PROFESSIONAL M OTOR M ECHANIC

ARE THE WINNERS OF THIS YEAR’S PMM AWARDS INSIDE...

Technically speaking…

GUIDES INSIDE ON FLAT BATTERIES, SPIN-ON OIL FILTERS & A FORD TRANSIT CUSTOM CLUTCH REPLACEMENT

TROUBLESHOOTERS SORTING OUT ISSUES WITH A VGA GROUP THROTTLE BODY, A PEUGEOT 108 USB SOCKET, A PEUGEOT 207’S ANTIPOLLUTION SYSTEM & A PORSCHE OIL SEPARATOR

INFORMATION PROVIDED ON IGNITION COILS, EMISSIONS SENSORS, E10 PETROL, EXHAUST BACK PRESSURE & AUXILIARY BELTS Also inside:

WHY YOU NEED TO PREPARE FOR CYBERCRIME NOW

Merry Christmas one and all! Although for the team at PMM, December really only means one thing… the PMM Awards! Every year we collect the statistics from across our various platforms, we put our heads together as a team and come up collectively with the top articles that have appeared in PMM over the previous year. It’s great fun and reconnects us with the contributors that make the magazine so great every month. Watch out on social media over the next few weeks as companies celebrate the good news. Elsewhere, we’ve got Laurence Abbott from Autotech Connect warning garages that they are not free from the threat of cybercrime (pg.32). And lastly, Matt Cleevely discusses that perennial issue garages face – the lingering suspicion of the backstreet garage. Head to page 31 to check that out. Have a nice time off this month, enjoy the brief rest and we’ll see you in 2025!

are now over 1.2

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Senior Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

UK £30 post paid

Air mail

£80 post paid

Europe £50 post paid

Printed by

PCP Telford

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF. Tel: Watford (01923) 237799 Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk Website: www.pmmonline.co.uk

Copyright © 2024

As the Chancellor Rachel Reeves announces a huge investment in public spending, funding it at least in part through increased National Insurance contributions from businesses including small, independent workshops – one thing is clear, it’s going to be tough times ahead for those garages which persist in a race to the bottom when it comes to charging customers.

There is much contained in the budget, announced on the day of writing, to raise a smile among our readers. The NHS will, finally, be getting the shot in the arm it’s needed for years –no longer will “waiting for a doctor’s appointment” be a good enough excuse for the apprentice not to show up until midday! Also, as much to my delight as to Kirsty’s (of Kirsty and Phil, of course) dismay, much of the money being used to properly fund the country is coming from private schoolers. About time, you might say. Lastly, there is a massive cash injection for housebuilding. Maybe that apprentice of yours will finally be able to move out of their mum’s house and buy their own flat, closer to the workshop.

But among the antidote, there is poison – strong enough, it may prove, to prove fatal to many workshops. According to a report by the IMI, the average wage among the 231,626 people employed under the umbrella of “Maintenance and Repair of Motor Vehicles” is £25,588. Currently, that employee would cost their employer £2,275 each year in National Insurance. Under the new plans however, which will see the threshold drop from £9,100 to £5,000 and the percentage rise from 13.8 to 15, that employee would cost £3,088, a rise of over £800. But, let’s take a look at technicians specifically, because that’s where it could really hurt. The IMI had the median advertised salary for a vehicle technician in 2023 as £35,000. In 2023, that technician would cost £3,574 in NI contributions. That tech in 2025? £4,500. Almost a grand extra. That’s a lot extra to have to pay per technician. A garage with three technicians will now be paying, on average, £13,500 in NI contributions for them, and that’s to say nothing of the reception staff, management, rents, rates and all the other costs associated with running a small business.

As all other costs continue to rise, the fact that the DVSA refuses to raise the maximum cost of the MOT from £54.85 is starting to feel like a slap in the face. With inflation, and this according to MOTester.co.uk, that figure, which has been frozen since 2010, should now have been inflated to £87.76. So essentially you are losing 30 quid every time you do an MOT test. When you consider the hour of a tester’s time it takes to do perform the test, the ongoing calibration and renewal of the equipment, the annual training and assessment, the space taken up in the workshop, the bills, etc etc, it’s not hard to see that raising the MOT price would be an easy, uncontroversial way to at least begin balancing out the scales for hard-pressed garages.

But, as many have pointed out to me over the years, garages are often their own worst enemy. You might think you’re doing your customers a service by swallowing these extra costs, but if you go out of business or all your top technicians leave for better paid roles in the garage down the road, don’t scratch your head and wonder what you could have done differently.

KieranNee Editor

■ SURGE REPORTED IN SERVICE AND REPAIR DISPUTES The Motor Ombudsman has reported a rie of 18 per cent in its service and repair complaints in the third quarter of 2024. The most common source of complaints contained issues with drivetains.

■ SCHAEFFLER REDESIGNS ONECODE It is hoped the redesign will ensure technicians will be able to see the code before making a repair, making it easier to access all the associated product-specific information on the REPXPERT garage portal.

■ DELPHI NAMED DIAGNOSTIC MANUFACTURER OF THE YEAR This was at the Auto Trae Awards held in Dublin, underscoring the company’s commitment to delivering diagnostic solutions for the evolving workshop.

■ CASTROL LAUNCHES CAMPAIGN AS PART OF 125 TH ANNIVERSARY As part of the oil company’s ‘Onward, Upward, Forward’ strategy, the company is offering one lucky workshop employee and one workshop customer a PalmerSport track day experience.

■ DRAPER INSPIRES THE FUTURE OF THE INDUSTRY Draper and successful BTCC team EXCELR8 Motorsport kicked off the new academic year by meeting hundreds of apprentices and aspiring mechanics and engineers on a tour of several educational facilities.

The Government is launching a national awareness campaign, ‘Fake Always Breaks’ about the dangers of buying counterfeit car parts, including wheels, airbags and brakes that can leave cars unsafe.

The fake parts campaign by the Government’s Intellectual Property Office is being backed by both the IGA and the IAAF which want garages as well as consumers to be alert for counterfeits.

The IPO fears the issue is ‘widespread’ as it commissioned a survey of almost 1,400 motorists and found one in six believed they had purchased a counterfeit part in the past 12 months, many of which did so to save money.

Many of the most purchased fake car parts

The debate over whether classic cars should undergo annual MOT tests has resurfaced, with calls for an end to the current exemption. While historic vehicles over 40 years old are currently exempt, some argue that annual safety checks are essential to ensure roadworthiness.

Derek Matthewson, host of the TV series Bangers and Cash believes that while the exemption was initially reasonable, older cars still require regular safety checks. He advocates for a basic MOT-style inspection

in the UK pose significant safety concerns if faulty, including car batteries (bought by 25 per cent of motorists who admit to buying counterfeit parts), tyres/wheels (23 per cent) and windscreen wipers (19 per cent).

Worryingly, 14 per cent of motorists who have purchased fake car parts bought counterfeit airbags, while over a tenth (12 per cent) have bought fake brake pads or discs.

The campain emphasises that counterfeit parts are often made from inferior materials and lack proper safety tesing, increasing the risk of failure, leading to serious accidents.

Drivers or workshops who suspect they have purchased counterfeit parts are urged to report the seller to crimestoppers.

focusing on brakes, lights, steering and suspension. Data from the DVSA supports this argument. In 2023, 48,848 classic car owners voluntarily tested their vehicles. Of those, 7,831 failed and 3,018 had at least one “dangerous” defect.

While the current rolling exemption is satisfactory for many classic car owners, there is a growing consensus that annual safety checks would provide an extra layer of assurance regarding the roadworthiness of these vehicles.

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

The Driver and Vehicle Agency says it’s currently on target to improve the average MOT waiting time in Northern Ireland to six weeks or less by next March. That's despite news that the longawaited opening of a new MOT centre is facing further delays.

The Hydebank facility, which was originally due to open in 2022, may now not begin operating until mid-2025 at the earliest. The new test centre was originally granted planning permission in 2019 with a

planned completion date of 2022. This was then pushed back to March 2023 and later to the end of last year.

Bosses from 13 major manufacturers have written to the Chancellor pleading for a fresh wave of electric vehicle incentives to boost floundering sales.

In a letter to Rachel Reeves, the Society of Motor Manufacturers and Traders and a host of car firms, including BMW, Ford, Toyota and Volkswagen, said government targets are putting too much pressure on the industry at a time when EV demand is

wavering. That’s despite September being the second-best month for EV sales on record.

However, as one electric car lobby group Electric Vehicles UK pointed out, registrations figures had downplayed the level of private demand for battery cars. The problem lies with how registrations are grouped into ‘private’, ‘fleet’ and ‘business’ sales –the three types of vehicle sales recorded by the SMMT. Therefore, is this incentive needed?

