PROFESSIONAL M OTOR M ECHANIC

ENTER THE CPD ZONE! YOU COULD EARN ONE CPD CREDIT THIS MONTH

Let’s get technical:

AN AUDI A4 HAS ITS DMF REPLACED

CABIN AIR FILTRATION EXPLORED

WHAT ROLE DO 12V BATTERIES PLAY IN EVS

COULD MOT TRAINING BE BETTER?

CHECK OUT JEN FROM HR VITALS’ NEW REGULAR COLUMN WIN A DAY AT THE RACES WITH KALIMEX

NOT GOING ANYWHERE: BELT-IN-OIL TIMING DRIVES

STABILISER BARS, BALL JOINTS, EV SUSPENSION AND MORE!

FREE TOTHE TRADE PMM

2024

JUNE

Editor’s Picks

22 TAKING CHARGE

As part of this month’s CPD Zone, automotive battery specialist Varta is taking readers through the importance of the traditional 12V battery as the UK heads towards an electric future. Make sure to scan to QR code at the end of this feature to claim your CPD point.

31 WORKING WITH OTHERS

Looking for some top tips from the aftermarket’s HR expert? Look no further than our new regular column from Jennifer Webb, owner and director of HR Vitals.

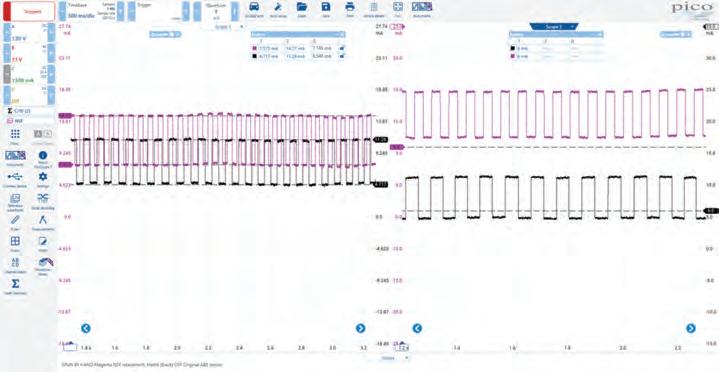

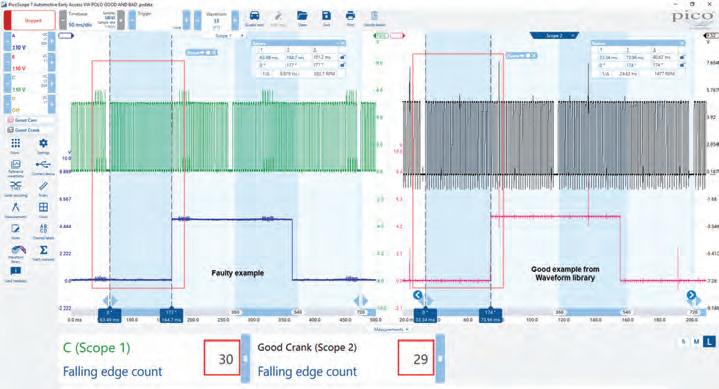

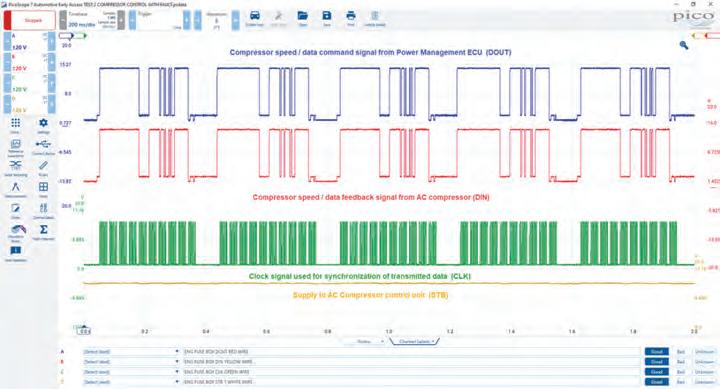

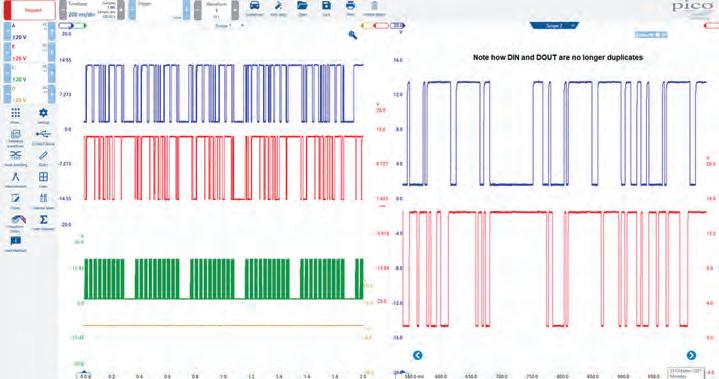

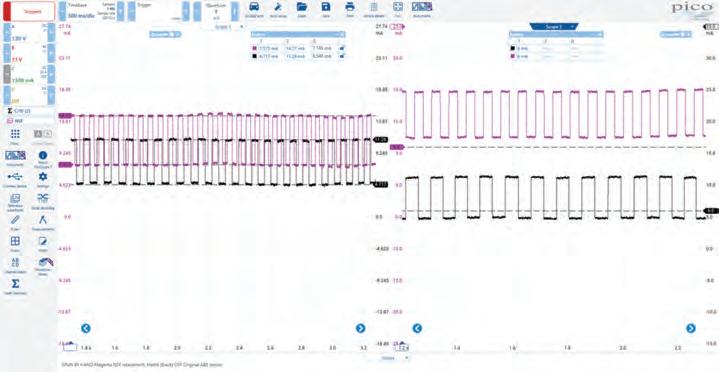

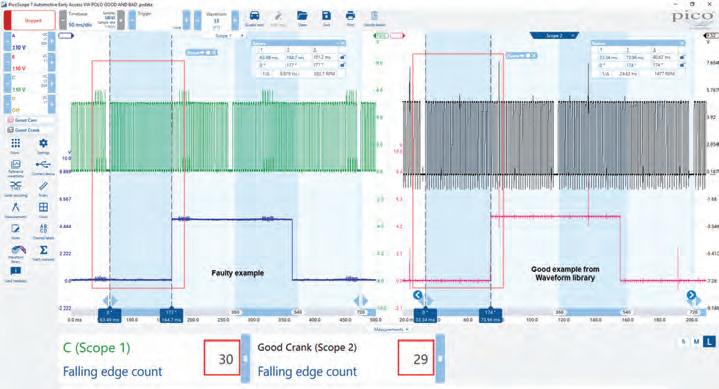

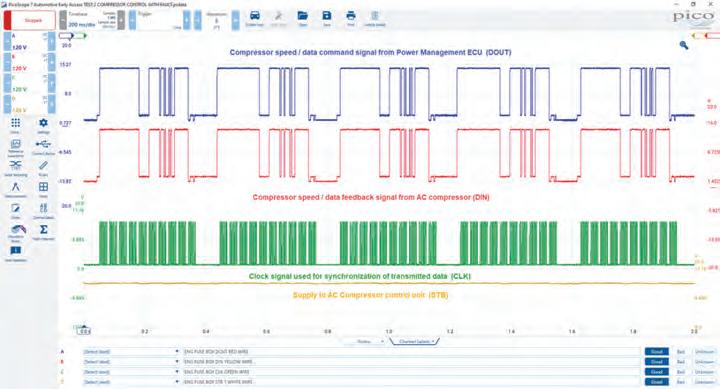

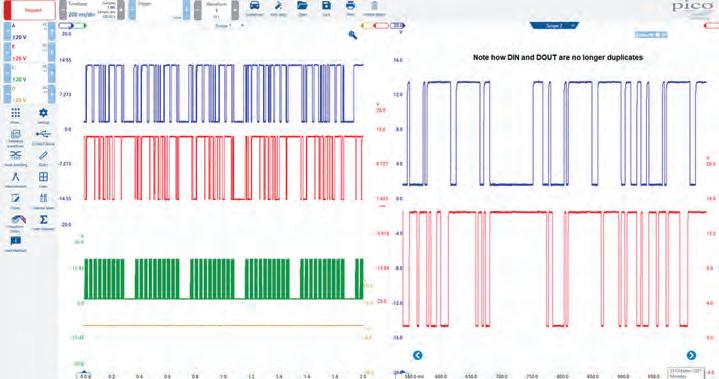

Sitting pride of place in our bumper diagnostics and engine management feature is an article from Pico’s technology specialist Steve Smith, providing us with a comprehensive guide on how to do oscilloscope diagnostics with some best practice tips.

PMM has a rare prize opportunity for one lucky reader and their family to spend a day with a world championship winning race team, thanks to sponsors Kalimex! Turn to page 59 of the magazine to find out how to enter.

Features

Contents VOLUME 25 ISSUE 6 JUNE 2024

Total Average Net Distribution 53,353 1st July 2022 – 30th June 2023 PMM JUNE 2024 3

6-9 NEWS & VIEWS 10 PMM PODCAST: THE BEST BITS 13-29 CPD ZONE 30 PIT STOP 31-33 SPECIAL REPORTS 61-65 IN THE WORKSHOP

Regulars

39 OSCILLOSCOPE DIAGNOSTICS GUIDE

59 WIN!

44-51 OILS, LUBRICANTS & ADDITIVES 35-43 DIAGNOSTICS & ENGINE MANAGEMENT 52-57 STEERING & SUSPENSION

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Senior Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

UK £30 post paid

Air mail

£80 post paid

Europe £50 post paid

Printed by

PCP Telford

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF. Tel: Watford (01923) 237799 Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk Website: www.pmmonline.co.uk

Copyright © 2024

WHEEL OF FORTUNE

We could be gearing up for a general election by the time you’re reading this, as at the time of writing, Rwanda Rishi is refusing to rule out a summer vote. Also at the time of writing, it’s starting to look like a Labour landslide in the local elections. Either way, one thing I can be confident of is that by June, both parties (there are more than two?) will be in full battle mode, fighting for the hearts and minds of UK voters. I would say they’ll be fighting for our wallets too, but both parties have acknowledged that wallets (and coffers) are rather light these days and that that’s unlikely to change much, whatever the outcome.

