PMM

BAILCAST PROFILE

FOUR-PAGE TROUBLESHOOTER FROM BEN JOHNSON

AUTOMECHANIKA PREVIEW

DEALING WITH WASTE OIL

ENTER THE CPD ZONE!

YOU COULD EARN ONE CPD CREDIT THIS MONTH

Let’s get technical INSTALLATION TIPS ON CLUTCHES, BELTS & EGRS

BEST PRACTICE ADVICE ON DIAGNOSTICS, OILS & SUSPENSION

DO YOU WANT TO BE A SCHAEFFLER BONUS POINT MILLIONAIRE?

TOTHE TRADE

FREE

JUNE 2023

PROFESSIONAL M OTOR M ECHANIC

LETS

Looking for a step-by-step guide on an EGR replacement? Delphi Technologies is here to provide PMM readers with just that, courtesy of its Masters of Motion Hub.

Automechanika Birmingham is just around the corner, taking place at the NEC from the 6-8th of June. If you’re not already planning on going and need a little convincing, check out what’s on offer at the trade show such as the EV training academy. 46

GOOD TO BOOT

Get the lowdown on Bailcast, manufacturer of CV boots and a UK manufacturing success story as PMM’s Kieran Nee speaks to its sales manager Martin Calley.

67-69

Contents VOLUME 24 ISSUE 6 JUNE 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM JUNE 2023 3 45-55 STEERING & SUSPENSION 57-65 OILS, ADDITIVES & LUBRICANTS Regulars 6-10 NEWS & VIEWS 15-33 CPD ZONE 34-40 BUSINESS & TRAINING 42-43 SPECIAL REPORTS 70 PRODUCT SPOTLIGHT 71 MYTHBUSTERS 72 WHAT’S NEW? 74 PIT STOP Editor’s

Picks 24

GET

TECHNICAL

SHOW

38 AUTOMECHANIKA

PREVIEW

DIAGNOSTICS

& ENGINE MANAGEMENT

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

1 year (11 issues) £50

Airmail 1 year (11 issues) £65

Printed by Walstead Peterborough

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk

Website: www.pmmonline.co.uk

Facebook: /ProfessionalMotorMechanic Twitter: @pmmmagazine Copyright © 2023

P

Ispoke to Garage Industry Trends’ Alex Lindley recently for an episode of the PMM Podcast to discuss the MOT data they’d collated and recently released for the industry to check out for free. Alex, who was kind enough to come down to our studio for the chat, runs a workshop himself as well as a garage management software solution, so he’s not exactly a disinterested observer of the aftermarket; rather, he has a very real desire to see workshops become more successful.

The morning Alex visited, he announced that the fall in forward bookings he had been expecting had started and that in a few weeks’ time there would be a fall in booked in jobs. He could predict this (and it happened exactly as he described it) using data alone.

‘‘

Knowing, or being able to accurately predict, what’s coming down the line is a major help for businesses of all sizes.”

Someone else I spoke to recently for the podcast, Ross Crook, an area workshop manager for the NHS, explained that one of the big advantages of servicing a fleet of vehicles over running an independent workshop was that he knew exactly what vehicles needed to be serviced at any point in the year.

Knowing, or being able to accurately predict, what’s coming down the line is a major help for businesses of all sizes. Unfortunately it is more easily achieved by larger businesses, such as the main dealers, than smaller, independent workshops – but that’s not to say it’s impossible. Using the tools at your disposal, such as Garage Industry Trends, adds an extra weapon to your arsenal. Imagine the advantages offered by knowing what jobs are coming a few weeks down the line. If you knew a quiet period was coming up, you could sign up to some training courses or take some annual leave, or indeed you could start telling customers they can bring their cars in sooner than you normally would. Alternatively, if you know a busy period is coming up, you can start spacing out the incoming bookings, which might mean you end up not having to turn anyone away – no one wants to have to turn customers away because they are fully booked for the next two weeks with nothing else lined up for week three.

Planning ahead Kieran Nee

Editor

PODCAST

VIEWPOINT

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available:

MM

JOIN M E EACH M ONTH ON THE

p.68 ©AdobeStock/cat_027 (Maverick)

PMM NEWS with

NEWSIN BRIEF

■ NGK BECOMES NITERRA The spark plugs company has officially changed the name of its UK operations to Niterra combining the Latin words ‘niteo’ meaning ‘shine’ and ‘terra’ meaning ‘earth’ to reflect its future strategy. Despite the new signage, the Japanese firm says customers should expect the same quality components.

■ GARAGES SEEK COST-SAVING GUIDANCE The IGA has revealed that garages are turning to them for guidance on how to reduce costs and manage their suppliers due to cost of living being on the rise.

■ BATTERY TRAINING PARTNERSHIP With battery technology continuing to develop at pace, GS Yuasa has announced a partnership with the IMI to run an online battery training platform to keep up with modern vehicles.

■ HOURLY RATES ‘What Car?’ has compared the hourly rates of 279 garages and the figures showed that rates can differ by more than £50 an hour, even with garages just a mile apart.

■ CAR PARK CHECKS Civil and structural engineer Chris Whapples has told The Telegraph that the rise in the number of EVs could cause multi-storey car parks to collapse due to their weight. He also emphasised that the average weight of vehicles has increased from 1,500kg to 2,000kg.

Launched into digital

Autotech Group has launched a new division – Autotech Connect – in a bid to mitigate the growing risk of cybercrime threats and help the automotive aftermarket effectively implement technology into their businesses. This is aiming to improve efficiency and overcome skills gaps.

As software defined vehicles enter the market and the proliferation of connected vehicles continues, consumers are increasingly expecting their cars to be an extension of their smart phones. Layered on-top of the skills shortage, the lack of training, a failure to invest in technology and the risk of cyber-attacks; garages must engage in building their digital infrastructure to ensure their survival.

Through the new division, the company has secured partnerships with leading

Freya Coleman

hardware, software, training and IT providers to deliver technology driven solutions that bring their expertise and application knowledge from other industries, including government, banking, and healthcare, into the automotive aftermarket.

EV Battery degradation “hugely” overestimated

56 per cent of consumers “hugely overestimate” the likely degradation of used electric car batteries over a five-year period, believing a 30 per cent range drop is likely when it is suggested that 20 per cent or less is more likely.

This is according to April’s Startline Used Car Tracker. EV batteries degrade at an average of 2.3 per cent per year, according to a study of 6,300 EVs by Geotab.

Commenting on the findings from the latest instalment of the monthly poll, Startline Motor Finance CEO Paul Burgess said: “Anecdotal feedback shows there is a lot of misinformation among the

general public about used car EV batteries and how quickly they degrade and our findings clearly back that up. It’s an important subject for the future of the used car market. If someone is considering buying an EV for the first time, they are likely to be put off if they hugely overestimate the speed at which electric cars lose range.

“The fact is that there is now quite a lot of real-world information about battery life available and, as long as the previous owner has been sensible about the way in which the car has been charged, the drop-off in range is likely to be relatively low over time.”

6 JUNE 2023 PMM

Autotech Connect was announced at an intimate event at Millbrook Proving Ground where PMM were in attendance.

Startline Motor Finance CEO Paul Burges

FOR UP-TO-DATE NEWS, SIGN UP FOR THE WEEKLY E-NEWSLETTER AT WWW.RDR.UK/AAY001

EV complaints

The Motor Ombudsman has recorded the highest quarterly volume of consumer complaints about EVs during the first three months of 2023.

A total of 273 disputes were logged during the first quarter of this year, compared to 104 for the same period in 2022. Furthermore, in March alone, one of the key periods for new car registrations, 115 complaints were received from consumers about EVs.

Examples of dissatisfaction included cancellations and delays for the delivery and handover of new vehicle orders, incorrect vehicle specifications at the point of delivery due to parts shortages, and the miscommunication about the provenance of a vehicle when it was sold. For those who encountered purchase issues, around 70 per cent were in relation to a brand new car, with the remainder originating from the acquisition of a used model.

NEWSIN NUMBERS

79 %

of motorists would only buy a used vehicle that has a full or nearly fullservice history according to a study from BookMyGarage.com. In the same survey, 42 per cent would insist on a full-service history without a missed service.

$66.2 billion

the amount Tesla is now valued at, surging 44 per cent and jumping two places to become the most valuable automobile brand.

Get in the know

Schaeffler REPXPERT members can collect bonus points on tools with 20 per cent off the usual points value in the Bonus Shop promotion.

The Bonus Shop is integrated into Schaeffler’s service platform, technicians can use the app to scan the QR code on the label of any LuK, INA or FAG product, which takes them straight to the product information, checks the authenticity of the components, or adds bonus points to their account. This year Schaeffler is also going to turn three REPXPERT members into ‘bonus point millionaires’, with the next phase of the promotion taking place between June and August, with a free entry into the draw every time bonus points are claimed for INA products, including Timing Belt Kits and FEAD Belt Kits.

50 % of women surveyed by Venson Automotive Solutions said they would not consider a career in the motor industry. Currently female representation in the automotive sector is around 19 per cent.

14,800 technicians qualified for the IMI’s TechSafe professional recognition in 2022, making the total number of qualified technicians able to safely work on electric vehicles in the UK 39,000.

PMM JUNE 2023 7

Eden Tyres and Servicing has become the first Castrol SERVICE workshop in the UK to obtain independent certification by TÜV Rheinland.

with Freya Coleman

DATES FORTHE DIARY

■ PMM has confirmed it will be hosting a stand at this year’s Automechanika Birmingham, which will take place at the NEC in Birmingham on 6-8th June

Come and visit our stand for your chance to be featured on the PMM Podcast!

■ Garage management software Garage Hive has announced the Blend is back on 7th October 2023 at the Eastside Rooms in Birmingham, with tickets now on sale. It is a two-in-one event featuring a conference during the day where you can hear from industry speakers on how to run your business more efficiently, before the evening event with a three-course meal and the chance to network.

■ The BIG Awards have established are back this year on Friday 22nd September at Leicester City Football Club Categories include the business improvement award, the diversity equality and inclusion award and the training and development award among many others.

Smart motorways scrapped

The government has announced that all new smart motorways will be scrapped as part of a major overhaul of the UK’s road network. 14 planned schemes, including 11 already on pause and three set for construction will now be halted due to finance and low public confidence. The Department for Trasport has said the new schemes would have cost more than £1bn. Smart motorways were initially introduced to increase capacity on the heavily congested road network by converting the hard shoulder into a running lane, using technology to manage traffic flow

and lane closures and reduce congestion to improve journey times. However, these motorways have been linked to several accidents and fatalities, leading to growing concerns over their safety.

Emergency servicing recruitment issues

Ever wondered what life is like working in a Make Ready Centre in the UK? Working to keep the NHS’s fleet of vehicles up and running and ready to respond to emergencies at any moment is just the beginning.

In this podcast episode, we went to the service’s Make Ready Centre in Banstead to visit Ross Crook, area workshop manager for the Southeast Coast Ambulance Service, who managed 12 workshops covering over 600 vehicles for find out what is involved in repairing vehicles for the NHS. Whilst we covered topics such as the day to day running of the workshops, editor Kieran Nee and Ross also discussed the subject of recruitment – an issue that might be all too familiar to independent workshops.

On the topic, Ross said “I’ve talked to the

manufacturer garages. We’ve also talked to other ambulances and other blue light response teams, and it seems that there really is a national skill shortage for people. It is something that's really hitting us hard. I mean, we’ve got vacancies and recruiting.” When asked if the problem was getting worse, he responded “It’s definitely getting worse”.

So, listen as the team take you into the workshop where high mileage ambulances get serviced and repaired, and discuss the day-to-day running of an NHS workshop.

To find out more about running an NHS garage and listen to the PMM podcast, make sure to scan to QR code.

8 JUNE 2023 PMM PMM

NEWS

NEWSIN QUOTES

“ The results of our 2023 survey reveal that, 12 months on, the automotive aftermarket’s recruitment landscape remains relatively unchanged, but employers are finding that the situation is impacting their business even more,”

Simon King, managing director of Autotech Group comments on their survey results finding that almost 75 per cent of automotive employers have admitting they are finding it even more difficult to recruit skilled staff compared to 12 months ago.

“ Certified Recycled parts can be a huge benefit to customers and businesses alike. With parts delays, rising costs and more focus than ever on making the right choices to reduce our carbon footprint, these parts have the potential to help save money, time and the environment.”

Dr Tony Tong, head of automotive at eBay UK, on the online marketplace’s latest foray into the world of replacement parts supply.

Stressing the issue

According to Ben’s latest survey results, a total of 66 per cent of respondents said stress had most affected their health and wellbeing, followed by poor sleep and low mood.

The survey also revealed that the proportion of people suffering from stress in

the workplace has increased by 8 per cent year on year, with ‘high workloads’, ‘pressure to meet targets’ and ‘not enough staff’ driving this. The survey also reveals that there has been an increase in people affected by ‘poor work-life balance’ and ‘not taking enough time to rest and relax’.

Social media buzz

Actress Sydney Sweeney is taking TikTok by storm, partnering with Ford to encourage more women to feel comfortable working on their vehicles.

The actor is best known for her roles in The White Lotus and Euphoria, started her ‘Syd’s Garage’ TikTok channel in 2021, since amassing 1.6 million followers and 6.8 million likes, posting content on her restorting a 1969 Ford Bronco. So far in her collaboration with Ford, she has posted video tutorials such as how to check your oil, which has been viewed 7.1 million times and she will be releasing a female-forward workwear collection.

In pictures: Established in 1983, family-run tyre garage Walkers Tyres Darlington is celebrating 40 years in business.

10 JUNE 2023 PMM

MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS –ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS –ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

PMM JUNE 2023 15

CPDZONE READ ME TO COLLECT YOUR CPD POINT

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

TROUBLESHOOTER

Why did the BMW i3 suffer a total vehicle shutdown?

PMM ’s diagnostics expert, Ben Johnson investigates a PT-CAN 2 failure on a vehicle perhaps a little too close to home…

The morning was crisp and chilly, but nothing could dampen my spirits as I prepared to hit the road in my trusty BMW i3. However, as I reached for my phone to send the preheat command, I was greeted with a strange check control message on the “My BMW” app. Curiosity and concern gripped me, and I quickly wrapped myself up in my warm work gear to investigate the issue.

As I stepped outside, the freezing Finnish winter hit me like a tonne of bricks, and I was grateful for the advanced heat pump preheater system in my electric car. However, my heart sank as I looked at the frosted windows of my i3 and realised that it had failed to preheat the cabin; my worries only multiplied when I saw the myriad of warnings on the instrument cluster, including a troubling “powertrain fault” message. What’s more, the cooling fan was going at full speed, which made no sense in such freezing temperatures. I knew that a check control message combined with the fan coming on usually meant serious trouble –and on the i3, that meant serious money. For instance, replacing the EME – the electrical machine electronics unit that powers the vehicle – could cost upwards of five and a half thousand euros. Ouch! I kept my fingers crossed as I sat inside.

As I attempted a quick, initial diagnosis, my fears were confirmed when the gear selector near the steering wheel – known as the GWS – refused to budge. Panic set in as I realised I couldn't select forward or reverse, and with no manual release available, my only option was to call a tow truck. It was a frustrating and disappointing experience, especially for a car that was only four years

old. I couldn't help but think of the simplicity and reliability of the trusty Diesel 5 series that I owned prior to purchasing the i3, which had been flawless up to 350,000 km.

Within an hour of my distress call, the tow truck arrived. The driver was friendly and eager to help, but as he began to winch my i3

onto the truck, I was horrified. I knew that the locking pawl system in my car required a different approach. With a heavy heart, I explained to the driver that the i3 needed to be winched on with dollies under the rear wheel. Nobody likes to tell somebody how to do their job but needs must, at times.

To his credit, the driver took my instructions in stride and quickly made the necessary adjustments. Despite my frustration and disappointment with my car’s failure, I couldn't help but feel grateful for the kind and understanding tow truck driver who went out of his way to help me.

Getting started

The journey from my home to Schmiedmann, a distance of about 50 kilometres, was a breeze despite the snowy weather. We arrived in no time, and the car was promptly pushed to the side of the diagnostics ramp.

After a long day of work, I finally had the chance to inspect my little i3 and read the fault codes. I was determined to get to the bottom of what had gone wrong with my pocket rocket.

As I scrolled through the long list of fault codes, one in particular caught my eye – the PT-CAN 2 bus. This bus was meant to serve as a backup to the main PT-CAN bus, but it was reporting missing messages and the main failure was “PT-CAN 2 open circuit.”.