80 %

of motorists back new driving assessments for the over-60s according to Startline Used Car tracker.

Furthermore, 59 per cent say it will help older drivers check if they are still safe on the road, and 47 per cent claim they’d happily take the test.

30 %

increase in mental health problems among workers in the motoring industry has been reported by money.co.uk business insurance, analysing government data. This makes the industry the third most affected sector overall.

24 %

of all MOT bookings are made during September and October according o analysis from BookMyGarage. This is largely due to the impact of new car registrations and the aftermath of the MOT extension from 2020.

20 %

The amount of growth motor factor GSF is reporting, with the potential for 40 more branches.

■ After a successful show in Surrey last month, Mechanex-PMM

Live is heading back up toHarrogate on the 15th and 16th of May 2025. The event is free to attend (and so are the bacon rolls!), so scan the QR code to register now.

■ The IAAF Annual conference is taking place on Thursday 5th of December at the DoubleTree Hilton in Milton Keynes. The ‘Everyday Leader’ theme reflects that everyone in the automotive industry has a role to play in positively influencing others to raise standards. In the evening, the awards dinner will feature comedian Dara O’Briain as the headline entertainer.

■ The Ben Ball is happening on Wednesday 11th of December at Old Billingsgate Market in London. The Great Gatsby-themed event is the perfect opportunity to network and support the industry’s largest charity.

In a bid to attract more staff, one garage, JP D’Arcy Car Care and Performance, is now offering its employees the opportunity to work their 40hour week across just four days. This comes after the idea was promoted on the PMM Podcast.

The garage’s co-owner, JP D’Arcy, told us the new arrangement has benefitted both the business and its employees. In fact, the two most recent hires were drawn to the garage because of the flexibility and worklife balance on offer.

None of it would have come to light he explained, had he not attended an Andy Savva business course. Savva is a key proponent of the four day week in the automotive aftermarket, as evidenced by his recent appearance on the PMM Podcast. Also helpful to the success of the garage’s

new system was a chance meeting with Jim Lang from Garage Services Online. JP said after the website rebrand that provided to the by Garage Services Online:

“The increase in productivity and profitability gave me the security and confidence to think differently about staffing issues. We put the four-day week into place, and it’s been another game-changer. Staff either work Monday to Thursday, or Tuesday to Friday.”

He continued: “Not only do employees love the longer day and shorter week, but it’s also facilitated an increase in opening hours. We open at 7am which works better for customers dropping their vehicle before work. Productivity has increased massively. I don’t know of any other independent garage working this way.”

Ecobat Battery is reminding readers of PMM of the importance of discovering the root cause of a problem before proceeding with a replacement.

s workshops are very aware, many of the problems that vehicles are brought to them to resolve, are very often caused by faults with other components or glitches within systems, so it’s these underlying issues that need to be discovered and subsequently put right, before technicians are able to successfully complete a repair.

Although diagnosis of this kind is accepted to be a necessary part of the job for many repairs, battery-related analysis is still very often overlooked and a faulty or discharged battery simply swapped, without any proactive consideration as to why it might have failed. While replacement might fix the immediate problem, failure to understand why it failed may mean that simply replacing the battery merely provides a temporary fix, after which, the fault will return.

Irrespective of the powertrain, a 12-volt battery is almost always at the heart of a

vehicle’s electrical system, powering many of its related functions, but, in common with every other component, they have a natural service life, after which their performance will deteriorate and eventually they will fail. However, Ecobat Battery, the UK’s largest battery distributor, is encouraging technicians to be inquisitive and ask themselves why the battery is discharged, for example, and follow a simple step-by-step guide to make sure that battery replacement is a first-time fix, not an ongoing saga.

As it is likely that the vehicle will be brought in by the driver themselves, start by asking how regularly it is driven, typically for how long and what type of journeys does it generally take, around town or on the open road, for example. This will reveal whether the battery should be getting a decent amount of charge on a regular basis, or if it is usually using more power starting the engine, than it gets back from the alternator.

Assuming the initial problem is reported as a ‘flat battery’, instead of just checking the voltage, which is likely to be around 12-volts (the rate that constitutes a fully discharged battery), the battery should be charged and its state of health (SOH) tested to find out whether it can still hold a charge. If it can, it is a good indication that there is another underlying issue that is causing the battery to discharge, rather than it just reaching the end of its life. Also, consider its age, because under normal circumstances, even a reasonable quality battery should last two or three years.

If the SOH is okay, then begin with the obvious things such as the condition of, and how secure, are the battery cables and terminal clamps, and whether there is any corrosion evident, because any of these factors could be impeding the charging process.

If everything there is in order, then it could be a problem with the alternator that is affecting its charging performance. So, it should be tested to assess whether it is operating to the vehicle manufacturer’s specifications.

Parasitic drains are a persistent problem, so look for any aftermarket additions, such as alarm systems or daytime running lights etc. that might not have been installed correctly, or for simple issues like the light in the boot, glove box or under the bonnet staying on.

In more modern vehicles, updates to apps can be the cause of considerable electrical demand and combined with a vehicle that has been used infrequently or only for multiple

short journeys, this could bring the battery’s state of charge to a potentially problematically low level.

If none of these potential issues can be identified as the cause of the battery problem and its SOH is found to be low, then its replacement is unavoidable, but even in this instance, questions should be asked and procedures followed.

“Parasitic drains are a persistent problem, so look for any aftermarket additions, such as alarm systems or daytime running lights etc. that might not have been installed correctly.”

First, rather than simply replacing it with an equivalent battery, make sure it matches the VM’s specification for the make and model by using a resource such as the Ecobat Battery battery finder. The only normal exceptions to this rule are if the vehicle covers an unusually low annual mileage, or is fitted with additional, non-original electrical equipment, both of which could mean it requires a higher capacity battery. In these instances, consulting with a battery expert, such as Ecobat Battery, is crucial.

Second, after the correct battery has been identified, workshops need to offer the most suitable option for their customers’ needs, which might vary depending on their annual mileage or the distance of their typical

journeys etc. and could therefore make a difference in the battery technology to go for – SLI, EFB or AGM, as examples. Once this has been established, it is always wise to encourage them to opt for the best quality replacement for such an important component, as they won’t want to experience the same issue again.

Third, make sure the replacement battery is fully charged before its installation, as missing this simple step can have serious repercussions, particularly if the customer doesn’t use their car regularly, or uses it only for short journeys.

Finally, ensure the battery is securely mounted in its tray, with the appropriate clamps to hold it in its correct position. Problems here could indicate the battery isn’t of the correct size or specification, which emphasises the need for the first step to be properly followed. In addition, to prevent any possible electrical short circuit, attach the positive cable to the terminal first, then the negative cable (clearly, the reverse procedure applies when disconnecting the battery).

ALLDATA Europe walks technicians through an issue affecting a 2015 Porsche 981 Cayman S.

ALLDATA Repair, a single, easyto-navigate information portal that allows independent workshops and bodyshop professionals to gain instant access to genuine repair and maintenance instructions from 41 VMs. The repair info centre service is a crucial cog in the operation; its qualified and experienced technical support specialists can receive and answer requests within four hours – but will often respond quicker.

Check out our Q&A with the head team at ALLDATA on PMMOnline

In this recent example, the ALLDATA repair info centre service team tackled a problem on a 2015 Porsche 981 Cayman S. The owner of the car was experiencing a “strange noise” emanating from the engine compartment whilst driving – they described it as a “high-frequency, pulsating” noise. After various checks and road tests were carried out, there was no obvious reason for it or where it was being generated from.

The ALLDATA team had encountered this issue before. The cause of the noise is from the vehicle’s oil separator. If there is an excessive spring force tolerance from within the oil separator, it can cause that “highfrequency, pulsating” noise. The solution is to first check the part number of the separator on the vehicle; if this is ‘9A1.107.042.01’, the part will need to be replaced with a later, modified one. Once fitted, the issue should be solved. TO SIGN UP TO A FREE TRIAL WITH ALLDATA simply scan the

In this month’s Schaeffler LuK clutch feature, REPXPERT Alistair Mason is replacing the clutch on a 2006 1.5 TDCi Ford Transit Connect that has covered just over 51,000 miles. The customer has reported that the clutch has “slipped” on a couple of occasions.

VEHICLE INFORMATION

Make: Ford

Model: Transit Connect

Year: 2006

possible wear to the dual mass flywheel. A short road test concluded that the clutch had reached the end of its service life. The customer was advised clutch replacement is required and that the DMF would be inspected at the same time. Authorisation was given for the repair, parts were ordered in and technical bulletins were checked using Schaeffler’s REPXPERT app.