We’re just coming out of a high employment period in which jobs were seemingly there for the taking, but now the “phantom” recession is starting to take hold and the economic seesaw tilts back again from ‘high inflation’ to ‘fewer jobs’. You can’t have both affordable goods and money to pay for them at the same time, it seems, but don’t worry, it’s only a technical recession. You’ll only ‘technically’ be losing your job.

All this doesn’t apply, thankfully, to workers in the automotive independent aftermarket. The previous years of economic hardship have meant that drivers have been repairing rather than replacing their cars and, what’s more, supply chain issues have meant that new cars just haven’t been available for those who have replaced. All in all, the UK car parc has never been older and never been in need of more repair.

In turn, garages have never been busier, with no shortage of cars needing servicing and repair. Does this mean, then, that garage owners are enjoying the good times? Does this mean that when you are asked, repeatedly this summer, whether you are better off now than you were prior to... well, prior to something (it's hard to see where either political party will draw the line to make themselves look good), you will respond yes, indeed, my garage has never been so busy and by the simple laws of finance, I have never earned so much profit. Unlikely.

More likely is that most of you will be in a position where you are having to turn work down because you haven’t got the staff, you are having to prioritise time-consuming work over profitable jobs and what extra profit you are making is quickly being lost to inflation, rising rents, living costs and that’s not to mention the plethora of industry-specific costs which seem to pile on from nowhere.

Being busy is a poor indicator of profit, just as high employment is a poor indicator of growth when the majority of those jobs are zero hours, zero pride, zero hope. It’s time quality was priveliged over quantity and that’s something all of us could work on this summer.

KieranNee Editor

VIEWPOINT

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE PMM PODCAST

PMM NEWS

NEWSIN BRIEF

■ NORTHERN IRELAND MOT EXEMPTION CERTIFICATES

ISSUED The infrastructure minister John O’Dowd has announced temporary on-year MOT exemption certificates for cars aged between five and seven years old in an aim to tackle the current test backlog.

■ DIGITAL MOT CERTIFICATES

ISSUED The DVSA has announced that drivers can access MOT pass certificates digitally, by default, at the time of the test, rather than waiting for the official letter.

■ FAMILY GARAGE BREAK IN Wellington Garage in Middlesbrough has been left devasted after a late-night break in. The business that has been serving Teesside motorists for the last six decades saw the loss of three snap-on toolboxes with a potential replacement value of over £40,000.

■ RING AUTOMOTIVE TURNS 50 To celebrate, Ring is ensuring its 50th year is memorable for everyone associated with the company. Included in the celebrations, the team has produced unique limited-edition gifts for customers with a custom designed Lego kit and a specially brewed Yorkshire beer.

with Freya Coleman

Complaints on the rise

The Motor Ombudsman has recorded the highest ever volume of service and repair cases brought by consumers to its dispute resolution service in a single quarter.

Between 1st January and 31st March 2024, 1,604 new cases about routine and ad hoc maintenance conducted by repairers were logged by motorists under The Motor Ombudsman’s Motor Industry Code of Practice for Service and Repair. This equates to a 35 per cent rise versus the opening three months of 2023 (1,189) and surpasses the

Diversity insights

Insight from the IMI’s diversity task force, published in its latest report reveals a more positive picture of diversity in many areas, but female representation is still lacking.

The proportion of automotive employees with a disability has increased since the force’s first report in 2022, as has the

previous high of 1,372 seen in the fourth quarter of 2023.

Service and repair disputes have accounted for nearly a fifth of the total cases opened by consumers during the first quarter of 2024. Similarly, phone calls from consumers were received during the same period increased by 56 per cent compared to January to March 2023. The notable year-on-year jump in demand is said to most likely be a reflection of the sustained financial pressures on consumers from the heightened cost of living.

proportion of non-white British employees. However, female representation in the workforce has taken a backward step compared to the 2022 report. Based on these findings the professional body is urging employers and individuals to get involved in the IMI diversity task force working group.

Driving Towards Inclusion: Key findings

■ The proportion of female employees across the whole industry has fallen by 2.1 per cent over the past two years, now standing at 17.5 per cent.

■ 15.5 per cent of automotive workers have a disability, 2.2 per cent higher than in 2022.

■ Ethnic diversity has increased by 1.1 per cent compared to the 2022 report to 13 per cent – however the automotive

sector remains behind the UK where 18 per cent of the general working-age population is non-white British.

■ The female automotive workforce is statistically younger and more ethnically diverse than males.

■ Males with disabilities and non-white British males are under-represented in automotive.

6 JUNE 2024 PMM

in

association with

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

Matching BEV and ICE vehicle prices

According to a new white paper released by Indicata, there is indication that prices of some used battery electric vehicles and ICE cars are starting to equal each other in Q1 of 2024.

Entitled ‘Reaching used BEV and ICE car price parity’ the white paper follows used retail car prices of all fuel types from 2020-2024. This includes using its data to track used prices of five popular BEVs from Citroen, MG, Vauxhall, Peugeot and Hyundai against their equivalent ICE models. Dean Merritt from Indicata said: “Price

parity is vital for BEVs in the used market as consumers are now being offered all the latest fuel types at similar prices, where before used BEVs were commanding a 25-30 per cent price premium which put buyers off going electric.”

One example listed was a Citroen C4 BEV vs a two-year-old C4 with 20,000 miles. The Citroen C4 BEV reached price parity with its diesel equivalent in May 2023 at £17,400 but prices continued to fall. As of March 2024, BEVs were worth £14,200 against £16,200 for the diesel.

IMI-approved Hella academy opens

The PMM team were on hand to witness the opening of the new Hella Academy, which has been given the official thumbs up from the IMI. Whilst there, Hella’s technical team gave the journos in attendance much food for thought on the thorny issues surrounding cyber security. Representatives from the IMI were at the event, where the certificate and plaque confirming IMI centre status was presented to Steve Fox, training manager at Hella Academy. He said: “This is a momentous day for all of us at Hella Academy. Much work has gone into putting together this

brand-new training centre. We can now work to support the sector up-skill, with the initial focus on advanced driver assistance systems.”

In pictures: Motul has been announced as a Circuit Partner & Event Sponsor of Wiltshire’s Castle Combe Circuit for the 2024 season.

In pictures: Motul has been announced as a Circuit Partner & Event Sponsor of Wiltshire’s Castle Combe Circuit for the 2024 season.

PMM NEWS with Freya Coleman

NEWSIN NUMBERS

53 %

of drivers say the rising cost of petrol and diesel is their biggest car concern, followed by insurance (52 per cent) and MOT servicing (37 per cent). This is according to research conducted by Close Brothers Motor Finance.

£ 941

is now the average price of car insurance in the UK, increasing by 43 per cent in the past 12 months according to the latest Confused.com car price index.

79 %

of drivers prefer buttons over screens for essential controls in their car, shows April’s new Startline Used Car Tracker with only 51 per cent believing that having all controls on touchscreens is safe.

50,776

MOT appointments were missed across Northern Ireland in 2022/23, which comes after the chief executive of the DVA said motorists face an average wait of 72 days for MOT tests.

Jump starting battery woes

In a recent post on the online biking forum Singletrack World, one unfortunate user told a shocking tale of how a routune service at a Halfords service centre has potentially ended in disaster for their car.

Asking fellow users whether Halfords had “killed” their car, the worried poster detailed how their woes began when their Renault Grand Scenic’s battery needed a jump start: “It went into Halfords for an interim service and MOT last week, had to replace one tyre, the ball joints and suspension arms (which hurt) but otherwise fine.”

A few days later, the battery was gone again. The poster called the same people to jump start their car again but this time it doesn’t start back up and “dies altogether”, with all dash lighting completely dead. The engine eventually restarts, but sounds “really rough”. They continue “Helper guy drives off and I try to go home – no power! The car sounds awful and won’t get above 20mph. Also, the dash lights up with warning

Big car ban?

April’s Startline Used Car trackers has shown that six out of ten people believe that drivers of four by fours and other large cars should pay more to park in city centres.

This question was asked following the news that parking charges in Paris have been trebled for any vehicle weighing more than

messages: the ‘needs service’ light comes back, I also briefly see a message to check the injectors. The car’s now at home. Called Halfords, they say the battery seemed fine when they checked it, no other comment unless I bring it in again.”

They finish the post by asking if Halfords caused the car’s problems, or if it’s the engine or electronics. The responses to the post by other users were mixed, one urging the original poster to “get it to a trusted local garage to check it out”, others insisting on a battery replacement or arguing that Renaults have notoriously ‘dodgy electrics”. Either way, it’s hard to say who is at fault!

1.6 tonnes. The company wanted to see if there was an appetite for this French move here in the UK and the answer was found to be ‘oui’, with 37 per cent saying that these vehicles are too big for city streets and are too polluting.

Mechanex returns to Sandown Park

Following the success of heading up north to the Yorkshire events centre in Harrogate. Mechanex PMM Live, the UK’s longestrunning trade show dedicated solely to the independent aftermarket is headed back to Sandown Park in Surrey on the 12th and 13th of November. Exhibitors anounced so far include Opus IVS, Motul and Bosch. The event is free to attend (and so are the bacon rolls!) so scan the QR code to register now.

8 JUNE 2024 PMM

in association with

News in quotes

“EVs will be part of the picture, of course they are. But at the current rate of electrification even if we could keep it up – which we can’t because China is withholding the rare earth minerals we need – by 2050 the majority of cars on the road will still be, and have to be, internal combustion engines. So we have to solve that, and synthetic fuels will be the way.” Richard Hammond, journalist and TV presenter.

Mental health MOT

The automotive charity Ben has announced it will be launching health checks for automotive people, offering the chance for those who work in the industry to have a personal MOT for their physical and mental health.

Ben health checks can be booked by any automotive employer wanting to invest in the health and wellbeing of their employees. In today’s fast-paced world and work environment, with multiple additional challenges, prioritising employee health and wellbeing has never been more important for any business. This is further supported by results from Ben’s health and wellbeing survey which indicated 99 per cent of respondents said they had experienced an issue with their

health or wellbeing over the past 12 months. The health checks offer the opportunity for automotive employees to have one-onone conversations about their physical and mental health with a qualified health professional and also identify potential issues and suggest making positive changes so people can live and work well.

DATES FORTHE DIARY

■ The IAAF is launching its inaugural Summer Conference and Networking Event, taking place on Wednesday the 12th June at The Belfry, West Midlands . The event will be IAAF’s first member Summer Conference in over a decade and will feature key guest speakers from within the automotive industry and beyond, as it looks at how the sector can inspire, nurture and develop talent. Members will have the opportunity to network with other likeminded professionals and take away key insights on skills, training and recruitment from leading aftermarket speakers.