Based on my experience with the i3, I suspected that the issue might be originating from the front left wheel arch. This was a known fault in the i3, as the main vehicle harness is routed outside of the car, over the front subframe, and down to the back subframe inside the chassis rail cavity. While this design might work in the milder Bavarian

PMM JUNE 2023 17

READ ME TO COLLECT YOUR CPD POINT

CPDZONE

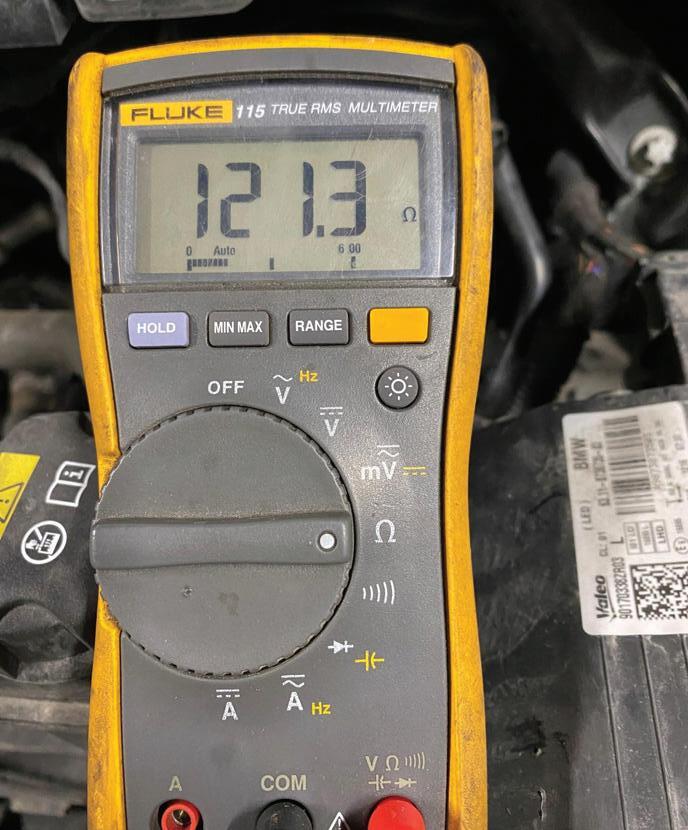

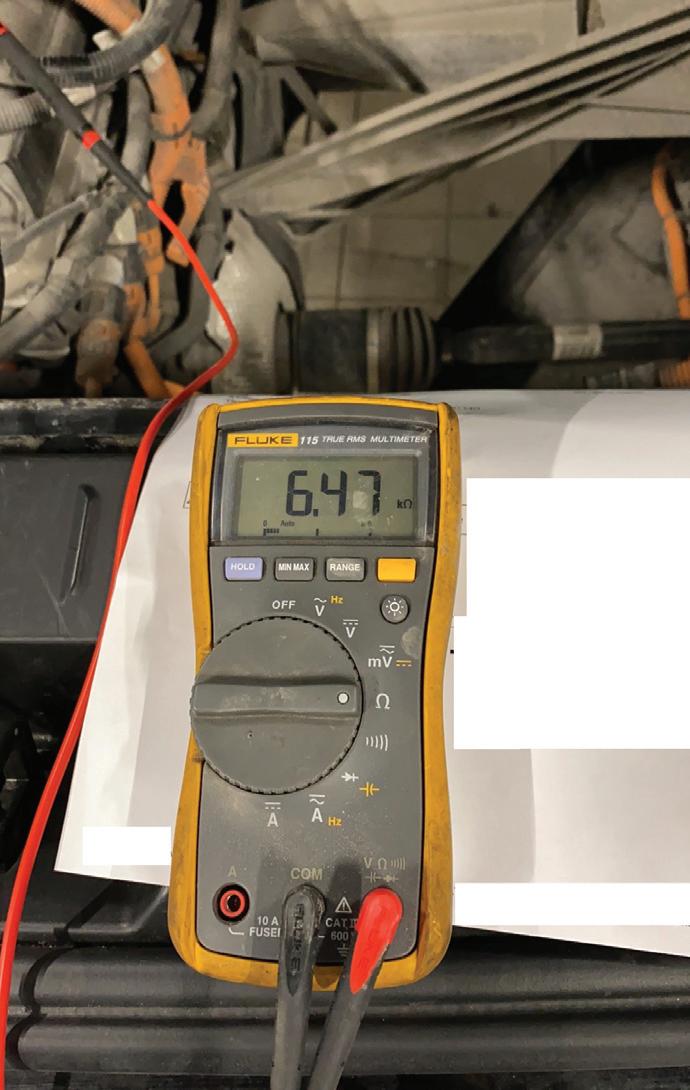

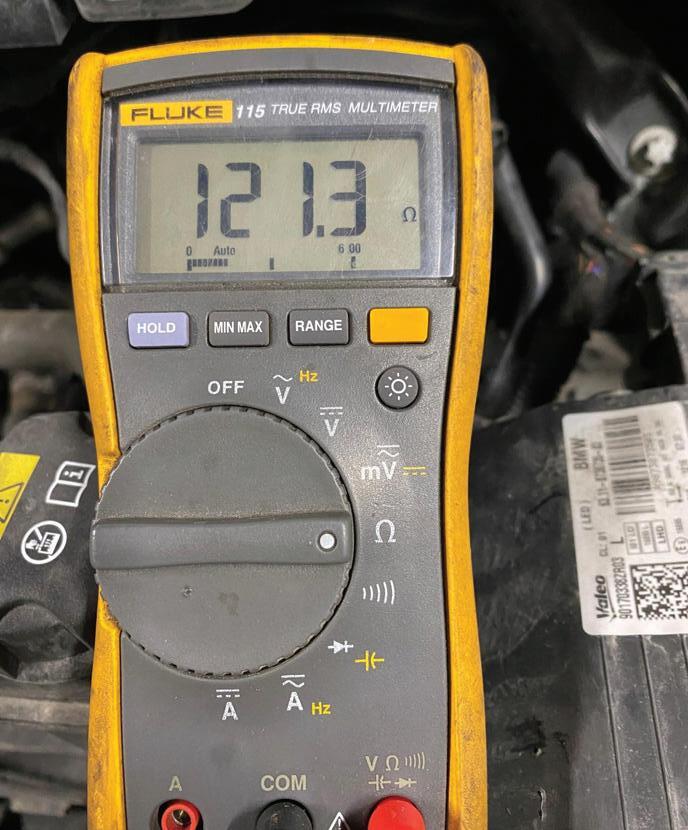

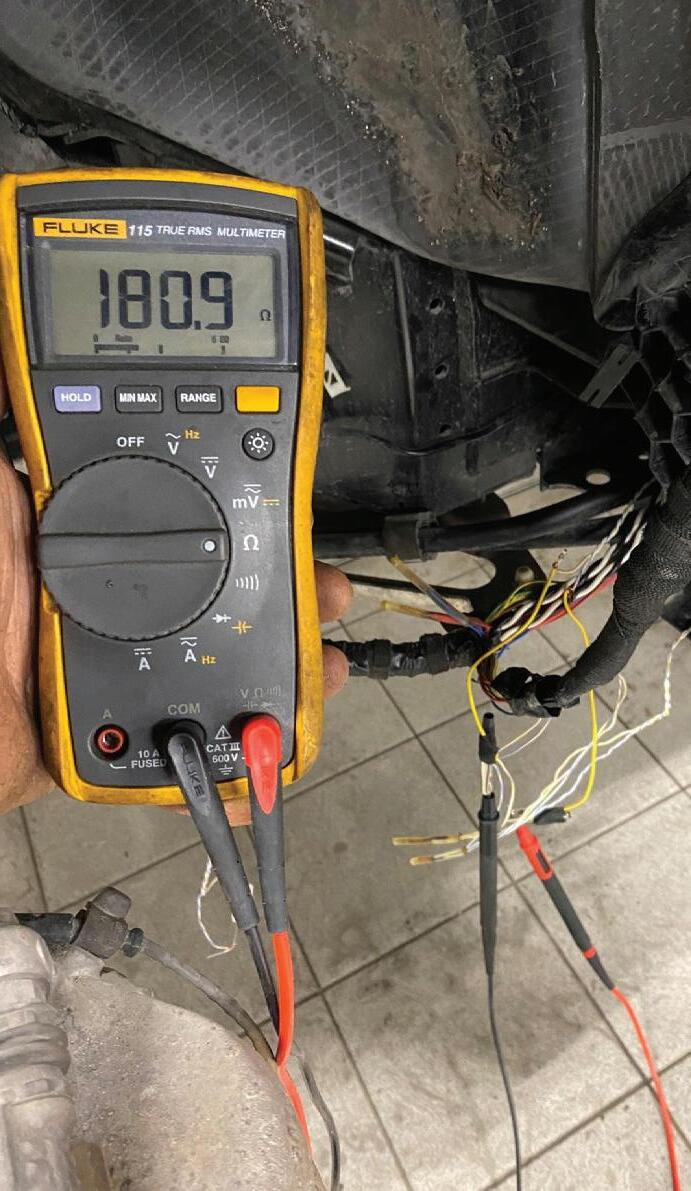

Fig 1 – 120 Ohms measured from the frunk harness to the terminating resistor in the GWS – the gear selector switch in the vehicle.

weather, it is wholly unsuited to the salty and harsh Finnish roads. It was only a matter of time before something went wrong.

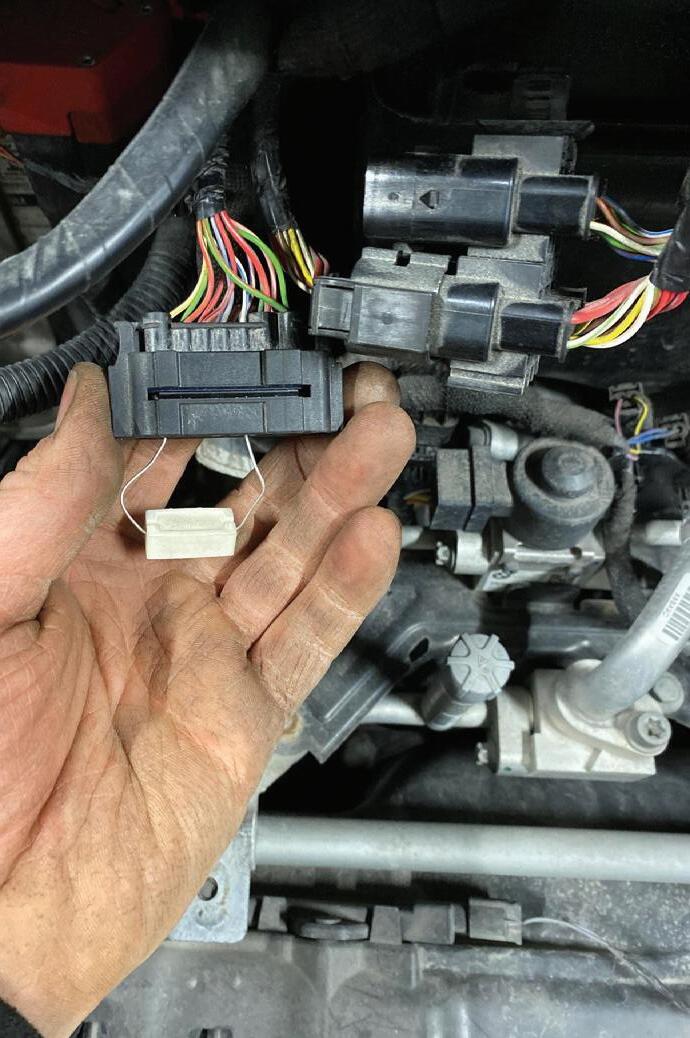

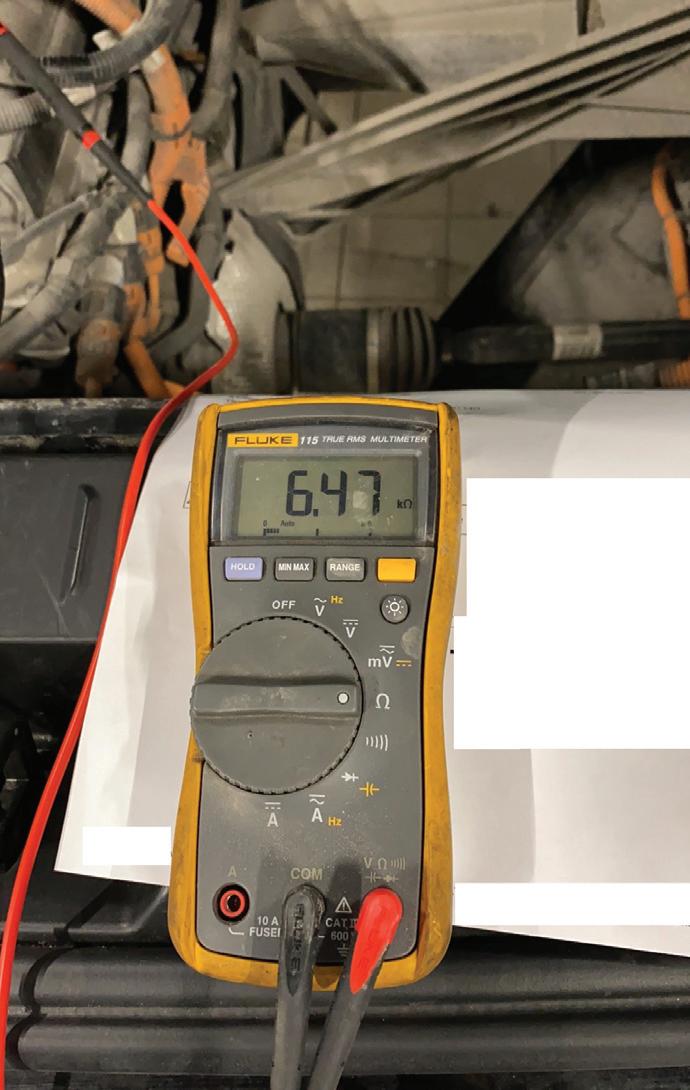

When I removed the “frunk” storage box in the i3, I uncovered a useful harness connector on the bulkhead that contained all the buses, including PT-CAN 2, flexray, and more. I quickly took a measurement and discovered a healthy 120 Ohms. I felt relieved, as it seemed that the issue was an intermittent open circuit on the main line of the PT-CAN 2. Following the wiring diagram led me to the realisation that the terminating resistors were located in the EME and the GWS. I would have been more worried to find 60 Ohms at this point as it might have meant a dreaded control unit failure of some sort.

Access challenges

Although the i3 is not a complicated car and contains only a handful of control units, the mountains of harness tape, zip ties, and plastic conduits that are fitted throughout can pose a challenge, especially in hard-to-reach places. However, finding the problem with the CAN bus open circuits was not too difficult, even on the main line. The only issue was that with the car on the ramp, accessing the two and a half metres of wiring in the main harness was

proving to be quite a challenge due to the ramp legs getting in the way.

Undeterred, I came up with a solution by devising a bungee cord setup that allowed me to pull the loosened lower sill trim and anchor it to the ramp legs, giving me the

space I needed to access the wiring. It was a bit of a makeshift solution, but it did the trick, and soon enough, I was able to decide where to make a start.

After removing the main line connector, I was able to take a measurement from this point and trace it back into the car to the GWS. This test confirmed that I had a solid reading of 120 Ohms (Fig.1), so I decided to eliminate this wiring from further checks, saving me the trouble of having to inspect an additional 2 m of wiring. I put the connector back temporarily.

Working again

After going for a quick coffee break, I returned to find that the car had seemingly fixed itself like magic. I then disconnected the HV interlock loop again, put the car into safe mode and tested the CAN resistance –60 Ohms were measured, signifying an intact bus. The main line had seemingly restored itself, and to my delight, the car started working again flawlessly. It selected gear with no issues and there were no check control messages to worry about. That's when the real fun began!

Any experienced diagnostics technician will tell you that there’s no such thing as a problem that fixes itself. In fact, for us, this is the worst-case scenario because a permanent fault has now become a sporadic one, which can be incredibly challenging to solve. Tracking down these types of issues can take up a significant amount of time!