With the vehicle placed on the lift, open the bonnet and remove the following items: engine cover, air filter assembly, battery cover, battery, DPF senser (Fig.1). Unclip the battery wiring loom from the battery tray, remove the battery tray and its retaining bracket. This now gives good access to the top of the gearbox.

Engine: 1.5 TDCi

Mileage: 51,000

Scheduled Time: 4.2 hours

Disconnect the reverse light switch and the gear recognition switch multiplugs, disconnect the gearchange cables and earth strap.

Clamp the hydraulic clutch pipe and disconnect from the hydraulic concentric slave cylinder (CSC). Remove the top bell housing bolts and the starter motor bolts.

Raise the vehicle lift to gain access to the underside. Remove the undertray and drain the gearbox oil. Whilst draining, lower the vehicle lift to waist height and remove the N/S/F and O/S/F wheels.

Next, remove the N/S/F hub nut and both bottom ball joint pinch bolts. Lever down on the bottom arms to disconnect the ball joint from the hub assembly.

Raise the vehicle lift and lever the N/S driveshaft out of the gearbox, removing it from the vehicle. On the O/S driveshaft, remove the centre bearing clamp (Fig.2) and ease the O/S hub assembly outwards. This will draw the driveshaft out of the gearbox. Prop the hub assembly in the outwards position to hold the driveshaft out of the gearbox, refit the oil drain plug and tighten to the manufacturer’s specification.

Remove the gearbox lower pendulum mounting (Fig.3). Remove the lower bell housing bolts and starter motor bolt, remembering to leave two easily accessible bolts to support the gearbox.

Remove the front subframe to front panel brace bar. Support the gearbox with a transmission jack and remove the gearbox mounting before, slightly, lowering the engine and gearbox to aid removal.

With the engine and gearbox supported, remove the final bellhousing bolts to ease the gearbox off the engine alignment dowels. Draw the gearbox far enough back so the gearbox input shaft is clear of the clutch. Once clear, lower the transmission jack and remove the gearbox from the vehicle.

With the gearbox removed, remove the six clutch pressure plate bolts. Remove the clutch pressure plate and clutch plate. At this point clutch slip was evident due to the “bluing” on the pressure plate and DMF surfaces. The clutch plate was worn close to the lining rivets. Rotational free play was evident on the DMF and, with the presence of the “bluing” (excess heat) (Fig.4), DMF replacement was advised and authorised. Remove the DMF, checking for any leaks on the back of the engine, rectifying if required. Clean the back of the engine with a clutch and brake dust cleaner (Fig.5).

Mount the new DMF onto the crankshaft. Insert the new DMF bolts and tighten to the manufacturer’s specification.

Finally, degrease the DMF face with clutch and brake dust cleaner. Remove all the clutch dust from the bell housing using brake and clutch dust cleaner, remove the old concentric slave cylinder and ensure the mounting surface for the new CSC is clean.

When fitting the new CSC, do not squeeze the cylinder as this can cause internal damage and when fitting it to the gearbox. Take care not to damage the gearbox input shaft seal located in the new CSC and, once in position, fit the new bolts and torque to the manufacturer’s specification.

Smear a small amount of high melting point grease on the splines of the input shaft and slide the new clutch plate onto the input shaft. This will evenly distribute the grease on the splines and also ensure the spline fitment is correct. Remove the clutch plate and wipe off any excess grease.

The new clutch we are fitting is a different design in self-adjusting clutches. Known as a travel adjusting clutch (TAC), it can be identified by the square sprung steel plate controlling the adjuster wheel (Fig.6).

Note: It is strongly advised, when mounting a self-adjusting clutch, to use the self-adjusting clutch mounting tool. Mount the clutch plate on the flywheel using a clutch plate alignment tool and ensure the clutch plate is fitted correctly with “gearbox side” (or “Getriebe Seite”: German for

gearbox side) stamped in the centre of the clutch plate is facing outwards.

Locate the clutch pressure plate/cover and install into position correctly with the selfadjusting clutch tool (Fig.7). Once in position, secure with three bolts. Remove the self-adjusting clutch tool and fit the remaining three bolts, then torque to the manufacturer’s specification.

Before re-fitting the gearbox, it is always best practice to flush/change the clutch hydraulic fluid. This is done by simply placing a drain tray under the clutch pipe, removing the clamp and allowing the fluid to drain out. As the fluid is draining, top up the reservoir as required until clean/new fluid is flowing through and then re-clamp. This will ensure that the new CSC and rubber seal will not become contaminated.

Check that the alignment dowels are located correctly in the engine block. Re-fit the gearbox, taking time to ensure correct alignment and angle is achieved during installation. Once located on the dowels, refit in reverse order of removal.

Once the gearbox is bolted to the engine and secured on the mounting, install the hydraulic clutch pipe and bleed the clutch as it is easily accessible. When the drive shafts have been fitted, remember to replace the gearbox oil with the correct quantity and specification of oil. After battery installation, reset electrical systems and control units as required.

Technicians can benefit from Comline’s technical nous and comprehensive portfolio by learning about the technology inside its spin-on oil filters and absorbing some useful fitting advice.

In this latest article by Comline, PMM readers will gain a deeper understanding of the technology behind oil filters as well as some of the common oil filter fitting errors and how to put them right.

Oil filters play an integral role in maintaining engine performance and longevity as they remove contaminants from engine oil. There are several types of oil filters, all designed for specific tasks and applications. These include spin-on, cartridge, magnetic, centrifugal, synthetic and bypass. Here, we are focusing on spin-on oil filters: The most common type of oil filter, typically used in passenger cars and consisting of a metal canister with an internal filter element. The filters screw directly into the engine block and, of course, filter engine oil as it circulates through the engine.

Comline points out there are three valve types that are prevalent with spin-on filters: anti-drainback, bypass and anti-syphon valves. Each plays an important role and

work together to ensure efficient oil flow, filter functionality and engine health. These are explored in more detail below:

Anti-drainback: Found on the ‘dirty side’ of the filter, this valve prevents oil from draining back into the engine when it is switched off. This valve is particularly important for applications where the filter is installed on the side or top of the engine. Without it, oil would simply flow out of the filter and leave the engine unprotected at start-up.

Bypass: Acting as a safety feature, the bypass valve comes into play when a filter becomes blocked – whether that’s due to dense oil from cold starts or a delayed filter change. When clogging occurs, pressure builds up on the dirty side of the filter. This prompts the bypass valve to open and unfiltered oil to flow, which is preferable to starving the engine of oil altogether. Without it, the engine would be exposed to potential failure.

Anti-syphon: Located on the ‘clean side’ of the filter, this valve stops clean oil from flowing back into the engine when it is switched off. This valve also retains a small ‘reservoir’ of oil inside the filter, which means quicker lubrication after ignition. By maintaining this reservoir, the engine wear during start-up is significantly reduced, which increases the protection of critical components.

In addition to these three valves, Comline filters incorporate several other design features, including perforated centre tubes to help oil flow, robust housings and nitrile butadiene rubber (NBR) gaskets for flexibility and durability in harsh conditions. These characteristics mean Comline filtration meets OE-matching standards.

The quality of a filter must be matched by the accuracy of the installation. Here, Comline points out some common pitfalls and explains how to avoid them during installation:

Overtightening: Comline recommends that technicians ‘hand-tighten’ oil filters during installation. The best method is to twist the filter until the gasket contacts the vehicle, then add a quarter turn. Using a removal tool to tighten risks issues with removal down the line, plus it can also damage the filter’s protective coating. The latter can lead to corrosion and early failure.

Cross-threading: This occurs when the filter is not aligned with its housing, leading to poor gasket contact, an insecure seal and the potential for leaks. All of these issues can crop up later when the filter needs to be removed –and it makes the task more challenging during the next service. Comline urges technicians to take extra care when aligning the filter; doing so will mean better installation and a smoother removal process later on.

Always lubricate the gasket: Applying a small amount of oil to the gasket before installing the filter will help create a stronger seal and make the filter easier to remove during its next service. Comline recommends a fingertip’s worth of oil is all that’s required to sufficiently lubricate the gasket and install the filter correctly.

By following these simple but important instructions, technicians can ensure prompt and precise oil filter installation.

Consequently, customers will drive away with filters that will function correctly throughout the service life of the part.

Comline is committed to providing technicians with quality products and invaluable technical tips. In profiling the design features of its spin-on oil filters, and providing practical installation advice, technicians will be better-placed to service their customers and the vehicles on which they rely.

To download a technical bulletin about Comline’s spin-on filter valves

WWW.RDR.LINK/ABO004

To download a technical bulletin about Comline’s oil filter fitting guidelines

WWW.RDR.LINK/ABO005

Problem

Febi outlines a common issue with the throttle body on certain Audi, Seat, Skoda, Volkswagen and Mitsubishi models with 1.9 and 2.0 TDi engines. This relates to febi part 44945.