■ Schaeffler has announced its upcoming REPXPERT 2CT training course is scheduled to take place on 16th - 17th July, at the South Devon College Skills Academy in Newton Abbot, Devon. The two-day course combines theory with hands-on practice to equip technicians with the confidence and repair solutions needed to efficiently undertake VW double clutch system repairs.

MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

A look inside:

PMM THE PODCAST

MOT Tester training – needs fixing?

LM: As a mechanic myself I left school with “some” qualifications – I wasn't very academic. I got into the industry because I was good with my hands and knew and understood how things worked; I couldn't tell you how they worked, I couldn’t write it down, not in a very good format. But now, as MOT testers we’re expected to be more academic, to do those minimum hours of training a year, to keep a training log, to read some very awkwardly worded questions sometimes and give awkwardly worded answers and that’s what people dread. It takes you back to school, to your exam days, with the fear of having to sit in a hall full of hundreds of students and sit quietly and write a paper. I think that’s what a lot of testers still do now. And we do have testers

with learning disabilities, dyslexia and such like. And I don’t think the annual assessment and online assessment is geared up for those people.

I think that the training has certainly slid since DVSA relinquished the training inhouse. The message was consistent back before 2016. We did our five-year refreshers. We had to go to DVSA or VOSA back then for two days. You met like-minded people, you discussed other situations... In that environment, you were free to talk, whereas now the online assessment is sold as flexibility – you can do it at home, you can do it at work, you can do it at the weekend. That does suit some people, absolutely, but we always get the feedback that the old way was better.

The most recent episode of the PMM Podcast is focused on the MOT, how the training is administered and what needs to change to improve engagement with the testers themselves. Here, we take a sample of the conversation Kieran had with Leigh Marsden and Kallum Dorman from Protech Academy, an MOT training organisation.

Face-to-face training

KD: With face-to-face training you can ask questions to a trainer like myself and Lee.

LM: I don't think testers get the support like they used to you know back in the day of the vehicle inspectorate and VOSA. There were vehicle examiners that used to visit the garages quite often and they were a form of education. You could ask the

The DVSA needs to be reaching out to the industry more?

LM: I think they definitely need to do more. I think they need to engage more with the garages, listening to the boots on the ground and actually at the coal face, vehicle examiners aren't visiting the garages as we know, like they used to. And I don't think that testers are being listened to, especially around the annual training. I think there are a lot of complaints about how it's done and how long they've got to do it and it’s absolutely a valid point that DVSA is

vehicle examiner and garages would be looking forward to seeing the vehicle examiner in some cases because they had a burning issue. Some not so much, I’m sure! But also you used to have the vehicle examiner’s phone number and you could ring the vehicle examiner and ask him the question and he would answer you and they were very experienced guys.

expecting these testers to do this annually with little resource other than any learning package.

TO LISTEN TO ALL OF THE EPISODES SO FAR ON THE PLATFORM OF YOUR CHOICE, SIMPLY SCAN THE QR CODE

10 JUNE 2024 PMM

Leigh inspects our microphone with suspicion

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS –

ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

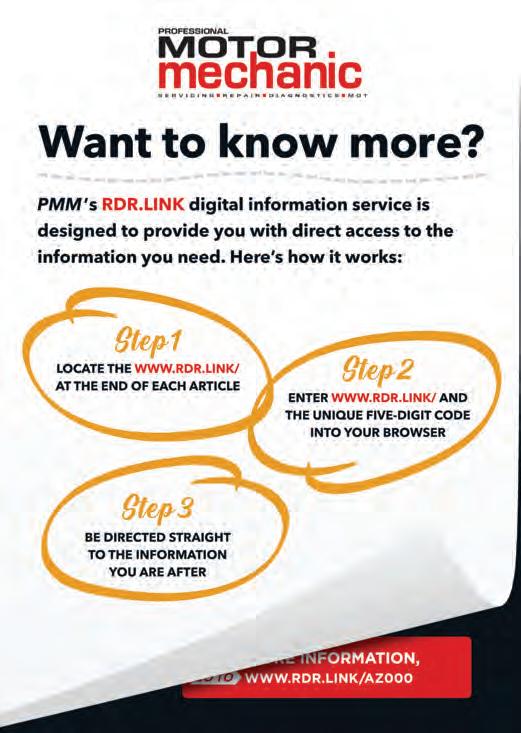

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS –ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

PMM JUNE 2024 13

READ ME TO COLLECT YOUR CPD POINT CPDZONE

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts

TROUBLESHOOTER

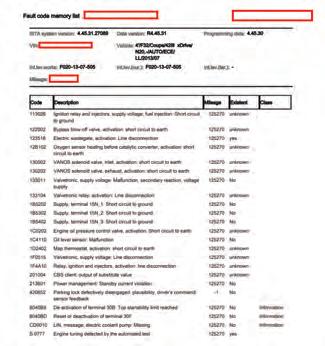

What was wrong with the engine on this BMW N20?

PMM ’s troubled troubleshooter Ben Johnson stambles through numerous fault codes and takes a look at fixing a BMW N20 that staggered its way into his workshop.

It’s a rarity these days, a genuine anomaly, to have a vehicle stagger into the shop, presenting a problem more intriguing than the textbook misfire caused by a rebellious coil or an injector shedding more tears than a reality show contestant on the brink of being sent home. So when this particular vehicle was towed in, I was already convinced that a mundane misfire wouldn't be on the day’s agenda. Such was my conviction until I perused the epic tale etched across the job card, a veritable odyssey of mishaps. After battling through the dense Finnish prose, converting into English as I went, I was left with only the remotest possibility of an easy passage home. My woes were matched only by those of the vehicle’s owner, who had, in a burst of optimism, attempted to clinch the pole position at the impromptu Vantaa Grand Prix off the traffic lights. However, whether it was the automotive gods looking down disapprovingly, or simply the quirky little habit BMWs tend to have of failing at the most inopportune moments, this driver’s quest for motoring glory was cut short with a dramatic thud and a blaze of warning lights, his trusty steed stuck to the tarmac, unable to carry on.

This was a stark reminder, a nudge from the universe, that to assume anything in the realm of fault finding is to invite chaos itself for tea. It's as if the gremlins lurking within these headaches on wheels conspire to keep us humble, underscoring a truth known all too well in our line of work: the moment you believe you've seen it all is precisely when you find yourself on the threshold of yet another automotive odyssey. So, it's time to fasten our seatbelts – figuratively speaking –as it appears the deities of fault finding have deemed it necessary to refresh our memory. In the unpredictable world of car repair, the

only constant is, ironically, the sheer unpredictability of it all.

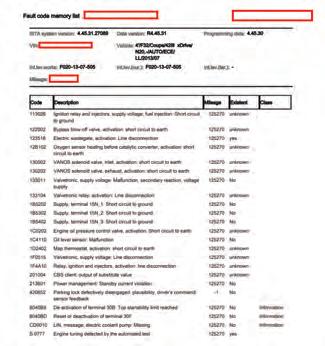

Diving into the labyrinth of fault codes is a bit like trying to decipher the Rosetta Stone with a hangover – challenging, mildly infuriating, but oddly rewarding when you start to see the patterns emerge. Among the hieroglyphics that modern cars throw at us, a few symbols – or in our case, fault codes –stand out not just for their ability to confuse

but for their sheer, unadulterated clarity. Yes, amidst the chaos, there are beacons of light and for those of us who fancy ourselves as automotive Sherlock Holmes, these highlighted images are our Dr. Watsons.

Now, let’s cast aside the usual headache of trying to wrestle every single fault code to the ground and focus on the most important ones. Glancing at fault code 113026, we're not just looking at a short to ground – oh no, we're staring into the abyss of an electrical Armageddon, a short so bold it might as well have its own theme music. And then, as if to add insult to injury, code 1F4A10 waltzes in, casually announcing that the fuel injectors and coil packs power supplies have decided to take a sabbatical.

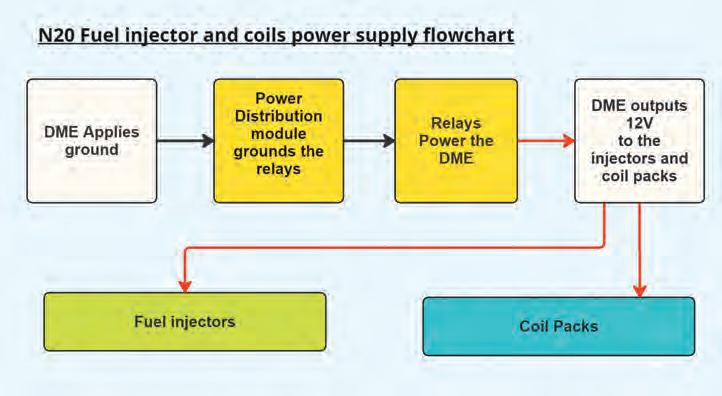

So here we are, left pondering the existential questions of our time: Why has our trusty set of coil packs ceased to spark? And why oh why have our fuel injectors taken an unexpected leave of absence from their daily grind of atomising fuel into the cylinders of this trusty N20? (Fig.1). We can't help but feel a tingle of excitement – because solving this puzzle is what gets our sprockets turning (Fig.2).

PMM JUNE 2024 15

READ ME TO COLLECT YOUR CPD POINT CPDZONE

the cause

simple

The N20 gets a lot of bad press but if looked after it isn’t so bad

A large number of fault codes yet

is

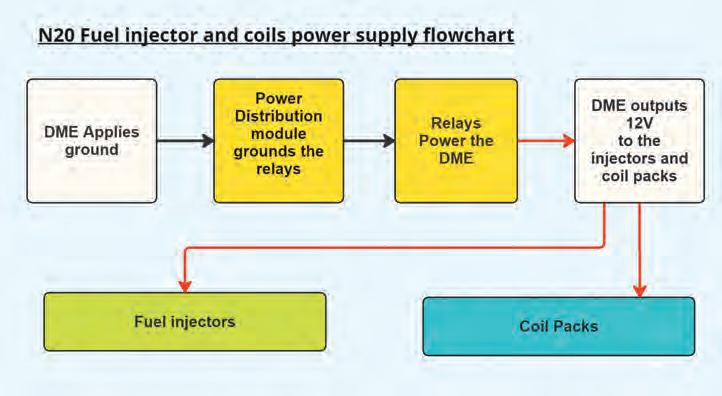

At the heart of diagnosing this puzzle is understanding the system. Essentially, the injectors and coils have been benched because of an active short. Shorts to ground are notorious for their potential to escalate from a spark to a bonfire. Sensibly, the DME has decided to cut the power to prevent any pyrotechnics. Here’s how it works: the DME grounds the relays in the power distribution module, which in turn energises the relays nestled inside. Once energised, these relays supply 12V to the fuses within the same module. This action makes voltage available to the DME, powering up our coil packs and injectors (Fig.3).