18 MAY 2023 PMM

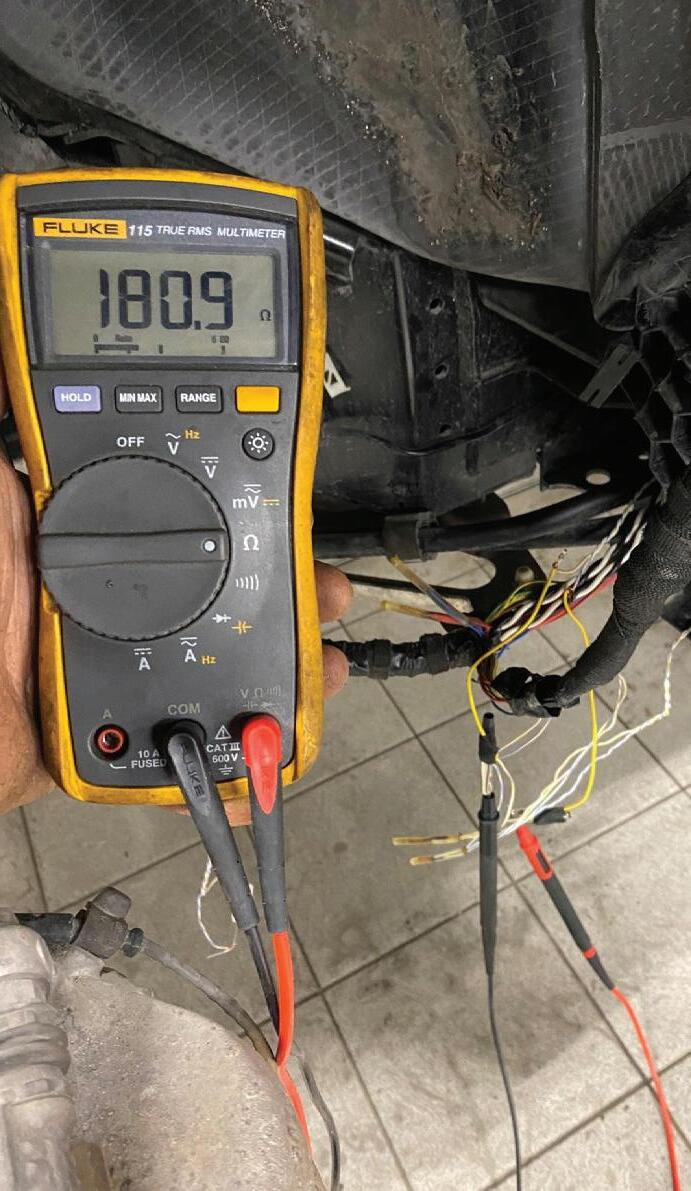

Fig 3 Aft wheel arch area. Measuring back to the EME. Note the high resistance value and the crimped branch lines that run alongside the main line between the GWS and the EME. This made identifying the main line more difficult underneath the car.

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Fig 4 Main vehicle harness. Not easy to work with on a two-poster ramp. Note the PT-CAN 2 wiring as a twisted pair in yellow/white and blue/white

Fig 2 - 120 Ohm resistor added in place of GWS.

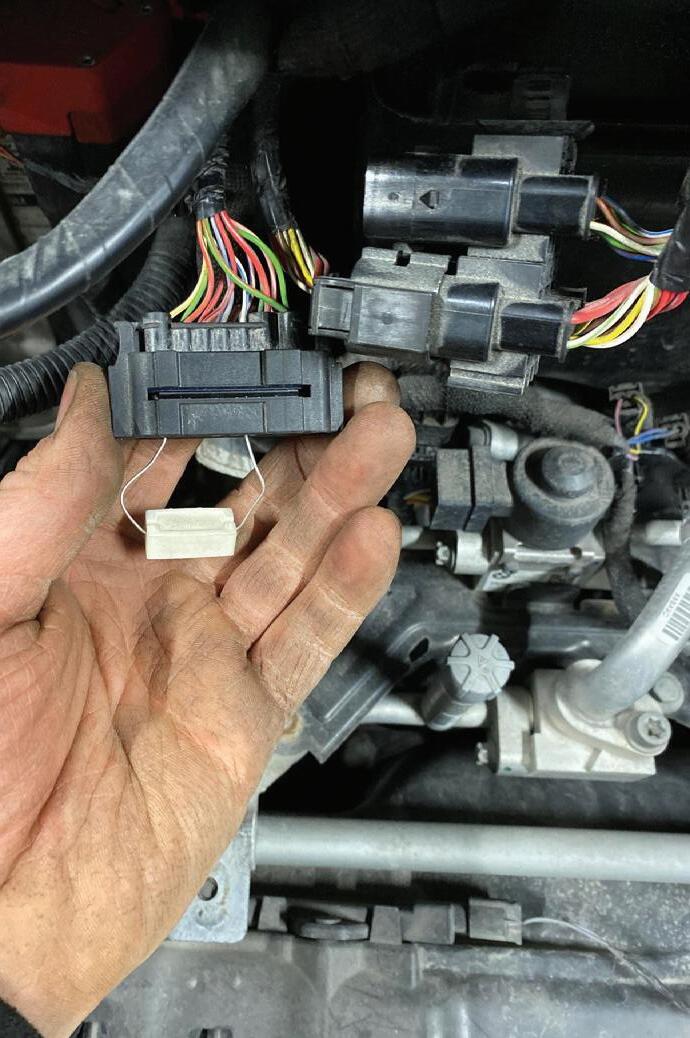

Knowing this, I removed the frunk area harness connector once again and inserted a 120 Ohm resistor into the harness leading to the main harness and back to the EME (Fig.2). This restored the circuit and simulated the GWS being plugged in once more.

To investigate further, I stripped back some of the CAN harness and inserted piercing probes, then set up the Fluke to measure the resistance. Surprisingly, I had 120 Ohms, and nothing worse than that. I twisted, pulled, and moved the harness around, but it didn't change anything on the Fluke meter display.

With no visible issues in the front left wheel arch area, I decided to measure to the rear of the car and measure from the aft wheel arch to the EME. I made a cut in the main line to do this. At first, I found an immediate 120 Ohms, which was a good sign. However, my joy was short-lived as I began to get some strange sporadic readings. At one point, I even had an unusual kOhm value. I knew then that I was dealing with a

“As I scrolled through the long list of fault codes, one in particular caught my eye – the PT-CAN 2 bus.”

Ben Johnson, diagnostics expert

bad wire, but the question was where? During the sporadic episode I found that I had 180 Ohms. I had now ticked off the front part of the harness from the aft of the wheel arch to the GWS. I had around three metres or so of wiring to check from the aft wheel arch back to the EME (Figs.3-5).

I realised that the faulty wire was somewhere in the main harness, which meant that finding it was going to be a challenge.

In the back subframe area, I noticed that the branch lines were unfortunately running alongside the main line, making it challenging to distinguish which of the eight wires was the main line and which were the branch lines, especially since the colours were the same. After some intense focus, I managed to solve the problem, but it wasn’t

PMM MAY 2023 19

Fig 7 - PT-CAN 2 cut at rear subframe to narrow down the area of the break. Measuring here with the EME connected (second terminal resistor location.) Note the cut CAN wiring shows one blackened wire on the blue/white wire whereas the yellow/white wire is in good condition.

Fig 6 - Sporadic strange resistance readings meant a bad wire somewhere.

Fig 5 Measuring down the PT-CAN 2 from the EME harness connector.

easy. By twisting the wiring harness in the trunk area, I determined that the wire break was located between the trunk and the rear shock absorber. All of my previous testing went out the window. I then exposed all of the CAN wires that had the same colour at the front wheel arch and found seven clean copper wires and one that was blackened. The same results were found when I repeated this process at the rear shock absorber area: a black wire (Fig.7).

Temporary wire

Running in a temporary wire and restoring the GWS to the main harness ensured that the problem was solved. I had 60 Ohms and the car worked flawlessly. All that remained was to make a new twisted pair which ended up around four metres long (Fig.8). On top of that I designed a much better conduit and taped metres of wiring tighter and most importantly waterproofed as much of it as possible. I even used some coolant hose as a flexible conduit in the worst exposed area –the rear subframe. All that remained was to build it up and check the PT-CAN 2 signal on the AVI scope. Result was a good signal. One

thing that I am never annoyed about is even though the job was very stressful, being my own car, I learned more about the architecture of the i3 during the experience than I had ever learned before. The car is now running well and ready for the daily commute.

And the wire? Well, finding the exact area of concern proved time consuming but I found one part of the CAN wiring severed in two pieces and it had been making and breaking a connection for some time, perhaps even a year or two until the ingress of moisture started to cause such deep corrosion that it eventually caused the wire to break completely. What is always staggering to me is that even with such a high resistance CAN messaging was still able to get past it. Quite incredible, I think and a testament to just how robust the CAN protocol is.

20 JUNE 2023 PMM

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAY002 READ ME TO COLLECT YOUR CPD POINT CPDZONE

WANT

Fig 10 - PT-CAN 2 break location at rear shock absorber area.

Fig 9 - Break location near to the rear shock absorber and deeply buried in the middle of the main harness.

Fig 8 - Green/white and blue/grey temporary twisted pair that ended up being the permanent PT-CAN 2 new wiring harness. Here it is in place to check the restoration of the can bus.

KILOWATT HOURS EXPLAINED E V

The term kilowatt hour (kWh or kW-h) is often used in connection with electric vehicle batteries, but also to household electricity supply.

A kilowatt (1,000 watts) is a measurement of power. It means how much a device will consume, or how much a device can supply. A one horsepower (hp) engine for example, is about 745 W or, one metric horsepower (Ps) is 735.5 W. In a vehicle’s electrical system, an old 60 W headlamp bulb will consume ten times more power than a 6 W sidelight bulb. A 200 kW EV motor will consume a lot more.

A kilowatt hour (kWh) is a unit of energy measurement, specifically it represents the amount of energy used or produced over a period of time.

One kilowatt hour is equal to the energy consumed by a power of

one kilowatt over a period of one hour. It is commonly used to describe vehicle traction batteries and as a measure of domestic and industrial electricity consumption. It is the billing unit for electric companies – which is why we have heard so much about it recently!

A kilowatt-hour is a non-SI unit of energy: one kilowatt of power for one hour. It is equivalent to 3.6 MJ (megajoules) in SI units. A kilowatt hour (kWh) is used to measure the energy capacity of electric vehicle (EV) batteries because it provides a convenient and standardised way to compare the energy storage capacity of different EV batteries. By expressing the energy storage capacity in kilowatt hours, manufacturers and consumers can easily compare the range and potential driving distance of different EVs. Note that the range of an EV also depends on many

other factors including driving style. For example, a 50 kWh battery in an EV can be expected to provide a certain range, and this information can be used to compare it with a similar EV that has a 75 kWh battery. This helps us make informed decisions about the range and energy efficiency of different EVs. Additionally, using kilowatt hours to measure the energy storage capacity of EV batteries in the same way that electricity is sold and billed, makes it a convenient and widely recognised unit of measurement.

state of health. Battery capacity can degrade over time, especially if the battery is frequently fast charged and discharged or if it is exposed to extreme temperatures.

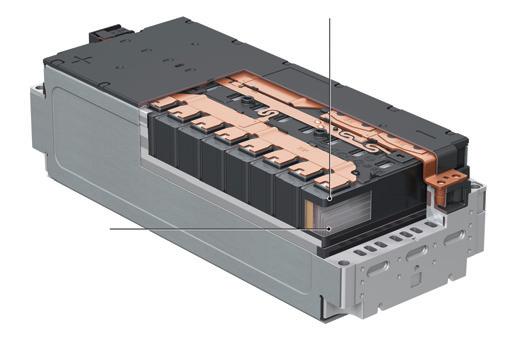

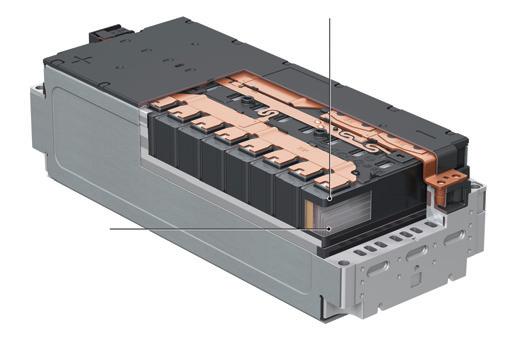

An example of one of the latest high-voltage battery systems is in the new Audi Q8 e-tron. This car operates with a nominal voltage of 396 V. Two different battery sizes are available:

• Q8 50 e-tron, the battery has a usable capacity of 89 kWh

• Q8 55 e-tron and SQ8 e-tron, have 106 kWh.

In both cases, the space required for the drive battery is the same; thanks to further developments in cell technology and structure as well as in cell chemistry, the individual cells boast an increased energy density.

The prismatic cells used in battery production are assembled via a process called stacking technology, whereby the cell material is stacked in layers, thus filling the rectangular space much more efficiently – up to 20 per cent more active cell material for power storage fit in the battery cell.

The actual amount of energy that can be used from the battery will depend on a variety of factors, including the discharge rate (how fast energy is used), the temperature, and the battery's

Sponsored by FORMOREINFORMATIONGOTOWWW.RDR.LINK/ AAY003

FIG.1 AudiQ8e-tronbatterypack

READ ME TO COLLECT YOUR CPD POINT DevicePower(kW)Usage(hours)Energy(kWh) FlatscreenLEDTV0.1101 ACsystem2.525 DomesticEVcharger3.51035 ACfastcharger22.05110 DCfastcharger60.02120 DCfastestcharger*350.020mins117 *availableatthetimeofwriting

FIG.2 Batterymodulewith12prismaticcells (Source:AudiMedia)

