filled with coolant. If stored empty the pump could seize which would lead to overheating and potential engine damage. If the pump should ever become dry, the pump impeller should be turned by hand before connecting the coolant hoses to ensure it hasn’t seized. The system should then be immediately filled with coolant. Care should be taken during assembly to ensure that the electrical connector is clean and dry and that the connections are undamaged. When replacing or refitting the water pump the aluminium fixing bolts must be replaced and correctly tightened to the vehicle manufacturer’s specification.