Engine management lamp illuminated, poor performance, increased engine temperature and/or engine shuddering during switch off. Fault codes logged relating to the throttle body, intake manifold flap and coolant fan motor.

Cause

The above symptoms can be caused by an excessive build-up of carbon deposits, failed throttle body drive components or a seized throttle plate. This results in a blown fuse which protects both the cooling fan and throttle body circuits.

Solution

Check and rectify all circuits relating to the faulty component and replace throttle body.

“The

above symptoms can be caused by an excessive build-up of carbon deposits, failed throttle body drive components or a seized throttle plate.”

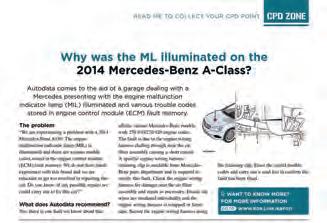

Autodata cuts through the noise for a garage struggling with one car whose snaps and crackles are drowning out the pop…

The problem:

“We are having difficulty diagnosing a crackling noise from the radio speakers when a mobile telephone is connected to the universal serial bus (USB) socket on a 2014 Peugeot 108. There are no trouble codes stored and we have visually checked the wires to the audio unit but have not found the cause of the fault. We are hesitant to replace any components in case a software update will fix the fault. Can you assist us?”

What does Autodata recommend?

Yes, we have come across this fault before and it affects all 108 models with a universal serial bus (USB) socket up to 10/05/17. The cause is likely to be due to an internal fault with the audio unit.

Remove the audio unit and then locate the identification label on the audio unit and check the version code. If the version code is not N, replace the audio unit with a modified version. This should rectify the fault.

FOR MORE INFORMATION simply scan the QR code

REDEEM YOUR CPD CREDIT

Congratulations, you have reached the end of the CPD Zone! To access your CPD credit from The CPD Group, scan the QR Code

Every month, the PMM team works tirelessly to produce a magazine that is informative, instructive and entertaining for our readers. It is important to us that you remain as engaged, whether that’s with our social media channels, our digital newsletter, tuning into the podcast or even reaching out to us on the telephone or dropping us an email. We love hearing what you think about the magazine – what you liked and what you think we could improve.

Over the past year we have featured some fantastic articles, if we do say so ourselves, contributed from a huge range of sources. Every year, we round up the best

ones and present the winners with that year’s PMM Award. As you can imagine, it’s no easy task! This year, we had a real struggle going through the articles we felt made the most impact and generated the most response among our readers. We weighed up the most popular articles on the e-newsletter each week, the most scanned QR codes, the most popular articles on our website and our social media platforms – in short, compiling this list now encompasses a wider range of media than ever before. Because of this, we are confident it represents every aspect of the automotive aftermarket, including the hottest and most contested topics.

You might be thinking “hold on, didn’t the monthly guide to Bosch’s KTS ESI[tronic] 2.0 diagnostics software feature in last year’s PMM Awards?” And you would be right, but it’s testament to both the length and enduring popularity that the series has made the cut yet again! The fourteen-part series finished up this year in last month’s magazine, but the most popular instalment covered the benefits available when evaluating the ‘actual values’ of a system. If you want to make ‘ESI’ work of diagnostics, make sure to look back over our CPD zone from the year!

WWW.RDR.LINK/ABO009

It’s like you’re there with him...

We would like to thank our readers who remain loyal and we hope you agree that this year’s PMM Awards represents the best selection of articles available within the aftermarket. We would also like to thank the many companies who supported us both editorially and commercially over the past year. Your support is what enables us to put together the best magazine we can each month, something our readers will no doubt thank you for as well.

For now, let’s celebrate what makes this fantastic industry what it is and raise a glass to the winners! Here, news and products editor Freya Coleman takes you through the past year.

One of the most popular articles on our website this year came courtesy of our always entertaining diagnostic troubleshooter Ben Johnson. In his January submission, tackling some fault codes on a BMW E90, the fault-finder turns sleuth and brings out his very best shakespearian language to evoke the feeling of despair and foreboding that accompanied the “pitiful soul” that was this particular E90. To tell you the truth, we don’t think he’s ever been the same since being haunted by this particular fault code’s “nonsensical dance”. We never imagined our diagnostic troubleshooters could be so emotive in their forlorn descriptions!

But it’s not just Ben’s pensive prose that keeps readers coming back to the edge of their seats, he also seems to know a thing or two about diagnosing difficult problems and dealing with difficult customers!

WWW.RDR.LINK/ABO 010

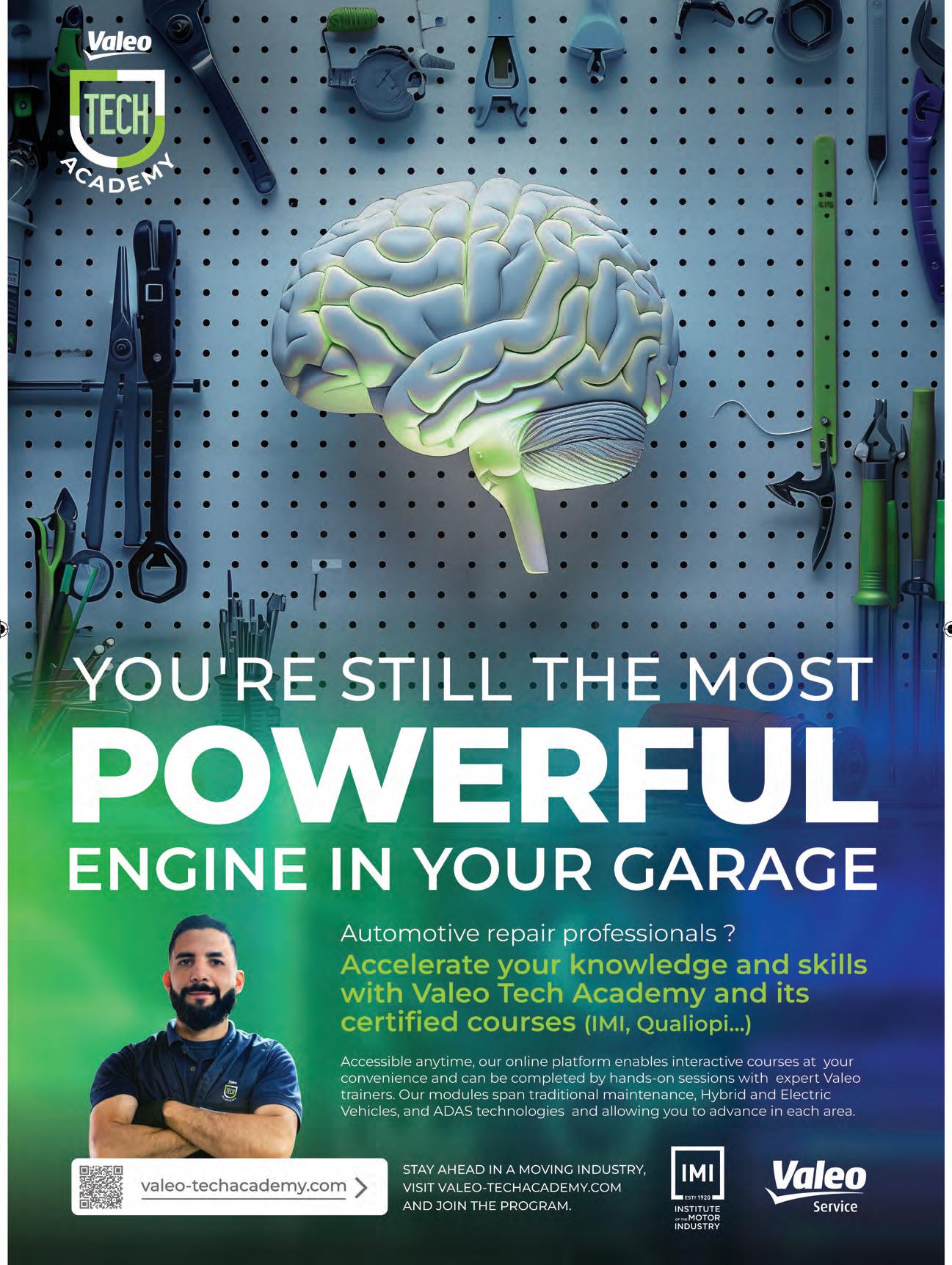

Next up is is Autodata with an article from the February issue of the magazine, if you can cast your mind back that far! Inside, the company comes to the aid of a garage dealing with a Mercedes presenting with the engine malfunction indicator lamp (MIL) illuminated and various trouble codes stored in the engine control module fault memory. At PMM, we pride ourselves on the technical content in the magazine, and the fact that we’ve been CPD accredited for well over a year now. One big contributor to the CPD zone this year was Autodata and this article was one of many offering common solutions to common problems so we wanted to honour this by including the company in this year’s winners.