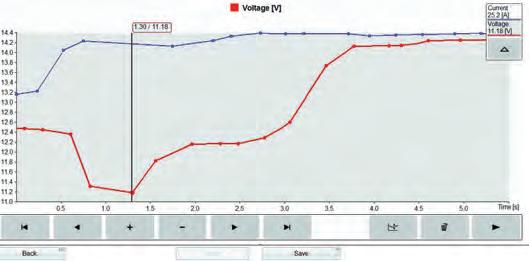

Convinced the culprit lay with a rogue injector or coil, I dove straight in, pulling the coils first. The second coil looked like it had seen better days. In a stroke of luck, leaving this coil disconnected allowed the engine to start on three cylinders. After this, I was able to clear the fault codes (Fig.4).

The source of the voltage comes from the power distribution module and sure enough it was as dead as a doornail, zero volts displayed on the red/green wires of the main connector and the trigger wire, a grey jobbie, was showing 12V – a sure sign of a ground switch not grounding (Fig.5). When we see 12V like this it should be understood that it is there as a substitute value, it is there in place of the ground to prevent the ground switching relays in the power distribution box. It may be 12V but it has no potential so to speak (Fig.6).

Armed with the Power Probe Maestro, the next logical step was to scrutinise the ground trigger. Upon testing, it was observed that reintroducing the number 2 coil pack caused

16 JUNE 2024 PMM

READ ME TO COLLECT YOUR CPD POINT CPDZONE

This type of deposit is a classic sign that petrol has been present at some point and has baked on this oily brown colour to the coil.

Disconnecting the number two coil allowed the engine to start.

A power distribution module. Three relays (not visible) sit on the opposite side of the circuit board. The yellow pin is the ground trigger from the DME.

Fuel injector and coil power supply flowchart

the ground trigger from the DME to switch to 12V (Fig.7). Replacing the coil with a new one didn't rectify the issue, leading to a detailed inspection of the coil pack wiring. Surprisingly, the ground and power supply were intact, but the switched signal wire from the DME exhibited a ground when it was expected to show around 3.7V. This anomaly pinpointed our culprit (Fig.8).

The critical question arose: was the fault due to a short in the wiring harness or a faulty DME transistor? A simple test by disconnecting the wire from the DME pin 13 allowed the car to start, suggesting a closer examination of the DME. Disconnecting the wiring and conducting a continuity check to ground on pin 13 of the DME (coil 2 signal) confirmed the diagnosis: the DME, or more precisely, its transistor, was compromised (Fig.9). The evidence suggested that the malfunction was not due to the wiring but likely caused by the problematic coil pack burning the transistor inside the DME. Usually, this fault would not prevent the car from starting but there is always a first time for everything.

With the diagnosis clear, the decision was made to replace the defective coil and spark plug. Meanwhile, a used DME was sourced and cloned using the Thinktool Euro Master, which facilitated the cloning process to a straightforward plug-and-play operation (Fig.10). This repair strategy brought the 428i

back to life, running smoothly once again. This N20 engine is back in action, purring away without any current threats that might lead to another transistor meltdown in the number 2 coil pack. As is often the case, budget considerations guide many repair decisions. This time, the focus was solely on replacing the offending parts: the number 2 coil and, as a precaution, its spark plug. Ideally, a full set of four coils and plugs would be the recommendation for a comprehensive fix, yet the reality of customer preference and financial constraints led to a more targeted approach, addressing only the directly affected components.

The journey of automotive fault finding is as much about learning and applying knowledge as it is about the satisfaction of resolving issues. Each success builds more confidence and expertise. And remember, for more insights into fault finding and to see these principles in action, don't forget to check out my YouTube channel for further fault finding insights. Here's to continually expanding our horizons, applying what we've learned, and celebrating every victory along the way. Until next time, keep nurturing your skills and enjoy the journey.

WANT TO KNOW MORE? FOR MORE INFORMATION

PMM JUNE 2024 17

WWW.RDR.LINK/ABJ001

No ground at the ground trigger point at the DME with number two coil connected.

Very handy when you can clone a used DME in house.

A DME coil pack transistor shouldn’t have continuity to ground. This one did which meant a repair was needed.

Voltage missing at the power distribution module. This car will never start in this state.

REGISTER FOR FREE AT WWW.MECHANEX.INFO THE HANDS-ON TRADESHOW FOR INDEPENDENT WORKSHOPS TOP AUTOMOTIVE BRANDS ● LATEST PRODUCTS AND INNOVATIONS ● SPECIAL SHOW DISCOUNTS ● FREE CPD TECHNICAL SEMINARS ● FREE ENTRY ● FREE PARKING ● FREE PROFESSIONAL MOTOR MECHANIC T-SHIRT ● FREE BACON ROLL The regional Tradeshow for aUTo rePair Professionals PROFESSIONAL MOTOR MECHANIC MECHANEX FEATURING LIVE YORKSHIRE EVENT CENTRE HARROGATE YORKSHIRE EVENT CENTRE HARROGATE 15TH & 16TH MAY 2025 SANDOWN PARK SURREY SANDOWN PARK SURREY 12TH & 13TH NOVEMBER 2024

DIAGNOSTIC GUIDE

Using Bosch’s ESI[tronic] 2.0 software: a monthly guide

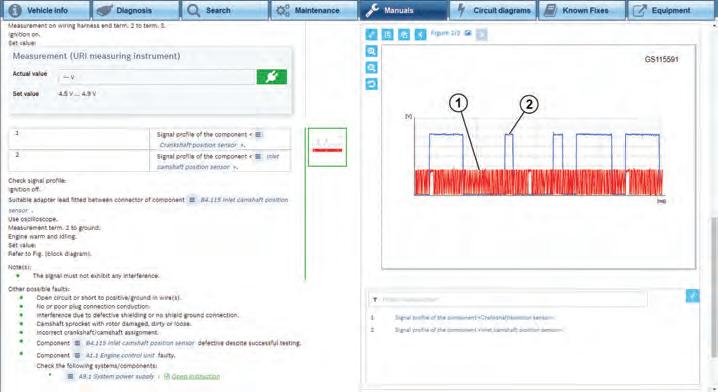

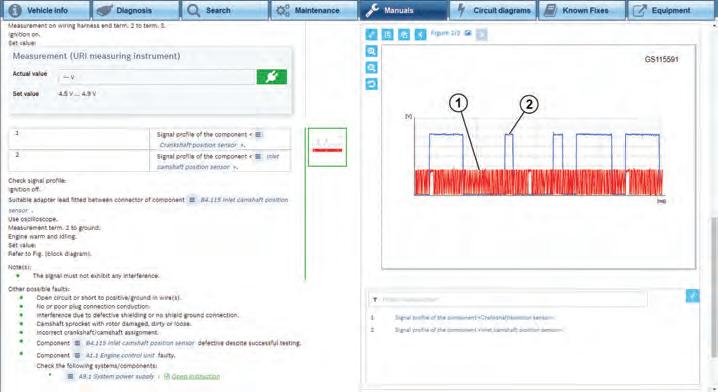

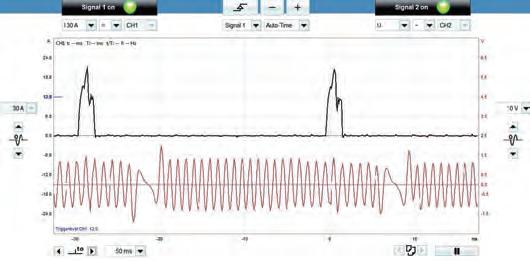

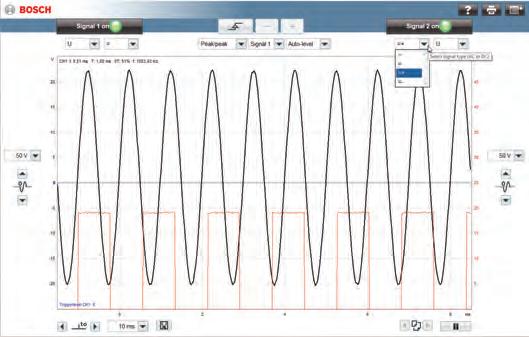

Last month in our guide to Bosch’s KTS diagnostics software, ESI[tronic] 2.0, we looked at the diagnosis tab and mastering actuator tests. This month, we’re testing out the built-in multi-meter and oscilloscope.

In the tenth article in our series, we’re going to introduce you to the added benefit of vehicle diagnosis with the built-in multi-meter or oscilloscope functions included in the KTS vehicle communication interface.

Alongside all of the other equipment required to effectively work on modern cars today, many technicians consider a graphing multi-meter or oscilloscope a luxury investment. The good news is, if you own a Bosch KTS 560, a single channel multi-

meter is included. While Bosch’s flagship tool – the KTS 590 – features a two channel multi-meter or oscilloscope which is all ready for you to use (Fig.1). The kit contains high-quality colour-coded test cables and probes, which use standard 4mm ‘banana’ type connectors.

First time fix rate

As we all know, a diagnostic trouble code (DTC) will often only give guidance to the general area of a system that is suspected to be faulty or out of range. Once a DTC is read from the error memory of a control unit, a robust fault-finding process is required to test the suspected component and its associated electrical circuit. In Bosch ESI[tronic] 2.0, there are many service information system repair instructions linked to an error memory code that will suggest a direct measurement needs to be made of the voltage supply, earth path, signal/command wire or component resistance in the system (Fig.2).

Your path to diag success!

PMM JUNE 2024 19 READ ME TO COLLECT YOUR CPD POINT CPDZONE

These values can be tested using the Bosch KTS multi-meter or oscilloscope, along with ‘guided’ fault-finding instructions and technical data. This added confidence in your results can lead to a dramatically improved first time fix rate.