Newcell chemicalmix withincreased energydensity

Prismaticcellinstacking technolody(72Ah)forbetter geometricuseofspace

HOW TO

Replace an EGR Valve

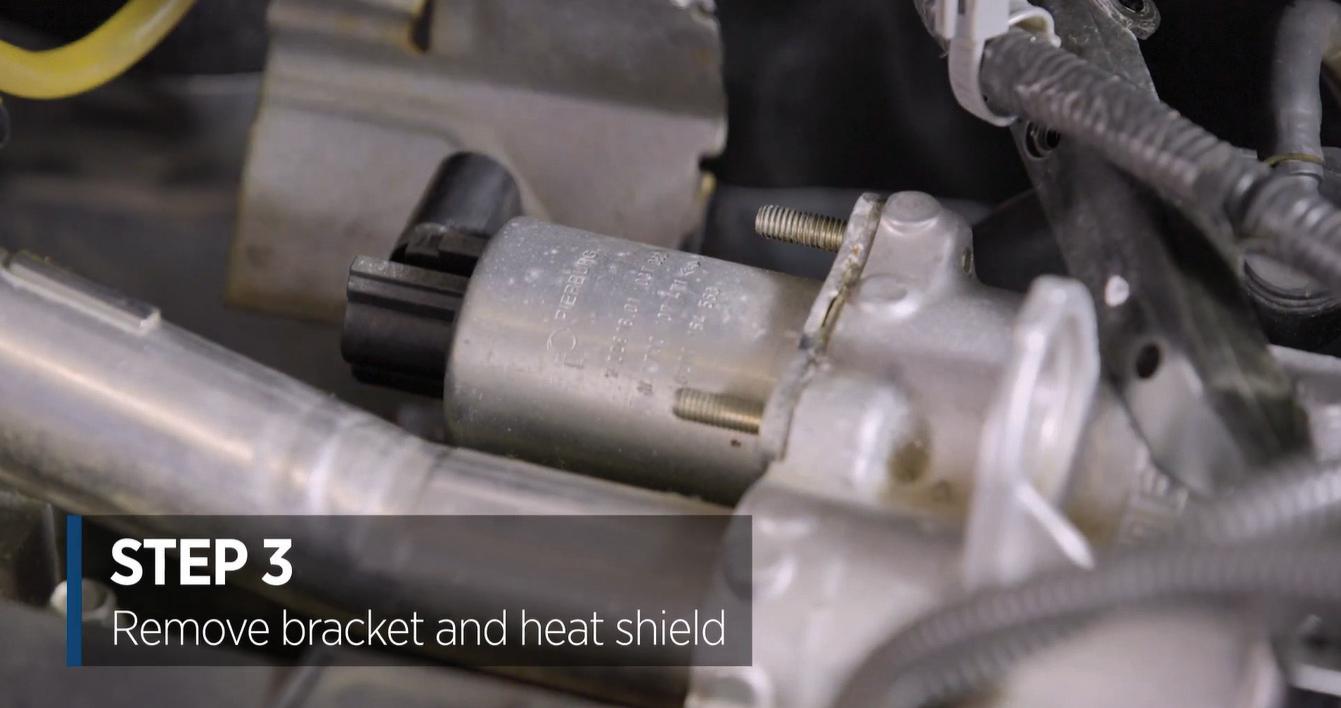

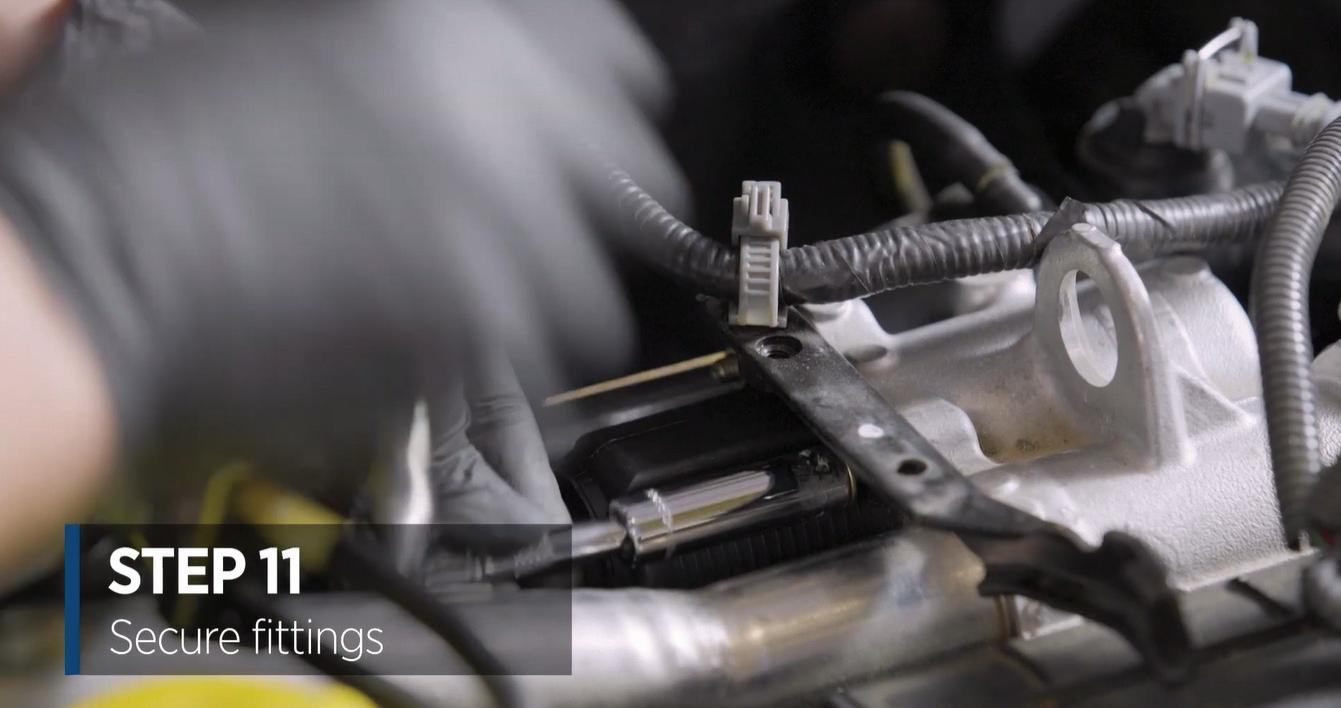

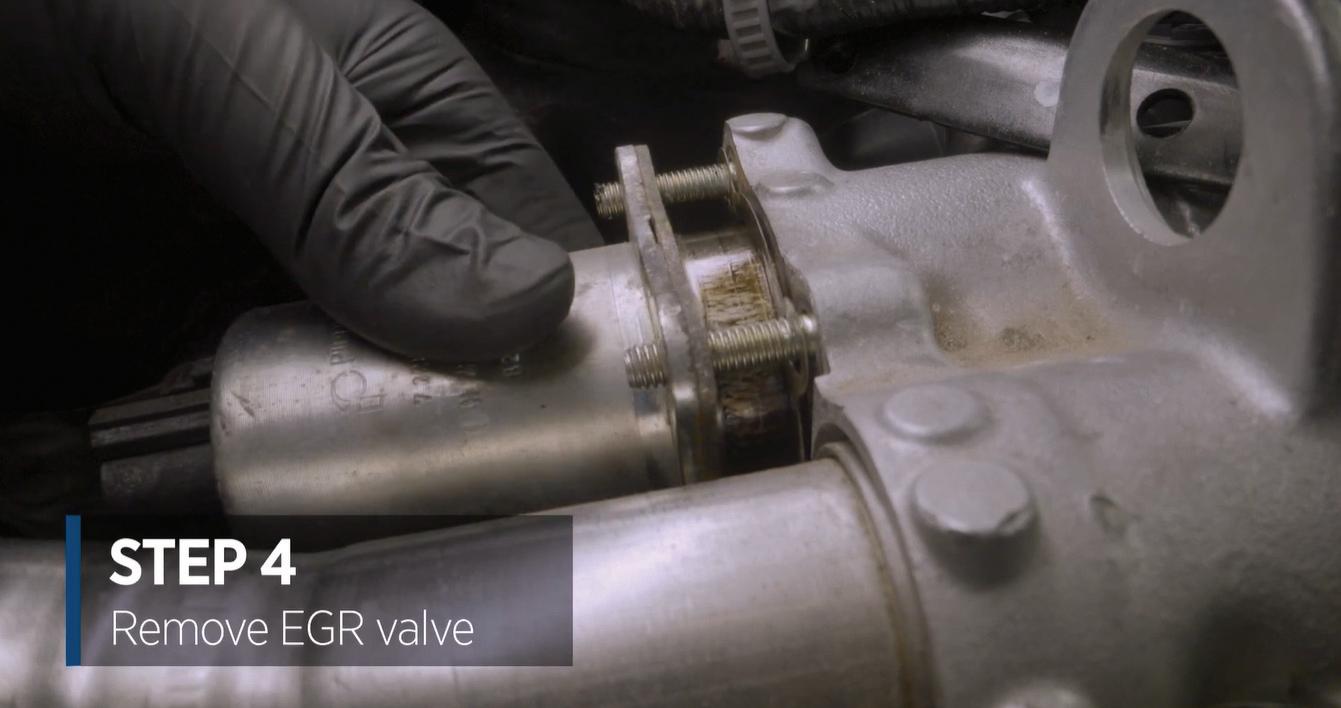

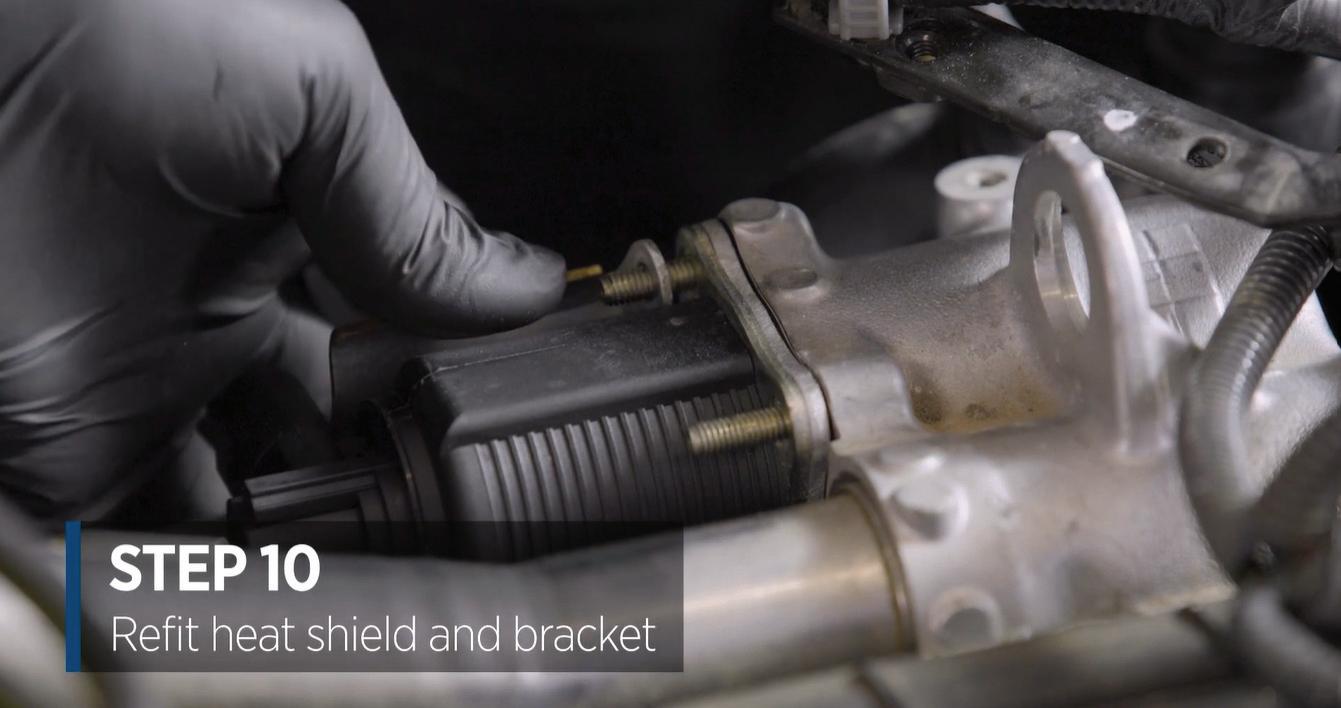

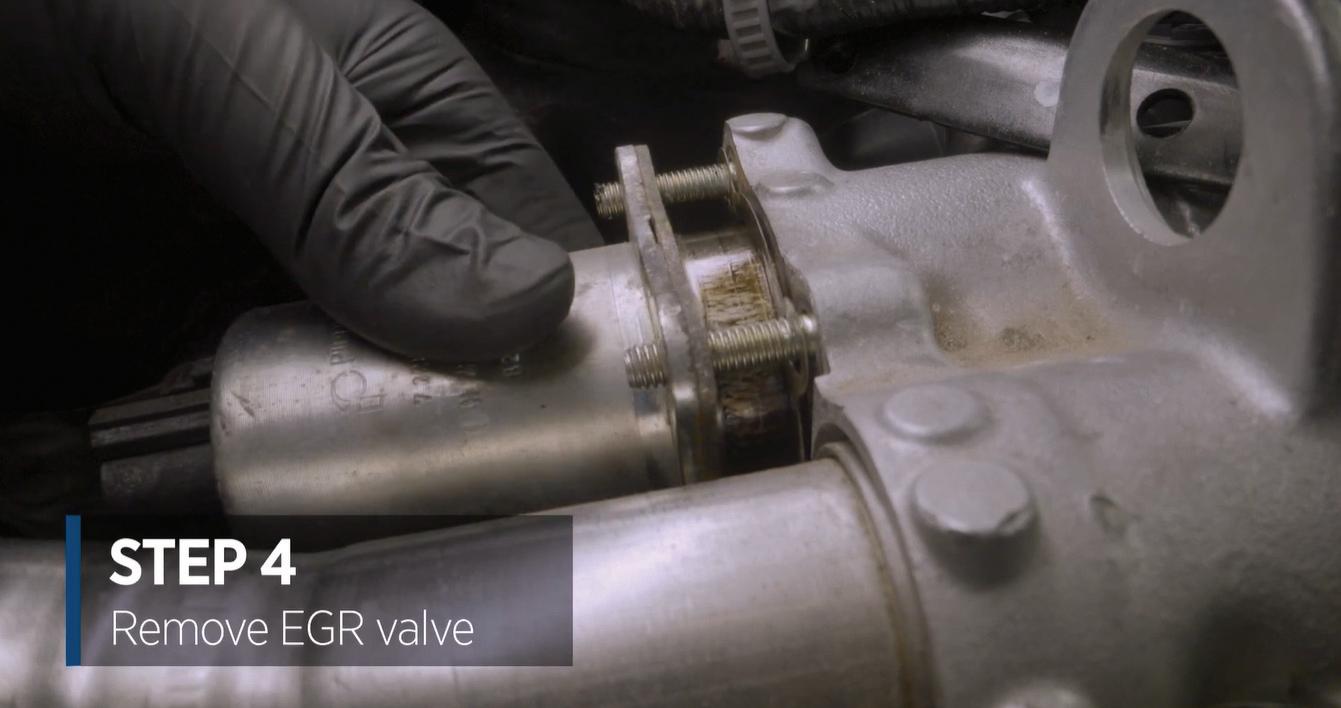

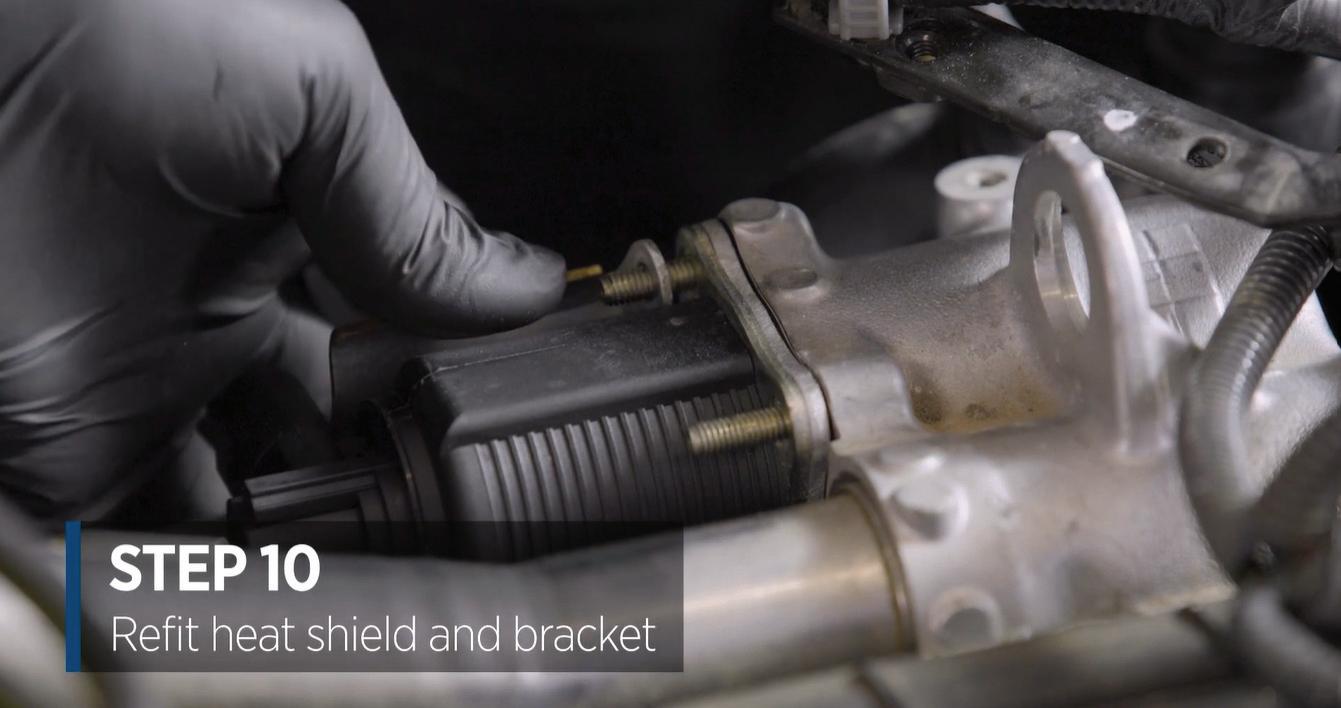

Delphi Technologies, a brand of BorgWarner, has supplied this step-by-step EGR Valve replacement guide courtesy of its Masters of Motion hub for independent garage technicians.

The Exhaust Gas Recirculation (EGR) valve recirculates precise quantities of exhaust gas to the engine intake system for increased engine efficiency, reduced fuel consumption and lower NOx emissions.

The EGR valve has two primary settings: open and closed, although the position can vary anywhere in between.

During engine start-up, the EGR valve is closed and gradually opens at idle and at low speeds. As more torque and power is required, the EGR valve closes to allow more oxygen to enter the cylinder.

The single biggest cause of EGR valve failure is the build-up of carbon particles from the exhaust gases along the EGR and intake system passages. With time, this can clog tubes, exhaust gas channels and eventually the valve’s plunger mechanism, causing it to either stick open or closed. Failures can also be caused by a rupture or leak in the valve diaphragm.

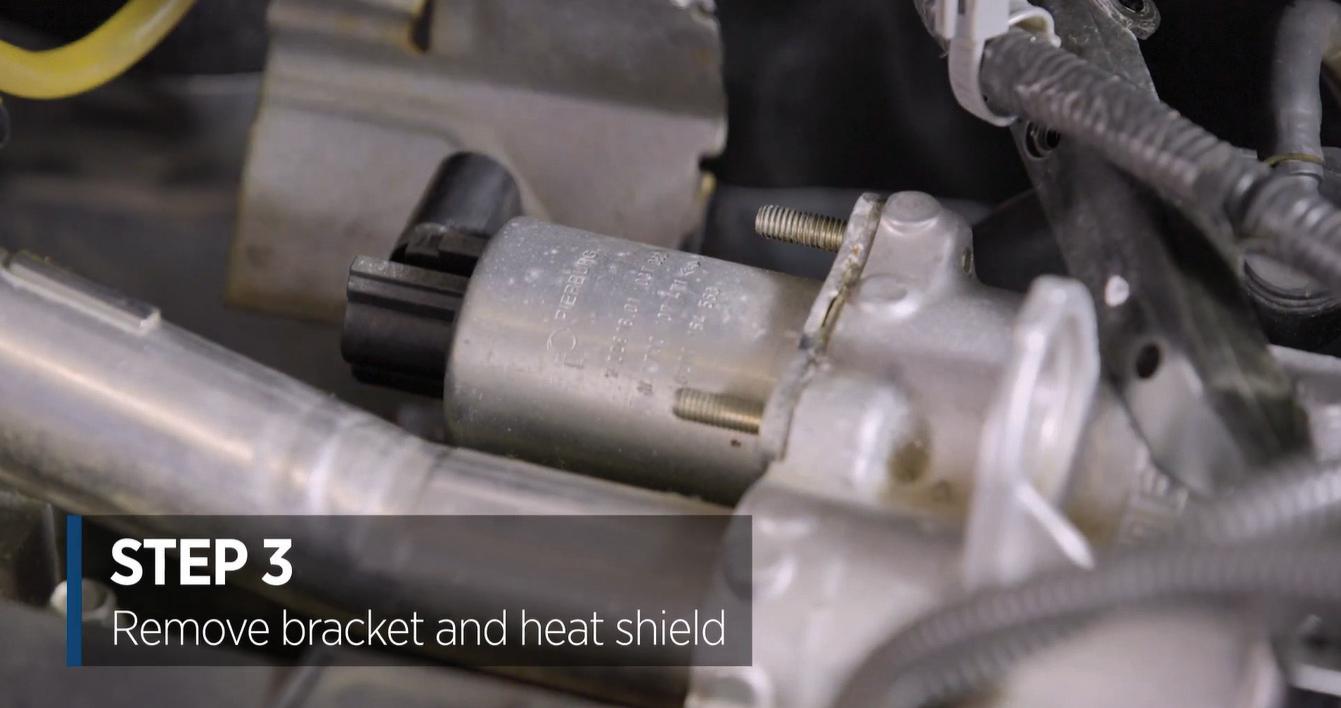

Step-by-step guide

Matt from Delphi takes us through the process of changing an EGR valve on a Nissan Micra at Delphi’s in-house training workshop in Warwick.