WWW.RDR.LINK/ABO 011

The next winner of a PMM Award is Draper Tools, the brand behind bunker storage, sharing some excellent advice on how effective storage solutions can transform your work environment in an article from the November issue. Investing in a modular storage system can result in a streamlined workflow, leading to profits on saved time, a safe environment for employees to work in and improved employee wellbeing as disorganisation can lead to frustration. As Draper points out in the article “a cluttered workshop isn’t just an eyesore – it's a productivity killer.” Because afterall, clean workspace, clean mind!

WWW.RDR.LINK/ABO 012

Next up is another troubleshooter article, this time from remanufacturer and fuel systems specialist Carwood, examining a common fault on a VW Caddy. The vehicle came into the workshop with an engine warning light illuminated and the owner reporting long engine cranking, rough idling and exhaust smoke. Whilst these issues are typical of engine misfire, it’s never that simple and determining why is no easy feat. Inside, follow along from the very start of interrogating the vehicle’s fault code history, to performing a relearn plus everything in between. With the amount of detail this technical article goes in to when troubleshooting this common fault, it’s no wonder our readers loved it, and that it made this year’s list of winners. I’ve said it before and I’ll say it again, sharing diagnostic solutions is caring!

WWW.RDR.LINK/ABO

Another big contributor to our technical content this year was febi, and the most popular of these amongst our online readers was from the February issue, shining a light on a common cause behind not one, but three whole fault codes. The vehicle in question was experiencing a lack of power and poor performance when accelerating under load. The engine management warning lamp was also illuminated and a diagnostic tool revealed three fault codes involving particulate filter regeneration, air mass meter/malfunction and low air pressure.

The cause of this was constant hot and cold operating conditions under the bonnet causing the deterioration of the turbocharger intake hose. This led to the hose splitting, reducing the amount of boost the turbocharger could generate. The increased amount of unmetered air entering the combustion process causing the vehicle to experience a reduction in performance. And the solution? Well, you’ll have to head over to PMMonline to find out!

WWW.RDR.LINK/ABO 014

Two years ago we told you EVs are coming –and we weren’t wrong! Anyone who tells you EVs haven’t made their arrival yet must be living in a cave on Sark... Whether they’ll stick around for long or be replaced by hydrogen is another matter. Following his appearance on the PMMPodcast back in March we thought it would be a great idea to get Matt Cleevely to write a regular column all about EVs, from finding the right customers, to preparing for the rise of EV work and servicing and repairing EVs. The amount of heated Facebook comments under anything we post on electric vehicles proves that Matt is a worthy winner of a PMM Award. His work does a lot in dispelling myths around EVs and what goes into servicing them.

WWW.RDR.LINK/ABO 015

Technical articles on Land Rovers and Range Rovers always prove to be popular among our readers. Luckily for us, there is no shortage of problems for us to cover! This year’s most well-received Schaeffler clutch replacement saw REPXPERT Alistair Mason replacing the clutch on a 2014 Range Rover Evoque 4x4 fitted with a 2.2 D engine. This step-by-step guide covers everything from the workshop equipment you’ll need, to tips on removing the clutch assembly and flywheel, with helpful pictures to get you through and you don’t need to keep rewinding if you miss something –bonus! A special shout out also goes to Schaeffler for this particular article as it was the most viewed on the website this year, testament to the quality of this clutch clinic!

WWW.RDR.LINK/ABO 016

This next PMM Awards 2024 winner is Ring, with an article issuing advice for technicians surrounding lighting and batteries as the MOT season hits its peak. This article was actually an online exclusive and was posted on PMM online in early October to help workshops prepare for the influx of customers needing MOTs this time of year, hence its popularity among garage readers.

The advice inside includes Ring stressing the need to offer bulb alignment as a paid service, keeping a range of bulbs in stock in case replacement is needed and checking every battery entering the workshop despite this not being a requirement in the MOT.

WWW.RDR.LINK/ABO 017

When companies come to us with exciting ideas for articles, we usually jump at the chance to include it in the magazine. Enthusiasm is infectious, after all. So, when Morris Lubricants phoned us up and suggested taking a behind-thescenes look at their latest oils video series with Guy Martin, we couldn’t say no! Engine oil, as you all know, is no dry subject – if you know what to ask. Luckily, the team behind this series know exacly what you need to know.

In the article, Morris’ technology manger Adrian Hill joined Guy in his workshop to share some oils knowledge and dispel a myth or two on the way. This included a whole episode dedicated to antifreeze coolant and the role Moneothylene Glycol plays and the common misconception that electric vehicles don’t require any oil. With how colourful this article made the October issue, we were more than happy to include it in this year’s PMM Awards winners.

WWW.RDR.LINK/ABO 018

Whilst the industry and the general public at large has been getting itself into a tizzy about electrification, car makers and legislators have been busy quietly preparing for an autonomous future, starting with ADAS. What’s becoming clear is that modern vehicles containing features such as lane assist and automatic emergency braking aren’t being calibrated in independent garages as much as they should be. In fact, just last month we featured an IMI article revealing a dangerous shortfall in the number of technicians qualified to repair and maintain vehicles featuring ADAS. Currently, only 2 per cent of technicians are IMI TechSafe registered and qualified to work safely on servicing, repairing and maintaining these complex and potentially life-saving systems. But where is the best place to start when it comes to ADAS? Well, in our May issue Snap-on provided workshops with a comprehensive guide to achieving OEM-level calibration for ADAS systems. So comprehensive in fact that we dedicated three whole pages to it! It covers everything from steps to perfect calibration to preparing your workshop space. Therefore, we believe it to be a worthy winner!

WWW.RDR.LINK/ABO 019

If you want to see your favourite article on the 2025 list of winners, please reach out to me at fcoleman@hamerville.co.uk. Are you a fan of our technical articles, or do you prefer skipping to the back of the issue to read all about what new products are out? Either way, we’d love to hear from you.

Scan the QR codes below to keep up with the latest in the world of PMM, with our Newsletter, Instagram and Podcast.

Last but certainly not least we have an article from the VLS from the June issue of the magazine which brought our readers up to the speed on the latest lubricant investigations. If you didn’t already know, VLS was launched in 2013 by lubricant blenders and manufacturers and is an independent organisation providing a credible and trusted means to verify lubricant specifications, bringing transparency to the lubricant marketplace. On its 10th anniversary in 2023 the organisation received an influx of cases that have now been settled, so what a great time for them to update us all!

For example, a complaint that concerned a product’s low temperature properties and its compliance with SAE J306 viscosity standard. VLS independently procured a product sample within the UK and tested it for low temperature viscosity characteristics against ASTM D2983. The results indicated that the product was not compliant. The named party informed the VLS that they believe the issue was due to batch contamination, and since the sample was produced it had changed its procedures. VLS undertook a six-month review, during which a new sample was testing and found to be compliant – case closed! The positive work the VLS do in protecting workshops and making the lubricant industry a level playing field for all participants is a great note to end this year’s awards on, bravo!

WWW.RDR.LINK/ABO 020

PMM’s Freya Coleman spoke to East Coast College student and apprentice Tia Marsh about her experiences learning in the workplace. To listen to the episode on spotify or the platform of your choice, simply scan the QR code at the bottom of this page.

A lot of people potentially have the idea that you don't really have to work that hard when you study car repair. That is so wrong. Mechanics is such a heavy course. It's so involved. It's so technical. You have to learn so much in order to just do the basic job, really. And to then, to do your job at a basic

level, you have to have a good understanding of cars, but to do your job excellent, to a very high standard, you have to know so much because how can you fix something if you don't know how it works? And everything in a vehicle is so interlinked, the systems interlink so much, it's like looking at the human body.

How do you think the trade could attract more young people?

Before I knew anything about the trade, before I started as an apprentice, I think what would have made it more attractive is seeing that it is a potential job prospect because I didn’t. From school, growing up, there was

never any encouragement. On careers day, they have the police and the ambulance and the firefighters and all these funky people in uniforms. I don’t ever remember mechanics.

How have you found your apprenticeship so far?

I am very nearly finished. It has come in two halves: A fantastic, absolutely amazing on one hand and absolute hell on the other hand. In terms of being at college and the educational side of things, it’s been absolutely fantastic. I have felt so supported being at college. From the minute I walked into class, I was a nervous wreck because I was the only female and I didn't know anything about cars. But the college have supported me more than I could

have ever asked for.