For this article, we’ll concentrate on the multi-meter and oscilloscope functions of the KTS 590. Remember that if you have a KTS 560, there is no scope capability built into the VCI. For technicians that use a separate oscilloscope – such as the Bosch FSA 500 or FSA 720/740 series – then the KTS 560 is perfectly suitable for multi-meter use.

KTS multi-meter functions

To get started, let’s take a look at the Bosch KTS multi-meter functions that can be used alongside the ESI[tronic] 2.0 vehicle diagnostic program. When the multi-meter is accessed via the main menu (Fig.3) a new window will appear on-screen with the multi-meter display and measurement selection options. Now you can overlay the multi-meter results screen over ESI 2.0 and see the serial diagnostic data and direct measurements side-by-side (Fig.4).

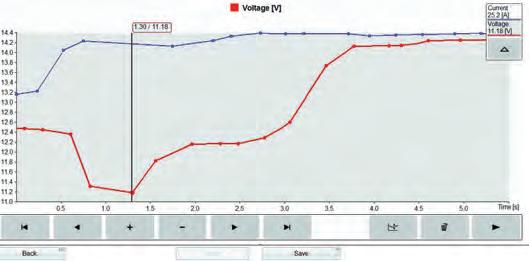

The test results will be wirelessly displayed on your PC screen, with the measurements taken by the probes attached to the KTS VCI connected to the vehicle. The readings can be shown in a numerical form, with a useful bar graph, or in a graphing trace format, with up to a minute shown across the screen for added convenience.

Another great feature is that, just like the actual value time profile display in ESI[tronic] 2.0, the multi-meter graph can be paused, reviewed, saved and printed (if necessary) for reference (Fig.5) – also showing battery voltage and current upon starting the engine.

For voltage and current readings, we have the choice of DC, AC or EFF (root mean square) settings on both channels and resistance measuring up to 1 MΩ on channel onw. You can connect a Bosch amps clamp

“Using an oscilloscope opens up a whole new dimension of system diagnosis by presenting you with a representation of voltage over time.”

with adapter for non-intrusive current measurements to be displayed on screen. A really useful additional feature of the KTS multi-meter is the circuit break and short circuit function, which you can configure to emit an audible warning signal when you conduct a wiggle test on the suspect harness to help you find wiring faults along a loom.

KTS Oscilloscope

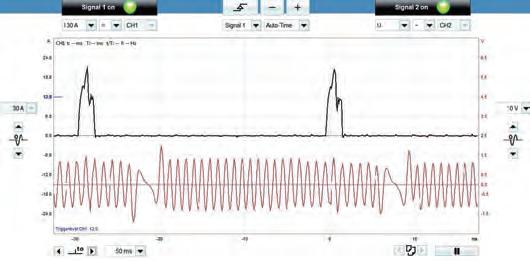

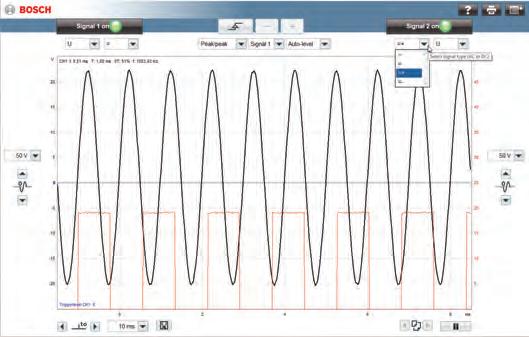

The Bosch KTS 590 two channel oscilloscope functions can be used for even greater in-depth testing of electrical systems

and components. The beauty of using an oscilloscope is that it opens up a whole new dimension of system diagnosis by presenting you with an accurate graphical representation of voltage over time. This means you can see in detail what is actually happening in an electrical circuit in real time.

Fig.6 shows a PD injector and crankshaft sensor signal. Opened from the main menu, the oscilloscope screen can be viewed alongside the ESI 2.0 program and offers many customisable settings that enable you to effectively capture and display the test results you need.

Trigger points can also be set to ensure that signal recording starts where you want it to, while waveform display options can be used to get the best results. There are too many options to describe them all here, but if you hover your cursor over any icon or soft key a ‘tool tip’ pops up with a description (Fig.7).

The time base for both channels can be set between five microseconds and one second across the screen. The safe continuous input voltage to the VCI is a maximum of 60V and the scale of measurement in voltage can display from 200mV (20mV/division) up to 200V (20V/div). The amps scale can also be selected between 30A and 1,000A in the current measurement. If you pause the oscilloscope recording the buffer memory holds the previous 25 screen captures, which can be scrolled through and reviewed – an essential feature if you’re searching for an intermittent fault.

20 JUNE 2024 PMM

If you only want a single channel measurement, then the blue and yellow cables can be used for potential free testing when the black earth cable is connected to channel two. This set-up can be particularly useful for testing both signal wires of an inductive speed sensor, for example. When a signal is being collected, the ESI 2.0 oscilloscope software automatically starts to calculate the specific signal on/off times as well as the frequency of the waveform if it is a repeated signal such as a pulse width modulated (PWM) duty cycle. This is really useful if you are checking the command

“Another benefit of the oscilloscope is the ability to choose the channel option for signal acquisition”

signal to a component, such as a radiator fan control module.

Another benefit of the oscilloscope is the ability to choose the channel option for signal acquisition via the coloured test cables connected to the channel inputs of the VCI. Additionally, you can switch to the ‘PIN’ input option, where the signal will be taken from the communication pins of the 16 pin OBD socket that will already be connected to the car. The earth pins 4 and 5 and power supply pin 16 are not available to scope this way, but any of the other pins are (depending on the vehicle configuration).

For example, a single wire ‘K’ line on pin 7 or a CAN Bus signal on the traditional pins of 3 & 11 or 6 & 14 could be ‘internally’ tested (Fig.8). This can be a very quick and easy way to investigate if any control unit communication problems occur.

Next month we will look at the maintenance and equipment tabs.

COMMON FAULTS

Why was the Citroen C4’s oil leaking?

Autodata clears up an issue a garage is having with a Citroen C4 Grand Picasso II (2015) whose engine oil leaking from the bell housing area.

The problem:

A customer of ours has a 2015 Citroen C4 Grand Picasso 1.2 petrol. The vehicle had an engine oil leak in the area of the transmission bell housing. We replaced the crankshaft rear oil seal with an aftermarket item. Now the vehicle has come back to the workshop with the same engine oil leak after only a few months. We suspect the crankshaft rear oil seal, are you aware of any other possible causes before we remove the transmission again?

What does Autodata recommend?

Yes, we have come across this engine oil leak issue before. It affects all C4 Grand Picasso models with HNY engine code and manual transmission produced up to 24/09/15 (RPO 14199). The fault is due to an unsatisfactory design of the crankshaft rear oil seal carrier allowing engine oil to seep out into the transmission bell housing area. To rectify this fault, fit a modified crankshaft rear oil seal carrier complete with new crankshaft rear oil seal, available from Citroen parts department. Inspect clutch assembly for oil contamination, replace if necessary. Carry out road test to confirm the fault has been rectified.

PMM JUNE 2024 21

WANT TO KNOW MORE?FOR MORE INFORMATION WWW.RDR.LINK/ABJ003 WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABJ002

BEST PRACTICE

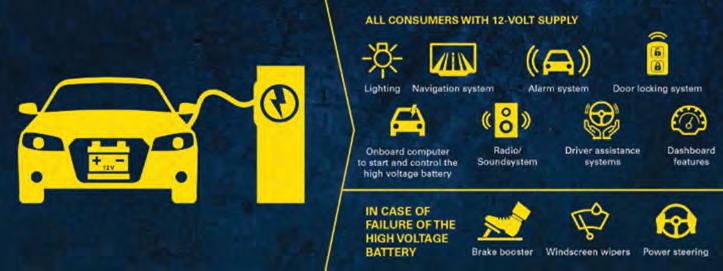

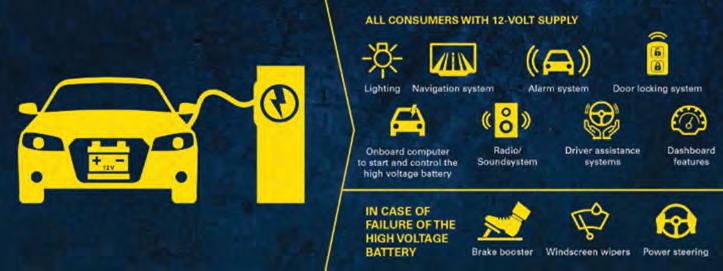

Battery testing and replacement on electr ic vehicles

Automotive battery specialist Varta outlines the important role traditional 12V batteries continue to play as the vehicle car parc transitions towards an electric future.

Did you know, as well as startstop and ICE vehicles, nearly all xEVs (BEV, PHEV, FCEV, hybrids) require a 12 volt power supply? As cars become more electrified and autonomous, the traditional 12 volt lead-acid battery is taking on a new and challenging responsibility as a critical source of power across the evolving range of xEVs.

There are an increasing number of electrified vehicles entering the market to support governmental targets of reducing CO2 emissions. Their emergence has intensified low-voltage power demands and is continually redefining the role of the 12V battery. Enhanced levels of vehicle electrification have driven the 12V battery to become a safety critical component, particularly if the high voltage battery fails.

Staying safe

An electric car’s high-voltage li-ion battery powers the drivetrain and the propulsion system, however not the whole vehicle, and not all of its electrical power devices. The internal electrical 12V power system with its comfort and critical safety features, is powered by a 12 volt battery. It works as a secondary power source for the vehicle’s electrical system and ensures that the car maintains its functionality while driving but also whilst parked and the high-voltage battery is disconnected from the drivetrain.

Comfort and safety features like lane assist, power steering and the brake booster are handled by onboard smart systems which also draw power from the 12V system. The same goes for most of the car's monitoring functions, it is therefore essential that a reliable 12 volt power supply is in good working order.

22 JUNE 2024 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

Why is lead-acid technology still being used in a modern electric vehicle?

Lithium-ion technology is often considered the successor of lead-acid technology when it comes to batteries. However, it is not as inherently robust as other battery technologies and requires continuous monitoring by the battery management system. Overall, it is a very sophisticated technology.

Lead-acid batteries, on the other hand, are known to be both reliable and affordable. Their wide operational temperature window intrinsically enhances the operational robustness of the entire system. The safety record of lead-acid batteries makes them invaluable for Europe’s future low-emission mobility sector, plus lifecycle analysis of a vehicle’s environmental impact show that lead-acid has a lower impact compared to other technologies.