Step : Locate the EGR valve and disconnect the electrical wiring. Loosen the cable on the valve and remove the electrical connections, checking for signs of damage.

Step : Remove the fixing nuts.

Three 10mm fixing nuts need to be removed. Once loosened with a socket, technicians are advised to spin the nuts by-hand, taking care not to drop them.

WATCH! Scan the QR code below to watch this step-by-step

Step : Remove the bracket and heat shield.

Step : Remove the EGR valve. Check the valve for damage, corrosion or carbon build-up.

Step : Remove the old gasket.

Step : Compare the old part with its replacement.

Step : Clean the manifold surfaces. Clean the EGR valve mounting surface thoroughly and remove any loose carbon

from the EGR supply port.

Step : Fit the new gasket.

Step : Fit the new EGR valve. The valve should be orientated so the electrical plug connection faces to the rear of the car.

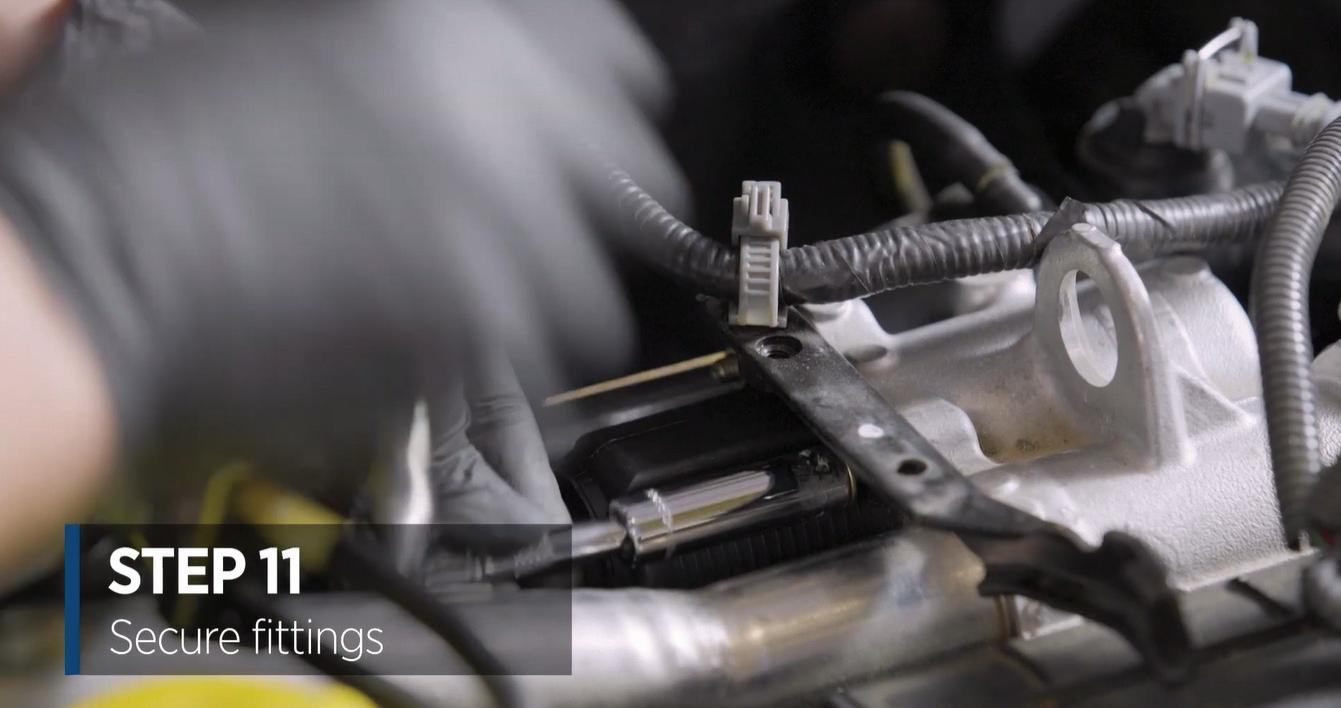

Step : Refit the heat shield and bracket.

Step : Secure the EGR valve and heat shield bracket with the original fittings.

Tighten all fasteners to the recommended torque settings.

Step : Reconnect the wiring hub.

This guide is one of around 30 ‘How To’ videos covering a range of workshop jobs including ADAS calibration, diesel injection, engine management and more.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAY004

24 JUNE 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

PMM JUNE 2023 25

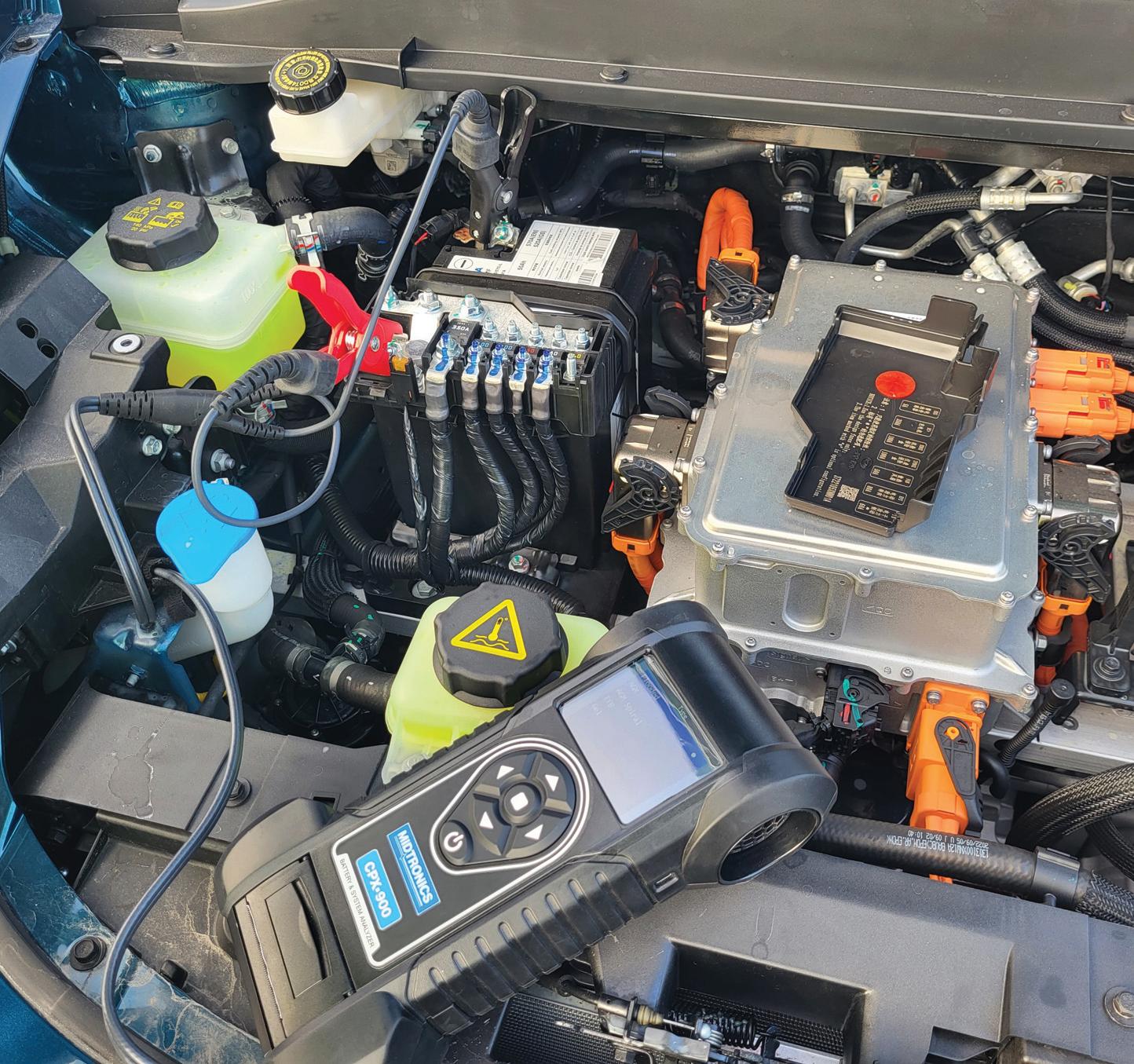

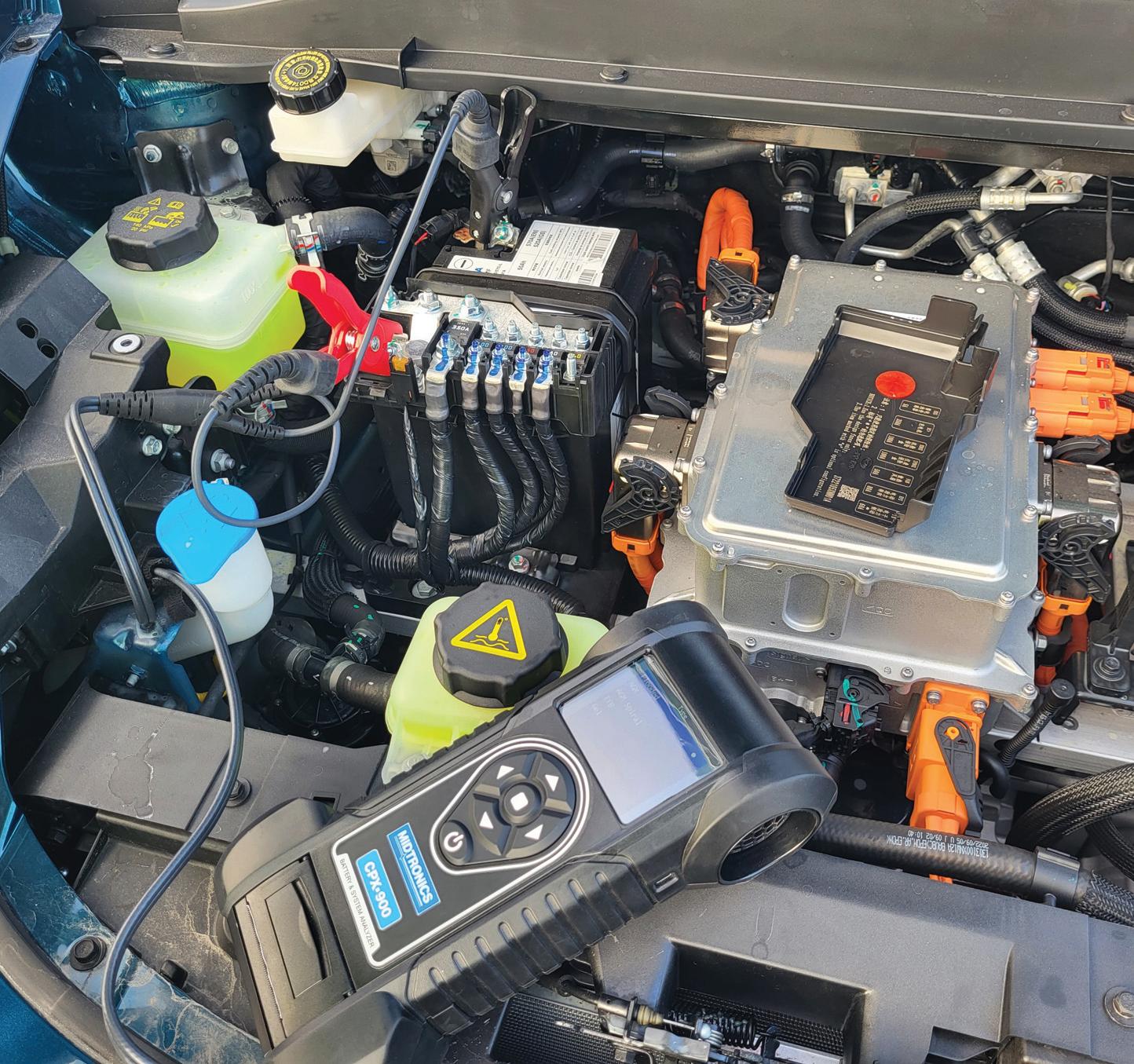

BEST PRACTICE Battery maintenance

Ken Clark, managing director at Rotronics explains the difference between modern 12 V battery types and what causes can lead to battery drain.

It’s vital to know what battery type you are testing and charging, and what is the purpose of the battery. For example, if you have an EFB/AGM for a start/stop vehicle, you must test and charge appropriately or replace it like for like. It cannot be replaced with a standard flooded battery as this simply won’t work. You must know the difference in the technology you are dealing with.

There’s usually always a giveaway on the label, so it’s important to read them correctly. If it has state of charge indicator (SOCI) on it, it will only be a standard flooded or EFB battery. If it’s a start/stop vehicle, the battery can only be EFB or AGM.

There are several great battery manufacturer tools online that will tell you what battery technology is recommended for each vehicle application. All you need to do is submit the vehicle registration and you will get the battery information as required.

Different 12 V battery types

The most frequently seen option in any workshop are Lead Acid batteries. These include: Flooded, EFB, and AGM. More and more 12 V Lithium-ion batteries are appearing because of growing power requirements in vehicles, and the increased presence of EV/PHEV vehicles.

Tip: EFB, AGM, or Flooded batteries should be tested at every opportunity in a workshop. Lithium-ion batteries currently have no means of being tested as they have their own battery management system (BMS), however they should be charged with a compatible charger.

Lead acid batteries are used because of their cranking capacity. Start/stop, PHEV, or BEV vehicles need alternative technologies, to support the cycle and consumer demands of the vehicle’s electronics. These will generally be EFB or AGM batteries.

Lead Acid batteries such as Flooded, EFB, and AGM batteries can be tested using most conductance-based battery testers. However, not all testers are equal. The latest generation battery testing technology incorporates a controlled load to measure the battery’s “reserve capacity” (an essential component supporting start/stop and 12 V EV battery health diagnosis) along with futureproofing with wirelessly updatable testing software.

Lithium-ion 12 V batteries are a different kettle of fish. They are designed not to get to a critical level of discharge and the only way to return the battery to normal is by using a lithium-enabled charging product.

TIPS TO HELP YOUR CUSTOMERS LOOK AFTER THEIR BATTERIES:

■ Adopt regular battery maintenance throughout the year

■ Be aware of changes in the electrics or the start-up

■ Monthly charging will triple the life of your battery

■ Charging technology is an important investment

WANT TO KNOW MORE? FOR MORE INFORMATION

26 JUNE 2023 PMM READ ME TO COLLECT YOUR CPD

CPDZONE

POINT

WWW.RDR.LINK/AAY005

TOP10

CAUSES OF BATTERY DRAIN

Here are Rotronics’ Top 10 things that are most likely to drain your customers’ batteries. Most vehicles are packed with power-draining tech, so you and your customers need to be aware of the following and make sure that their vehicles are tested and charged appropriately.

1 Self discharge: If a lead acid battery is sitting on a shelf, it can go from a fully charged state to chemically discharged in around eight months. Any stock batteries should be regularly charged each month.

2 Continual power draw, when parked: A vehicle’s battery is still working hard, even when parked, to keep the clock, alarm, cooling systems going. Some vehicles get regular manufacturer updates and you may give instructions from your phone. This takes power form the battery.

3 Opening doors: Each time a vehicle door opens, it springs into action, to disable the alarm and the locking system and lights go on. Just unlocking and opening a door and relocking will use around 50A from the battery. That has a daily toll.

4 Leaving your key near the car: Don’t do this because the keys and the car talk to each other and for long periods of time, eg overnight, this will significantly drain on the battery.

5 Too many short trips: Many short trips drain the battery. Just to get the vehicle started, it takes 150-350A of battery power and on short trips, the alternator has no opportunity to replace the charge.

6 Parasitic drain: These are constant drains, and you have to make sure that everything is switched off when you leave the vehicle.

7 Faulty alternator: The alternator helps charge up the battery and this process won’t work if the alternator is faulty.

8 Chilly weather: When the temperature freezes, about 35 per cent in battery performance is lost. This can drop to 50 per cent loss in performance. It is important to stay attentive to any clues of a declining battery.

9 Sulphation: Sulphation kicks in below 12.4V. Sulphate crystals build up, reducing the battery capacity, and the cranking ability. Sulphation accounts for 87 per cent of returned batteries under warranty claims and this can be avoided.