The other side of it has been very challenging. It's been very emotionally draining. It's been very difficult and very painful. It's been a rollercoaster of emotions – some good, some heartbreaking. I've spent a lot of time soul-searching over the last three years and trying to change who I am to fit the job role and trying to decide if that is the right thing to do. I don’t know if it's me or if it’s the industry that is the problem.

TO LISTEN TO ALL OF THE EPISODES SO FAR ON THE PLATFORM OF YOUR CHOICE, SIMPLY SCAN THE QR CODE

DEAR PMM, IN RESPONSE TO A RECENT NEWS ARTICLE REGARDING THE IMI’S STATISTICS ON THE SHORTFALL OF ADASQUALIFIED TECHNICIANS, I HAVE A GOOD IDEA FOR YOU. WHY DON’T WE PAY MECHANICS DECENT MONEY. THAT WAY, THEY MIGHT CONSIDER BECOMING QUALIFIED!

Nick Knight

That would be nice, although as we discussed on a recent episode of the PMM Podcast, money really is only one aspect of the skills crisis. Something certainly needs to shift, however, when it comes to ADAS.

Dear PMM,

Dear editor,

I am the owner of a respected local garage and am well-known in my area. I service all the cars around, well most of them anyway. It’s been a job of a lifetime for me, and when I think about when I was young and got into the job I don’t have any regrets. In fact, it was the best thing I ever did. But now I’m getting old and my two sons aren’t bothered about the garage, which makes me a bit sad. A bit sad, because it’s something I always thought would stay in the family but I think I must say I can’t blame them actually. Because it’s a thankless task sometimes. But I’m not going to complain about it. You get out what you put in. That’s what I believe.

Gary G

Thank you for your letter, Gary. It can be hard coming to the end of your career when you are a small business owner. All good things come to an end, they say, and certainly most businesses don’t pass down the generations. Instead of your garage being taken on reluctantly by a family member, it’s great to think that it might be taken on by a young, keen enthusiast.

I want to say simply that it’s a shame there is no Mechanex show in the NorthWest anymore. That’s all.

Kenny S

Not quite the North-West, but we are coming back to Harrogate again, on 15-16th May next year. Hopefully we’ll see you there!

Write to us at pmm@hamerville.co.uk or send us a good old fashioned letter at PMM, Regal House, Regal Way, WD24 4YF.

“DEAR PMM, IN RESPONSE TO YOUR RECENT LONG READ ABOUT GARAGE SCHEMES, I WOULD LIKE TO SAY THAT THERE ARE SIMPLY TOO MANY “BADGES OF HONOUR” TO CONFUSE THE PUBLIC. SOME OF THEM DEPEND ON YOU BUYING GOODS, SOME ARE SIMPLY MONEY-MAKING RACKETS AND SOME CLAIM TO BE THE BEST EVER.

P Robbie

Certainly some are better than others, but I must add that whilst I agree there are too many and this creates confusion (as I wrote in my article), I don’t disagree with the idea of garage schemes. As a point in fact, I recently took my own car to a member of probably the largest and most reputable of all the schemes and received exactly the great service I was hoping for based off the strength of that brand – and I will certainly return. What will always be true, I guess, is that you trade off some of your independence for the benefit of belonging to something bigger and more recognisable.

AAK Auto Services’ Anthony Jhally gives his verdict on two tools from Hickleys.

Ant’s got his hands on the next generation of smoke testing machines, including low and high pressure: 0-20psi!

The swish American-made machine isn’t exactly light, but because it replaces more than one tool it ends up us a vital tool in your workshop’s arsenal. Ant and the lads have been using it every day.

Want more than just Ant’s word for it? Well it’s used by the vehicle manufacturers themselves when they’re testing vehicles rolling off the production line, so it’s got their seal of approval.

This lifting table now has adapters so independent workshops can remove the high voltage battery from EVs. Ant’s getting more of them coming through the door (like Matt says on page 31), so he’s finding that very helpful indeed

The controls are a bit easier to grasp than the Redline machine, basically there’s UP ...and there’s DOWN

Although it can reach up to two metres high, it can fold down to nearly half a metre, meaning it can be neatly stored away when not in use, which is a big bonus!

TO WATCH THESE VIDEOS AND THE OTHERS ON THE PMM YOUTUBE CHANNEL SIMPLY SCAN THE QR CODE

After much anticipation, finally the new Delphi Academy training centre has opened and it looks great, woohoo!

We were up to the world-famous town of Wrexham recently to see the greatest sight it has to offer. I’m talking about Brake Engineering’s remanufacturing site, of course...

From factory tours to conferences, check out how the PMM team has been keeping itself busy recently.

Putting the class in classic Kieran was up at Jaguar Land Rover recently and after half an hour circling the estate looking for the right building, finally found the Historic and Classic Vehicle Alliance’s members day, where MP Greg Smith extolled the virtues of keeping beloved classics going. …

At The Blend 2024, I had the pleasure of delivering part two of my "To EV or Not to EV" presentation, following up on last year’s session. Through a simple yet powerful exercise, I asked attendees to raise their hands if they had seen an increase in EV work in their garages over the past 12 months. The sight of hands shooting up across the room confirmed what we already knew: EVs are quickly becoming a key part of our daily business. This offered a realtime snapshot of the growing impact the expanding EV car parc is having.

in my own workshop, the shift has been striking. Just the other day, out of 11 MOTs, only two were ICE vehicles. This is a clear indicator of where the market is heading.

The rise of hybrid and electrified versions of top-selling cars, like the Ford Puma and Kia Sportage, reinforces this trend. With technological advancements, especially in battery efficiency and range, and the growing charging infrastructure, EVs are more appealing and practical than ever before.

Last year, I made the case that this shift is a huge opportunity for

independent workshops. This year, the evidence is undeniable. The challenge now lies in educating EV owners, many of whom mistakenly believe their vehicles require little maintenance.

As industry professionals, we must take the lead in educating motorists. This is a real opportunity for independent garages to shake off the outdated ‘back-street’ stereotype we’ve struggled with for years.

By offering proactive advice, stressing the importance of preventative maintenance, and showing how regular servicing can boost the lifespan and performance of EVs, we not only build trust with our customers but also secure our place in this growing market.

A significant change this year has been the rise in EV MOTs. Many EVs sold in 2021 are now reaching MOT age, and

FOR MORE INFORMATION ON MATT CLEEVELY simply scan the QR code

In an era where cybercrime stalks every digital interaction, it's alarmingly naive to assume that smaller businesses, including independent garages and workshops, are exempt from such threats. This is according to the managing director of Autotech Connect, Laurence Abbott.

While automotive dealer groups have been the focus of many reported cyberattacks, these are merely the tip of the iceberg. The assumption that independent garages can fly under the radar is not just misguided; it is potentially disastrous.

Recent statistics paint a sobering picture. The UK’s Cyber Security Breaches Survey 2024 revealed that half of all businesses experienced a cyberattack or breach in the past year. These aren't mere anomalies but part of an escalating threat landscape that demands serious attention.

Independent garages are particularly vulnerable. According to reports, 60 per cent of SMEs cease trading within six months of a cyber-attack.

Alarmingly, 81 per cent of UK businesses affected by cyberattacks fall into the SME category, and even more tellingly, 97 per cent of such incidents could have been averted with cybersecurity measures in place.

Cybercriminals are evolving faster than traditional defences can adapt. While computers remain a primary target, pre-installed antivirus software has made them less accessible to attackers. Instead, the real threat now lurks in everyday devices such as phones and tablets — gadgets integral to both our personal and professional lives that often

slip through the cracks of a business’s cyber defences.

Their ubiquitous presence, combined with a lack of robust security measures, makes them ideal entry points for malicious hackers. Consider this — your employees' mobile phones are used for a myriad of tasks from banking to business communications. Yet, they also represent a significant security gap. Cybercriminals exploit easy gateways like unsecured WiFi connections or third-party apps to infiltrate these devices. Once compromised, they can harvest sensitive information through chat messages, emails, or apps. Some employees have access to a garage’s social media pages or website, viewing and accessing these via their personal devices which increases the risk. Phishing attacks against an employee’s number or email can grant cybercriminals access to sensitive business information or even bypass twofactor authentication, allowing them to infiltrate more secure systems.

A garage owner might argue that their primary focus should be on securing the vehicles themselves. Modern vehicles, with over 100 control units each, present numerous potential access points for cyber-attacks. While this is undeniably critical, the broader attack surface extends beyond just the vehicles or even

the computers within the garage. It encompasses the entire connected ecosystem.

The automotive industry has reached an inflection point where cyber threats are no longer a distant concern but a present reality. For independent garages, this necessitates a comprehensive understanding of the entire cyber ecosystem. Every Wi-Fi network, every connected device, and every digital interface presents a vulnerability. Recognising these weak points is the first step toward safeguarding business operations.