In the workshop

As with any 12 volt battery, there is a finite lifespan and once used, a replacement should be fitted. Varta always recommend testing the 12 volt battery of any vehicle when it enters your garage workshop, the same applies to any type of xEV.

When it comes to testing on an xEV:

n The battery cables for the high voltage battery are all orange in colour – do not touch these.

n The 12 volt battery cables are standard and the same as ICE cars in size and colours.

n The 12 volt battery testing method is the same as a standard ICE vehicle, however on full hybrid and BEV cars, the alternator and starting tests cannot be carried out as there is no starter motor or alternator fitted. Charging is completed via the inverter/converter, and starting is achieved using a motor generator in the gearbox.

n Ensure the battery tester you are using is capable of reading results from AGM (absorbent glass mat) and EFB (Enhanced flooded batteries), as well as traditional flooded batteries (sometimes referred to as SLI).

Replacement process on xEVs:

n Ensure the vehicle ignition is completely switched off.

n Remove the key and place it at least two metres away from the vehicle to prevent accidental ignition power up, of the smart entry/start system.

n Use the partner portal to identify the vehicle and the location on board of the 12 volt battery.

n Disconnect the 12v battery as per manufacturers’ instructions (there may be a high voltage ‘power-down’ waiting period).

n When the 12 volt battery is disconnected, the high voltage side of the vehicle is also powered down and cannot be powered up again until the 12 volt battery is installed.

n The installation process is the reverse of the removal, the partner portal will be able to advise if recoding of systems or components is required.

The OEMs’ choice

Varta AGM batteries have proven their reliability for many years. It is their sturdy construction, behavior and inherent safety that makes them the perfect companion in supporting the 12 volt electrical system of xEVs. The Varta 12 volt battery portfolio is engineered to support both today's and future electric vehicles.

Being the leading expert in battery solutions, Clarios has its Varta silver dynamic AGM portfolio ready for xEV, now with added designation to the AGM labelling. Designed and tested together with leading car manufacturers, the AGM portfolio for xEV is here to prepare you for servicing the future of mobility.

PMM JUNE 2024 23 WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LIN K/ABJ004

KNOW YOUR PARTS Ca bin air filtration

Mann+Hummel explores the role cabin air filters play in improving drivers and passengers’ health.

Millions of people around the world are suffering from the effects of polluted air, not only outdoors in spaces with a lot of traffic, but also inside vehicles. It is therefore becoming essential to improve air quality by reducing particulate matter and harmful gasses. With its latest innovation in cabin air filtration, global filtration expert Mann+Hummel is concentrating on a particle size that is becoming increasingly important – so-called ultra-fine particles (less than 0.1 micrometer). These can get particularly deep into the human body and cause harmful damage. The World Health Organization is also paying particular attention to ultra-fine particles and in its latestair quality guideline has called for this particle size to be included in routine measurements.

Regardless of the drive system, cabin air filters play a major role in providing drivers and occupants with clean and healthy air. In electric vehicles, there is also a trend toward improving air quality through multi-stage filter systems.

Are multi-stage HEPA filter systems the future?

Mann+Hummel has developed HEPA filter systems to effectively protect people from these microscopic impurities. The abbreviation HEPA stands for high wfficiency particulate air. It is not a protected term, so special care must be taken here. The addition of “in accordance with DIN EN 1822 and ISO 29463” indicates whether a filter actually meets the high requirements of European and international standards. “Our filter media meet these requirements,” explains Christiane Michel, business development manager at Mann+Hummel.

“Our multi-stage cabin air filter systems with highly efficient HEPA filters offer protection through clean room quality air filtration, as is also the case in operating rooms, for example. Depending on the HEPA class, at least 99.95 per cent of the particles are reliably removed from the air, including harmful bacteria, viruses and other microorganisms, even the previously mentioned ultra-fine particles. These are so small that they can easily penetrate into the bloodstream, cause severe damage to organs and be carcinogenic,” Michel adds. “We now know that more than 90 per cent of the particles in the air are ultra-fine particles. Whether they are safe or not depends on their source and chemical composition.”

PMM JUNE 2024 25

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Mann+Hummel uses the HEPA filter as part of a three-stage system along with a prefilter and a cabin air filter. Both can be equipped either as pure particle filters, in combination with activated carbon or as a third version with biofunctional and microbial coating. The particle filter uses a special nonwoven material that efficiently retains dust, soot and pollen, while the activated carbon filter adsorbs harmful gasses and odours. A biofunctional coating binds allergens that can be released from pollen and provides additional protection against the growth of mould and bacteria on the filter medium.

HEPA filter properties

Michel describes the situation: “Since a HEPA filter can capture much finer particles than a conventional cabin air filter, its fibre structure is significantly denser, which results in significantly lower air permeability. To compensate for this, a HEPA filter has more media surface area and thus achieves the lowest possible pressure drop. In fact, the surface area of the filter media in our HEPA filters is about five times larger than in a conventional element, thanks to a smaller pleat spacing. It is therefore currently not possible to replace a standard cabin air filter with a HEPA element. Air conditioning systems are not built for these high efficiency filters. Instead, the HEPA filter is located in a separate system – usually outside the air conditioning system – together with a prefilter, as protection for the HEPA filter."

Smart multi-stage HEPA filter systems are also designed to ensure that filtration only takes place when it is needed. An intelligent control system records the air quality and provides data on the basis of which the system decides which of the three filters the air should flow through. "This ensures that the HEPA filter is activated automatically as the final filtration stage only when required, for example, when the outside air is heavily contaminated. This allows the size of the system to be kept small and extends the life of the HEPA filter," according to Michel.

“In fact, the surface area of the filter media in our HEPA filters is about five times larger than in a conventional element, thanks to a smaller pleat spacing.”

Christiane Michel, Mann+Hummel

Reducing particulate matter

Another future filtration solution from Mann+Hummel for the independent aftermarket is the reduction of particulate matter generated in road traffic. These particulate emissions include not only exhaust gasses, but also particles that enter the air as a result of braking and the wear of tires and road surfaces. The problem of particulate matter is therefore independent of the drive system and also applies to electric vehicles. To prevent this particulate matter from entering the atmosphere in the first place, the experts at Mann+Hummel take care of these particles as soon as they are created. They have developed a wide range of solutions to improve the particulate matter balance of vehicles. In addition to a brake dust particle filter that reduces brake dust emissions

directly at the source, there is also a filter for the roof or underside of vehicles that collects particulate matter from the ambient air.

Cabin air filters will remain an essential component of future vehicles – regardless of the drive system. Up to 540,000 litres of air per hour can flow into a vehicle via the ventilator. In this way, pollutants can enter the vehicle interior from the outside and remain there for a long time – increasing the air pollution in the vehicle interior. This is precisely where multi-stage cabin air filter systems with their advantages come into play, but also effective cabin air filters such as the Mann-Filter FreciousPlus with its biofunctional coating and effective protection against allergens, harmful gasses and particulate matter. In order for a cabin air filter to function properly, it is important to replace it regularly. The recommended replacement interval is 12,000 miles or once a year.

“Our goal for the future is to offer further cutting-edge technologies inside the vehicle, such as digitally displaying the filter status and air quality in real time,” concludes Michel.

26 JUNE 2024 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LIN K/ABJ005

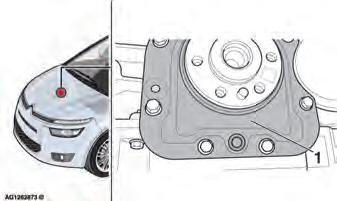

Replace the dual mass flywheel on an Audi A4 with Multitronic clutch HOW TO

In this month’s Schaeffler LuK clutch feature, REPXPERT Alistair Mason is looking at something a bit different, it is an Audi A4 2.0 TDI that has covered just over 114,000 miles fitted with a CVT Multitronic gearbox. The customer has reported that they can hear a rattling noise and would like it investigated.

VEHICLE INFORMATION

Manufacturer: Audi

Model: A4

Engine: 2.0 TDI

Mileage: 114,000

Schedule time: 7.7 hours

n The lockingwheel bolt key from thecustomer

Gearbox removal

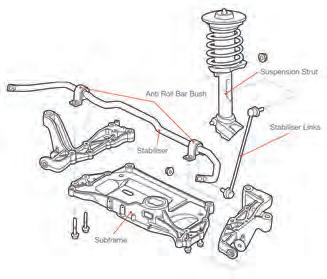

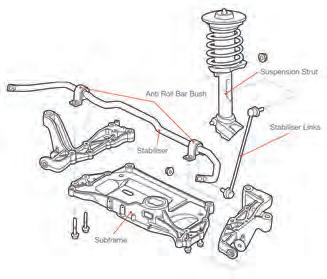

With the vehicle placed in the lift remove the ignition key and ensure the steering lock has activated, open the boot, remove the spare wheel and disconnect the battery lead, open the bonnet and raise the vehicle to waist height, remove both front wheels and plastic drive shaft shields, this now gives us access to the driveshaft flange bolts which can now be removed and also the N/S driveshaft shield (Fig.1). Raise the vehicle lift to gain access to the underside, remove the engine and gearbox undertrays, disconnect the metal power steering pipe from the O/S subframe, remove the floor brace bars (Fig.2), disconnect the steering column universal joint from the steering rack, remove the anti-roll bar to subframe clamps, move the anti-roll bar down and then remove the two bolts that secure the steering rack (Fig.3) and then ease the steering rack down, this now gives access to the two starter motor bolts that can now be removed. Remove the two subframe heat shields that are located by each driveshaft as this gives us a little more space, remove the front engine mounting, slacken the exhaust centre sleeve and slide back to disconnect the exhaust and also remove the exhaust front pipe bracket (Fig.4).

READ ME TO COLLECT YOUR CPD POINT CPDZONE 28 JUNE 2024 PMM

Support the gearbox with a transmission jack and remove the gearbox mounting assembly, lower the gearbox slightly, disconnect the large multiplug on the back of the gearbox and remove the gear change cable, then with a long extension the upper bellhousing bolt can be removed, place an oil drainer under the gearbox and disconnect the oil pipes that go into the top of the gearbox on the O/S (Fig.5), clamp the two oil pipes in front of the anti-roll bar on the N/S, disconnect and cap if possible to prevent leakage (Fig.6). Remove the plastic plate at the bottom of the bellhousing and remove the three bolts that secure the DMF to the engine drive plate (Fig.7), to rotate the engine, remove the rubber grommet from the bottom pulley, using a socket and bar, rotate the engine in 120° intervals to gain access to the bolts. Now remove the rest of the bellhousing bolts, using a second transmission jack or support, support the front of the engine, now ease the gearbox back and when it is clear of the engine carefully lower the transmission jack, keep an eye on the steering rack and cooler pipes as the gearbox is being lowered, when fully clear wheel the transmission jack clear of the vehicle.