10 Battery replacement needed: Ignoring the above hints and tips, will mean reducing the life of your battery and likely replacement. There will be geographical, weather and trip variations. Ultimately, the life of your battery could be reduced by two to three years without it being tested and charged.

HOW TO

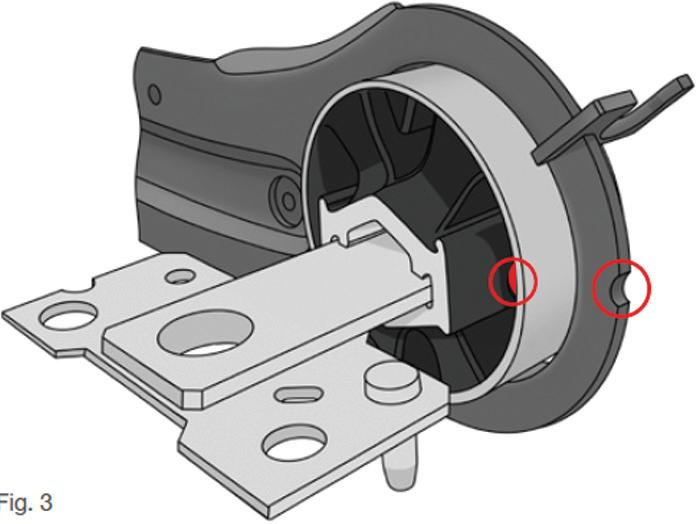

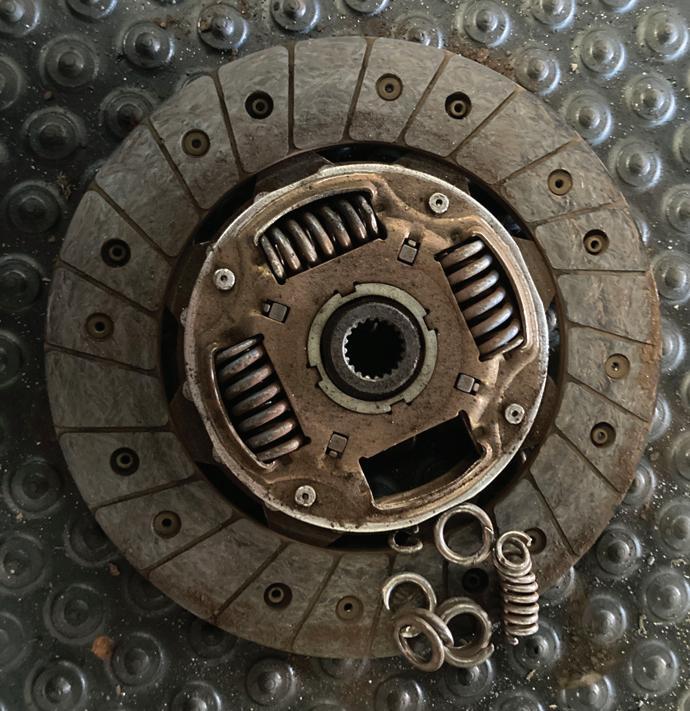

Replace the clutch on a Hyundai i30

In this month’s Schaeffler LuK clutch feature, REPXPERT Alistair Mason is investigating a clutch fault on a 2014 Hyundai i30, which has covered more than 162,000 miles, as the customer had reported that it was difficult to get the vehicle into gear.

Vehicle Information

Manufacturer: Hyundai

Model: i30

Year: 2014

Mileage: 162,000

On initial diagnosis, it was noticed that there seemed to be restricted clutch pedal travel and a lot of free play in the pedal, due to excess wear at the clutch master cylinder to pedal connection (Fig.1).

The clutch master cylinder was replaced, the clutch bled and full clutch pedal travel restored, but gear selection with the engine running was still difficult. However, with the engine switched off, the gears could be selected easily, which indicated that the clutch was not fully disengaging, so authorisation was given to remove the gearbox for further investigation.

Workshop equipment required:

■ Vehicle lift (two-post is ideal)

■ Engine support

■ Transmission jack

■ Clutch alignment tool

Scheduled time for clutch replacement –3.40 hrs

Gearbox removal

Starting in the engine bay, remove the engine cover, air filter housing and intake pipe, disconnect and remove the battery and battery tray, and then the engine ECU. This gives good access to the top of the gearbox (Fig.2), so remove the engine speed sensor from the back of the bellhousing, disconnect

the reverse light switch, gearbox earth strap, then disconnect both gear change cables and cable bracket, and stow them out of the way. Remove the upper bellhousing and starter motor bolts, then fit the engine support, if a bridge system is being used.

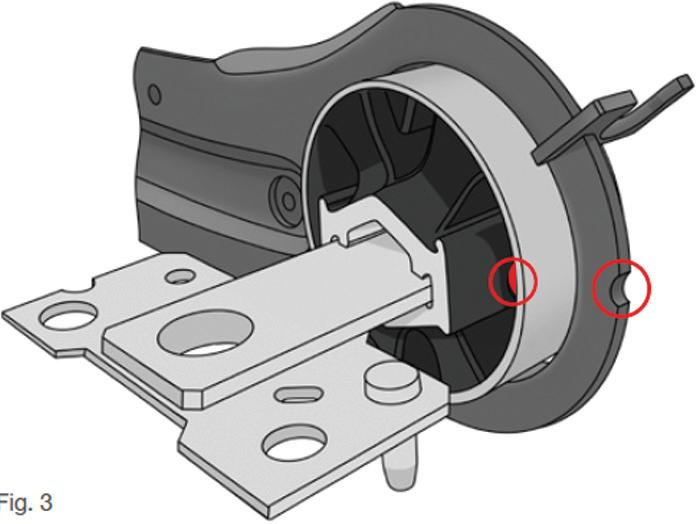

Before raising the vehicle from the ground, slacken both front hub nuts (note – on reinstallation, new hub nuts may be required if the locking tabs break), then raise the vehicle lift to waist height and remove both front wheels. Raise the lift to gain access to the underside, remove the engine undertray and the N/S splash guard (Fig.3) and drain the gearbox oil. While the oil is draining, disconnect both front bottom ball joints, ease the outer CV joints out of the hub assemblies and remove the driveshafts from the gearbox, which may need to be levered out.

PMM JUNE 2023 29

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Remove the two hydraulic clutch slave cylinder retaining bolts (Fig.4) and the flex pipe bracket bolt, then ease the slave cylinder away from the gearbox, and remove the air charge cooler pipe that runs under the engine/gearbox. Detach the lower gearbox pendulum mounting and retaining bracket, as well as the tin cover plate at the bottom of the bellhousing. Remove the lower bellhousing bolts, leaving a couple of easily accessible bolts to support the gearbox until the point of removal, lower the lift to waist height and remove the two gearbox mounting bolts that are accessed through the inner wing (Fig.5), then lower the lift and remove the mounting from the gearbox. Raise the lift to gain access to the underside, support the gearbox with a transmission jack and remove the final bellhousing bolts. Ease the gearbox away from the engine and when the gearbox input shaft is clear of the clutch, lower the gearbox, remove the gearbox from the vehicle and place it somewhere safe.

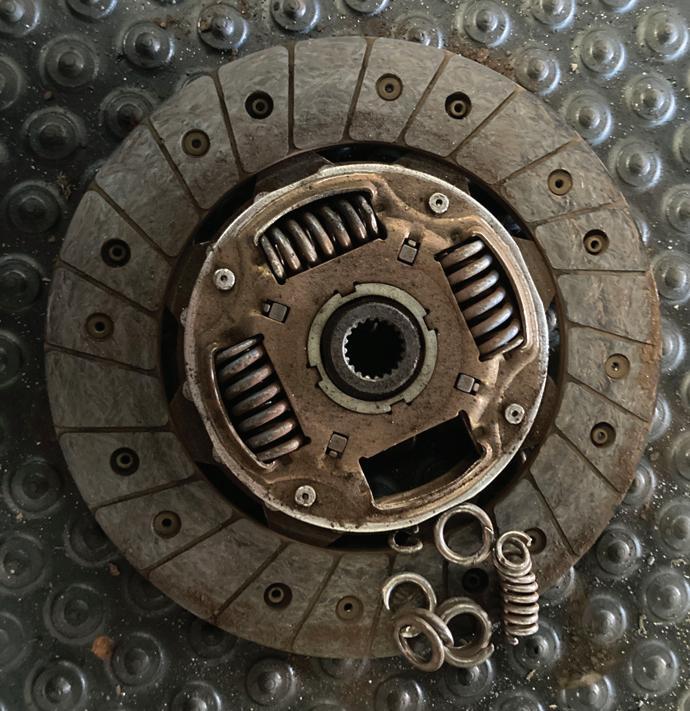

Fault diagnosis and clutch replacement

Remove the clutch assembly from the flywheel by unscrewing the nine clutch retaining bolts, and ease the clutch off of the flywheel. At this point the fault in this repair was identified (Fig.6): the clutch plate torsion damper spring had broken, come out of its retainer and was affecting clutch operation and clearance. The reason this spring can break is because of excess load/hard driving or vibration from an engine misfire, for example, being transmitted through the clutch, causing the springs to fully compress and then break.

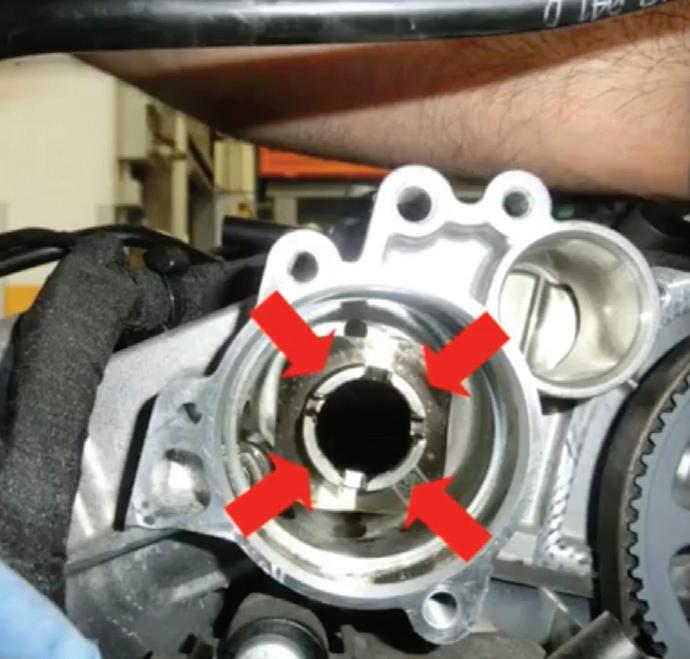

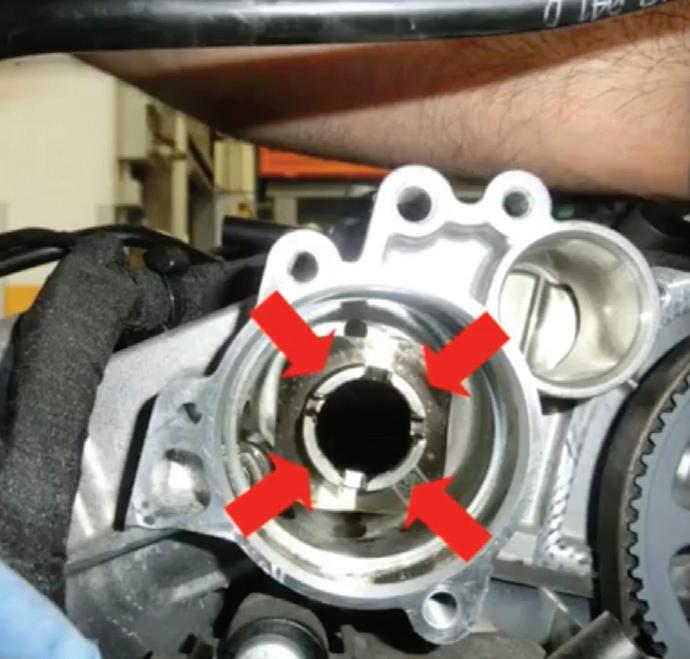

With the clutch removed, clean the back of the engine and flywheel with clutch and brake dust cleaner, inspect for any leaks, and rectify if required. Also, remove the glaze from the flywheel clutch plate surface using an Emory cloth. Remove the release bearing from the gearbox and clean the bellhousing area with clutch and brake dust cleaner, and check the bearing guide tube for wear (Fig.7) as it is known for both Hyundai and Kia engines to wear in this area and cause release problems.

Apply a light smear of high melting point grease onto the gearbox input shaft spline and mount the new clutch plate onto the input shaft, this will ensure the clutch plate is the correct fitment and also evenly distribute the grease. Remove the clutch plate and wipe off any excess grease.

Clean the new clutch pressure plate with clutch and brake dust cleaner to ensure the face is degreased and, using a clutch alignment tool, mount the new clutch (Fig.8). Tighten the bolts in an even and sequential manner and then torque to the manufacturer’s specification before removing the clutch alignment tool.

Check that all cables, wires and hoses are clear of the bellhousing area so not to interfere with the gearbox installation and make sure that the engine to gearbox alignment dowels are installed correctly.

Gearbox installation

Using a transmission jack, ease the gearbox into position, taking time to ensure the heights and angles are correct. Ensure that the gearbox mounts on the alignment dowels and, once home, insert and tighten a couple of easily accessible bellhousing bolts. Refit all other components in reverse order of their removal, and torque all bolts to the manufacturer’s specification.

After the battery lead has been connected, reset all required electrical systems and carry out a full road test to ensure that the repair has been successfully completed.