Ultimately, the call to action for independent garage owners is clear. While installing antivirus software on devices is the first step towards creating a barrier against cyber intruders, they must consider every devise and touchpoint within their cyber ecosystem to understand the vulnerabilities. Staff also need to be educated on the potential risks and trained to identify a threat.

The consequences of inaction could be dire, affecting not just a garage’s bottom line but their hard-earned reputation.

By taking proactive measures now, they can protect their businesses from becoming another statistic in an increasingly connected world.

37 Engines’ start-stop cycles are putting strain on the ignition coil. Delphi explains what needs to be done when failure occurs.

38 Do you remember the batteries of the past? Well, given the lead acid battery goes back 150 years, probably not! Rotronics takes us on a journey from the past to the present.

41 Automechanika Frankfurt was the place to be this autumn, and Varta took the opportunity to paint the town… all sorts of colours, actually.

42 Ring is reminding readers of the importance of testing, charging and starting every vehicle battery.

45 Klarius explores the thorny topic of cheap parts.

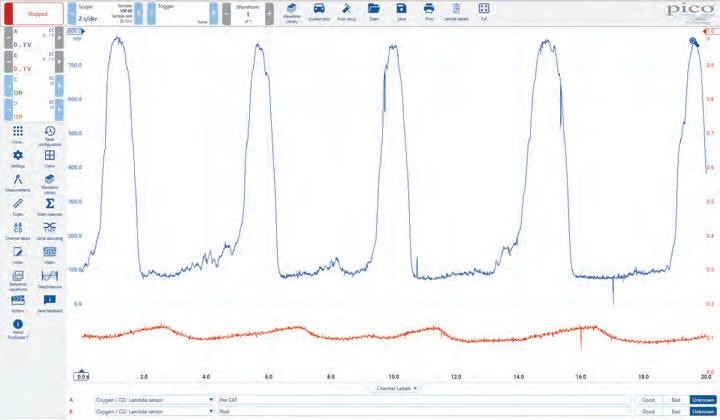

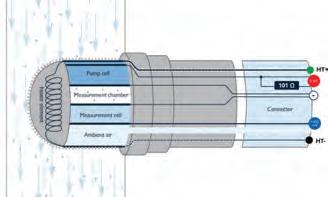

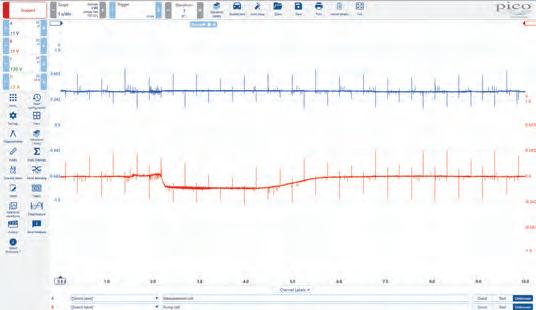

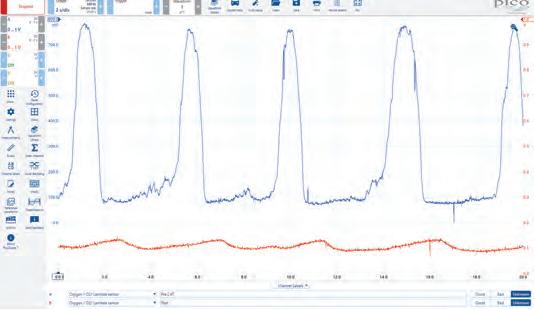

46 ICE emissions are monitored and controlled thanks to a series of sensors. Pico Technology explains how best to test these vital components.

48 A quirk in the anti-pollution system in the Peugeot 207 has had technicians scratching their heads for years. Here, ACTronics provides the answer.

49 Are E10 fuels more prone to holding water? Wynn’s investigates.

50 Sensor specialist NTK looks at engine management in the workshop.

51 EEC is helping technicians replacing exhausts.

52 Remanufactured turbochargers are now available from MS Motorservice

55 Are heavier electric vehicles affecting the way suspension is designed? Arnott explores.

56 How is braking technology evolving to meet the new needs of EVs? Brembo has the answer.

58 GYS discusses its mobile battery charging solution, perfect for EVs in the workshop.

59 Stock up your workshop with VDE-rated tools from Draper.

60 Febi takes a look at a key component in mild-hybrids.

In January, we’ve got Diagnostics & Engine Management, Oils, Lubricants & Additives and Winter Service & Lighting.

According to Delphi, the increased use of hybrid, startstop, and smaller engines by vehicle manufacturers to comply with strict emissions regulations has significantly increased the demands placed on ignition coils. The coils are required to generate up to 45,000 volts for efficient combustion and are expected to operate in larger temperature swings, with more highload start cycles, increased performance expectations and weight reductions.

“Ignition coils today deliver the high electrical loads of starting cycles far more frequently due to start-stop and hybrid engines,” Luke Garratt, technical services manager at Delphi, explains. “Short urban journeys can extend gaps and increase starting cycles further. Ignition coils still need to reliably deliver a strong spark, at the right time, to the right cylinder thousands of times per minute.”

Ignition coils are under more strain than ever. When failure happens, workshops need to know what to look out for and what to replace them with.

plug, distributor coil and distributorless coil types. As part of its commitment to providing complete workshop solutions for independent garages, Delphi’s Masters of Motion hub includes videos on replacing and testing ignition coils.

Ignition coils are designed for durability but

Damaged spark plugs or wires can cause the coil’s voltage to exceed 35,000 volts, damaging internal insulation and leading to misfires or starting issues.

■ Backfiring: Unburnt fuel in the exhaust causes backfiring, potentially damaging the exhaust system.

■ Stalling: Irregular current to spark plugs results in stalling or failure to restart.

■ Misfires: A weak coil causes engine misfires, especially during acceleration.

■ Starting problems: Insufficient spark affects start-up, potentially preventing the vehicle from starting altogether.

To diagnose a faulty ignition coil, start by reading fault codes and comparing live data from the suspected coil with a known good one.

Every coil in the Delphi line is manufactured to exacting specifications according to the firm’s global OE experience. Construction uses high quality wiring, insulation and coatings, along with efficient windings. Vacuum production ensures air bubbles are removed from materials to prevent arcing or shorting. All Delphi ignition coils will additionally have been subjected to thousands of hours of testing before being released for sale to ensure they can withstand vibration, temperature swings and moisture over many years of use.

Multispark ignition coils have recently been developed by Delphi and will soon be made available to the aftermarket. They fire multiple sparks rather than a single spark on each cycle to burn fuel more efficiently.

Delphi’s UK and European range occupies a market-leading position, with 89 per cent of the car parc covered – and particular strength on hybrids. There are over 430 coils in range, comprising oil filled, cassette, pencil, coil on

■ A worn or widened spark plug gap also forces the coil to generate higher voltage, risking overload and overheating.

■ Vibration from the engine can damage coil windings or loosen connections, further straining the system.

■ Overheating from engine temperatures reduces its ability to conduct electricity.

■ Varying resistance within the coil can lead to system damage, while excessive moisture, such as from oil leaks or water, can degrade both the coil and spark plug.

Identifying and resolving these root causes is essential to prevent repeated coil failure.

A faulty ignition coil can cause several engine performance issues, including:

■ Check engine light: A malfunctioning coil triggers the light due to poor engine performance.

■ Poor fuel economy: Less spark energy leads to inefficient combustion, reducing fuel efficiency.

Inspect the coil for physical damage and check the spark plug and wire resistance. Use a multimeter to measure the coil’s voltage supply (above 10.5V) and test primary (0.4-2 ohms) and secondary (5,000-20,000 ohms) circuit resistance, following manufacturer specs.

A zero reading indicates a shorted coil, while a high reading suggests an open coil. For multi-wire coils, consult the wiring diagram for specific design details.

To replace an ignition coil, turn off the ignition and locate the faulty coil. Unplug the connector, remove the securing bolts, and lift the coil out.

Apply dielectric grease to the new coil’s foot and socket to prevent corrosion, then install it. Tighten bolts and reconnect the connector. It’s advisable to replace all spark plugs at this time.

Use a diagnostic tool to clear fault codes and reset the engine management light. Finally, perform a road test.

As cars continue to evolve rapidly, batteries are increasingly being recognised as the glue that holds everything together. Here, Rotronics gives an overview of how batteries have evolved to cope with increasing demands both from drivers and the manufacturers and explains how garages can capitalise on this change.

Lead-acid battery technology is 150 years old and still found in most vehicles on the road today. It’s gone through transformations over the years to increase stability and durability, which you see in batteries for today’s ICE vehicles. The first rechargeable battery for electric vehicles was invented by Thomas Edison in 1901 – a nickel-iron battery that could be charged twice as fast as a lead-acid battery. Of course, we know now that EVs were ahead of their time!