DMF replacement

We now need to remove the driveshaft from the gearbox, rotate the gearbox so that the differential is closer to the floor, this will prevent oil leaking out of the differential when the driveshaft is removed. Remove the three bolts from the plate that retains the driveshaft (Fig.8) and the ease the driveshaft out of the gearbox. The DMF can then be lifted off the clutch input shaft and removed from the gearbox, clean the bellhousing area, inspect the clutch input shaft for any wear. If all is ok, apply a light smear of high

melting point grease to the splines of the clutch input shaft.

If we turn are attention to the removed DMF (Fig.9), unfortunately there is no way these can be tested in the workshop, all we can do is carry out a visual inspection and

feel the rotation of the secondary mass, this flywheel did not feel smooth in operation when compared to the new one.

Now mount the new DMF onto the clutch input shaft with the aid of the handle provided in the DMF kit and support with the special tool also provided (Fig.10), the driveshaft can now be carefully inserted back into the gearbox and secured with the three bolts.

Gearbox installation

Level the gearbox on the transmission jack ready for installation, check all cables etc. are clear of the back of the engine and that the engine to gearbox alignment dowels are installed correctly.

Carefully ease the gearbox into position, when the gearbox is located on the alignment dowels, push the gearbox so it is fully against the engine, install a couple of easily accessible bellhousing bolts and tighten. Installation is then in reverse order of removal. Remember to:

■ Top up the gearbox oil

■ After connecting the battery, reset all effected electrical consumers

■ Always carry out an extended road test to ensure a quality repair

REDEEM YOUR CPD CREDIT

Congratulations, you have reached the end of the CPD Zone! To access your CPD credit from The CPD Group, scan the QR Code or WWW.RDR.LINK/ABJ006

PMM JUNE 2024 29

Laser Tools Racing with MB Motorsport launch celebratory tenth-anniversary livery

This issue, we look back to just before this year’s season start when Laser Tools Racing with MB Motorsport revealed the team’s striking new livery for the 2024 Kwik Fit British Touring Car Championship campaign. This year’s iteration of the affectionately named ‘Laser Beamer’ is a particularly special one for the team as Laser Tools Racing celebrates their tenth campaign in the UK’s premier motorsport series. With this in mind, the team’s BMW 330e M Sport features the iconic Laser Tools Racing chrome blue with the livery designed to feature ten chevrons from every angle of the car.

Once again, the team’s on-track efforts are being spearheaded by fan favourite, Jake Hill. Having finished third in the Drivers’ Championship in 2022 and 2023, the Kentbased driver is looking to challenge once again for overall honours and is delighted to be doing so in a special livery for him and the team.

Jake commented at the livery launch: “It is fantastic to see the covers come off our 2024 challenger today and I have to say, although I loved the Laser Beamer last year, I think we have managed to top it once again this time around. The chrome blue has been iconic across the series for so long so it’s only right we have levelled this up in 2024 as Laser Tools Racing celebrates its tenth anniversary in the championship.”

Laser Tools Racing’s Motorsport Sponsorship Coordinator, Keith Anderson, has played a pivotal role in the team’s decade in the BTCC and the launching of their ten-year anniversary car marks a proud moment for the organisation. “I’m not quite sure where the time has gone,” said Keith, “but it is fantastic to mark a decade of success for Laser Tools Racing in the BTCC with the launch of our 2024 challenger. We cannot wait to see Jake leading from the front in the second iteration of the Laser Beamer!”

Laser Tools Racing also revealed the livery that Nelson King will run for his second season in the Vertu MINI CHALLENGE season. King joined forces with Laser Tools mid-way through his rookie campaign and he looks to improve on the top-three championship finish he secured last year. The Mini is running a special celebration livery similar to that seen on the BTCC BMW. Nelson is also very enthusiastic: “I’m incredibly excited to be teaming up with Laser Tools Racing for a full season, especially during their tenth anniversary. I believe that together, we can achieve phenomenal results this year.”

CONNECTIONS QUIZ

Try and figure out what connects each of the answers!

1. Which book won John Steinbeck the National Book Award and the Pulitzer Prize?

2. Which British girl group covered “Venus” in 1986, reaching number one in six countries?

3. What awards are given out to the worst films in “competition” with the Oscars?

4. Which global company was founded by Steve Jobs in 1976?

5. James Franco and Seth Rogan starred in which film together in 2008?

6. Which Harry Styles song features the lyrics “Tastes like strawberries, on a summer evening.”

7. Complete the phrase “When life gives you _ make _”

8. What are people from New Zealand called?

9. Which English former footballer played as a goalkeeper for Manchester United, Middlesbrough, Liverpool and Hartlepool United in a career spanning 20 years?

10. What connects all the answers?

Answers: 1. The Grapes of Wrath 2. Bananarama 3. The Golden Raspberry 4. Apple 5. Pineapple Express 6. Watermelon Sugar 7. Lemons, lemonade 8. Kiwis 9. Stephen Pears 10. Fruit

TheHRdepartment wouldlikeaword!

Jennifer Webb, owner and director of HR Vitals, has been taking the aftermarket by storm with her tailored advice guiding garages through the personnel pitfalls inherent in running a business. In her new column for PMM, she will be sharing her experiences, her top tips, her thoughts and anything else that will encourage you to take the human resources aspect of your business as seriously as any successful business owner should. In her first column, she paints her impressions of the aftermarket so far.

Hi, I’m Jen. I have been working in the aftermarket since 2018 and from what I can see – that means I am still a newbie in comparison to most, and probably you.

What was my background before? Well, I have worked in quite a mix of places, including a zoo, a hospital, the bank, a rehab centre… I’ve worked in care, in a bar and, finally, in HR. Fast forward to 2024, I have worked with over 200 garage owners and even married one!

So, what are my first impressions? Here are just two that come to mind immediately.

Firstly, people value people. This is my biggest observation. Technicians leave main dealers because they don’t want to feel like a number. The boss is

LIFE IN AN EV GARAGE

vitally important to how the team thinks about the day. People want to be good workers and to be seen as such. And the employers? Employers want to find good, reasonable, trustworthy and conscientious people. One bad apple can really upset the workplace.

Secondly, you don’t realise how much you value people. You may think my first point is obvious, but from an outsider perspective, you (generally speaking) value the first point

In his third instalment, Matt Cleevely argues garages need to stop burying their heads in the sand when it comes to EVs in the UK.

There are more than one million pure battery electric cars and vans on the road in the UK and, with new regulation requiring vehicle manufacturers to sell an increasing number of EVs each year, there will soon be many more. The sale of all new petrol and diesel cars will be banned in the UK by 2035 as part of the government’s zero emission mandate and under Labour this could be sooner.

This year, VMs must ensure at least 22 per cent of all new cars sold in the UK are zero emission. This figure will rise to 80 per cent by 2030. VMs could be fined up to £15,000 for each non-zero-emission vehicle sold outside of the allowance. What we’ve seen so far – and what we’ll continue to see – is the exponential growth of EVs. The Nissan Leaf has been on our roads for more than ten years now. Look at

more than you give credit to. The bad apple stays for longer than they should, you pray that the good people stay and you like to employ people who you already know. People want to feel involved, they like to know where they stand, they don’t want to feel pushed out or left behind. Humans, after all, are the ones who can make or break the aftermarket.

And these are my top two observations, what do you think? Am I stating the obvious? Does it ring true? Let me know what you think.

what happened during that time and then consider the impact of the zero emission mandate. Like them or not, EVs are here to stay and, for garages prepared to integrate them into their day-to-day workload, they’re bringing an untapped opportunity for growth.

Cleevely EV happened to be the UK’s first independent EV specialist – that’s why we’ve seen the success we have. I’m appealing to other independents to be the first in their county, city or town because there’s plenty of EV work for all of us. I’m not saying close the door on ICE vehicles. Around 55 per cent of the jobs in our workshop are still on ICE. But it’s about preparing now to secure your future, a future in which EVs will play an increasingly important role.

The irony is that even main dealers still aren’t ready to work on EVs in volume either. That's why independent garages have a genuine opportunity to come out on top, capture and retain a new customer base.

FORMOREINFORMATION GO TO WWW.RDR.LINK/ABJ 008 PMM JUNE 2024 31

FOR MORE INFORMATION GO TO WWW.RDR.LINK/ ABJ007

A look inside: YouTube

Your favourite trade magazine is now on YouTube, bringing you reviews and video guides on the best tools and workshop solutions. Find us at @professionalmotormechanic . Recently, we got Ed from Uckfield Motor Services to give us his thoughts on Hickleys’ new Zenith Z5 diagnostic tool.

“ First impressions on this is it's rugged. It looks really well thought out and well built. The software on it's based on Android, so the systems are all good. We've got this Mitsubishi L in today. As you probably seen for the previous videos, it's had a front-ender, it's been to the body shop and it's had some repairs done to it. And since that, the car won't start when the headlights are plugged in. So we're going to carry out a complete full code scan and see what we've got in there. Obviously this takes a little bit of time to go through all the various modules, so we'll see what it comes up with in a minute.”

“ So now we've had a good play with the Zenith Z diagnostic tool in the workshop and I'm really happy with it. It fills a gap in my diagnostic computer array. We've got about three or four tools and this fits in really well with what we've already got. The main reason is because it's small, robust and it's just nice to hold and use. Most diagnostic computers we've got are either bulky or laptop-based, so this is really good to use around the workshop and really quick and easy. Obviously it's Android-based so you know it's going to be relatively reliable and really good like that. The handheld bit on the back as well is lovely.”