30 JUNE 2023 PMM

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAY006 READ ME TO COLLECT YOUR CPD POINT CPDZONE

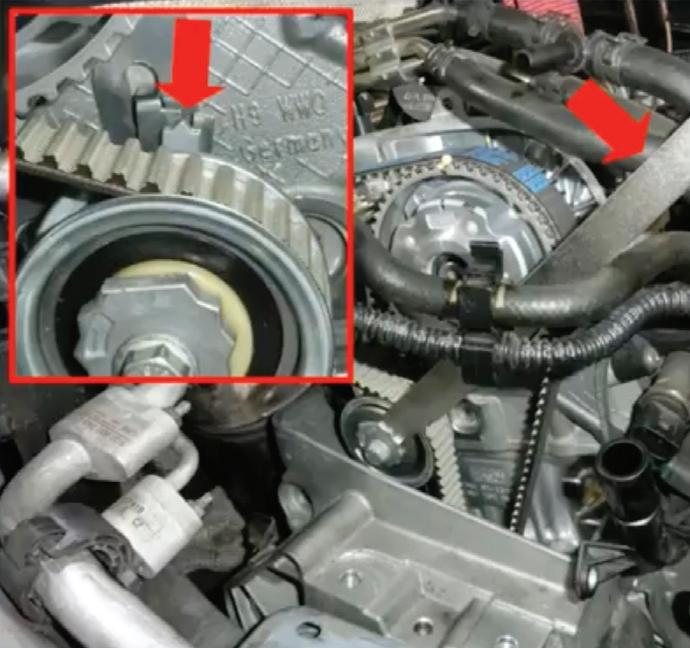

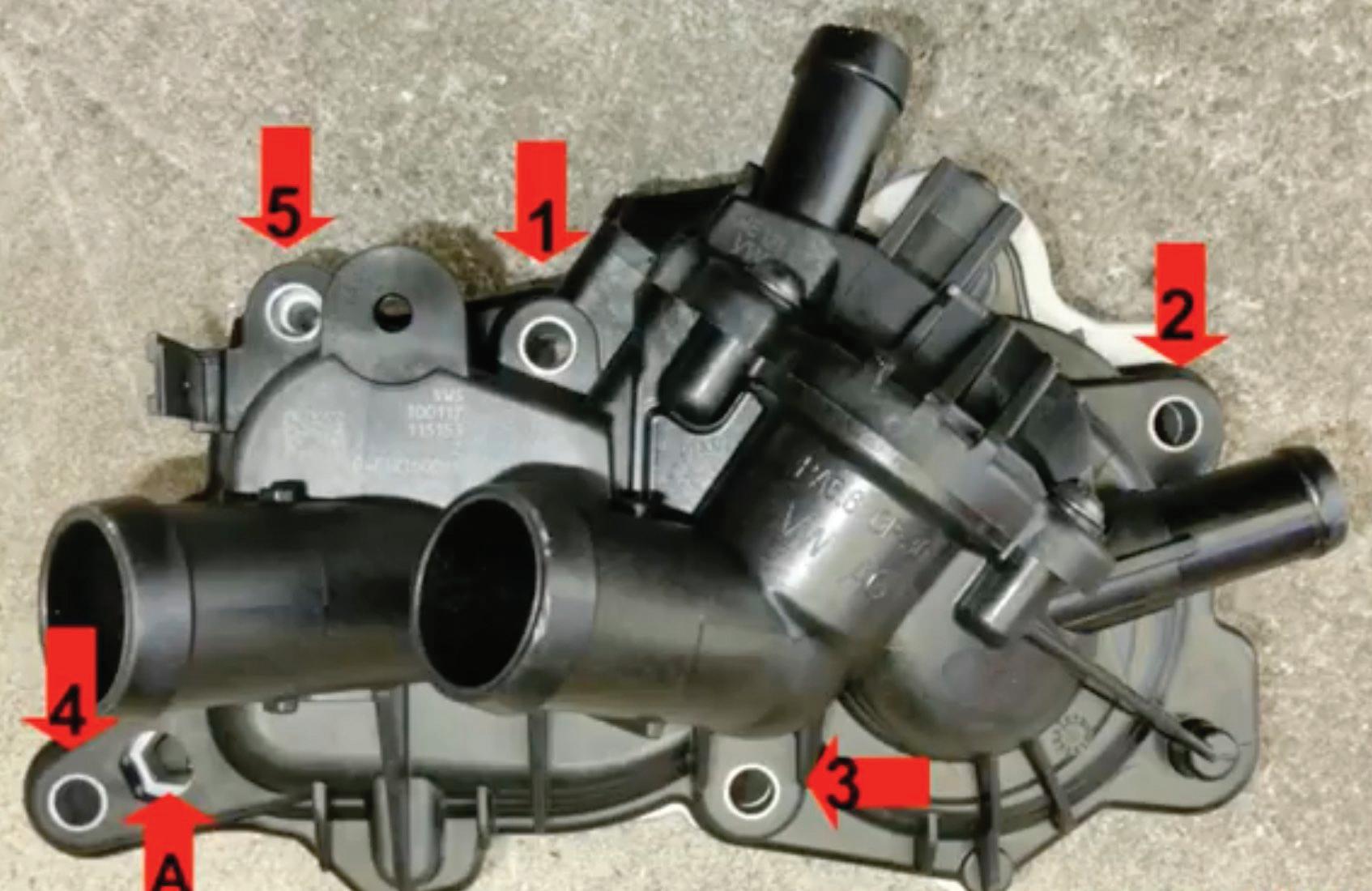

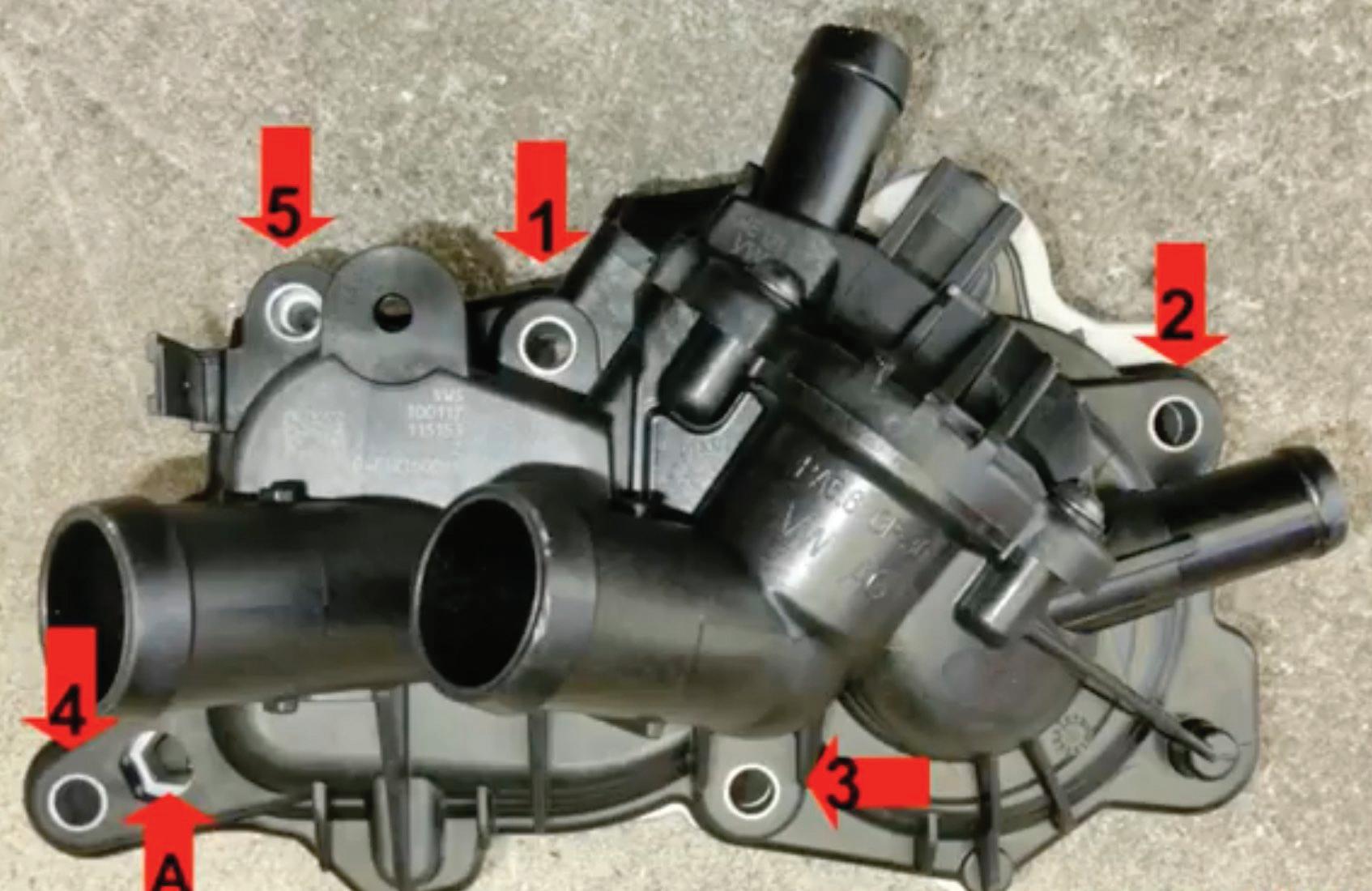

HOW TO Replace the timing belt on a Škoda Octavia

Dayco guides PMM readers through the replacement of the timing belt on a Škoda Octavia, using Dayco Kit KTB819.

On its launch in 2013, the 1.4litre TSI (CHPA) powered mark III Octavia, was the largest petrol engine in the Octavia range, a unit Auto Express magazine claimed at the time was ‘arguably the best engine in the line-up, as it combines impressive pace with good economy’. The powerplant is used across several VAG models, so is likely to be familiar to workshops throughout the country.

As replacing the timing belt requires the removal of the auxiliary belt, Dayco recommends that in addition to replacing all the primary system’s components, technicians check, and if necessary, change the auxiliary components at the same time.

This step-by-step technical guide will help technicians through the process, avoiding complications and ensuring a first-rate outcome. As with all primary drive system jobs, always check the timing marks before removing the timing belt and ensure the work is undertaken when the engine is cold, so ideally, the vehicle will not have been run for at least four hours.

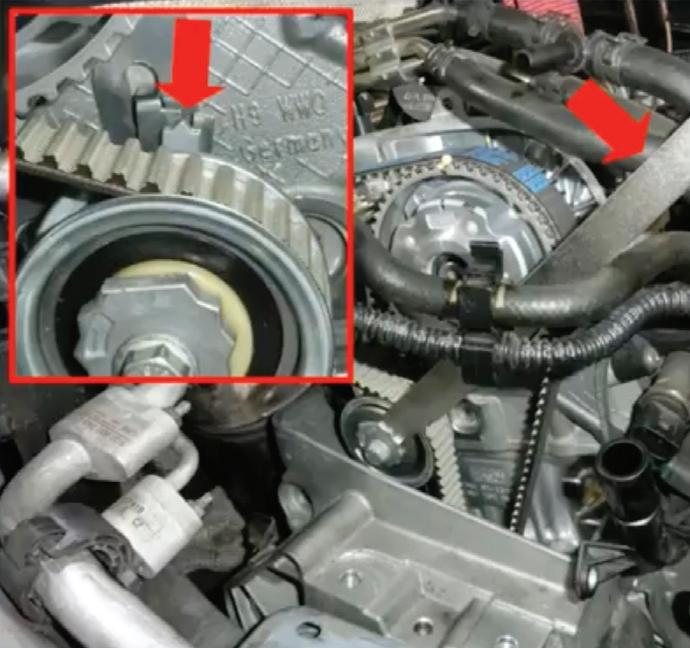

Start by removing the plastic guard from underneath the engine and then, after taking off the front offside wheel, the lower part of the plastic cowling from inside the wheel arch. This will reveal the auxiliary belt system and by relaxing the tension on the belt with a spanner on the tensioner, the belt can be removed. Before disconnecting the tensioner,

lock it by inserting a pin as shown (Fig.1).

Remove the cap in the engine block used to close the hole in which the crankshaft timing tool will be inserted and then disconnect the air intake to the filter box, take out the filter box and detach the pipes between the throttle and turbo, and the filter box and turbo, as well as the oil vapour recirculation pipe and the turbo air intake connector.

Now remove the water pump belt cover and the cover on the gearbox side of the intake camshaft, drain the cooling system and take off the upper cover of the water pump and the expansion tank, as the pump and belt should be changed at the same time.

Detach the upper timing belt cover, which will expose the variable exhaust valve timing unit on the left and intake on the right, and rotate the central crankshaft pulley screw clockwise and position the intake camshaft as viewed from the gearbox side as shown (Fig.2).

32 JUNE 2023 PMM READ ME TO

YOUR

COLLECT

CPD POINT CPDZONE

After disconnecting the ignition coil and removing the spark plugs, insert a screwdriver, which is long enough to touch the top of the number one piston at BDC and rotate the crankshaft to its TDC (the screwdriver will rise by 35mm). Insert, and fully screw into place, the crankshaft timing tool (T10340) and rotate the crankshaft until the shaft rests on the tool. Then fit the camshaft tool (T10494) and after making sure it is in the correct position, lock it with a screw.

Using a special tool (T102475), remove the crankshaft pulley, followed by the lower timing belt cover and the two alternator retaining screws to detach it. Then take off the plate shown (Fig.3), support the engine appropriately from above and remove the top engine mount adjacent to the timing belt and take off the central timing belt cover to access the tensioner and idler. After removing the cover of the left (exhaust) and the central cap of the right (intake) variable valve timing units, take off the tensioner and timing belt. Appropriately lock the valve timing units, remove the centre screws and the units themselves.

Attach the new idler and torque to 45Nm, and tensioner ensuring it is fitted as shown (Fig.4), and then fit the valve timing units on the corresponding camshafts, but do not fully tighten their screws.

Fit the new timing belt, installing it clockwise from the crankshaft pulley via the tensioner, exhaust and then intake camshaft pulleys and the idler. Use the special tool (T10499) to move the needle of the tensioner to the right, about 10mm beyond the fixed reference and then back to the middle of the fixed reference as shown (Fig.5), finally tighten the tensioner fixing screw to 25Nm.

Suitably lock the valve timing units and tighten their screws to 50Nm before removing the camshaft timing tools and temporarily refitting the crankshaft pulley to enable the engine to be turned through a few clockwise revolutions.

Check the belt tensioner needle remains in the right position, and using the crankshaft and camshaft tools, the timing is still correct. If so, appropriately lock the valve timing units and tighten their screws another 135°.

Now remove the water pump with the belt drive and after flushing out the cooling system to remove any debris and cleaning the water pump facing, reposition the replacement pump, with the new belt, Dayco 941094, at the same time.

It is extremely important to follow the correct tightening procedure when reattaching

the water pump cover, so first tighten the screws to 10Nm in the sequence shown (Fig.6) and then loosen by one turn. Put a hex screw in ‘A’, torque to 30Nm and hold the torque wrench in position while retightening screws 2, 1 and 5 to 10Nm and then 3, 4, 5, 1 and 2 to 12Nm.

Refit the components in reverse order of their removal, tension the crankshaft pulley screw to 150Nm + 180° and the crankshaft timing tool cap to 30Nm. To follow best practice, Dayco also recommends the replacement of the auxiliary tensioner Dayco APV3270 and the auxiliary belt Dayco 6PK1000

Finally, refill the cooling system, start the engine and carefully check for leaks and ensure the radiator fan is operating correctly. Then, once the engine is cold, check the level of the fluid again.

REDEEM YOUR CPD CREDIT

Congratulations,

PMM JUNE 2023 33

you have reached the end of the CPD Zone!

access your CPD credit from The CPD Group, scan the QR Code below or WWW.RDR.LINK/AAY007

To

Real mechanics go to MECHANEX

2023 sees PMM once again rounding up the most important suppliers in the aftermarket to provide workshop owners and technicians with an engaging, informative day out of the workshop.

The UK’s longest-running trade show dedicated solely to the independent aftermarket will once again be held at Sandown Park on Tuesday 7th and Wednesday 8th November.

Mechanex is well known within the independent aftermarket for offering visitors a hands-on experience, bringing them the latest updates and expertise from across the industry and providing an exciting day away from the workshop.

7th-8th November

Registration to visit the show is free and so is parking, so why not come and take a look at what the biggest names in the aftermarket have to show you. In such a competitive industry, Mechanex is an opportunity you can’t afford to miss.

If you like PMM, you’ll love Mechanex –it’s simply the magazine in a live format.

The hands-on show for hands-on techs is more committed than ever to bringing PMM to life with new opportunities to debate the future of independent workshops.

NEW FOR 2023

This year, Mechanex will be featuring the brand new PMM LIVE format for the first time. PMM LIVE aims to educate and inform visitors to the show in the same way the magazine does. We will be keeping you up to date on the latest issues affecting your business on our seminar stand as well as bringing you our FutureDrive Zone. We’ll be hosting a raft of forward looking exhibitors who will be demonstrating the products and technology necessary for the workshops of the future. Plus, we’ll be hosting exclusive talks including a debate from the foremost experts in the field on the real future of how cars in the UK are powered.

TO FIND OUT MORE ABOUT THIS YEAR’S MECHANEX AND PMM LIVE GO TO WWW.MECHANEX.INFO BUSINESS & TRAINING

34 JUNE 2023 PMM

PROFESSIONAL MOTOR MECHANIC MECHANEX

TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS

● FREE CPD TECHNICAL SEMINARS ● FUTUREDRIVE ZONE ● FREE ENTRY ● FREE PARKING ● FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL

R E G I S T E R F O R F R E E AT W W W. M E C H A N E X . I N F O THE HANDS-ON TRADESHOW FOR INDEPENDENT WORKSHOPS

S A N D O W N PA R K , S U R R E Y 7 T H & 8 T H N O V E M B E R 2 0 2 3

The regional Tradeshow for aUTo rePair Professionals

FEATURING LIVE

ONLY CONNECT

At an intimate event at Millbrook Proving Ground recently, Autotech Group announced the launch of its latest division – Autotech Connect.

Autotech Group has launched a new division – Autotech Connect – in a bid to mitigate the growing risk of cybercrime threats and help the automotive aftermarket effectively implement technology into their businesses to improve efficiency and overcome skills gaps.

Technology is transforming mobility; as software defined vehicles enter the market and the proliferation of connected vehicles continues, consumers are increasingly expecting their cars to be an extension of their smart phones. Layered on-top of the skills shortage, the lack of training, a failure to invest in technology and the risk of cyberattacks; garages must engage in building their digital infrastructure to ensure their survival.

Through its new Autotech Connect division, Autotech Group has secured partnerships with leading hardware, software, training and IT providers to deliver technology

“Consumers are increasingly expecting their cars to be an extension of their smart phones.”

driven solutions that bring their expertise and application knowledge from other industries, including government, banking, and healthcare, into the automotive aftermarket.

“Our intention is to help aftermarket businesses understand the threats and opportunities created by software defined and connected vehicles and, through our partners, help them navigate the challenges with the aim of increasing productivity, reducing risk and exploring potential solutions,” comments Gavin White, CEO of Autotech Group.

Assisted Reality (AR) devices to support vehicle technicians is just one part of the Autotech Connect solution. “Using AR is a tremendously exciting opportunity and, if used correctly, can help streamline processes and empower vehicle technicians as the most up-to-date technical information they need will be right in front of them. However, AR is just one small part of addressing the challenges facing the industry. There is a journey to undertake, and the digital foundations must be laid to allow the aftermarket to capitalise.” Gavin concludes.

Struggling to keep up

“For many years, we have talked about the skills shortage, how aftermarket businesses are struggling to keep up with the evolving vehicle marketplace and the need for training. The industry, particularly independent businesses, is permanently on the back foot, pedalling to keep up and they are now facing further issues presented by evolving vehicle technology.”

By using specialists, Autotech Connect will help aftermarket businesses implement technology effectively to drive business efficiency, build robust cyber security defences and increase productivity.

Since 2010, Autotech has striven to stay one step ahead, creating solutions to support the industry in its quest to keep up with the evolution of vehicles. This has included the launch of dedicated divisions –Autotech Training and Autotech Academy – to meet the challenges head on and now, Autotech Connect.