In the late 1990s, hybrid electric vehicles started gaining popularity with Toyota’s introduction of the Prius. This marked a significant development in the automotive industry, with manufacturers shifting their focus towards developing more efficient and sustainable vehicles.

“Some manufacturers are integrating lithium-ion batteries and new battery management systems to extend lifespan and performance.”

Since then, EV battery technology has undergone several transformations to improve power output, energy density, and overall performance. The use of various lithium-ion battery chemistries has become commonplace due to their high power-to-weight ratio and longer lifespan compared to traditional leadacid batteries. More recently, manufacturers have started experimenting with solid-state batteries, which promise even higher energy density and faster charging times.

The evolving technology inside

At the core of every electric vehicle is battery technology. It’s a critical component that stores and supplies the electrical energy necessary to run EVs, hybrid cars and traditional ICE models. Lithium-ion batteries are the mainstream choice for today’s electric vehicles. Renowned for high energy density and longevity, they represent a vast improvement over their predecessors. They’re the prevalent choice for EVs today.

However, they are not without their shortcomings including issues of thermal management and resource scarcity. For these reasons, manufacturers are continuously developing new methods to improve their performance and address these concerns.

Solid-state batteries promise higher energy density, faster charging times and improved safety. Still in the development stage, once commercially viable they could revolutionise battery propulsion and manufacturers are watching developments closely.

Graphene-based batteries are another technology, offering potentially huge improvements in conductivity and charge rates. They use compounds of graphene and other materials in the cathodes of lithiumsulphur cells. This could see batteries charged in minutes rather than hours. This technology is also still in its early stages.

While advanced batteries are generally associated with electric vehicles, innovations in traditional 12-volt car batteries are also ongoing. Enhanced flooded batteries (EFB) and absorbent glass mat (AGM) technologies have come to the forefront, offering greater durability and efficiency than standard lead-acid batteries.

EFB batteries are an evolution of the standard wet-flooded battery, designed to better support the stop-start technology commonly found in modern vehicles. This technology reduces the engine’s idle time, saving fuel and decreasing CO2 emissions, but it demands more from the battery. EFBs meet this need through improved charge acceptance and greater cyclic durability.

AGM batteries are known for their superior power and reliability. They feature a glass mat separator that holds the electrolyte solution between the battery plates, which allows the AGM battery to offer better electrical performance under high discharge and recharge cycles. AGM batteries are ideal for vehicles with heavy-load electrical demands and advanced power systems.

Some manufacturers are integrating lithium-ion batteries and new battery management systems to extend lifespan and performance. While these developments may not be as radical as those seen in EV batteries, they represent an important step in enhancing the functionality and efficiency of conventional automotive power systems.

In the EV area Rotronics sees a growing opportunity for workshops – every EV vehicle has a traditional 12V battery onboard, which is critical to the vehicle’s operation – the same proportion of EVs have 12V battery-related breakdowns as do traditional ICE vehicles. Servicing the 12V battery is an excellent ‘bridge’ into wider EV servicing. The Midtronics CPX900ROBISP tester performs not only the traditional cold cranking test but also a reserve capacity (RC) test – which demonstrates the ability of the battery to run electrical systems. An RC test on a 12V battery on a customer’s EV will identify the health of that battery and if it requires charging or replacement.

individually, avoiding the expense of replacing a full battery pack. For the pack to operate as designed, the voltage for replacement modules need to be balanced. Designed specifically for aftermarket use, the xMB9640 allows individual cell modules to be replaced avoiding expense of an entire pack. It supports major EV and hybrid manufacturer brands and will allow workshops to offer a simplified and safe high voltage.

The 12V battery still offers the workshop huge business potential. ‘Best practice’ is to test every vehicle that comes in, not just those with battery related issues. This proactive approach allows early identification of problems before they become major issues. Customers appreciate this level of service, and it enhances the workshop reputation for reliability and thoroughness. The Midtronics CPX900ROBISP tests battery cranking health and also reserve capacity (RC) giving the technician a complete picture of battery health and recommended actions.

The new Midtronics xMB9640 module balancer allows any workshop to diagnose and service EV and hybrid high voltage battery systems. High voltage packs are designed with smaller sections called modules that can be replaced

Crucially, the detailed printouts provided by the Midtronics CPX900ROBISP, and integration of test data within the Rotronics ROBIS online battery information portal. It delivers a comprehensive and accurate overview of the battery condition, supporting any workshop process. When customers see the clear report of their battery test supported with a quick ‘traffic light’ guide to the results of the criteria tested, they are more likely to understand the necessity of replacements or charging services. This builds trust and makes it easier for the workshop to explain the need for additional services.

At this year’s Automechanika in Frankfurt, VARTA announced the launch of its latest product portfolio.

ARTA Automotive’s new lineup is intended to help simplify the battery selection process and expand product offerings for growing market segments.

The new portfolio is organised by technology, making it easier for workshops to navigate the growing complexity of vehicle types. Each technology within the portfolio is now identified by a distinct label colour across all applications: SLI batteries (traditional flooded batteries; Starter, Lights, Ignition) are colour coded blue; EFB batteries (enhanced flooded battery) silver and AGM batteries (absorbent glass mat) feature a gold label. The new portfolio is a customer-focused solution that simplifies choices and saves valuable workshop time.

As the automotive industry rapidly evolves, new start-stop, hybrid and EV are presenting increased demands on their low voltage networks and batteries. To better serve these new vehicles VARTA has launched new EFB H9 and AGM H3 batteries. These new products aim to deliver superior performance in demanding conditions, to help ensure new vehicles operate efficiently and reliably.

Going off the grid doesn’t mean you don’t have to go without power or luxury amenities. VARTA’S new premium lithiumion (Li-Ion) battery range, designed to meet the growing demands of the leisure market, particularly in deep-cycle applications like caravanning and marine use. These batteries represent a significant leap forward in technology, offering up to twice the usable capacity and over 3,000 cycles, all while reducing weight by approximately 45 per cent compared to traditional lead-acid batteries. The new Li-Ion range is also equipped with advanced smart connectivity features, including Bluetooth and CAN bus communication, allowing users to monitor battery status in real-time and optimise performance across various applications.

Furthermore, these Li-Ion batteries are built to withstand harsh conditions, such as winter camping or exposure to wet and humid environments, with IP67 protection ensuring reliable operation even in extreme conditions. This launch underscores VARTA’s commitment to leading the market in innovation, providing customers with cutting-edge energy solutions that enhance their on-the-go lifestyles.

A recent €200 million investment by Clarios will increase AGM battery production in EMEA by 50 per cent by 2026. This effort will ensure workshops and consumers have access to the advanced batteries their startstop, hybrid and EV vehicles demand.

Ring is urging technicians to undertake the ‘holy trinity’ of battery support with every vehicle that enters the workshop: test, charge, start.

As the cold settles in, drivers will be looking at their battery and worrying about its health.

While batteries have to work harder in the cold, the damage to a battery is done in the summer months as the heat increases the chemical reaction within a battery, depleting its energy. This means it sends out a weaker charge and has a reduced capacity to crank in cold temperatures. The damage this heat causes to the battery can remain for months, meaning that when the weather turns colder, as now, it’s likely the battery will fail due to the previous effects the heat had on it.

To react to this inevitable demand, Ring Automotive is advising technicians to undertake the holy trinity of battery care –test, charge, start – but to do this, technicians need premium quality battery support units they can rely on, which is where Ring assists.

Ring has had a growing battery support range for 15 years and continues to develop and invest in its range with it growing to 21 references.

The first task a technician should undertake is testing the battery to see if there’s an issue. This should be done to every battery that enters a workshop, as it’s not always clear the battery is failing and technicians should be trying to prevent this before it happens.

Ring’s new battery analyser (RBAG950) can provide a complete health check of the battery and electrical systems in both 12V and 24V vehicles, including motorcycles, cars and vans. Suitable for 12V lead acid, AGM, EFB, gel and LiFePO4 lithium, as well as start/stop batteries, this multi-functional analyser is able to test the battery, alternator, starter and vehicle earth, via its intuitive graphical interface.

The first task a technician should undertake is testing the battery to see if there’s an issue. This should be done to every battery that enters a workshop.

The battery analyser test simply carries out a battery health check and gives the user a reading detailing the state of the battery, whereas the alternator test, for both normal and smart 12V/24V alternators, will detect battery charging problems by checking if the alternator voltages fall within normal operating ranges.

In a similar vein is the starter test for both 12V and 24V vehicles, which checks for potential starting problems by measuring battery voltage drop during engine cranking.