“ It's carried out a complete full code scan and the good thing about this is you can click on this show diagnostic trouble code button here and it'll bring up all the codes that are present. The main ones we're looking at is the engine switch and internal errors and the PCM of altercation timeout on here. We've had a quick look at it where it's been repaired and basically the headlight has been poorly repaired. So I'm going to have to get it booked back in with one of my diatechs to have a further look into the wiring and hopefully get this problem sorted. Another cool feature we spoke about was the fact that you can record live data while you're driving. We've all been there, we've had to have a passenger to record the live data. So you can now do it with just yourself on this. ”

“ But the main things I love is the service menu. It's got the quick service task that can do DPF regeneration, injector coding, even the ADAS side of things. The ADAS capabilities are really good on it as well, but you can go in a lot more depth and where it's really, really good and where it's fitted in really nicely in our workshop is the Asian stuff. Kia, Hyundai, Toyota, all that sort of stuff that we tend to struggle with in the workshop. This really fills a gap there. Don't get me wrong, it's still really good across all the other European and the British cars but it's that Asian stuff it's really brilliant with.”

TO WATCH THIS VIDEO AND THE OTHERS ON THE PMM YOUTUBE CHANNEL, SIMPLY SCAN THE QR CODE

PMM JUNE 2024 33

Keep it INDEPENDENT

Performing simple tasks on certain vehicles is posing difficult diagnostic issues to garages. Here, managing director at A1 Diagnostic Solutions, Iain Molloy argues its time for independent garages to take back their time and stop losing profit to the main dealers.

The increasing complexity of systems on modern vehicles is something that’s now front of mind for technicians on a day-today basis. Diagnosing fault lights can be time-consuming and frustrating; something that’s exacerbated by the increasing problem of accessing secure gateways. It’s one of the main reasons I think garages are struggling with key-to-key times.

We’re now seeing garages struggle with something as basic as resetting the service light on a VW ID3. It’s crazy to think a garage may feel its only option is to take the vehicle to a main dealer; this can easily add a week or two onto what should be a 5-minute job. It erodes the garage’s profit margin, takes skilled technicians away from the ramps to transport vehicles backwards and forwards, and causes congestion in the workshop space.

Remote diagnostics

It’s imperative that garage owners can access a solution to this that suits their garage and the profile of its work. This solution might not only involve investing in the right diagnostic equipment. With diagnostics, we all know one job can lead to another, so it’s important to build a relationship with a specialist company that can be relied upon as a bolt-on service to work hand-in-hand with the garage; either remotely or in person. The main objective is to be able to access all the expertise required, in the minimum amount of time, whilst keeping the vehicle in one place.

We had a prime example of this recently. Leo Jayawardena at Ansam Autocentre, an independent garage in Croydon, contacted us with a copy of the diagnostic scan carried out on a Peugeot 3008. The customer had reported the lane assist system wasn't working and a warning light on the dash appeared to support this.

From the scan, Adam, our operations director, recognised a B1004:96 fault code which indicated a faulty camera. This was confirmed by checking the OE technical information for this particular digital trouble code (DTC). As nothing can be done to resolve an ‘internal fault’, we advised the only option was to replace the camera.

Once Leo was in receipt of the new camera, he contacted us again to ask if we could provide OE documentation to remove and fit it. Quite rightly, he wanted to ensure he did so correctly and without disturbing any other component. Whilst this isn’t a service we generally provide, we love a challenge and were able to get the document over to him within 15 minutes.

Once fitted, Leo logged on with us via his A1 Remote Diagnostics interface – from 130 miles away. We configured the new camera to the vehicle using the Peugeot OE diagnostic system; something Ansam Autocentre didn't have access to. The whole process was completed on-demand and in just 14 minutes, at which point one of our ADAS-trained technicians arrived in Croydon and calibrated the camera dynamically.

Overall, by using both our A1 remote service and A1 ADAS mobile service in

conjunction with his inhouse diagnostic equipment, Leo’s interaction time with us was just 30-minutes. Compare this to a week or more away at a Peugeot main dealer, and it’s easy to see how this route makes for efficient garages and happy customers.

I estimate the profit margin on the job was increased by around 50 per cent, and by dramatically reducing the key-to-key time, the customer’s invoice was cleared earlier too.

It’s the best way garages have of controlling the diagnostic demands of increasingly complex vehicles. We’re going to see an inevitable surge in these types of issues. It’s only a matter of time before these systems begin to develop internal failures – as all electronic components do – especially those which are in constant use like ADAS systems.

As the car parc’s original tranche of mainstream technically equipped vehicles are now out of warranty, they’re filtering through to independent garages who need a solution to be able to keep the job in-house.

If garages already have the latest generation Autel diagnostics, they can access the ‘Remote Expert’ function on the tool. A1 Remote Diagnostics has carried out more than 1,500 jobs in the last 18 months.

This tells me garages are finding solutions but there’s still a long way to go in helping them to just get on with what they do best –fix vehicles in a time-efficient, profitable, and hassle-free way.

PMM JUNE 2024 35

DIAGNOSTICS & ENGINE MANAGEMENT WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LIN K/ABJ009

KNOW YOUR PARTS

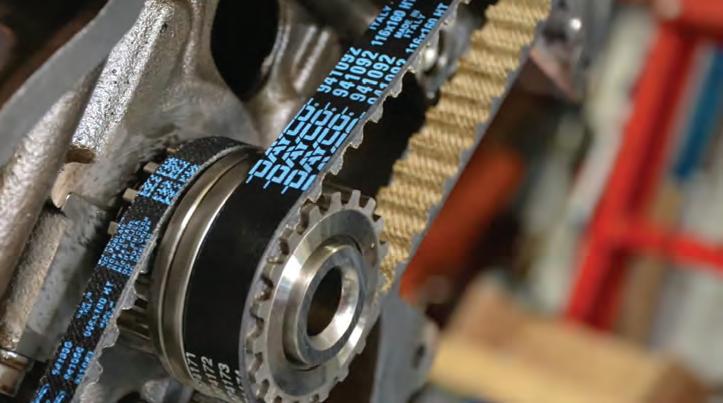

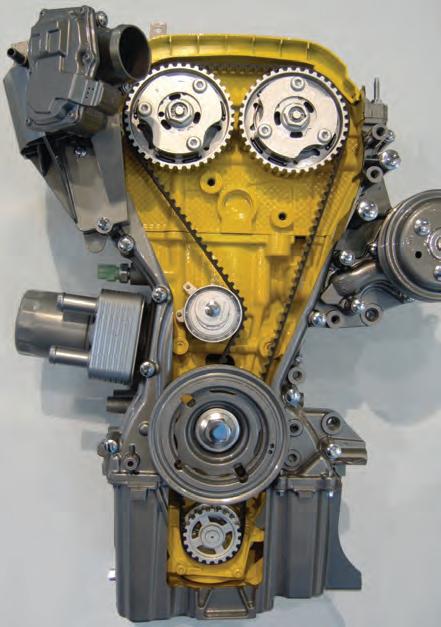

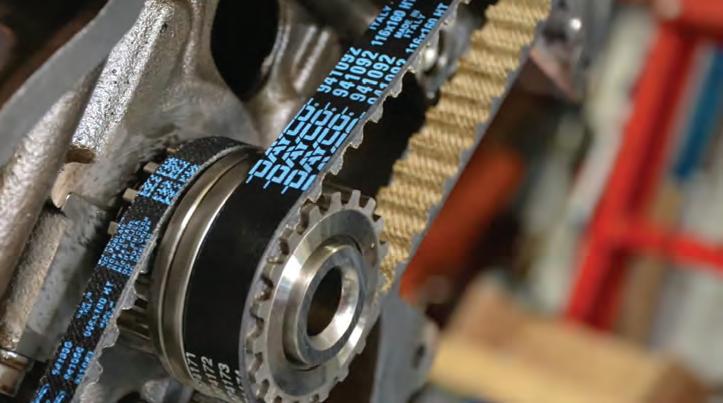

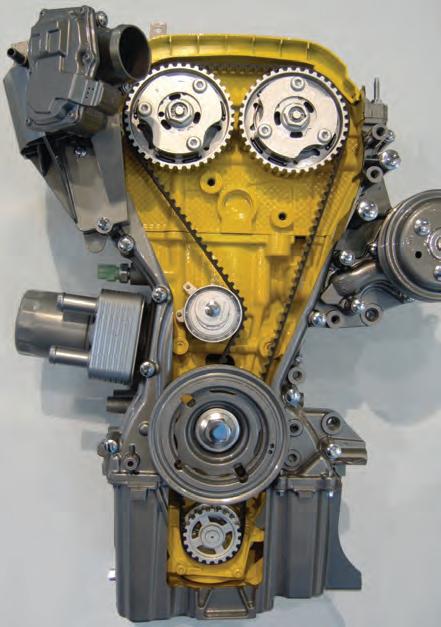

Belt-in-oil timing dri ve systems

Dayco’s national sales manager Steve Carolan reminds readers of the benefits of belt-in-oil timing drive systems and the replacement opportunity they provide independent workshops.

Although some might question the validity of the concept, preferring the traditional chain drive solution, the fact that many VMs have long since moved to belt driven timing systems and a growing number are adopting the BIO route, means that the replacement process, driven both by the scheduled service interval and by a repair requirement, will be a more frequent workshop activity.

To help ensure the ongoing reliability of these engines, Dayco, as the pioneers of BIO on behalf of VMs such as Ford, PSA and VW, has for some time been highlighting the importance to workshops nationally of carrying out regular maintenance in line with the VMs scheduled service intervals. This is because, apart from the catastrophic consequences that would result from belt failure, belt degradation can also have serious implications to several other components, such as the oil pump and brake system vacuum pump.

BIO is a fantastic solution that helps small and efficient engines to deliver increased levels of power, alongside lower emissions and better fuel economy, primarily because it reduces friction in the drive system by up to 30 per cent. However, to maintain this level of performance and to continue to operate as the manufacturer designed, they need to be serviced regularly and the condition of the belt assessed.

Replacement tips

Naturally, should the belt need to be replaced, as the original equipment supplier for many BIO applications, we have replacement kits in the Dayco aftermarket range and this provides workshops with a genuine revenue opportunity because over the last year, our sales of BIO kits have doubled, which proves there is a growing demand for the parts and means they can directly benefit from the BIO revolution.

Following developments at the OE level, Dayco has superseded its original replacement kits for the 1.2 petrol engine used in many PSA applications, such as the C-Elysee, C3, DS3 and Expert, and the 1.2 diesel engine for models including C3, C3 Picasso, C4 Cactus, 208, 2008, 308 and 3008, previously KBIO07 and KBIO08, with KBIO14 and KBIO15 respectively.

Alongside the positive revenue generation benefits that the growth in BIO applications provides, Dayco remains active with the workshop, delivering technical messages, ongoing training and general support, all of which helps to promote sales and reduce the risk of returns and unnecessary warranty claims.