PMM JUNE 2023 37

BUSINESS & TRAINING WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAY008

AUTOMECHANIKA Birmingham, 6-8th June

This month sees the return of Automechanika Birmingham to the NEC, so let’s take a look at what the automotive trade show has in store.

EV TRAINING ACADEMY

In partnership with the IMI and Our Virtual Academy, the EV Training Academy will provide a series of 30-minute training sessions throughout each day of the trade event.

With two demo vehicles also on display, attendees can get hands-on to discover more about the opportunities of EV, gain key insights and information, plus ask EV experts anything and everything on hybrids and EVs.

The EV Training Academy programme will cater for all technicians with both beginner and advanced-level tuition on offer. The free sessions, delivered alongside training vehicles to add invaluable practical elements, include Essential EV Training; HV System Isolation (low-voltage service disconnect) for beginners and Advanced EV Training; as well as Plug-in Charging (proximity pilot circuit), suitable for those more experienced in the EV industry.

Essential EV Training will provide delegates with the chance to learn about the high-voltage isolation process using a lowvoltage service disconnect, which is becoming an increasingly popular solution used by vehicle manufacturers.

This training session will compare this solution to other types, explain its function and operation, plus offer some top tips for disconnecting and reconnecting the device during the high-voltage isolation procedure.

The Advanced EV Training session offers businesses the opportunity to learn about the proximity pilot circuit used in Type 2 plug-in charging system.

Type 2 is the most common method for charging plug-in hybrids and electric vehicles, and much like any electrical system, there’s more than enough potential for faults. These sessions will look at the

SAVE THE DATE

Automechanika Birmingham takes place 6-8th June at NEC Birmingham. It is free for workshops to attend.

Automechanika Birmingham

Opening Times:

Tuesday 6th June 20239:30am - 4:30pm

Wednesday 7th June 20239:30am - 4:30pm

Thursday 8th June 20239:30am - 4:00pm

Venue: Halls 18 - 20 NEC, North Avenue, Marston Green, Birmingham, B40 1NT

details of Type 2 charging, including wall boxes and differences between cables, as well as the function, operation, and testing of the proximity pilot circuit.

Steve Nash, CEO of the IMI added: “This focus on EV skills is great news because our latest data shows that by 2030, 103,000 IMI TechSafe qualified technicians will be needed to work with electric vehicles in the UK alone. However, we are currently predicting a potential shortfall of 4,500 qualified technicians by 2029, increasing to a massive skills gap of 16,000 by 2032.”

Here are some of the exhibitors at the show:

PMM (Hall 18, ZZ72)

For the first time Professional Motor Mechanic will be exhibiting at Automechanika Birmingham, offering you the opportunity to come and engage with the team behind your favourite trade mag! We’ll

BUSINESS & TRAINING

38 JUNE 2023 PMM

REASONS TO VISIT

■ 500+ exhibitors

■ 192 hours of workshops

■ 50 product launches

■ £50k worth of show discounts

■ Free parking

be bringing a touch of showbiz to the aftermarket show where we’ll be podcasting throughout the three days. We’re giving you the chance to appear on the PMM podcast, simply hop onto our stand and get in the hot seat armed with nothing more than your opinion. So if you’ve got something to say (and we know you do), come and say it on the aftermarket’s number one podcast!

We’ll also have the red carpet rolled out for the special occasion, so if you want to bag yourself a free PMM t-shirt don’t forget to say CHEESE – you could even win the mystery prize...

MAM Software (Hall 19, J100)

Throughout the event, MAM Software will be championing its core business belief that ‘digitisation, sustainability and profitability go hand in hand’. Attendees will get the chance to see live demonstrations of Autowork Online, the intuitive and featurerich cloud-based garage management software. Autowork Online is constantly being developed to remain an industry leading software, with new enhancements including KPI dashboards, Auto-Link module and many more features designed with efficiency and productivity in mind.

Niterra (Hall 20, E90)

Niterra – owner of the NGK and NTK brands – will focus on its NGK Academy training initiative and its EGR valves range. Garage visitors will also be able to test their skills on a race car simulator when the fastest competitor will win the Niterra Trophy, walk away with a BoxClever gift bag and also have the chance of meeting some of the company’s motorsport ambassadors.

British racing driver Nic Hamilton, who has confirmed he is to drive Team HARD. Racing’s Cupra Leon in the 2023 Kwik Fit British Touring Car Championship (BTCC) season, will be on the stand on the Tuesday. Hamilton, the brother of seven-time World Formula 1 champion Lewis Hamilton, has a long-standing relationship with the NGK brand and will be available to meet visitors as will North Yorkshire based racing car driver Max Coates who will be on the stand on the Thursday.

The Tool Connection (Hall 19, M120)

Visit The Tool Connection on stand M120 in Hall 9, adjacent to the EV Technology Hub, for up-to-the-minute advice and to discuss solutions The Tool Connection provides. Covering both workshop and bodyshop markets, with the Laser Tools and PowerTEC brands, along with Connect Workshop Consumables for both markets, The Tool

Connection keeps up to date with automotive technology, constantly researching and launching new products into the market. This year the company will be featuring many of the latest advancements that relate to electric vehicles, and their service and repair requirements.

Also, there are prizes to be won! When you visit The Tool Connection’s stand, you can enter a competition with a chance to win one of these three prizes:

1st Prize:

2 x VIP Passes to the BTCC at Donington Park on 27 Aug 2023 as guests of Laser Tools Racing

2nd Prize:

£250 worth of tools from the Laser Tools range

3rd Prize:

A magnificent Laser Tools Racing Chair (part no. 6656)

Hella (Hall 19, Q90)

As one of the event’s Platinum partners, Hella will be exhibiting a broad range of its workshop equipment, as well as its original equipment replacement parts programme, that includes a wide range of vehicle electrics and electronics.

As each new vehicle becomes increasingly ‘connected’ and technology dependent, the independent sector is faced with a stark choice: invest in the equipment necessary to gain access to these vehicles and partner with

PMM JUNE 2023 39

a supplier that can provide the OE quality replacement parts needed to reliably repair them, or be left behind and not only lose ground, but potentially lose everything!

Through its Hella Gutmann brand, HELLA will be demonstrating that it has the answer to this most pressing challenge by showing its market leading workshop solutions for both vehicle diagnostics and advanced driver assistance systems (ADAS), from stand Q90 in hall 19.

Delphi (Hall 19, R64)

New-to-range Delphi parts, including a Tesla suspension arm, a raft of first-to-market brake components, and new bi-metallic, high-carbon alloy brake discs are to be set out for all to see, alongside a complete programme of workshop support in the form of Masters of Motion and Delphi Academy.

“Automechanika is a golden opportunity for garages to see what’s happening in our industry,” said Nigel Duffield, UK Country Director at Delphi. “We’ll be demonstrating how we’re helping garages service increasingly complex vehicle systems through the supply of premium quality parts, OE-level diagnostic equipment, technical support and training.”

The brand’s Alpine sponsorship is also set to be celebrated at Automechanika. Visitors to the Delphi stand will be invited to

compete for the best lap time on an Alpine F1 simulator and reaction time on a Batak machine, with daily prizes for the top performers. Elsewhere at the exhibition, Delphi’s Technical Services Manager Luke Garratt will be presenting ‘Hydrogen Internal Combustion – Is this the future?’ as a keynote speaker on Wednesday 7th June.

Dayco (Hall 19, P102)

Dayco, the company that pioneered the belt in oil (BIO) innovation on behalf of vehicle manufacturers such as Ford and VW, will be highlighting the opportunity regular BIO replacement for these engines provides the aftermarket. In addition to timing and auxiliary drive systems and thermal management, Dayco will also be showcasing its range of dampers, wheel bearings and steering and suspension products.

Ecobat (Hall 20, G90)

Demonstrating the spectrum of solutions the company has to offer, the Ecobat Battery stand will be divided into five defined areas: automotive, leisure, mobility/motorcycle, chargers/invertors, with a fifth being dedicated to sister company Ecobat Solutions, which, reflecting the industry’s focus on electric vehicle (EV) technology, offers a fully integrated EV battery logistics, re-engineering and recycling service to manufacturers.

Meyle (Hall 20, E60)

Meyle’s focus during the trade fair will be on its HD product line and its new eSolutions. Among the highlight products, visitors will find automatic transmission service kits as well as the new and innovative Meyle HD control arm for Tesla Model 3 and Model Y, which provides a durable solution that promises to be a standout in its category. In addition to the product highlights, the firm will also display its other high-quality products giving an overview of the product range. A comfortable meeting area invites visitors to sit down and chat with the experts over a cup of coffee.

Ring & Osram (Hall 19, M111)

Lighting specialists, Osram and Ring will be sharing a stand with an extenstive display of their products, including a focus on the OE lighting solutions Osram provides, as well as Ring’s aftermarket battery care, workshop tools, and inspection lamps.

Highlights will include new products that have been recently introduced, including the Night Breaker 200, Osram’s Professional Series of working lights and Ring’s coloured inspection lamps, cordless tyre inflator, pro jump starter and worklamps.

The stand will host interactive features and experts from both brands will be on hand throughout the show to discuss products.

40 JUNE 2023 PMM

BUSINESS & TRAINING

Fill your BOOTS

One debate which will always get workshop owners’ neurons firing is the relative advantages and disadvantages of OE vs. aftermarket parts. On the one hand, you have OE parts, which are, of course, the original parts – when a part fails on a customer’s car, often the best thing you can do is to replace that part like for like; after all, the vehicle was designed with that part in mind. On the other hand, however, aftermarket parts present a cheaper alternative, which allows you to pass savings back to the customer – the downside being that the quality of manufacture, materials and design hasn’t been assessed and approved by the original vehicle manufacturer. So, would it be fair to say that OE parts are always more expensive and always better quality? Well, perhaps not. Speaking to Bailcast’s sales director Martin Calley, I got the distinct impression that when it comes to CV boots, the aftermarket solution has roundly trumped the OE part, for a number of reasons.

Boot range

You almost certainly have handled a Bailcast product before – the number of units shifted over the years is astronomical. The firm’s main products are CV boots, but it also manufactures steering rack boots, universal ball joint dust covers and tools for fitting the CV boots; Duragun and the newly launched DuragunPRO. There are two lines of the CV boots – 8 Duraboots which are aimed squarely at the trade and cover 93 per cent of the car parc; and three universal boots (including a split boot aimed at driveway mechanics). All of the boots are produced right here in the UK. Martin was keen to stress the importance of manufacturing

products in the UK: “When we sell our products in Europe, our customers are happy to pay more because they recognise that products made in the UK are of a higher quality than those imported from the far east. I would like to add that when we put Made in Britain on the side of the box, it’s because it is actually manufactured here and not simply imported and reboxed here. The boots have been made here since our inception in 1980 and we monitor their quality very closely” Rewinding back to 1980. The company

You almost certainly have handled a Bailcast product before – the number of units shifted over the years is astronomical.

was started by Philip Hayward, who remained the managing director right up until his retirement in 2020, selling the business to his existing management team. Despite retiring Philip can still be found offering support and advice to the team around the office. In Martin’s words, Phil lives and breathes Bailcast and no matter what happens, “Bailcast will always be Phil”. The concept of the stretch boot all came about when Phil was tinkering away on a classic Rolls Royce passion project that required him to change the CV boot. Phil began to wonder whether he could transfer the steering rack gaiter concept of the concertina pliable rubber boot to the CV joint.

The enterprising rubber engineer drew up

SPECIAL REPORT

PMM ’s Kieran Nee speaks to Bailcast’s sales manager

Martin Calley to find out more about the CV boot firm’s manufacturing pedigree.

42 JUNE 2023 PMM

plans for a neoprene CV boot, whose material properties would provide several advantages over its OE equivalent and sent them out to parts suppliers and distributors in the industry, hoping for some advice and words of encouragement in return. What came instead were orders, and the CV24 Universal boot was born and with it the Bailcast stretch boot. The boot design and materials have undergone changes since then, but the concept of a synthetic rubber boot in a concertina style has remained the same. The material blend used in its manufacture allows the boot to stretch up to four times its size, as well as withstanding very low and very high temperatures. OE boots come mainly in two forms: natural rubber and thermal plastic. Natural rubber, Martin tells me with a smile, degrades over time when it comes into contact with oil, which is exactly what the

“When we put Made in Britain, it’s because it is actually manufactured here and not simply imported and reboxed here.”

Martin Calley, Bailcast

boot is designed to do. What’s more, it doesn’t react well to ozone. Thermal plastics, on the other hand, are rigid and brittle, not suited to bending – the other requirement of a CV boot. In short, neither of the OE solutions are very durable and so aren’t normally covered under the VM warranty.

Bailcast’s boots, on the other hand, come with a two-year warranty, as their oil and grease resistance, flexibility and aforementioned

thermal resistance ensure that once fitted, they will last a long time. So, my question was, why haven’t the VMs been a-knocking?

“They have!” Martin replies, “but we can’t produce them as cheaply as they want. When it comes to the CV boot, all they care about is cost. When it fails, which it will, it’s up to the driver to pay for a replacement. They can either get the OE boot, which will be expensive and will fail again, or they can get the aftermarket solution for a lot less and not have to worry about it again for a long time.” I know if I was running a workshop which one I’d be fitting.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAY009

BEST PRACTICE

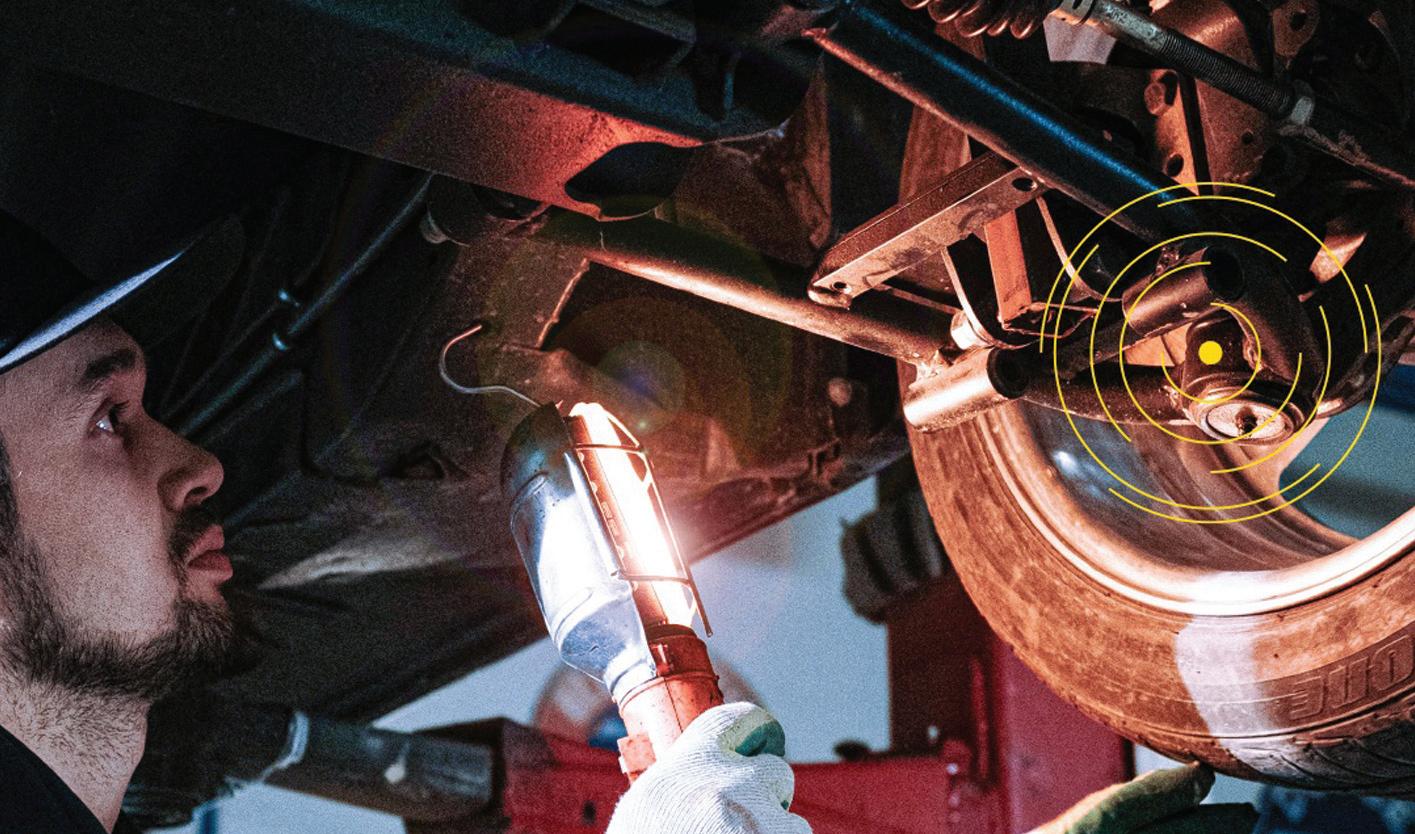

Replacing the rear suspension on a Ford Mondeo 2007-14

Febi takes us through the rear suspension on the trusty Ford Mondeo.